Patents

Literature

77results about How to "Minimal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microparticles

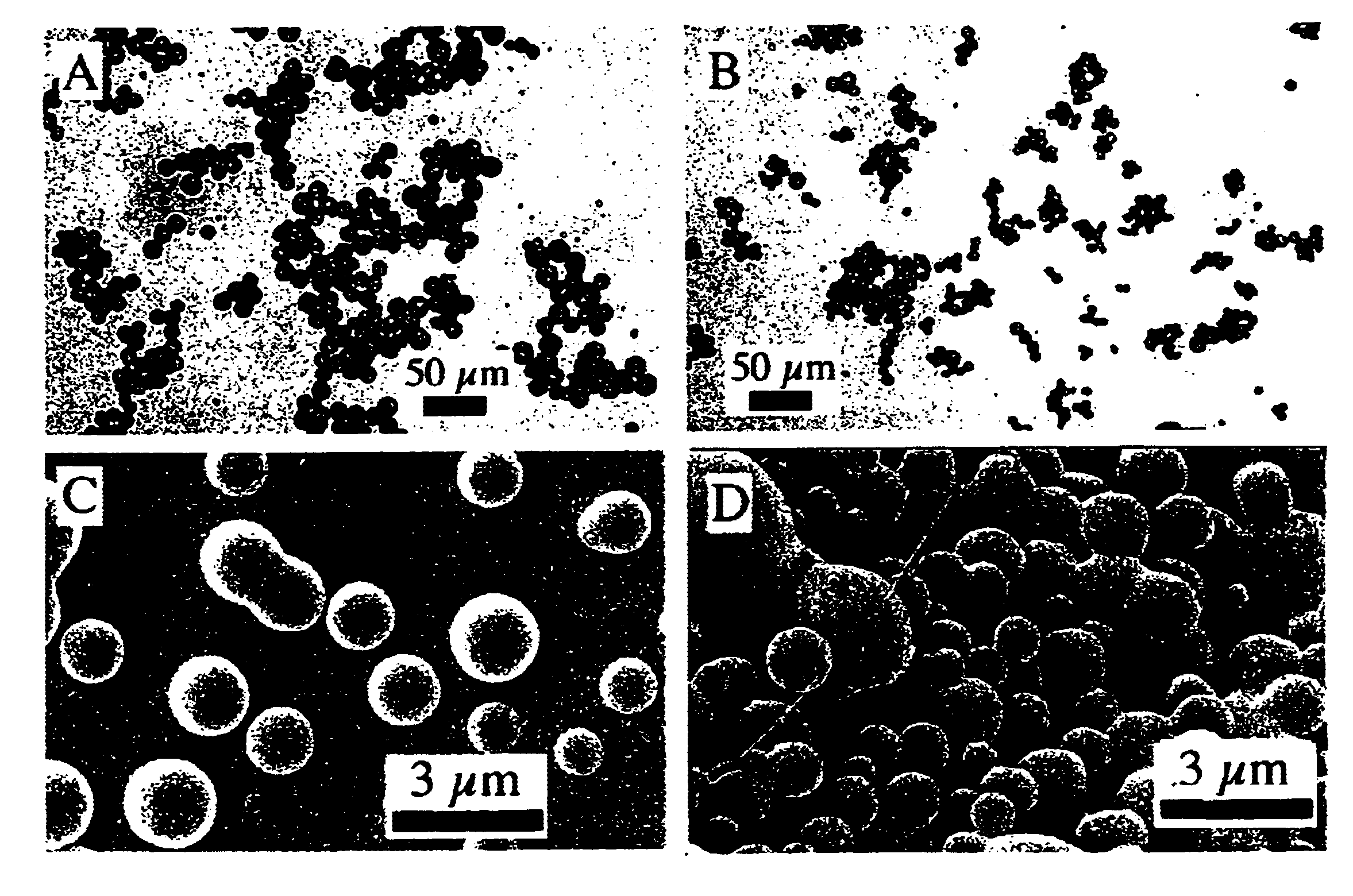

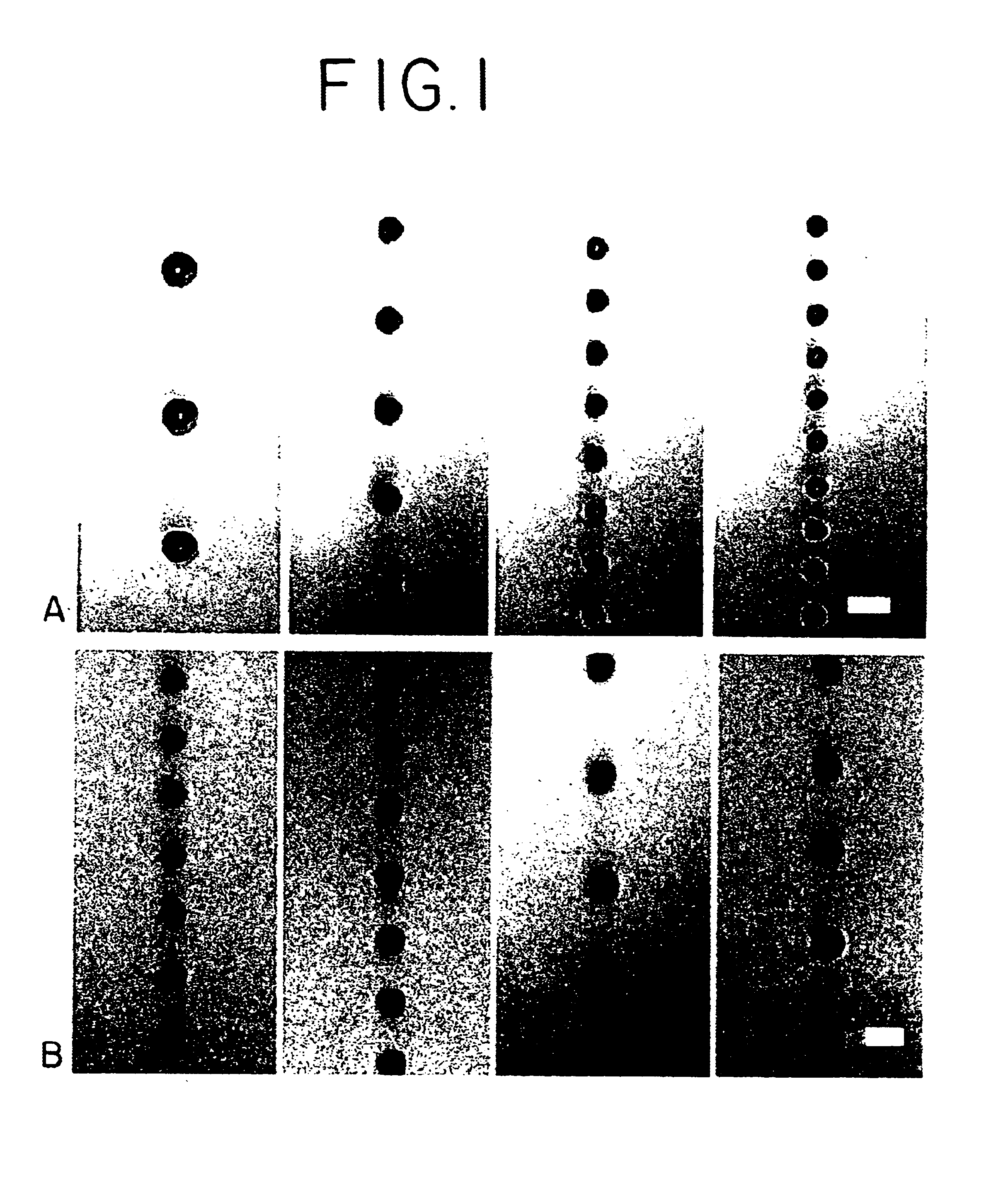

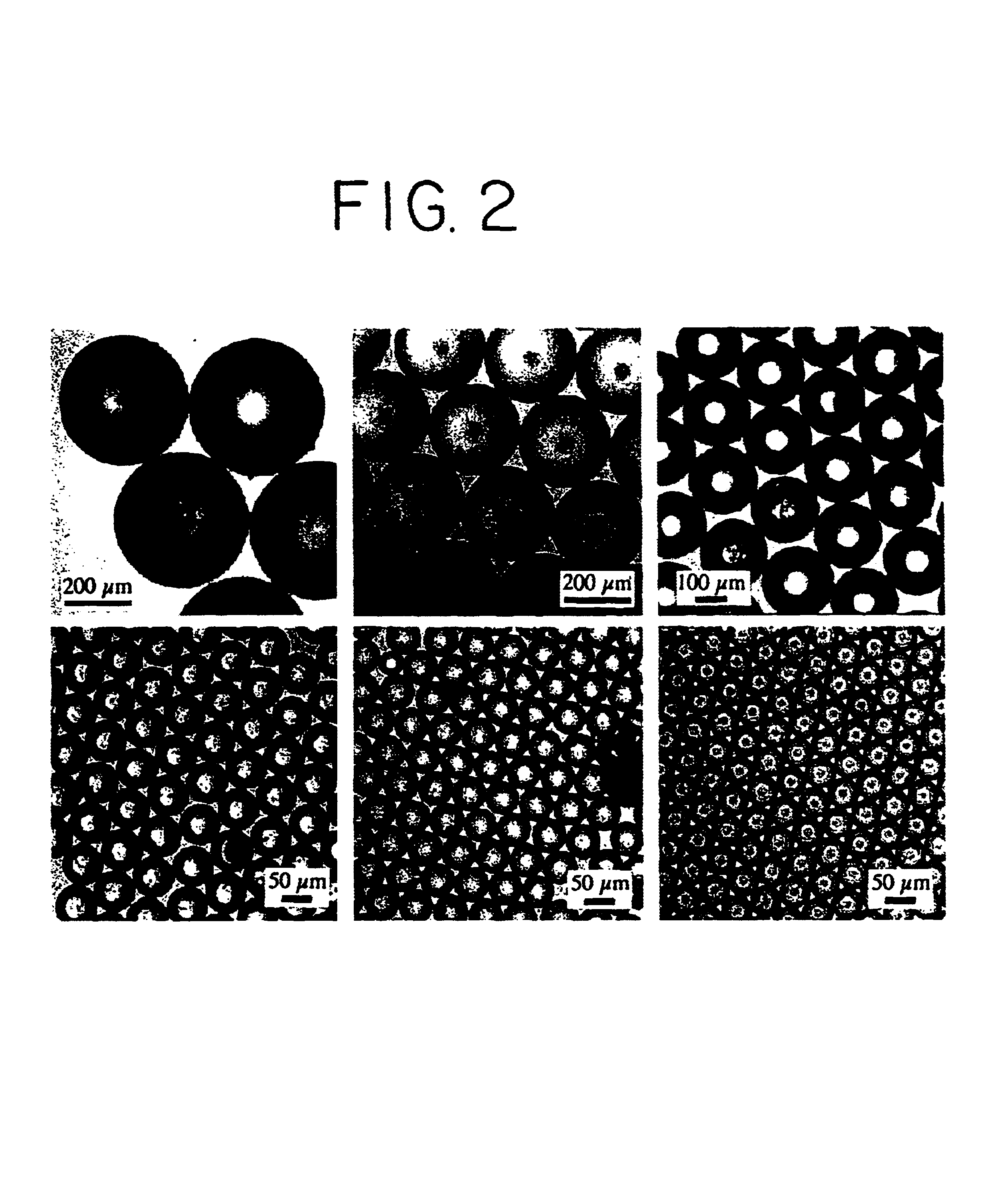

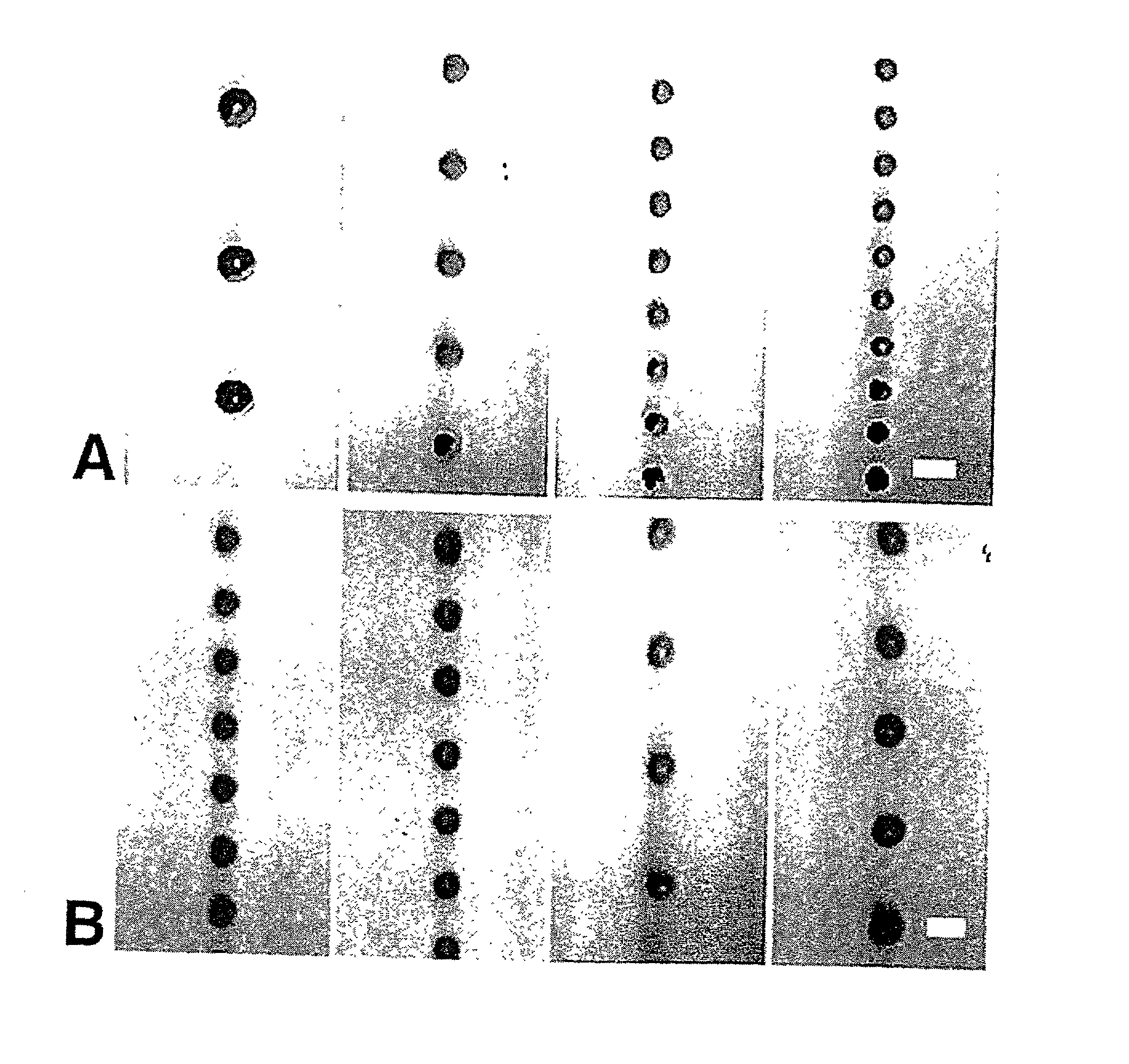

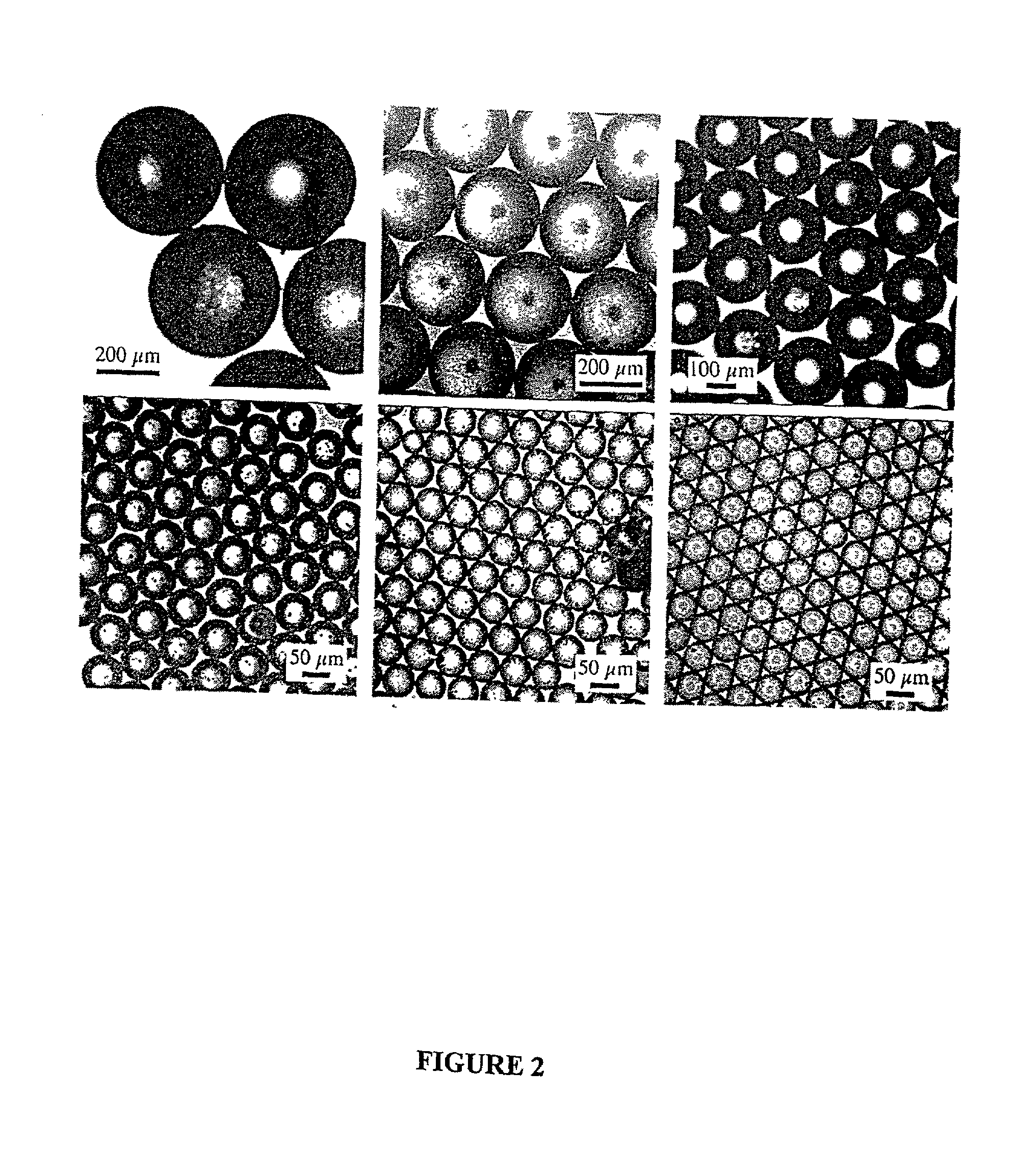

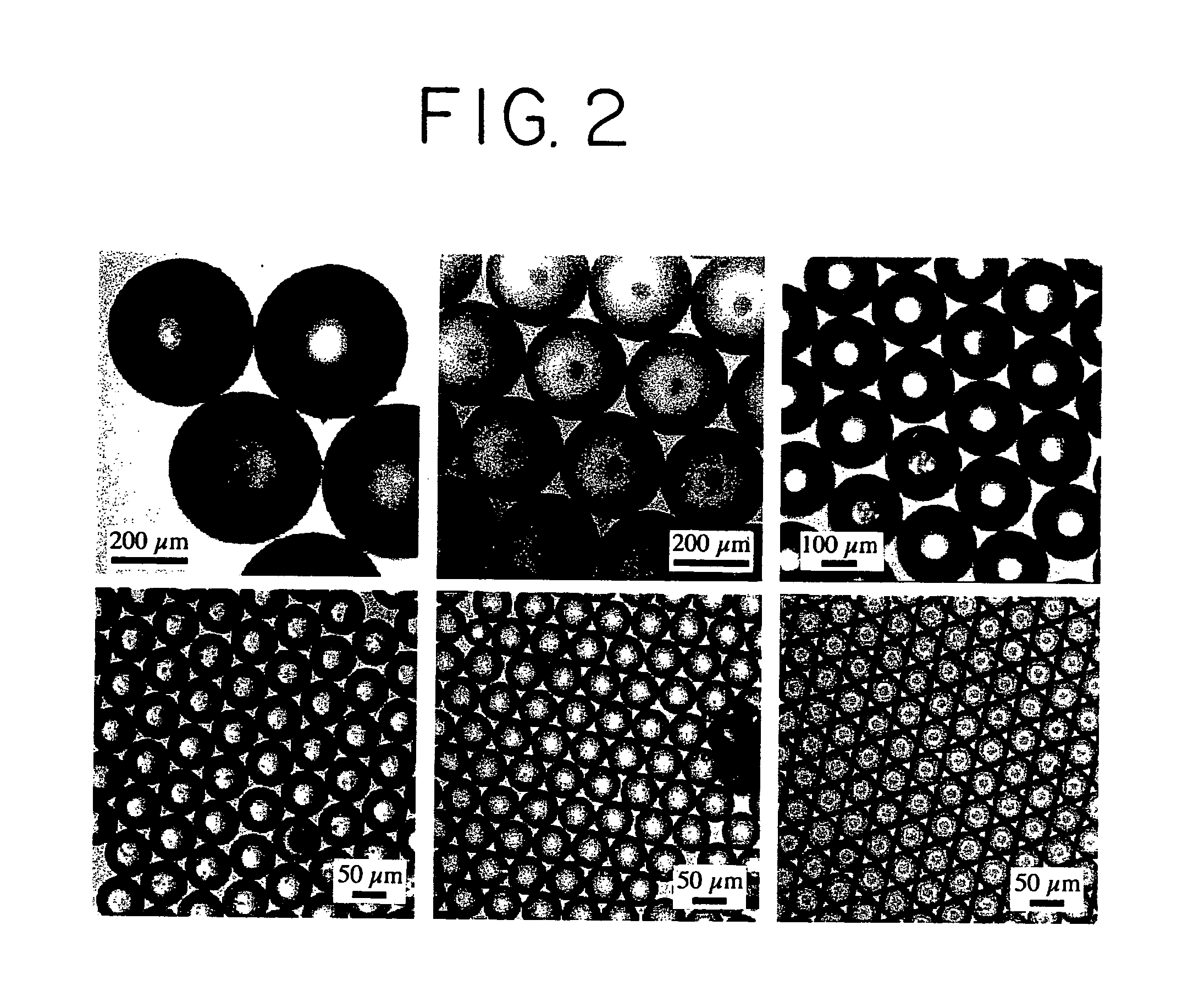

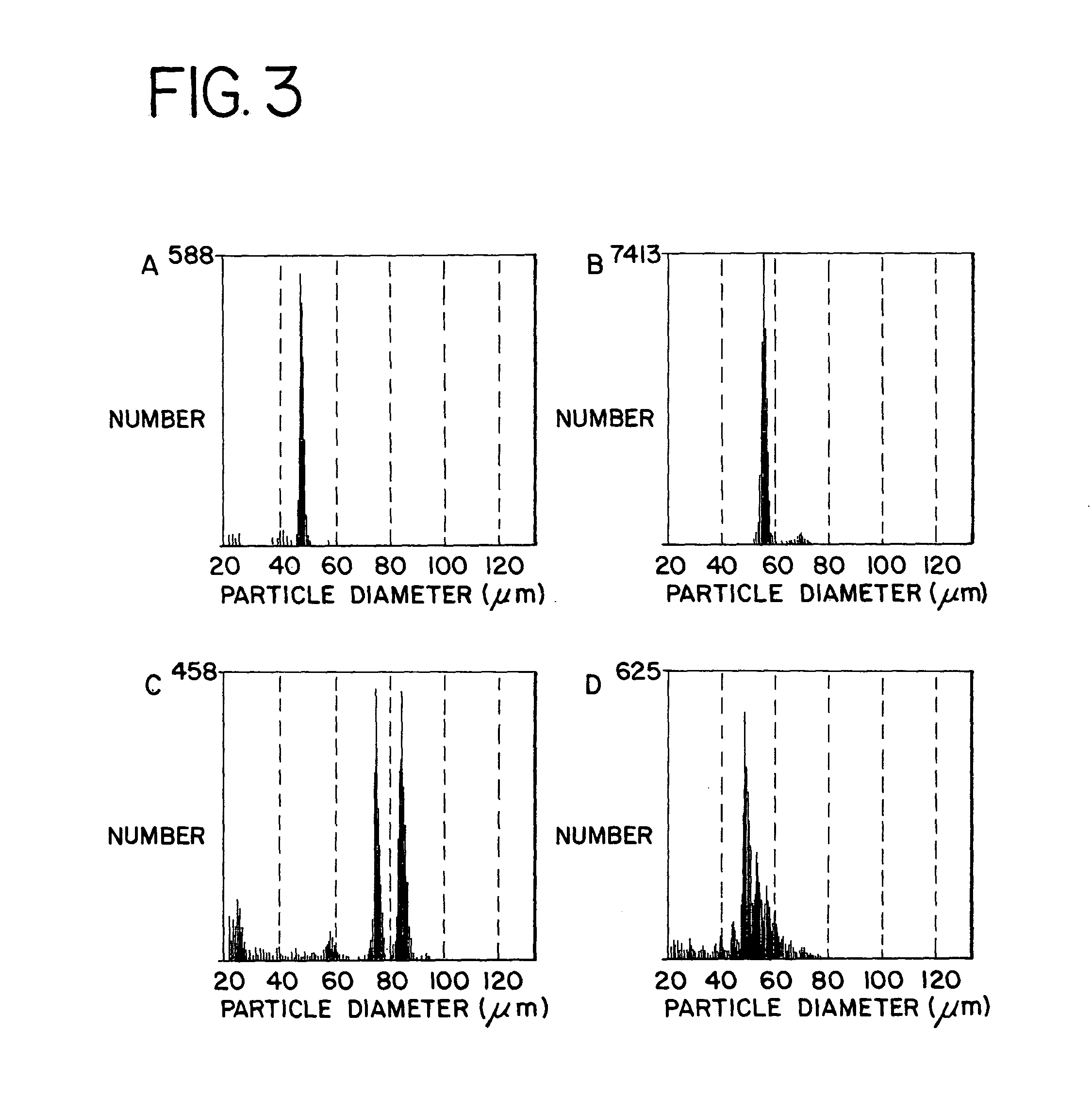

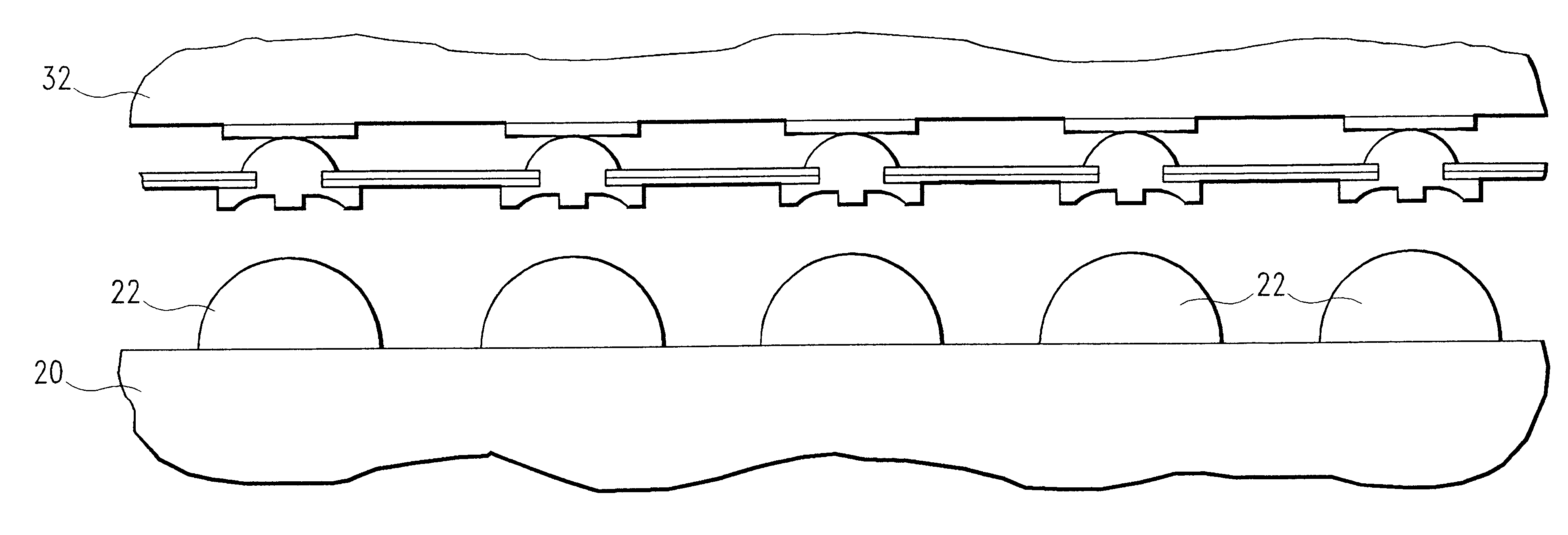

InactiveUS6669961B2Minimal deformationHardening of the spheresPowder deliveryNanostructure manufactureMicroparticleNanometre

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Microparticles

InactiveUS20020054912A1Poor controlControlling drug release ratePowder deliveryNanostructure manufactureEngineeringPhysics

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Microparticles

InactiveUS20040022939A1Minimal deformationHardening of the spheresPowder deliveryNanostructure manufactureMicroparticlePhysics

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

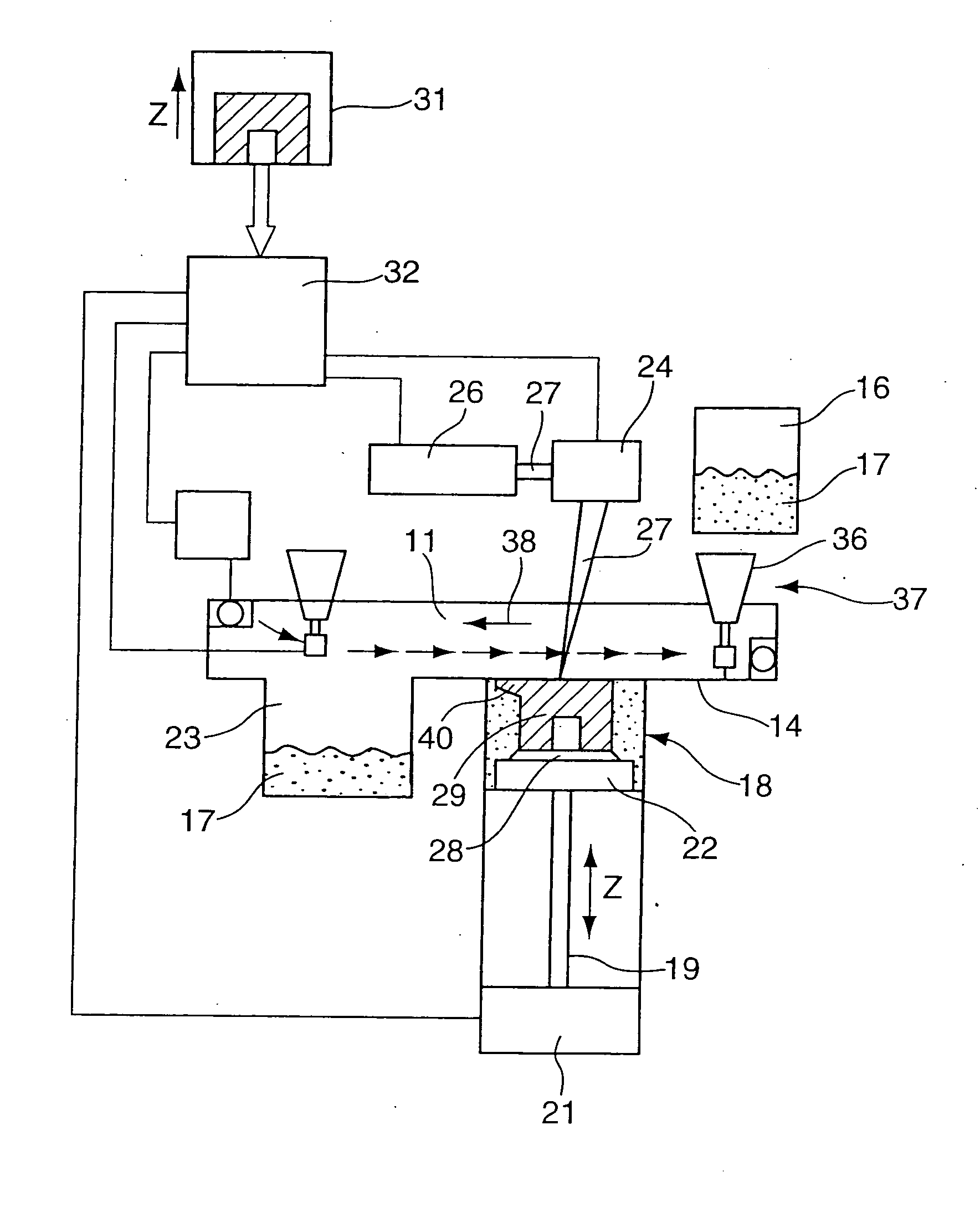

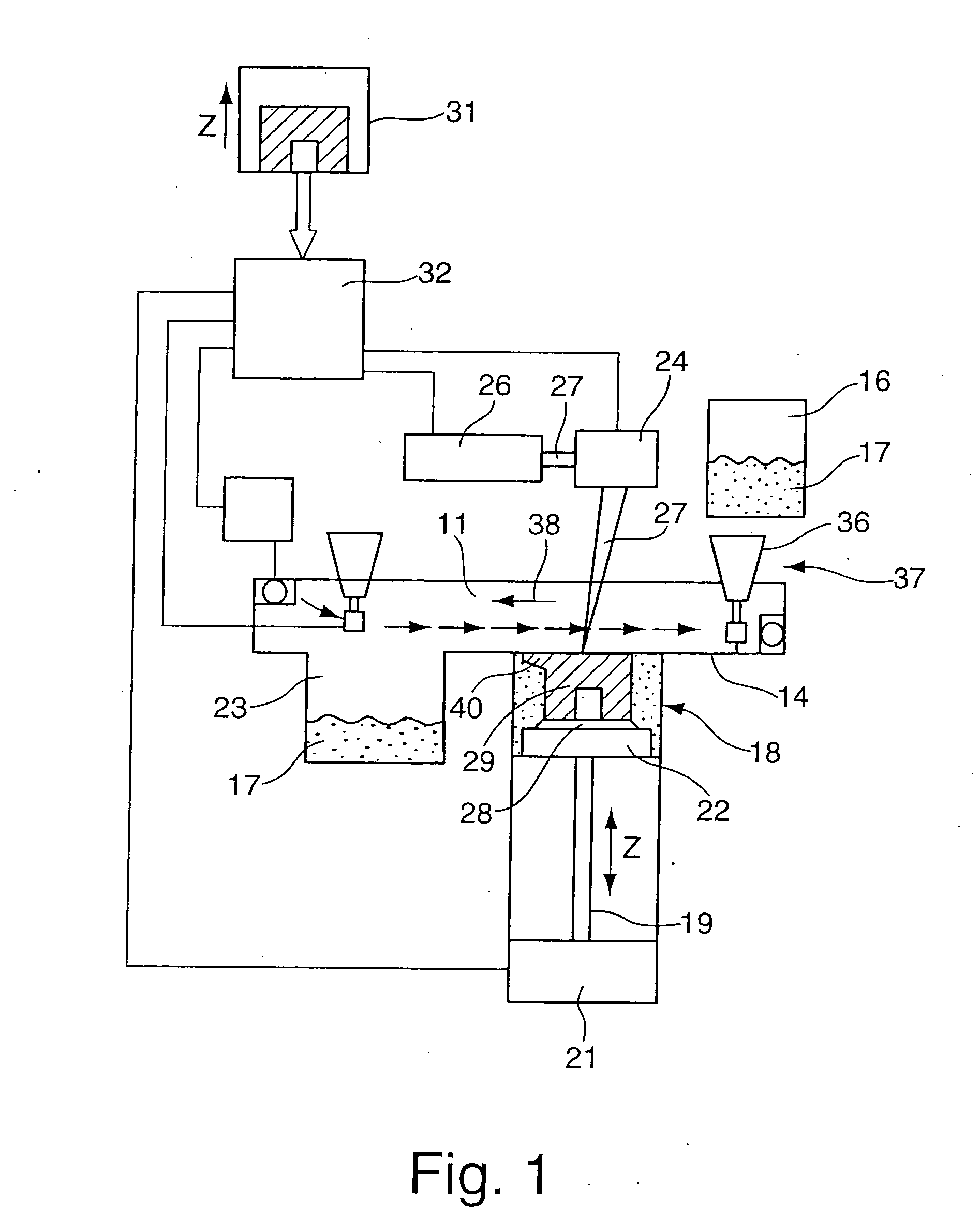

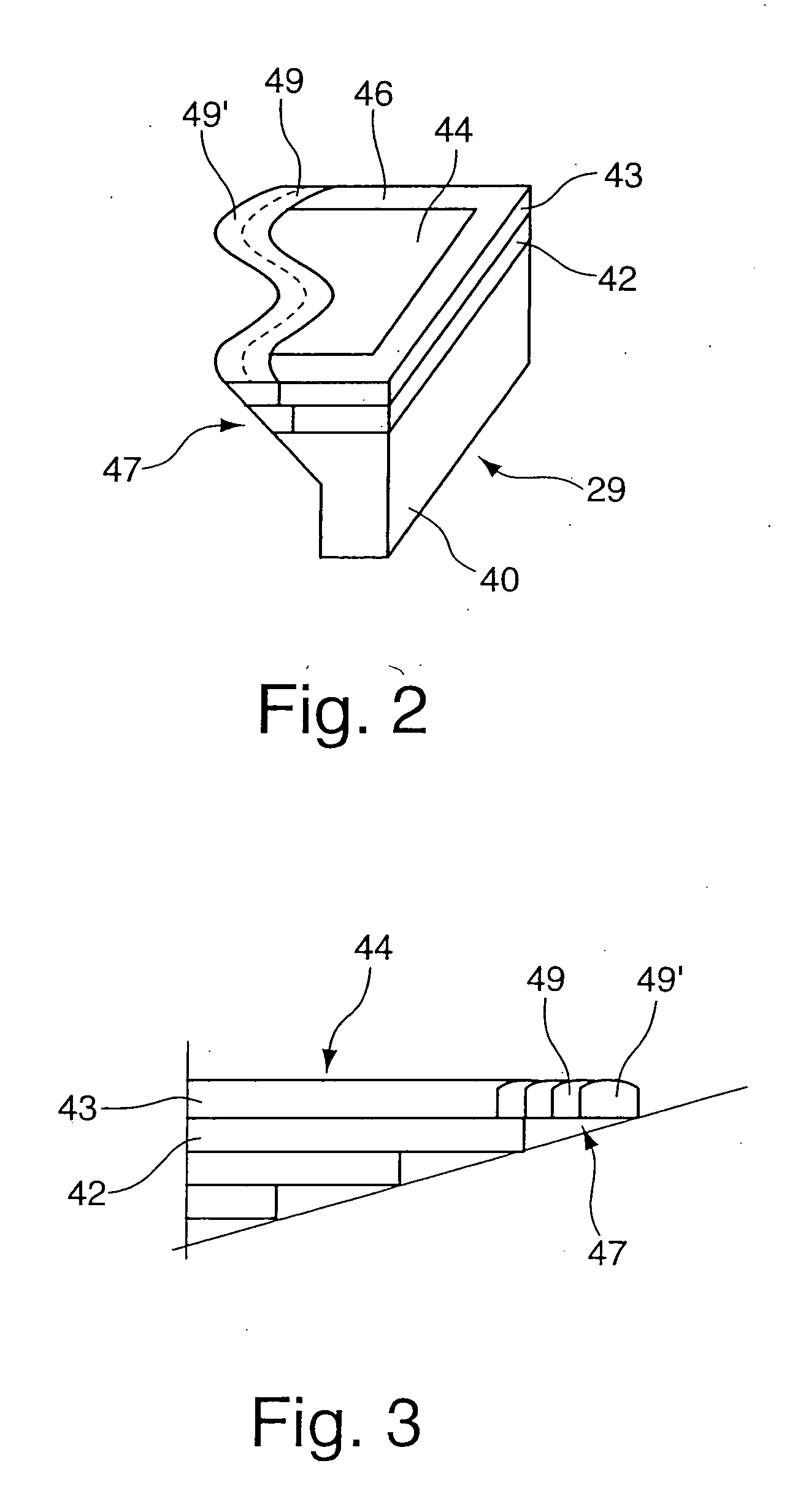

Method for the manufacture of a three-dimensional molding

InactiveUS20070035069A1Improve surface qualityHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceRadiation

The invention relates to a method for the manufacture of a three-dimensional molding (29), wherein the molding (29) is generated from a solidifiable powder material by consecutively solidifying individual layers through the effect of radiation (27), while generating a new layer by exposing traces that are arranged adjacent to each other to radiation, wherein, in order to form an overhang region (47), a contour trace (49) is formed on a coherently solidified region and on a powder material (17) that has not solidified yet, the contour trace (49) is adjusted to an outer contour at least in the region of transition from the solidified region to the powder material (17) that has not solidified yet, and the at least one further contour trace (49′) adjusted to the outer contour is formed of non-solidified material (17) while comprising a high overlapping degree in relation to the previously formed contour trace (49).

