Substrate with hard coat film and coating solution for forming hard coat film

A technology of hard coating film and coating liquid, which can be used in devices for coating liquid on the surface, coatings, synthetic resin layered products, etc. Insufficient durability and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

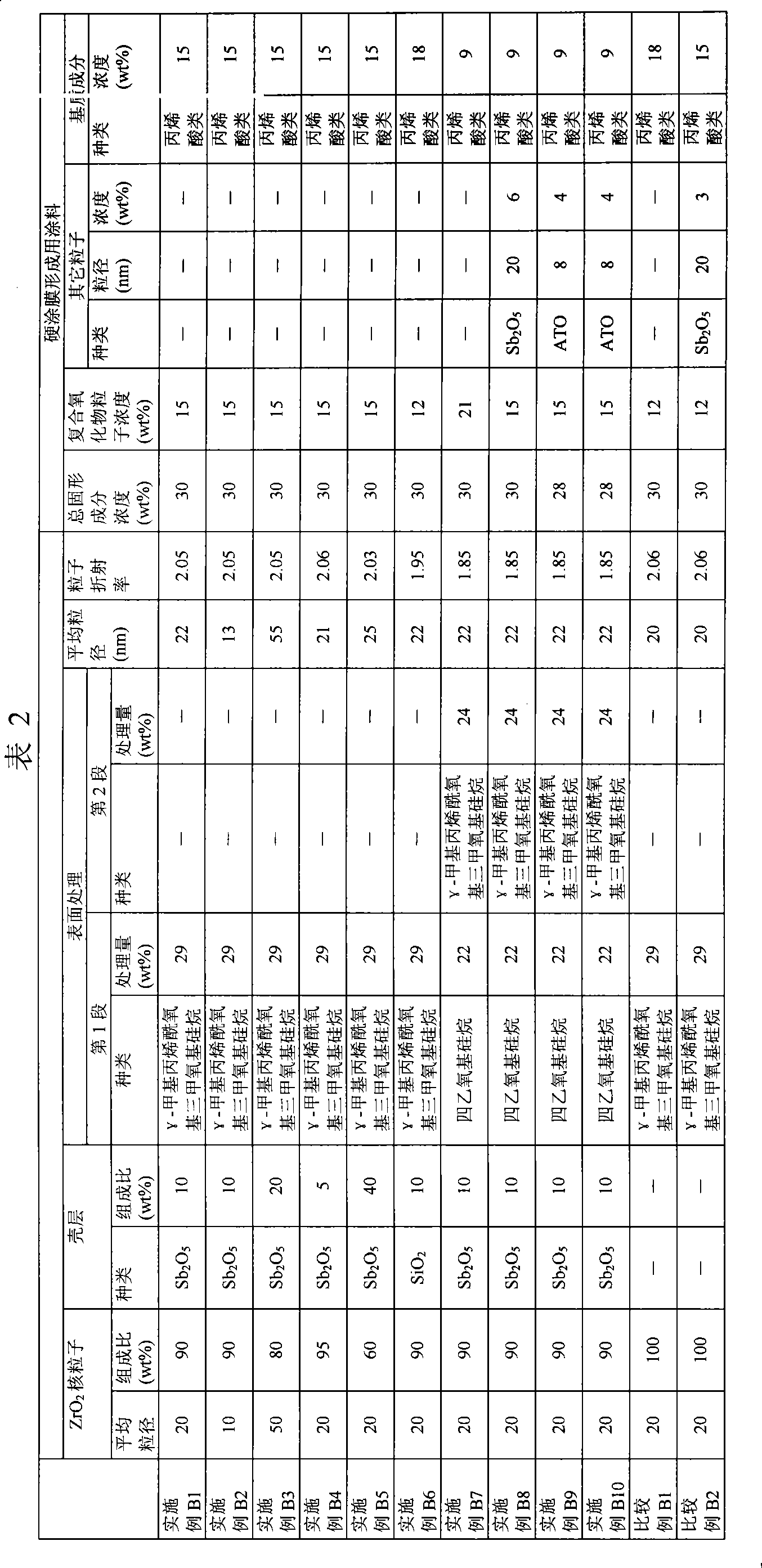

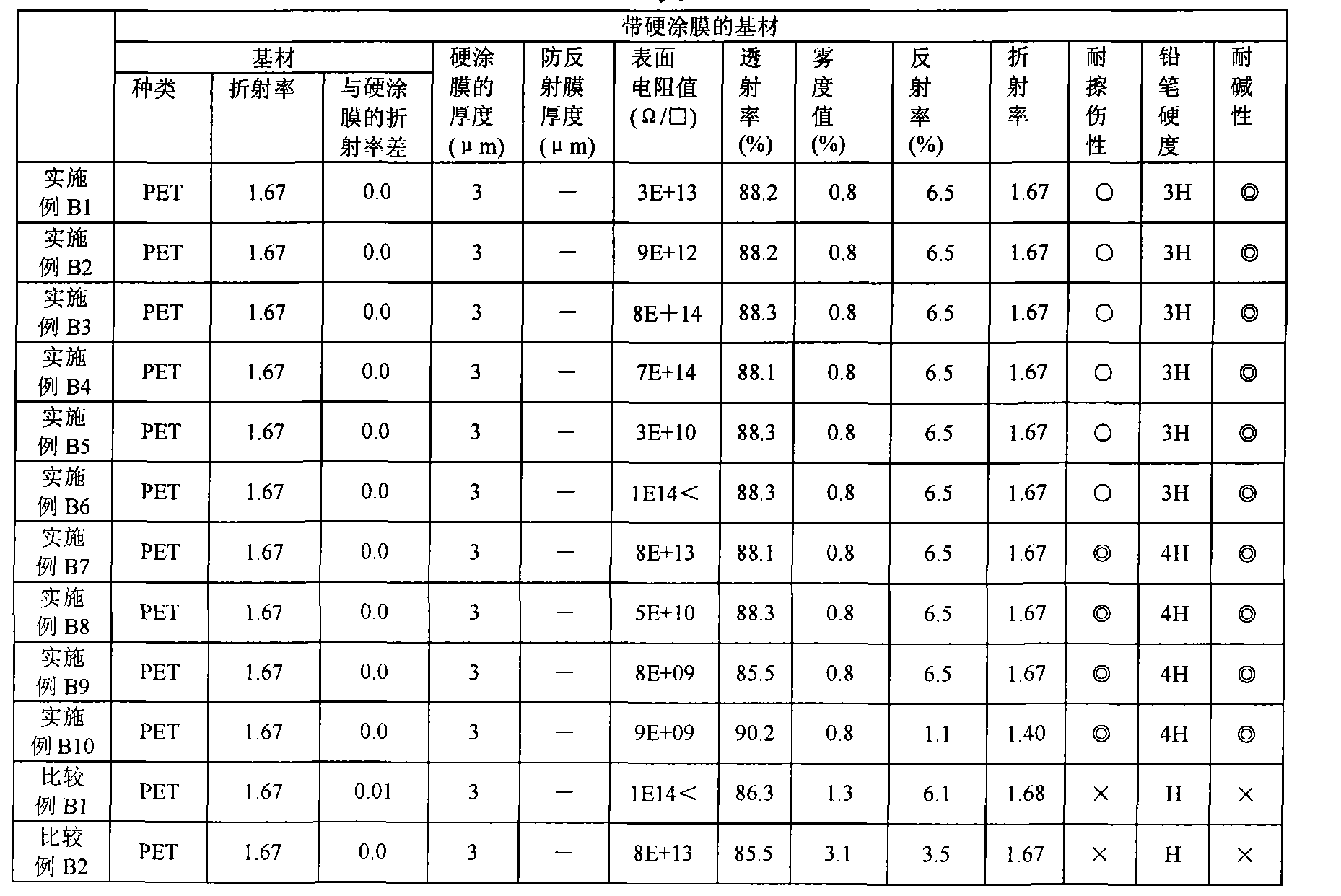

Examples

Embodiment A1

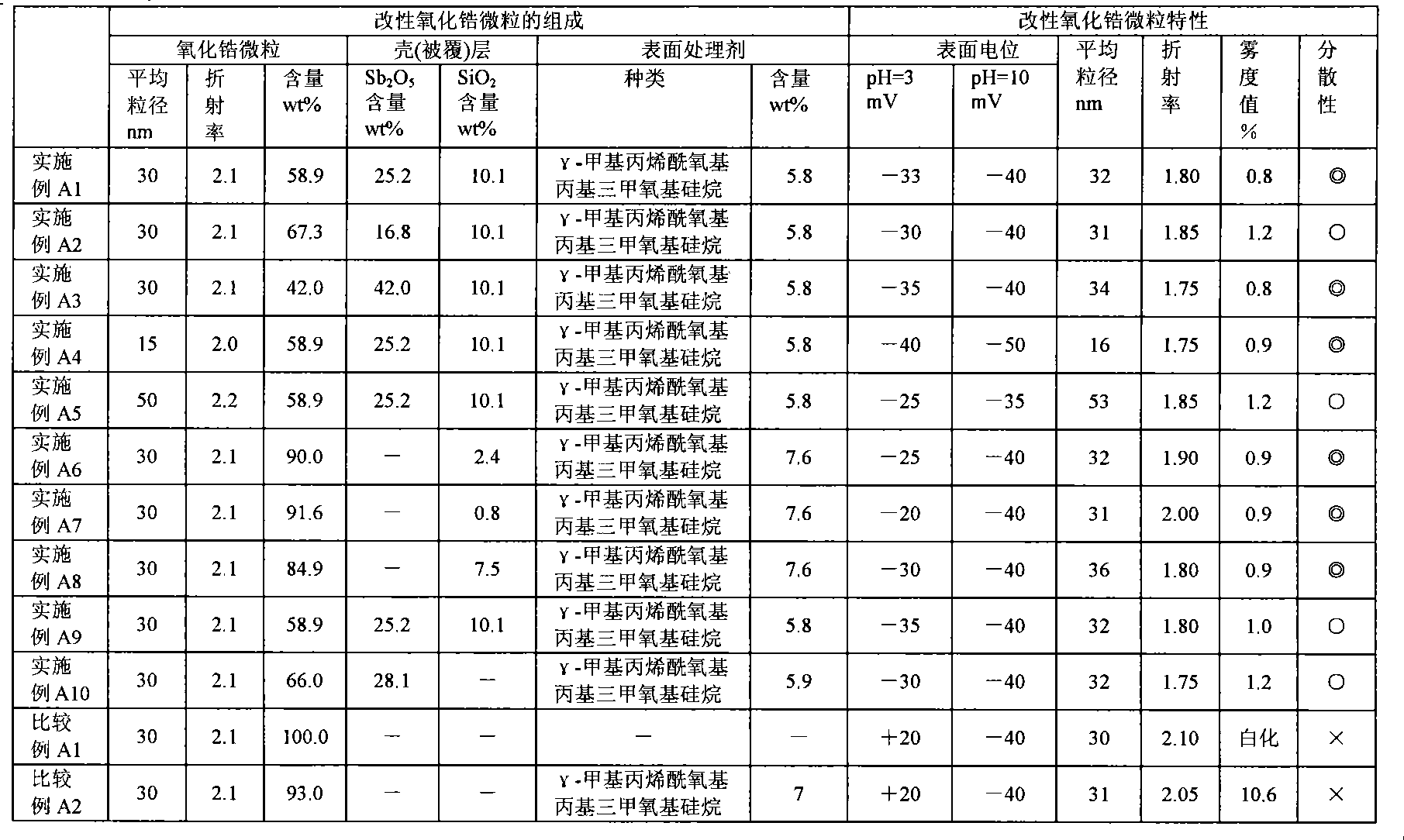

[0285] Preparation of Modified Zirconia Microparticles (A-1) Dispersion

[0286] Preparation of zirconia sol (A-1)

[0287] Zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 (O) 35g was dissolved in 1302g of pure water, and 122.8g of aqueous KOH solution with a concentration of 10% by weight was added thereto to prepare zirconium hydroxide hydrogel (ZrO 2 Concentration 1% by weight). Thereafter, the zirconium hydroxide hydrogel was allowed to stand still for 5 hours, and 750 g of the supernatant (pH 11.0) was removed. Next, after adding 750 g of pure water and stirring, it left still again for 5 hours. Repeat the above operations until the conductivity of the supernatant reaches below 0.5 ms / cm.

