Copper stranded wire pressing structure

A technology of crimping structure and copper stranded wire, applied in conductor/cable supply devices, electrical components, circuits, etc., can solve the problems of stress concentration, reduction of copper stranded wire tension, and copper stranded wire relaxation, etc., to increase the tension, The effect of avoiding jumping and avoiding metal fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

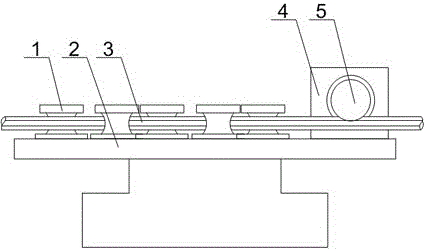

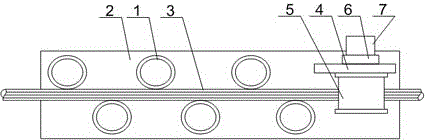

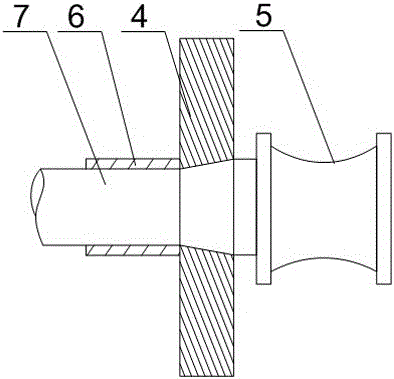

[0021] Such as Figure 1~Figure 3 As shown, this embodiment includes a workbench 2 and two rows of staggered lateral pressure rollers 1 installed on the workbench 2, and a support plate 4 is also arranged on the workbench 2, and the support plate 4 A sleeve 6 is installed on one side, and a tapered hole coaxial with the sleeve 6 is opened on the support plate 4. The connecting rod 7 is composed of a straight section, an enlarged section, and an extension section whose ends are sequentially connected. The straight section is provided with threads, and the sleeve 6 is threadedly connected with the straight section, and the tapered hole fits with the enlarged section in clearance, and a pressing roller 5 is connected at the end of the extended section, and the inner diameter of the expanded section is along the The axis of the sleeve 6 points toward the direction of the roller 5 and increases progressively. When working, the copper strand 3 moves along the aisle formed by two ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com