Motor

A motor and casing technology, applied in the field of motors, can solve the problems of the bus bar cage being not firmly fixed, generating vibration or noise, reducing the service life of the motor, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

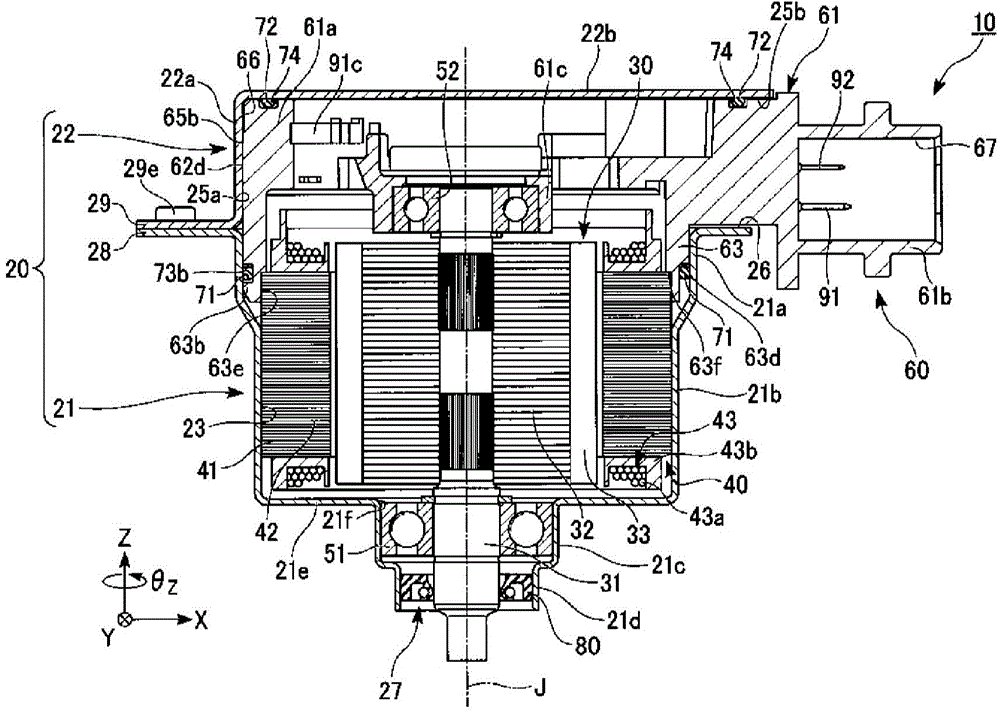

[0025] figure 1 It is a cross-sectional view showing the motor 10 of this embodiment.

[0026] The motor 10 of this embodiment is a brushless motor. Such as figure 1 As shown, the motor 10 includes a housing portion 20, a rotor 30 having a shaft 31, a stator 40, a bus bar unit 60, a plurality of O-rings, a front bearing (first bearing) 51, a rear bearing (second bearing) 52, and Oil seal 80. The plurality of O-rings includes a front O-ring (first O-ring) 71 and a rear O-ring (second O-ring) 72.

[0027] [Chassis Department]

[0028] The housing part 20 is a cylindrical metal member in which the bus bar unit 60 is press-fitted inside. The cabinet part 20 has a front cabinet part (first cabinet part) 21 and a rear cabinet part (second cabinet part) 22. The rotor 30, the stator 40, the bus bar unit 60, the front bearing 51, the rear bearing 52, the front O-ring 71, the rear O-ring 72, and the oil seal 80 are held inside the casing portion 20.

[0029] (Front case)

