Patents

Literature

86results about How to "Reduce radial clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

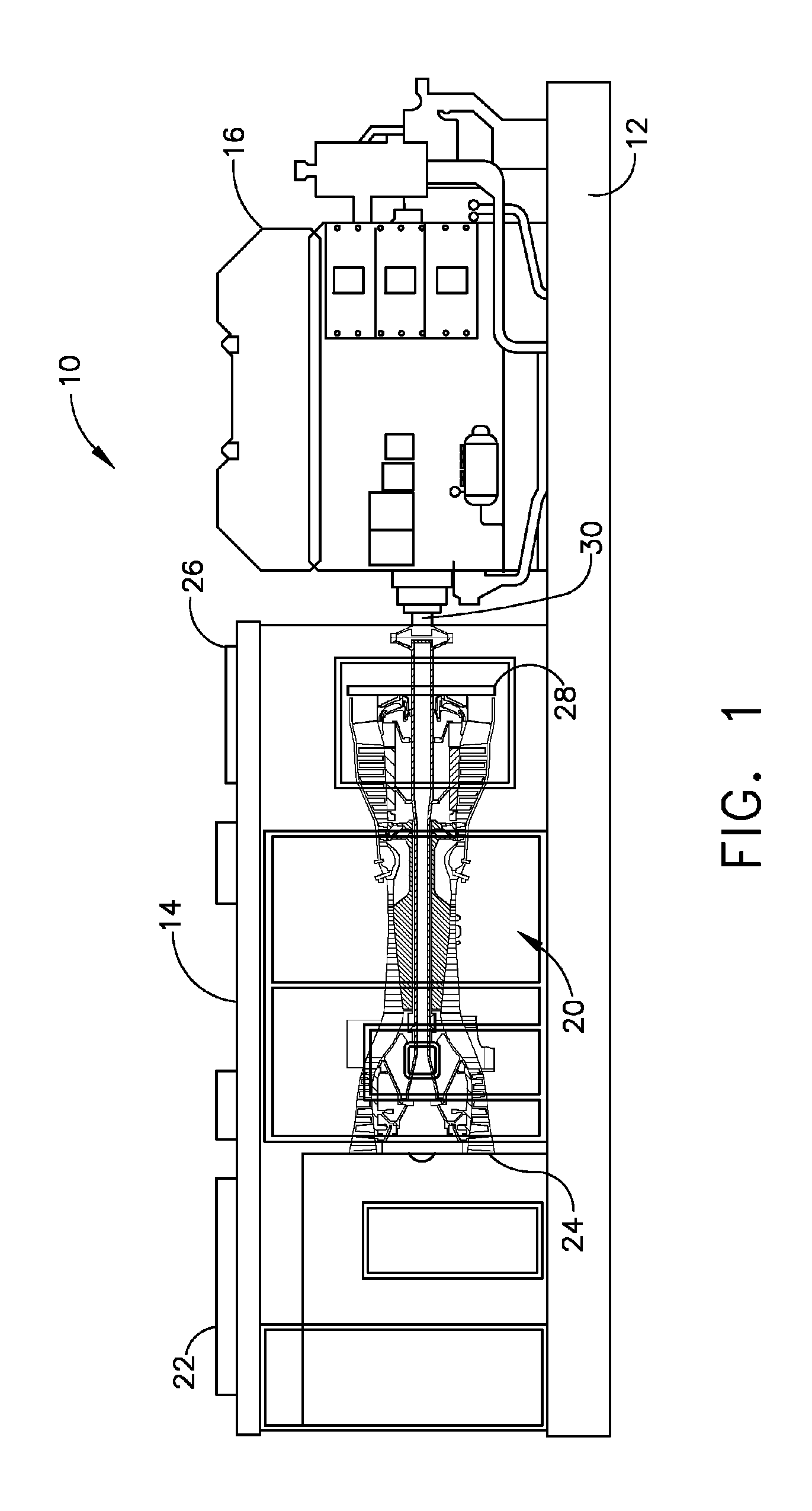

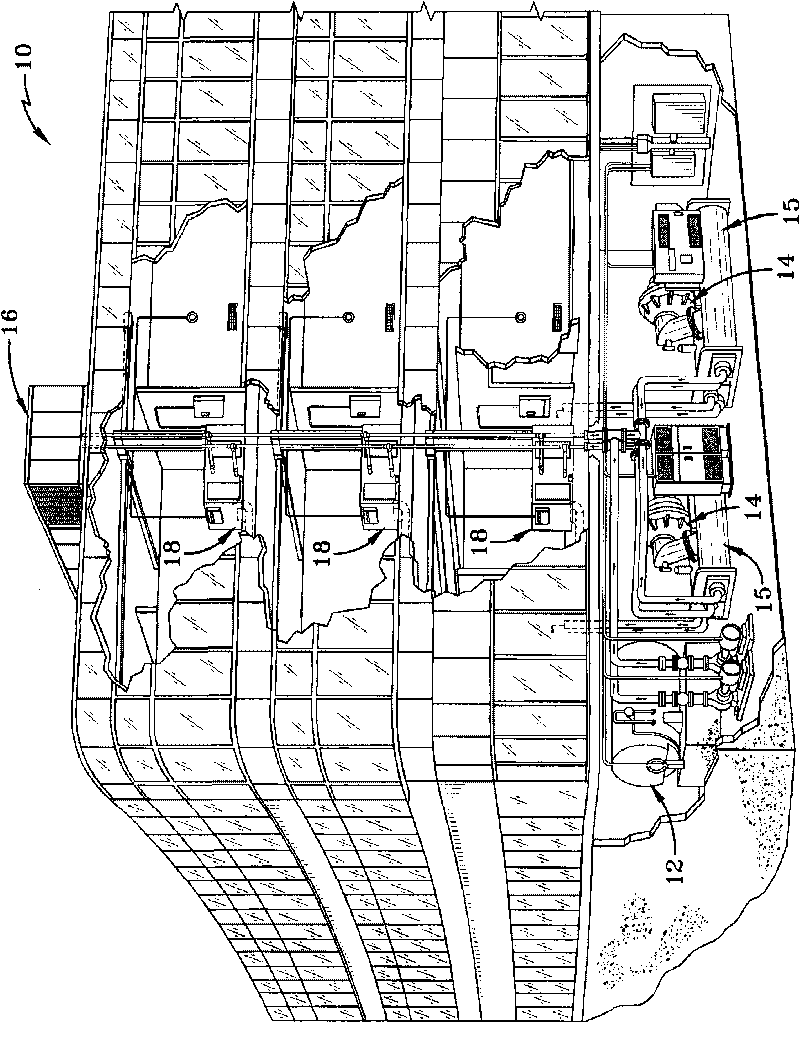

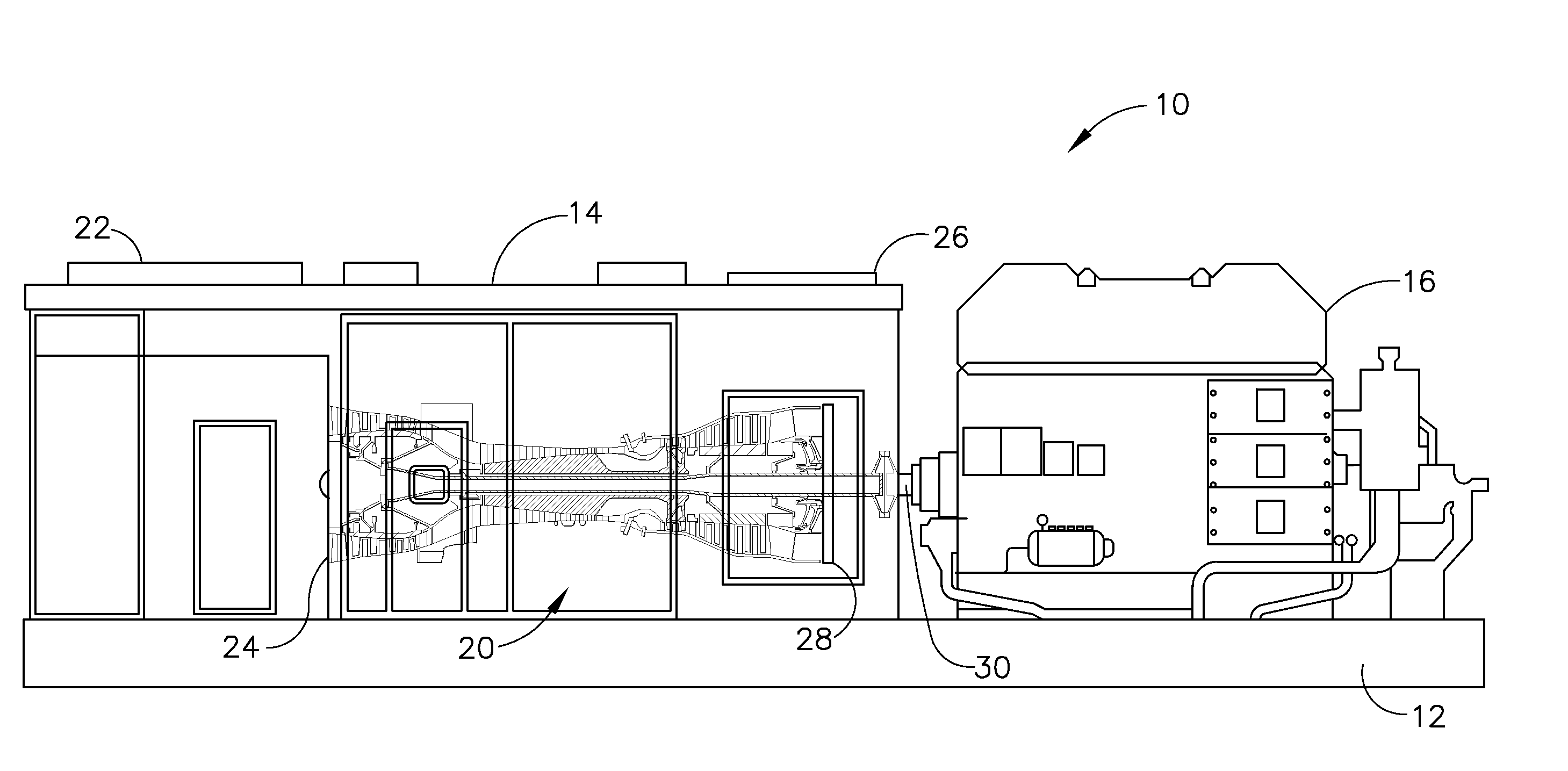

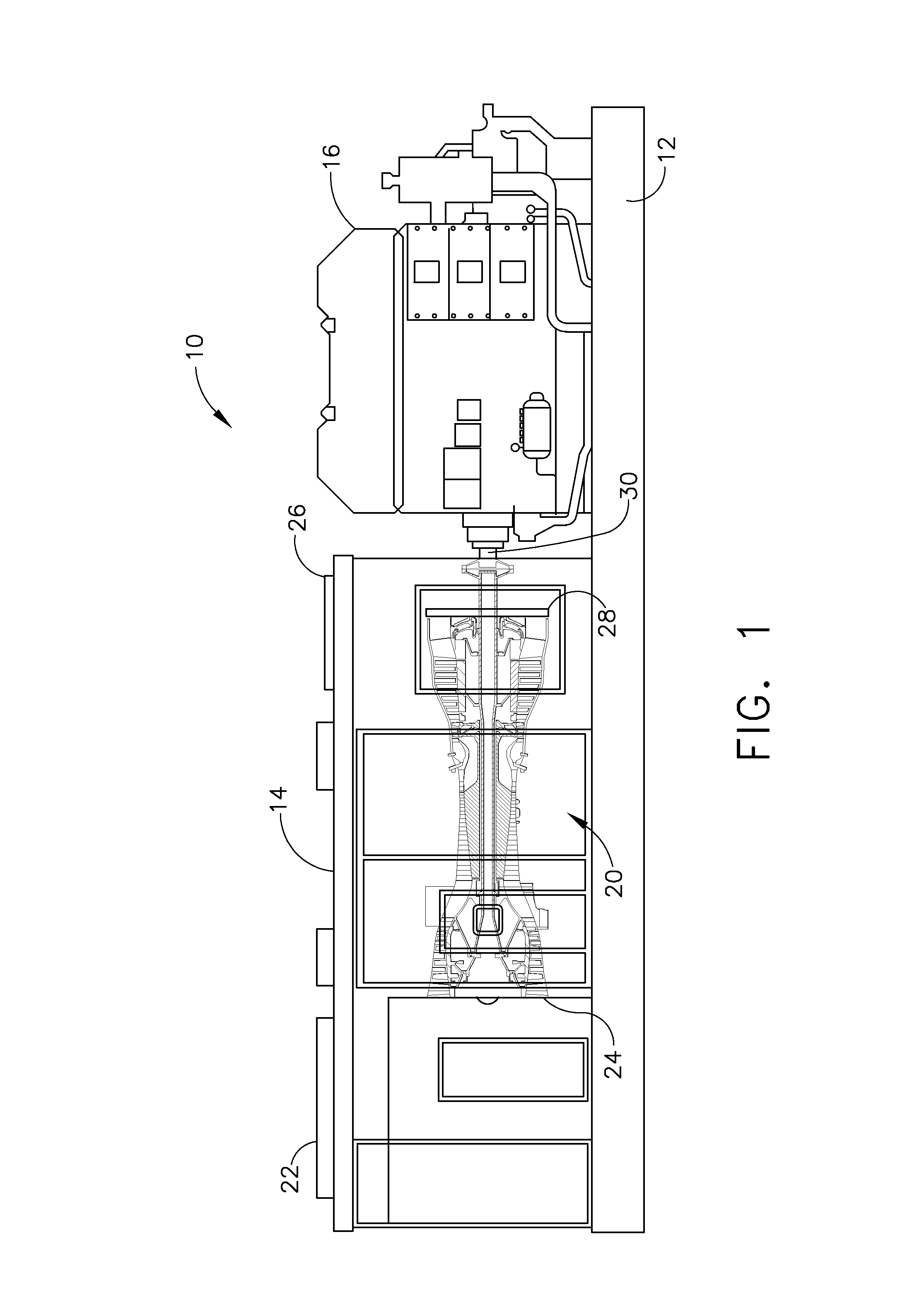

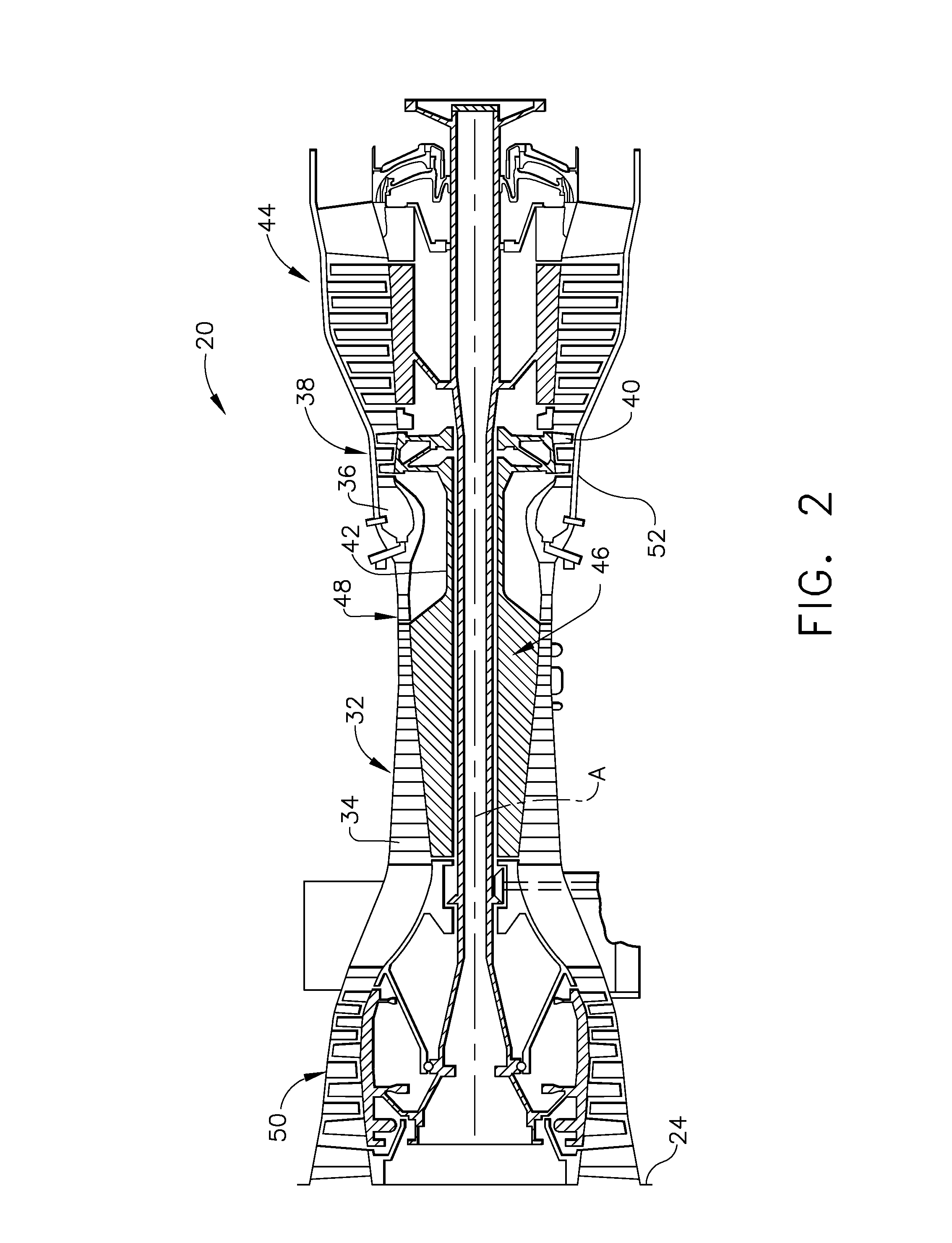

Gas turbine engine lockout reduction

ActiveUS8776530B2Shorten the overall cycleShorten the timeLeakage preventionGas turbine plantsCombustorTurbine

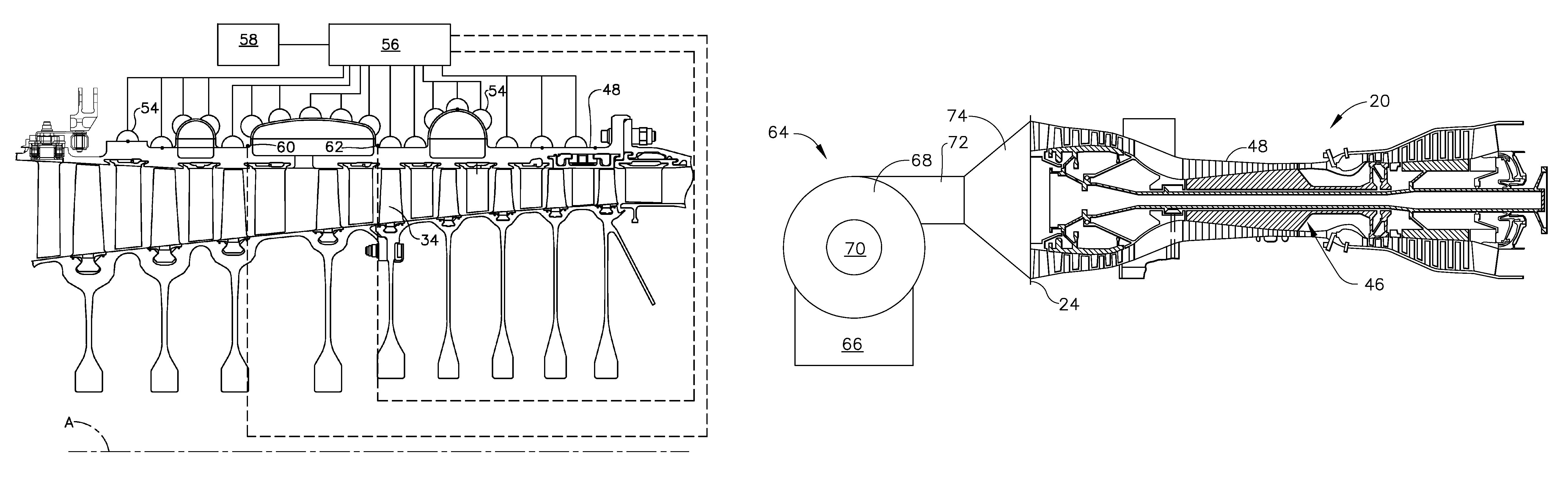

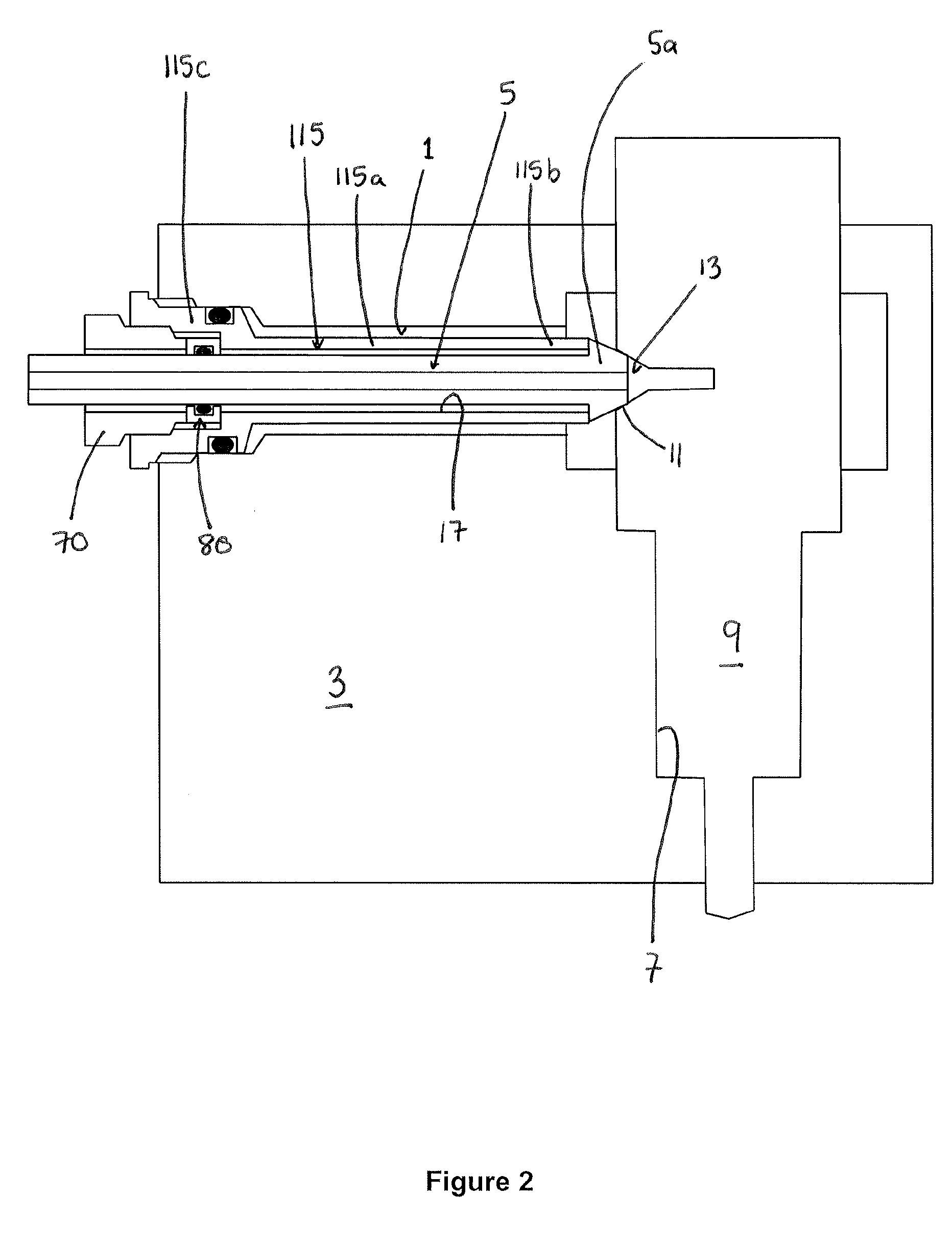

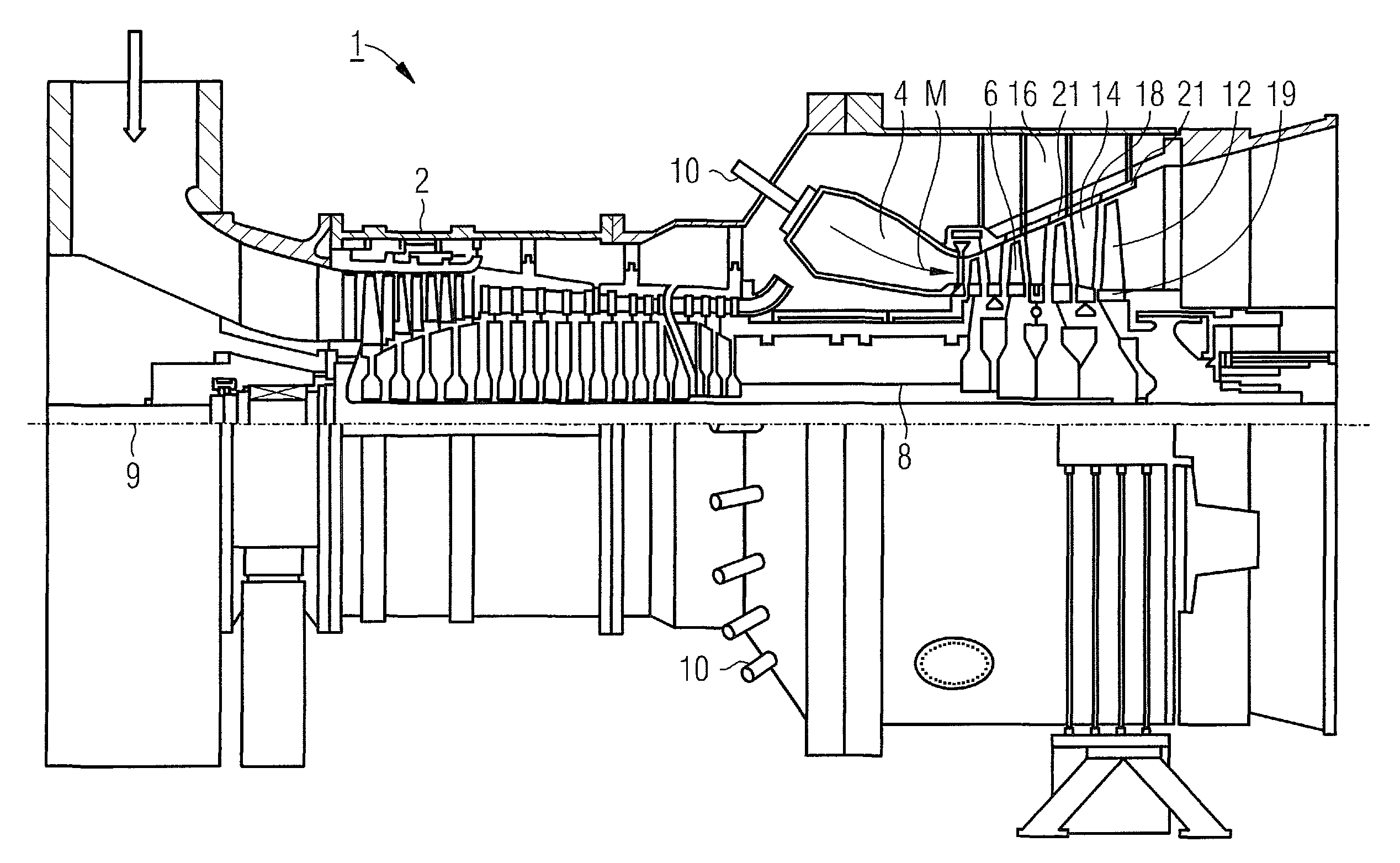

A method is provided of reducing lockout time of a gas turbine engine which includes: an inlet, a compressor, a combustor, a turbine, and an exhaust duct, where the compressor and the turbine are carried on a turbomachinery rotor and each include an array of blades mounted for rotation inside a casing of the engine. The method includes: operating the engine at a first power output; shutting down operation of the engine without substantially reducing the power output beforehand, wherein thermomechanical changes occur in the engine subsequent to shutdown that tend to reduce a radial clearance between at least one of the blades and the casing; and subsequent to shutting down the engine, (1) heating the casing and / or (2) pumping an airflow of ambient air into the inlet and through the casing, past the rotor, and out the exhaust duct, so as to reverse at least partially the thermomechanical changes.

Owner:GENERAL ELECTRIC CO

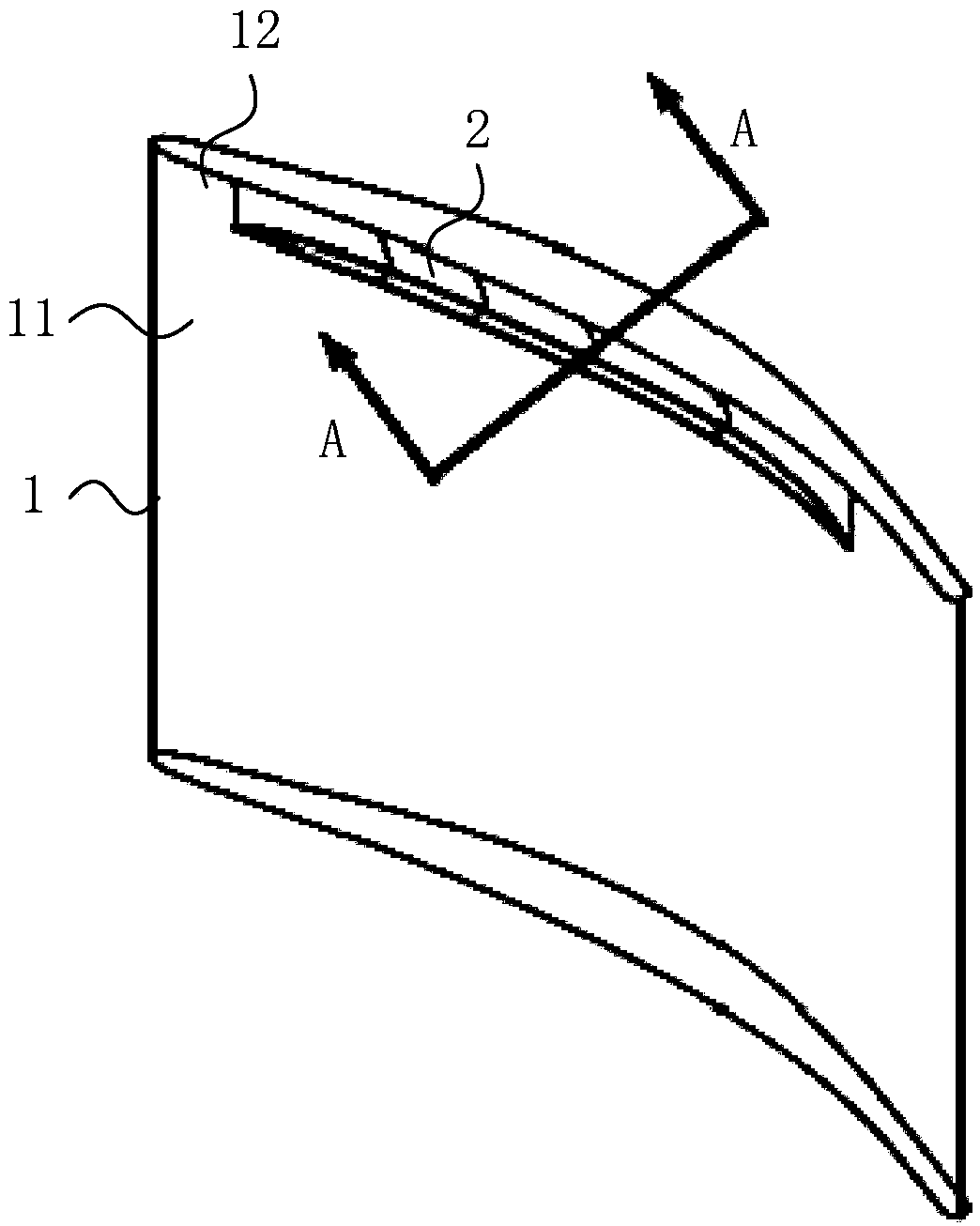

Free-standing turbine blade

InactiveUS20080213098A1Low gap lossReduce differential pressurePropellersPump componentsTurbine bladeAirplane

There is described a blade for a turbomachine, such as a steam turbine. The blade has a blade tip, which is curved in relation to the blade airfoil profile. The curvature has the shape of a winglet, which is known from aircraft construction.