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

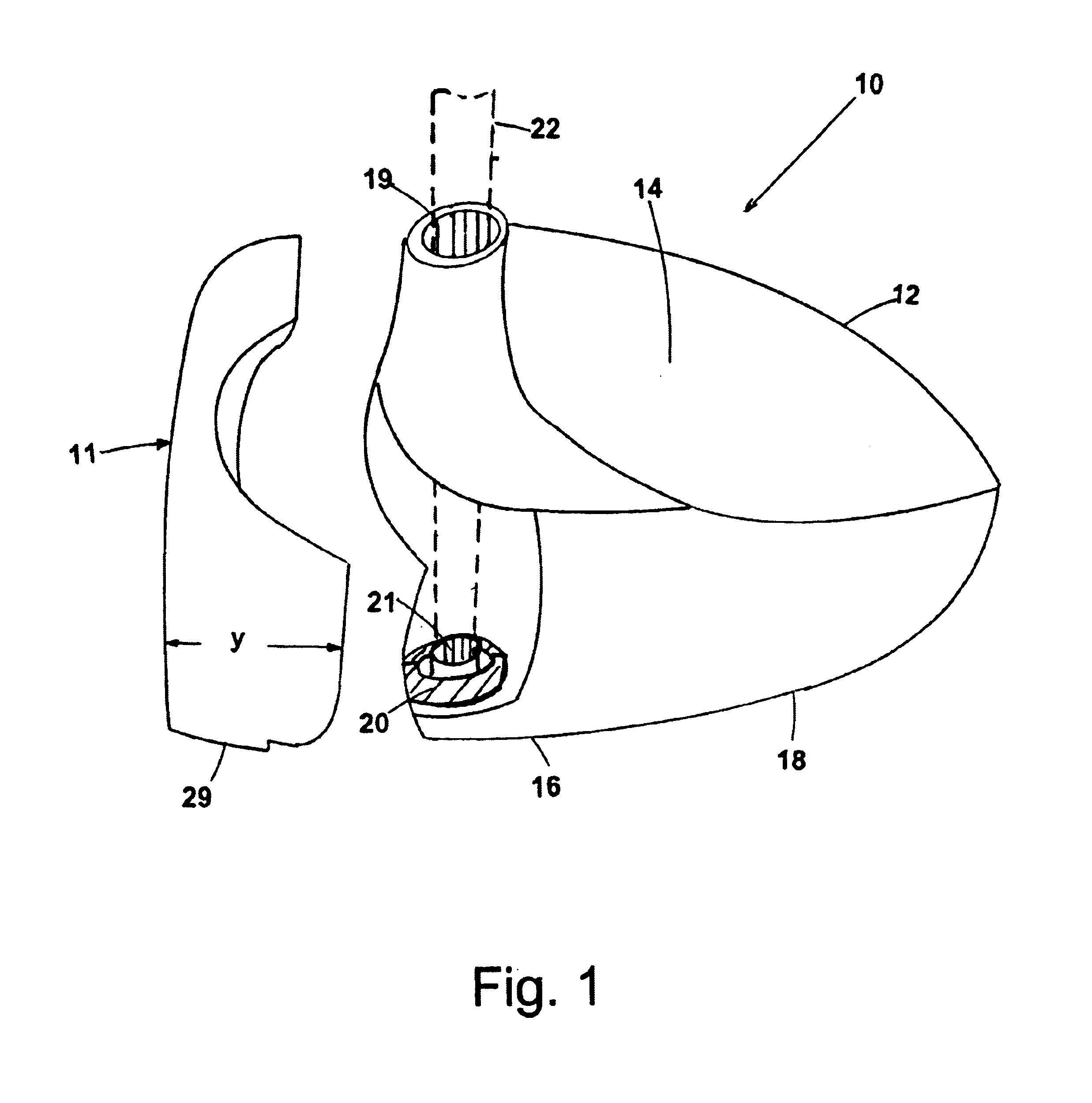

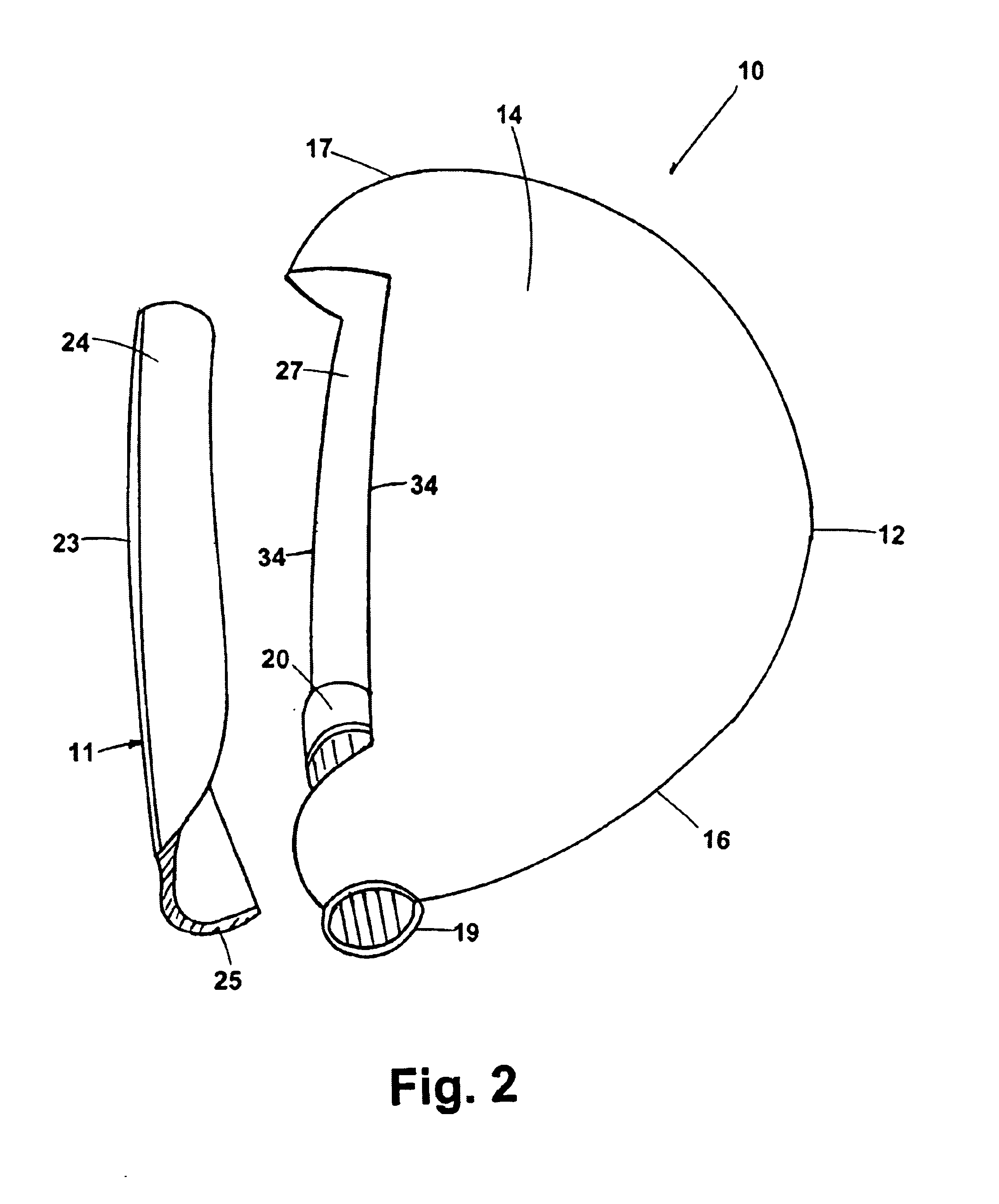

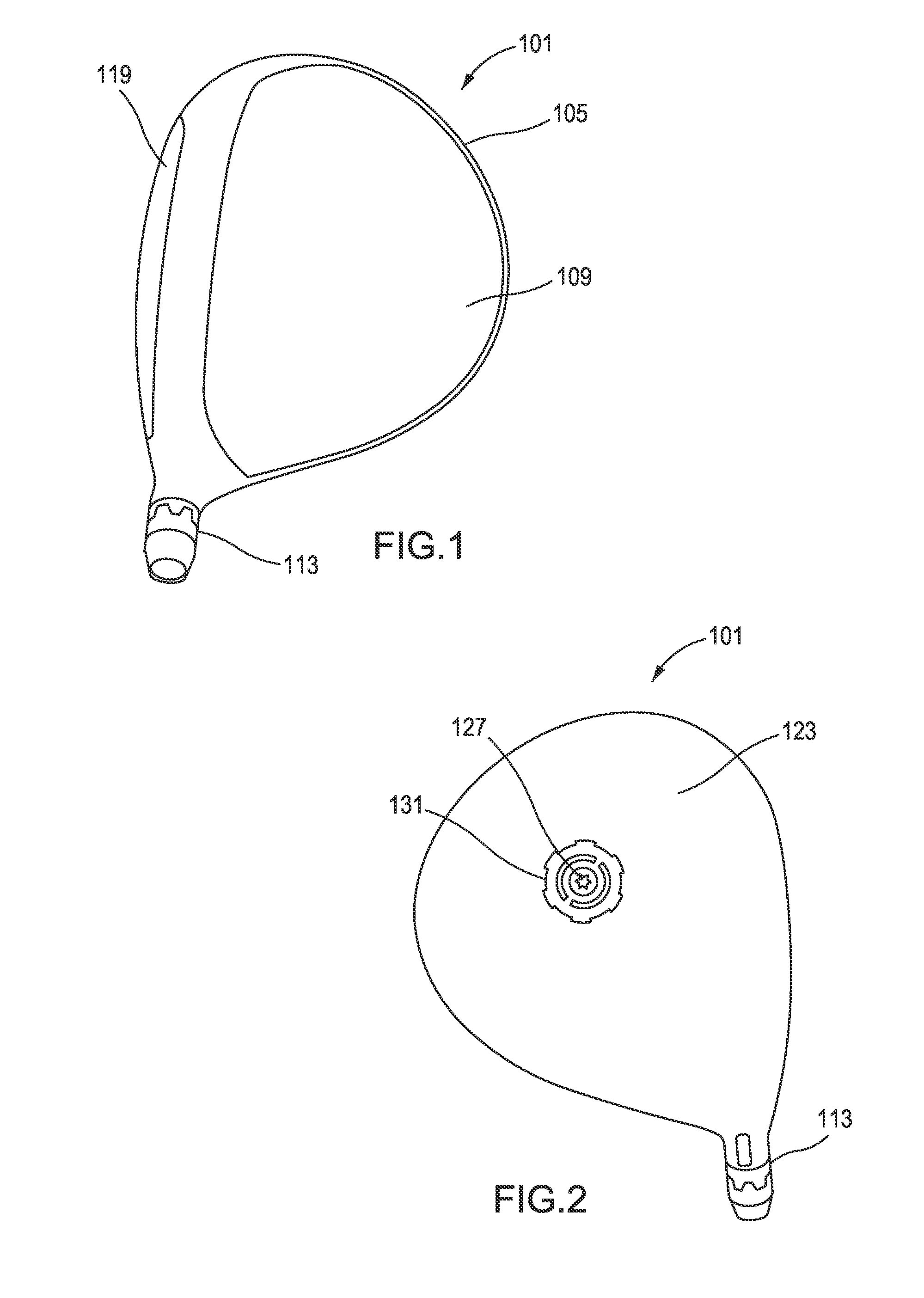

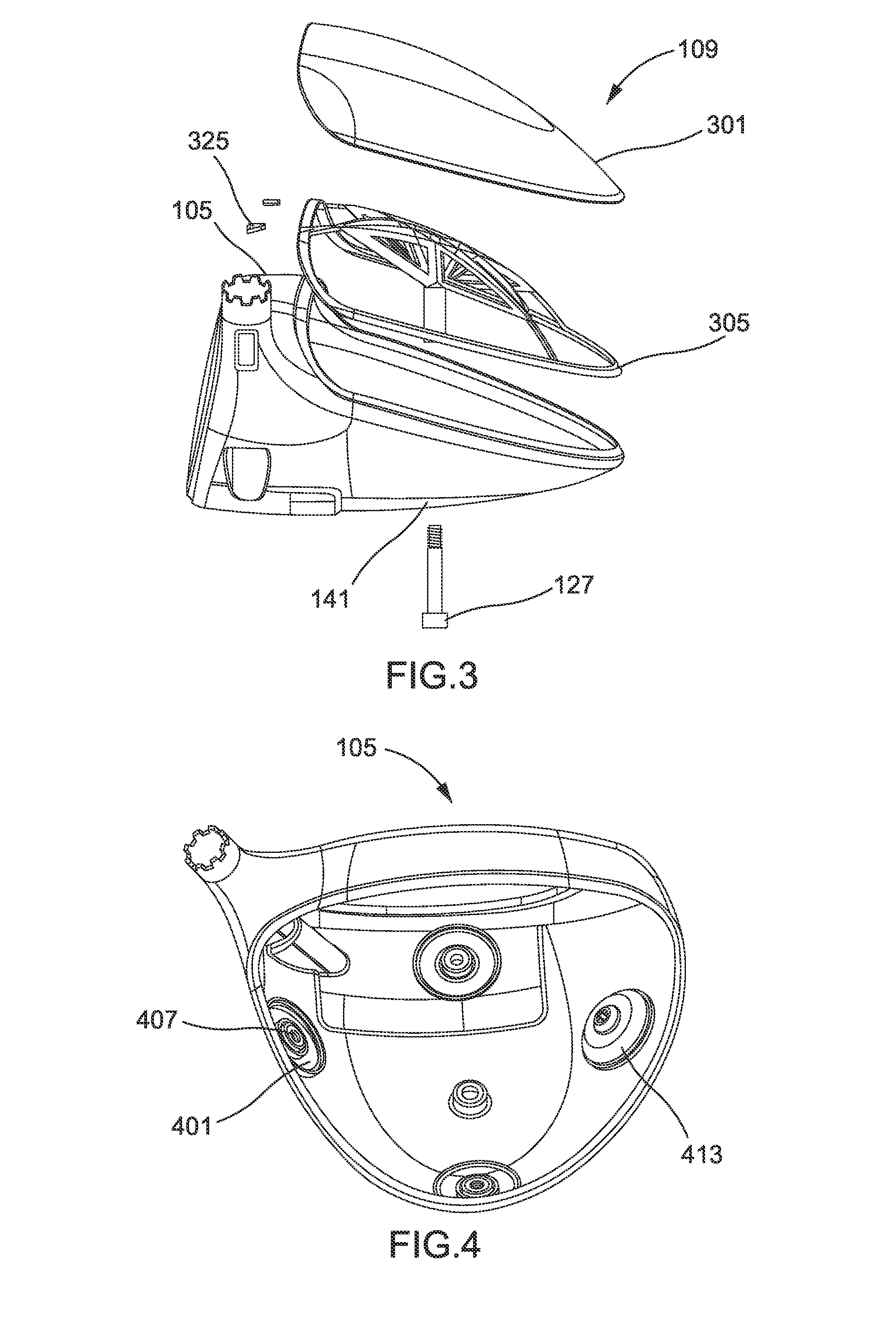

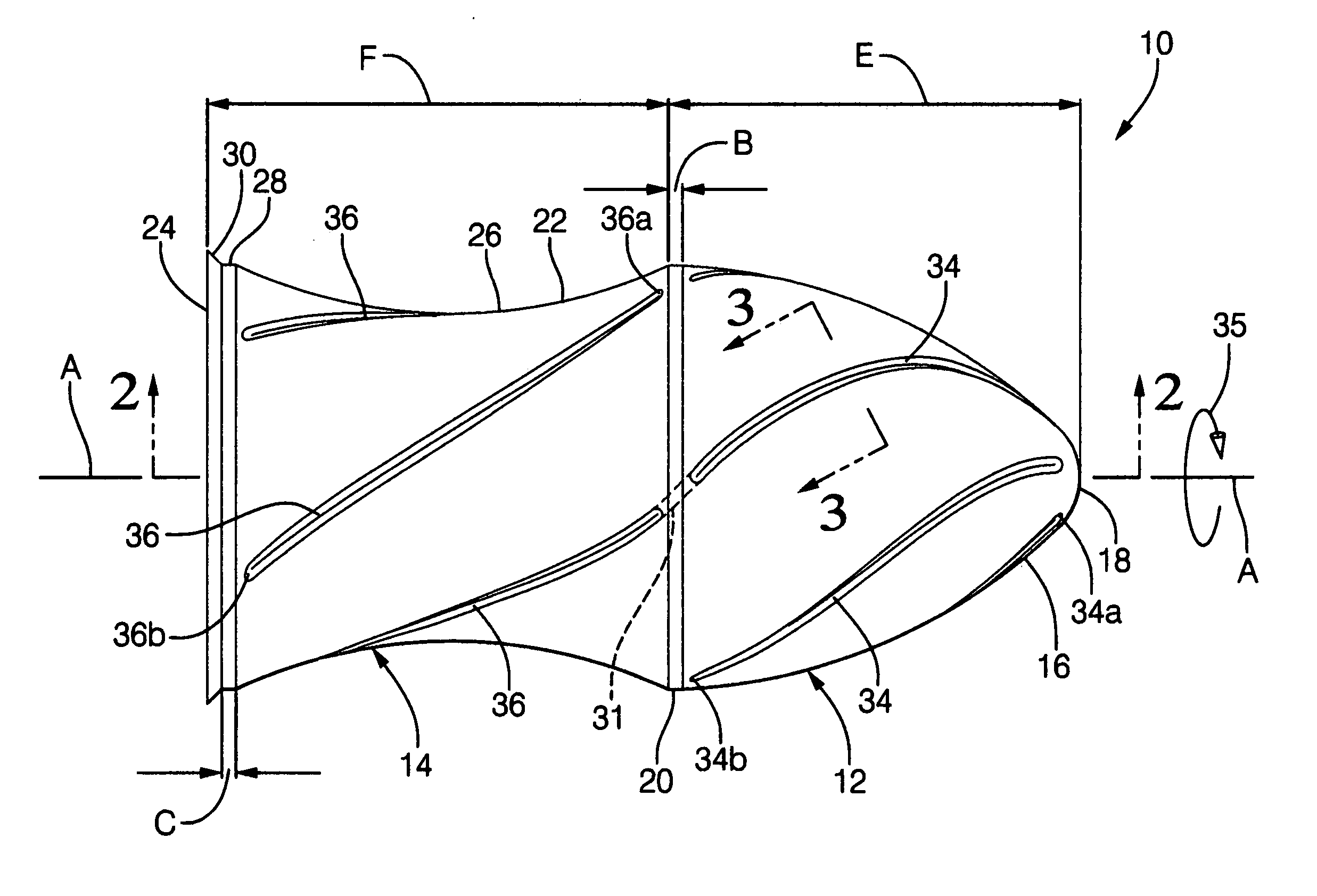

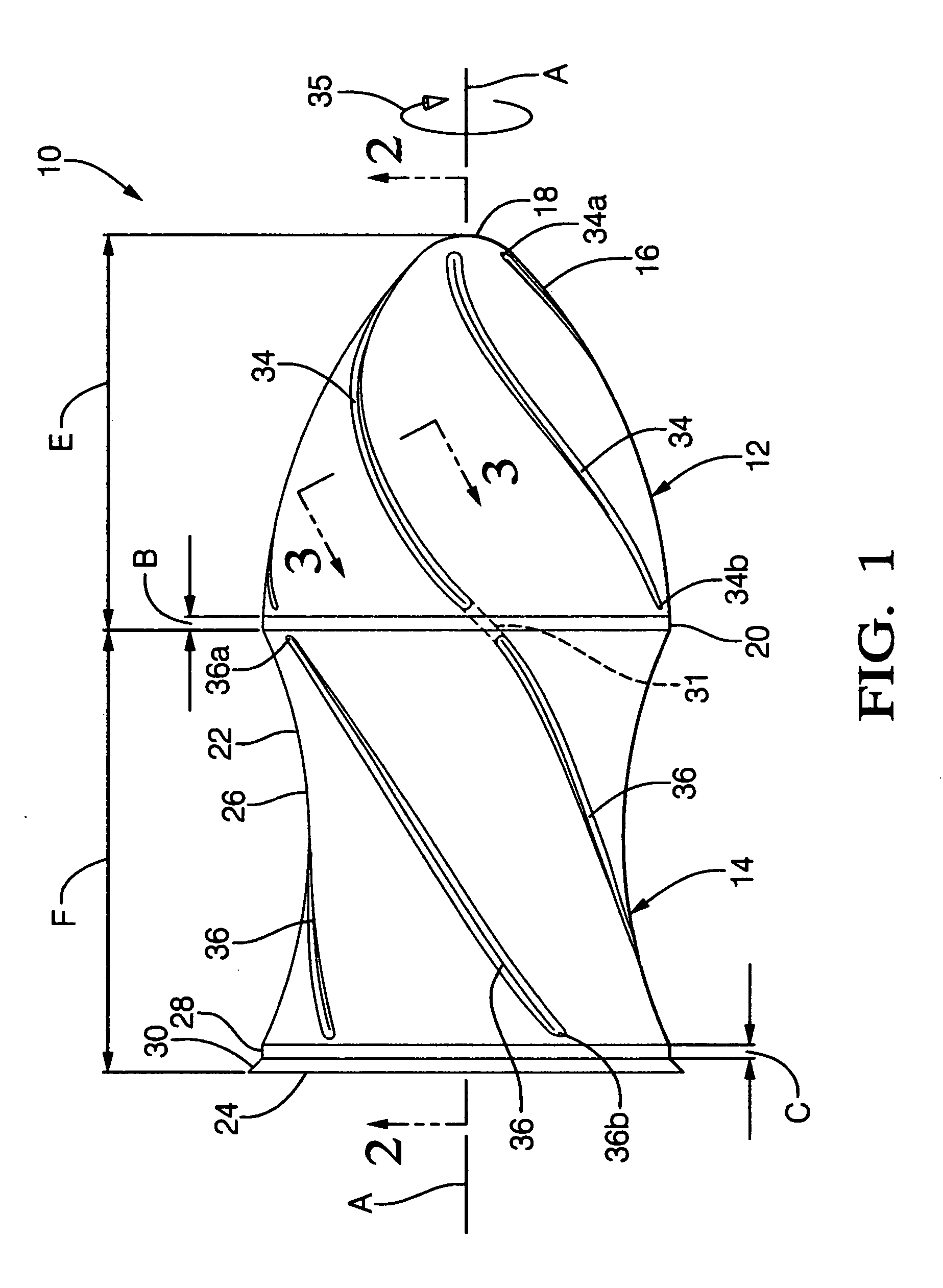

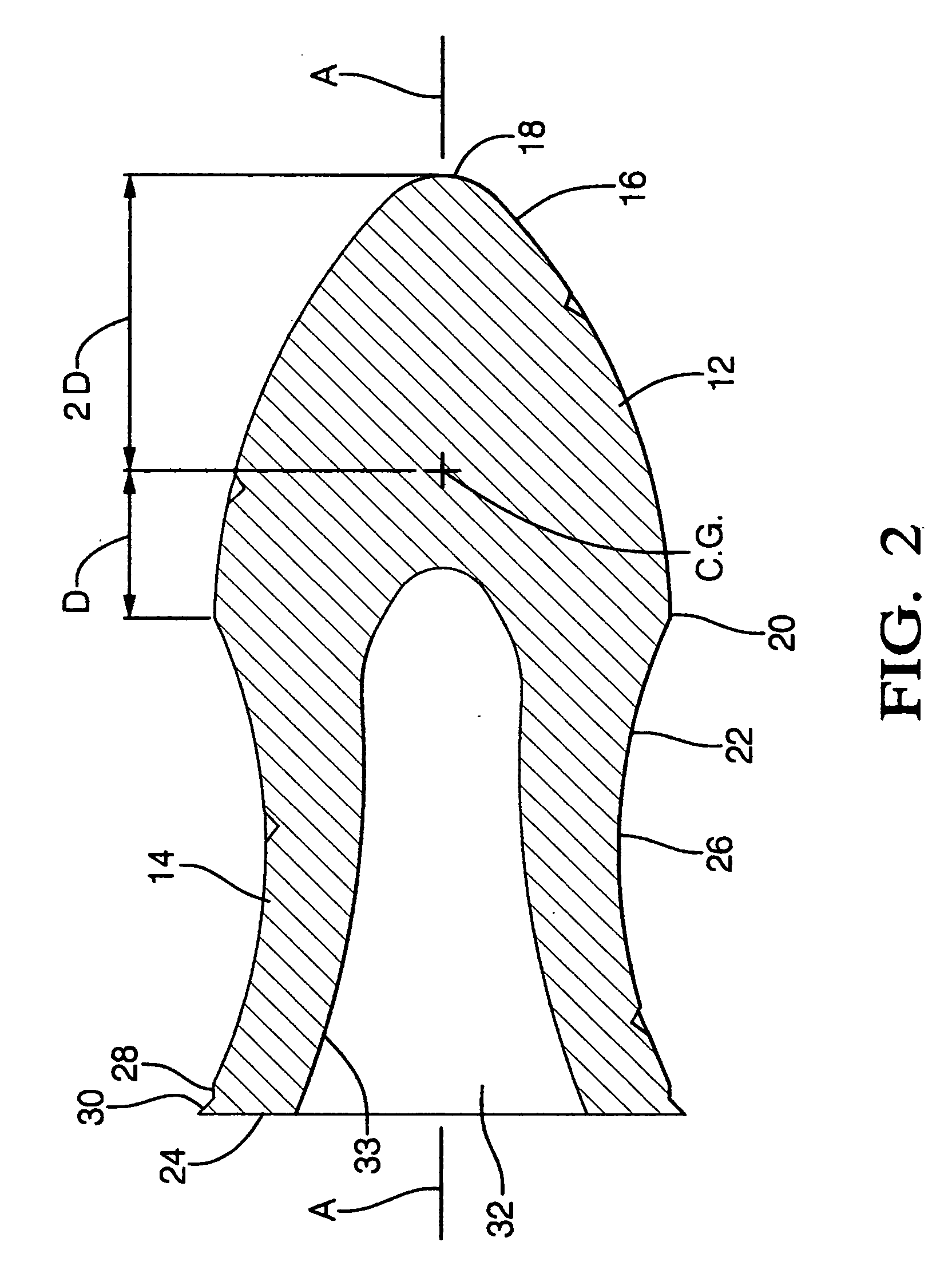

Metal wood

Owner:COBRA GOLF

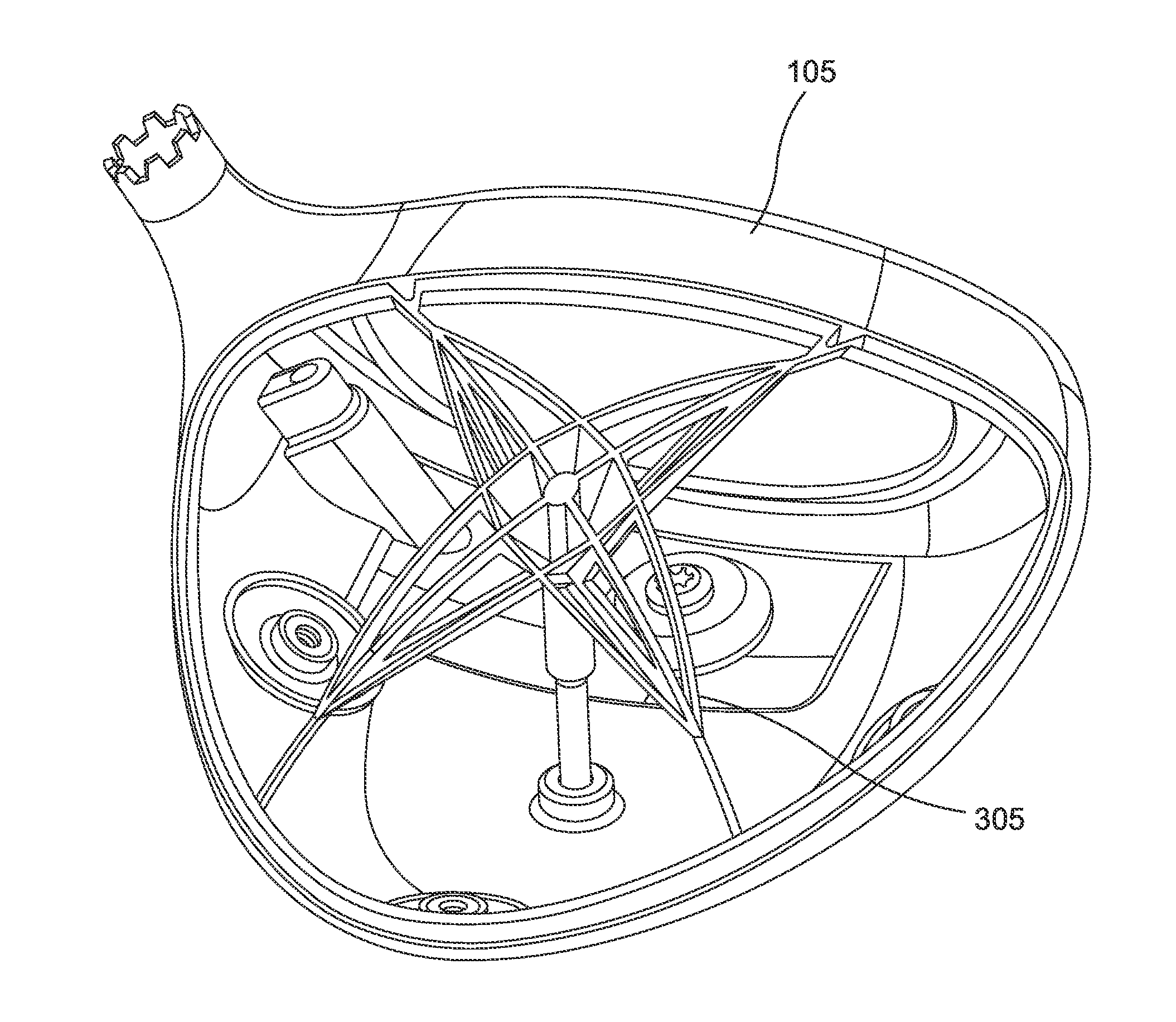

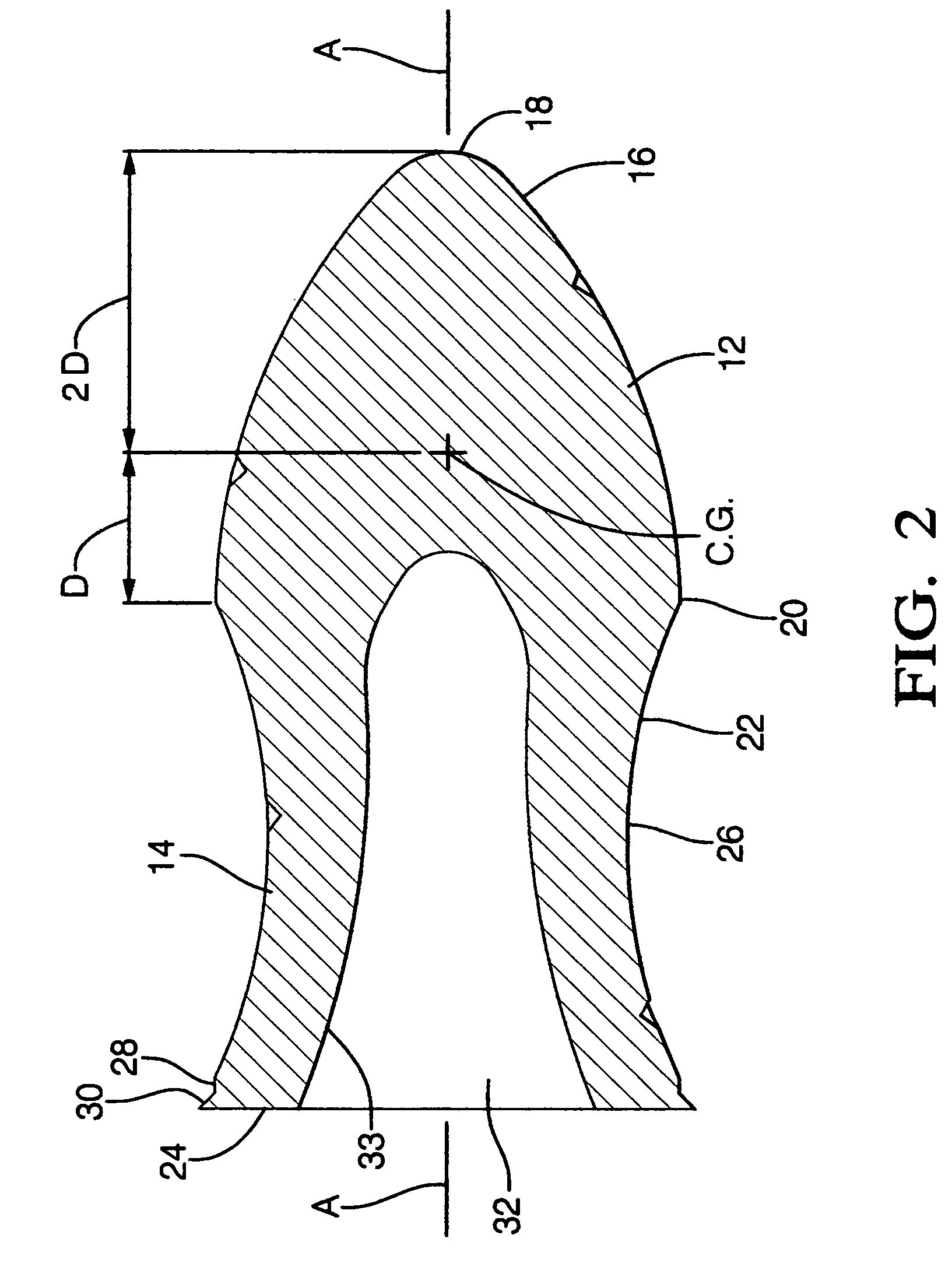

Golf club head with removable component

ActiveUS20140187346A1Highly effective for playing golfDurableGolf clubsRacket sportsWeight adjustmentEngineering

The invention provides a golf club head with a fully removable component that can withstand the stress of repeated hits. When assembled, the removable component is held in place by a fastening mechanism that includes structural elements that distribute the holding force across the component and tend to equalize the forces around the periphery where the component meets the body. The fastening mechanism may include a post that reaches across the open space within the hollow club head, pulling the removable component towards an opposed main club head body. Since a golf club of the present invention can be opened, it may include a mechanism on the inside for use by a golfer, such as an electronic device or an adjustment mechanism. The golf club may include a weight adjustment system that allows the club to be custom-fitted to a golfer.

