Socket contact terminal and semiconductor device

A technology for sockets and terminals, which is applied in the field of contact terminals for sockets, can solve the problems of inability to remove the oxide film of the connection pad, heat generation or increased voltage drop, and high contact resistance, and achieve the effect of good processing ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

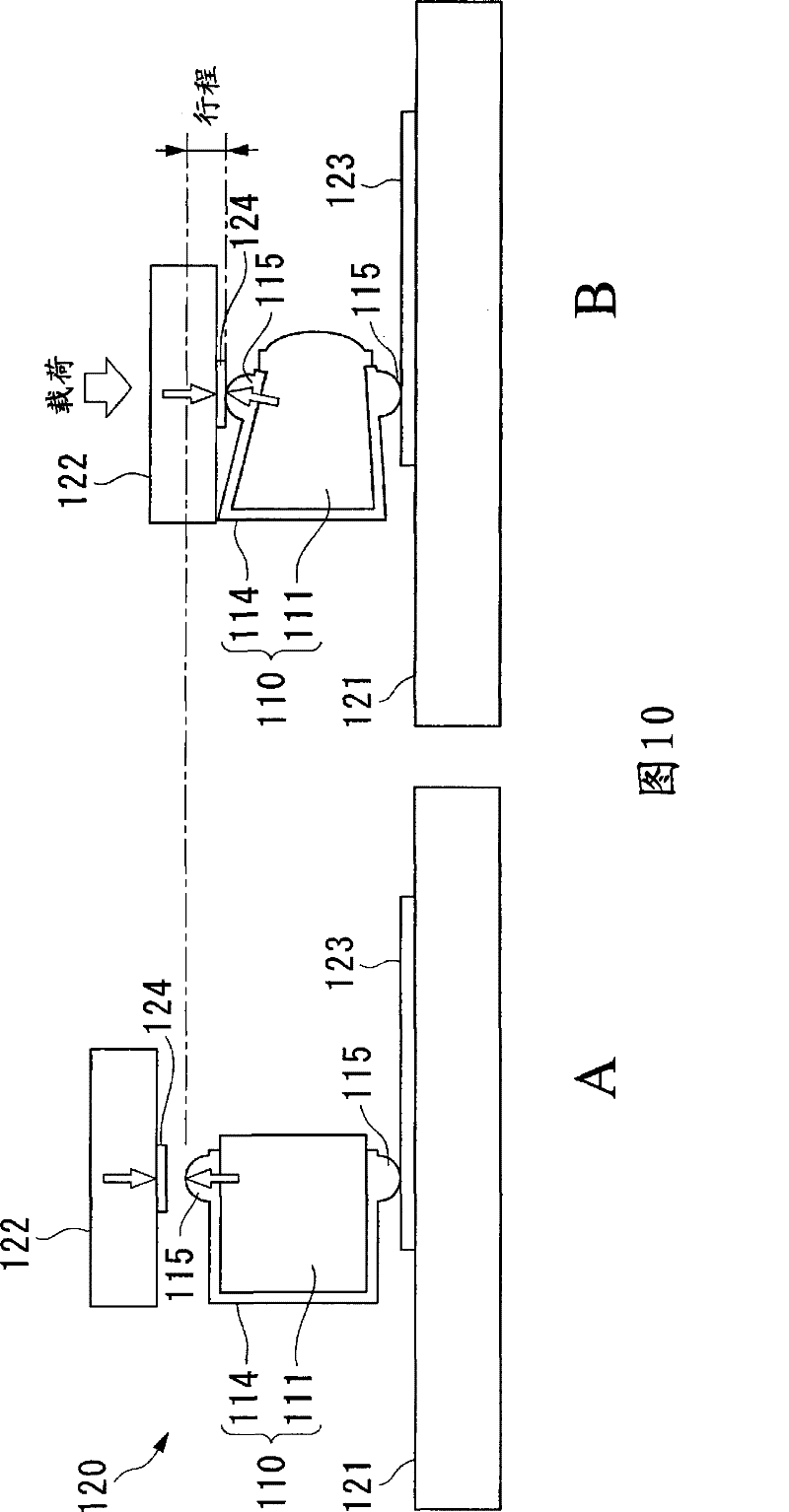

[0175] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0176] Figures 1A-1D It is a figure which shows the 1st Embodiment of the contact terminal for sockets of this invention (Hereinafter, it is abbreviated as contact terminal.), Figure 1A is a side view of the contact terminal 10, Figure 1B is a top view, Figure 1C is the main view, Figure 1D is the rear view. In these figures, reference numeral 10 is a contact terminal, 11 is a metal terminal, 12 is an elastic member, 13 is a main column portion, 14 is an arm portion, and 15 is a contact portion.

