Patents

Literature

133results about How to "Suppression gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

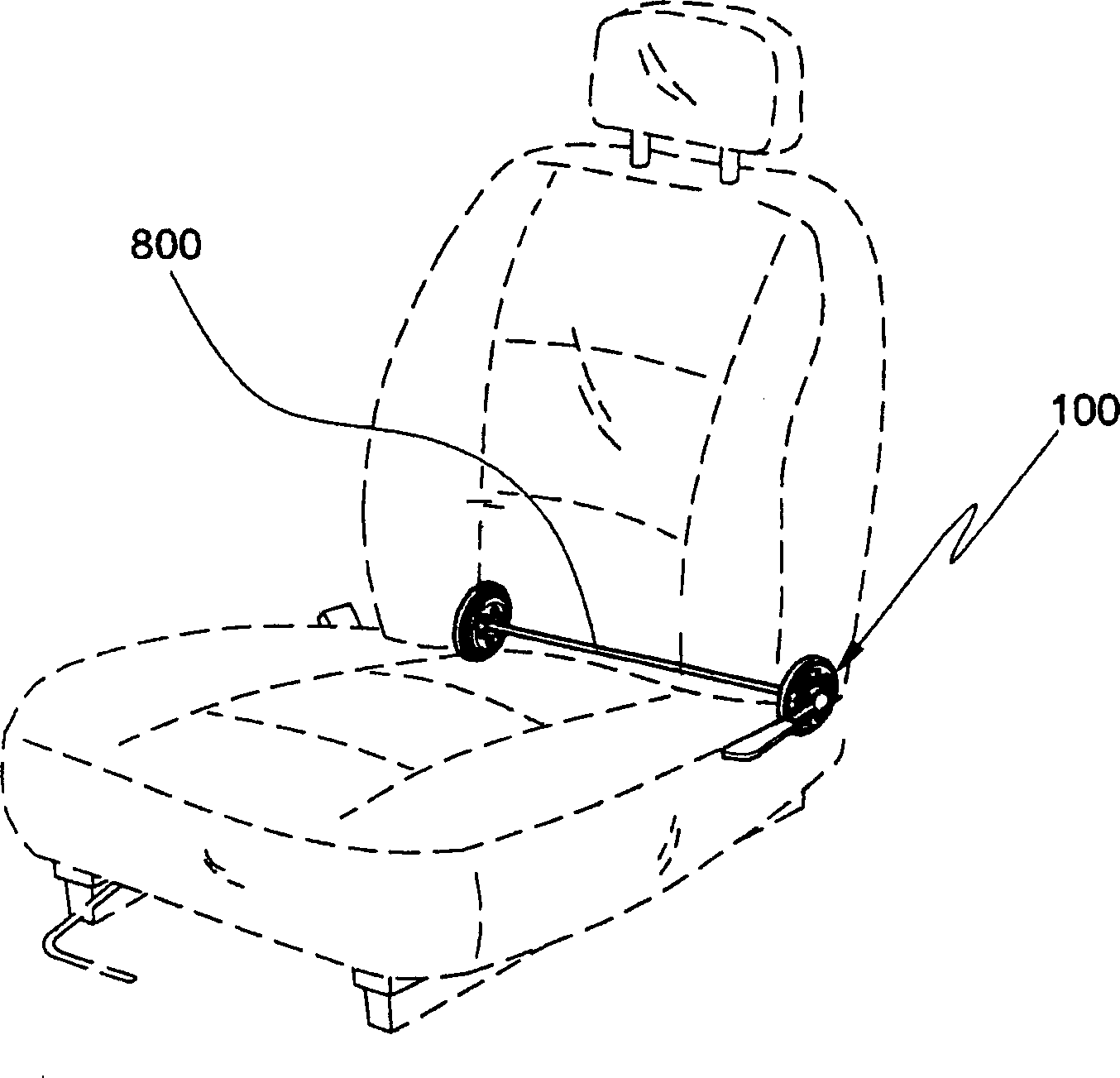

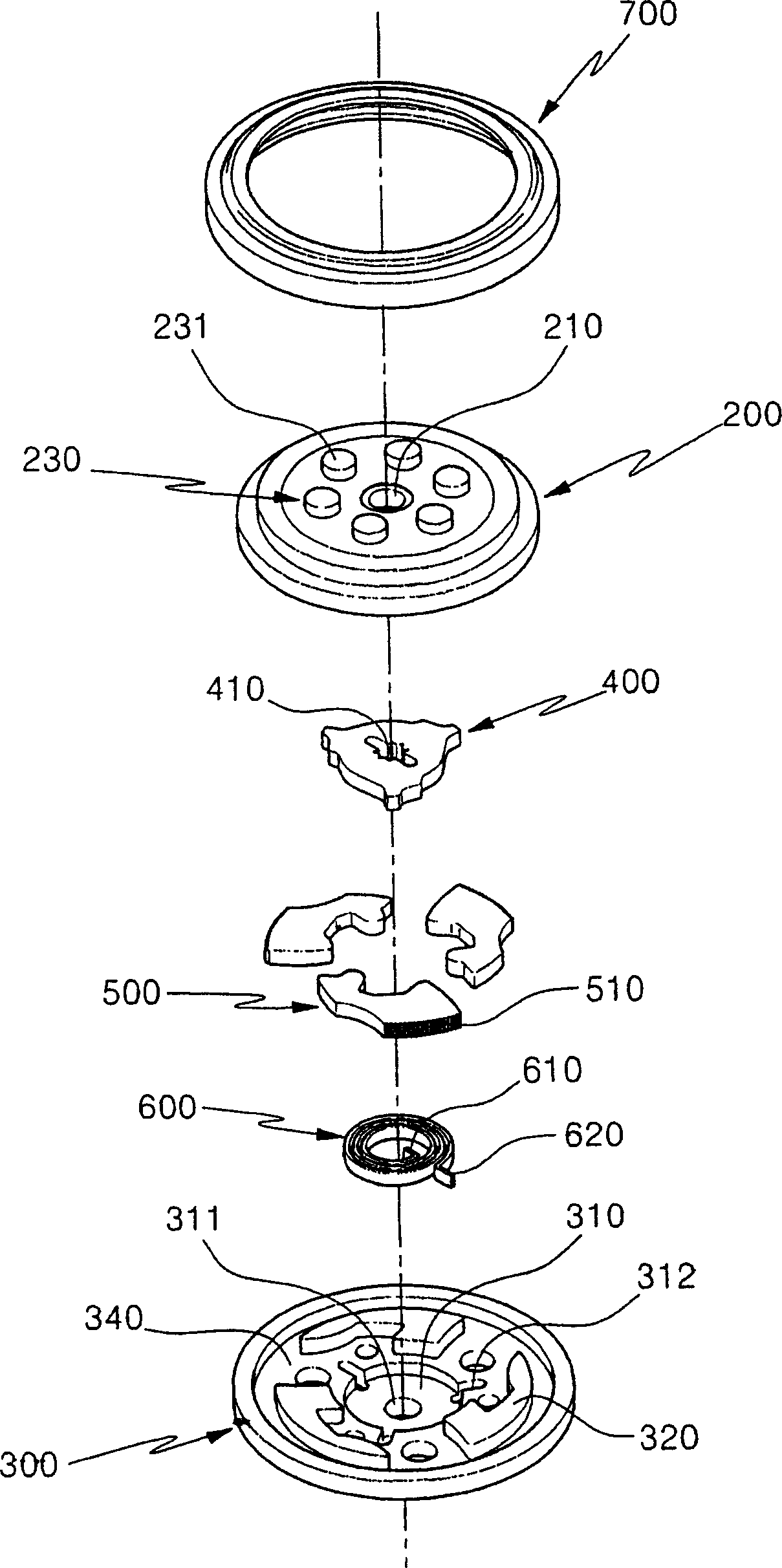

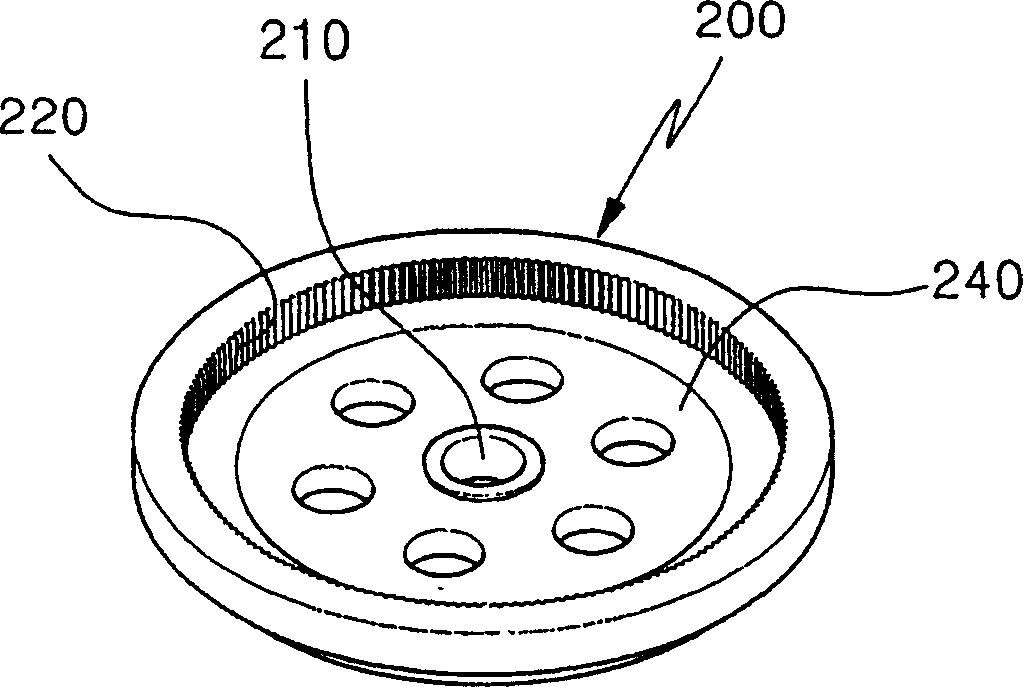

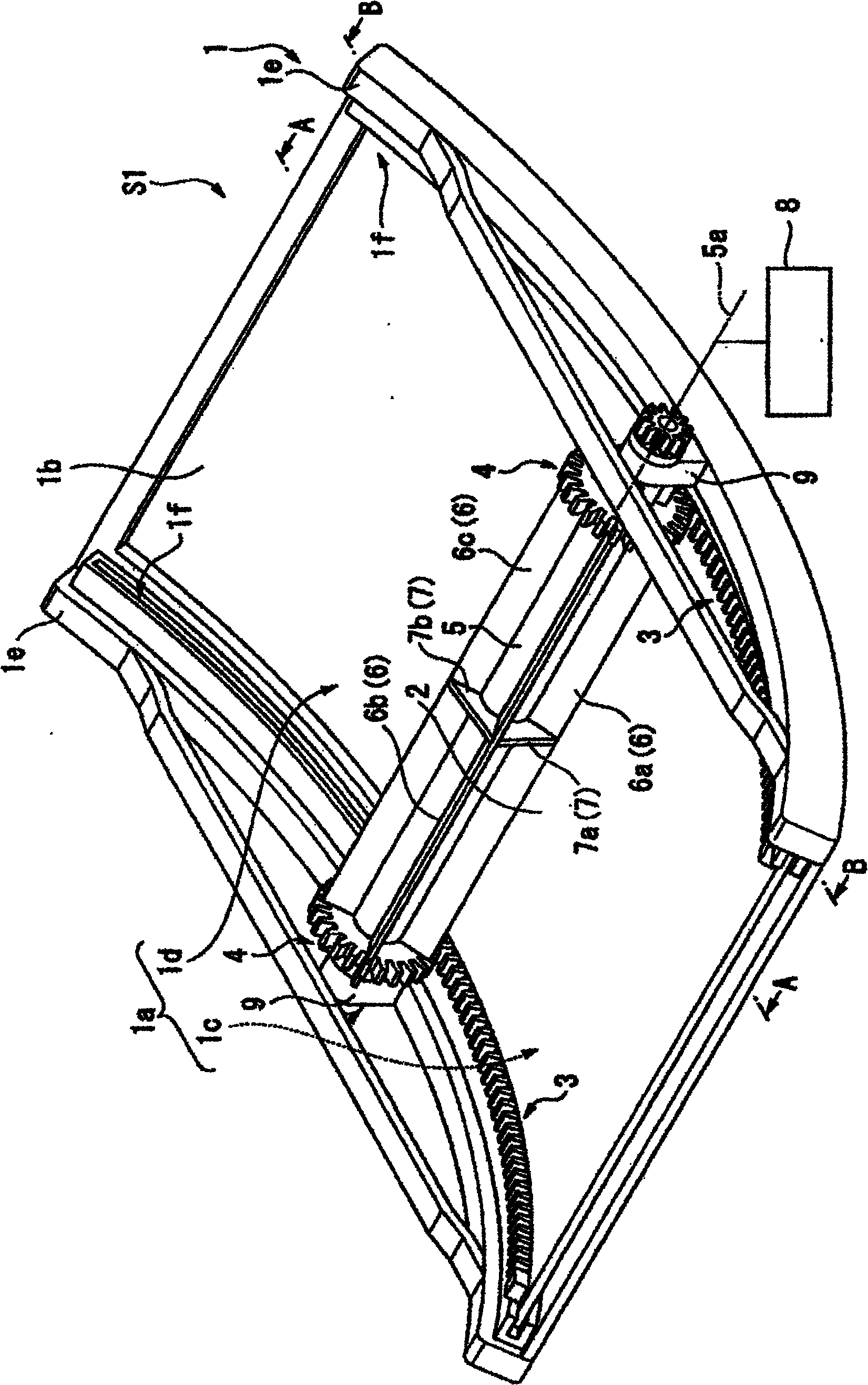

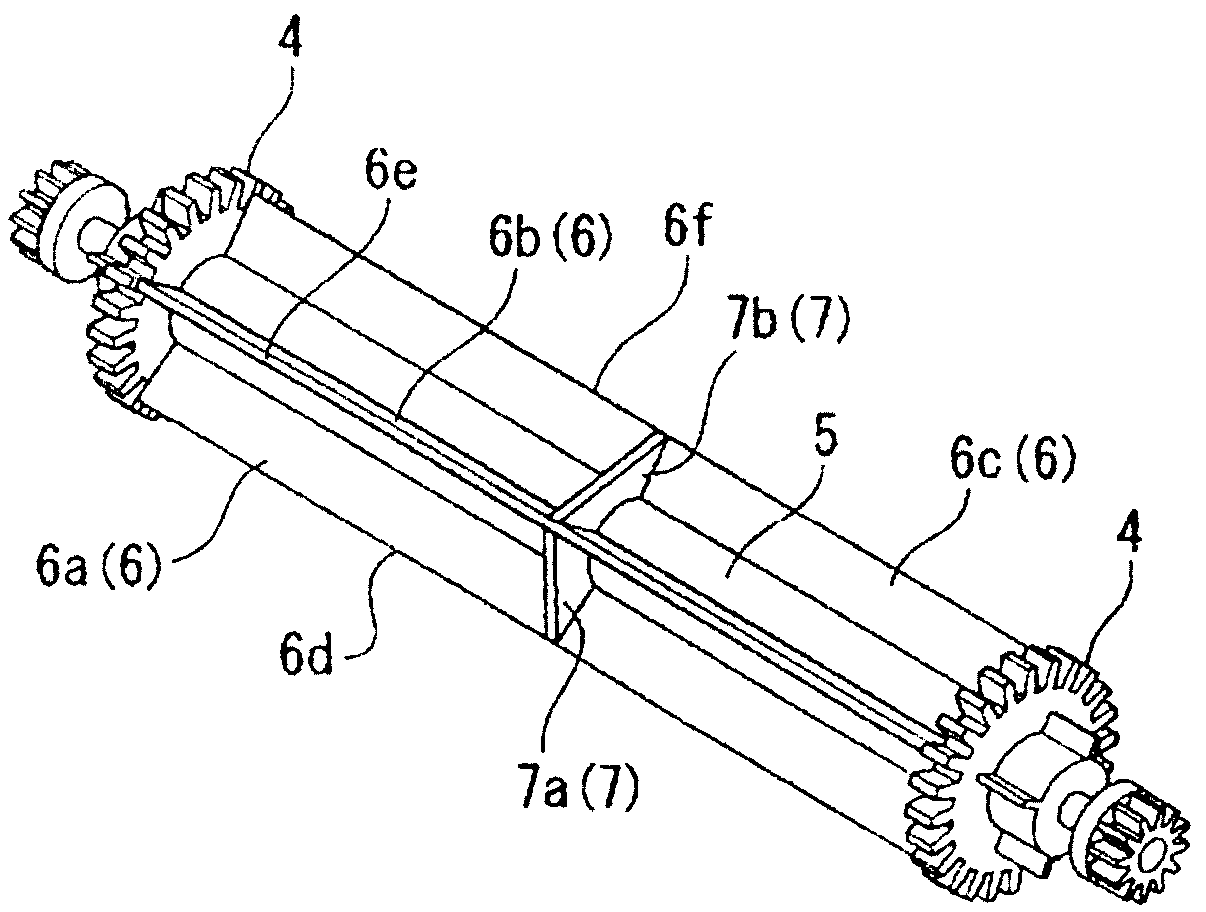

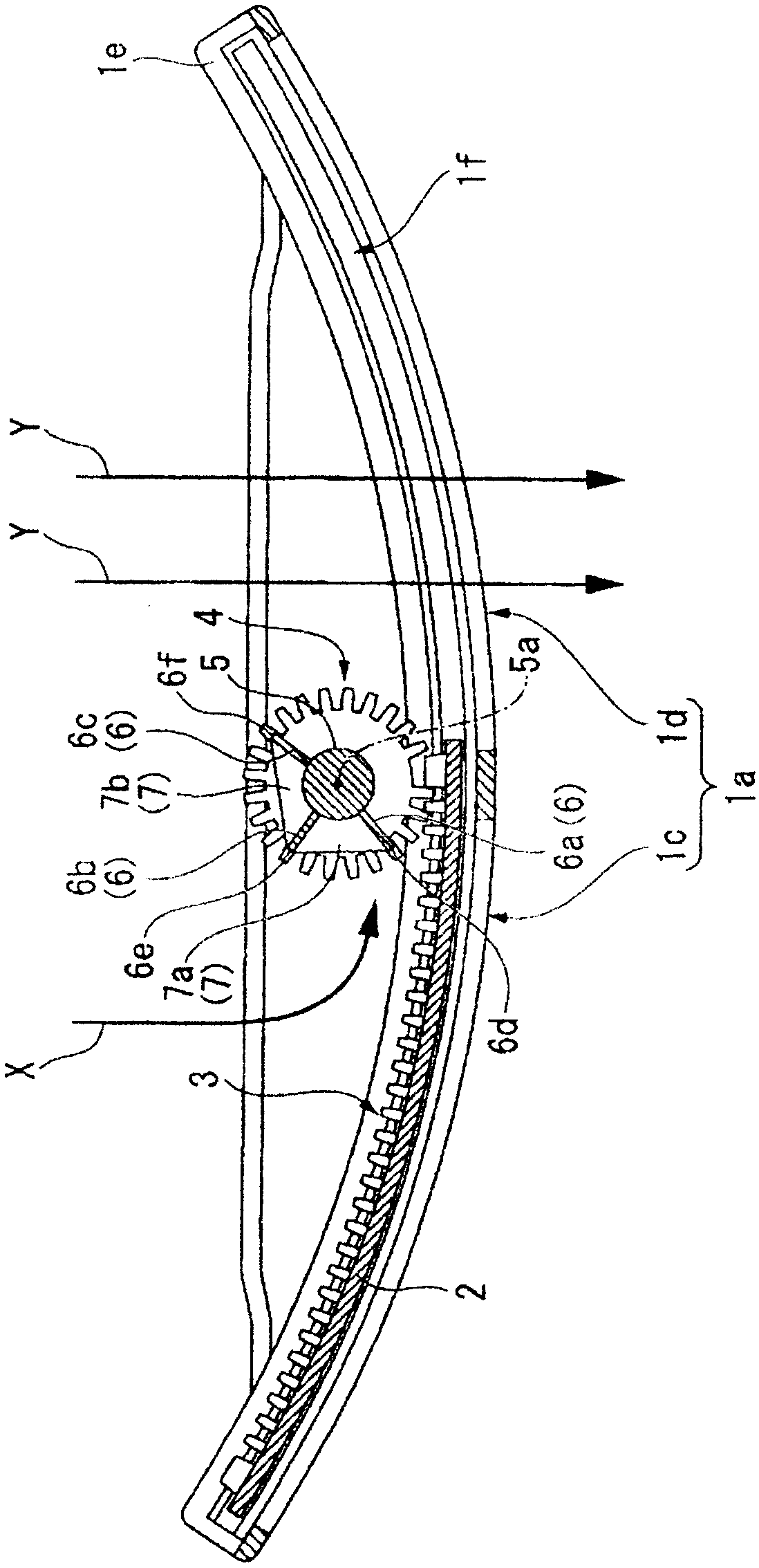

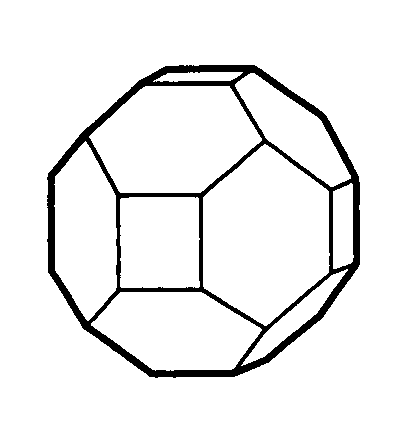

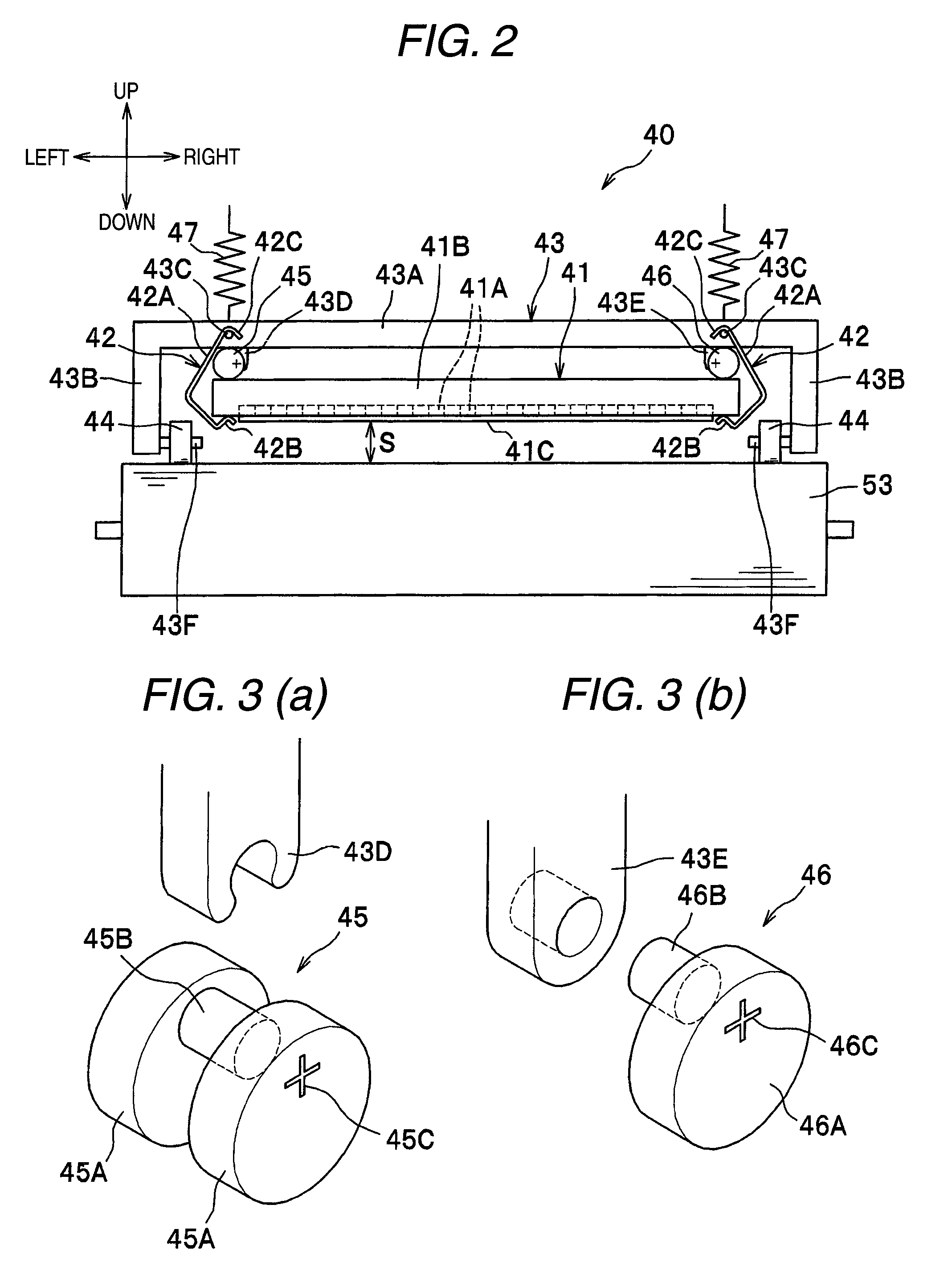

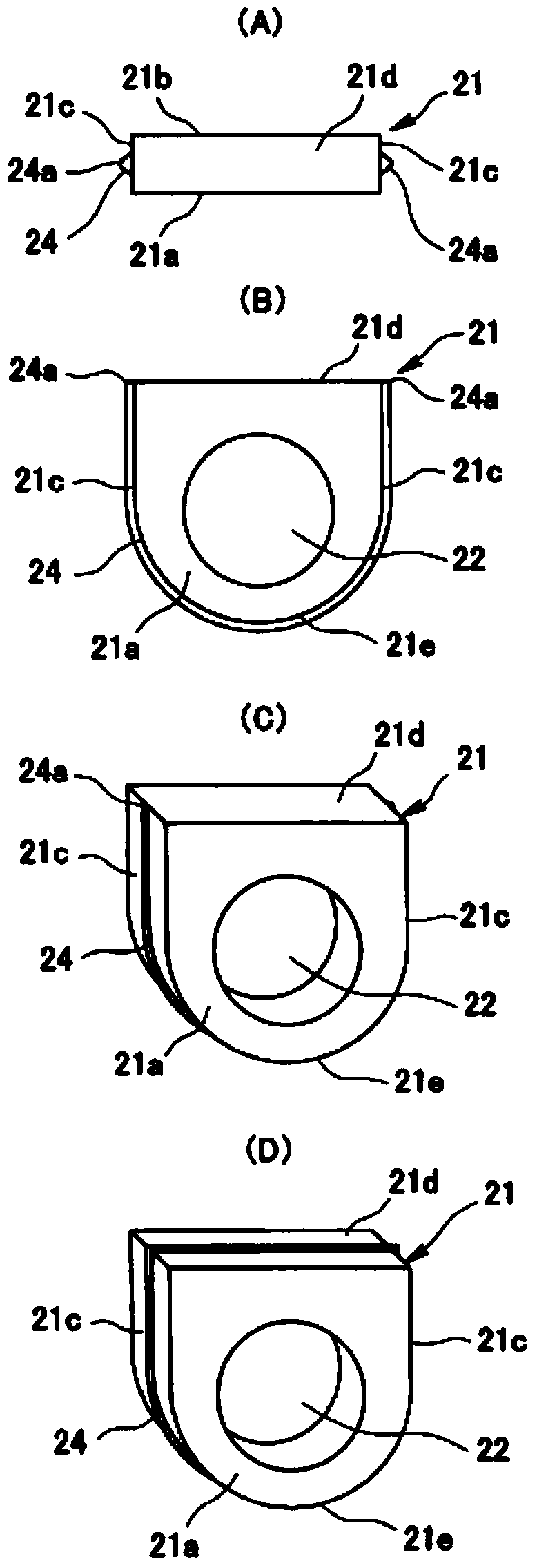

Round gapless angular modulation device for vehicle

InactiveCN1522891ASuppression gapPrevent improper engagementMovable seatsReclining chairsRotational axisCam

A round recliner for a vehicle having three lock gears evenly spaced apart from each other. Each of the lock gears are interposed between a cam and a corresponding lock gear supporting member in such a manner that the lock gears are engaged with a circular inner gear part of a sector gear, wherein the lock gears are turned along the lock gear supporting members so that an outer gear part of each of the lock gears is disengaged from the inner gear part of the sector gear or the outer gear part of each of the lock gears is engaged with the inner gear part of the sector gear, thereby minimizing occurrence of clearances in the recliner and preventing any irregular engagement of the recliner.

Owner:AUSTEM CO LTD

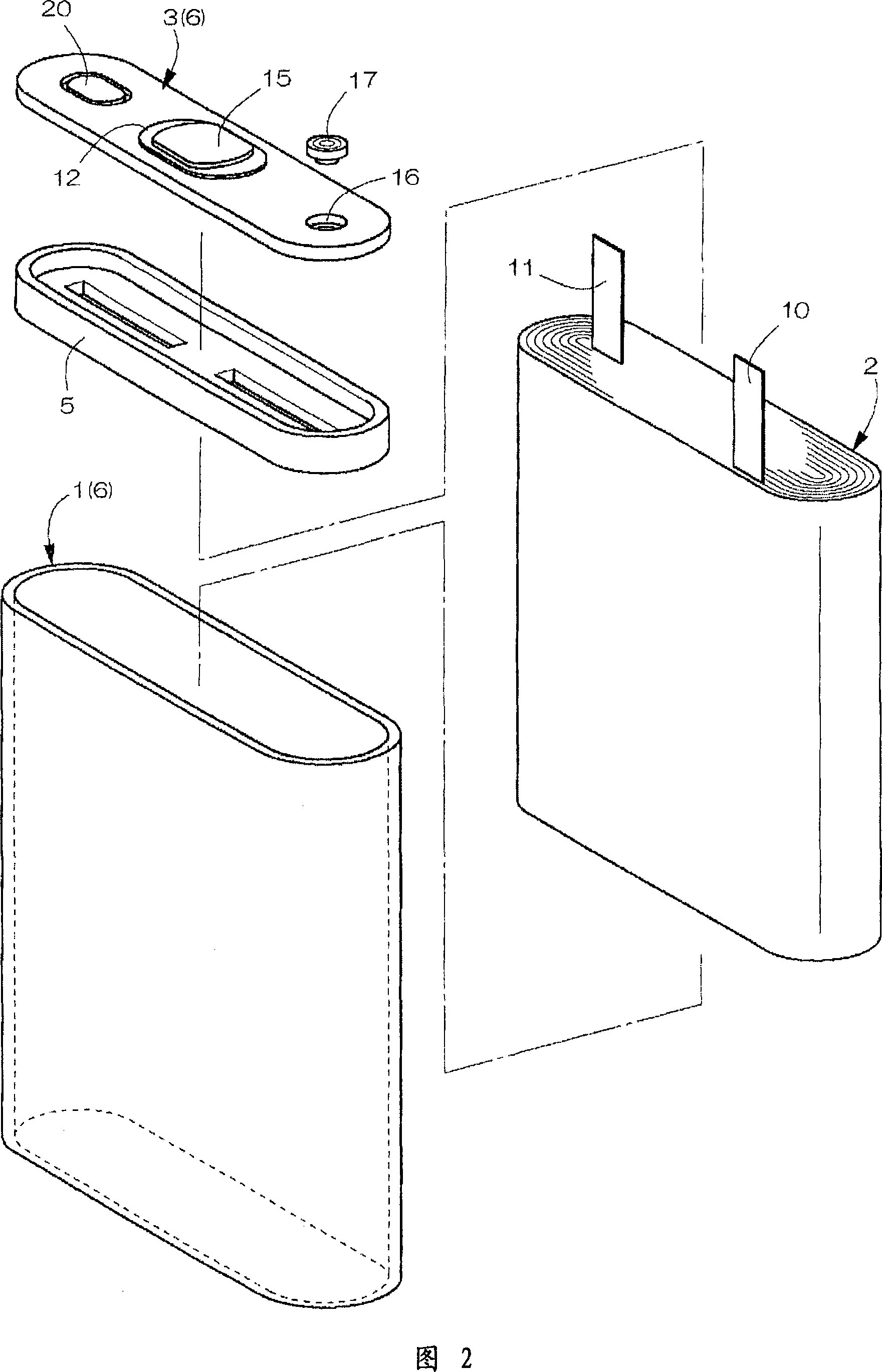

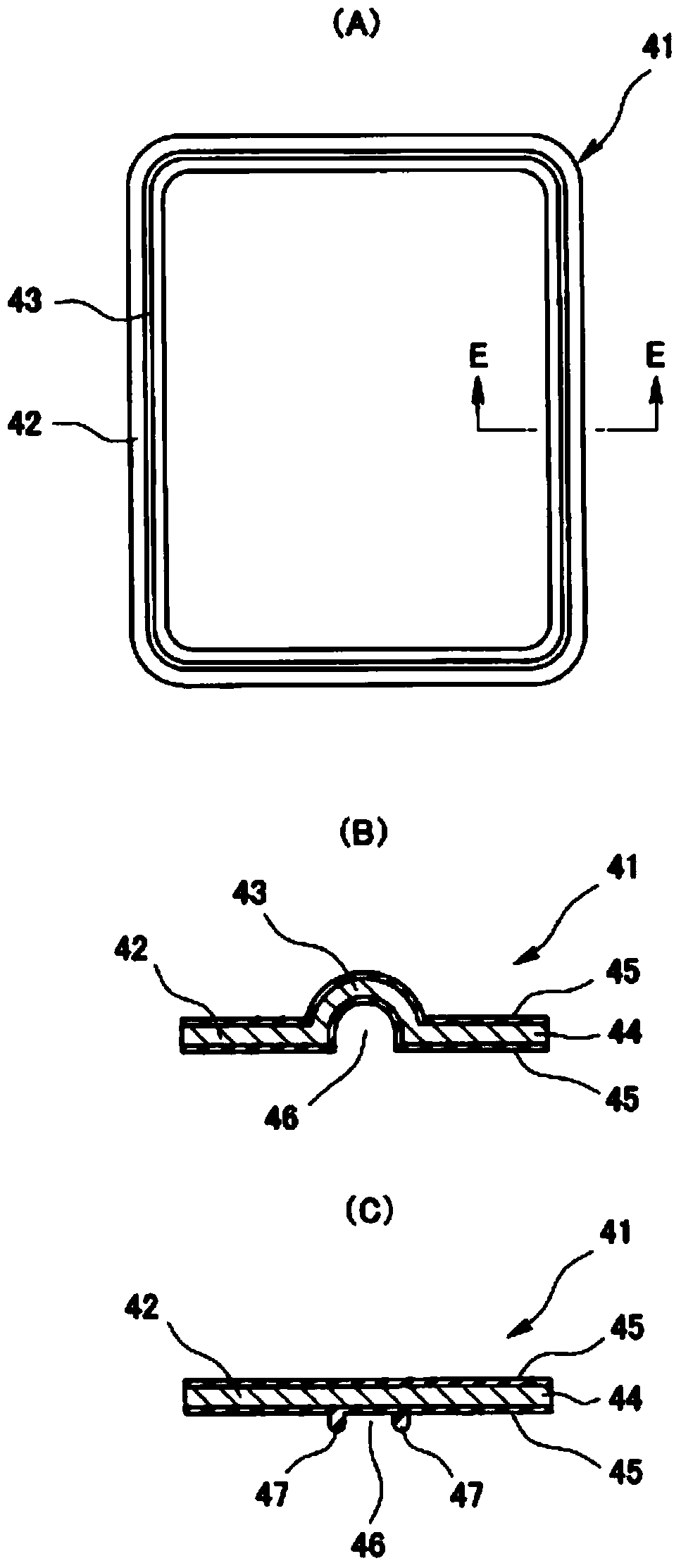

Sealed battery

ActiveCN101083310AReduce areaReliable leak tightnessNon-aqueous electrolyte accumulatorsCell component detailsEngineeringBearing surface

The present invention provides a sealing battery, which prevents electrolyte from remaining in the injecting hole and joints a sealing bolt and injecting hole. After injecting electrolyte into the battery box through the injecting hole, to joint the sealing bolt on the injecting hole to seal the injecting hole. The sealing bolt is arranged with a head and a axis extending from the lower surface of the head. The injecting hole is arranged with a chimeric concave part to table the head of the sealing bolt and a chimeric part of the axis part which is pressed into the sealing bolt. The chimeric part of the injecting hole includes: vertical inner surface part; taper inner surface part with taper surface shaped which turns narrow downwards; and bearing surface part to support the lower surfaceof the head of the sealing bolt. The head of the sealing bolt includes: lower surface; vertical outer surface part which is opposite to the vertical inner surface part of the injecting hole; and taper outer surface part with taper surface shaped which is opposite to the taper inner surface part of the injecting hole and turns narrow downwards.

