Patents

Literature

55results about How to "Avoid excessive gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

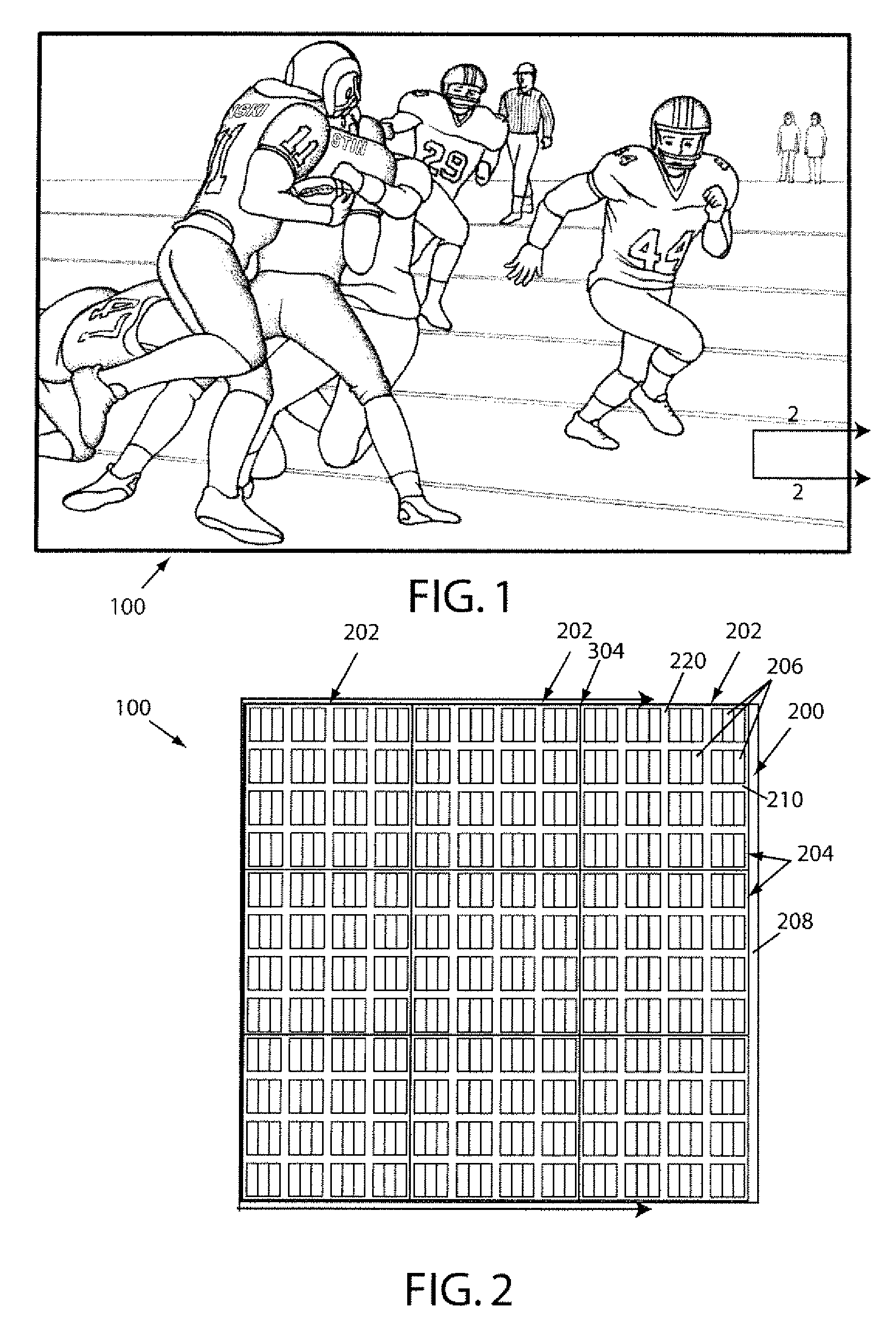

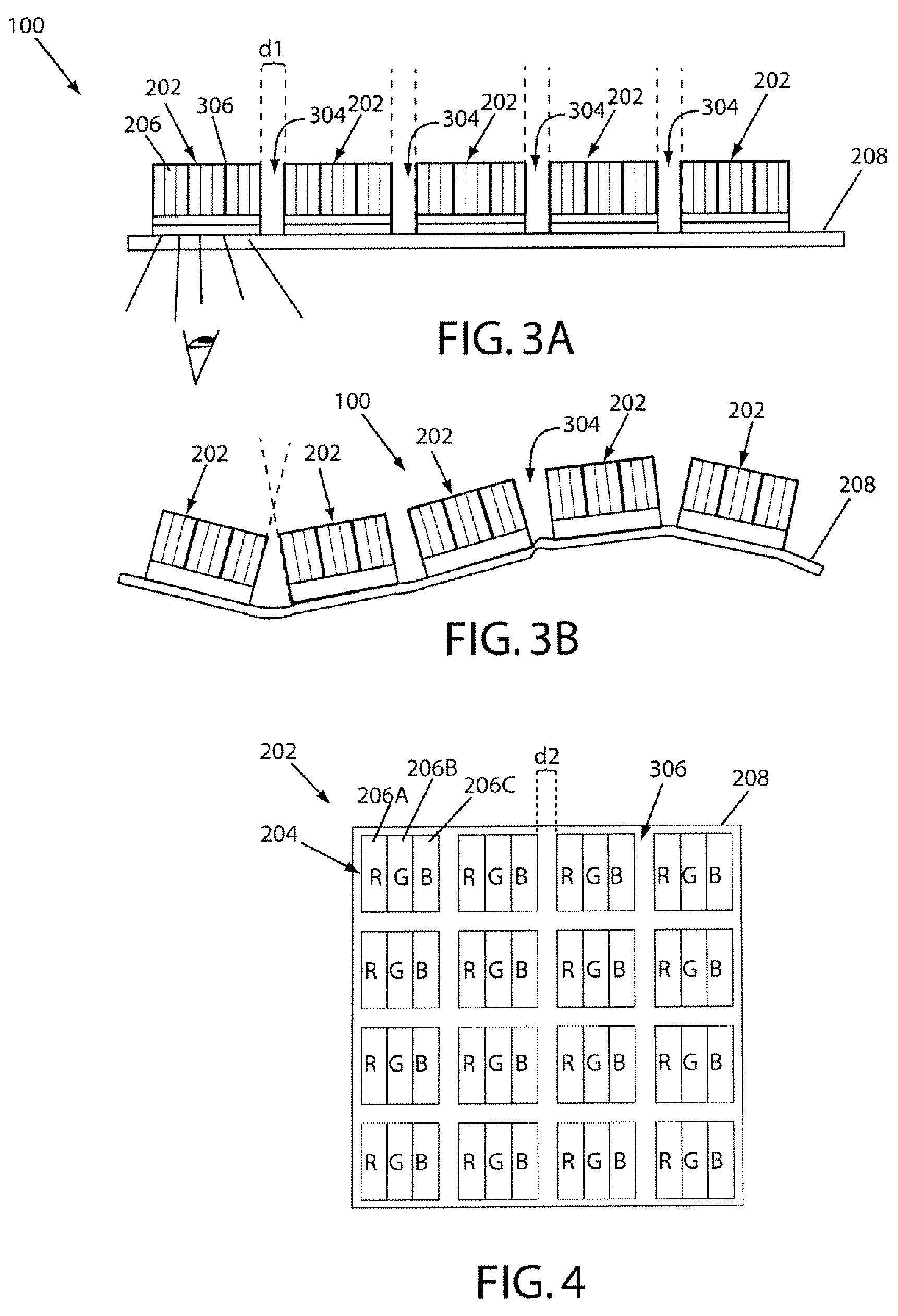

Flexible display

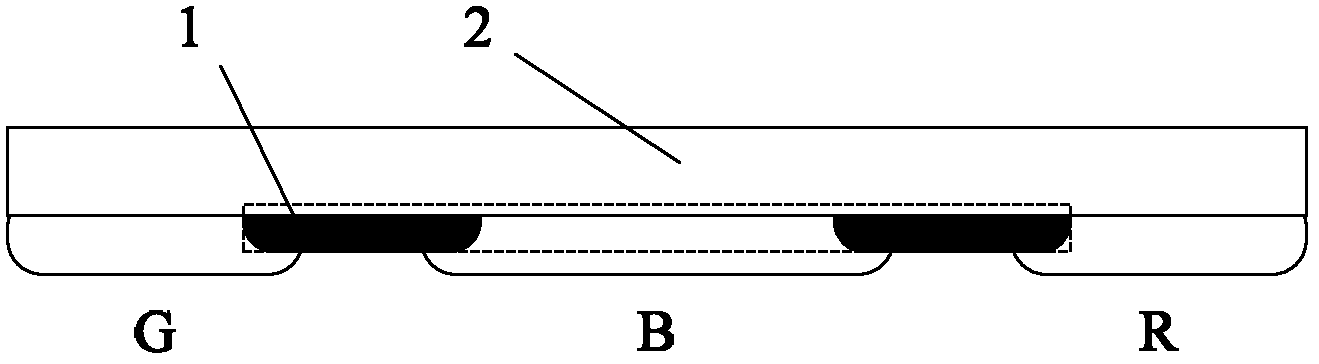

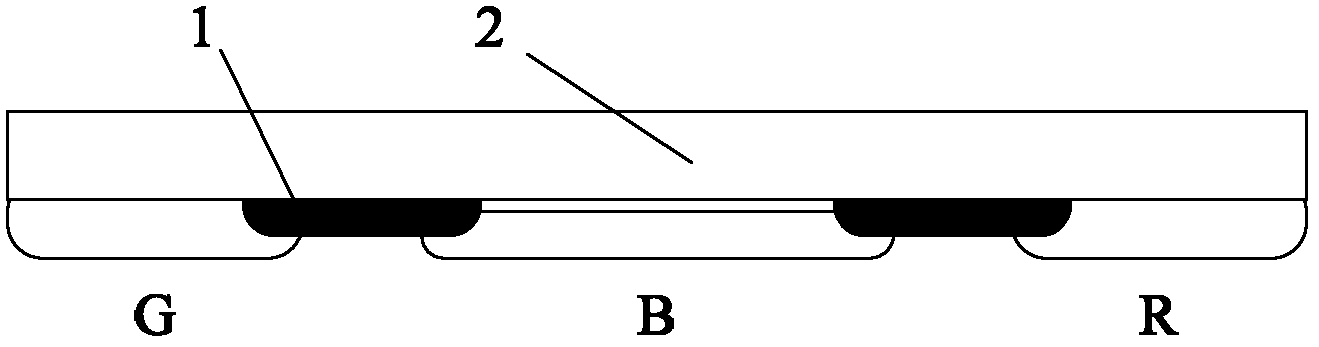

ActiveUS20090219225A1Small subpixelSmall pixel gapStatic indicating devicesFinal product manufactureManipulatorFlexible display

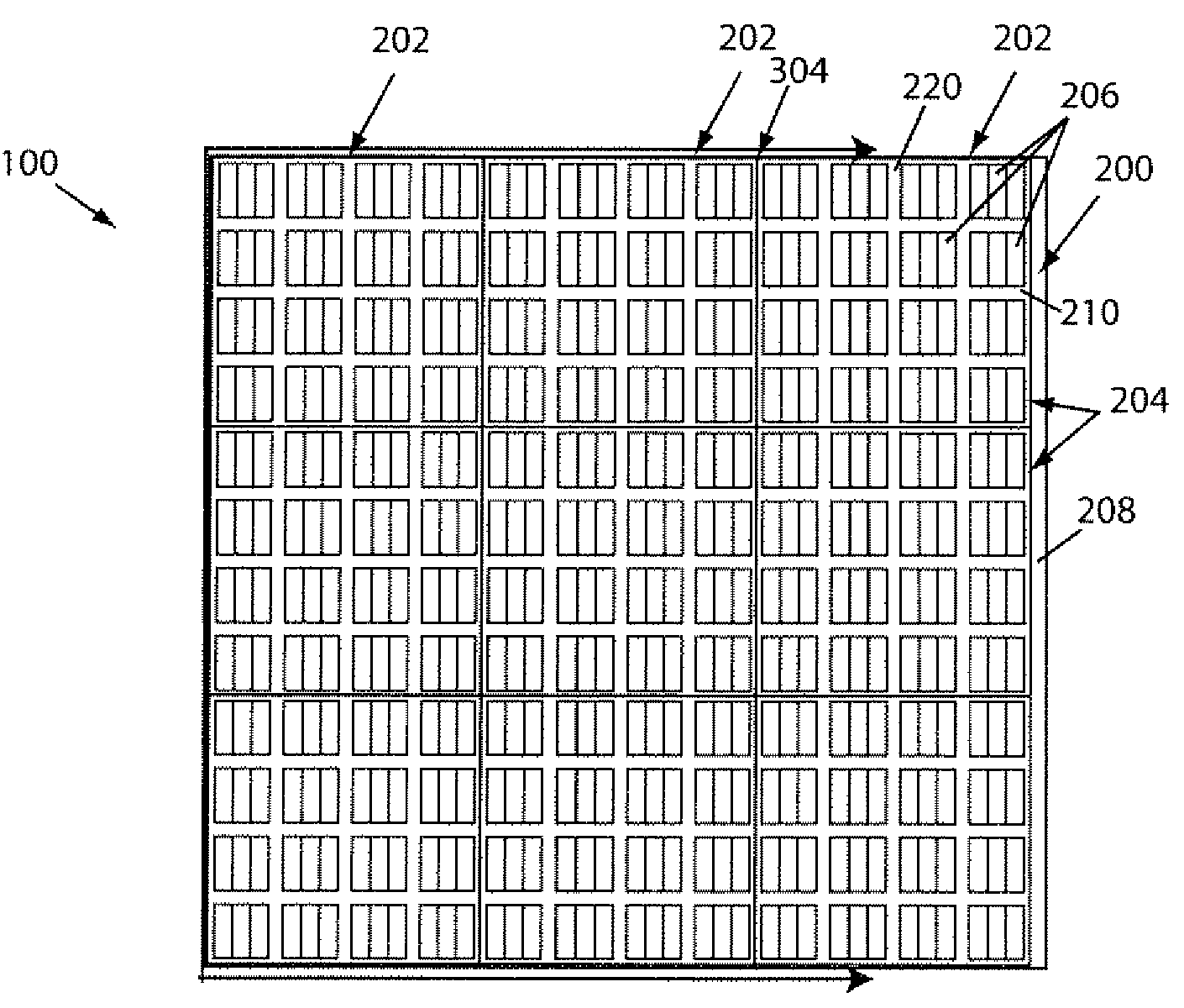

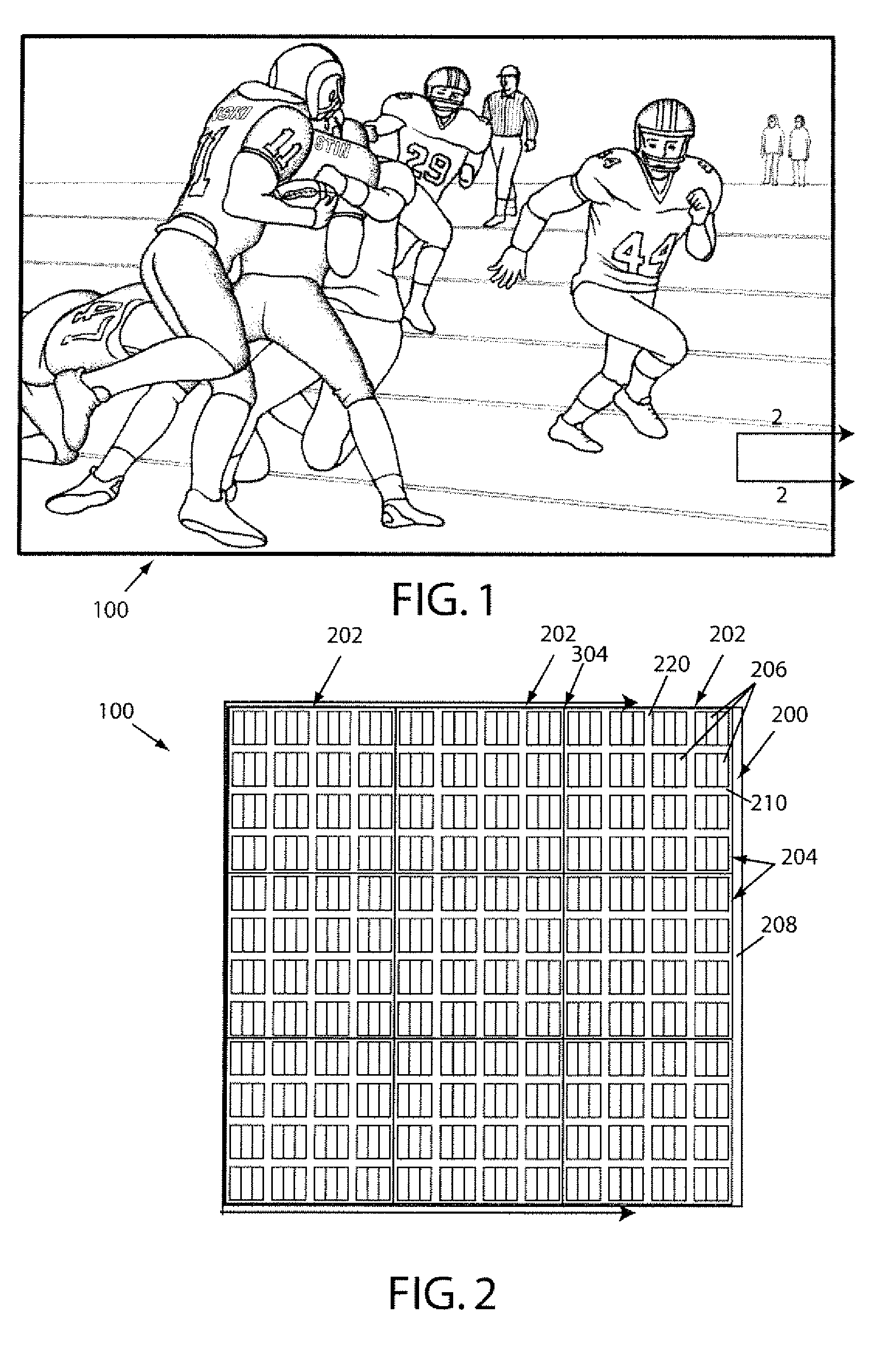

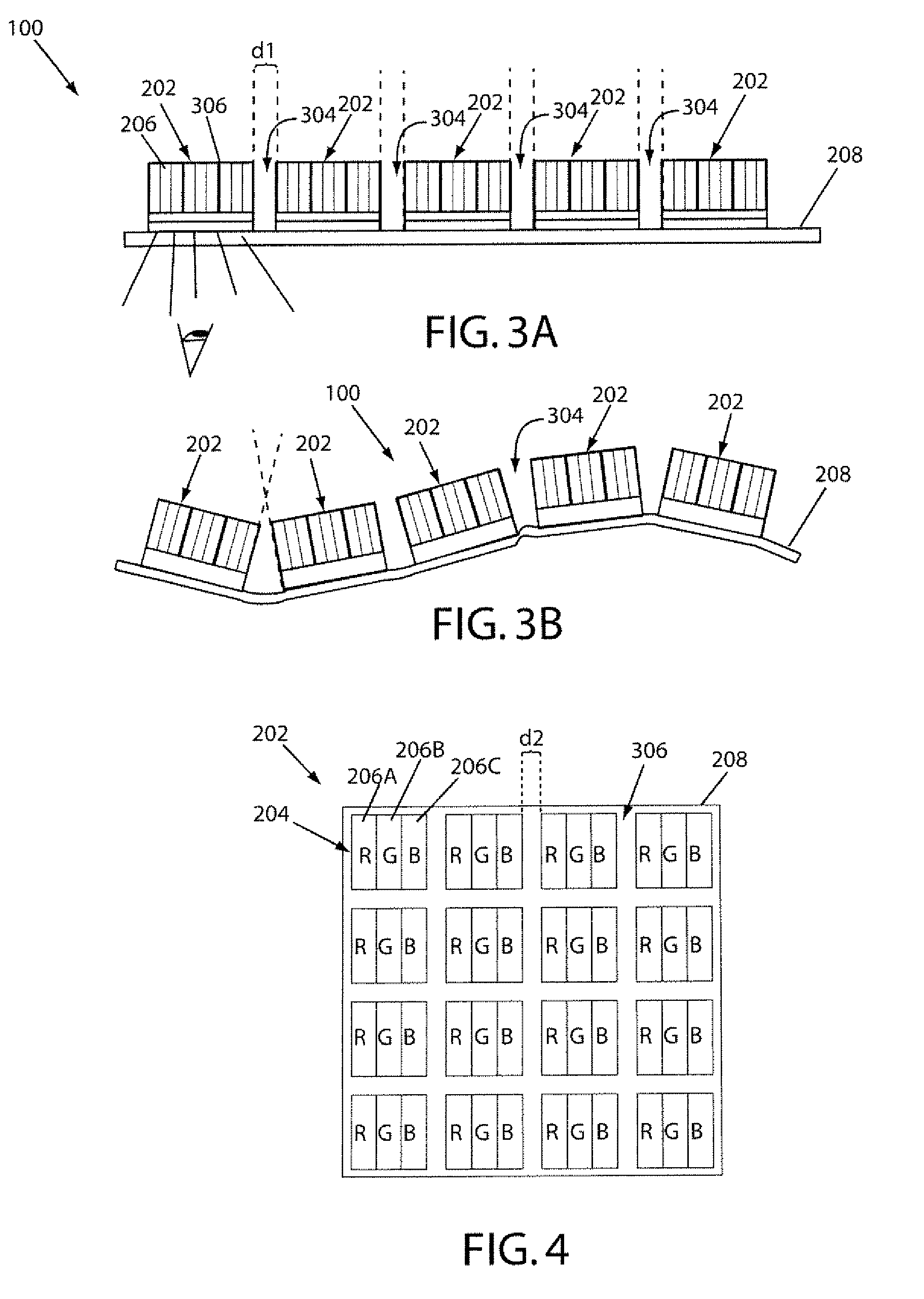

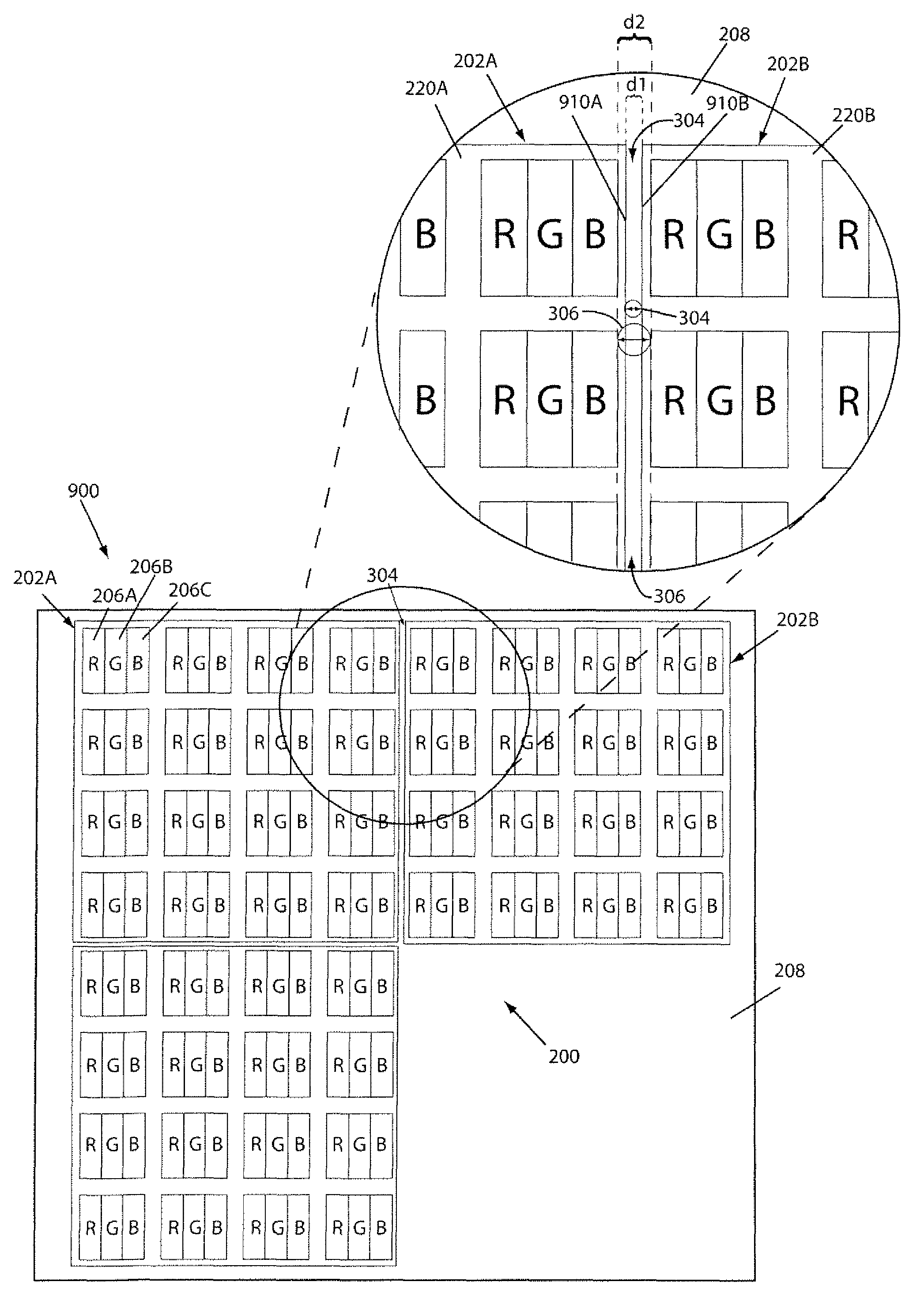

A flexible display includes a plurality of pixel chips, chixels, provided on a flexible substrate. The chixels and the light emitters thereon may be shaped, sized and arranged to minimize chixel, pixel, and subpixel gaps and to provide a desired bend radius of the display. The flexible substrate may include light manipulators, such as filters, light convertors and the like to manipulate the light emitted from light emitters of the chixels. The light manipulators may be arranged to minimize chixel gaps between adjacent chixels.

