Planning method of prepreg tape laying track based on specified geodesic curvature

A technology of laying trajectory and geodesic curvature, which is applied in the direction of instruments, digital control, control/regulation systems, etc., and can solve problems such as large calculation errors and large gaps between prepreg tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

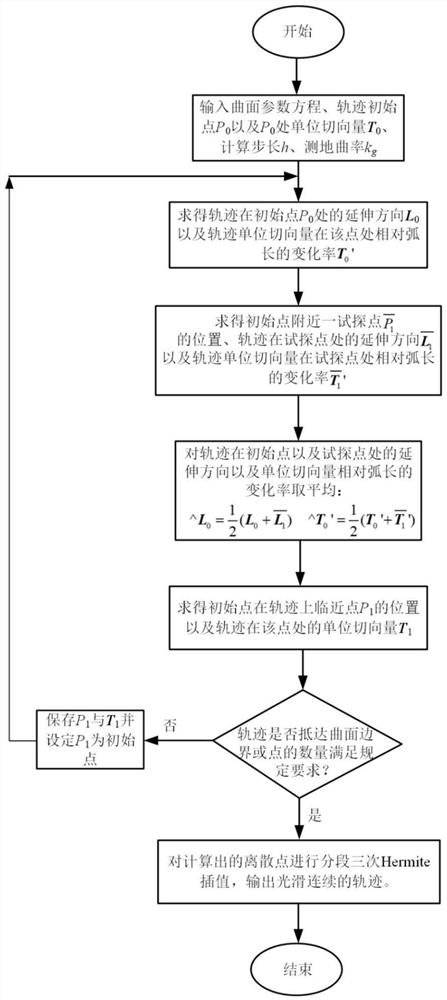

[0030] Such as figure 1 As shown, a planning method for prepreg tape laying trajectory based on prescribed geodesic curvature includes the following steps:

[0031] S1. Input the three-dimensional model of the mold surface to be laid, the initial point P of the laying track of the prepreg tape 0 The location of the prepreg tape laying track at the initial point P 0 The unit tangent vector T at 0 , calculation step size h, specified geodesic curvature value k g ;

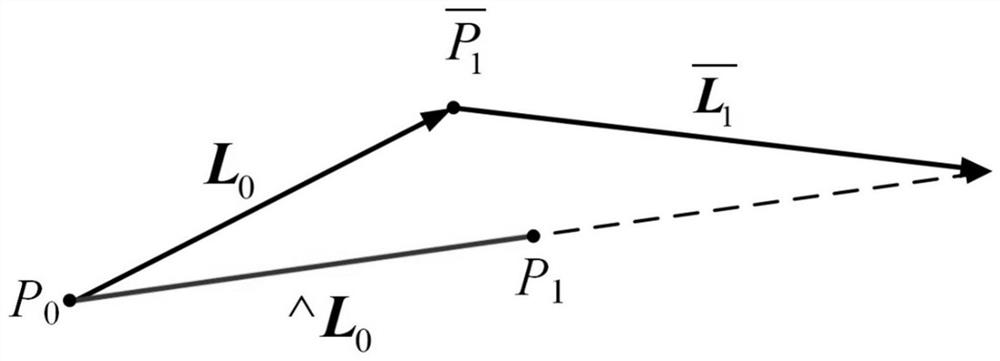

[0032] S2. According to the unit tangent vector T in step S1 0 Get the prepreg tape laying trajectory at the initial point P 0 The extension direction L at 0 ;According to the specified geodesic curvature value k g Compute the unit tangent vector T 0 at the initial point P 0 relative arc length change rate T 0 ';

[0033] S3. According to the initial point P in step S1 0 The position of , the calculation step size h, and the extension direction L in step S2 0 , get the tentative point According to the ...