Owner:SIEMENS AG

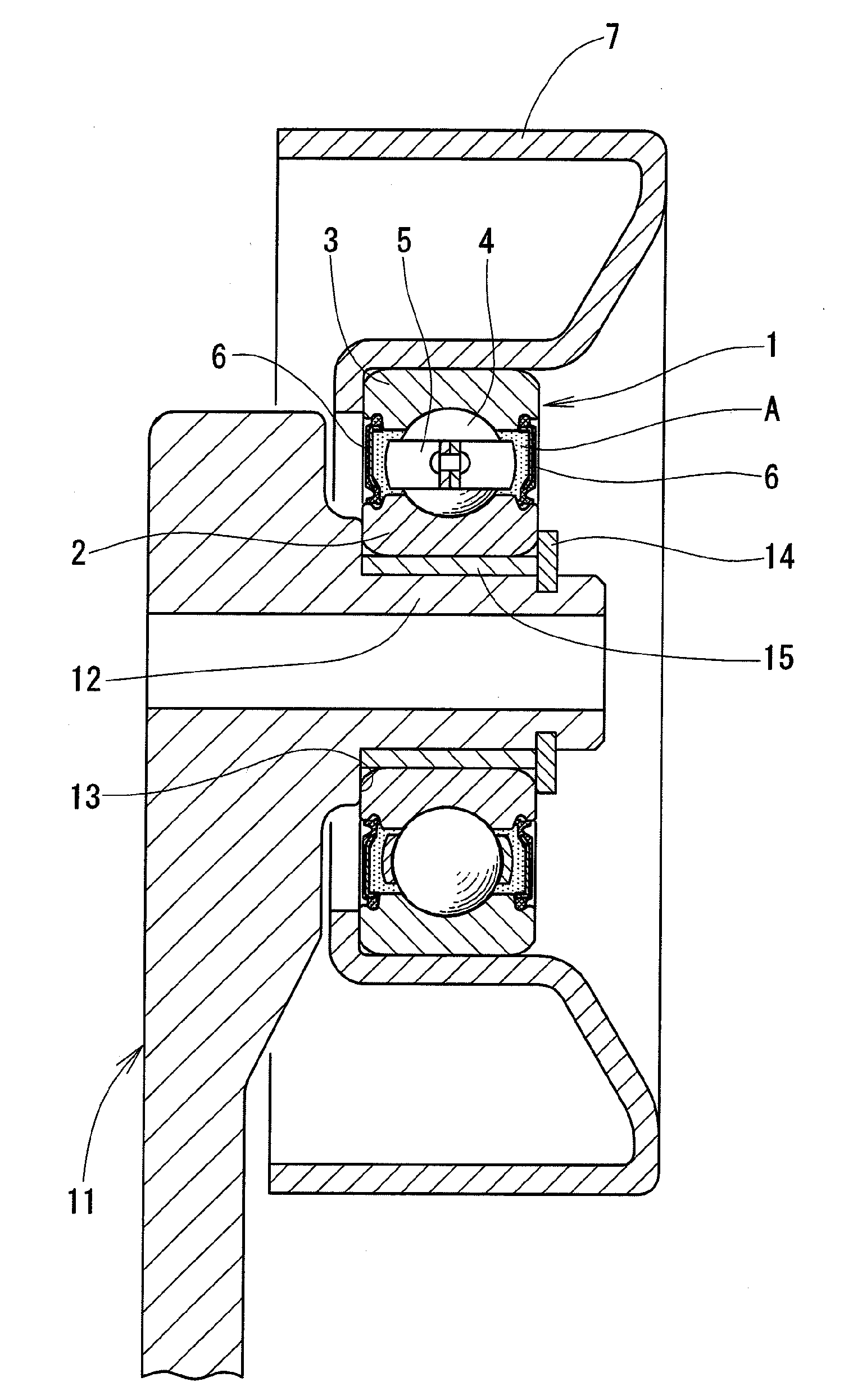

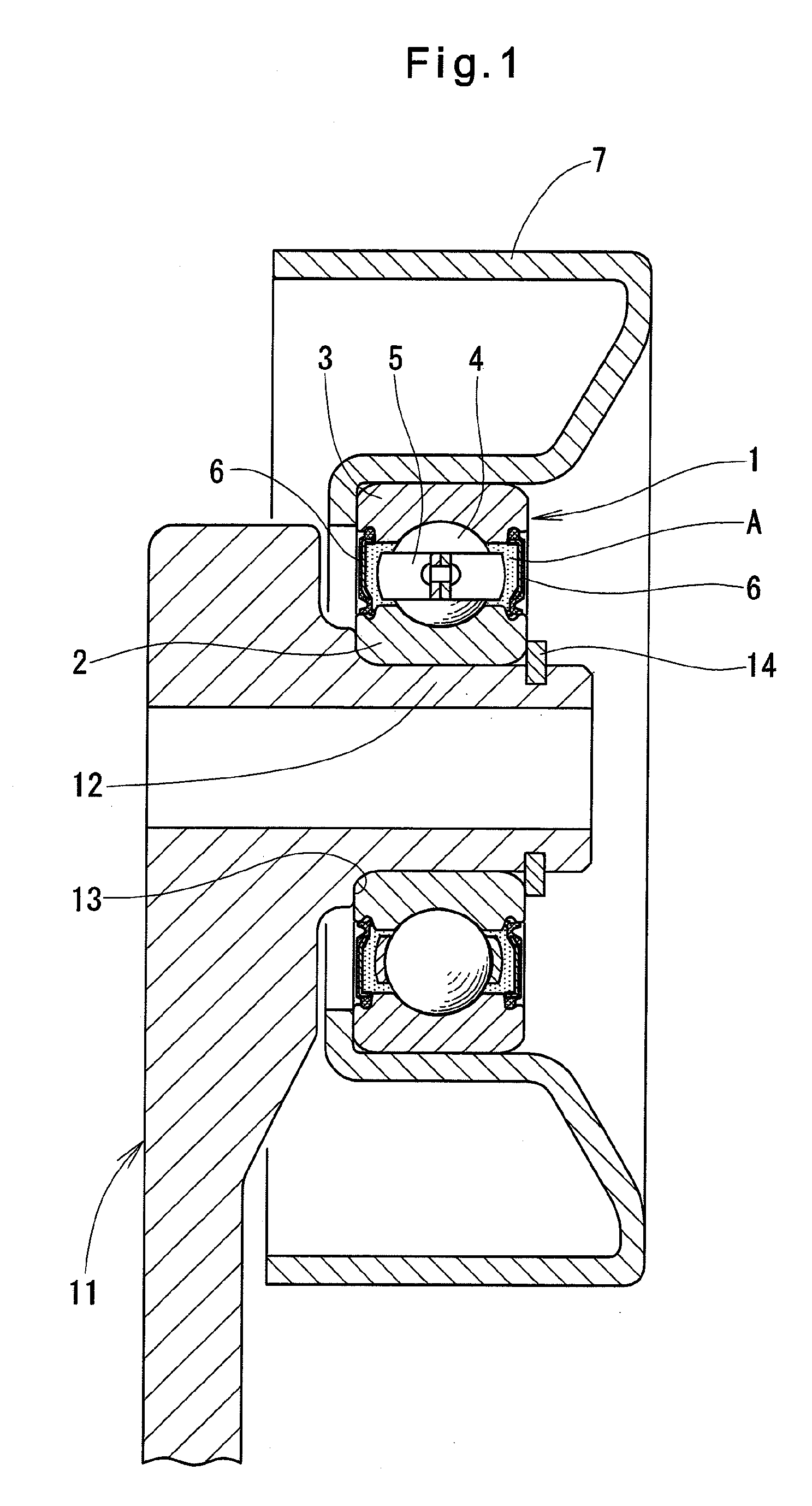

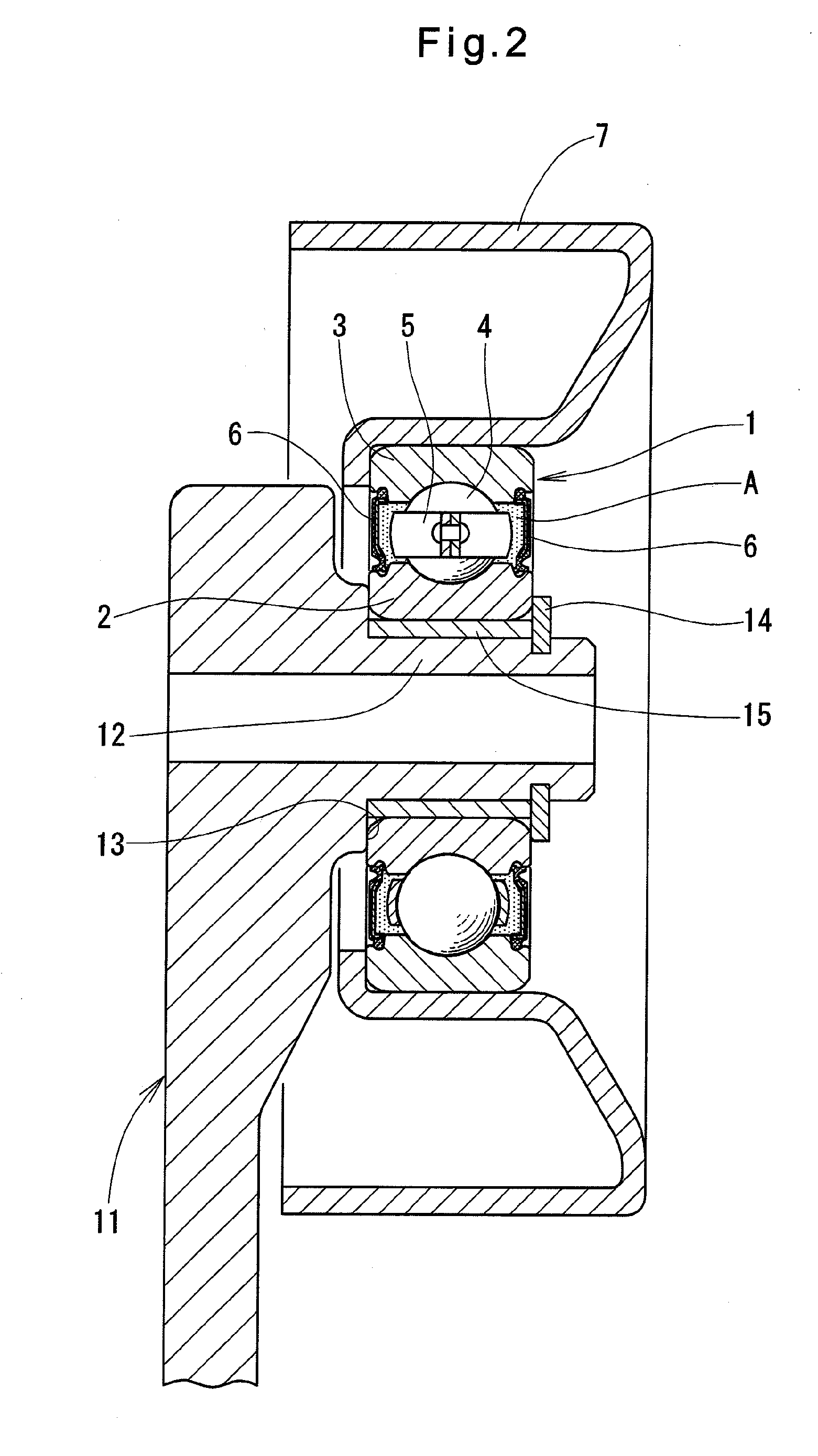

Pulley fixing structure

InactiveUS20090298630A1Reduce in quantityReduce radial clearanceGearingBall bearingsInterference fitBall bearing

A pulley fixing structure includes a pulley with a ball bearing, and a bracket having a shaft portion on which the inner race of the bearing is pressed with an interference fit. The thermal expansion of the radially outer portion of the shaft portion of the bracket is larger than that of the radially inner portion of the inner race of the bearing. The interference thus decreases at a low temperature. Reduction of the radial clearance of the bearing 1 by pressing is thus compensated, and cold weather noise can be prevented while reducing the number of required parts and making the assembly process simple.

