Method for manufacturing stacked rotor core

A manufacturing method and core technology, applied in the manufacture of motor generators, stator/rotor bodies, magnetic circuit rotating parts, etc., can solve problems such as hindering preparation time and shortening, and achieve improved rigidity, extended life, and plate thickness. thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Next, an embodiment of the present invention will be described with reference to the drawings so that the present invention can be understood.

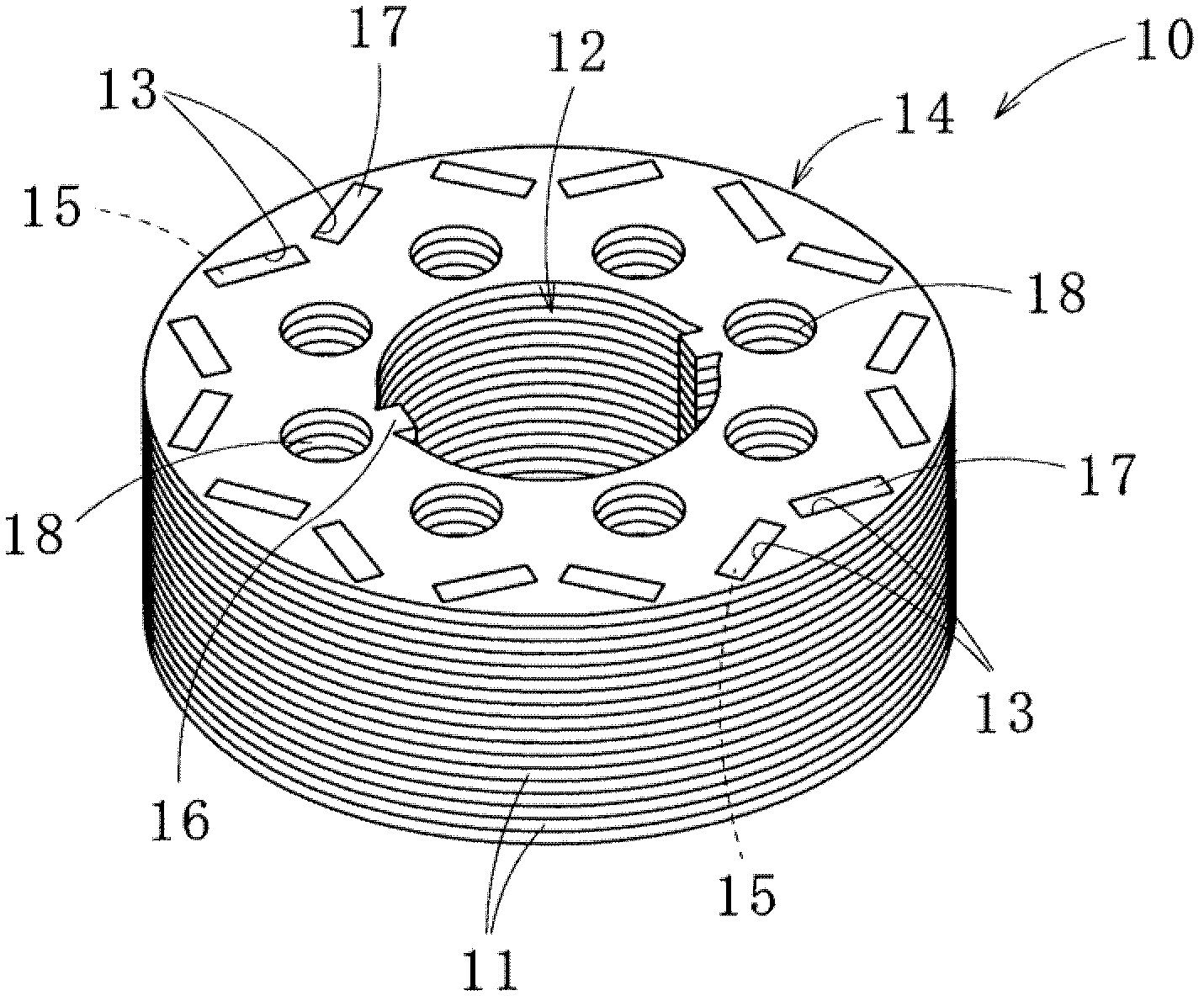

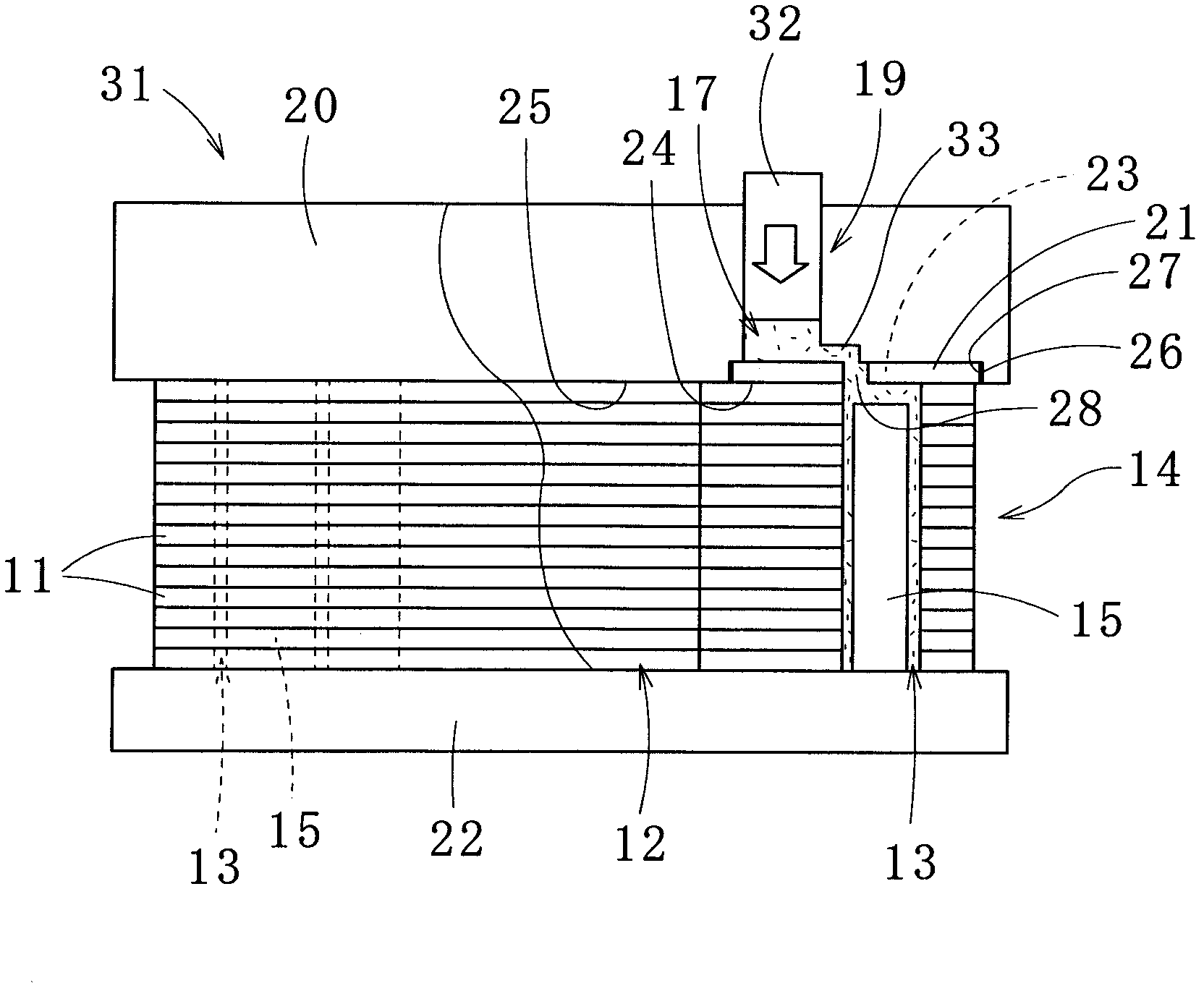

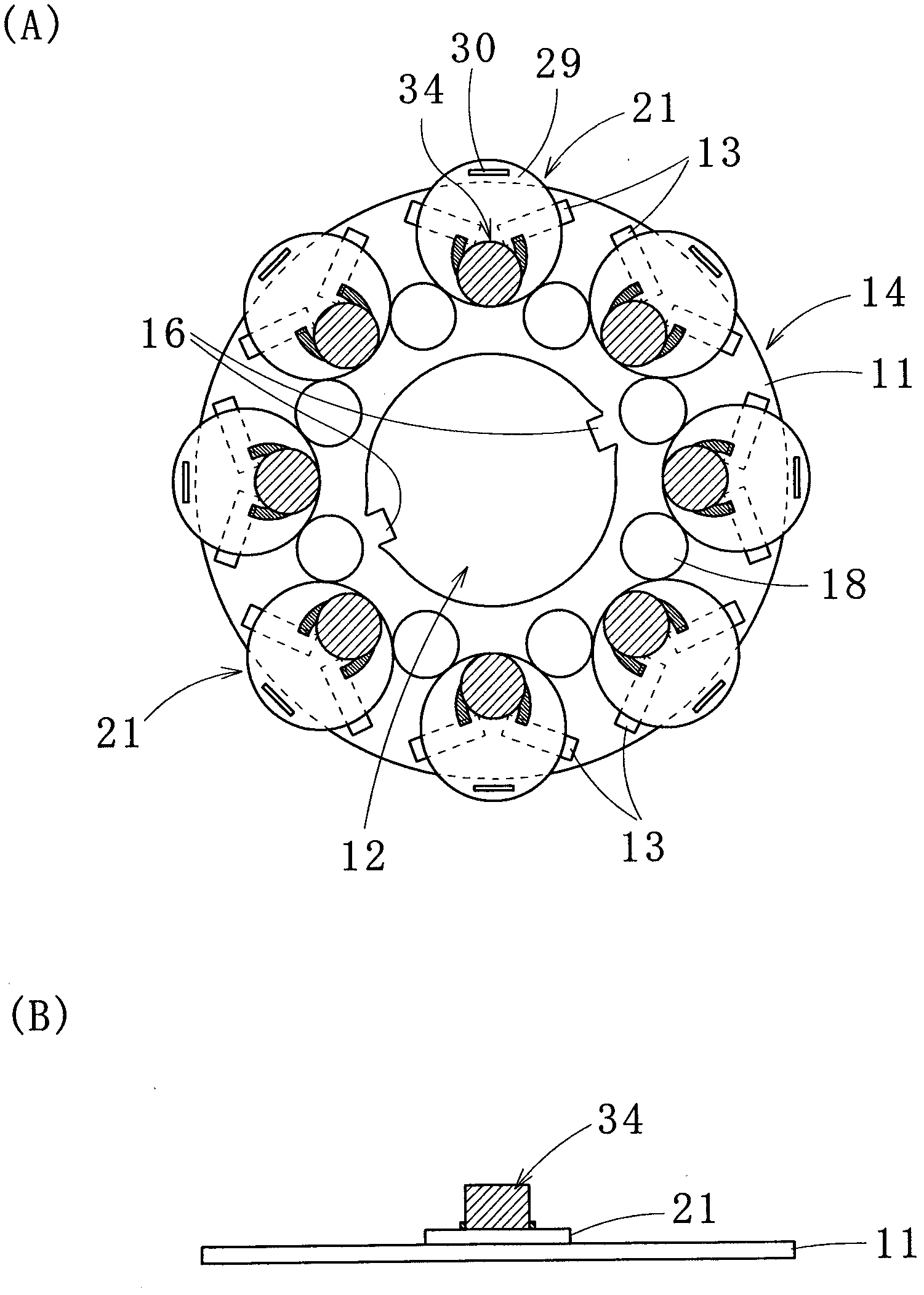

[0059] First, refer to figure 1 , figure 2 A laminated rotor core (hereinafter also simply referred to as a rotor core) 10 manufactured by the method for manufacturing a laminated rotor core according to the first embodiment of the present invention will be described.

[0060] The rotor core (rotor) 10 is formed by stacking a plurality of core pieces 11, and the core body 14 has a plurality of magnet insertion holes (an example of a magnet insertion part) 13 formed around a central shaft hole 12, and the magnets inserted into the core body 14 are A permanent magnet 15 is inserted into the hole 13 .

[0061] The core piece 11 constituting the core main body 14 is a ring-shaped core piece punched from an electrical steel sheet having a thickness of, for example, about 0.5 mm or less (specifically, 0.15 to 0.5 mm). Furthermor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com