Owner:MAXELL HLDG LTD

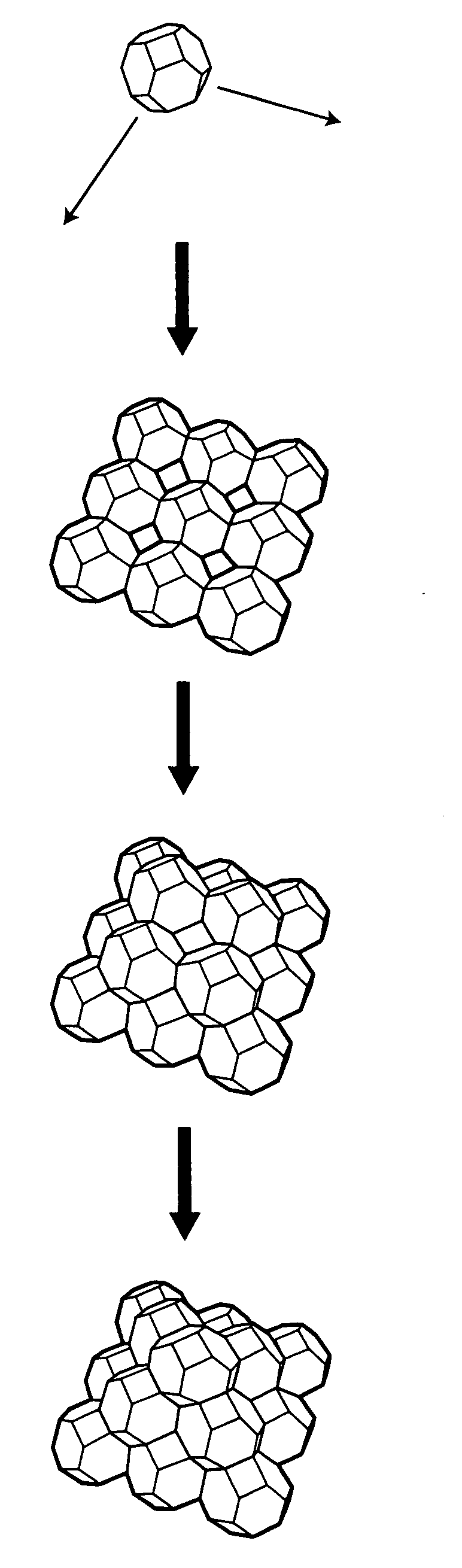

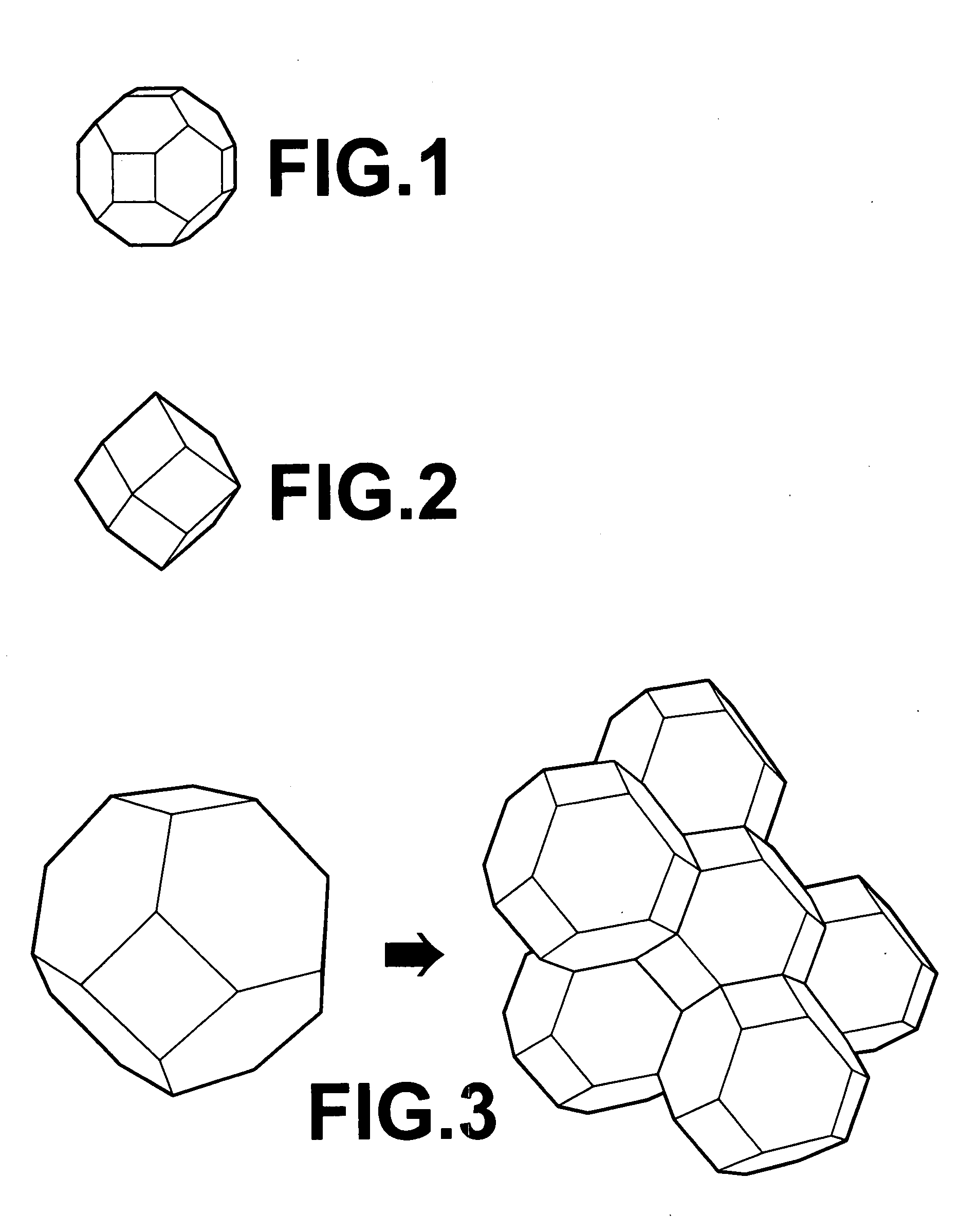

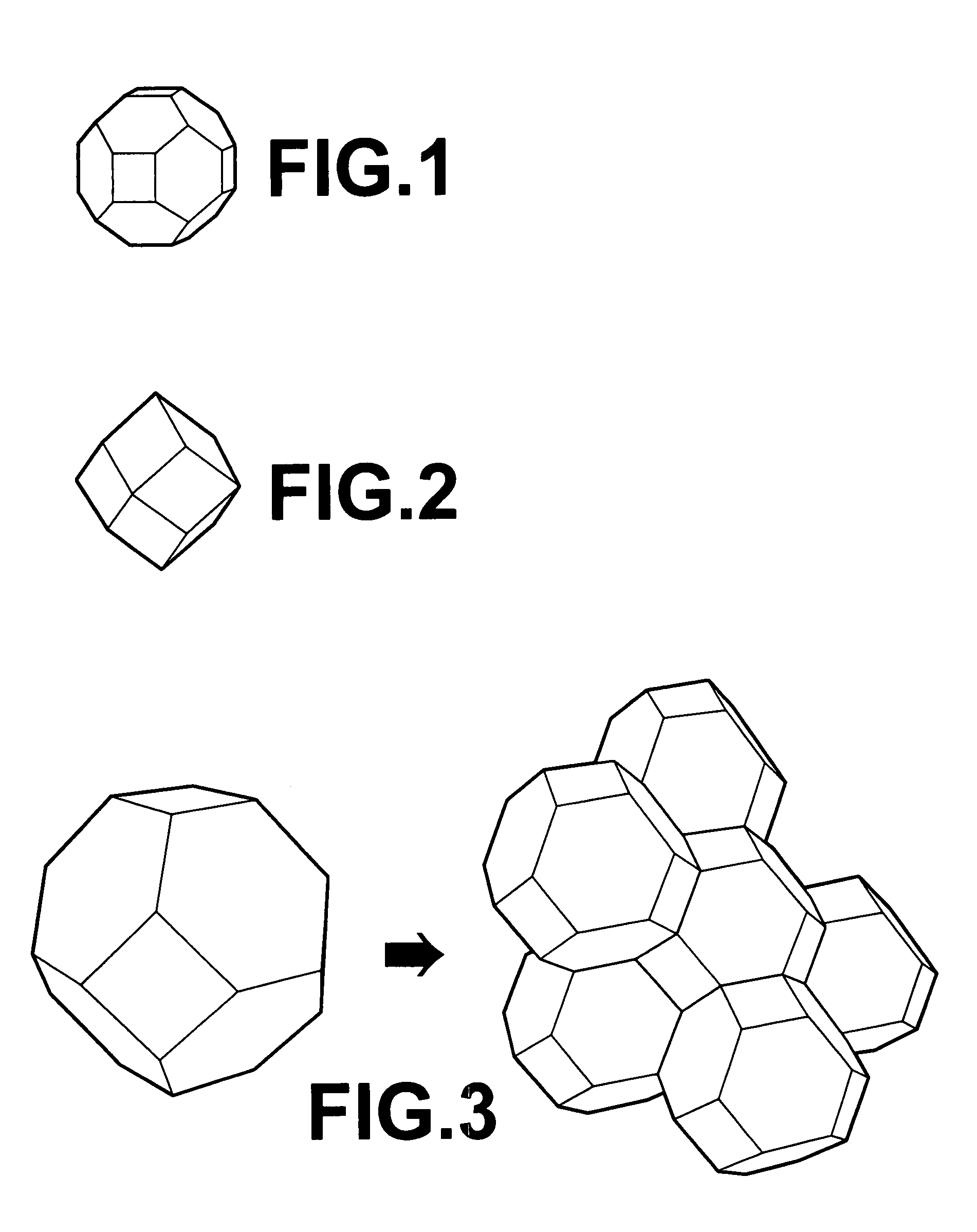

Translucent material and manufacturing method of the same

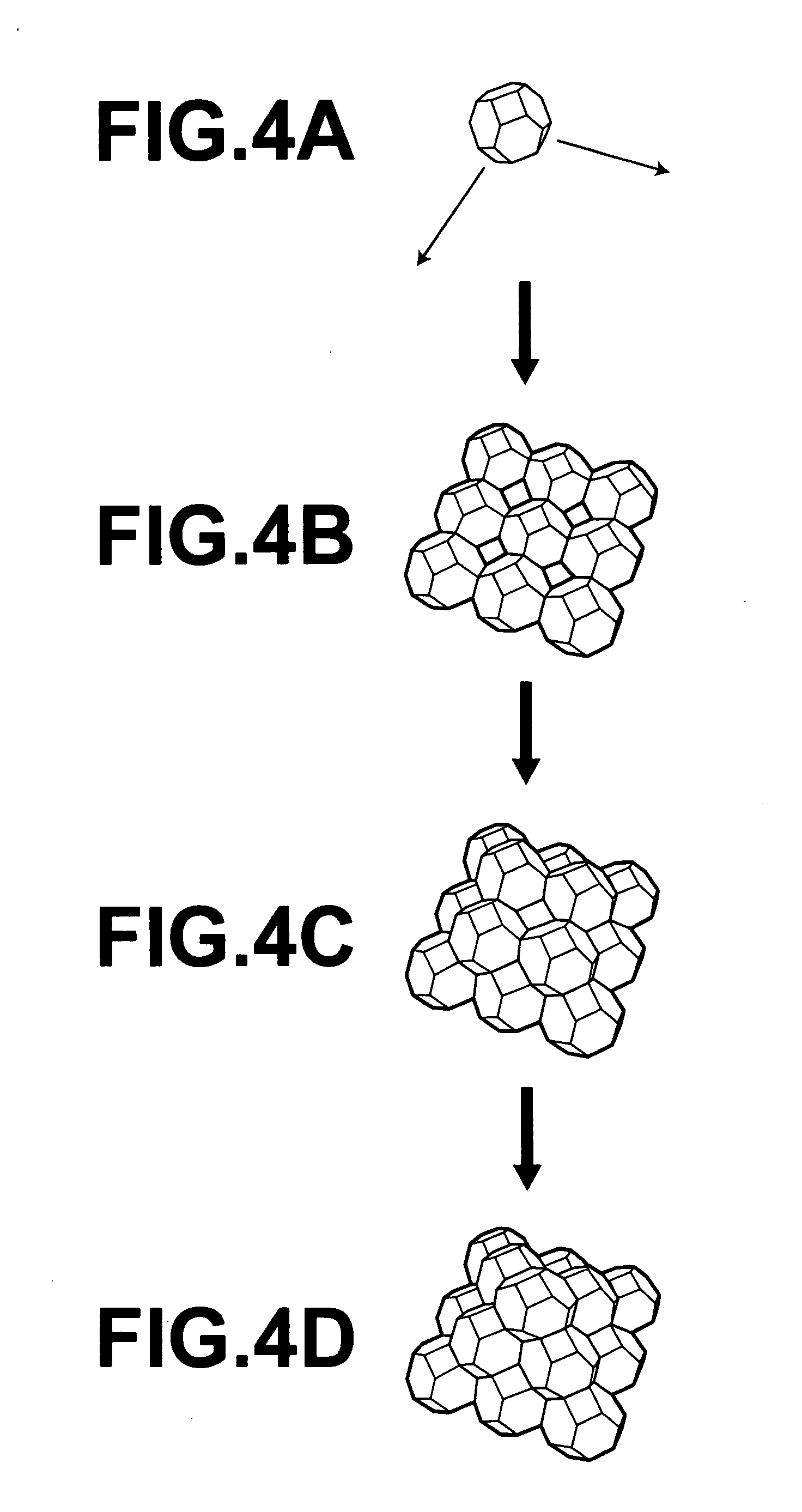

InactiveUS20090081100A1Suppression gapPromote sinteringCeramic shaping apparatusActive medium materialShell moldingMicroparticle

After synthesizing particles by liquid phase synthesis, the solution is substituted without drying these particles, and here, a solution comprising a grain boundary phase composition consisting of at least one or more types selected from a group consisting of Al2O3, yttrium oxide, silicon oxide, yttrium-silicon complex oxide, aluminum-silicon complex oxide, and a compound having a garnet structure with a lower melting point than the aforementioned particles, or a solution comprising a precipitate is introduced. Microparticles are adjusted by allowing adhesion and growth of the solution comprising a composition of grain boundary phase or the solution comprising a precipitate on the surface of the particles; these microparticles are allowed to align in 3-dimensions in solution and are formed into a molded body, and this molded body is sintered.

Owner:FUJIFILM CORP

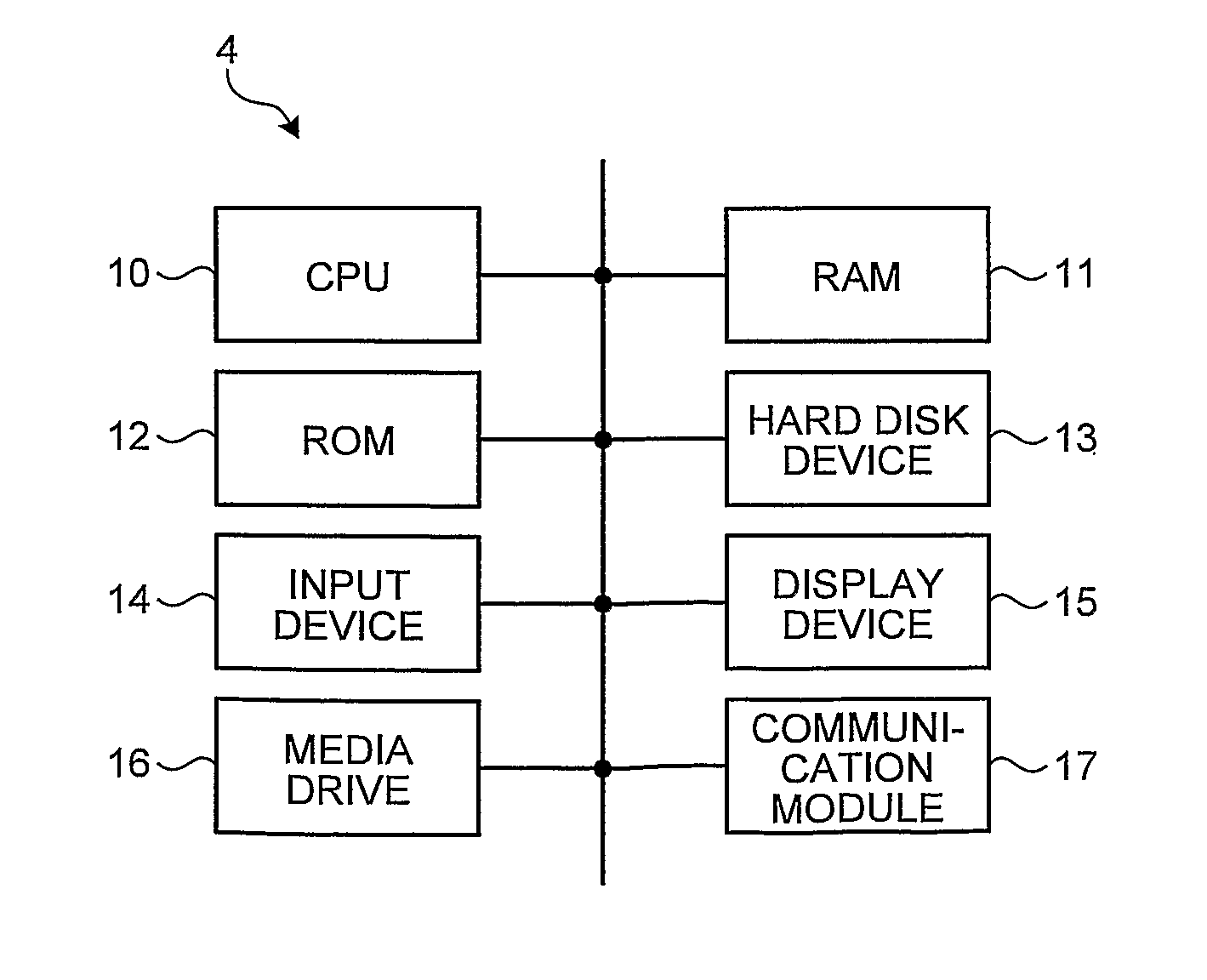

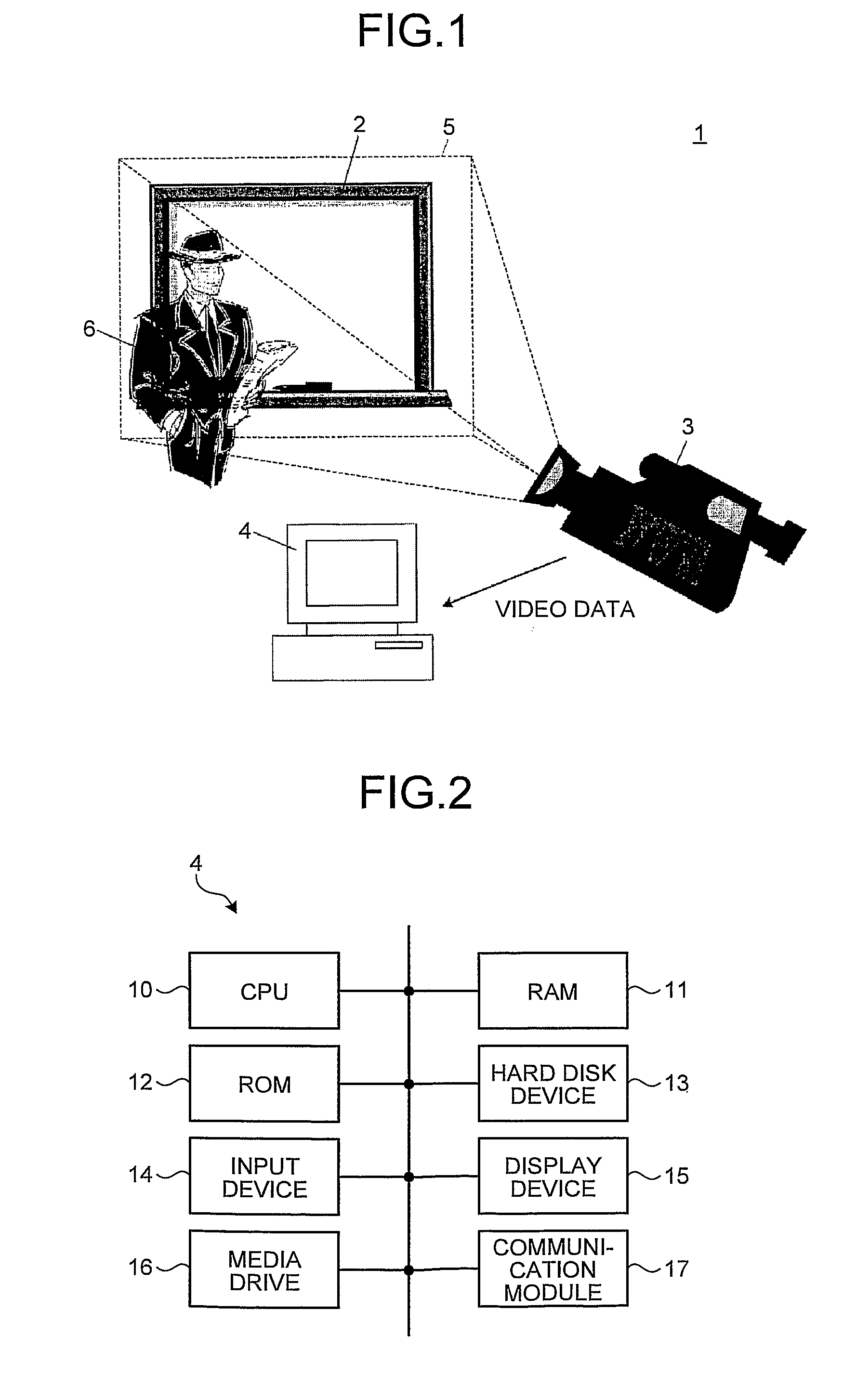

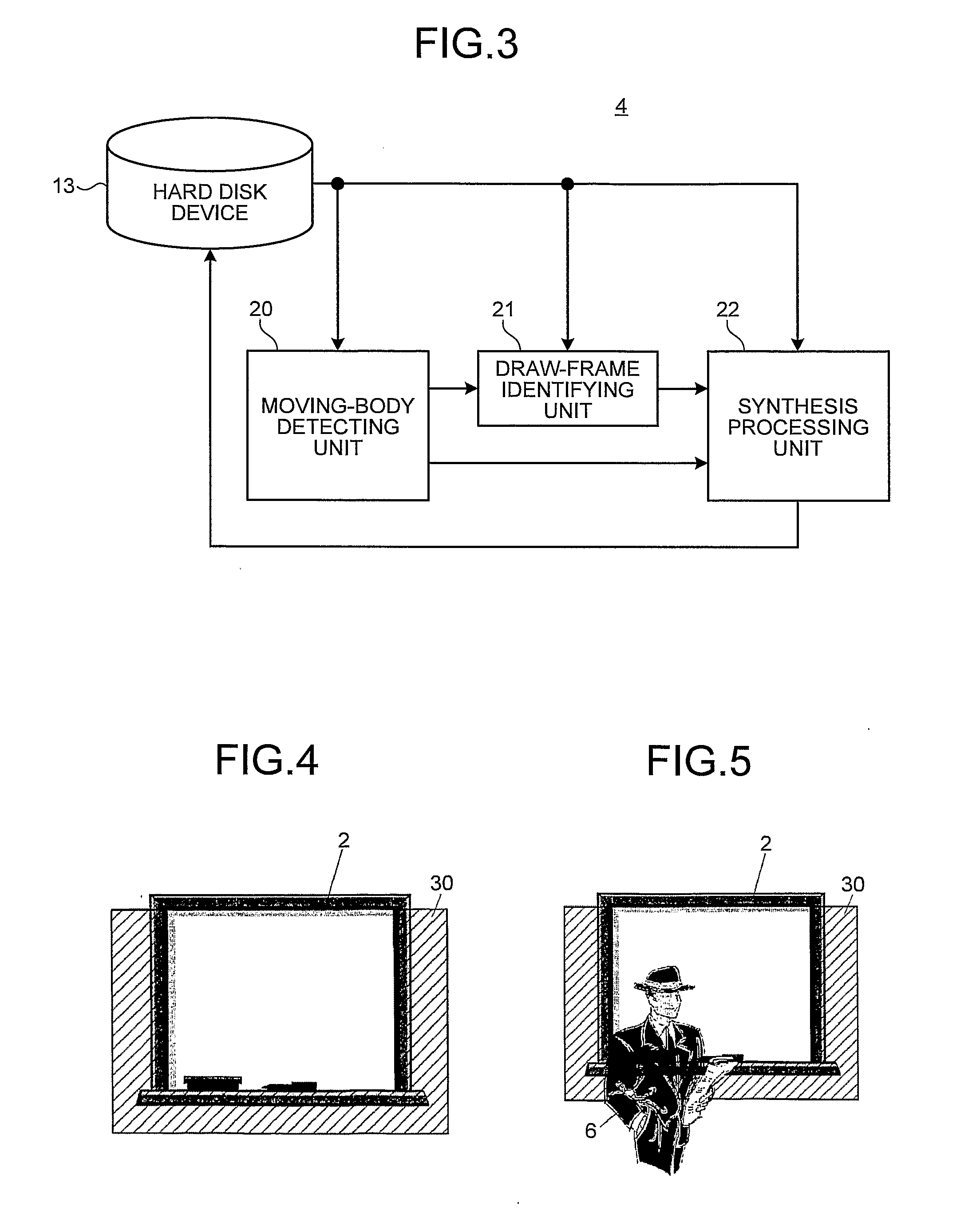

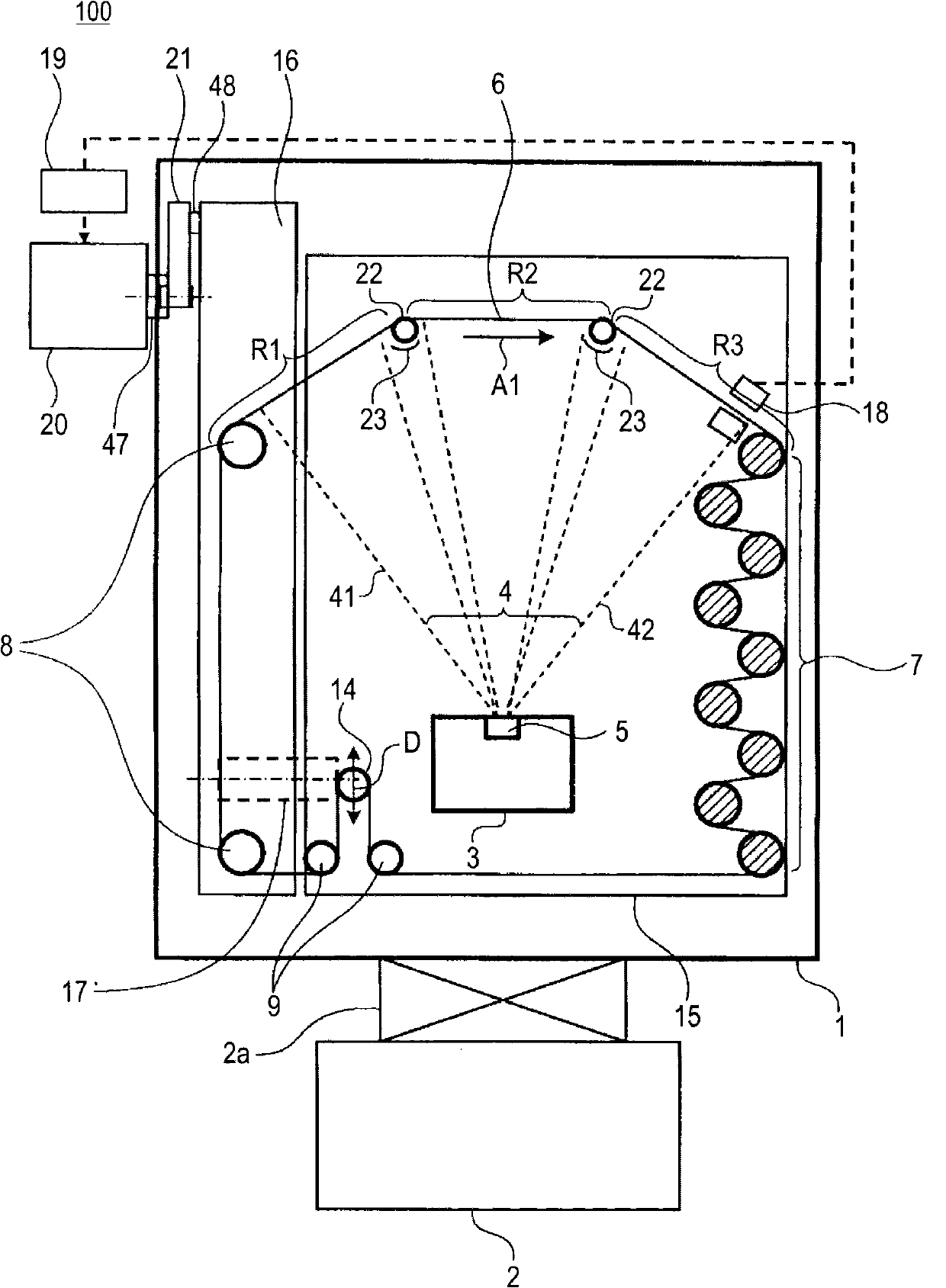

Video editing device and video editing system

InactiveUS20120014672A1Suppression delaySuppression gapTelevision system detailsImage enhancementInformation synthesisVideo editing

A video editing device, which edits a video of an object on which image information is drawn, includes a moving-body-frame detecting unit that detects a frame on which a moving body obstructing the object is captured; a draw-frame identifying unit that identifies a frame at which drawing of the image information is started by comparing a post-detection frame that is an obstructed frame detected by the moving-body-frame detecting unit with each of detection frames that are not-obstructed frames detected by the moving-body-frame detecting unit; and a synthesis processing unit that performs a synthesis process of synthesizing image information included in the post-detection frame onto a frame anterior to the frame identified by the draw-frame identifying unit.

Owner:RICOH KK

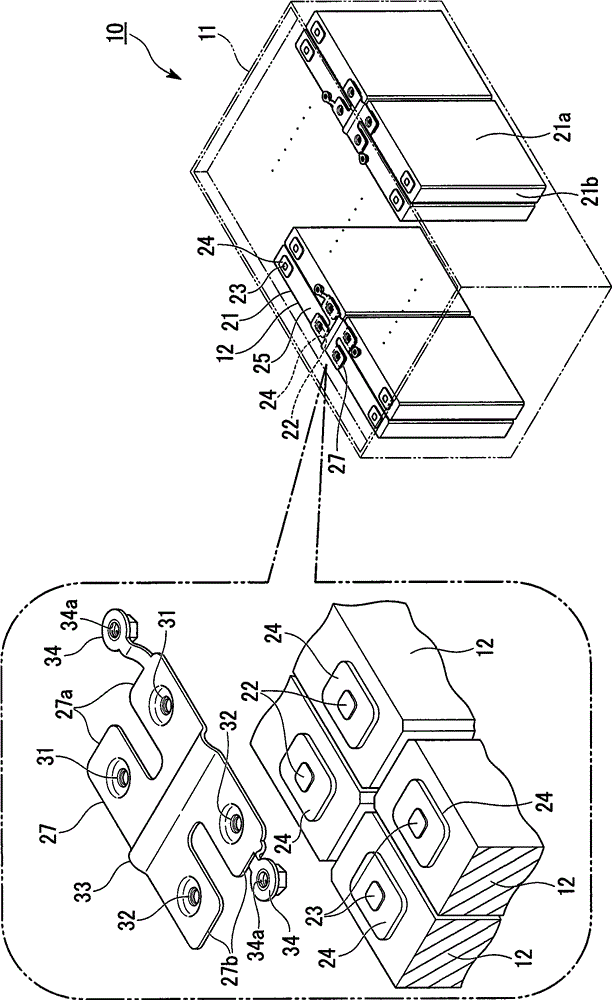

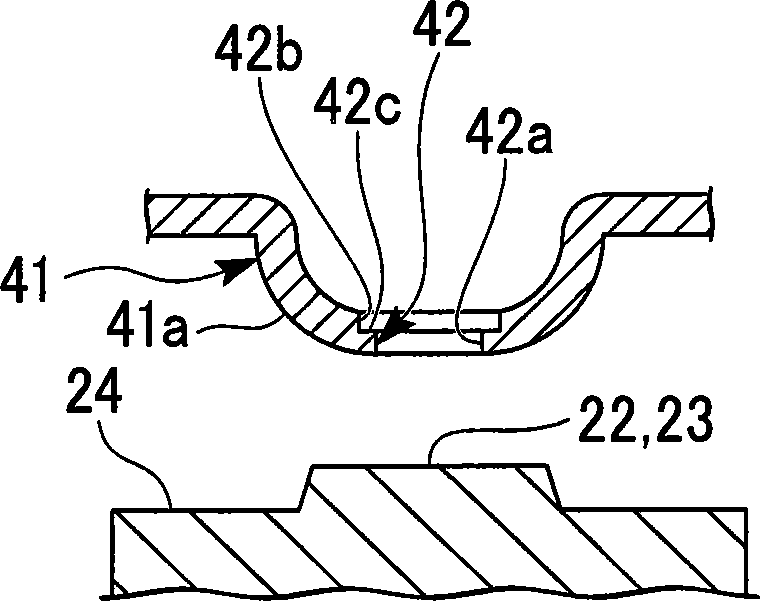

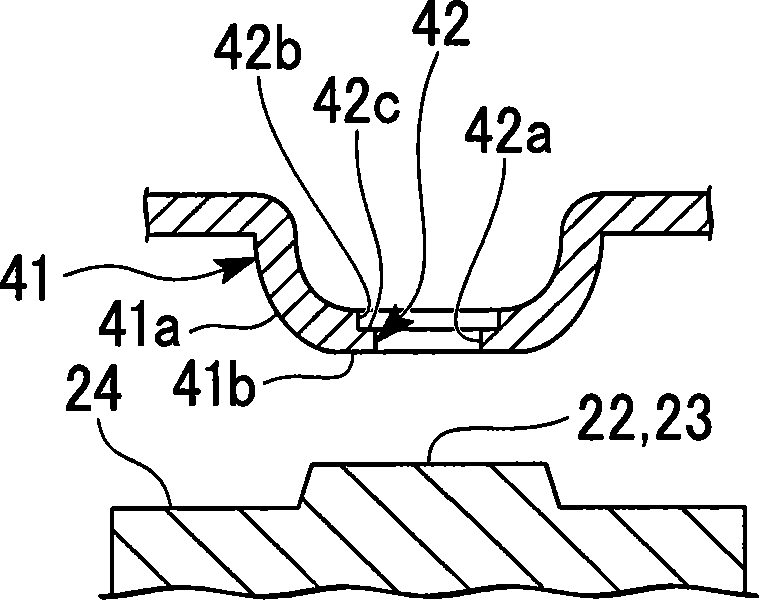

Busbar for assembled battery and assembled battery

InactiveCN104659317ASuppression gapElectric connection structural associationsCell component detailsBusbarCoupling

According to one embodiment, a connecting busbar includes a pair of first connecting portions provided on first end portions, a pair of second connecting portions provided on second end portions, and a coupling portion that couples the first end portions and the second end portions. Each of the first connecting portions and the second connecting portions is provided with projecting portions that project toward each of positive electrode terminals and negative electrode terminals, and a connecting opening portion provided on a tip end of the projecting portion. The projecting portion is joined to the positive electrode terminal and the negative electrode terminal by performing welding such as laser welding on a thinned portion in a state that a surface of a curved portion contacts with the positive electrode terminal and the negative electrode terminal while the connecting opening approaches the positive electrode terminal and the negative electrode terminal.