Owner:NANOLUMENS ACQUISITION

Flexible display

ActiveUS9013367B2Increase flexibilityCustomize flexibilityFinal product manufactureSemiconductor/solid-state device detailsDisplay deviceBend radius

Owner:NANOLUMENS ACQUISITION

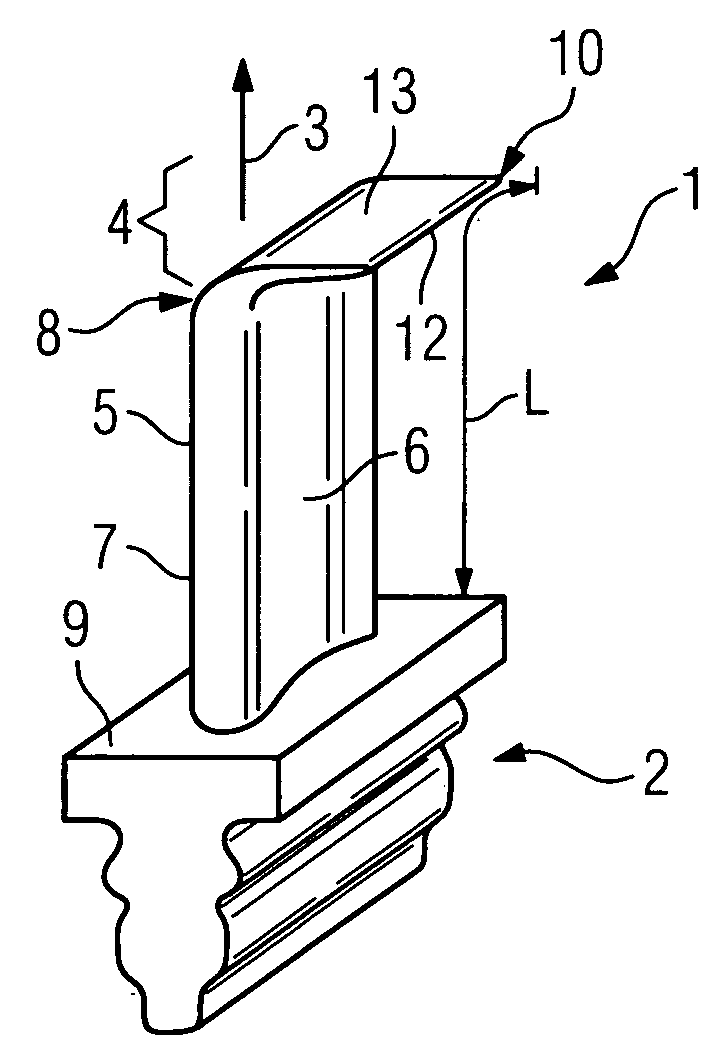

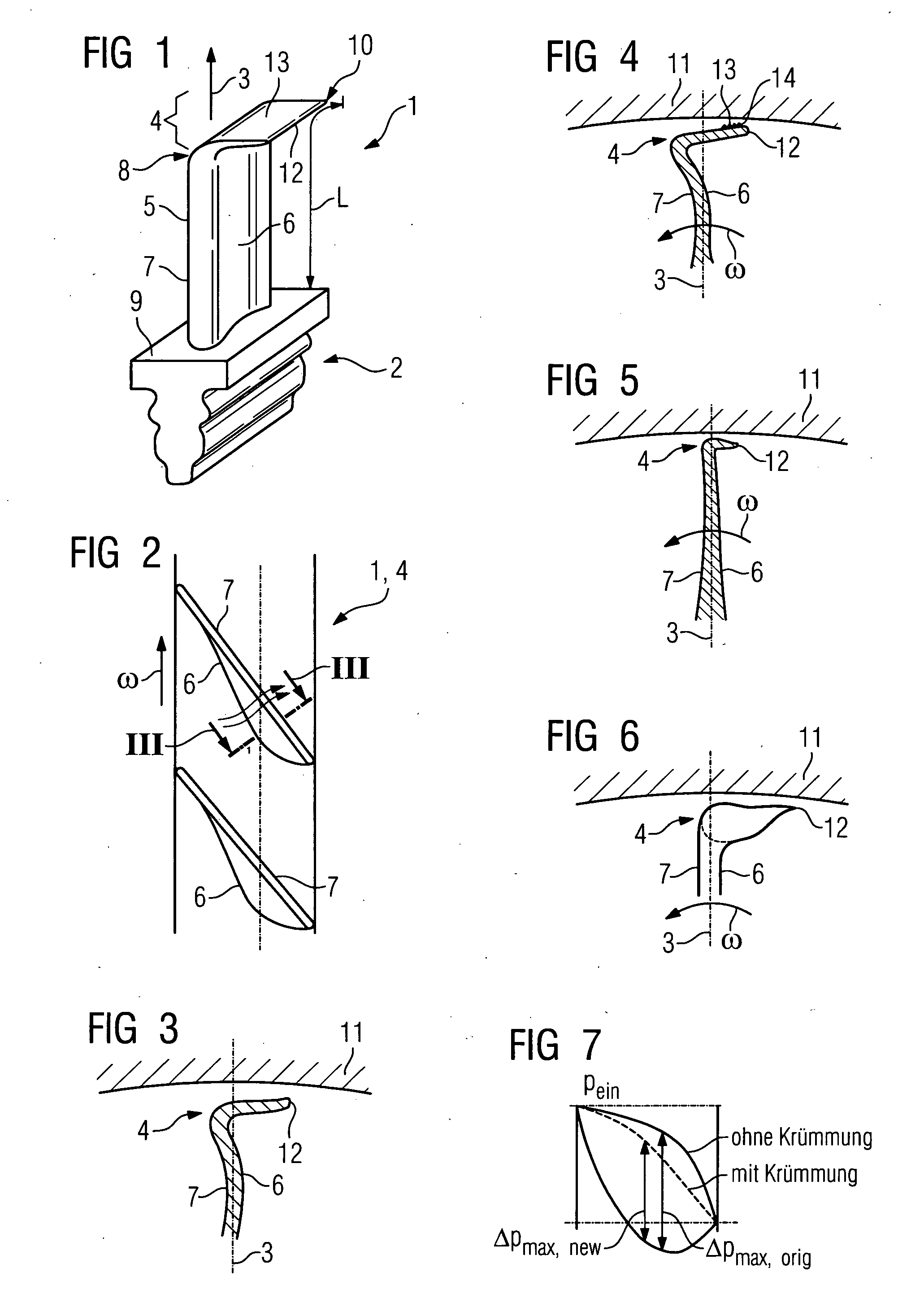

Free-standing turbine blade

InactiveUS20080213098A1Low gap lossReduce differential pressurePropellersPump componentsTurbine bladeAirplane

There is described a blade for a turbomachine, such as a steam turbine. The blade has a blade tip, which is curved in relation to the blade airfoil profile. The curvature has the shape of a winglet, which is known from aircraft construction.

Owner:SIEMENS AG

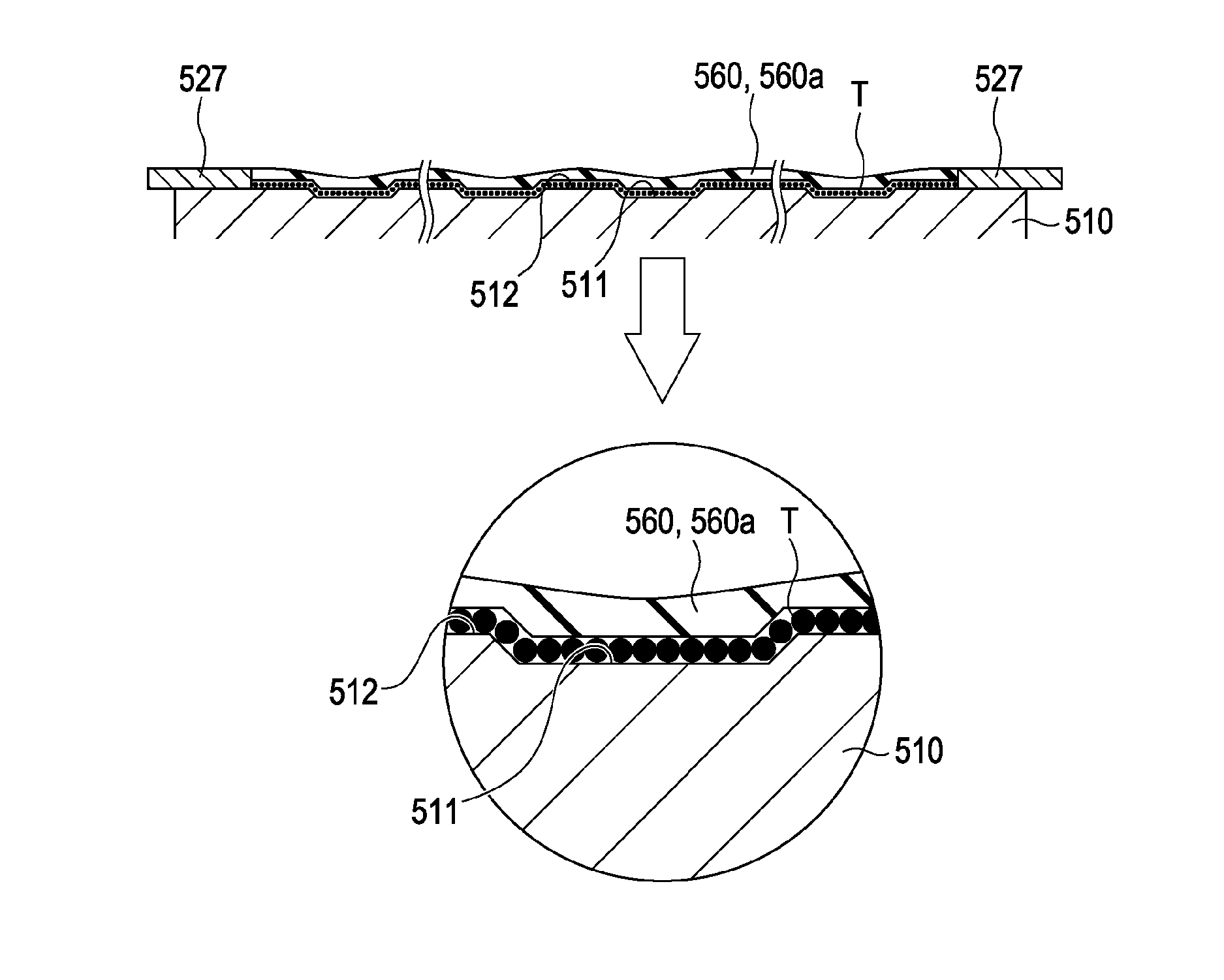

Vcsel module and manufacture thereof

ActiveUS20150071320A1Increase in sizeLessSemiconductor laser arrangementsSemiconductor/solid-state device manufacturingBiomedical engineering

