Patents

Literature

313results about How to "Suppression delay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

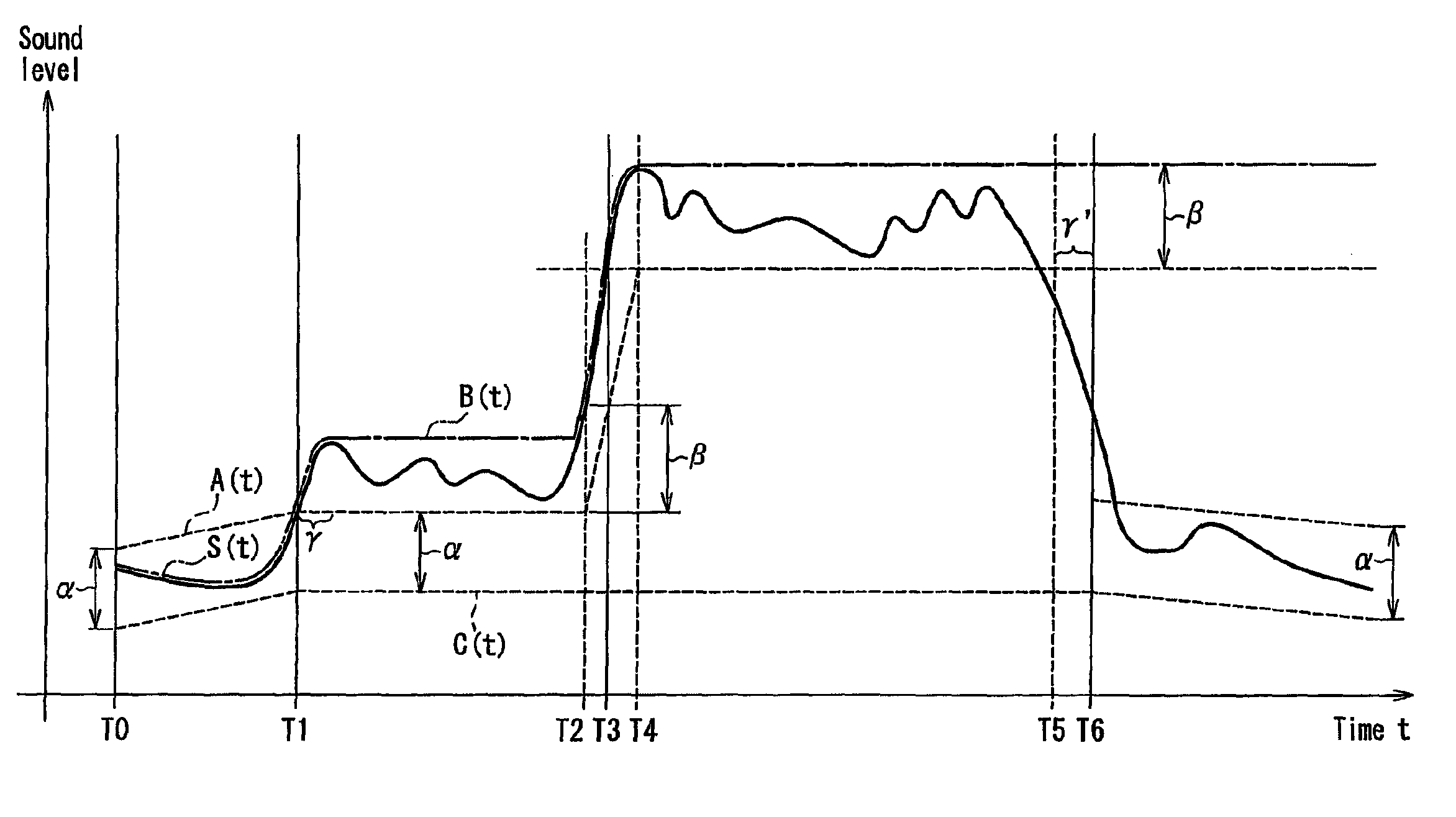

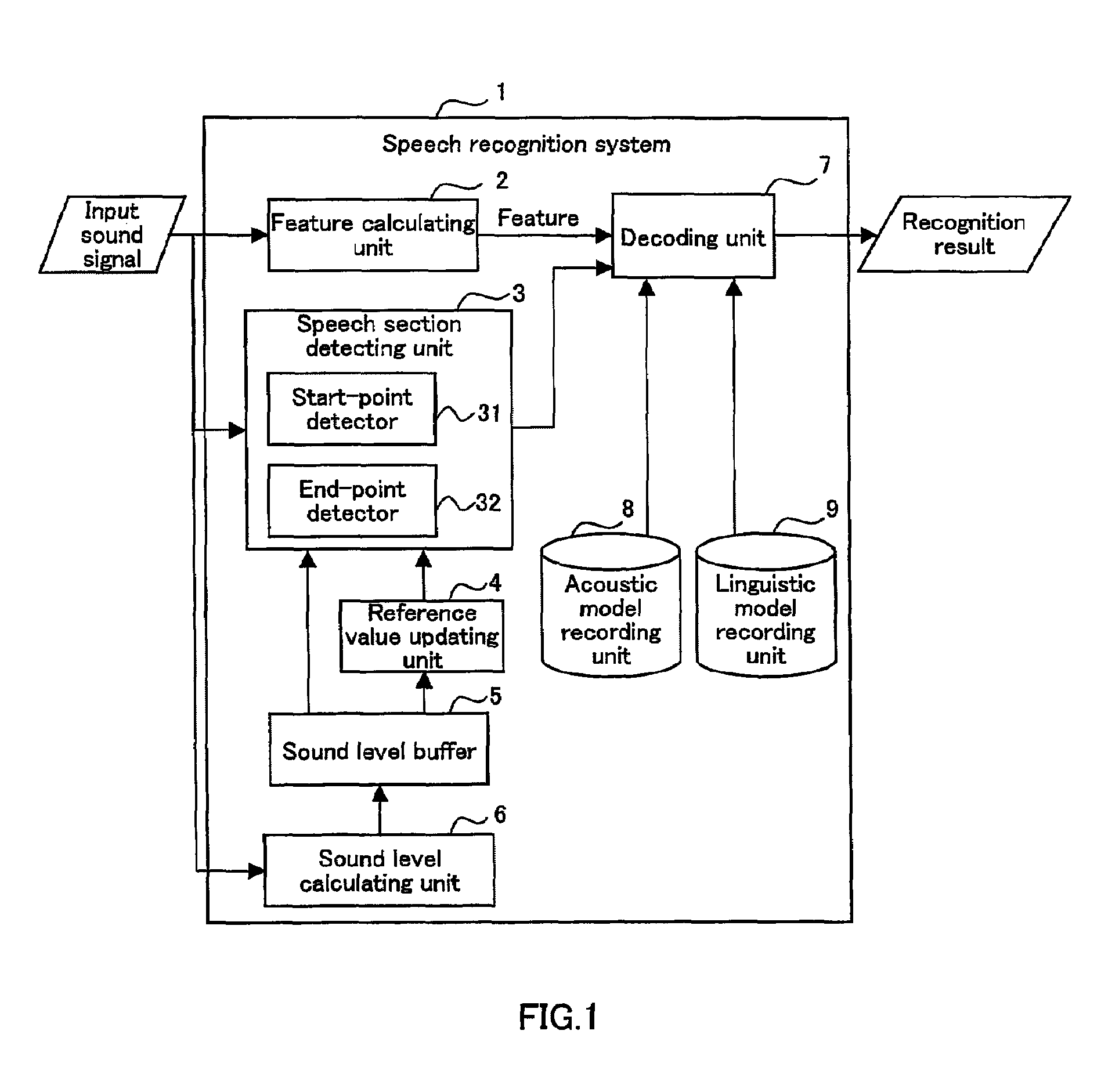

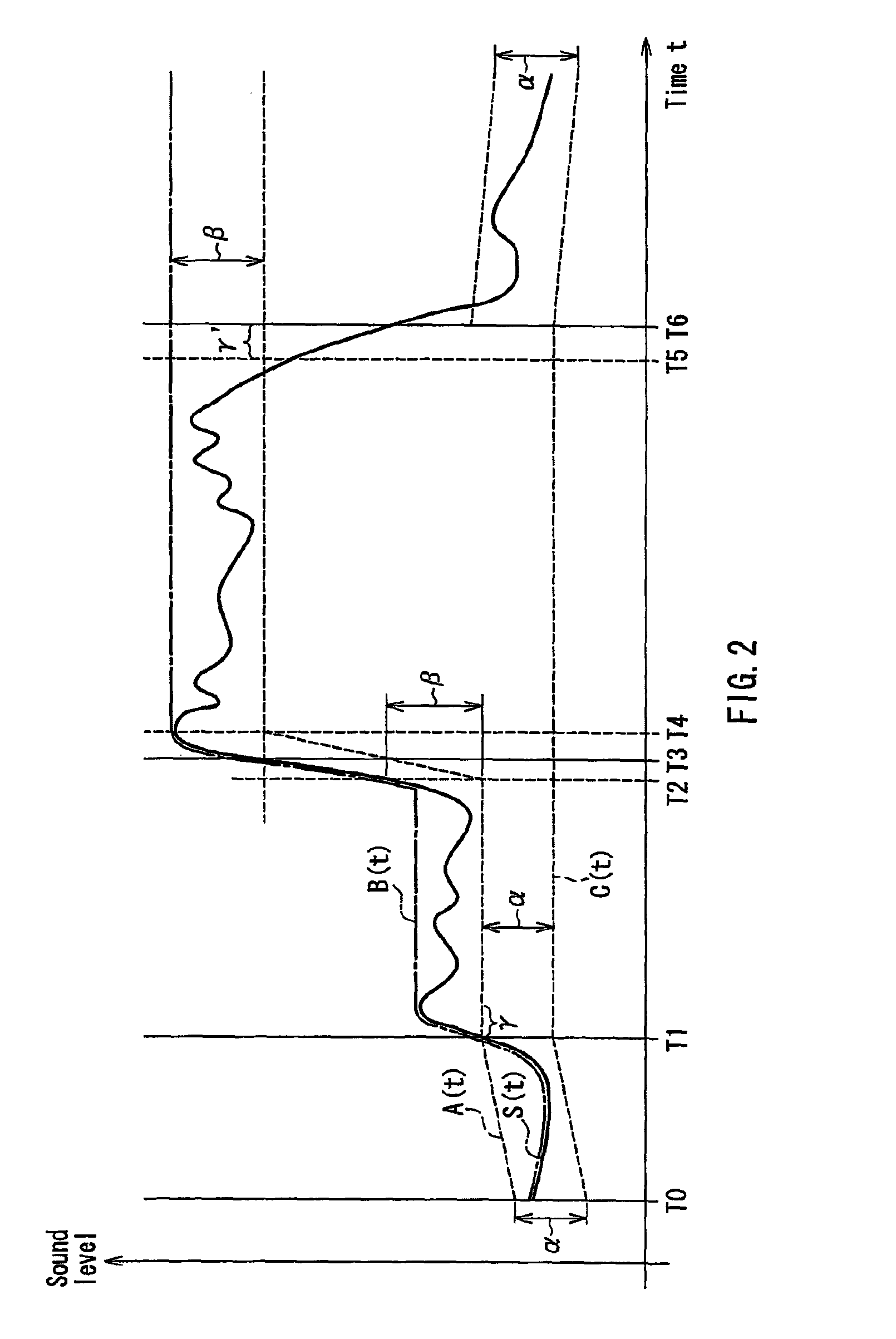

Correction of matching results for speech recognition

A speech recognition system includes the following: a feature calculating unit; a sound level calculating unit that calculates an input sound level in each frame; a decoding unit that matches the feature of each frame with an acoustic model and a linguistic model, and outputs a recognized word sequence; a start-point detector that determines a start frame of a speech section based on a reference value; an end-point detector that determines an end frame of the speech section based on a reference value; and a reference value updating unit that updates the reference value in accordance with variations in the input sound level. The start-point detector updates the start frame every time the reference value is updated. The decoding unit starts matching before being notified of the end frame and corrects the matching results every time it is notified of the start frame. The speech recognition system can suppress a delay in response time while performing speech recognition based on a proper speech section.

Owner:FUJITSU LTD

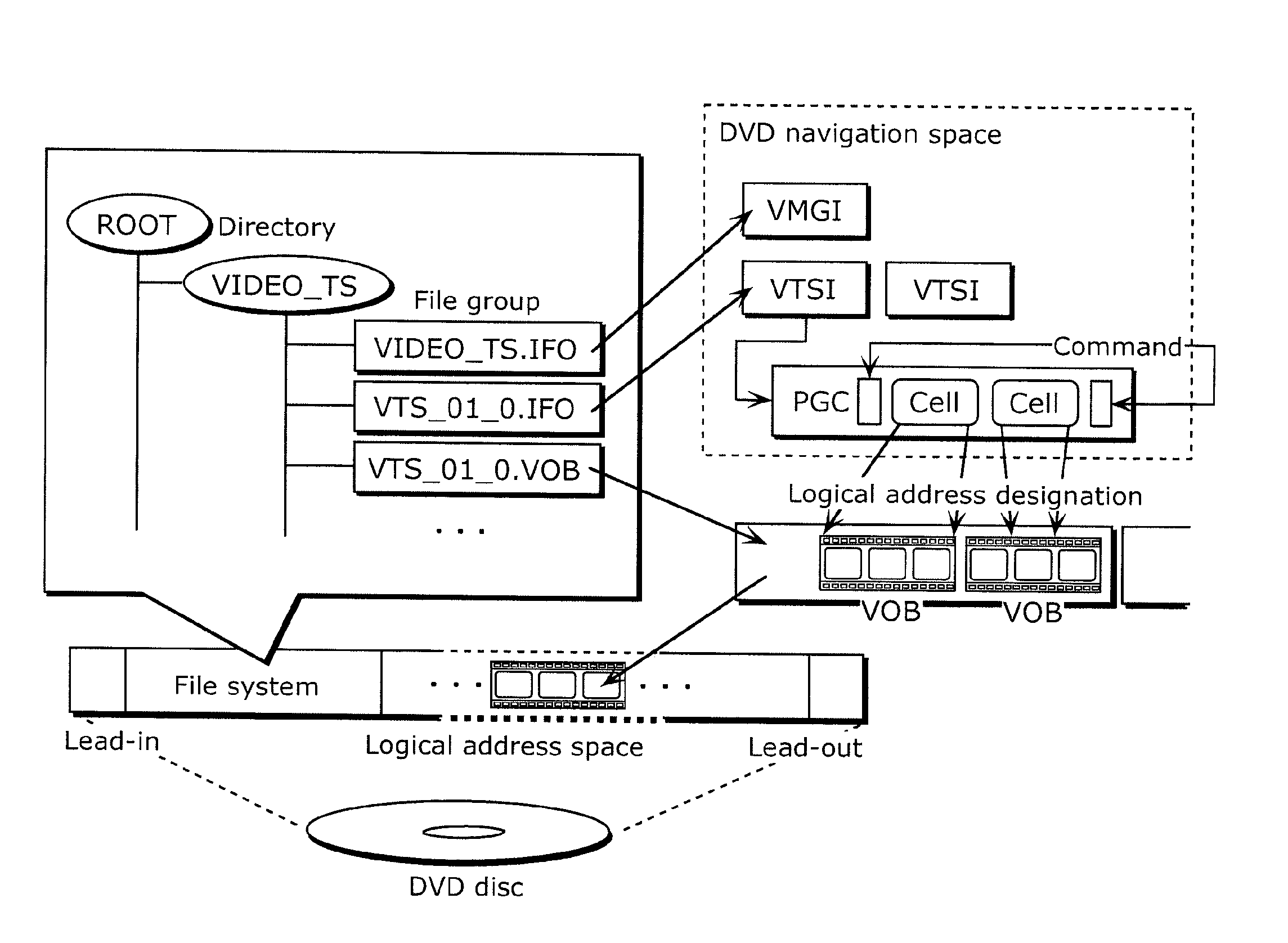

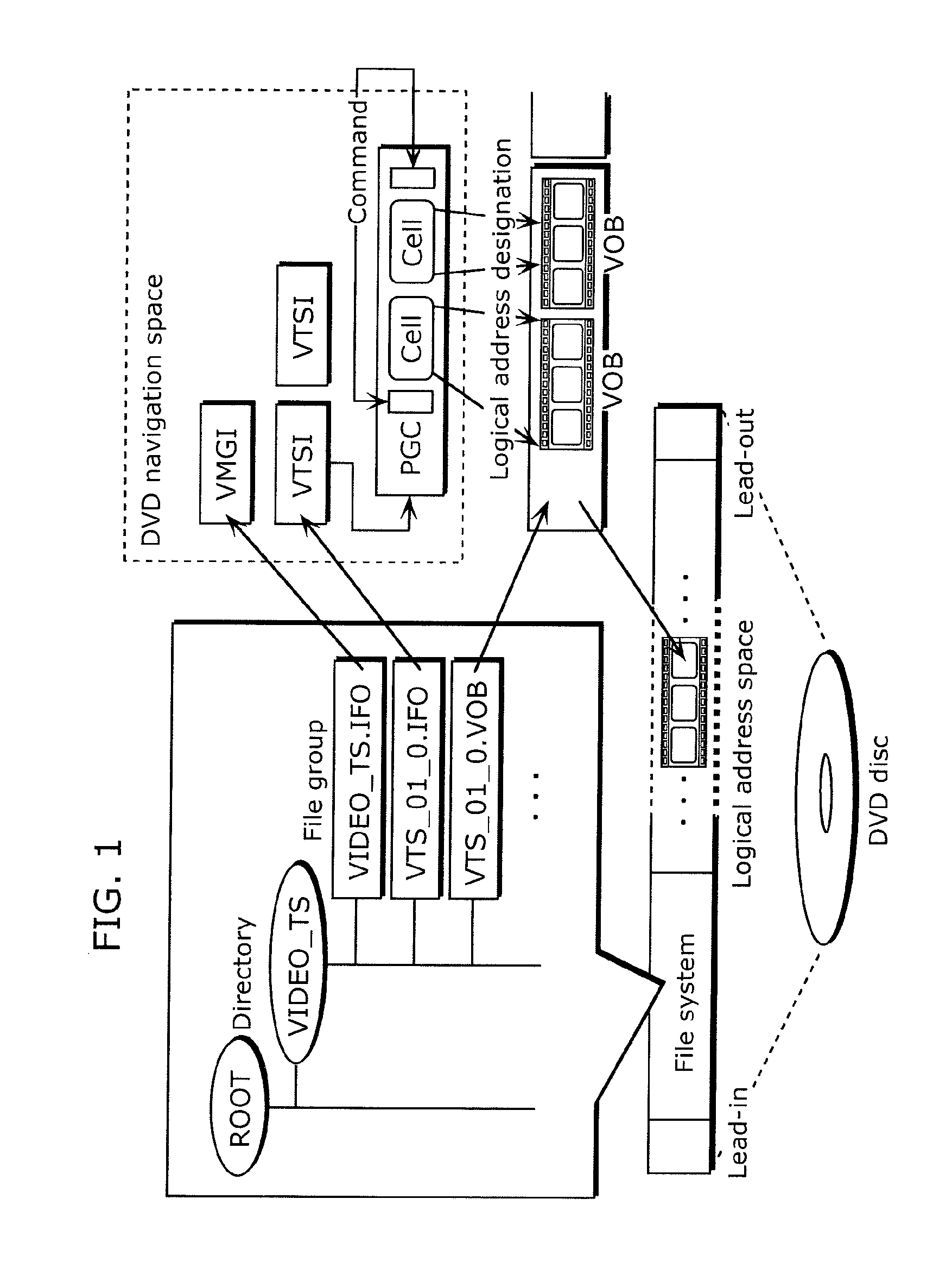

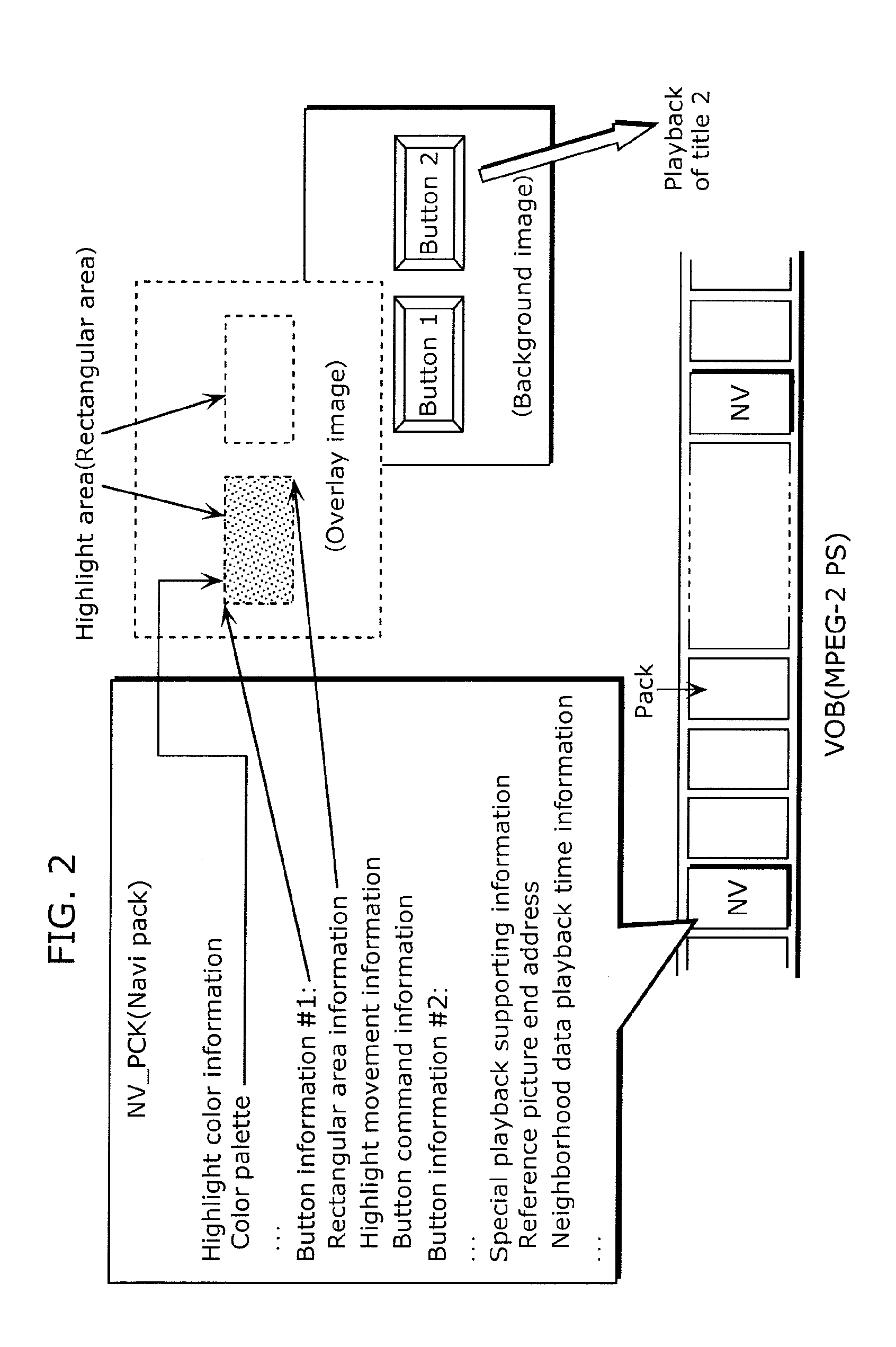

Moving image coding method, moving image coding device, moving image recording method, recording medium, moving image playback method, moving image playback device, and moving image playback system

ActiveUS20100040351A1Reduce processing loadImprove packaging qualityTelevision system detailsRecording carrier detailsComputer hardwareImage recording

A moving image coding method that can prevent playback discontinuity without an increase in processing load during playback is provided.The moving image coding method codes a video stream that includes a first moving image and a second moving image to be overlaid on the first moving image. The moving image coding method includes: a step of determining a continuous playback section that is a group of partial sections and is subject to continuous playback, in the video stream (S5301 to S5303); a step of coding the first and second moving images in the partial sections constituting the continuous playback section, under a constraint that prevents a threshold from being changed in the continuous playback section, the threshold being used for a transparency process by a luminance key in the overlaying (S5304); and a step of generating management information including flag information which indicates that the threshold is fixed in the continuous playback section (S5305).