Owner:KK TOSHIBA

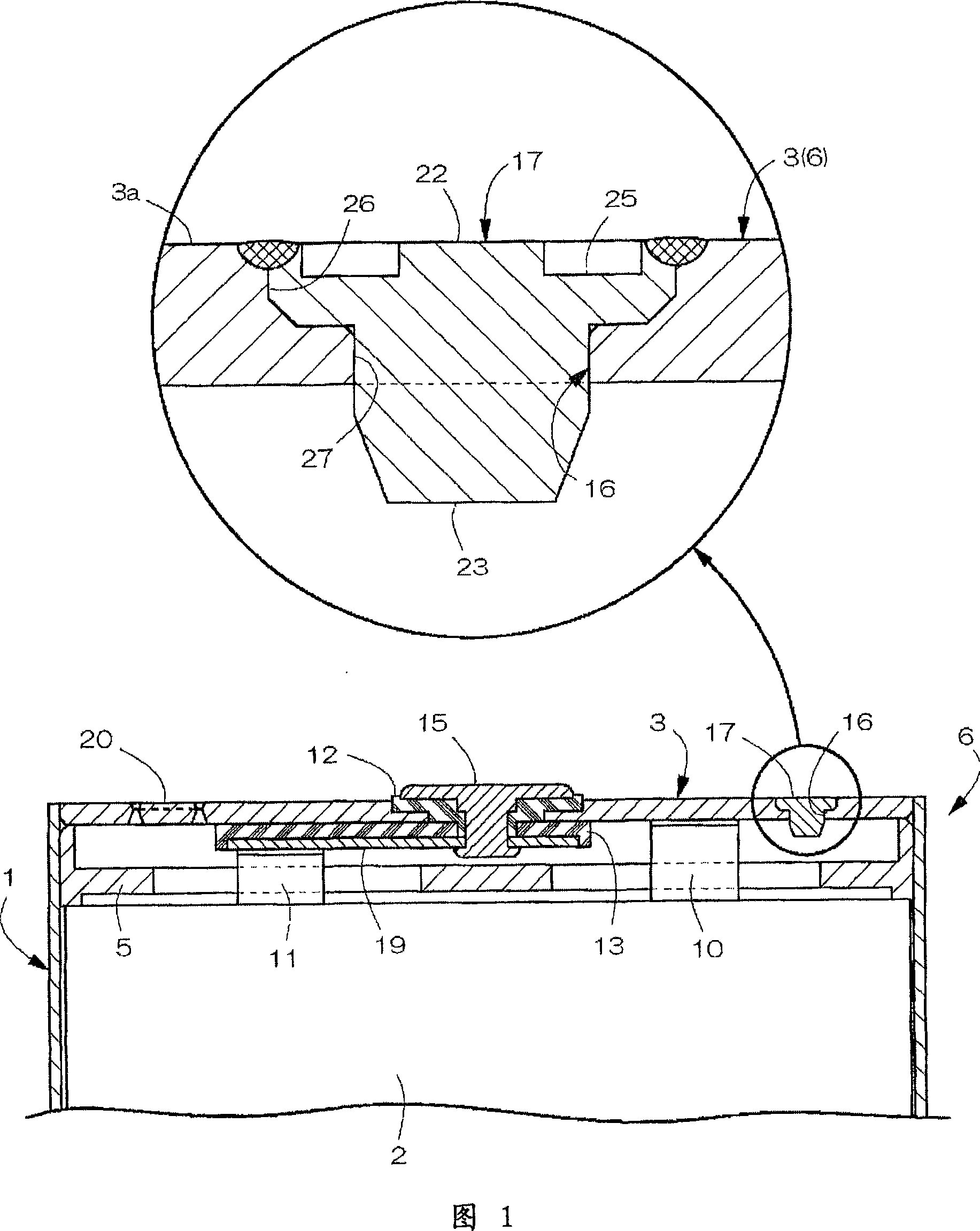

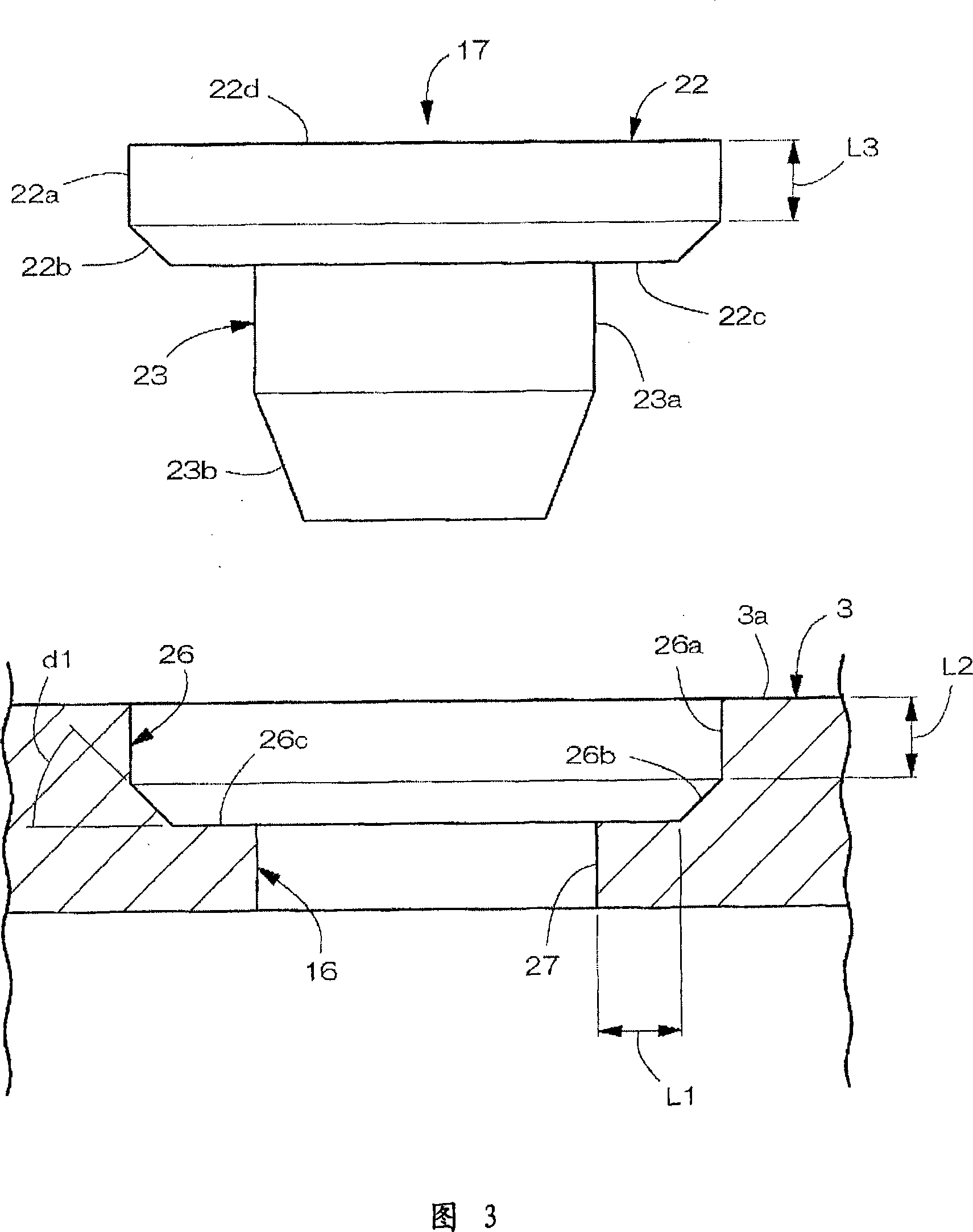

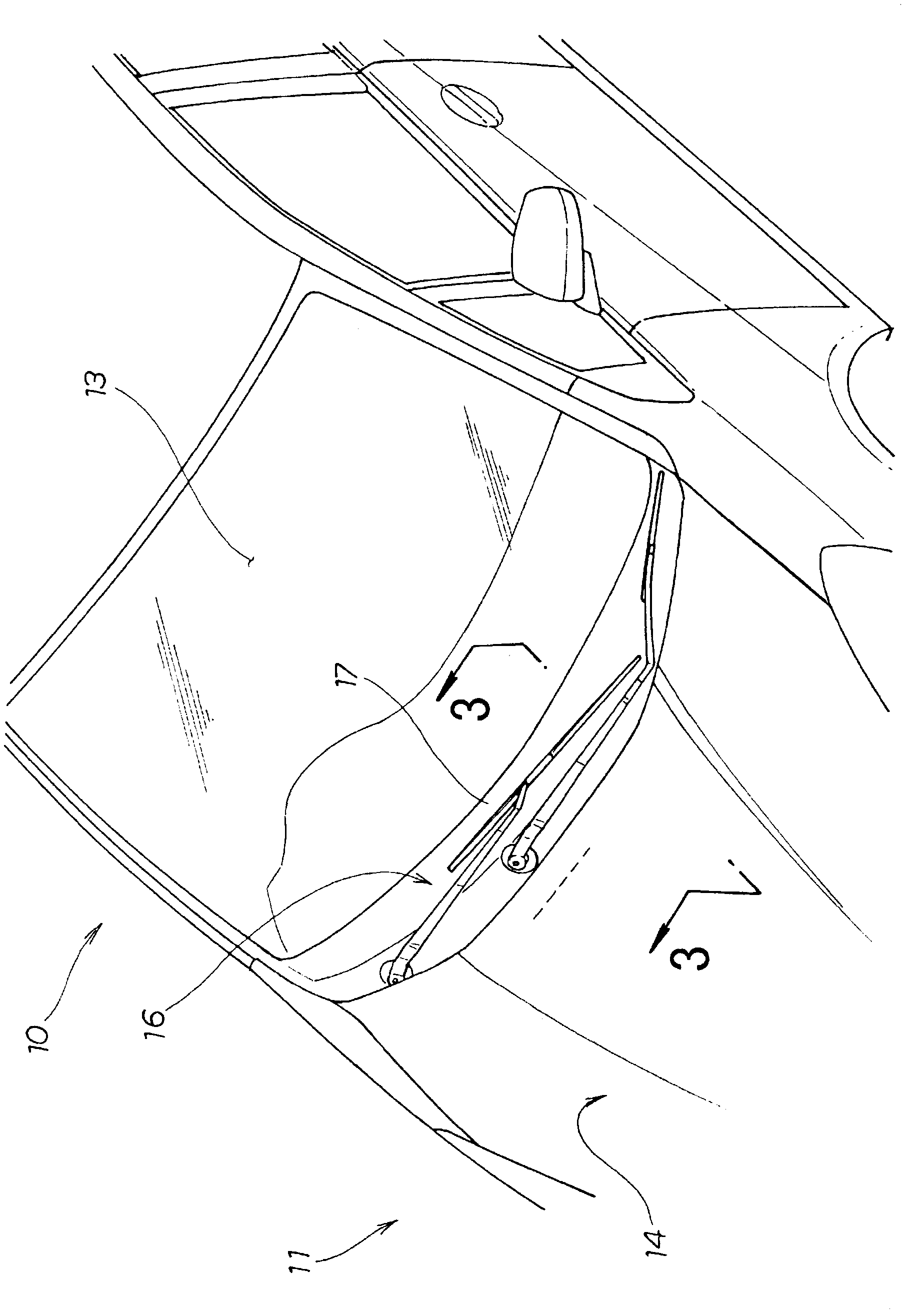

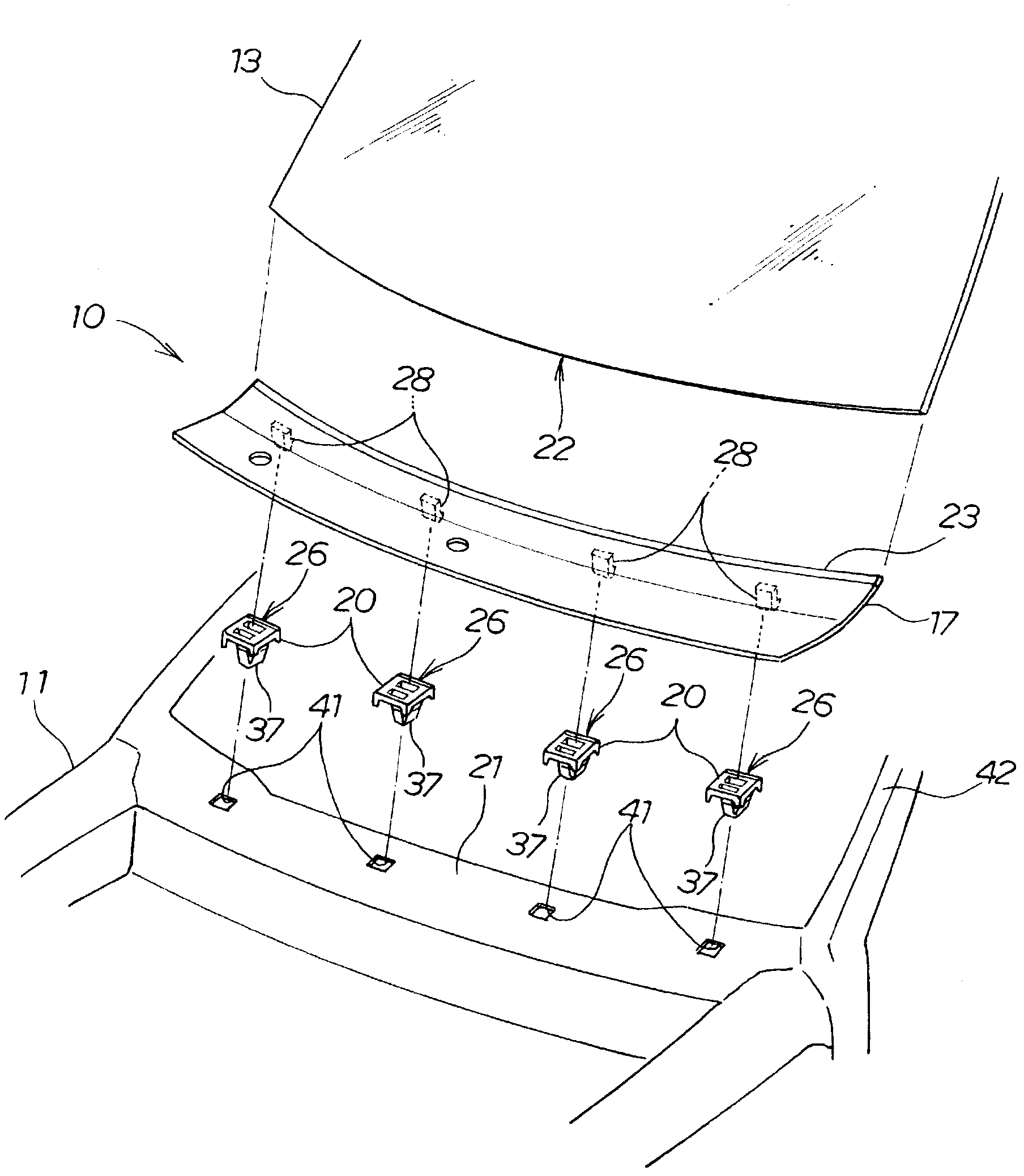

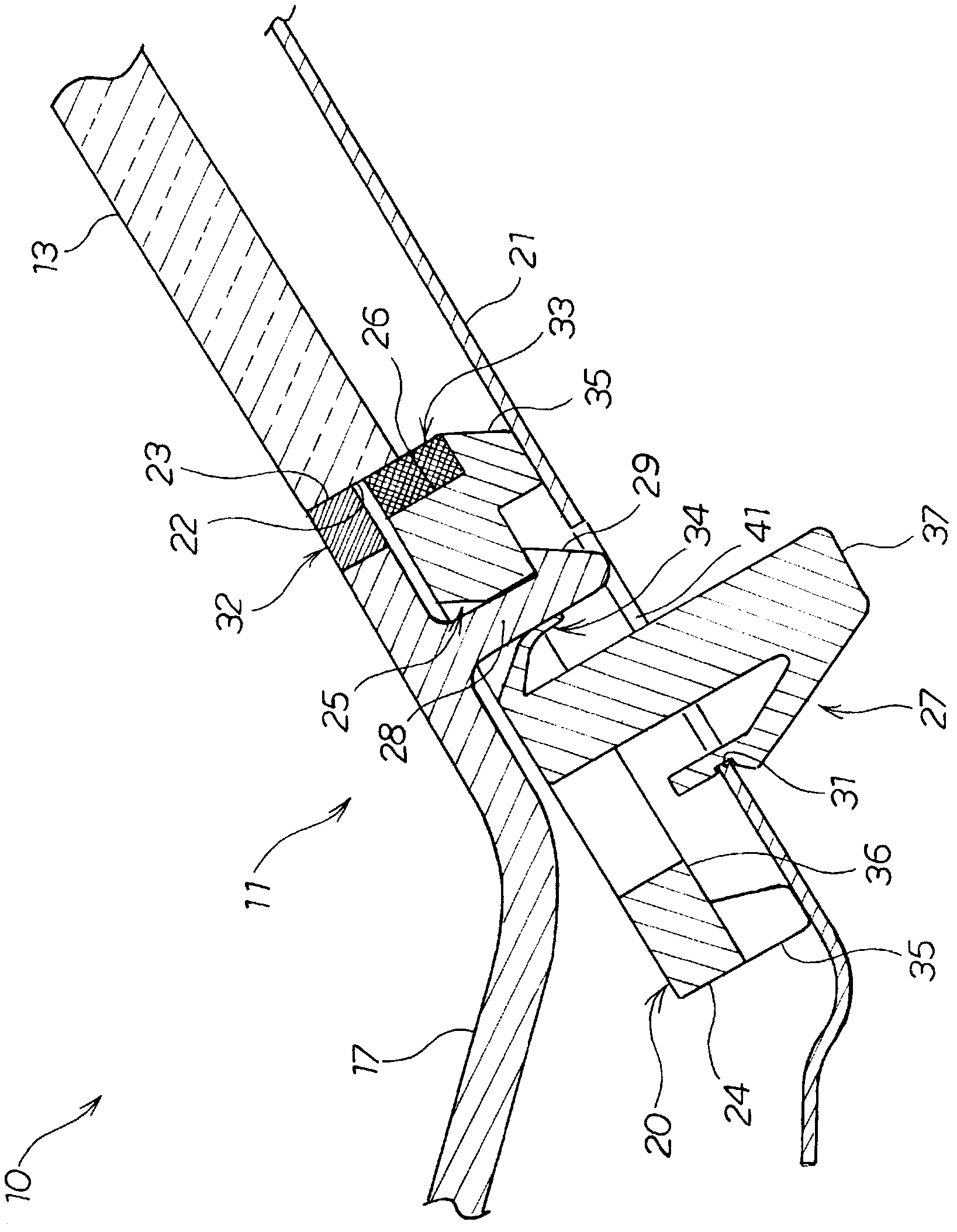

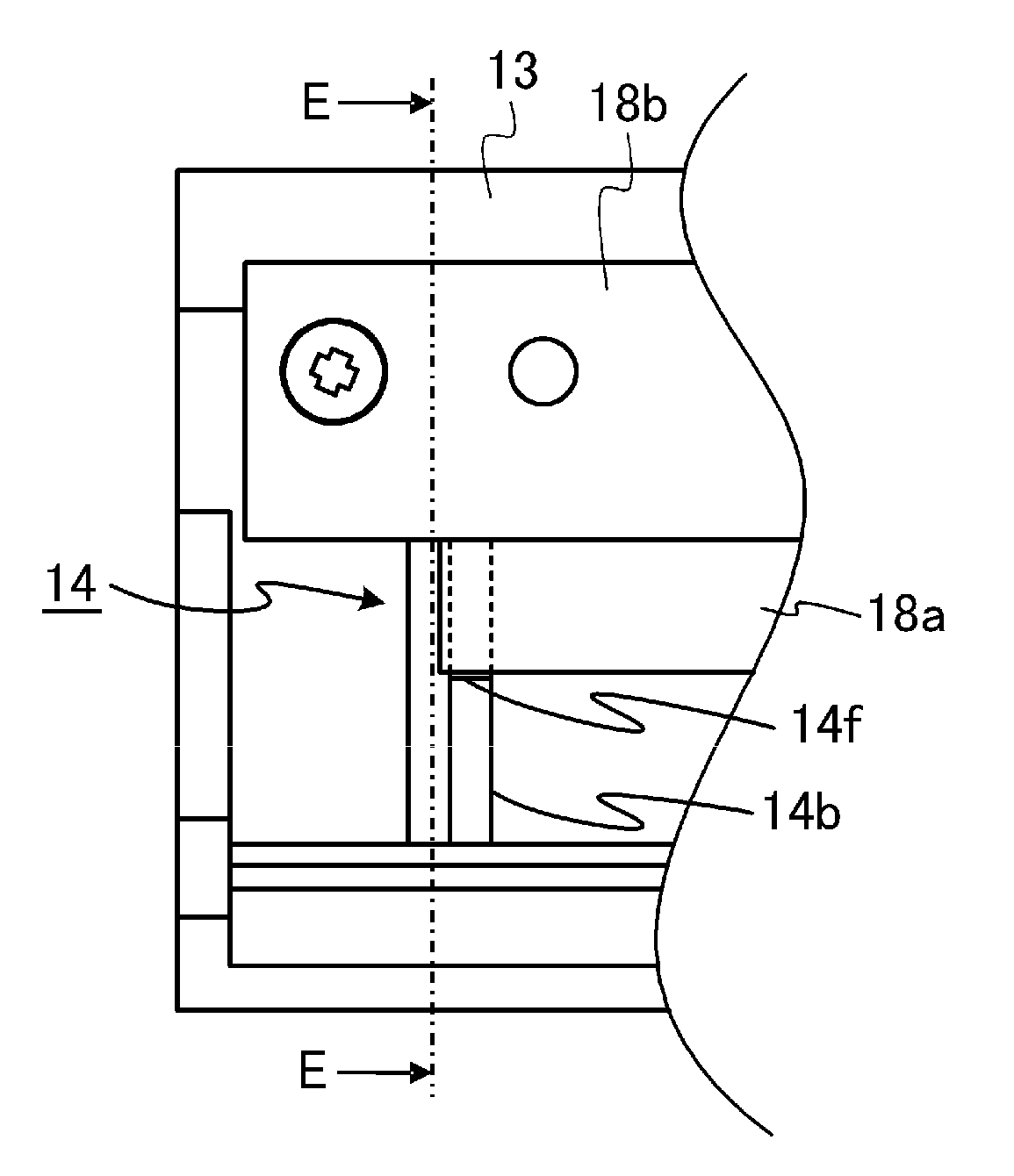

Structure for positioning cowl top for vehicle

ActiveCN103153760AInhibition of entry of foreign matterImprove appearanceWindowsWindscreensEngineeringForce generation

Disclosed is a cowl top positioning structure for determining the relative positions of a windshield (13) and a front cowl top (17) by means of a clip (20). The clip (20) has: a cowl top mounting section (25) to which the front cowl top (17) is mounted; a windshield facing section (26) facing the lower end surface (22) of the windshield (13); and a reaction force generation section (27) for generating a reaction force acting against a pushing force with which the lower end surface (22) of the windshield (13) pushes the windshield facing section (26) toward the front of the vehicle body (11). The relative positions of the windshield (13) and the front cowl top (17) are determined by causing, by means of the reaction force generated by the reaction force generation section (27), the rear end surface (23) of the front cowl top (17) to abut against the lower end surface (22) of the windshield (13).

Owner:HONDA MOTOR CO LTD

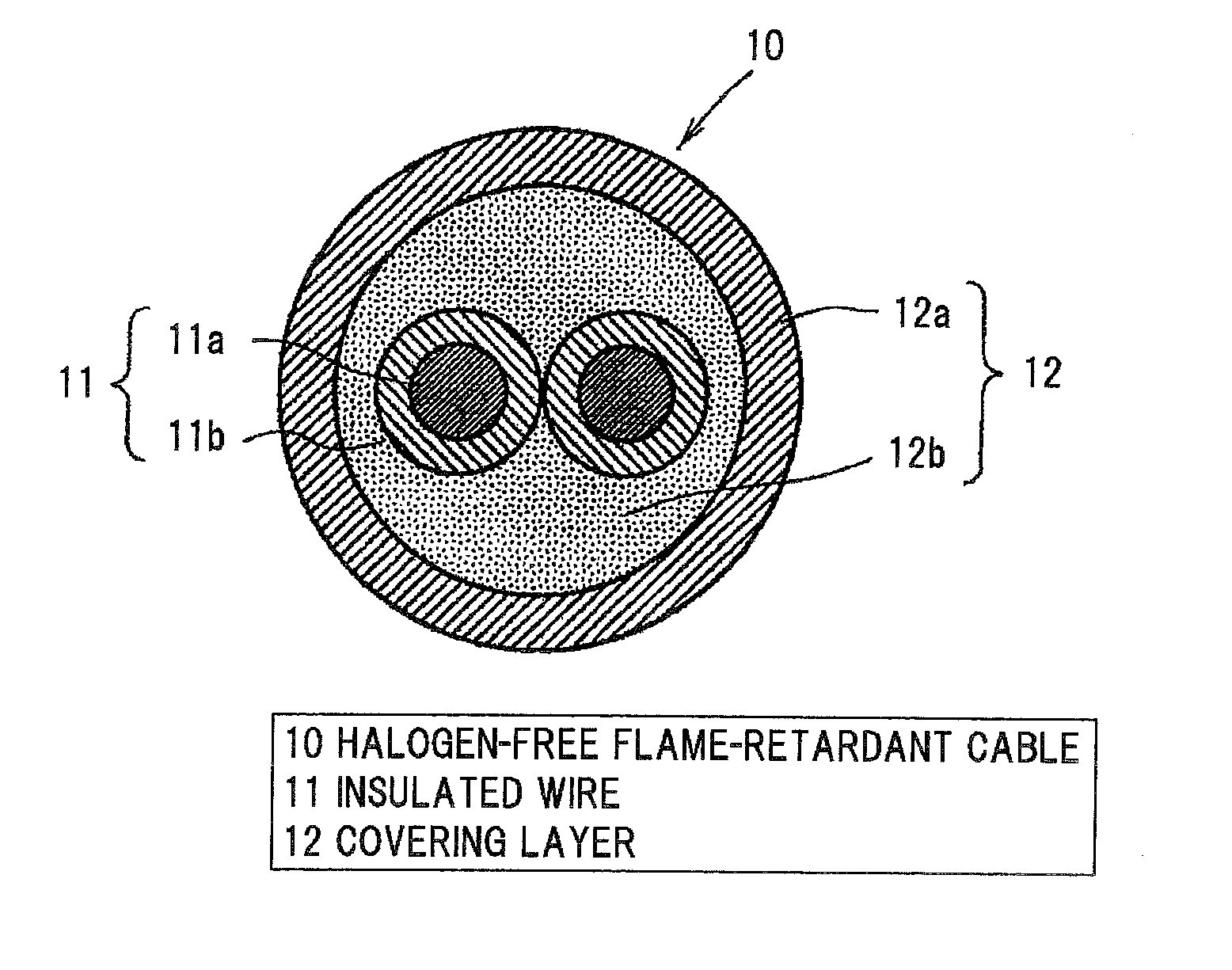

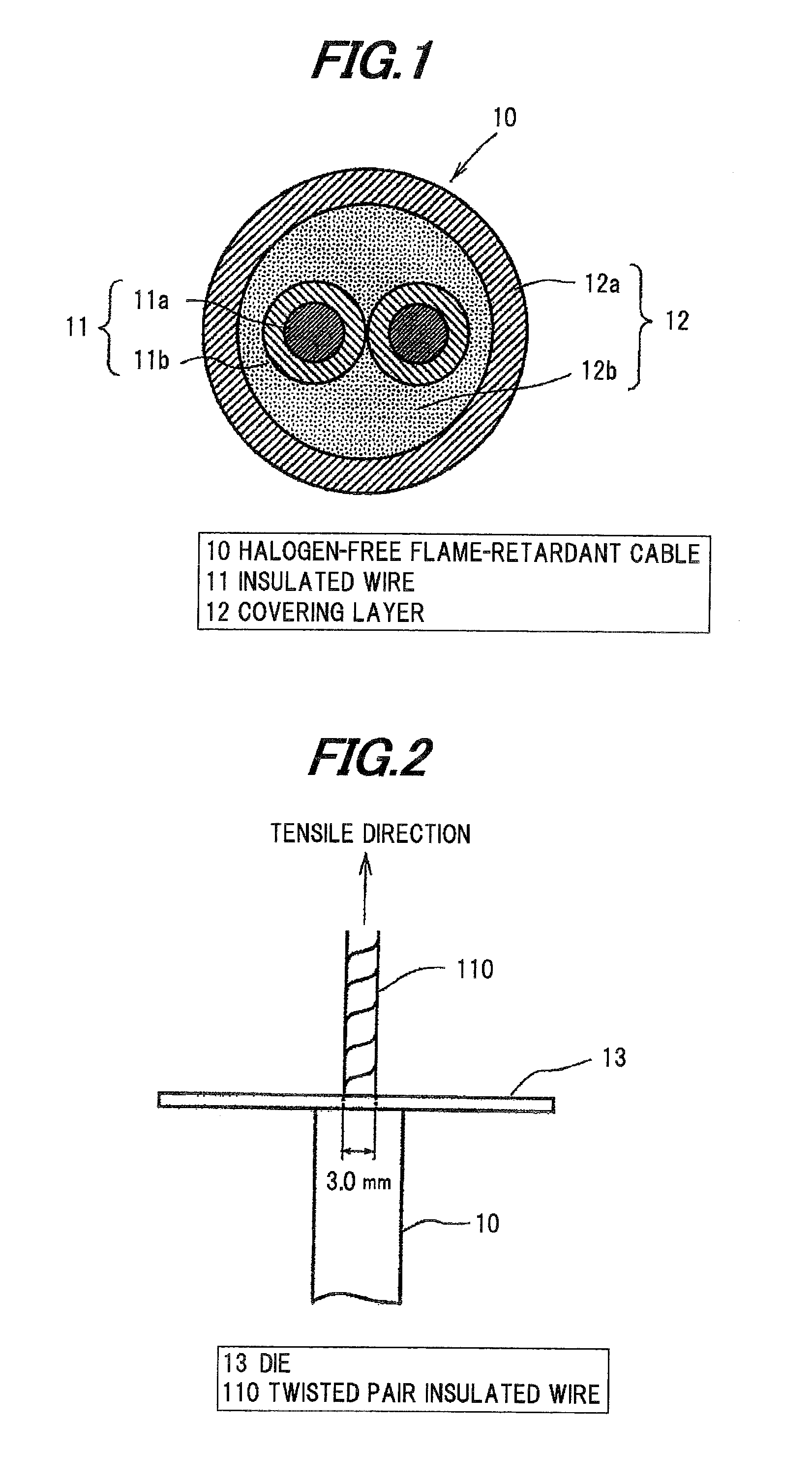

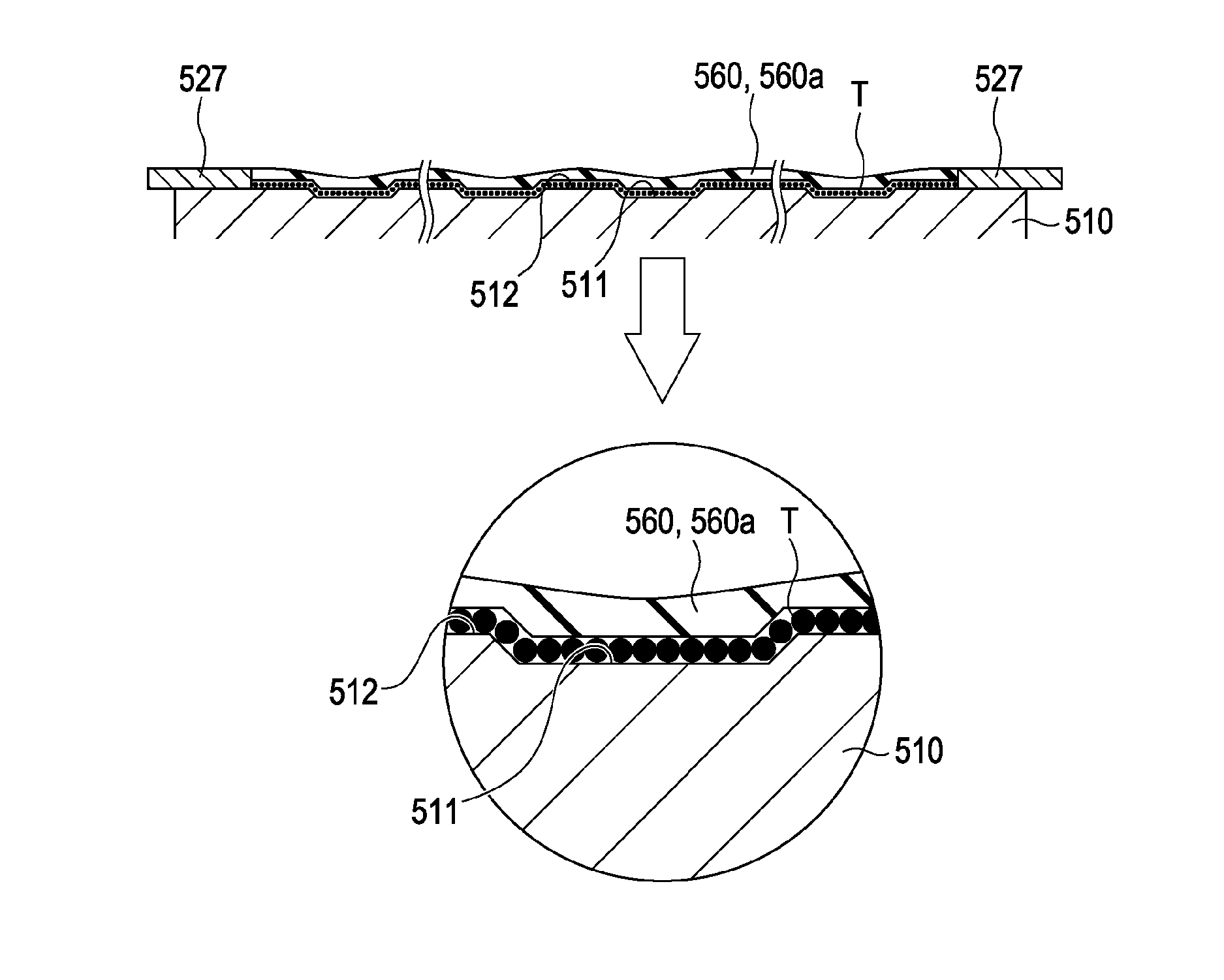

Halogen-free flame-retardant cable

ActiveUS20110174518A1Suppression gapReduce bond strengthInsulated cablesInsulatorsCross-linkInsulation layer

A halogen-free flame-retardant cable includes a multi-core twisted wire including a plurality of insulated wires twisted together, the plurality of insulated wires each including a conductor and an insulation layer on an outer periphery of the conductor, an inner layer formed on an outer surface of the multi-core twisted wire, and an outer layer formed on the inner layer. The outer layer includes a resin composition including not less than 30 parts by mass of a flame retardant with respect to 100 parts by mass of thermoplastic polyurethane (TPU). The inner layer includes a resin composition comprising an ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate (VA) content of not less than 33%, and the outer layer is subjected to cross-linking treatment.

Owner:HITACHI CABLE

Stator core for rotating electric machine

ActiveCN104242496AIncrease lossInhibition distance increasesMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsProduction rateElectric machine

A stator core for a rotating electric machine includes a plurality of split cores. Each of the plurality of split cores includes a back yoke, a tooth, and a single caulking portion. When each of the plurality of split cores is seen in an axial direction, two inner circumferential-side intersections and two outer circumferential-side intersections are defined, both circumferential-end surfaces of the tooth intersect an inner circumferential surface of the back yoke at the two inner circumferential-side intersections, virtual lines drawn by extending both the circumferential-end surfaces of the tooth intersect an outer circumferential surface of the back yoke at the two outer circumferential-side intersections, a central position of the caulking portion is disposed in an opposing angular region on a radially outer side out of four opposing angular regions defined by lines diagonally connecting the two inner circumferential-side intersections to the respective two outer circumferential-side intersections.