Owner:NTN CORP

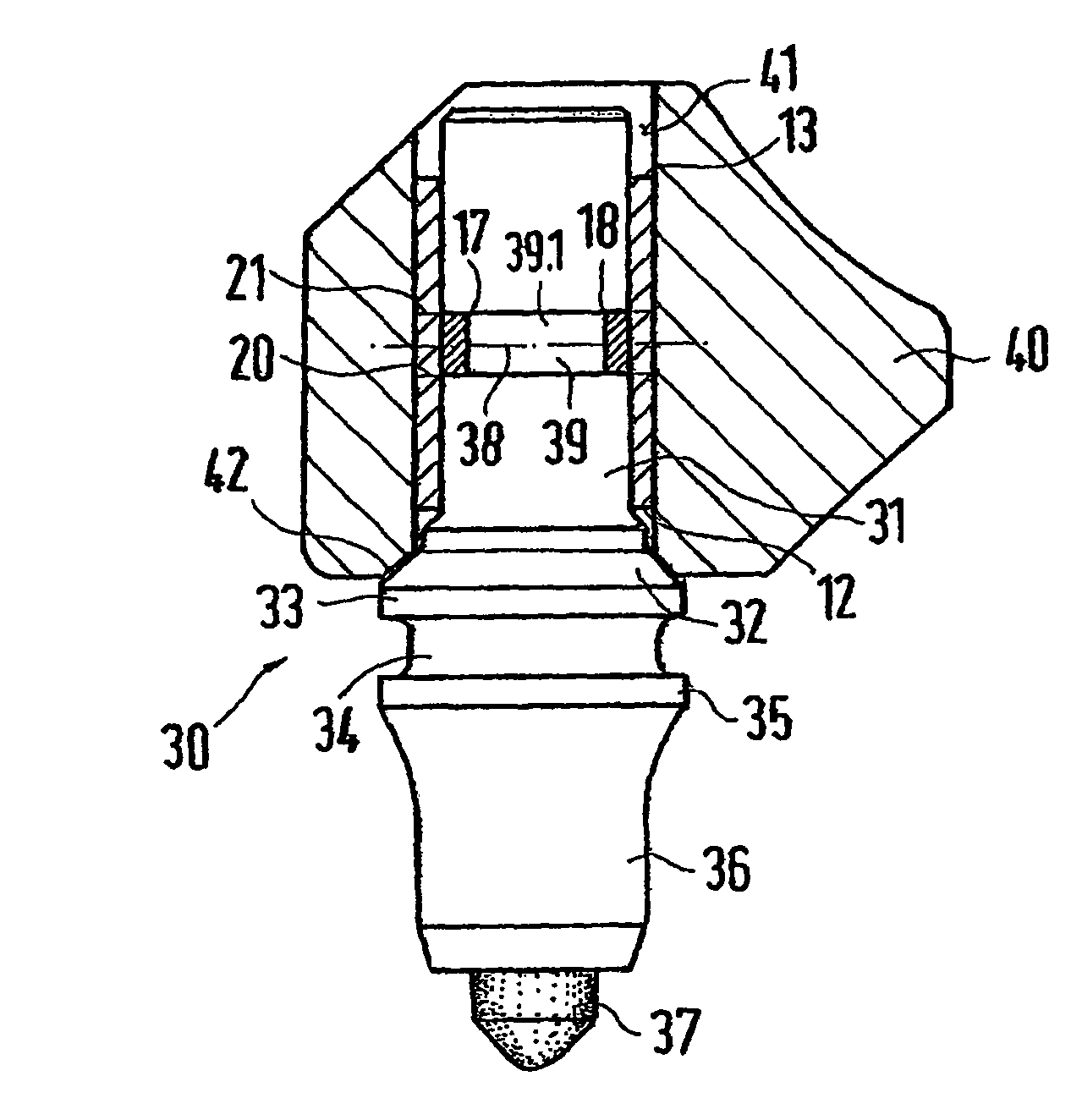

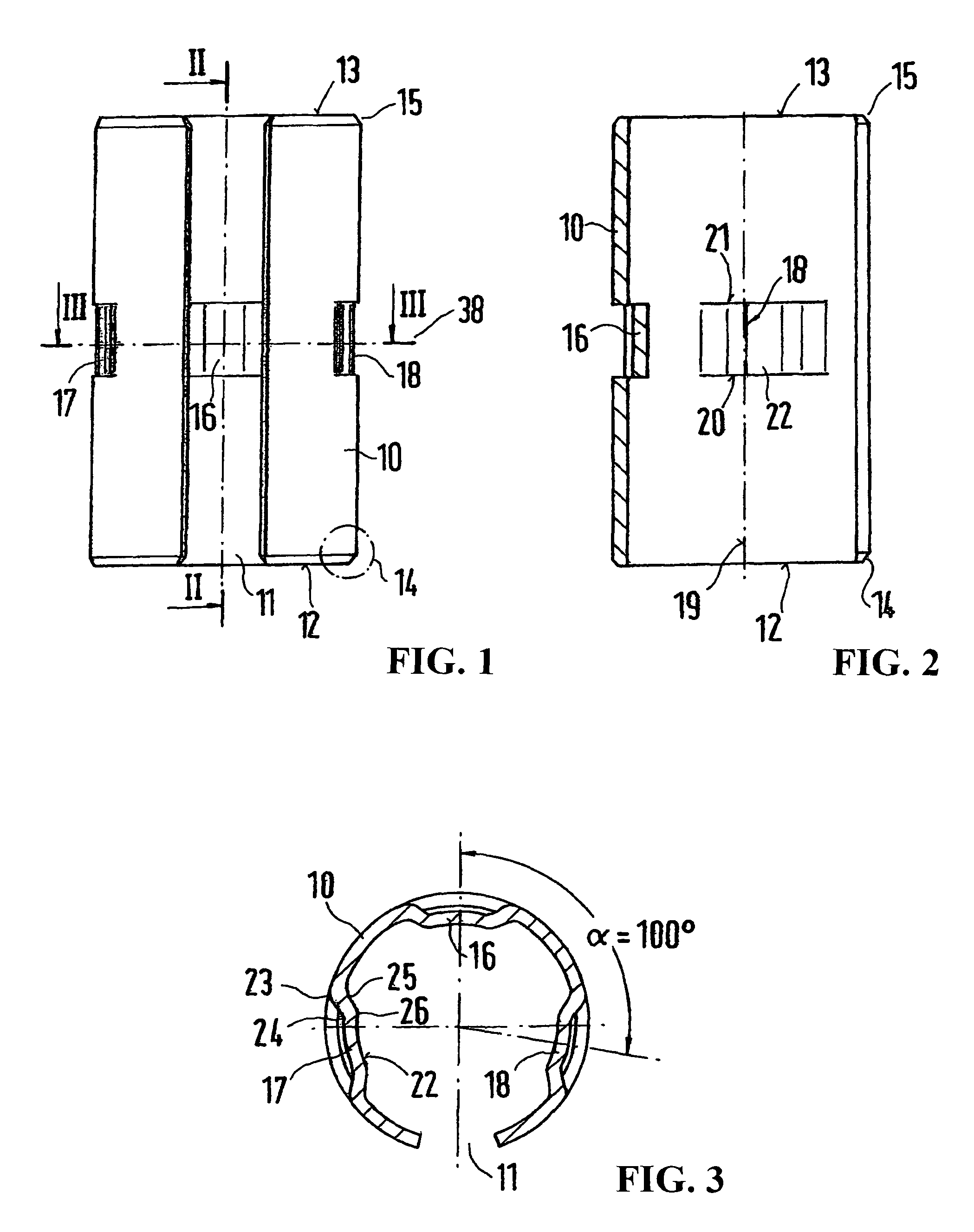

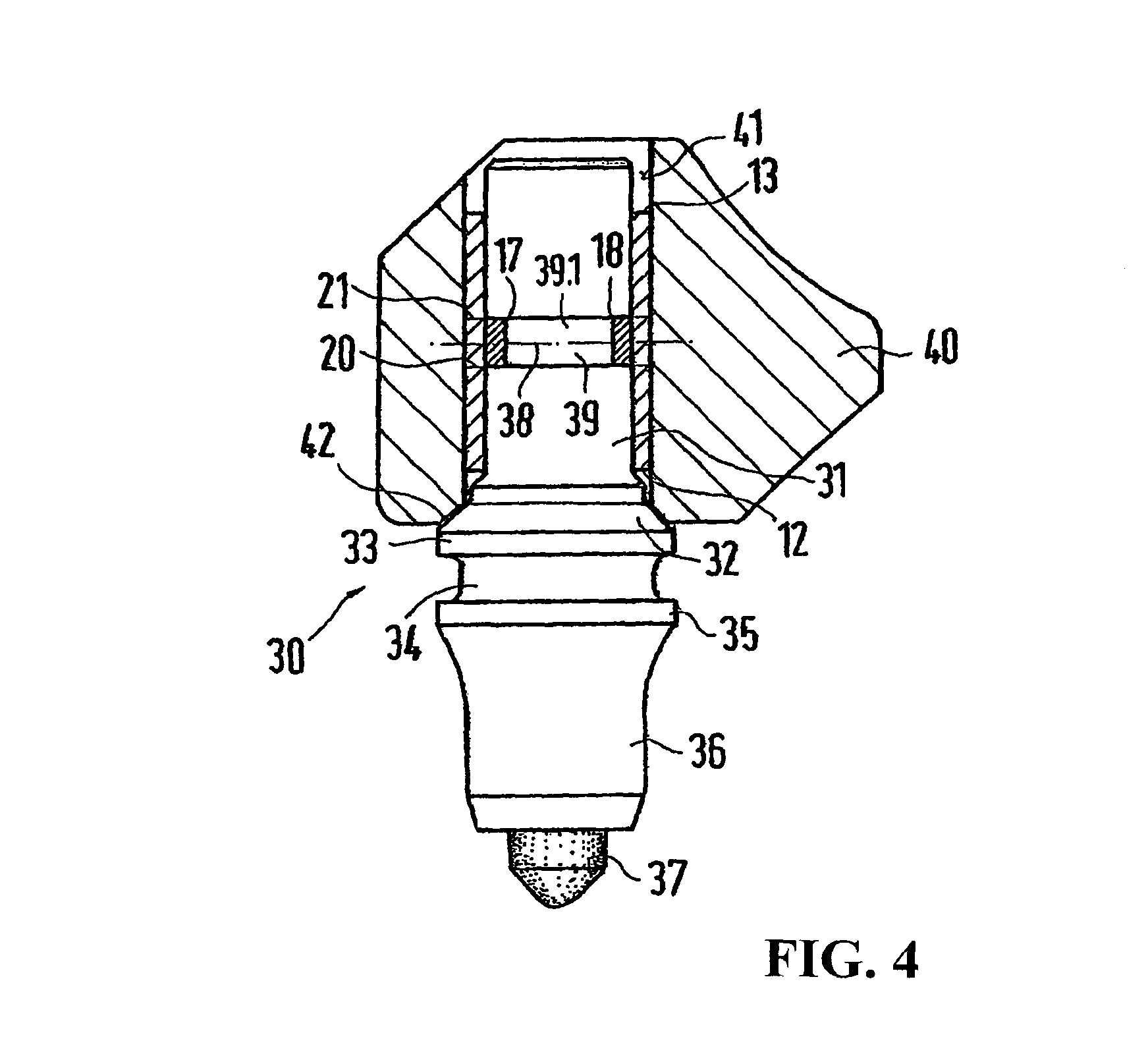

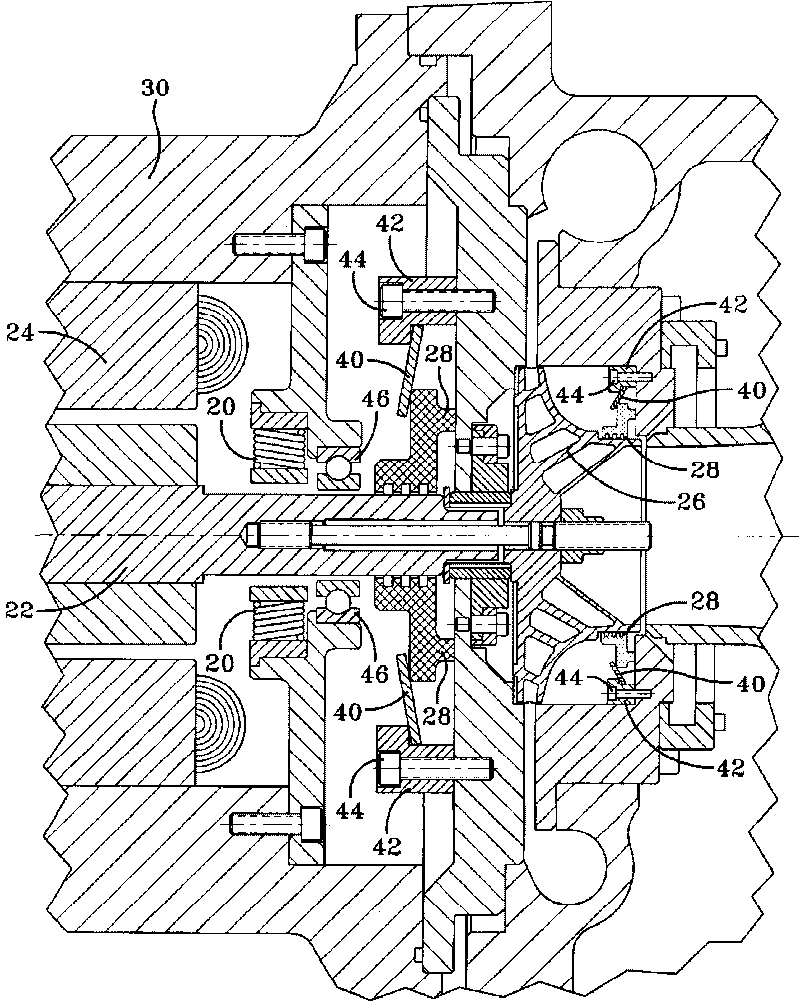

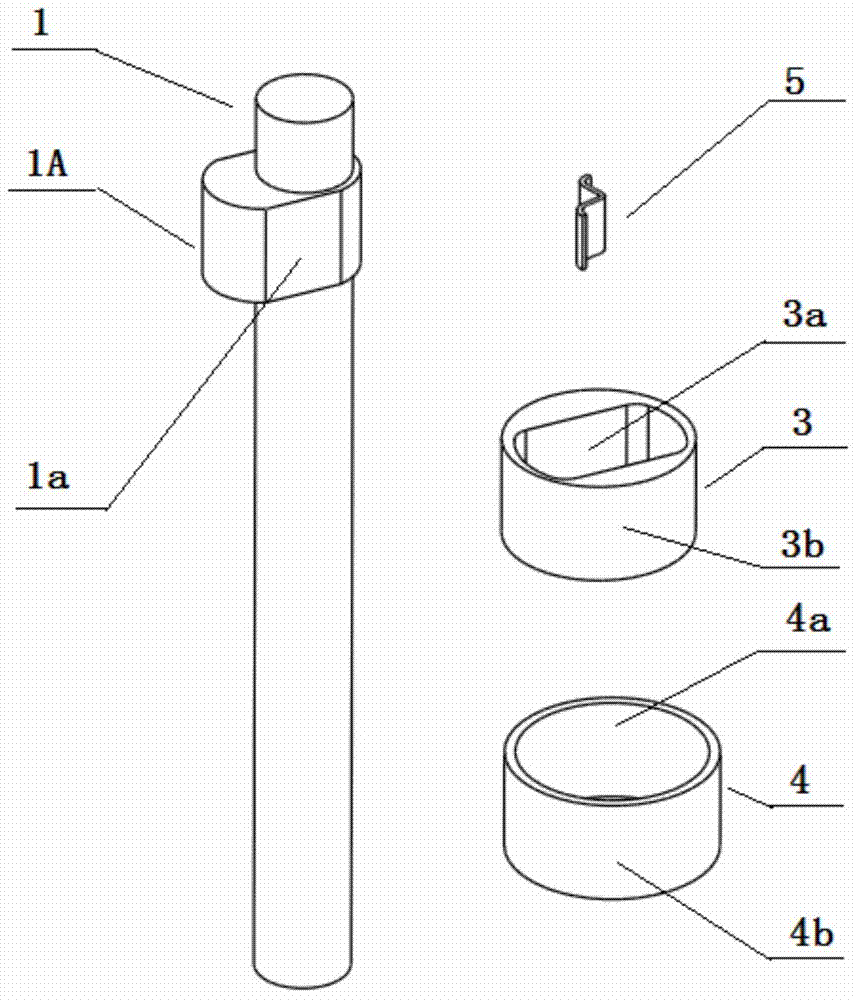

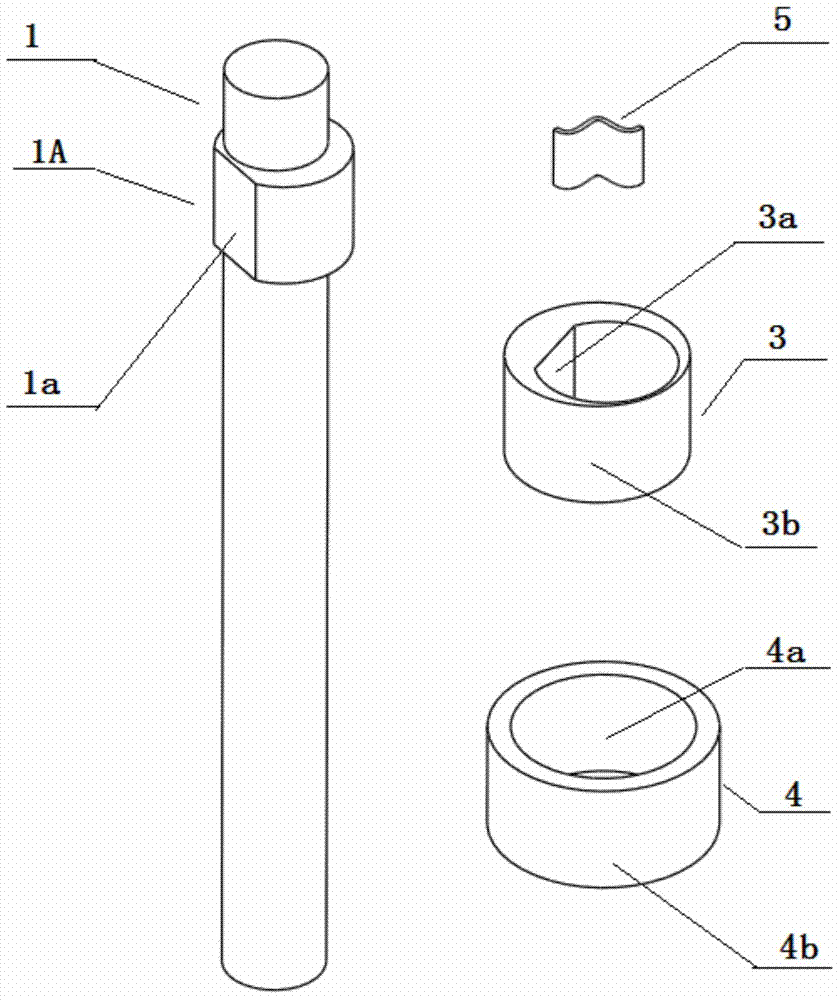

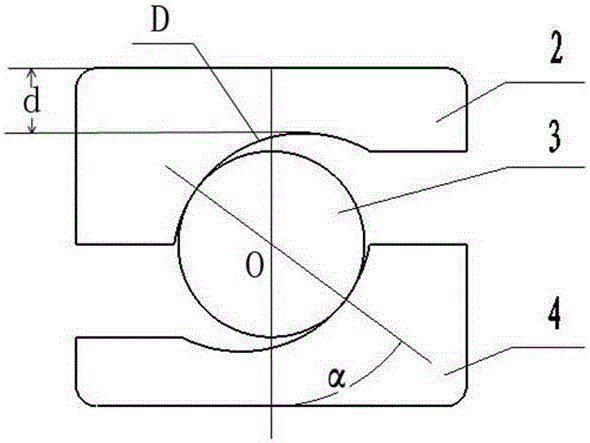

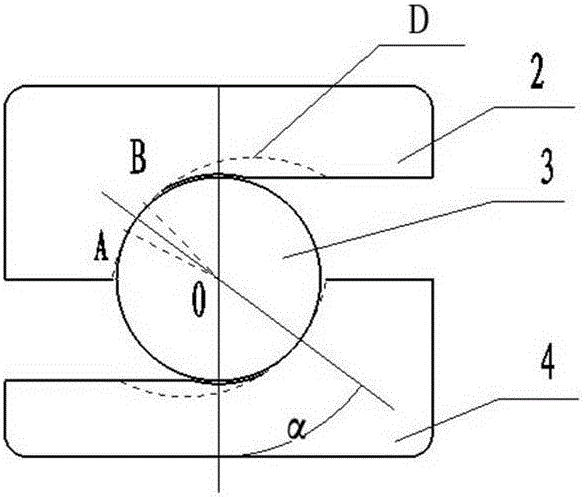

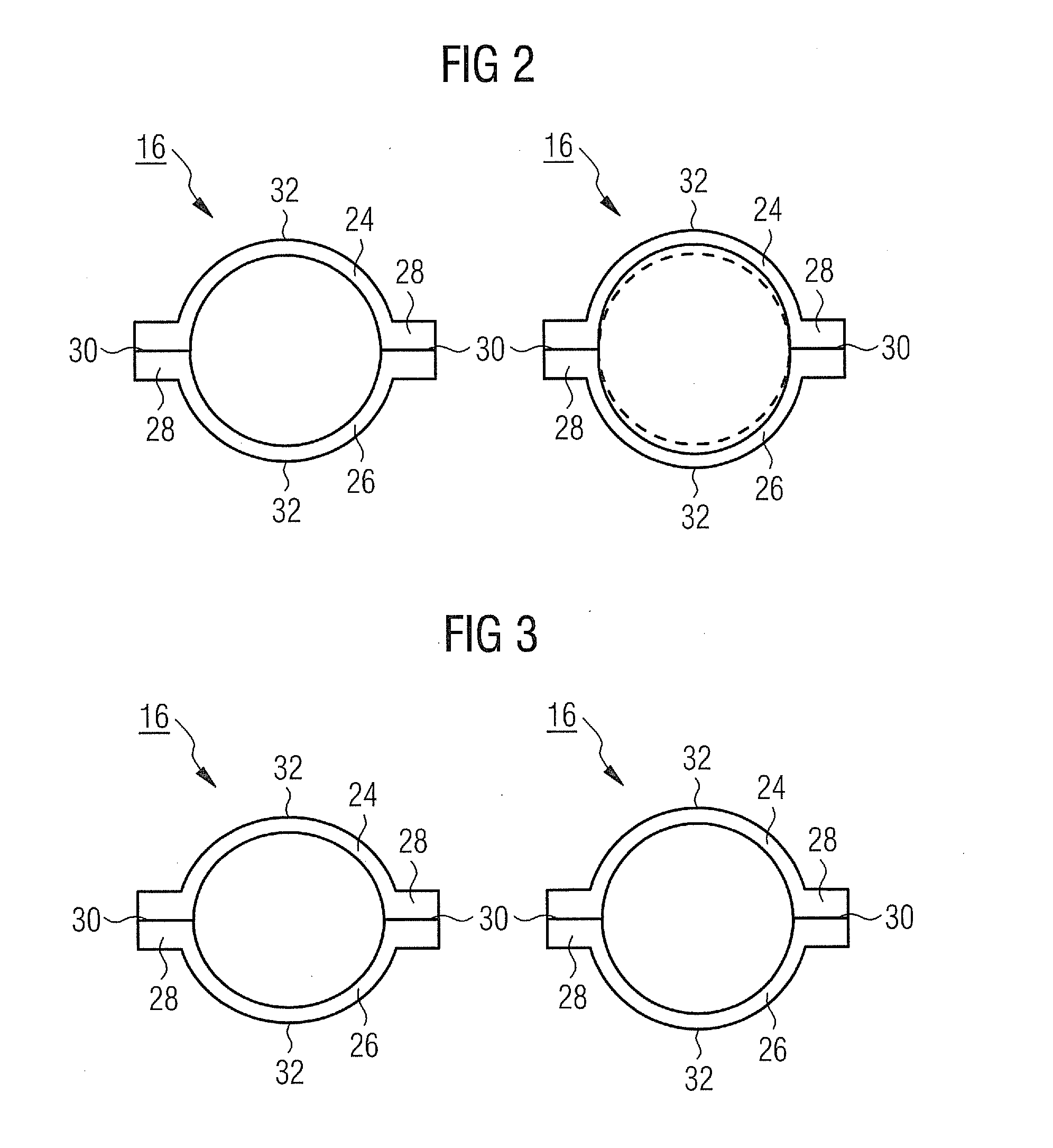

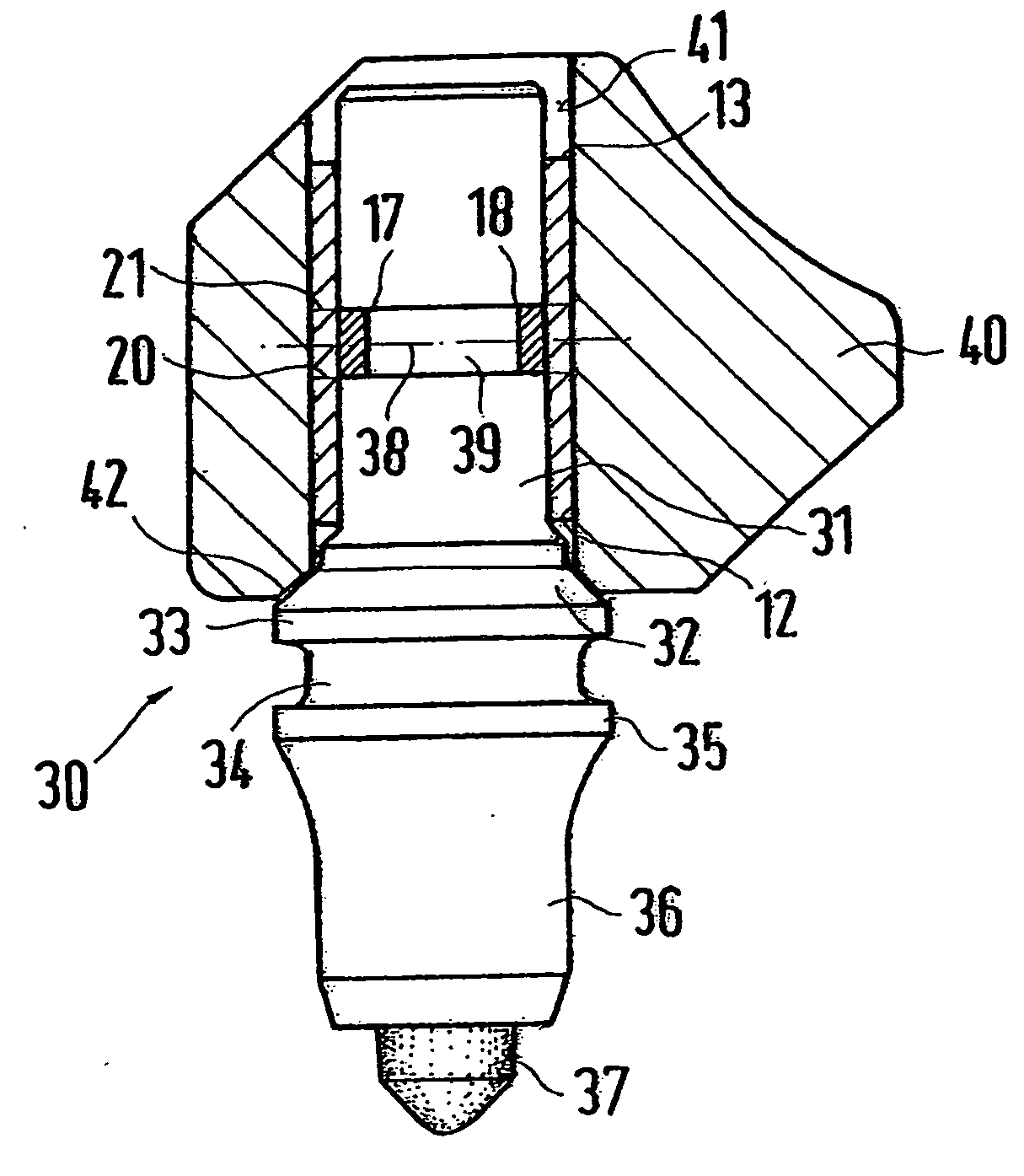

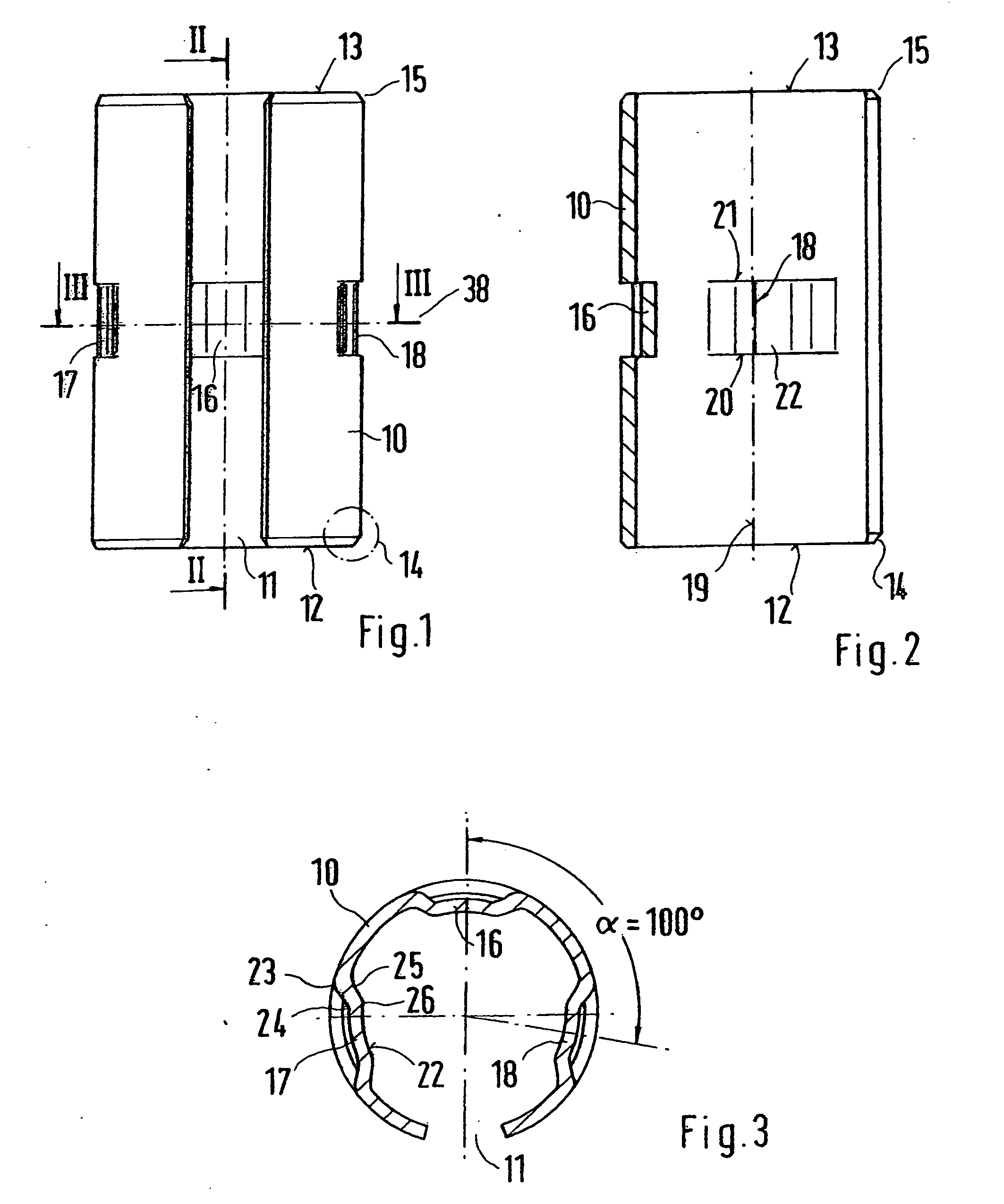

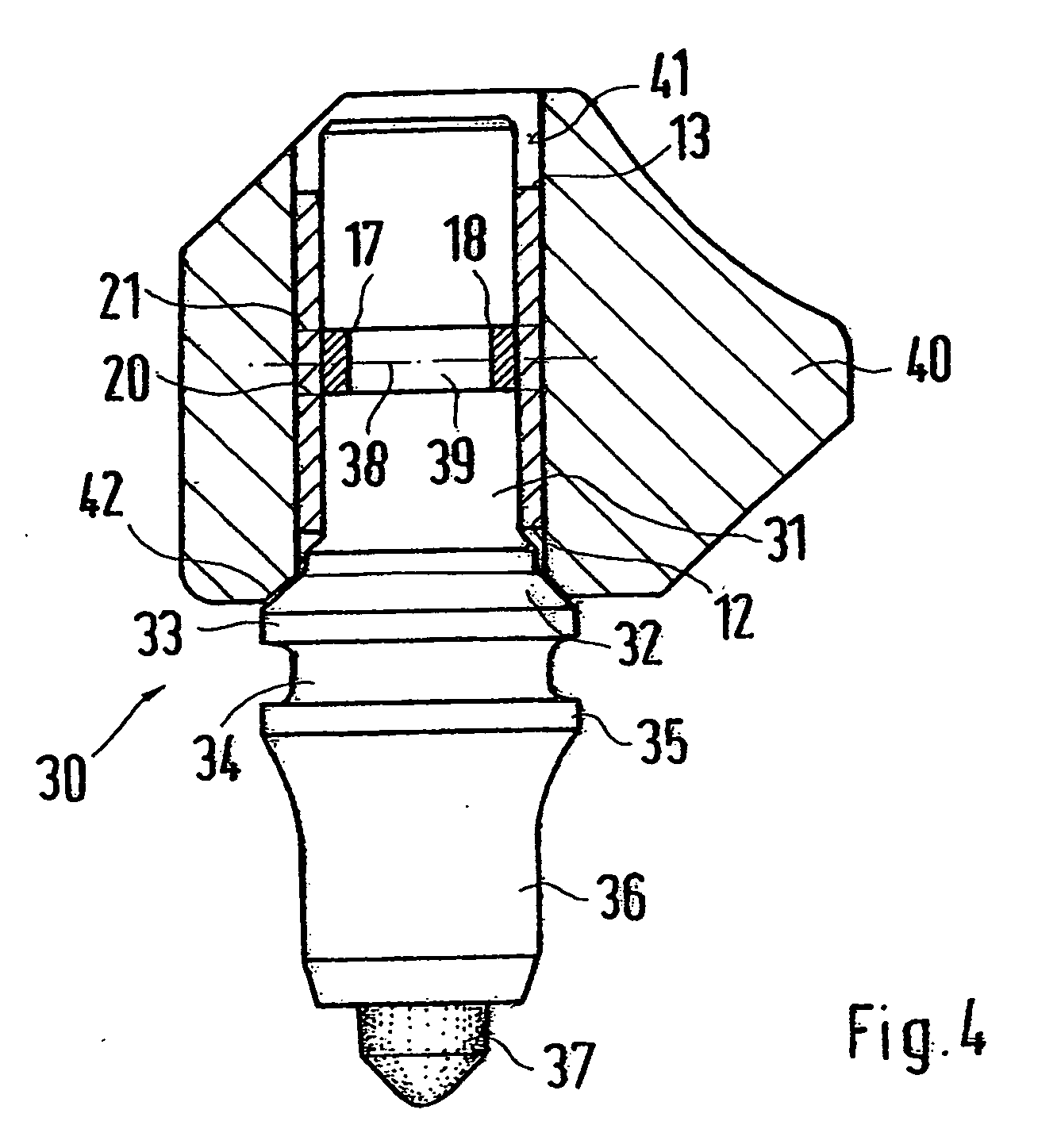

Circular-shank tool comprising a tool holder

InactiveUS7922256B2Attached with easeImprove convenienceTransportation and packagingSlitting machinesEngineeringKnife holder

A circular-shank tool including a shank held in a bore of a tool holder by a locking sleeve, the shank being rotatably held in the locking sleeve. The locking sleeve has one or more retaining elements that project inwards and engage in a peripheral groove in the shank of the tool, thus indisplaceably securing the locking sleeve in an axial direction on the shank of the tool. Because the locking sleeve is mirror-symmetrical to the central transversal plane, the locking sleeve can be fixed to the shank in a position that is rotated through 180°.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

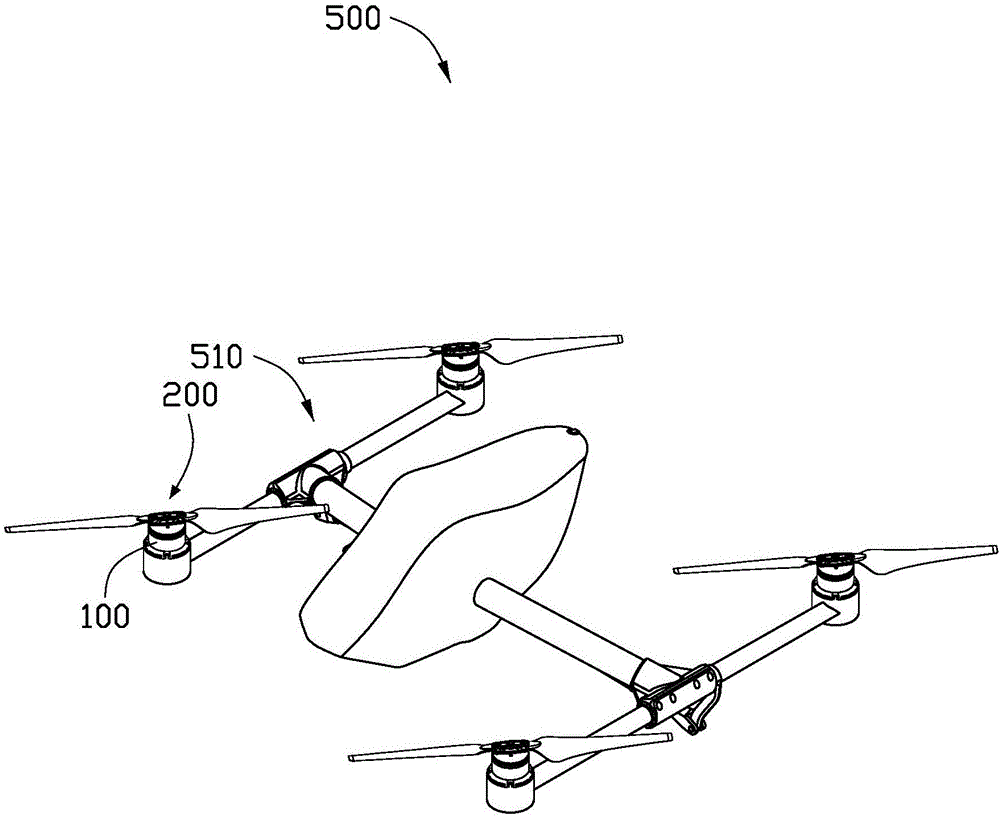

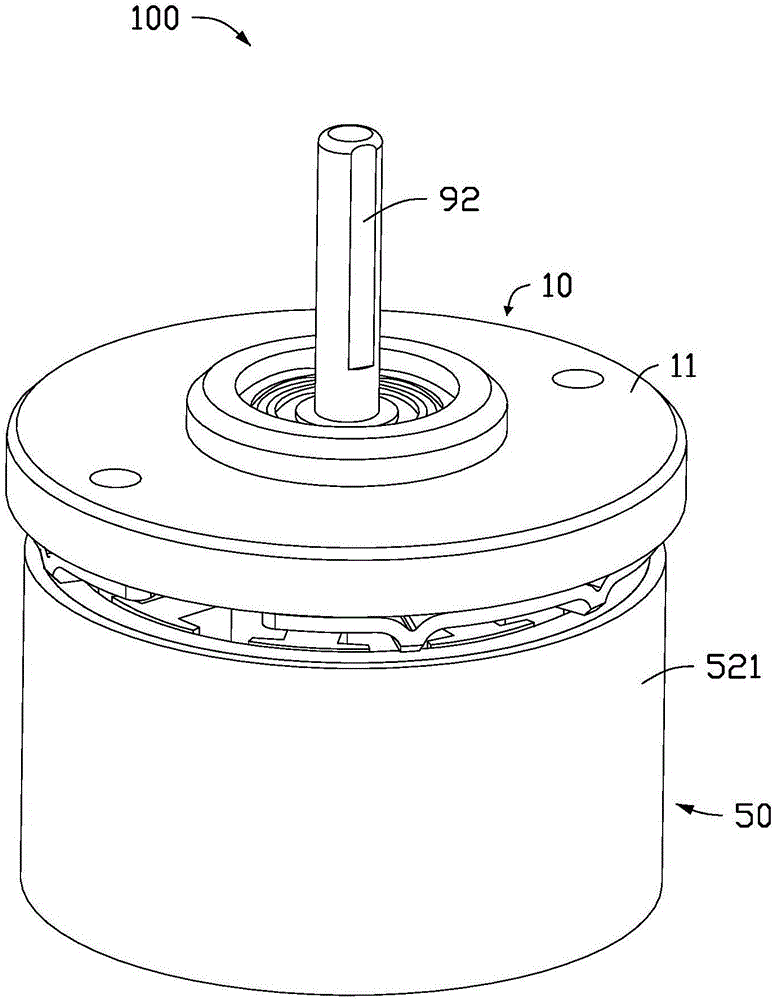

Electric motor, power device and unmanned aircraft using the power device

ActiveCN106063089ALow rotational noiseReduce spacingMagnetic circuit rotating partsBearing componentsInterference fitPropeller

Disclosed are an electric motor, a power device using the electric motor and an unmanned aircraft. The unmanned aircraft comprises an aircraft body, an electric motor provided on the aircraft body, and a propeller provided on the electric motor. The electric motor comprises a base, a rotor, a rotating shaft and a bearing. The rotor is rotatably sheathed on the base, the rotating shaft has one end thereof fixedly provided on the rotor, and the other end rotatably connected to the base via the bearing. The propeller is connected to the rotating shaft. The bearing comprises an inner ring, an outer ring and a roller, wherein the inner ring is fixedly sheathed on the rotating shaft, the outer ring is fixed provided on the base and surrounds the inner ring, and the roller is movably provided between the inner ring and the outer ring. The outer ring and the base are connected by means of an interference fit. The operation noises of the above-mentioned unmanned aircraft and the electric motor thereof are relatively small.

Owner:SZ DJI OSMO TECH CO LTD

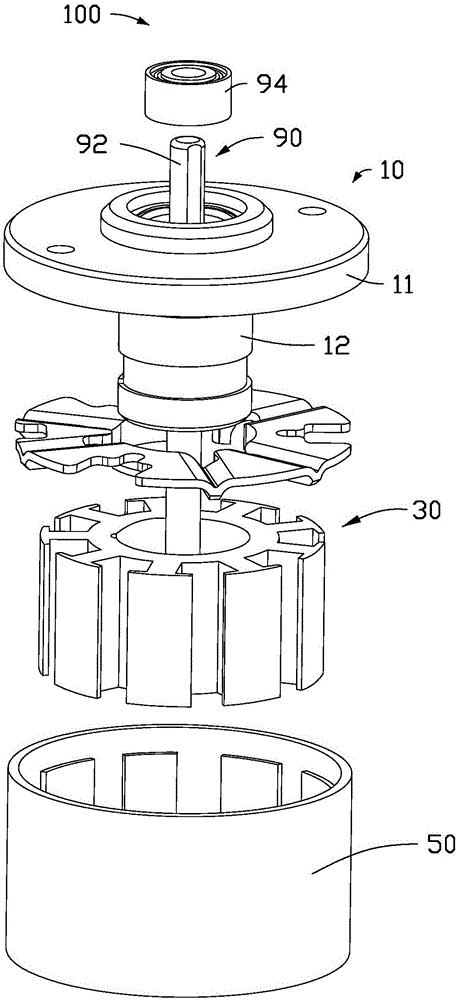

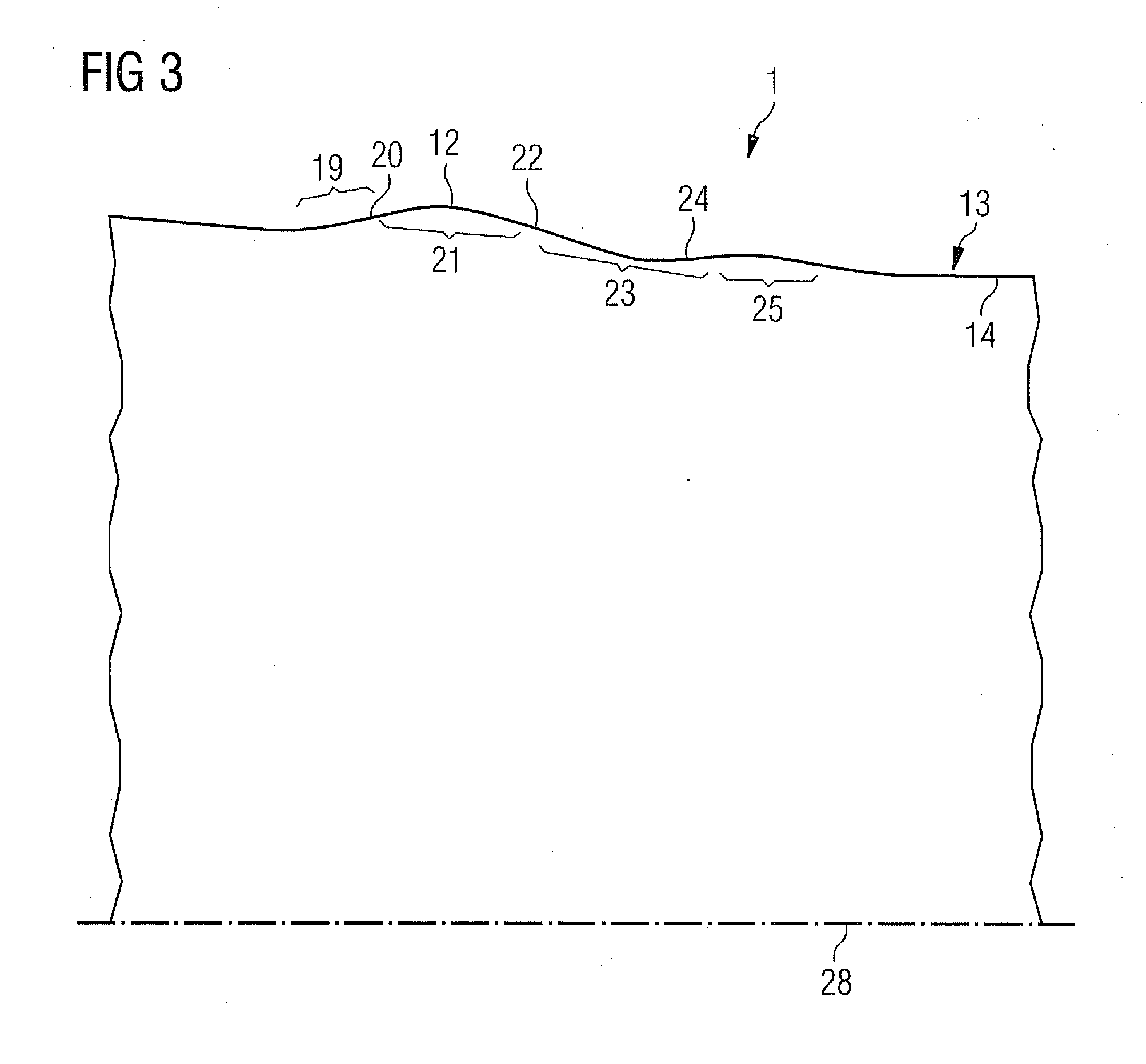

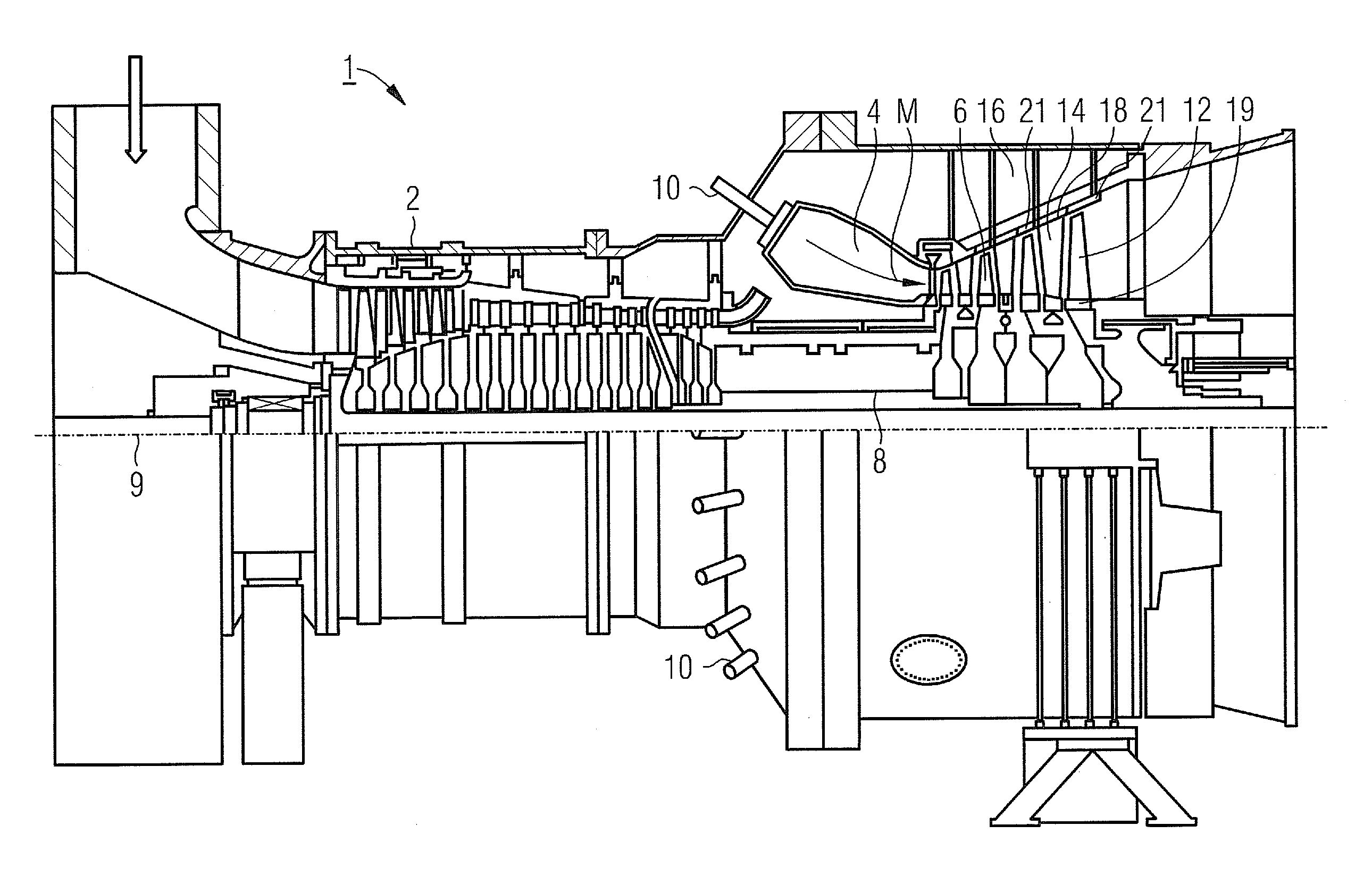

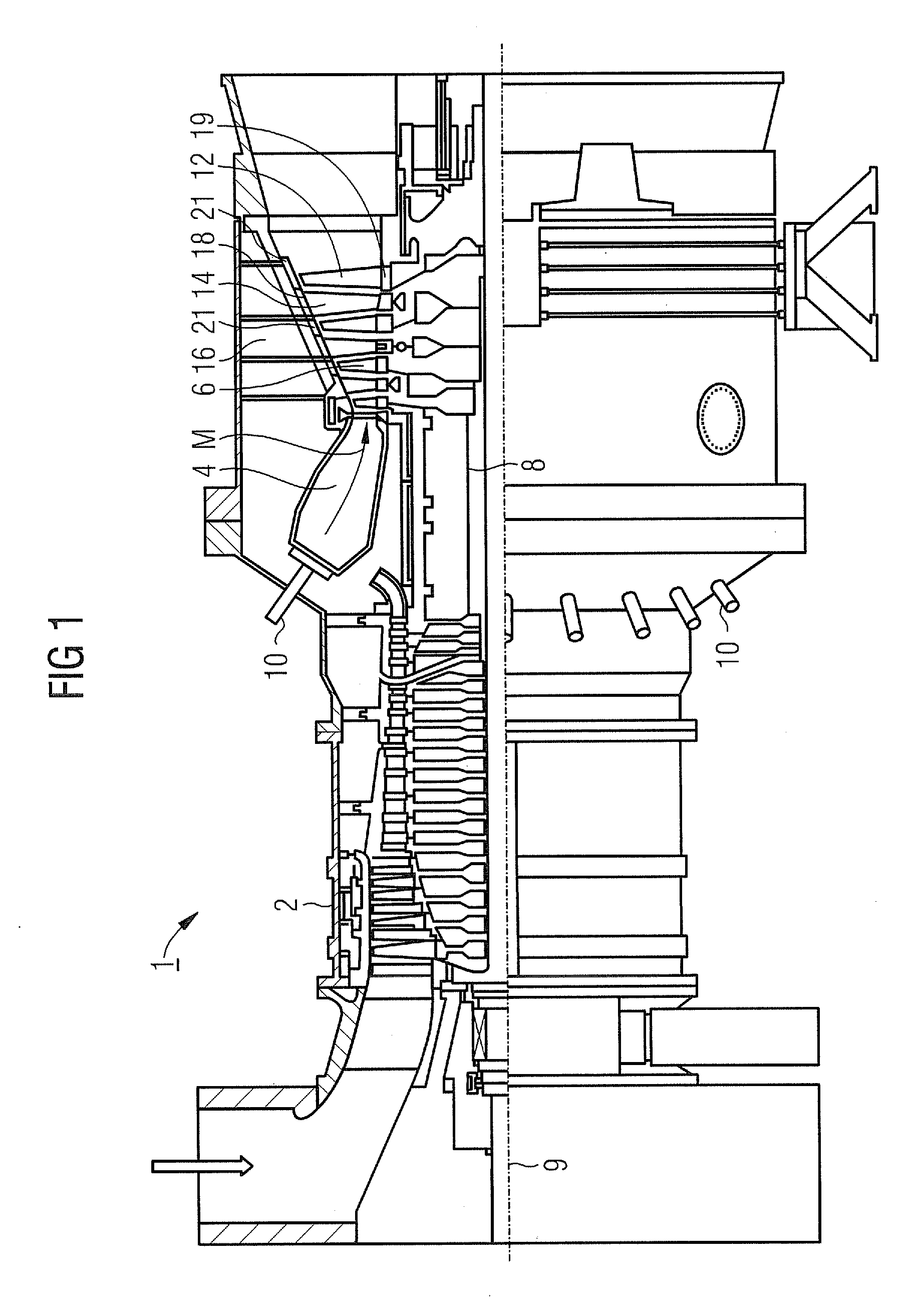

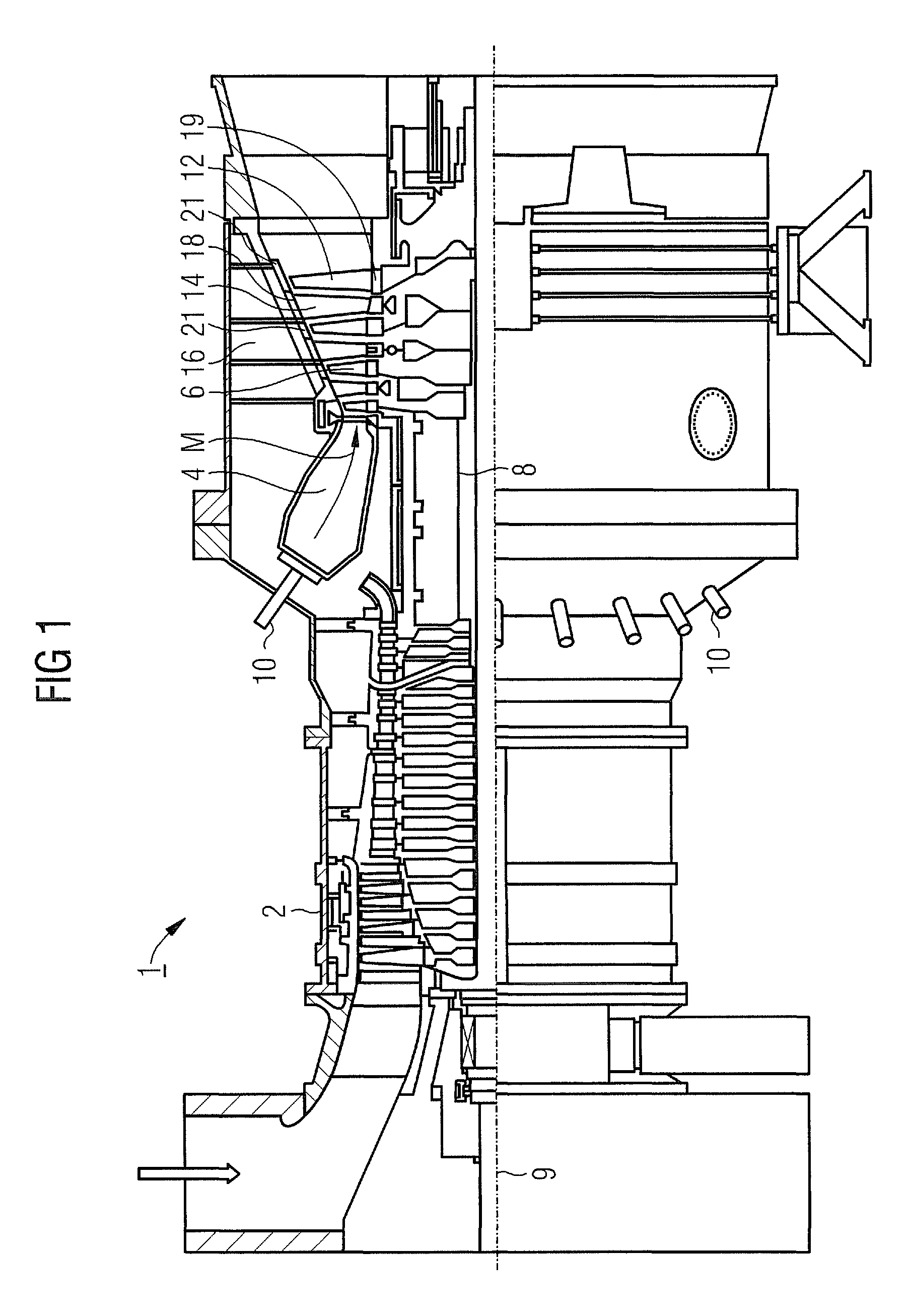

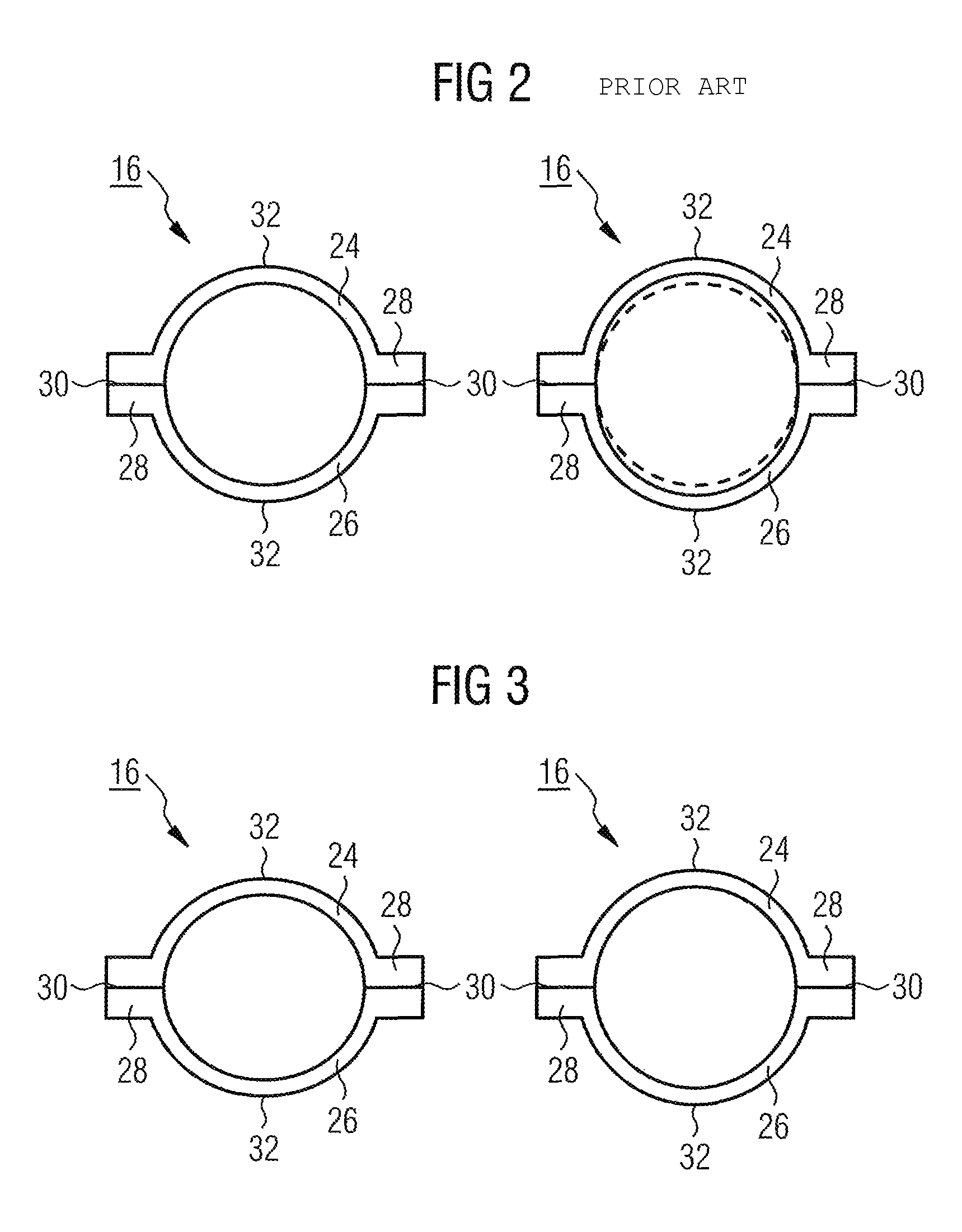

Casing for a steam or gas turbine

InactiveUS6336789B1Reduce radial clearanceAvoid inefficiencyPump componentsStatorsTurbine bladeEngineering

A casing for a steam or gas turbine comprises a shell and two flanges. The wall thickness of the shell is varied in an upper region facing away from the flange, in two central regions and in two lower regions facing the flanges, such that the upper region facing away from the flanges is reinforced in comparison with the lower regions facing the flanges. The lower regions facing the flanges are more flexible than the flanges which are attached by screws, and the partially reinforced central region and the reinforced upper region, and act as a joint to compensate for deformation, particularly in the radial direction. Consequently, the casing remains considerably more round in operation. The reduced radial clearance (achieved by reduced deformation) between the casing and the ends of the turbine blades leads to considerably increased efficiency during operation of the turbine.