[0288] 0.96 g of tartaric acid was added to the obtained zirconium hydroxide hydrogel and stirred well. Then, a KOH aqueous solution with a concentration of 10% by weight was added until the pH reached 11.0, ultrasonic treatment was performed for 1 hour to disperse the hydro...

Embodiment A2

[0306] Preparation of Modified Zirconia Microparticles (A-2) Dispersion

[0307] Antimony pentoxide coating

[0308] Mix zirconia sol (A-1) 240g and potassium antimonate aqueous solution (as Sb 2 o 5 concentration of 1% by weight) 60 g, the mixture was passed through an ion exchange tower filled with 330 g of cation exchange resin (manufactured by Mitsubishi Chemical Corporation: DAIAION PK-216H), and aged at 90° C. for 1 hour to prepare antimony pentoxide-coated Zirconia sol (A-2). The resulting sol had a pH of 2.5.

[0309] Silica coating

[0310] Except for using 277 g of prepared antimony pentoxide-coated zirconia sol (A-2), other operations were the same as in Example A1, and a solid content concentration of 10% by weight of antimony pentoxide / silica-coated zirconia was prepared. Microparticle Alcohol Dispersion (A-2).

[0311] surface treatment

[0312] Next, except that 119 g of antimony pentoxide / silica-coated zirconia fine particle alcohol dispersion (A...

Embodiment A3

[0315] Preparation of Modified Zirconia Microparticles (A-3) Dispersion

[0316] Antimony pentoxide coating

[0317] Mix zirconia sol (A-1) 150g and potassium antimonate aqueous solution (as Sb 2 o 5 concentration of 1% by weight) 150 g, the mixture was passed through an ion exchange tower filled with 330 g of a cation exchange resin (manufactured by Mitsubishi Chemical Corporation: DAIAION PK-216H), and aged at 90° C. for 1 hour to prepare antimony pentoxide-coated Zirconia sol (A-3). The resulting sol had a pH of 2.7.

[0318] Silica coating

[0319] Except for using 277 g of antimony pentoxide-coated zirconia sol (A-3), other operations were the same as in Example A1, and an alcohol dispersion of antimony pentoxide / silica-coated zirconia fine particles with a solid content concentration of 10% by weight was prepared. solution (A-3).

[0320] surface treatment

[0321] Next, except that 119 g of antimony pentoxide / silica-coated zirconia fine particle alcohol d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com