Owner:HONDA MOTOR CO LTD

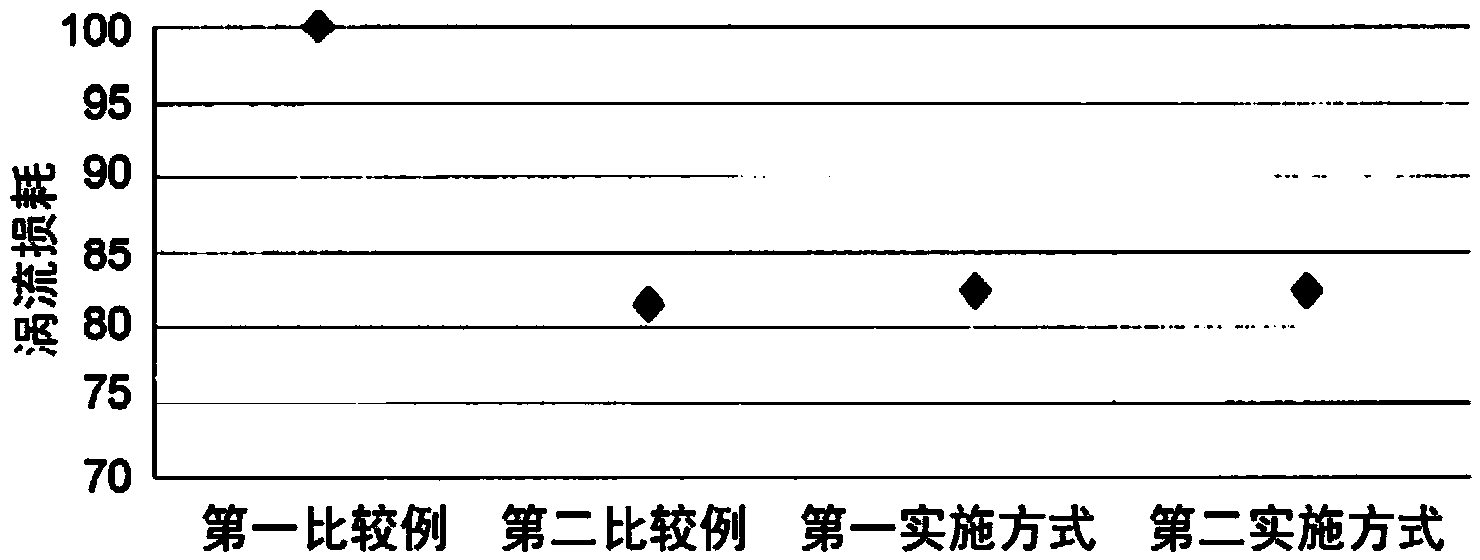

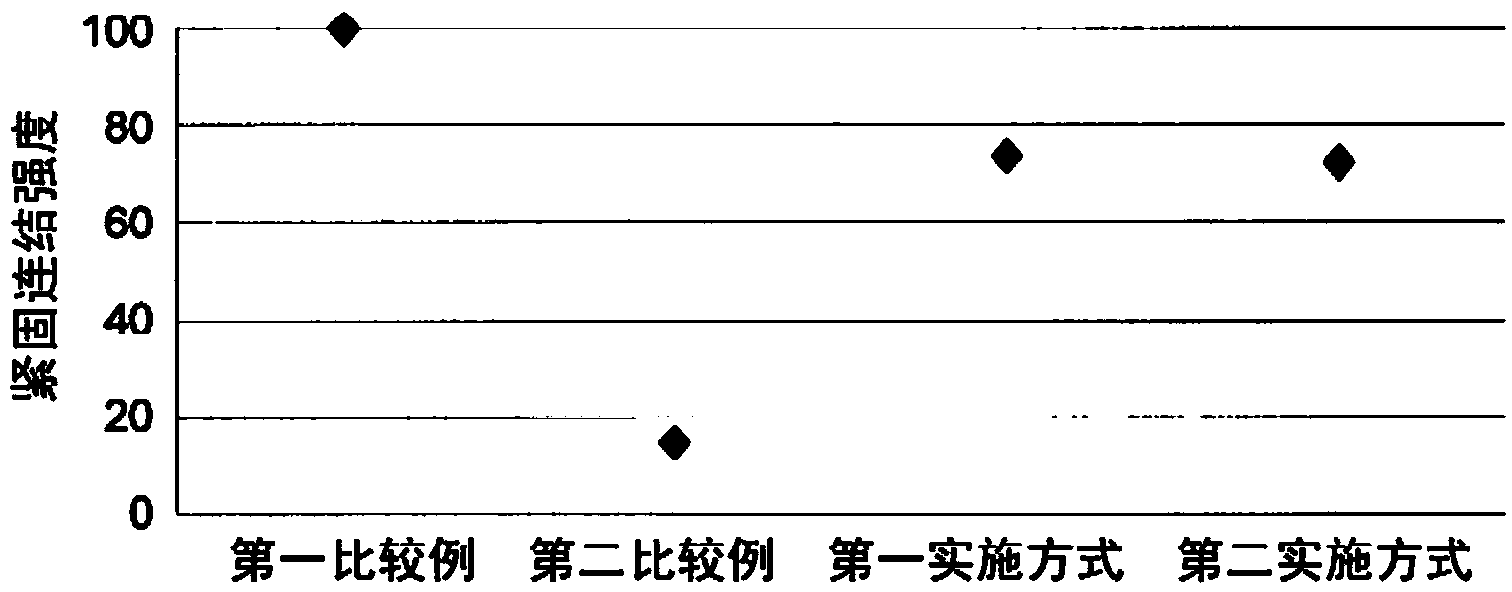

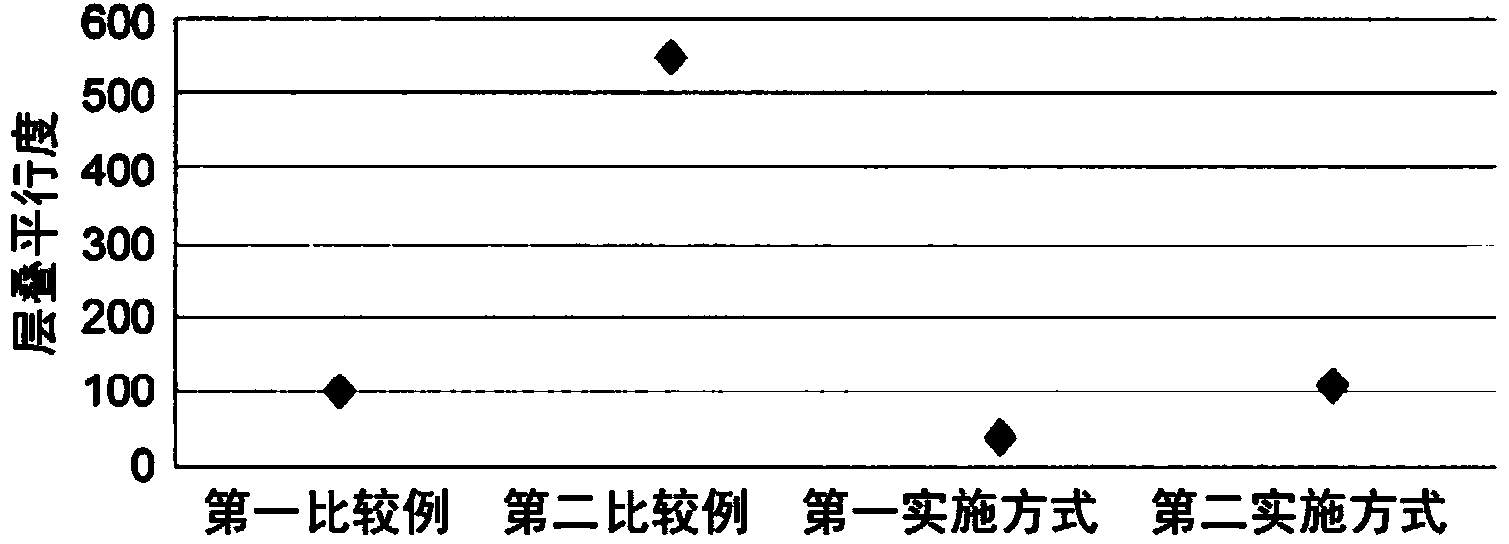

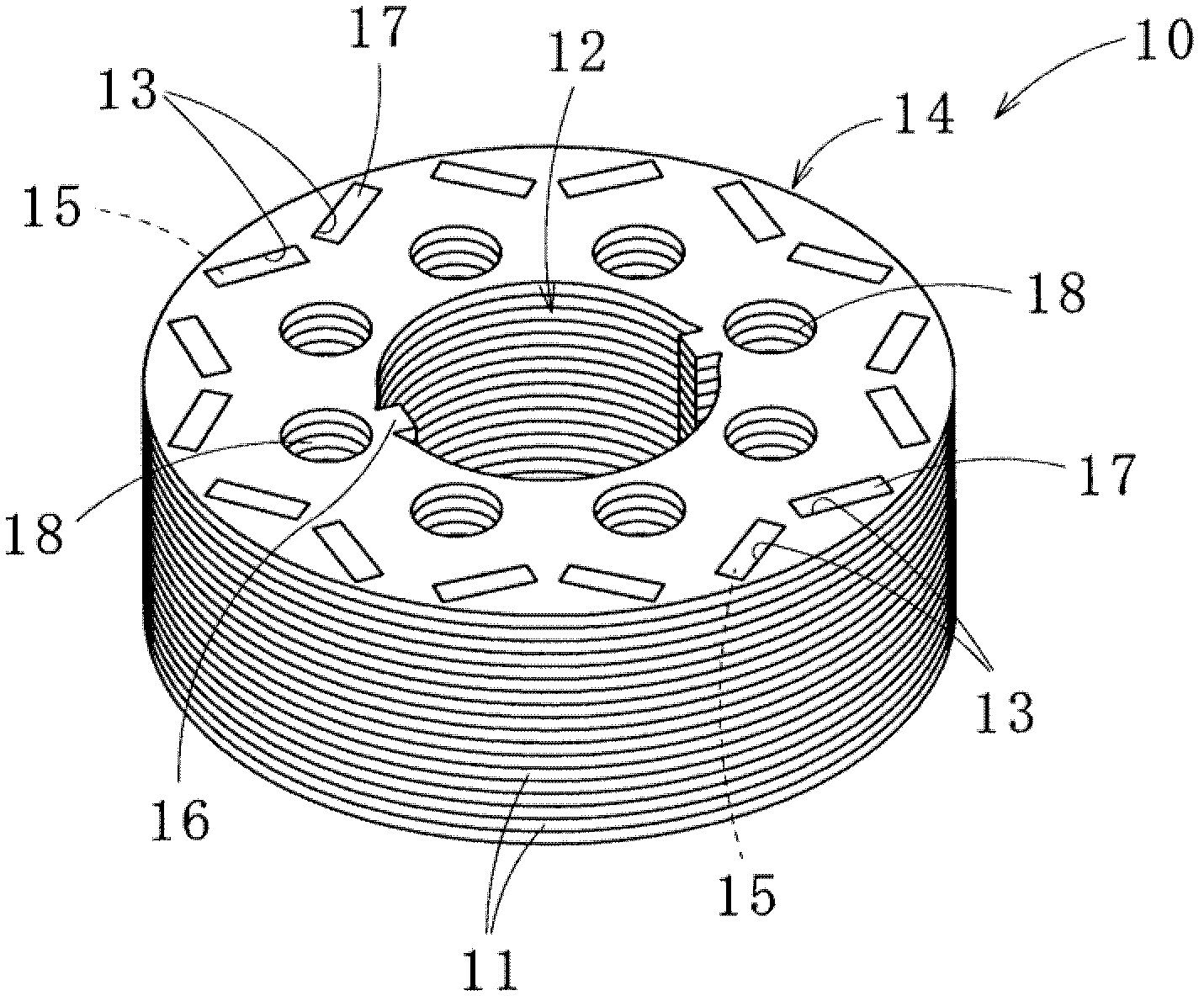

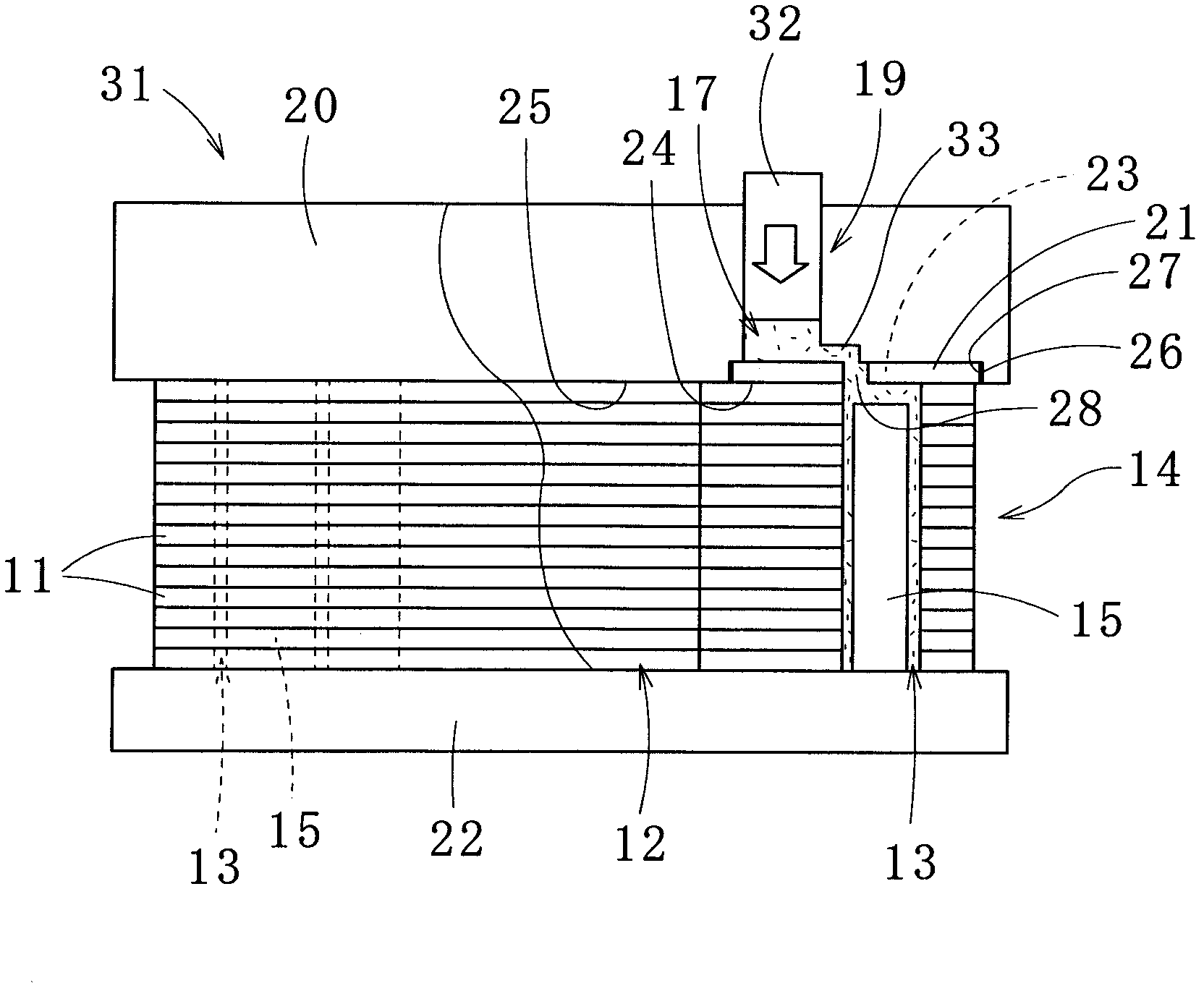

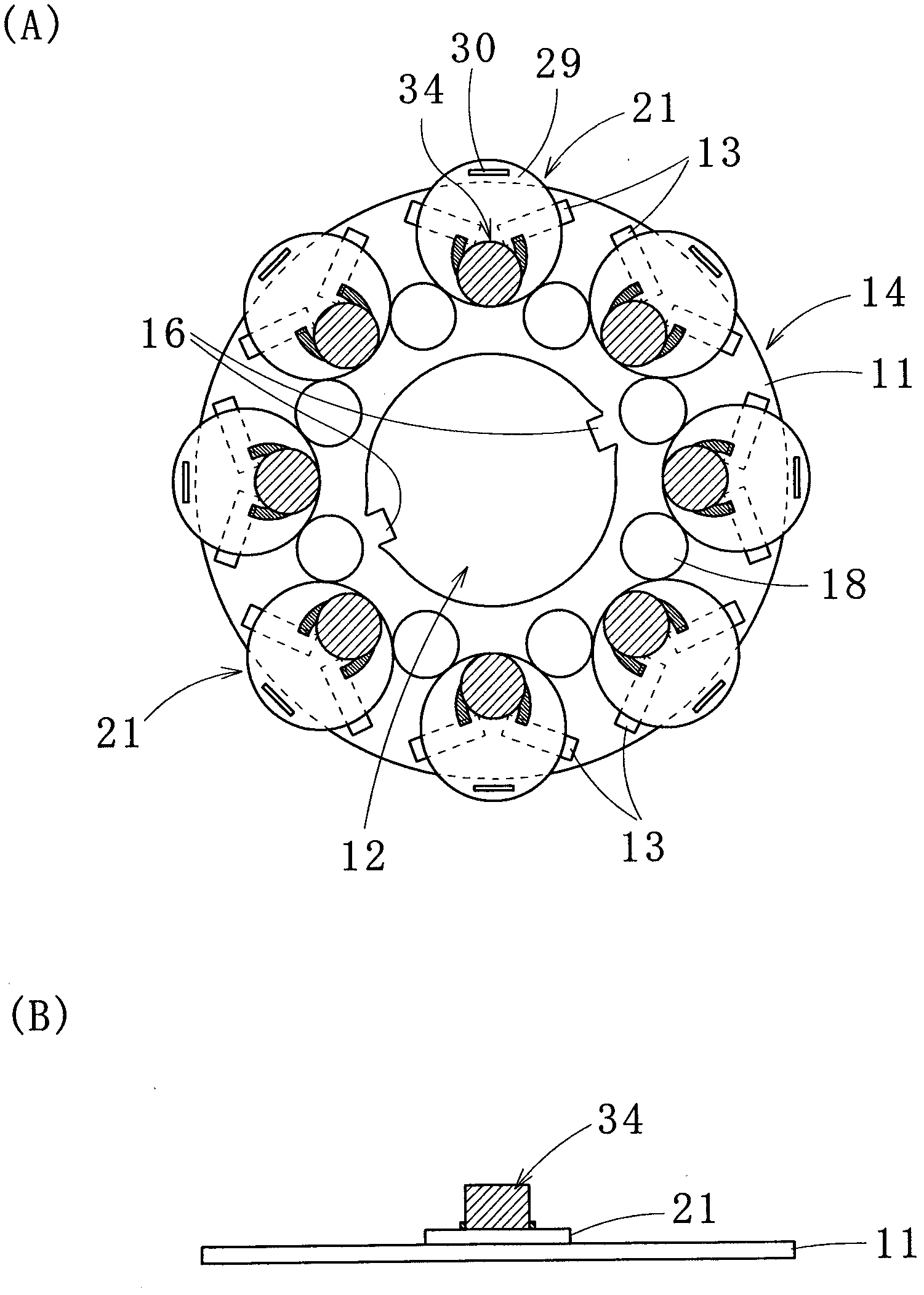

Method for manufacturing stacked rotor core

ActiveCN102598490AReduce the effects of warpingSuppression gapMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMetal

A method for manufacturing a stacked rotor core (10) is performed in such a manner that a permanent magnet (15) is inserted in each magnet insertion section (13) of the core body (14) formed by stacking core pieces (11) and then the permanent magnet (15) is affixed by filling the magnet insertion section (13) with a resin (17) from a resin storage section (19) provided to molds for sandwiching and holding the core body. The method has: a first step for disposing divided dummy plates (21) between the core body (14) and a mold, the divided dummy plates (21) each covering one or more magnet insertion sections (13) and having resin pouring holes (28) communicating with the magnet insertion sections (13); a second step for pouring the resin (17) into the magnet insertion sections (13) from the resin storage section (19) through the resin pouring holes (28) provided in the divided dummy plates (21) and corresponding to the magnet insertion sections (13); and a third step for removing the divided dummy plates (21) together with an excess resin (34) after the resin (17) inserted in the magnet insertion sections (13) is hardened. In the method, the easiness of the resin sealing work is improved.

Owner:MITSUI HIGH TEC INC

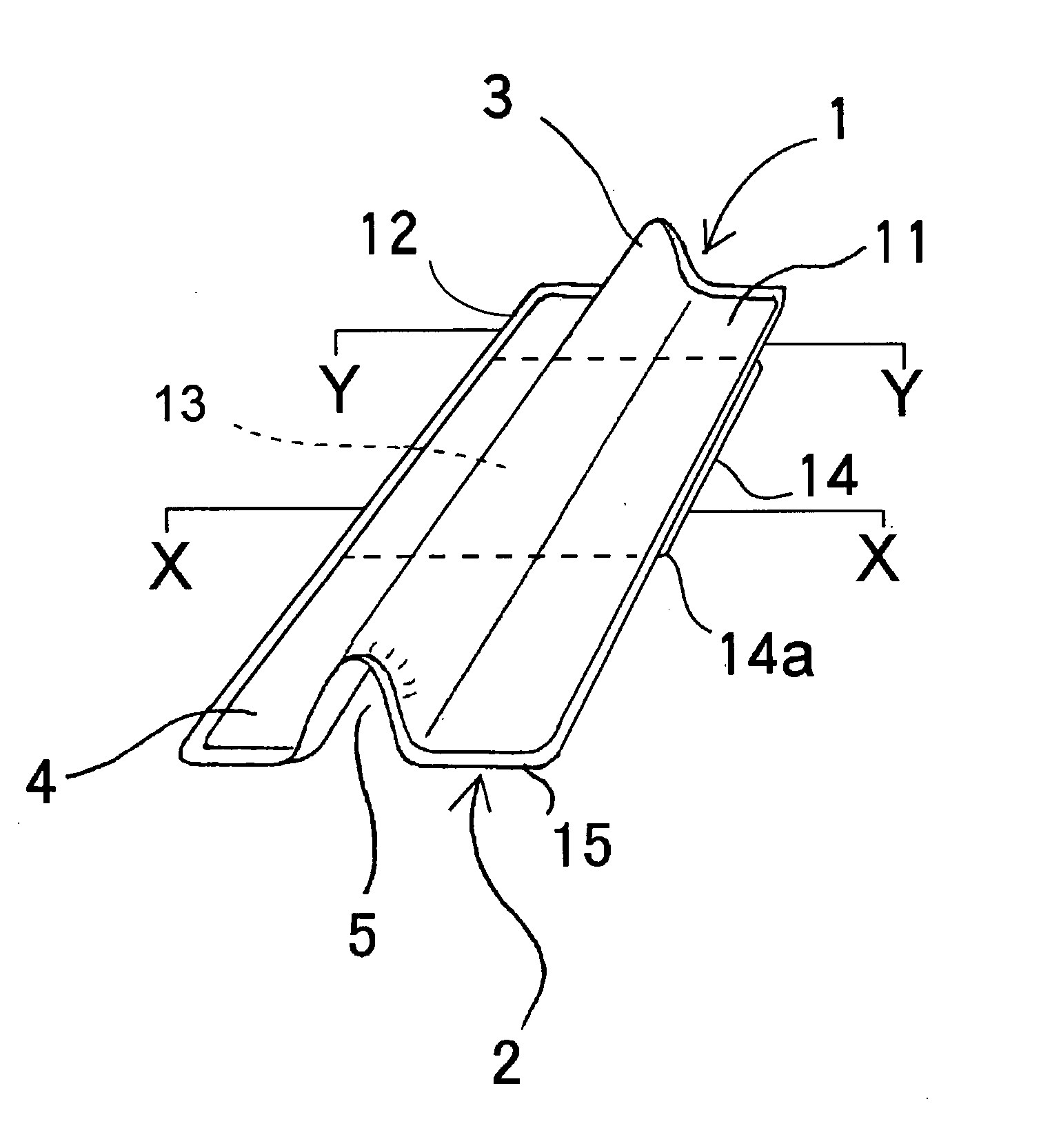

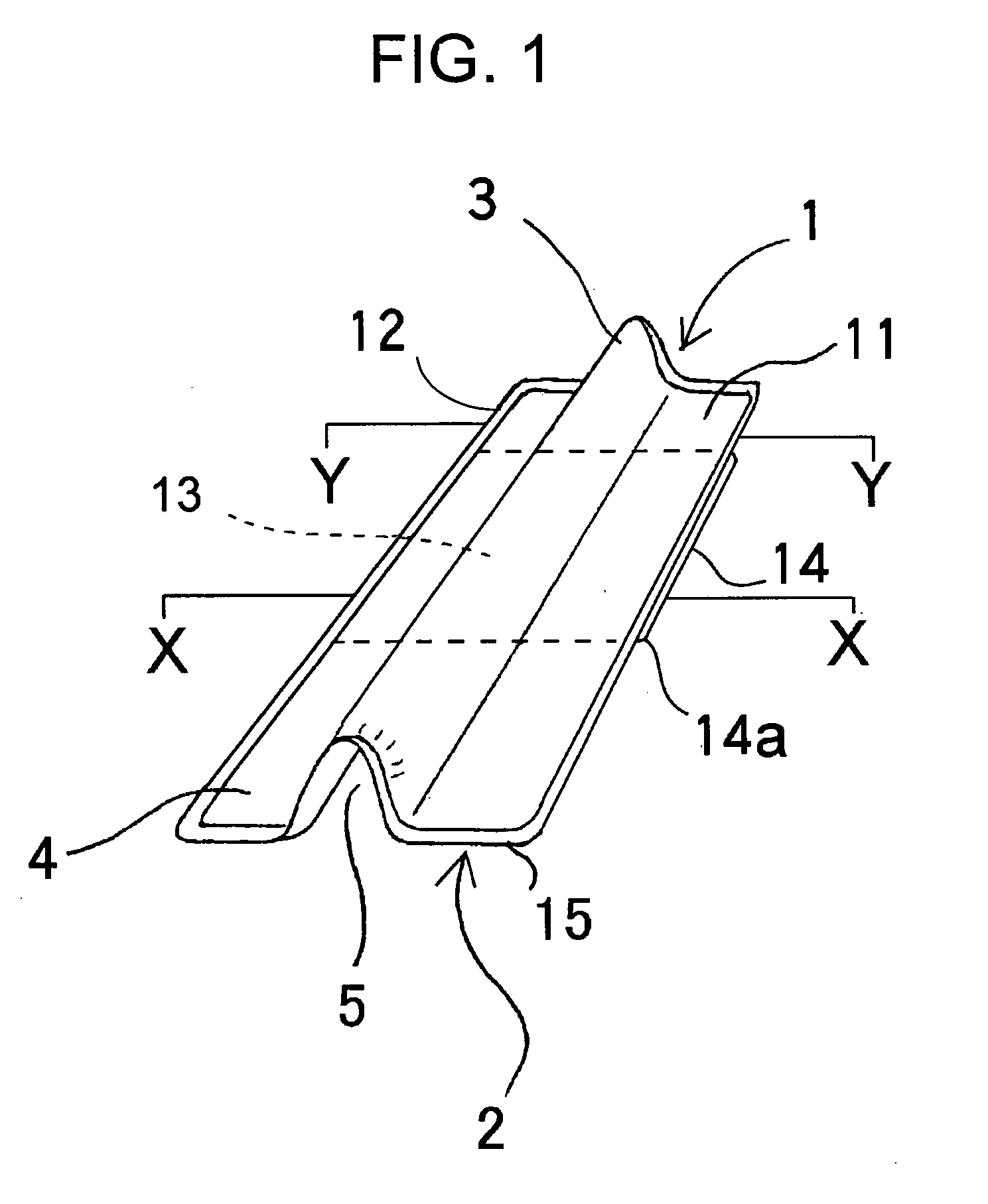

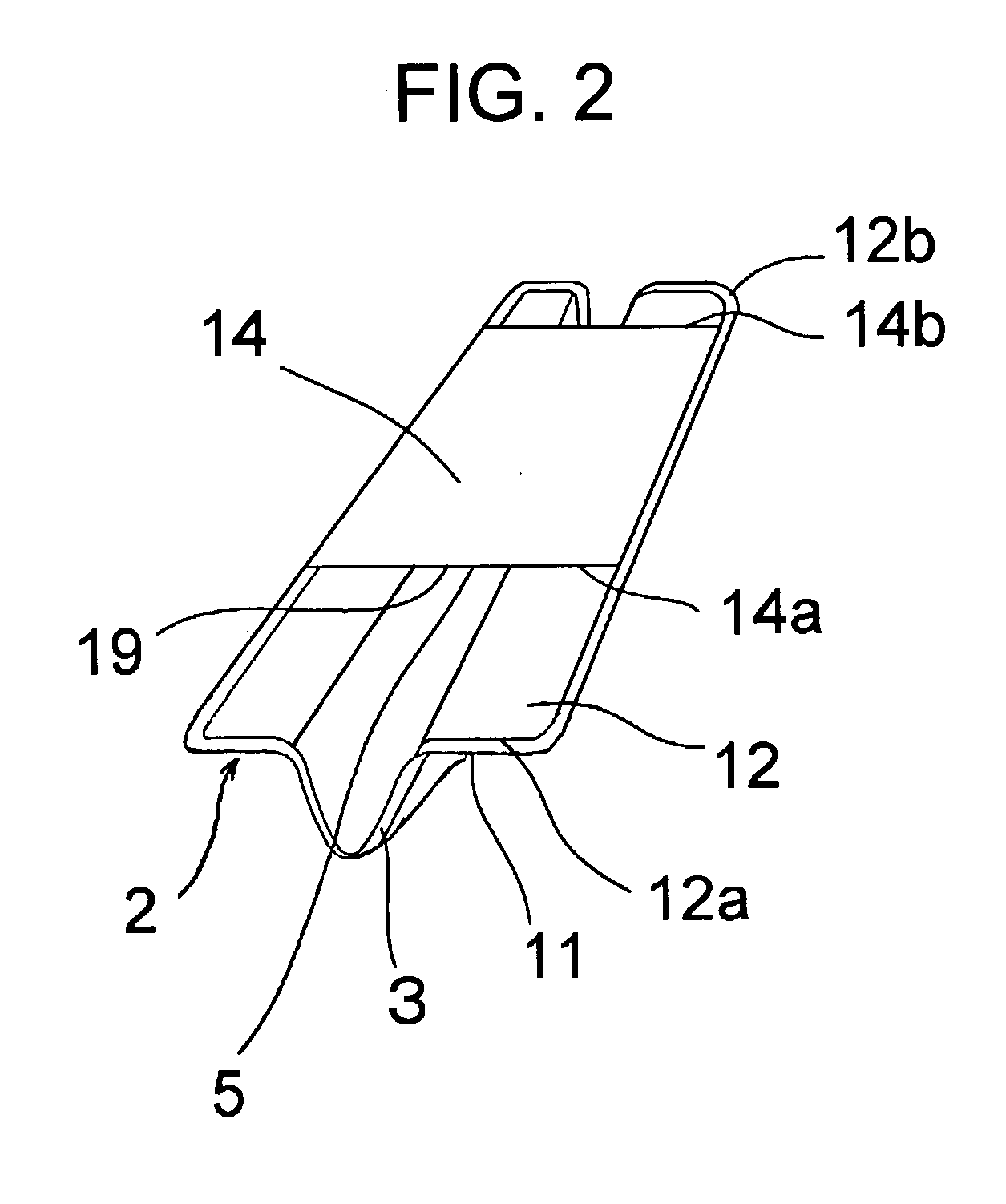

Interlabial pad

Provided is an interlabial pad that can be closely fixed to the interlabial space, having a structure to realize better contact with user's body irrespective of personal differences of labia providing secure and hygienic fit. An interlabial pad having a long convex area (3) formed by folding an absorbent layer sheet (2) at the body-facing side of the interlabial pad (1) to fit to the inside of the interlabial space, a ready-made mini sheet piece (14) attached to the opposite side face to the body side of the interlabial pad (1) to restrict broadening of a flexion area of the absorbent layer sheet (2) and form a space between the ready-made mini sheet piece (14) and the back side sheet (12) to which a finger can be inserted.

Owner:UNI CHARM CORP

Sliding door device

InactiveCN102162674ASuppress turbulenceSuppression gapNoise suppressionVehicle heating/cooling devicesMechanical engineeringAperture ratio

A sliding door device includes a frame case that includes an opening through which an air flow passes, a slide door that is moved relative to the opening to adjust an aperture ratio of the opening, a shaft that is disposed at an upstream side of the slide door when viewed along the flowing direction of the air flow, and moves the slide door, and a windbreak member that blocks a gap between the shaft and the slide door.