Owner:GENERAL ELECTRIC TECH GMBH

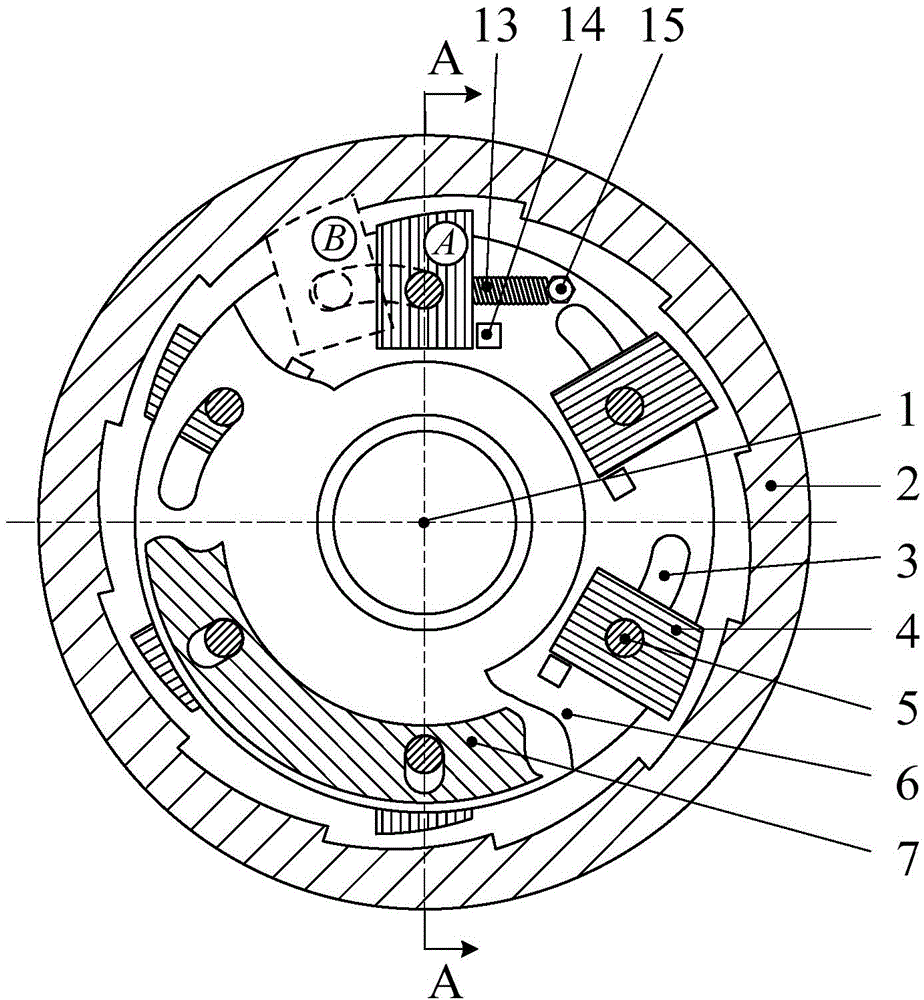

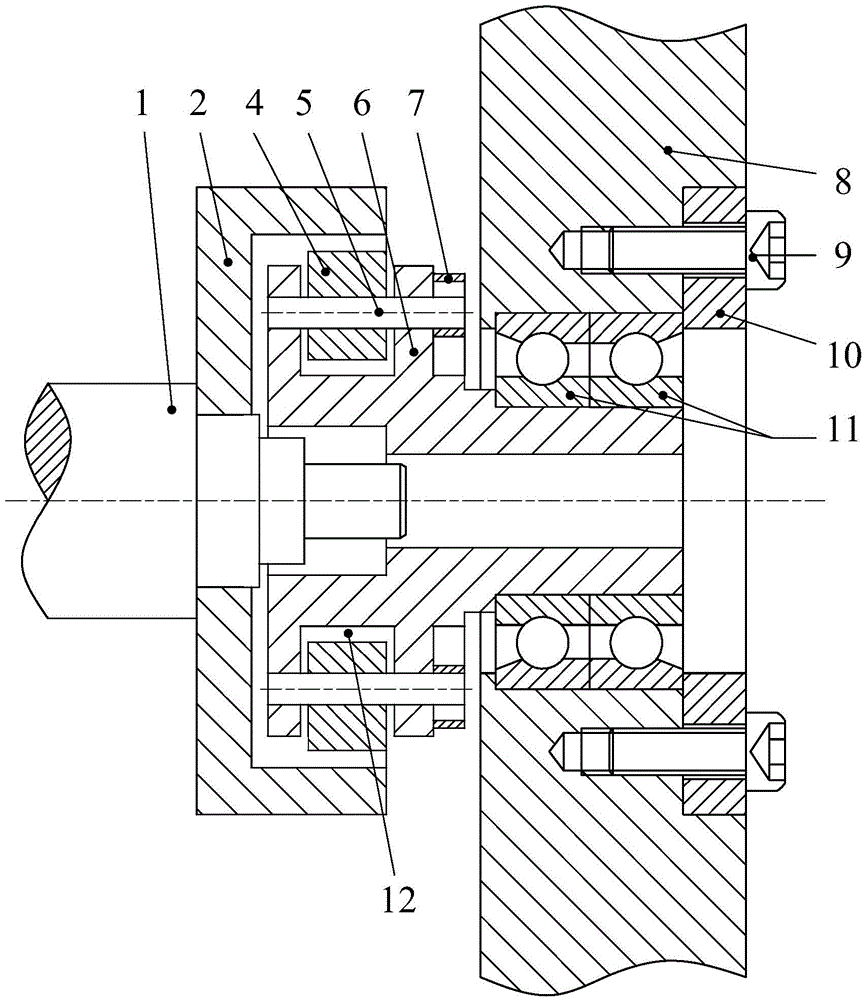

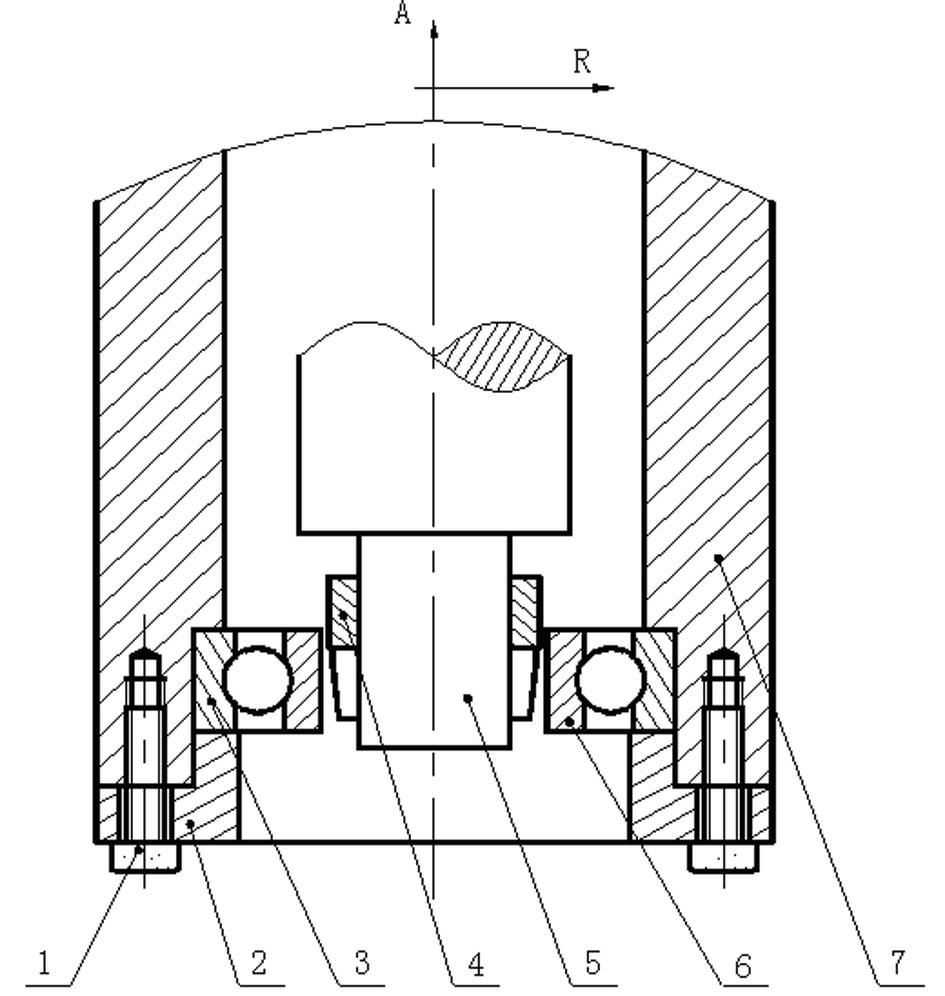

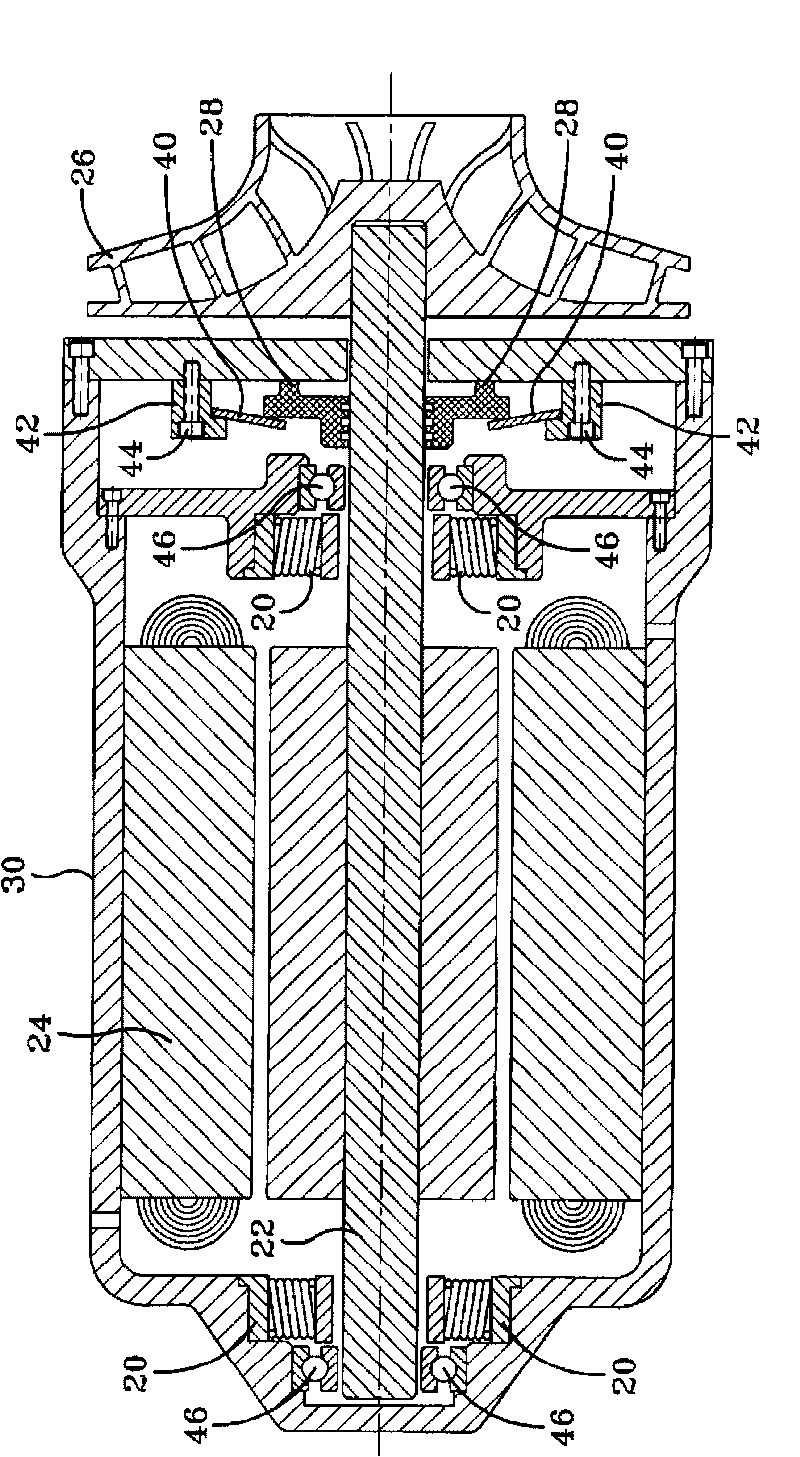

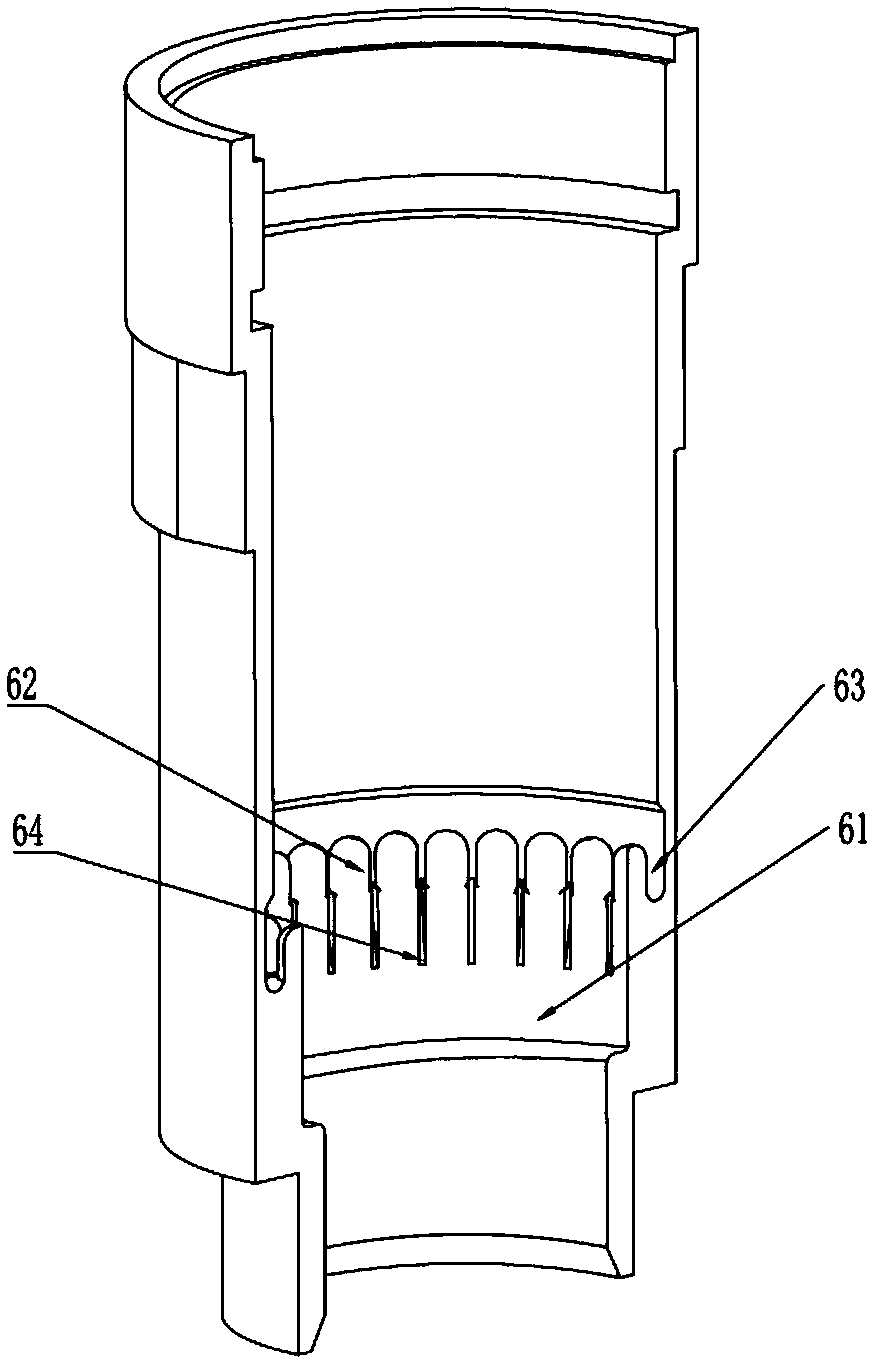

Centripetal thrust protection bearing device for automatically eliminating clearance

InactiveCN103912589AAchieve axial protectionReduce gapRolling contact bearingsBearing unit rigid supportBall bearingRolling-element bearing

The invention discloses a centripetal thrust protection bearing device for automatically eliminating a protection clearance in a magnetic suspension bearing system. The centripetal thrust protection bearing device comprises a rotary shaft, a rotor assembly, a sliding block, an installation seat and a bearing seat, wherein two angular contact ball bearings are arranged between inner cavities of the installation seat and the bearing seat; the sliding block comprises more than two sliding block sub-bodies; each sliding block sub-body is arranged in a sliding block guide groove through a sliding rod; all the sliding rods are connected into a whole through an annular connecting piece; waist-shaped holes are formed in positions, corresponding to the sliding rods, on the annular connecting piece; at least one sliding block sub-body is provided with a sliding block retaining device; a proper axial clearance is formed between the rotary shaft and the installation seat. Therefore, the device can protect a rotor in the radial and axial directions when the magnetic suspension bearing system fails and the rotor drops, and a radial clearance between the rotary assembly and a rolling bearing can be eliminated, so that vibration and impact on the rolling bearing after the high-speed rotor drops are eliminated, and the reliability and the safety of a centripetal thrust protection bearing are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fuel pipe assembly and clamping means

ActiveUS20110174272A1Easy clamping actionReduce radial clearanceFuel injection apparatusMachines/enginesCylinder headEngineering

A fuel pipe assembly for supplying fuel to a fuel injector located within a bore of an engine cylinder head comprises a tube nut for connecting the fuel pipe to the fuel injector and a securing arrangement comprising a locking nut and a deformable clamp member for securing the fuel pipe within the tube nut. The tube nut comprises a tubular member defining an axial bore to receive the fuel pipe, a distal end shaped for cooperation with the head of the fuel pipe, and a proximal end having an attachment mechanism for engaging a compatible attachment mechanism of the locking nut. The locking nut has an axial bore to receive the fuel pipe, and an attachment mechanism for engaging a compatible attachment mechanism of the tube nut. The clamp member defines a bore to receive the fuel pipe and is deformable under compression. In a first state of engagement, the locking nut and tube nut define a volume therebetween that accommodates the clamp member in an unstrained configuration and the fuel pipe is able to move laterally. In a second state of engagement, the clamp member is compressed between the locking nut and tube nut into a strained configuration such that lateral movement of the fuel pipe is constrained.

