Highlight maintaining method for liquid crystal display

A liquid crystal display, bright spot technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as low success rate, and achieve the effect of improving success rate, avoiding too large gaps, and solving low success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

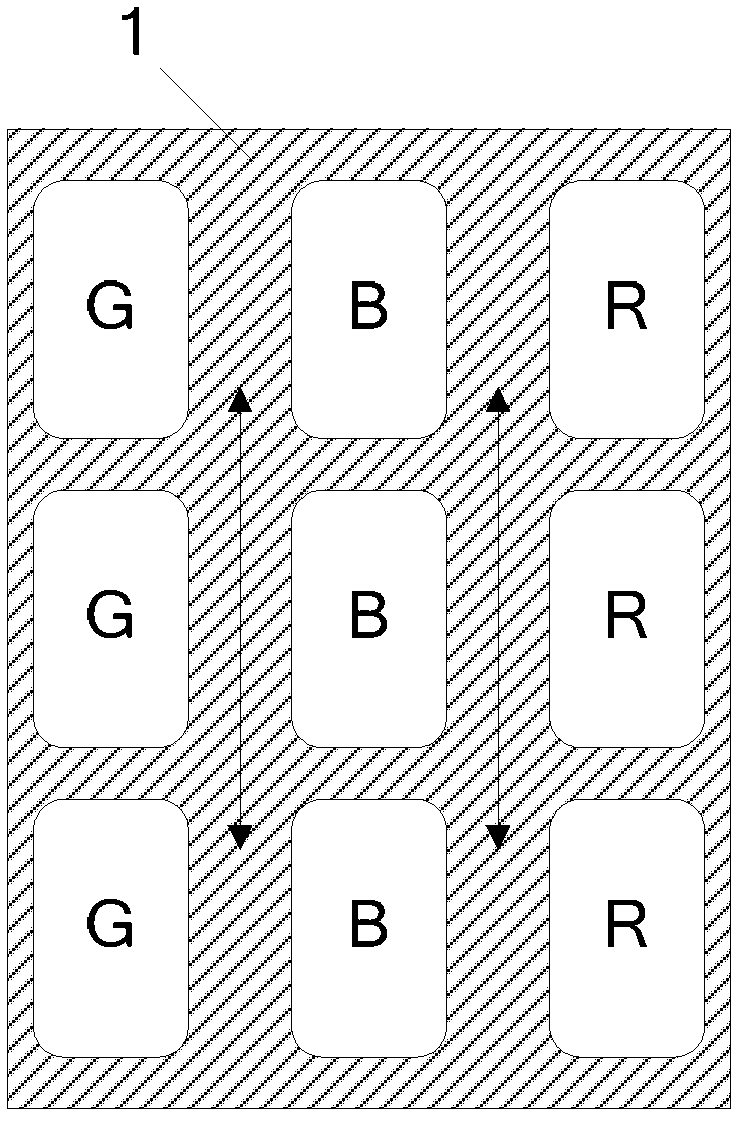

[0034] Such as figure 1 As shown, taking a liquid crystal panel with sub-pixels arranged in a square matrix as an example, the blue sub-pixels in the middle of the figure are sub-pixels to be repaired. In the liquid crystal display bright spot repair method provided by the embodiment of the present invention, the laser is used to perform the following steps when repairing the blue sub-pixel:

[0035] Preferably, the laser wavelength used in the embodiment of the present invention is 355nm.

[0036] S101: Perform aging on the color filter of the repaired sub-pixel and the black matrix (black matrix, BM) 1 around it.