[0177] The contact terminal 10 of the present embodiment provides electrical conduction between the connection portion made of a metal conductor on the printed circuit board and the connection terminal of the IC package, and includes a square U-shaped metal terminal 11 having a main column portion 13 and The arm parts 14 on both sides; and the rectangular...

no. 2 Embodiment approach

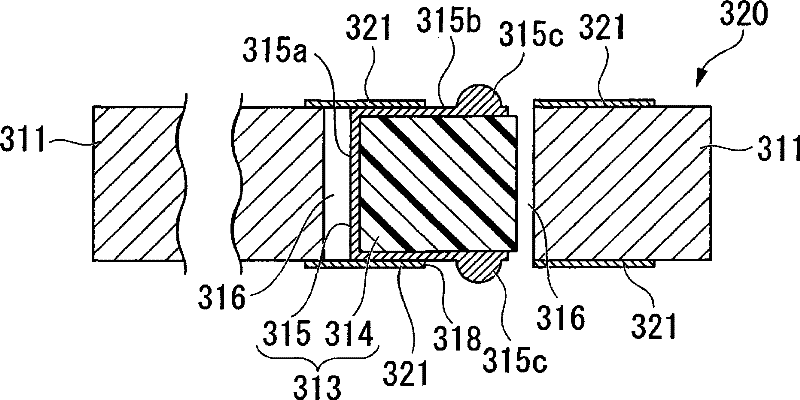

[0191] Figures 3A-3C It is a figure which shows 2nd Embodiment of the contact terminal of this invention. In FIG. 3, only the metal terminal 31 of the contact terminal 30 of this embodiment is shown. Figure 3A is a top view of the metal terminal 31, Figure 3B is a side view, Figure 3C is the rear view. In these figures, reference numeral 31 is a metal terminal, 32 is a main column portion, 33 is an arm portion, 34 is a wide and thick plate portion, and 35 is a dome-shaped convex portion.

[0192] The contact terminal 30 of the present embodiment is characterized in that it has substantially the same constituent elements as the contact terminal 10 of the first embodiment described above, and furthermore, a dome-shaped protrusion is provided on the outer surface of the arm portion 33 of the metal terminal 31 . At the same time, in the central part of the main column part 32, a wide thick plate part 34 having a wider width than other parts and a thicker plate than the oth...

no. 3 Embodiment approach

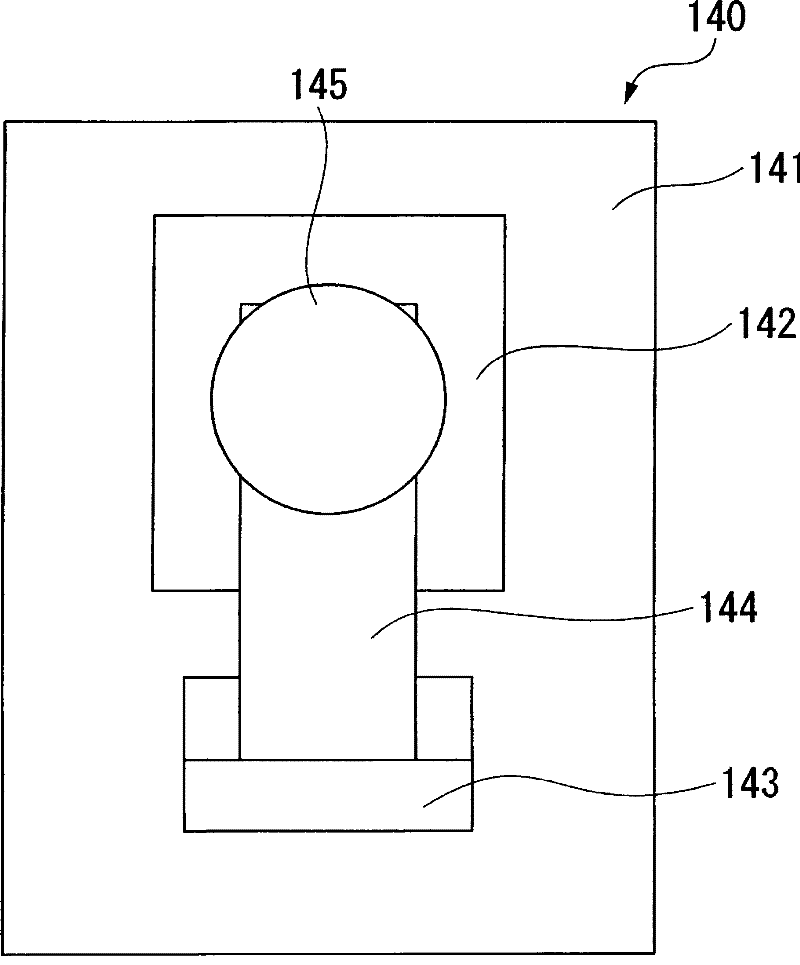

[0202] 4 is a view showing a third embodiment of the contact terminal of the present invention. In FIG. 4, only the metal terminal 41 among the contact terminals of this embodiment is shown. Figure 4A is a side view of the metal terminal 41, Figure 4B is a top view, Figure 4C is the rear view. In these figures, reference numeral 41 is a metal terminal, 42 is a main column portion, 43 is an arm portion, 44 is a wide and thick plate portion, and 45 is a semi-cylindrical convex portion.

[0203] The contact terminal of the present embodiment is characterized in that it has the same components as the contact terminal 30 of the second embodiment described above. In the present embodiment, the arm portion 43 of the metal terminal 41 is formed into a semi-cylindrical shape by bending. shaped convex portion 45 . In addition, like the contact terminal 30 of the second embodiment, the wide thick plate portion 44 is provided in the center of the main column portion 42, but the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com