Owner:DELPHI TECH IP LTD

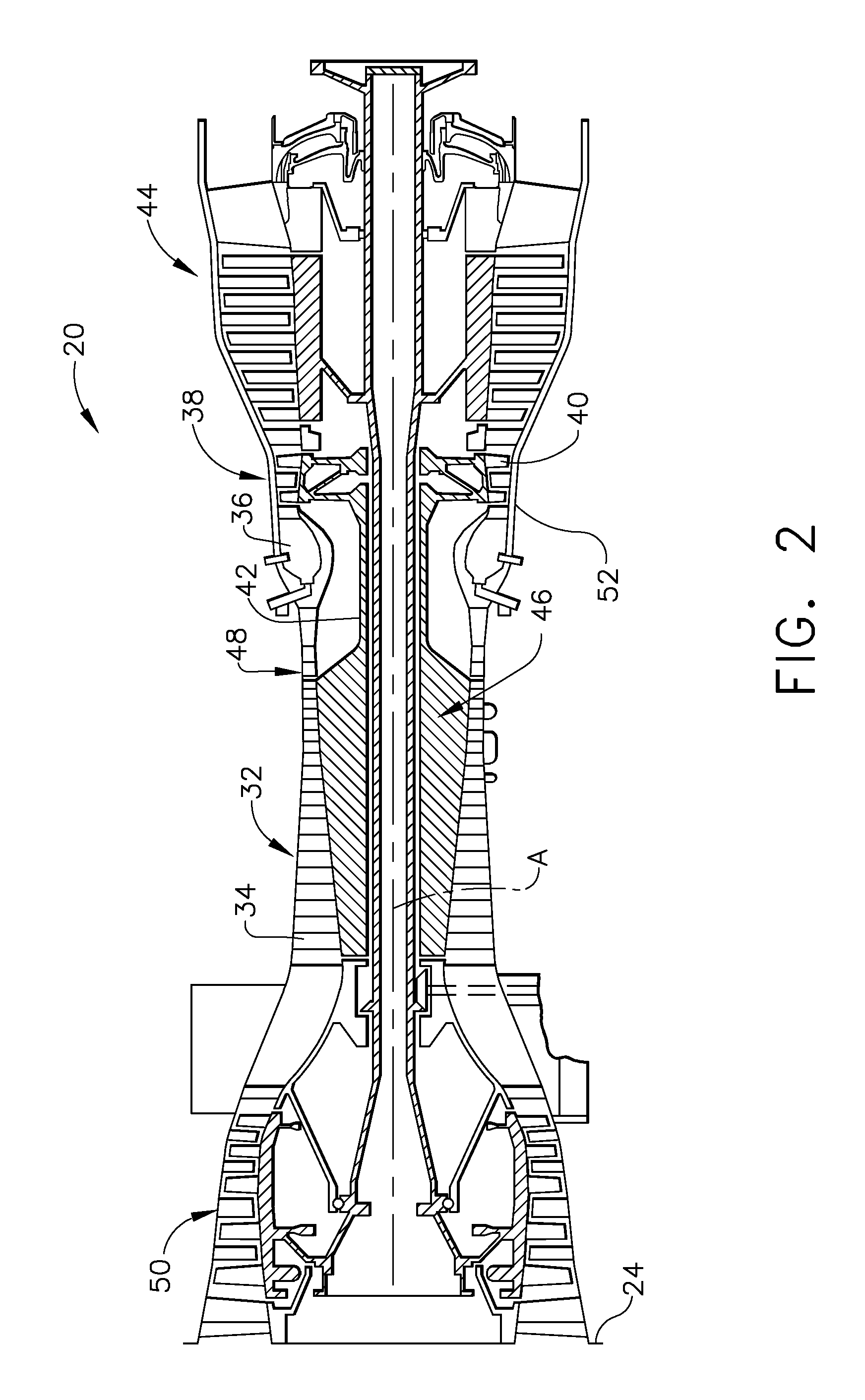

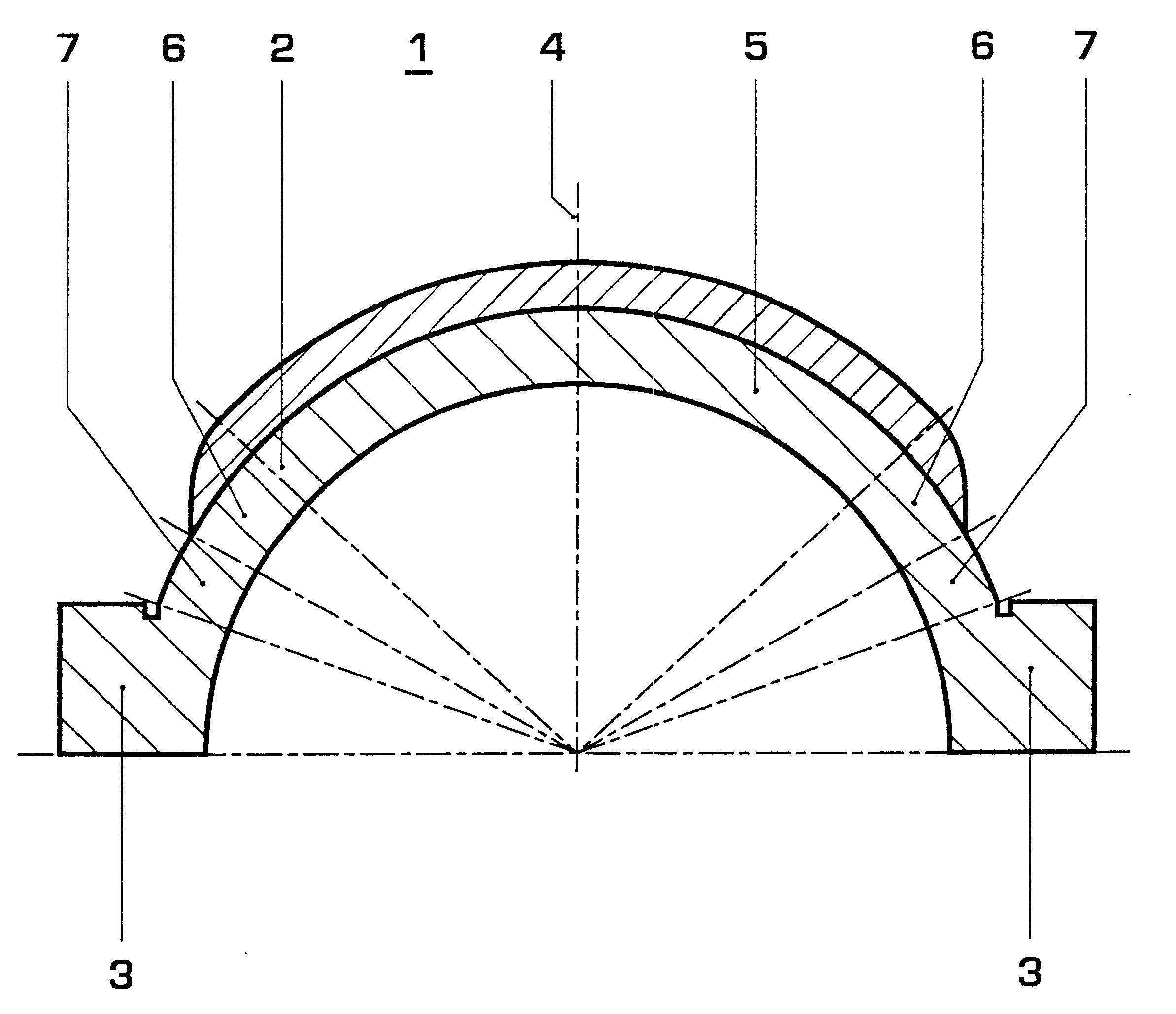

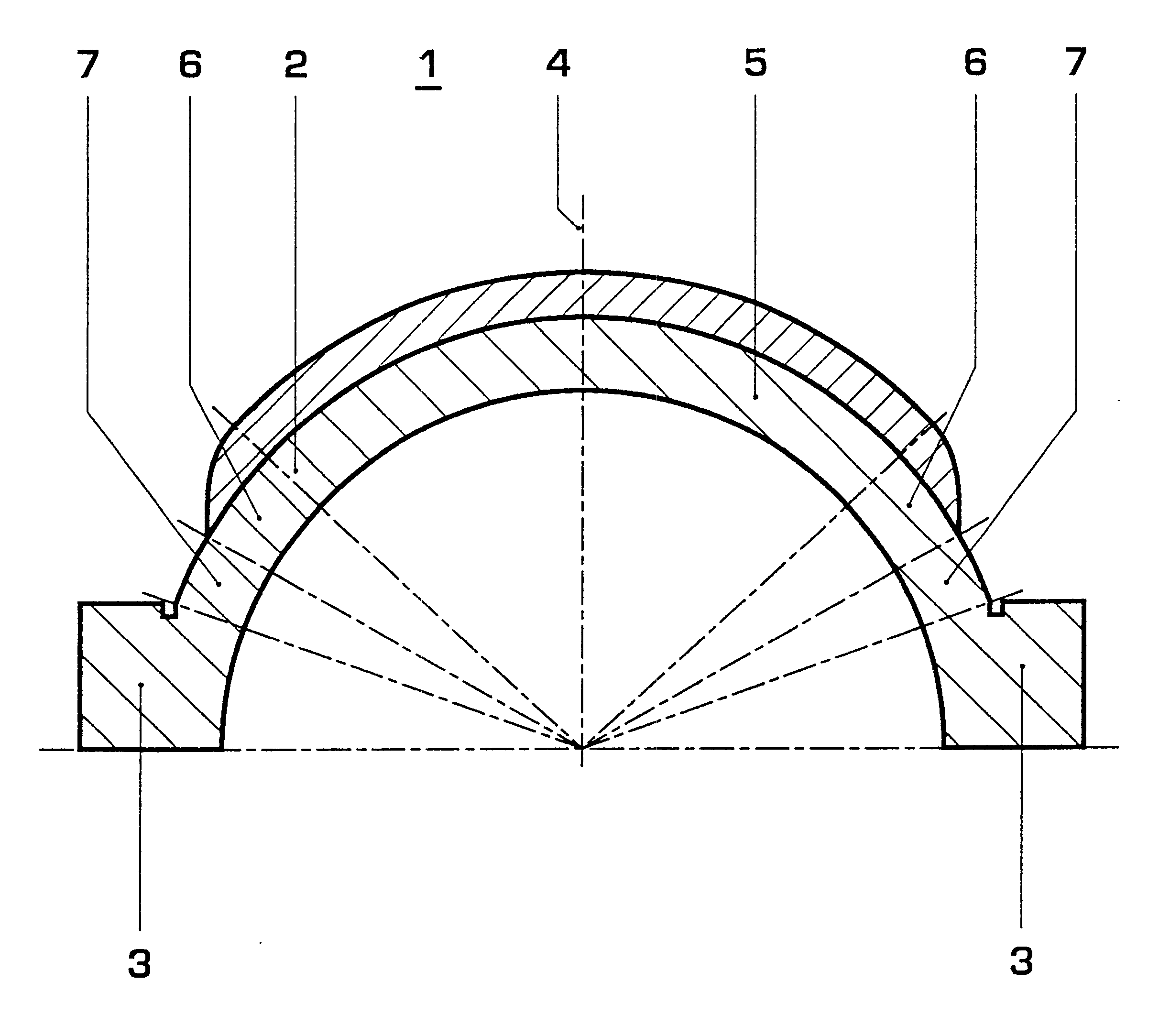

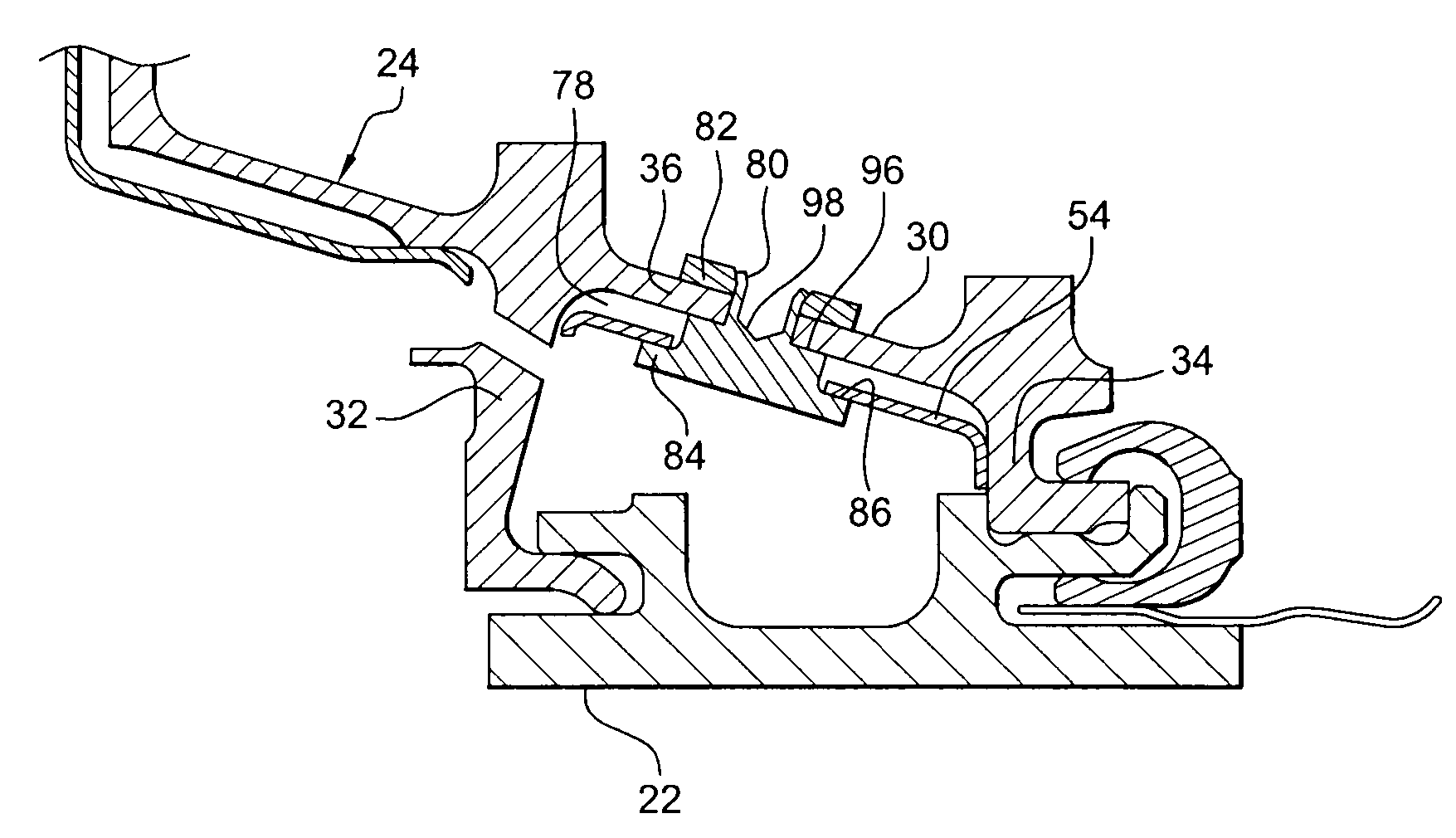

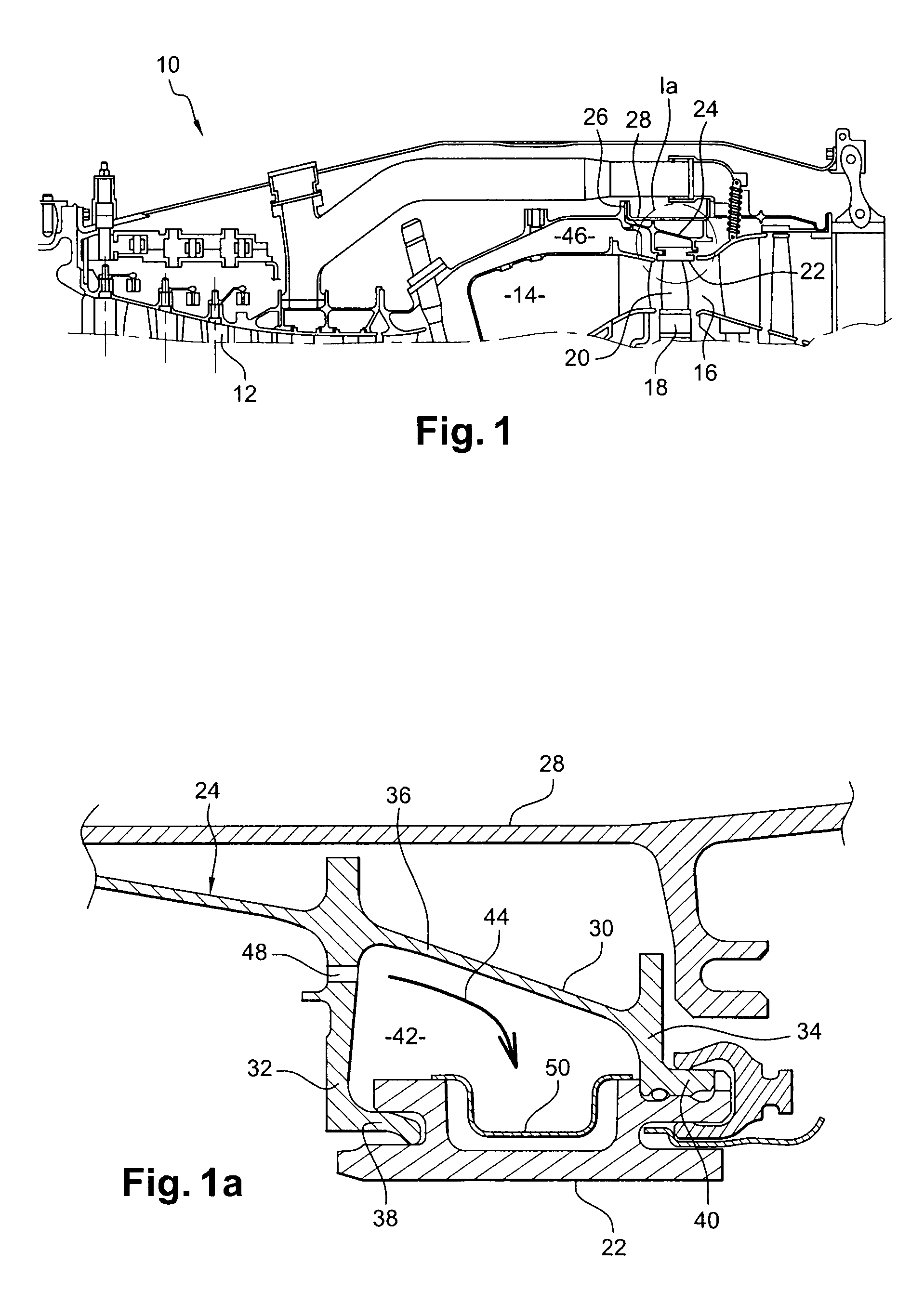

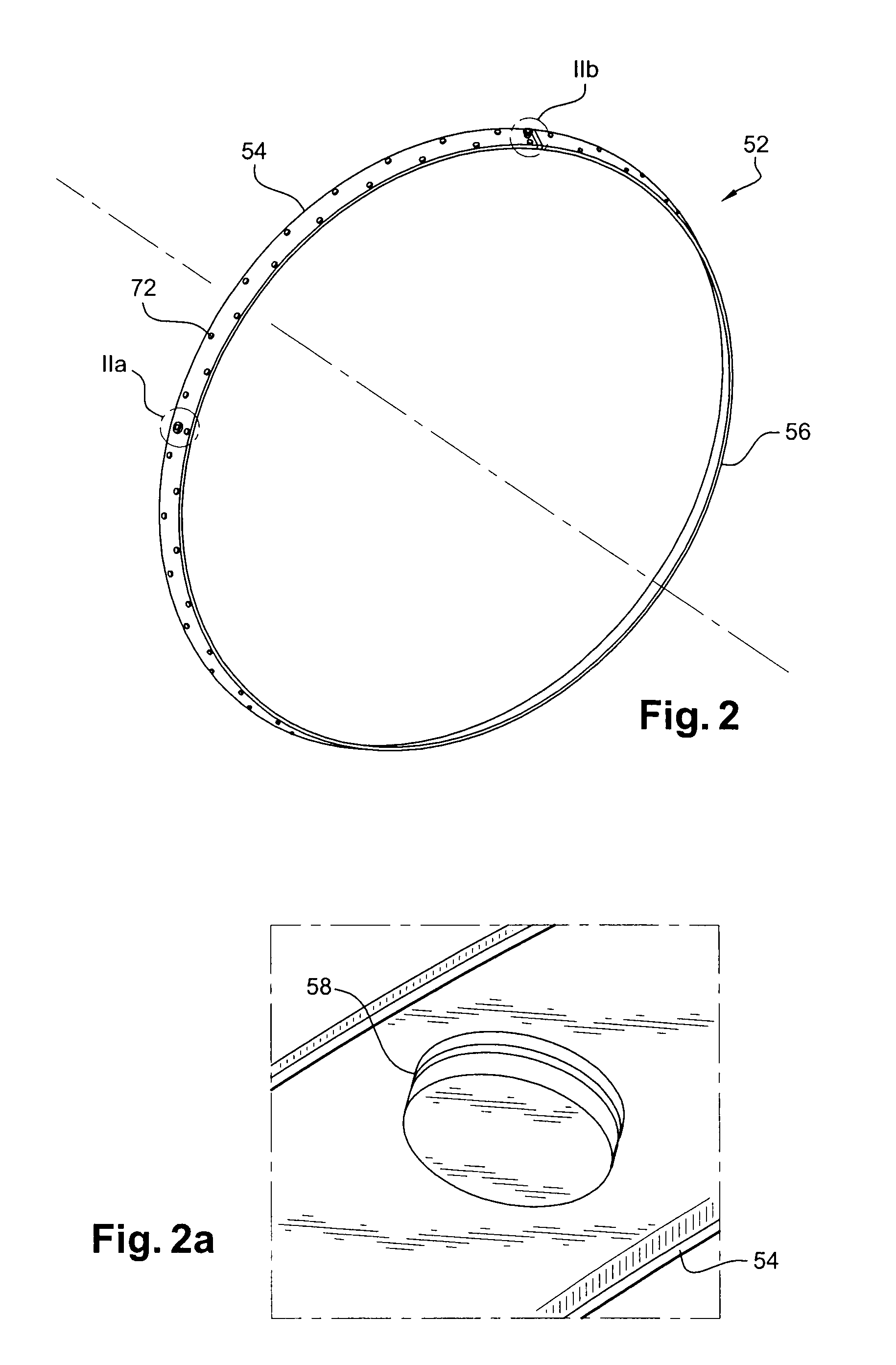

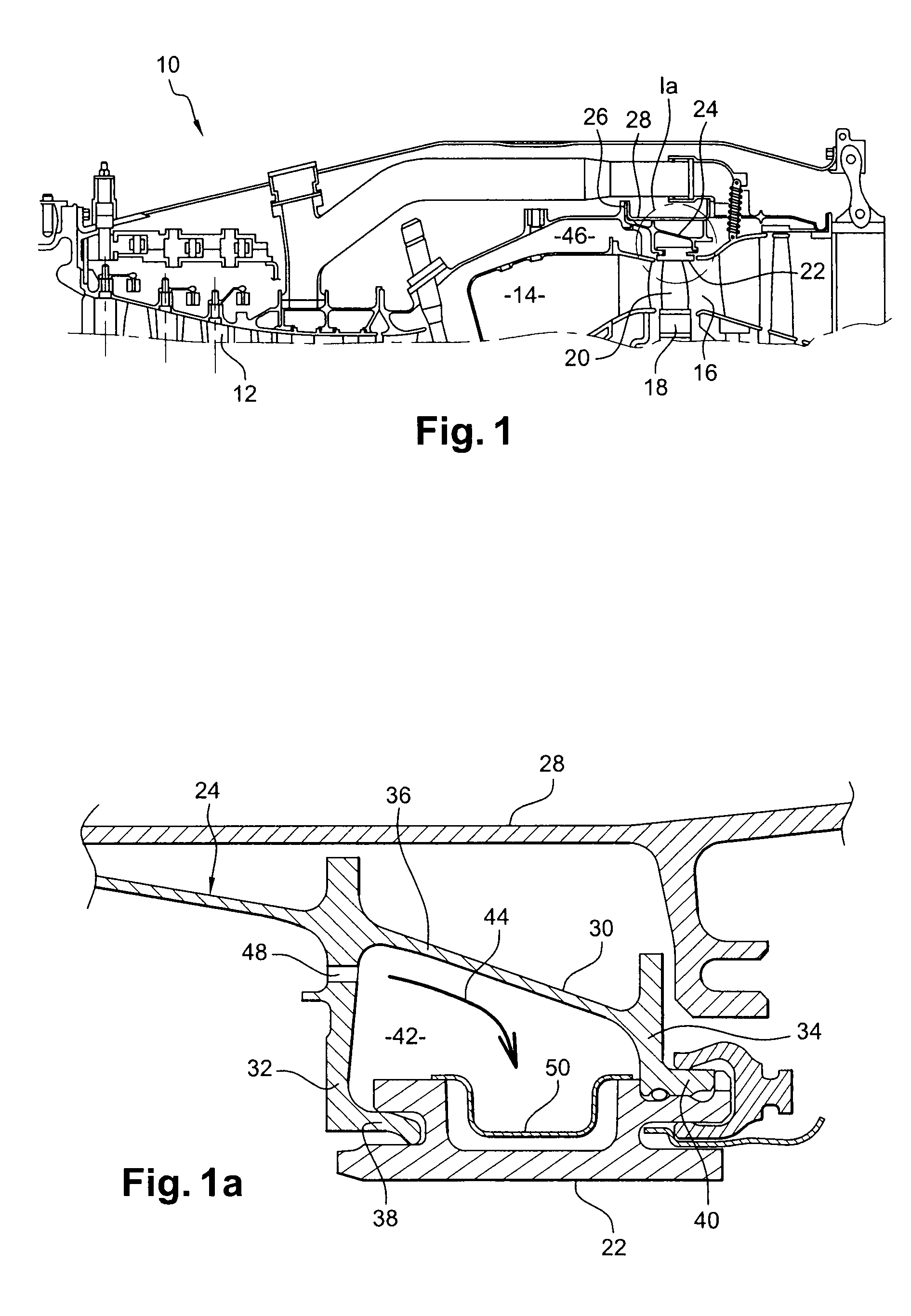

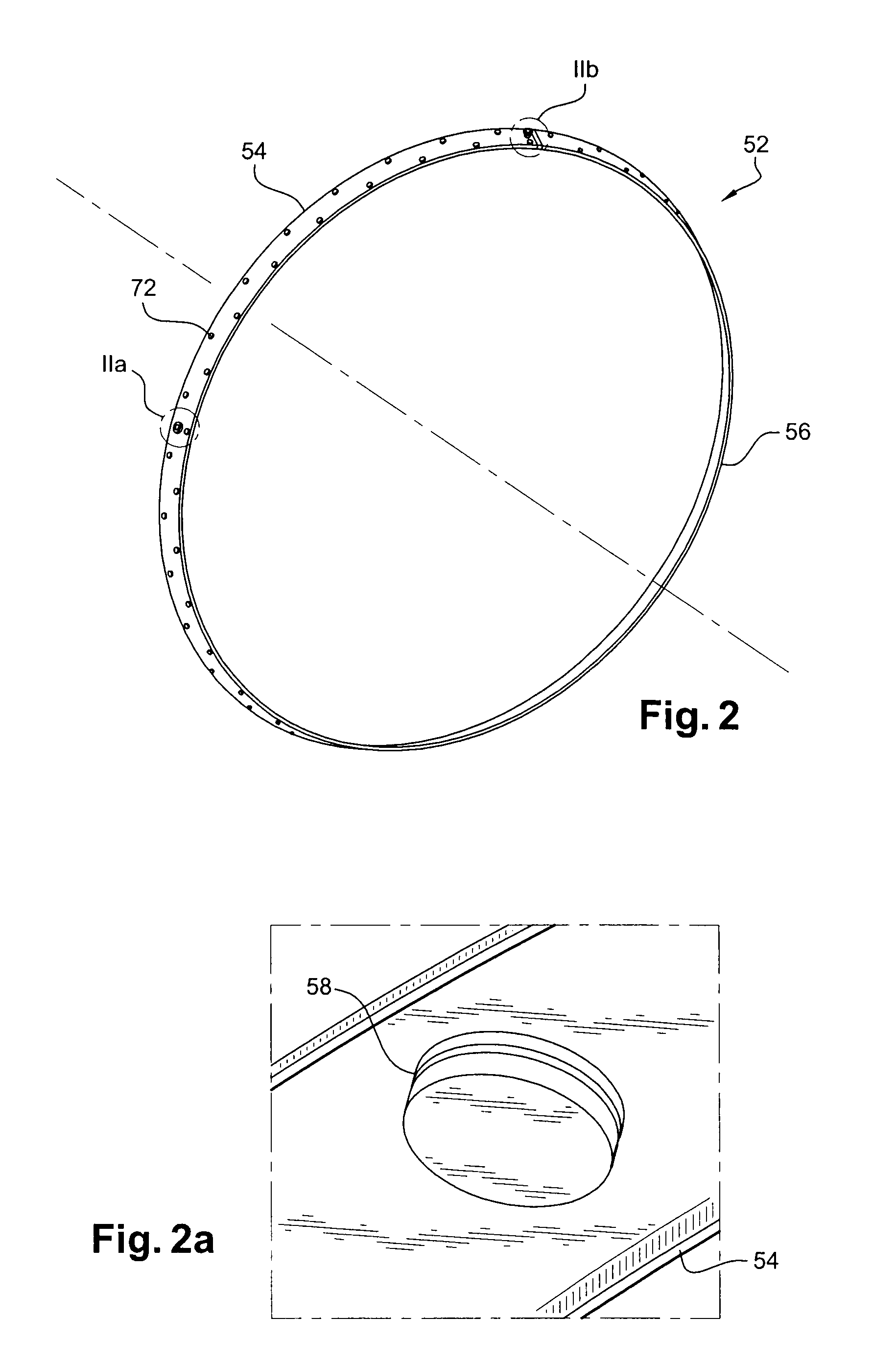

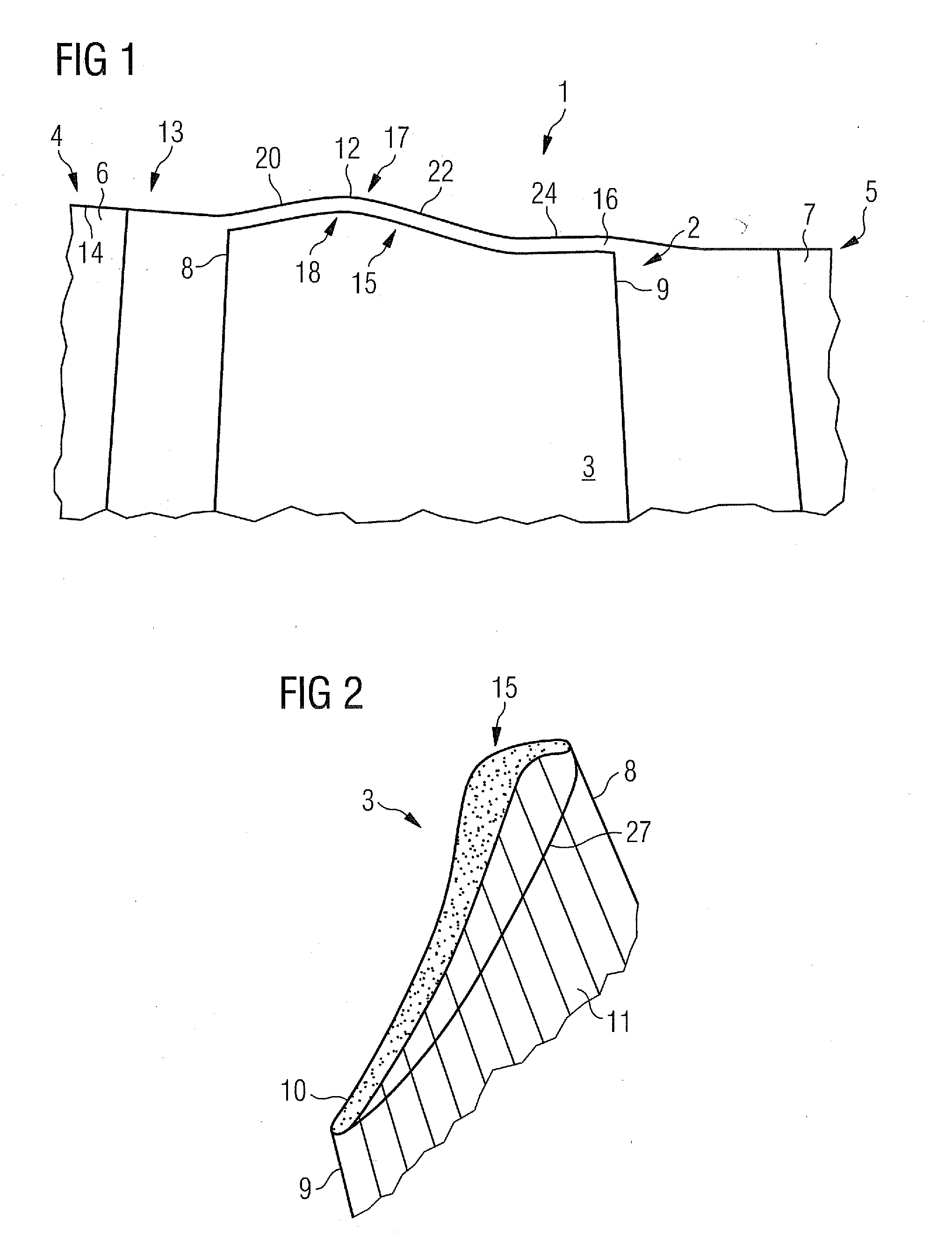

Control of clearance at blade tips in a high-pressure turbine of a turbine engine

ActiveUS20090104026A1Simple and economical and effectiveOvercome disadvantagesPump componentsBlade accessoriesHigh pressureTurbine

Turbine stage in a turbine engine, including a wheel with blades rotating inside a sealing ring (22) held by a casing (24) of the turbine, and an annular thermal protection sheet mounted between the casing (24) and the ring (22), wherein the annular thermal protection sheet is formed by a plurality of curved plates (54, 56) mounted end-to-end and attached by pins (70) to the casing (24).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Control of clearance at blade tips in a high-pressure turbine of a turbine engine

ActiveUS8100635B2Simple and economical and effectiveOvercome disadvantagesPump componentsBlade accessoriesEngineeringHigh pressure

A turbine stage in a turbine engine, including a wheel with blades rotating inside a sealing ring held by a casing of the turbine, and an annular thermal protection sheet mounted between the casing and the sealing ring is disclosed. The annular thermal protection sheet is formed by a plurality of curved plates mounted end-to-end and attached by pins to the casing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

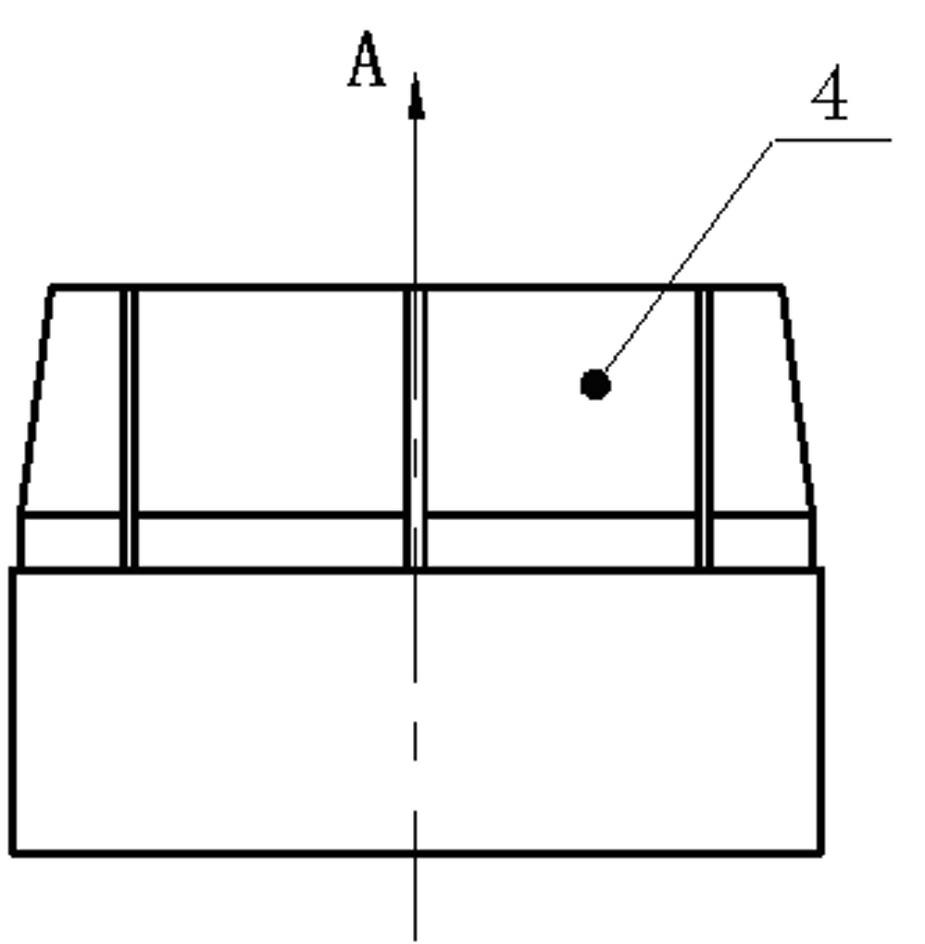

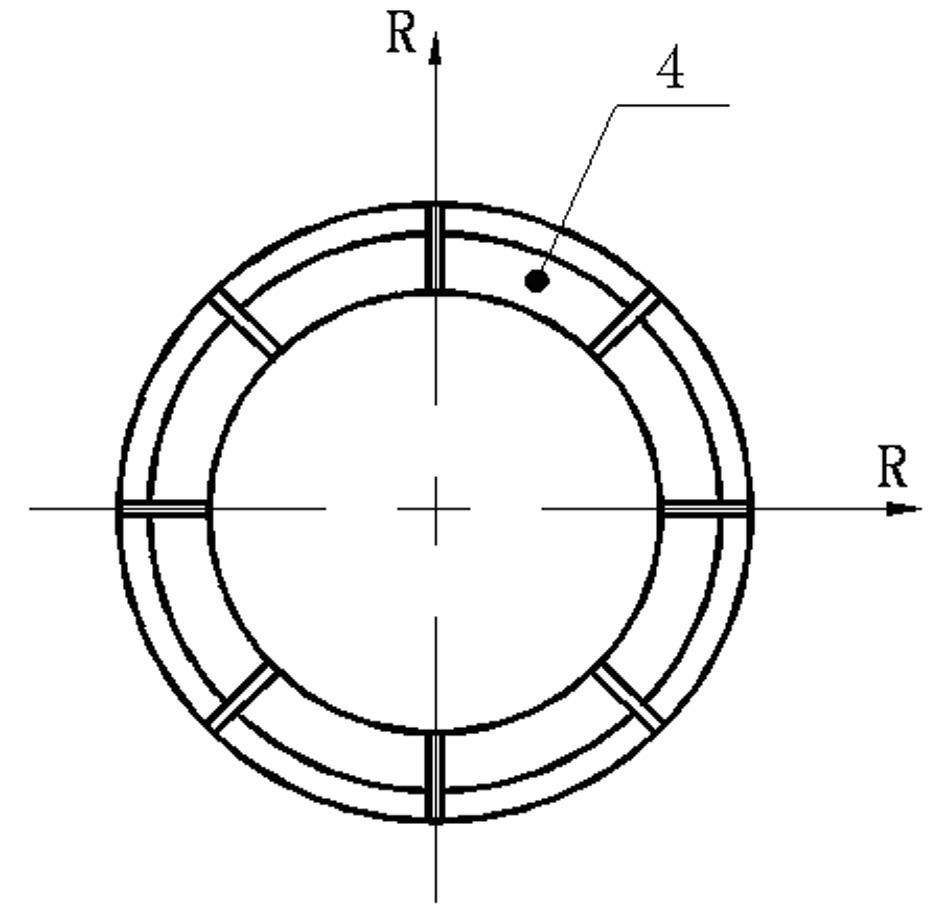

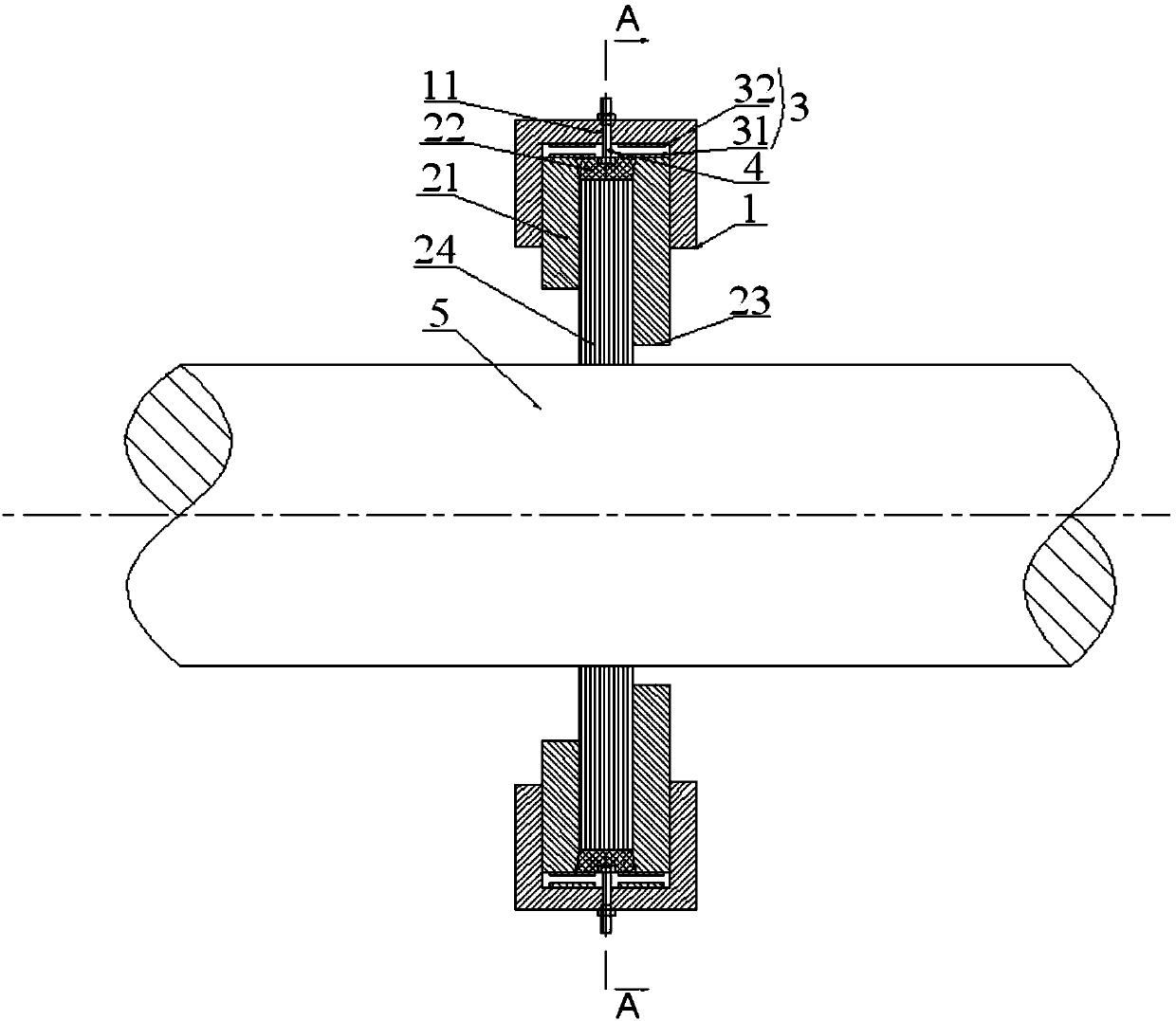

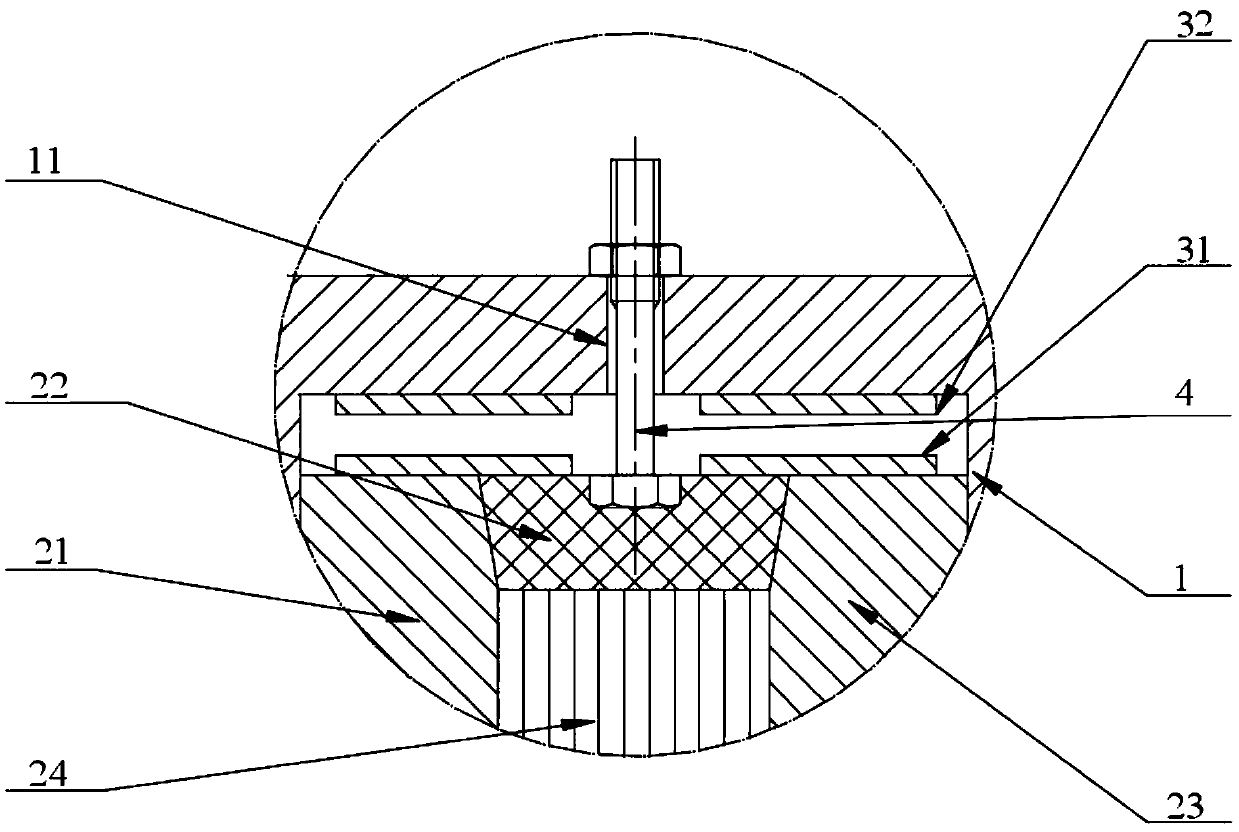

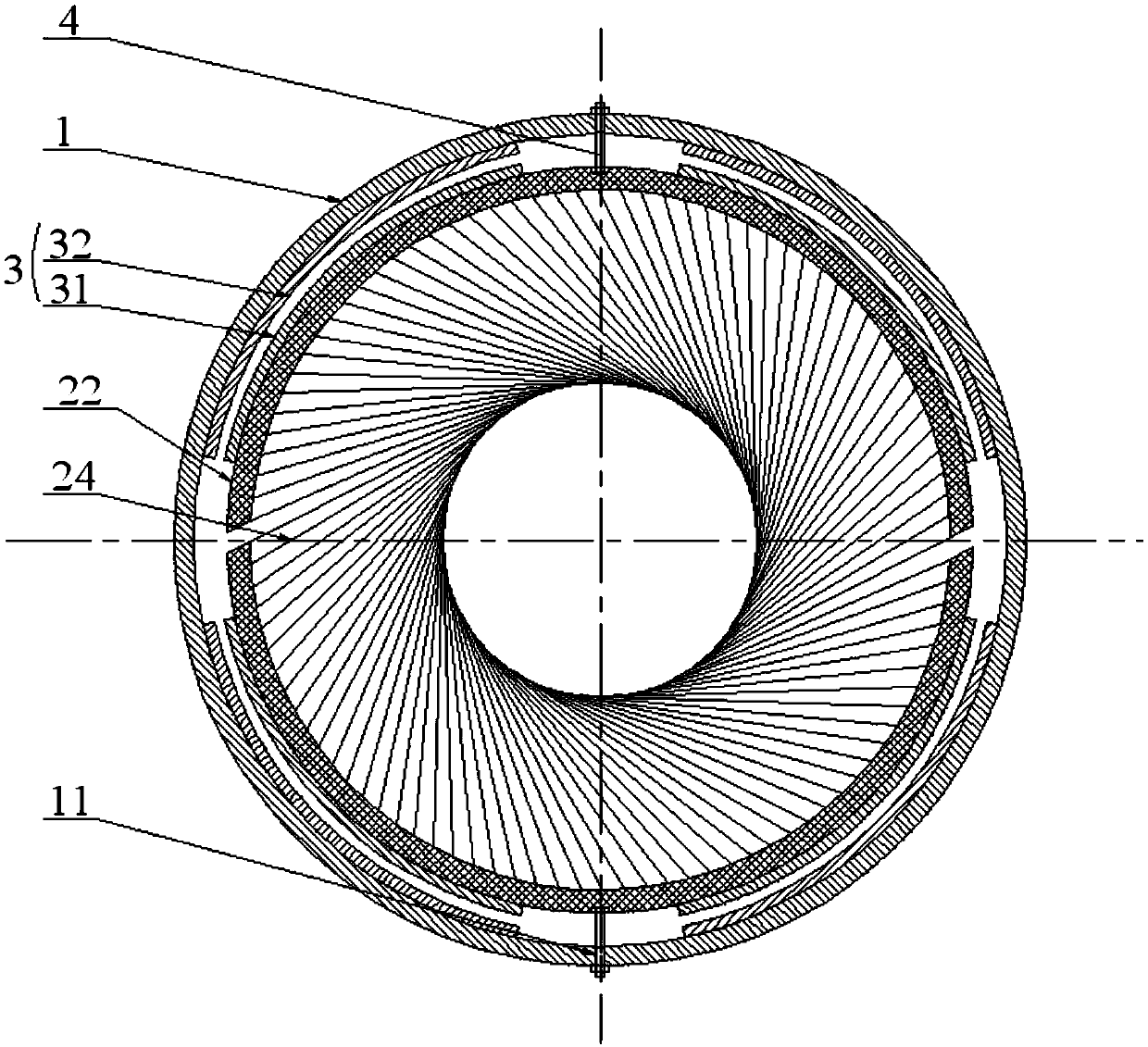

Radial protective bearing

The invention relates to a radial protective bearing belonging to the field of magnetic suspension bearing systems. The radial protective bearing comprises a bolt (1), an end cover (2), a rolling bearing, a slotting protective jacket (4), a rotor assembly (5) and a base (7). The radial protective bearing can bear a radial load. A radial gap between the rotor assembly (5) and a rolling bearing inner ring (6) is reduced through the slotting protective jacket under an eccentric force because a slotting section deforms along the radial direction, and a cantilever beam structure is formed, thus the energy generated by impact is reduced and the structure of the radial protective bearing is greatly simplified, and the service life of the protective bearing is prolonged.