Owner:PANASONIC CORP

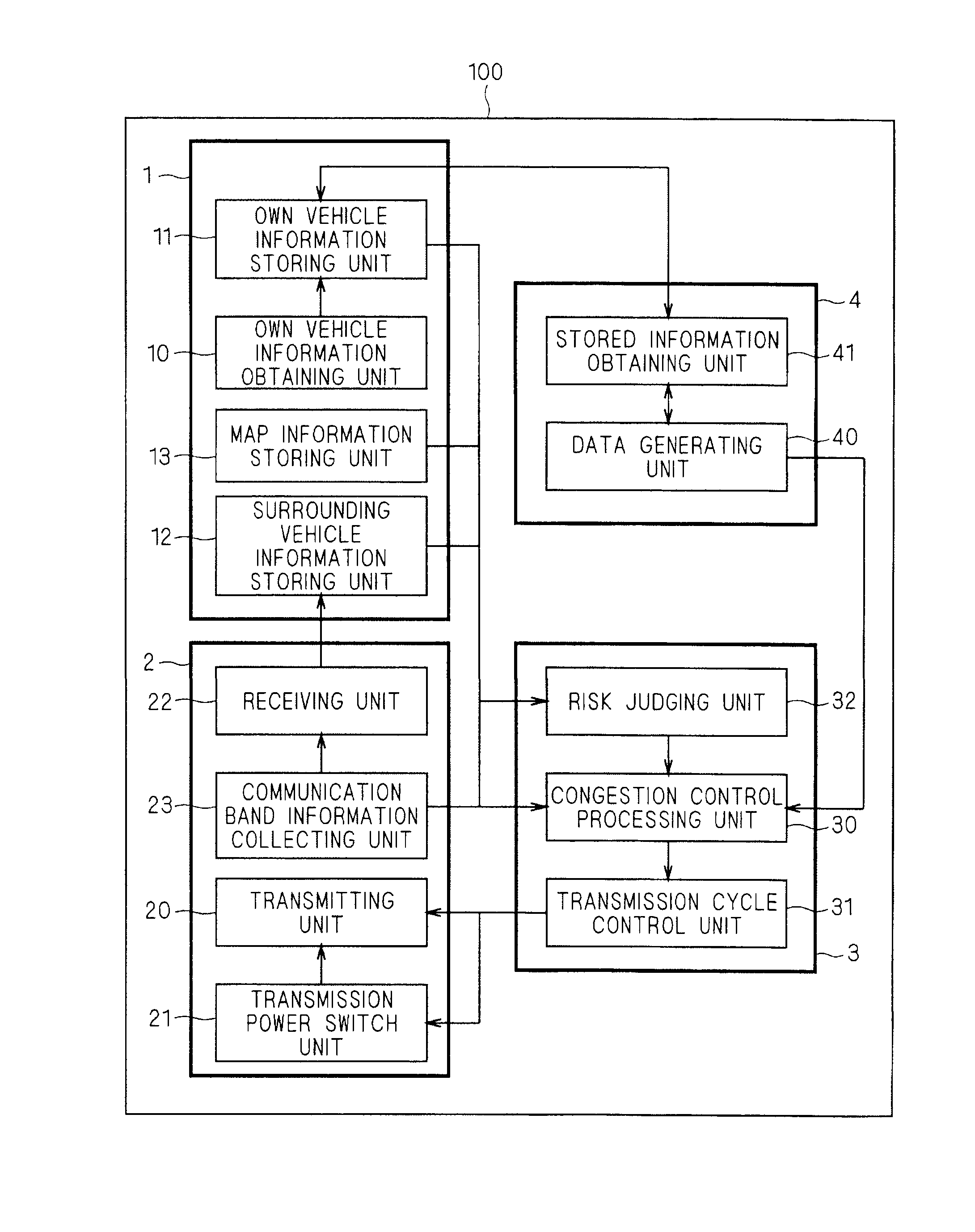

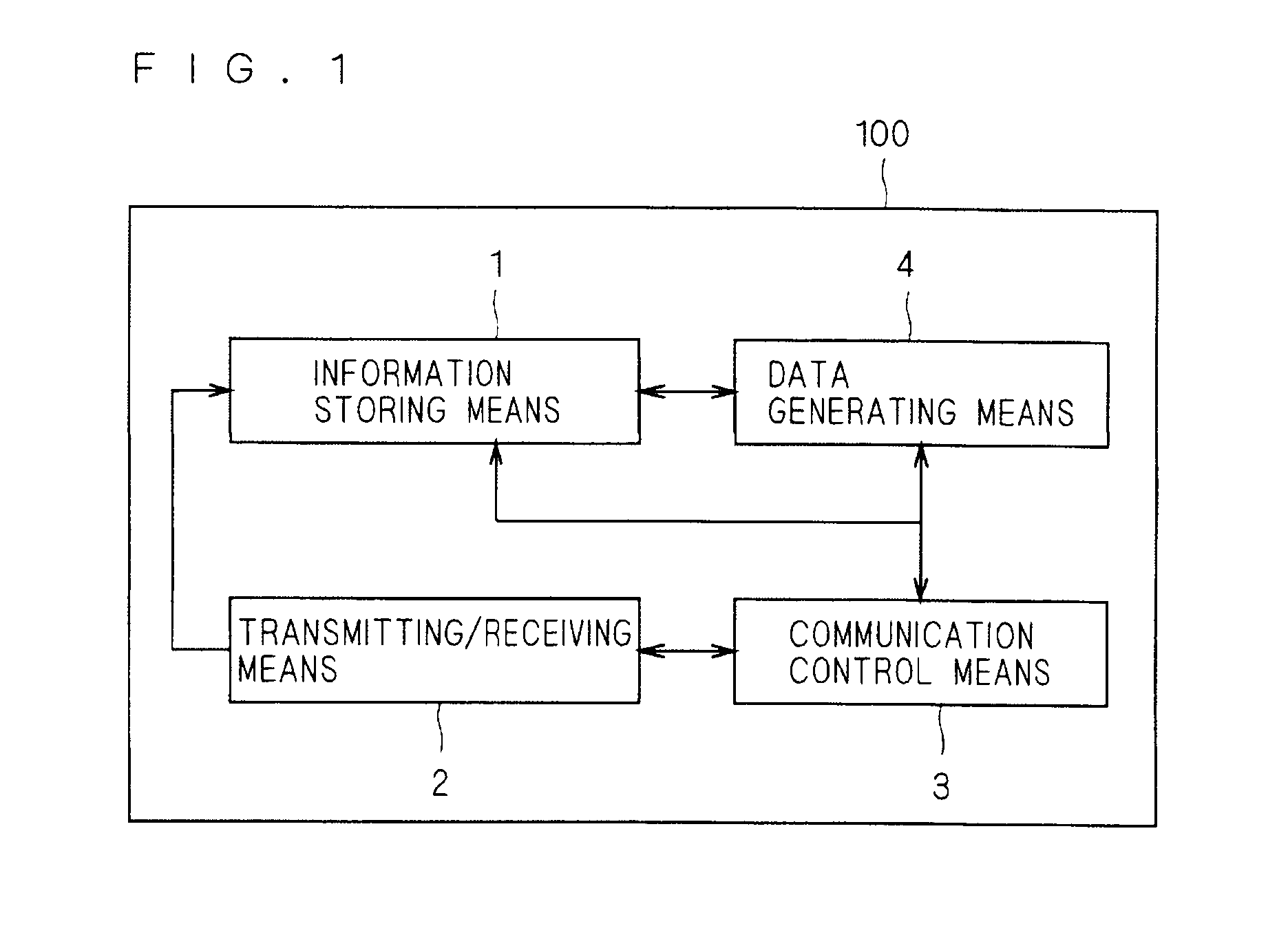

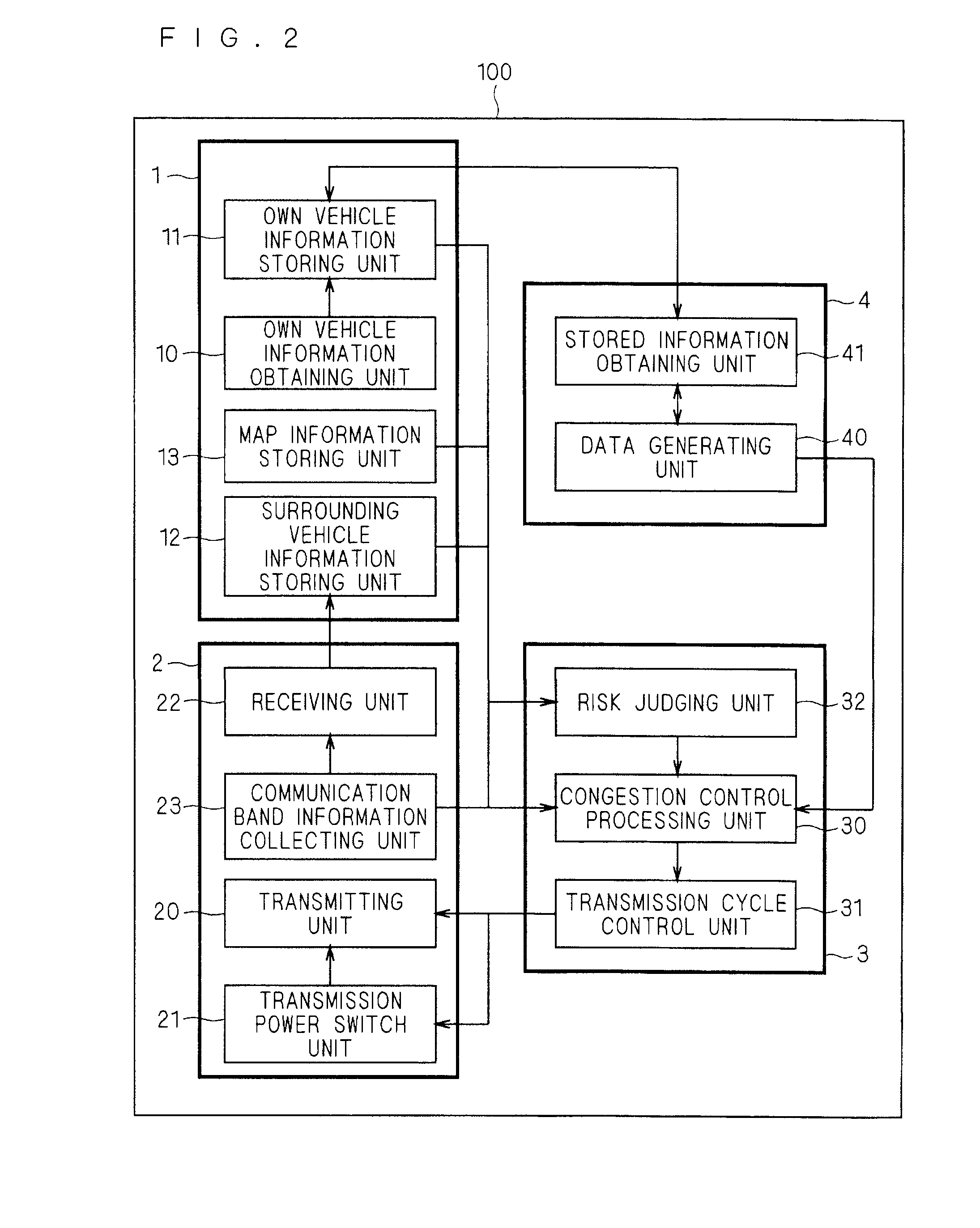

On-vehicle communication device

InactiveUS20100312432A1Avoid congestionSufficiently securing transmission powerVehicle testingRegistering/indicating working of vehiclesIn vehicleCommunication control

The present invention provides an on-vehicle communication device capable of suppressing a delay in providing information, avoiding congestion, and sufficiently securing transmission power. An on-vehicle communication device (100) according to the present invention includes communication control means (3) that controls a transmission cycle and transmission power when data is transmitted from transmitting / receiving means (2). The communication control means (3) uses own vehicle information and surrounding vehicle information to estimate a degree of risk (R) and a safe distance (Ds) of own vehicle. The communication control means (3) controls the transmission cycle of own vehicle based on a communication channel utilization rate of own vehicle, a communication channel utilization rate of a surrounding vehicle and the degree of risk (R) of own vehicle. The communication control means (3) controls the transmission power of own vehicle based on the communication channel utilization rate of own vehicle, the communication channel utilization rate of the surrounding vehicle and the safe distance (Ds).

Owner:MITSUBISHI ELECTRIC CORP

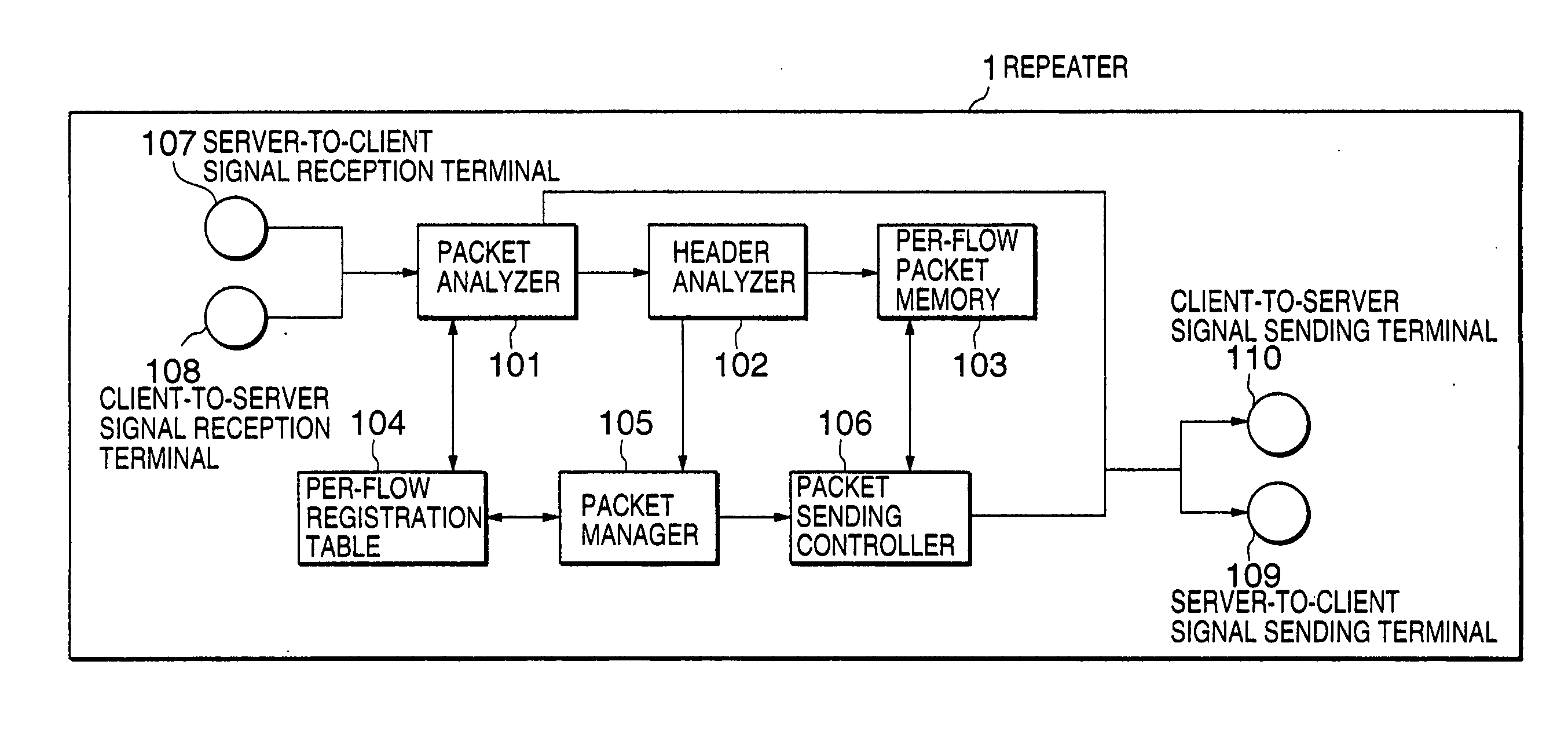

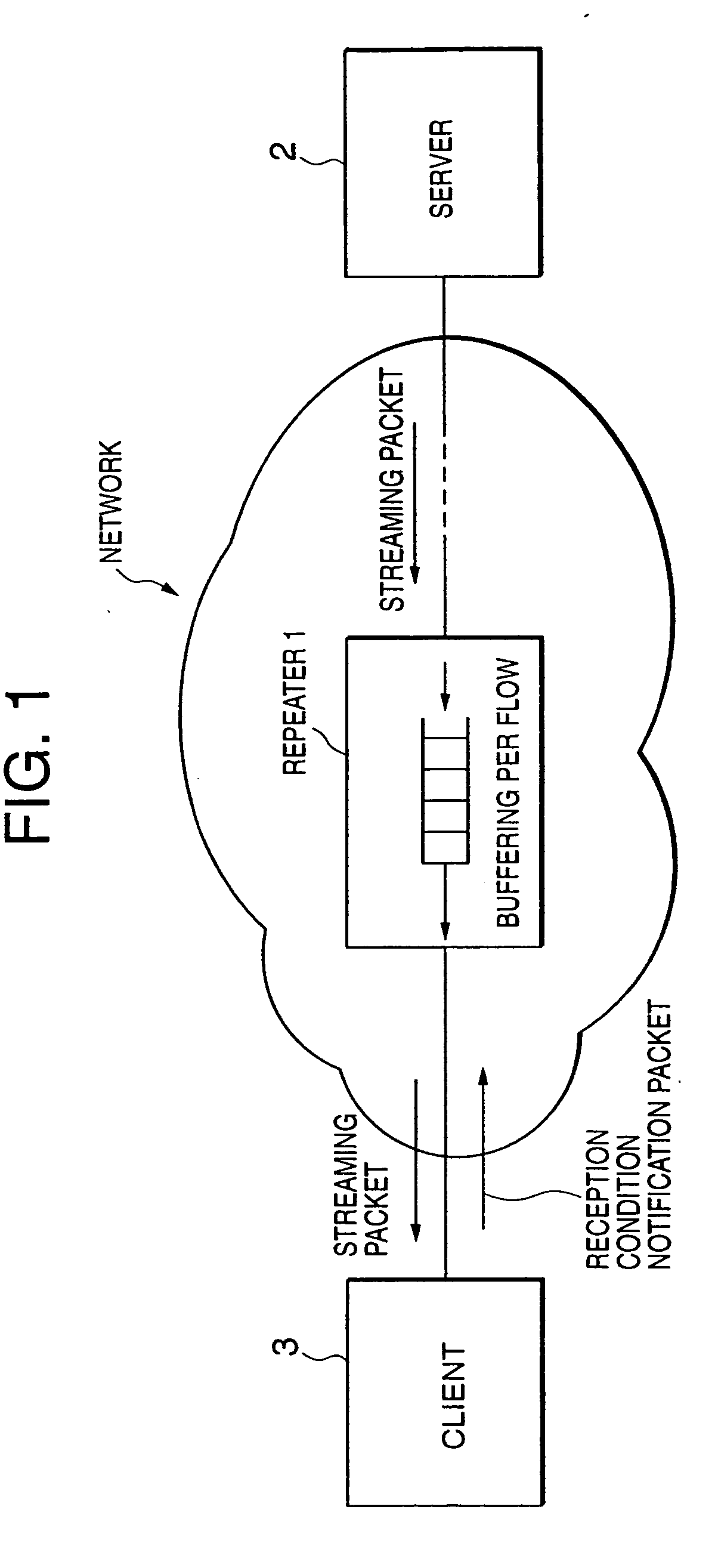

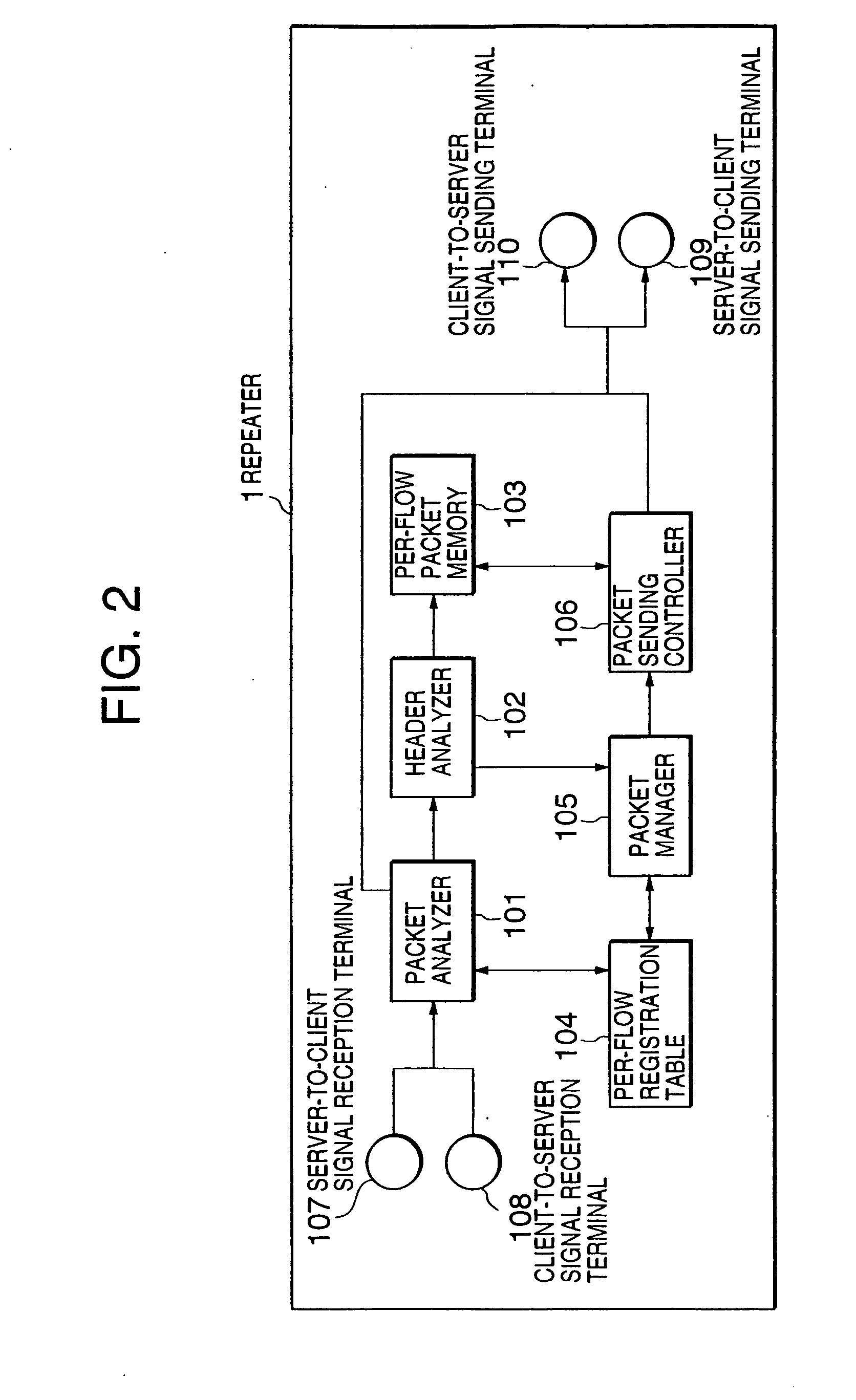

Streaming data transfer system and repeater therefor

InactiveUS20060106961A1Reduce quality problemsSolve large capacityPulse modulation television signal transmissionTransmissionNetwork packetTransfer system

A data transfer system allowing high-quality transfer of streaming data through a network having a relatively large delay variation in data delivery is disclosed. When transferring streaming data in packets from a server computer to a client computer through a repeater provided in the network, the repeater buffers a streaming packet for a set time period before forwarding it to the client computer. The set time period is determined so that a receiving time interval of packets at the client computer is substantially equal to a sending time interval of packets at the server computer.

Owner:NEC CORP

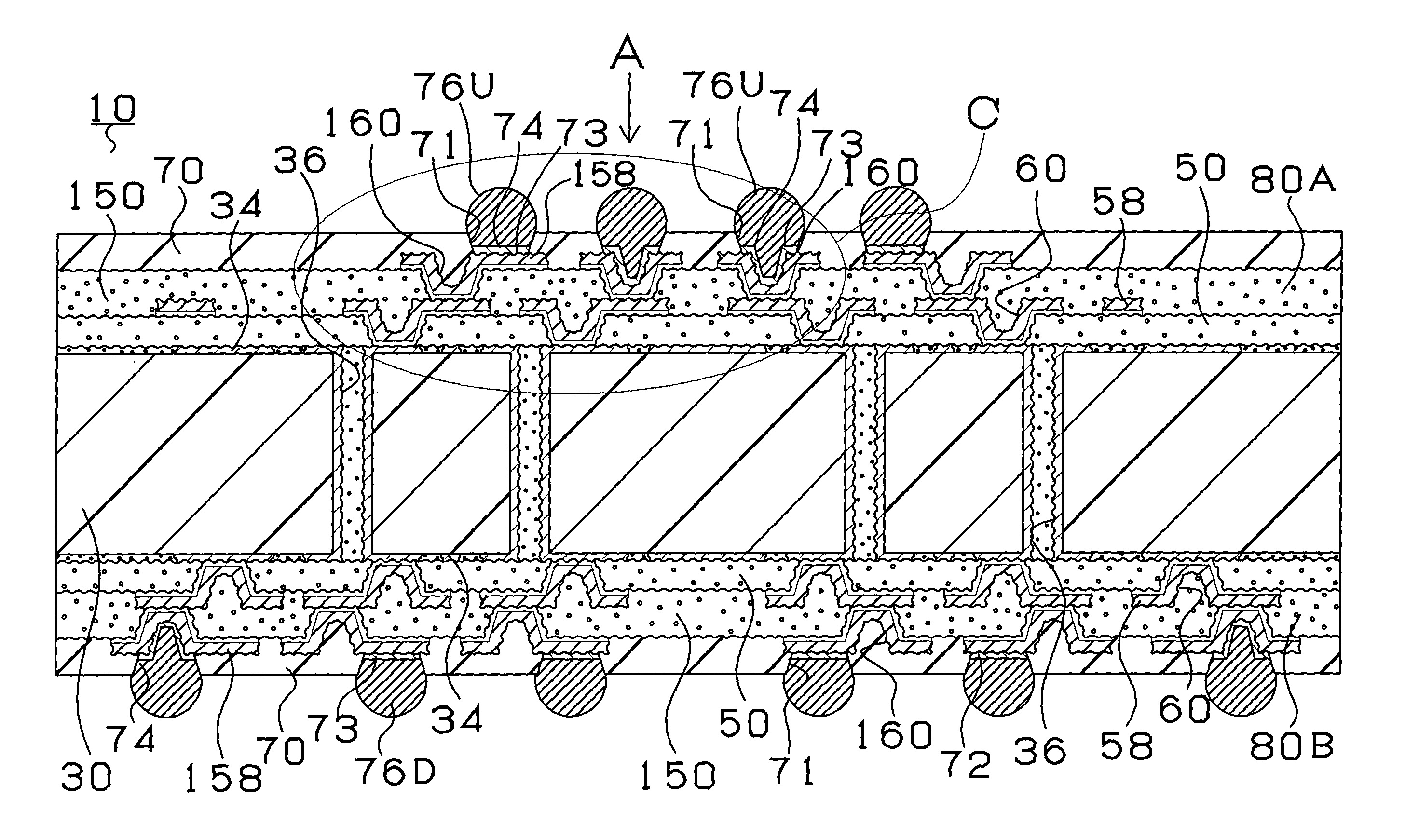

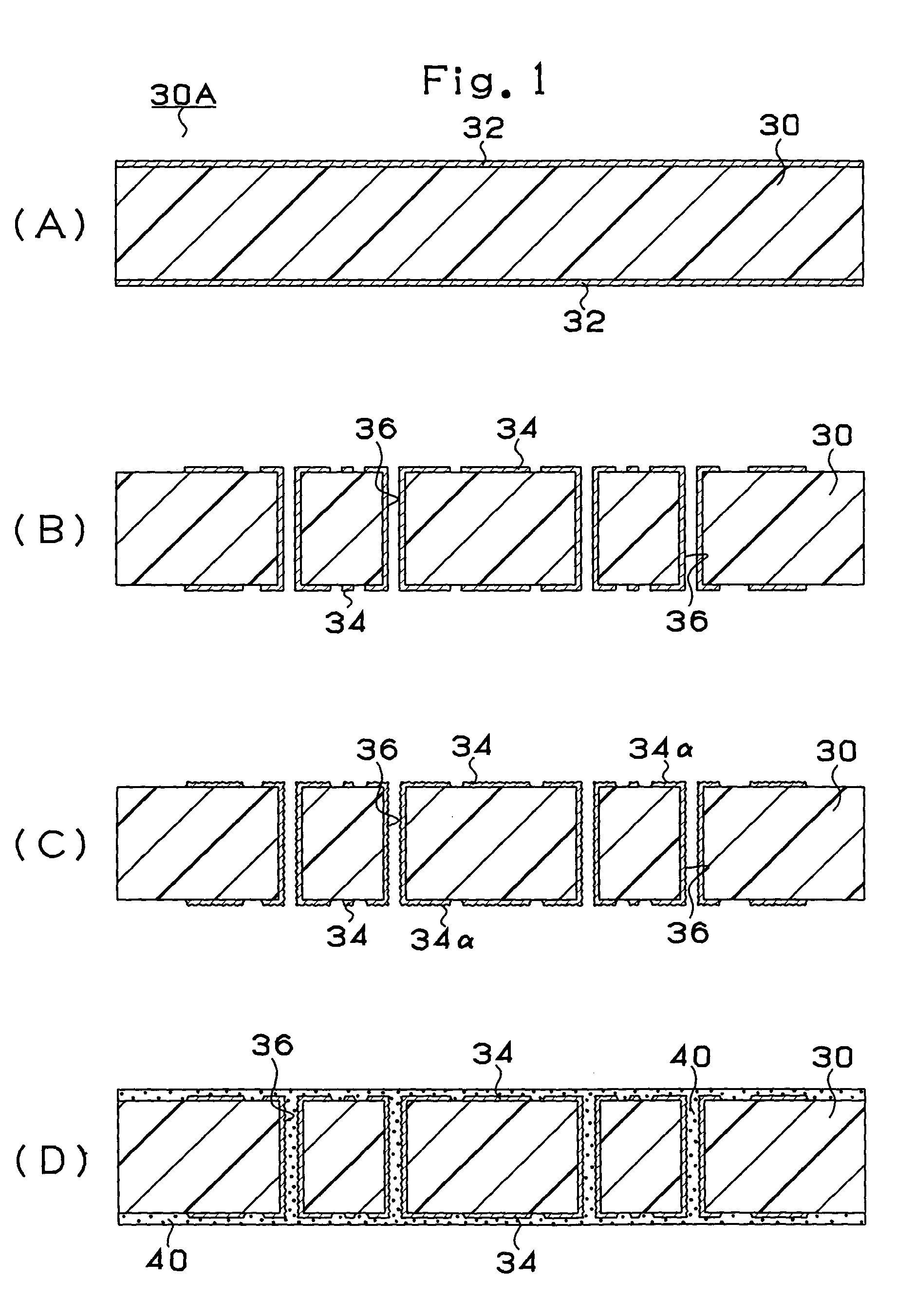

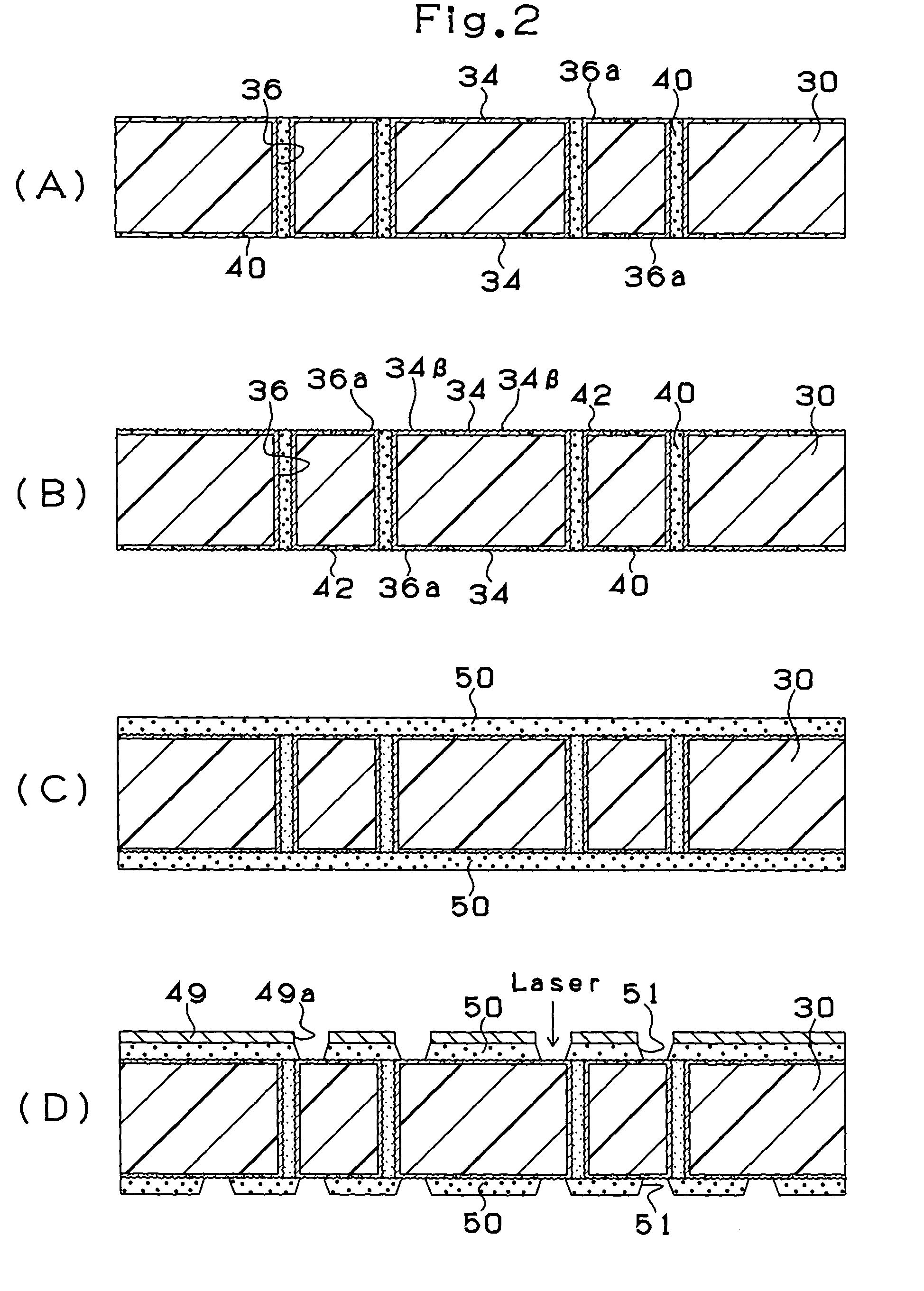

Printed wiring board and production method for printed wiring board

InactiveUS7129158B2Improve adhesionIncrease the propagation speedPrinted circuit assemblingInsulating substrate metal adhesion improvementManufacturing cost reductionElectrical conductor

A printed wiring board including solder pads excellent in frequency characteristic is provided. To do so, each solder pad 73 is formed by providing a single tin layer 74 on a conductor circuit 158 or a via 160. Therefore, a signal propagation rate can be increased, as compared with a printed wiring board of the prior art on which two metal layers are formed. In addition, due to lack of nickel layers, manufacturing cost can be decreased and electric characteristics can be enhanced.