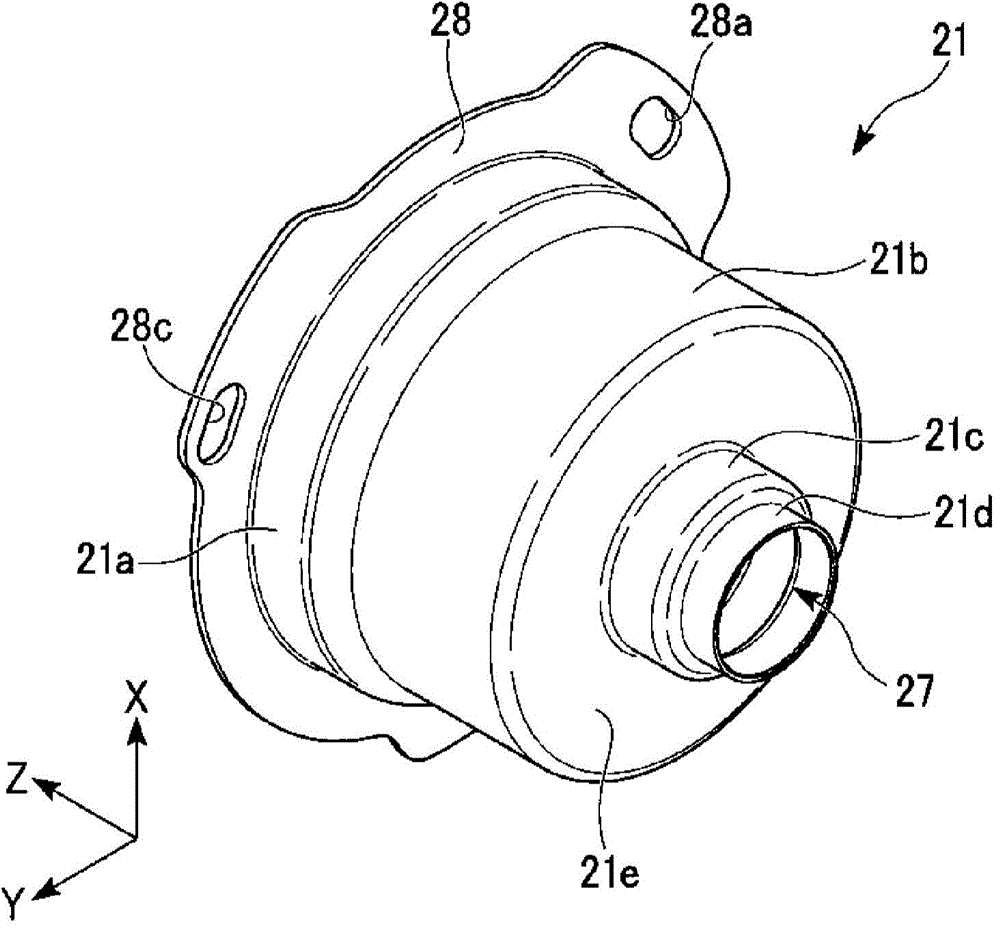

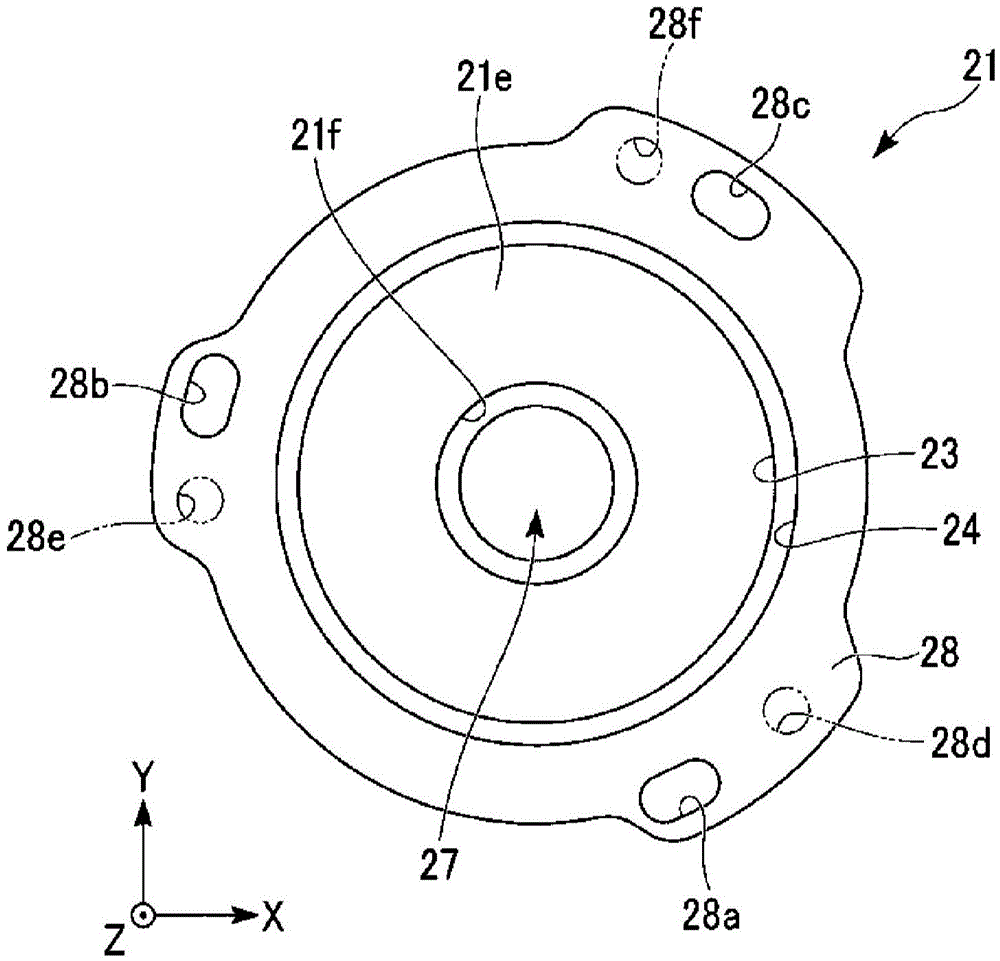

[0030] Figure 2 t...

no. 2 approach >

[0170] The second embodiment is different from the first embodiment in that the main body has a protrusion group.

[0171] In addition, regarding the same configuration as the first embodiment, the description may be omitted by appropriately attaching the same reference numerals.

[0172] Figure 13 with Figure 14 It is a diagram showing the bus bar unit 260 of this embodiment. Figure 13 It is a three-dimensional view. Figure 14 It is a top view.

[0173] The bus bar unit 260 has a bus bar holder 261. The bus bar holder 261 has a main body portion 261a. The main body 261a has a plurality of protruding part groups (contact part groups). In this embodiment, there are three or more protrusion groups. As an example, in Figure 14 An example is shown in which three groups of protrusions (contact part groups) 267a, 267b, and 267c are provided as a plurality of protrusion groups.

[0174] The protrusion groups 267a, 267b, and 267c are each composed of a plurality of protrusions (contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com