Owner:COBRA GOLF

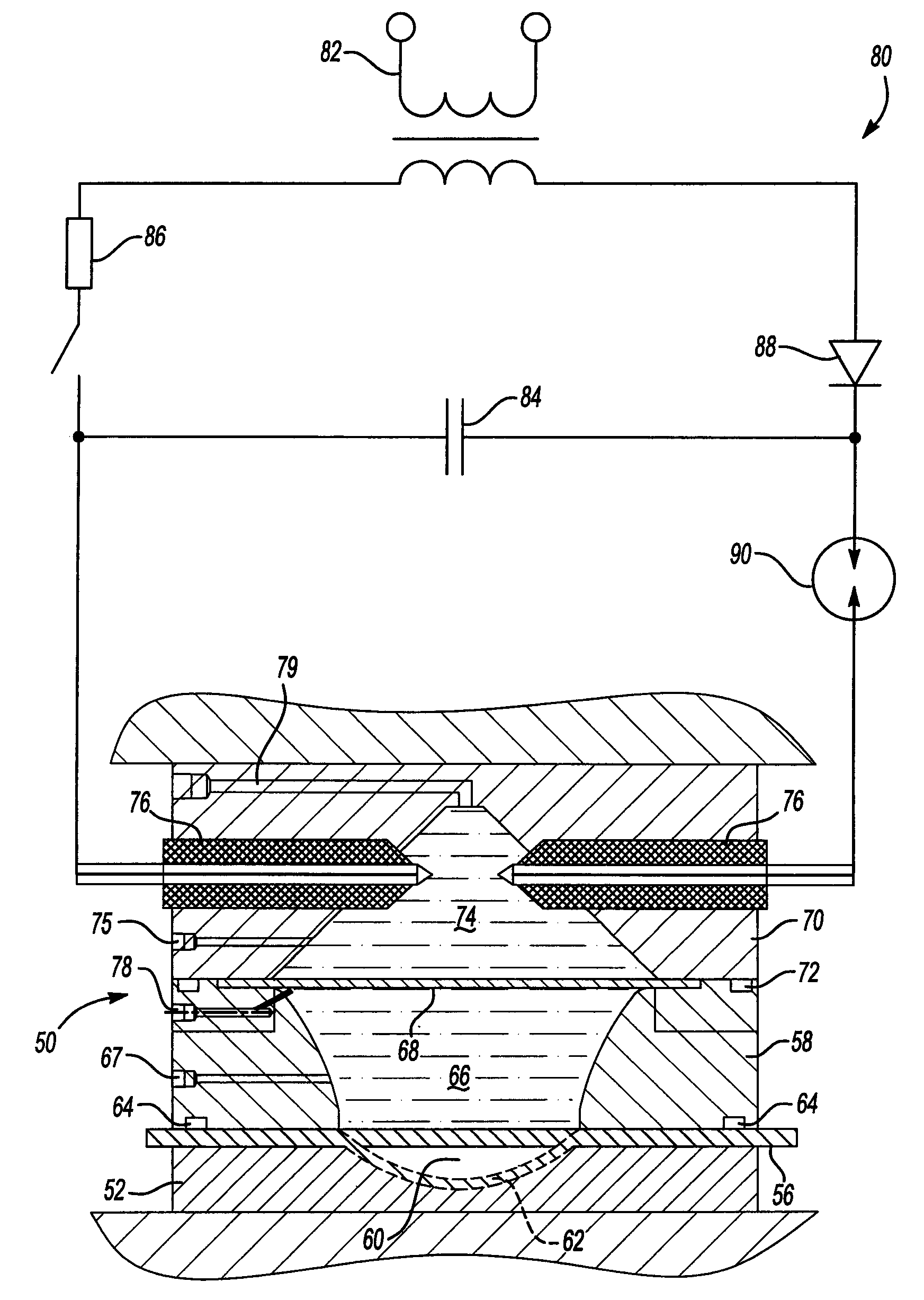

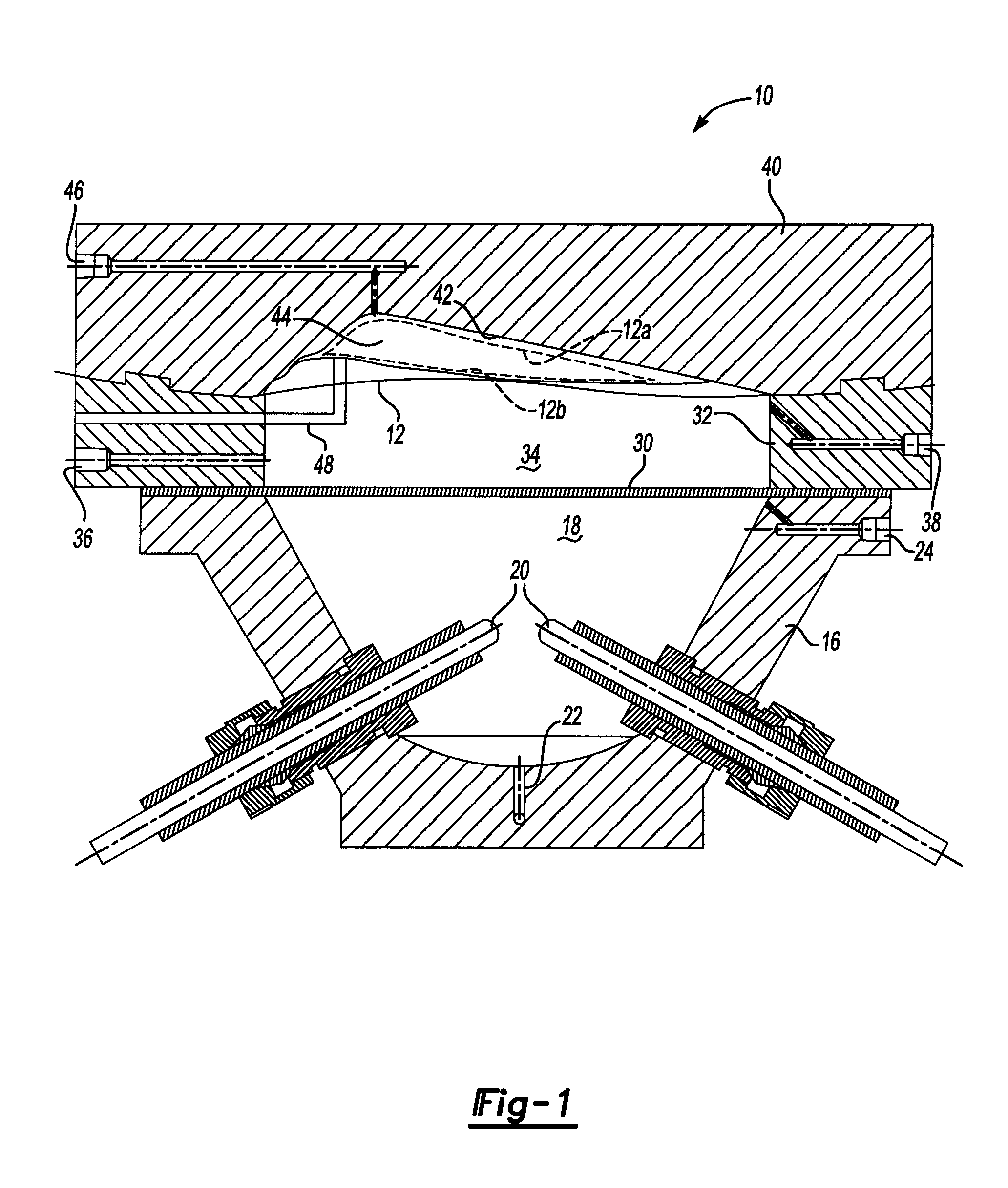

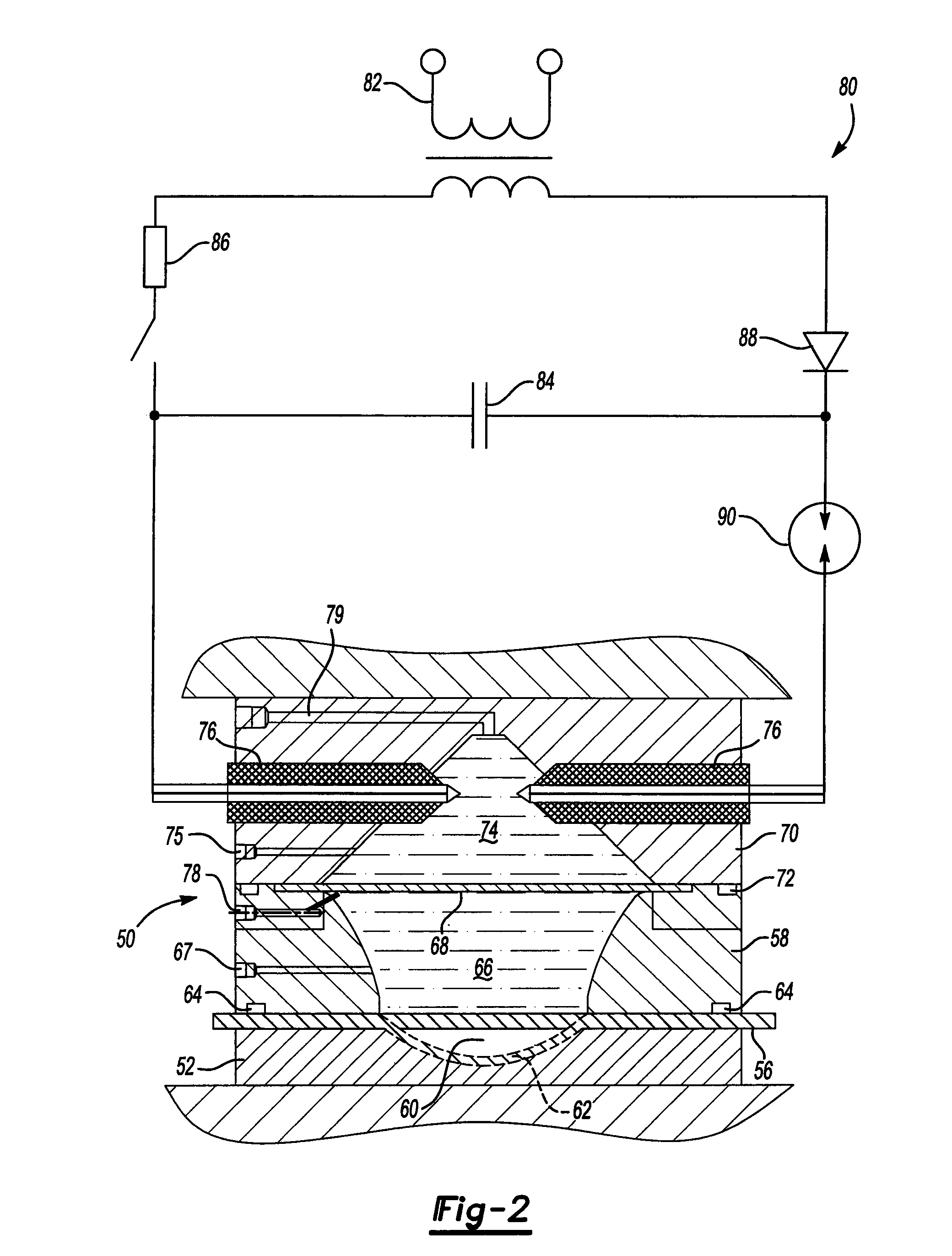

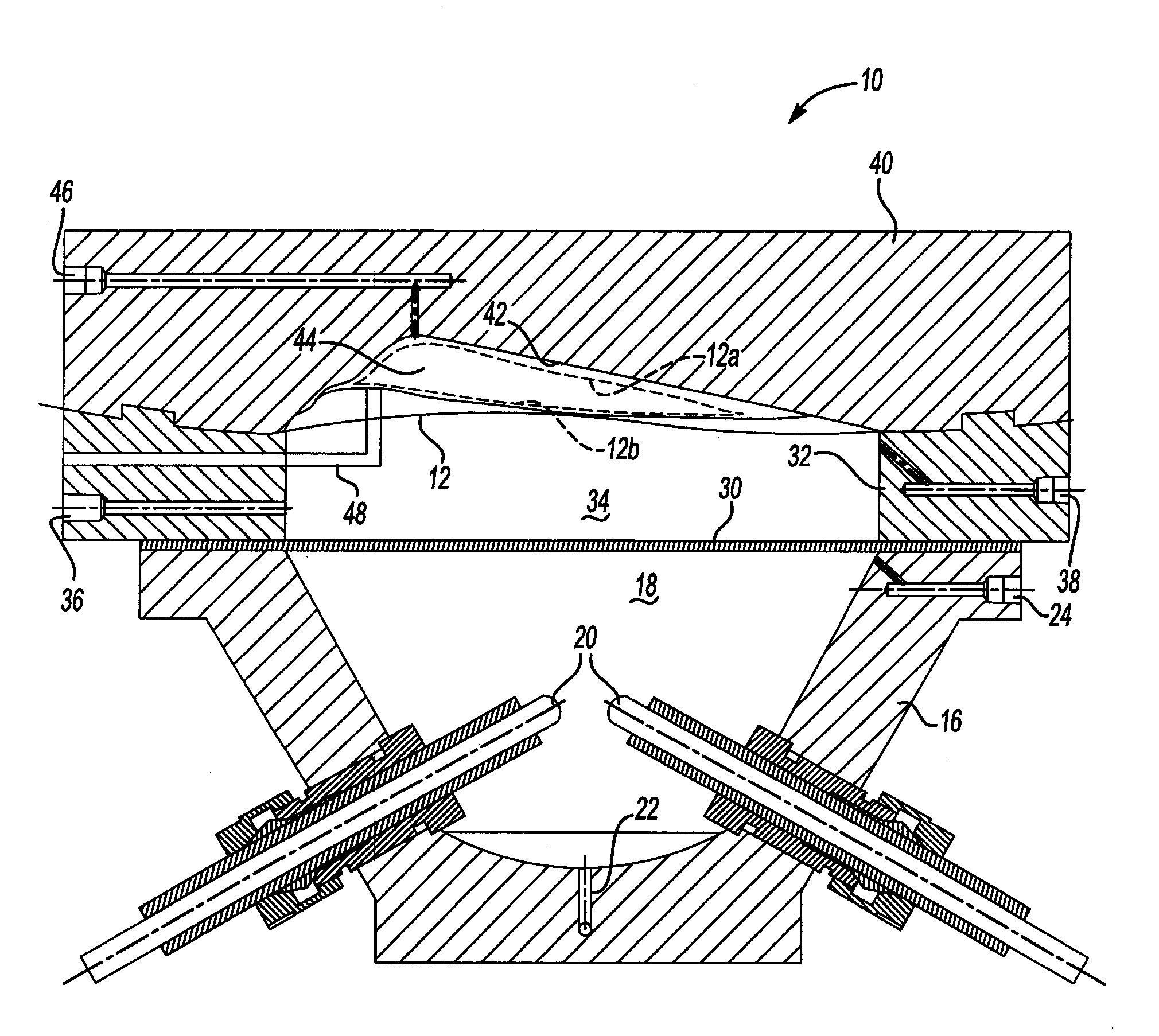

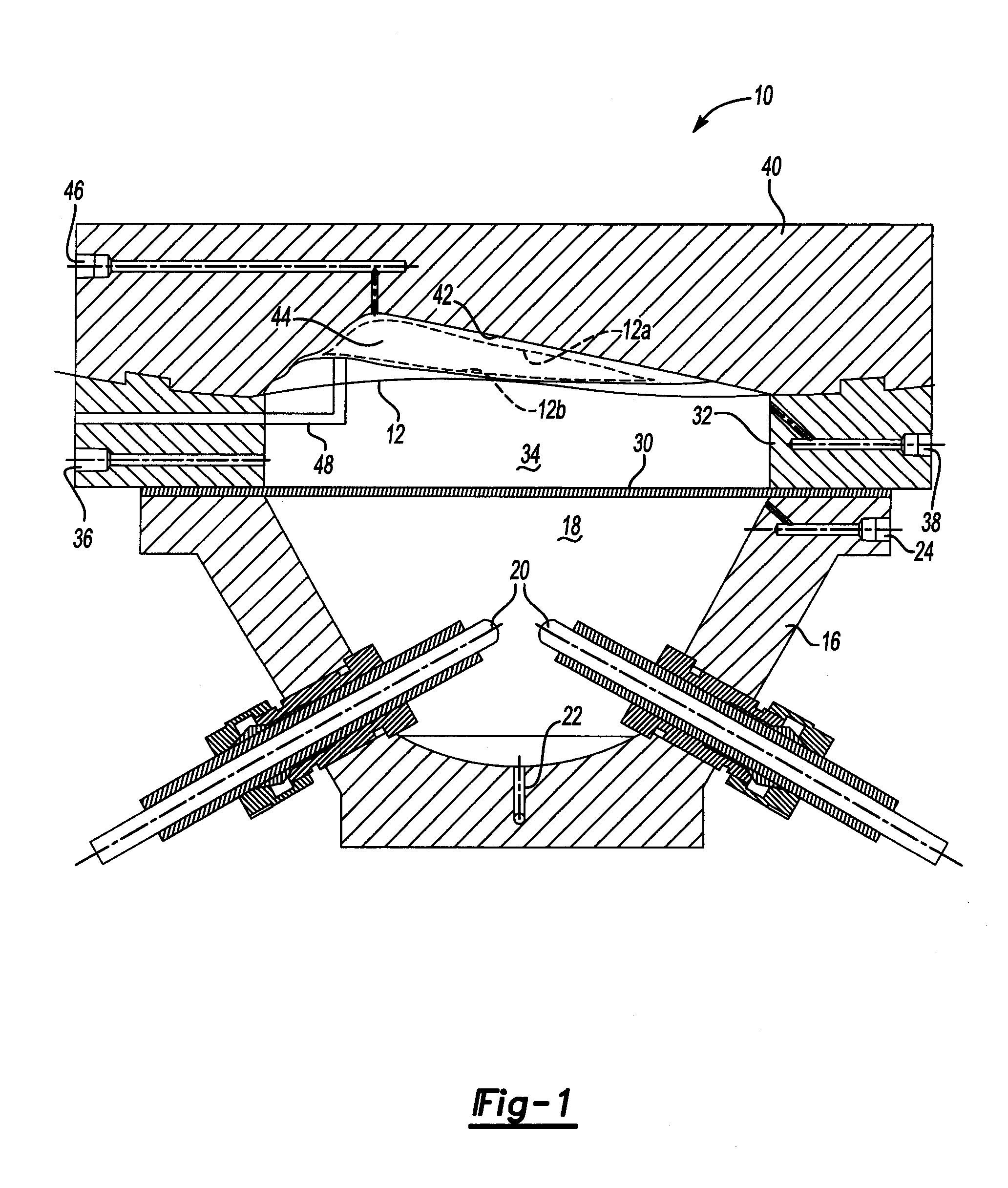

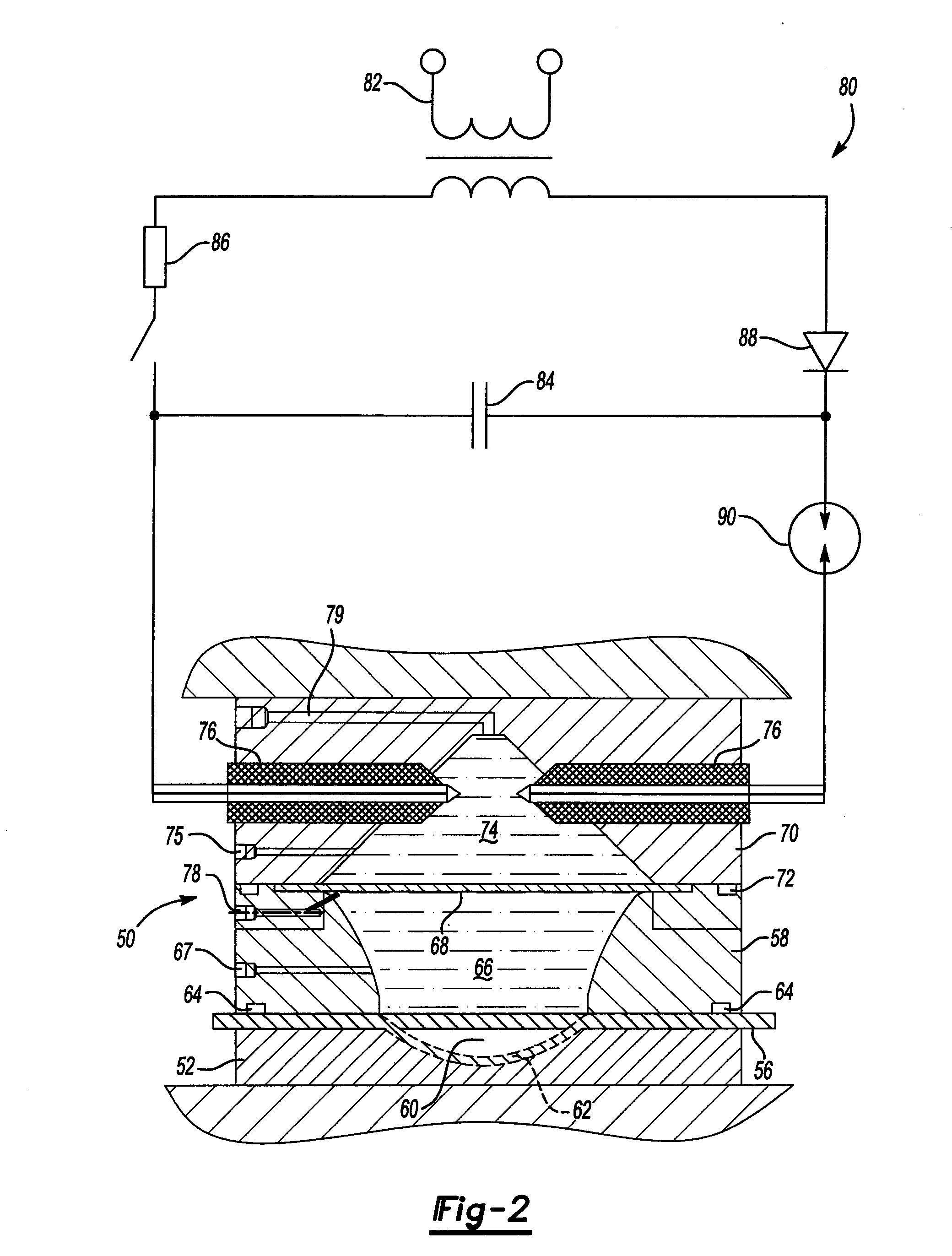

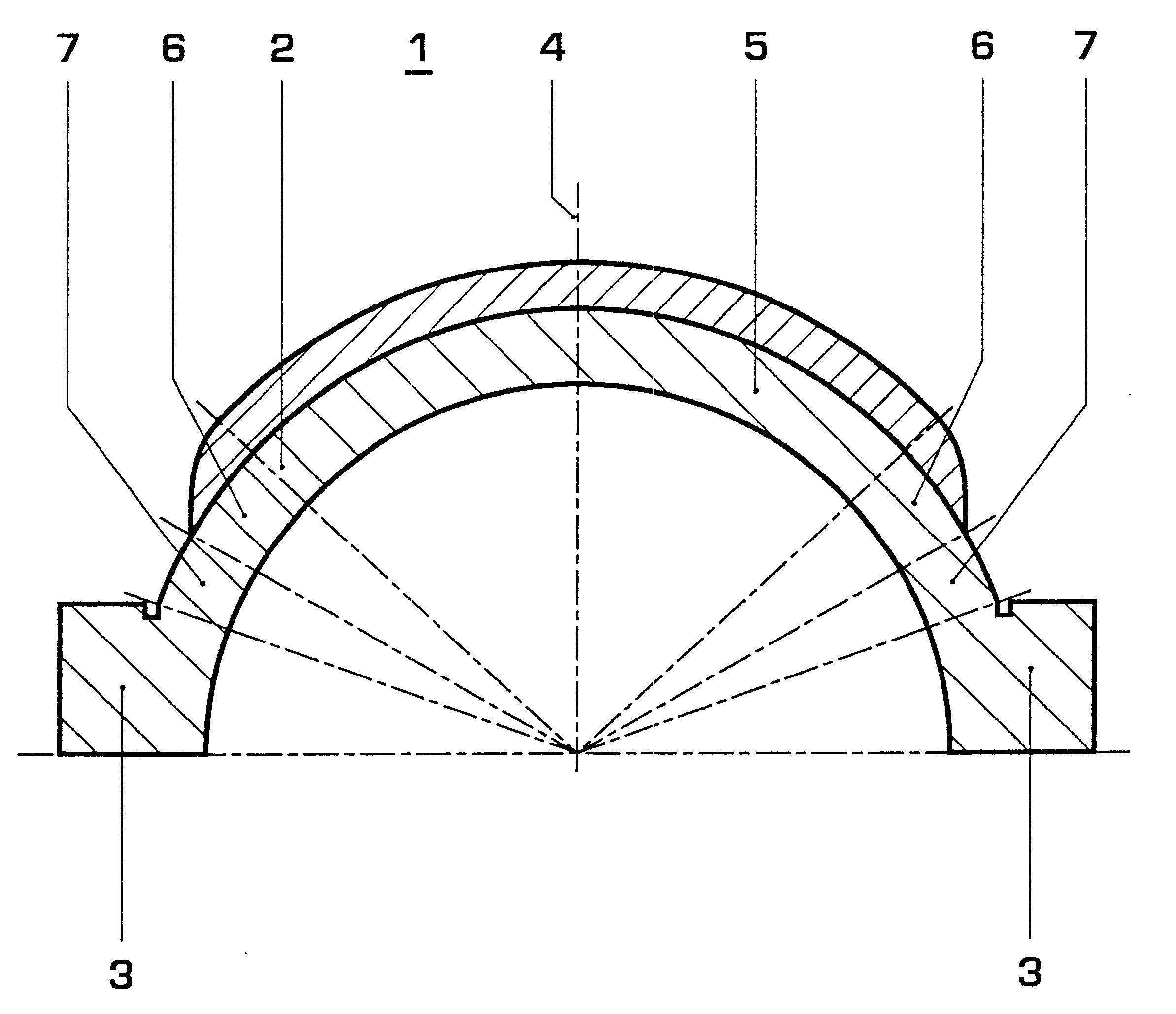

Electro-hydraulic forming tool having two liquid volumes separated by a membrane

An electro-hydraulic forming tool is disclosed in which a membrane is retained between two volumes of liquid that are separated by a membrane. Electrodes are provided with a high voltage impulse to create a shockwave in one of the volumes of fluid that is transferred through the membrane to the other volume of fluid. The shockwave is transmitted to a blank that is formed into a one-sided die. The blank is formed against the forming surface of the die. Air evacuation means are provided to remove air from the upper surface of one or both volumes of liquid.

Owner:FORD GLOBAL TECH LLC

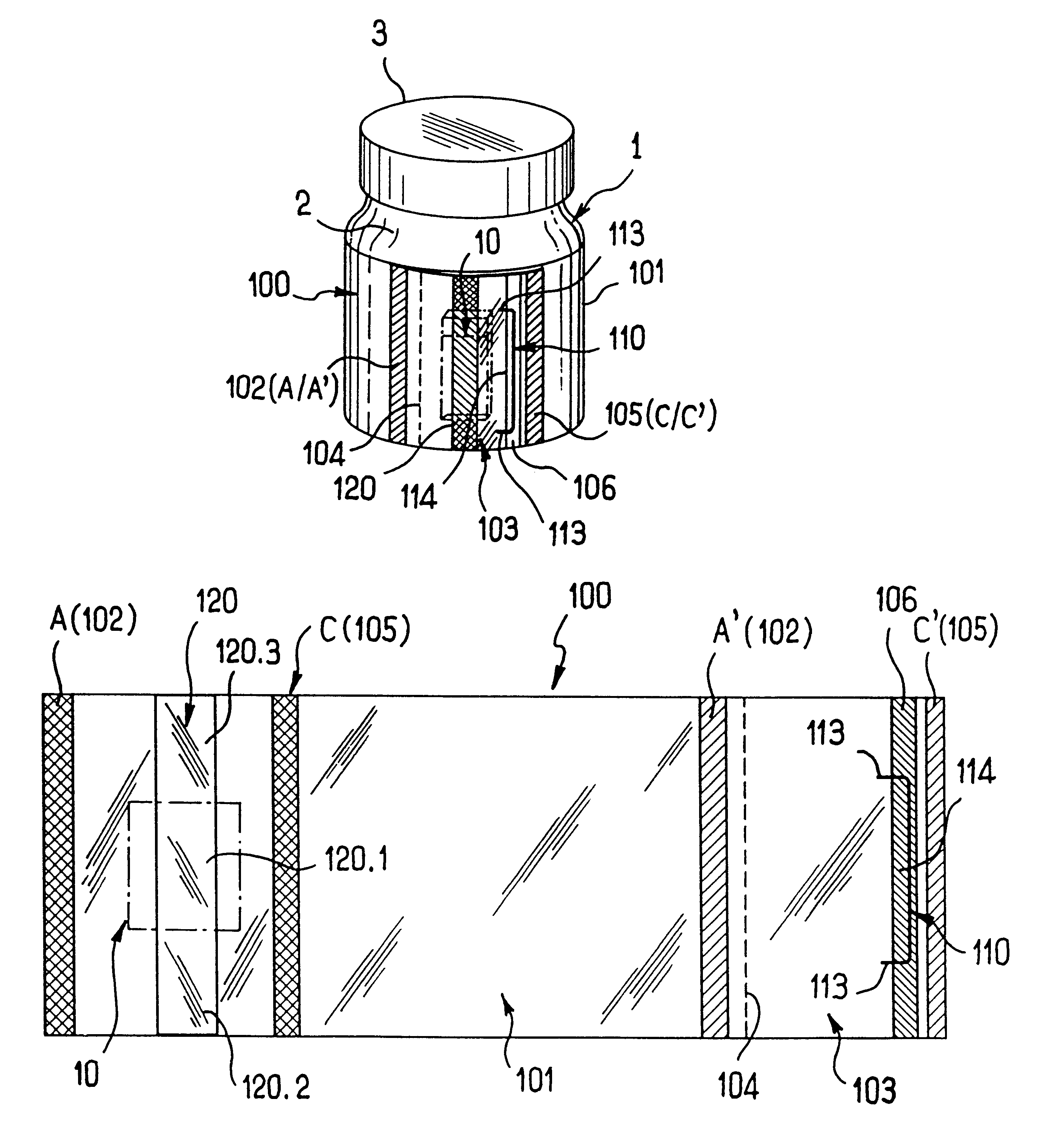

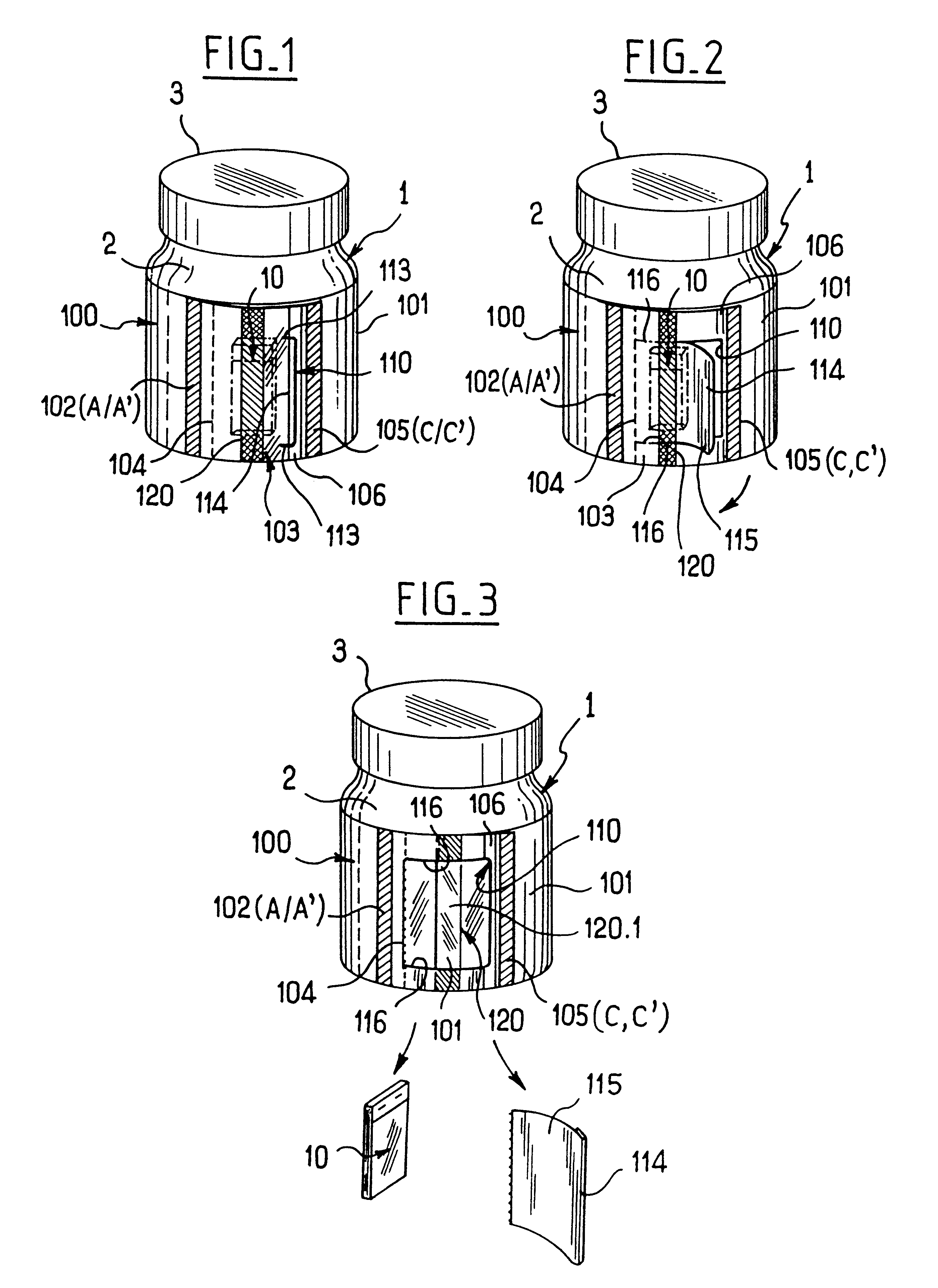

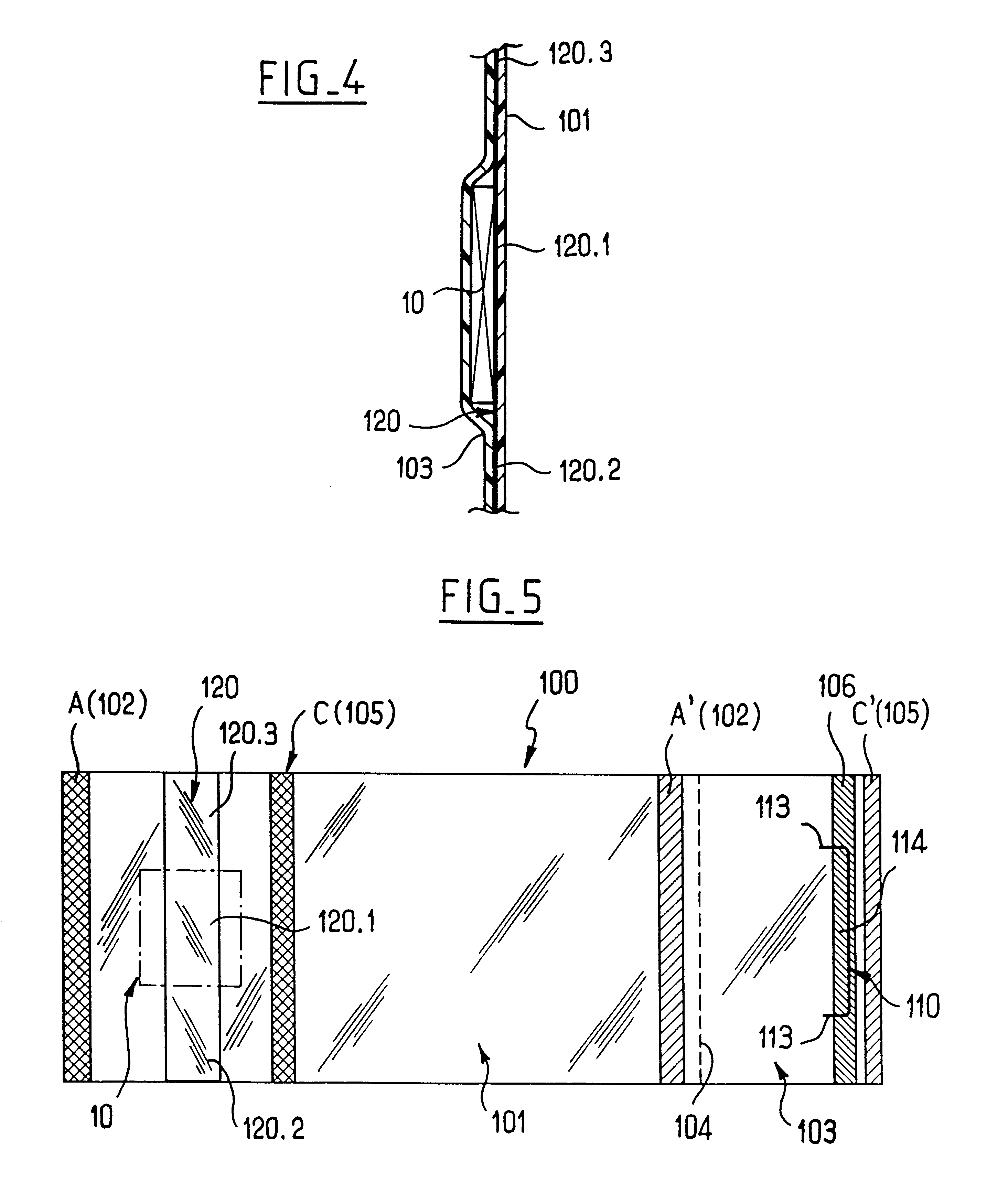

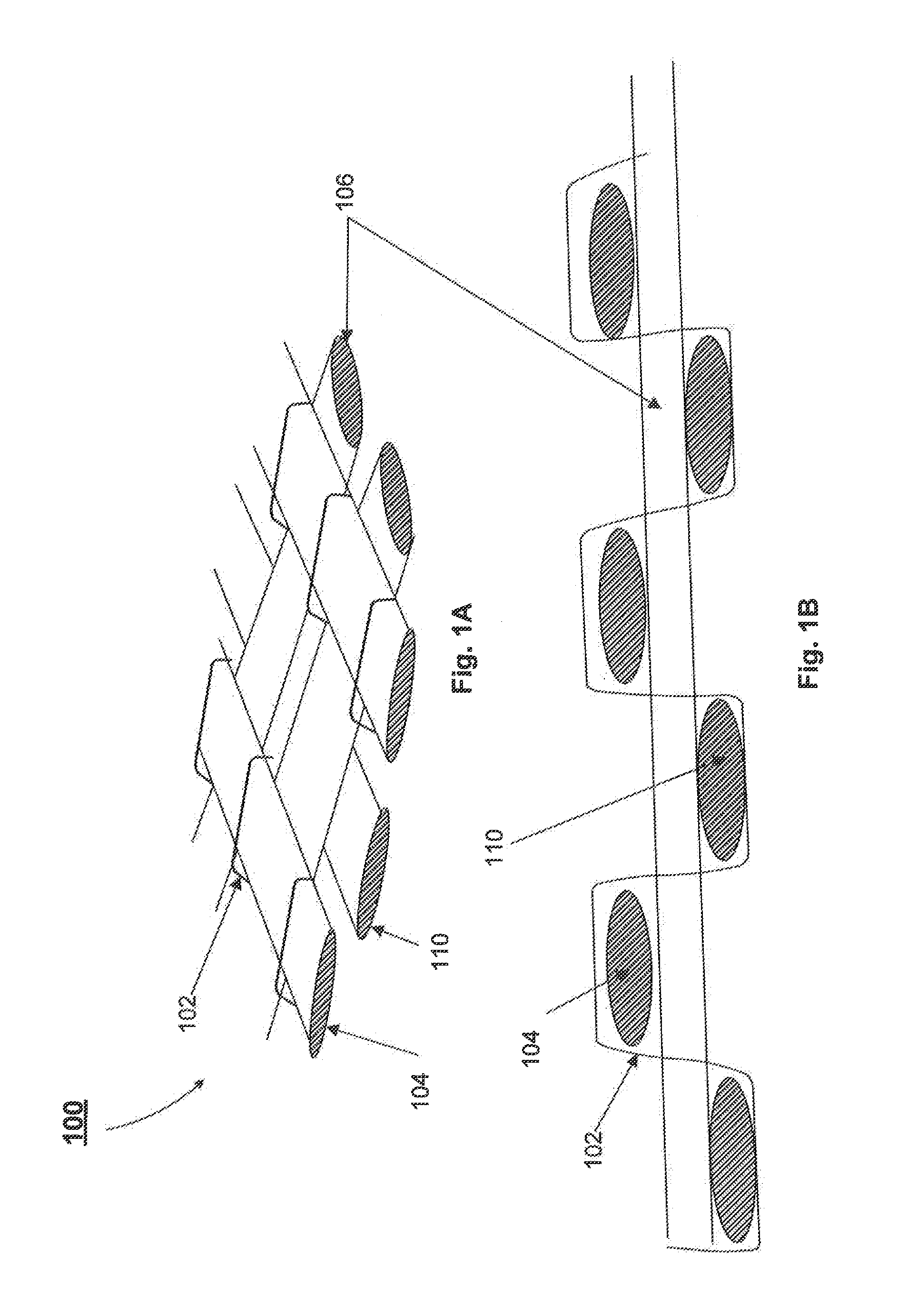

Envelope for packaging at least one article, the envelope being of the type constituted by a sleeve of heat shrink plastic material

InactiveUS6722495B2Increase heightImprove envelopeStampsWrappers shrinkagePlastic materialsEngineering

The invention relates to an envelope (100) for packaging at least one article, the envelope being of the type constituted by a sleeve of heat-shrink plastics material having a main portion (101) suitable for encapsulating at least a portion of the article or a group of articles, said sleeve also having an additional flap (102) overlapping the outside of the sleeve and connected to the main portion (101) of the sleeve via two parallel lines of heat sealing (102, 105) at its lateral ends, said flap having a panel-forming portion (115) which is detachable by being torn off. In accordance with the invention, at least one adhesive strip (120) extending along a generator line of the sleeve is provided on the outside face of the main portion (101) or on the inside face of the additional flap (103), said strip serving to retain a flat item (10) in the pocket formed by said additional flap, in such a manner that said item is held captive behind the detachable panel (115) and is recoverable once said panel has been detached.

Owner:SLEEVER INT

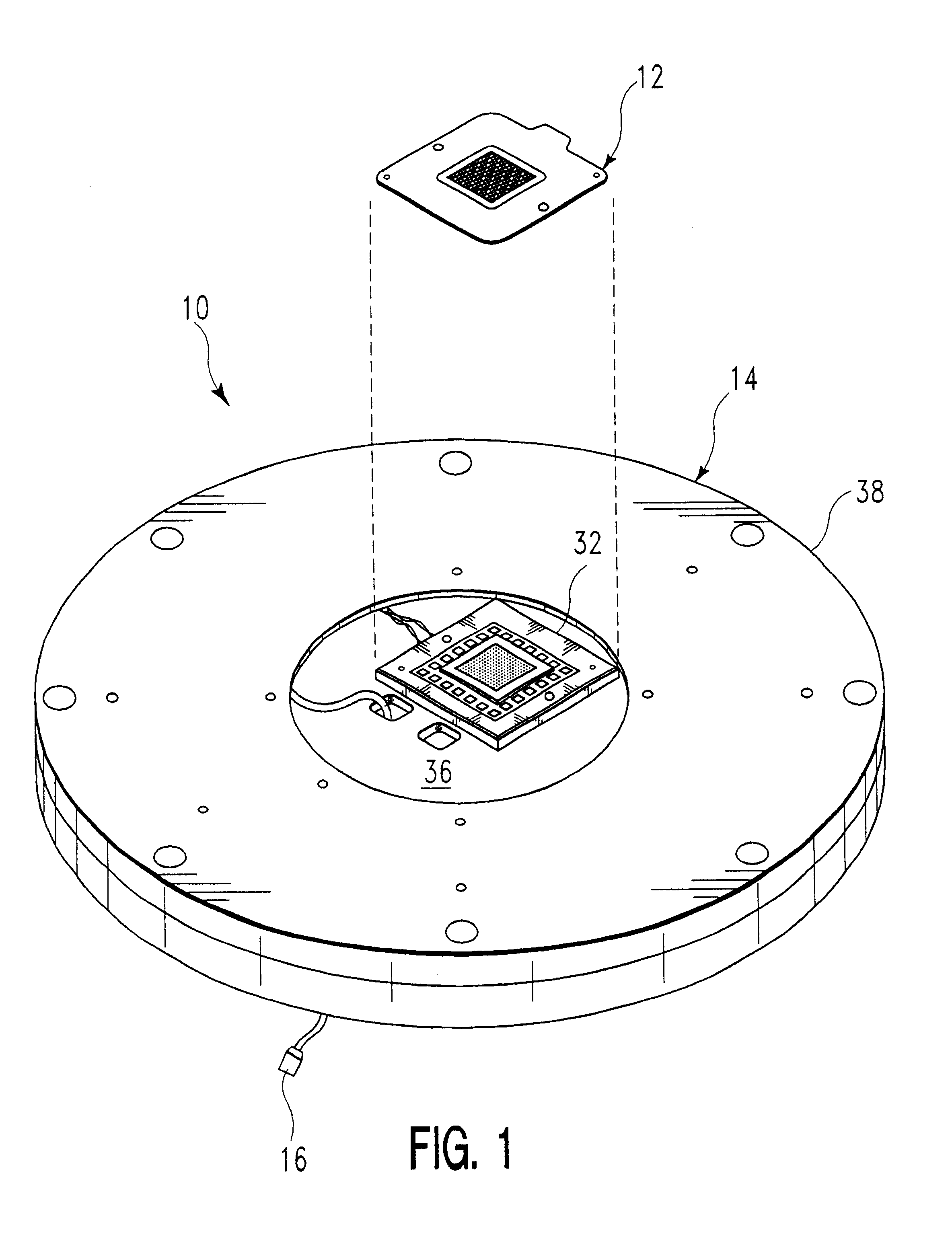

Wafer probe interface arrangement with nonresilient probe elements and support structure

InactiveUS6426636B1Eliminate conditionImproved testing and probingElectrical measurement instrument detailsIndividual semiconductor device testingSiliconBolt connection

A nonresilient rigid test probe arrangement which is designed for testing the integrity of silicon semiconductor device wafers or chips, and which eliminates pliant conditions encountered by current text fixtures, which are adverse to the attainment of satisfactory test results with rigid probes. The test system interface assembly includes a rigid ceramic substrate which forms a pedestal over which the rigid probe makes electrical contact. A PC board is located on the opposite side of the ceramic substrate. A clamp ring retains the PC board to a test head system with mating precision reference surfaces formed therebetween. Pogo pin connectors extend between the PC board and the test head system. A stiffening element having a control aperture is bolted through the PC board to the clamp ring, all of which form a rigid test probe arrangement.