Embodiment 2

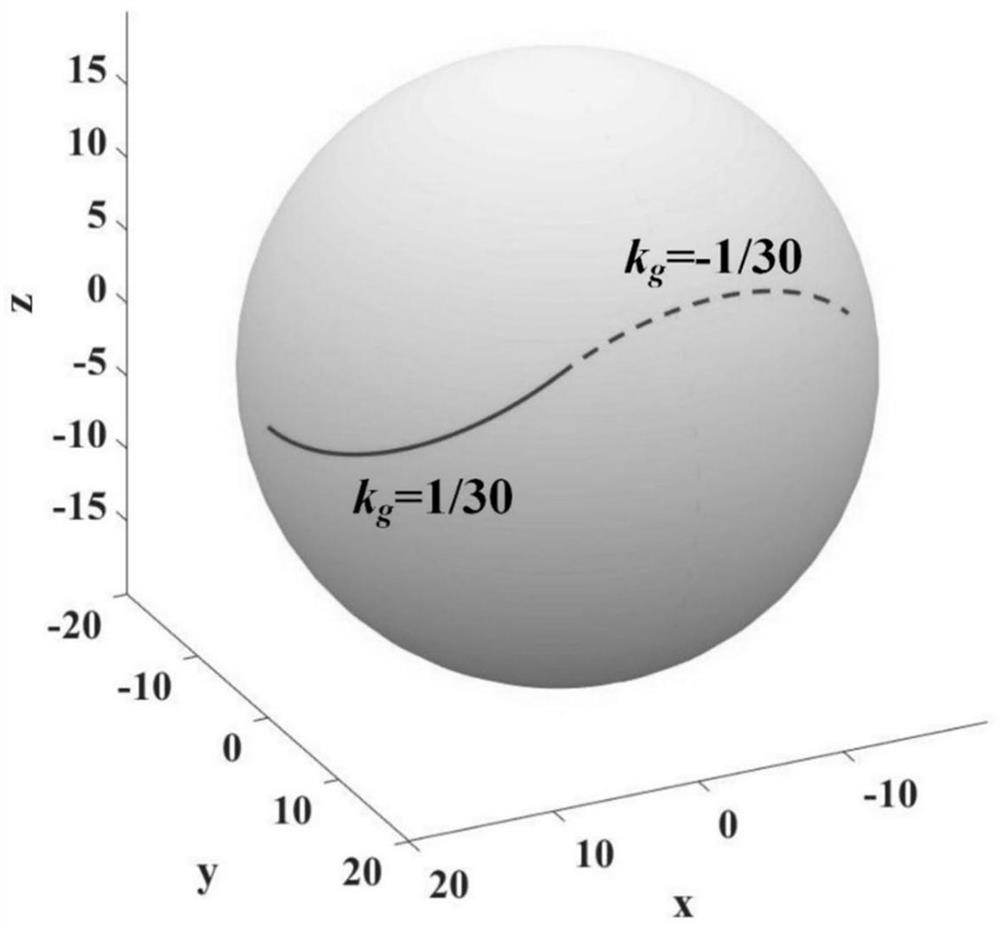

[0053] In this embodiment, the spherical surface is used as the parametric surface of the mold to be laid, and the specific process is as follows:

[0054] S1. Input the spherical parameter equation r(u,v)=[20cos(u)cos(v), 20sin(u)cos(v), 20sin(v)], the initial point P of the prepreg tape laying track 0 =(0,0) is located on the spherical surface, and the laying track of the prepreg tape is at the initial point P 0 The unit tangent vector T at 0 =[0,1,0]; input calculation step size h=1 and geodesic curvature k g distribution along the track

[0055] S2. Obtain the laying track of the prepreg tape at the initial point P 0 The extension direction L at 0 and the unit tangent vector T of the prepreg tape laying trajectory 0 at P 0 The change rate T of the relative arc length at 0 ’, the specific steps include:

[0056] (2.1) The unit tangent vector T on the three-dimensional model 0 Inversely mapped to the parameter surface of the mold surface to be laid to obtain the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com