Owner:MAHLE INT GMBH

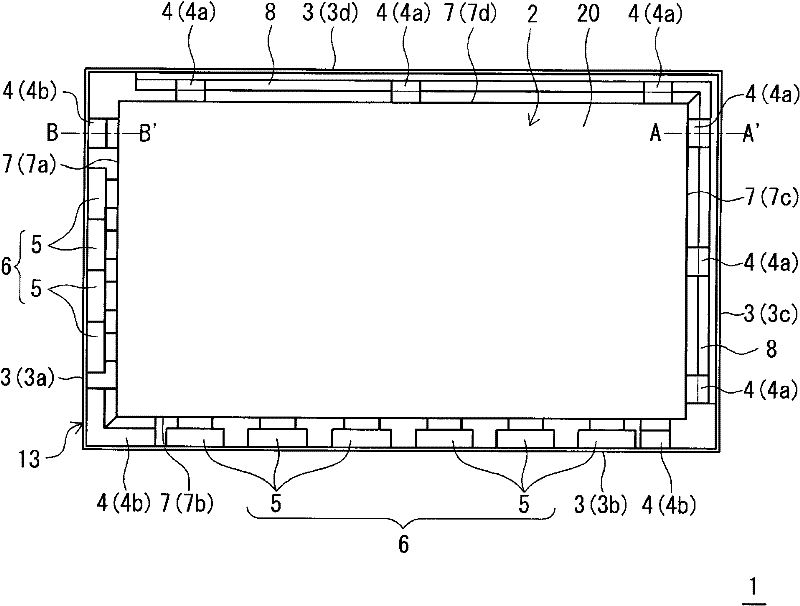

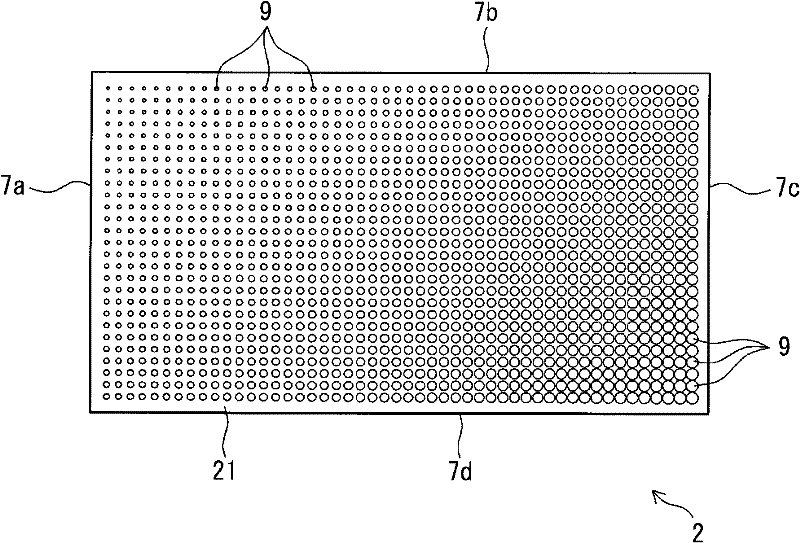

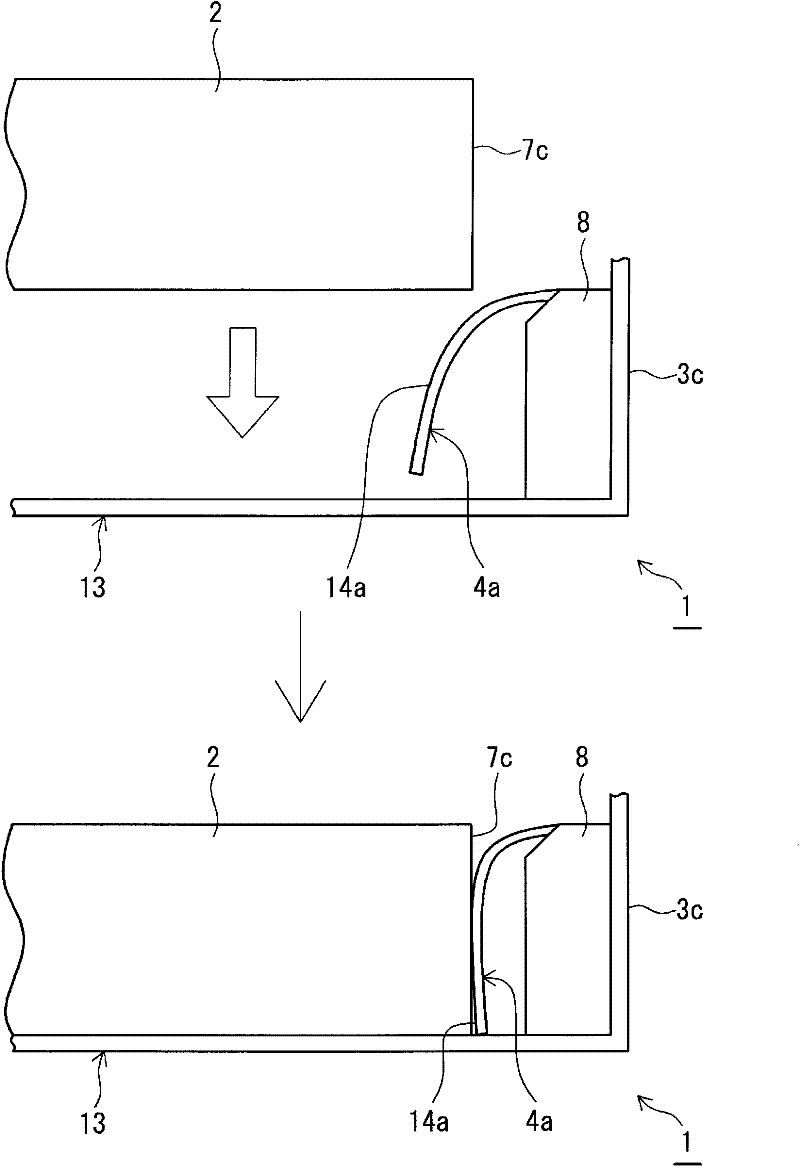

Edge-light-type illuminating device, liquid crystal display device, and television receiver

InactiveCN102472453AThermal expansion allowedSuppression gapTelevision system detailsPoint-like light sourceLiquid-crystal displayTelevision receivers

Owner:SHARP KK

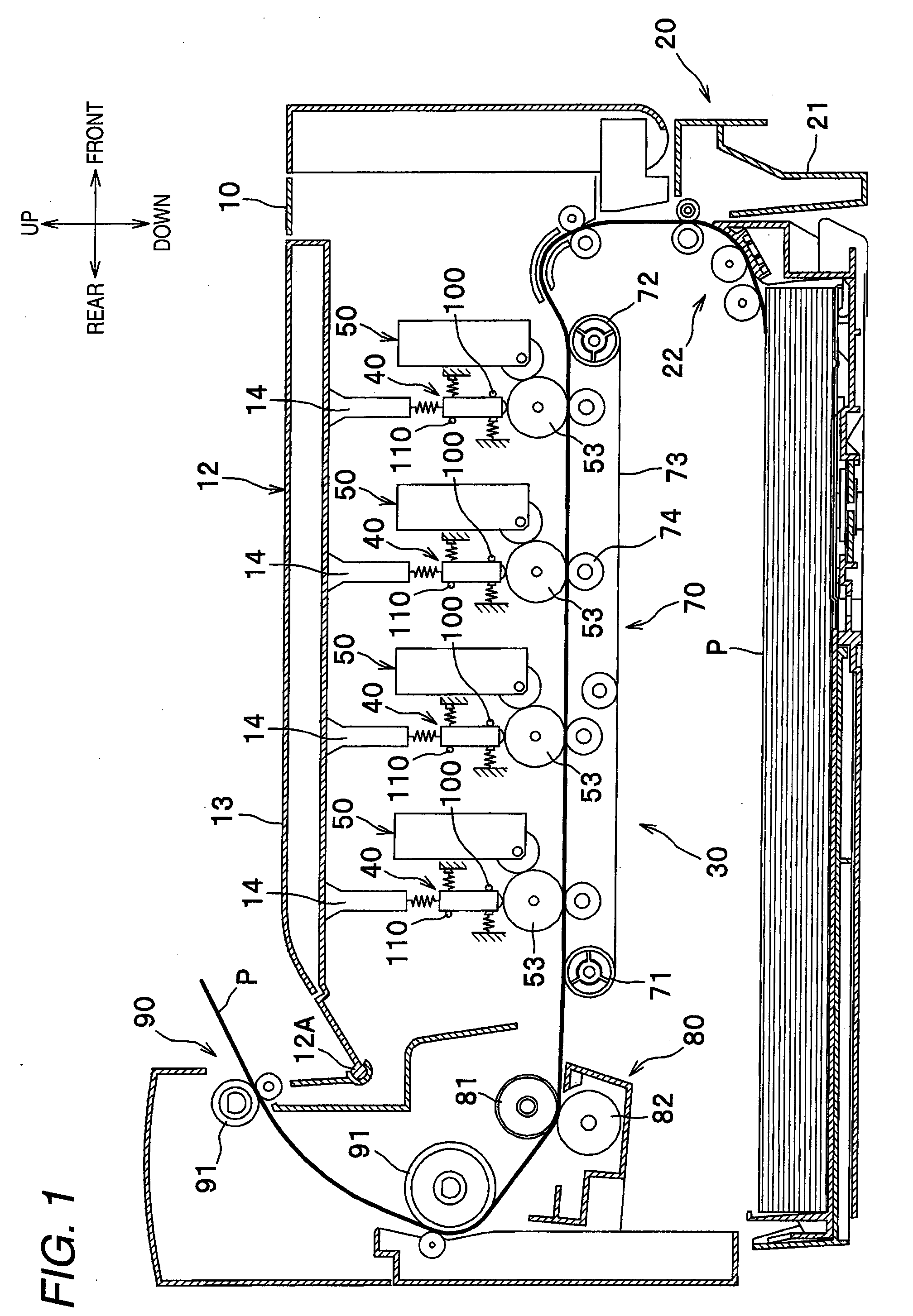

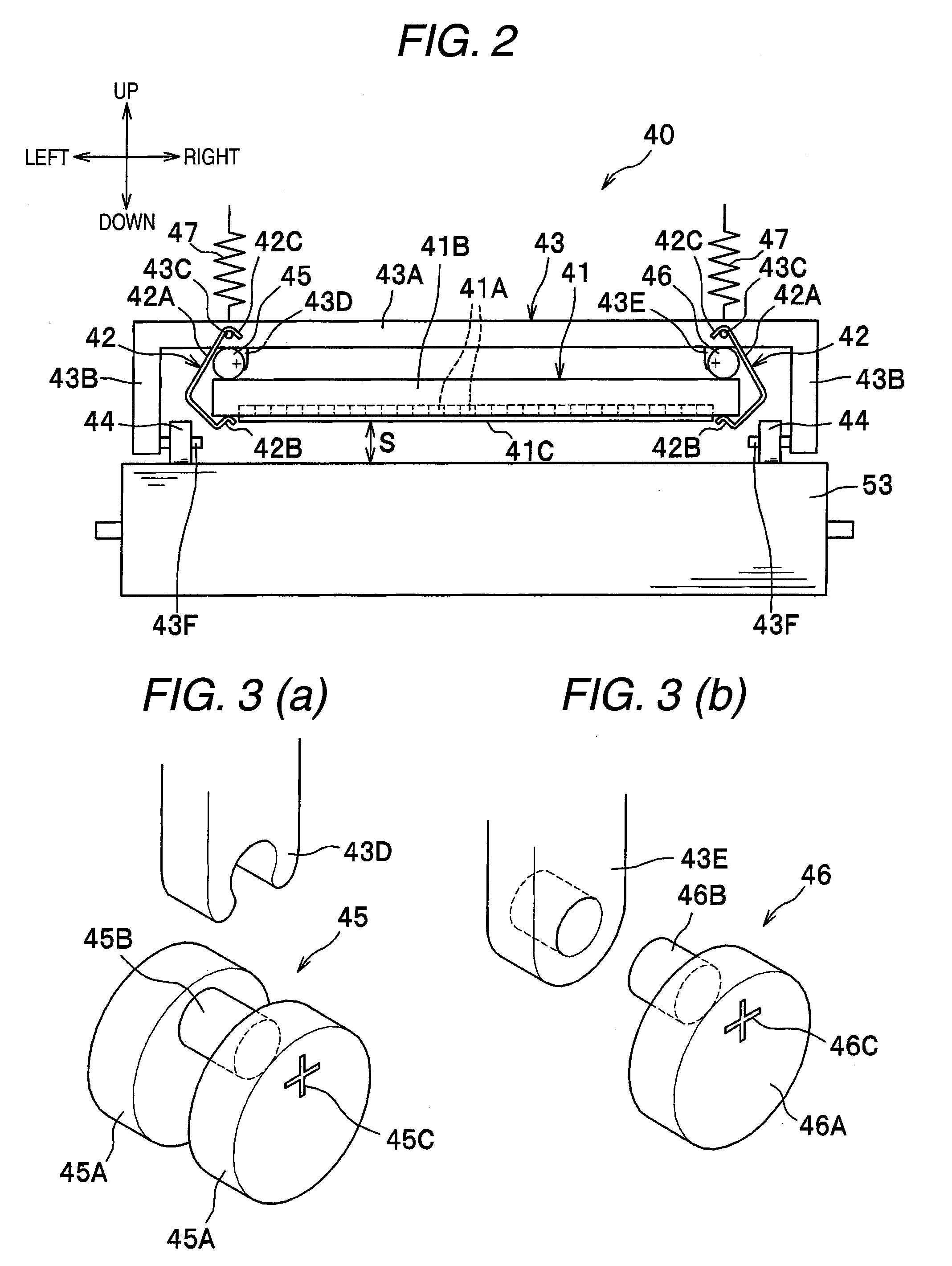

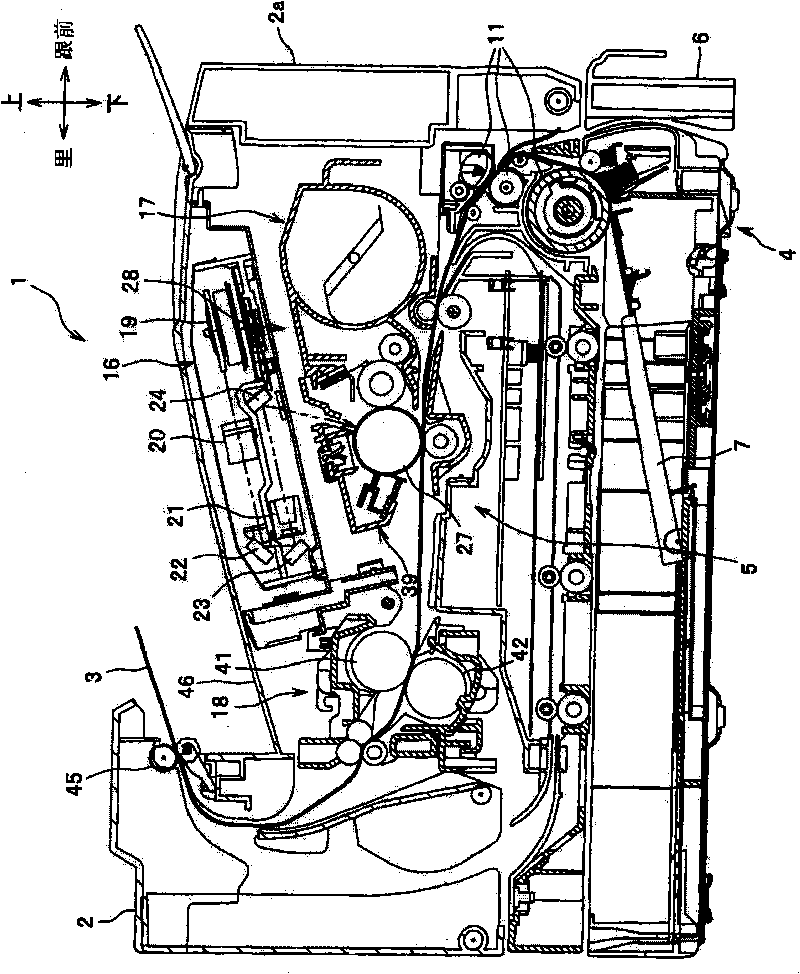

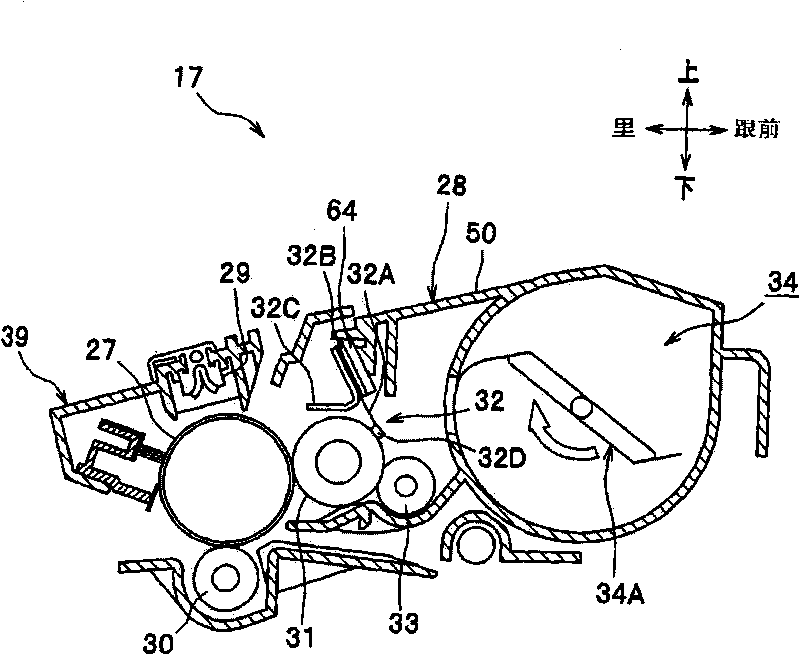

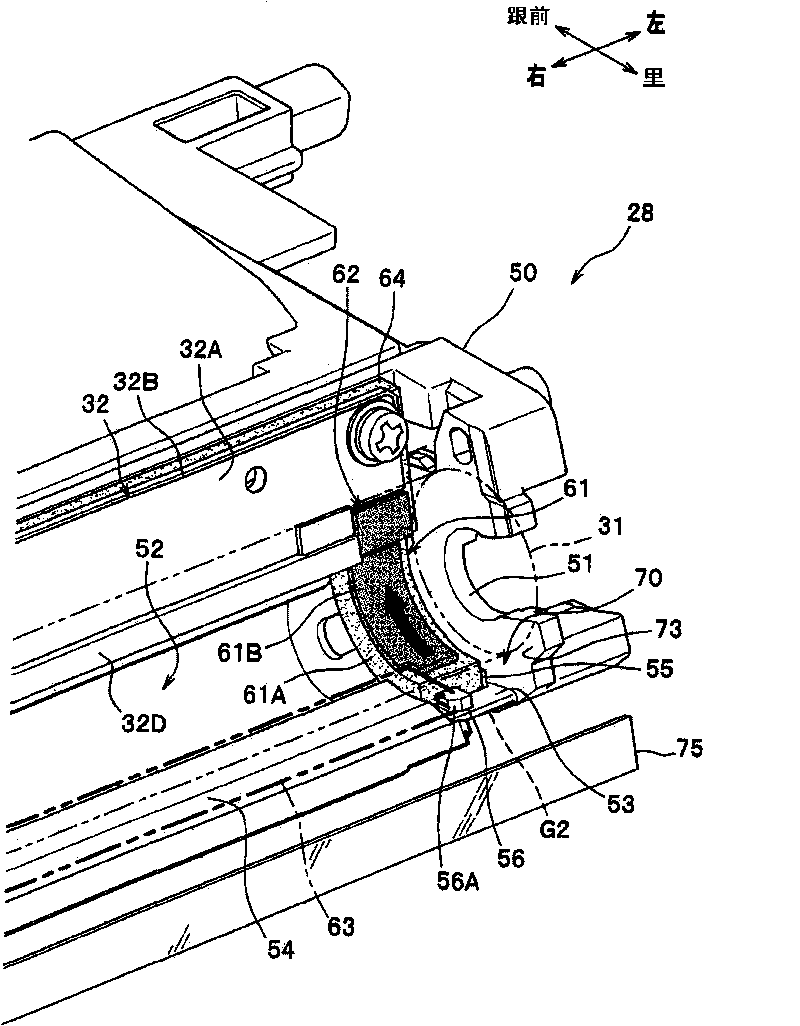

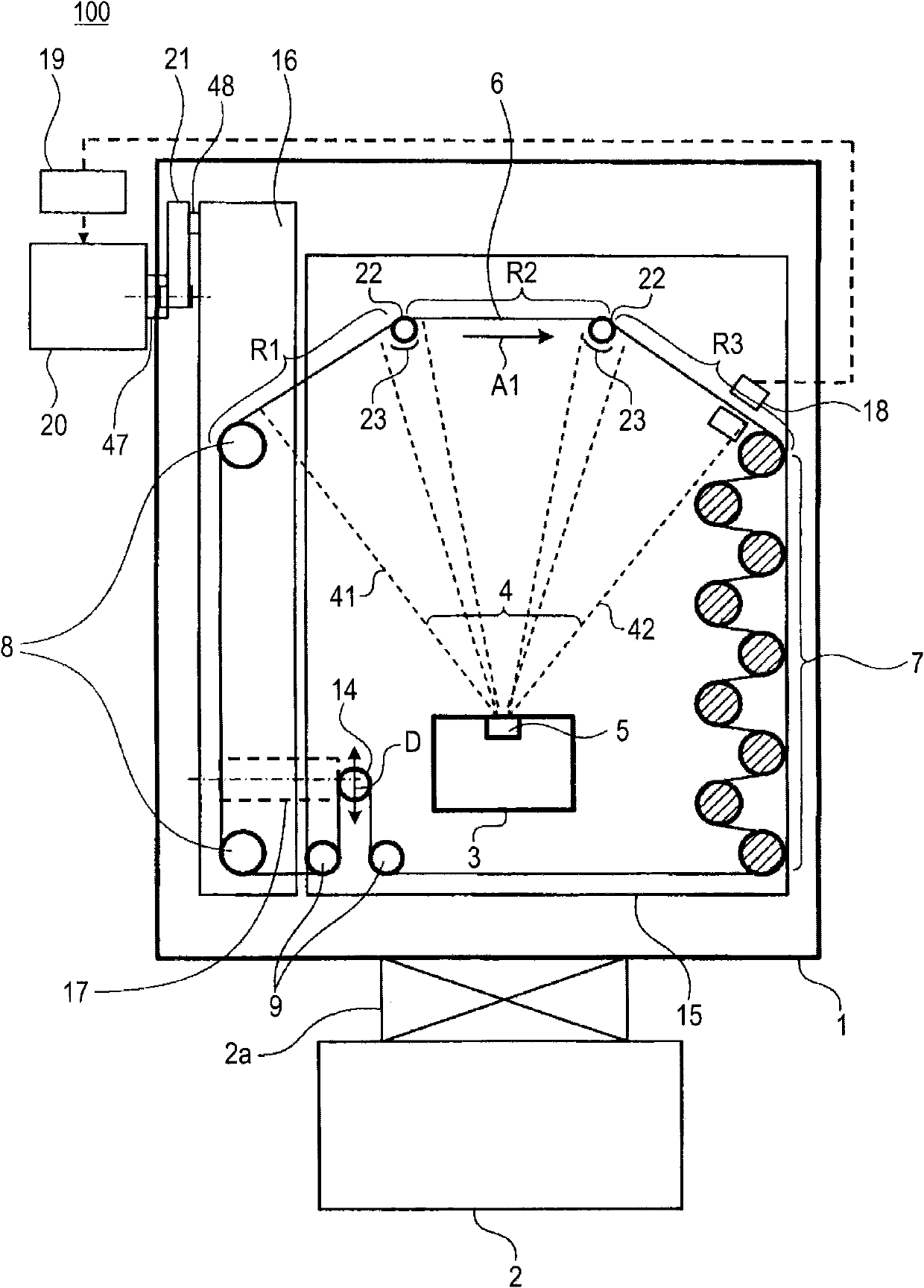

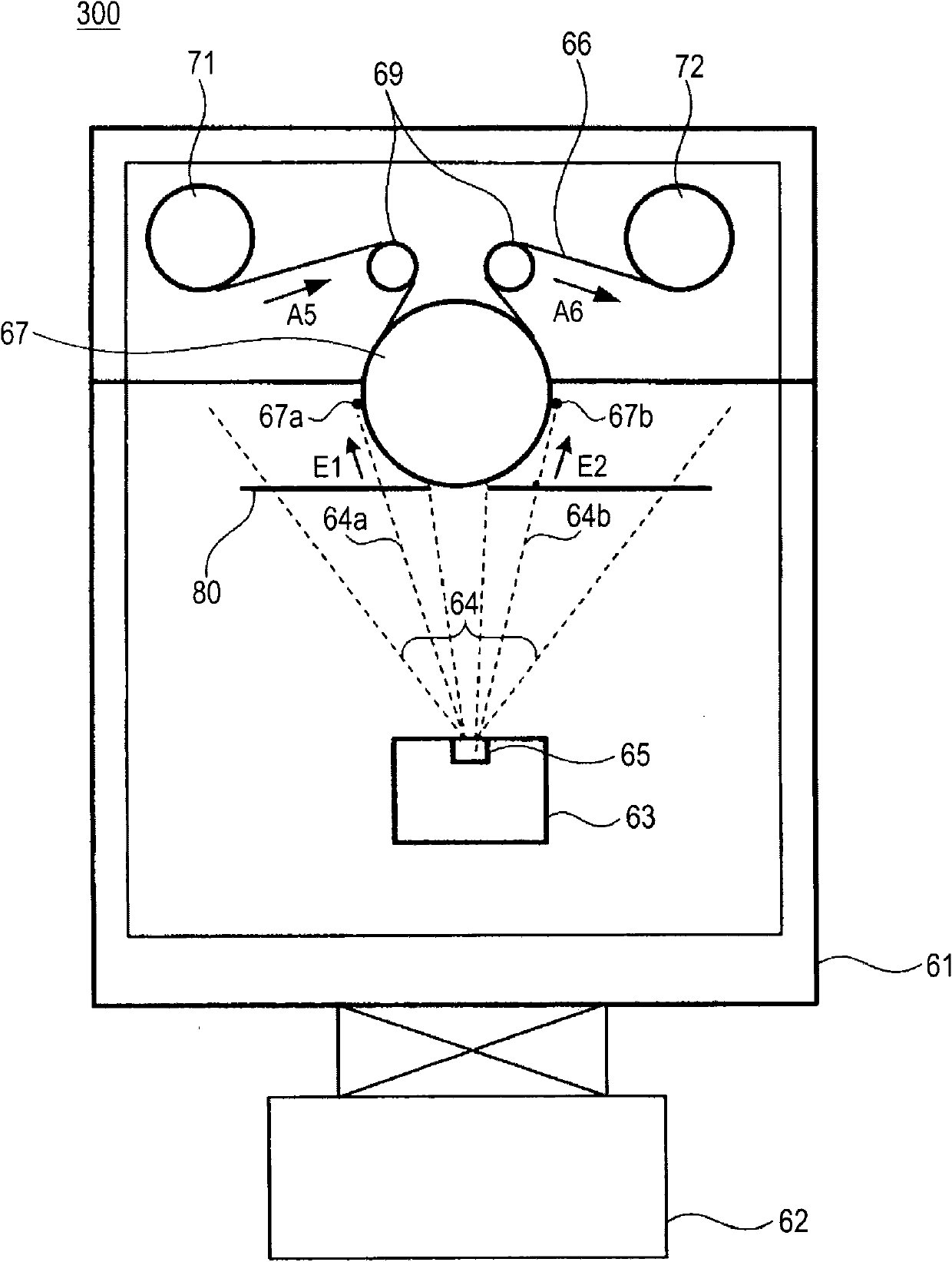

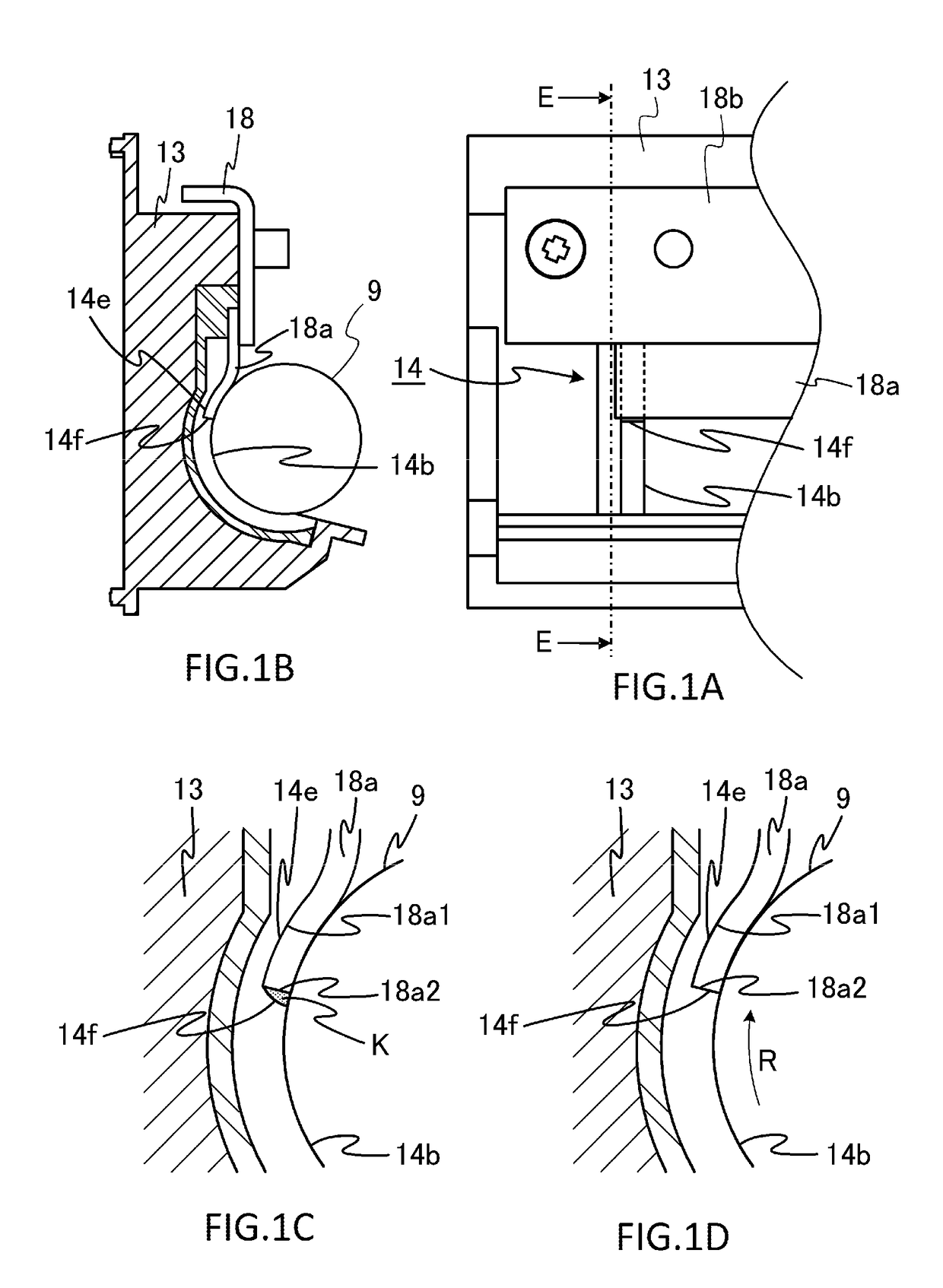

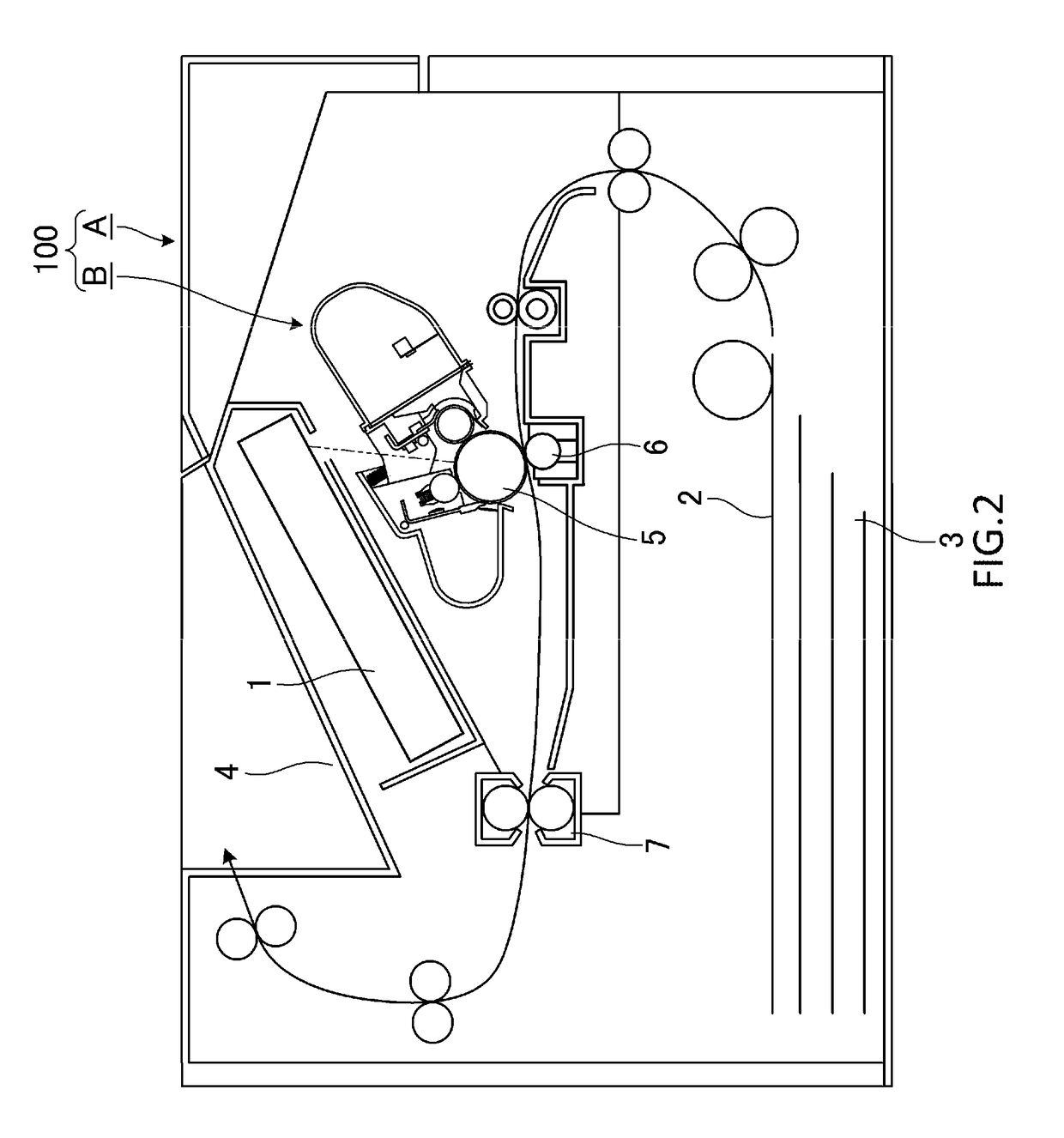

Image Forming Appartaus

ActiveUS20090322850A1Improve qualitySuppress gapInking apparatusPower drive mechanismsBiomedical engineeringContact position

An image forming apparatus is provided, which includes: a photosensitive member; an exposure member; a gap keeping member; a positioning member and a swing regulating member. The swing regulating member is configured to come in contact with the exposure member at a contact position that is more upstream than the exposure member and that is more separated from the photosensitive member than a contact position between the positioning member and the exposure member.