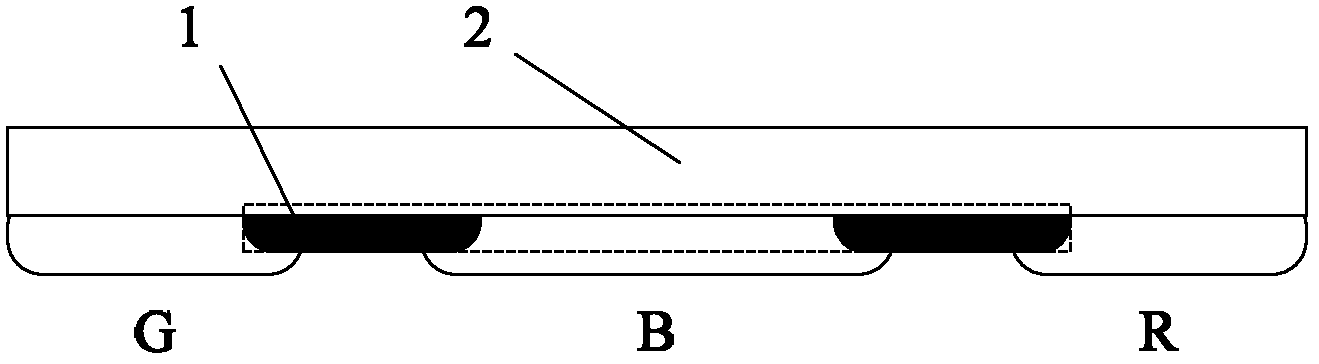

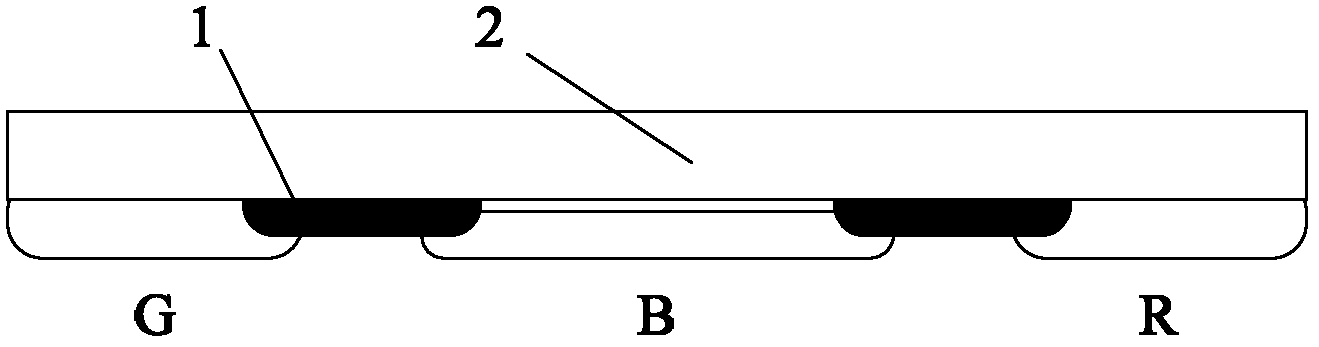

[0037] Specifically, laser is used to preheat the color filter of the repaired sub-pixel and the surrounding black matrix 1 to achieve the purpose of aging. figure 2 The dotted box in the middle indicates the granulated part. As a preferred solution, the intensity of the laser in this process is 2 to 3 A.U, where A.U (Arbitrary Unit, arbitrary unit) represents...

Embodiment 2

[0059] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 5 As shown, the sub-pixels to be repaired in this embodiment are green, and the bright spot repair method is to use laser to perform the following steps:

[0060] S201: Perform aging on the color filter of the repaired sub-pixel and the black matrix 1 around it.

[0061] Specifically, the laser is used to preheat the color filter of the sub-pixel to be repaired and the black matrix 1 around it, so as to achieve the purpose of aging. As a preferred solution, the intensity of the laser during this process is 2 to 3 A.U.

[0062] It has been verified by experiments that if the laser energy is too low, the subsequently formed gap will be incomplete, and if the laser energy is too high, it will cause defective pixels in the sub-pixels around the sub-pixel.

[0063] S202: Forming a gap between the color filter and the glass substrate, using a laser with an intensity of 17 to 19 A.U.

[006...

Embodiment 3

[0083] This embodiment is basically the same as Embodiment 1, the difference is: as Image 6 As shown, the sub-pixels to be repaired in this embodiment are red, and the bright spot repair method is to use laser to perform the following steps:

[0084] S301: Perform aging on the color filter of the repaired sub-pixel and the black matrix 1 around it.

[0085] Specifically, the laser is used to preheat the color filter of the sub-pixel to be repaired and the black matrix 1 around it, so as to achieve the purpose of aging. As a preferred solution, the intensity of the laser during this process is 2 to 3 A.U.

[0086] It has been verified by experiments that if the laser energy is too low, the subsequently formed gap will be incomplete, and if the laser energy is too high, it will cause defective pixels in the sub-pixels around the sub-pixel.

[0087] S302: Forming a gap between the color filter and the glass substrate, using a laser with an intensity of 23 to 25 A.U.

[0088] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com