Brake-shoe installation structure

A technology for installing structure and brake shoe, which is applied in transportation and packaging, railway braking system, mechanical equipment, etc., and can solve the problems of unavailability of brake shoe and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

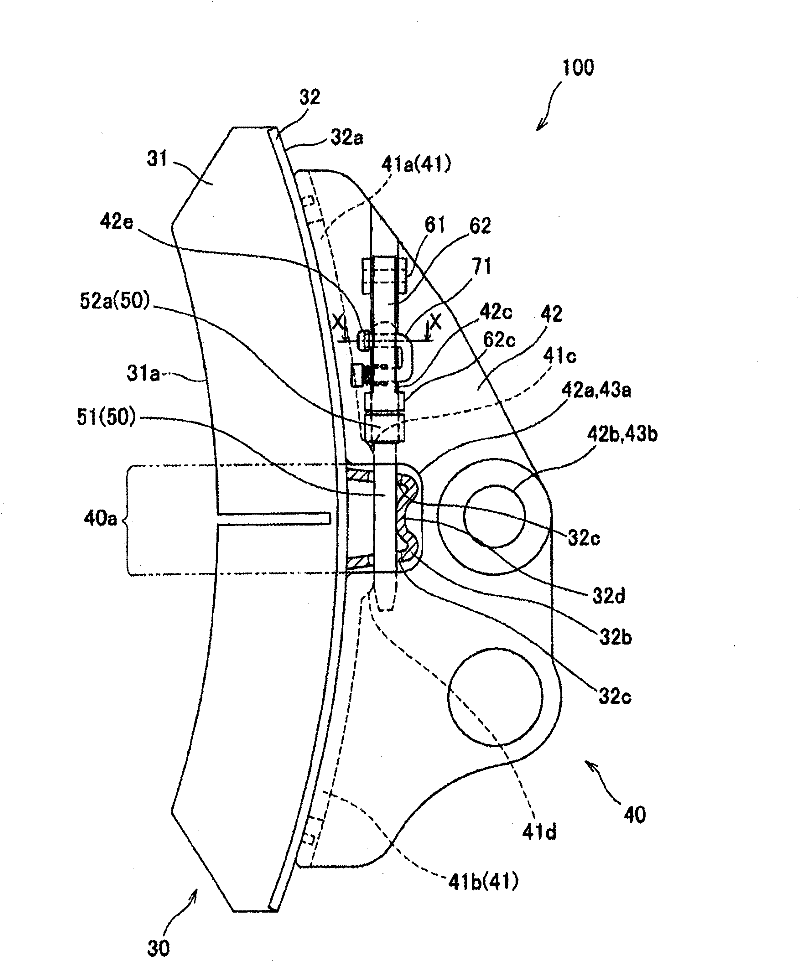

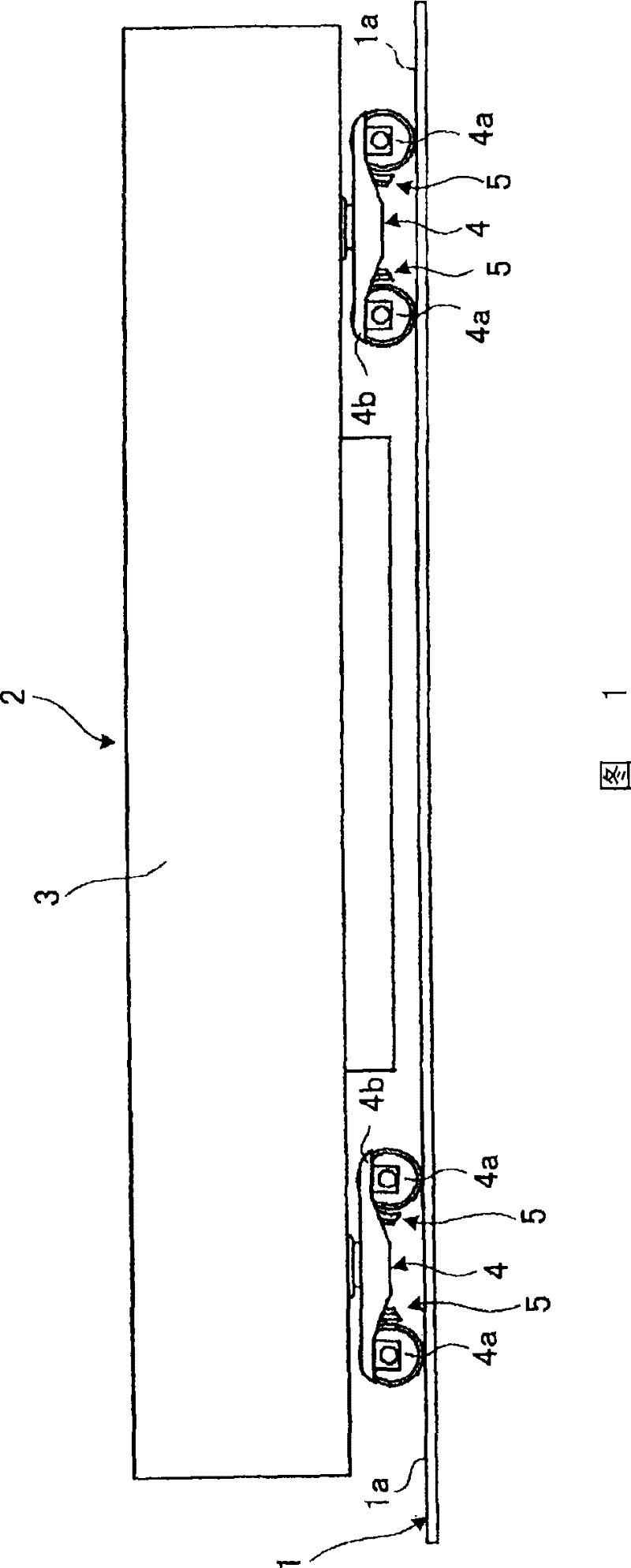

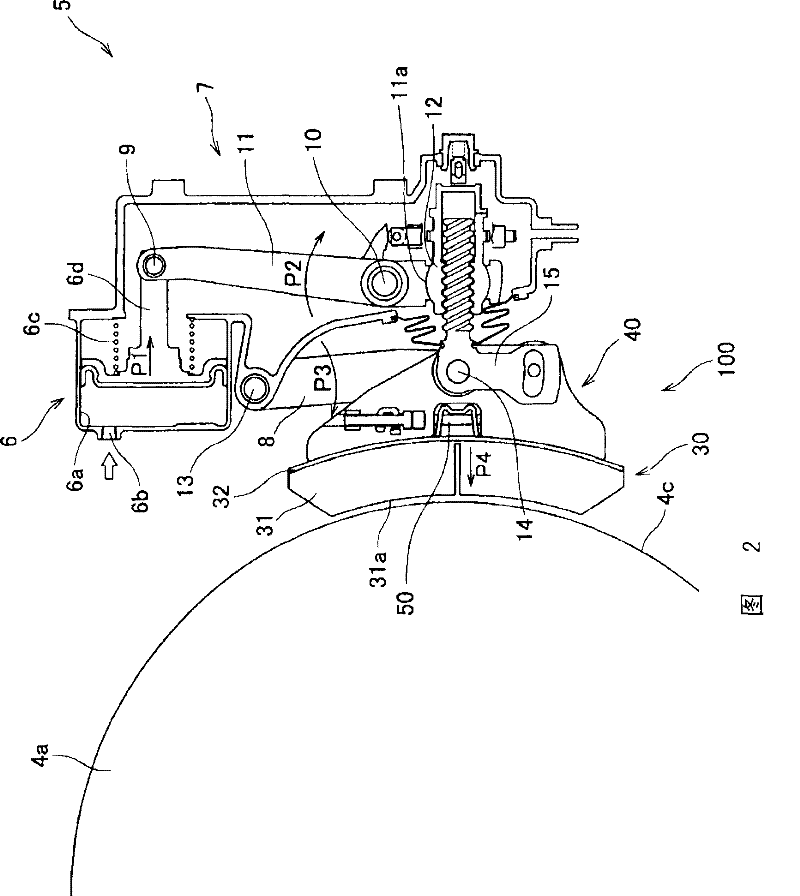

[0057] The best mode for carrying out the present invention will be described below with reference to the drawings. figure 1 It is a side view of a railcar provided with a brake device for a railcar to which the brake shoe mounting structure according to the embodiment of the present invention is applied. figure 2 It is a side view of a railcar brake device to which the brake shoe mounting structure of the present invention is applied.

[0058] figure 1 The illustrated track 1 is a path (route) on which the vehicle 2 travels, and is constituted by guide rails 1 a for supporting and guiding the vehicle 2 , and the like. The vehicle 2 is a rail vehicle such as an electric train or a diesel train, and includes a car body 3 , a bogie 4 , a brake device 5 to which a brake shoe mounting structure 100 is applied, and the like. The vehicle body 3 is a structure for loading and transporting passengers, and the trolley 4 is a device that supports the vehicle body 3 and travels. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com