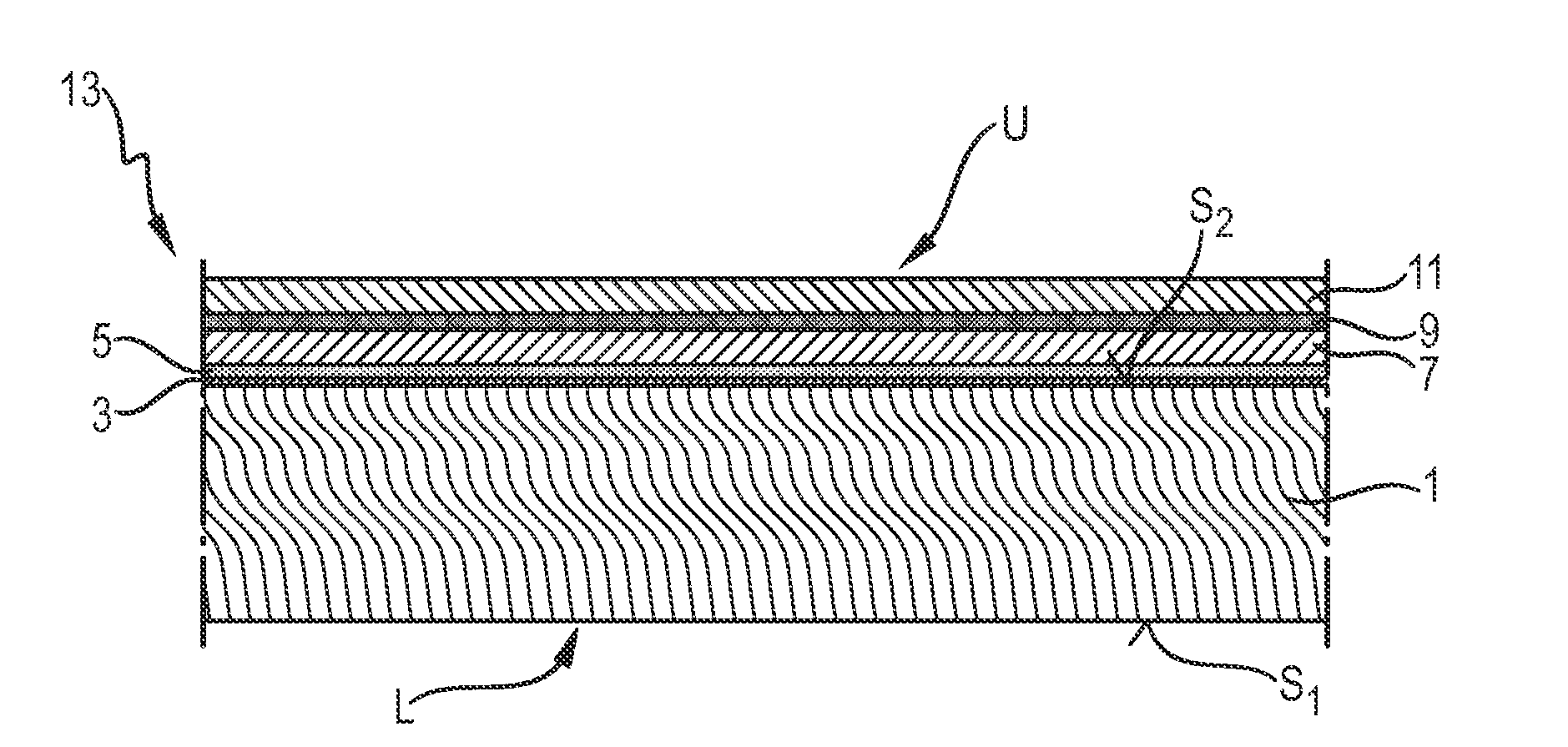

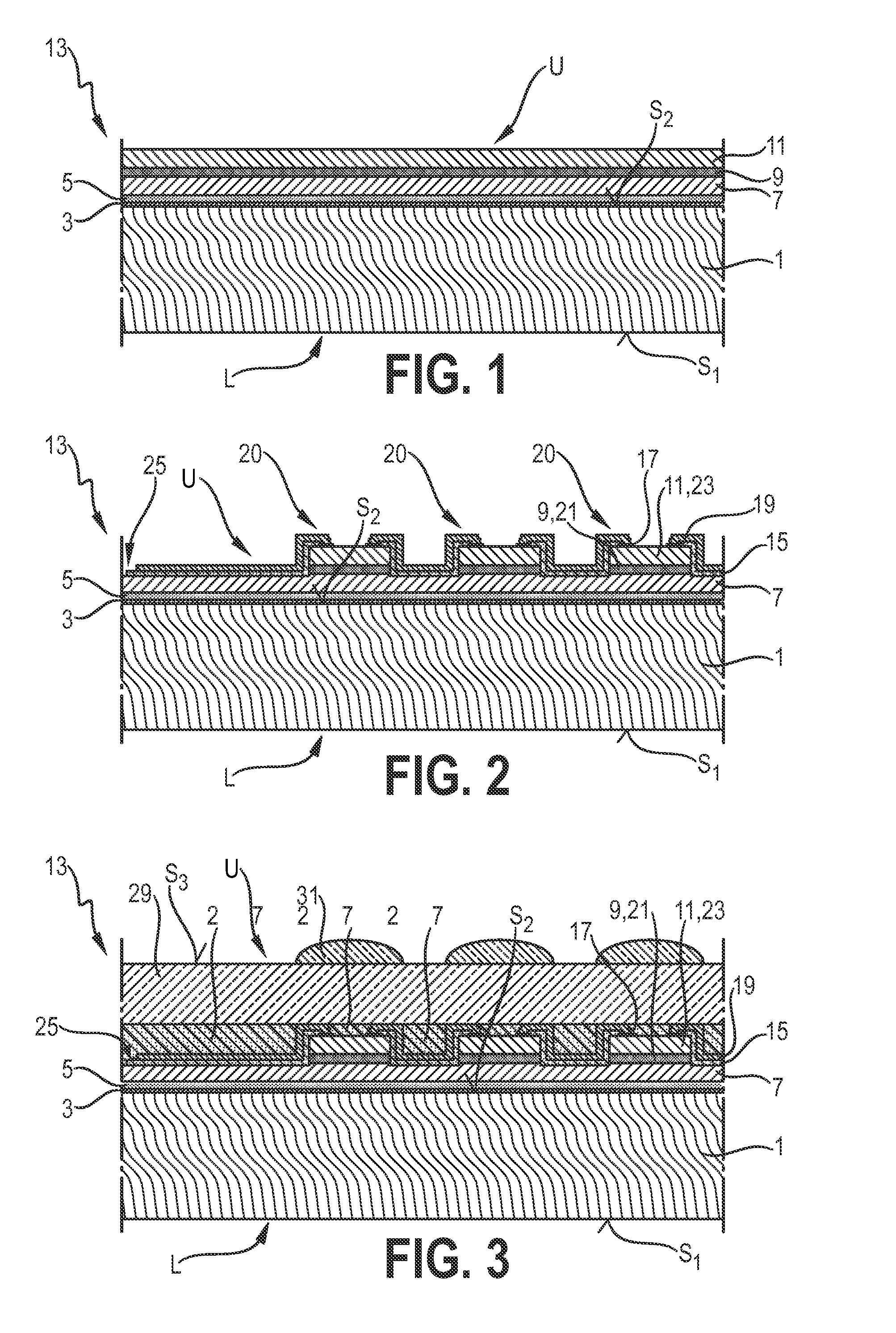

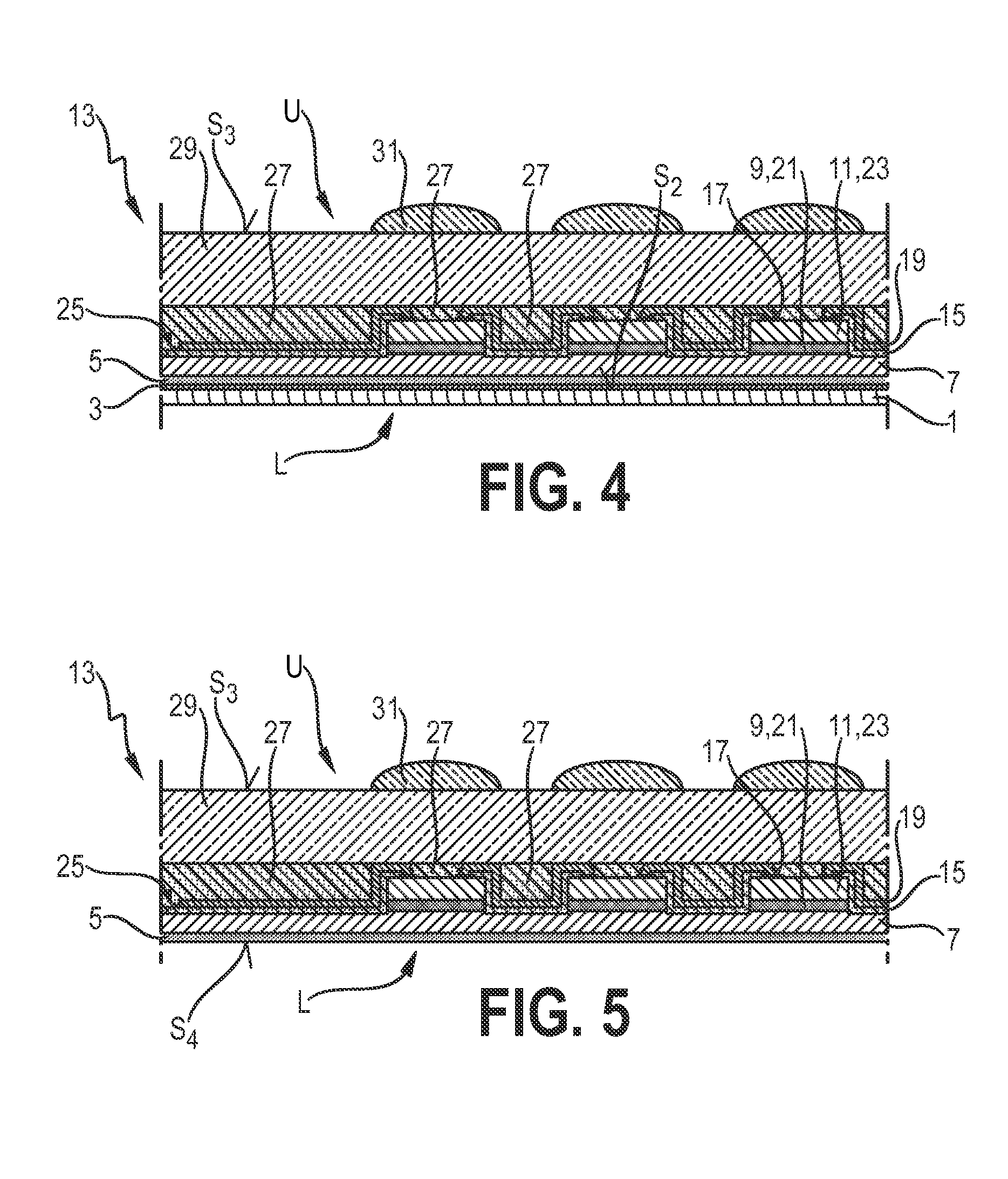

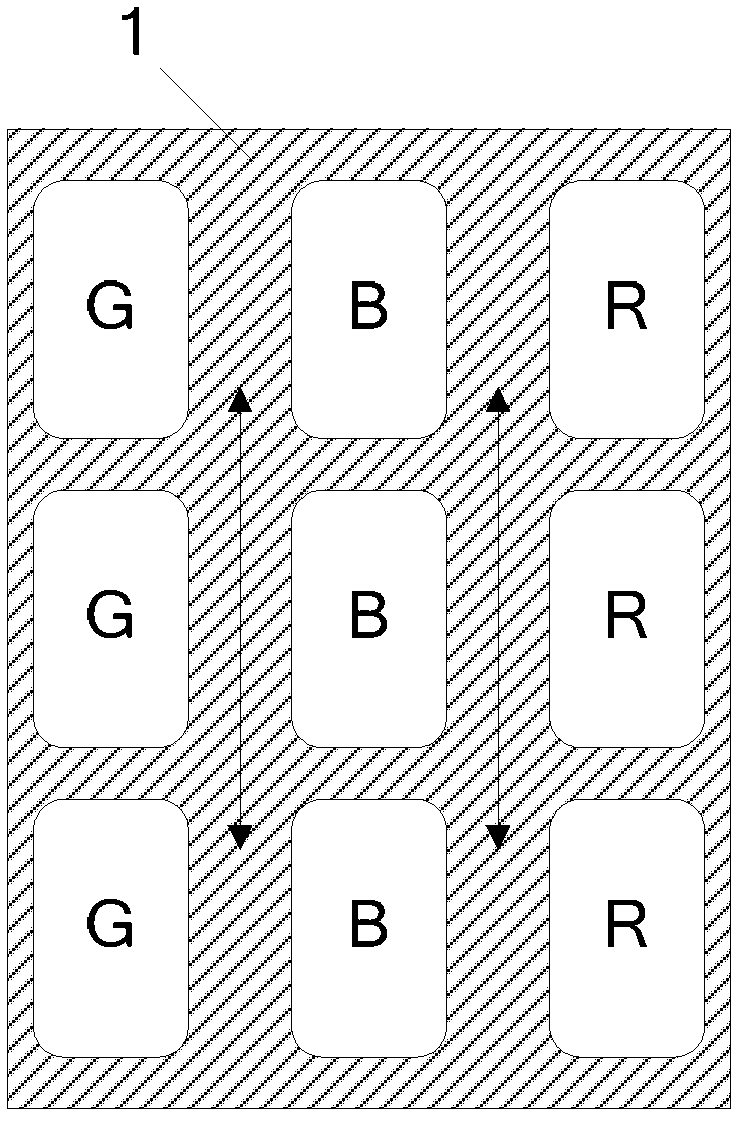

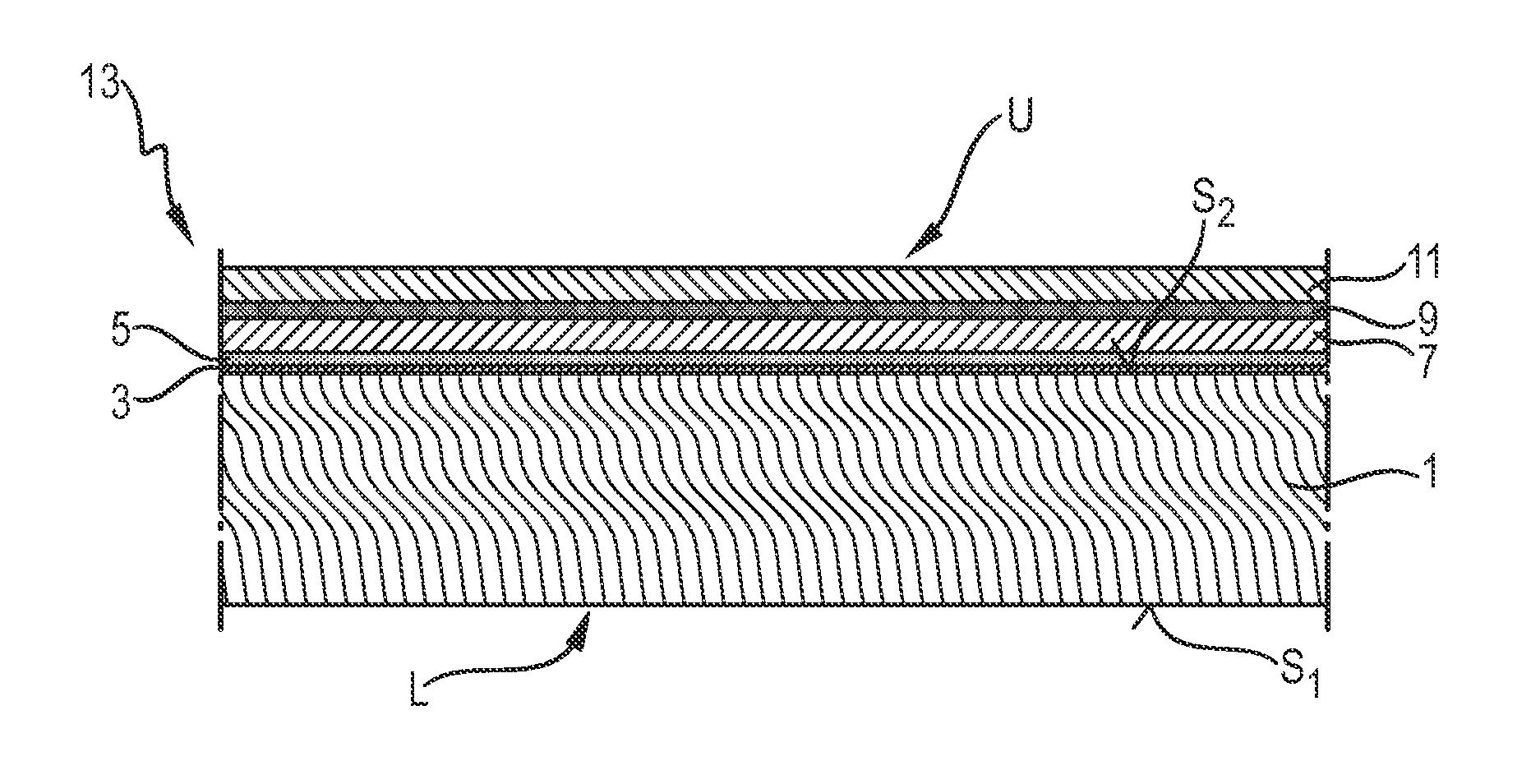

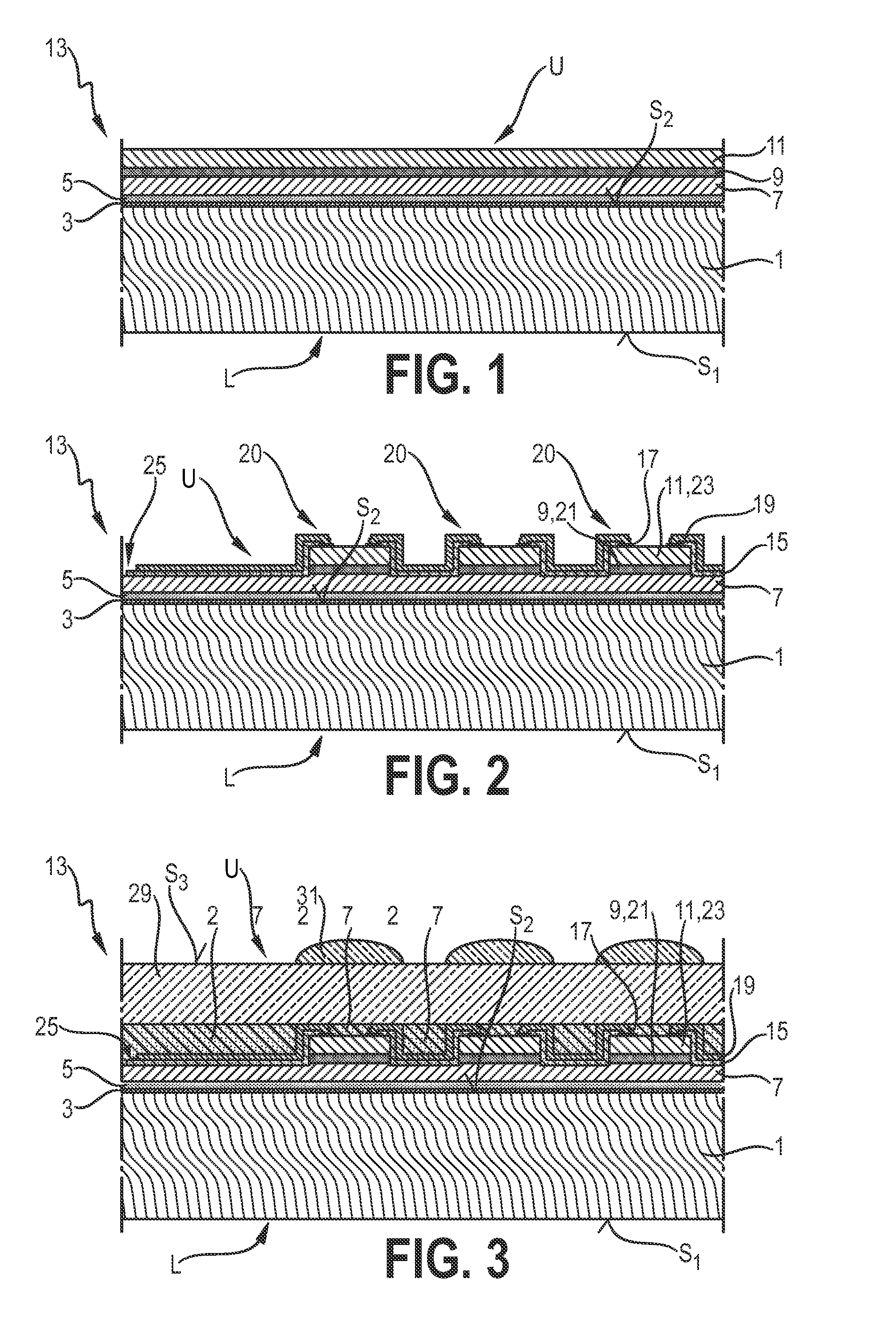

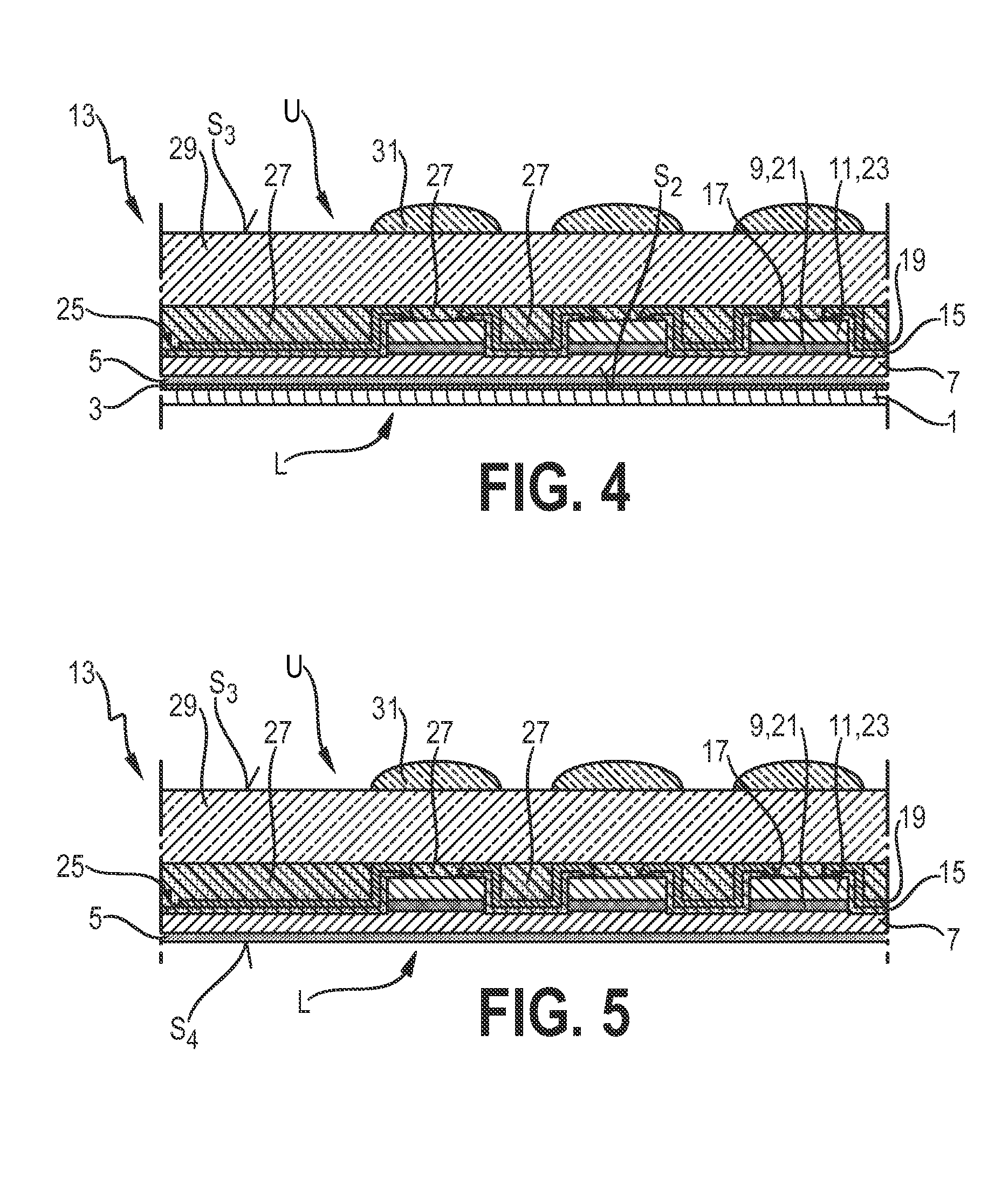

The invention describes a method of manufacturing a VCSEL module (100) comprising at least one VCSEL chip (33) with an upper side (U) and a lower side (L) and with a plurality of VCSEL units (55) on a common carrier structure (35), the VCSEL units (55) comprising a first doped layer (50) of a first type facing towards the lower side (L) and a second doped layer (23) of a second type facing towards the upper side (U). The method comprises the steps of dividing the VCSEL chip (33) into a plurality of subarrays (39a, 39b, 39c, 39d, 39e, 39f, 39g, 39h, 39i) with at least one VCSEL unit (55) each, electrically connecting at least some of the subarrays (39a, 39b, 39c, 39d, 39e, 39f, 39g, 39h, 39i) in series. The invention also describes a VCSEL module (100) manufactured in such process.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

Highlight maintaining method for liquid crystal display

ActiveCN102650750AAvoid excessive gapsIncrease success rateNon-linear opticsLiquid-crystal displayLaser

The embodiment of the invention discloses a highlight maintaining method for a liquid crystal display. According to the maintaining method, a color diaphragm plate of the liquid crystal display is maintained and comprises a base plate as well as a black matrix and red-green-blue color diaphragms arranged on the base plate, wherein red-green-blue color diaphragms are separated by the black matrix, and laser is utilized for implementing the following steps of: ageing the color diaphragms of sub pixel points to be maintained and the black matrix at the peripheries of the sub pixel points; forming seams between the color diaphragms and a glass base plate; granulating the black matrixes at the peripheries of the color diaphragms to generate black particles; dispersing the black particles at the peripheries of the color diaphragms into the seams; using the laser with the strength being 12-17A.U if the color diaphragms of the sub pixel points are blue in the process that the seams are formed between the color diaphragms and the glass base plate; using the laser with the strength being 17-19A.U if the color diaphragms of the sub pixel points are green in the process that the seams are formed between the color diaphragms and the glass base plate; and using the laser with the strength being 23-25A.U if the color diaphragms of the sub pixel pints are red in the process that the seams are formed between the color diaphragms and the glass base plate. The highlight maintaining method is applied to the improvement of the highlight maintenance.