Owner:IBIDEN CO LTD

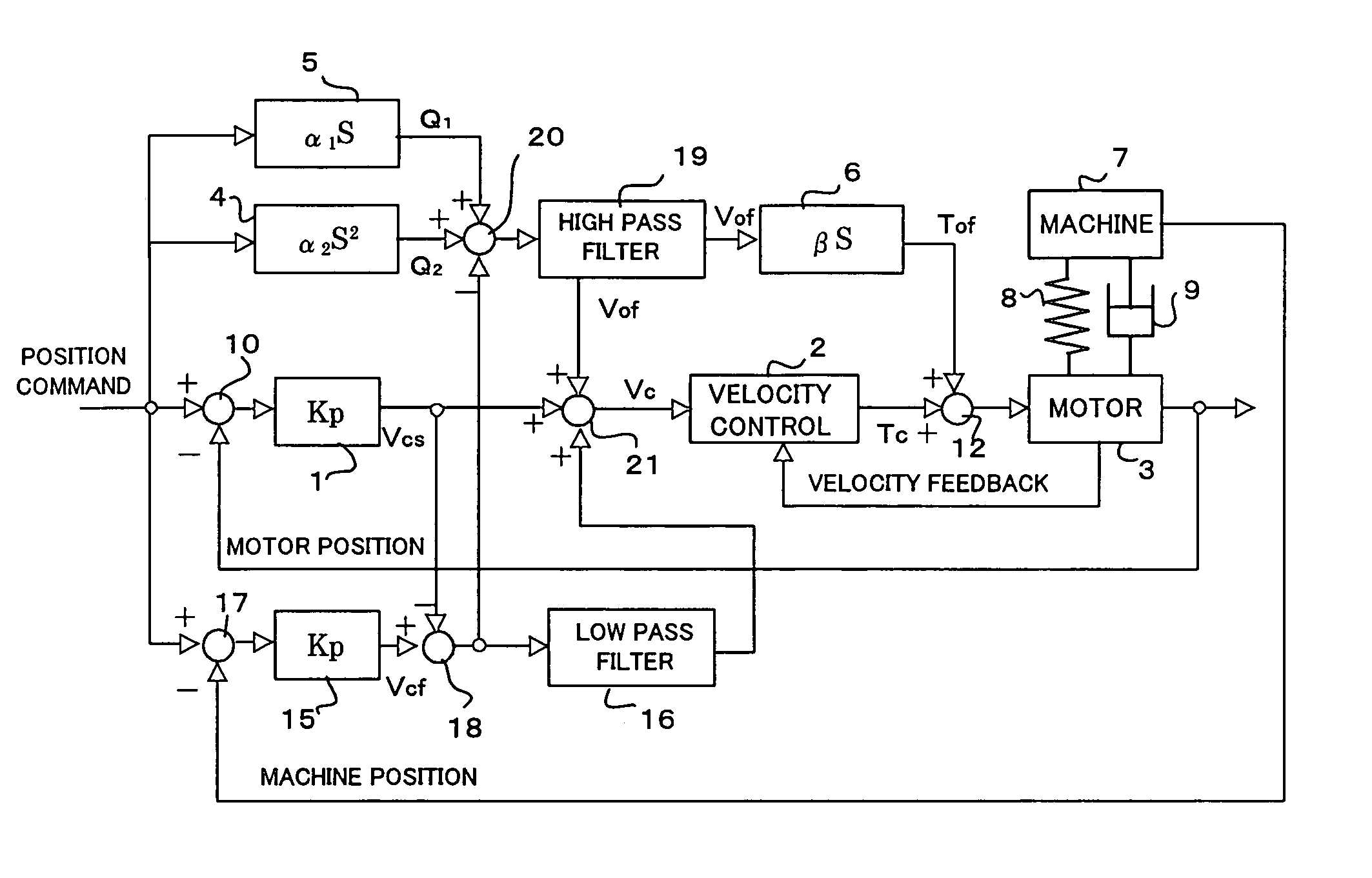

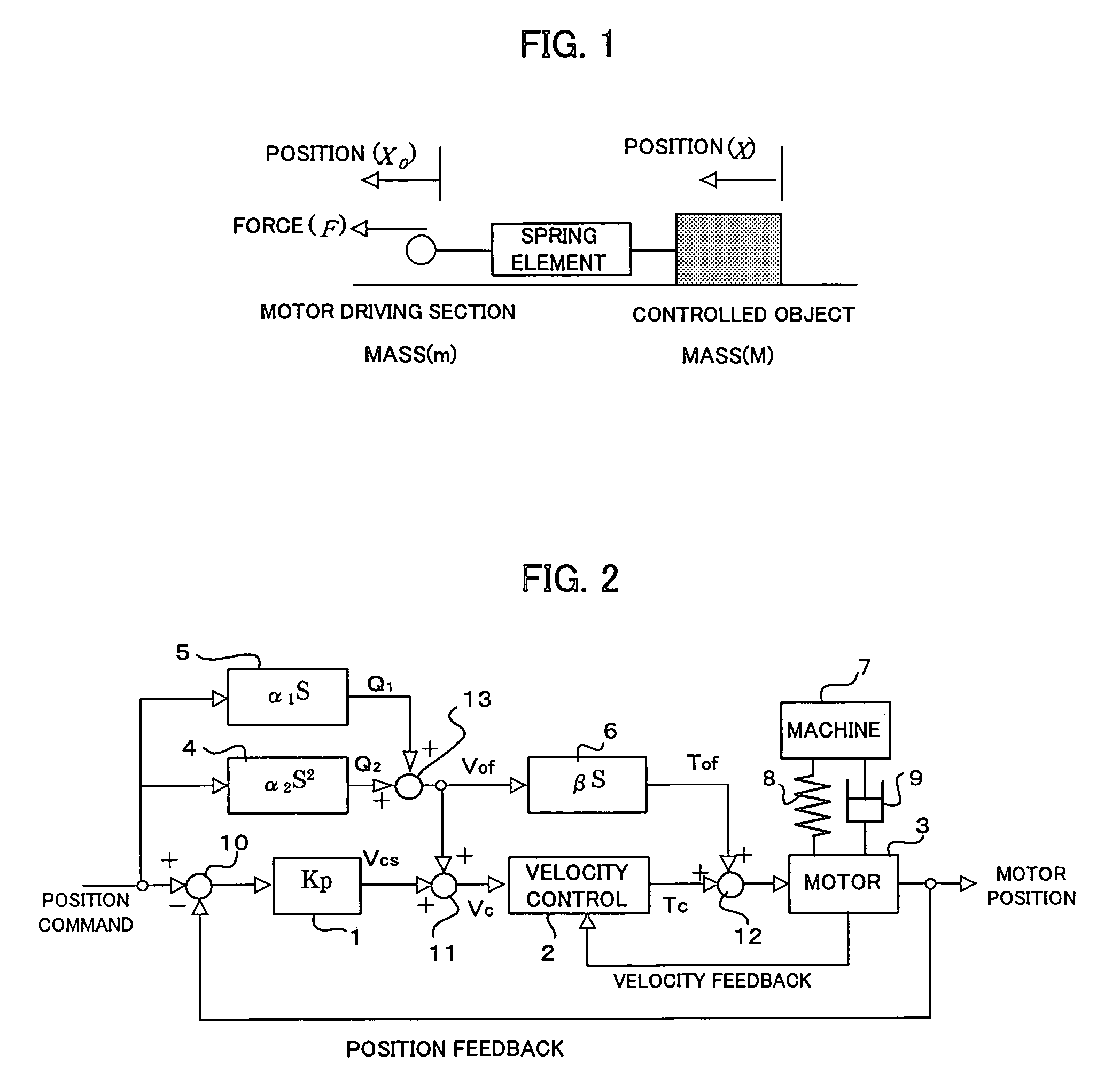

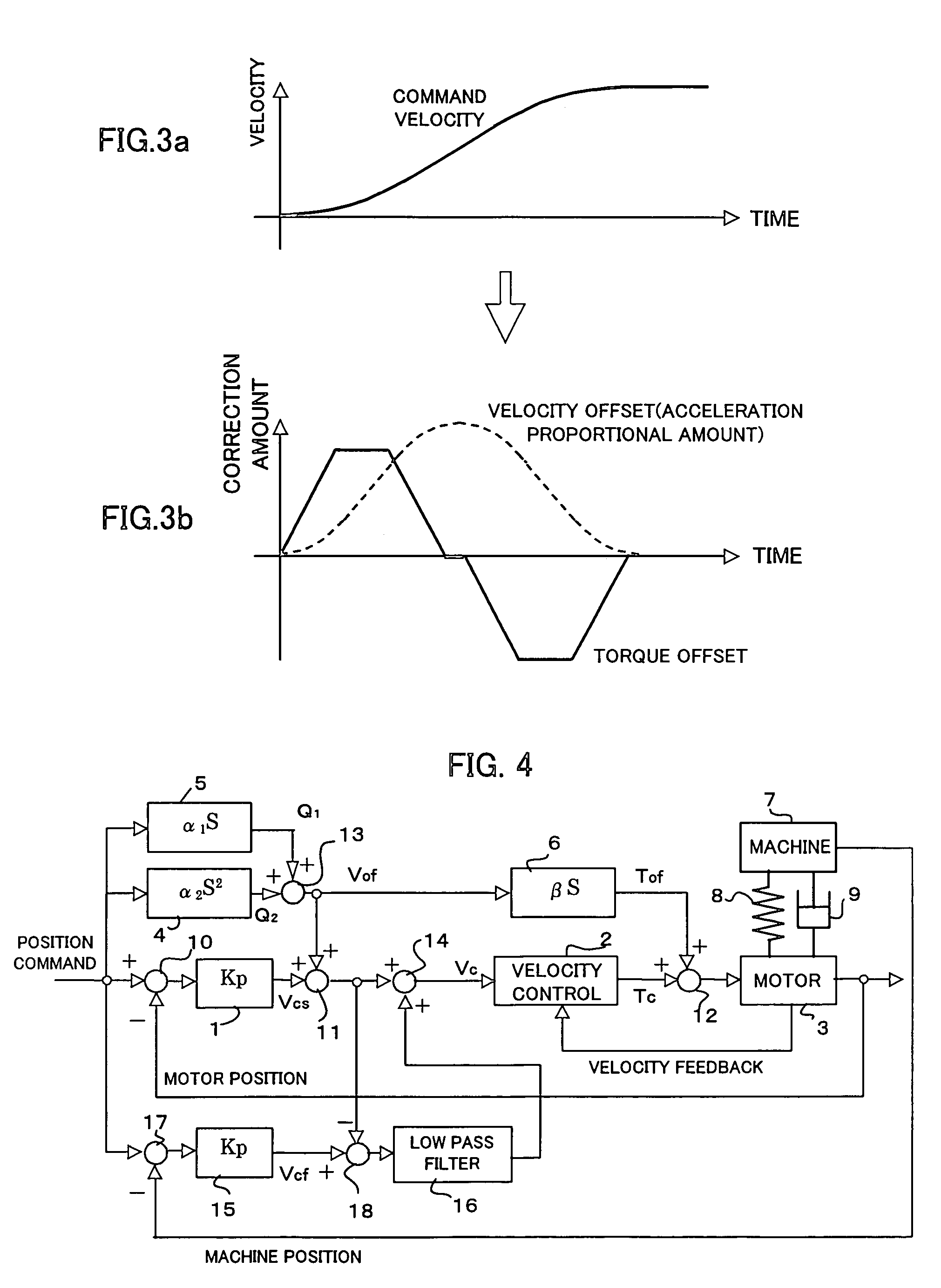

Controller

ActiveUS7030585B2Suppression delayReduce delaysElement comparisonFeeding apparatusLoop controlResponse delay

A controller capable of preventing response delay and generation of vibrations attributable thereto during position control of a movable part of a machine having low rigidity. A motor for driving a machine having low rigidity is subjected to position and velocity loop control. Compensation amount Q1 proportional to command velocity obtained by differentiating a position command and compensation amount Q2 proportional to second-order differentiated command acceleration are obtained. Compensation amounts Q1 and Q2 are added together, thus obtaining a velocity offset amount Vof corresponding to a estimated torsion amount. A differentiated value of the velocity offset amount is multiplied by coefficient β to obtain a torque offset amount Tof. The velocity offset amount Vof is added to a velocity command Vcs obtained by position loop control 1. The torque offset amount Tof is added to a torque command Tc outputted in velocity loop control 2, and the result is used as a drive command to the motor. Based on the velocity and the torque offset amount Vof and Tof, a torsion amount between motor 3 and the machine is controlled. The machine position and velocity are controlled with accuracy by regular position and velocity loop control.