Owner:IBM CORP

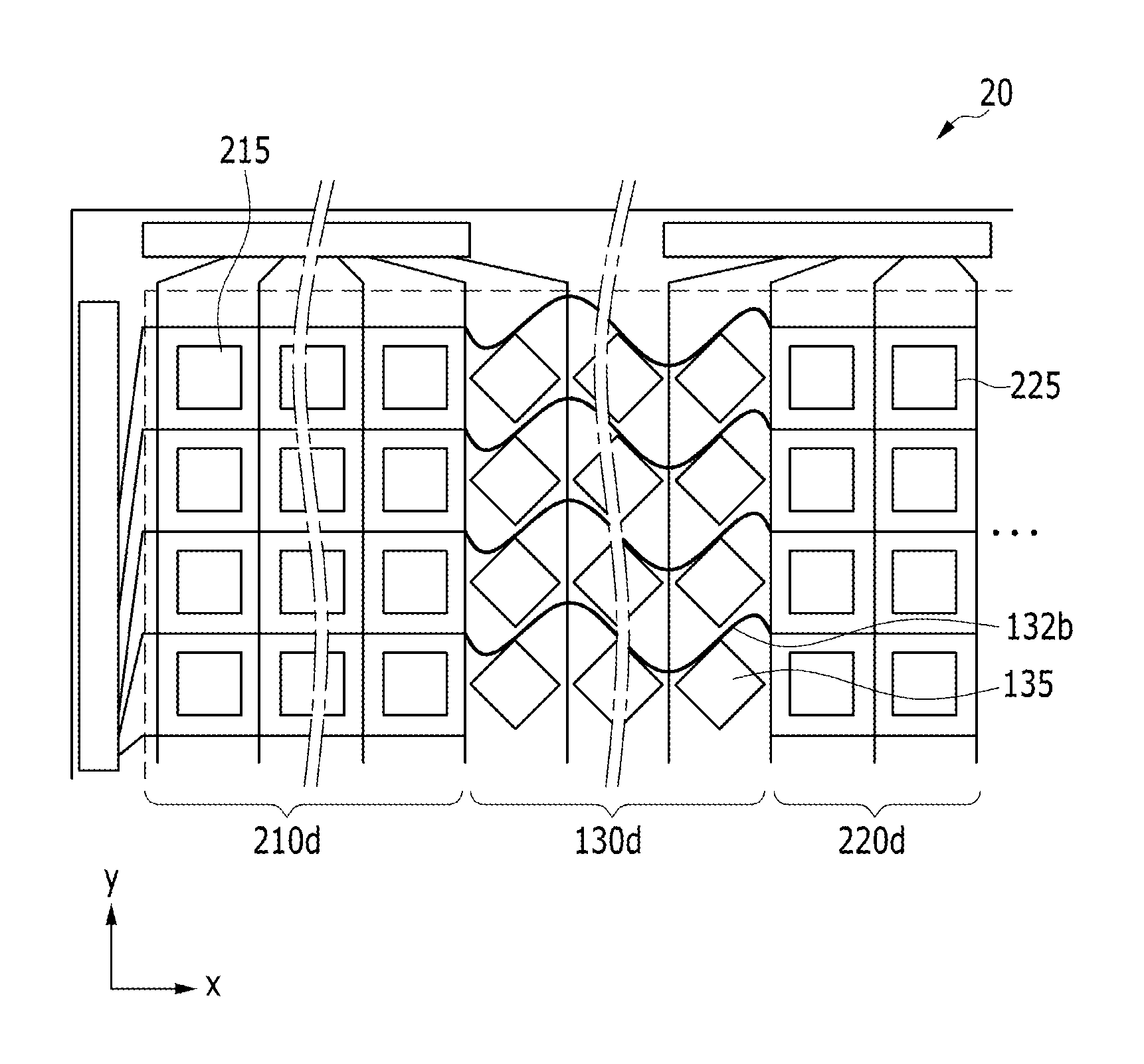

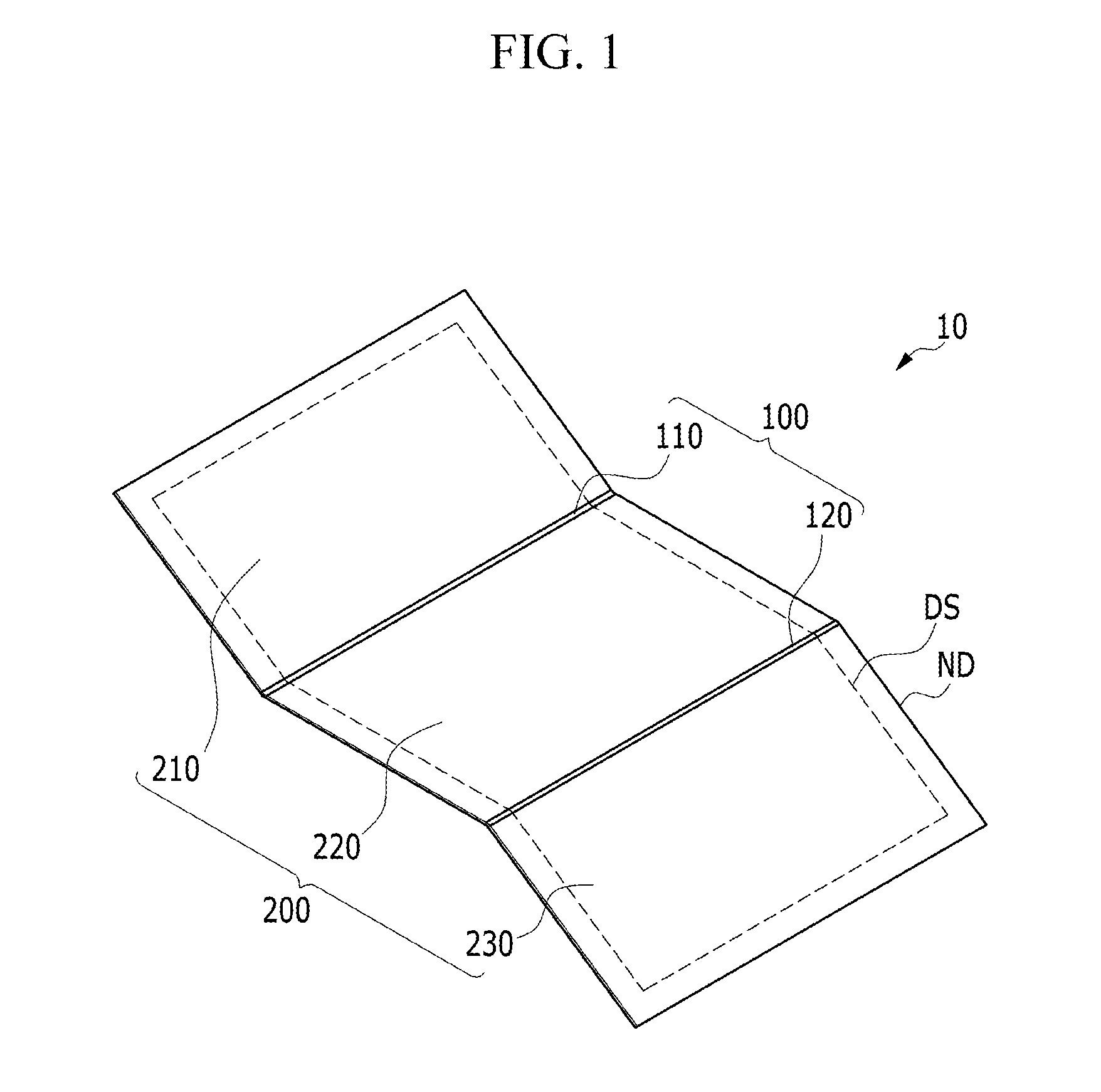

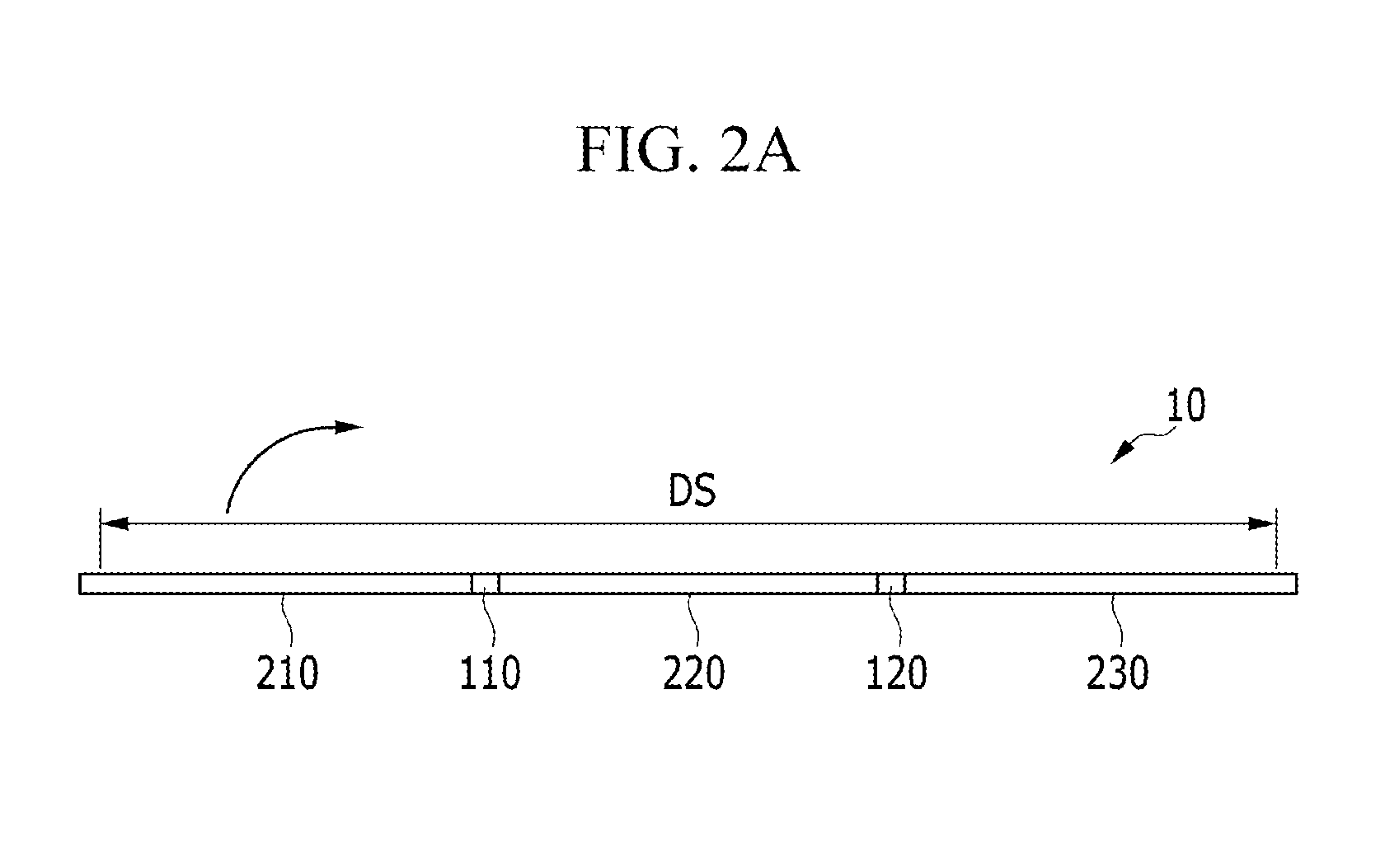

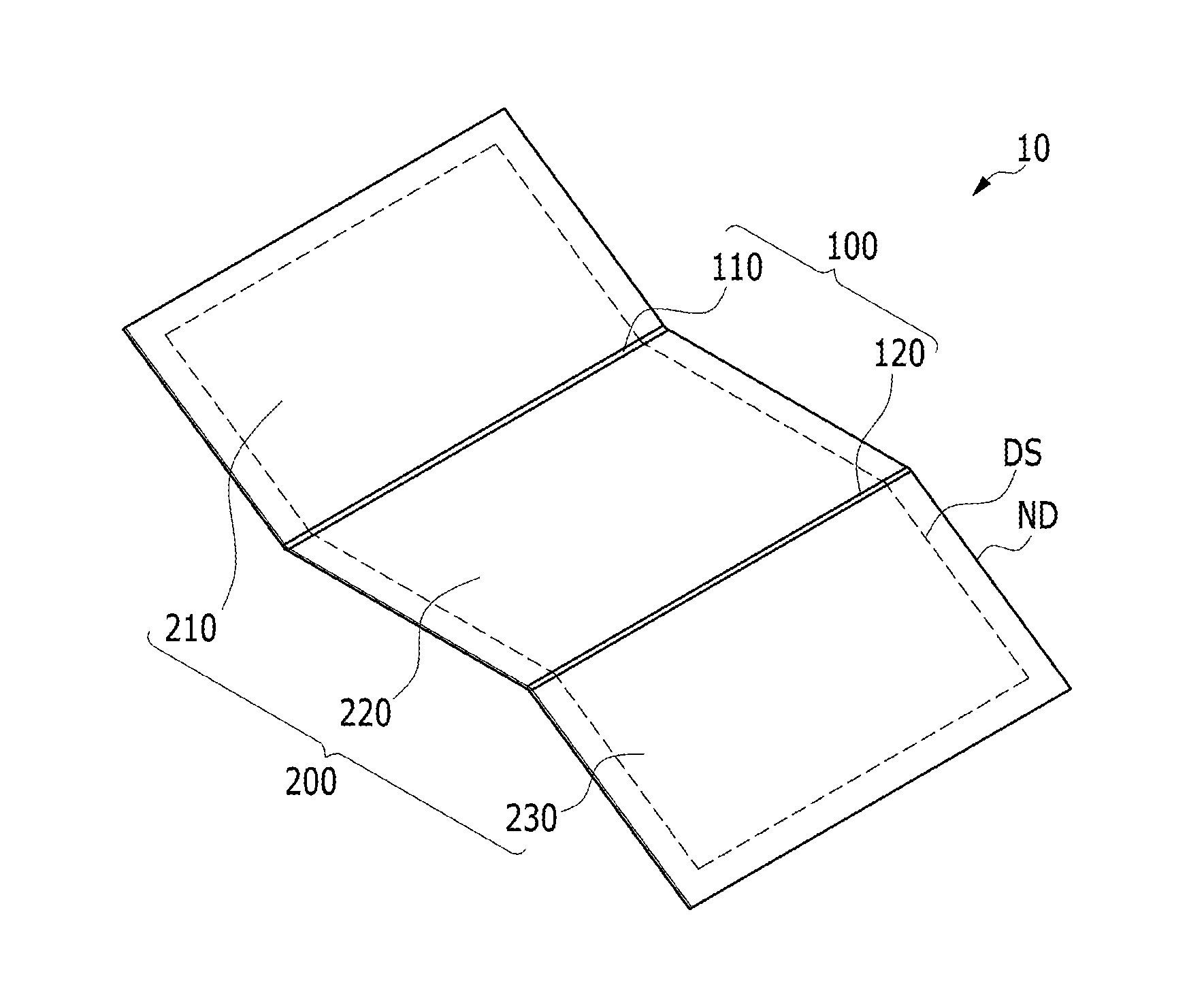

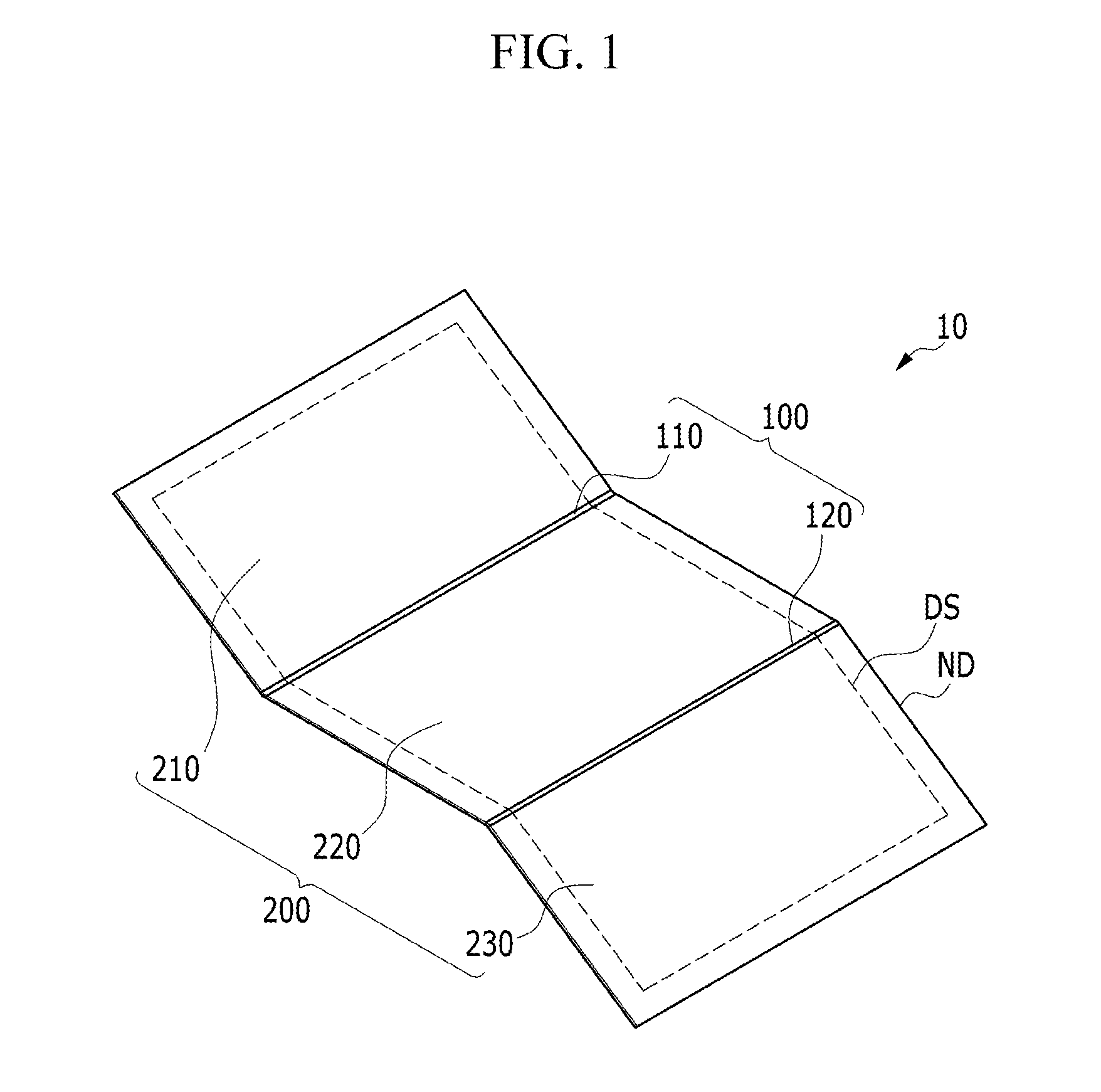

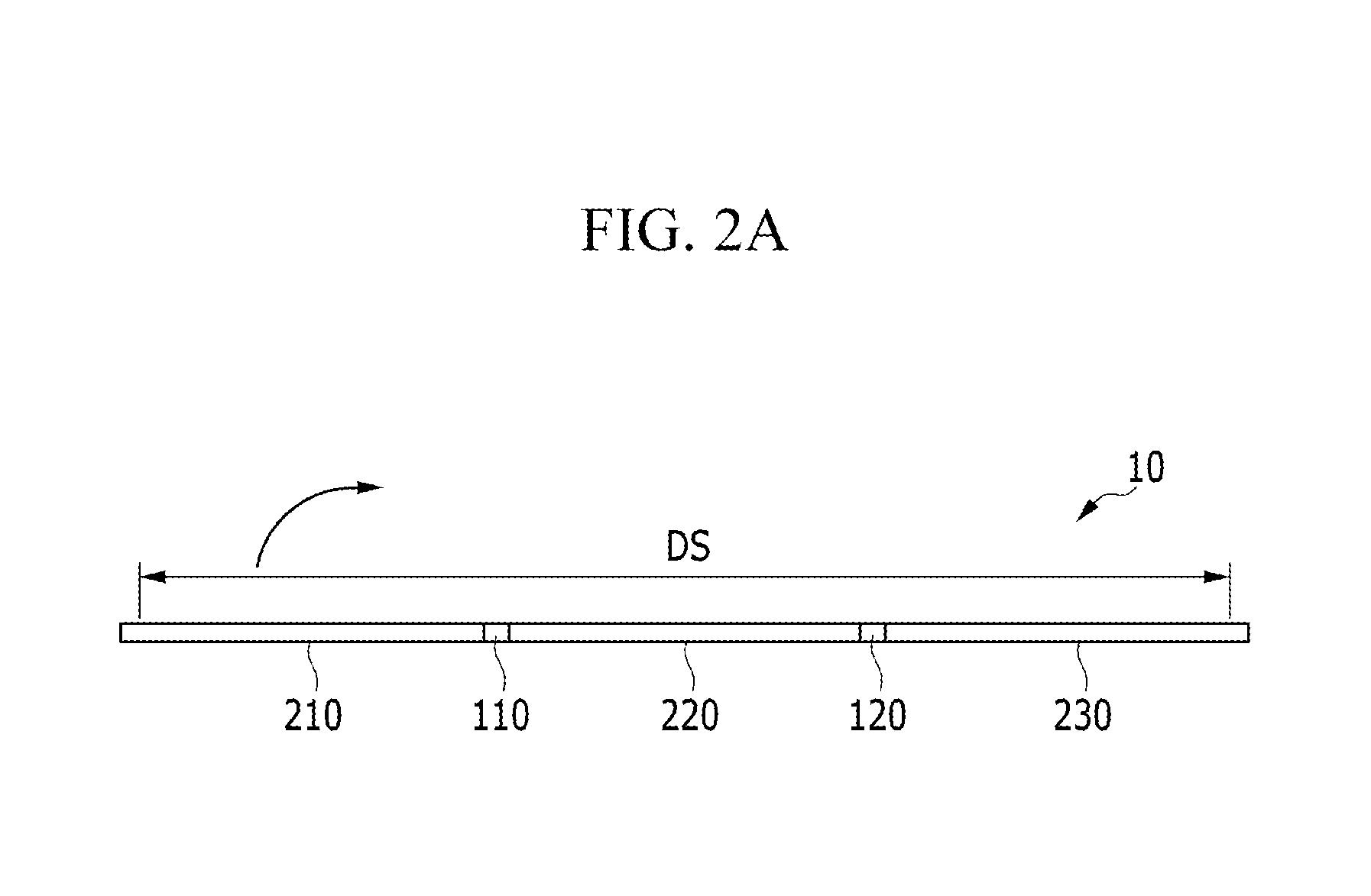

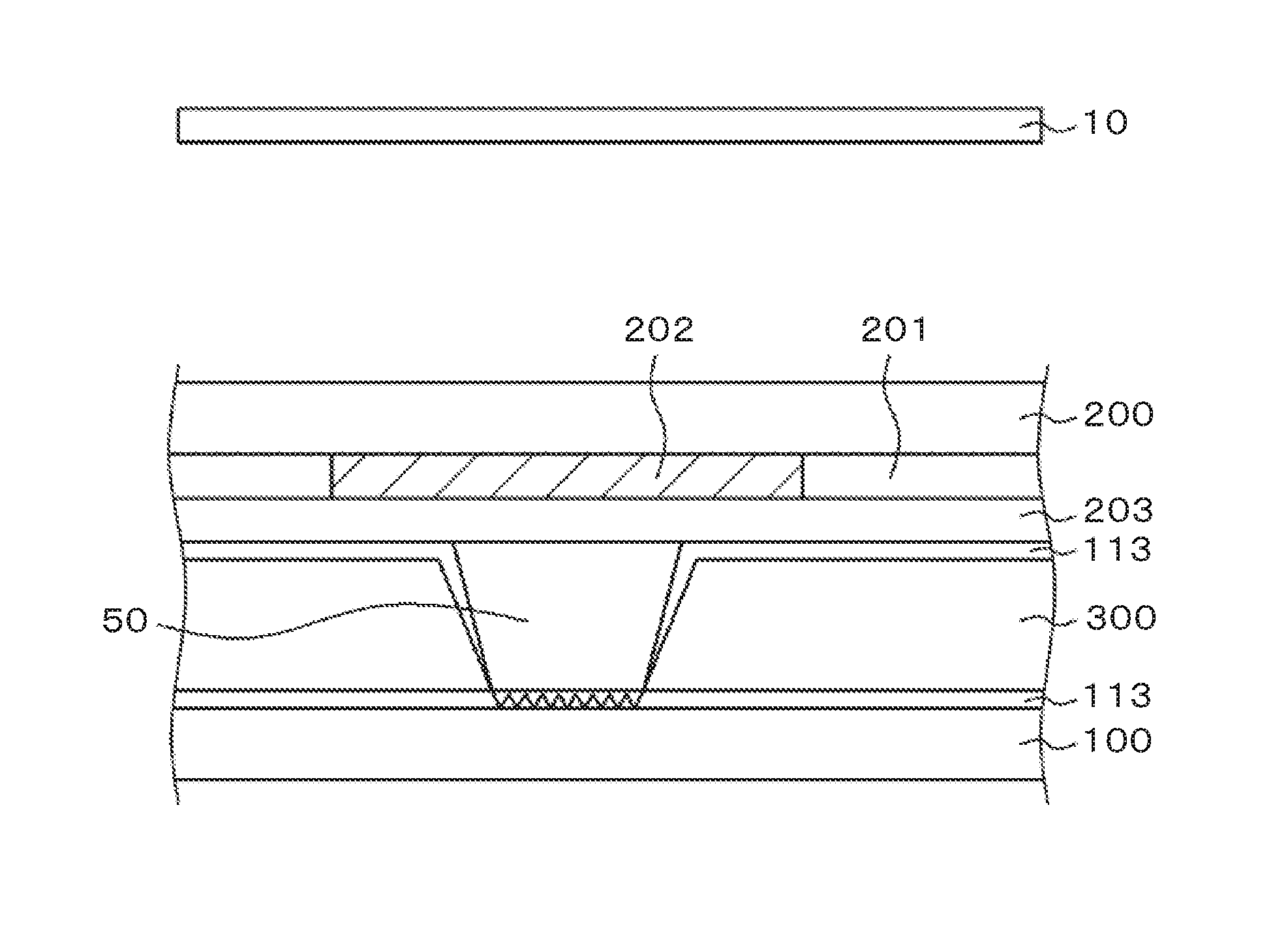

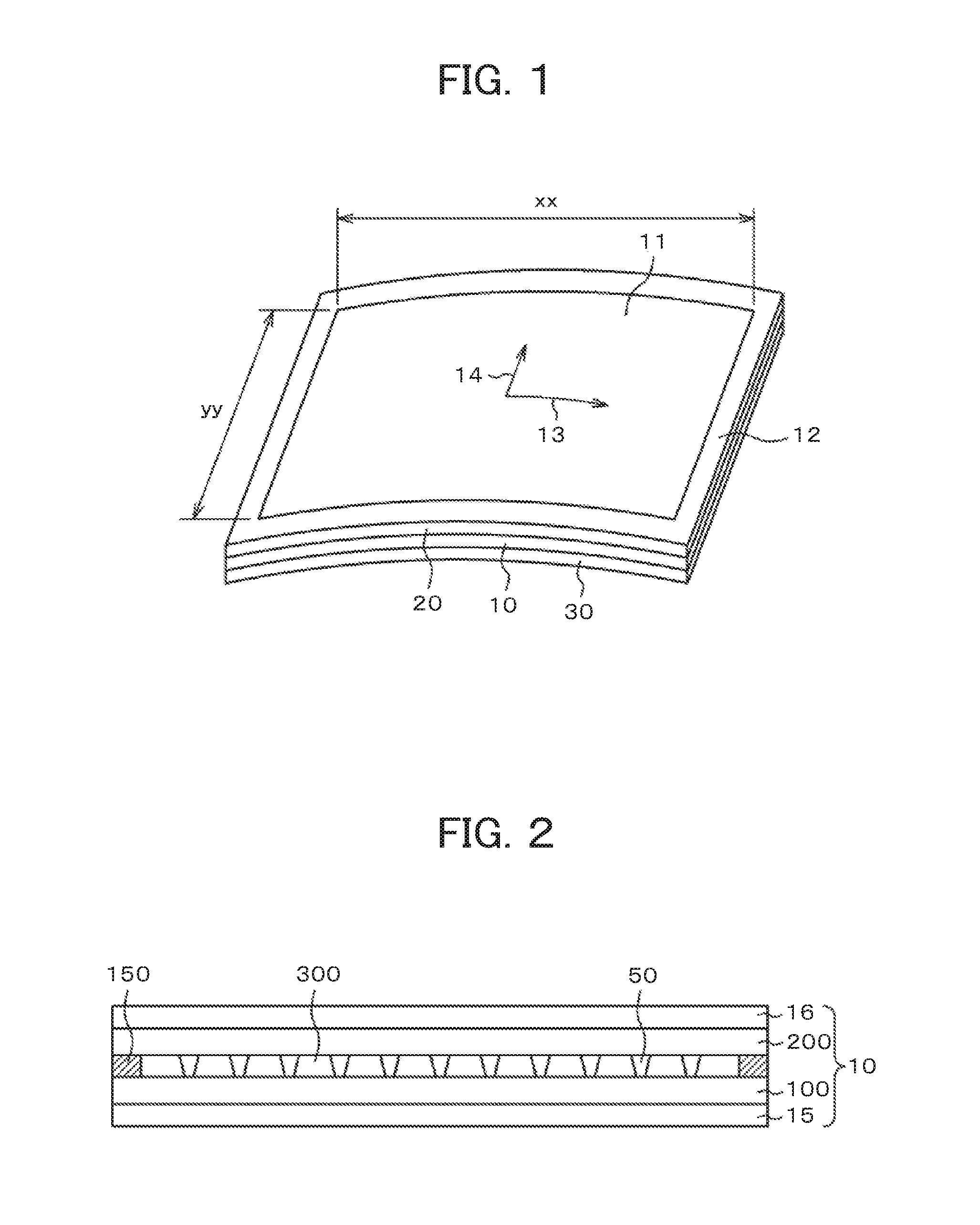

Flexible display device including folding section

ActiveUS9287341B2Minimal deformationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

A flexible display device includes a folding section formed on a flexible substrate, a flat section connected to the folding section, and a display area for displaying an image, wherein the display area is formed on the folding section and the flat section, wherein each of the display areas of the folding section and the flat section includes a plurality of pixels and a plurality of wires for supplying electrical signals to the pixels, and wherein the wires in the display area of the folding section include a winding wire extending in a winding configuration on the flexible substrate.

Owner:SAMSUNG DISPLAY CO LTD

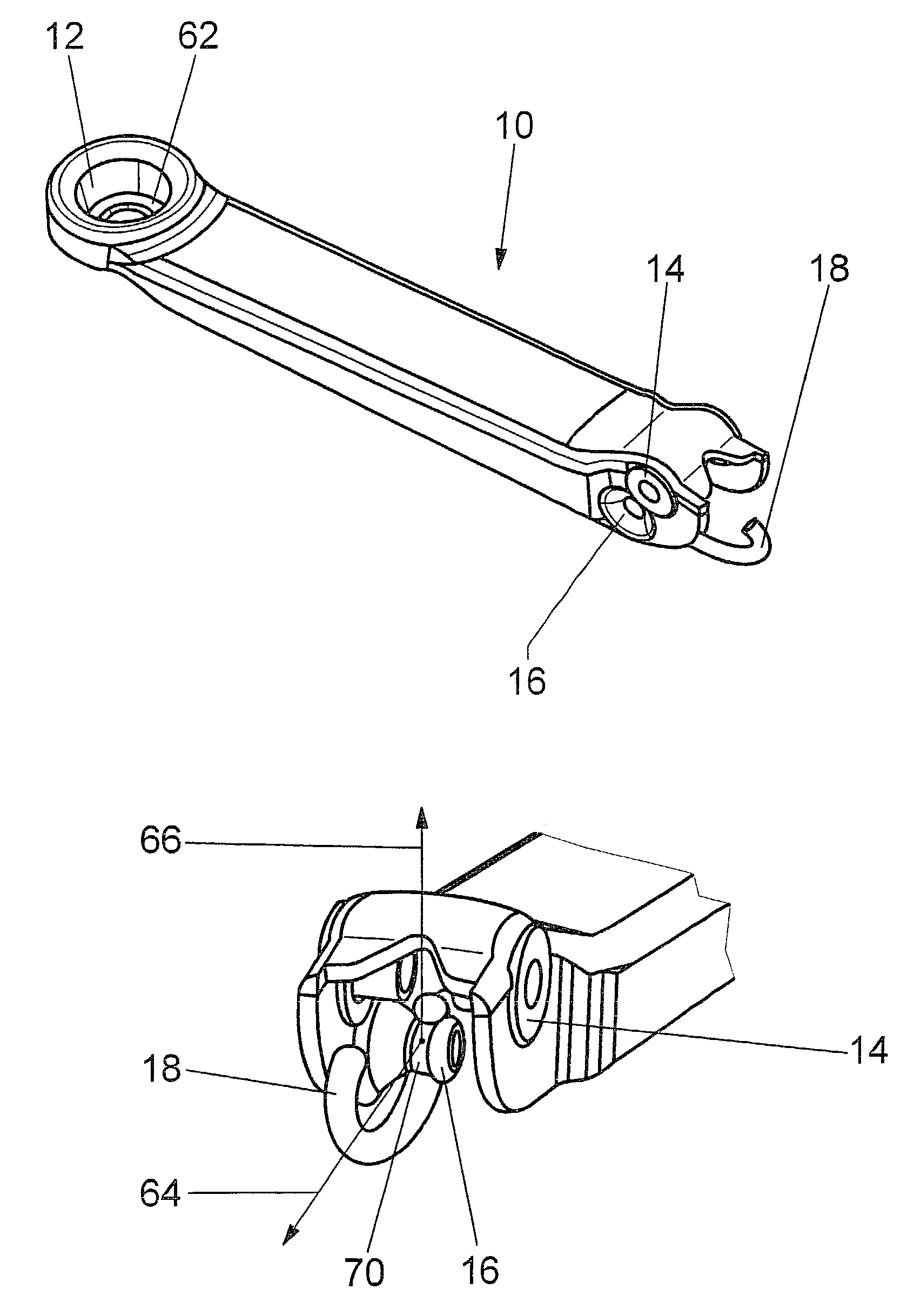

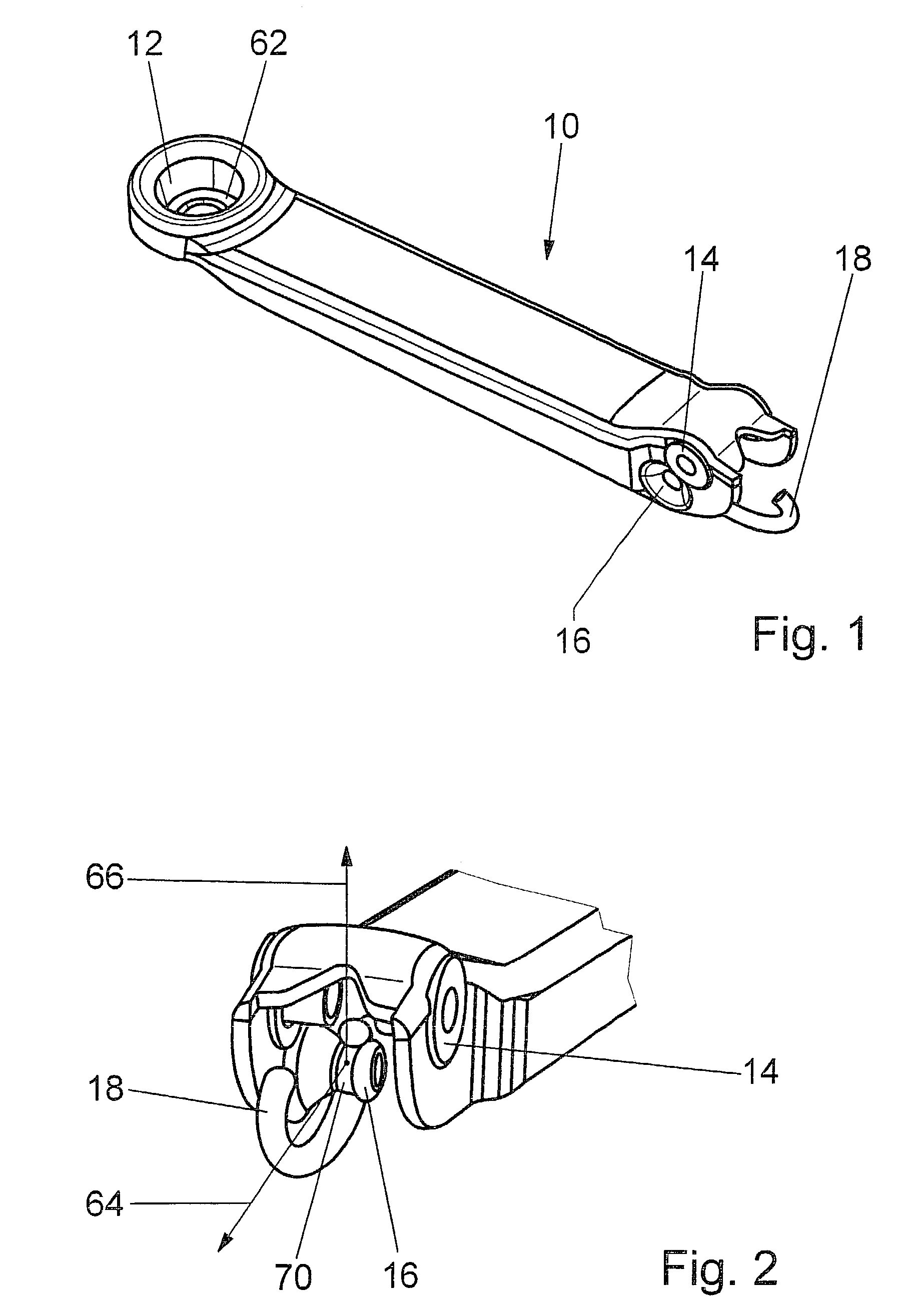

Fixing piece for a windscreen wiper

InactiveUS7036181B2Low costShorten the timeMetal-working apparatusWindow cleanersPunchingEngineering

A mounting part of a windshield wiper, having a receiving opening for a wiper shaft at one end, and forming a part of a fold-away hinge at the other end, and being formed from a flat sheet metal by deep-drawing, punching and bending and having a u-shaped cross-section profile and a spring mount. The spring mount is formed by deep-drawing from a sidewall of the u-shaped cross-section profile.