Owner:BROTHER KOGYO KK

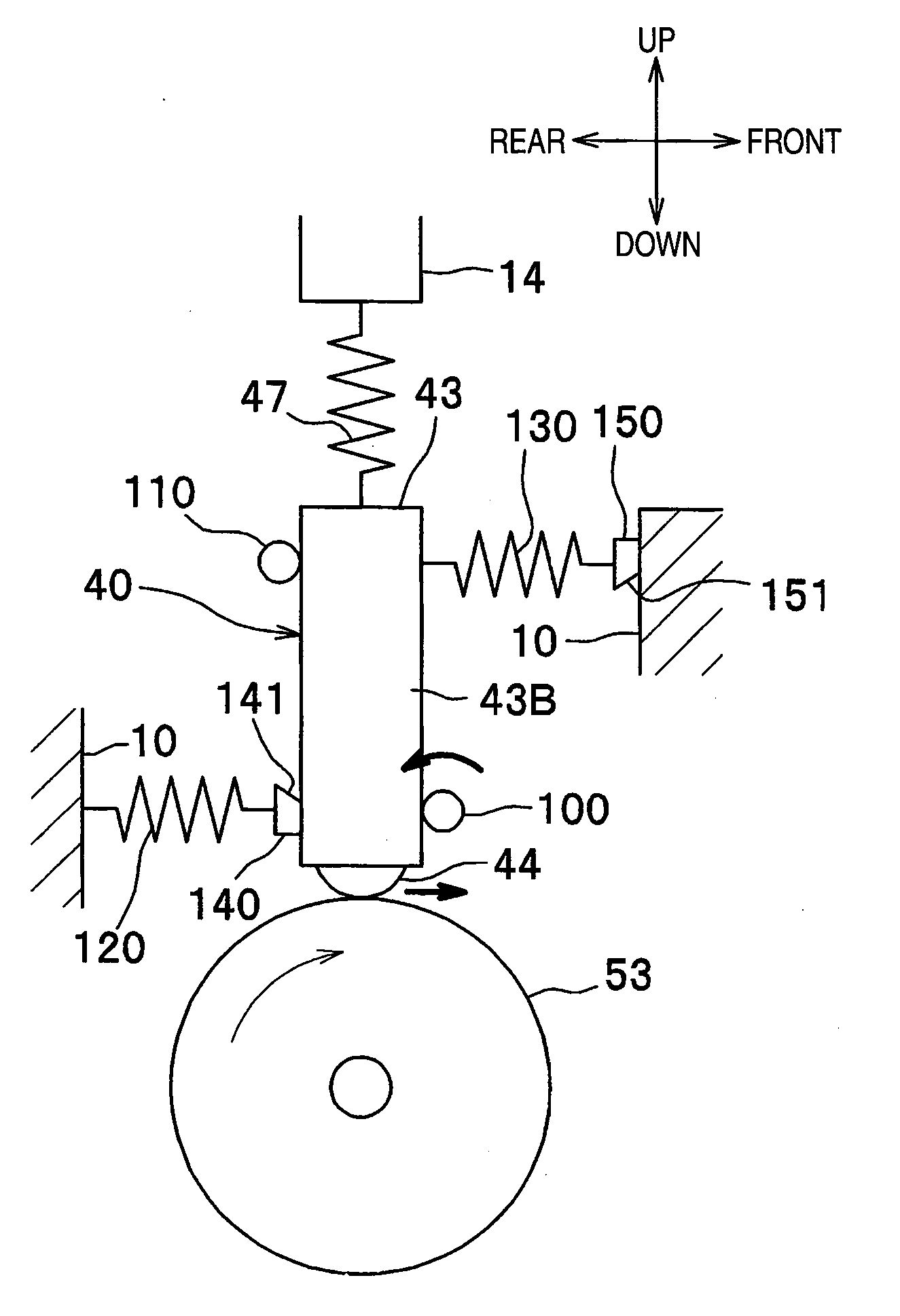

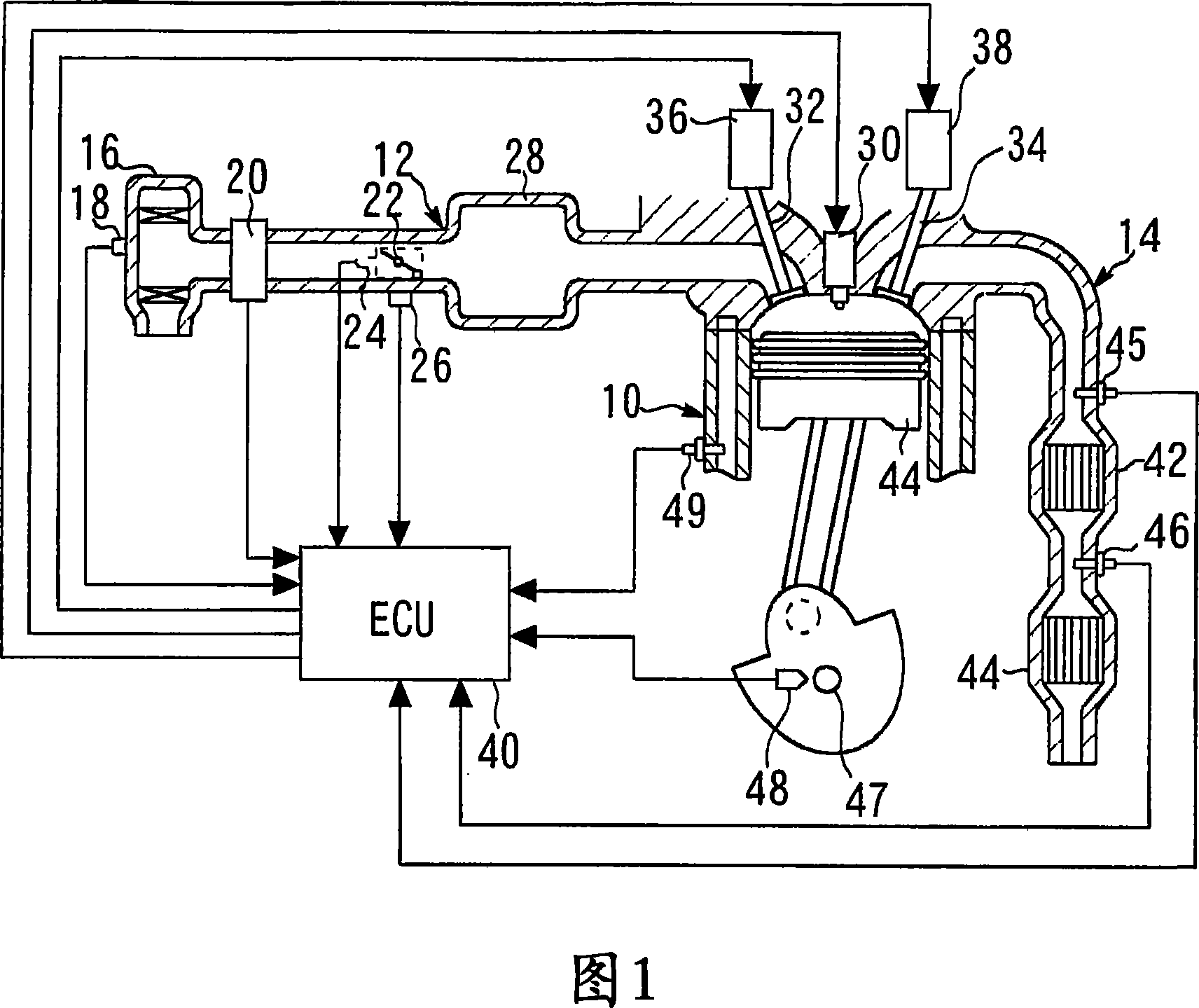

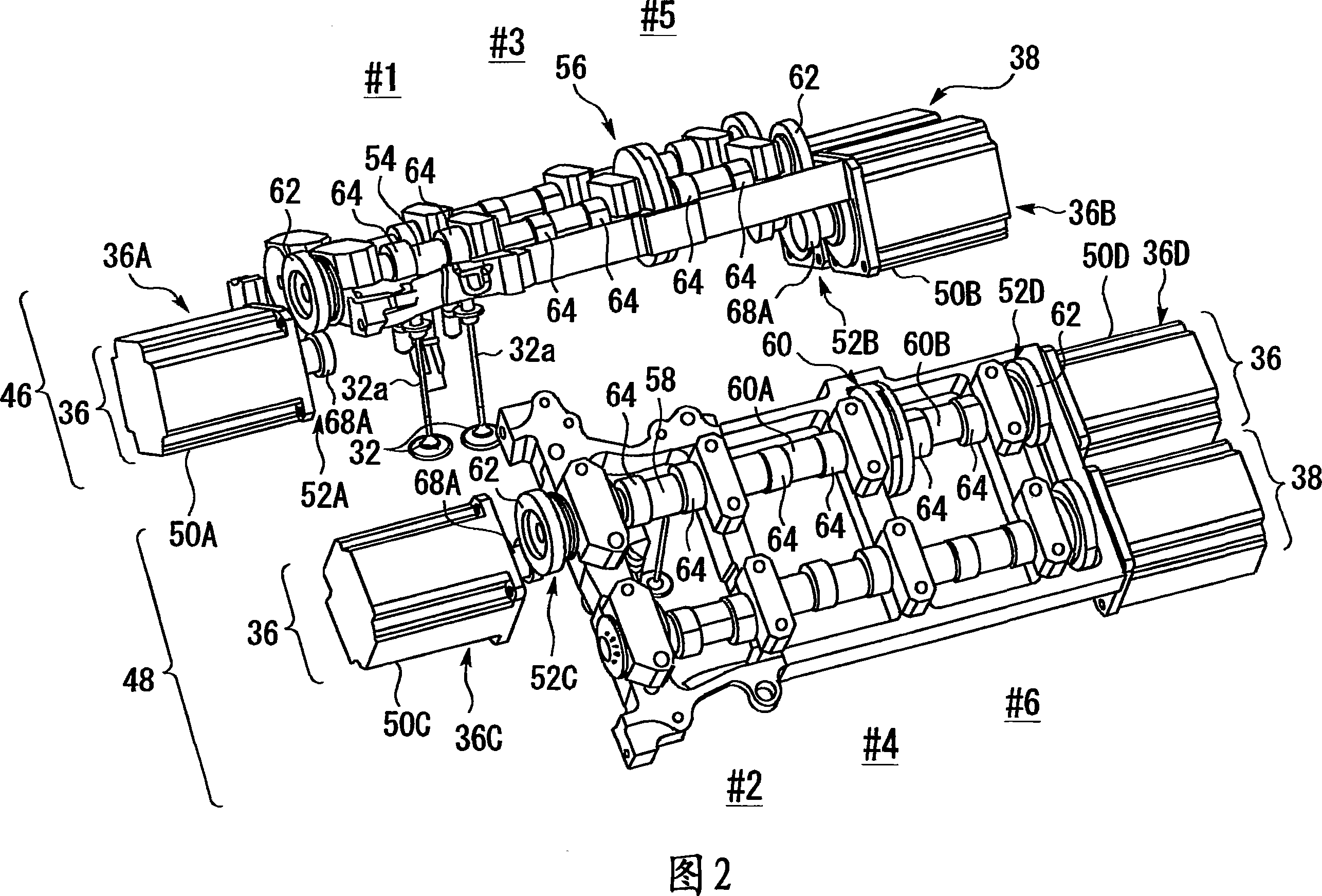

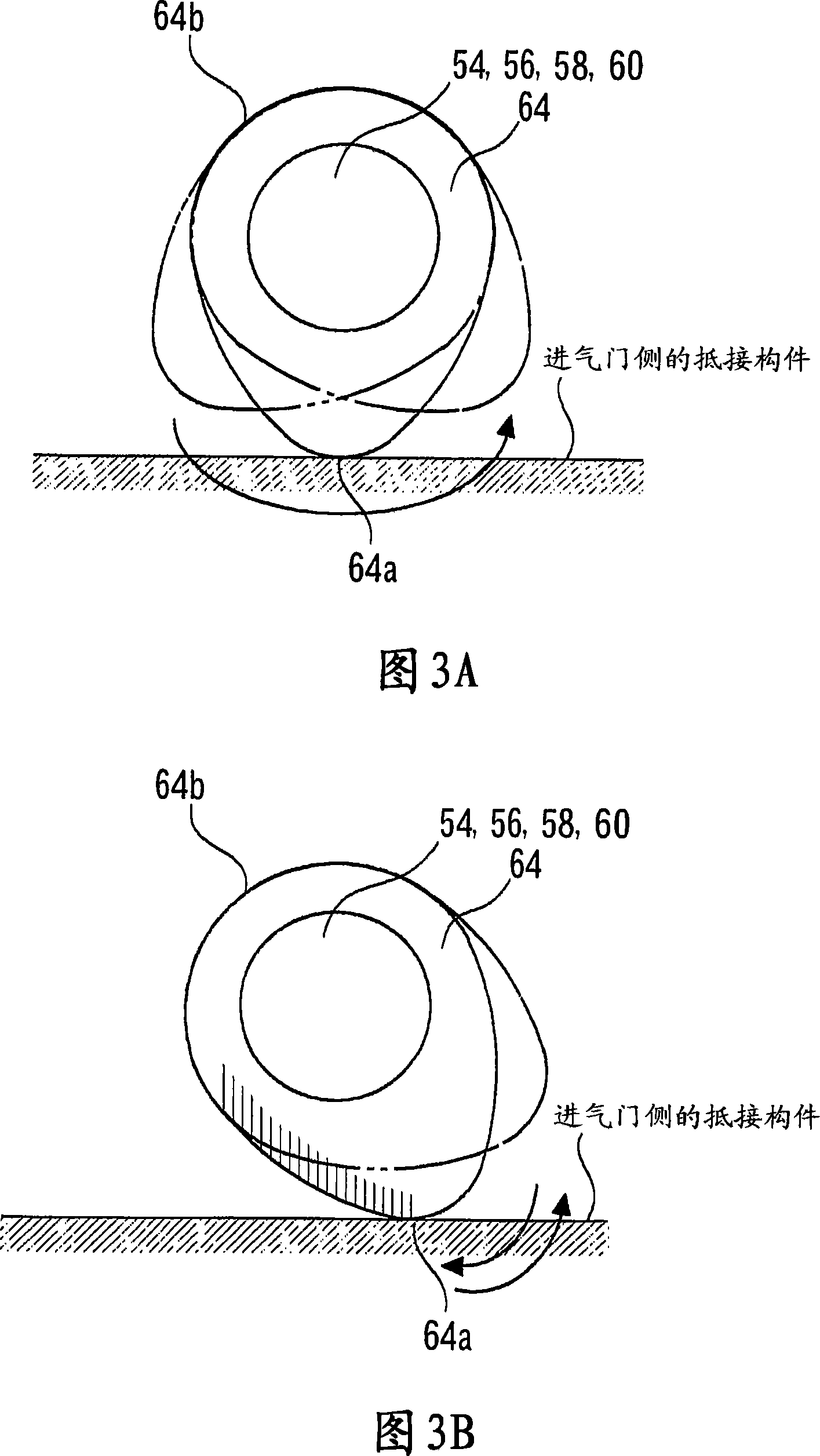

Valve moving device for internal combustion engine

InactiveCN101166891AIncrease freedomEasy to controlInternal combustion piston enginesValve drivesCamEngineering

A valve moving device (36) for an internal combustion engine, where a valve body (32) of each cylinder is opened and closed by a motor. The valve moving device (36) has a cam shaft (60) rotated by a motor (50D) and having cams (64) for driving the valve bodies (32) of the cylinders, a control means for driving the motor (50D) while switching a drive mode between a normal rotation drive mode where the cam shaft (60) is continuously rotated in one direction to drive the valve bodies (32) and a rocking drive mode where the cam shaft (60) is rocked to drive the valve bodies (32), and a variable means for varying, when the mode is switched, a relative angular position of the cam (64), provided on the cam shaft (60), corresponding to each cylinder.

Owner:TOYOTA JIDOSHA KK

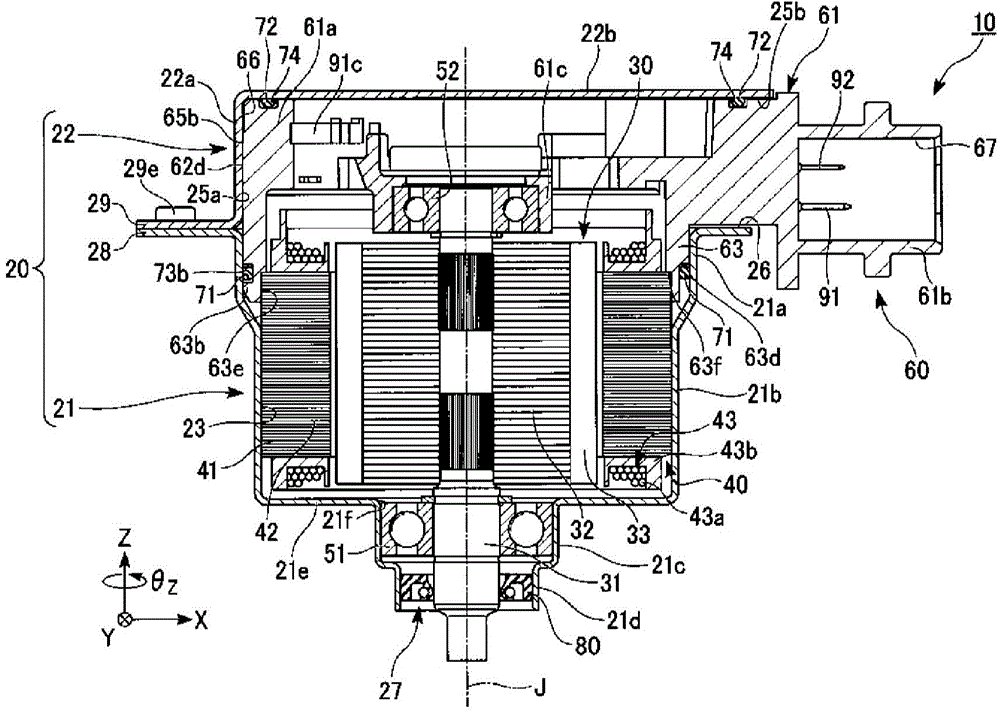

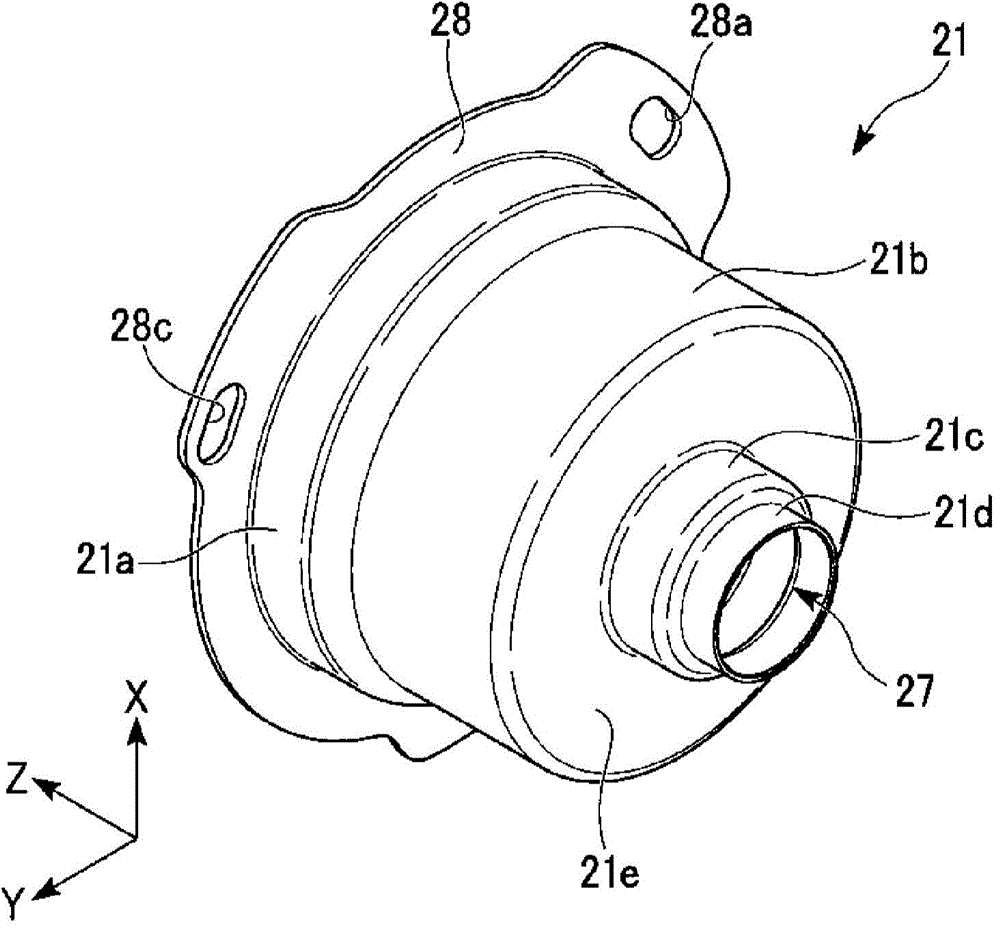

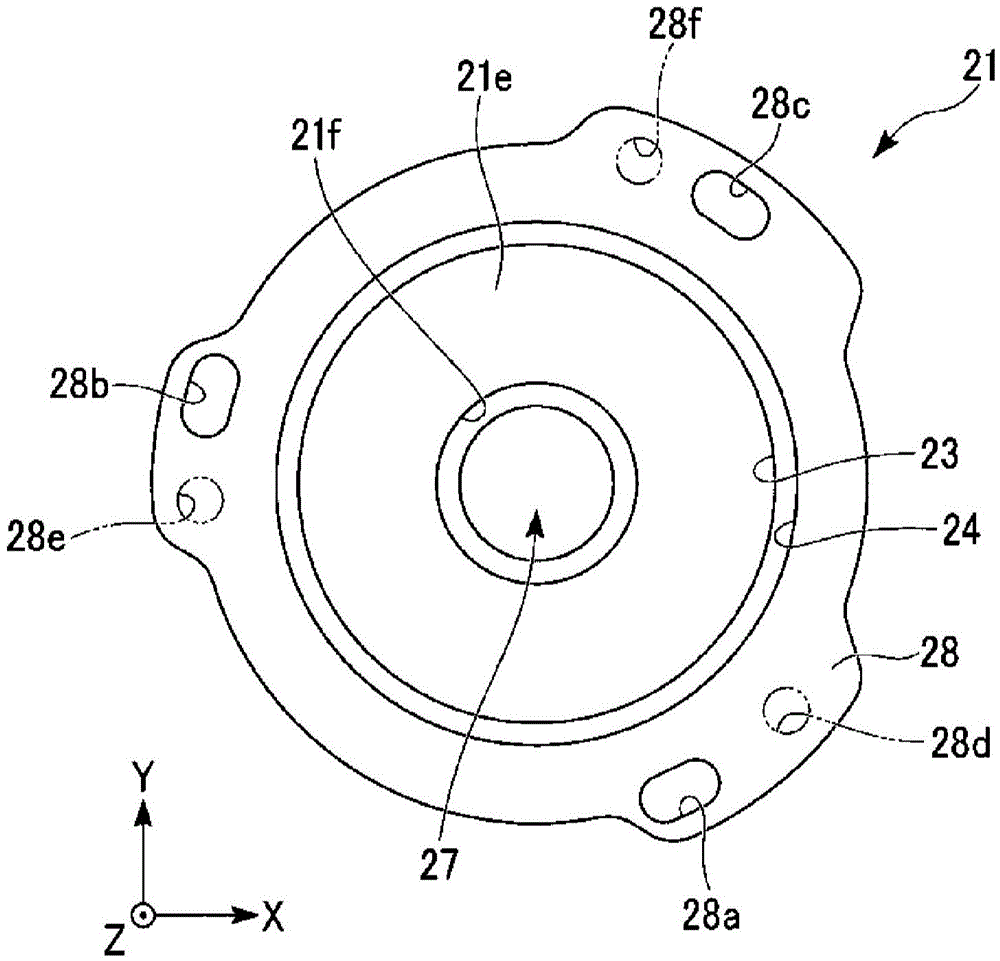

Motor

ActiveCN105305691AInsufficient fixation of inhibitionSuppression gapWindingsSupports/enclosures/casingsEngineeringMechanical engineering

The invention provides a motor which operates stably in a large temperature range. The motor according to one embodiment of the invention comprises a rotor having a shaft, a stator, a first bearing and a second bearing supporting the shaft, a busbar unit, and a metallic housing portion in which the busbar unit is pressed to the inside of housing and the stator and the first bearing are maintained. The busbar unit comprises a busbar and a busbar holder made of resin. The busbar holder supports the busbar and has a second bearing holding portion for holding the second bearing and a tubular main body portion which has a tubular housing portion. The housing portion has a housing accommodating periphery pressed in the housing portion. The motor is characterized in that a contact portion and a non-contact portion are arranged at the periphery of the housing accommodating periphery, the contact portion is in contact with the inner periphery of the housing portion, the contact portion of the housing portion, and the non-contact portion is seperated from the inner periphery of the housing portion.

Owner:NIDEC CORP

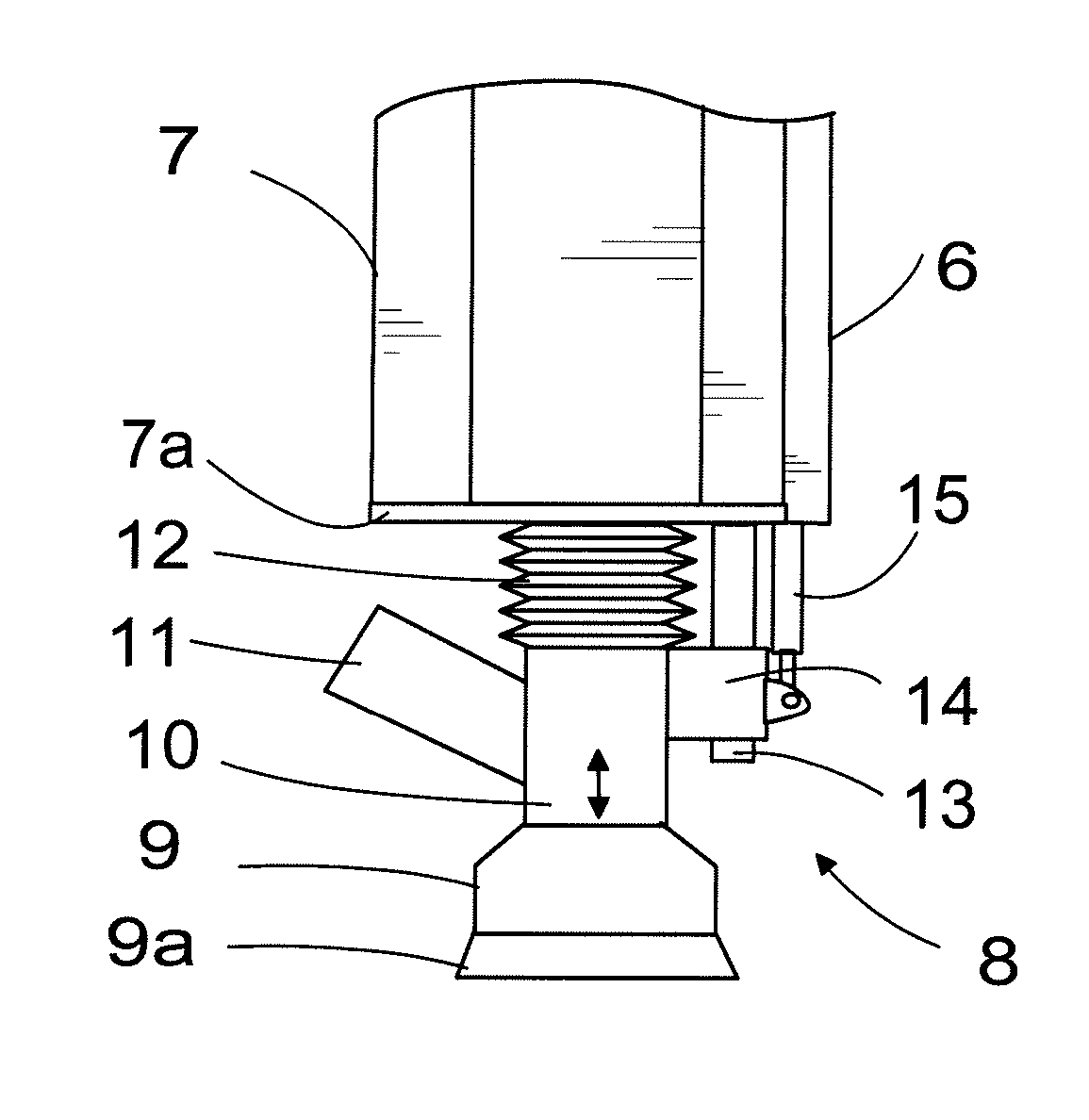

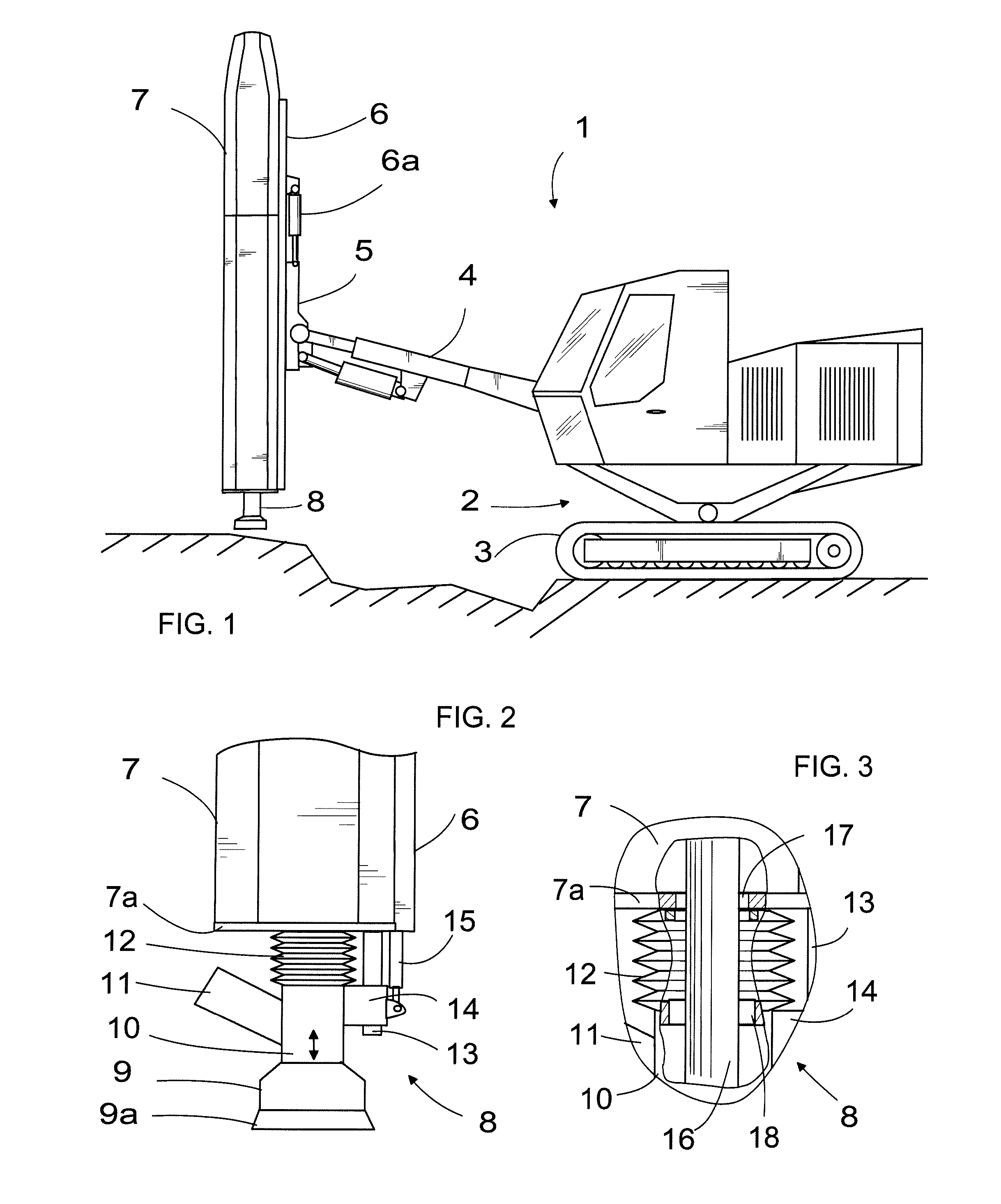

Noise-dampening shield structure for rock drilling apparatus

The invention relates to a shield structure of a rock drilling apparatus for dampening noise, the rock drilling apparatus comprising a feed beam whose one end is a drilling end, whereby the drilling end of the feed beam comprises a first shield part mounted immovably relative to the feed beam, and a second shield part mounted movably relative to the feed beam. A tubular shield flexible at least in its longitudinal direction is mounted between the shield parts, the shield being tightly attached by its ends to the first and the second shield part.

Owner:SANDVIK MINING & CONSTR OY

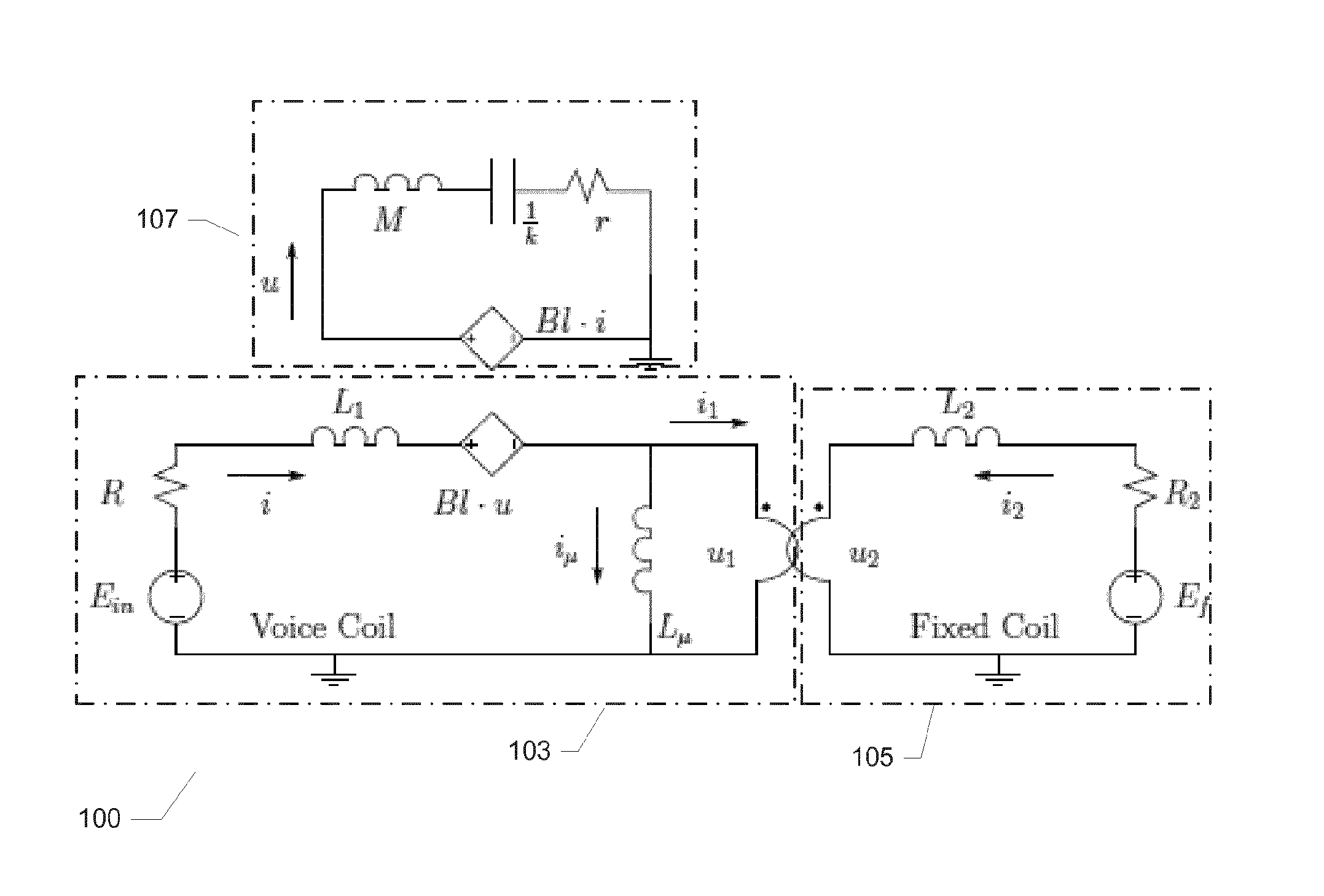

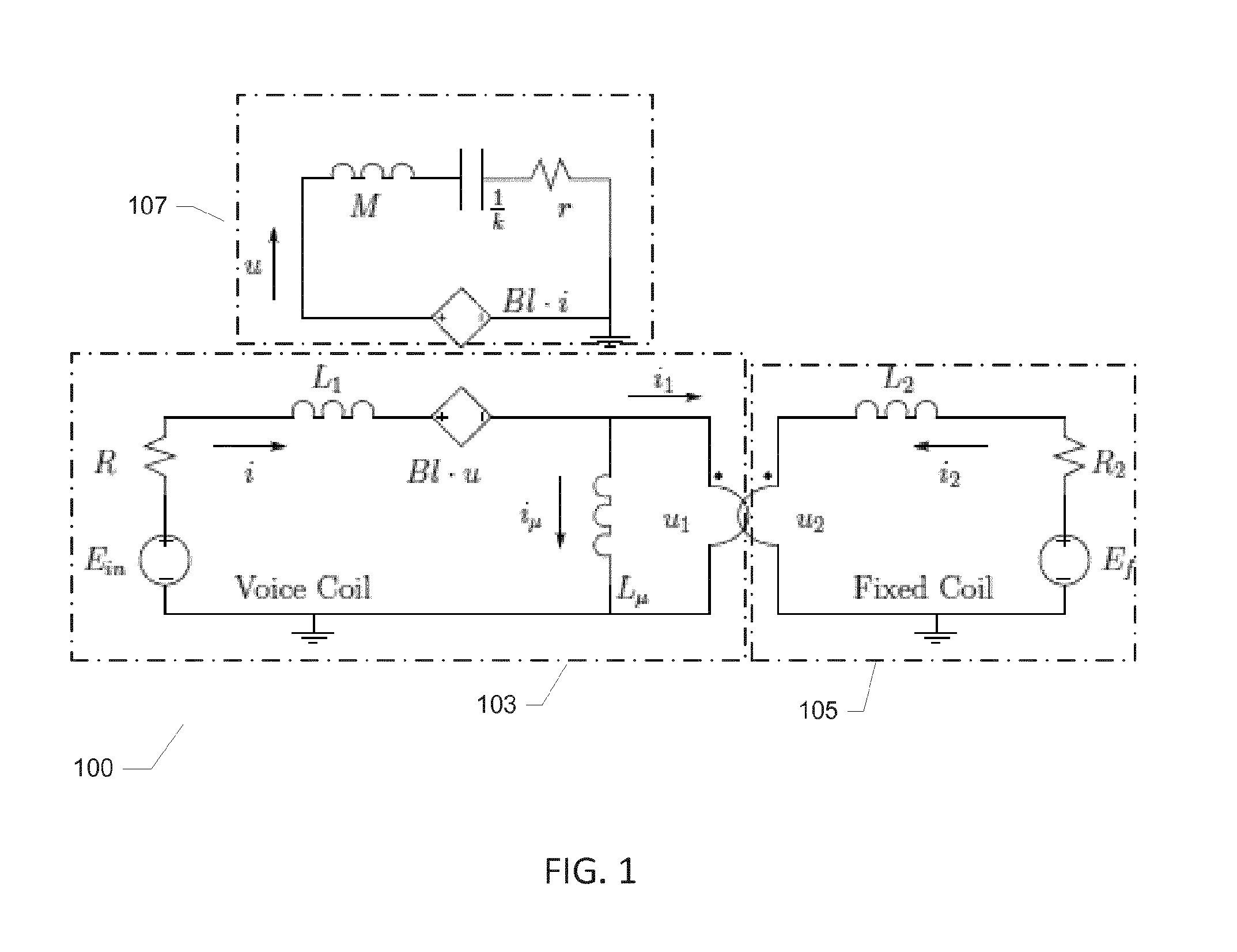

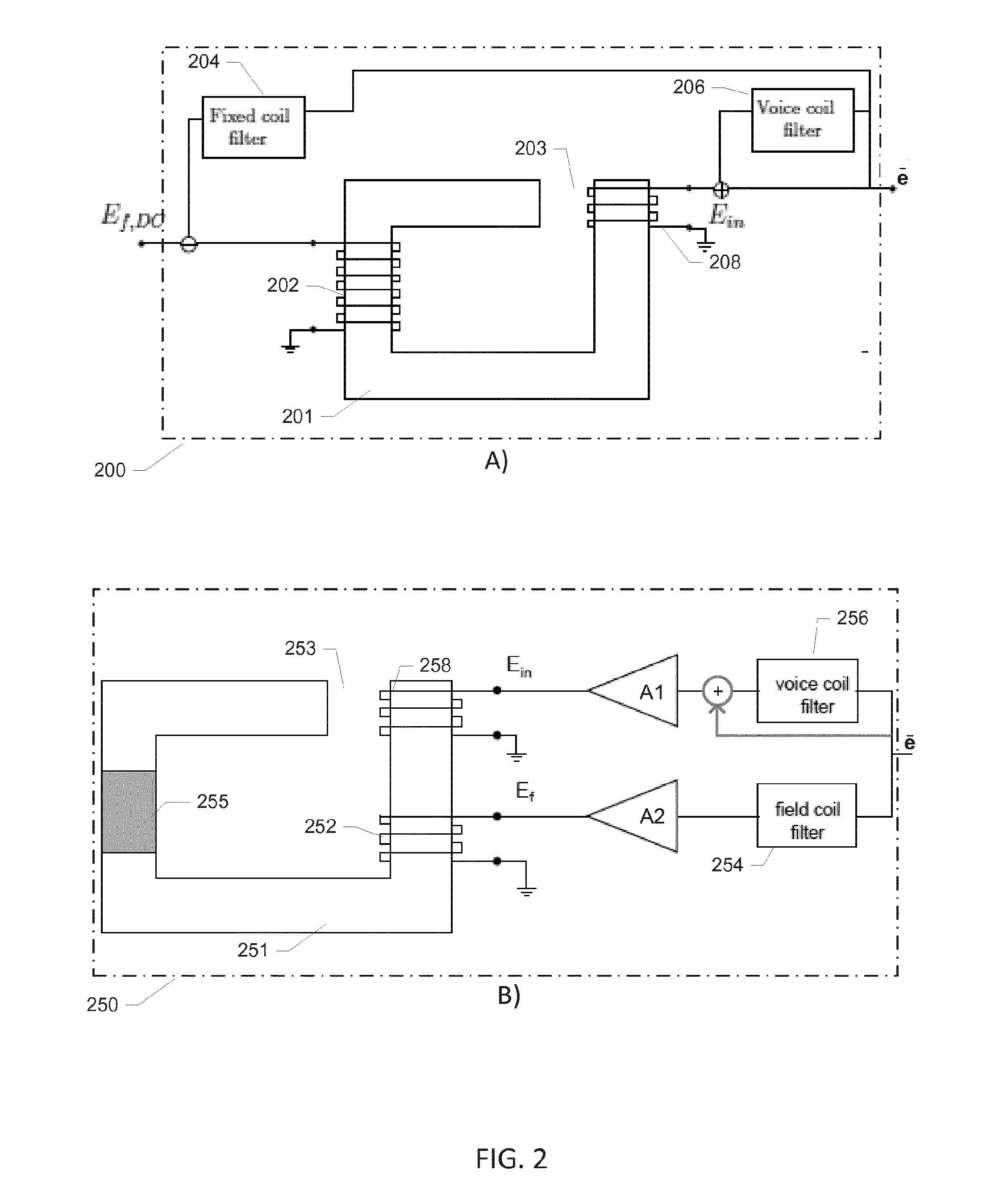

Loudspeaker assembly with suppression of magnetic flux modulation distortion

InactiveUS20160286301A1Suppressing magnetic flux modulationAccurate pressingMicrophonesLoudspeakersEngineeringLoudspeaker

An electrodynamic loudspeaker assembly having an electrodynamic loudspeaker and first and second compensation filters. The electrodynamic loudspeaker includes a voice coil arranged in an air gap of a magnetically permeable structure and a compensation coil wound around a portion of the magnetically permeable structure. The first compensation filter filters an audio input signal to the loudspeaker assembly with a first frequency response to generate a voice coil compensation signal for application to the voice coil. The second compensation filter filters the audio input signal to the loudspeaker assembly with a second frequency response to generate a second compensation signal for application to the compensation coil. The first and second frequency responses, across a predetermined audio frequency range, suppress a time-varying or AC magnetic flux in the air gap caused by voice coil current such that magnetic flux modulation in the air gap of the loudspeaker is suppressed.