Owner:FANUC LTD

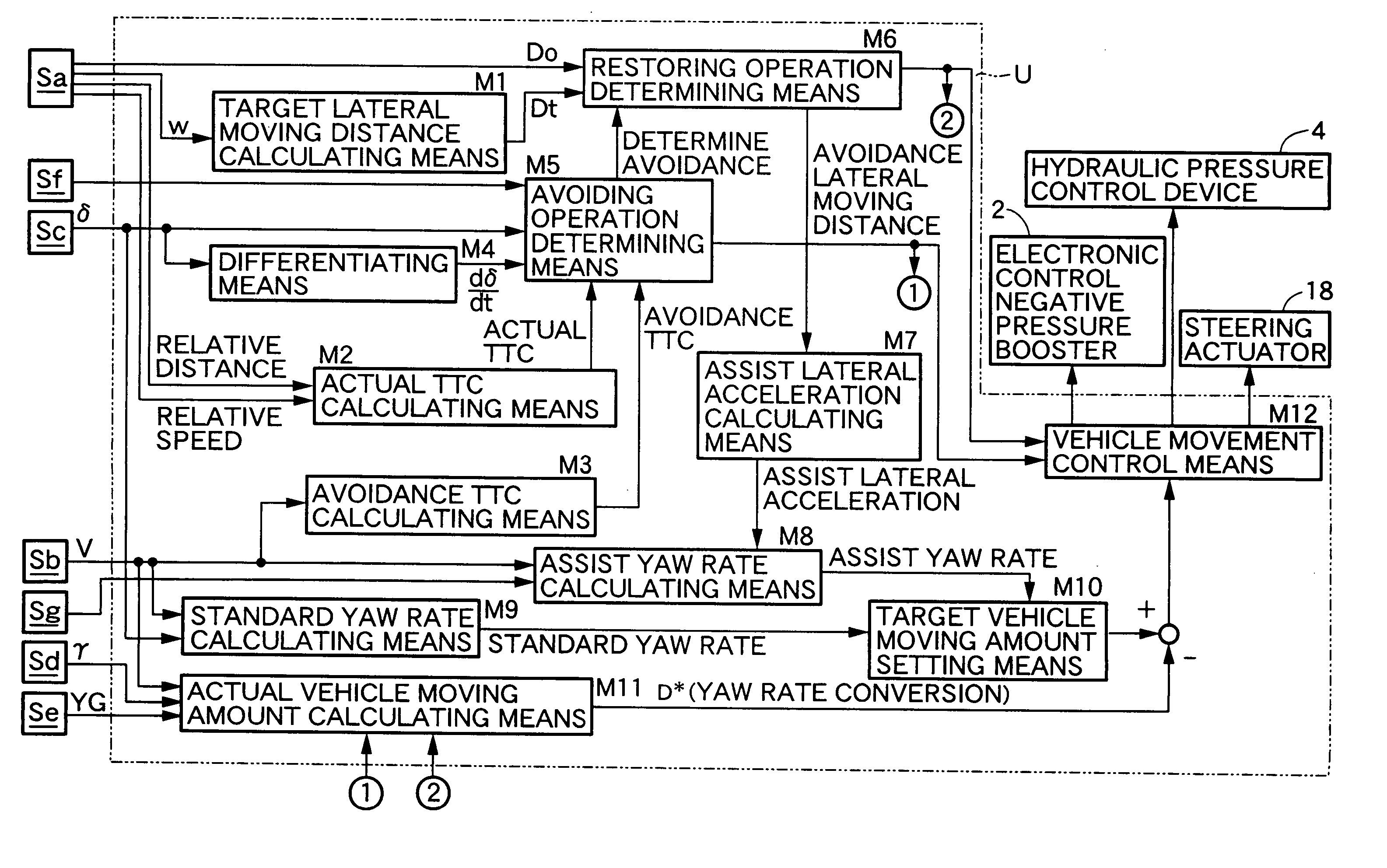

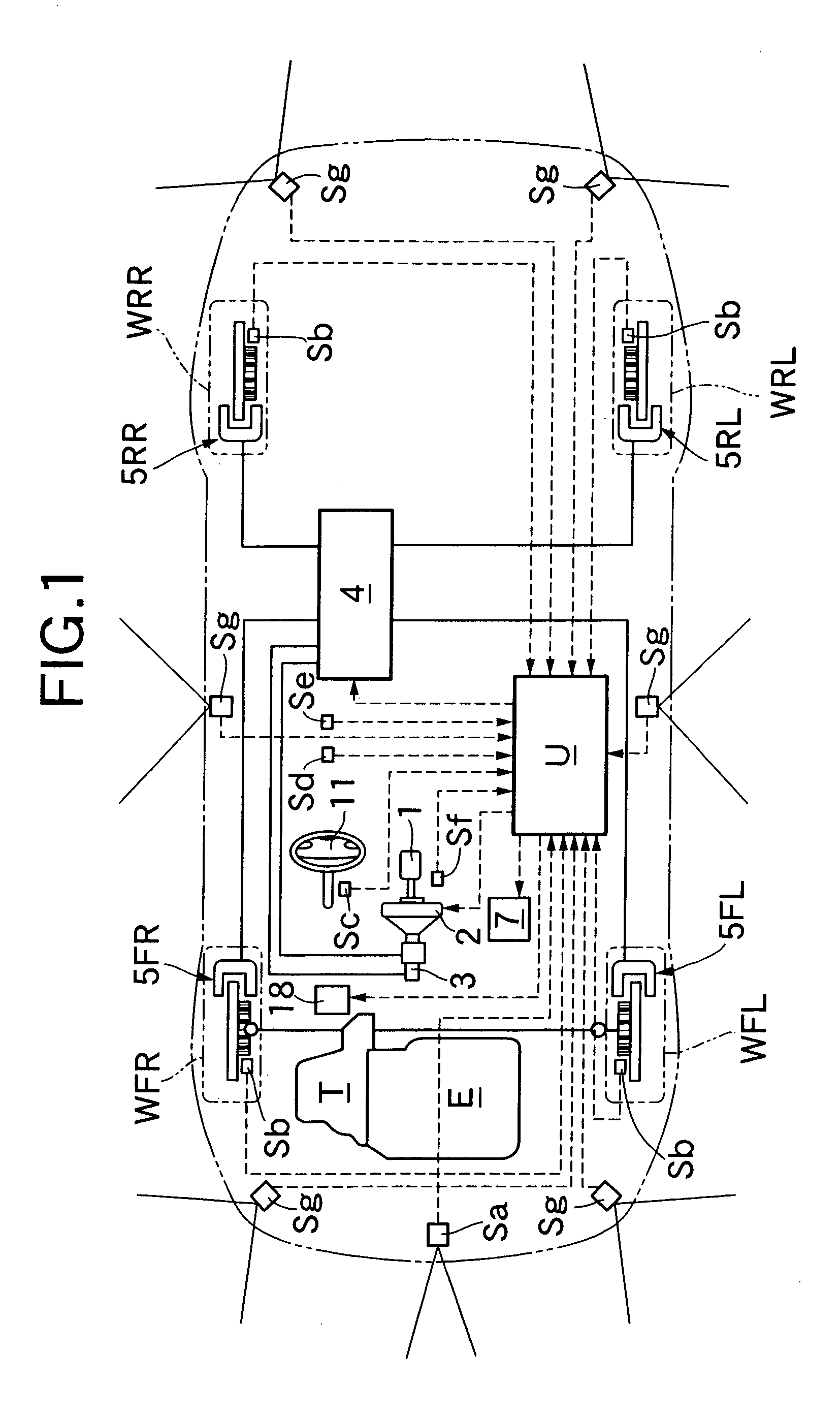

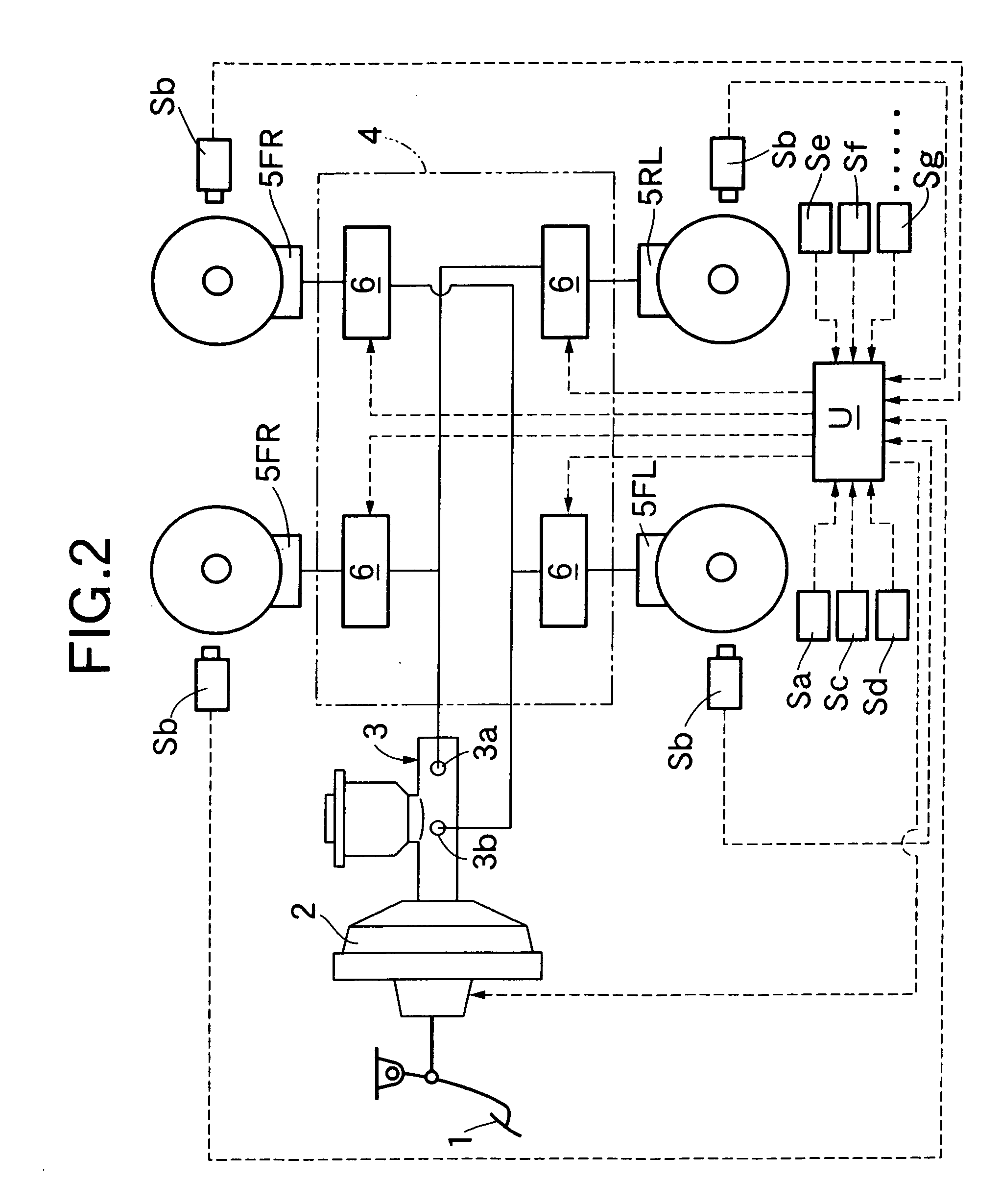

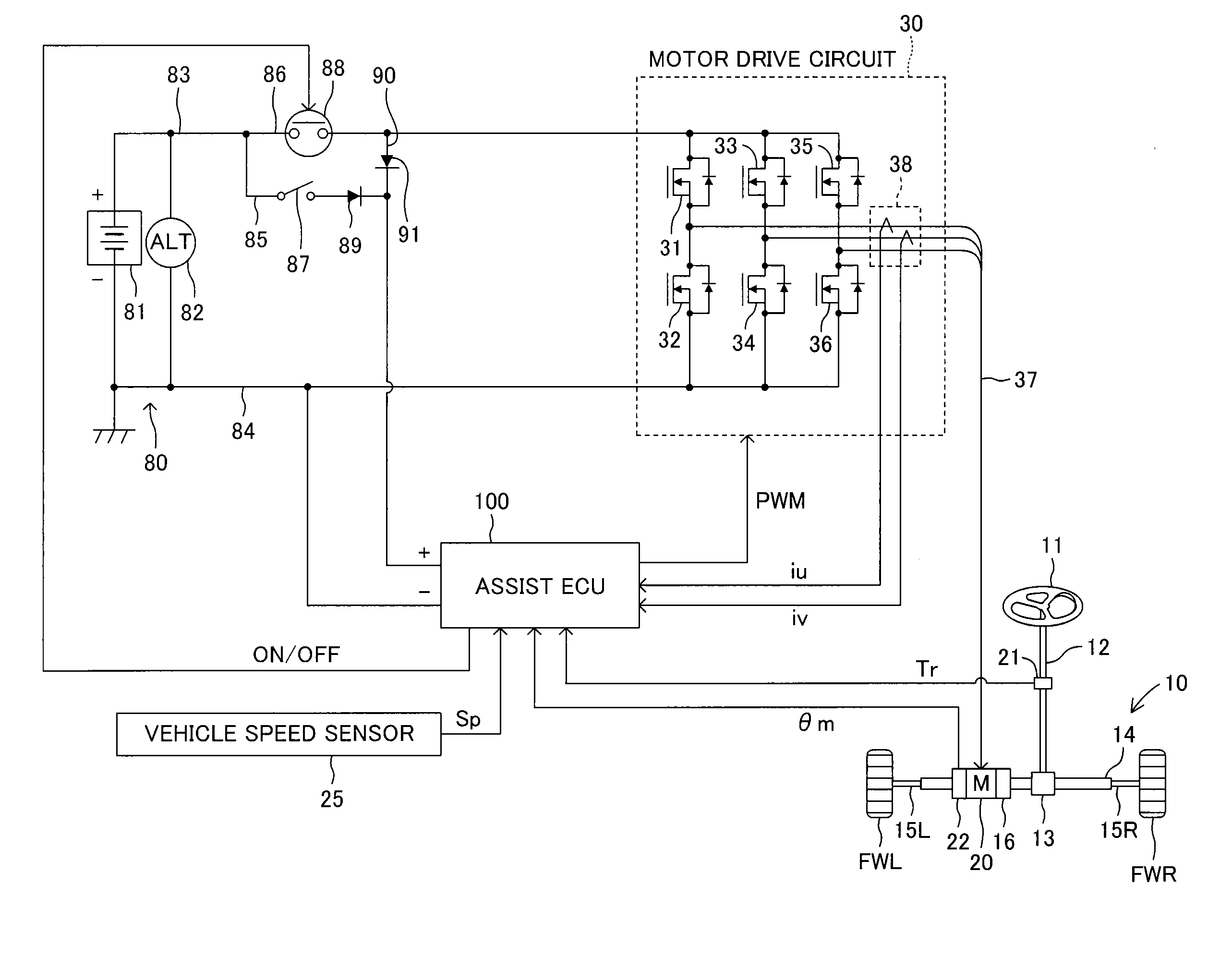

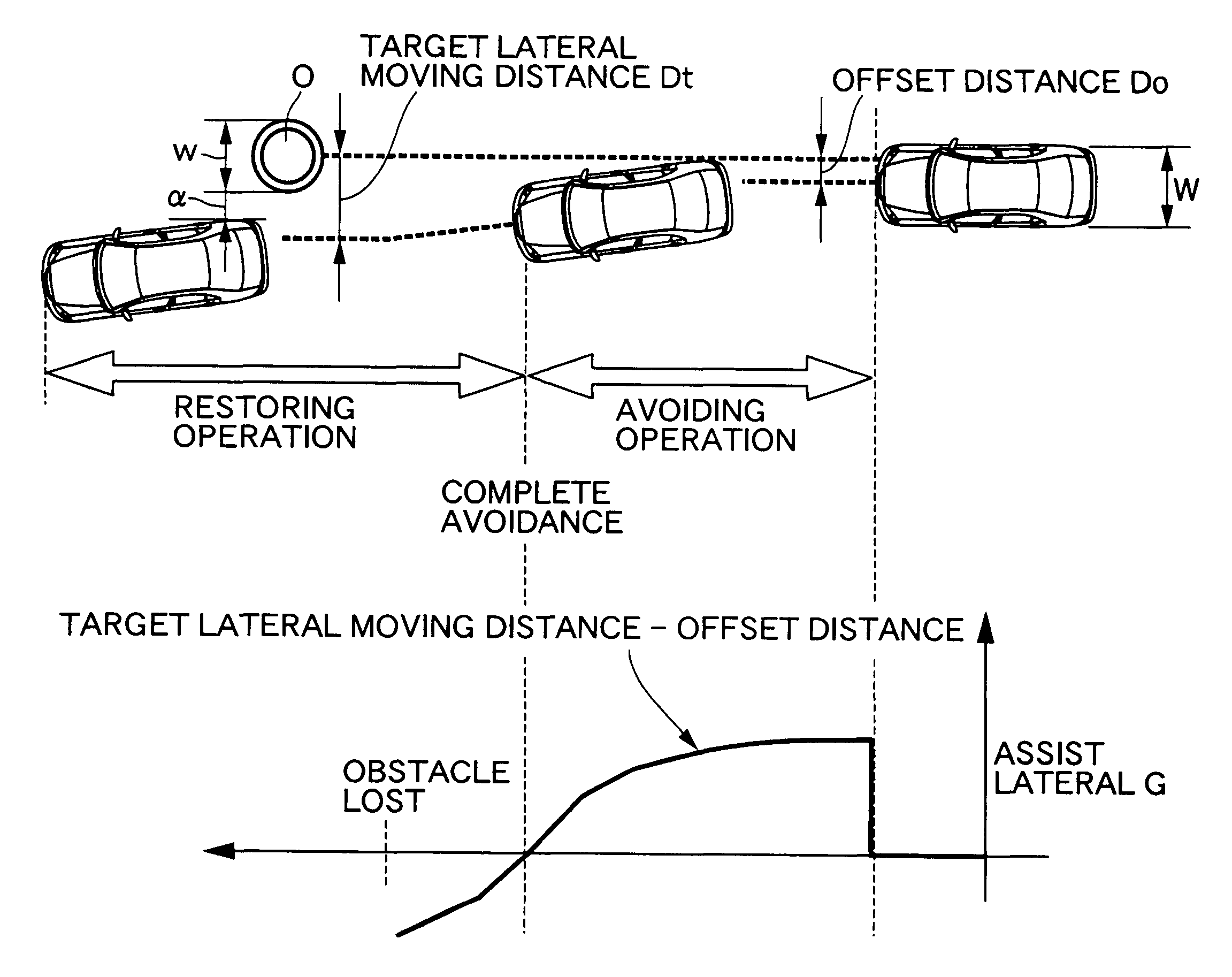

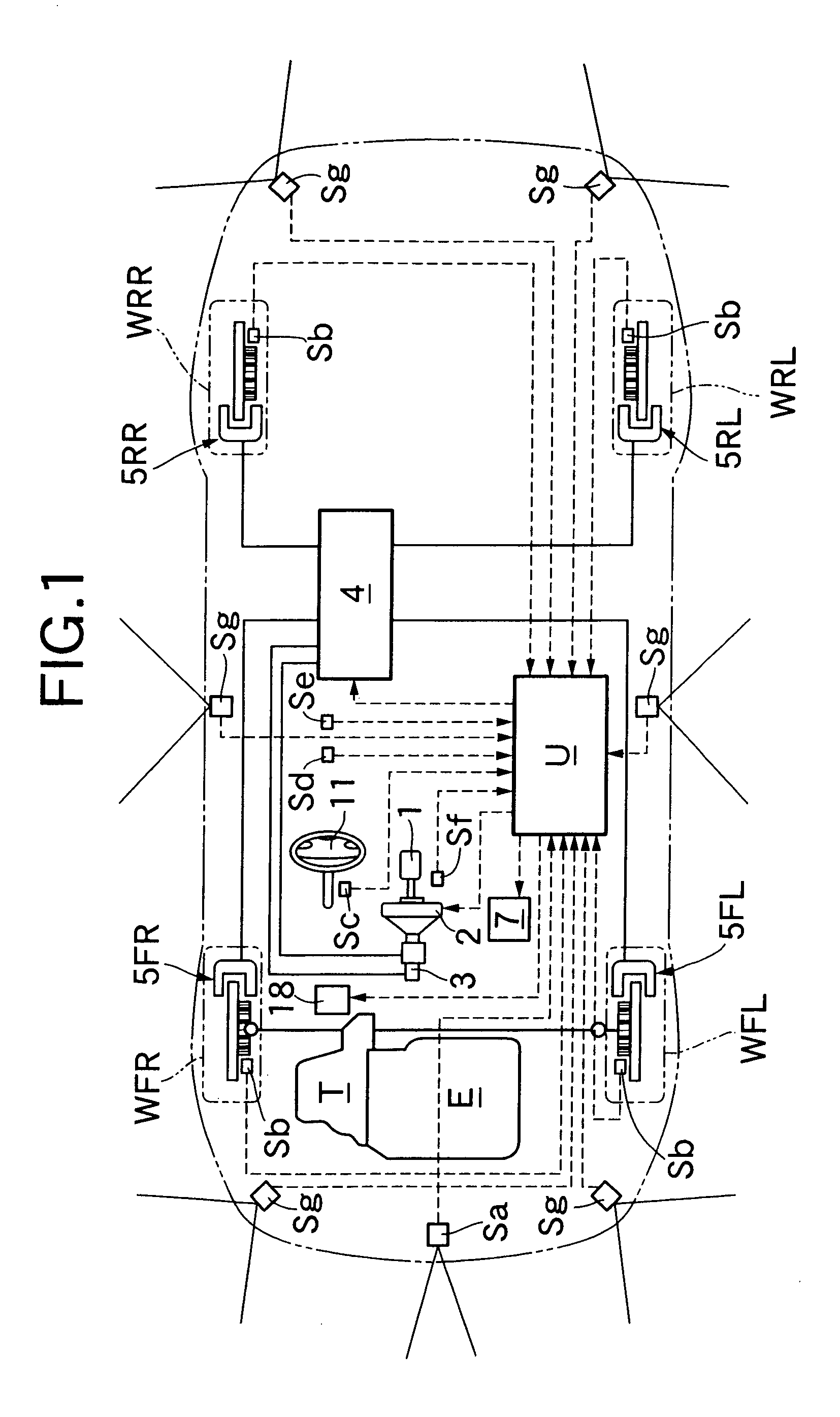

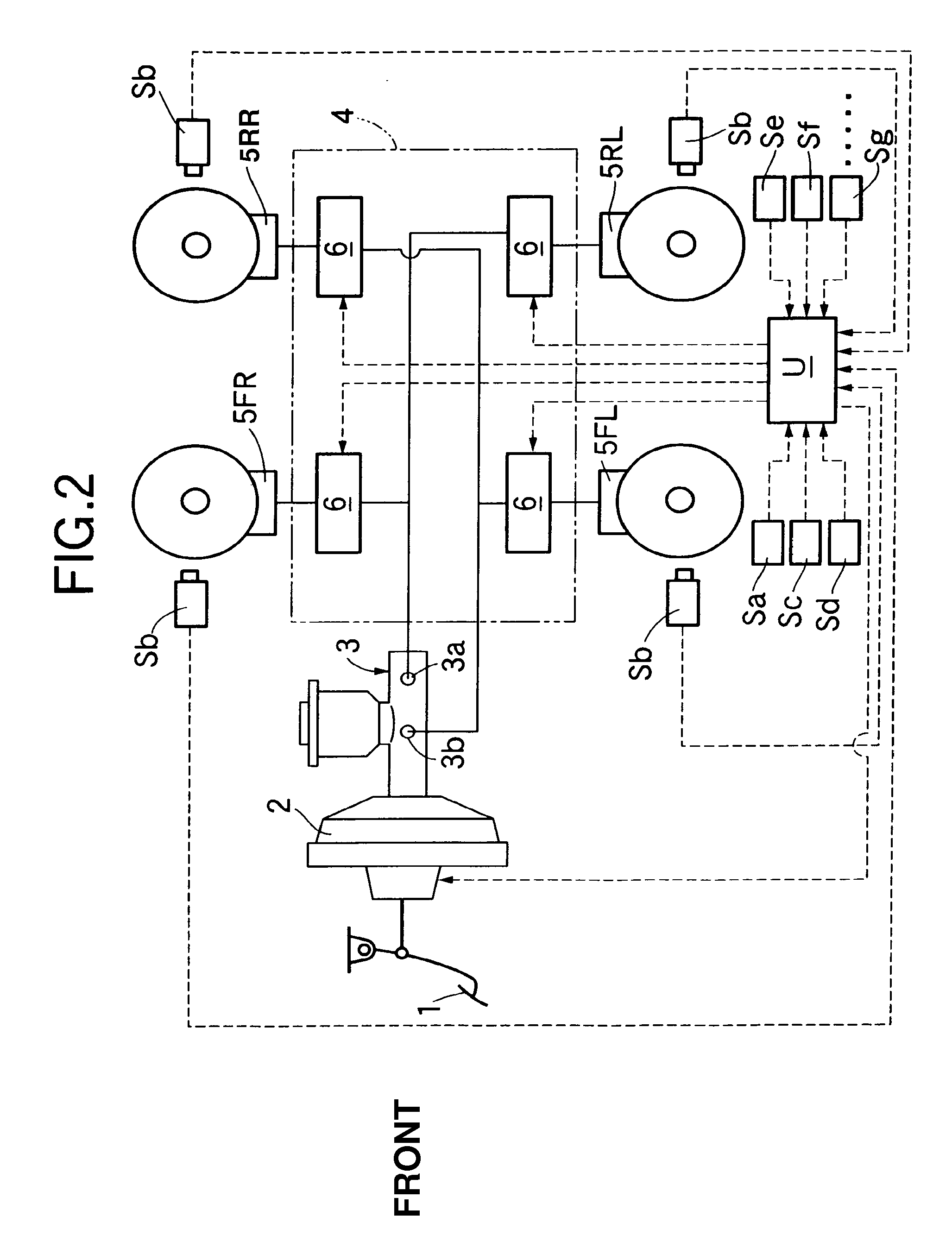

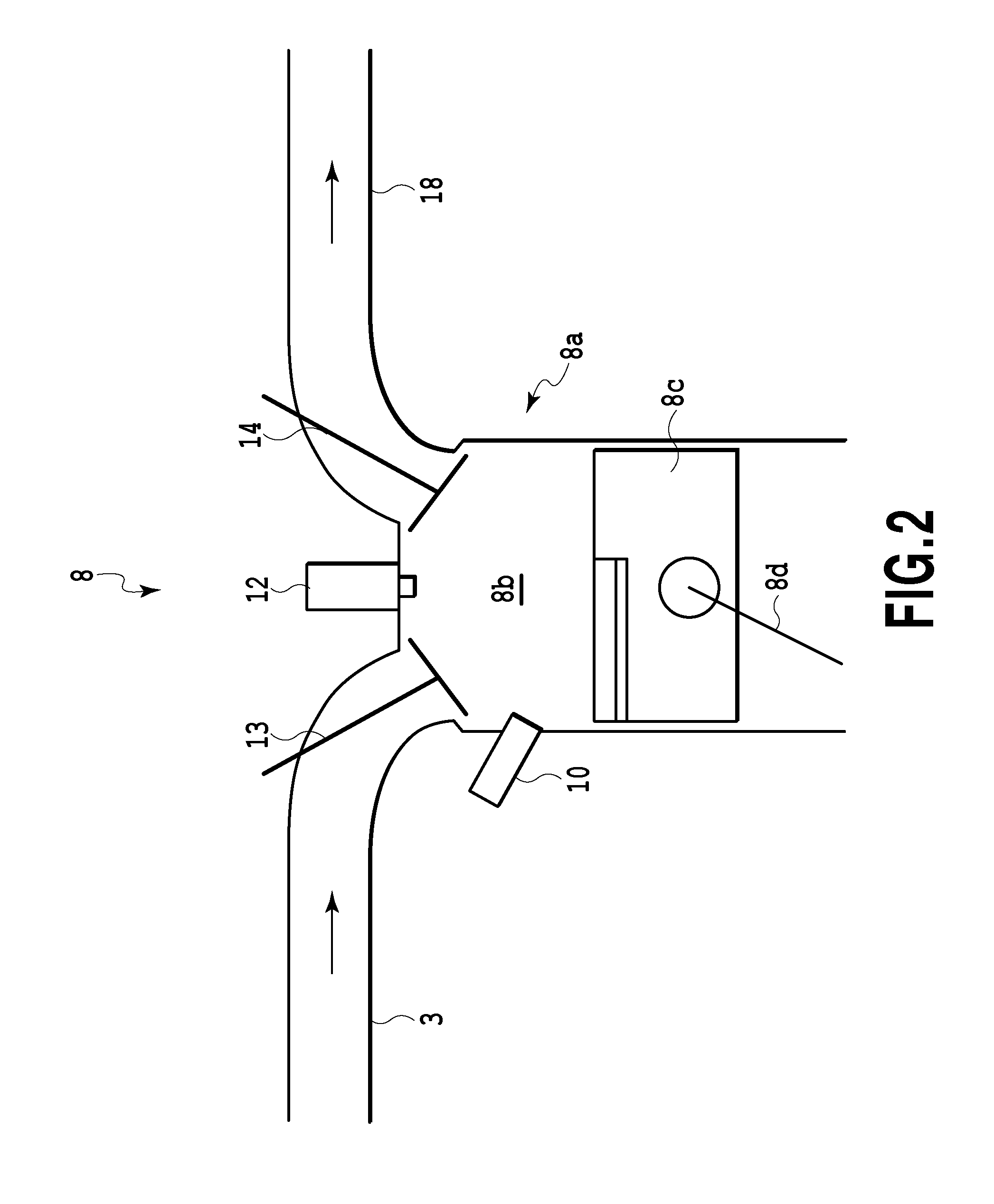

Vehicle operation assisiting system

InactiveUS20050267660A1Reduce stepsStabilizing the vehicle behaviorDigital data processing detailsAnti-collision systemsVehicle behaviorDriver/operator

A vehicle operation assist system includes an assist yaw rate calculator which calculates a necessary moving amount to avoid an obstacle based on a detection result of the obstacle by a radar device, and a vehicle movement controller controls lateral movement of the vehicle based on the calculated moving amount. When an avoiding operation detector determines initiation of an obstacle avoiding operation by the driver, the vehicle movement controller operates a braking device to control the lateral movement of the vehicle, so that the obstacle can be reliably avoided. When a restoring operation detector determines initiation of a restoring operation, the vehicle movement controller operates a power steering device to control the lateral movement of the vehicle, so that delay in the steering operation by the driver, and excessive restoring operation of the steering handle to compensate for the delay are suppressed, thus stabilizing vehicle behavior. A vehicle operation assisting system capable of properly assisting in both an obstacle avoiding operation and a restoring operation by a driver is thereby provided.

Owner:HONDA MOTOR CO LTD

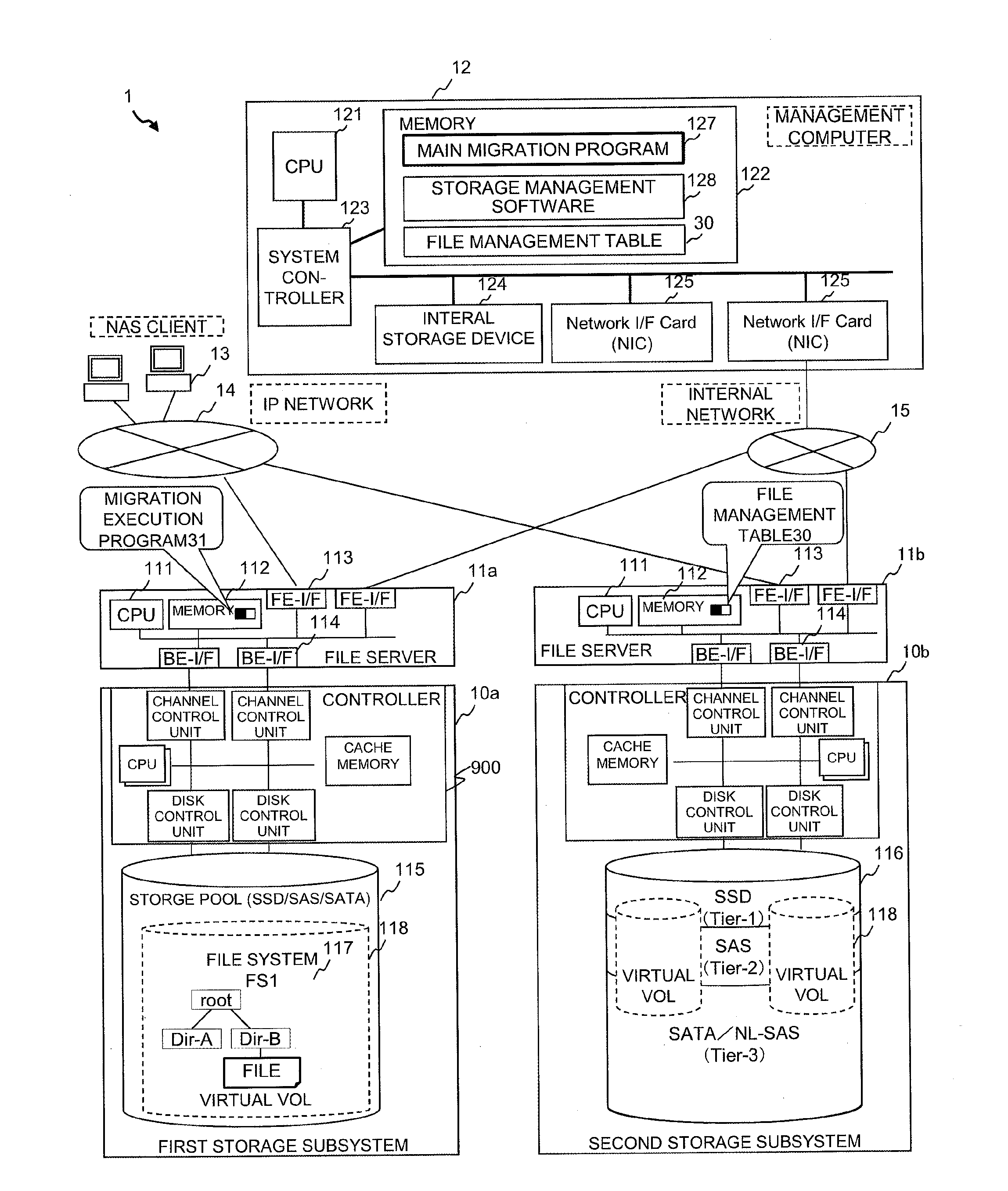

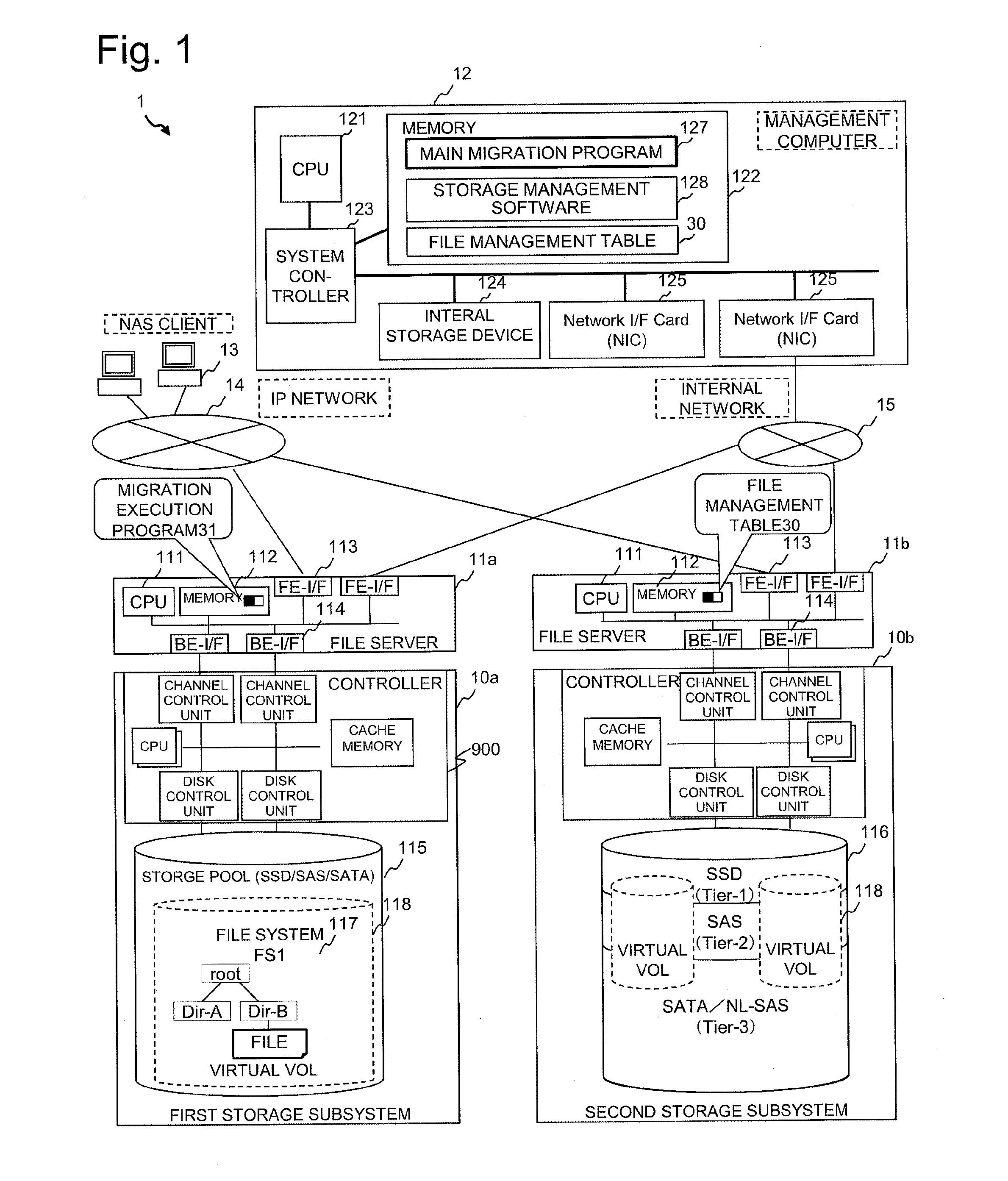

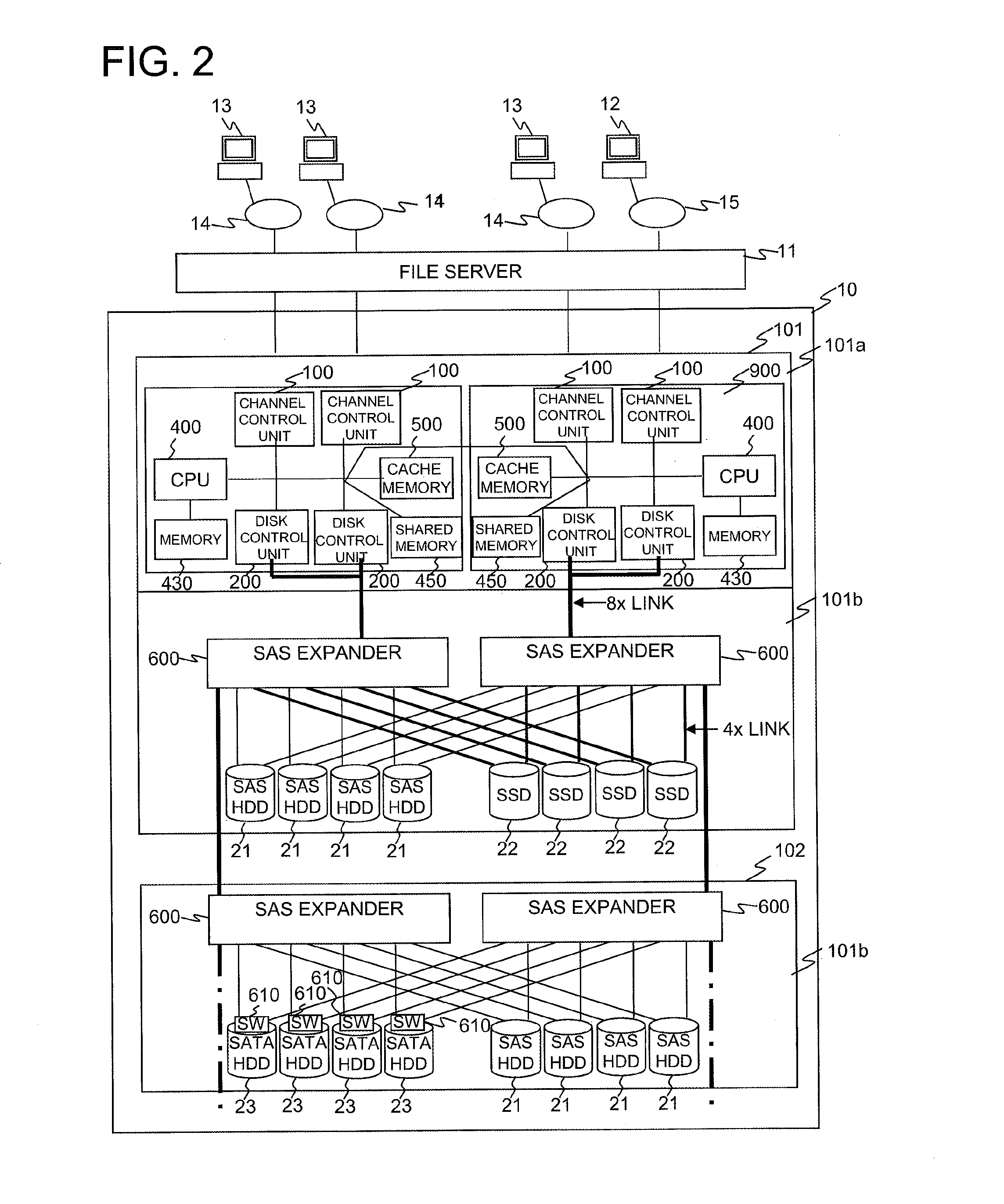

Storage system, computer system and data migration method

ActiveUS20150356078A1High frequencyOccurrence of delay of responses can be suppressedDigital data processing detailsFile access structuresTemporal informationAccess frequency

The present invention provides a storage subsystem capable of realizing efficient data migration and high access performance. During migration of data between storage subsystems, data migration methods are selected between a “PUSH” type and a “PULL” type method based on a data migration policy set in advance to perform data migration processes. An access characteristics of a file and a folder storing the file are determined based on a file access frequency or a final access date and time information in a migration source storage subsystem, and the migration order of a file group determined to have a high possibility of being accessed during data migration is changed between the “PUSH” type and the “PULL” type.