Owner:BOE TECH GRP CO LTD +1

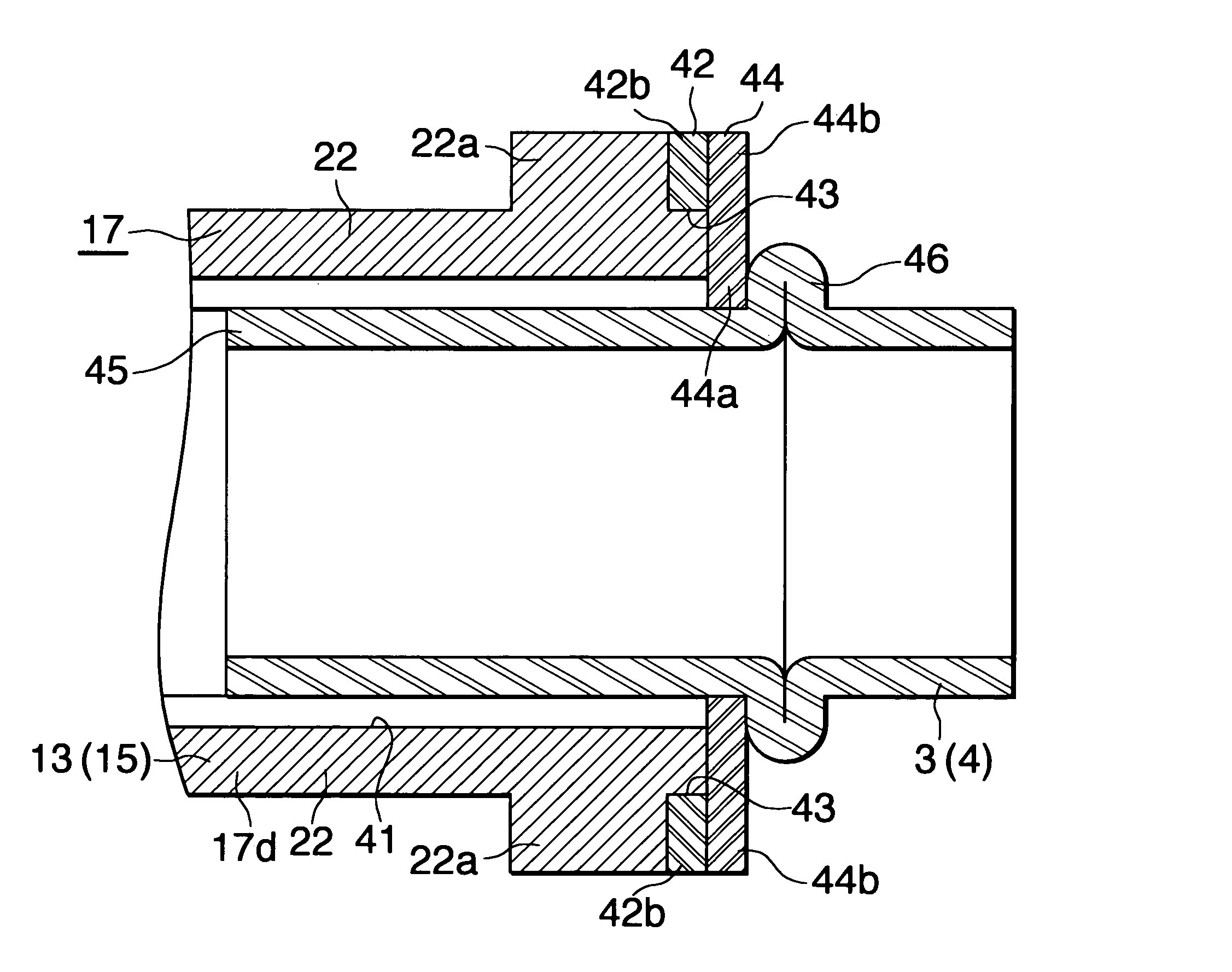

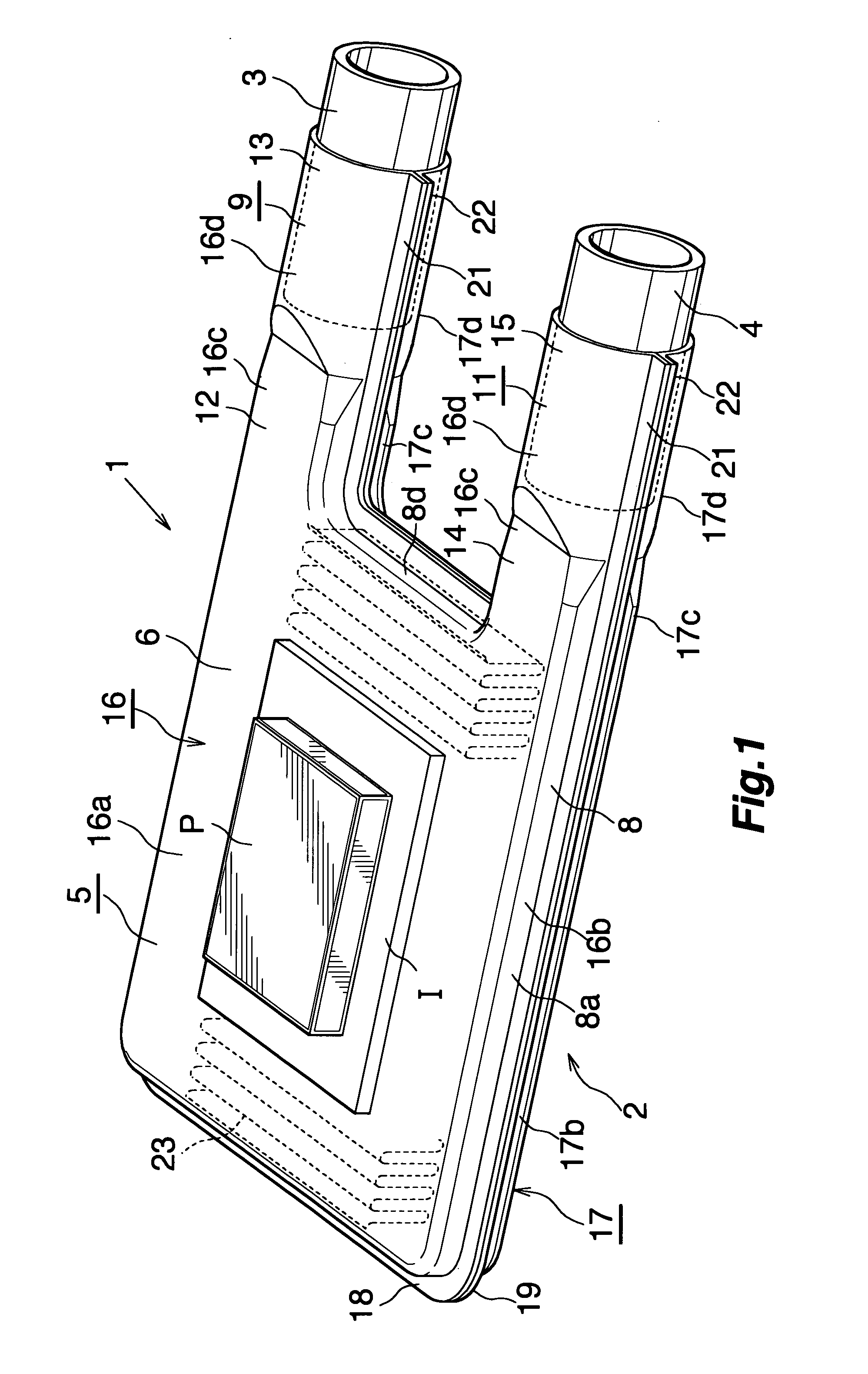

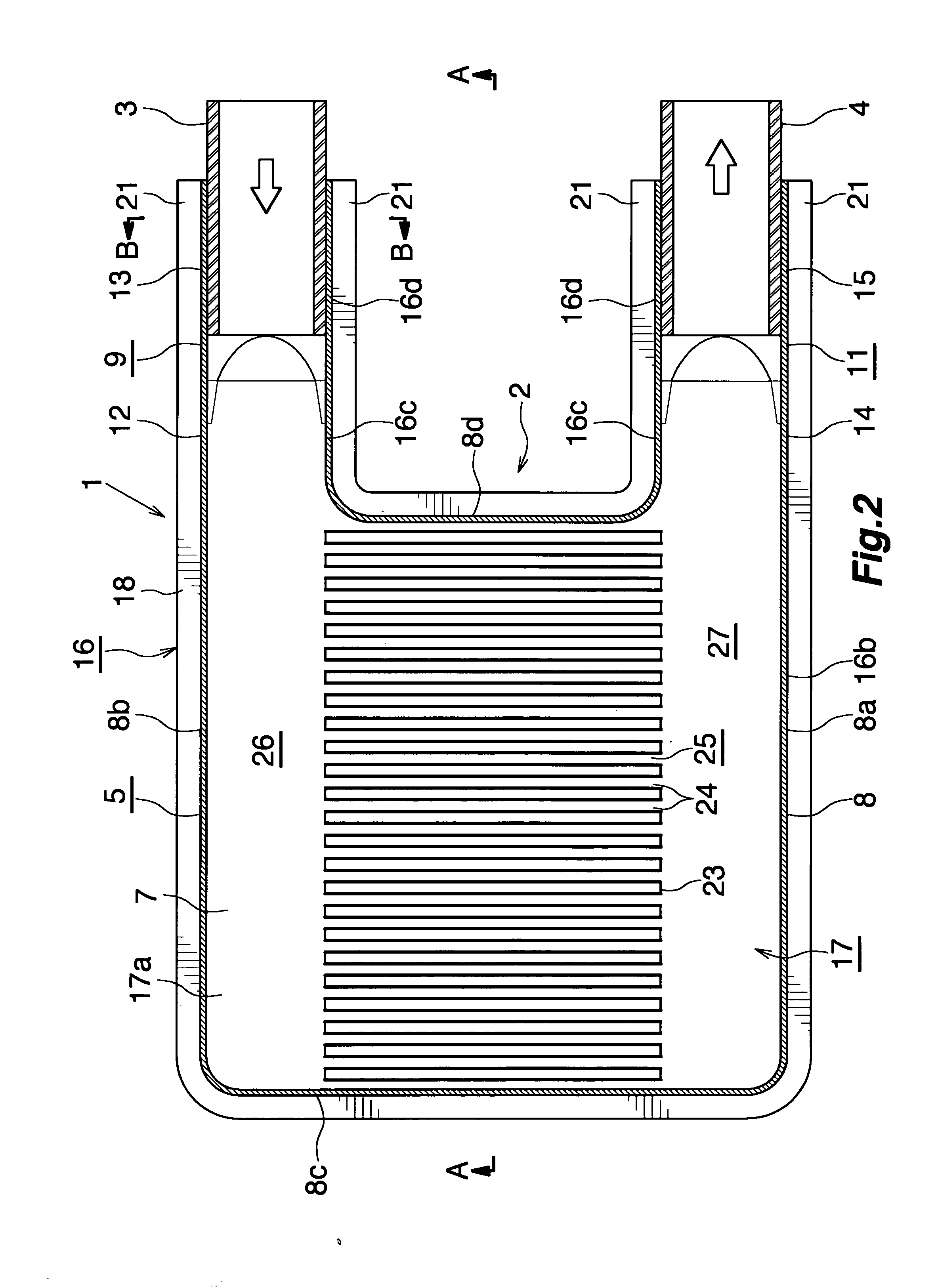

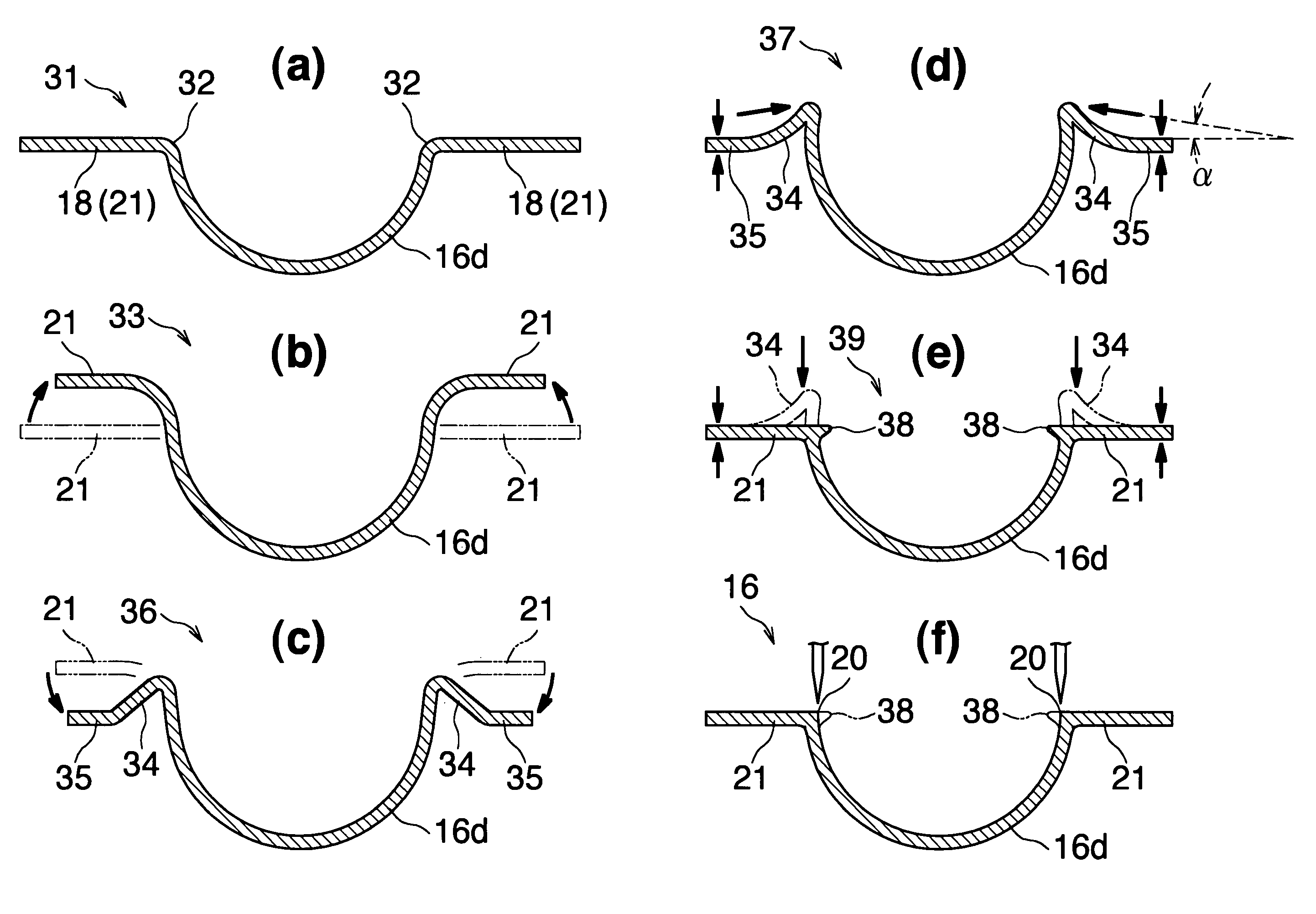

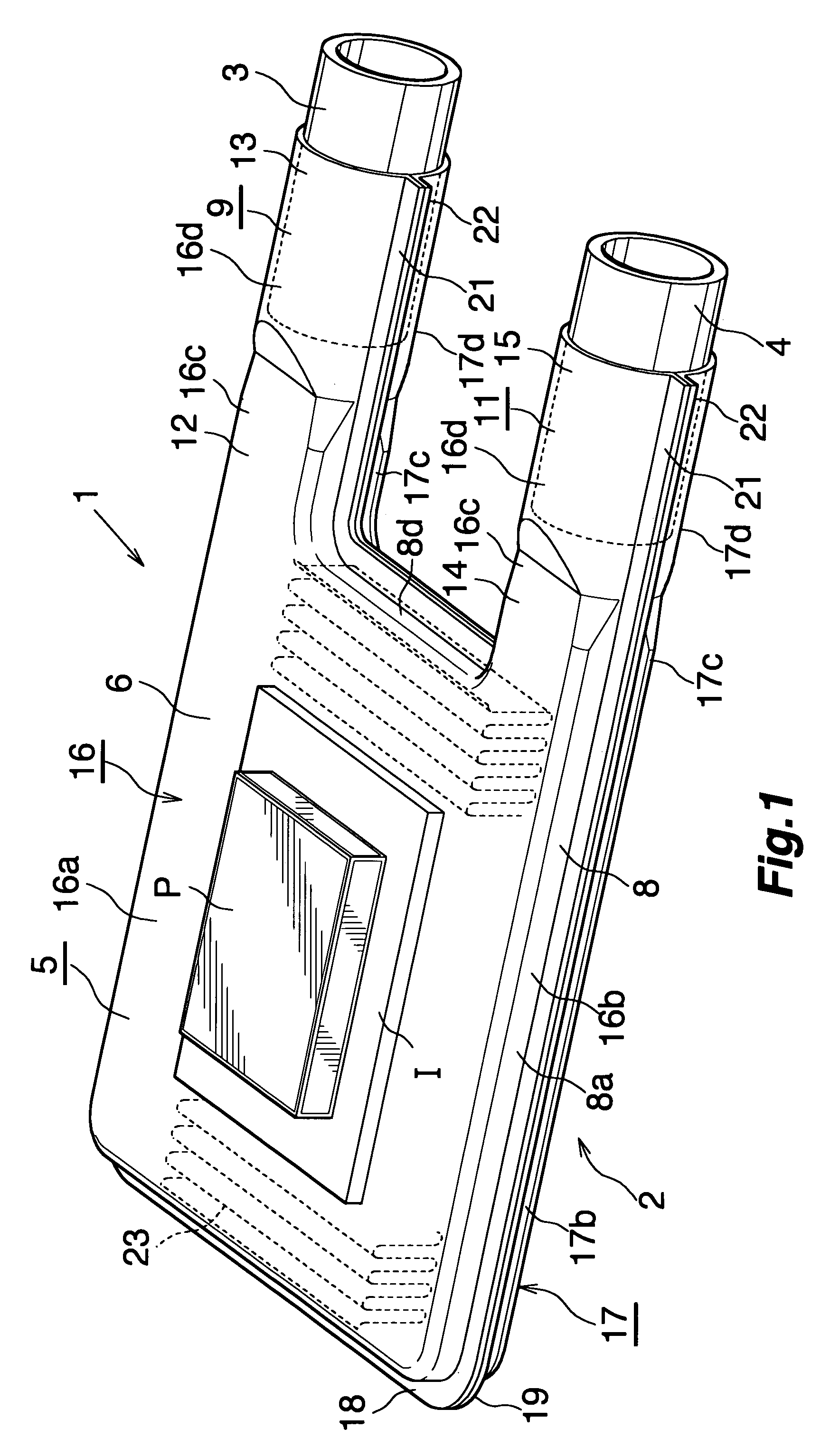

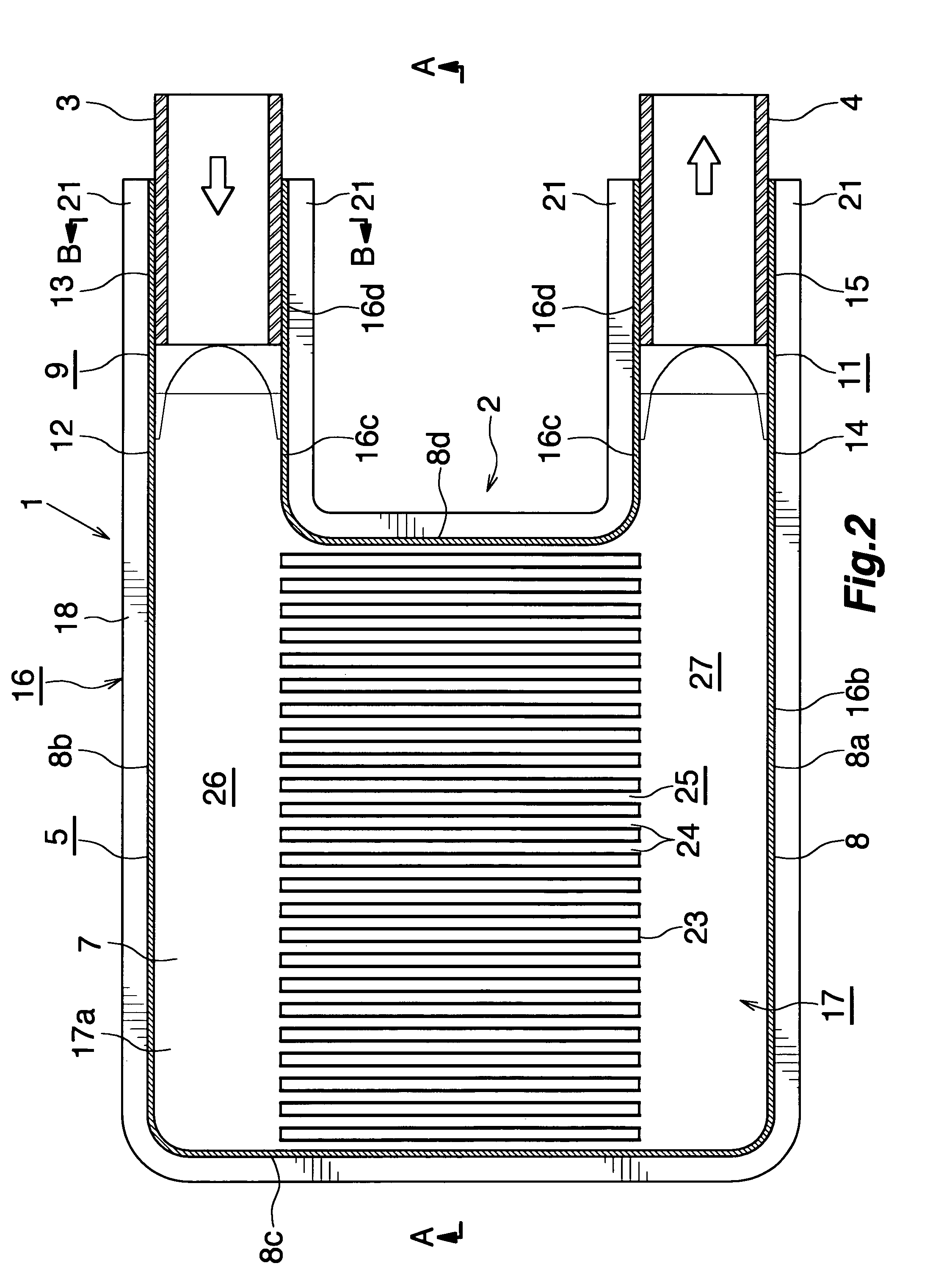

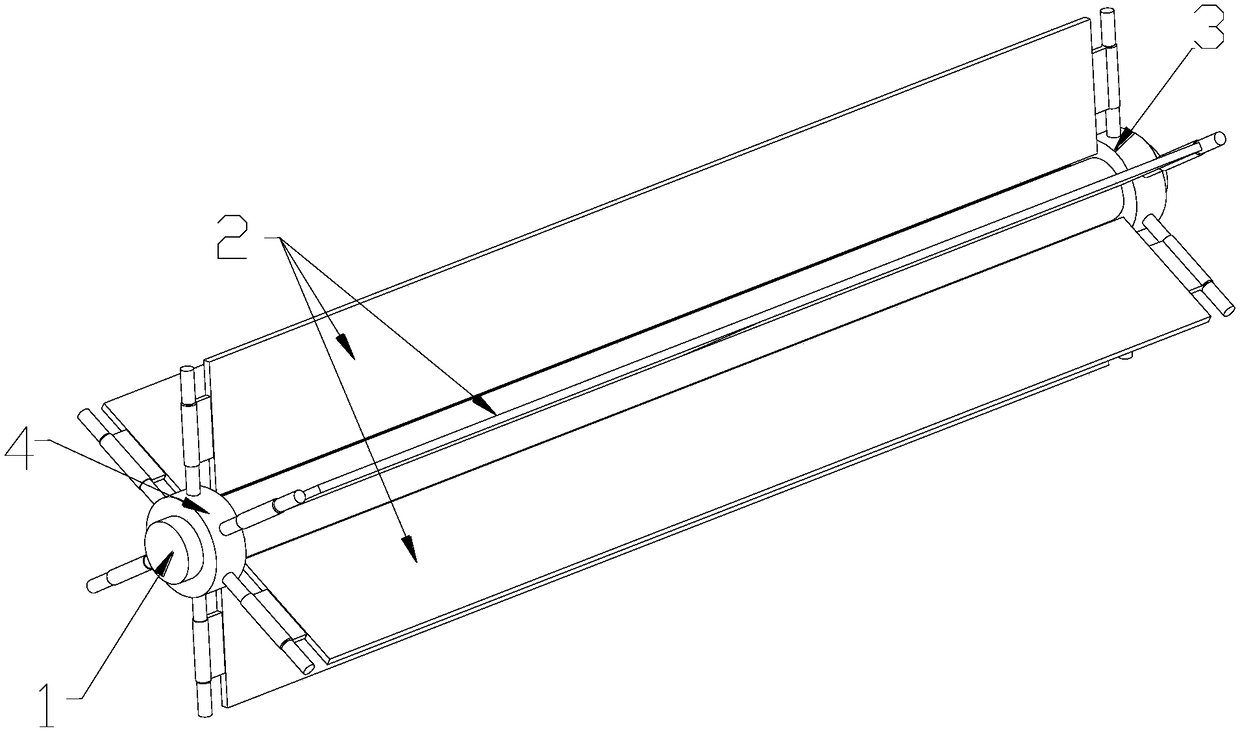

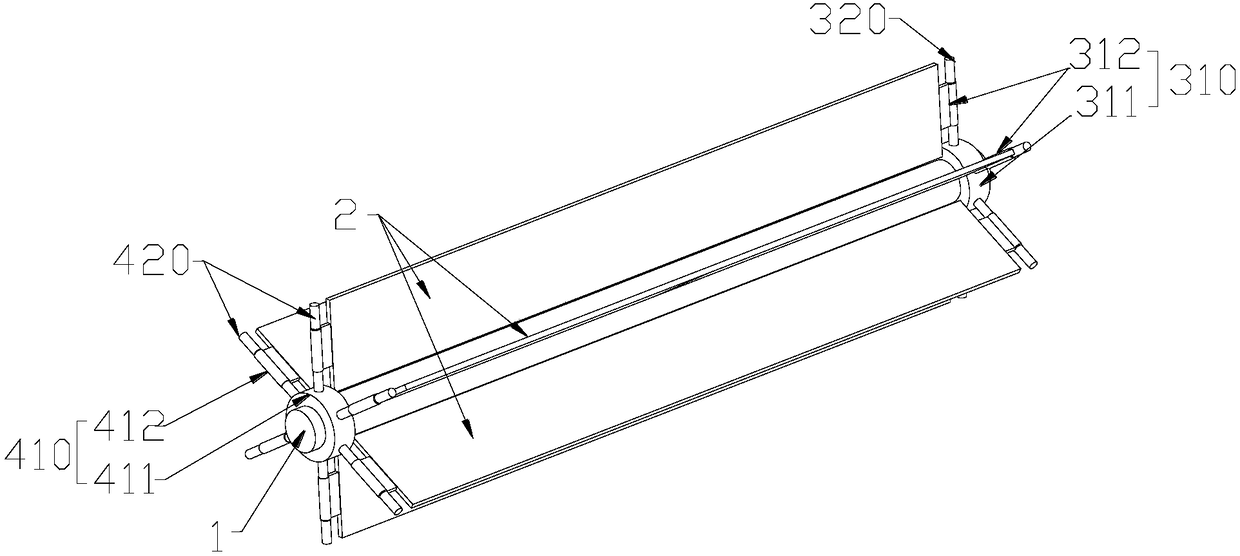

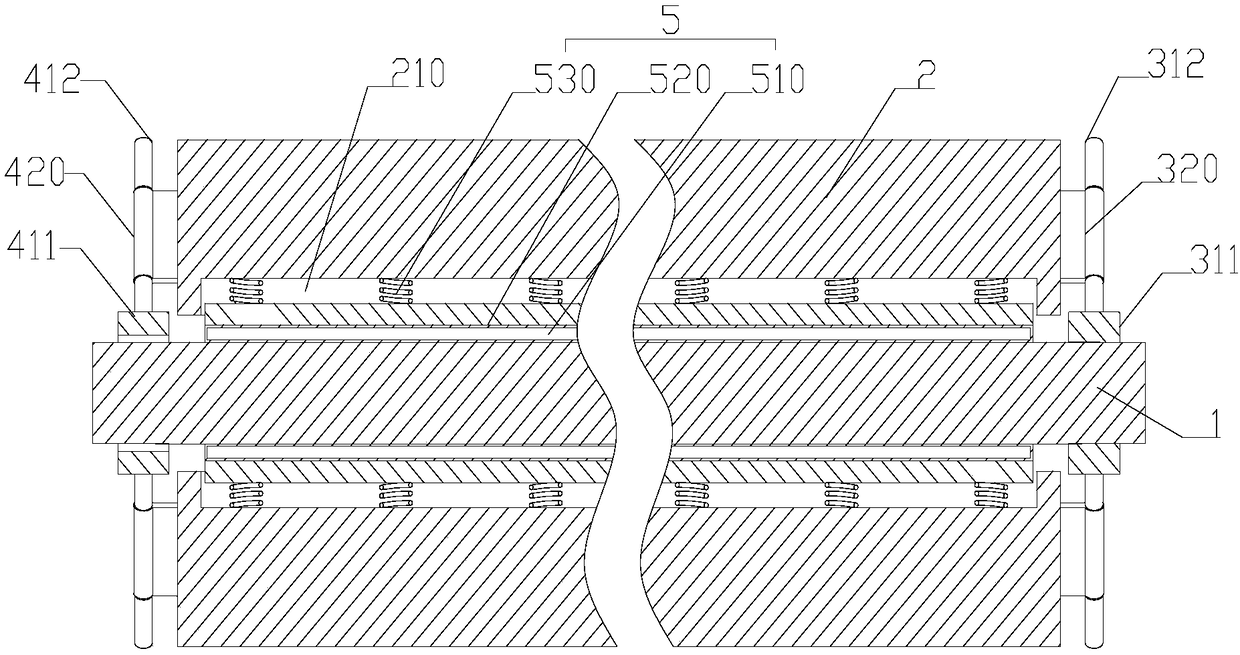

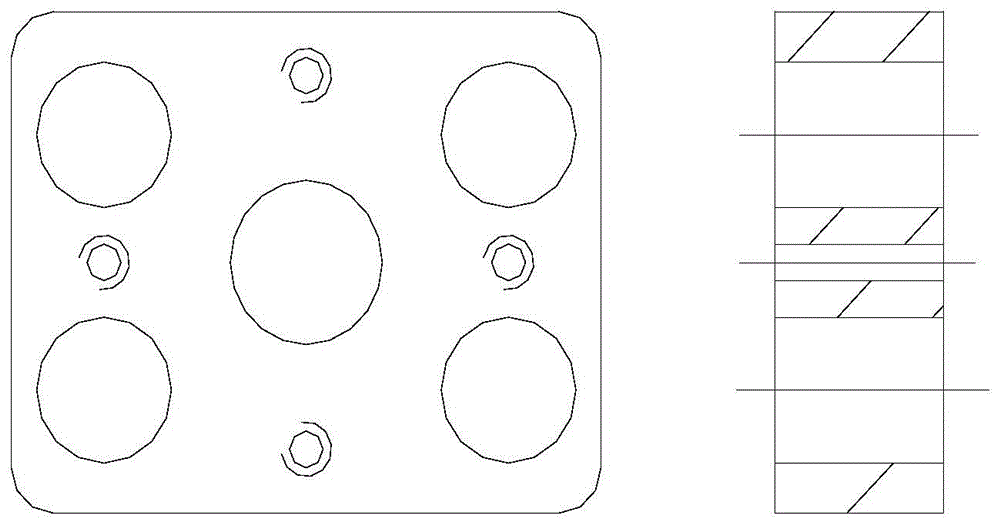

Method of manufacturing a pipe coupling component, method of manufacutring a casing structural member, and pipe coupling sturcture for a hollow part

InactiveUS20100320753A1Avoid formingPrevent liquid leakageSemiconductor/solid-state device detailsSolid-state devicesCouplingEngineering

In a first step of this method, a first intermediate product 42 having a coupling portion forming portion 16d and flat portions 21 is produced. In a second step, there is produced a second intermediate product 44 which is larger in the bending depth of the coupling portion forming portion 16d and is smaller in width of the flat portions 21 than the first intermediate product 42. In a third step, a third intermediate product 36 having the coupling portion forming portion 16d, sloping flat portions 34, and narrow flat portions 35 is produced. In a fourth step, the sloping flat portions 34 of the third intermediate product 36 are pressed obliquely upward so as to cause the material to move to the boundaries between the sloping flat portions 35 and the side walls of the coupling portion forming portion 16d, to thereby produce a fourth intermediate product 37. In a fifth step, the side walls of the coupling portion forming portion 16d, the sloping flat portions 34 and the narrow flat portions 35 of the fourth intermediate product 37 are pressed from the upper and lower sides, to thereby form a fifth intermediate product 39 in which burrs 38 are formed at the opening-side end portions of the side walls of the coupling portion forming portion 16d. In a sixth step, the burrs 38 are removed, whereby a casing structural member 16 produced. This method enables manufacture of casing structural members which can prevent leakage of fluid.

Owner:SHOWA DENKO KK

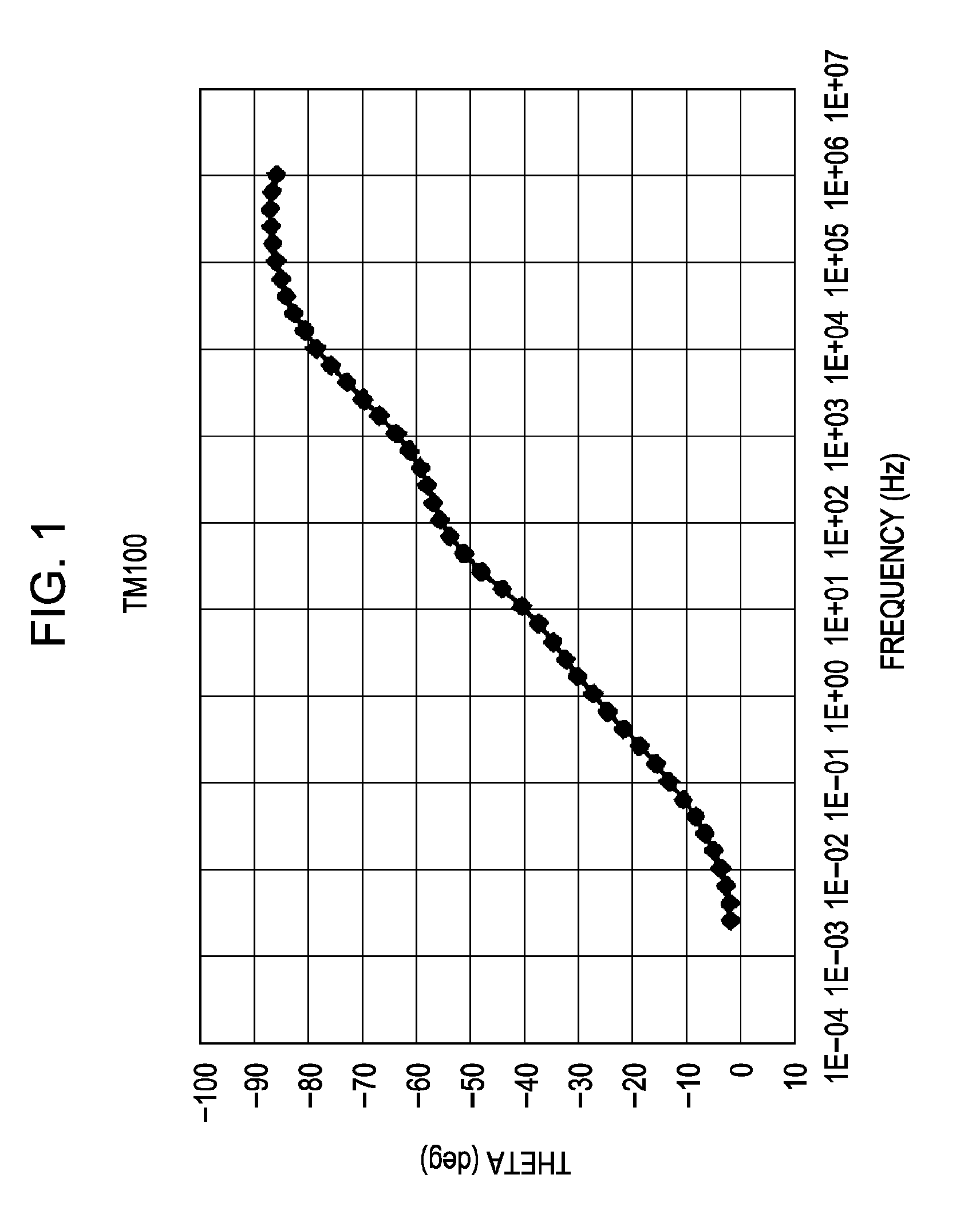

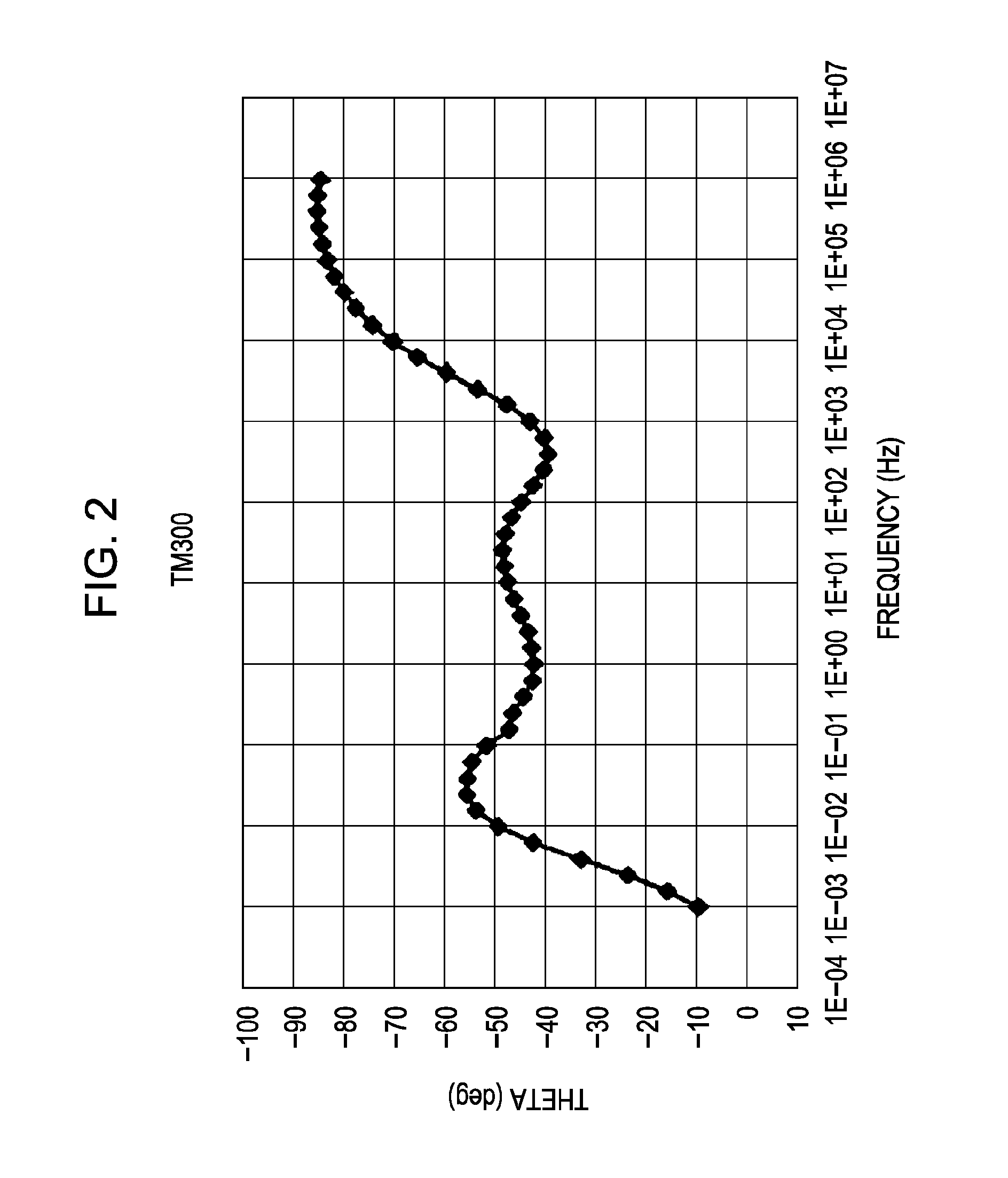

Toner, method for forming image, and image forming apparatus

InactiveUS20100261109A1Suppression gapLess dustElectrographic process apparatusDevelopersImage formationEngineering

A toner includes toner base particles containing at least a binder resin, a coloring agent, and a release agent; and alumina fine particles whose phase angle (θ) is |80°| or less at an alternating current frequency of 1 to 10 kHz in an alternating current impedance method.

Owner:SEIKO EPSON CORP

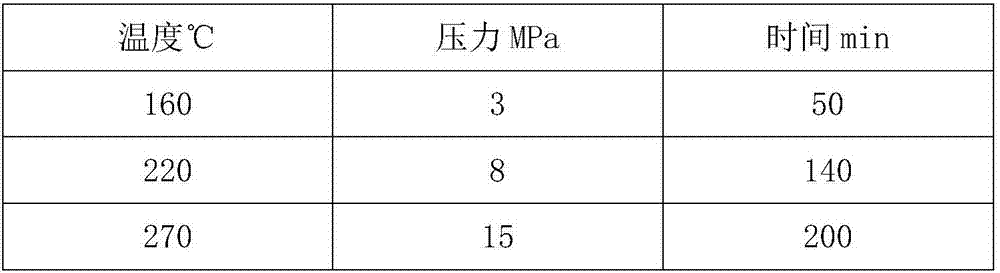

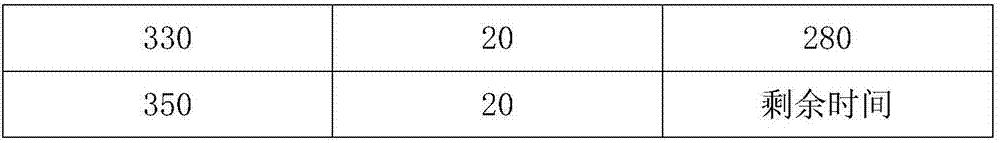

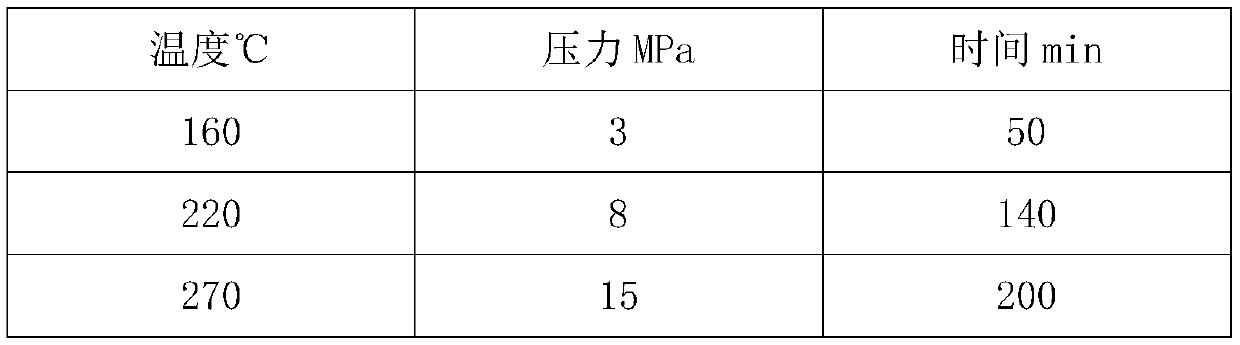

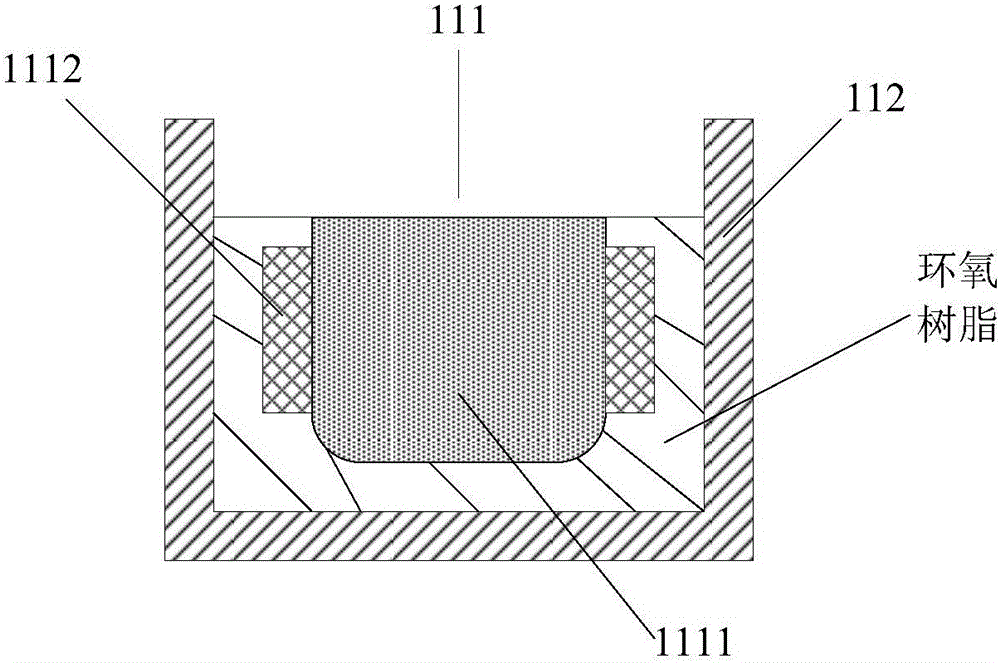

Preparation method for compact aluminum titanate ceramic

The invention belongs to the technical field of a ceramic material and specifically relates to a preparation method for a compact aluminum titanate ceramic. The method comprises the following steps: by taking tetrabutyl titanate and aluminum nitrate as raw materials, taking an alcohol solution containing a dispersing agent as a solvent and taking butyl silicate as an internal additive; introducing ammonia gas, refluxing, aerating and reacting, thereby acquiring a gel solution; by taking ferric chloride as an external additive, adding a curing agent, reducing pressure and distilling, thereby acquiring the gel; adding the gel into a mold, vibrating, heating and curing; and raising temperature in gradient, pressurizing, drying and sintering in a muffle furnace, thereby acquiring the compact aluminum titanate ceramic. The invention solves the problem of complex preparation process of the liquid phase compound in the prior art; the method provided by the invention is high in plasticity and is capable of customizing the ceramic shape according to the requirement; the prepared aluminum titanate is high in purity, fine in structure and high in uniformity.