Owner:NANJING CIGU TECH CORP LTD

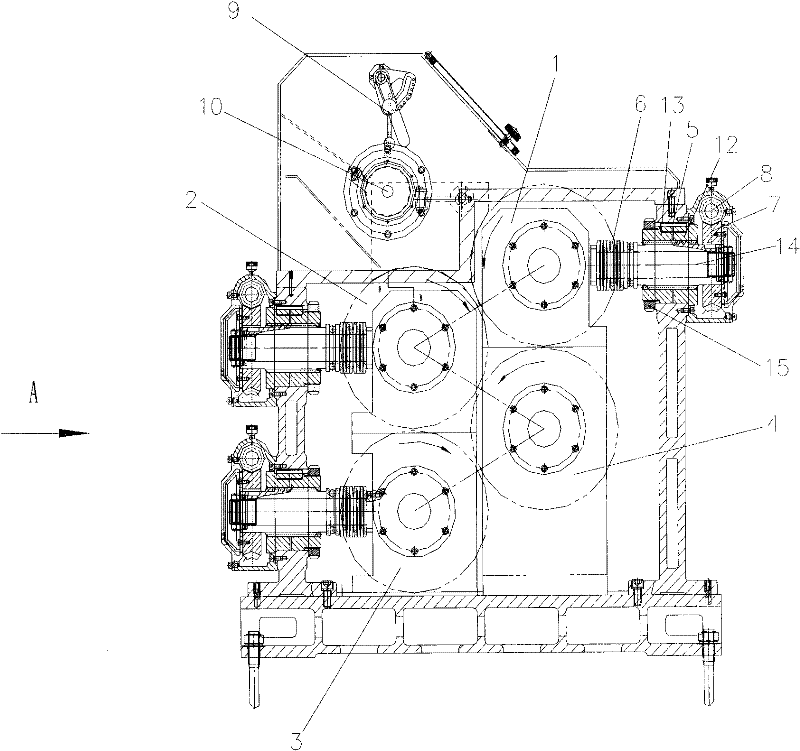

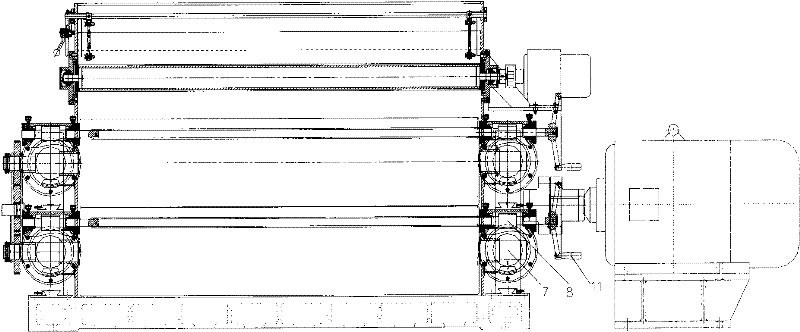

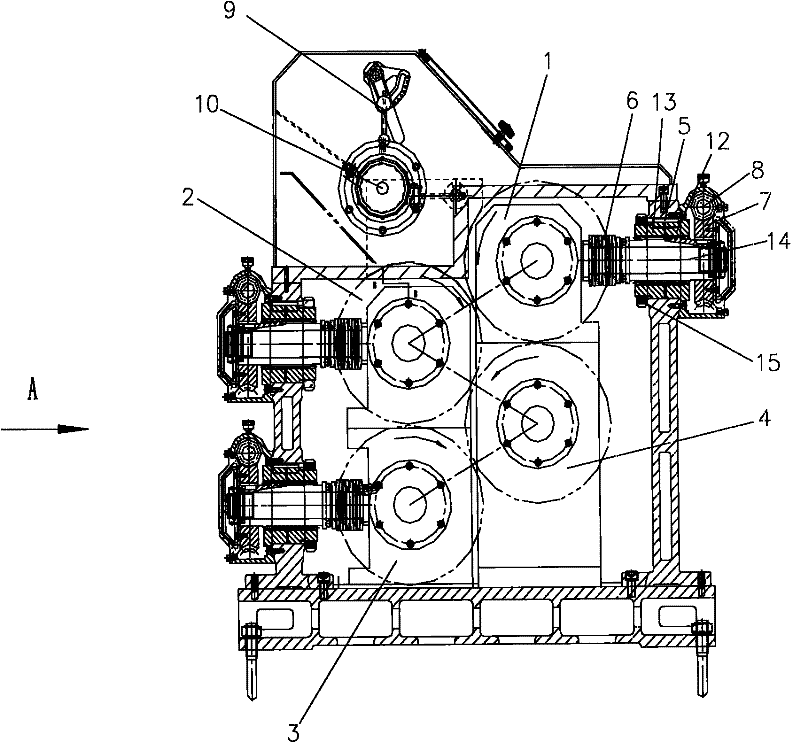

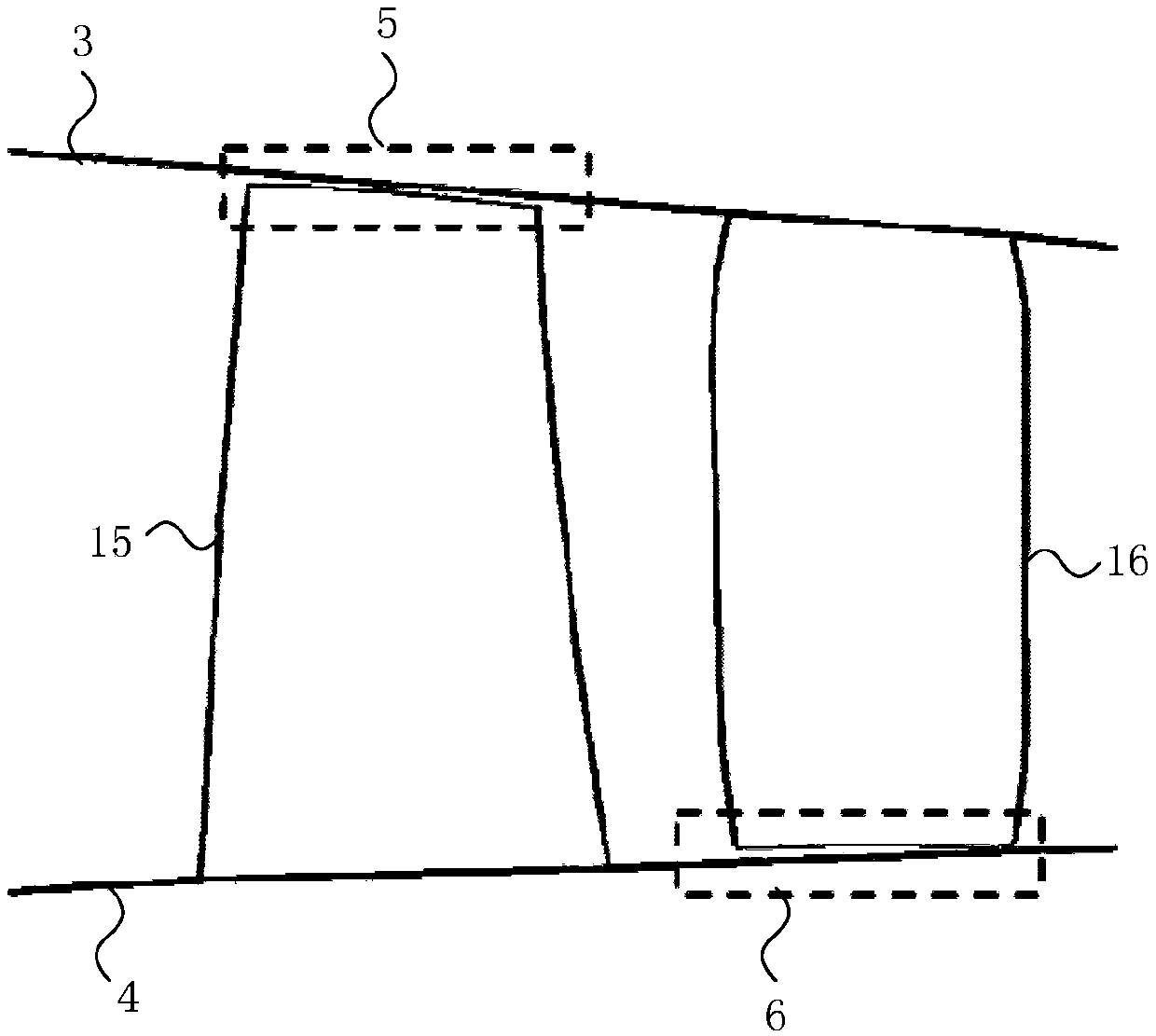

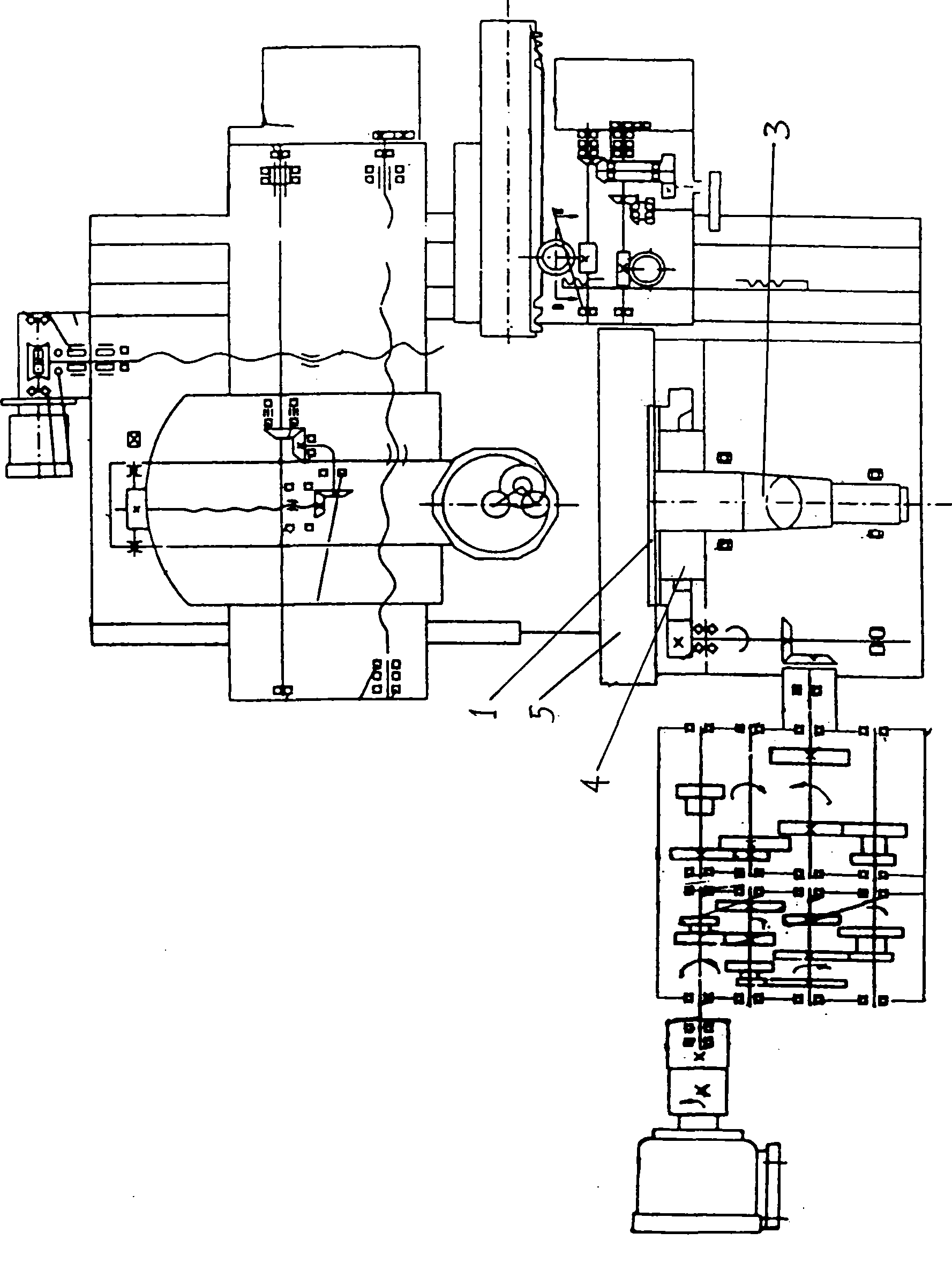

Tooth-roller crusher

The present invention discloses a tooth-roller crusher. The tooth-roller crusher is provided with a material feed inlet, tooth rollers and a roller spacing adjustment device. The tooth-roller crusher is characterized in that the tooth-roller crusher is provided with the four tooth rollers, wherein the first tooth roller (1) and the second tooth roller (2) are the roller couple, the third tooth roller (3) and the fourth tooth roller (14) are the roller couple, and the rolling match is formed between the second tooth roller (2) and the fourth tooth roller (14); a nut of the roller spacing adjustment device comprises two parts of a front nut (12) and a rear nut (13), wherein the two parts are connected by using a pin (5), the front nut (12) is fixed, the tail end of the rear nut (13) is provided with external threads, and the position of the external threads is provided with a round nut (15). The prominent characteristic of the tooth-roller crusher of the present invention is that: the three crushing operations are completed in the one device, such that the workload of the one device of the present invention is the workload of the three devices so as to substantially improve the production efficiency. In addition, in the adjustment device, the rear nut can move forward by turning the round nut, and the front nut is fixed, such that the radial gap between the screw and the nut is reduced, the screw is prevented from movement so as to provide high stability; meanwhile, the gap is reduced, such that the uncontrollable error is removed so as to improve the assembly accuracy.

Owner:大连宝锋机器制造有限公司

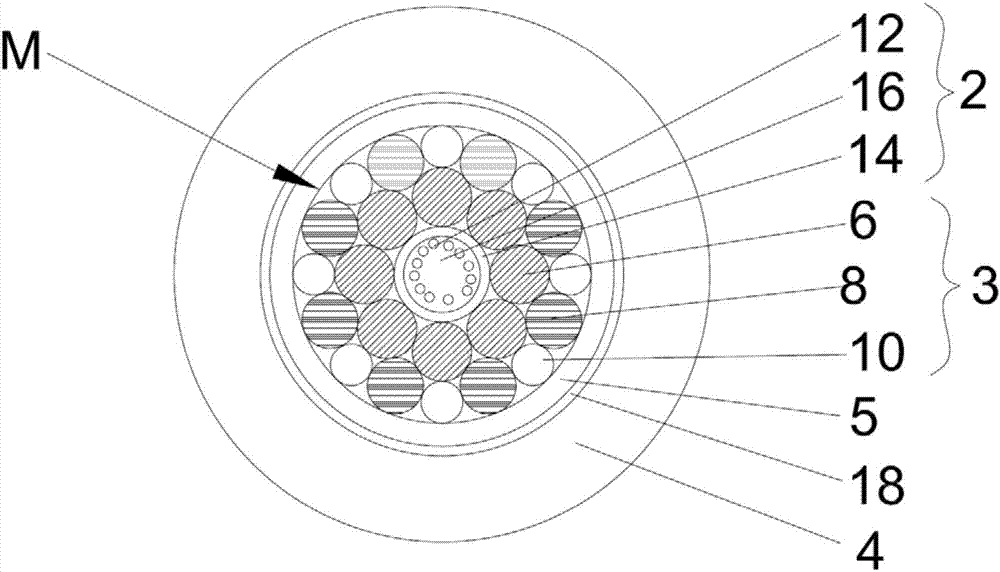

Feeding deep-sea optical cable

InactiveCN107219597AReduce gapImprove vertical water resistanceFibre mechanical structuresMechanical stretchingElectricity

The invention provides a feeding deep-sea optical cable, which comprises an optical unit, an armored layer, a feeding layer and an insulating layer, and is characterized in that the armored layer comprises an inner stranded layer and an outer stranded layer, the inner stranded layer is provided with a plurality of first stranding metal wires, the outer stranded layer is provided with a plurality of second stranding metal wires and a plurality of third stranding metal wires, the second stranding metal wires and the third stranding metal wires are alternatively arranged in sequence, and the diameter of the third stranding metal wires is less than the diameter of the second stranding metal wires; the plurality of first stranding metal wires are stranded outside the optical unit, the second stranding metal wires and the third stranding metal wires are stranded on the first stranding metal wires at intervals, the third stranding metal wires are stranded on the second stranding metal wires, and stranding directions are the same. The feeding deep-sea optical cable improves the impact resistance, the flattening resistance and the mechanical stretching performance of submarine cables, improves the longitudinal water blocking performance and the radial water blocking performance of the submarine cables, reduces the manufacturing cost and maintenance cost of the submarine cables, reduces damages for an optical fiber in the manufacturing process and improves the insulating performance of the submarine cables.

Owner:JIANGSU HENGTONG MARINE CABLE SYST CO LTD

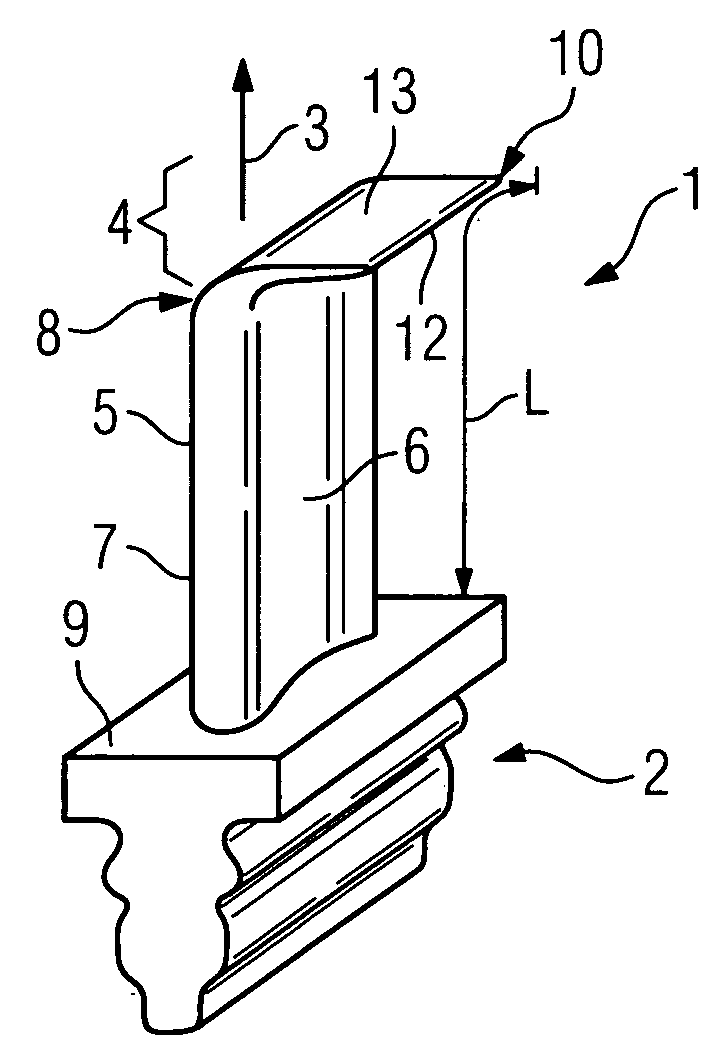

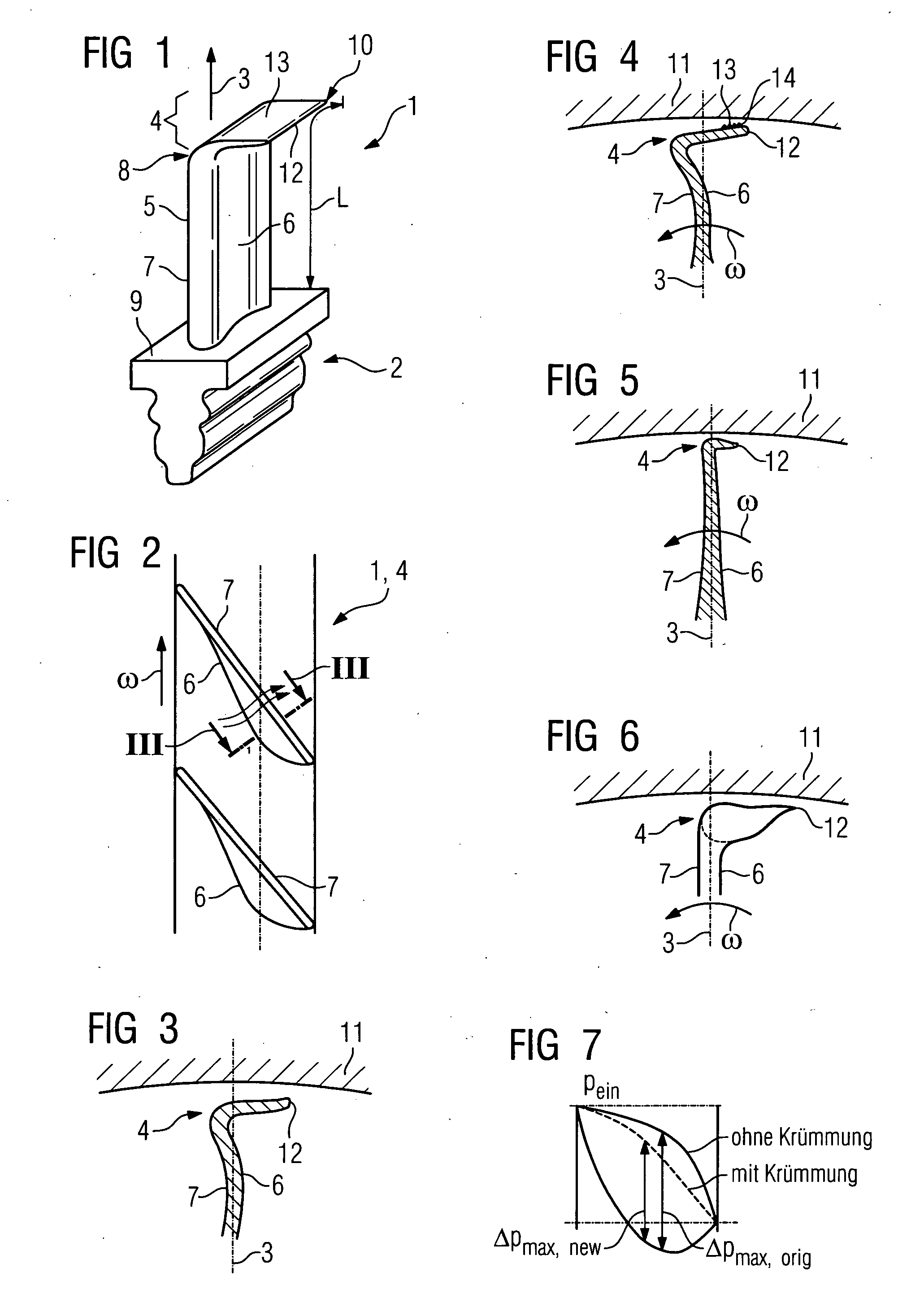

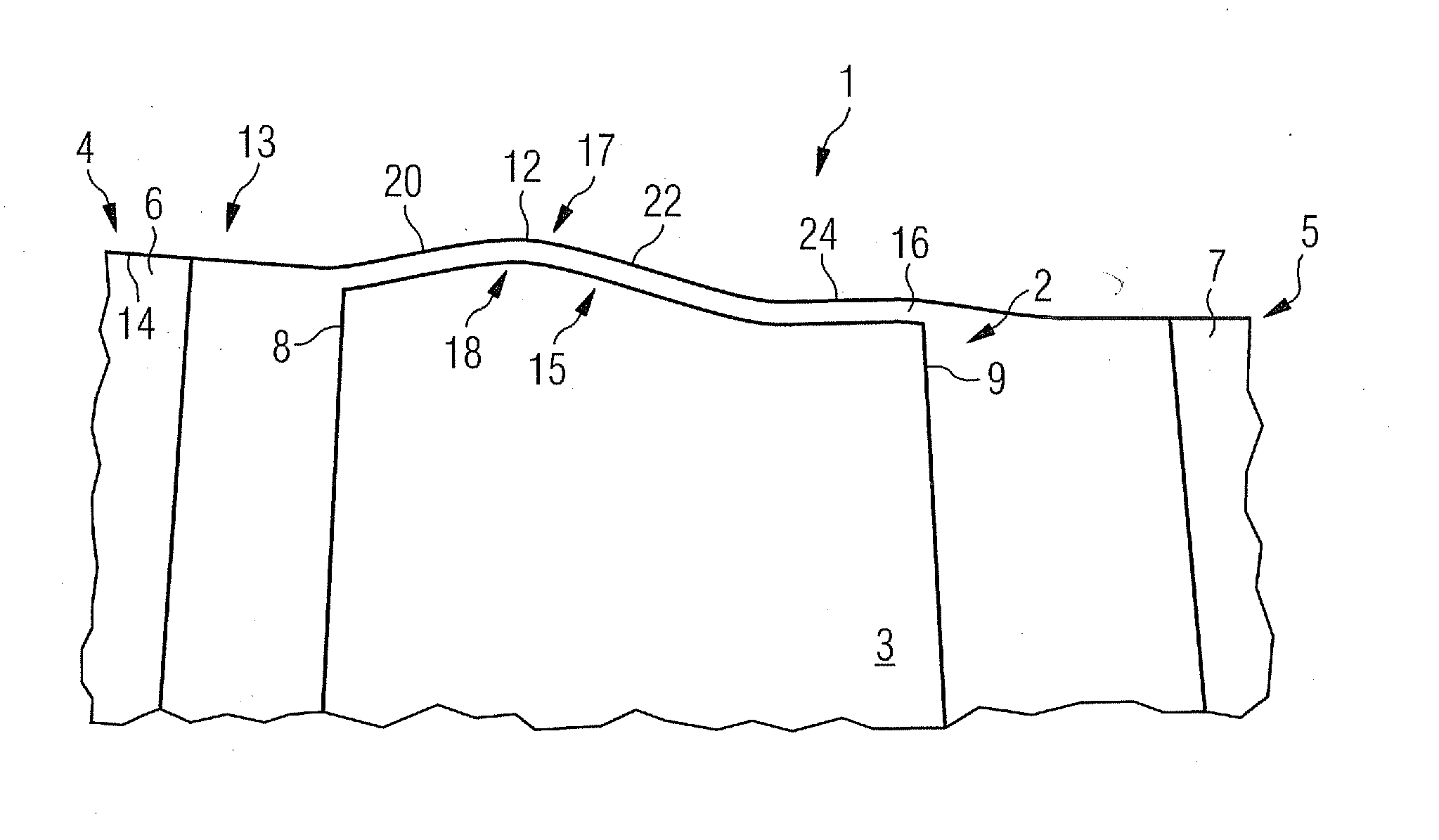

Axial turbo engine with low gap losses

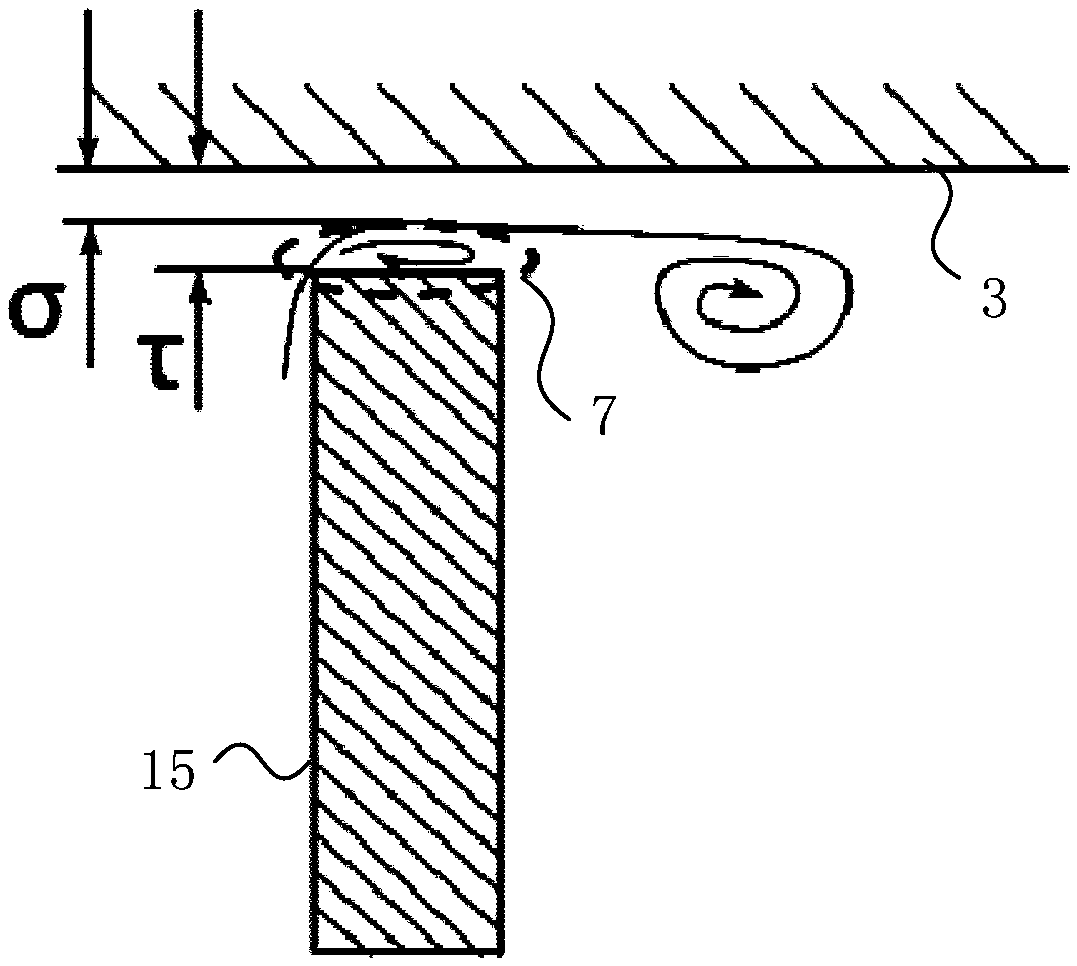

InactiveUS20110189020A1Reduce radial clearanceReduce leakage flowPropellersEngine manufactureEngineeringFront edge

An axial turbomachine including a rotor blade cascade is provided. The rotor blade cascade includes rotor blades each including front edge, a radially outer free blade tip and an annular enclosure enclosing the rotor blade cascade with an annulus inner side by means of which the annular enclosure is arranged directly adjacent to the blade tips to give a radial gap between the enveloping ends of the blade tips and the annulus inner side. The rotor blades include a radial projection in the region of the front edge on the blade tip and the annular enclosure has an annular radial recess in the annulus inner side, arranged at a radial distance from the ends of the blade tips, such that in the main flow direction of the axial turbomachine the line of the radial projections on the side facing the radial gap matches the line of the radial recess.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

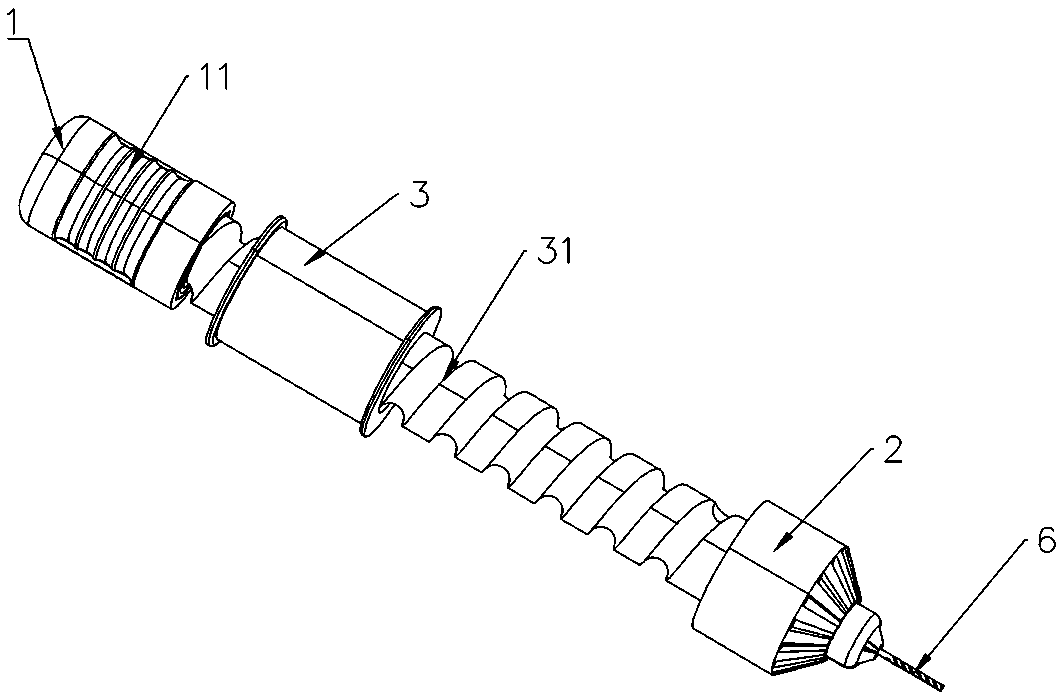

High-precision hand drill

PendingCN107598230AHigh structural transmission efficiencyImprove transmission efficiencyWood turning toolsWood boring toolsEngineeringDrill

A high-precision hand drill comprises a handle, a chuck and a drive pair. The high-precision hand drill is characterized in that the drive pair comprises a lead screw and a holding sleeve; the inner side of the holding sleeve is provided with a thread corresponding to the lead screw and balls; the holding sleeve and the lead screw form a lead screw and nut pair through the thread and the balls; the chuck is fixedly connected to the front end of the lead screw; the handle is provided with a cylindrical hole; and the cylindrical hole is rotationally connected to the outer side of an unthreaded rod in a sleeving manner. The high-precision hand drill has the beneficial effects that the structure is simple, labor is saved, high efficiency is achieved, and drilling accuracy is high.