Owner:HITACHI LTD

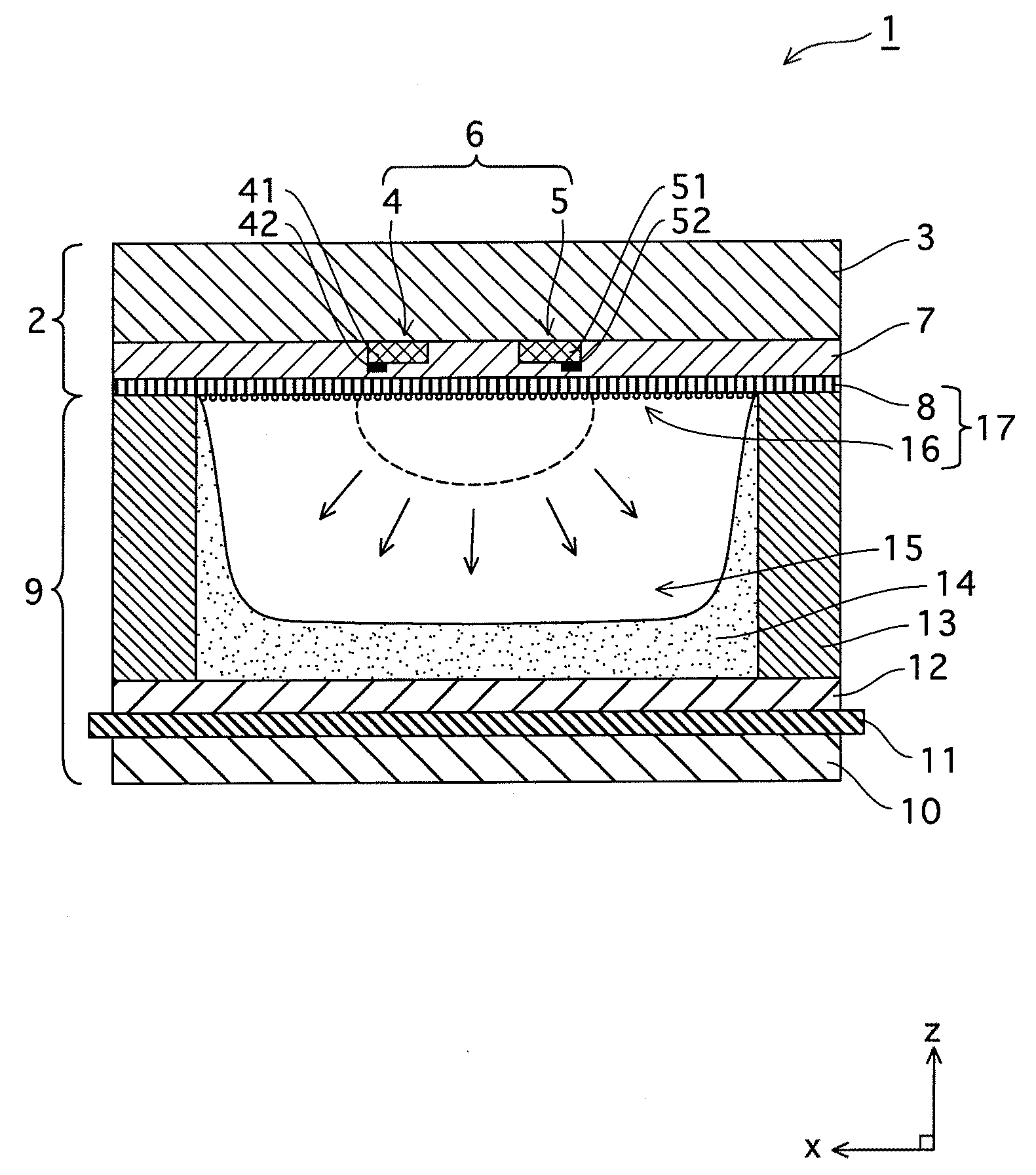

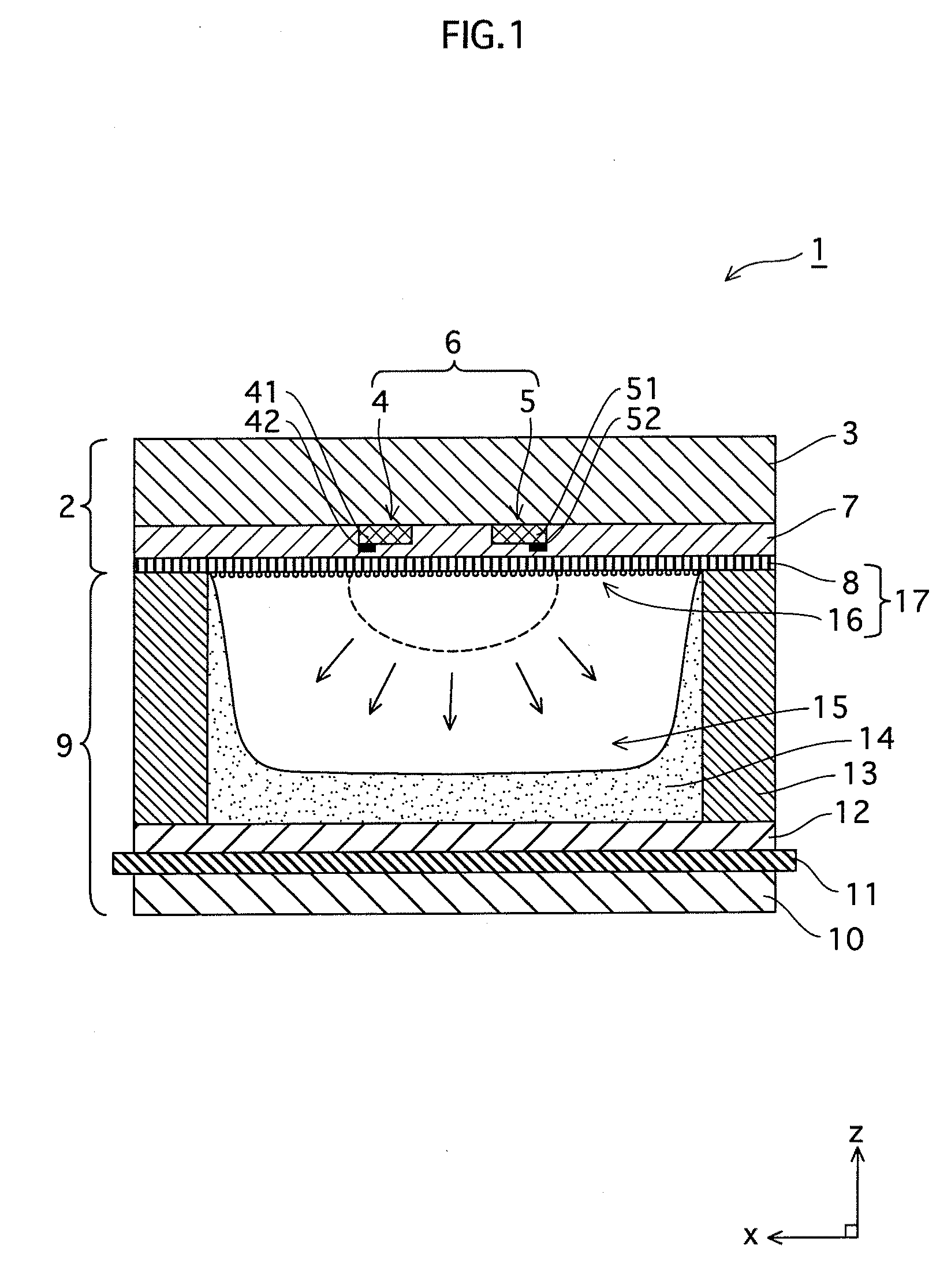

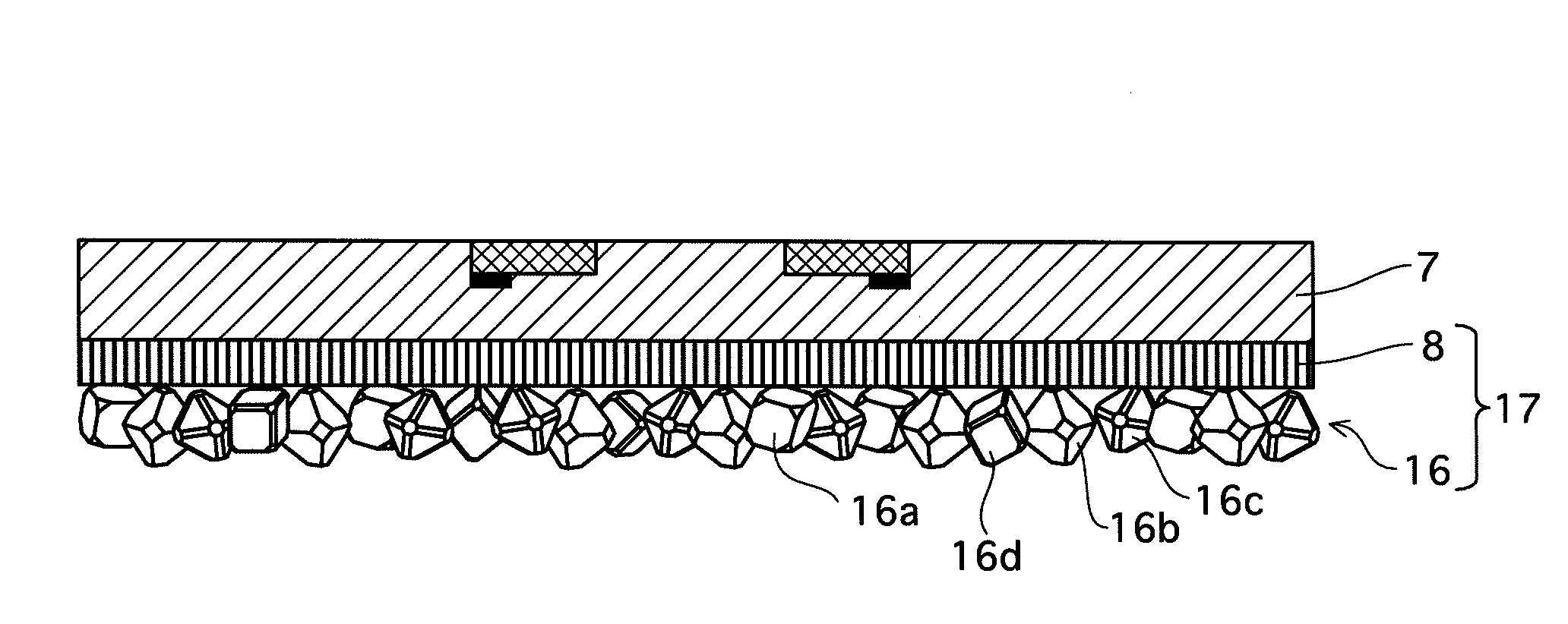

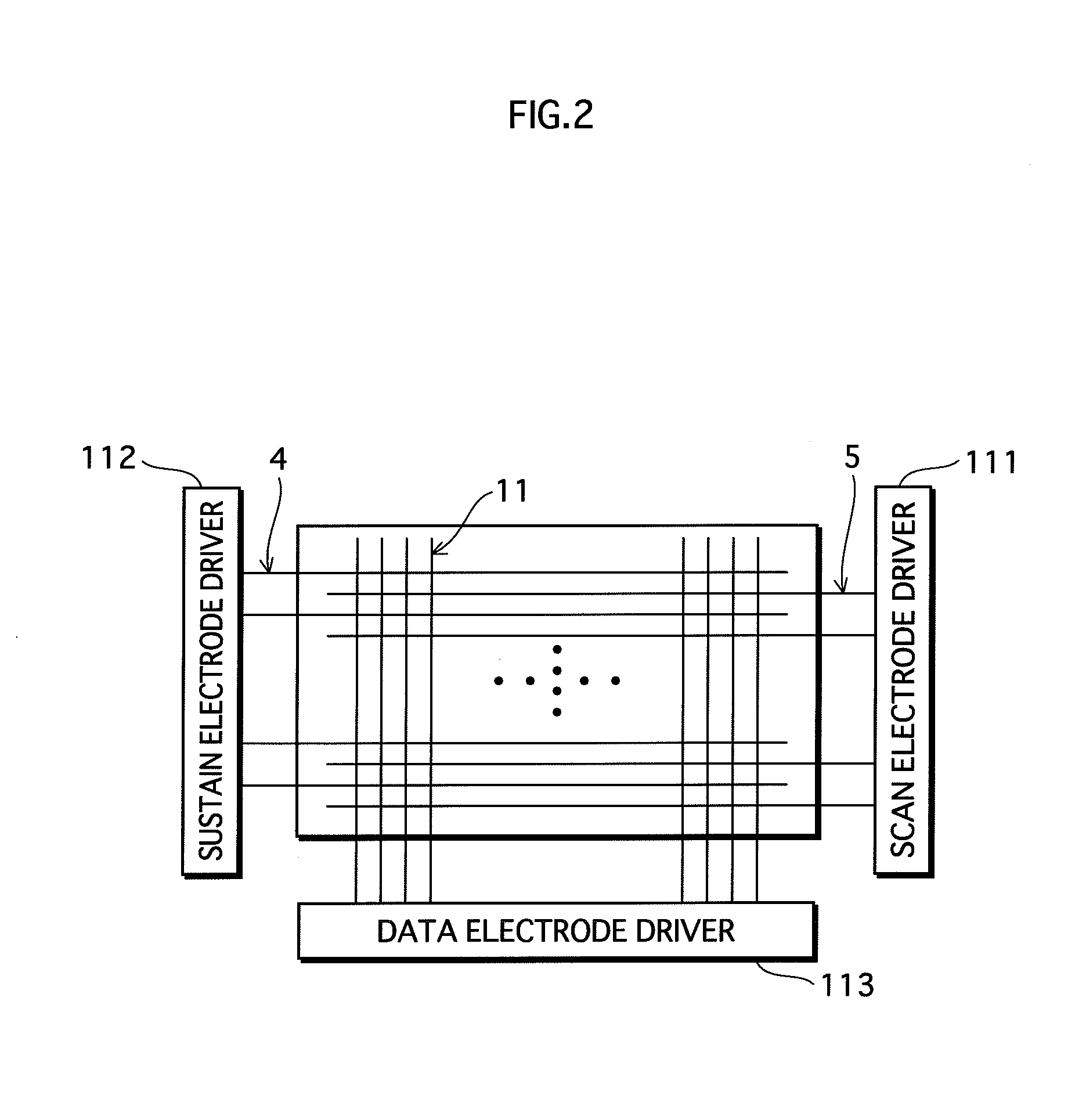

Plasma display panel and method for manufacturing the same

ActiveUS20090140652A1Large secondary electron emission coefficientLaunch evenlyTube/lamp screens manufactureAddress electrodesLow voltagePlasma display

“Discharge delay” and “dependence of discharge delay on temperatures” are solved by improving a protective layer, thus a PDP can be driven at a low voltage. Furthermore, the PDP can display excellent images by suppressing “dependence of discharge delay on space charges.” Liquid-phase magnesium alkoxide (Mg (OR)2) or acetylacetone magnesium ate whose purity is 99.95% or more is prepared, and is hydrolyzed by adding a small amount of acids to the solution. Thus, a gel of magnesium hydroxide that is a magnesium oxide precursor is formed. Burning the gel in atmosphere at 700° C. or more produces powder containing MgO particles 16a-16d having the NaCl crystal structure with (100) and (111) crystal faces or with (100), (110) and (111) crystal faces. By pasting the powder on a dielectric layer 7 or a surface layer 8, the MgO powder 16 is formed so as to serve as the protective layer.

Owner:PANASONIC CORP

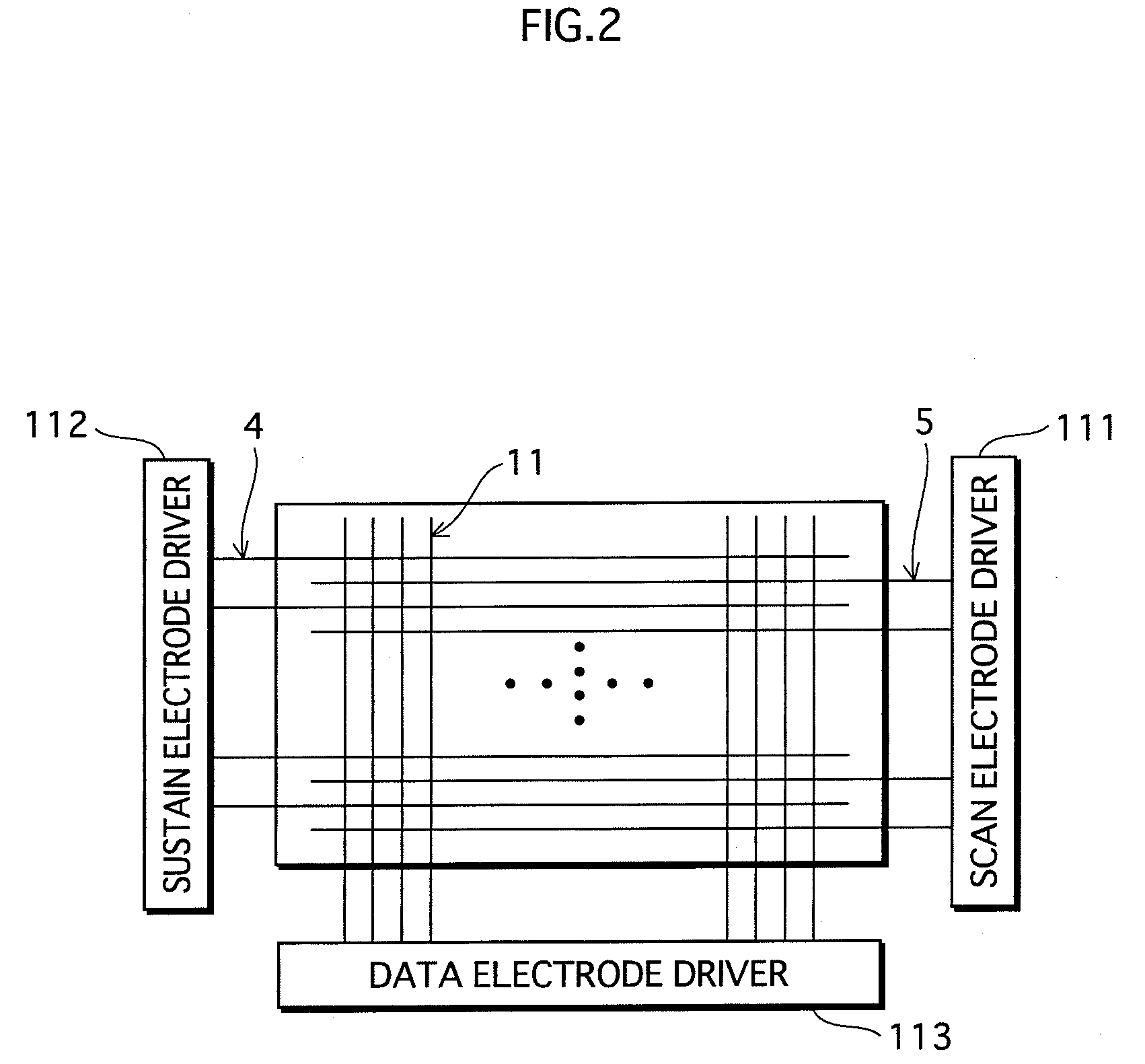

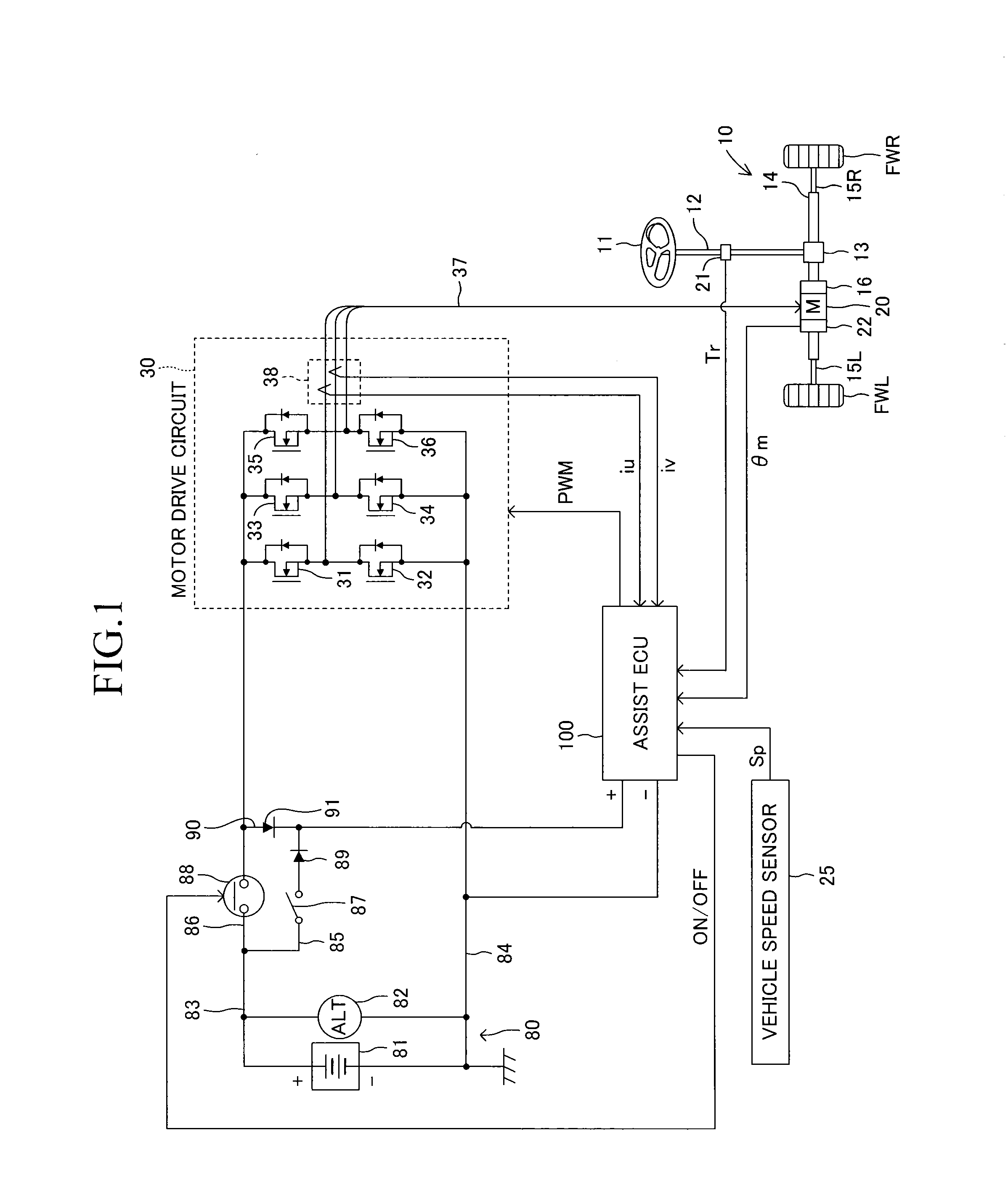

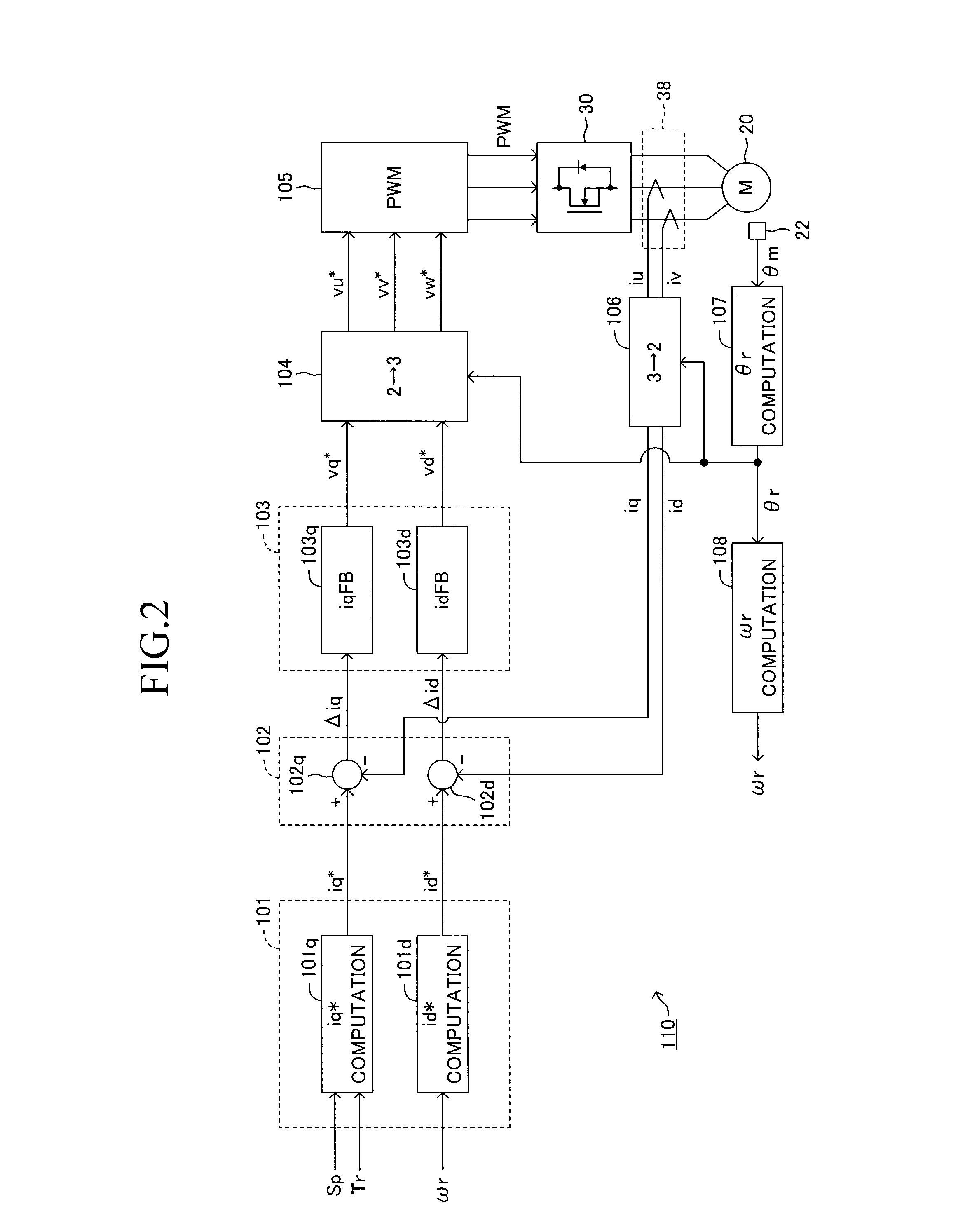

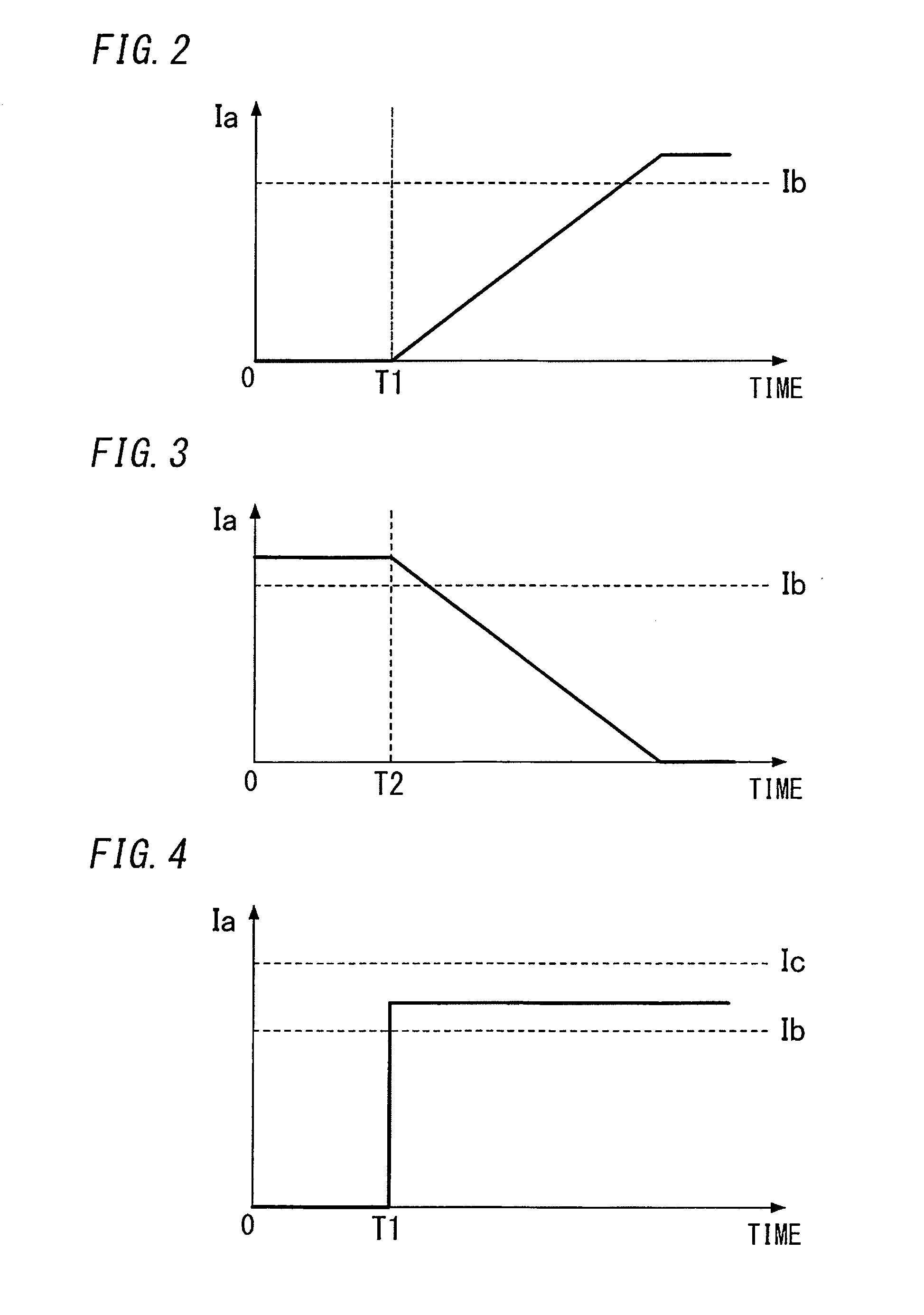

Electric power steering system

InactiveUS20130013154A1Improve performanceTorque can be increasedAC motor controlVector control systemsElectric power steeringDriver circuit

A feedforward control section computes, on the basis of a target current absolute value, a voltage limit value of a motor drive circuit, and a rotational speed ωr of a motor, a phase angle of a voltage vector which represents the output voltage of the motor drive circuit by a d-q coordinate system, the phase angle being a phase angle in relation to the d-axis of the d-q coordinate system. A feedback control section computes a phase angle based on a deviation between the target current absolute value and the actual current absolute value. A PWM control signal generation section outputs PWM control signals such that the motor drive circuit outputs a three-phase drive voltage whose electrical angle is advanced by a phase angle. Thus, in the case where a large reverse input is applied to a steering mechanism, the motor is caused to generate a large torque to thereby prevent the steering wheel from being rotated.