Owner:无锡特科精细陶瓷有限公司

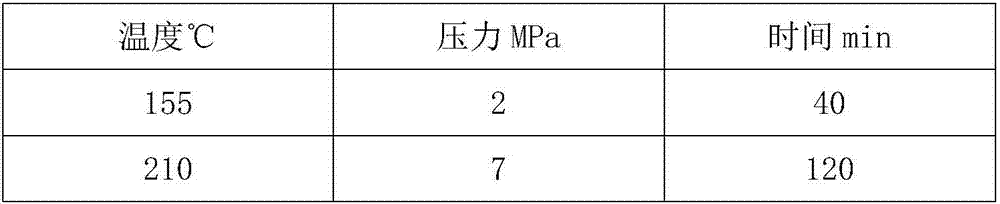

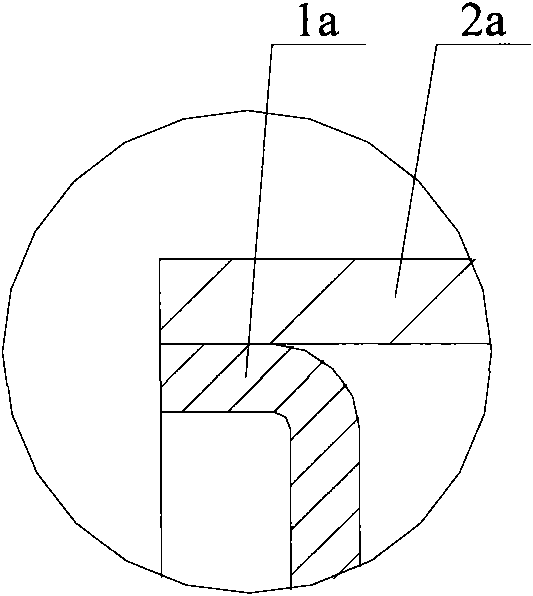

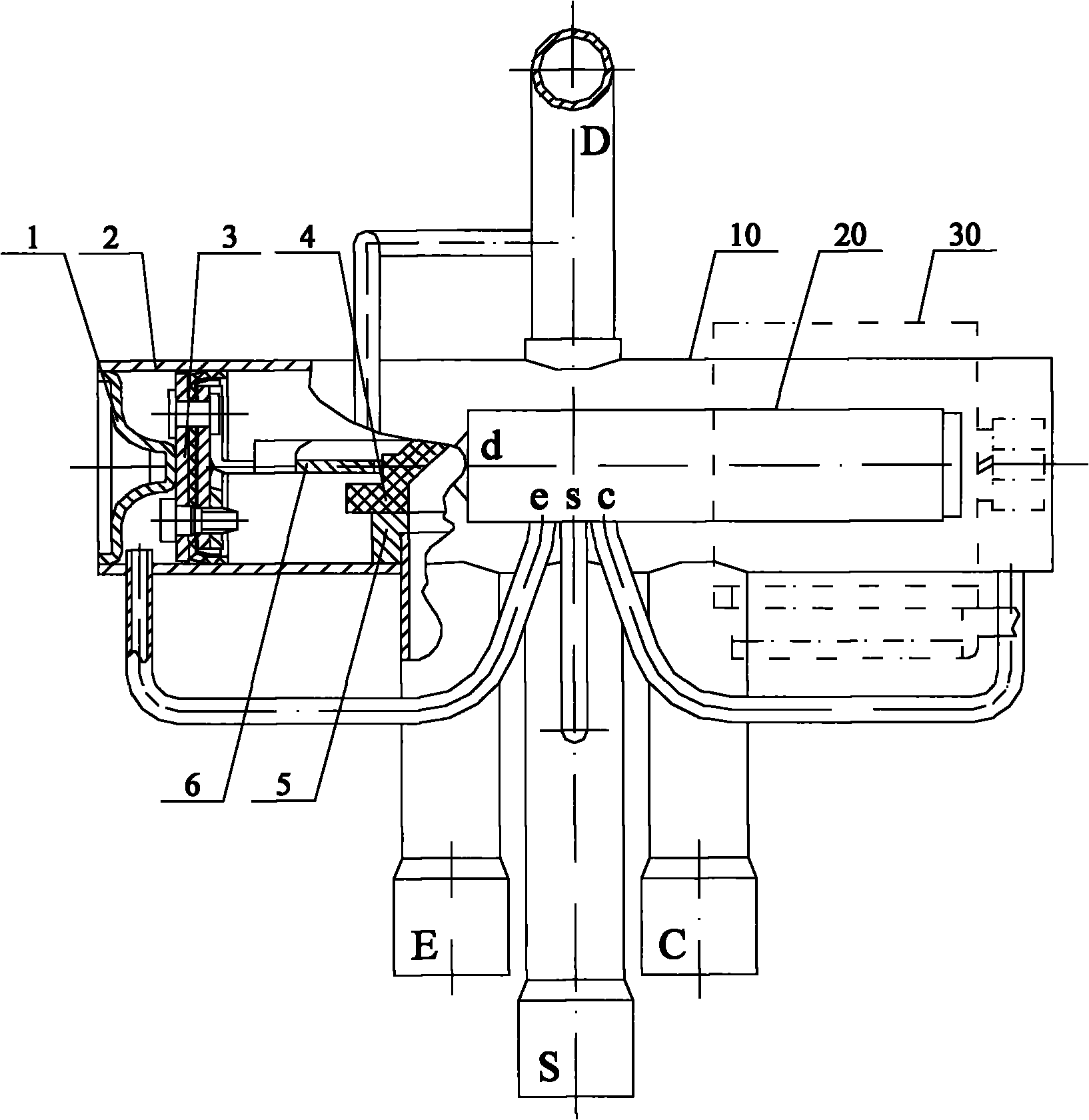

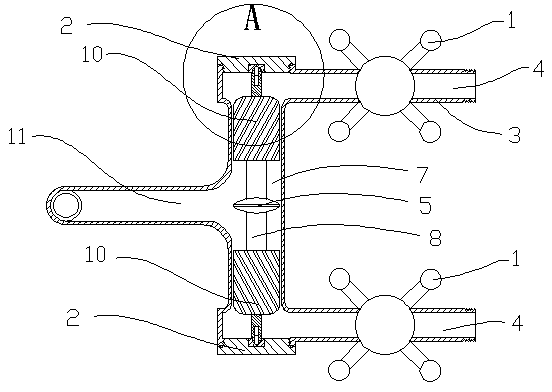

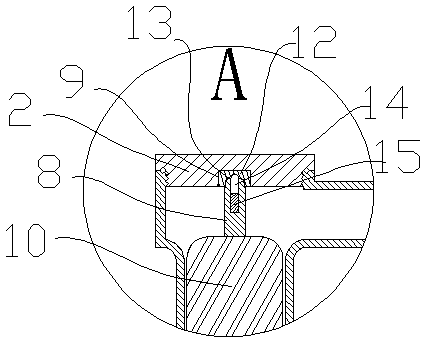

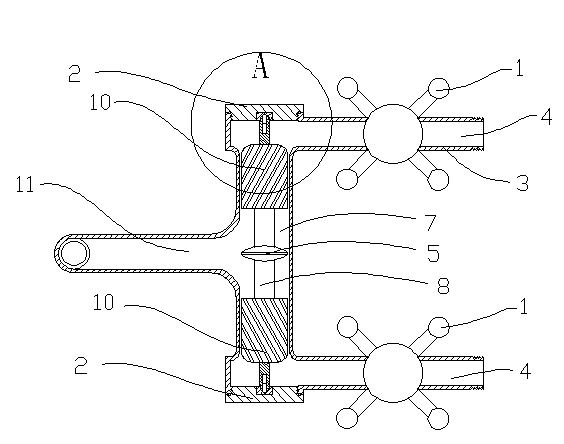

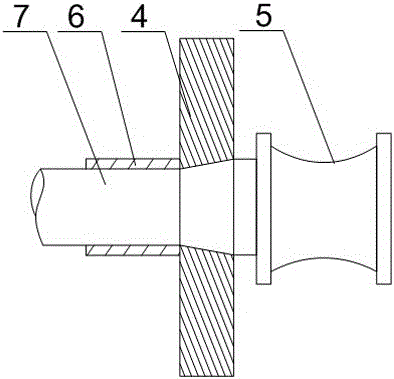

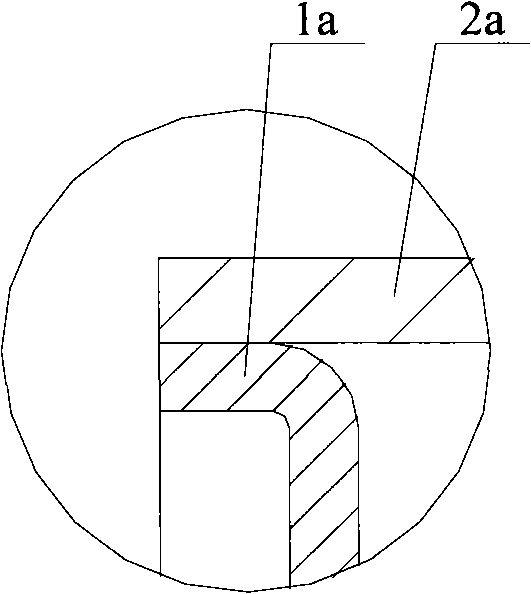

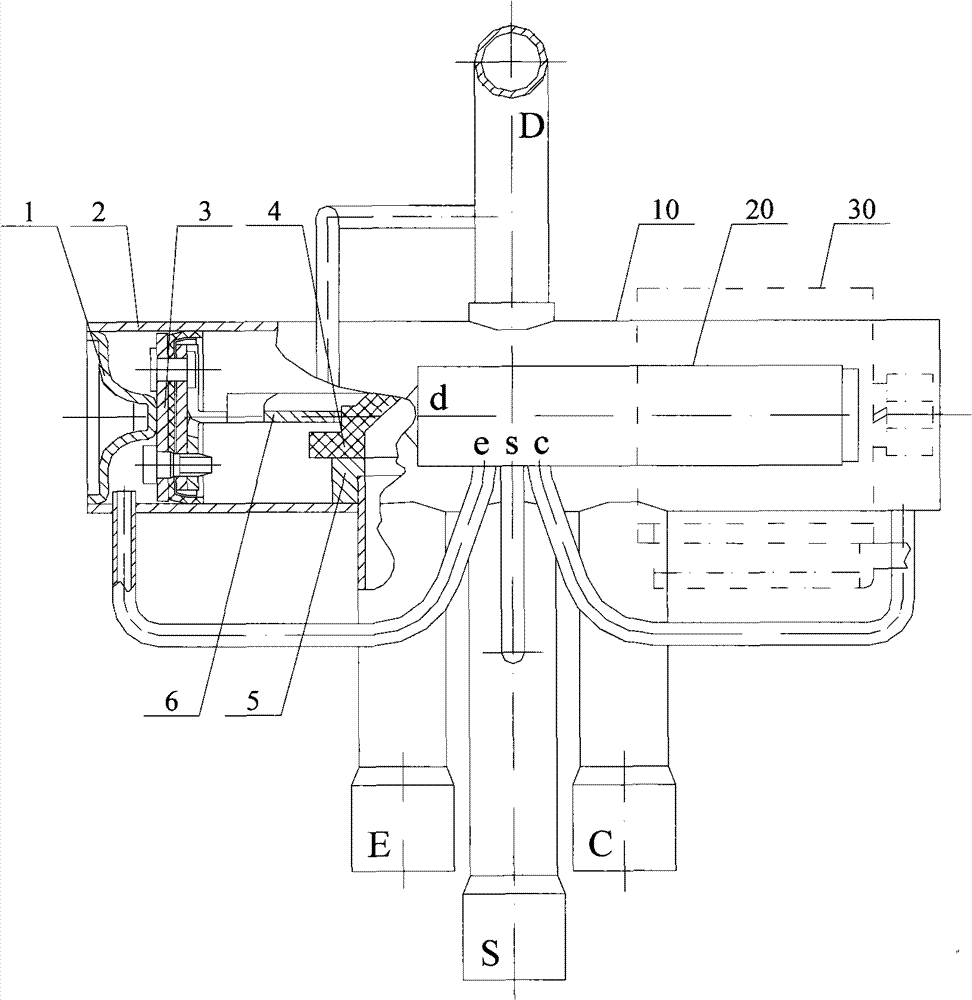

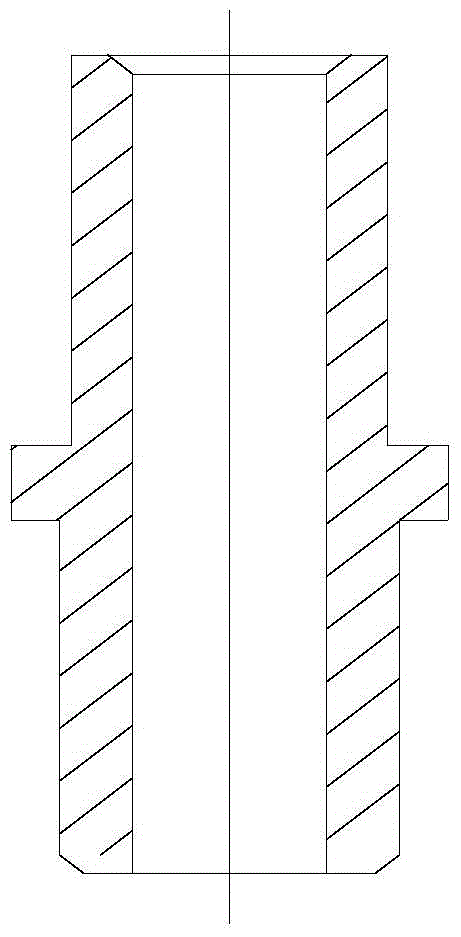

End cover as well as main valve of four-way reversing valve and four-way reversing valve using same

ActiveCN101963255ALarge radial extrusion forceThe large diameter section presents a large radial extrusion force at the outer endEqualizing valvesMultiple way valvesMechanical engineeringPiston

The invention discloses an end cover used for a main valve of a four-way reversing valve. The end cover is provided with a large-diameter segment and a small-diameter segment axially arranged in sequence, wherein the periphery of the large-diameter end cover is fixedly connected with a valve body; the end part of the small-diameter end cover is matched with a piston of the main valve to limit theworking position of the piston; and the large-diameter end cover is in a frustum shape with a larger external end and smaller internal end. The end cover is suitable for the valve body determined by the permissible range of the size of the internal diameters at both ends; after assembling, the peripheral surface of the large-diameter end of both end covers or the near large-diameter end is matched with the inner wall of the valve body so as to meet the position precision requirement therebetween and further improve the welding precision therebetween. On this basis, the invention further provides a main valve of a four-way reversing valve and a four-way reversing valve using the end cover.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Method of manufacturing a pipe coupling component

InactiveUS8418517B2Avoid formingPrevent liquid leakageSemiconductor/solid-state device detailsSolid-state devicesAcute angleCoupling

A method of manufacturing a pipe coupling that prevents leakage including: forming a semi-tubular portion and flat portions along opposite sides of the semi-tubular portion; deforming the flat portions to produce larger bending depth and smaller width; bending portions of the flat portions so that the bent portions form acute angles in relation to the semi-tubular portion with sloping flat portions extending from the semi-tubular portion, and distal narrow flat portions; pushing the sloping flat portions away from the semi-tubular portion; pressing the semi-tubular portion, the sloping flat portions, and the narrow flat portions to produce a final shape; and removing burrs so that the semi-tubular portion of the final shape comes into close contact with an outer circumferential surface of a pipe, and the final flat portions are integrally formed along opposite side edges of the semi-tubular portion in a common plane.

Owner:SHOWA DENKO KK

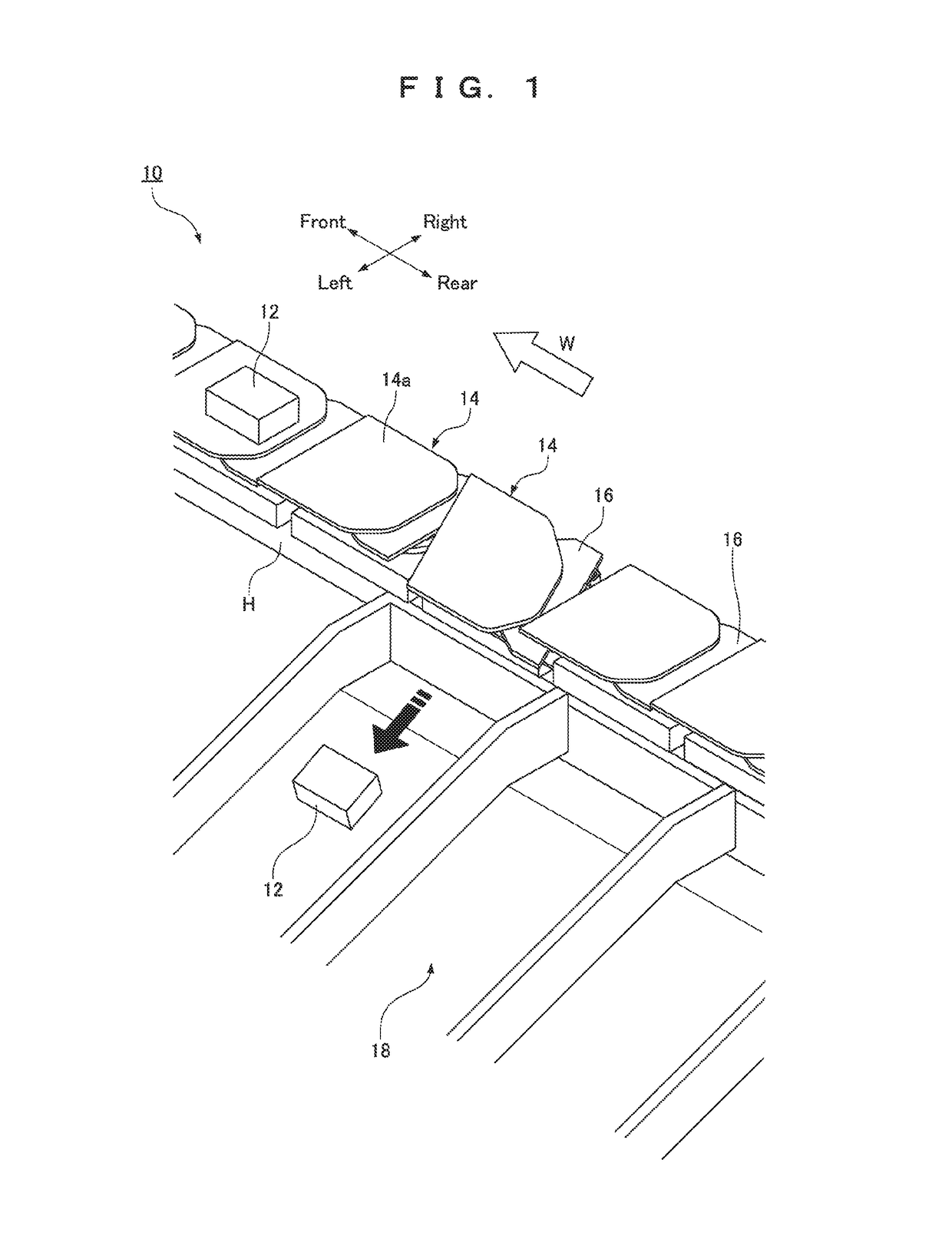

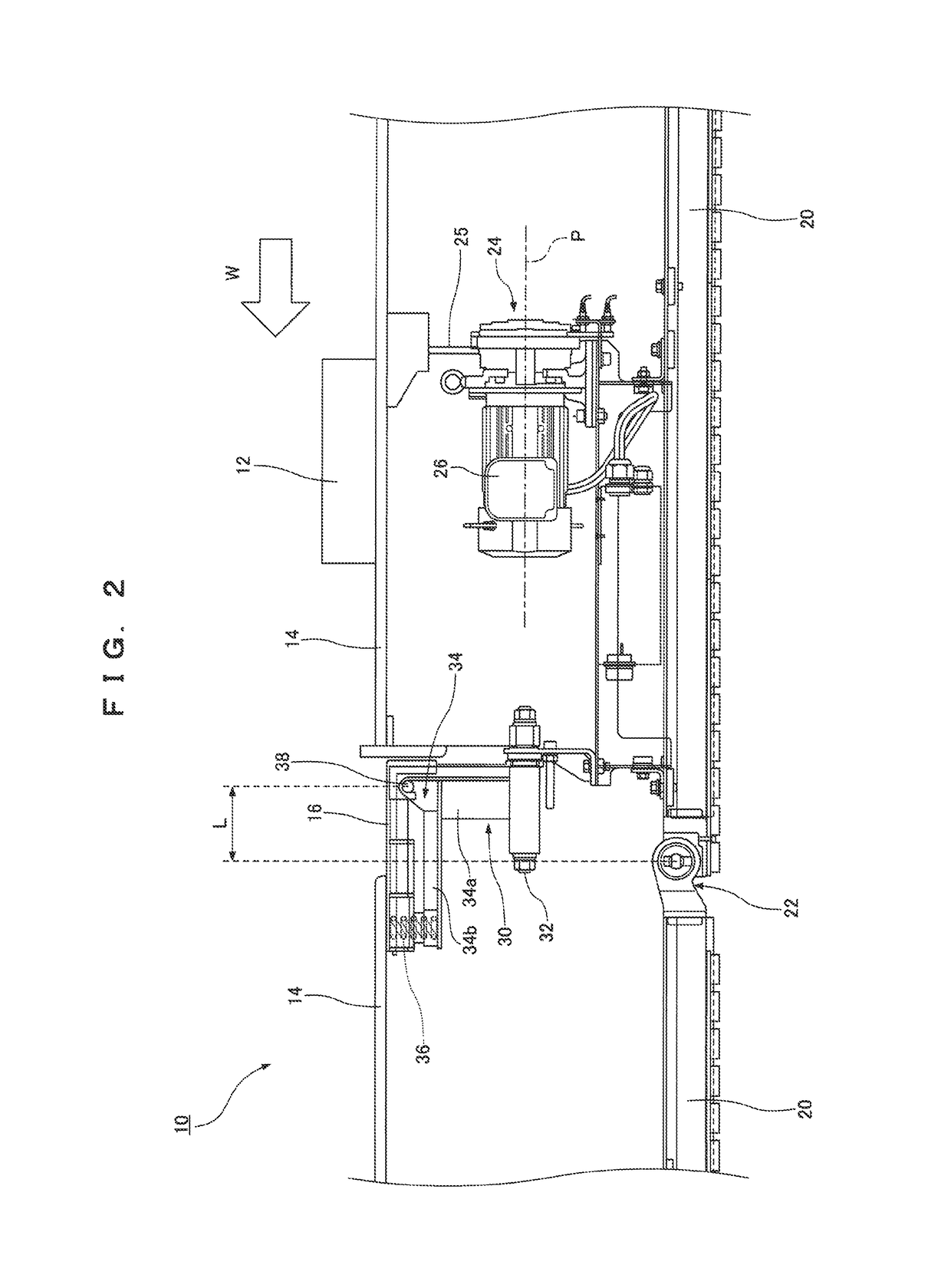

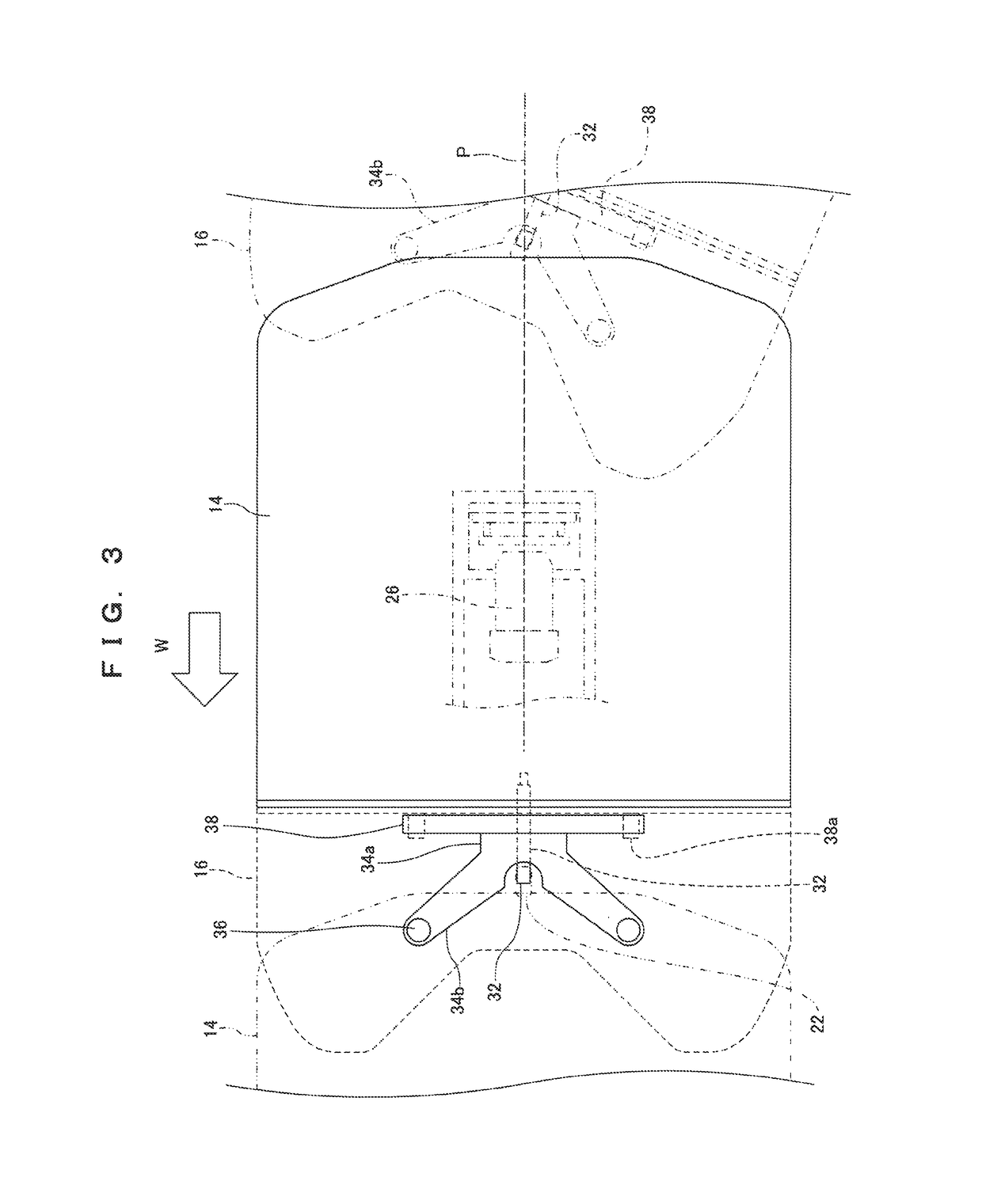

Conveyor device

A conveyor device for conveying articles includes: travel units, trays provided for the respective travel units, and infill plates, each covering a clearance left between the trays. A swing bar supports the infill plate so as to vertically swing the infill plate and is provided at a position shifted by a predetermined distance L in a direction opposite to the traveling direction of the travel unit from the position of a coupler connecting the travel unit supporting a plate-tilting shaft and the travel unit traveling ahead, the plate-tilting shaft supporting the infill plate so as to laterally tilt the infill plate.