Owner:ROBERT BOSCH GMBH

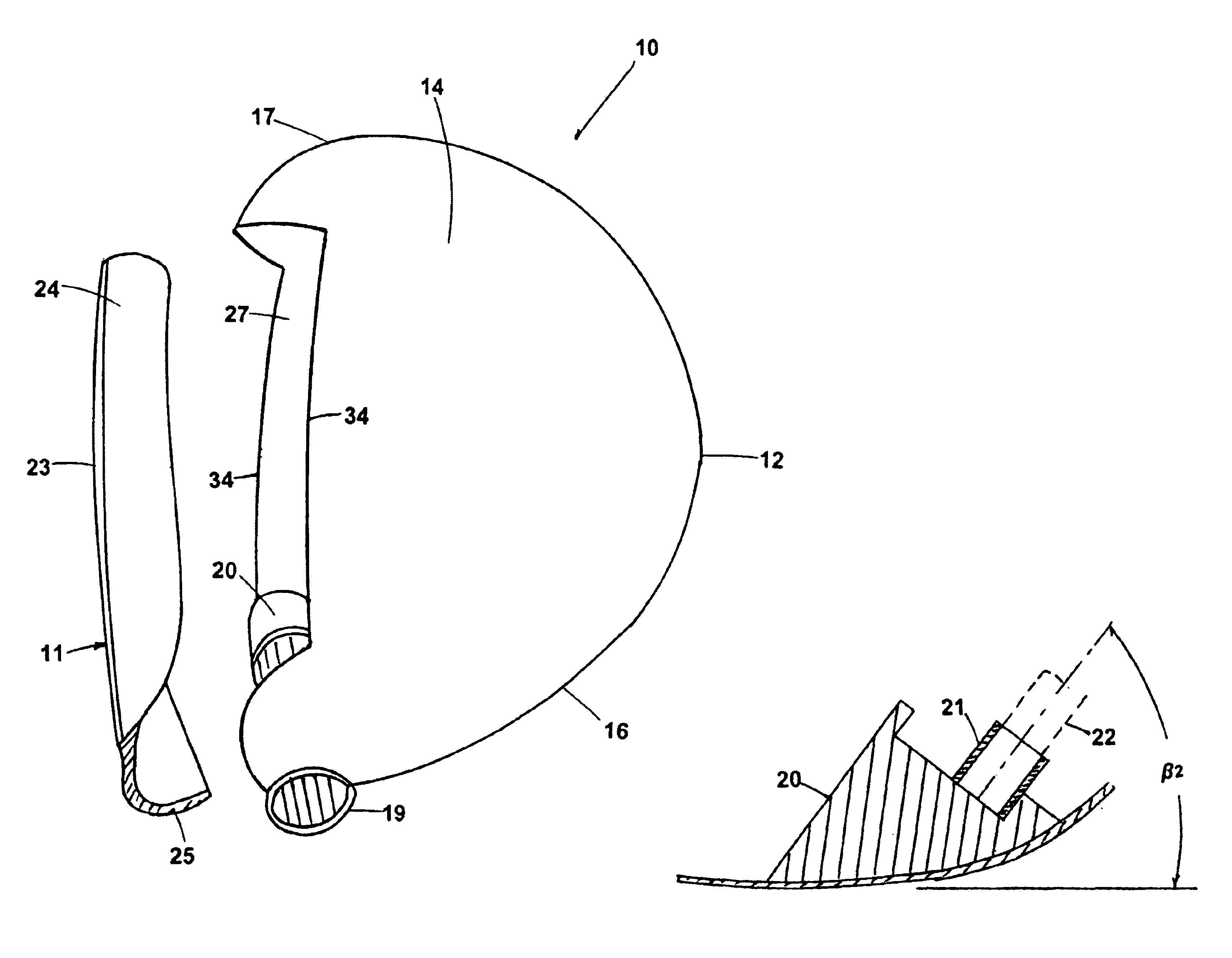

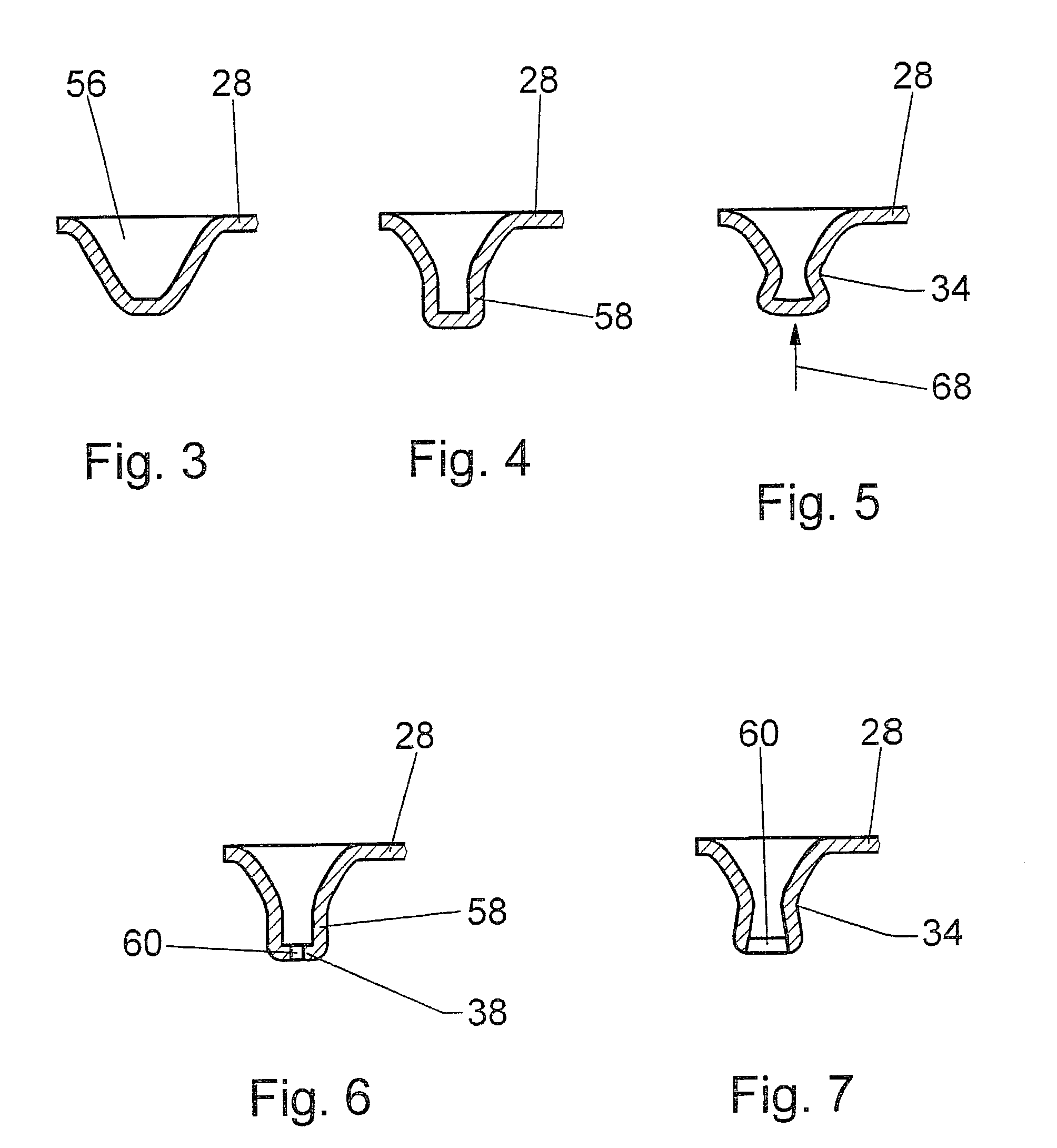

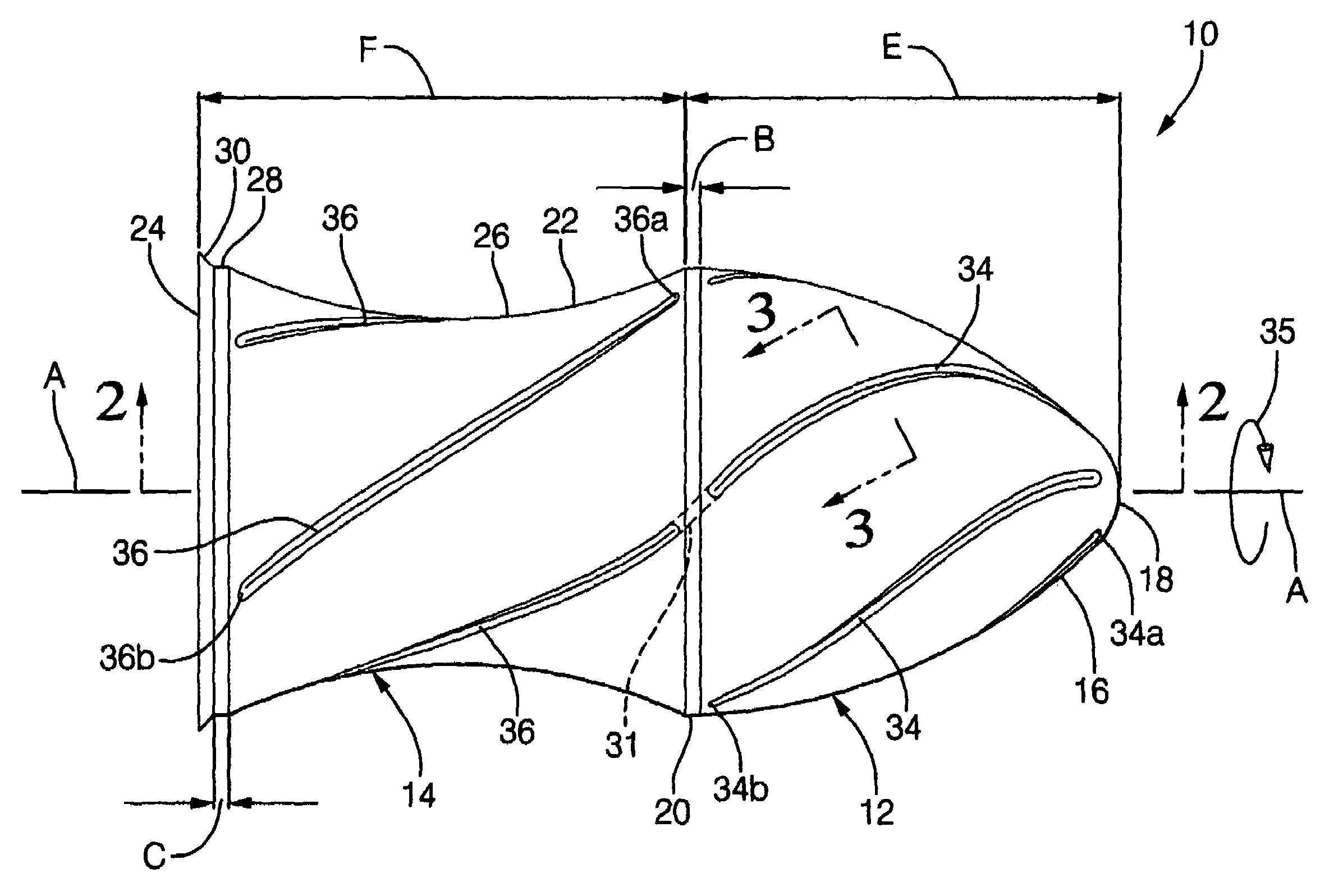

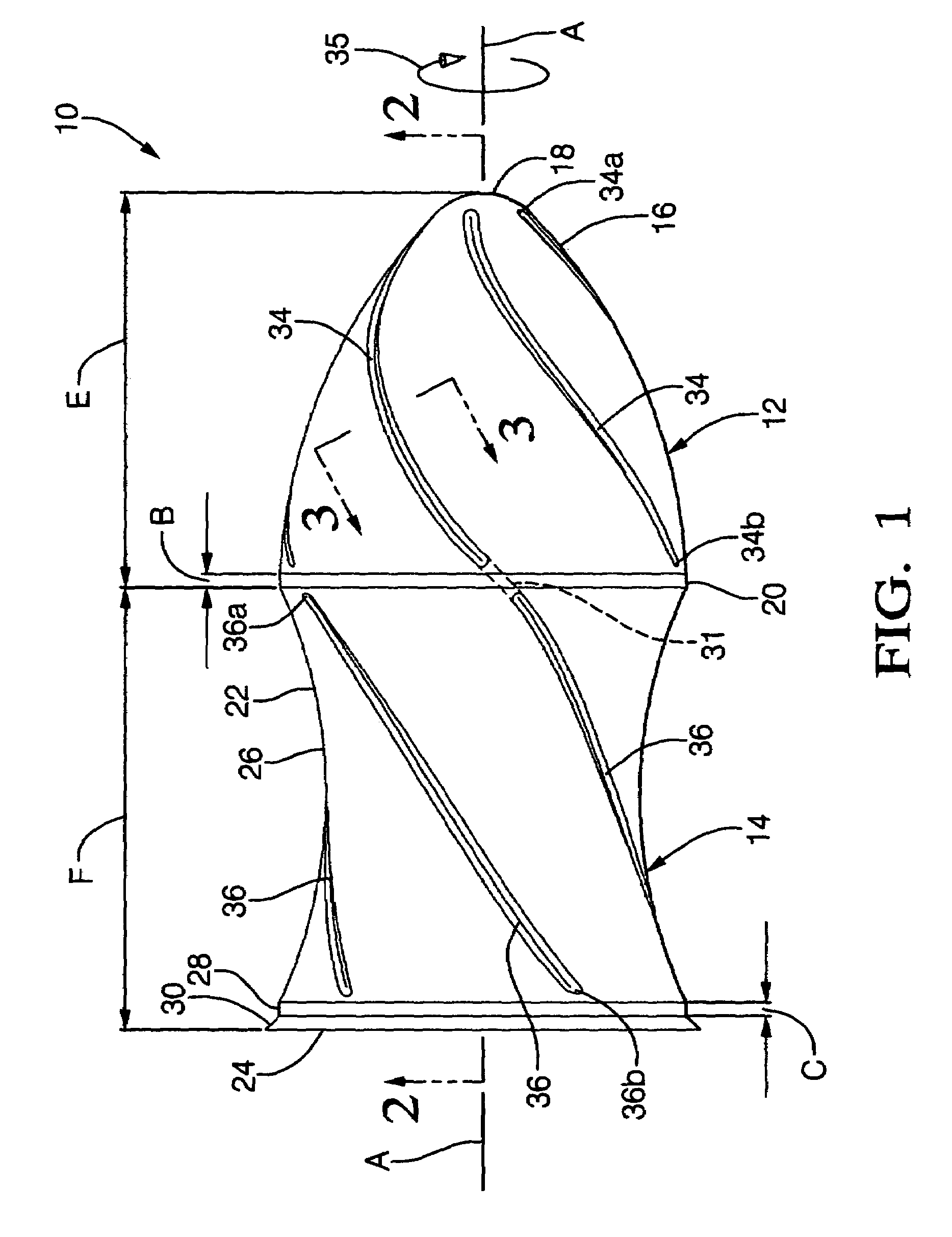

Aerodynamic air gun projectile

InactiveUS20070074637A1Reduce turbulent airflowGood laminar flowAmmunition projectilesHollow inflatable ballsInterference fitConical forms

A projectile for an air arm is integrally formed from a single piece of dense malleable material formed as a body of revolution about a longitudinal axis having a head portion dimensioned for free sliding in the bore of an air arm and a skirt-like portion of frusto-conical form. The rearward end of the skirt portion is dimensioned to be in slight interference fit with the bore and the forward end is joined with the head portion to define a reduced diameter waist. The frustum is shell-walled, having a central recess opening to the rear and extending forwardly into the head portion. The head portion has a parabolically shaped outer surface which transitions smoothly into a hyperbolically shaped outer skirt surface for aerodynamic efficiency. Vanes are formed on the head portion to enhance in-flight spiraling rotation.

Owner:PONTIERI JAMES M

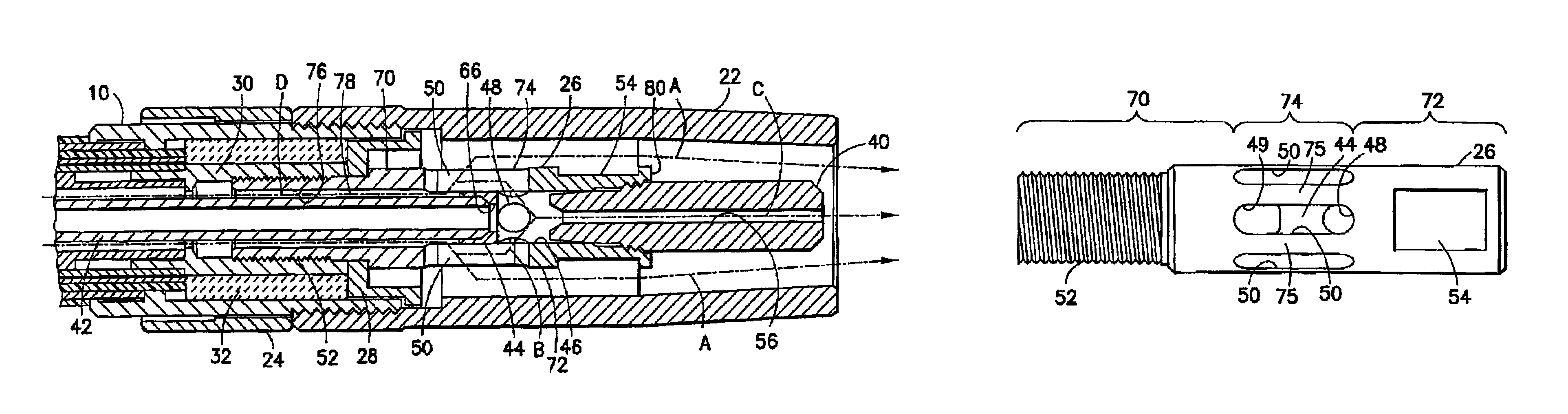

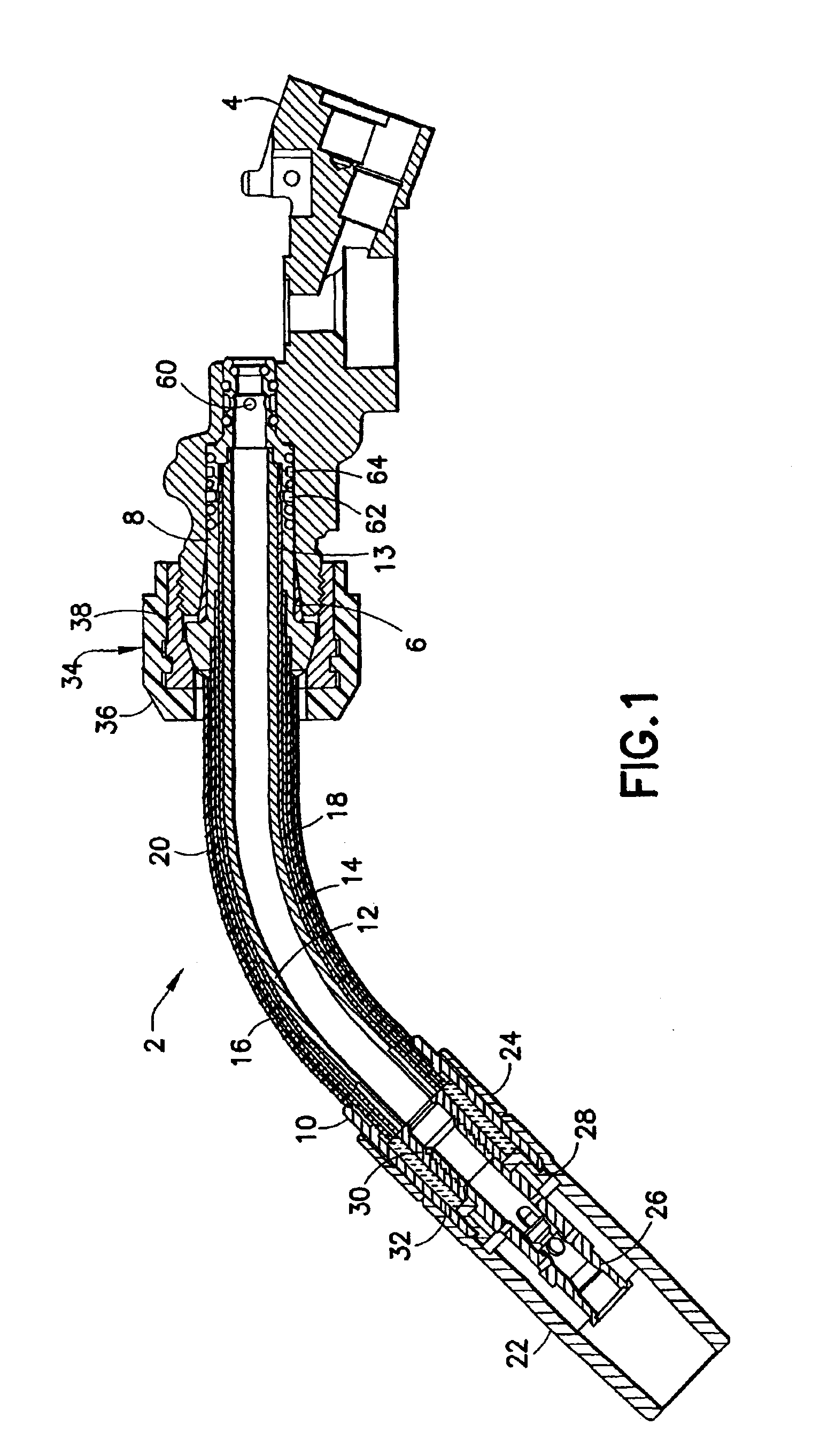

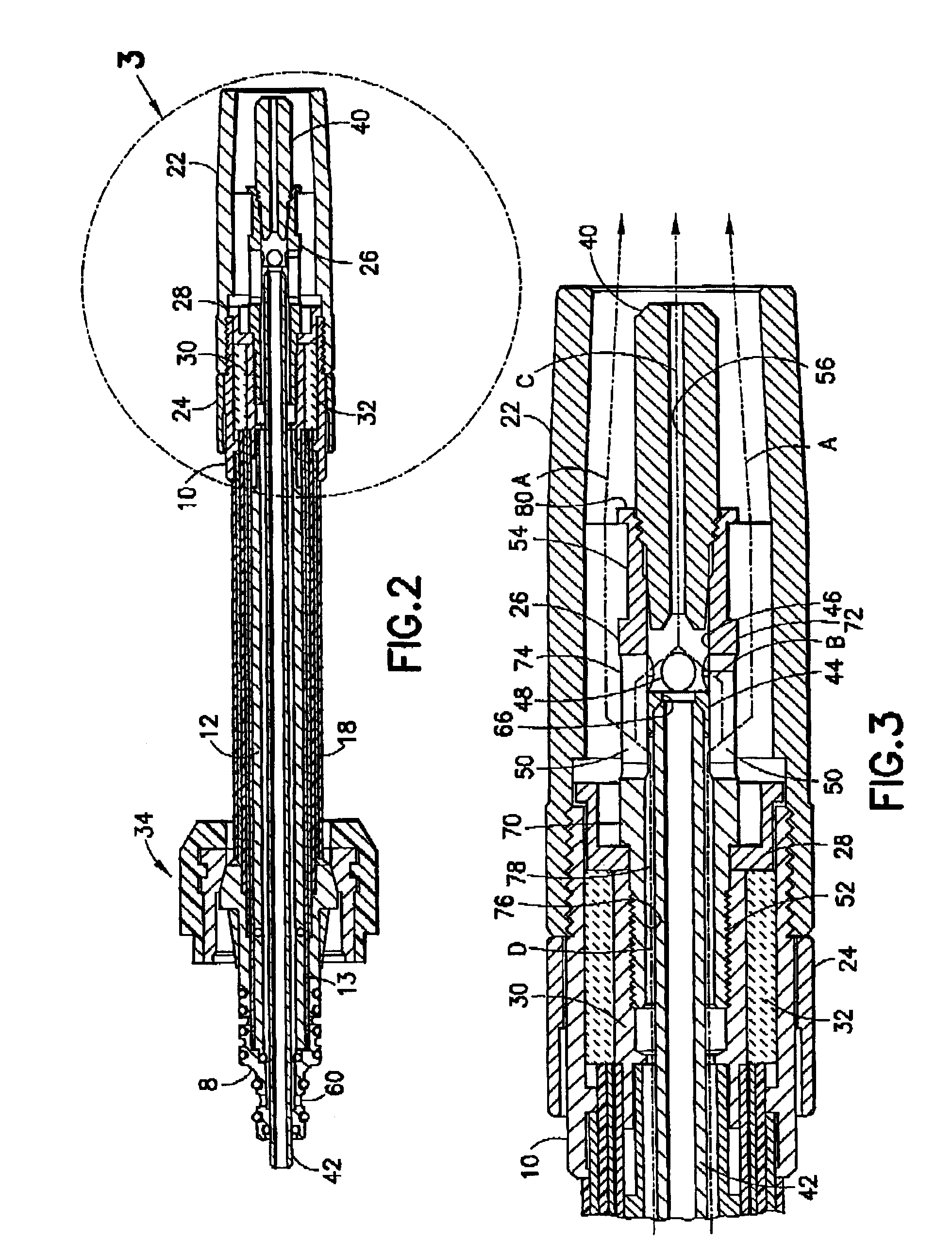

Gas diffuser for head tube assembly of welding gun

InactiveUS6924461B2Improve shielding effectLess complexWelding coupling meansAtmospheric airEngineering

A gas diffuser for a welding gun in which atmospheric air in the interior of the liner is substantially prevented from entering the contact tip hole. The gas diffuser includes a cradle having a hole and a section of a concave surface disposed around a periphery of the hole, and an outer peripheral body having a first axial bore on one side of the cradle and a second axial bore on the other side of the cradle. The outer peripheral body includes one or more generally axial slots, each slot having one end that opens into the first axial bore and another end that opens into the second axial bore. Each slot is open to the exterior of the diffuser along its length and is disposed radially outward of the cradle. The first and second axial bores communicate via the hole in the cradle and via the slots.

Owner:ILLINOIS TOOL WORKS INC

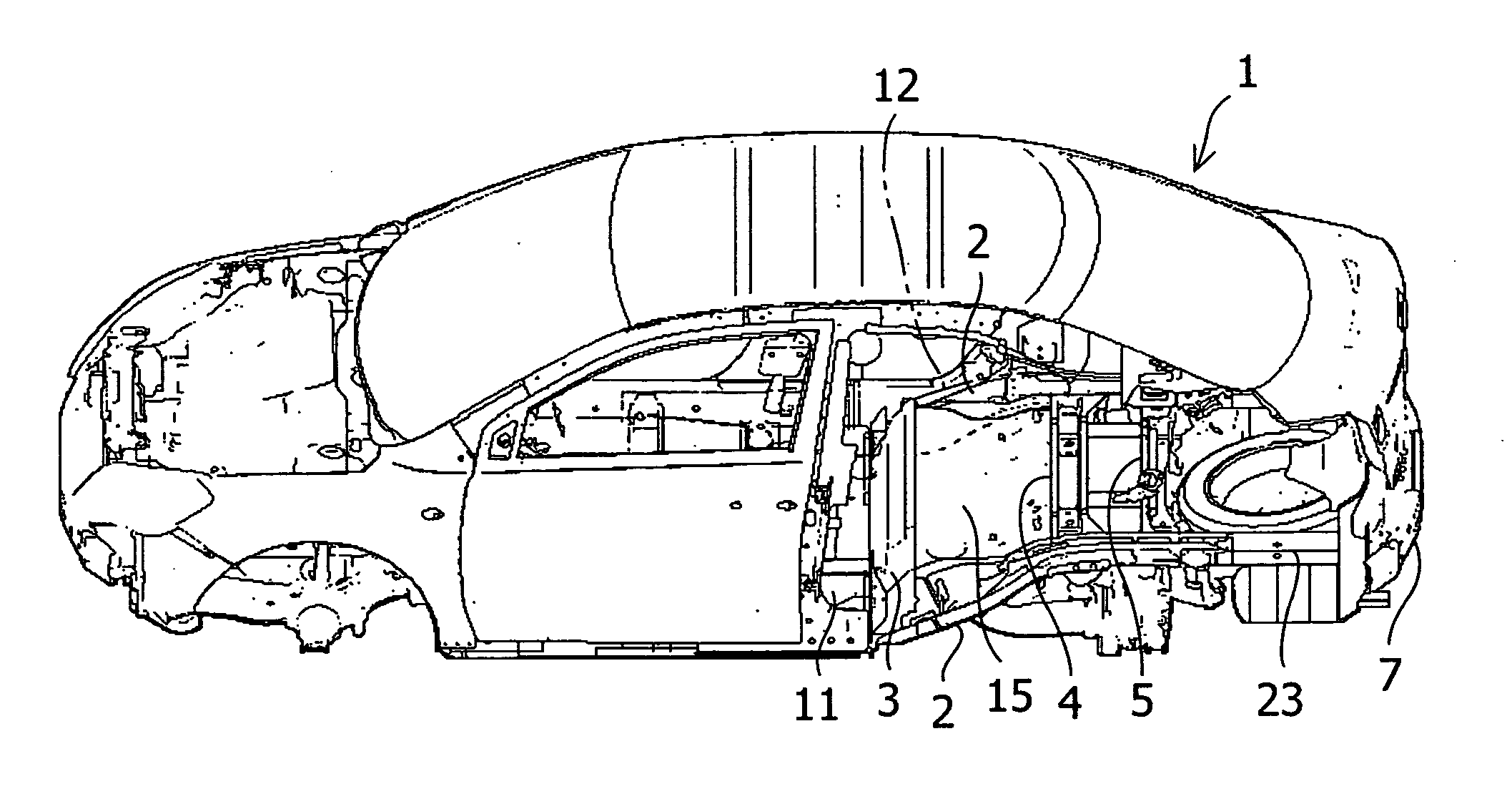

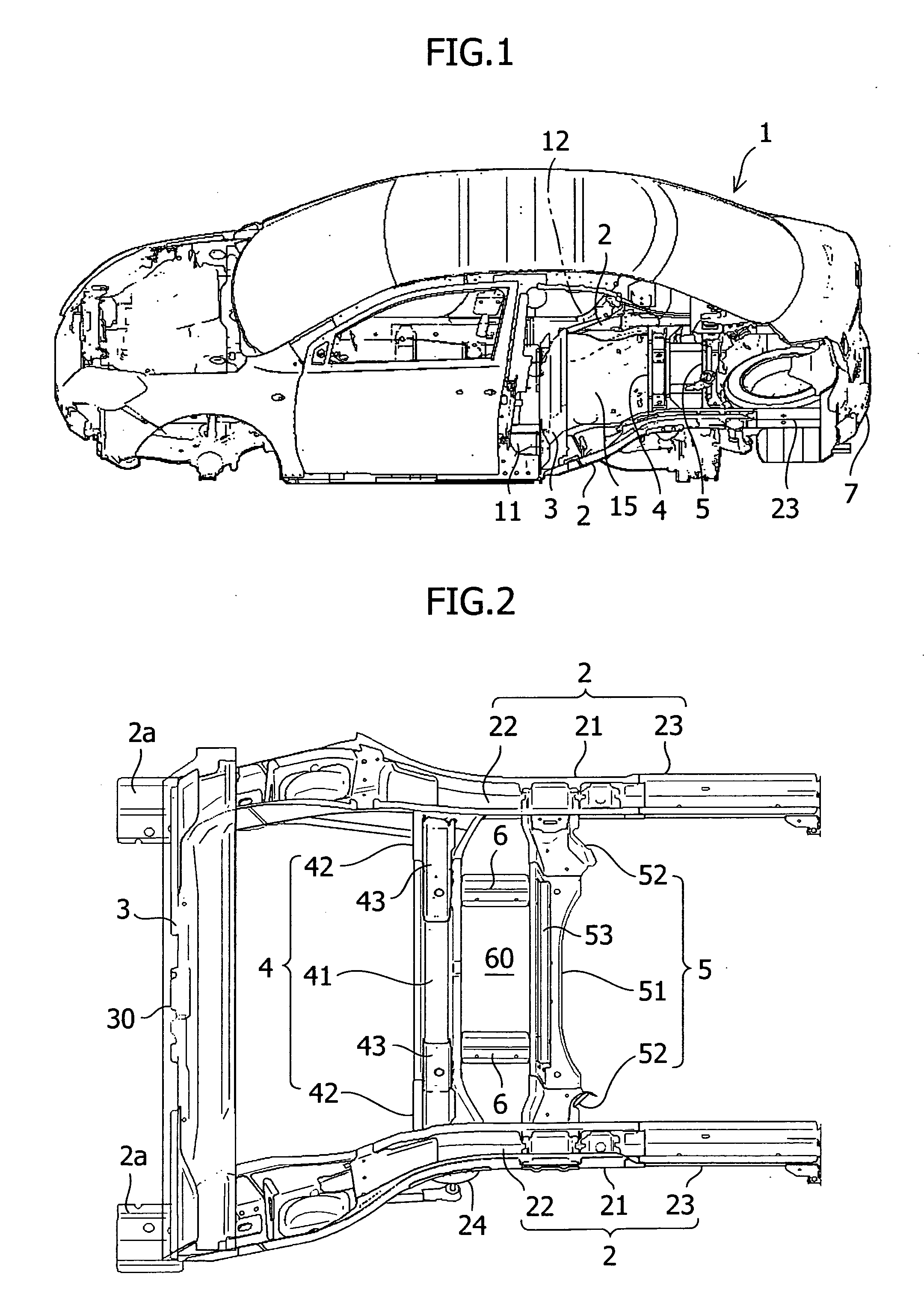

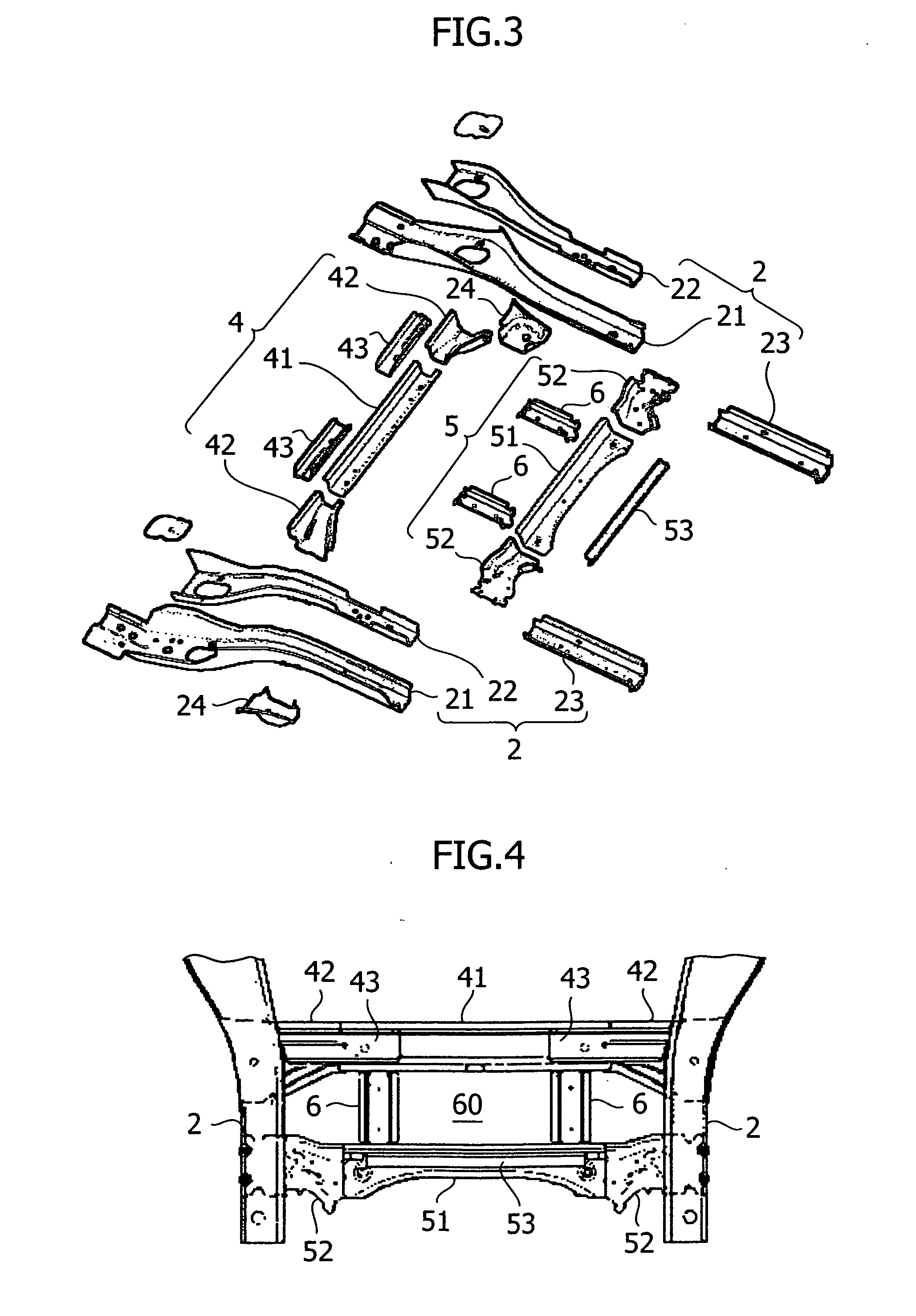

Vehicle body rear structure

InactiveUS20100072786A1Easy to assembleEasy maintenanceVehicle seatsUnderstructuresEngineeringImpact energy

Owner:SUZUKI MOTOR CORP

Electro-Hydraulic Forming Tool Having Two Liquid Volumes Separated by a Membrane

InactiveUS20080134741A1High pressure transmission efficiencyReduce frictionMetal-working apparatusElectro hydraulicMembrane configuration

An electro-hydraulic forming tool is disclosed in which a membrane is retained between two volumes of liquid that are separated by a membrane. Electrodes are provided with a high voltage impulse to create a shockwave in one of the volumes of fluid that is transferred through the membrane to the other volume of fluid. The shockwave is transmitted to a blank that is formed into a one-sided die. The blank is formed against the forming surface of the die. Air evacuation means are provided to remove air from the upper surface of one or both volumes of liquid.