Owner:TOYOTA JIDOSHA KK

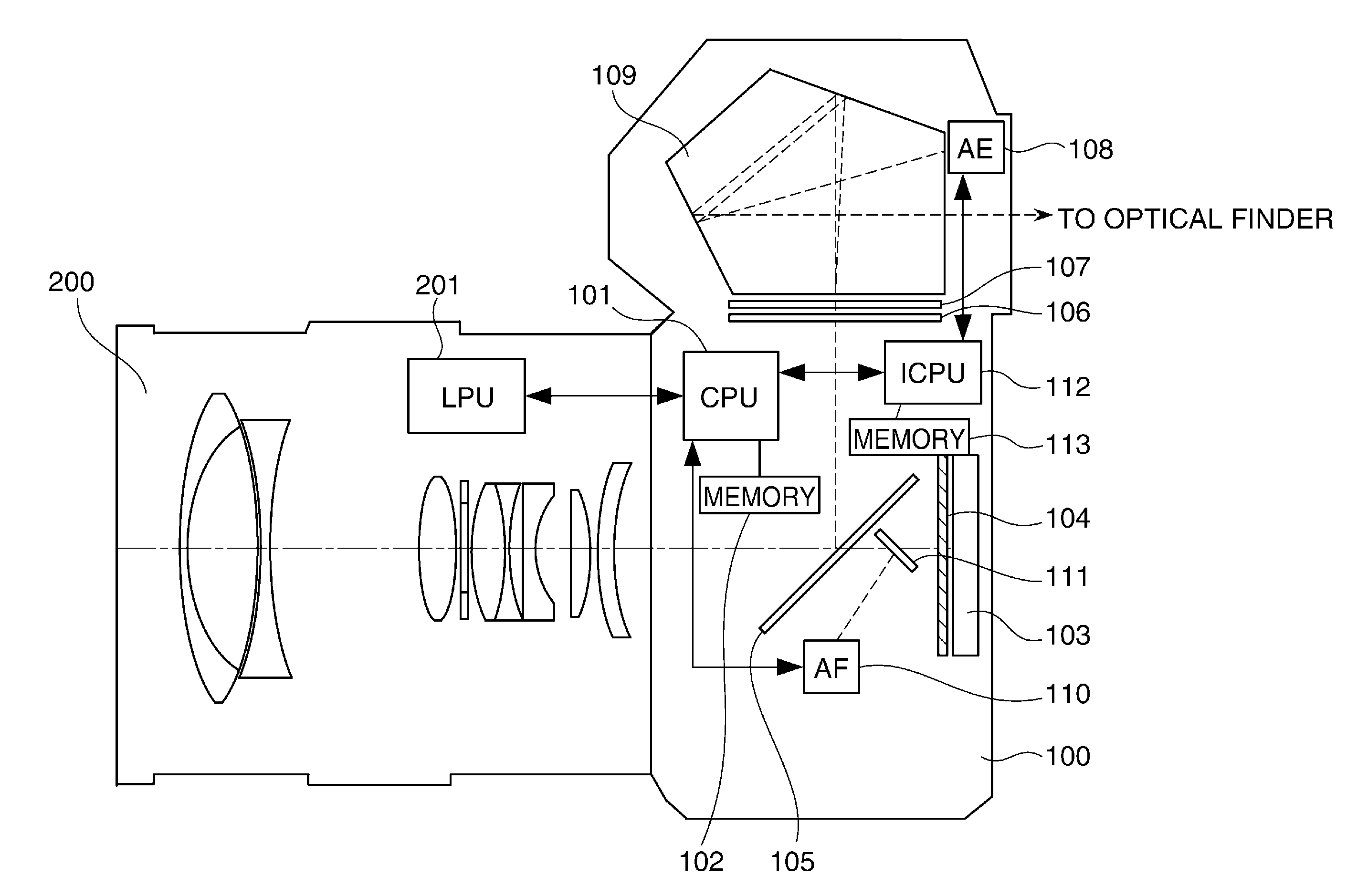

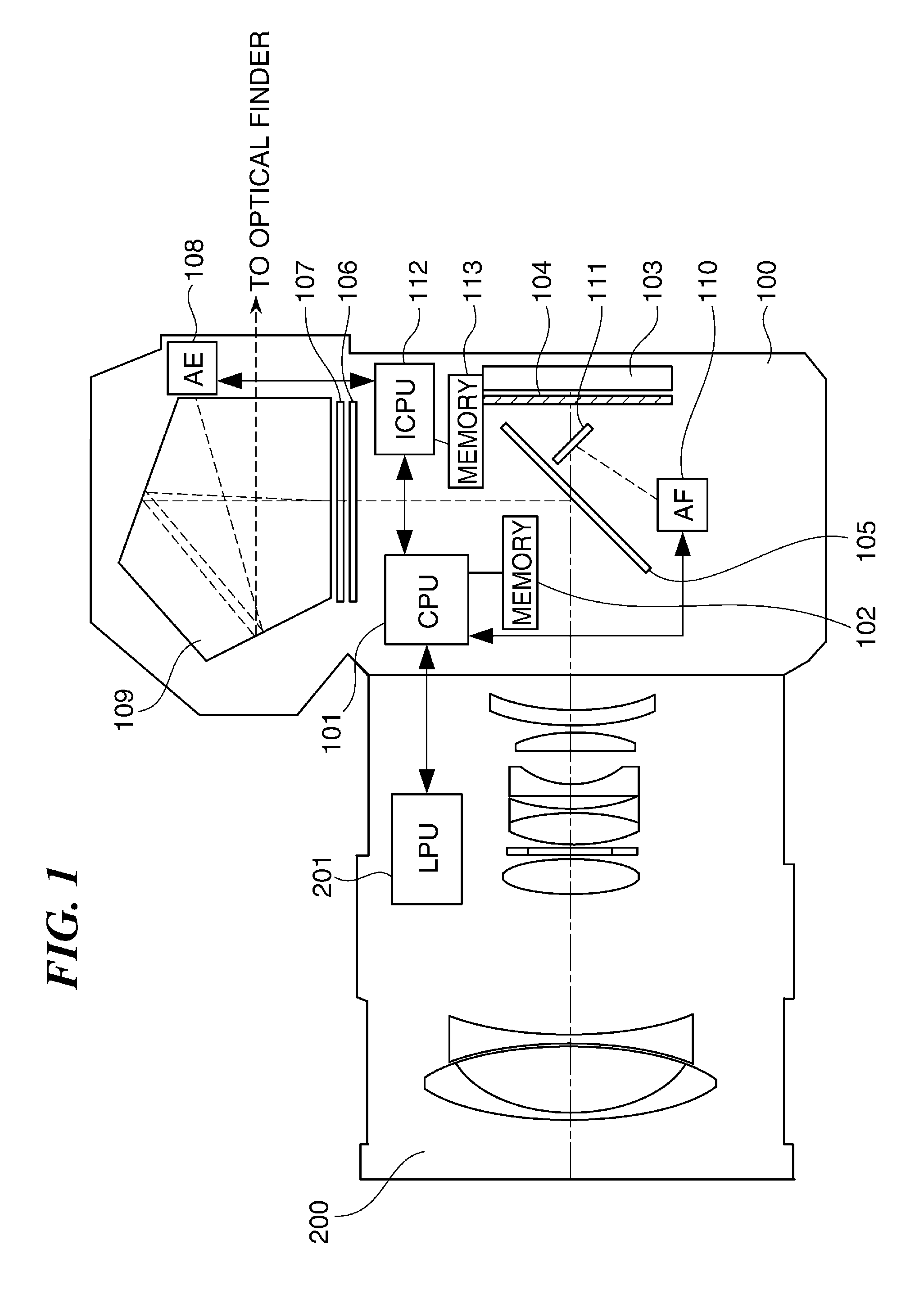

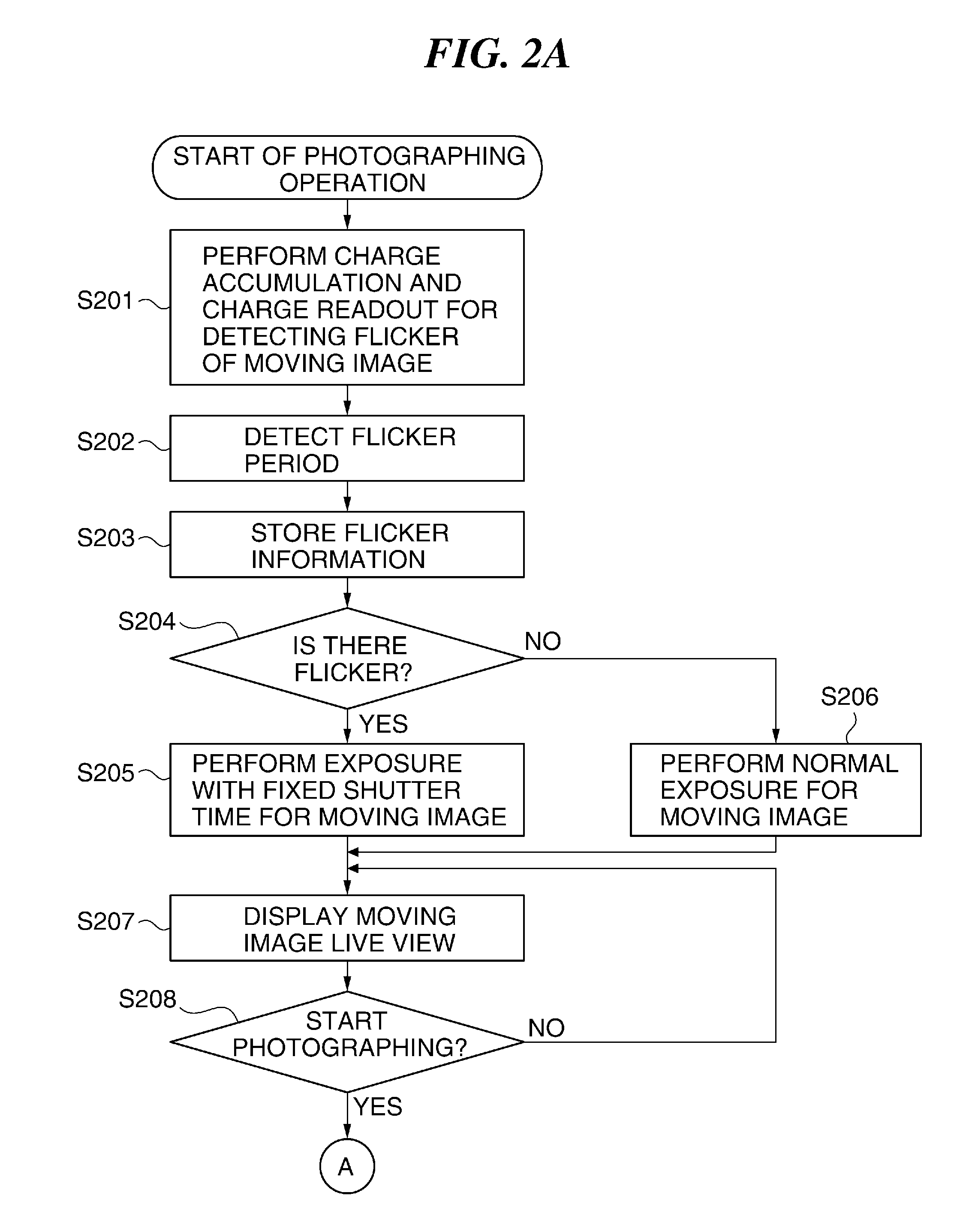

Image pickup apparatus capable of reducing influence of flicker, method of controlling the same, and storage medium

ActiveUS20160006919A1Reduce influenceReduce impactTelevision system detailsPhotometry using reference valueControl equipmentLight source

An image pickup apparatus capable of reducing influence of flicker while suppressing delay of start of photographing. An image pickup device and a photometric sensor pick up images of an object. A CPU obtains images by controlling driving of one of the device and the sensor to perform charge accumulation and charge readout. Further, the CPU detects a flicker frequency and a flicker phase of a flicker light source, and stores them in a memory as first information. When photographing, if the CPU determines that the first information is not valid, an ICPU obtains images by controlling driving of the other of them to perform charge accumulation and charge readout. Further, the ICPU detects the flicker frequency and the flicker phase and stores them in a memory as second information. The CPU controls exposure timing according to the second information to perform photographing.

Owner:CANON KK

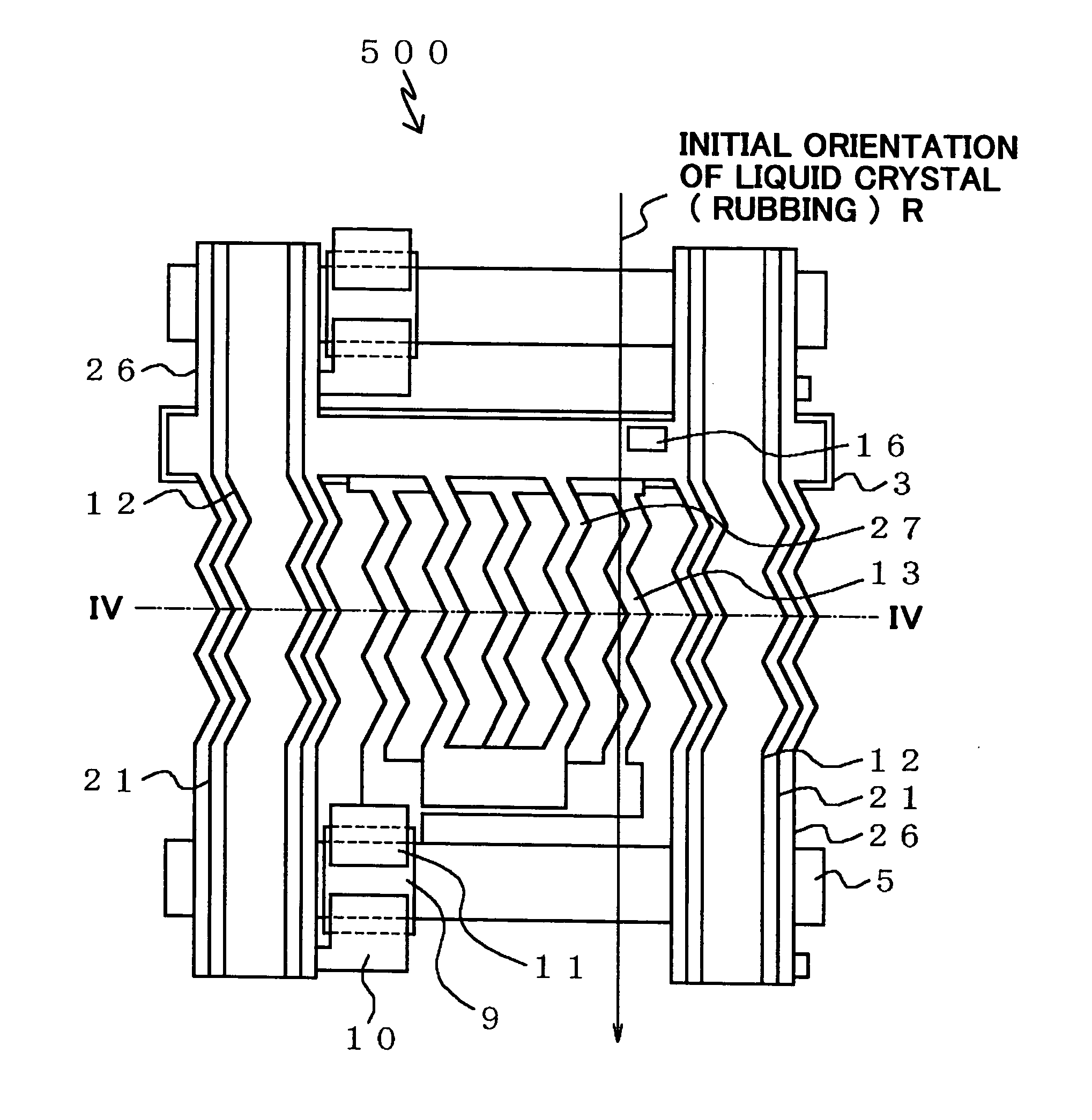

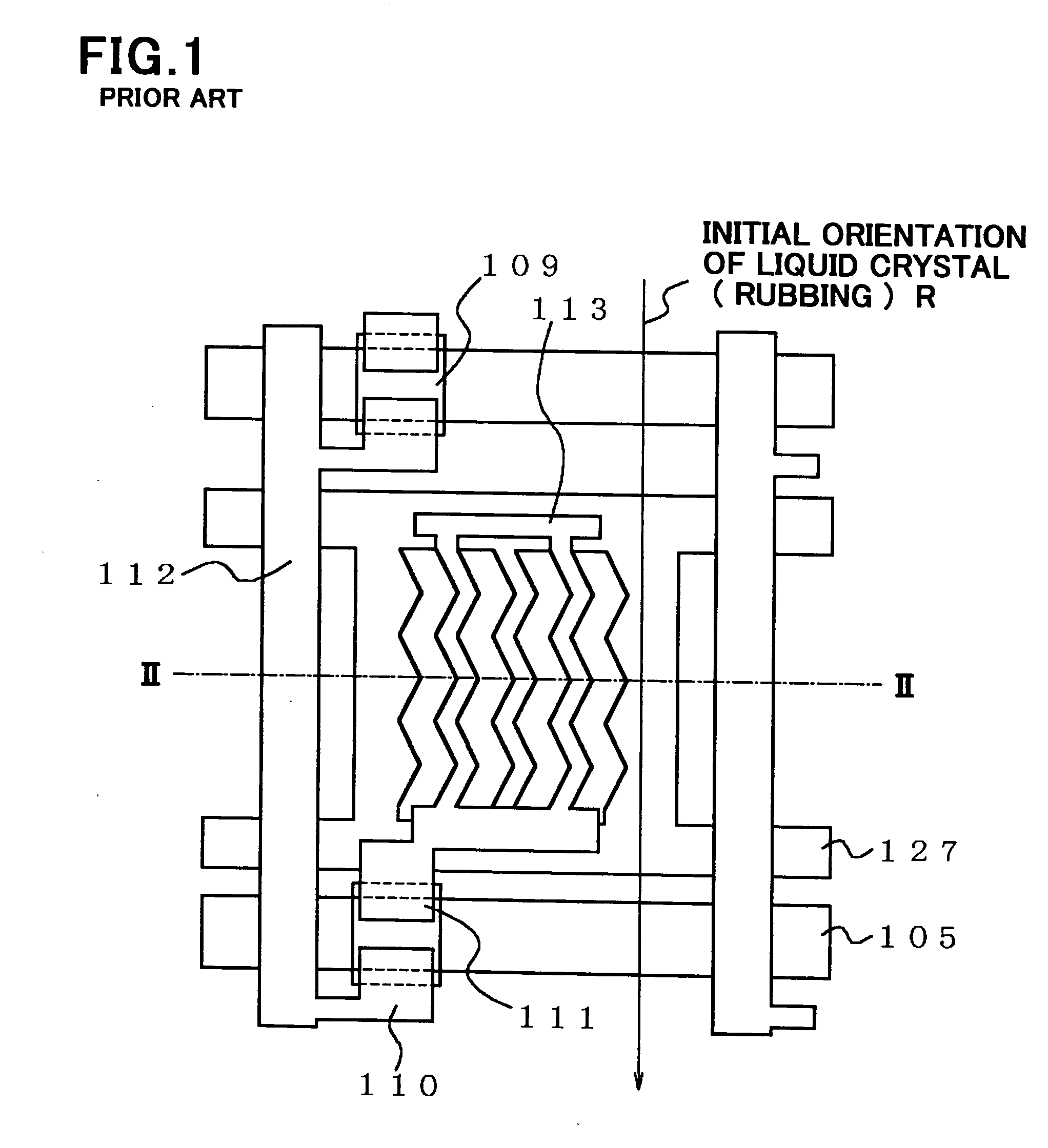

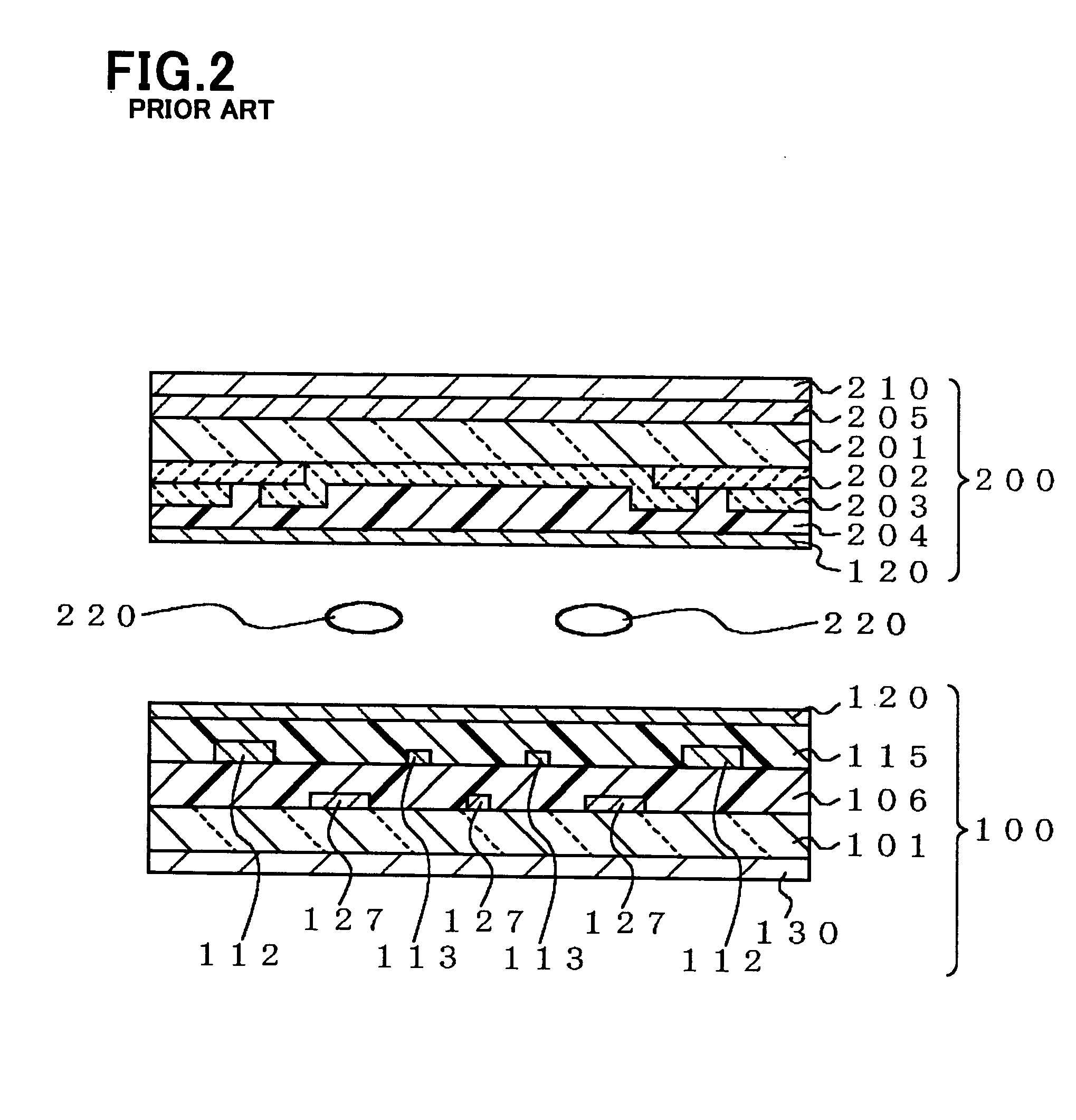

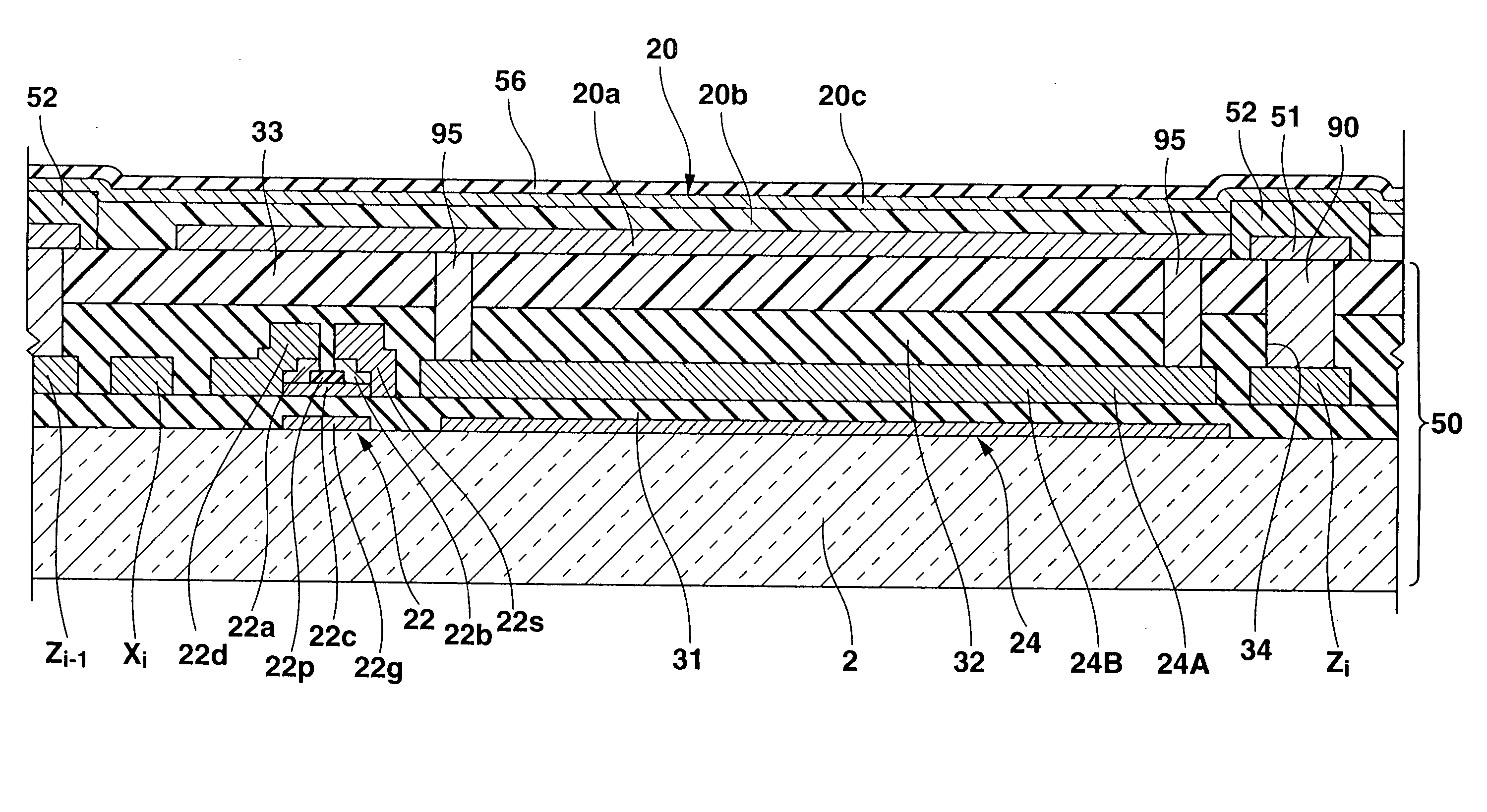

Liquid crystal display device and method of fabricating the same

ActiveUS20040183977A1Reduce capacitySuppression delayTransistorSemiconductor/solid-state device detailsOrganic filmLiquid-crystal display

A liquid crystal display device includes a first substrate including a thin film transistor, a data line, a pixel electrode, and a common electrode, a second substrate, and liquid crystal sandwiched between the first and second substrates, wherein an image signal is applied to the thin film transistor through the data line to generate an electric field between the pixel electrode receiving the image signal and the common electrode such that the liquid crystal is rotated by the electric field in a plane which is in parallel with the first substrate. The first substrate includes an electrically insulating inorganic film covering the data line therewith, a first island-shaped electrically insulating organic film formed on the electrically insulating inorganic film above the data line, and a shield common electrode covering the first island-shaped electrically insulating organic film therewith and overlapping the data line when viewed vertically.