Owner:DAIFUKU CO LTD

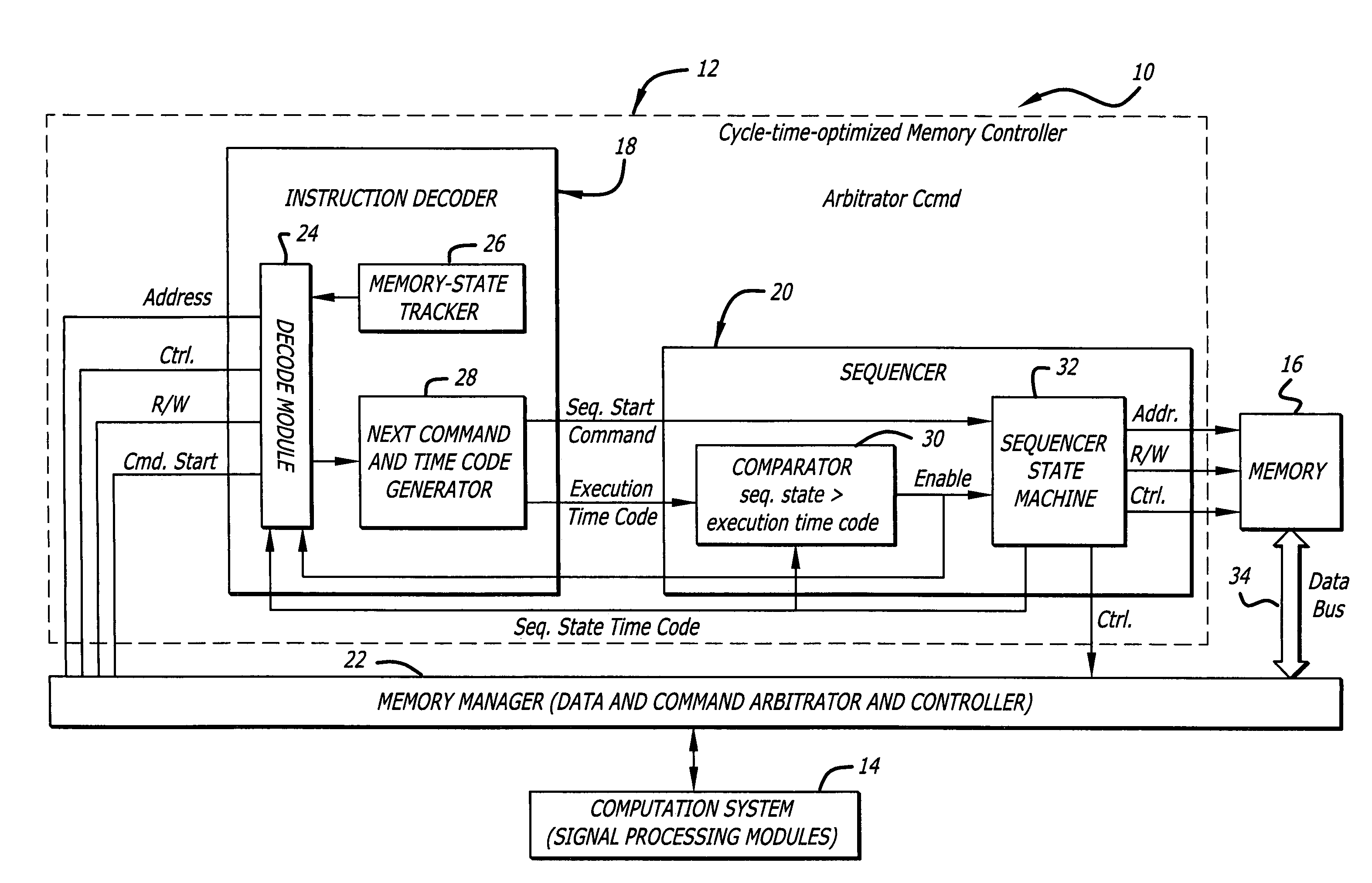

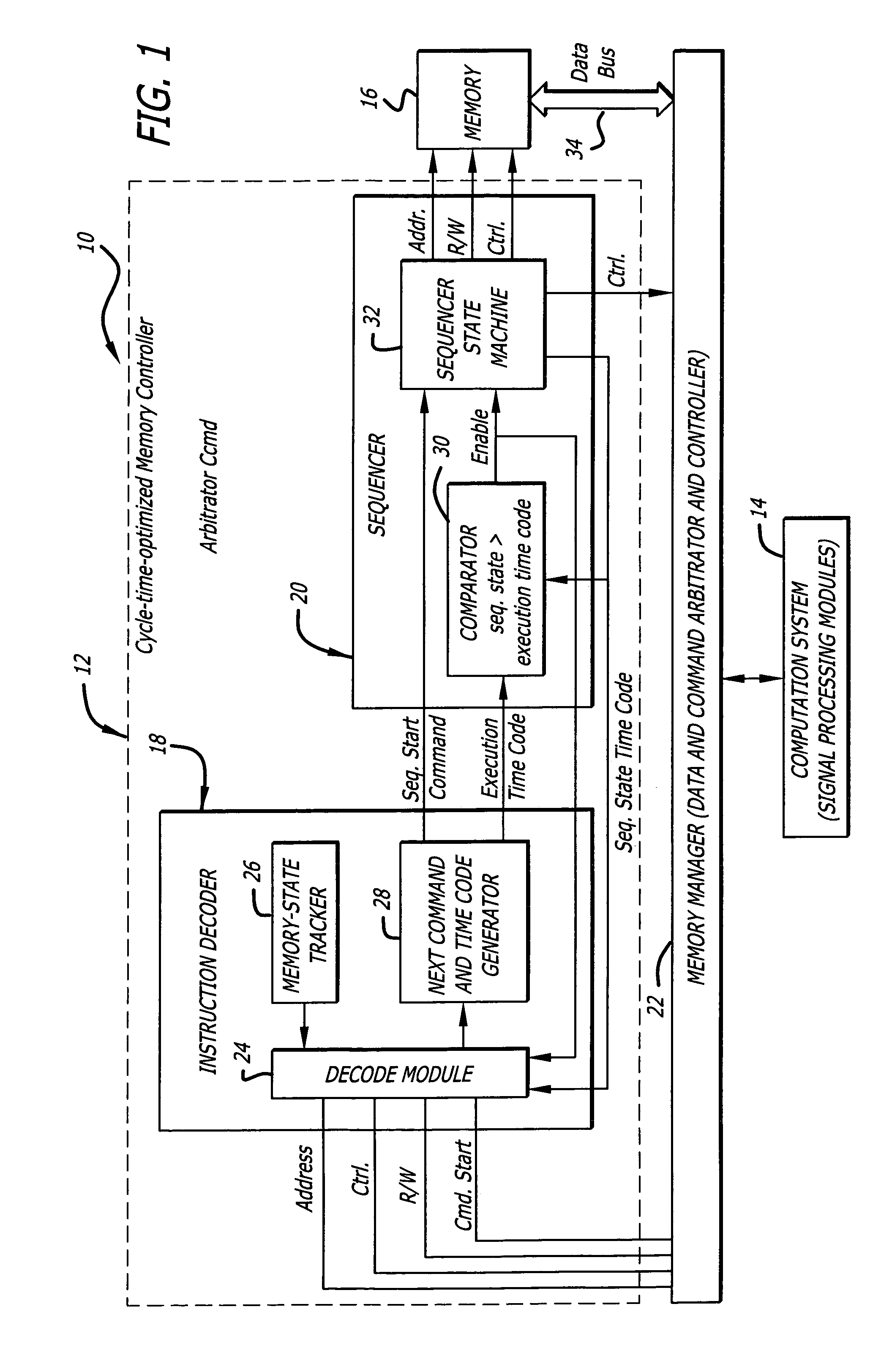

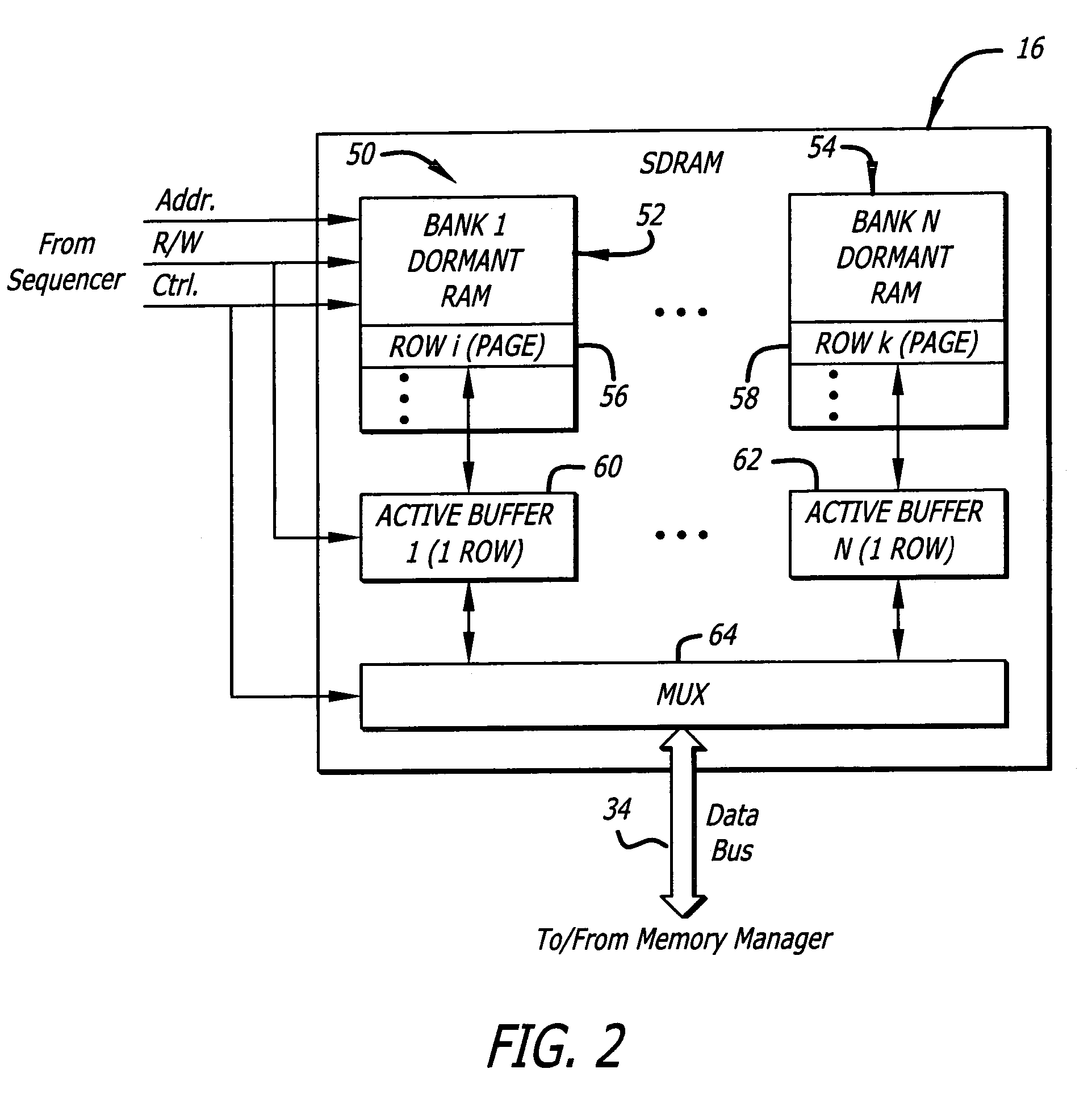

Efficient memory controller

ActiveUS7370169B2Avoid excessive gapsOverlap between commands, addresses, and data may be maximizedTelevision system detailsColor television detailsComputer moduleMemory controller

An efficient memory controller. The controller includes a first mechanism for associating one or more input command sequences with one or more corresponding values. A second mechanism selectively sequences one of the one or more command sequences to a memory in response to a signal. A third mechanism compares each of the one or more values to a state of the second mechanism and provides the signal in response thereto. In a specific embodiment, the one or more corresponding values are execution time code values, and the second mechanism includes a sequencer state machine that provides the state of the second mechanism as a sequencer time code. In the specific embodiment, a compare module compares the sequencer time code to a time code associated with a next available command sequence and execution time code pair and provides the signal in response thereto.

Owner:RAYTHEON CO

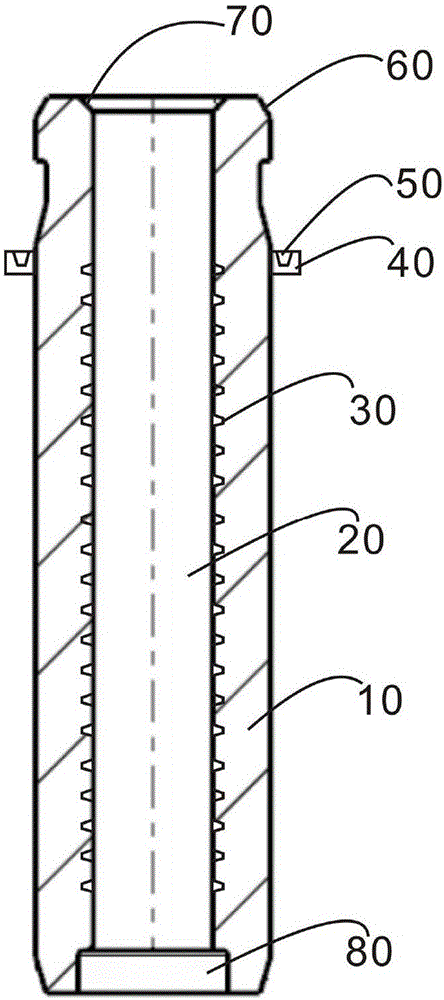

Valve guide pipe

InactiveCN106499459AReduce wearAvoid excessive gapsLubrication of auxillariesMachines/enginesLubricationOil storage

The invention relates to a valve guide pipe. The valve guide pipe comprises a guide pipe body, wherein a through hole is arranged in the guide pipe body along the axial direction of the guide pipe body; a plurality of oil storage grooves are arranged in the surface of the through hole; a boss is arranged on the outer surface of the guide pipe body; an oil injection port is arranged in the boss and communicates with an oil storage groove; externally tangential surfaces are arranged on the outer walls of ports in the two ends of the guide pipe body; an internally tangential surface is arranged on the inner wall of the port in one end of the guide pipe body; and a groove structure is arranged on the inner wall of the other port. According to the valve guide pipe disclosed by the invention, lubricant oil is input in the oil storage groove through the oil injection port, thus wear of a valve rod due to insufficient lubrication with the valve guide pipe during cold start is reduced; meanwhile, a part of the lubricant oil can be stored on an inner cutting surface, thus formation of oil film lubrication between the valve guide pipe and the valve rod is benefited, and conduction of heat to a cylinder cover from the valve rod through the valve guide pipe is facilitated; and in addition, a sharp corner generated by the inner wall of the groove structure has a scraping function, and coking and carbon deposition already formed by the valve rod and the valve guide pipe part are removed and prevented from entering the valve guide pipe.

Owner:YIZHENG CHANGDA POWDER METALLURGY PROD CO LTD

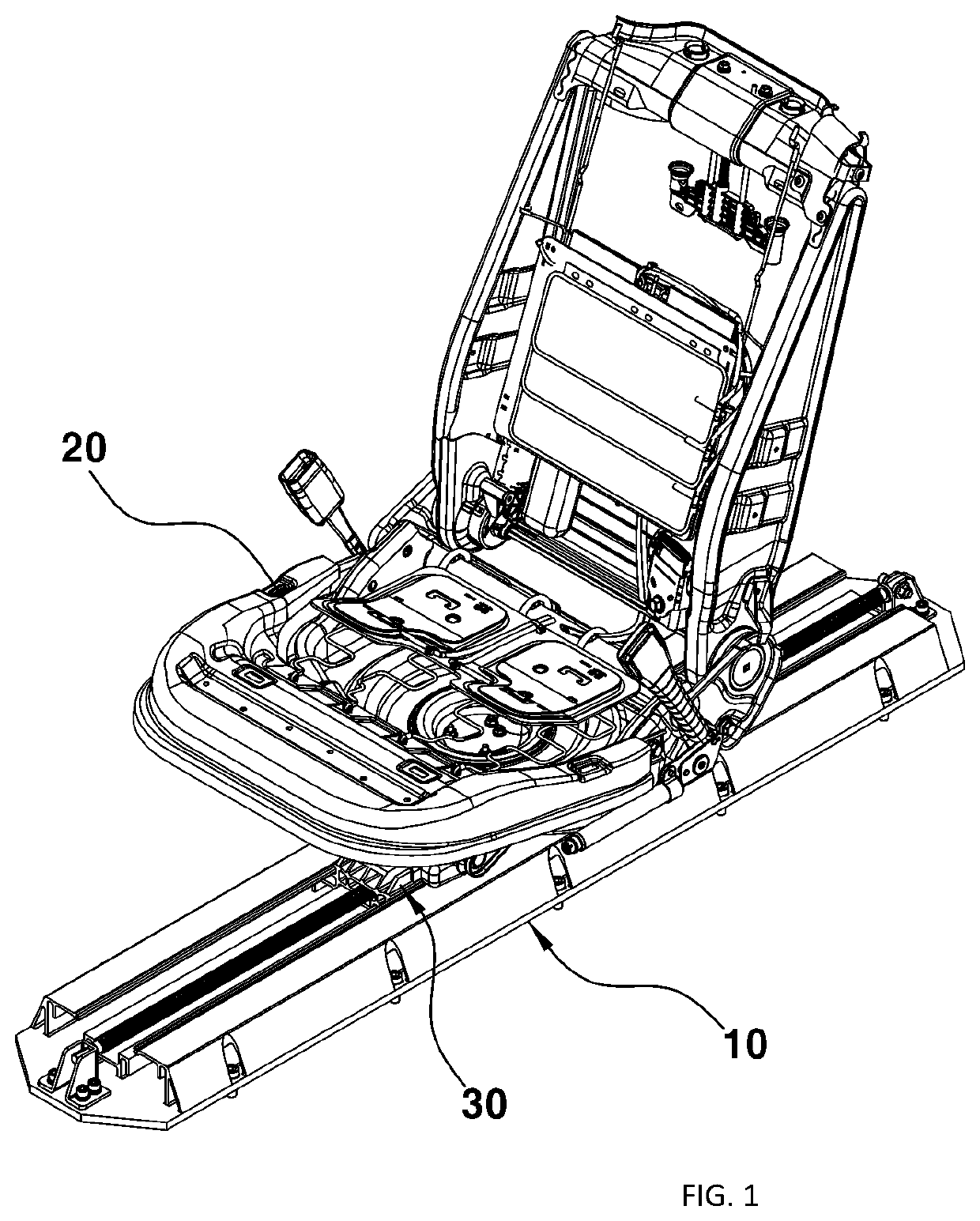

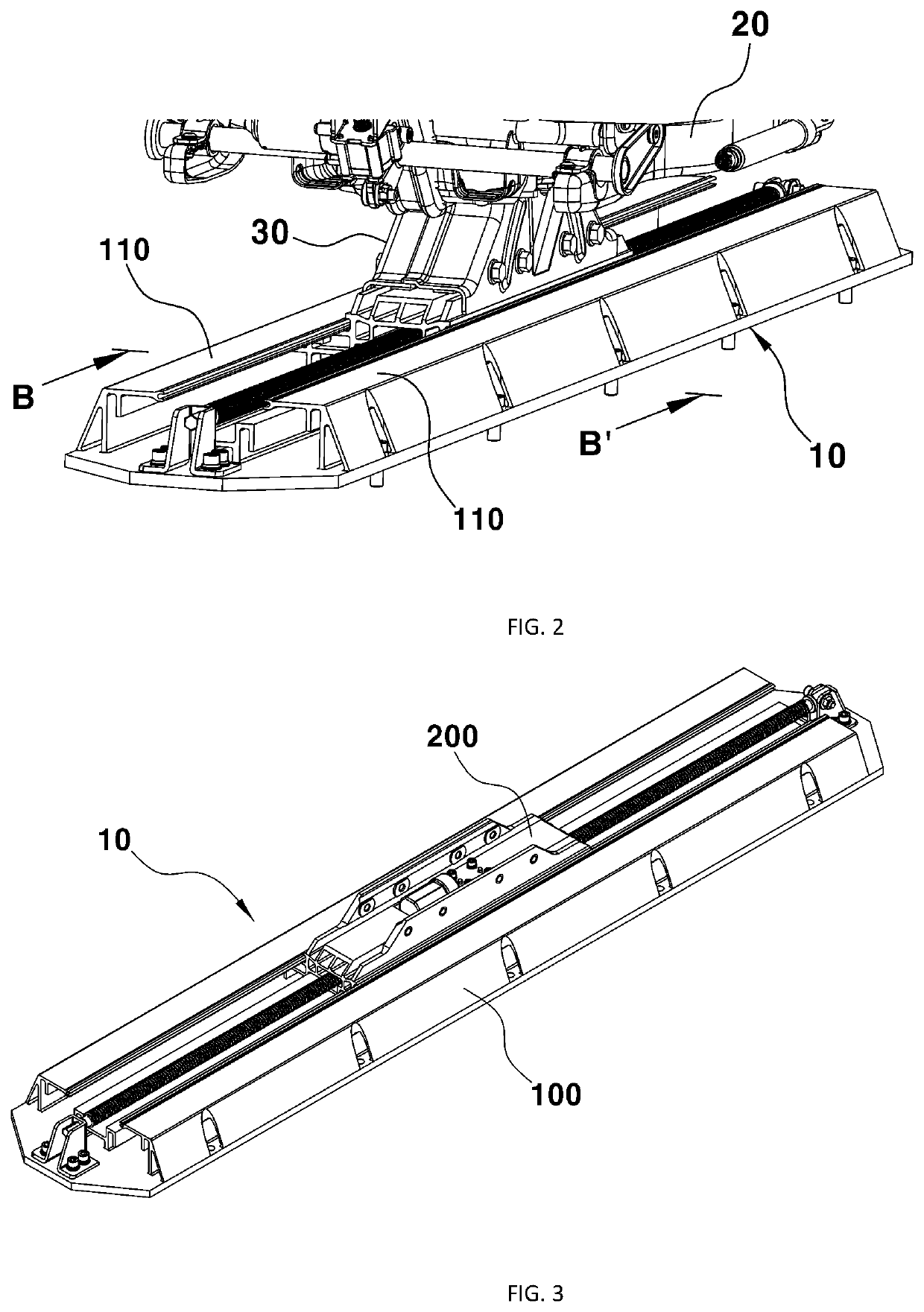

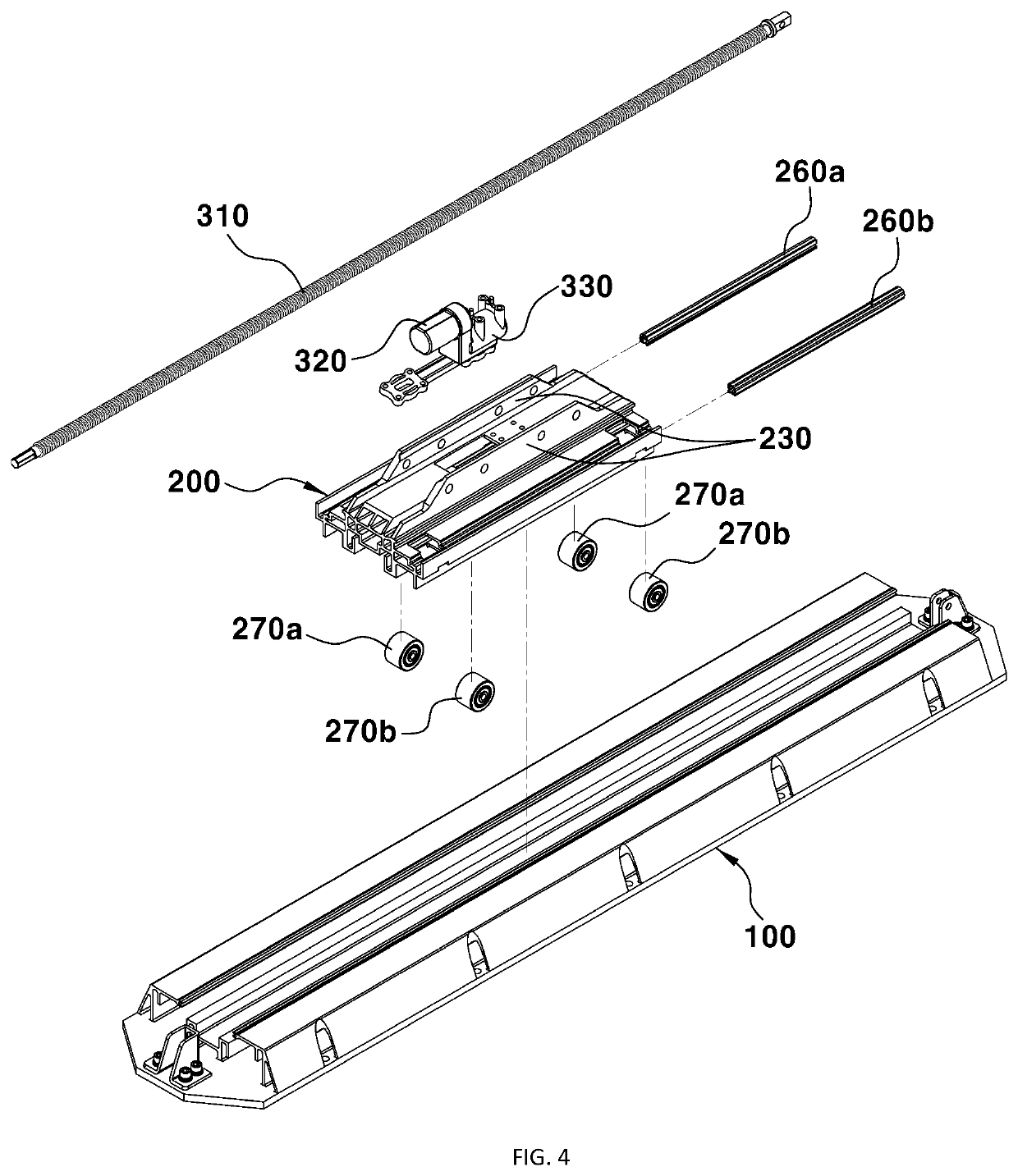

Seat track mechanism for vehicle

ActiveUS11110823B2Slimness and autonomySimple structureBus seatsMovable seatsControl theoryMechanical engineering

Owner:HYUNDAI TRANSYS INC

A kind of preparation method of densified aluminum titanate ceramics

The invention belongs to the technical field of a ceramic material and specifically relates to a preparation method for a compact aluminum titanate ceramic. The method comprises the following steps: by taking tetrabutyl titanate and aluminum nitrate as raw materials, taking an alcohol solution containing a dispersing agent as a solvent and taking butyl silicate as an internal additive; introducing ammonia gas, refluxing, aerating and reacting, thereby acquiring a gel solution; by taking ferric chloride as an external additive, adding a curing agent, reducing pressure and distilling, thereby acquiring the gel; adding the gel into a mold, vibrating, heating and curing; and raising temperature in gradient, pressurizing, drying and sintering in a muffle furnace, thereby acquiring the compact aluminum titanate ceramic. The invention solves the problem of complex preparation process of the liquid phase compound in the prior art; the method provided by the invention is high in plasticity and is capable of customizing the ceramic shape according to the requirement; the prepared aluminum titanate is high in purity, fine in structure and high in uniformity.