Owner:DANMARKS TEKNISKE UNIV

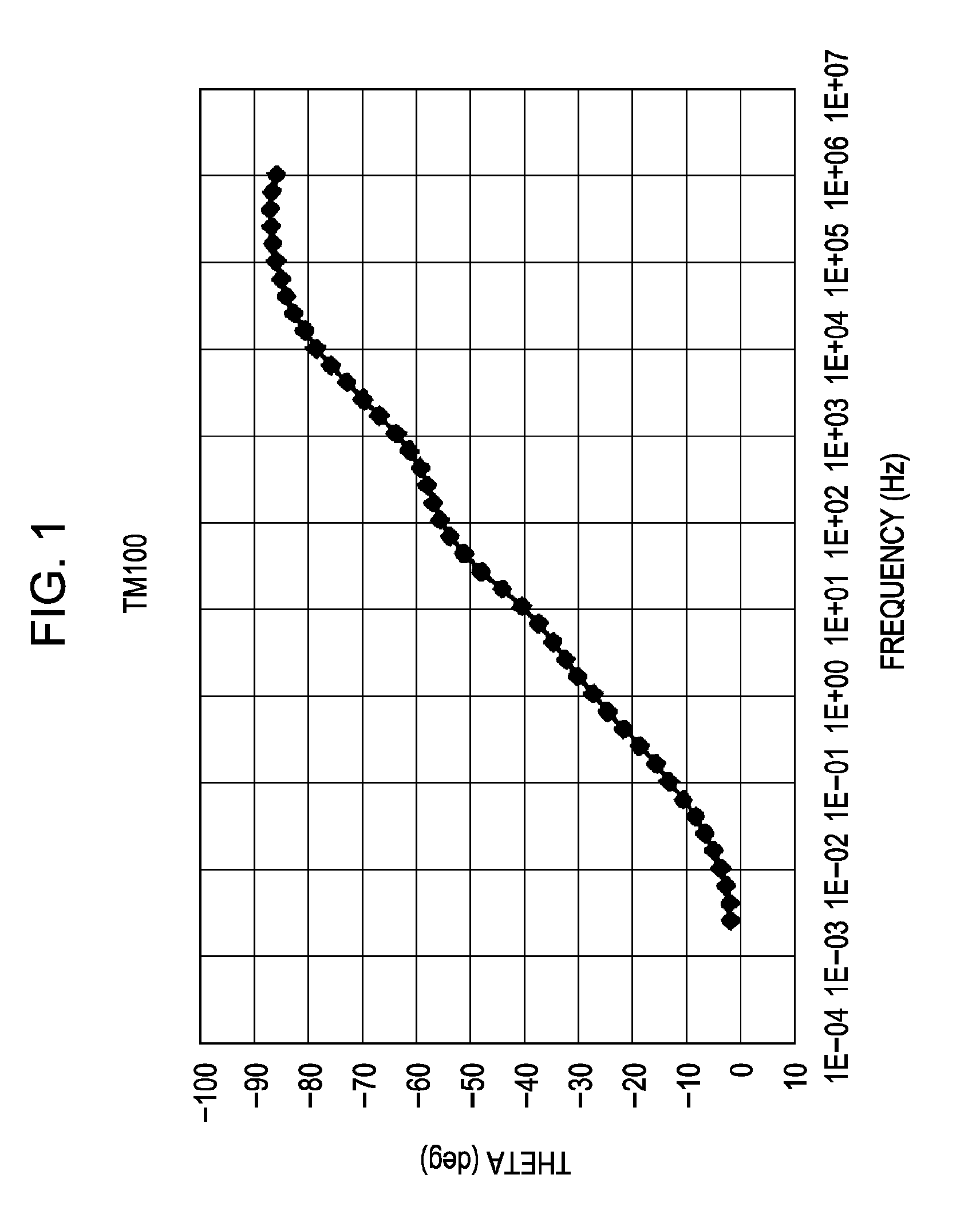

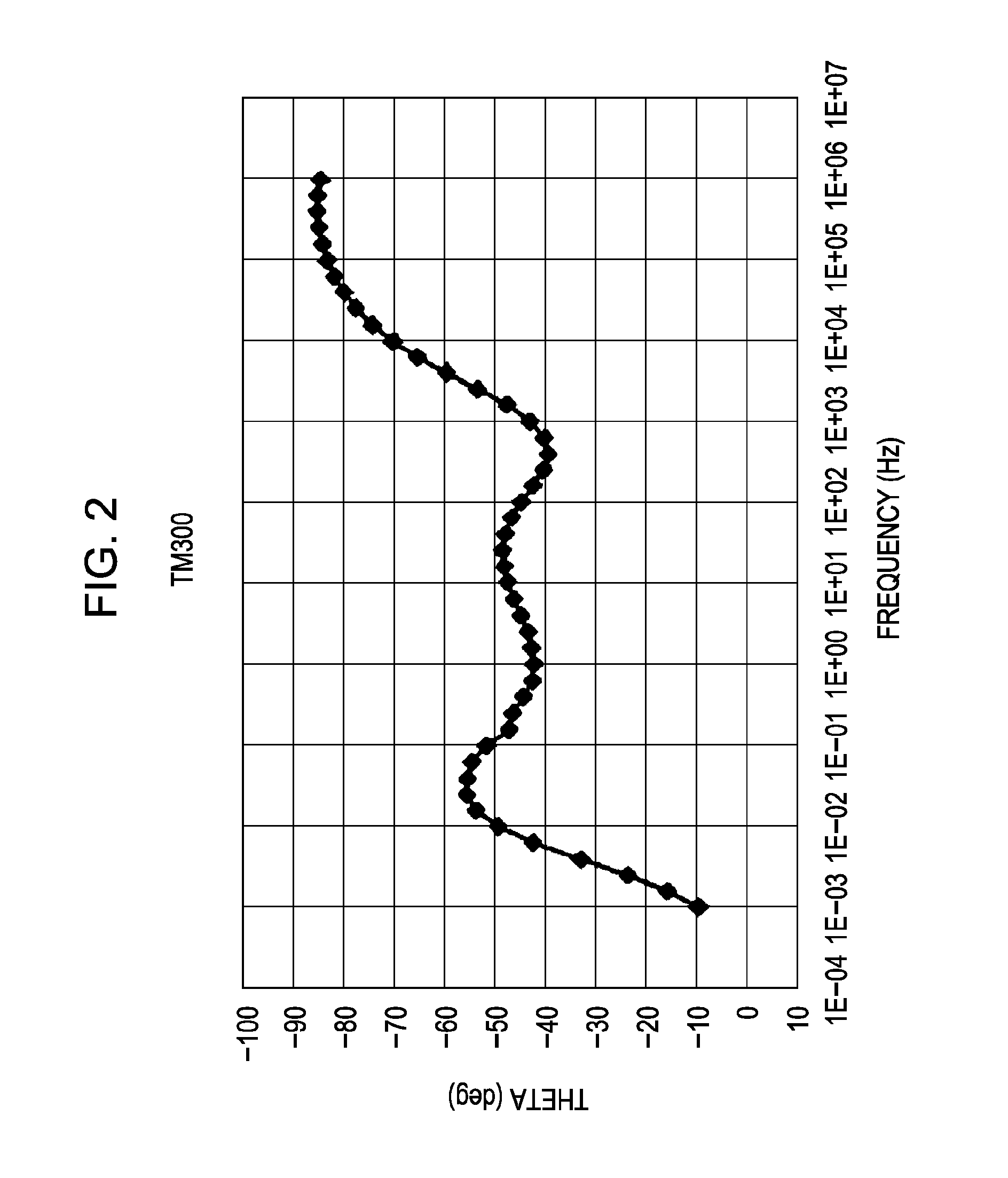

Toner, method for forming image, and image forming apparatus

InactiveUS20100261109A1Suppression gapLess dustElectrographic process apparatusDevelopersImage formationEngineering

A toner includes toner base particles containing at least a binder resin, a coloring agent, and a release agent; and alumina fine particles whose phase angle (θ) is |80°| or less at an alternating current frequency of 1 to 10 kHz in an alternating current impedance method.

Owner:SEIKO EPSON CORP

Translucent material and manufacturing method of the same

InactiveUS7691765B2High filled space percentageHigh transparencyCeramic shaping apparatusActive medium materialShell moldingSilicon oxide

After synthesizing particles by liquid phase synthesis, the solution is substituted without drying these particles, and here, a solution comprising a grain boundary phase composition consisting of at least one or more types selected from a group consisting of Al2O3, yttrium oxide, silicon oxide, yttrium-silicon complex oxide, aluminum-silicon complex oxide, and a compound having a garnet structure with a lower melting point than the aforementioned particles, or a solution comprising a precipitate is introduced. Microparticles are adjusted by allowing adhesion and growth of the solution comprising a composition of grain boundary phase or the solution comprising a precipitate on the surface of the particles; these microparticles are allowed to align in 3-dimensions in solution and are formed into a molded body, and this molded body is sintered.

Owner:FUJIFILM CORP

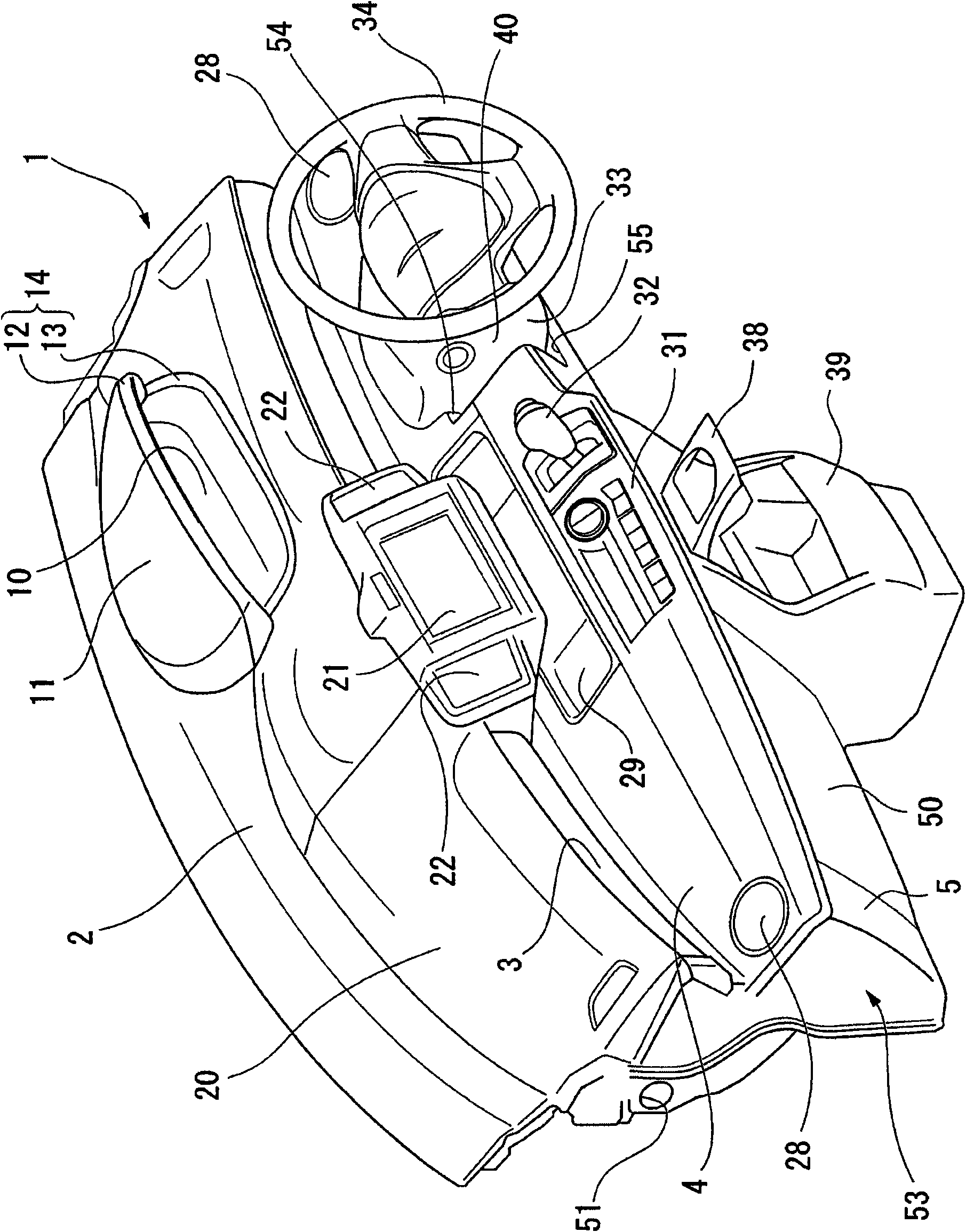

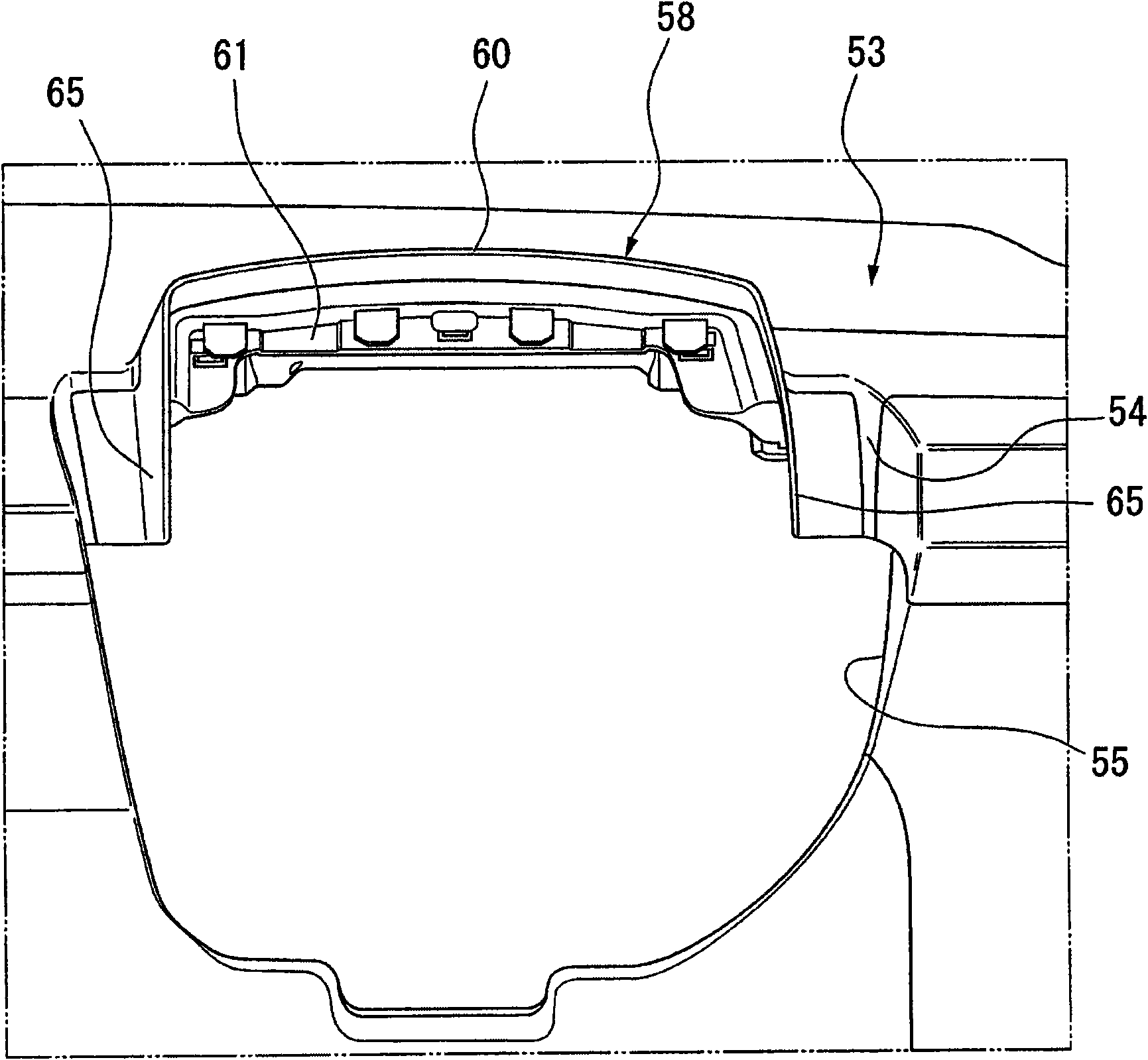

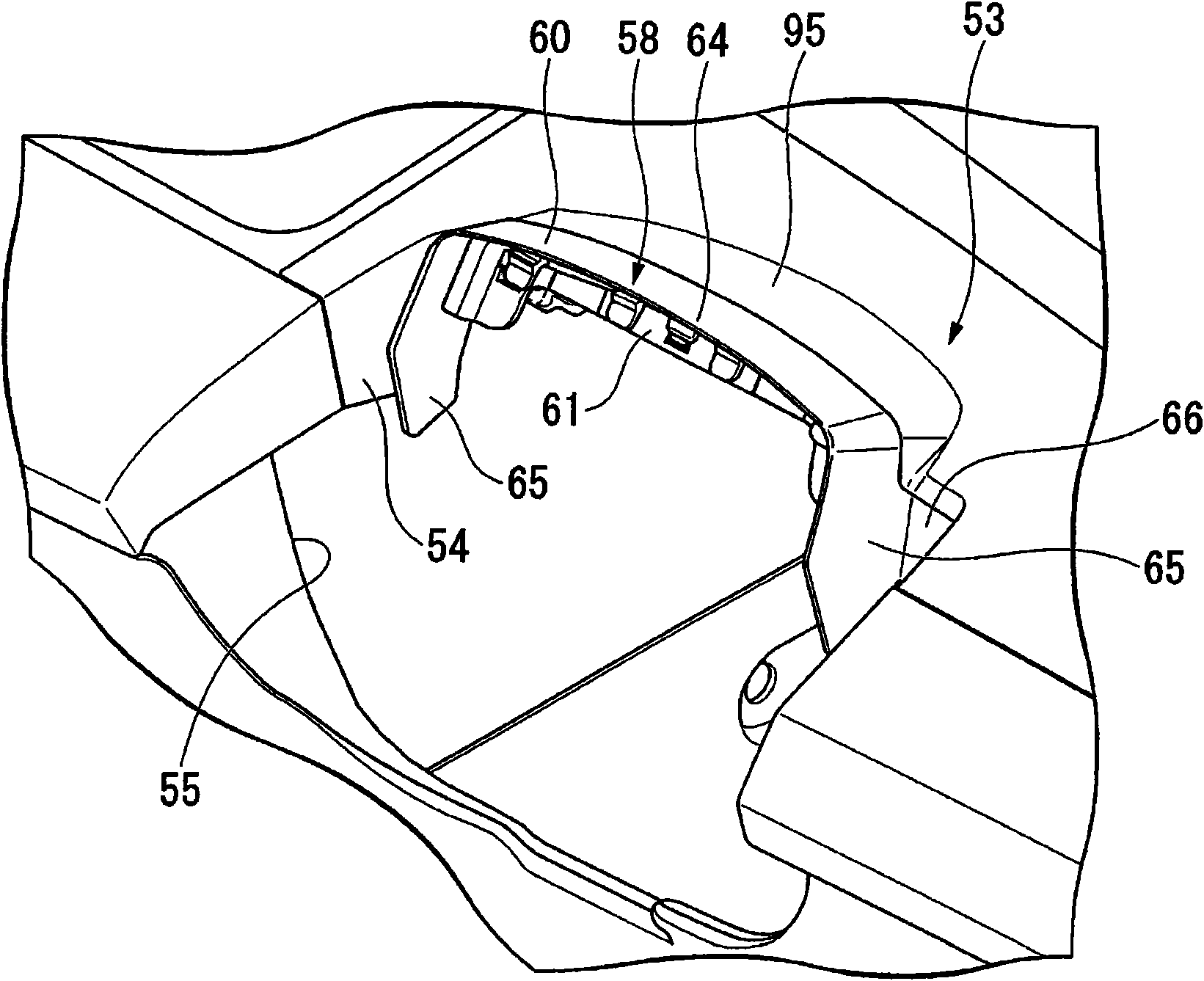

Instrument panel and shield member

InactiveCN101570140AImprove commodityIncrease freedomInstrument arrangements/adaptationsSteering columnsSteering columnElectrical and Electronics engineering

The present invention provides an instrument panel and a shield member capable of simplifying an assembling process and of improving the quality of commodities by shielding a gap between an instrumentpanel body and a column cover so as to have a good appearance. A shield member 58 protrudes from the upper end part of the opening 55, and is inserted in a steering column cover 40 at a position lower than the upper part of the steering column cover 40. The lower part of the side surface is inserted in the opening 55, so that the lower part of the side surface is configured at a position in frontof the rear end of the shield member 58 in the vehicle body fore-and-aft direction, to shield a gap between the opening 55 and the steering column cover 40.

Owner:HONDA MOTOR CO LTD

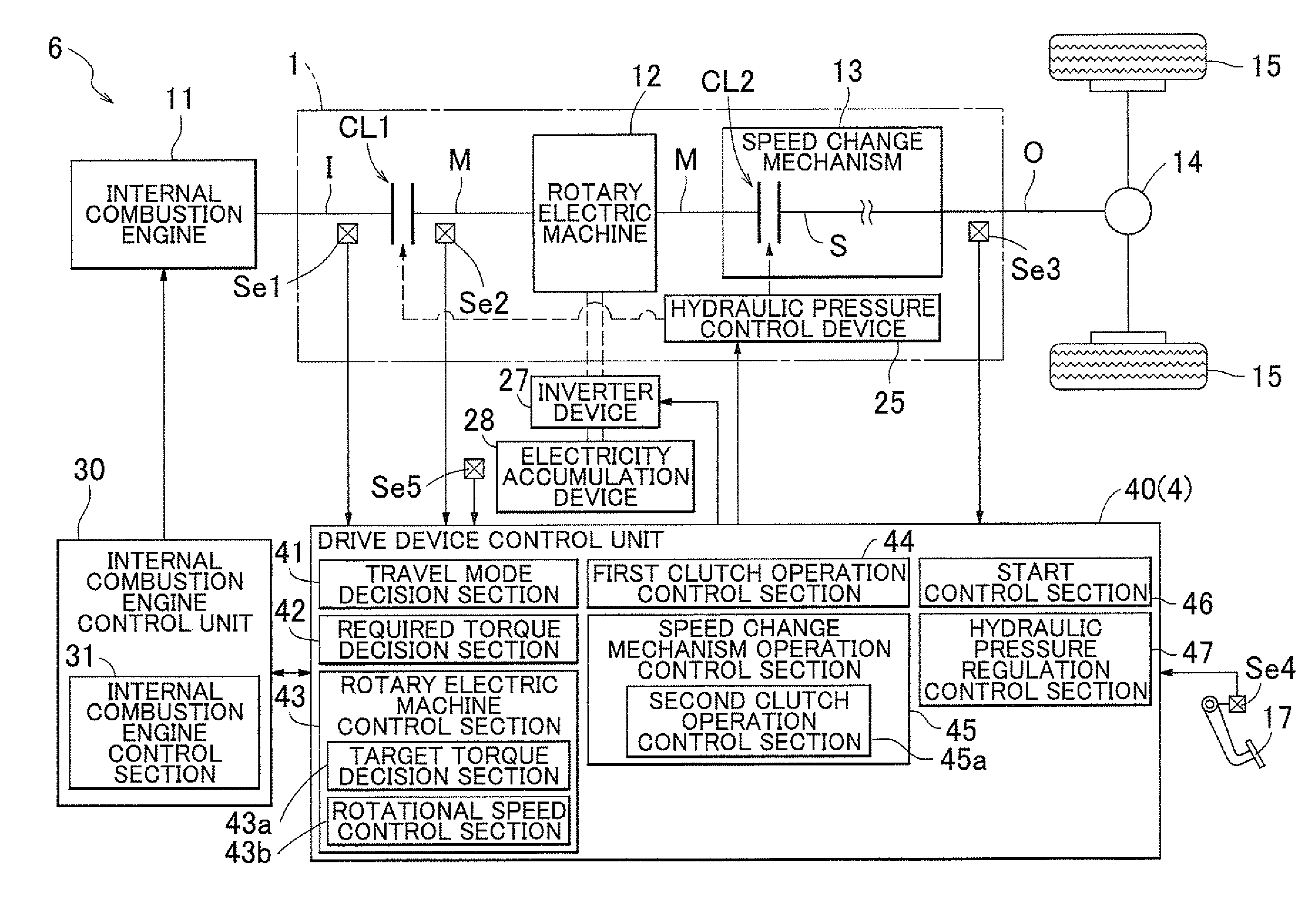

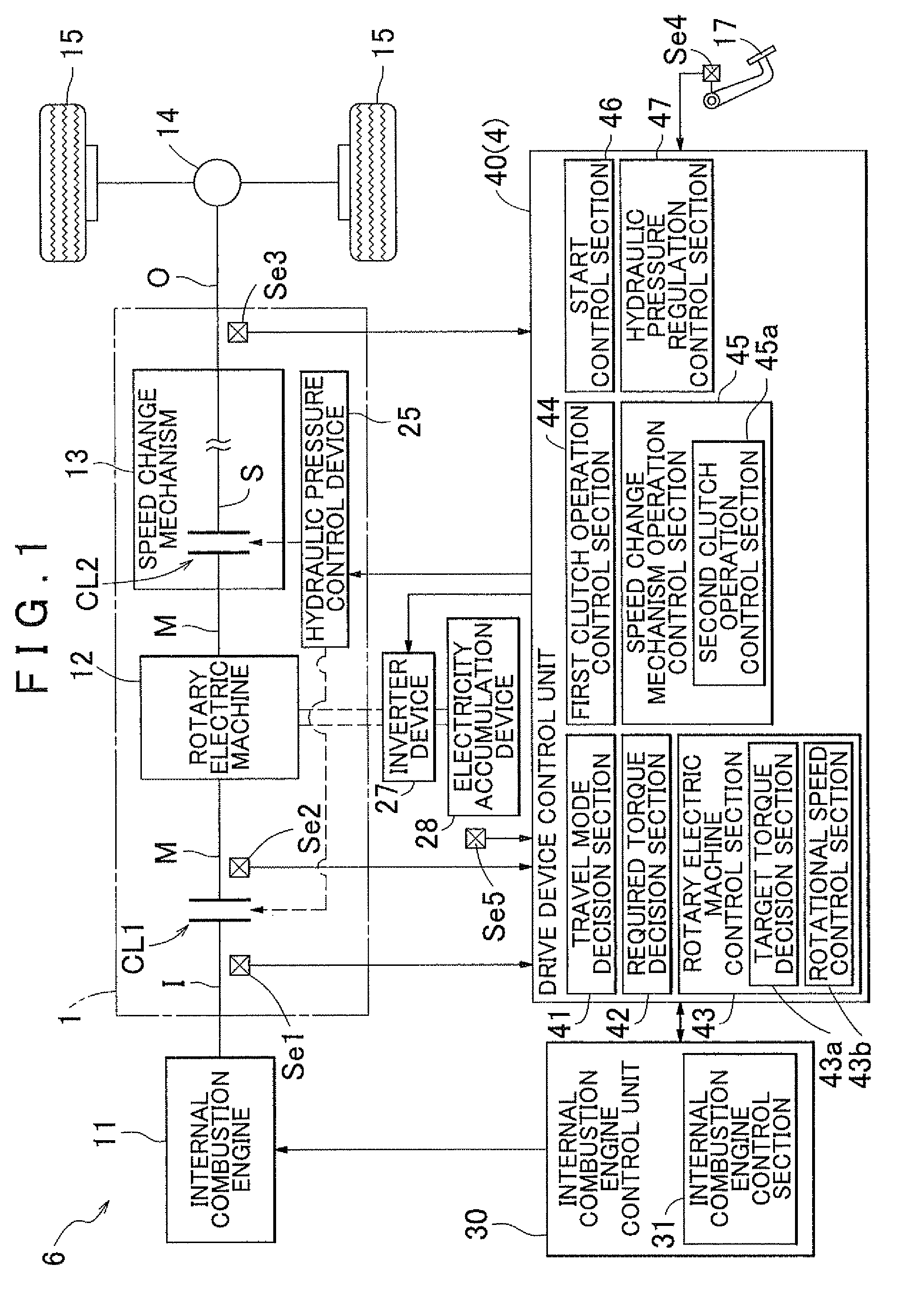

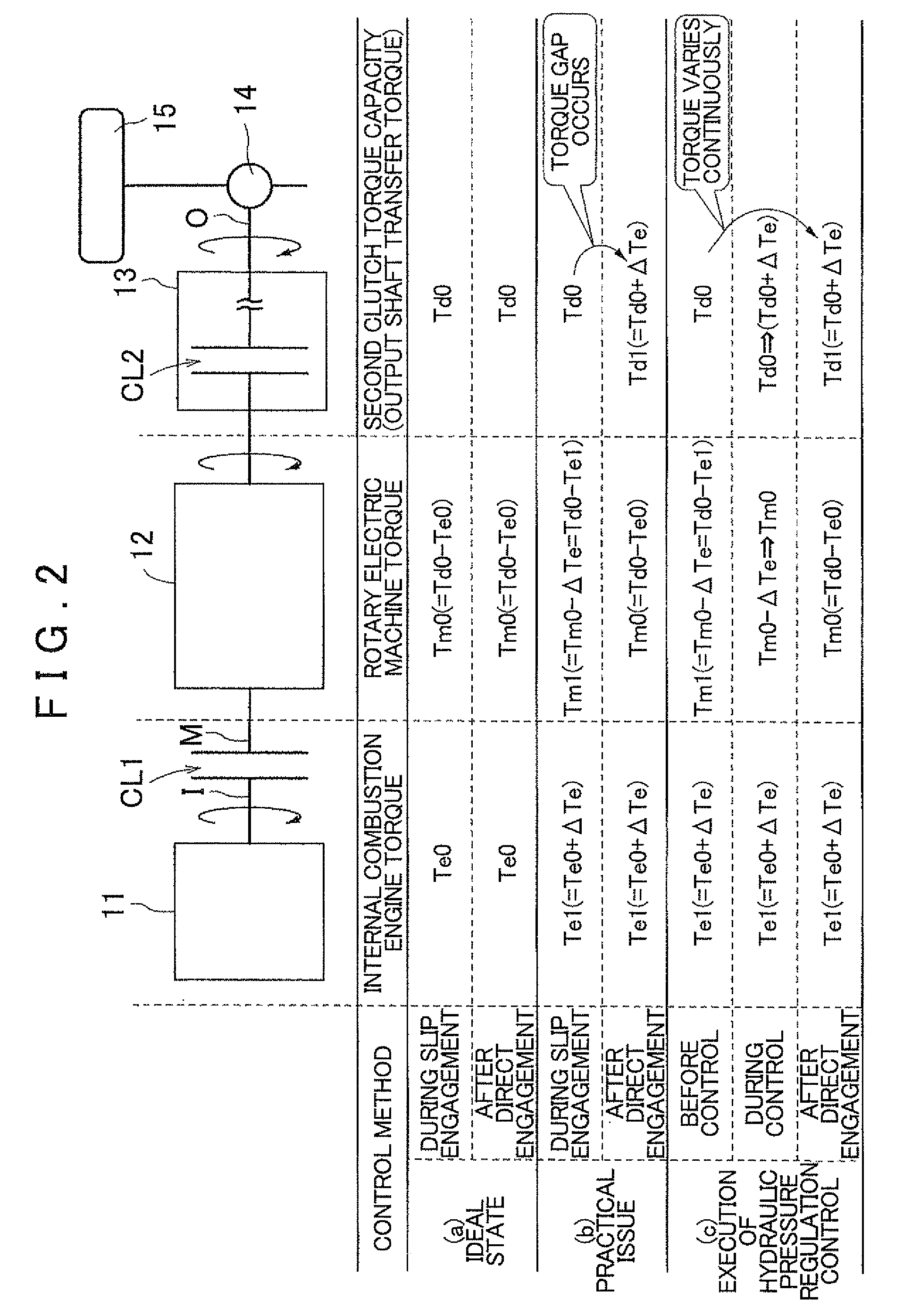

Control device

ActiveUS8668621B2Suppression gapEngine controllersPlural diverse prime-mover propulsion mountingDrive wheelElectric machine

A control device that controls a vehicle drive device, including a rotary electric machine and internal combustion engine that drive wheels, a first friction engagement device and a second friction engagement device. The control device is configured to execute rotational state control in which a rotational state of the rotary electric machine is controlled so as to establish a target rotational state with the second friction engagement device in a slip engagement state, and hydraulic pressure regulation control in which a hydraulic pressure supplied to the second friction engagement device is controlled on the basis of torque of the rotary electric machine produced during the rotational state control after the first friction engagement device is transitioned to a direct engagement state while the second friction engagement device is transitioned from the slip engagement state to a direct engagement state.