Owner:FORD GLOBAL TECH LLC

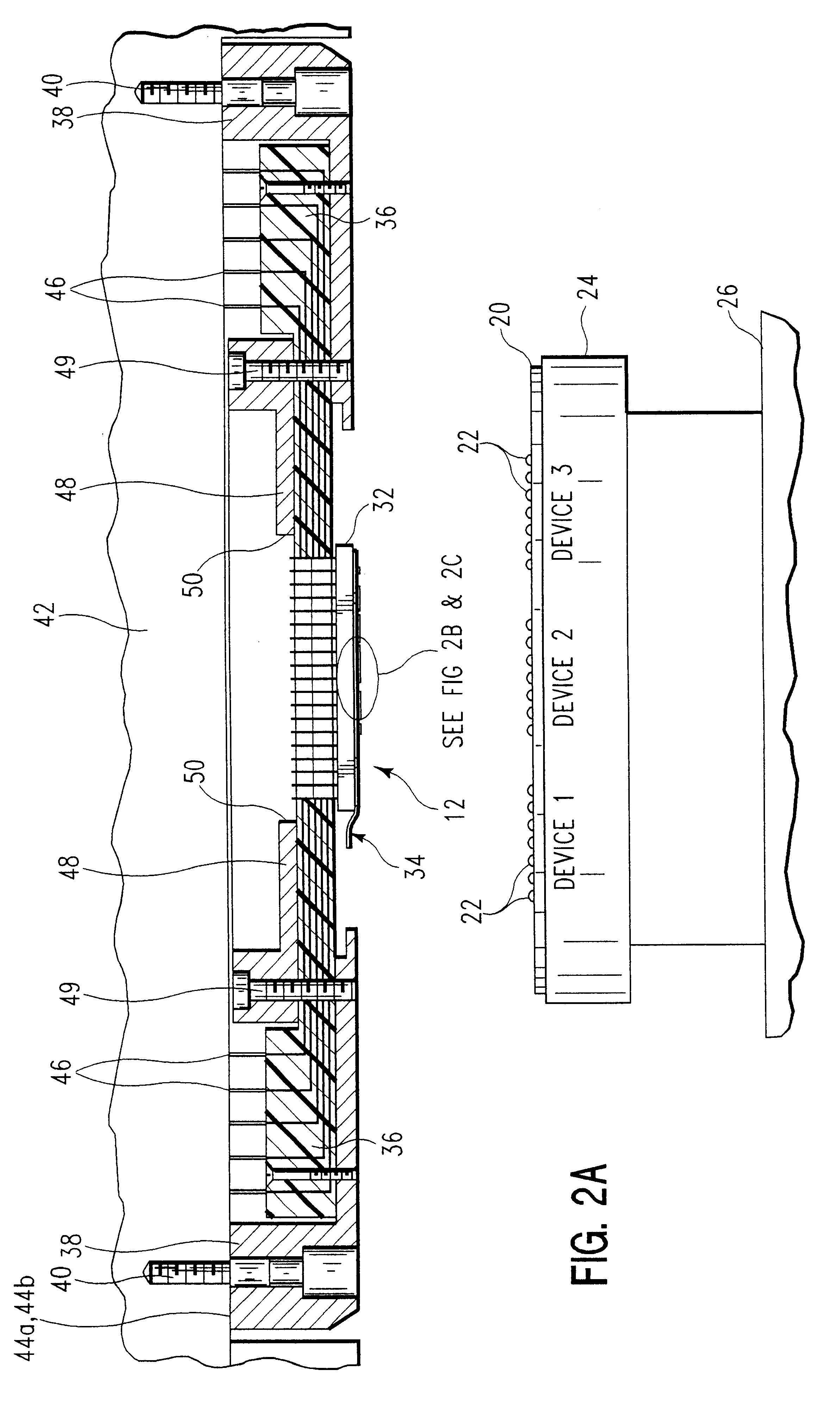

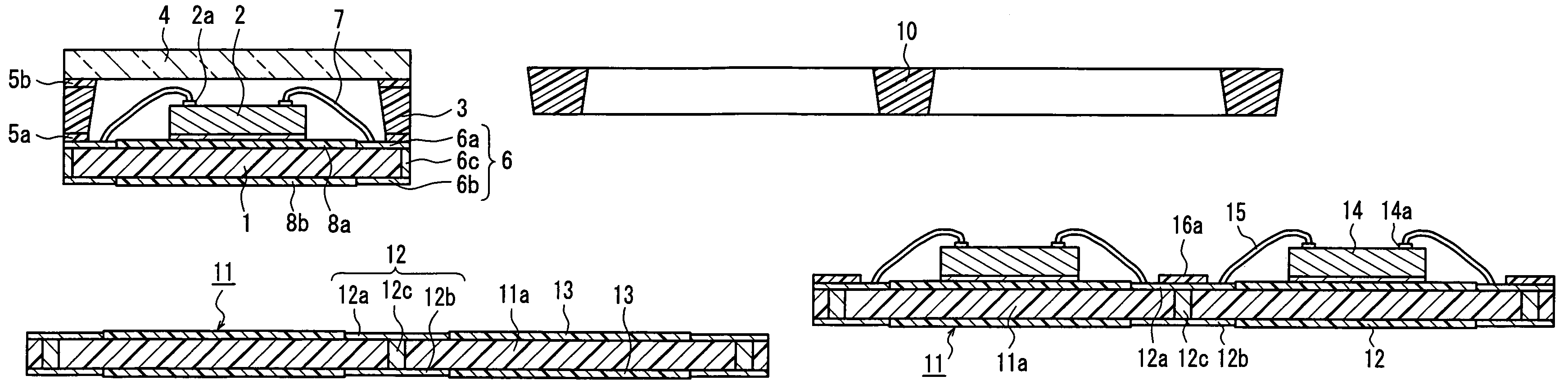

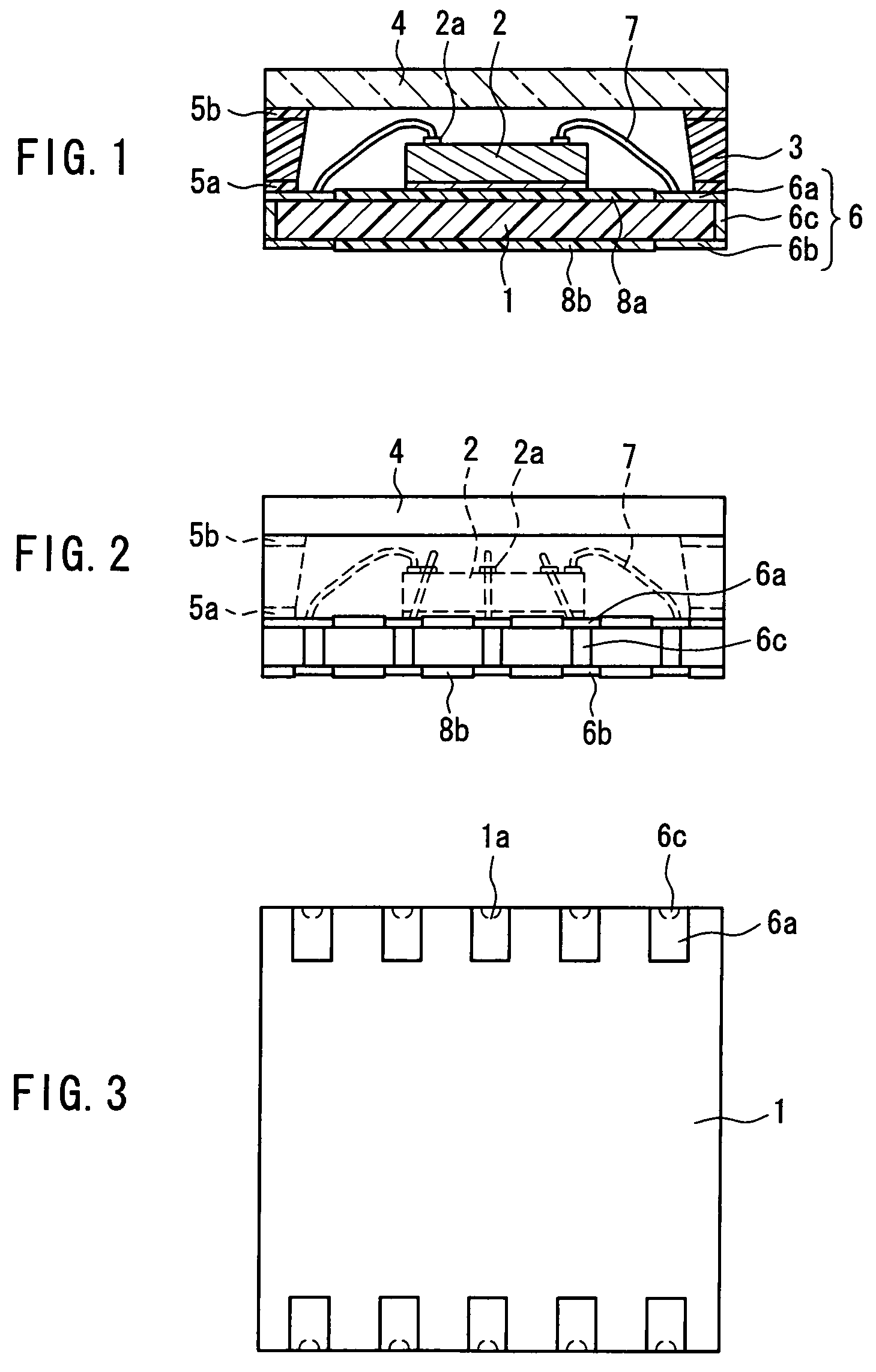

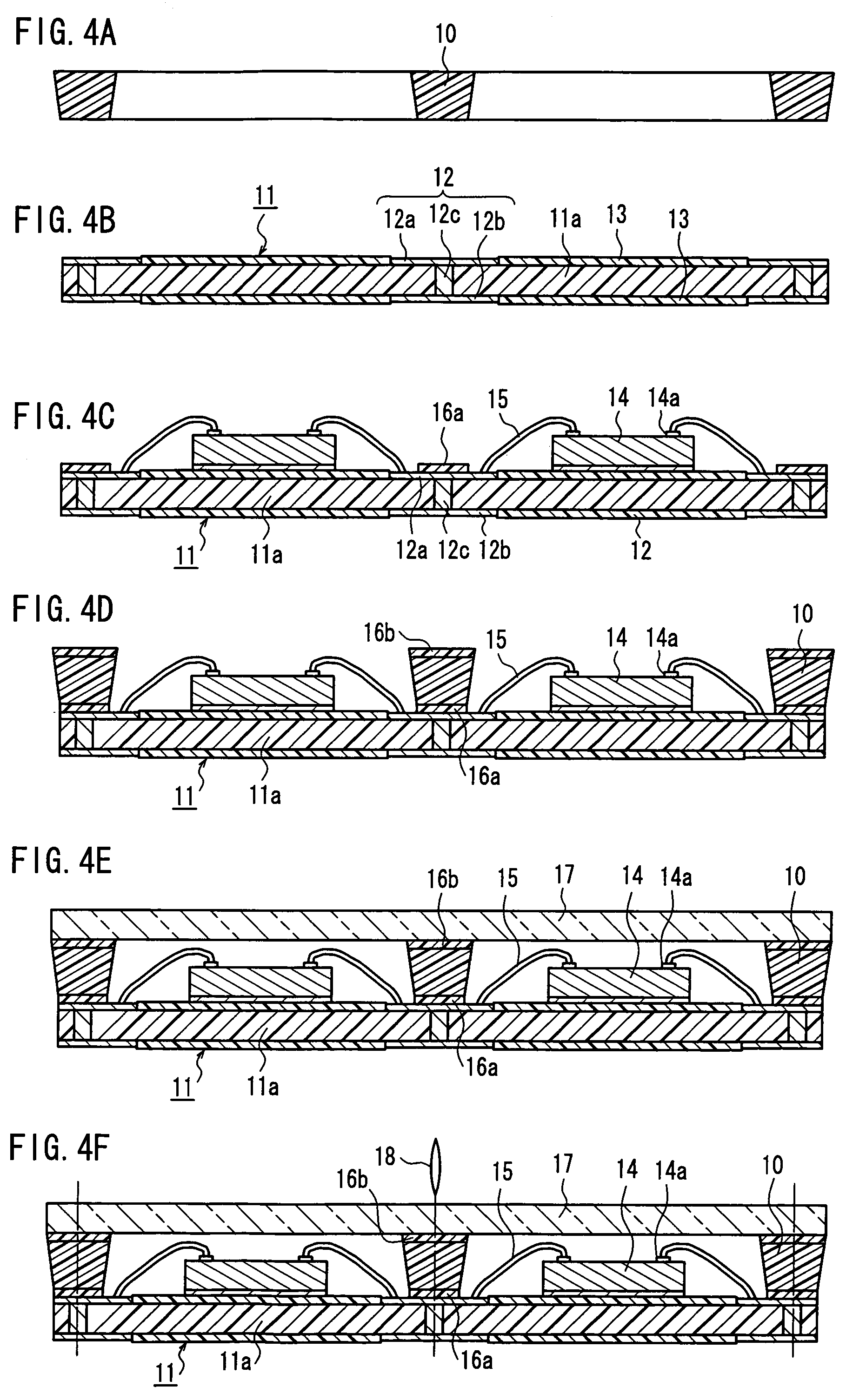

Method for manufacturing solid-state imaging devices

ActiveUS7247509B2Low costMinimal deformationTelevision system detailsSemiconductor/solid-state device detailsThin metalThermal expansion

A solid-state imaging device is manufactured according to the steps below. A lattice-shaped rib forming member, which is an aggregation of a plurality of frame-shaped ribs for configuring a plurality of solid-state imaging devices, is resin-molded. An aggregate wiring board is used, which has regions corresponding to a plurality of the wiring boards, and in which a plurality of the wiring members are provided in each of the regions, and the imaging element is fastened to each region of the aggregate wiring board and the electrodes of the imaging elements and the wiring members are connected by a thin metal wire. The rib forming member is placed on the wiring board face and joined to the wiring board face, so that the imaging element is disposed inside the lattice elements of the rib forming member. The transparent plate is fastened to an upper face of the rib forming member, and each housing is cut in a direction perpendicular to the base portion, and in a direction dividing into two the width of the rib forming member, and separating the solid-state imaging devices into individual pieces It is possible to make a low cost housing, avoiding deformations caused by a difference in thermal expansion between the wiring board and the ribs made of a resin, when forming a plurality of housings together.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Aerodynamic air gun projectile

InactiveUS7222573B2Increase relative motionImprove stabilityAmmunition projectilesHollow inflatable ballsInterference fitConical forms

A projectile for an air arm is integrally formed from a single piece of dense malleable material formed as a body of revolution about a longitudinal axis having a head portion dimensioned for free sliding in the bore of an air arm and a skirt-like portion of frusto-conical form. The rearward end of the skirt portion is dimensioned to be in slight interference fit with the bore and the forward end is joined with the head portion to define a reduced diameter waist. The frustum is shell-walled, having a central recess opening to the rear and extending forwardly into the head portion. The head portion has a parabolically shaped outer surface which transitions smoothly into a hyperbolically shaped outer skirt surface for aerodynamic efficiency. Vanes are formed on the head portion to enhance in-flight spiraling rotation.

Owner:PONTIERI JAMES M

Casing for a steam or gas turbine

InactiveUS6336789B1Reduce radial clearanceAvoid inefficiencyPump componentsStatorsTurbine bladeEngineering

A casing for a steam or gas turbine comprises a shell and two flanges. The wall thickness of the shell is varied in an upper region facing away from the flange, in two central regions and in two lower regions facing the flanges, such that the upper region facing away from the flanges is reinforced in comparison with the lower regions facing the flanges. The lower regions facing the flanges are more flexible than the flanges which are attached by screws, and the partially reinforced central region and the reinforced upper region, and act as a joint to compensate for deformation, particularly in the radial direction. Consequently, the casing remains considerably more round in operation. The reduced radial clearance (achieved by reduced deformation) between the casing and the ends of the turbine blades leads to considerably increased efficiency during operation of the turbine.