Owner:HUZHOU VOCATIONAL TECH COLLEGE

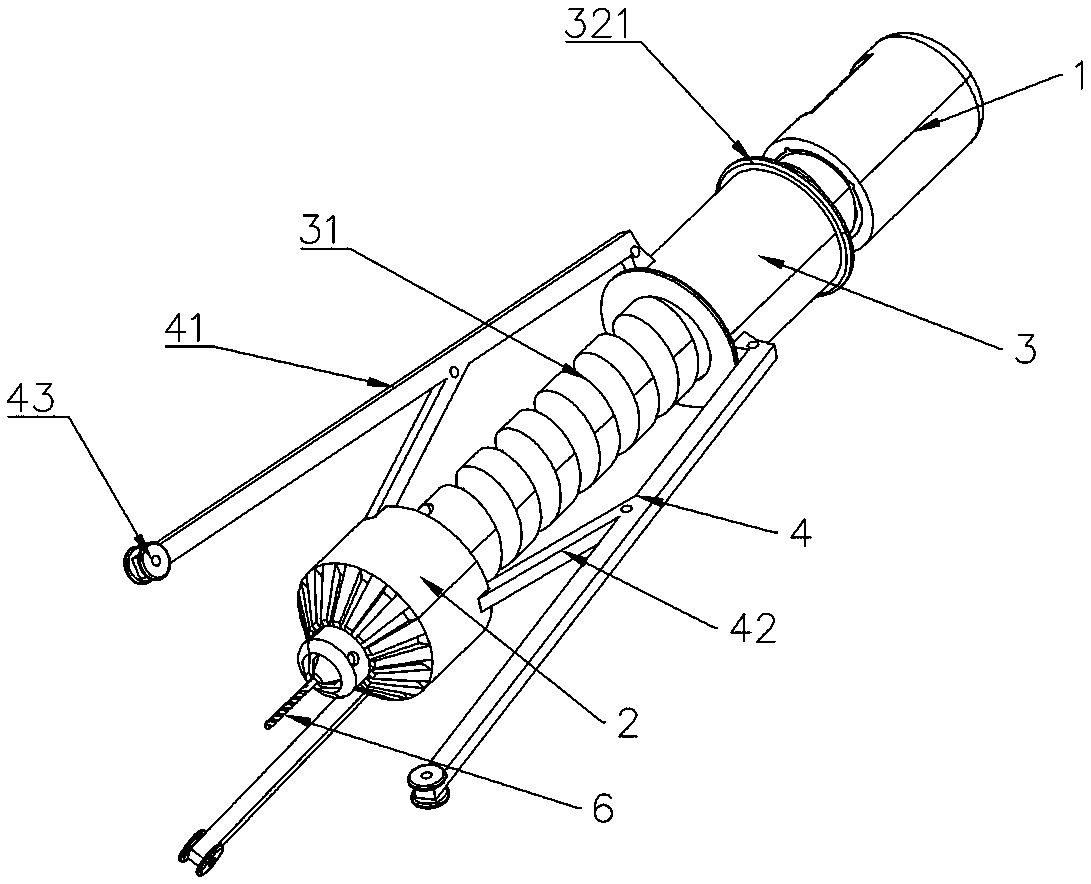

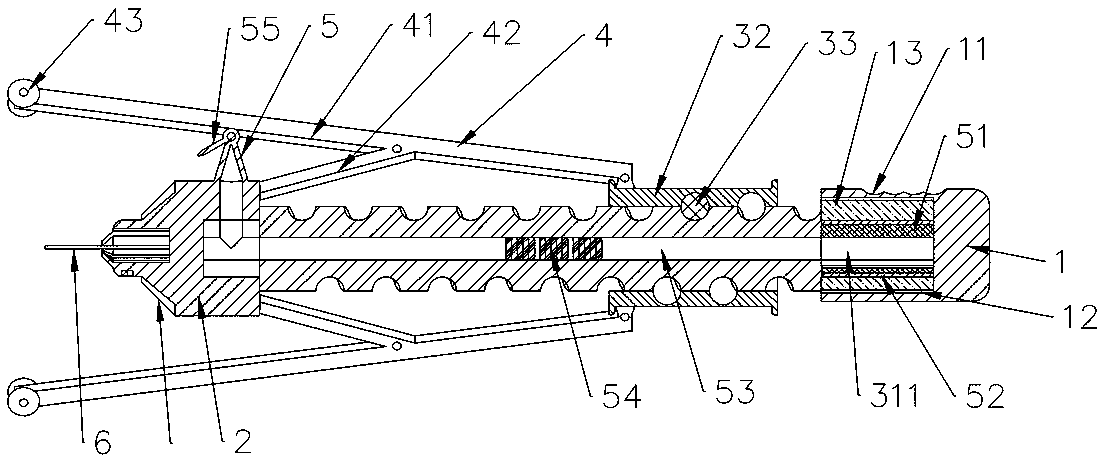

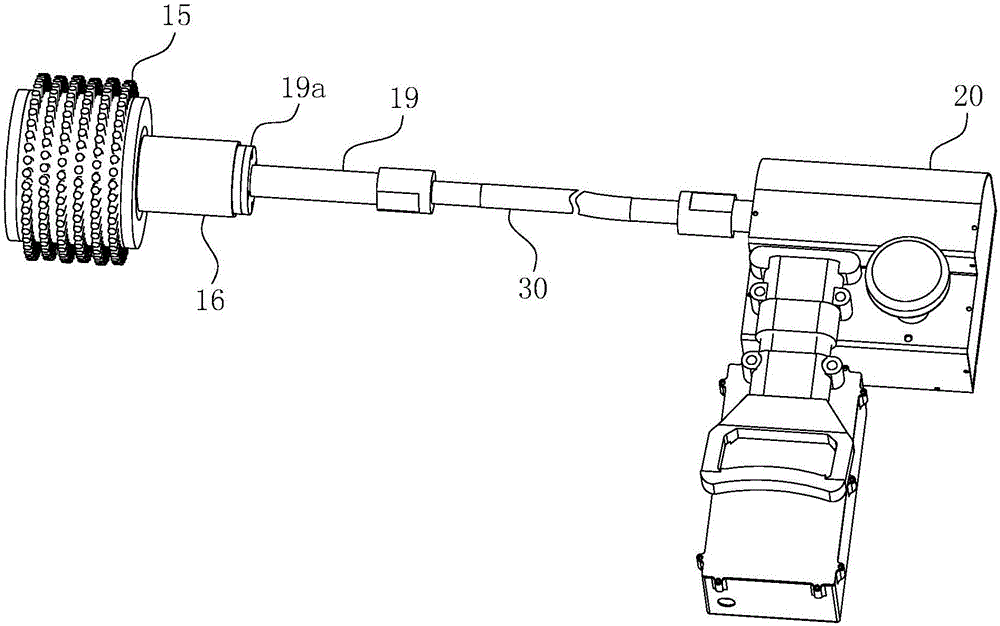

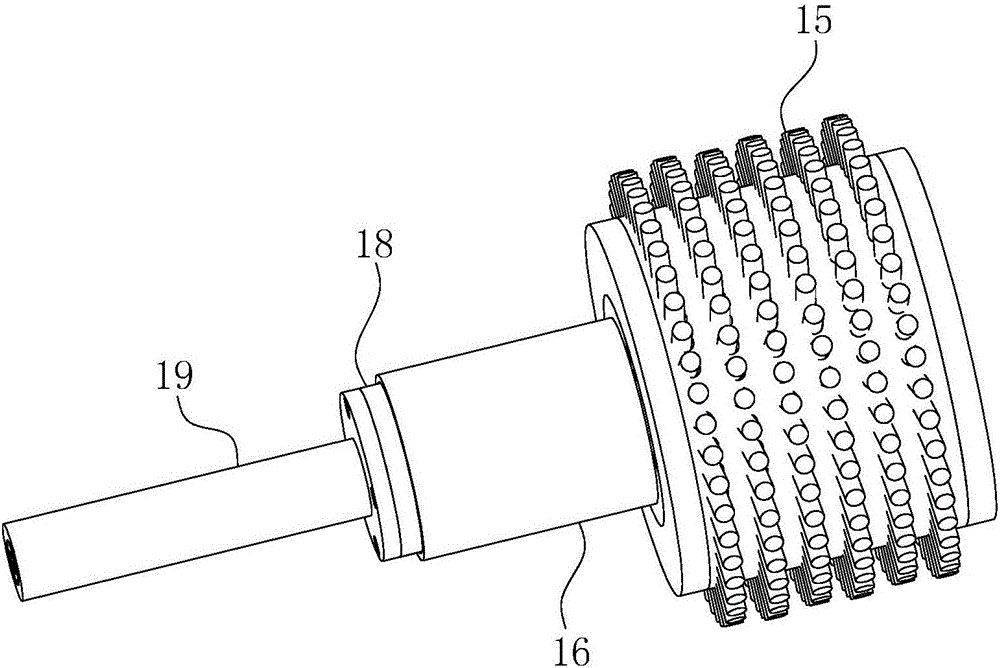

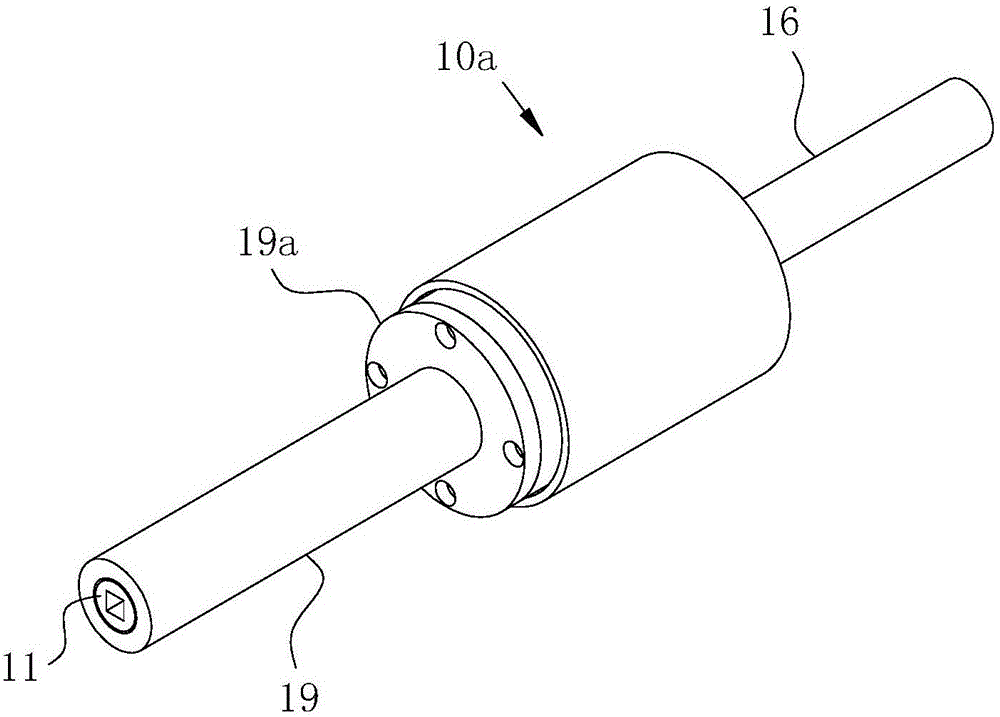

Portable pipeline inner wall electric cleaning device

InactiveCN106623291AGuaranteed AxialGuaranteed fixed effectHollow article cleaningPower controllerAxis of symmetry

The invention belongs to the field of pipeline cleaning equipment and particularly relates to a portable pipeline inner wall electric cleaning device. The portable pipeline inner wall electric cleaning device comprises a work assembly, a power controller and a flexible shaft. A special-shaped sheave is fixed to a power input shaft in a sleeving mode, the appearance of the special-shaped sheave is cylindrical, the cylinder surface of the special-shaped sheave is surrounded by a wavy groove part, the waving direction of the groove part is parallel to the axis direction of the special-shaped sheave, and the groove part is of an axial symmetry structure with the axis of the special-shaped sheave as the axis of symmetry. The special-shaped sheave is coaxially sleeved with a cleaning shaft sleeve, a ball containing hole or a ball containing groove is formed in the inner cylinder wall of the cleaning shaft sleeve in a recessed mode, and containing space for containing a ball and enabling the ball to roll is defined by the ball containing hole or the ball containing groove and the groove part jointly. The outer wall of the cleaning shaft sleeve is fixedly connected with a cleaning brush. The device is low in use cost and high in portability, and meanwhile conforms to the operating purposes of high efficiency, automation and the high cleaning effect required by existing pipeline cleaning.

Owner:中国人民解放军陆军军官学院

Axial flow compressor blade, axial flow compressor and gas turbine

InactiveCN111219362AReduce radial clearanceReduce leakage flowPump componentsPumpsEngineeringCompressor blade

The invention relates to an axial flow compressor blade, an axial flow compressor and a gas turbine. The axial flow air compressor blade comprises a pressure side wall, a blade tip, and a flow guide structure, wherein the flow guide structure is arranged in the area, where the blade tip is located, of the pressure side wall and extends in the chordwise direction of the axial flow compressor blade,and the flow guide structure is used for increasing separation bubbles formed by airflow passing through the flow guide structure on the outer side of the top end face of the blade tip so as to reduce leakage flow at the blade tip. According to the axial flow compressor blade, the axial flow compressor and the gas turbine, the flow guide structure is arranged in the area, where the blade tip is located, of the pressure side wall, so that the shape of the pressure side wall is changed, and a preset angle is formed between the pressure side wall of the axial flow compressor blade and the end face of the top of the blade tip; and gas flows to radial gaps after being guided by the flow guide structure, so that separation bubbles generated by leakage flowing of the gas on the outer side of thetop end face of the blade tip are increased, the effective radial gaps are reduced, the leakage flow is reduced, the leakage vortex strength is weakened, losses caused by gap leakage flowing are reduced, and the performance of the axial flow compressor is improved.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

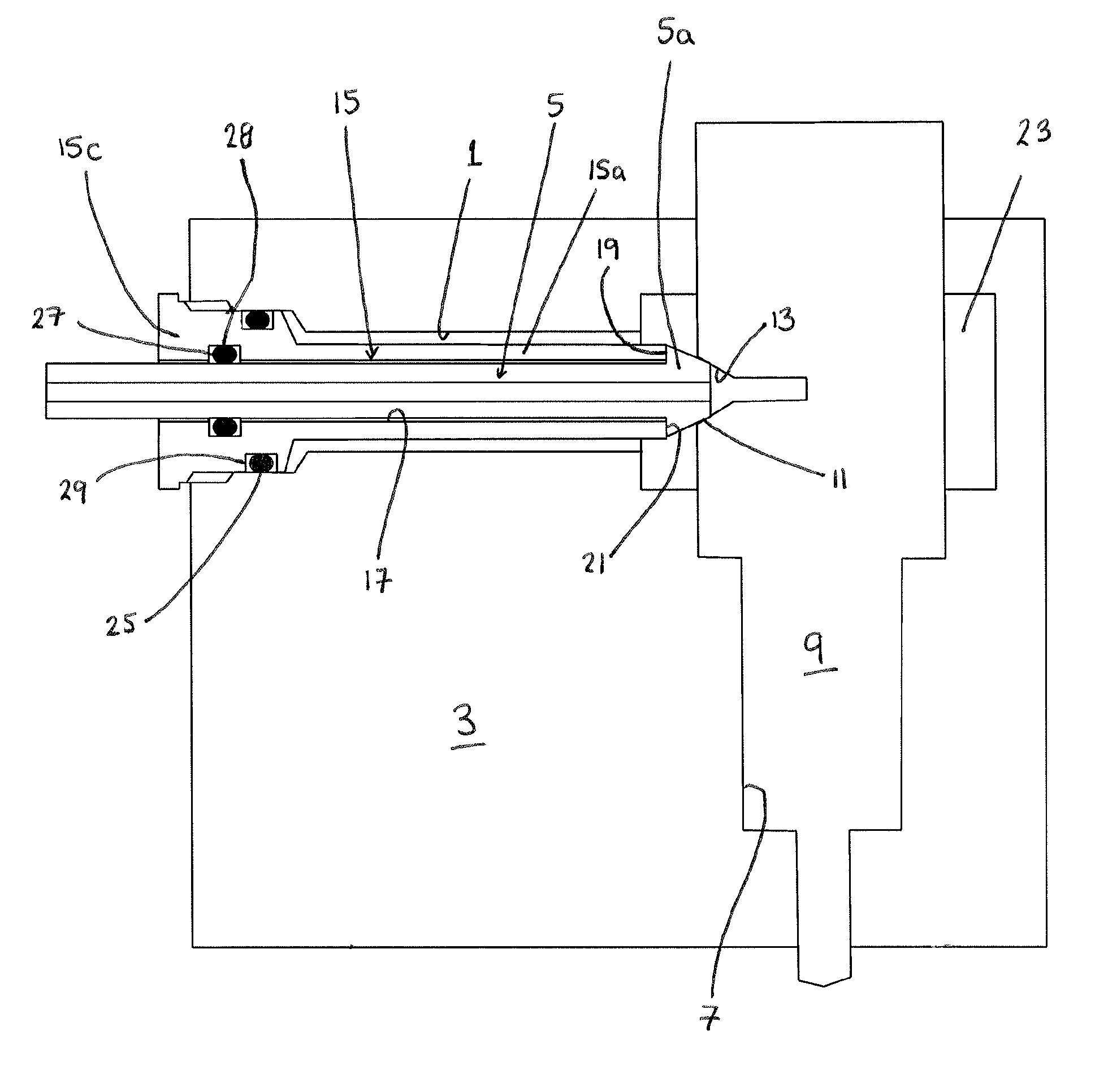

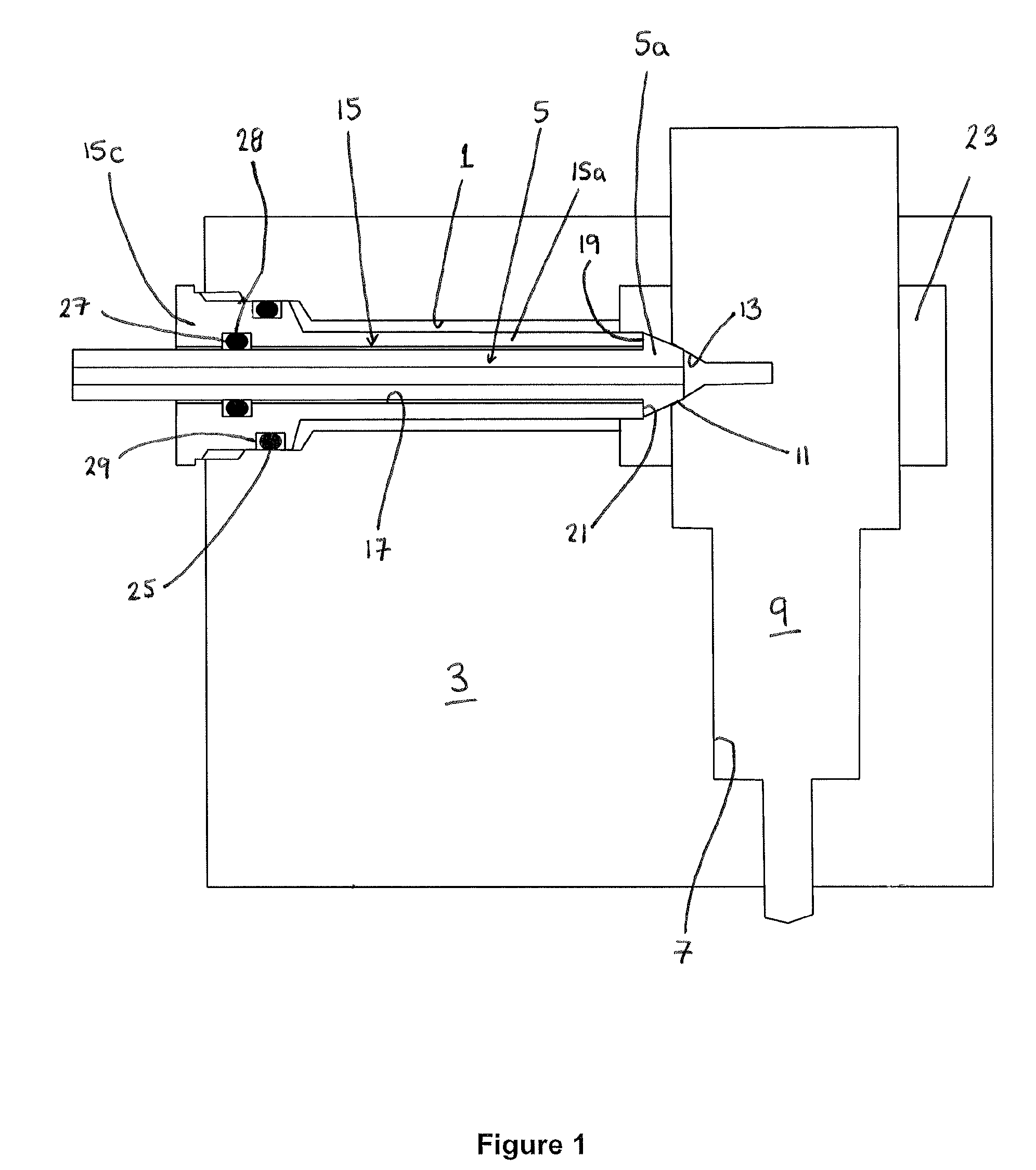

Method of positioning seals in turbomachinery utilizing electromagnetic bearings

InactiveCN101765719AReduce exposureExtend the lifespanLighting applicationsCombustion processMagnetic bearingEngineering

A method of positioning a shaft and an associated seal in turbomachinery utilizing electromagnetic bearings. The method comprises the steps of applying electrical power to the windings of the electromagnetic bearings in which the shaft center is in a first position and wherein the shaft is in contact with the associated seal. By adjusting the power to the electromagnetic bearings, the seal can be manipulated with the shaft by movement of the shaft in a series of moves of decreasing amplitude to a position in which the seal is out of contact with the shaft when the shaft is rotated at its centered position during normal operation of the turbomachinery. The shaft is in its centered position during normal operation when the shaft axis is substantially coaxial with an axis of the electromagnetic bearings. The series of movements of decreasing amplitude may include oscillations of decreasing amplitude about one or more axes, or may include rotation in a spiral with a radius of decreasing amplitude to move the center of the shaft from an initial position to a final position. Movement of the shaft is accomplished by adjusting the electrical power to the windings of the electromagnetic bearings.

Owner:JOHNSON CONTROLS TECH CO

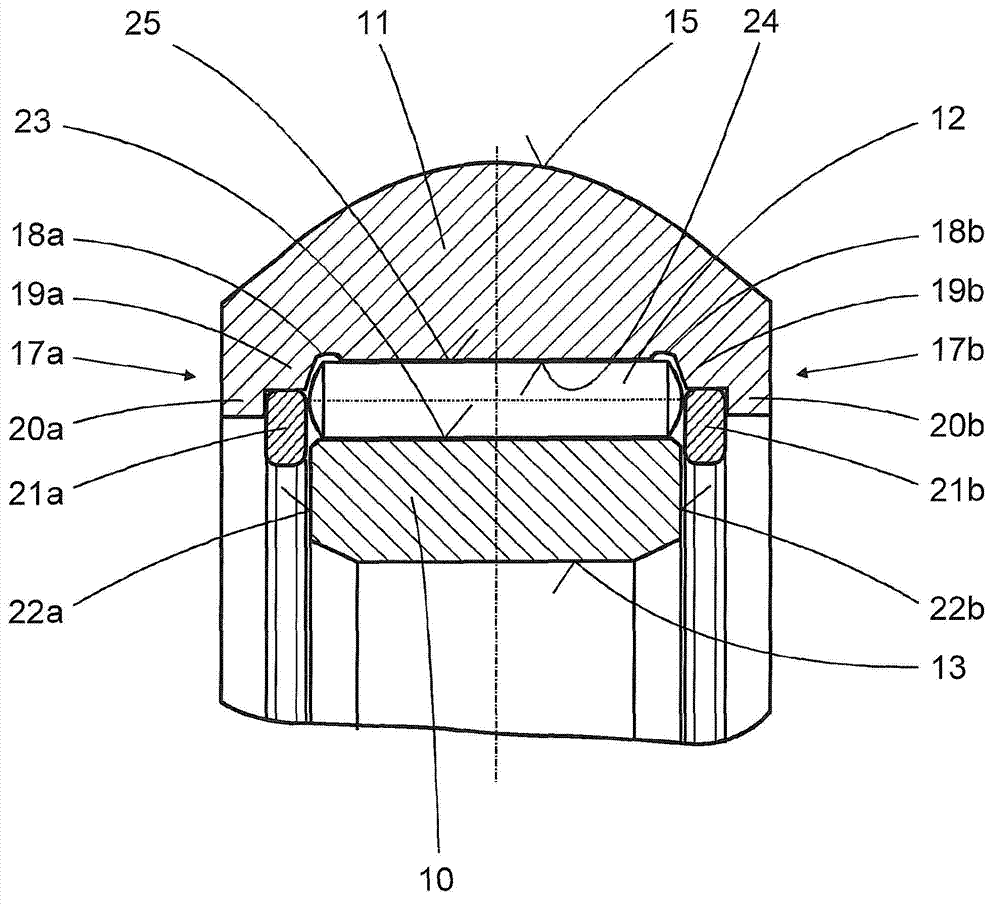

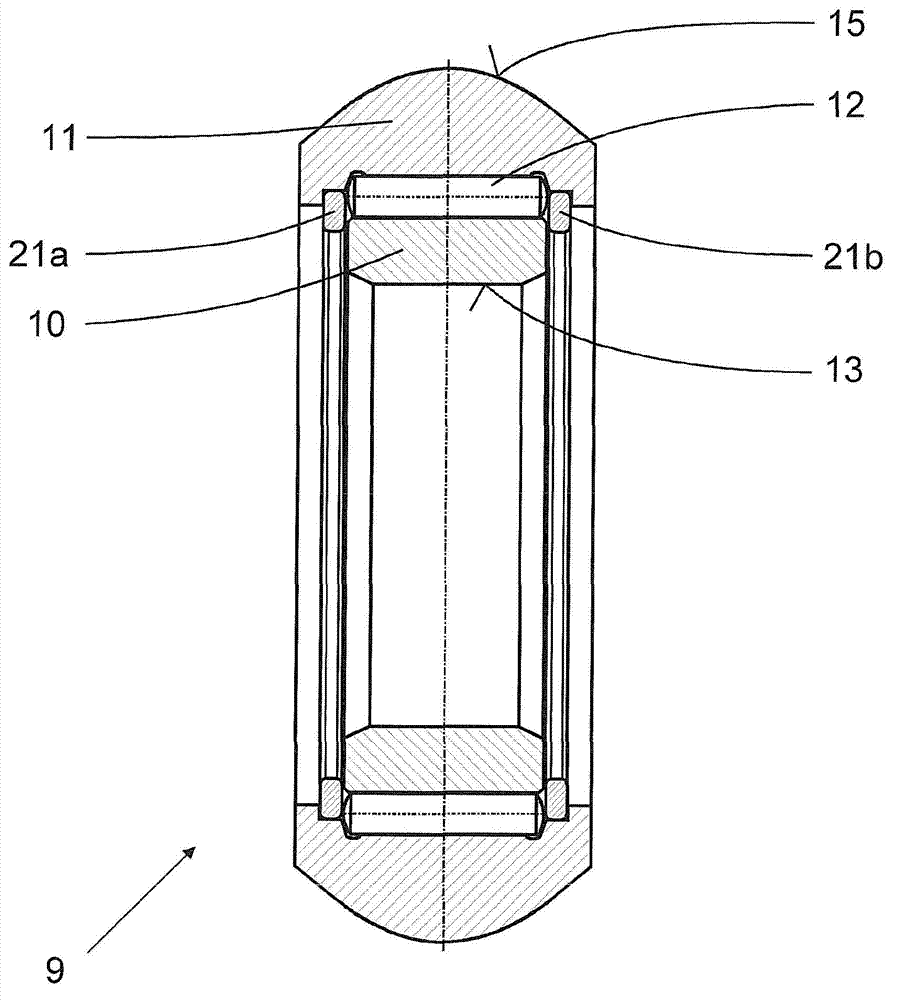

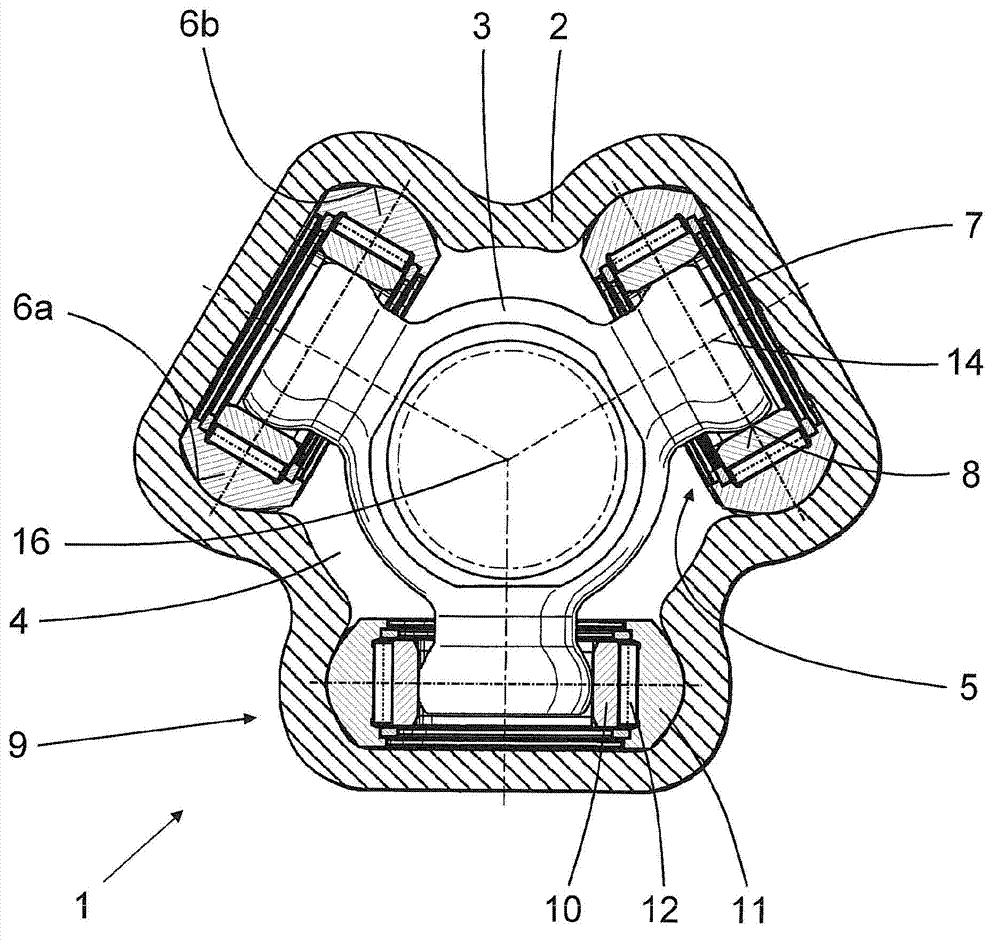

Tripod constant velocity joint

InactiveCN103026088AIncrease frictionImprove featuresYielding couplingBearing componentsEngineeringSliding contact

Owner:SCHAEFFLER TECH AG & CO KG

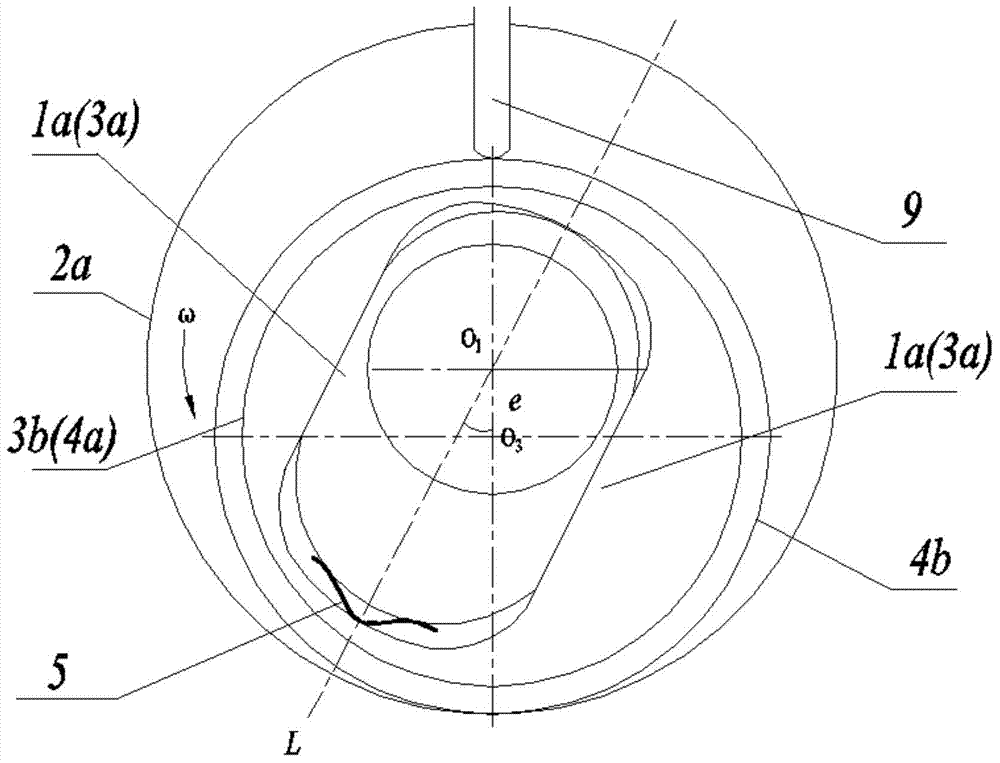

Slipper-type radial flexible compensation mechanism of rolling piston-like fluid machine

ActiveCN103591022AReduce leakageReduce radial clearanceRotary/oscillating piston pump componentsLiquid fuel engine componentsInertia forceHigh pressure chamber

Owner:XI AN JIAOTONG UNIV

Gas turbine engine lockout reduction

ActiveUS20130125552A1Reduce lockout periodShorten the timeLeakage preventionEfficient propulsion technologiesCombustorTurbine

A method is provided of reducing lockout time of a gas turbine engine which includes: an inlet, a compressor, a combustor, a turbine, and an exhaust duct, where the compressor and the turbine are carried on a turbomachinery rotor and each include an array of blades mounted for rotation inside a casing of the engine. The method includes: operating the engine at a first power output; shutting down operation of the engine without substantially reducing the power output beforehand, wherein thermomechanical changes occur in the engine subsequent to shutdown that tend to reduce a radial clearance between at least one of the blades and the casing; and subsequent to shutting down the engine, (1) heating the casing and / or (2) pumping an airflow of ambient air into the inlet and through the casing, past the rotor, and out the exhaust duct, so as to reverse at least partially the thermomechanical changes.

Owner:GENERAL ELECTRIC CO

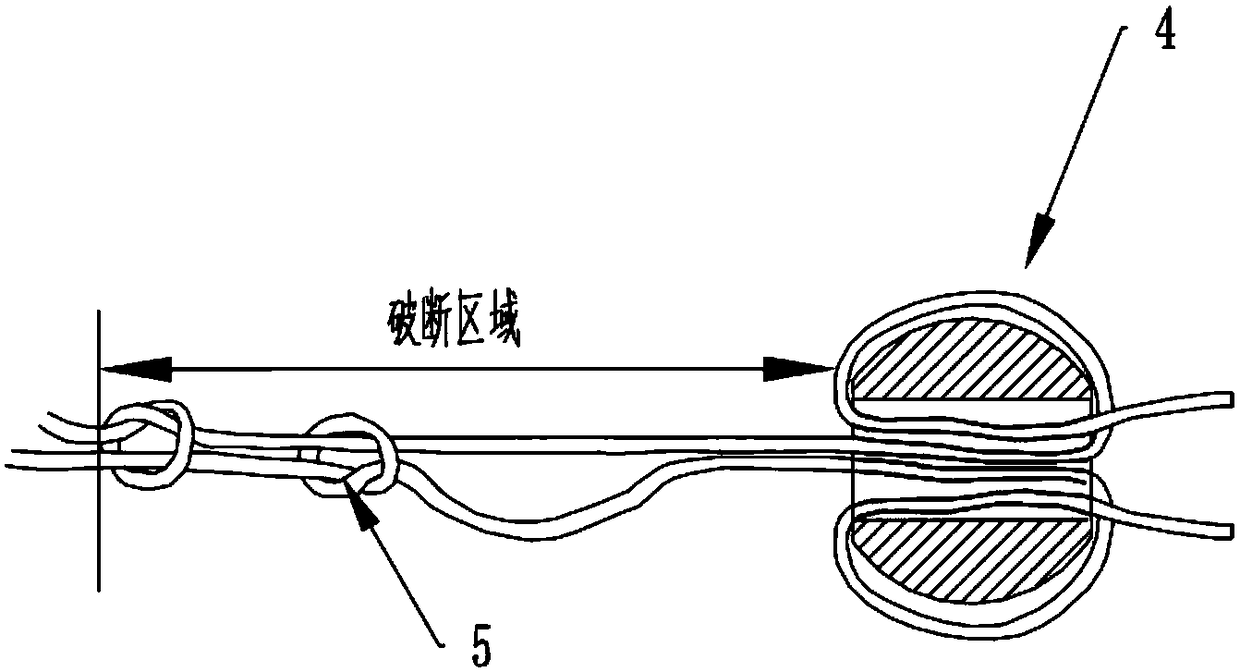

Sealing assembly with comb-tooth-shaped limiting device for core-taking soft bag

ActiveCN108661581AIncrease package lengthReduce radial clearanceCore removalEngineeringMechanical engineering

The invention provides a sealing assembly with a comb-tooth-shaped limiting device for a core-taking soft bag. The sealing assembly comprises a core-taking mechanism, a buckling mechanism and the comb-tooth-shaped limiting device. The core-taking mechanism comprises a lifting rope, the soft bag, a core-taking pipe and an outer protective pipe. The inner wall of the part, matched with the tail endof the core-taking pipe, of the comb-tooth-shaped limiting device is provided with a core-taking pipe centering ring face, and a plurality of protrusions are evenly distributed at the upper end of thecore-taking pipe centering ring face in the circumferential direction. A gap is formed between every two adjacent protrusions, and a strip-shaped line containing groove is connected with the lower portion of each gap. Annular ball containing grooves are formed in the positions, corresponding to the radial outer sides of the protrusions, of the inner wall of the comb-tooth-shaped limiting device,the protrusions correspond to the annular ball containing grooves in position, and the buckling mechanism comprises seal openings, fisherman knots and limiting balls. The sealing effect of while-drilling sealing and multi-time sealing in the drilling process is achieved, the sampling sealing reliability is improved, and by decreasing the random eccentric magnitude of the core-taking pipe, reducingcore lifting force in the drilling process and the sealing process and reducing fluctuation of the core lifting force, smooth implementation of lunar exploration sampling engineering is guaranteed.