Owner:HANNSTAR DISPLAY CORPORATION

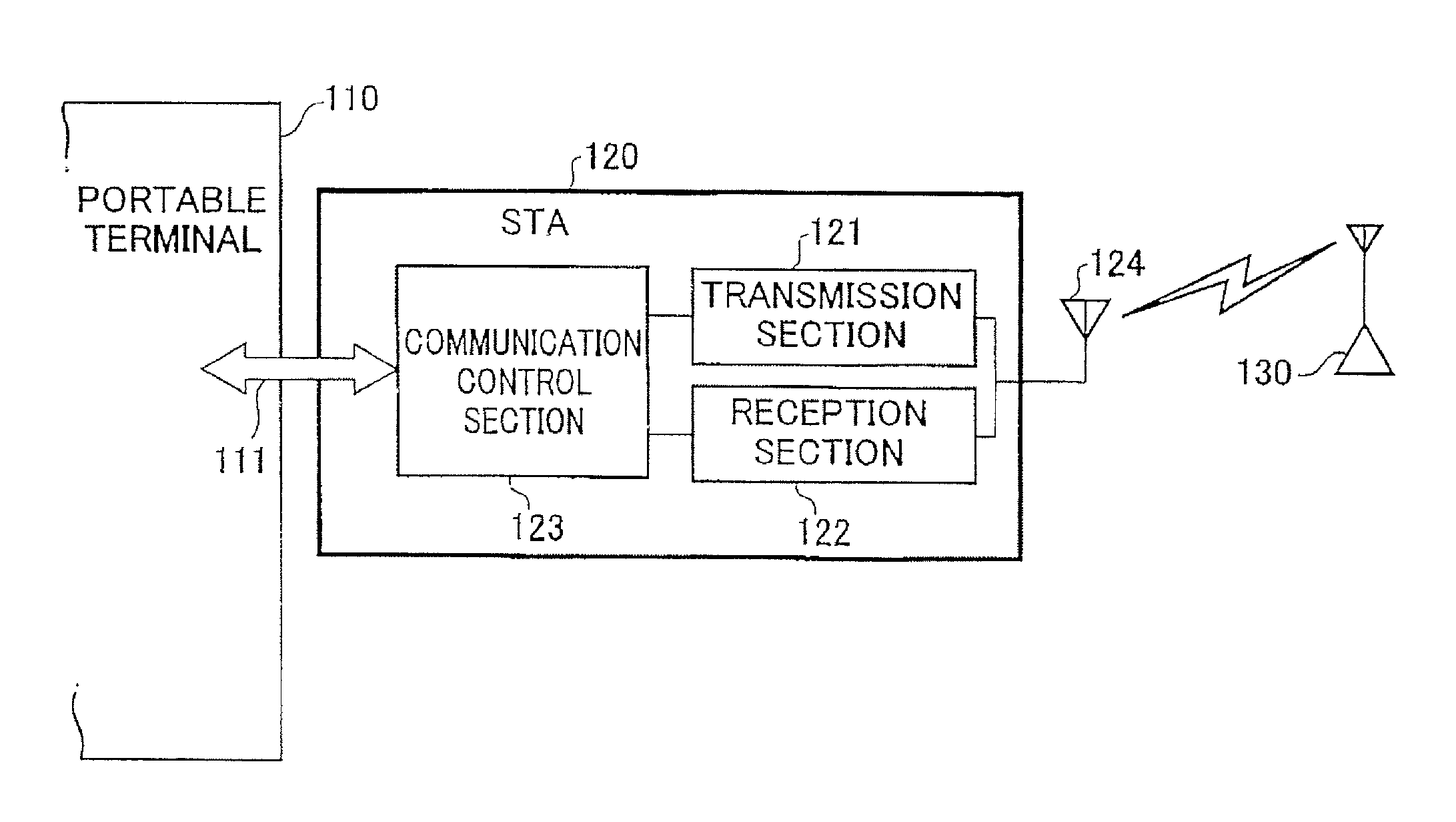

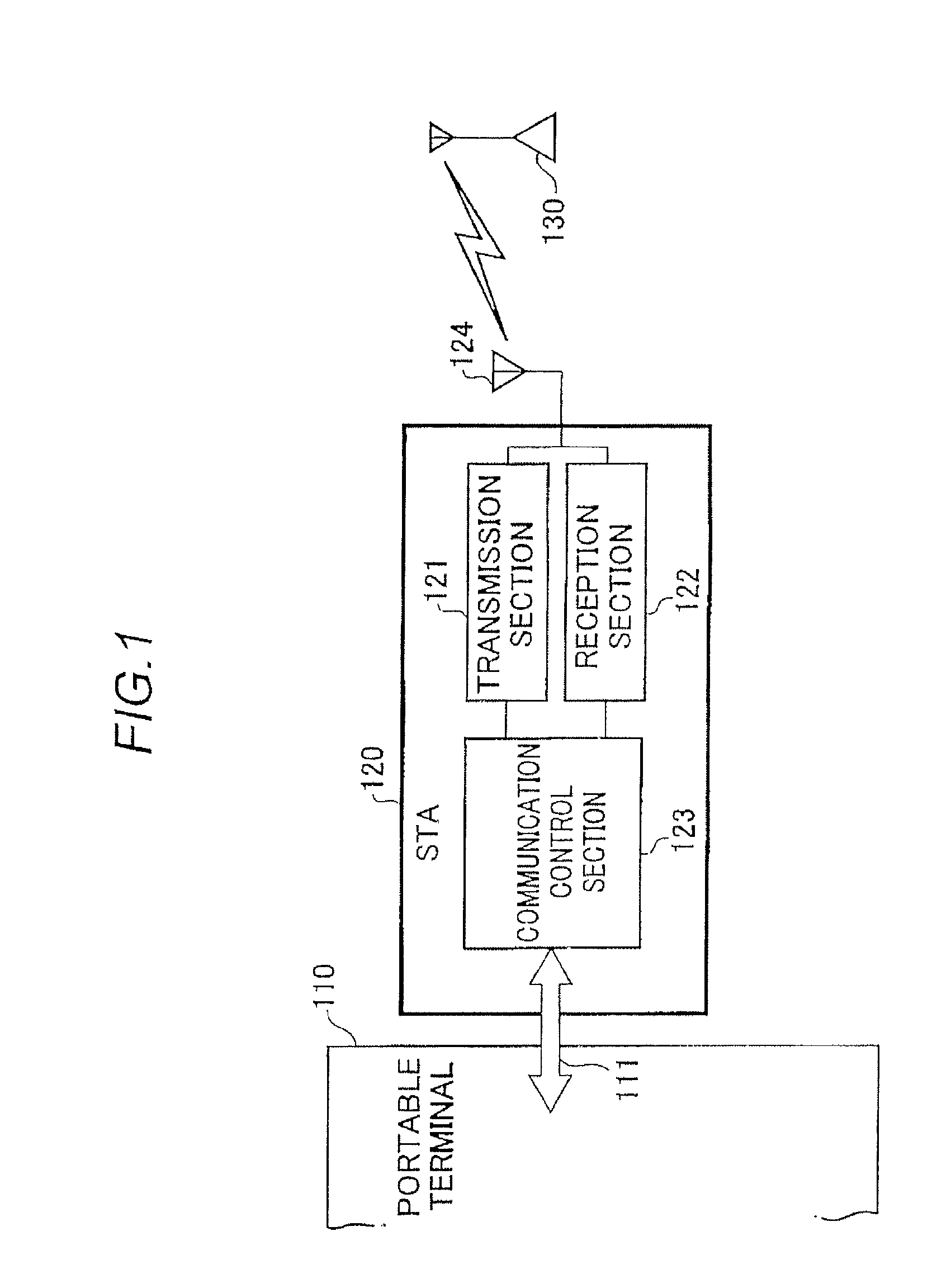

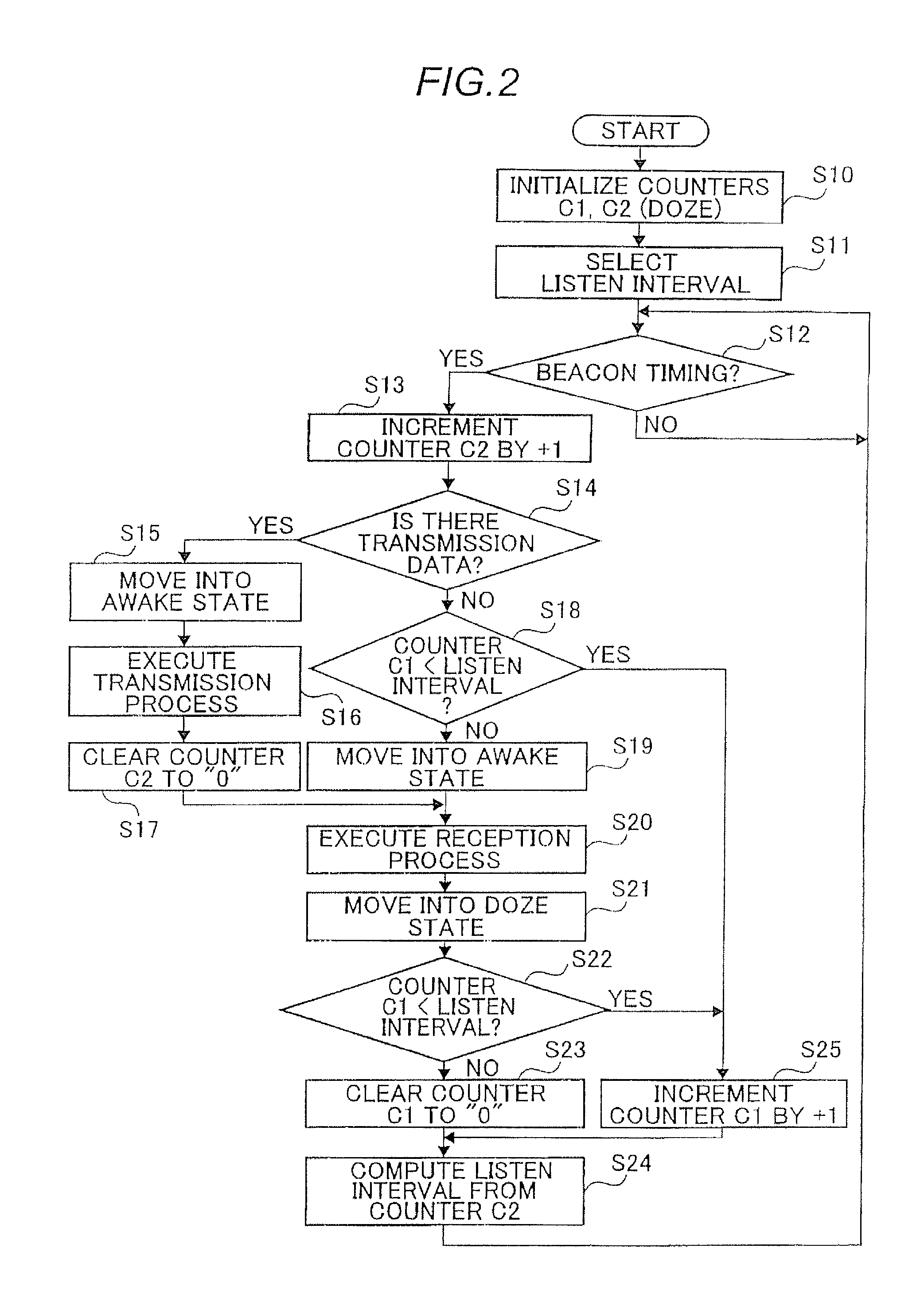

Wireless communication method for wireless LAN system, wireless communication device and wireless terminal

ActiveUS20100226299A1Suppress reception delaySave powerPower managementTransmission systemsWireless lanData transmission

In a wireless communication method of a wireless communication device to which a power management mode of a wireless LAN is applied and to which a parent device communicates, the method includes updating a listen interval of receiving a beacon signal from a parent device to be shorter than a current listen interval in response to a data transmission to the parent device; and periodically increasing the updated listen interval between the time span from the data transmission to a next data transmission, wherein reception of the beacon signal is carried out after switching from a doze state to an awake state.

Owner:NEC PLATFORMS LTD

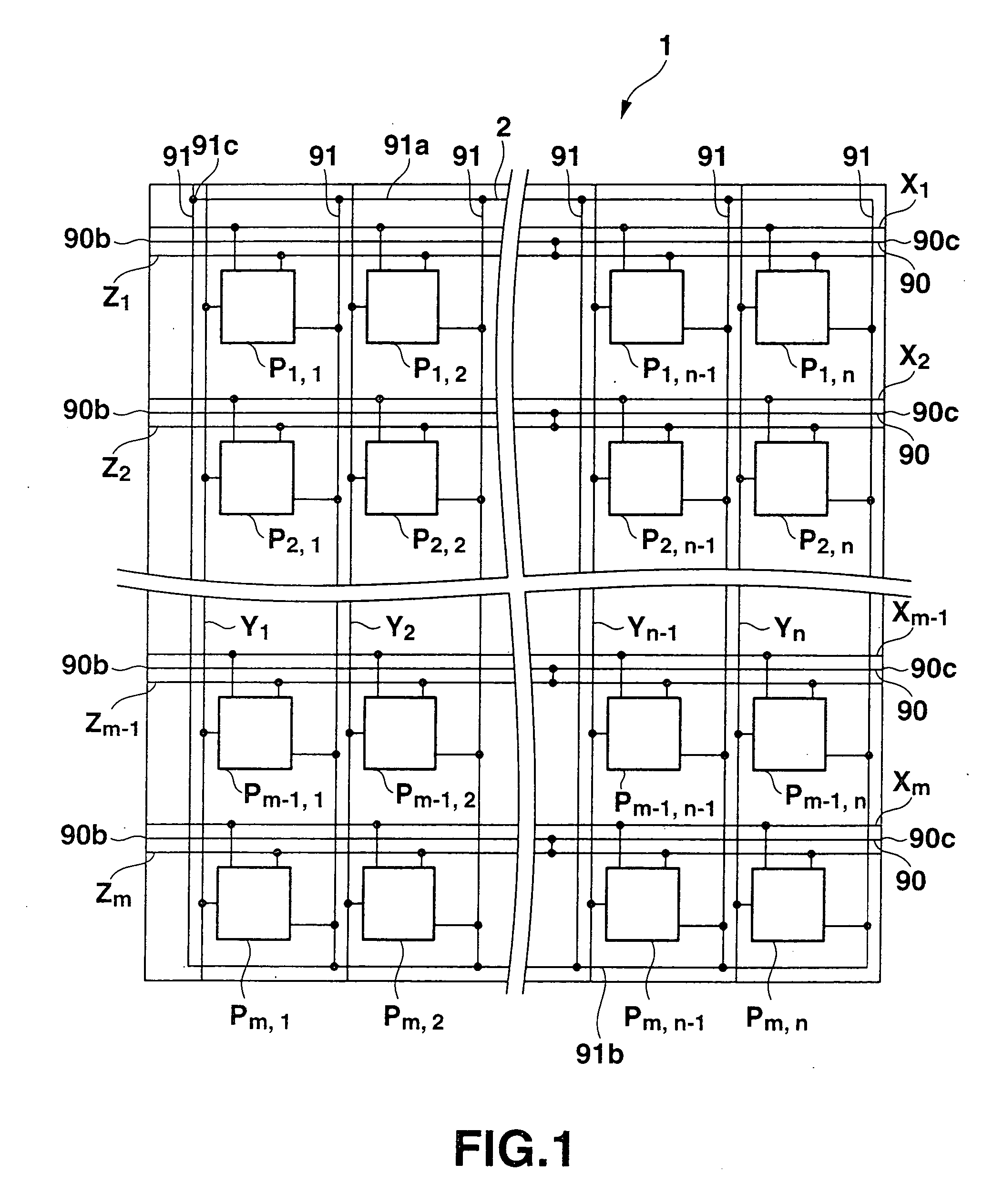

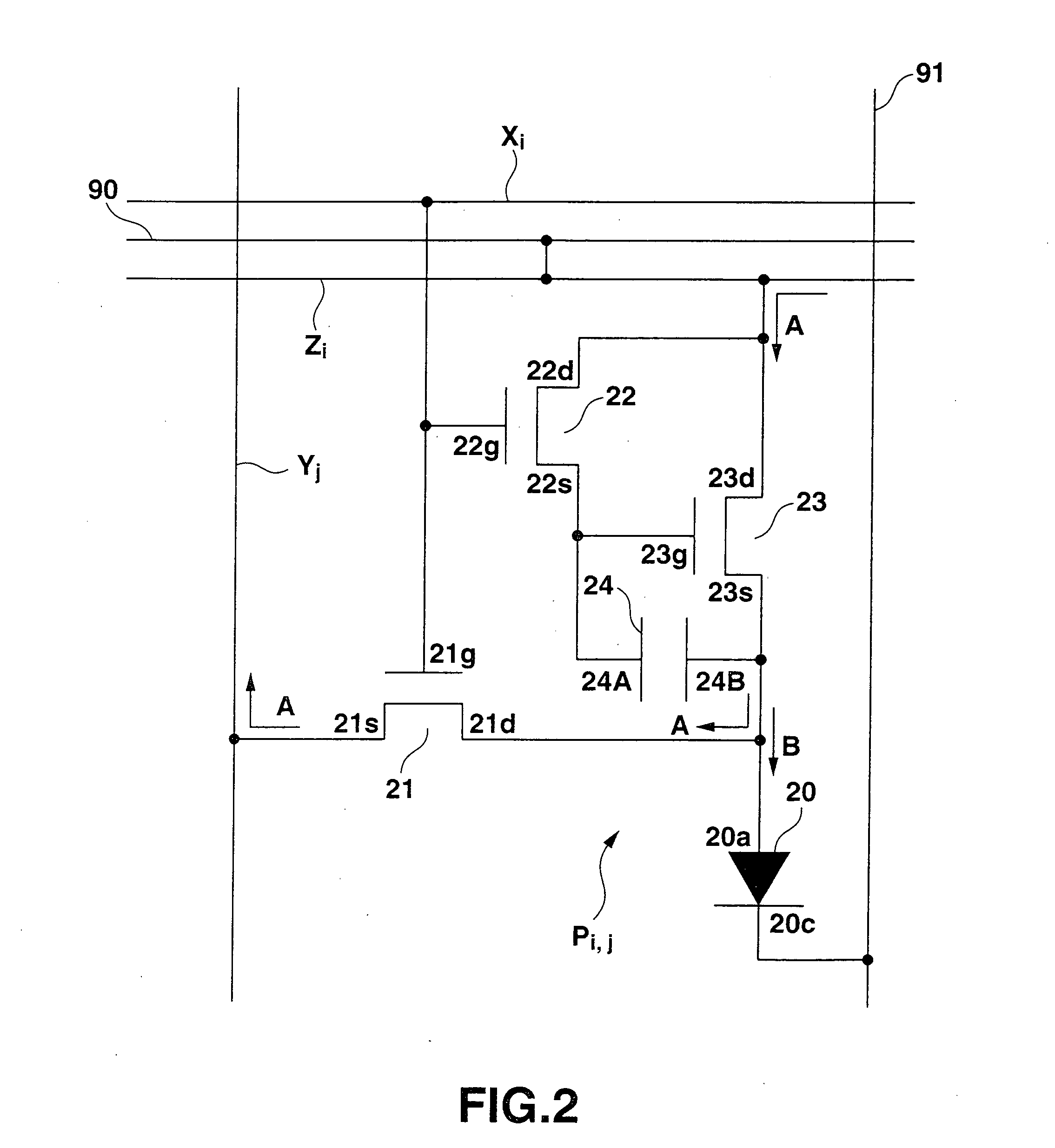

Transistor array substrate and display panel

ActiveUS20060098521A1Increase widthReduce feed resistanceSemiconductor/solid-state device detailsElectroluminescent light sourcesTransistor arrayEngineering

A transistor array substrate includes a plurality of driving transistors which are arrayed in a matrix on a substrate. The driving transistor has a gate, a source, a drain, and a gate insulating film inserted between the gate, and the source and drain. A plurality of signal lines are patterned together with the gates of the driving transistors and arrayed to run in a predetermined direction on the substrate. A plurality of supply lines are patterned together with the sources and drains of the driving transistors and arrayed to cross the signal lines via the gate insulating film. The supply line is electrically connected to one of the source and the drain of the driving transistor. A plurality of feed interconnections are formed on the supply lines along the supply lines, respectively.

Owner:SOLAS OLED LTD

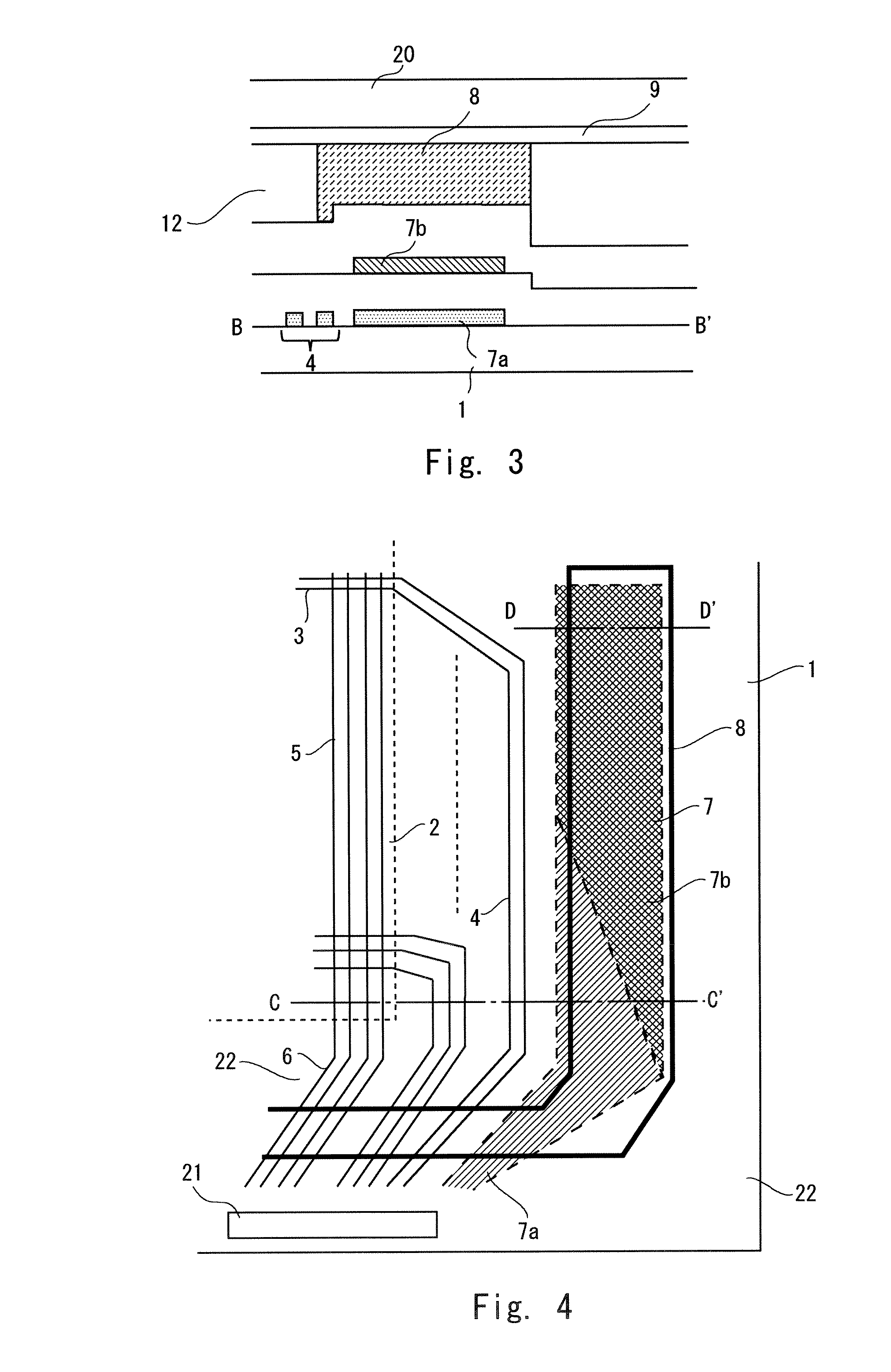

Liquid crystal display device

ActiveUS20070030409A1Reduce resistanceImprove display qualityNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device according to an embodiment of the present invention includes: a wiring substrate; an opposing substrate opposite to the wiring substrate; a sealing member for bonding the wiring substrate to the opposing substrate; a liquid crystal filled in a space defined by the wiring substrate, the opposing substrate, and the sealing member; a plurality of scanning signal lines formed in a display area formed inside the sealing member; a plurality of display signal lines formed in the display area and crossing the scanning signal lines with an insulating film interposed therebetween; and a common signal line formed outside the display area, the scanning signal lines, the scanning signal lines, and common signal line being formed on the wiring substrate, and the common signal line including at least two conductive layers with one of the conductive layers changing a pattern width below a pattern of the sealing member.

Owner:TRIVALE TECH

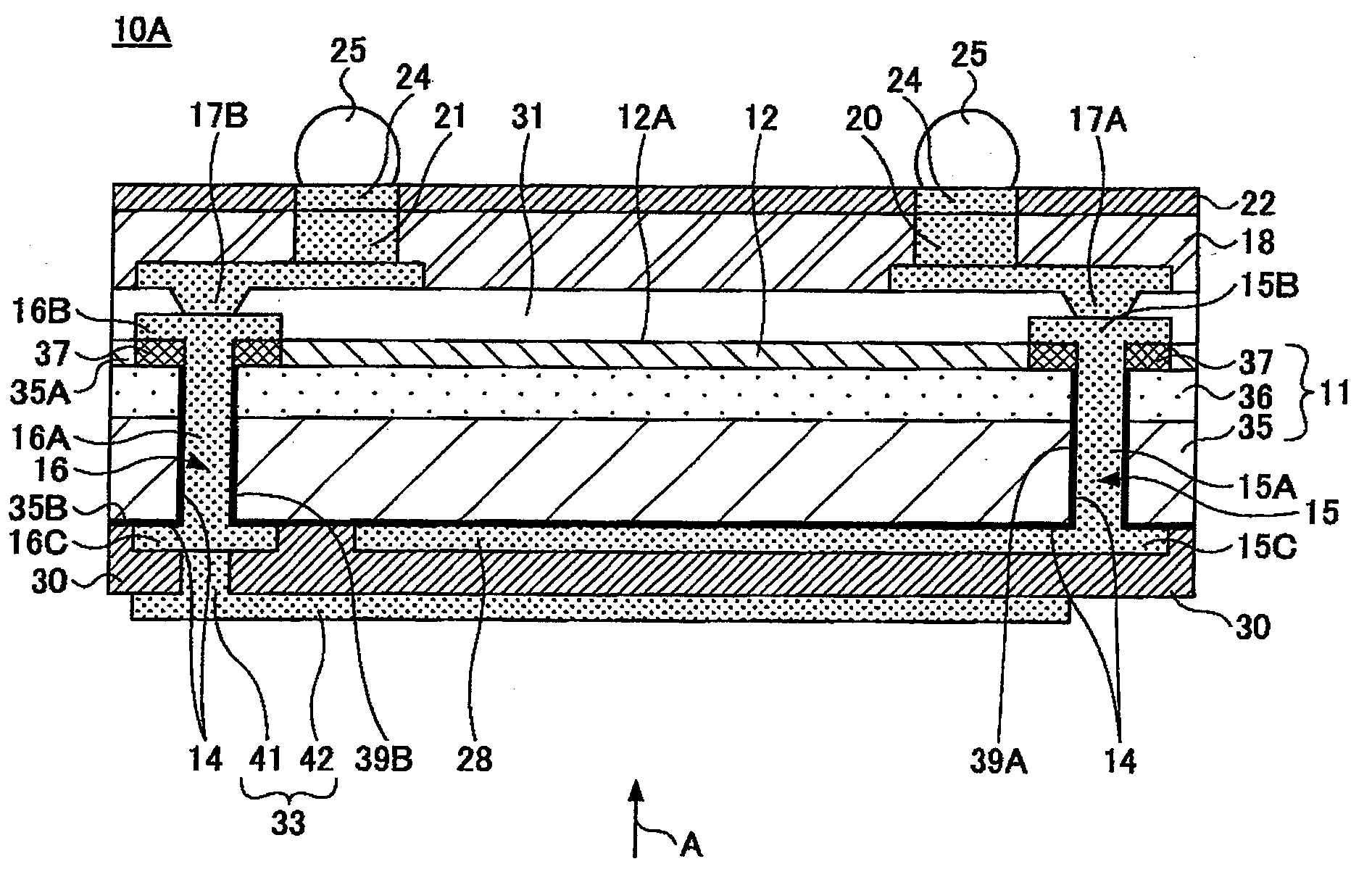

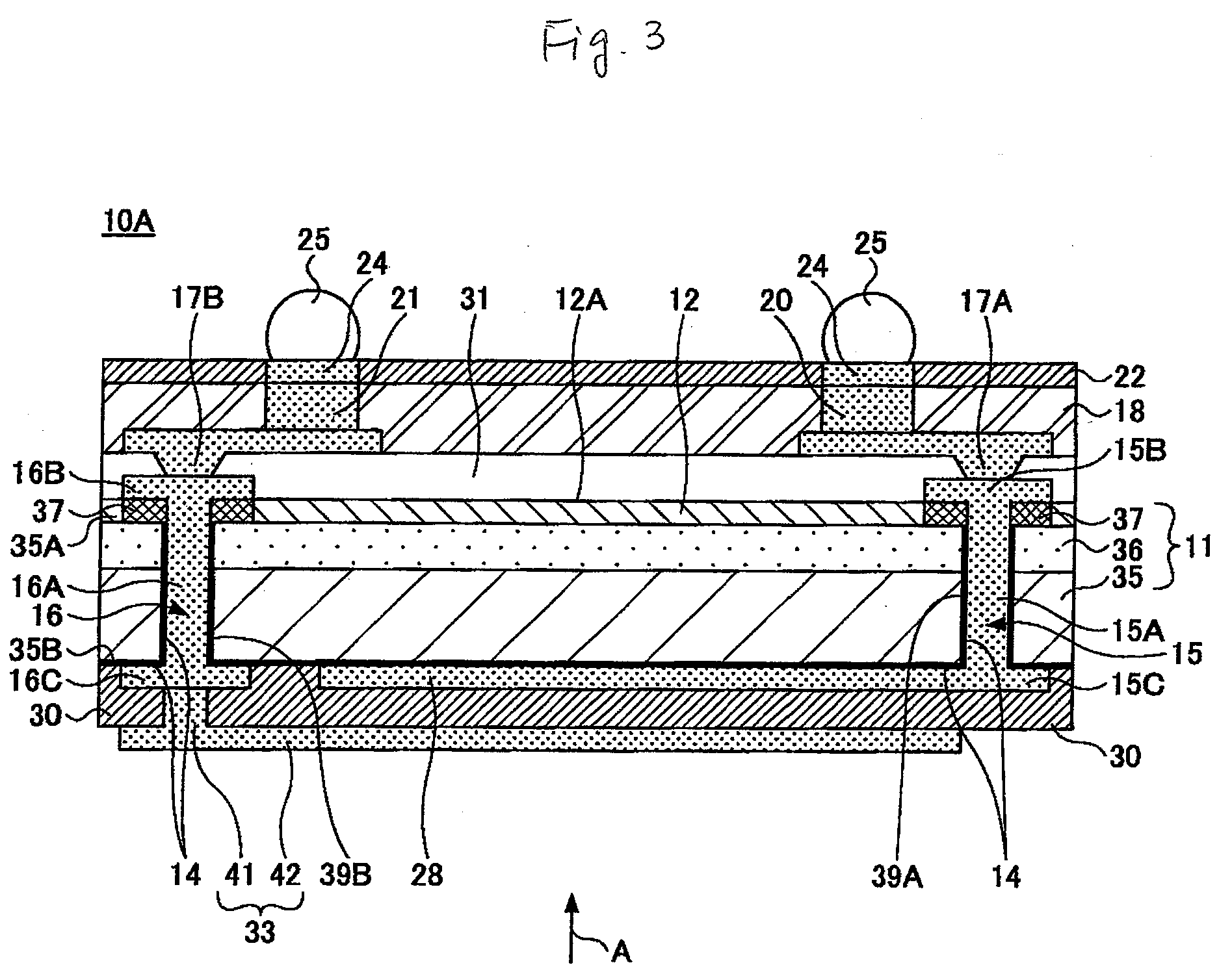

Semiconductor device and manufacturing method thereof

ActiveUS20090166811A1InhibitionSuppression delaySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipPhysics

A semiconductor device has a semiconductor chip and through electrodes formed passing through the semiconductor chip. A ground layer connected to the through electrode and a patch antenna connected to the through electrode are provided through an inorganic insulating layer formed of SiO2 or SiN on a second face opposite to a first face (main face) of the semiconductor chip.