Owner:GENERAL ELECTRIC TECH GMBH

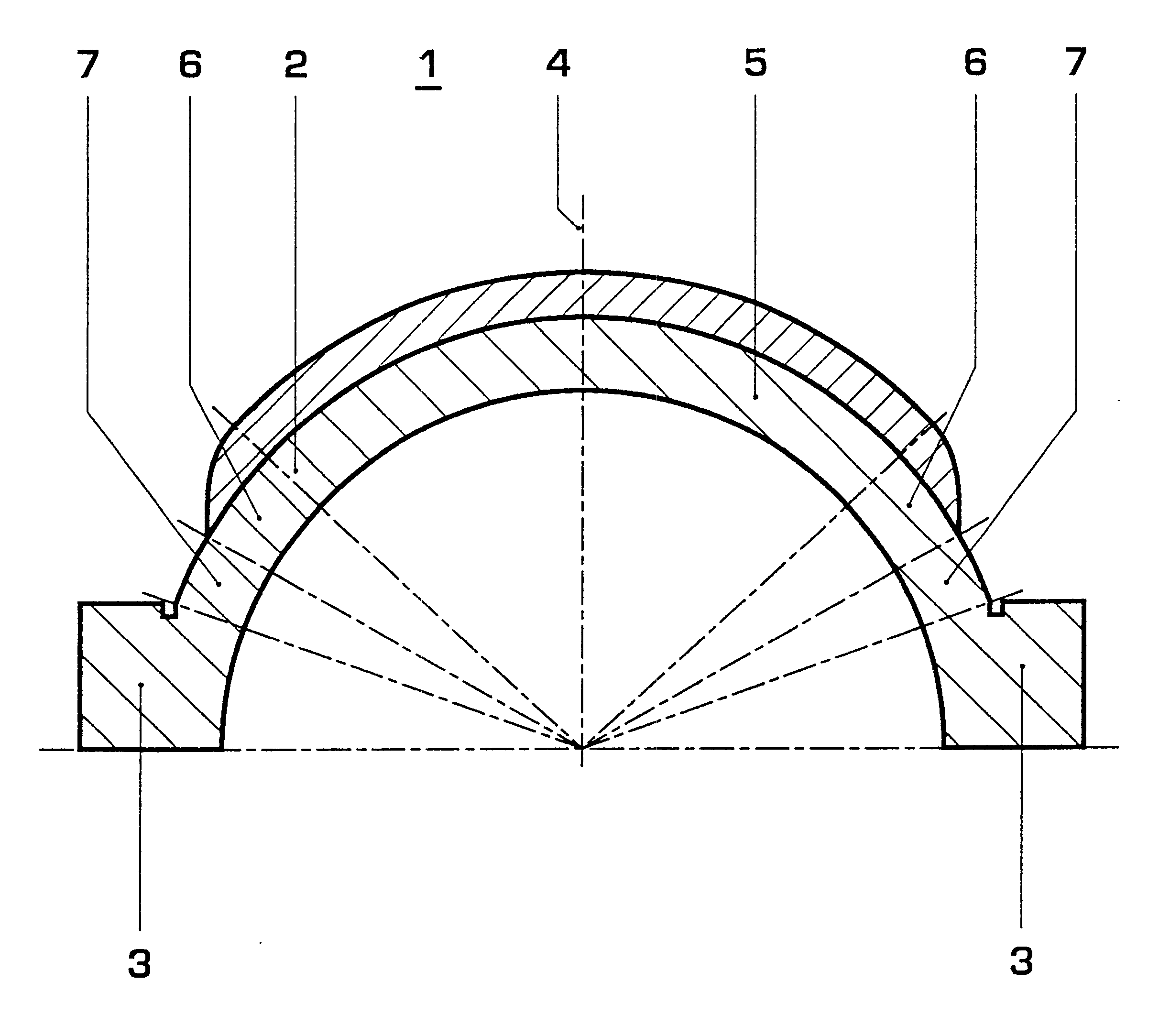

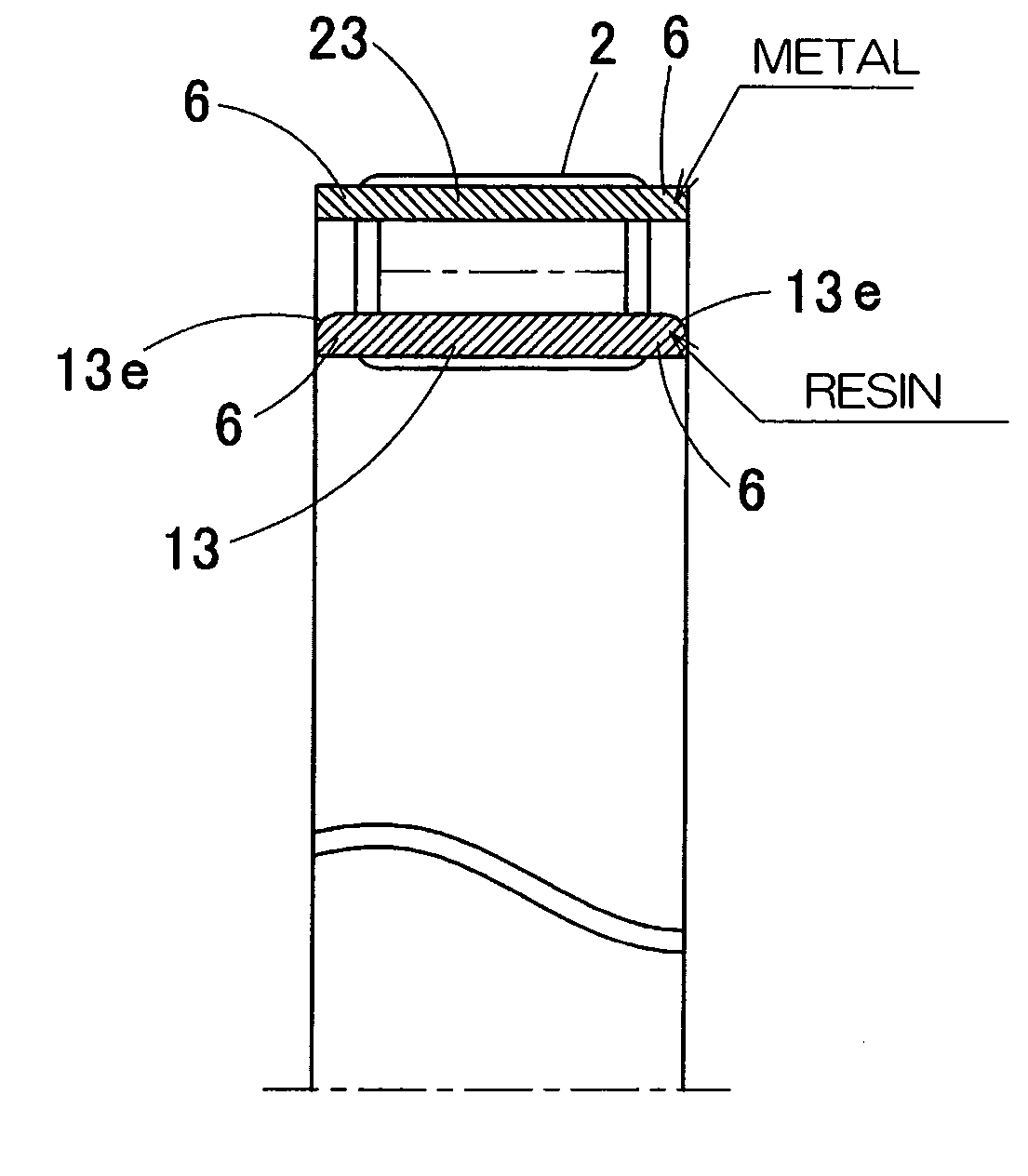

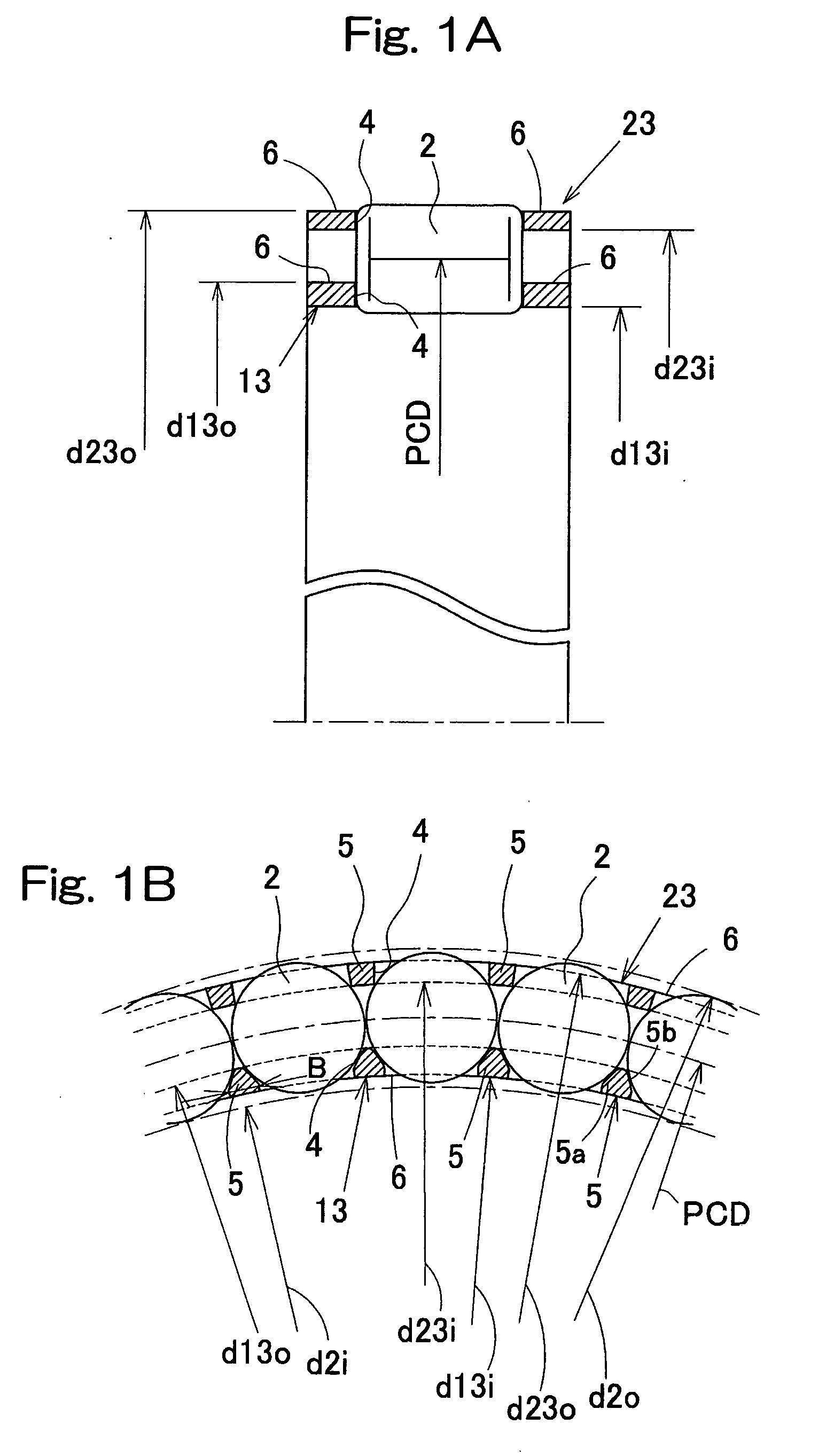

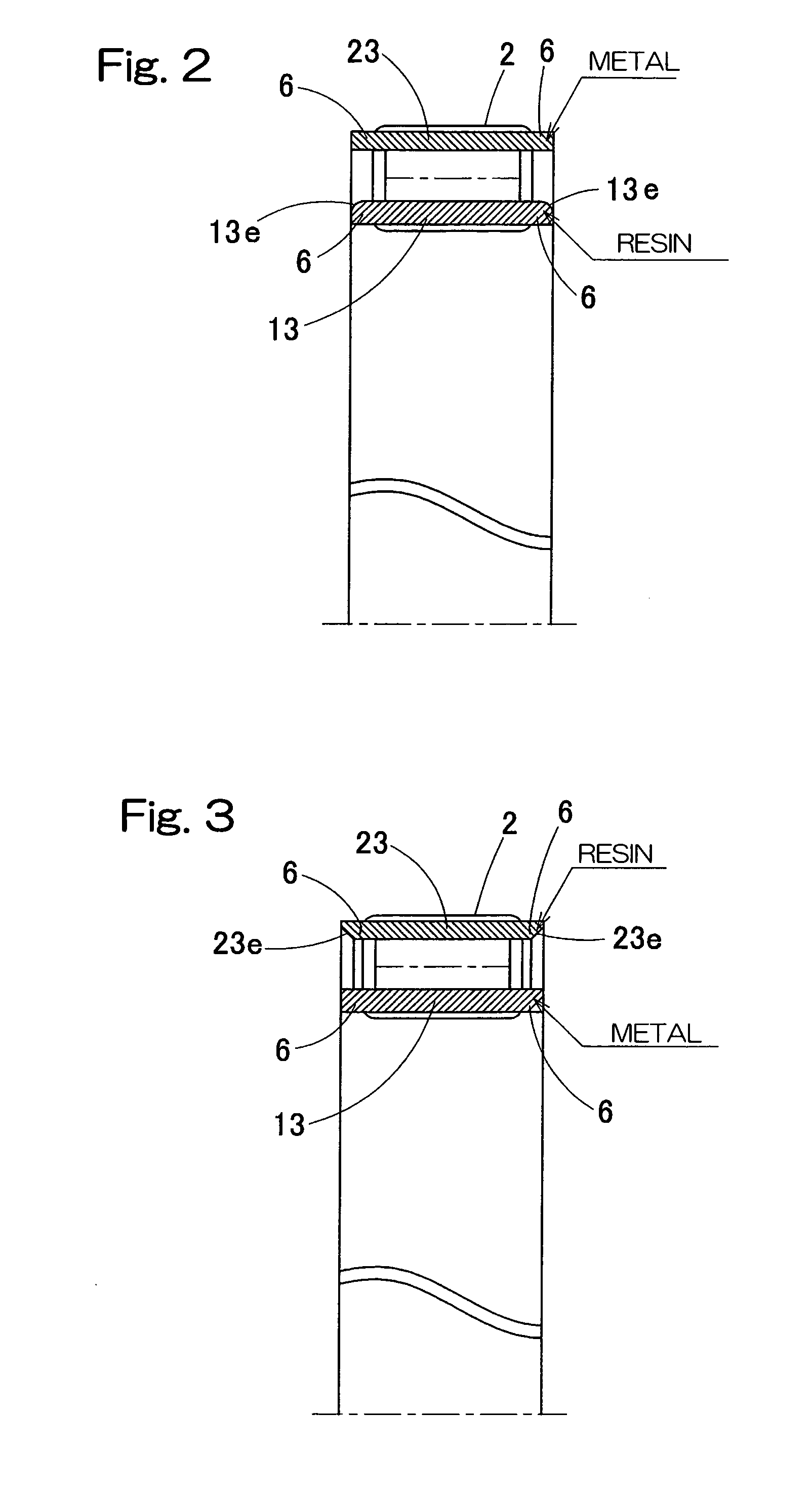

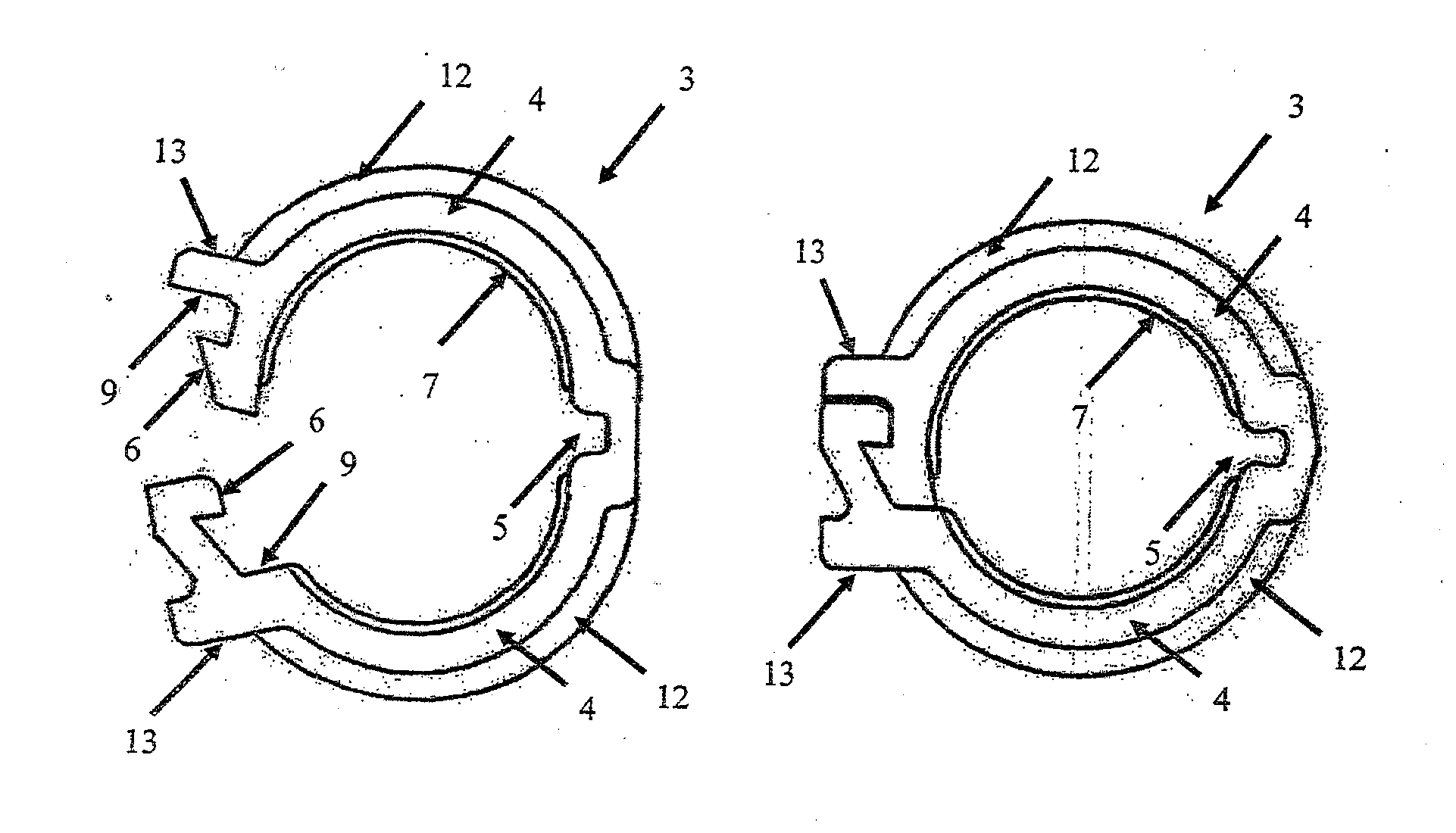

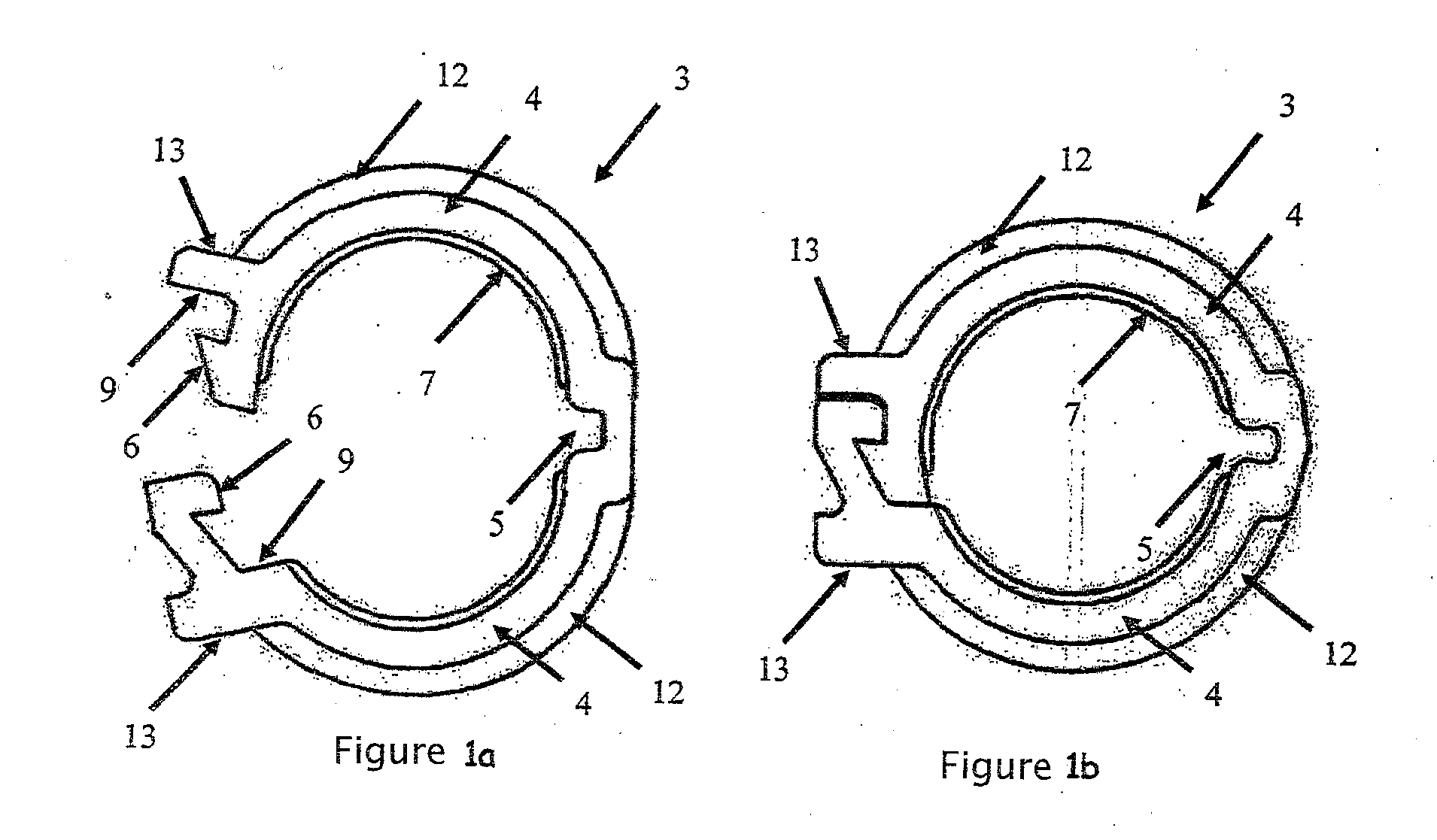

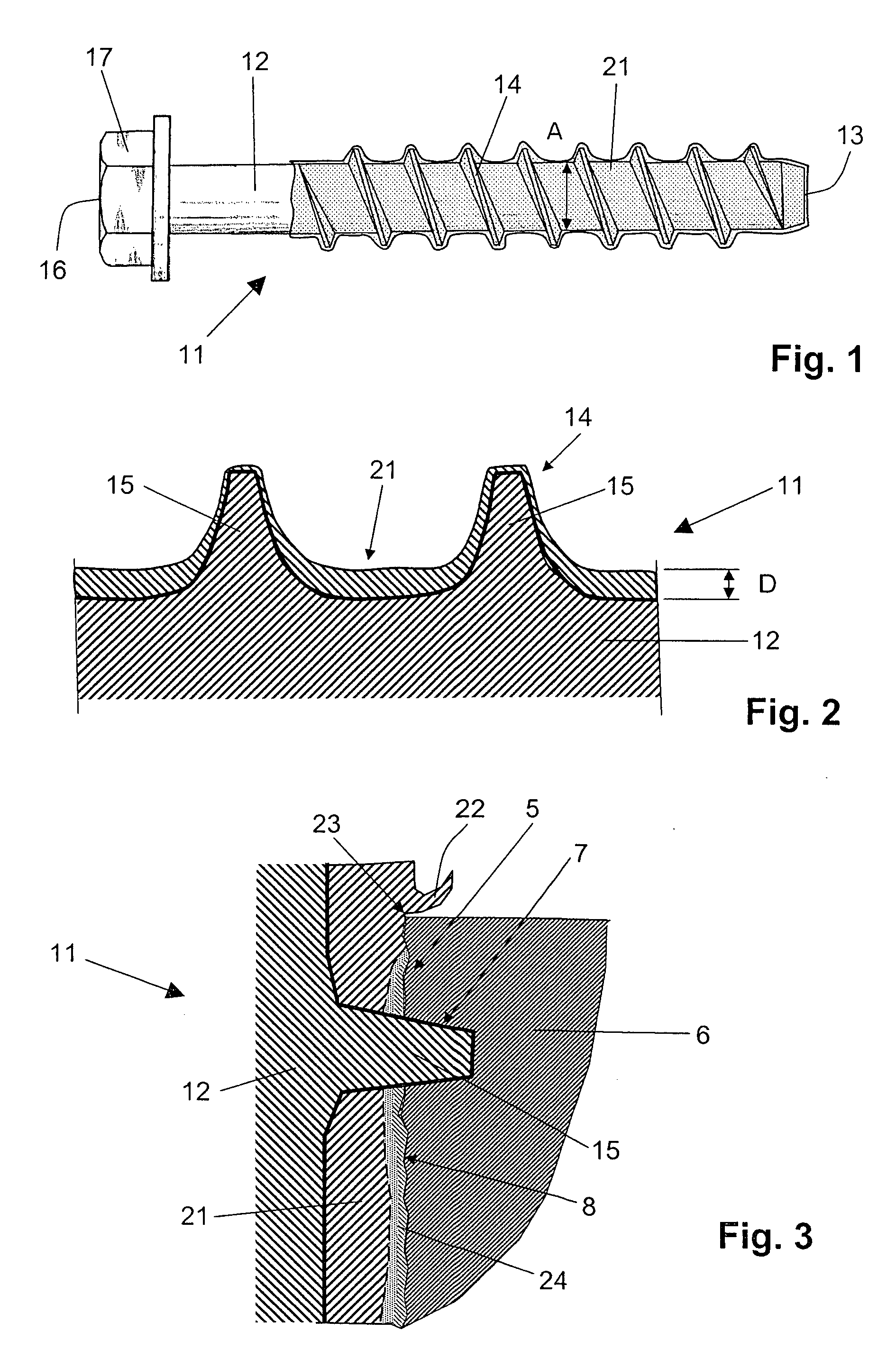

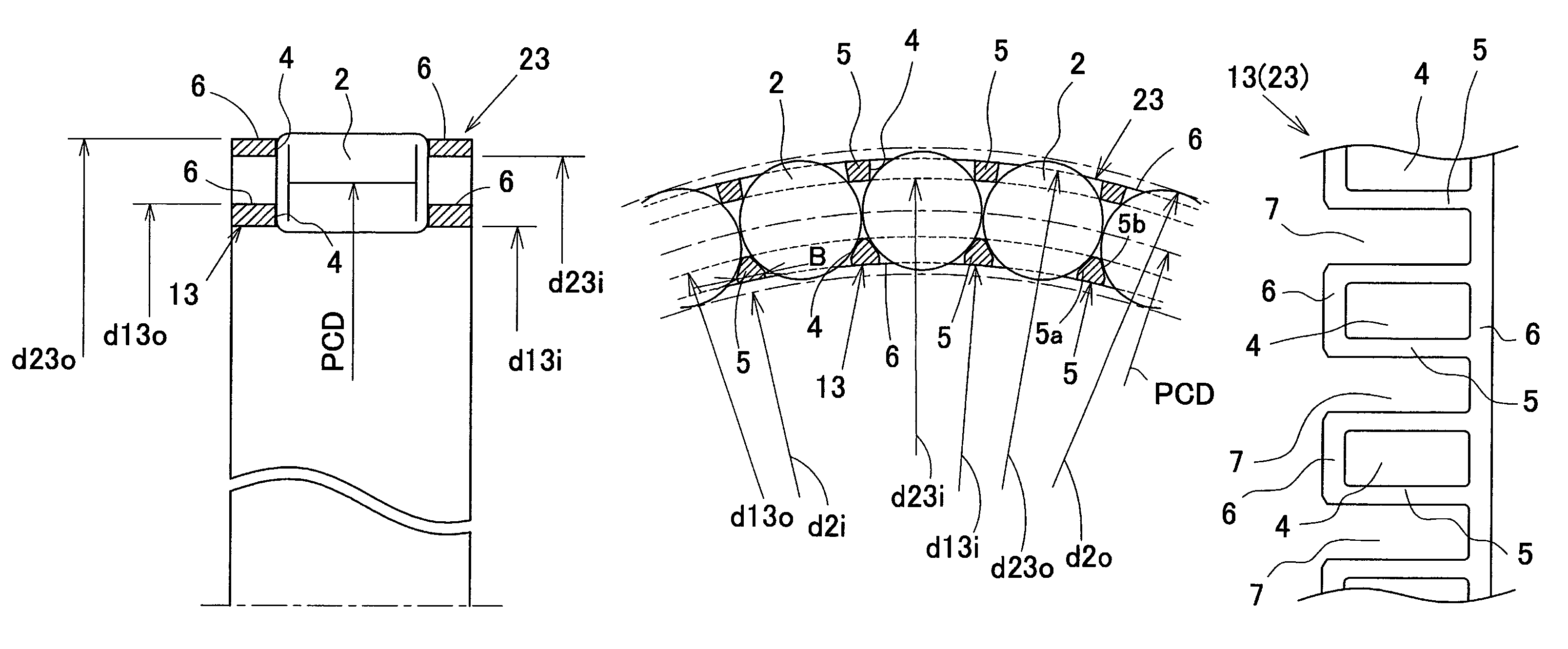

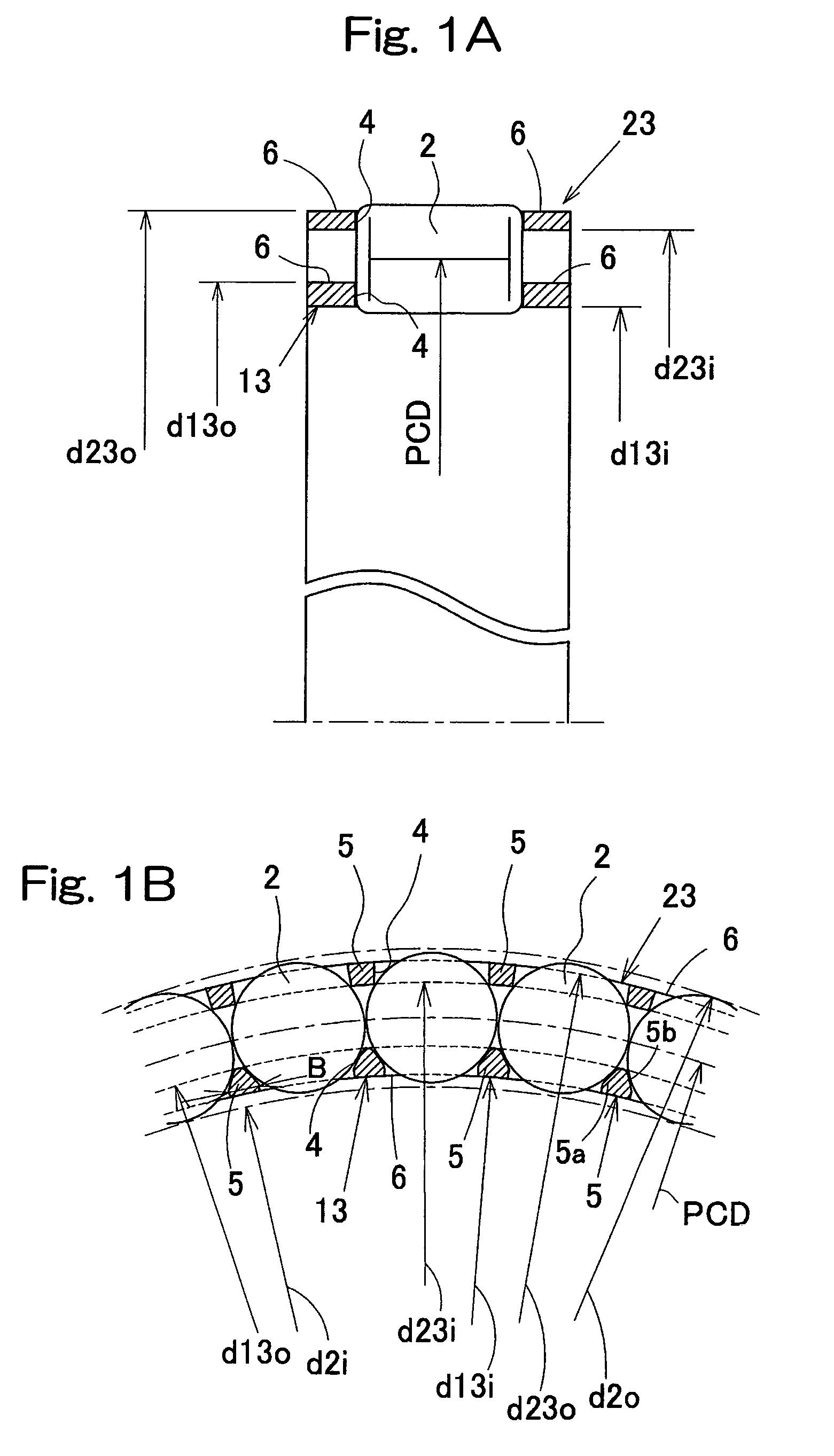

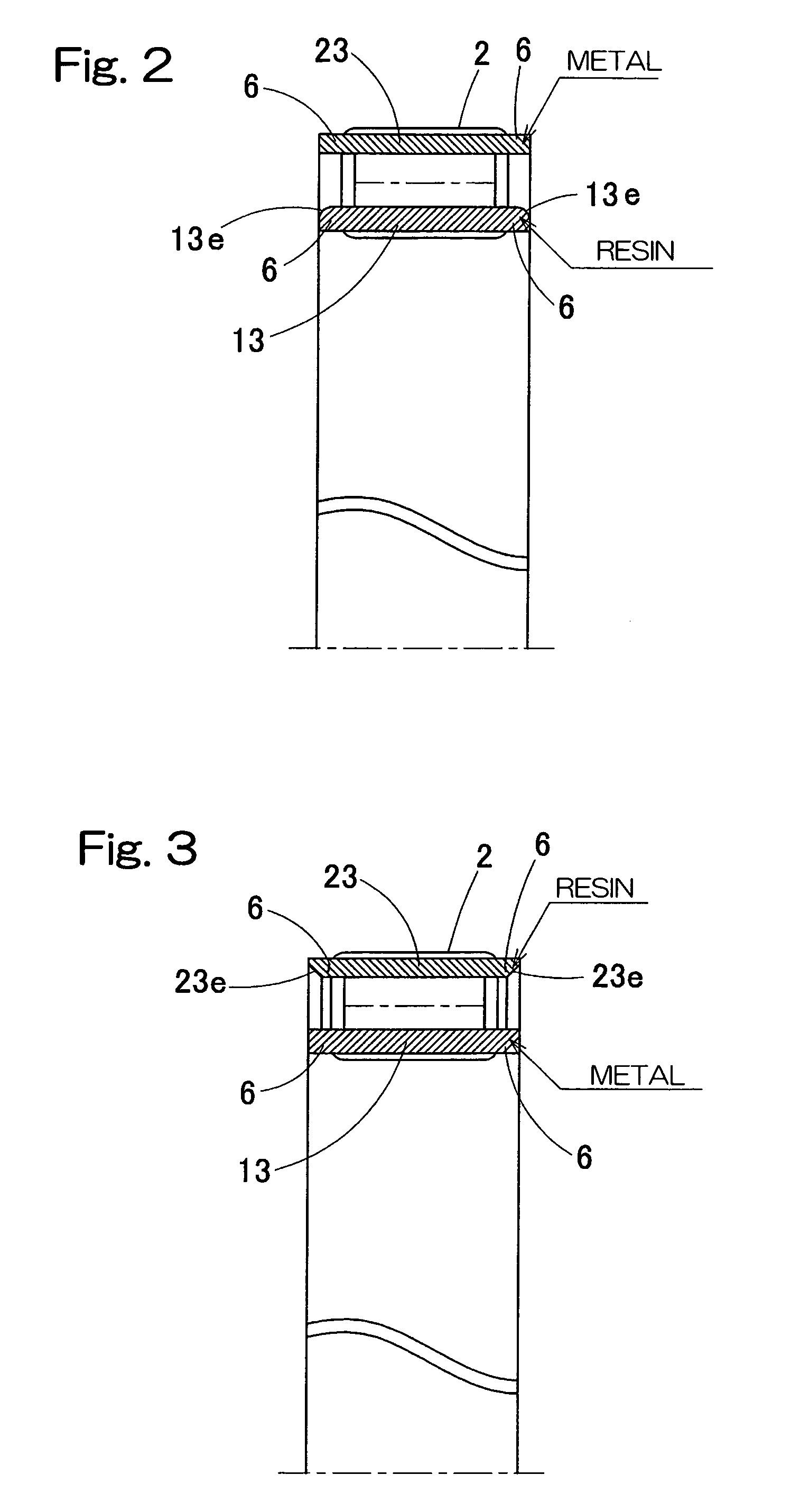

Roller bearing assembly

InactiveUS20060104560A1Flexure deformation be minimalIncrease of assemblability and precisionRoller bearingsShaftsMetallic materialsRoller bearing

To provide a roller bearing assembly that can provide a high load bearing capacity and in which the strength of roller retainers can be increased, the roller bearing assembly includes inner and outer roller retainers (13, 23) each having a plurality of circumferentially arranged pockets (4), and a circular row of rollers (2) received in part within the pockets in the inner roller (13) and in part within the pockets in the outer roller (23). The inner roller retainer (13) has pillars (5) each left between the neighboring pockets to retain the circular row of the rollers from radially inwardly and having an outer diameter smaller than the diameter of the pitch circle PCD of the circular row of the rollers. The outer roller retainer (23) has pillars (5) each left between the neighboring pockets to retain the circular row of the rollers from radially outwardly and having an inner diameter greater than the pitch circle diameter PCD. One of the outer and inner roller retainers is made of a metallic material while the other thereof is made of a resinous material.

Owner:NTN CORP

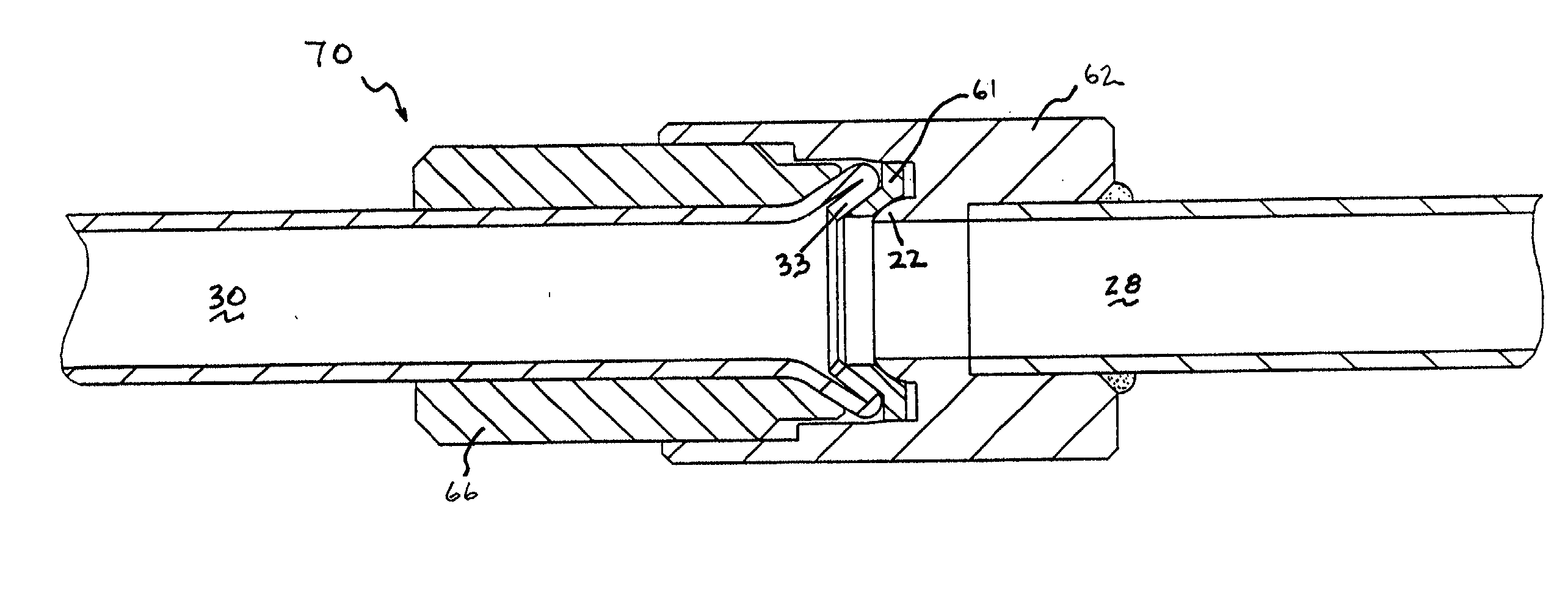

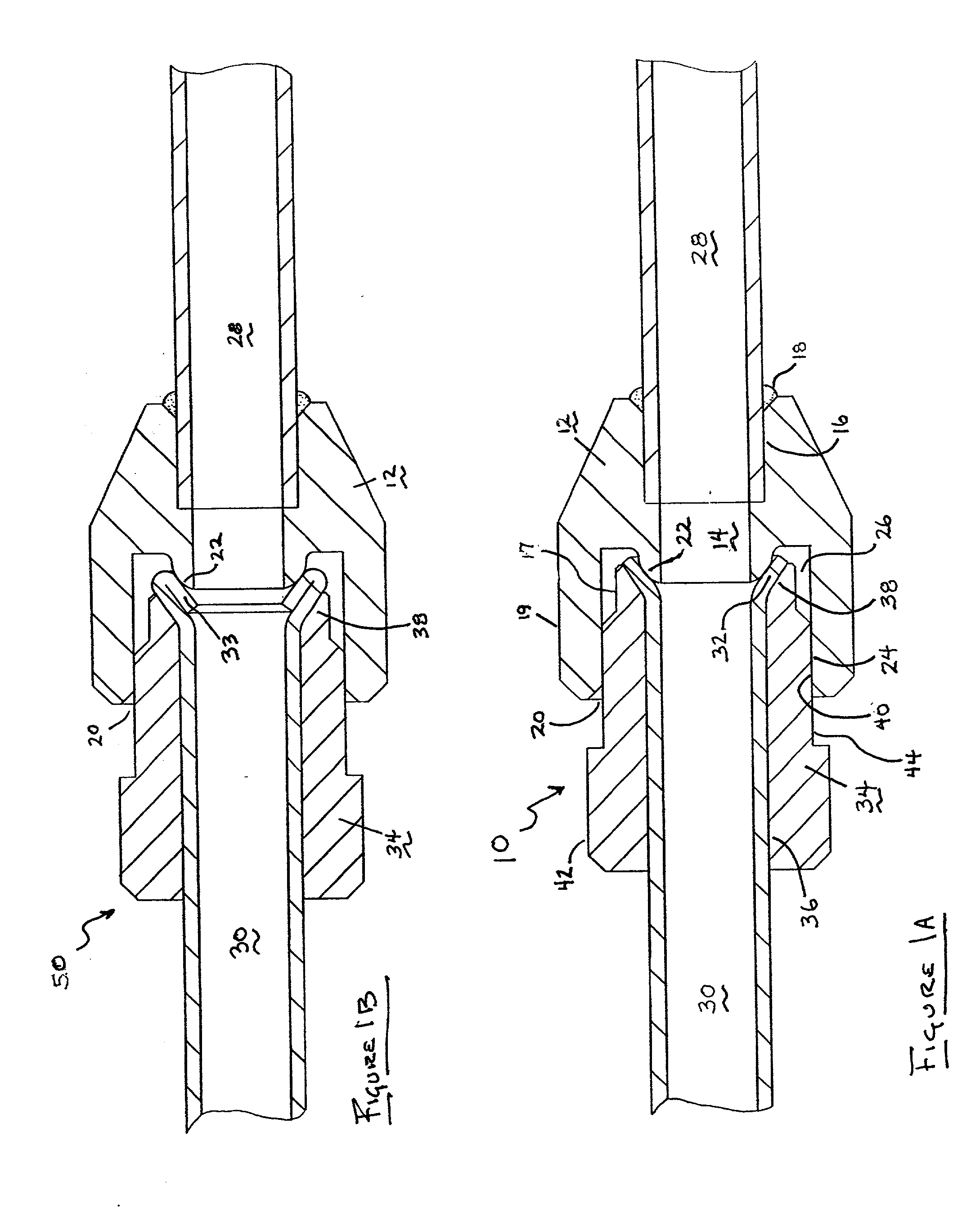

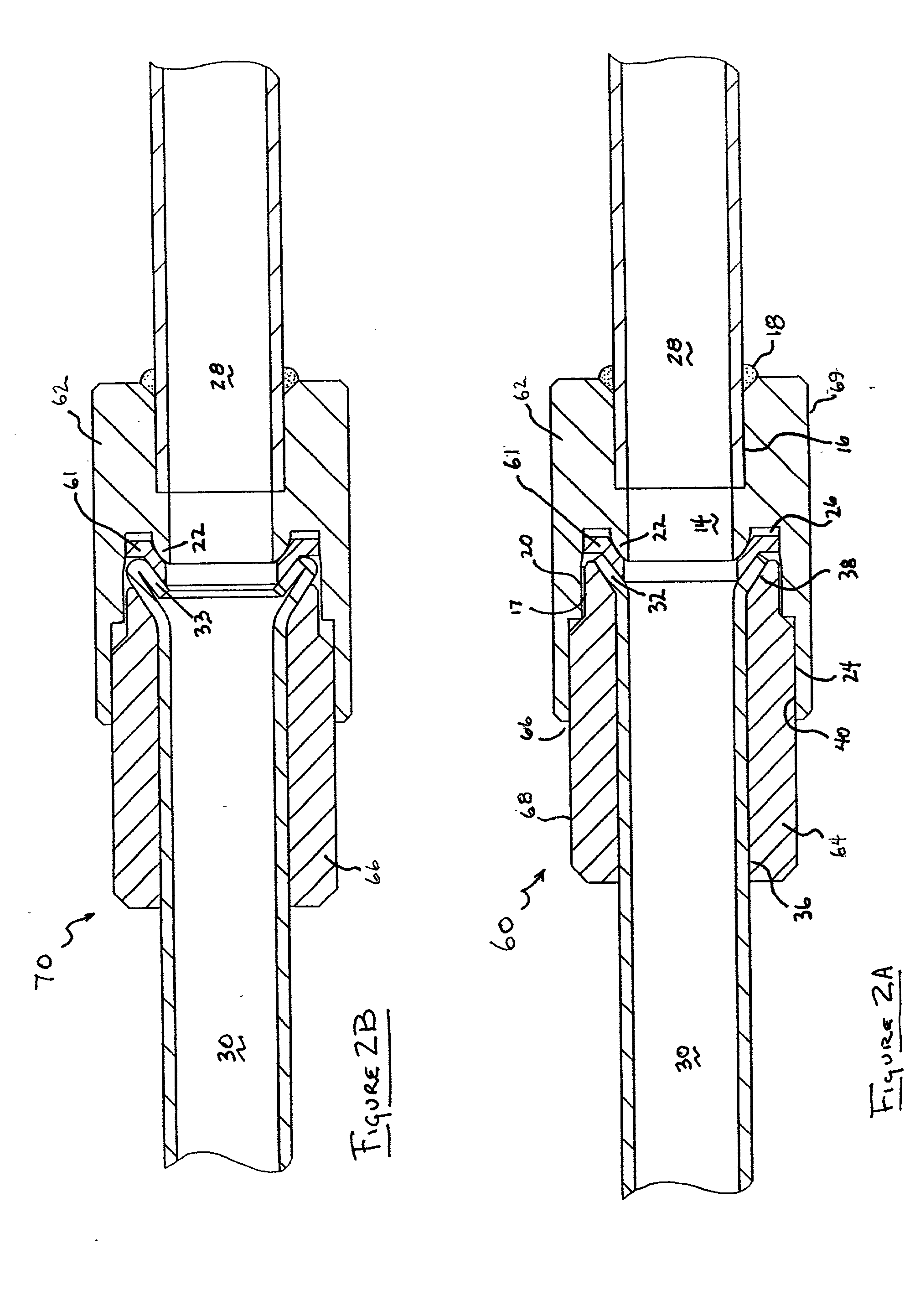

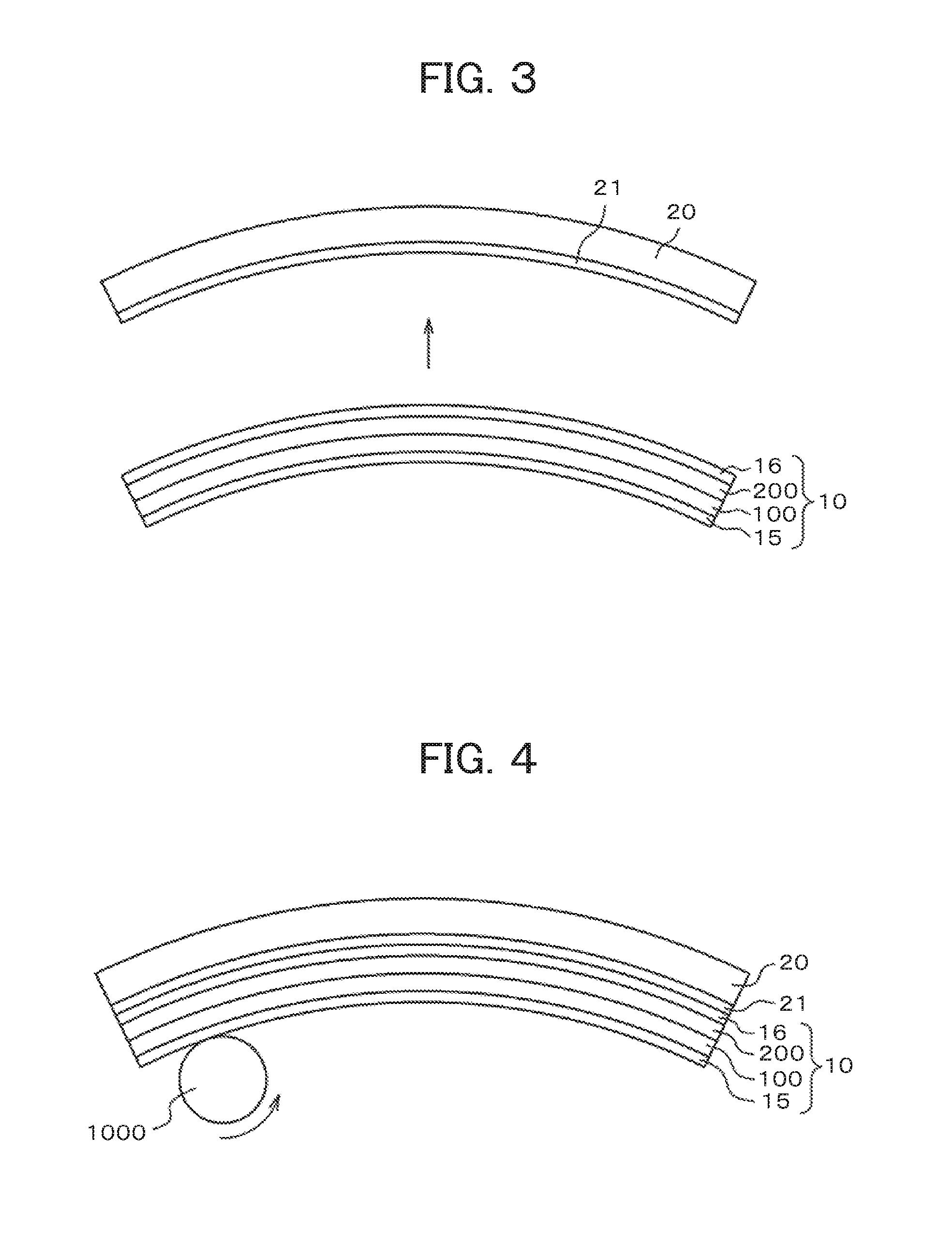

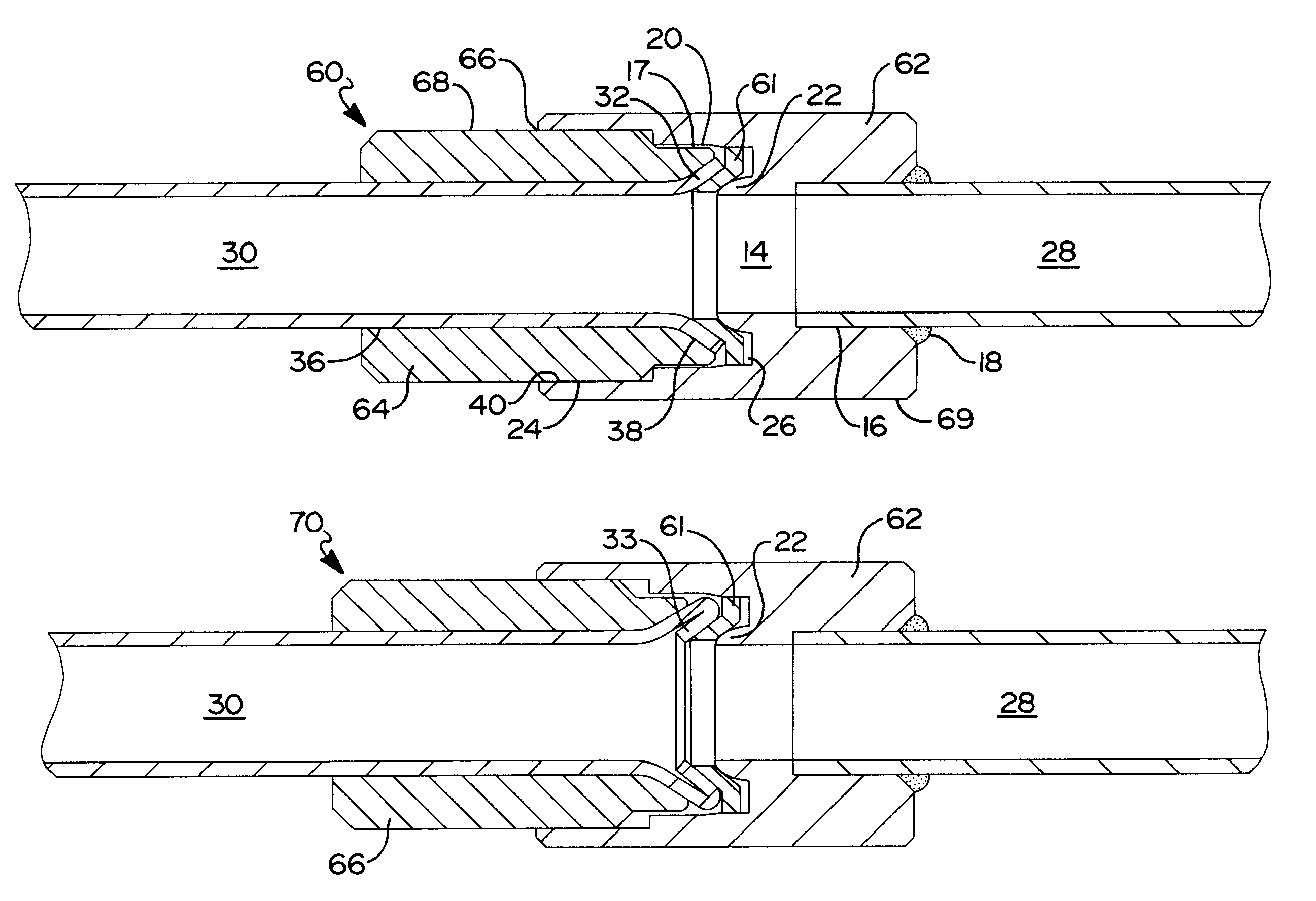

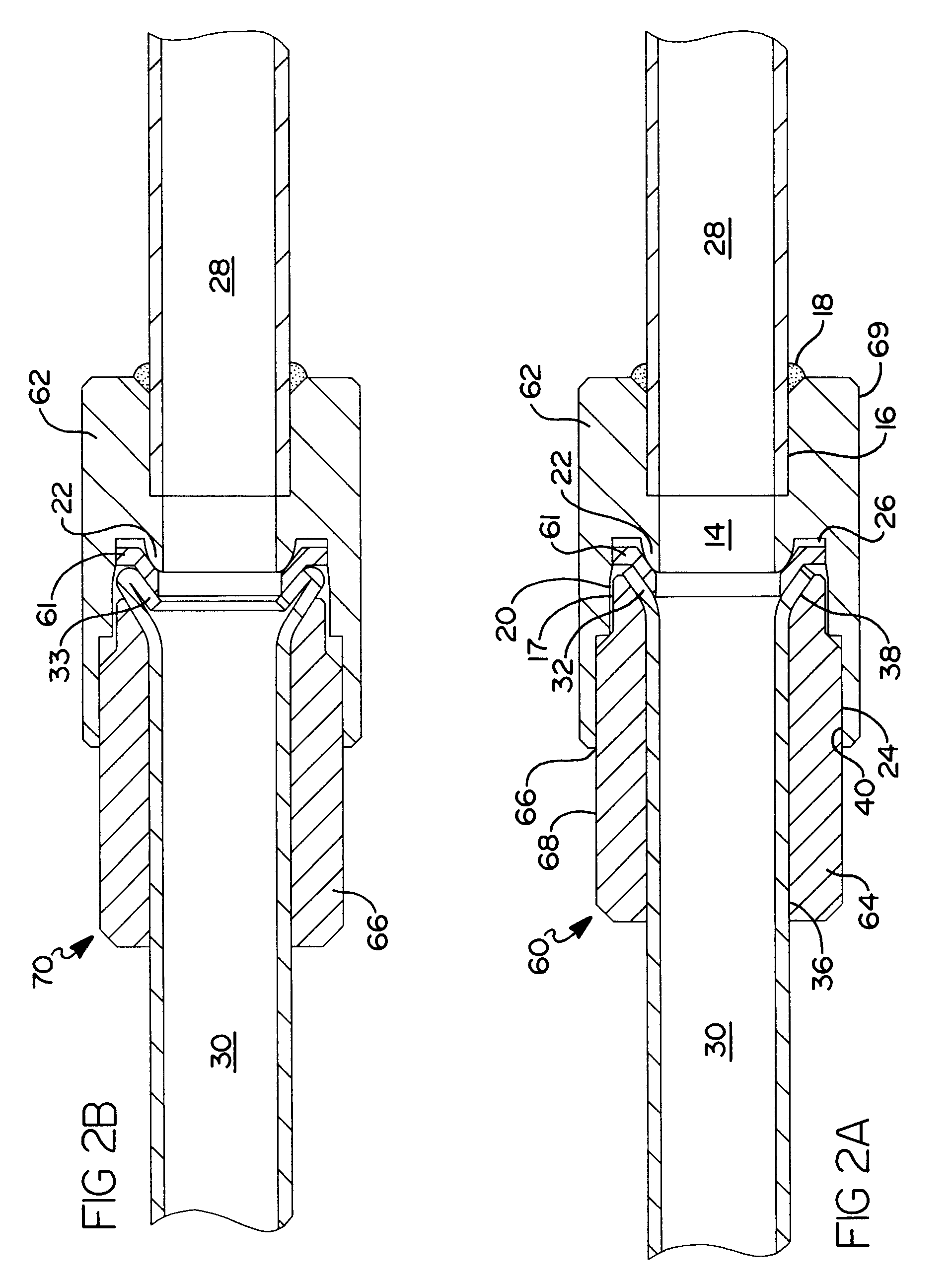

Flare fitting assembly with metal-to-metal line seal

InactiveUS20030047945A1Minimal deformationIncrease pressureFluid pressure sealed jointsJoints with sealing surfacesMetalFlare fitting

A flare fitting assembly includes a first coupling member and a second coupling member adapted to be cooperatively coupled together. The first coupling member has a first through bore with one end adapted to accept and retain a first tube. The second coupling member has a second through bore adapted to be disposed upon a second tube with an outwardly flared end. An arcuately shaped seating surface is disposed within the first through bore of the first coupling member. A conically flared seating surface is disposed within the second through bore of the second coupling member adapted to engage an outer surface of the flared end of the second tube such that a line seal is formed between the inner surface of the flared end of the second tube and the arcuate surface when the first and second coupling members are cooperatively coupled.