Owner:无锡特科精细陶瓷有限公司

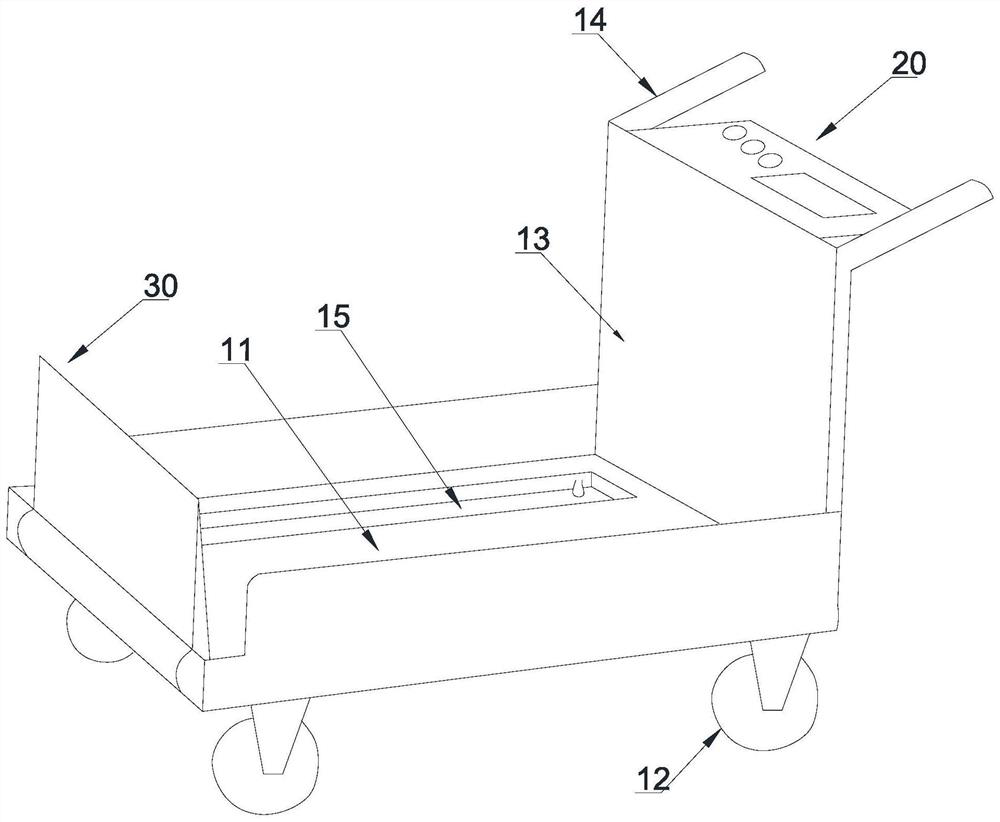

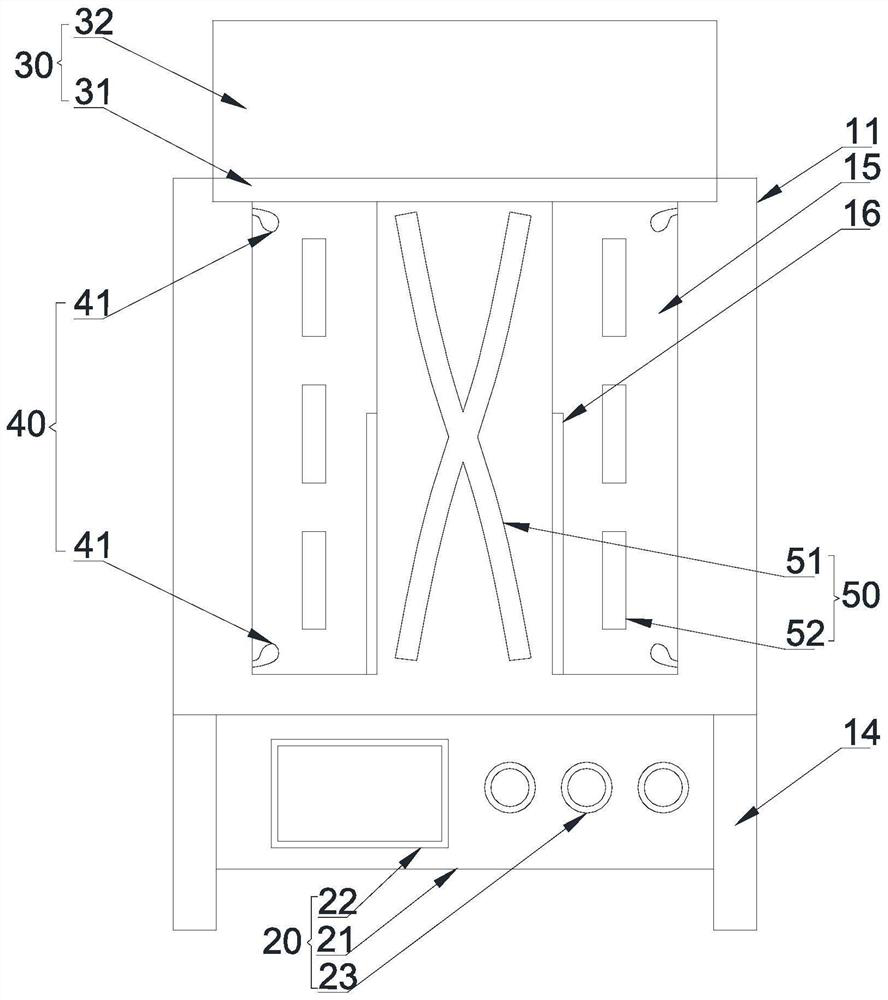

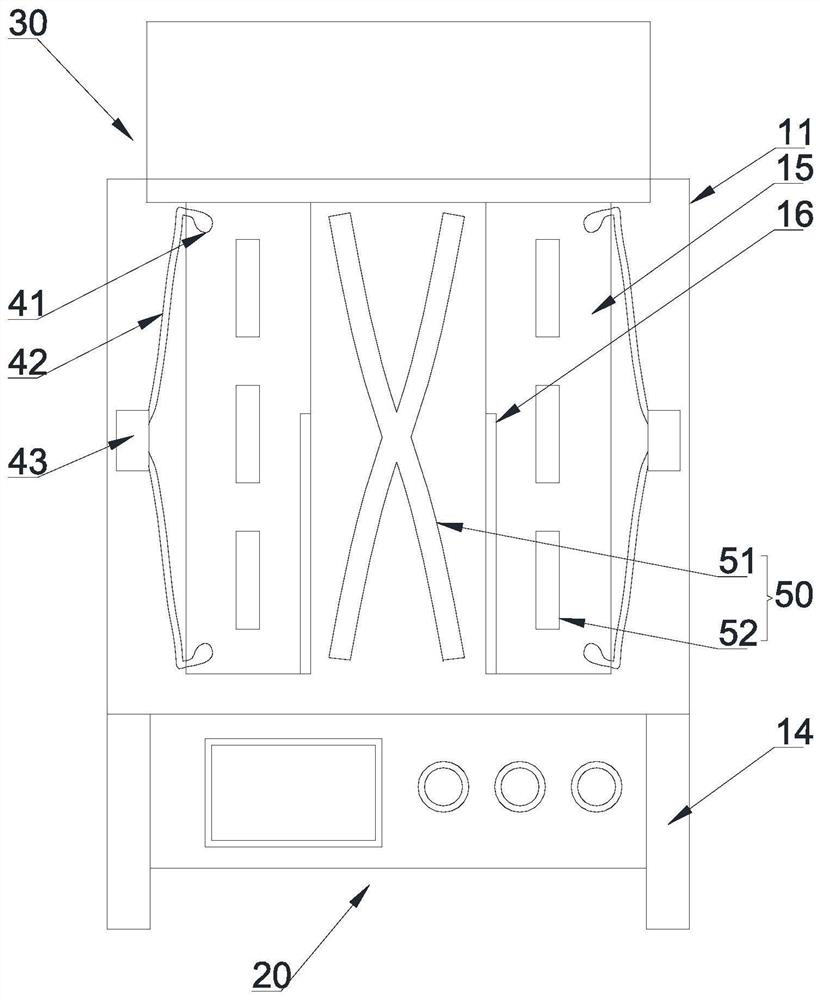

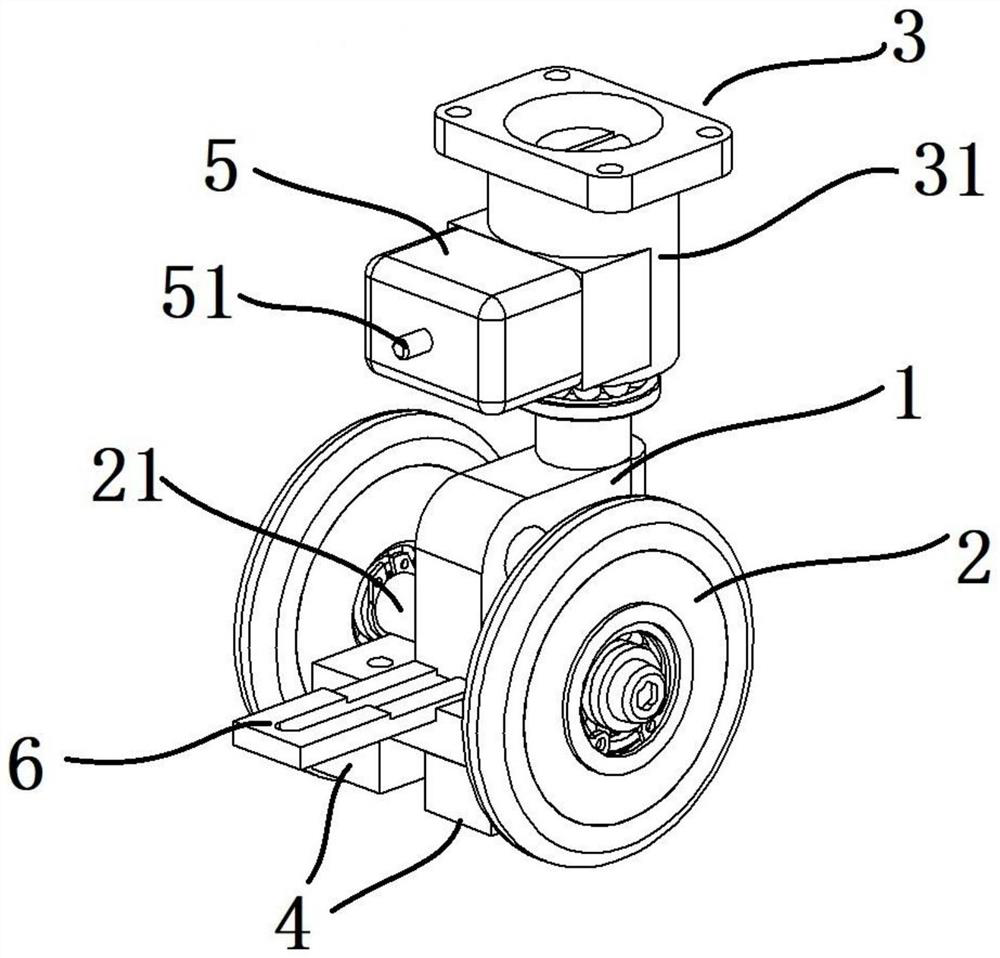

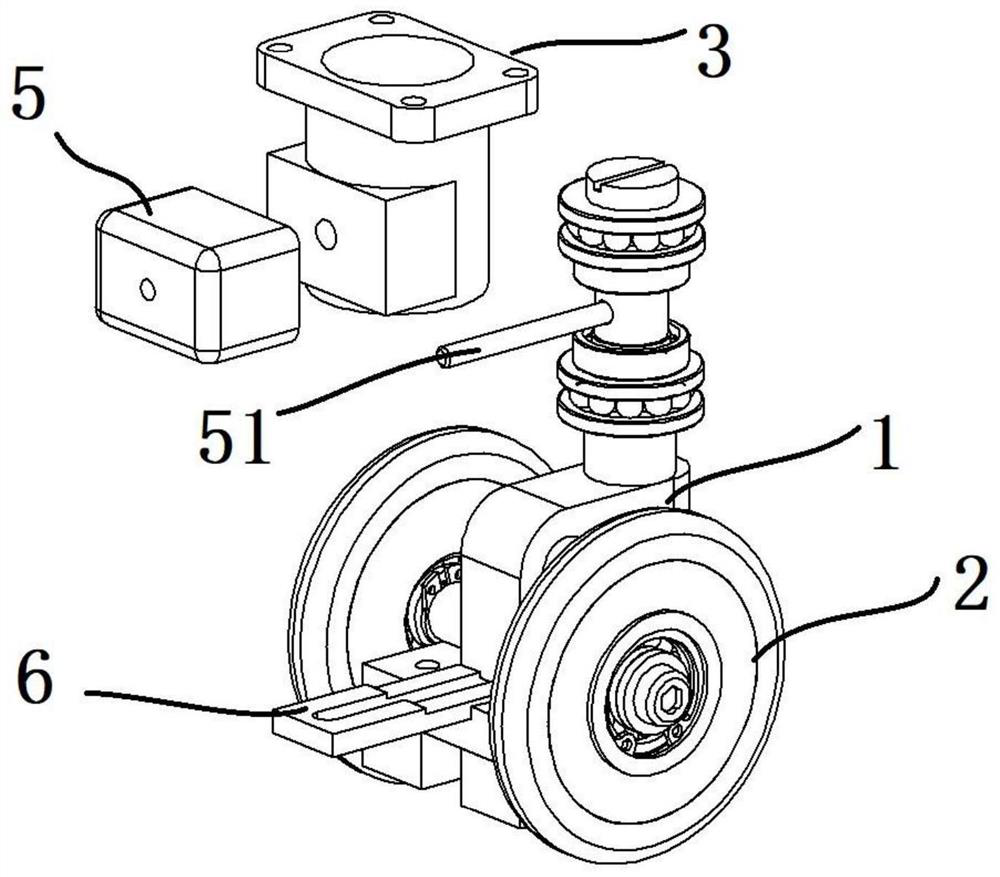

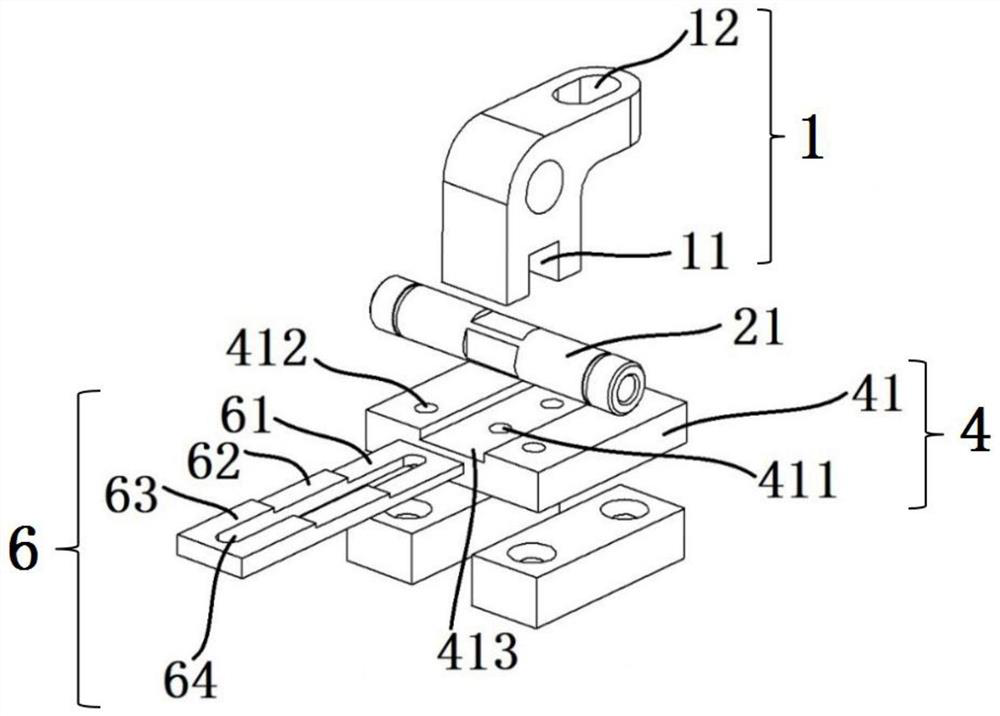

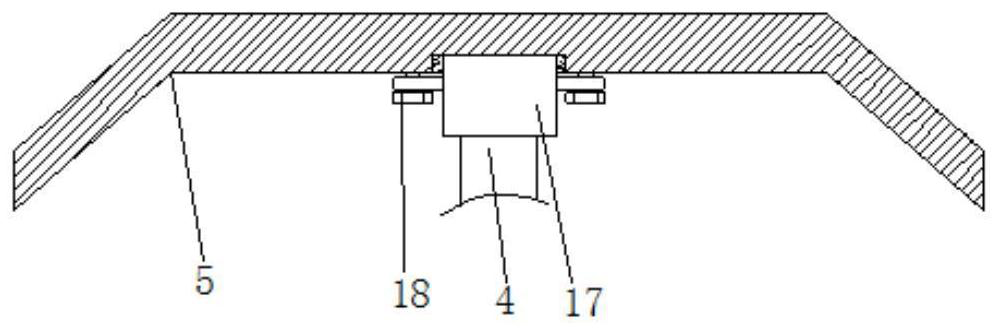

Purifying instrument pushing equipment for nephrology department and using method thereof

InactiveCN113911193AReduce labor intensityAvoid excessive gapsSupporting partsHand carts with multiple axesCartAssistive device

The invention discloses purifying instrument pushing equipment for the nephrology department and a using method thereof, and belongs to the technical field of medical auxiliary devices. The purifying instrument pushing equipment for the nephrology department comprises a cart, a control mechanism, a turning plate mechanism and a flexible limiting mechanism. When the pushing equipment is used for transferring a purifying instrument for the nephrology department, the turning plate mechanism can be rotated to enable one end of the turning plate mechanism to make contact with the ground, rolling wheels are usually arranged at the bottom of the purifying instrument for the nephrology department, the rolling wheels can enter a containing groove along the turning plate mechanism, and the purifying instrument can be moved to the cart without being lifted; the flexible limiting mechanism is in contact with rollers of the purifying instrument for limiting, so that the problem that effective limiting cannot be realized due to an overlarge gap between the rollers of the purifying instrument and the containing groove can be avoided, and the bottom of the purifying instrument can be prevented from being damaged by rigid limiting; and a touch control mechanism is arranged, so that the whole equipment can be conveniently operated and controlled during working, and the working efficiency is further improved.

Owner:南充市中心医院

Wind power generation impeller

InactiveCN108167114AImproved ability to capture wind energyEasy to limitMachines/enginesRenewable energy generationImpellerWind force

The invention relates to a wind power generation impeller. The wind power generation impeller comprises a rotating shaft, blades, a fixed connecting piece and an adjustable connecting piece, wherein the fixed connecting piece comprises a fixed base and first connecting strips; the adjustable connecting piece comprises a movable base and second connecting strips, the fixed base and the movable baseare arranged at the two ends of the rotating shaft correspondingly, the movable base is in threaded connection with the rotating shaft, the blades are arranged between the fixed base and the movablebase; each blade is connected with the fixed base through the first connecting strips, and the first connecting strips are rotationally connected with the blades, the first connecting strips are rotationally connected with the fixed base; each blade is connected with the movable base through the second connecting strips, the second connecting strips are rotationally connected with the blades, andthe second connecting strips are rotationally connected with the movable base. The invention has the beneficial effects that the fixed connecting piece and the adjustable connecting piece are used forconnecting the blades, when a angle of the blades needs to be temporarily adjusted, the adjustable connecting piece can be utilized, so that a current wind direction and wind power can be better adapted; and the capability of capturing wind energy is improved.

Owner:武汉力博物探有限公司

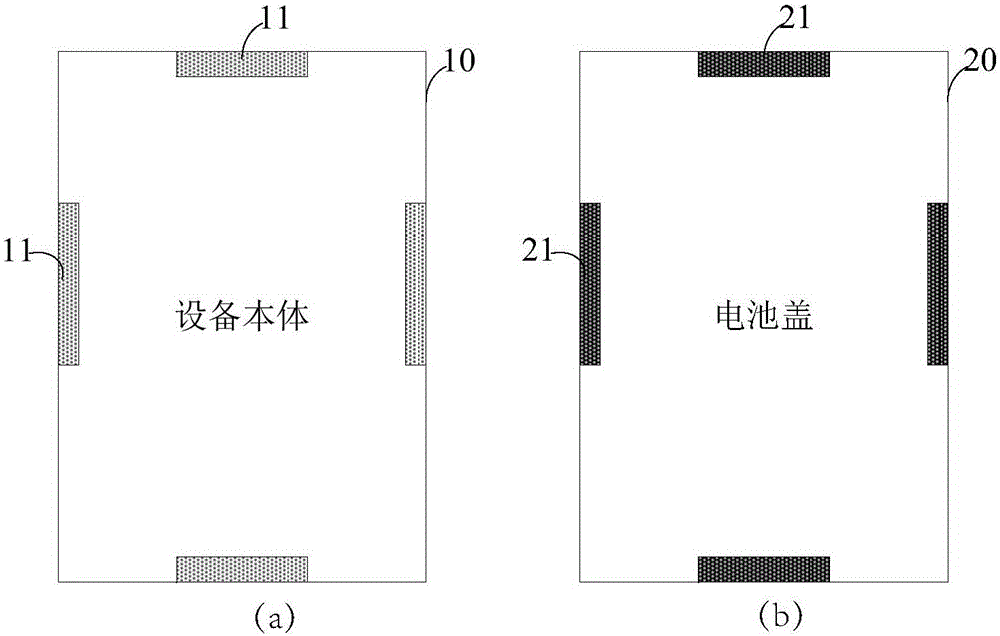

Battery cover installation structure and terminal device

InactiveCN106098980AReduce the difficulty of disassemblyAvoid excessive gapsCell lids/coversTelephone set constructionsMagnetic polesTerminal equipment

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

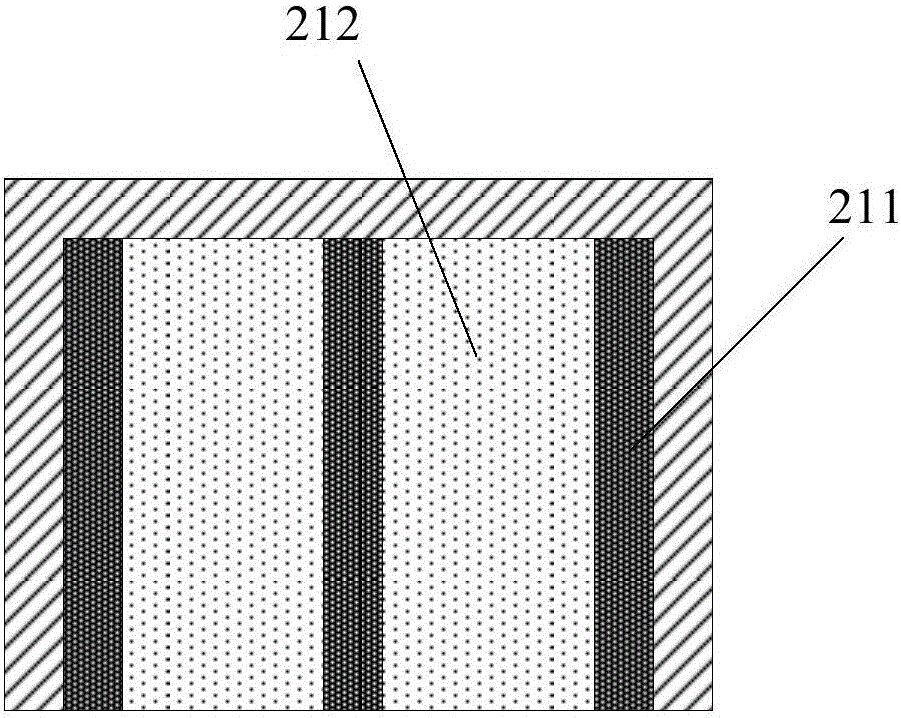

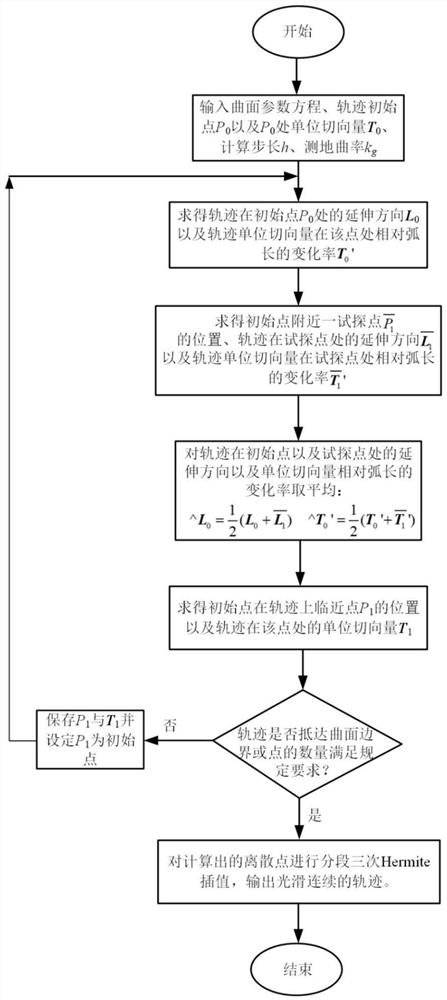

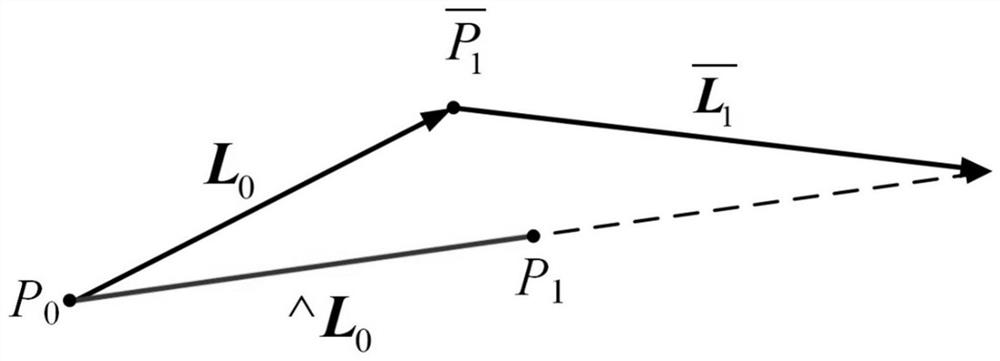

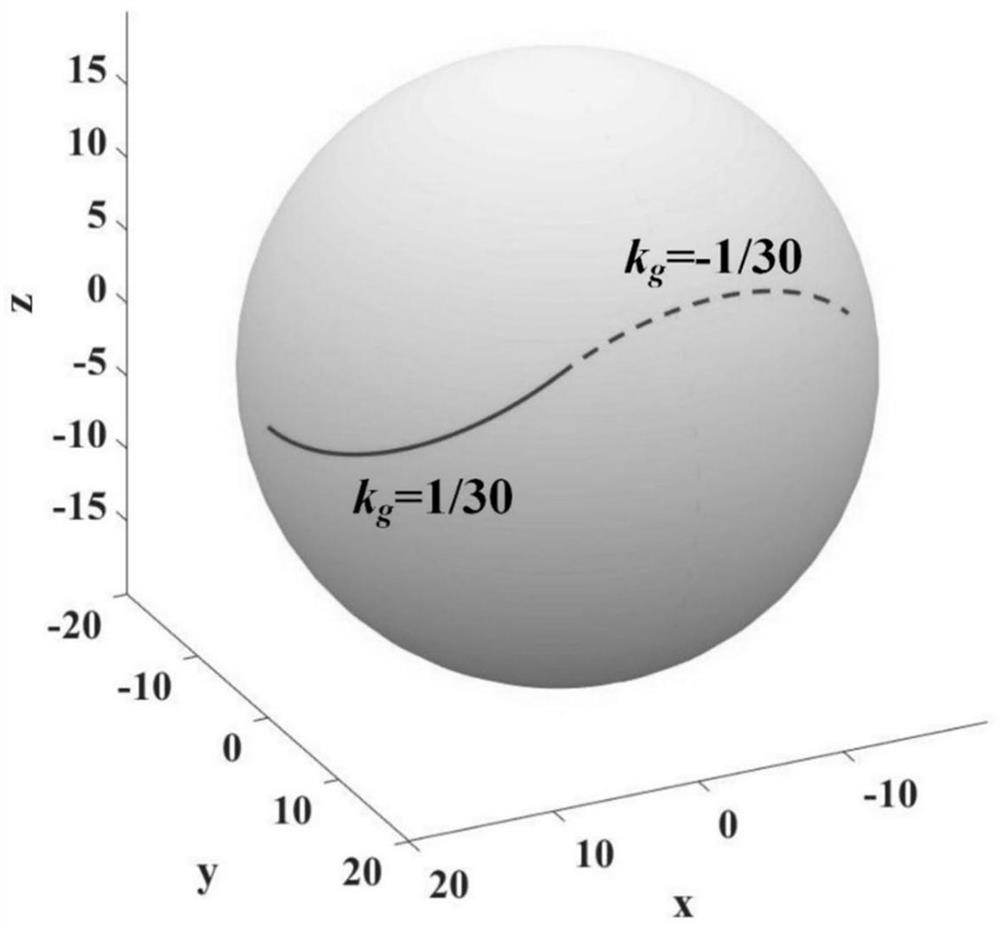

Planning method of prepreg tape laying track based on specified geodesic curvature

ActiveCN111857057AAvoid excessive gapsReduce complexityNumerical controlClassical mechanicsEngineering

The invention discloses a planning method for a prepreg tape laying track based on a specified geodesic curvature. The planning method comprises the following steps: inputting a three-dimensional model of a curved surface of a to-be-laid mold, the position of an initial point P0 of the prepreg tape laying track, a unit tangent vector T0 of the prepreg tape laying track at the initial point P0, a calculation step length h and a specified geodesic curvature value kg; calculating extension directions and relative arc length change rates of the initial point and the test point; the method comprises the following steps of: obtaining an initial point P0, averaging the initial point P0, then obtaining an adjacent point P1 of the initial point P0, replacing the initial point P0 with the adjacent point P1, repeating the steps to obtain subsequent discrete points, and performing Hermite interpolation on the discrete points for three times in sections to generate a smooth and continuous prepreg tape laying track based on the specified geodesic curvature. The method disclosed by the invention can be applied to a non-developable curved surface, and the precision of trajectory planning is ensured.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

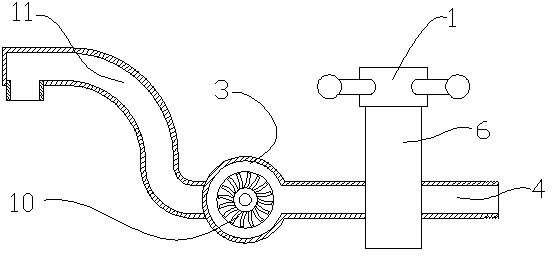

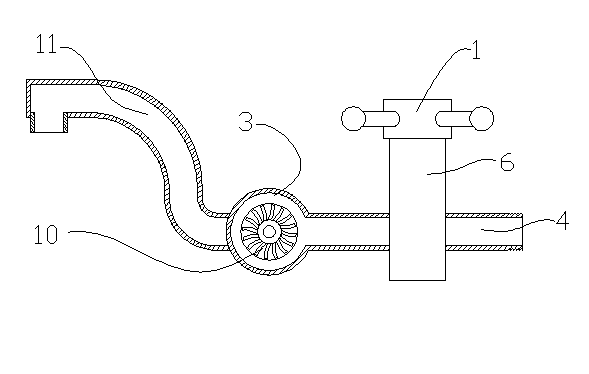

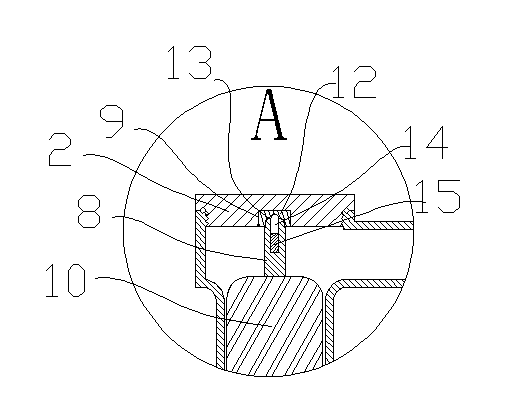

Cold and hot water faucet

InactiveCN102954254BFlexible rotationReduce frictionValve members for absorbing fluid energyMultiple way valvesWater flowEngineering

The invention discloses a cold and hot water faucet. The cold and hot water faucet comprises a cold and hot water faucet body, a cold water channel, a hot water channel, a water outlet channel, a cold water flow adjusting valve and a hot water flow adjusting valve. Valves are respectively arranged on the cold and the hot water channel. Screws and a screw shaft are respectively arranged on sections, intersected with the water outlet channel, of the cold water channel and the hot water channel. The screws are respectively coupled and fixed on the same screw shaft or the screws are integrated with the screw shaft. A guide wheel is arranged between the two screws and on a section, intersected with the water outlet channel, of the cold water channel and the hot water channel. When the valves are all switched on, flows of cold water and hot water are basically identical, pressure difference between the cold water and the hot water is effectively adjusted. When a user turns on other faucets on a same pipeline, only total flow is reduced, adjusted proportion between the cold water and the hot water is basically not changed, thus the temperature of water is effectively controlled.