Owner:HARBIN INST OF TECH

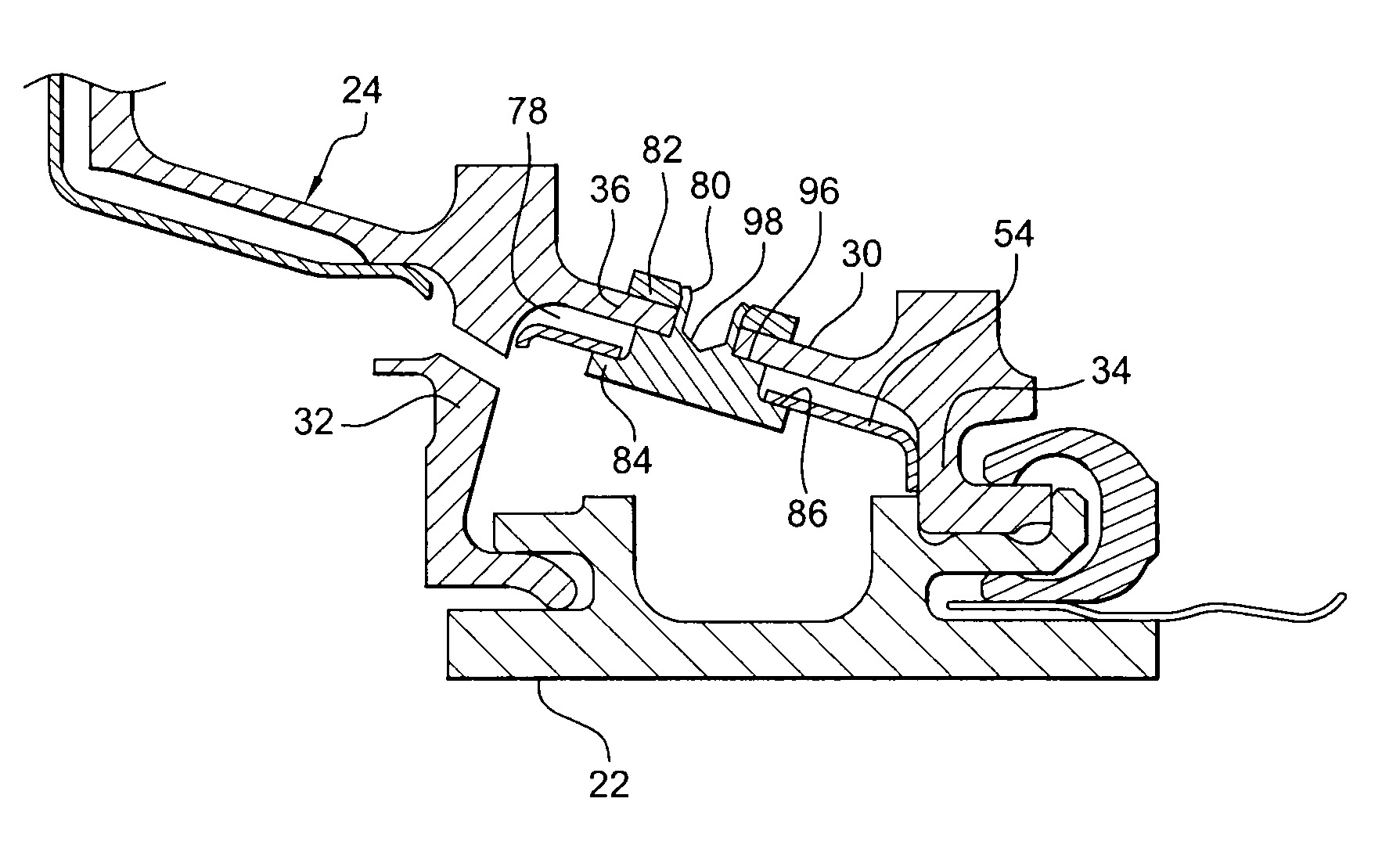

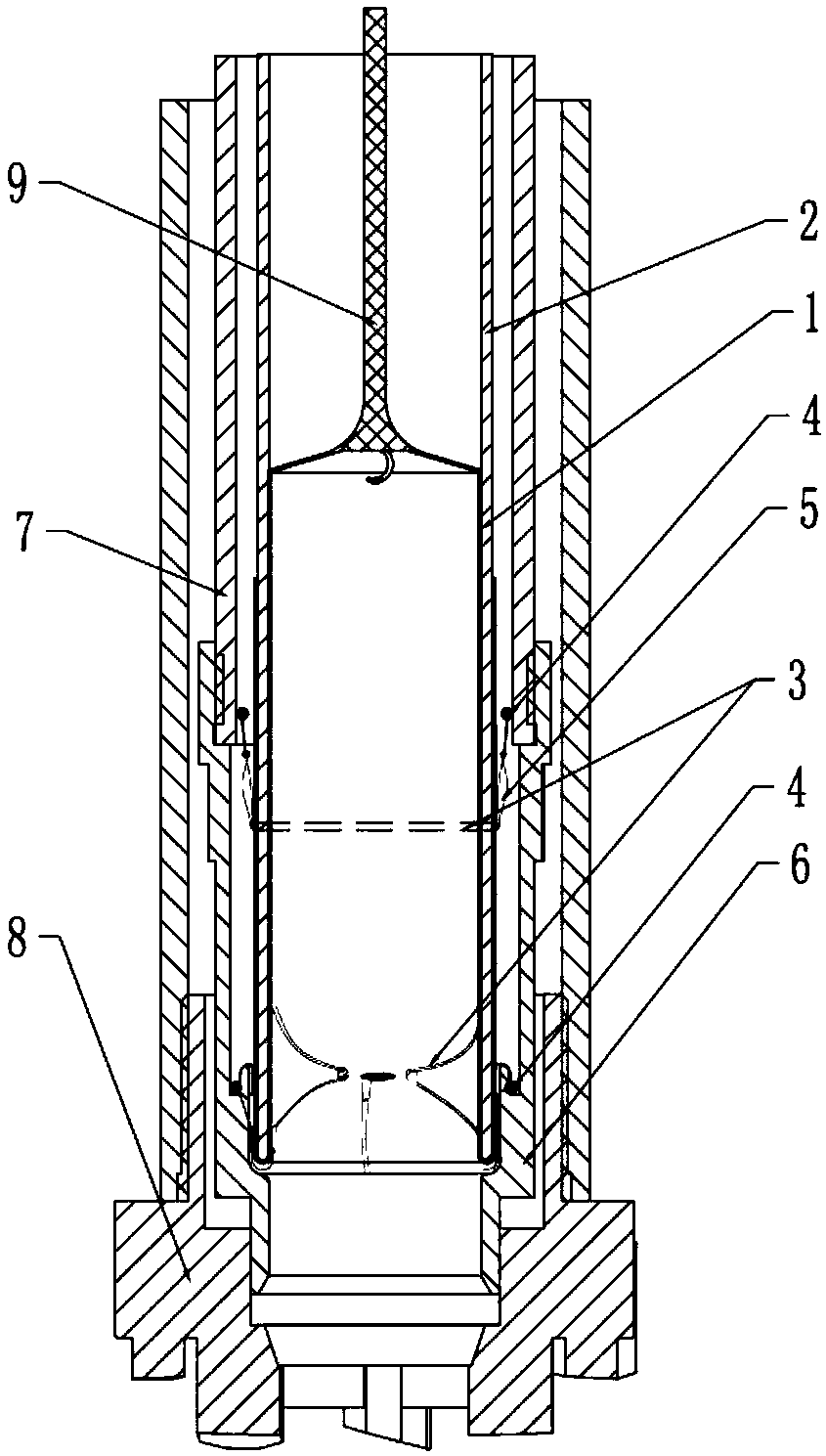

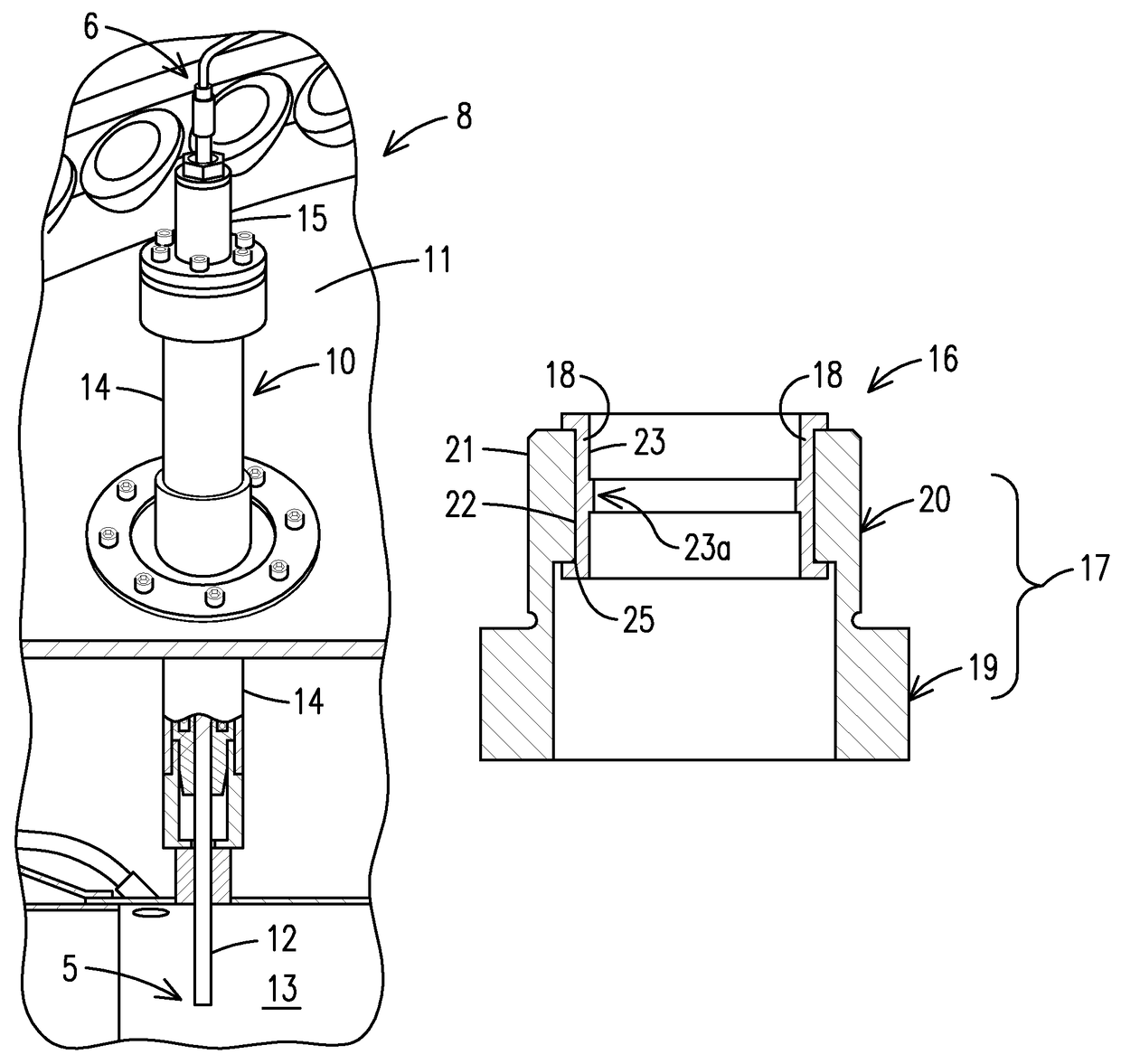

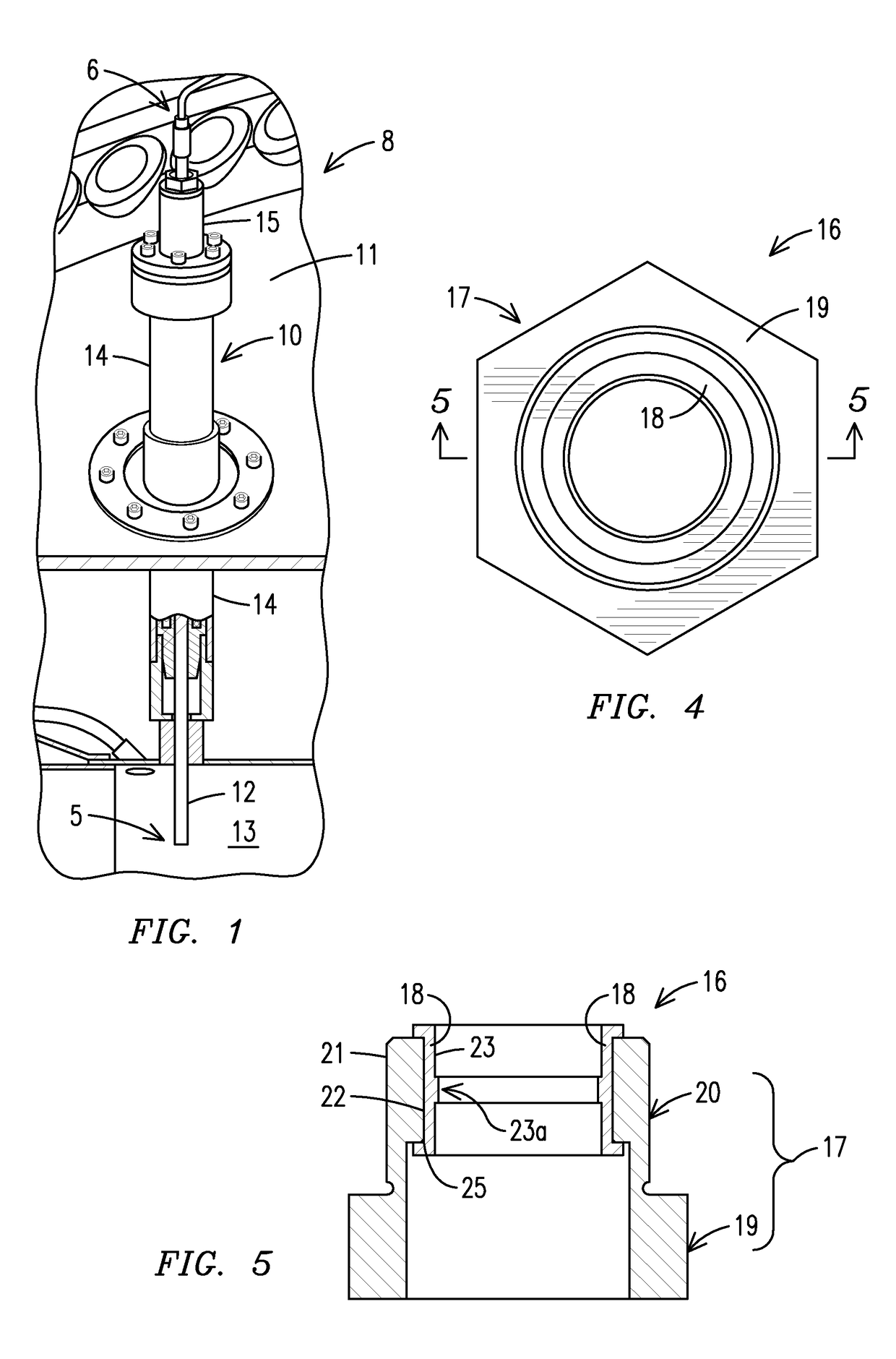

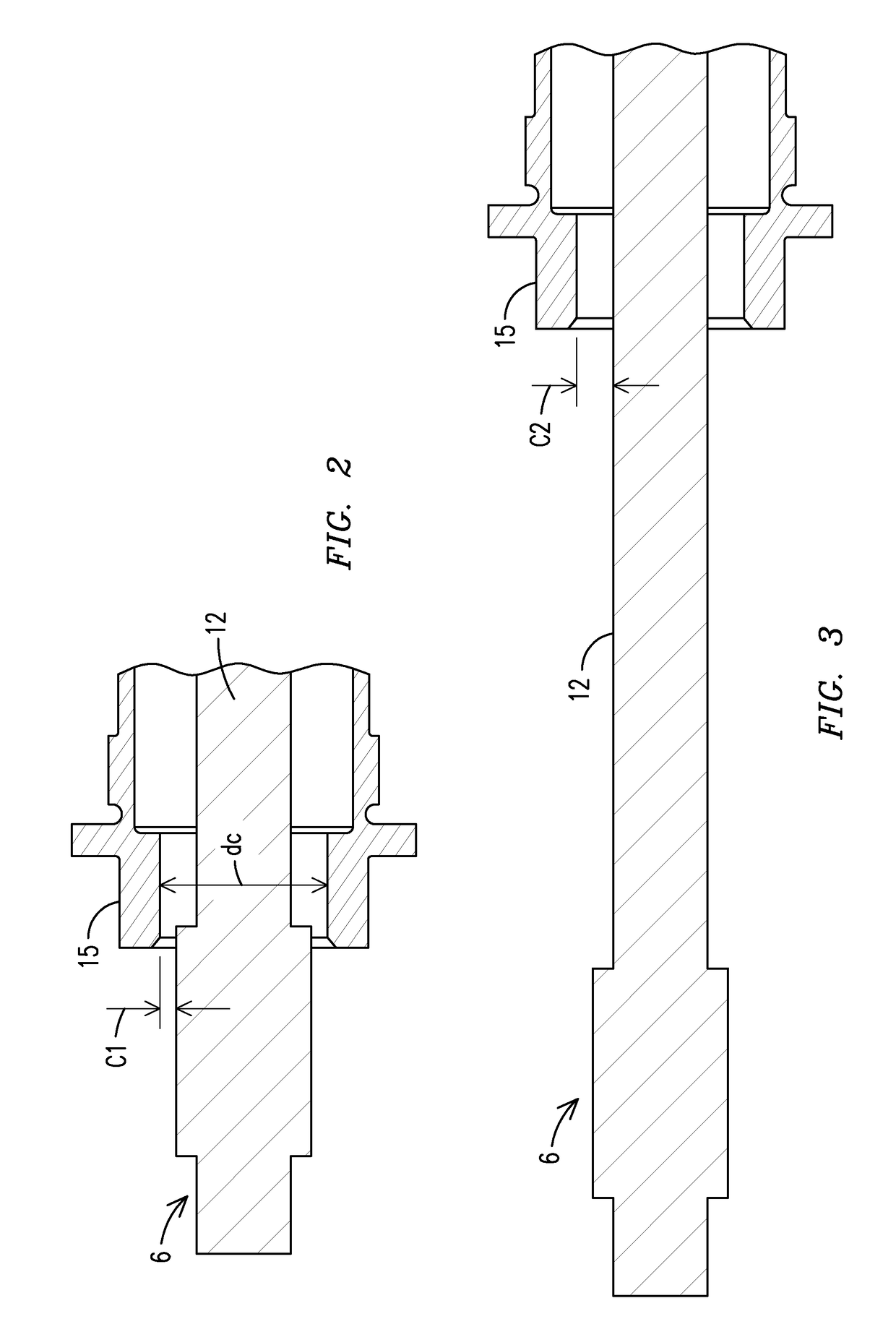

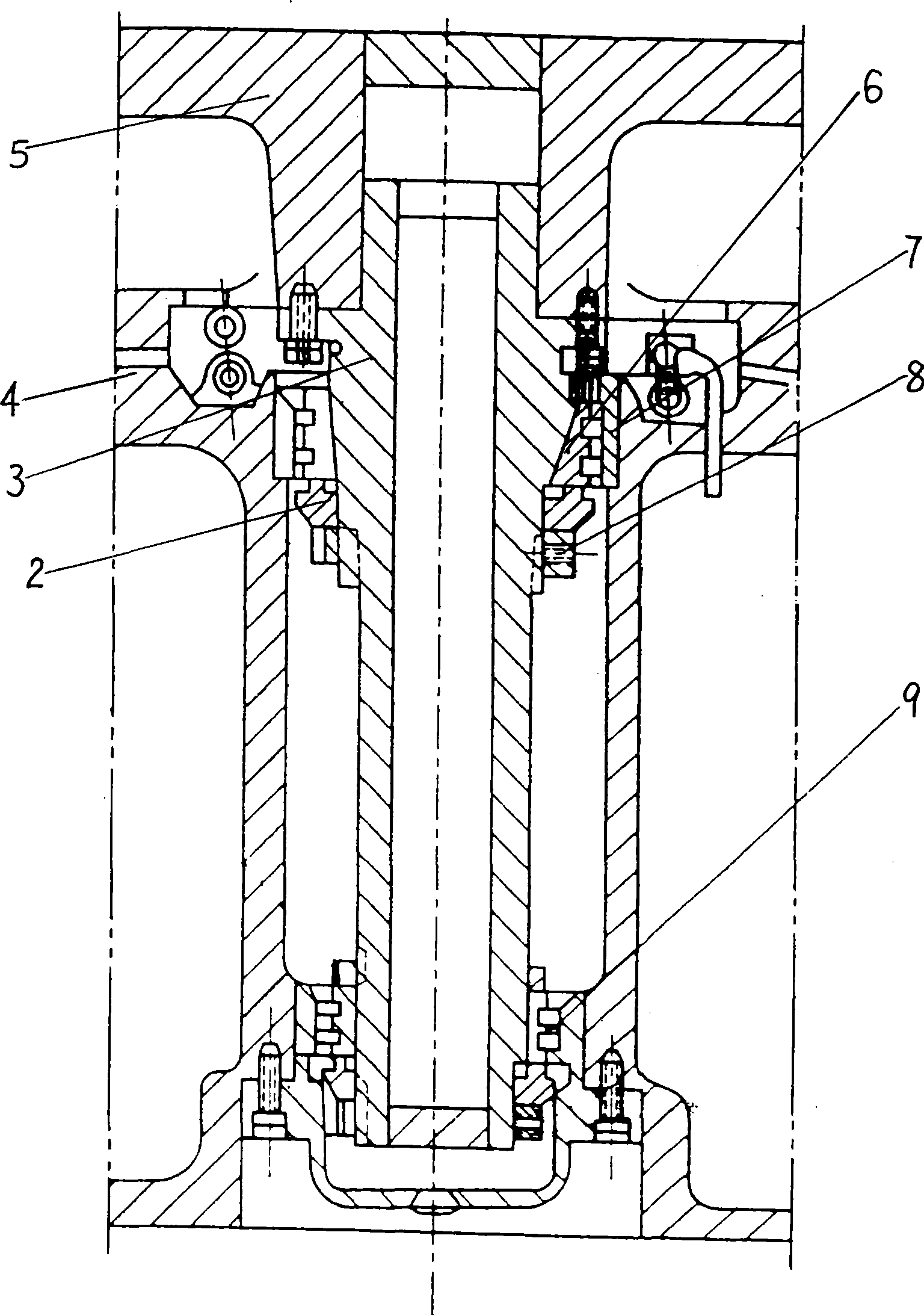

Igniter for a gas turbine

InactiveUS9739204B2Reduced moment loadReduce radial clearanceEngine fuctionsGas turbine plantsEngineeringGuide tube

A gas turbine igniter includes an igniter rod disposed within a guide tube configured for travel between a hot-end region and a cold-end region and a cap connected to the guide tube, the cap defining an access passageway for the igniter rod. An attachment structure is provided for reducing the moment loading at the cold end of the igniter rod. The attachment structure has threaded outer surface configured to engage in a threaded connection with a threaded inner surface of the cap in an end portion of the cap that is proximate to the cold-end region, whereby the attachment structure is attachable to the end portion of the cap via the threaded connection. An inner surface of the attachment structure forms a guide surface for the igniter rod, at a reduced radial clearance with the igniter rod in comparison to the cap, proximate to the cold-end region.

Owner:SIEMENS ENERGY INC

Angular contact ball bearing and design method thereof

ActiveCN106640947AReduce depthReduce radial clearanceBall bearingsBearing componentsEngineeringDesign methods

The invention provides an angular contact ball bearing and a design method thereof. The angular contact ball bearing comprises an inner bearing ring, an outer bearing ring, a steel ball installed between the inner bearing ring and the outer bearing ring, wherein the bearing rings are respectively provided with a roller path which is matched with the steel ball in a rolling way; the shape of each roller path on a cross section passing through the axis of the corresponding bearing ring is a multi-section camber line formed by connecting at least two sections of camber lines, wherein one section of camber line corresponds to a working area of the roller path and is a working area roller path camber line, the curvature radius R of the camber line is equal to f*Dw, f is a roller path curvature coefficient, and Dw is the diameter of the steel ball; the other section of camber line is connected with one end of the working area roller path camber line and is positioned at one side of the radial direction of the steel ball, and the radius of the camber line is equal to that of the steel ball. The angular contact ball bearing provided by the invention greatly reduces radial clearance and axial clearance, reduces channel depth, increases the wall thicknesses of the inner ring and the outer ring of the bearing, avoids the radial displacement of the inner bearing ring and the outer bearing ring, and is stable in rotation.

Owner:LUOYANG BEARING RES INST CO LTD

Gas turbine

InactiveUS20110280721A1Improve efficiencyReduce traffic lossPump componentsStatorsGas turbinesOperating life

A gas turbine including a plurality of hook elements disposed one inside the other and designed substantially in the form of hollow cones or hollow cylinders, and including a stator blade support, is intended to enable an especially high efficiency while maintaining the greatest possible operating safety and operating life. To this end, at least one of the hook elements or the stator blade support has a substantially elliptical cross-sectional contour.

Owner:SIEMENS AG

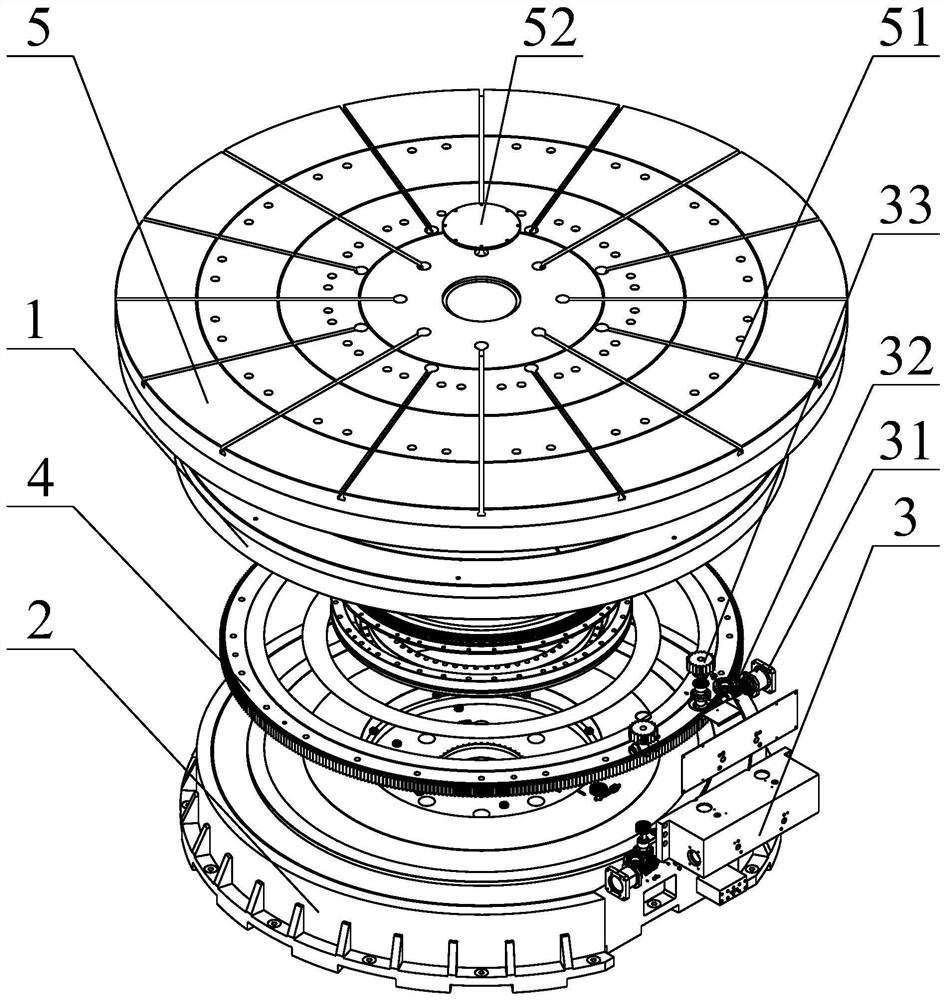

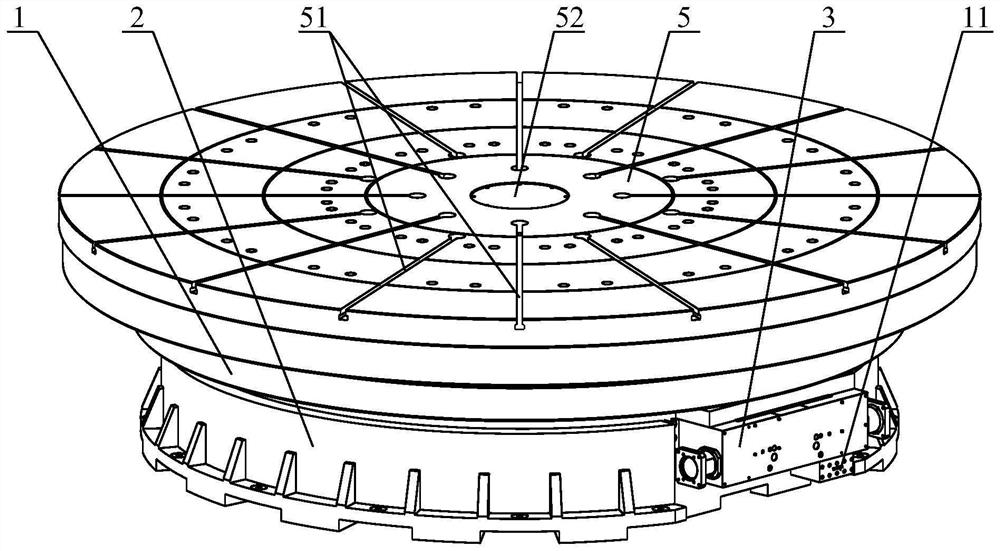

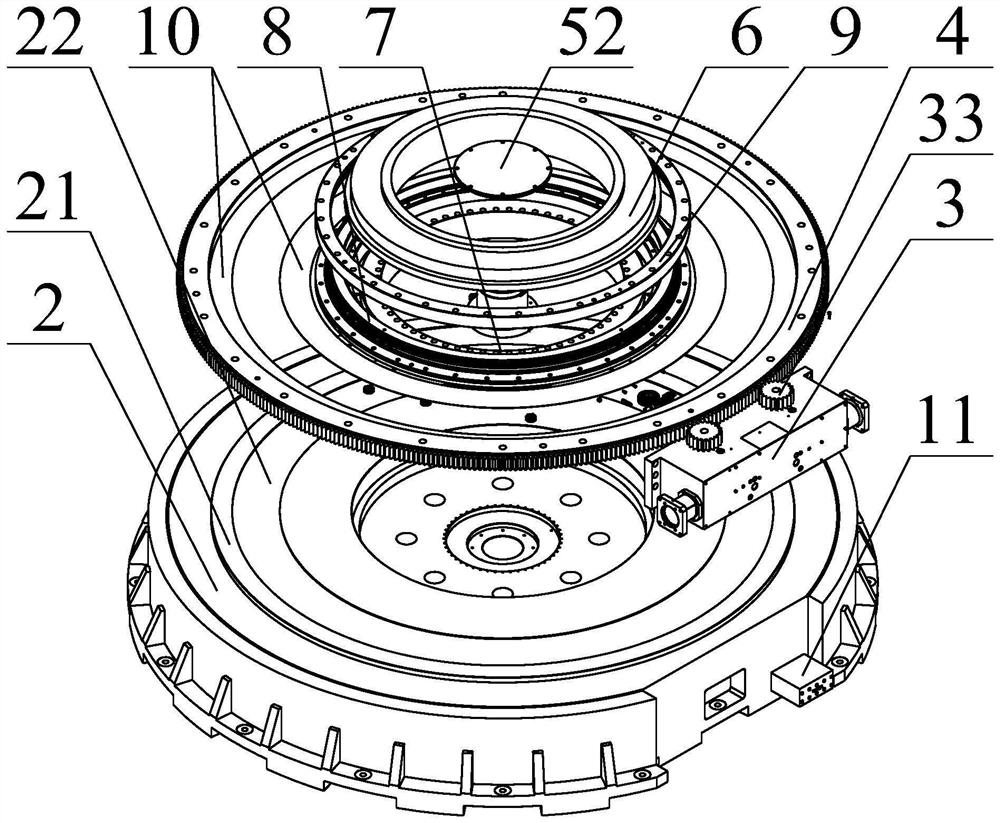

Numerical control rotary table

PendingCN114406730AReduce deformationImprove running stabilityLarge fixed membersDriving apparatusNumerical controlBrake

The invention relates to a numerical control rotating table which comprises a table top, a base and a driving mechanism fixedly installed on the base, a circular assembling groove is formed in the top of the base, an annular guide rail is arranged on the inner side edge of the assembling groove, a driving gear ring is fixedly installed at the bottom of the table top, and the driving gear ring is connected with the base in a matched mode through a thrust roller bearing; a disc shaft is fixedly connected to the bottom of the center of the table top and connected with the base in a matched mode through a double-row cylindrical roller bearing. An air floatation groove is formed in the area, between the disc shaft and the driving gear ring, of the base and used for supporting the radial middle area of the table top through air floatation, and an air cavity matched with the air floatation groove is formed in the position, corresponding to the air floatation groove, of the bottom of the table top; the driving mechanism adopts a double-lead worm gear pair; the numerical control rotary table further comprises a brake mechanism. Through the special structural design, the bearing capacity of 35 tons or above can be achieved, the operation precision is extremely high, operation is very stable, and the service life is long.

Owner:江苏恒望机械科技有限公司

Circular-Shank Tool Comprising a Tool Holder

InactiveUS20090162159A1Attached with easeImprove convenienceTransportation and packagingSlitting machinesTransverse planeKnife holder

A circular-shank tool including a shank held in a bore of a tool holder by a locking sleeve, the shank being rotatably held in the locking sleeve. The locking sleeve has one or more retaining elements that project inwards and engage in a peripheral groove in the shank of the tool, thus indisplaceably securing the locking sleeve in an axial direction on the shank of the tool. Because the locking sleeve is mirror-symmetrical to the central transversal plane, the locking sleeve can be fixed to the shank in a position that is rotated through 180°.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

Smooth and steady workstation of vertical lathe

InactiveCN101480725AStable jobHigh rotation accuracyAuxillary equipmentLarge fixed membersReduction driveEngineering

The invention relates to a lathe, in particular to a vertical lathe worktable which comprises a worktable turntable and a base, wherein a mainshaft is sleeved in the base through a bearing, the upper end of the mainshaft is fixedly connected with the turntable, and the lower end of the mainshaft is connected with a speed reducer; the outer diameter at the joint part of the mainshaft and the base is provided with a taper, a bearing with an inner ring provided with a taper is assembled at the mainshaft with the taper, and an adjusting nut is sleeved on the mainshaft and is close to the small internal diameter end of the bearing. In the invention, the mainshaft of the worktable is directly started by a main motor and dynamically braked, bearings are arranged at the upper part and the lower part of the mainshaft, and a radial clearance of the bearing can be adjusted as the inner ring of the bearing is provided with the taper; the bearings of the mainshaft are adjusted aiming at reducing the radial clearance of the bearings; and as the bearings of the mainshaft is provided with the tapers radially, the inner rings of the bearings can produce the radial deformation when being axially adjusted so as to adjust the combined clearance among a bearing roller, the inner rings and outer rings of the bearings, thereby ensuring that the mainshaft stably works under high rotating speed and high precision, and having large bearing capacity.

Owner:大连国丰机床有限公司

Gas turbine

InactiveUS9074490B2Compensation for ovalityImprove matchPump componentsStatorsEngineeringGas turbines

A gas turbine including a plurality of hook elements disposed one inside the other and designed substantially in the form of hollow cones or hollow cylinders, and including a stator blade support, is intended to enable an especially high efficiency while maintaining the greatest possible operating safety and operating life. To this end, at least one of the hook elements or the stator blade support has a substantially elliptical cross-sectional contour.

Owner:SIEMENS AG

Magnet-containing brush-type sealing structure capable of adjusting radial clearance between brush wire beams and rotor surface

ActiveCN109555564AClearance adjustableReduce radial clearanceLeakage preventionMachines/enginesFusion weldingMagnet

The invention discloses a magnet-containing brush-type sealing structure capable of adjusting the radial clearance between brush wire beams and a rotor surface. The brush-type sealing structure comprises a stator, a brush-type sealing component and tile-shaped magnets, wherein the brush-type sealing component is arranged on the inner circumference of the stator in a matching manner, is capable ofmoving on the inner side of the stator in the radial direction of a rotor, and comprises an upper brush-type sealing component and a lower brush-type sealing component; both the upper brush-type sealing component and the lower brush-type sealing component comprise front baffle plates, fusion welding zones, rear baffle plates and the brush wire beams; bolts are correspondingly fixed at the middlesof the outer circumferences of the upper brush-type sealing component and the lower brush-type sealing component; after penetrating through the through holes, matched with the bolts, of the stator, the bolts are screwed by nuts; the tile-shaped magnets are arranged in pairs and mutually repelled; and each pair of the tile-shaped magnets comprises the tile-shaped magnet fixed on the outer circumference of the brush-type sealing component and that fixed on the inner circumference of the stator. The brush-type sealing structure has the beneficial effects that the radial clearance between the brush wire beams and the rotor surface can be adjusted by loosening or tightening the nuts; and through the uniformly-distributed tile-shaped magnets, the smooth rotation of the rotor can be guaranteed.

Owner:SHENYANG AEROSPACE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com