Owner:VISTEON GLOBAL TECH INC

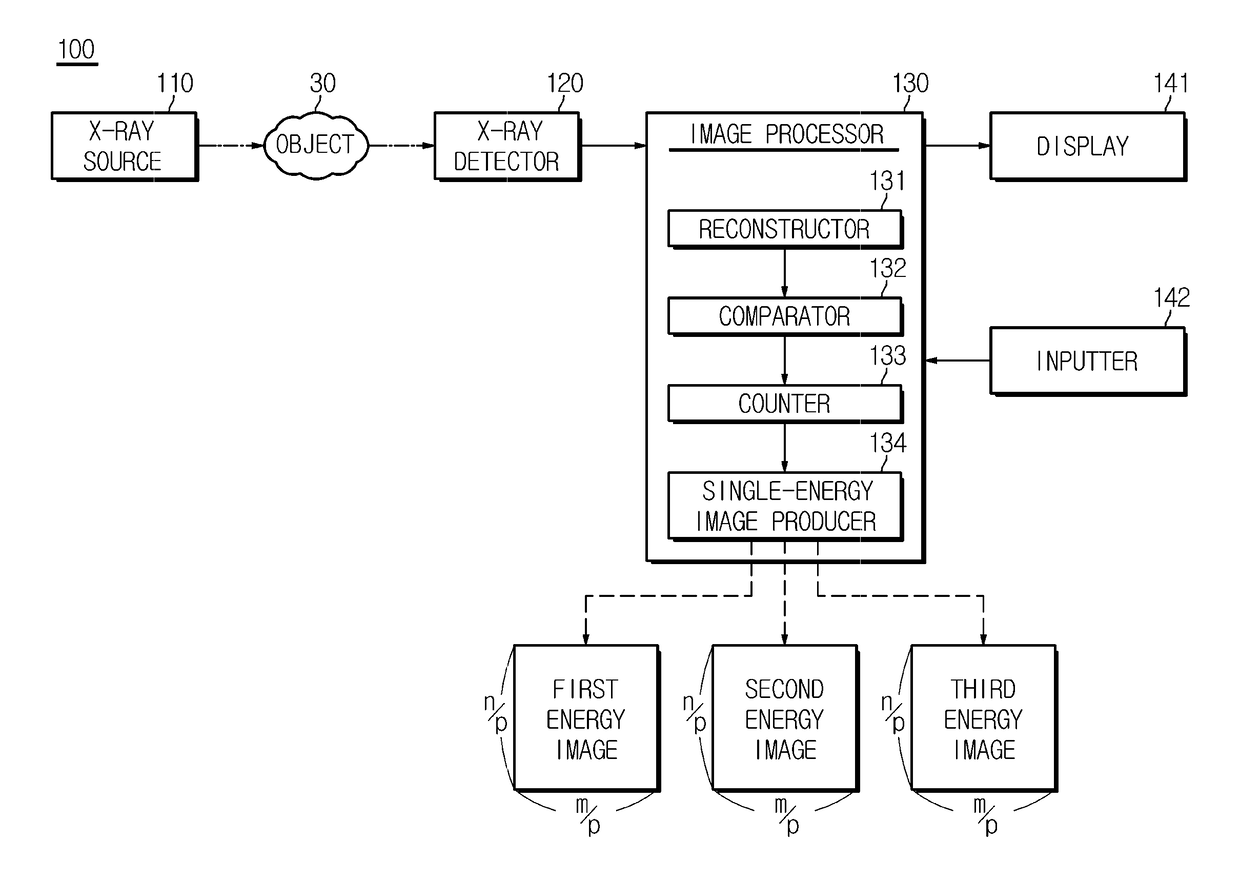

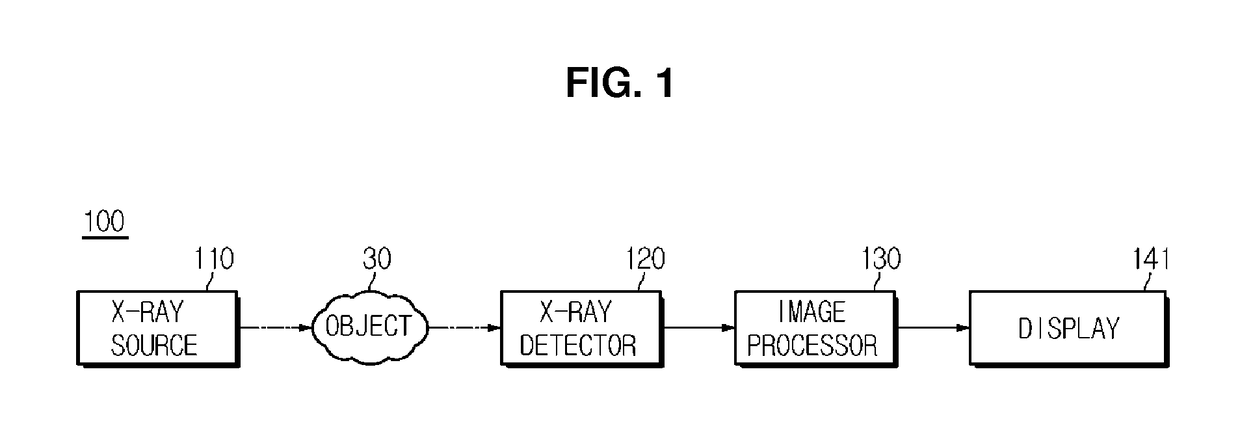

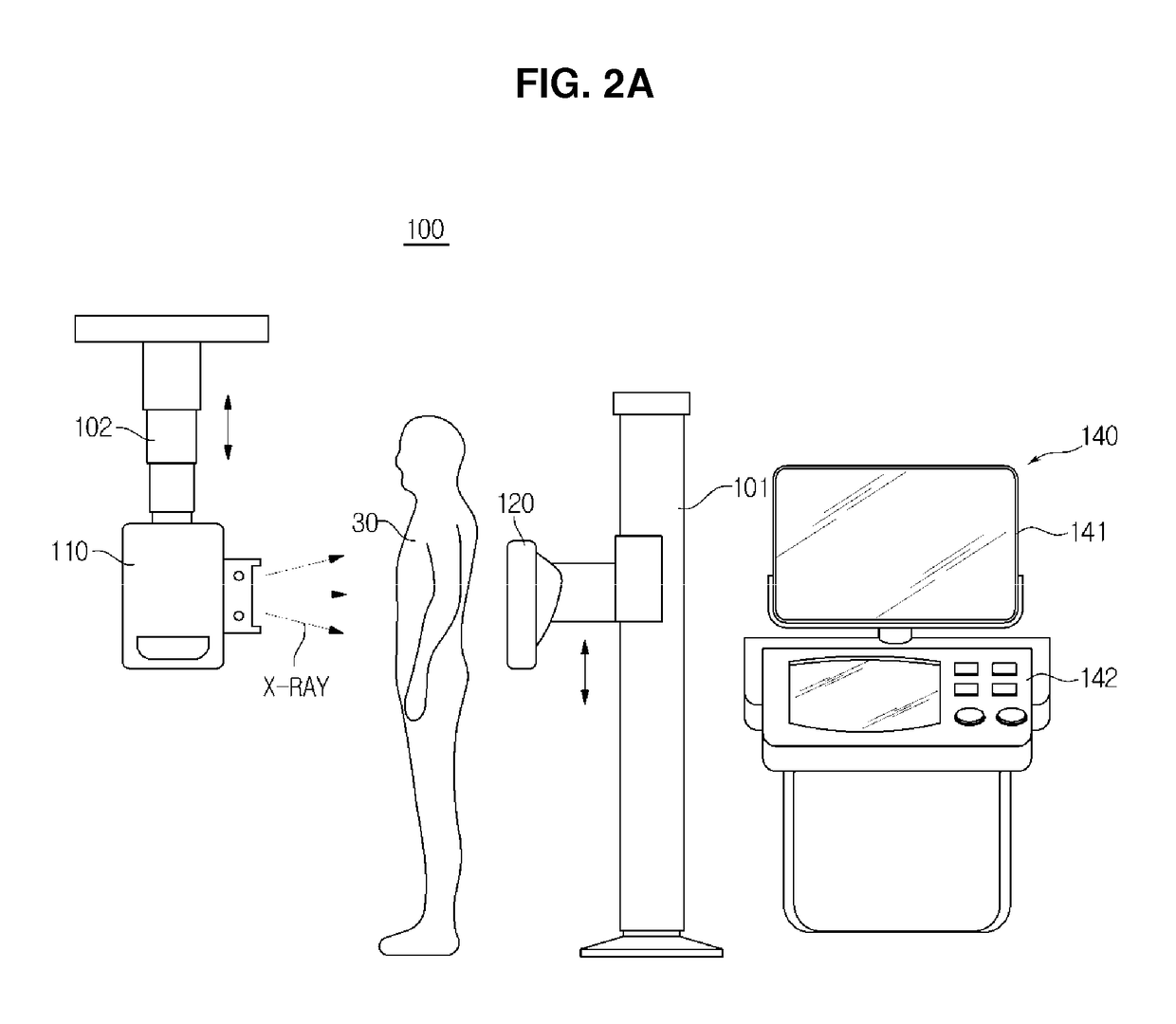

X-ray imaging apparatus and control method for the same

InactiveUS9700268B2Minimal deformationImage enhancementPatient positioning for diagnosticsX-rayBroadband

Owner:SAMSUNG ELECTRONICS CO LTD

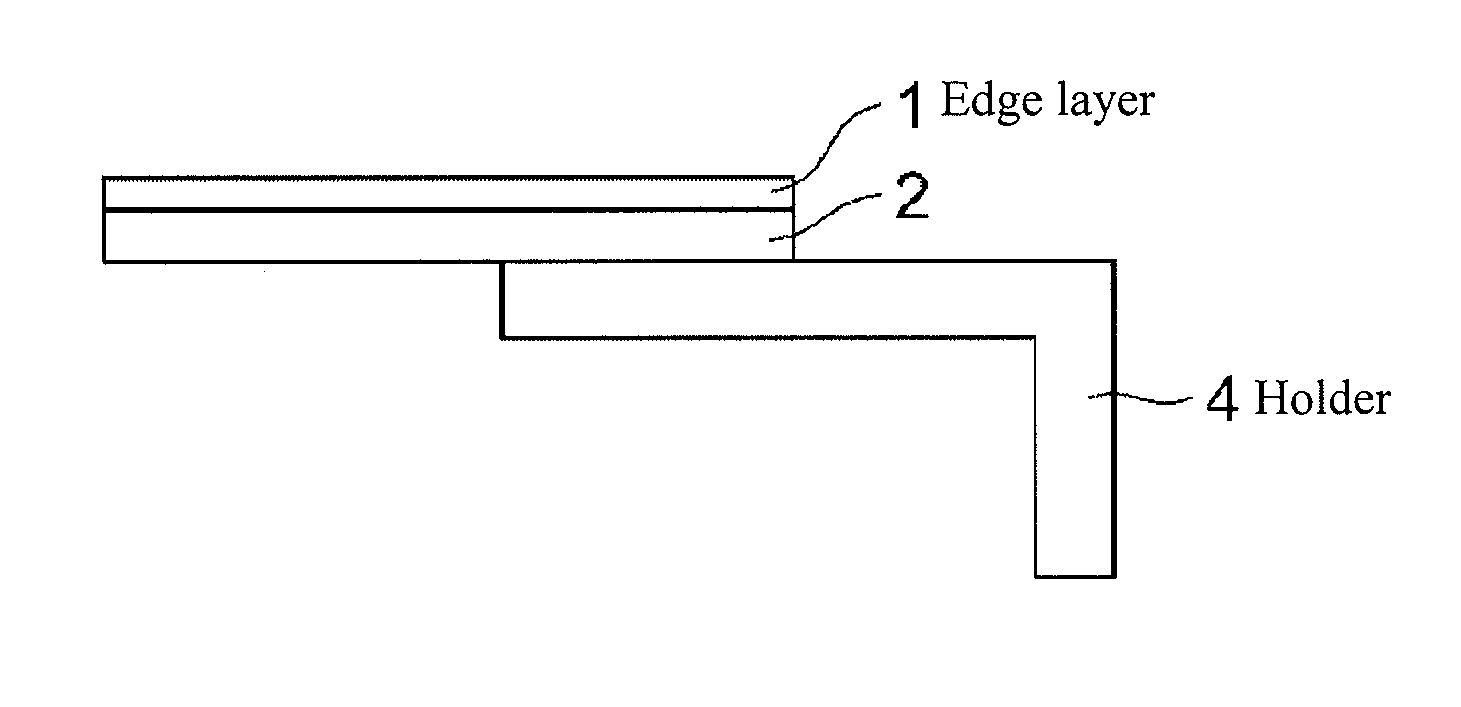

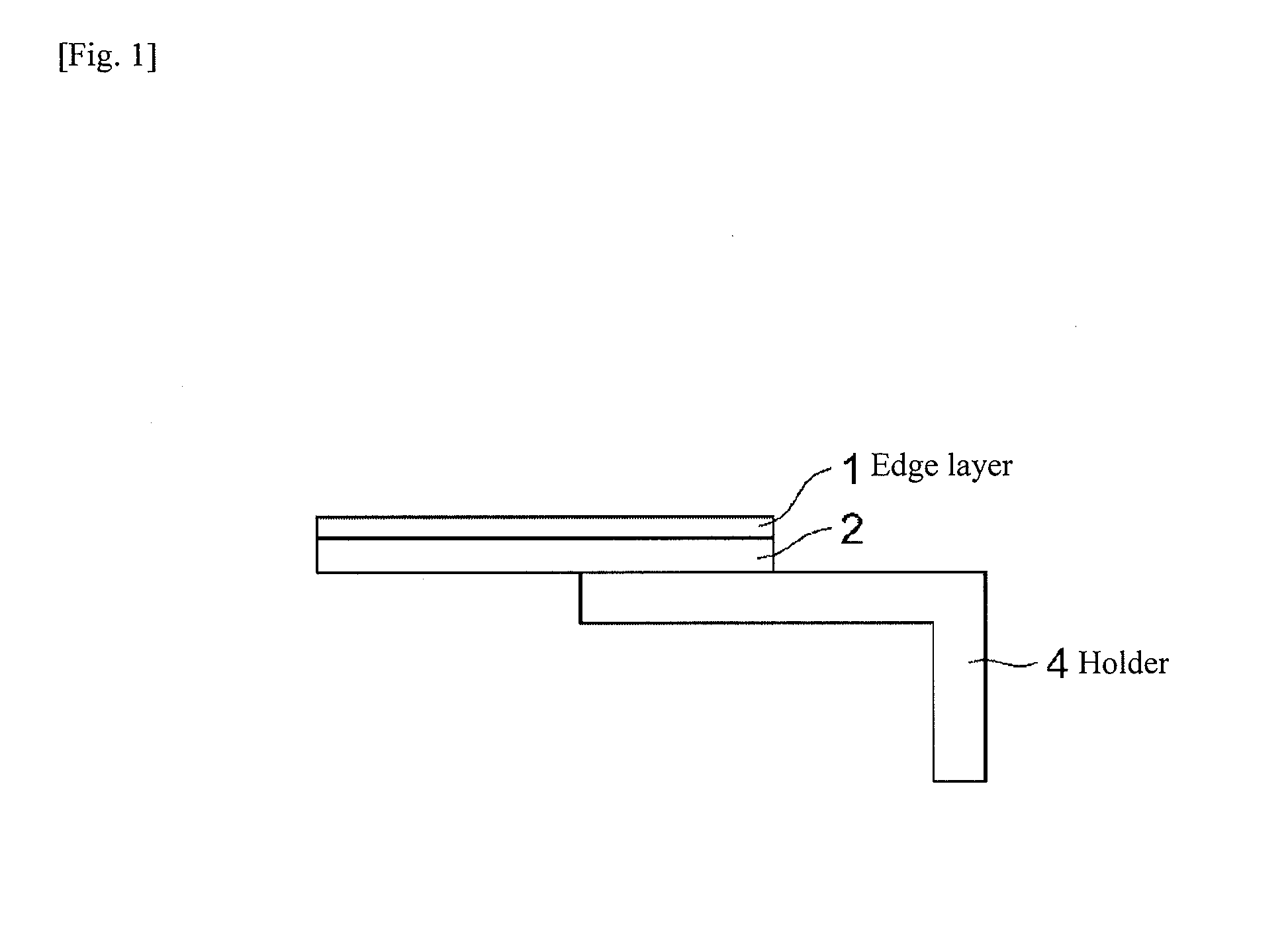

Blade for electrophotographic device and method for manufacturing the blade

An object of the present invention is to provide a blade for an electro-photographic device formed by two layers, which undergoes minimal permanent deformation and offers excellent mechanical strength, wear resistance and compliance to the use environment.A blade for an electro-photographic device whose edge and base are constituted by different materials, wherein such blade for an electro-photographic device is characterized in that at least the edge is made of ester polyurethane and the base other than the edge is made of ether polyurethane.

Owner:BANDO CHEM IND LTD

Flexible display device including folding section

ActiveUS20150357395A1Minimal deformationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

A flexible display device includes a folding section formed on a flexible substrate, a flat section connected to the folding section, and a display area for displaying an image, wherein the display area is formed on the folding section and the flat section, wherein each of the display areas of the folding section and the flat section includes a plurality of pixels and a plurality of wires for supplying electrical signals to the pixels, and wherein the wires in the display area of the folding section include a winding wire extending in a winding configuration on the flexible substrate.

Owner:SAMSUNG DISPLAY CO LTD

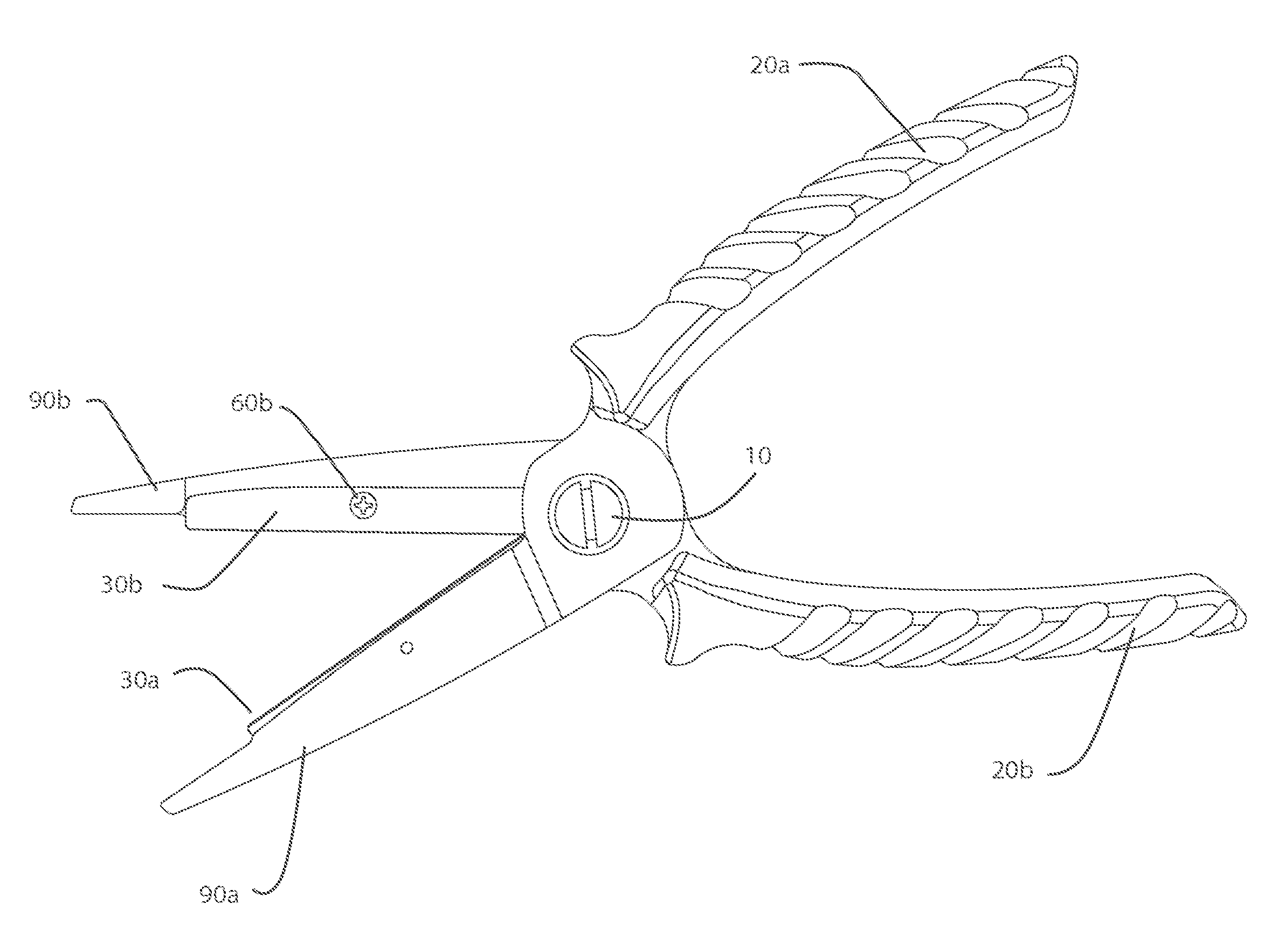

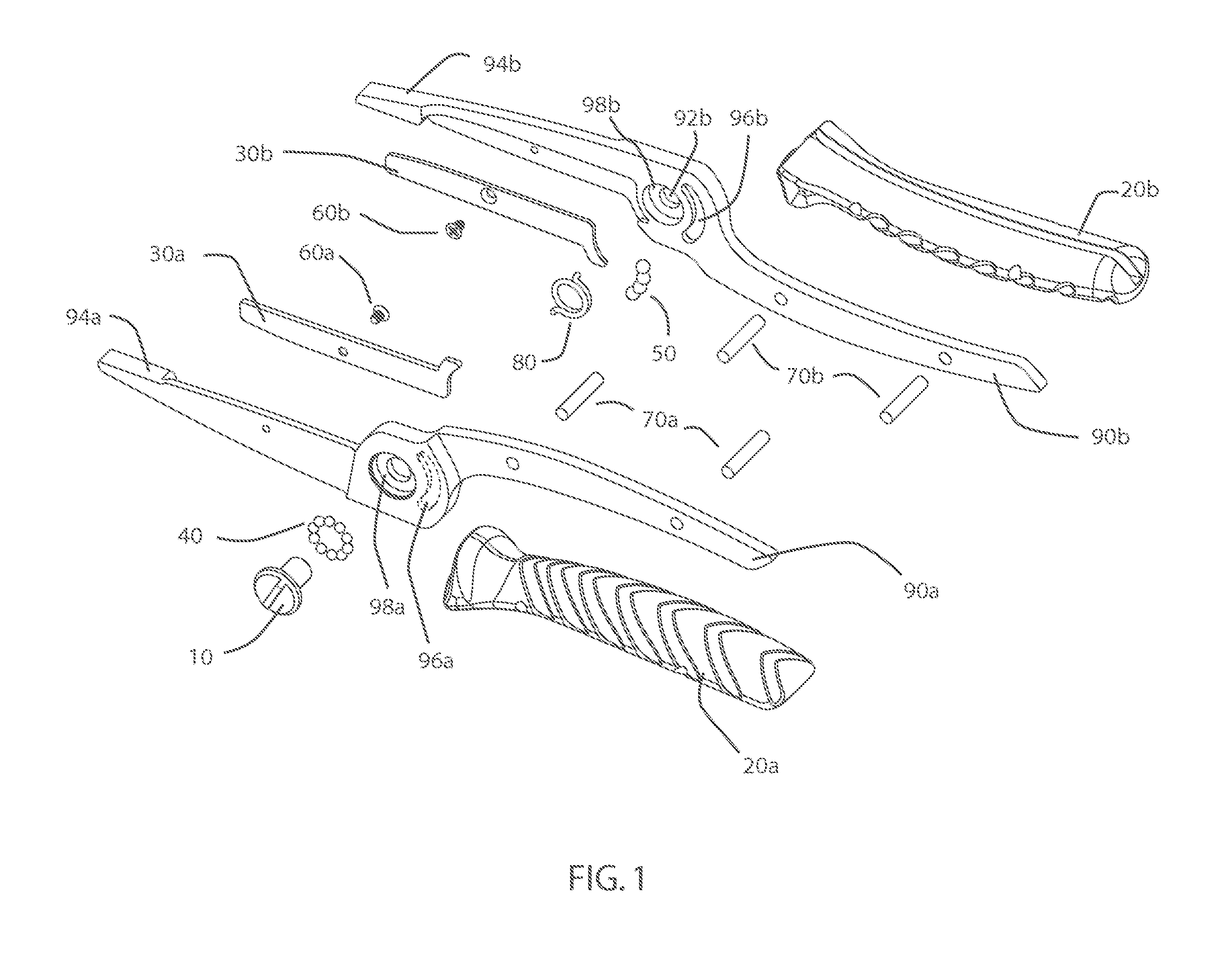

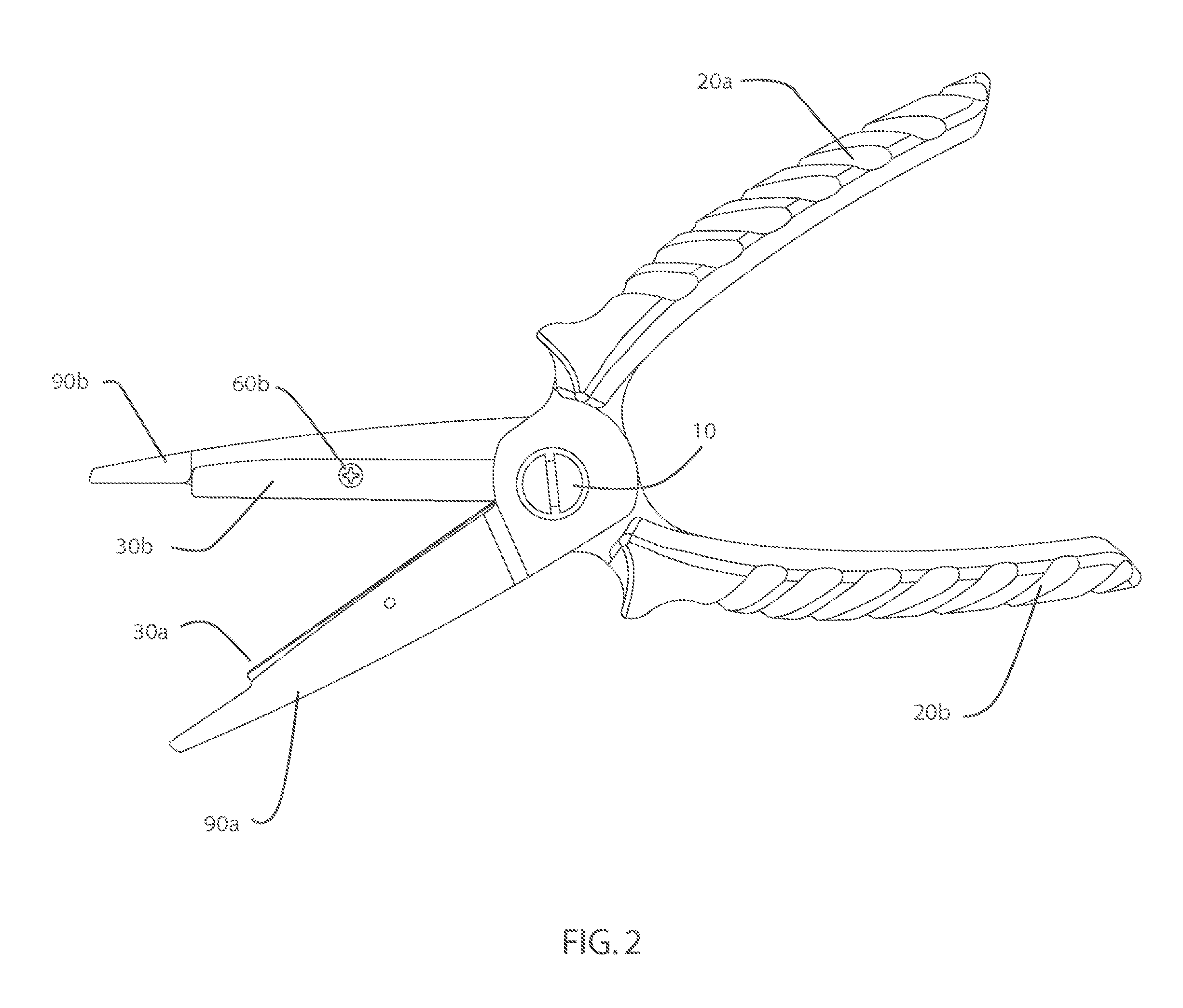

Scissors with replacement blades and ball bearings

InactiveUS20150128427A1High strengthMinimal deformationMetal working apparatusBall bearingKnife blades

A scissors tool having removable replacement blades and bearings in an arcuate bearing path disposed to stiffen the pivot and bias the blades together with greater inter-blade pressure at the cutting point. In some embodiments, the scissors tool has flexible arms which increase said cutting point edge pressure and provide that little to no gap forms between the blades proximate to and behind the cutting point.

Owner:BUCK KNIVES

Liquid crystal display device

InactiveUS20160349561A1Improve productivityProductivity of will not dropNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device has a liquid crystal display panel that includes a thin-film transistor (TFT) substrate having pixels formed thereon in a matrix pattern and a counter substrate, the two substrates having liquid crystal sandwiched therebetween to constitute a display area having a periphery encircled by a frame area. The display area has a first axis and a second axis perpendicular to the first axis. The liquid crystal display panel is curved along the first axis. The gap between the TFT substrate and the counter substrate is determined by columnar spacers formed on the counter substrate in a manner corresponding to positions of a black matrix over the counter substrate. The center of each of the columnar spacers is displaced in the first axis direction from the center of each of the corresponding positions of the black matrix.

Owner:JAPAN DISPLAY INC

Flare fitting assembly with metal-to-metal line seal

InactiveUS6729659B2Minimal deformationIncrease pressureFluid pressure sealed jointsJoints with sealing surfacesEngineeringMetal

A flare fitting assembly includes a first coupling member and a second coupling member adapted to be cooperatively coupled together. The first coupling member has a first through bore with one end adapted to accept and retain a first tube. The second coupling member has a second through bore adapted to be disposed upon a second tube with an outwardly flared end. An arcuately shaped seating surface is disposed within the first through bore of the first coupling member. A conically flared seating surface is disposed within the second through bore of the second coupling member adapted to engage an outer surface of the flared end of the second tube such that a line seal is formed between the inner surface of the flared end of the second tube and the arcuate surface when the first and second coupling members are cooperatively coupled.

Owner:VISTEON GLOBAL TECH INC

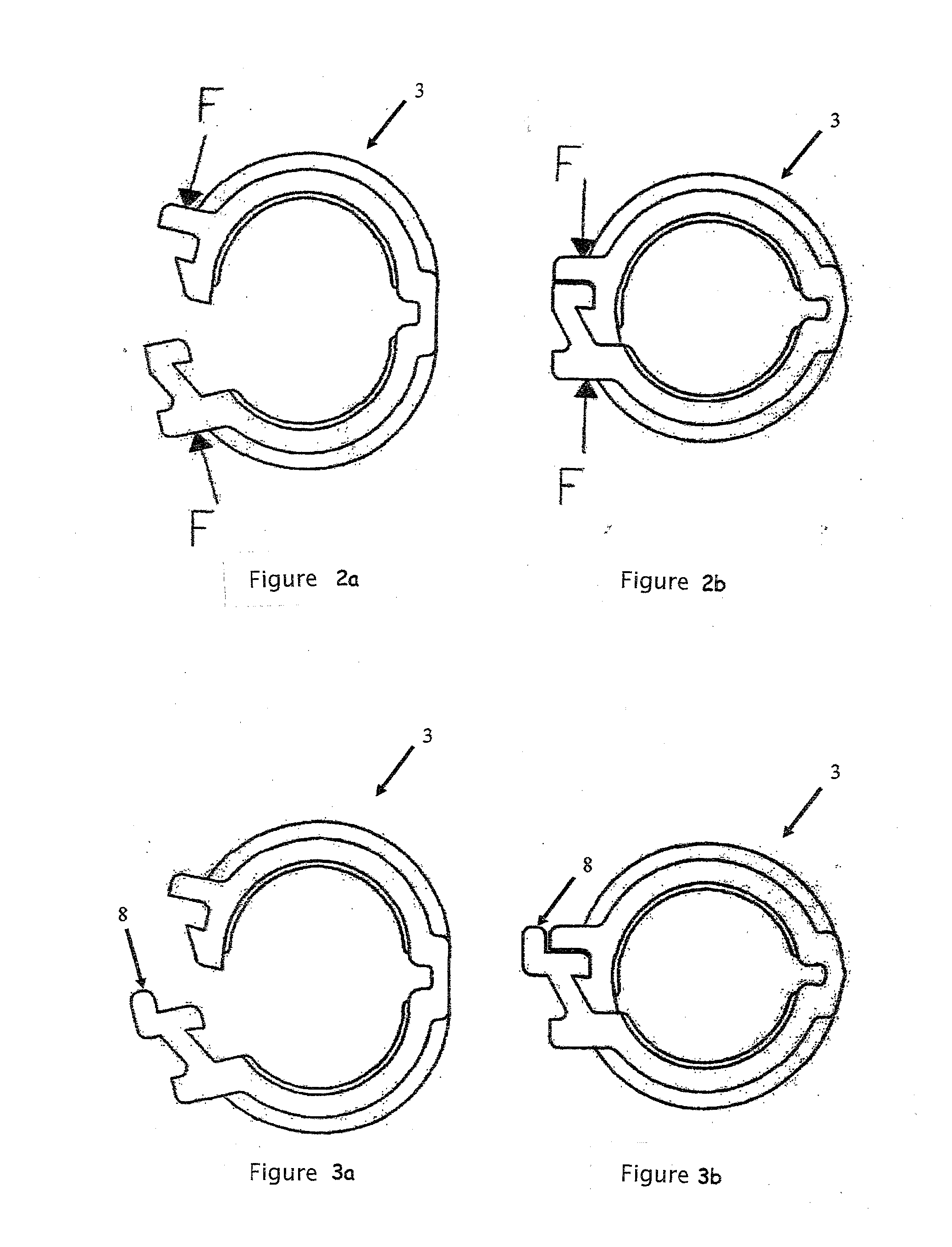

Connection system for connecting pex tubing to a fitting which includes a clamp

ActiveUS20160084420A1Low cost productionFirmly connectedSleeve/socket jointsFlanged jointsClamp connectionEngineering

Connection system to connect a tubing with a fitting comprises a tubular fitting including an exterior shoulder and an annular groove disposed a distance away from the shoulder, the tubular fitting is configured to be inserted into the tubing to overlie the groove; a clamp including first and second curved sidewalls, a flexible joint connecting a respective first end of the curved sidewalls, clenching means that connects respective second ends of the curved sidewalls, and an annular flange arranged in an internal region of the curved sidewalls; and the annular flange is disposed over the annular groove when the sidewalls are engaged with the shoulder such that the tubing underneath the annular flange is forced into the annular groove by the annular flange when the clamp is in a clamped position.

Owner:THC CHILE

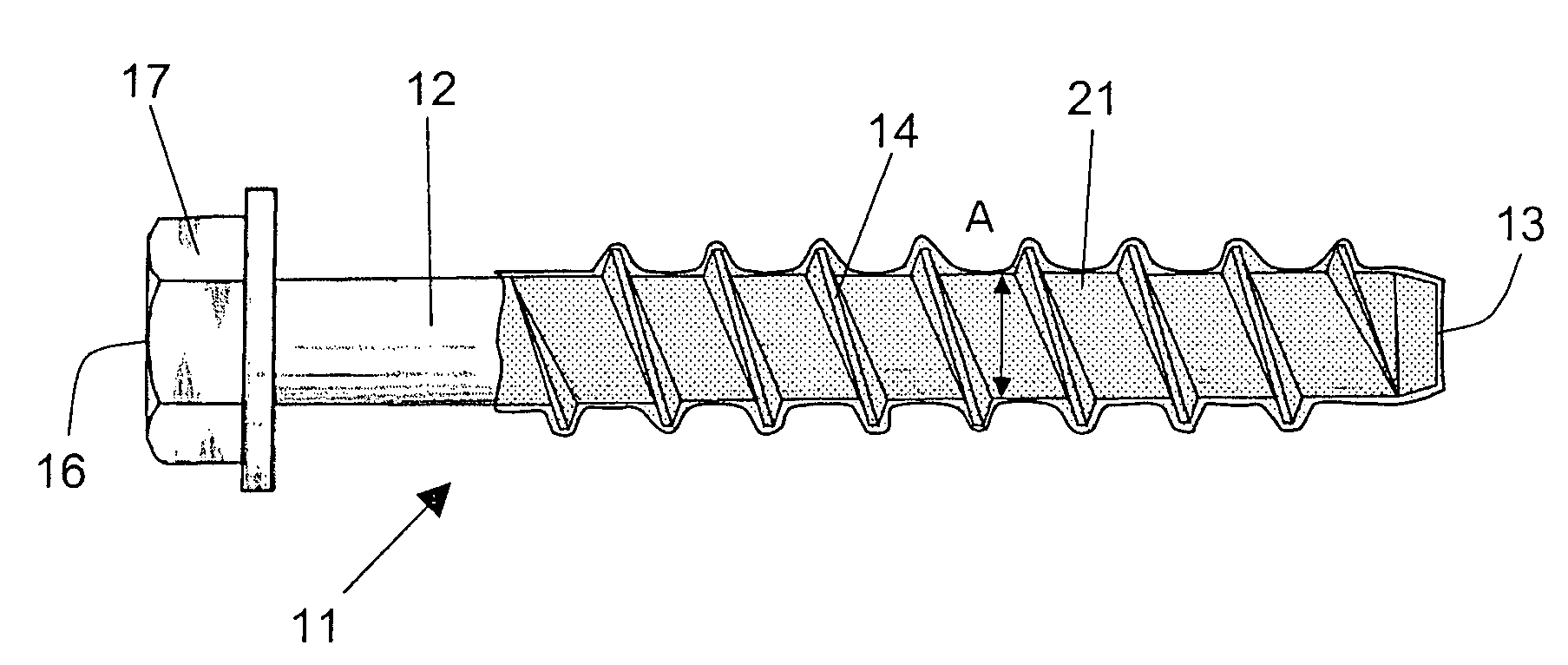

Fastening element

A fastening element for mineral constructional components has a shaft (12) provided with a tapping thread (14) extending, at least regionwise, along the shaft (12), and a coating (21) that covers the shaft (12) likewise at least regionwise and that is formed of a polar thermoplast.

Owner:RESTALYST PTE +1

Roller bearing assembly

InactiveUS7390127B2Improve AssemblabilityMinimal deformationRoller bearingsShaftsMetallic materialsEngineering

To provide a roller bearing assembly that can provide a high load bearing capacity and in which the strength of roller retainers can be increased, the roller bearing assembly includes inner and outer roller retainers (13, 23) each having a plurality of circumferentially arranged pockets (4), and a circular row of rollers (2) received in part within the pockets in the inner roller (13) and in part within the pockets in the outer roller (23). The inner roller retainer (13) has pillars (5) each left between the neighboring pockets to retain the circular row of the rollers from radially inwardly and having an outer diameter smaller than the diameter of the pitch circle PCD of the circular row of the rollers. The outer roller retainer (23) has pillars (5) each left between the neighboring pockets to retain the circular row of the rollers from radially outwardly and having an inner diameter greater than the pitch circle diameter PCD. One of the outer and inner roller retainers is made of a metallic material while the other thereof is made of a resinous material.

Owner:NTN CORP

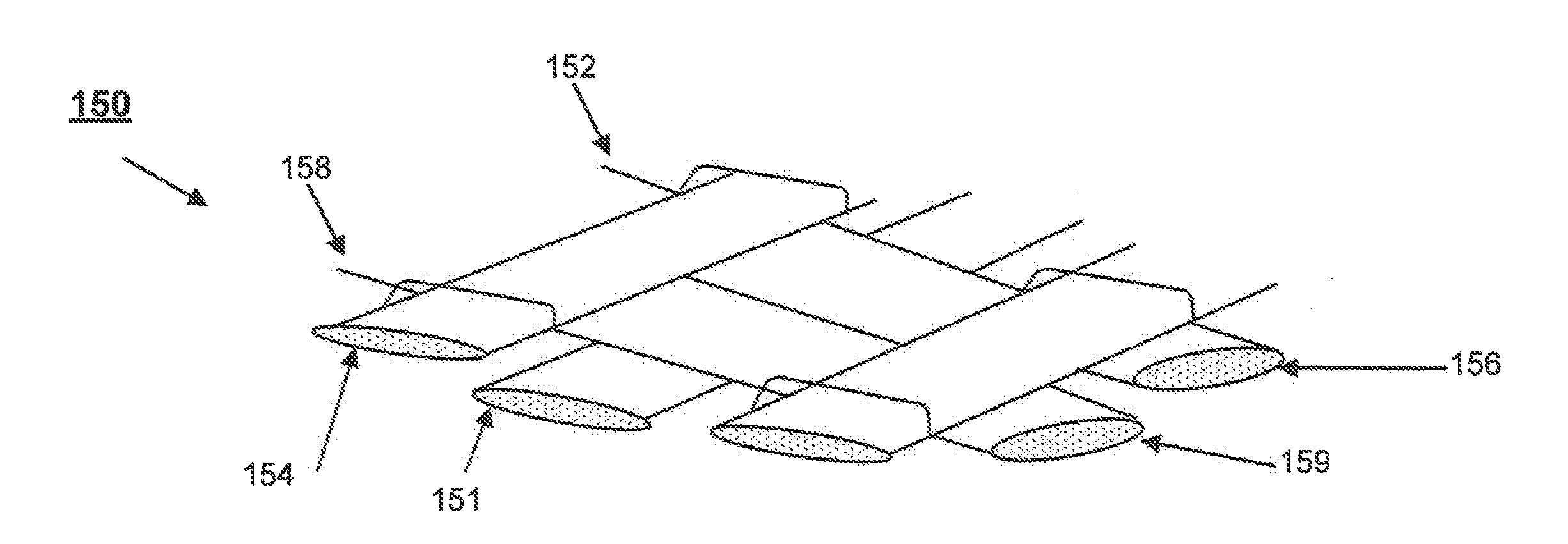

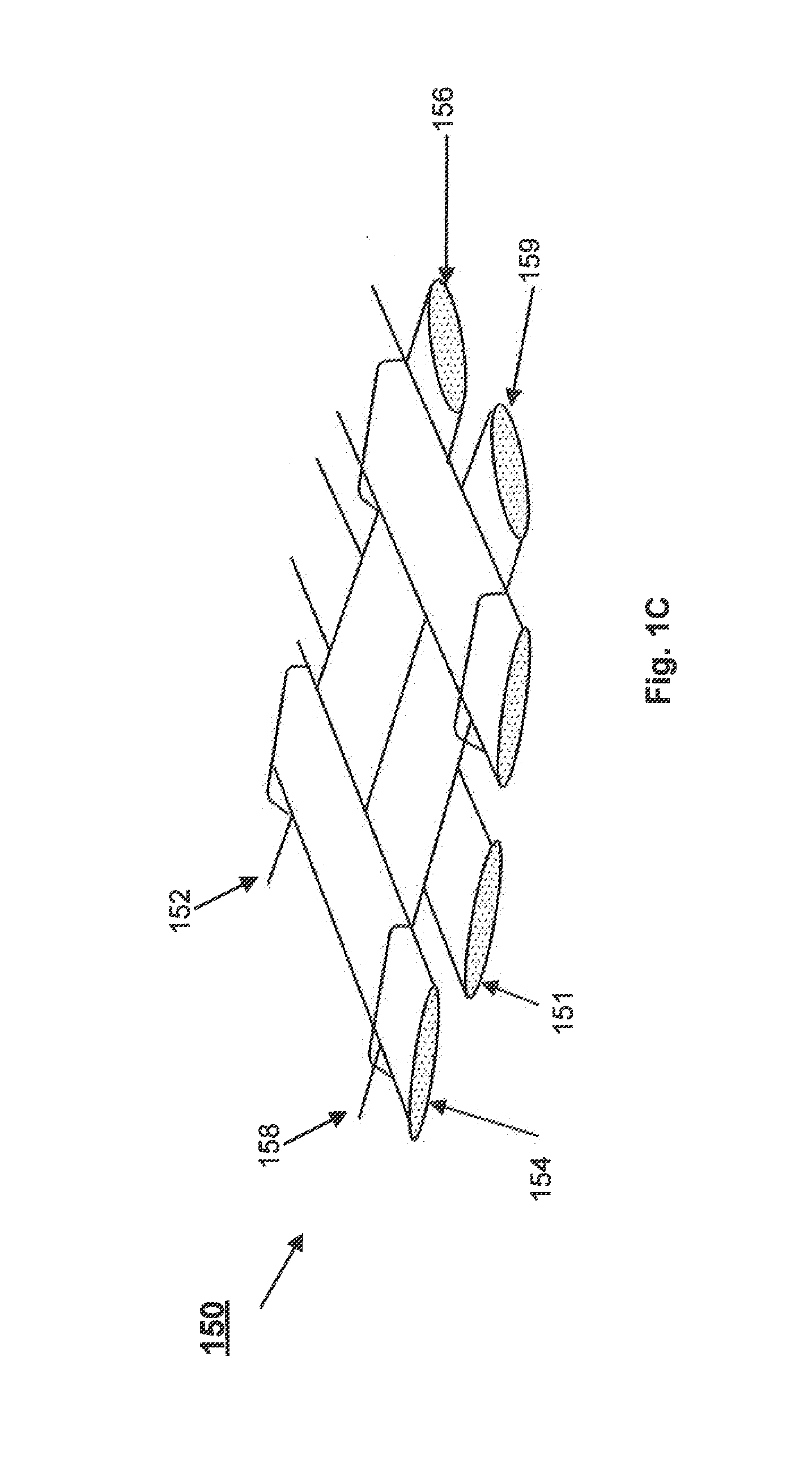

Systems and methods for reduced crimp carbon fiber helical fabric

Systems and methods for weaving helical carbon fabrics with minimum fiber crimp are provided herein. In various embodiments, small denier natural or synthetic yarns are used in the warp direction to interlace the carbon fiber wefts with minimum deformation. Specific weave designs are used in combination with the small denier yarn to maintain the primary carbon fiber weft and warp un-crimped.

Owner:THE BF GOODRICH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com