Owner:杨翠超 +3

Gap magnetic adsorption universal wheel

The invention provides a gap magnetic adsorption universal wheel which comprises a connecting frame, a driven wheel and a supporting bearing. A wheel shaft used for installing the driven wheel is arranged at one end of the connecting frame, the driven wheel is installed at the two ends of the wheel shaft, and the other end of the connecting frame is rotationally connected with a robot through thesupporting bearing; a magnet is further installed at the end, close to the driven wheel, of the connecting frame, and containing spaces for containing gaskets of different sizes are formed between themagnet and the connecting frame. According to the gap magnetic adsorption universal wheel, the problem that the resistance is too large when the robot steers can be solved, and certain adsorption force is provided for the robot through the magnet while the robot moves flexibly.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV +2

Cold and hot water faucet

InactiveCN102954254AFlexible rotationReduce frictionValve members for absorbing fluid energyMultiple way valvesWater flowEngineering

The invention discloses a cold and hot water faucet. The cold and hot water faucet comprises a cold and hot water faucet body, a cold water channel, a hot water channel, a water outlet channel, a cold water flow adjusting valve and a hot water flow adjusting valve. Valves are respectively arranged on the cold and the hot water channel. Screws and a screw shaft are respectively arranged on sections, intersected with the water outlet channel, of the cold water channel and the hot water channel. The screws are respectively coupled and fixed on the same screw shaft or the screws are integrated with the screw shaft. A guide wheel is arranged between the two screws and on a section, intersected with the water outlet channel, of the cold water channel and the hot water channel. When the valves are all switched on, flows of cold water and hot water are basically identical, pressure difference between the cold water and the hot water is effectively adjusted. When a user turns on other faucets on a same pipeline, only total flow is reduced, adjusted proportion between the cold water and the hot water is basically not changed, thus the temperature of water is effectively controlled.

Owner:杨翠超 +3

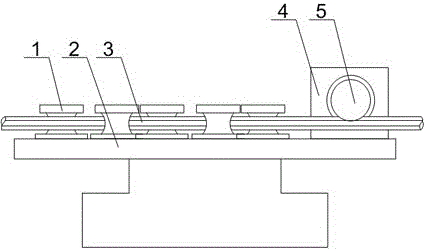

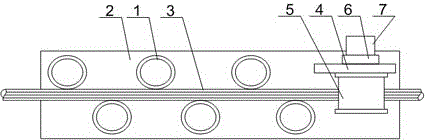

Copper stranded wire pressing structure

InactiveCN105719774AReduce tensionAvoid excessive gapsApparatus for feeding conductors/cablesReciprocating motionCopper

The invention discloses a copper stranded wire crimping structure, including a workbench and two rows of side pressure rollers, a support plate is also arranged on the workbench, a sleeve is installed on one side of the support plate, and a sleeve and sleeve are opened on the support plate. Concentric tapered holes, threads are provided on the straight section, the sleeve is threaded with the straight section, the tapered hole is matched with the enlarged section, and the end of the extended section is connected with a pressing roller. The inner diameter of the enlarged section Incremental along the axis of the sleeve pointing toward the roller. When the copper stranded wire jumps radially due to factors at the power output end, the groove on the pressing roller directly contacts the copper stranded wire, and at the same time, the straight section of the connecting rod is in contact with the sleeve by rotating the connecting rod back and forth. The thread fits to make the lower pressure roller reciprocate in the horizontal direction, that is, to adjust the left and right swing of the copper strand at any time to increase the tension of the copper strand itself, so as to avoid the part that enters the reel too loosely and cause the twisting after turning. The gap between layers of copper strands is too large.

Owner:CHENGDU XINGDA OF COPPER CO LTD

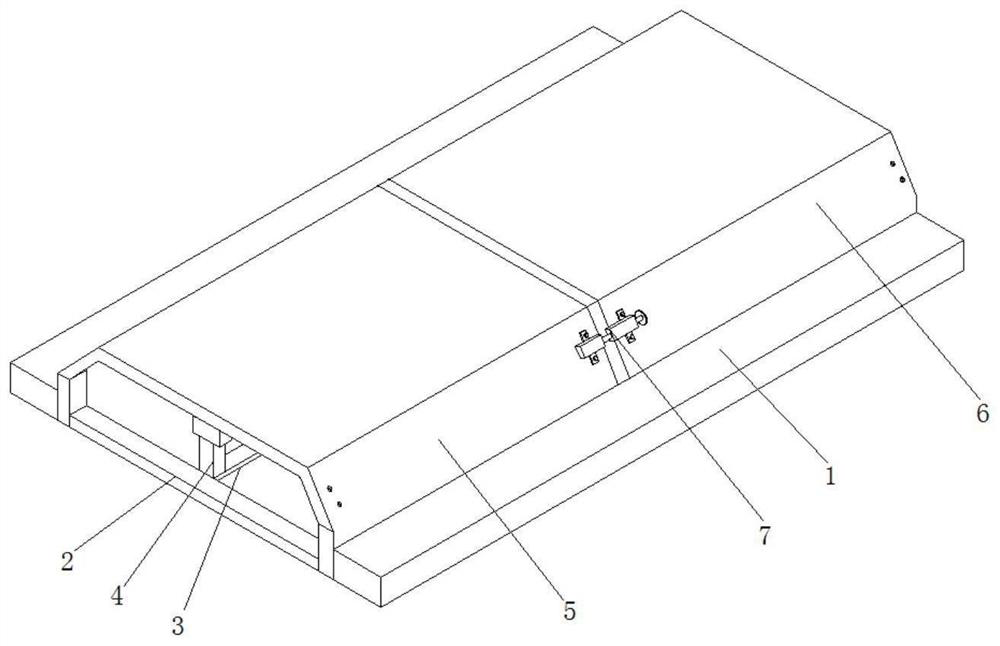

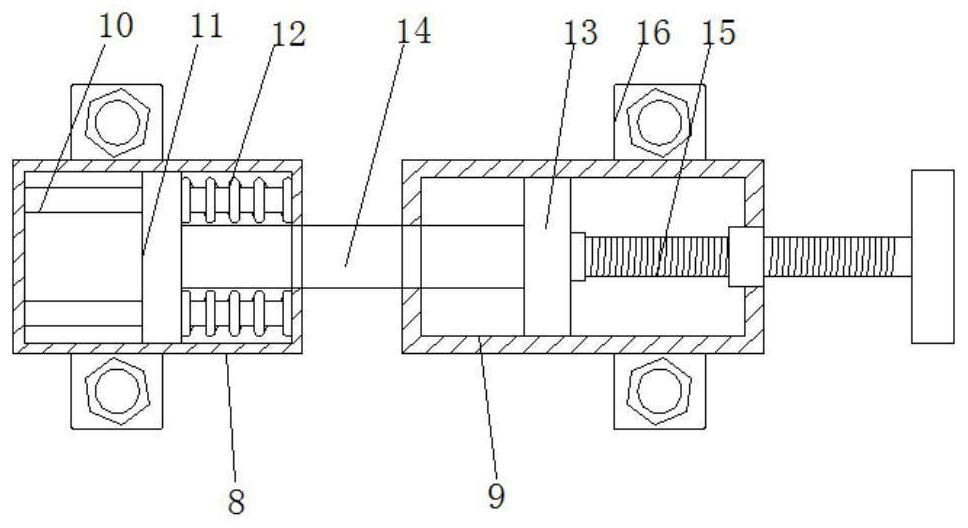

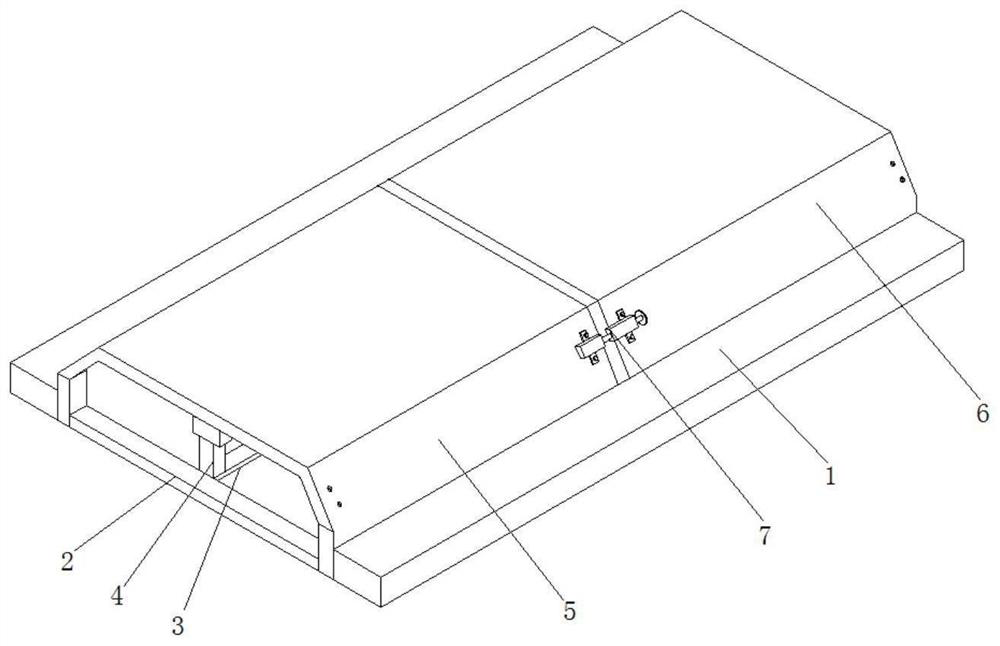

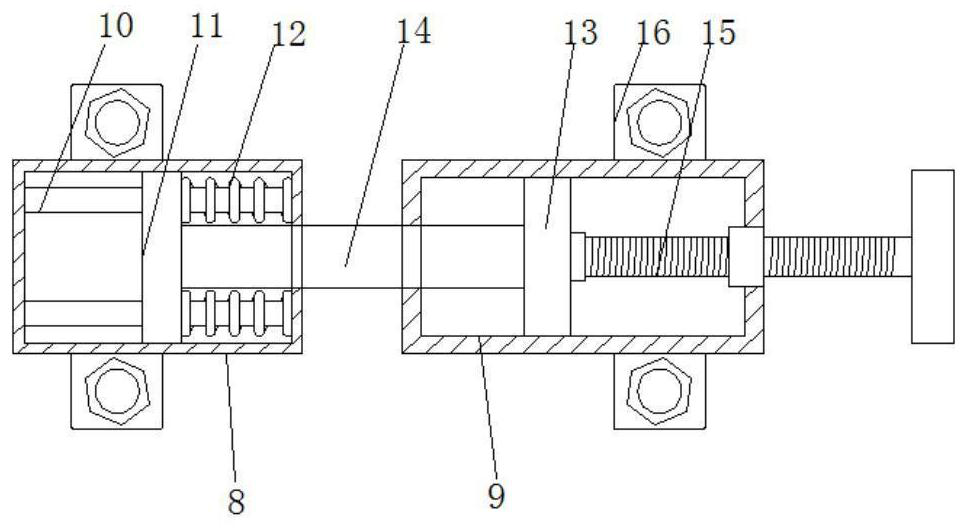

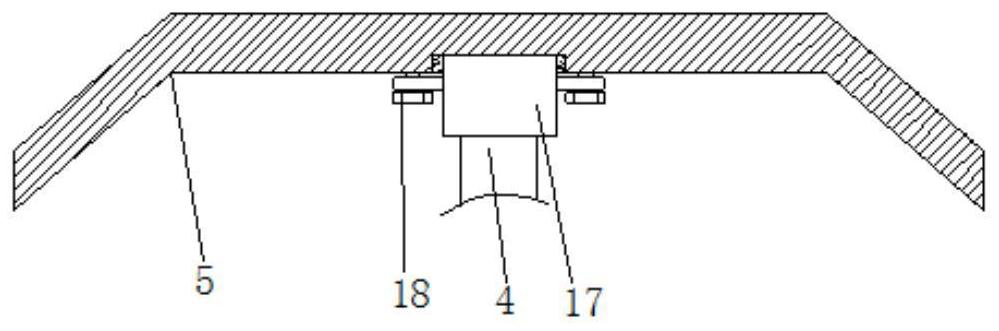

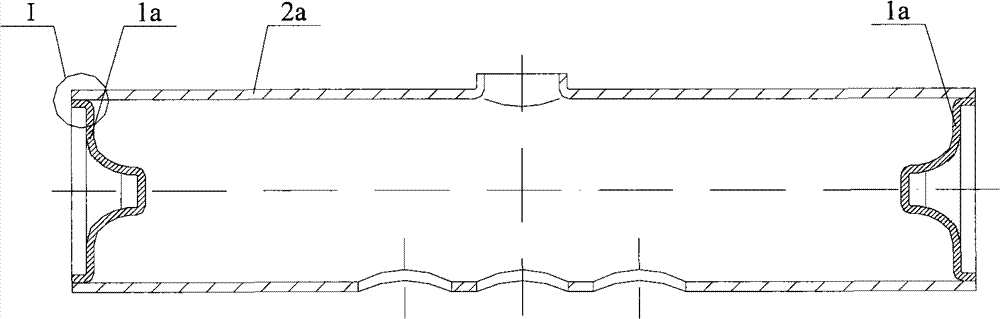

A New Type of Rail Vehicle Roof Frame

ActiveCN111688737BEasy to tightenAvoid excessive gapsRailway roofsStructural engineeringMechanical engineering

The invention discloses a new rail vehicle roof frame, which comprises two mounting plates, the outer walls of the opposite sides of the two mounting plates are fixed with connecting rods through bolts, and the same connecting rod is fixed with bolts between the two connecting rods. As for the fixed plate, the outer walls on the opposite sides of the two mounting plates are fixed with slide rails by bolts, and the inner walls of the two slide rails are respectively slidably connected with a first top plate and a second top plate, and the two sides of the first top plate and the second top plate are The side outer walls are provided with mounting holes, the outer walls on both sides of the first top plate and the second top plate are provided with connecting mechanisms, and support rods are welded on the fixed plates, and the connecting mechanisms include a first connection box and a second connection box. box. The present invention installs a detachable connection mechanism between the two top plates, and the two top plates are conveniently tightened by adjusting bolts on the connection mechanism, effectively preventing the problem of excessive gap between the top plates during welding.

Owner:安徽浦进轨道装备有限公司

Production technique of shrinkage prevention glue-free floor made of novel combined material

InactiveCN106592921APrevent archingAvoid excessive gapsSynthetic resin layered productsLaminationEngineeringAbsorption effect

The invention provides a production technique of a shrinkage prevention glue-free floor made of a novel combined material and relates to the technical field of floors. The production technique comprises the following steps that (1) a PVC decorative surface of a PVC decorative material is prepared; (2) natural cork wood chips, rubber and assistants are fused at a high temperature and subjected to tabletting to prepare a soft base material; (3) the soft base material is soaked in liquid paste resin, scraped to be flat and then dried at a high temperature; and (4) in the manufacturing process, the soaked and dried soft base material, a PVC backing material, the PVC decorative surface and an abrasion-resisting layer are sequentially stacked into a stacked body, and then an upper graining board and a lower graining board are used for conducting hot press molding on a flat-bed press. In the using process, arching and excessive gaps caused by expansion and shrinkage can be avoided; the adsorption effect to the ground is good, no glue is needed during construction, and the floor can be adsorbed to the ground directly; any single floor can be lifted after laying, and replacement and single floor cleaning are facilitated; no glue is needed for hot press molding during manufacturing, and the product is environmentally friendly and safe; and the material is soft, the sound absorption effect is quite excellent, and the feeling of feet is good.

Owner:ANHUI HANHUA BUILDING MATERIALS TECH

Novel railway vehicle roof framework

The invention discloses a novel railway vehicle roof framework. The novel railway vehicle roof framework comprises two mounting plates, connecting rods are fixed to the outer walls of the opposite sides of the two mounting plates through bolts, a same fixing plate is fixed between two connecting rods through bolts, sliding rails are fixed to the outer walls of the opposite sides of the two mounting plates through bolts, the inner walls of the two sliding rails are slidably connected to a first top plate and a second top plate correspondingly, mounting holes are formed in the outer walls of thetwo sides of the first top plate and the outer walls of the two sides of the second top plate, connecting mechanisms are arranged on the outer walls of the two sides of the first top plate and the outer walls of the two sides of the second top plate, supporting rods are welded to the fixing plates, and each connecting mechanism comprises a first connecting box and a second connecting box. The detachable connecting mechanism is installed between every two top plates, the two top plates are conveniently tensioned through adjusting bolts on the connecting mechanism, and the problem that a gap between the top plates is too large in the welding process is effectively solved.

Owner:安徽浦进轨道装备有限公司

End cover as well as main valve of four-way reversing valve and four-way reversing valve using same

ActiveCN101963255BLarge radial extrusion forceThe large diameter section presents a large radial extrusion force at the outer endEqualizing valvesMultiple way valvesStructural engineeringFrustum

The invention discloses an end cover used for a main valve of a four-way reversing valve. The end cover is provided with a large-diameter segment and a small-diameter segment axially arranged in sequence, wherein the periphery of the large-diameter end cover is fixedly connected with a valve body; the end part of the small-diameter end cover is matched with a piston of the main valve to limit theworking position of the piston; and the large-diameter end cover is in a frustum shape with a larger external end and smaller internal end. The end cover is suitable for the valve body determined by the permissible range of the size of the internal diameters at both ends; after assembling, the peripheral surface of the large-diameter end of both end covers or the near large-diameter end is matched with the inner wall of the valve body so as to meet the position precision requirement therebetween and further improve the welding precision therebetween. On this basis, the invention further provides a main valve of a four-way reversing valve and a four-way reversing valve using the end cover.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

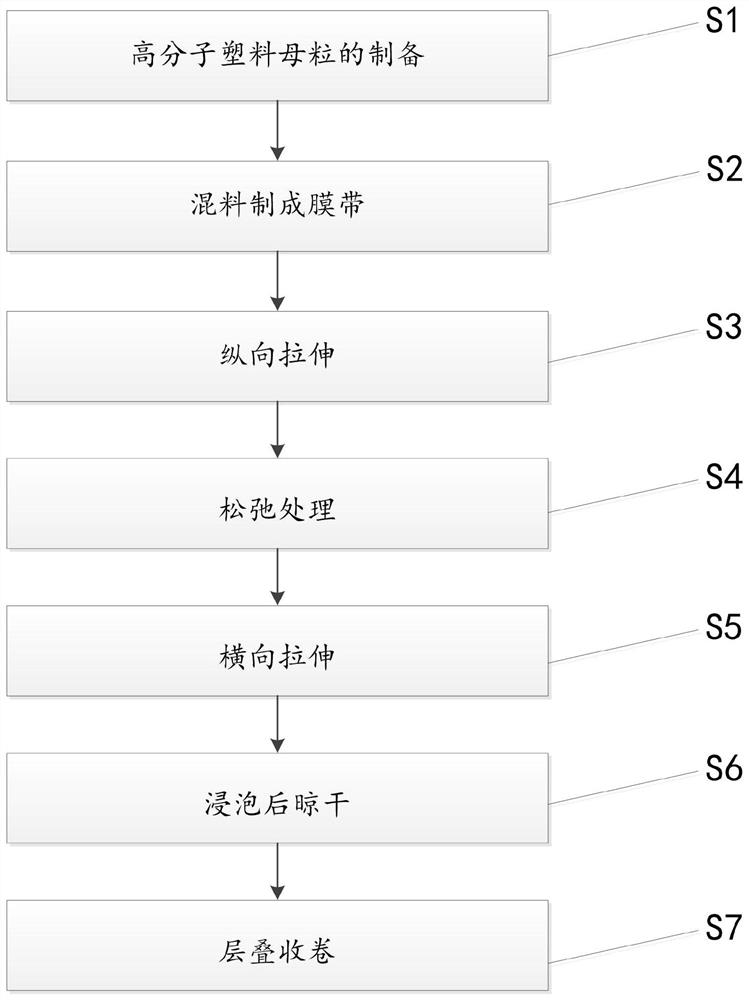

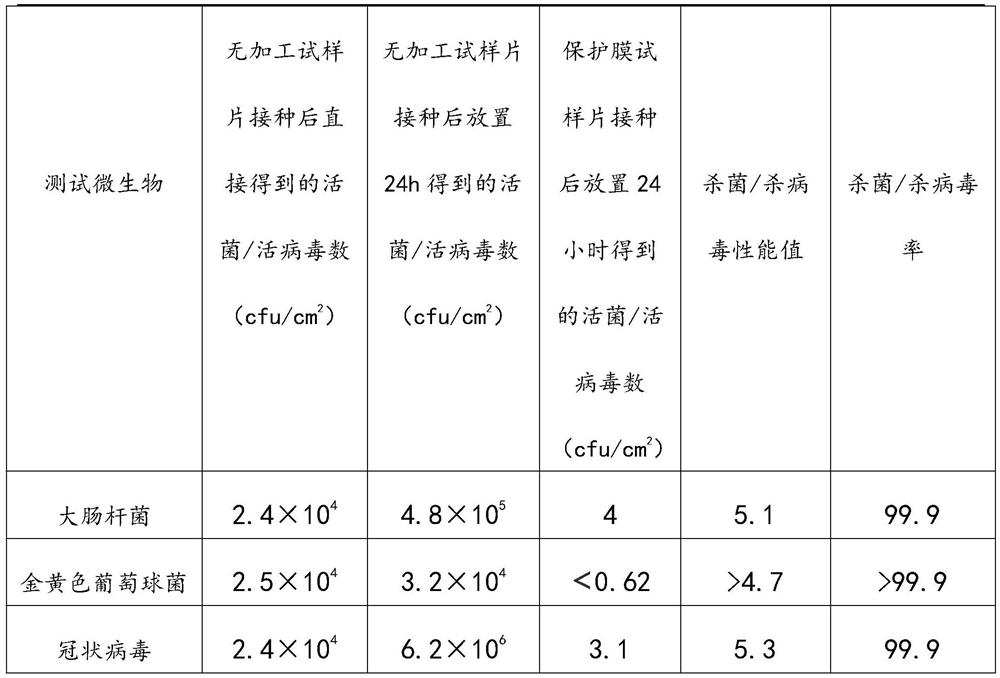

Sterilizing and virus-killing protective film and preparation method thereof

PendingCN112251025AStrong bioelectric field interference capabilityNot easily oxidizedFlexible coversWrappersDisinfectantCopper oxide

The invention relates to a sterilization and virus-killing protective film which comprises the following components in parts by weight: 90-95 parts of polymer plastic, 15-20 parts of a polyhexamethylene biguanide compound disinfectant, and 1-5 parts of nano silver-copper alloy particles, wherein the pH value of the polyhexamethylene biguanide compound disinfectant is 7-8, the polyhexamethylene biguanide compound disinfectant comprises the following components: polyhexamethylene biguanide and didecyl dimethyl ammonium chloride, and the weight percentage ratio of the polyhexamethylene biguanideto the didecyl dimethyl ammonium chloride is 1:2; the particle size of the nano-silver copper alloy particles ranges from 15 nm to 50 nm, the nano-silver copper alloy comprises, by weight, 40%-80% ofsilver and 20%-60% of copper, and copper metal atoms on the outer surface of the nano-silver copper alloy form copper oxide. According to the invention, the sterilization and virus killing protectivefilm can kill living microorganisms such as bacteria, mould and viruses attached to the surface of the protective film, the killing rate reaches up to 99% or above, and the path of contact infection of the bacteria, mould and viruses through the protective film is blocked.

Owner:SHENZHEN JIAN NANOCOMPOSITES CO LTD

VCSEL module and manufacture thereof

InactiveUS9172213B2Increase in sizeLessSemiconductor laser arrangementsSemiconductor laser structural detailsBiomedical engineeringEngineering

The invention describes a method of manufacturing a VCSEL module (100) comprising at least one VCSEL chip (33) with an upper side (U) and a lower side (L) and with a plurality of VCSEL units (55) on a common carrier structure (35), the VCSEL units (55) comprising a first doped layer (50) of a first type facing towards the lower side (L) and a second doped layer (23) of a second type facing towards the upper side (U). The method comprises the steps of dividing the VCSEL chip (33) into a plurality of subarrays (39a, 39b, 39c, 39d, 39e, 39f, 39g, 39h, 39i) with at least one VCSEL unit (55) each, electrically connecting at least some of the subarrays (39a, 39b, 39c, 39d, 39e, 39f, 39g, 39h, 39i) in series. The invention also describes a VCSEL module (100) manufactured in such process.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

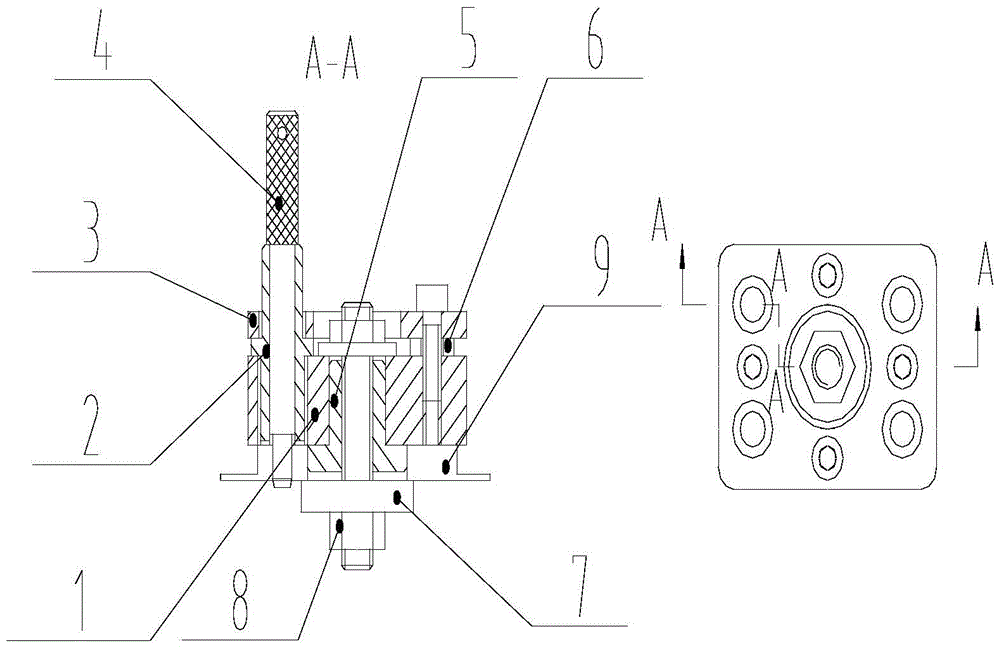

Tools for Tapping Group Threaded Holes

ActiveCN104475884BGuaranteed verticalityEliminate position deviationThread cutting machinesEngineeringUltimate tensile strength

The invention discloses a tapping tool for grouped threaded holes, and aims to reliably position and press, reduce the labor intensity and improve the tapping efficiency. The adopted technical scheme is that the tool comprises a drill plate and a baffle plate, wherein the drill plate and the baffle plate have consistent shapes and are both provided with guide holes and middle holes; a guide sleeve is arranged in the guide holes and is provided with an axial through hole; the position of the through hole corresponds to the position of a bottom hole of a case; the guide sleeve can move horizontally in the guide holes; a bolt is arranged in the through hole of the guide sleeve; one end of the bolt extends into the bottom hole of a boss of the case, and the other end of the bolt extends out of the through hole of the guide sleeve; a step-shaped positioning pin is arranged in the middle holes; a small end of the positioning pin extends into the middle holes, and big end of the positioning pin can be inserted into the positioning hole in a boss surface of the case and is axially provided with a pressing plate; the positioning pin and the pressing plate are provided with axial threaded holes; a bolt is arranged in the threaded holes and penetrates through the threaded holes of the positioning pin and the middle holes of the baffle plate; the entire device can be positioned and tightly pressed on the case through the nut.

Owner:AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com