Owner:AISIN AW CO LTD

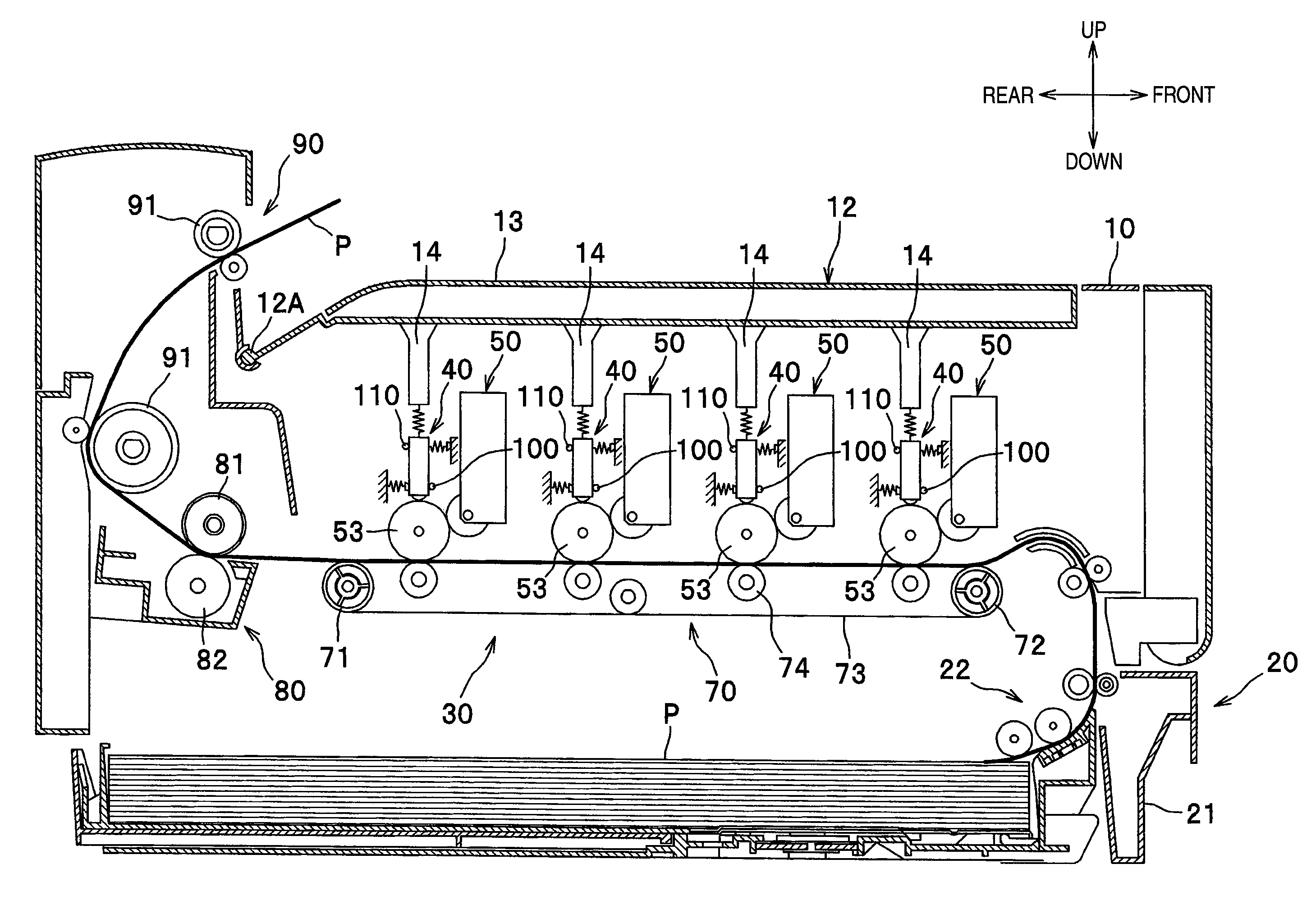

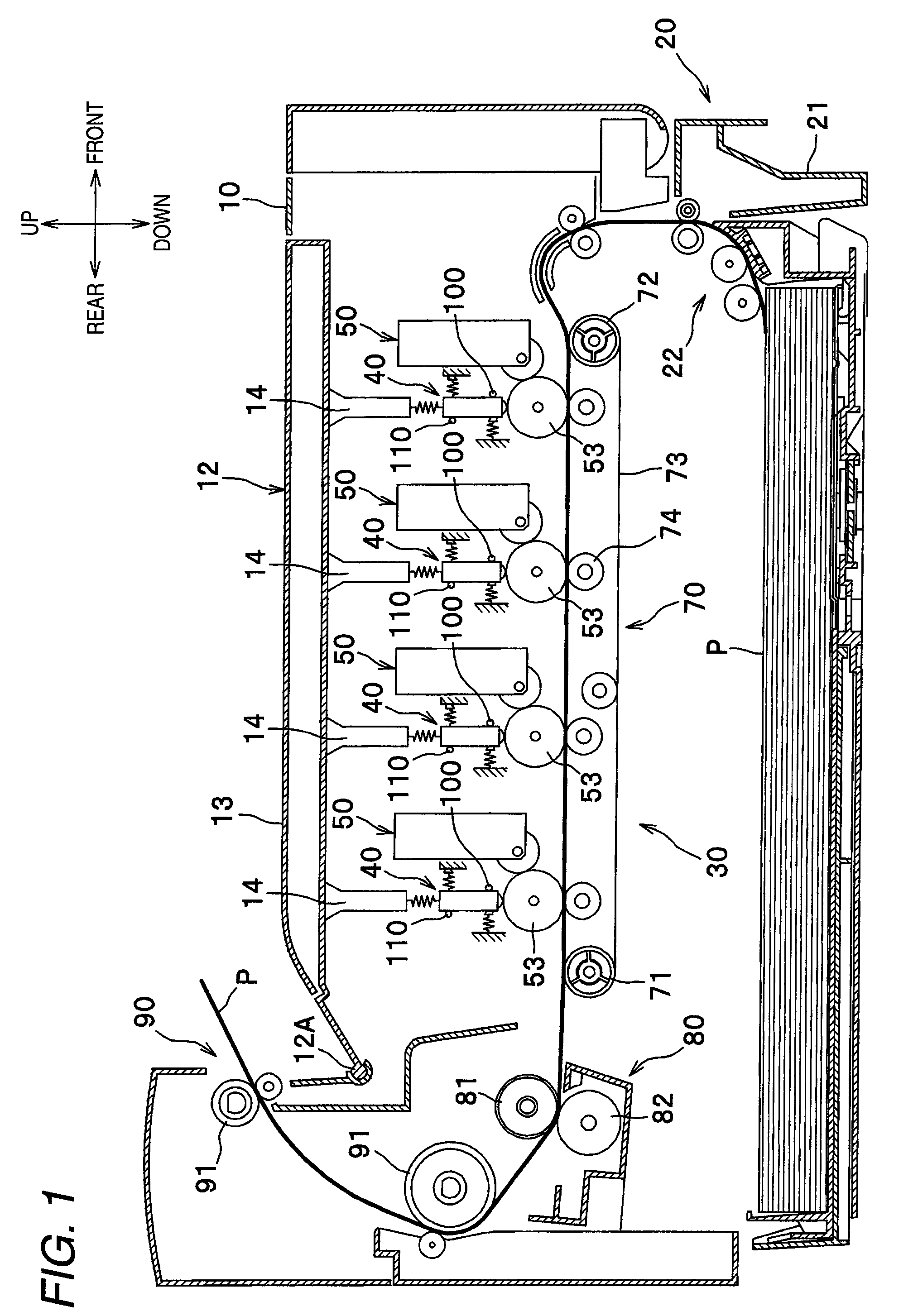

Developing device

ActiveCN101727050AReduce consumptionSuppress extreme compressionElectrographic process apparatusEngineeringMechanical engineering

A developing device includes a developer carrier which carries a developer, a developing unit housing which rotatably supports the developer carrier, a side seal member which comes into slidable contact with both ends of the developer carrier, a sheet-like elongated seal member which extends in the axial direction of the developer carrier so as to come into slidable contact with the developer carrier, a side seal attachment surface which is formed in the developing unit housing and to which the side seal member is attached, and a support portion which is formed in the developing unit housing and protrudes toward the developer carrier from the side seal attachment surface to support the elongated seal member. The elongated seal member is attached onto the support portion in a state where both ends thereof overlap the side seal member and are opposite the side seal attachment surface. A filler is filled in a gap surrounded by the elongated seal member, the side seal member, the support portion, and the side seal attachment surface. A protrusion for suppressing the spread of the filler is formed at the side seal attachment surface at a predetermined interval from the support portion.

Owner:BROTHER KOGYO KK

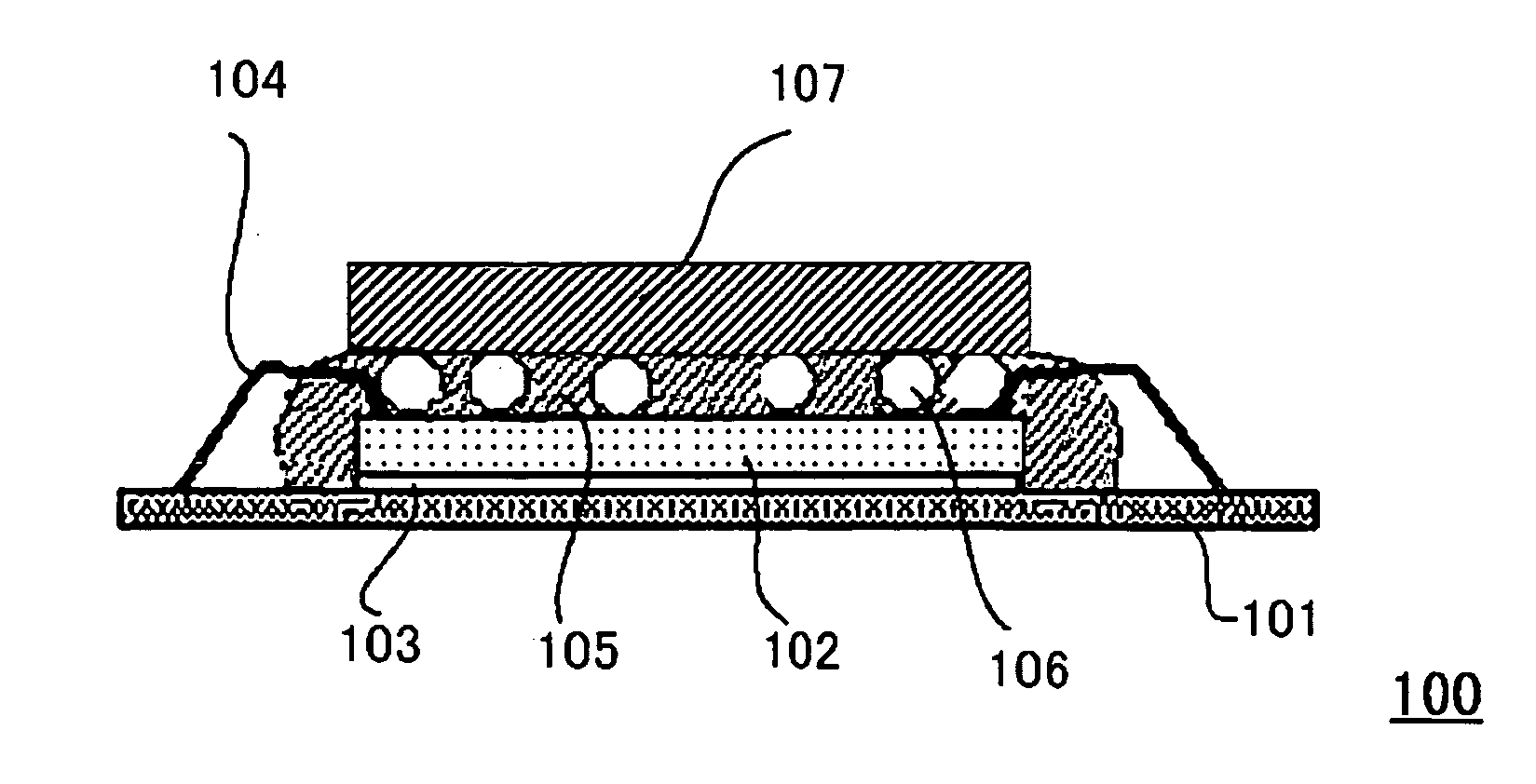

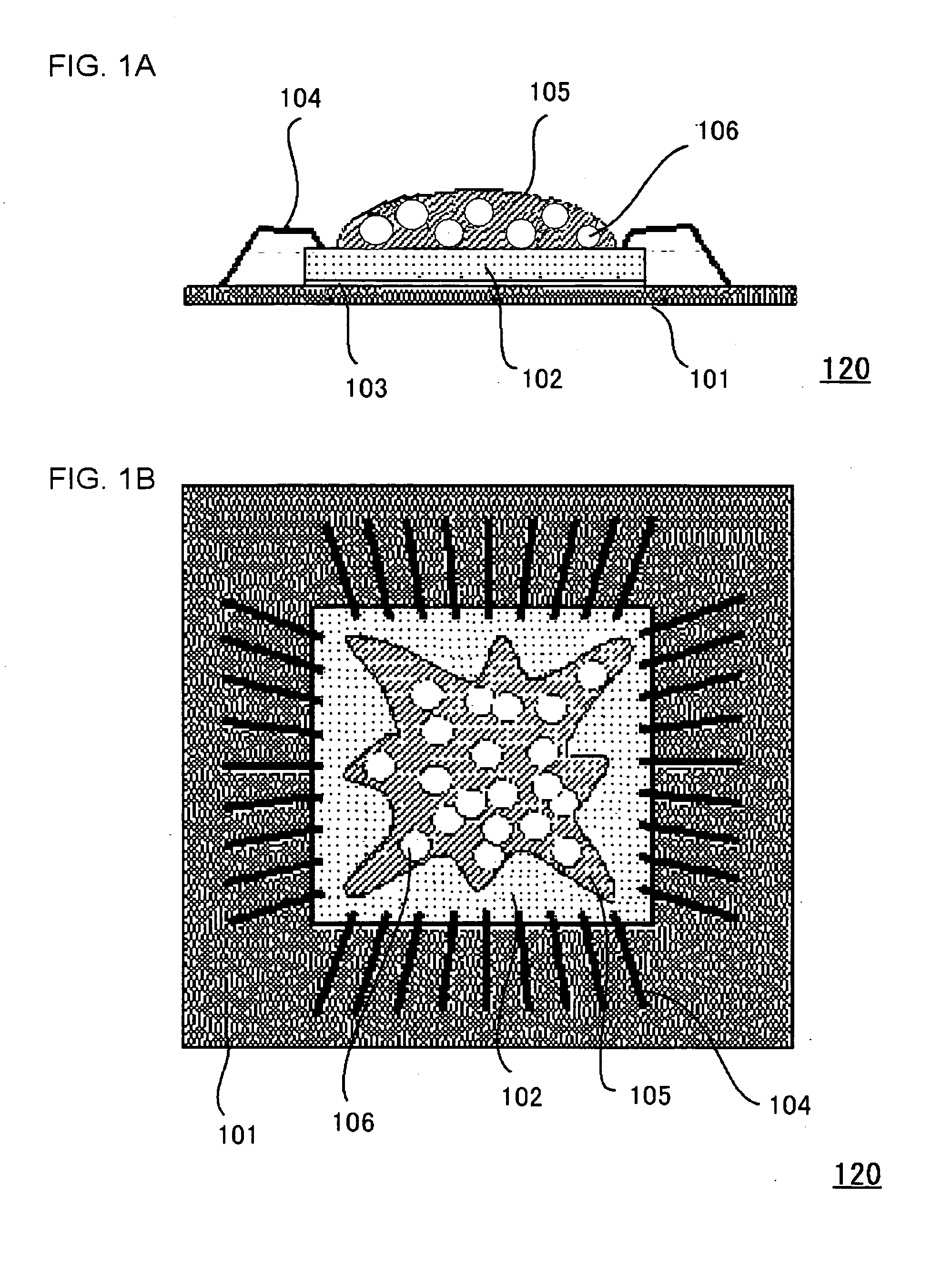

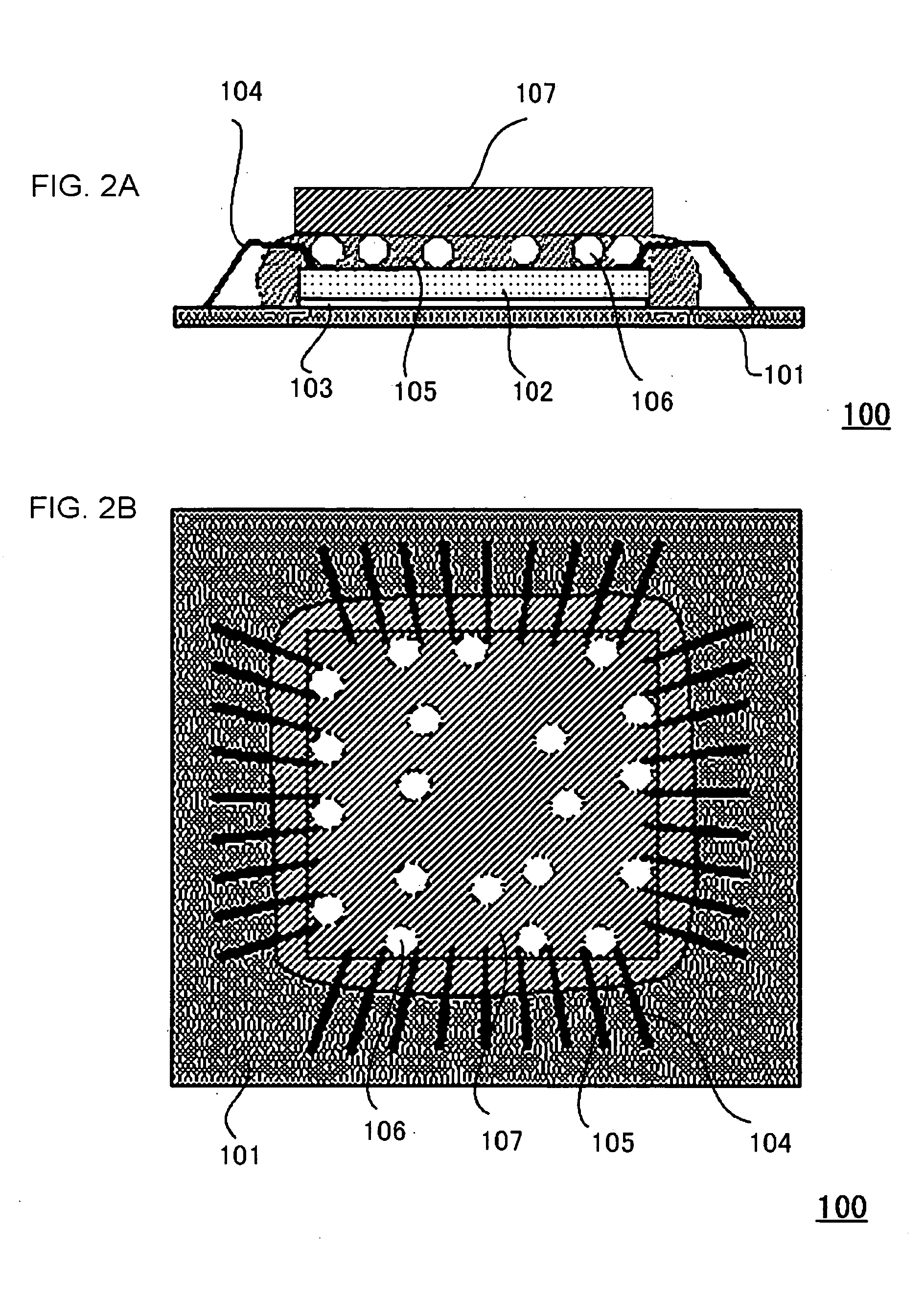

Semiconductor device

InactiveUS20060097409A1High-quality semiconductor deviceLarge grainSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

In a semiconductor device, an average grain size of a filler contained in an adhesive agent applied to the first chip is larger than an interval between adjacent wires. When the second chip is pressed downward, the filler is caught between the wires, a larger number of filler grains is held between the first and second chip. The interval between the first and the second chip can be stably maintained. Since the number of filler grains left to be held between the first and second chip is larger than that in the conventional art, a pressure applied to the second chip is uniformly distributed while suppressing the number of filler grains contained in the adhesive agent from increasing, and a pressure applied to the grains is lower than that in the conventional art.

Owner:NEC ELECTRONICS CORP

Vapor deposition apparatus and vapor deposition method

InactiveCN101906612AReduce the difference in deposition directionInhibition changeVacuum evaporation coatingSputtering coatingGas phaseEngineering

Owner:SONY CORP

Via Fill Substrate, Production Method Therefor, and Precursor Therefor

ActiveUS20180249581A1Improve airtightnessImprove conductivityPrinted circuit aspectsElectrical connection printed elementsElectrical conductorMetal

A method for producing a via-filled substrate includes a metal film forming step of forming a metal film containing an active metal on a hole part wall surface of an insulating substrate having a hole part, a filling step of filling a conductor paste having a volume change rate before and after firing of −10 to 20% in the hole part in which the metal film is formed, and a firing step of firing the insulating substrate in which the conductor paste is filled.

Owner:MITSUBOSHI BELTING LTD

Image forming apparatus

ActiveUS8207995B2Improve image qualitySuppression gapInking apparatusPower drive mechanismsImage formationContact position

Owner:BROTHER KOGYO KK

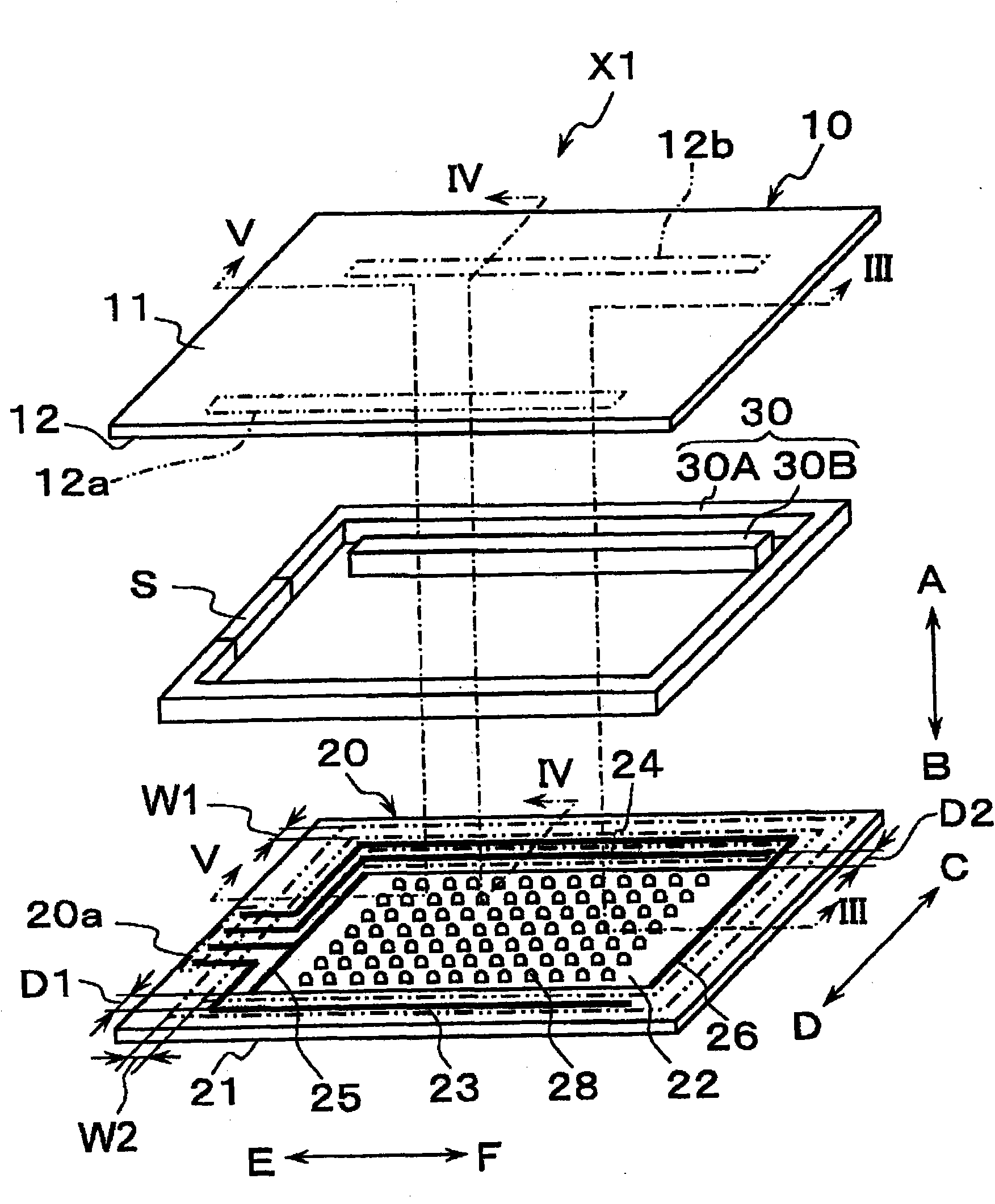

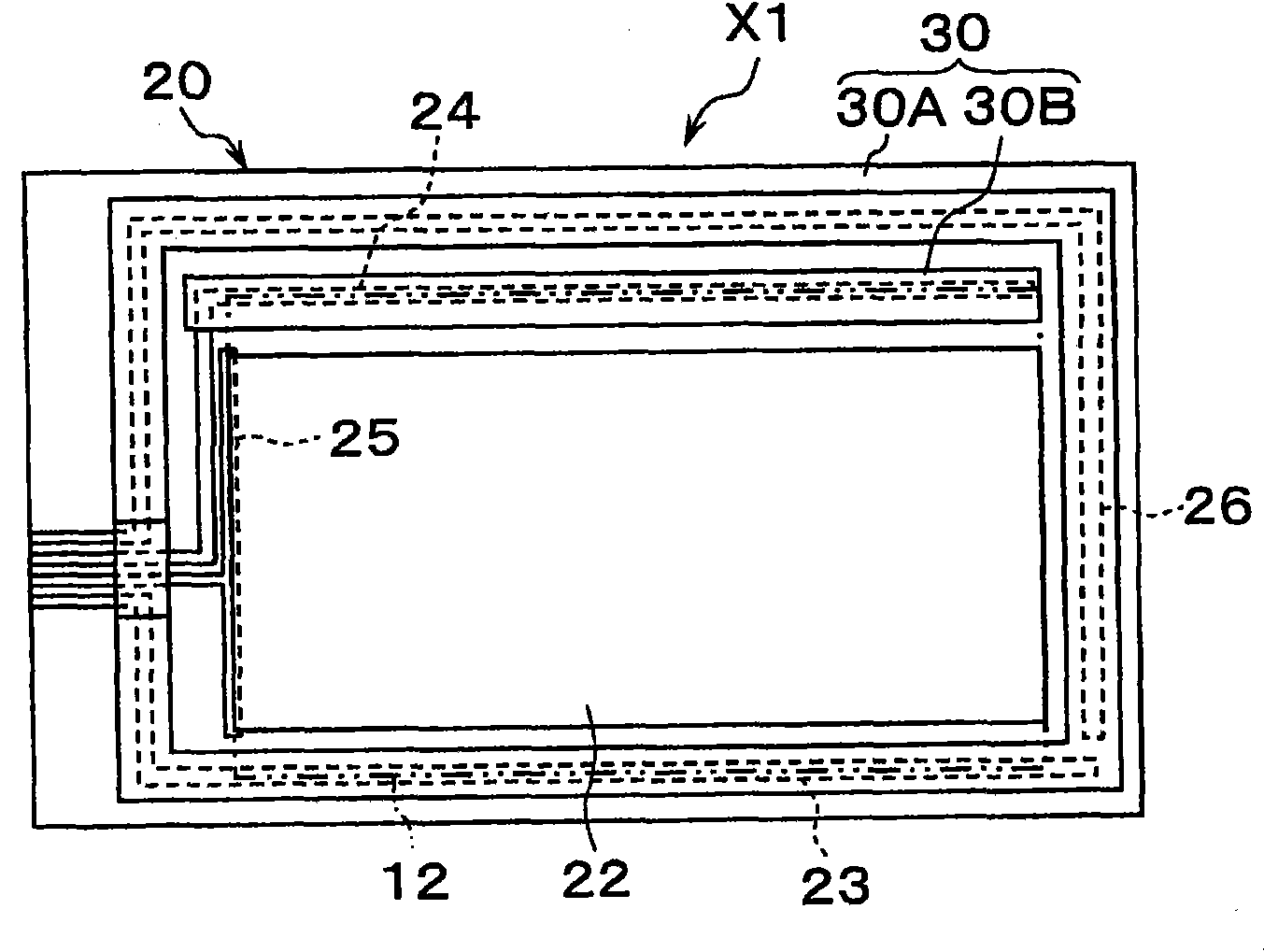

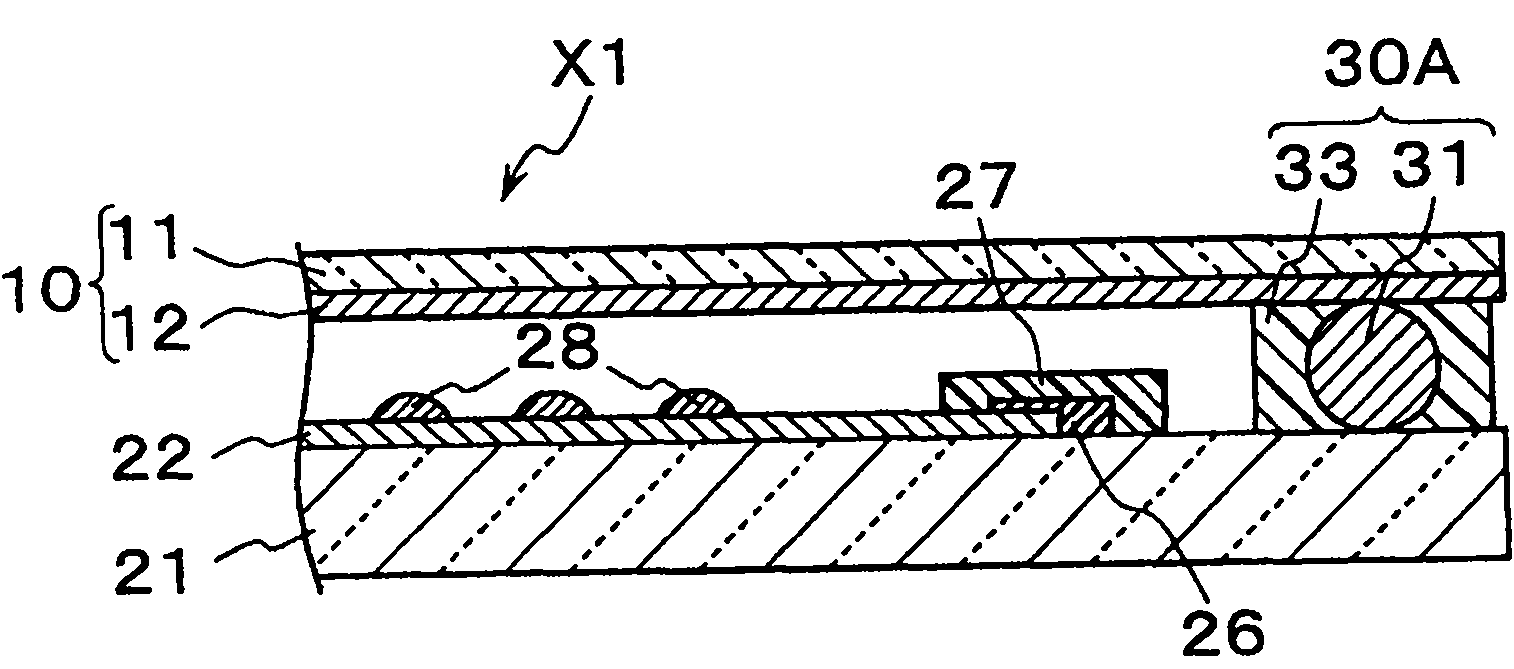

Touch panel and touch panel display device

InactiveCN101889257AReduce thermal stress differentialReduces the effects of differential thermal stressInput/output processes for data processingElectrical resistance and conductanceDisplay device

Disclosed is a touch panel (X1) comprising a first base (10), a second base (20) and a conductive connection member (30), wherein the first base (10) and the second base (20) are bonded with each other. The second base (20) has a wiring electrode (23) electrically connected to a first region (12a) of a first resistive film (12) and a wiring electrode (24) electrically connected to a second region (12b) of the first resistive film (12). The conductive connection member (30) has a first connection member (30A), which is so arranged as to surround a second resistive film (22) when viewed in plan and electrically connects the first region (12a) of the first resistive film (12) with the wiring electrode (23), and a second connection member (30B), which is arranged between the first connection member (30A) and the second resistive film (22) when viewed in plan and electrically connects the second region (12b) of the first resistive film (12) with the wiring electrode (24).

Owner:KYOCERA CORP

Covering material, covered rectangular electric wire and electrical device

InactiveUS20130008685A1Appropriate adhesivenessIncrease ratingsPlastic/resin/waxes insulatorsInsulated cablesElectric wireElectrical wiring

Provided is a covering material, which includes a backing having an upper surface and a lower surface opposite to the upper surface, and a viscoelastic layer formed on the upper surface of the backing, in which the covering material is a covering material for covering a rectangular electric wire, and an adhesive force of the viscoelastic layer to the lower surface of the backing as measured by peeling at a peeling angle of 180° and a tensile rate of 300 mm / min is 0.05 N / 20 mm or more and 10 N / 20 mm or less. A covered rectangular electric wire includes the covering material and a rectangular electric wire covered with the covering material. An electrical device is produced by using the covered rectangular electric wire.

Owner:NITTO DENKO CORP +1

Seal structure

ActiveCN103891073AInhibition formationInhibitionEngine sealsElectrical apparatus contructional detailsGrommetMetal substrate

In order to prevent gaps from occurring in corner sections in a section where three surfaces are joined together, comprising the combination of a housing, grommet and cover, or the like, thereby improve sealing, a seal structure, which is provided with a housing in which a notch-shaped grommet-mounting section is disposed, a grommet, a cover and a metal substrate gasket, is provided, wherein the grommet is provided with a seal projection, and the seal projection forms a protruding section due to a portion of the seal projection protruding toward the metal substrate gasket when the seal projection makes intimate contact with the inner surface of the grommet-mounting section. The metal substrate gasket is provided with two seal lines and a groove-shaped recess between the seal lines. When nipped, the protruding section of the seal projection is tightly compressed inside the groove-shaped recess in the metal substrate gasket.

Owner:NOK CORP

Seal member, unit, and image forming apparatus

ActiveUS20170219962A1Containment leakLeakage of a developer in a developer housing portion to be more effectively suppressedElectrographic process apparatusEngineeringImaging equipment

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com