Owner:SHINKO ELECTRIC IND CO LTD

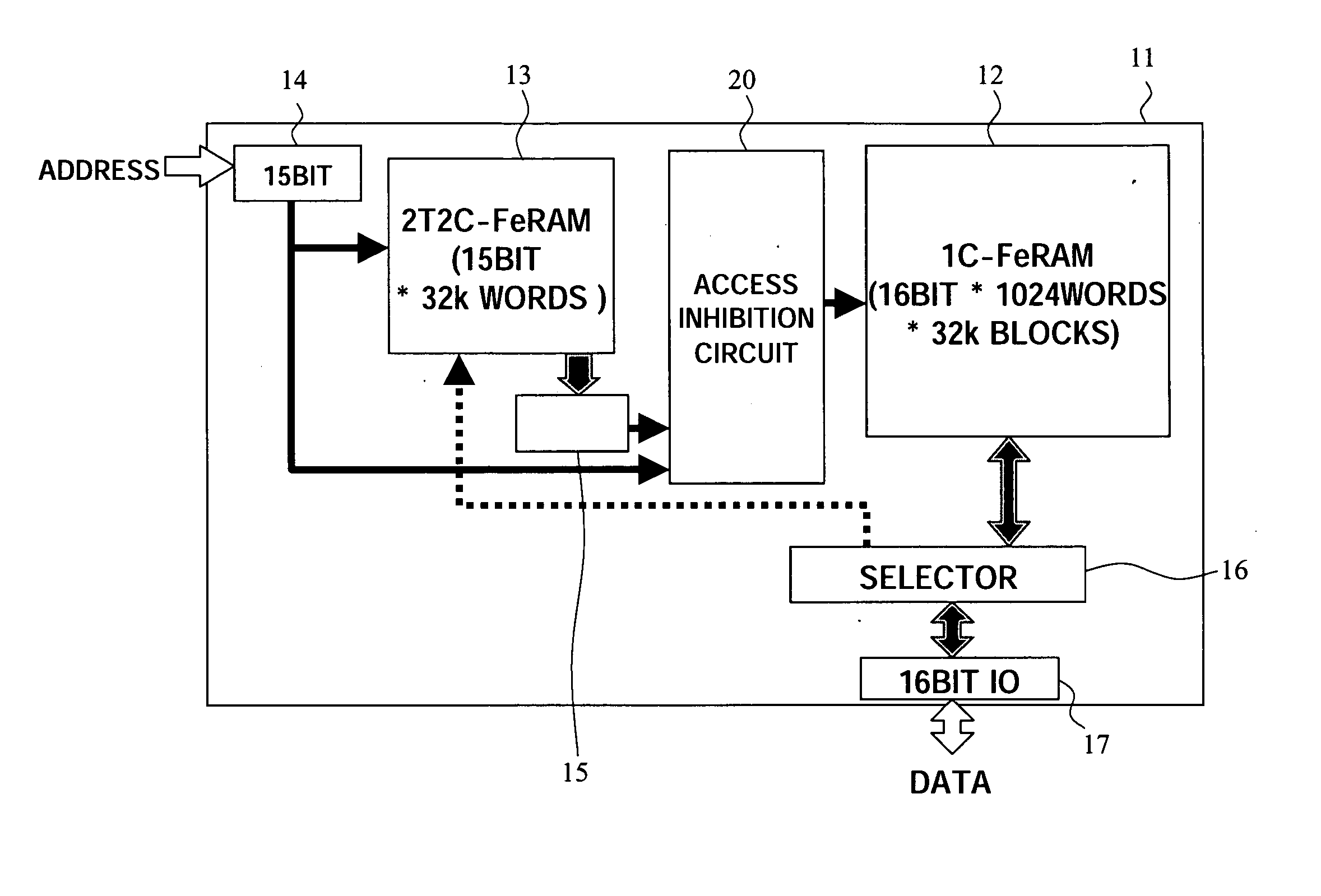

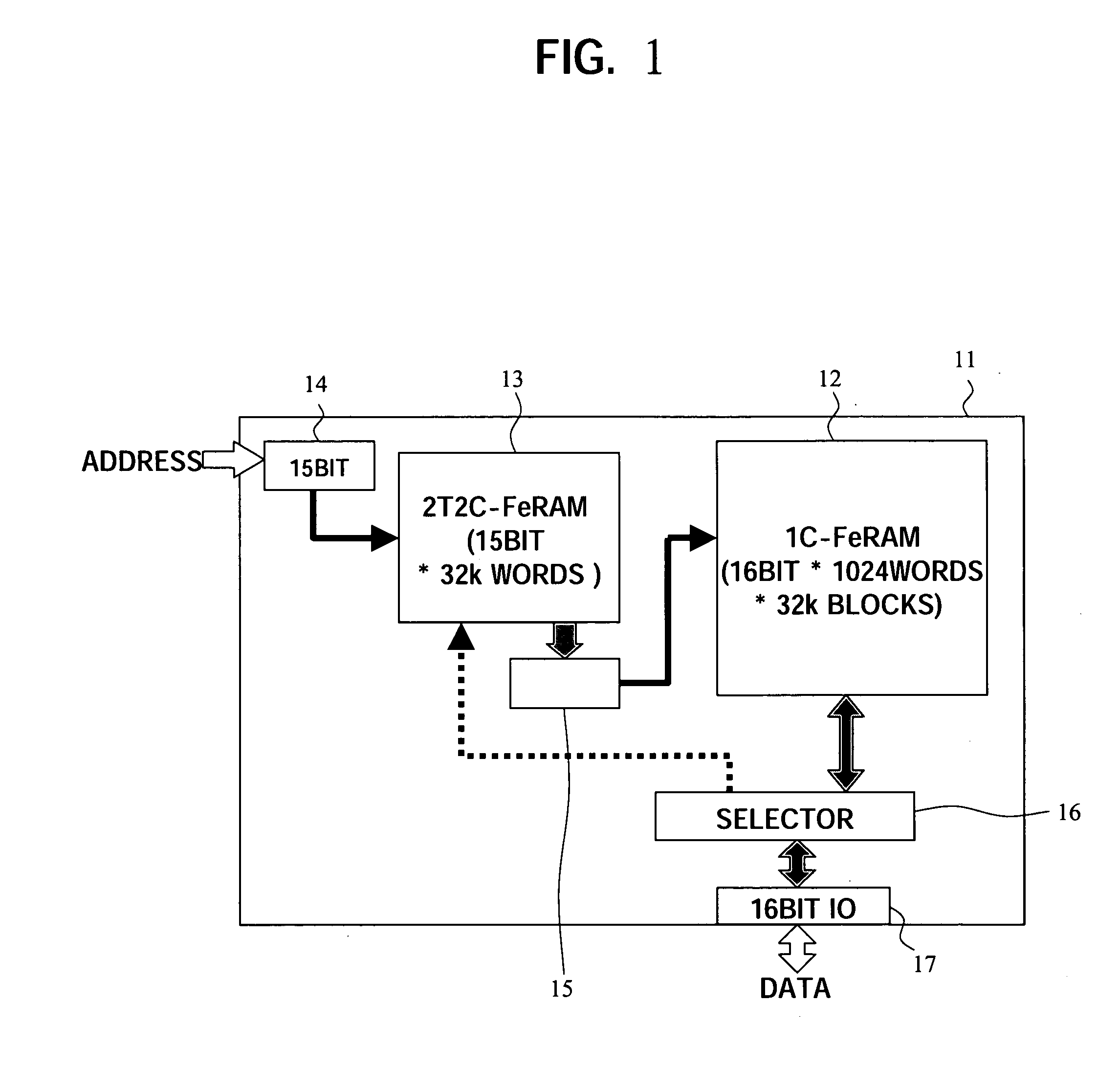

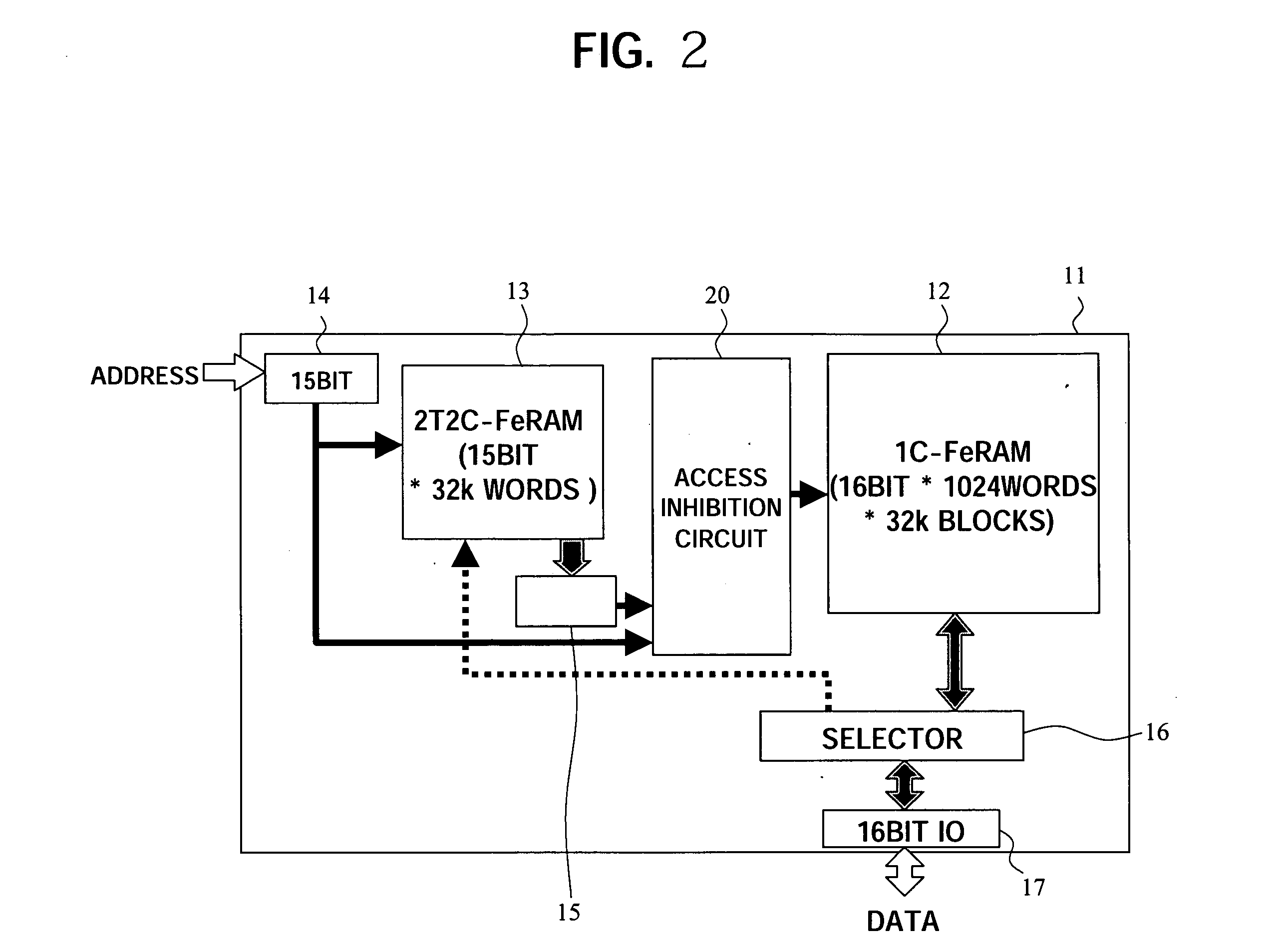

Semiconductor memory device

ActiveUS20050283657A1Flexibly relievingSuppression delayError detection/correctionDigital storageControl lineSemiconductor chip

A semiconductor memory device capable of flexibly relieving a defect of a memory and suppressing an access delay and an increase of a power consumption caused by defect relieving is provided, wherein an access to a first memory portion is made by referring to an address transformation table stored in a second memory portion, so that an access to a defective block is prevented; the second memory portion and the first memory portion are mounted on the same semiconductor chip, so that a part or all of address data input from outside the semiconductor chip can be made corresponding as it is to an address of the second memory portion and input to the second memory portion without executing any calculation, and a stored pointer can be taken out at a high speed; and an access can be made to a memory at a high speed by following the address transformation table without driving a system bus and a control line, which gives a heavy load, provided outside of the semiconductor chip or giving a load of processing on the CPU.

Owner:SONY CORP

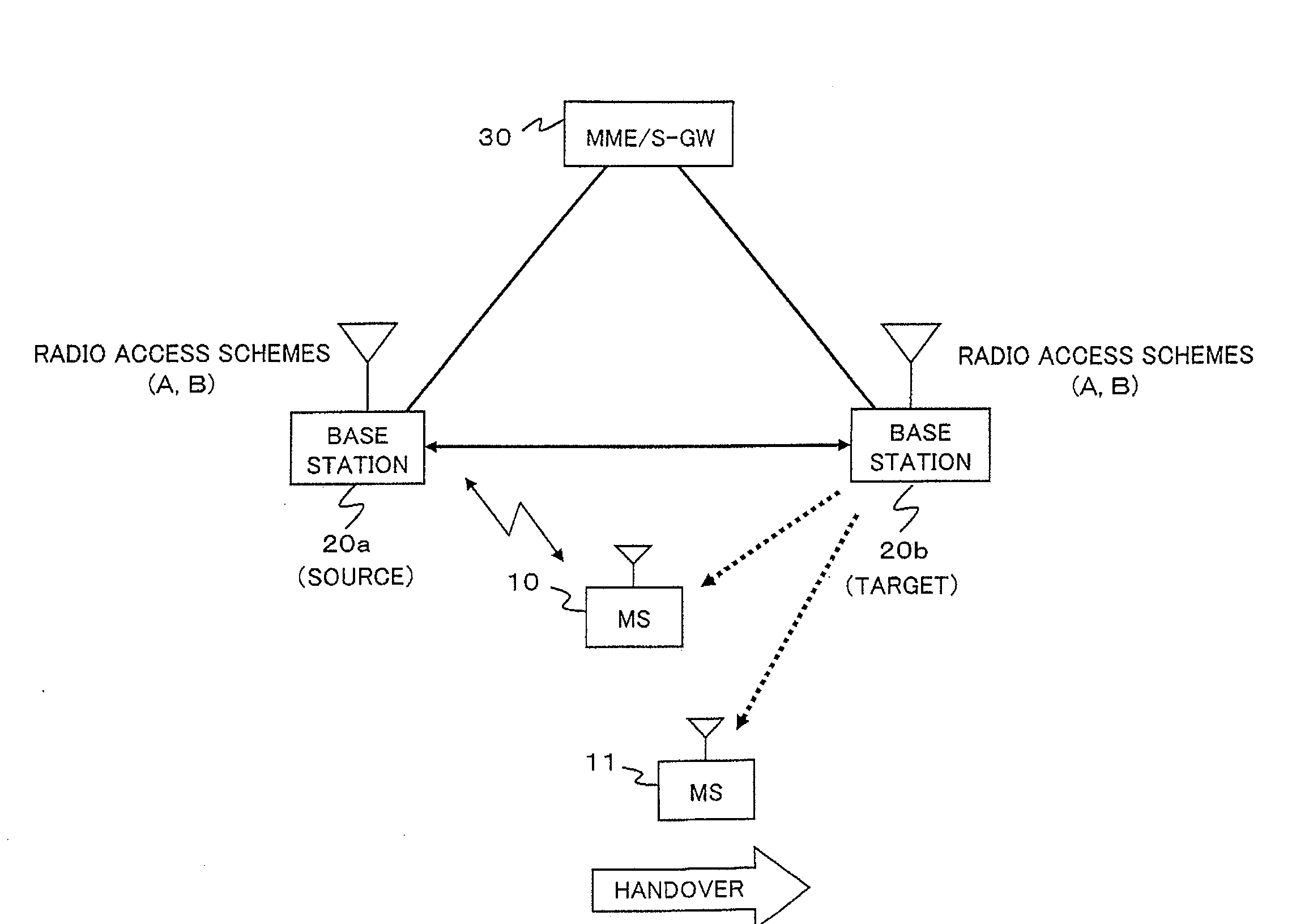

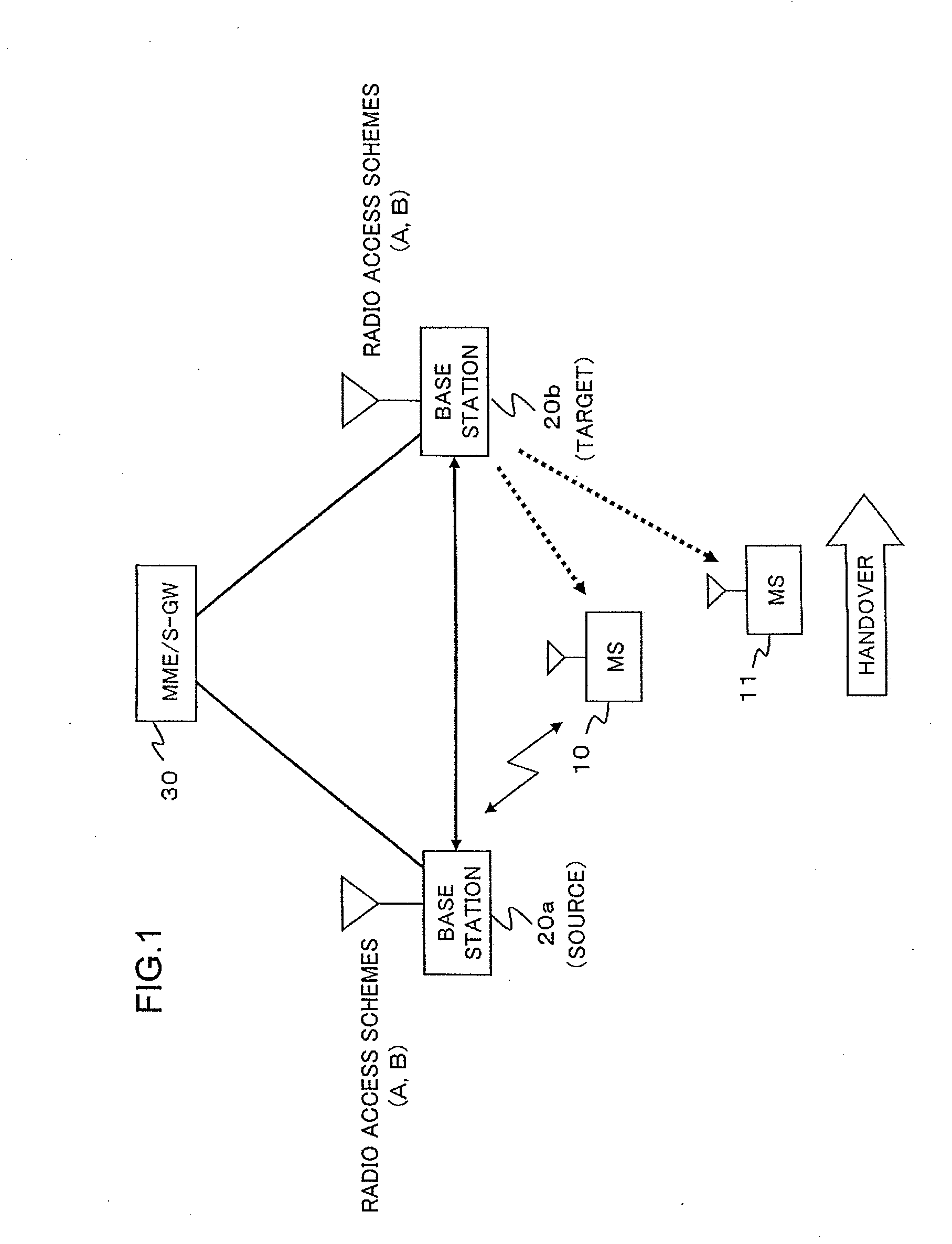

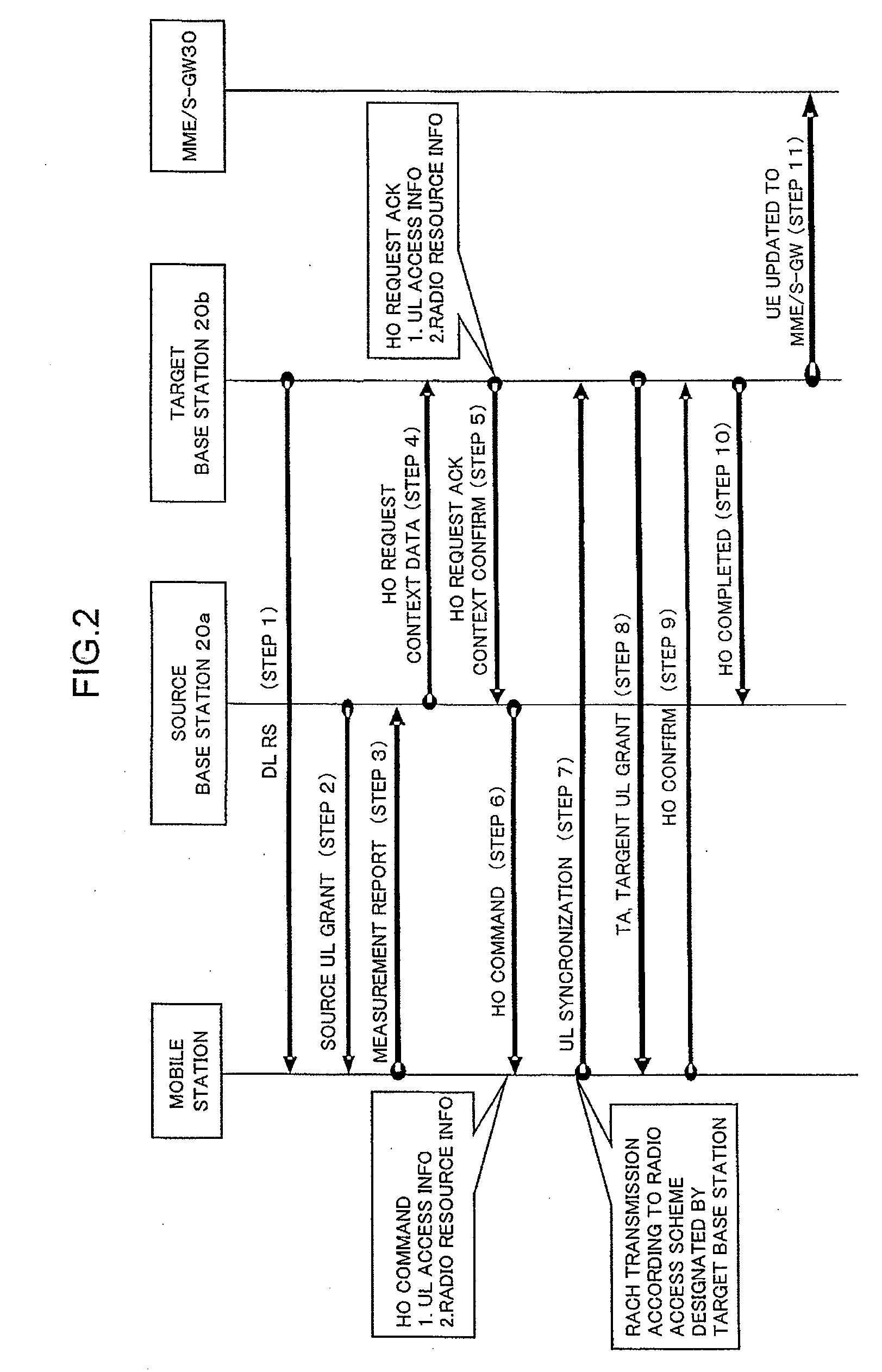

Method for handover between different radio access schemes and wireless communication system

ActiveUS20090239570A1Suppression delaySynchronisation arrangementRadio transmissionCommunications systemMobile station

In a wireless communication system including a plurality of base stations each supporting at least one of two or more radio access schemes and at least one mobile station capable of performing communication by using the two or more radio access schemes, before the mobile station moves from a source base station to a target base station, the target base station notifies the mobile station, via the source base station, of a transparent container containing uplink radio access information that specifies a radio access scheme enabling at least an initial connection to be made. Thus, the mobile station identifies the radio access scheme supported by the target base station from the transparent container before moving from the source base station to the target base station.

Owner:NEC CORP

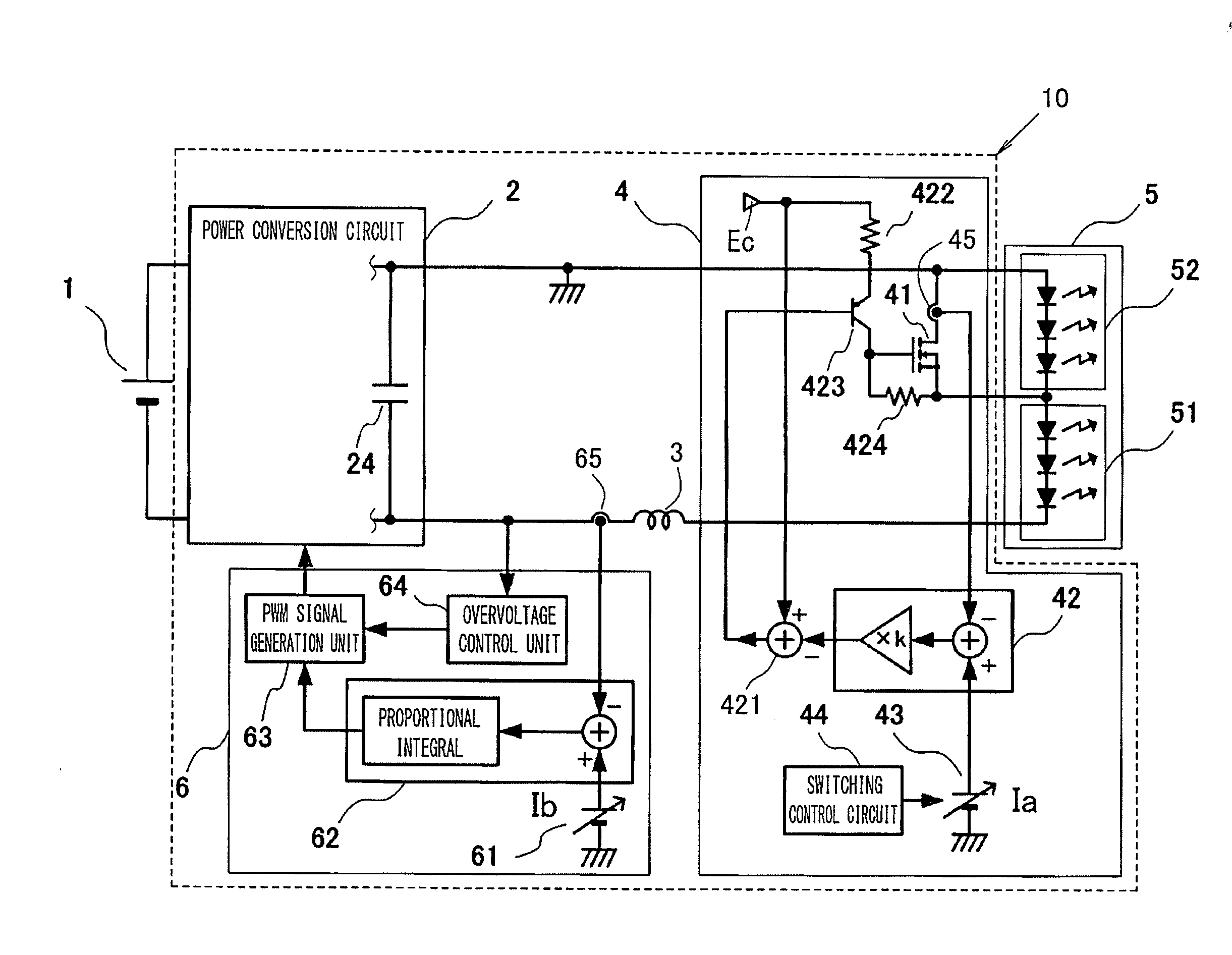

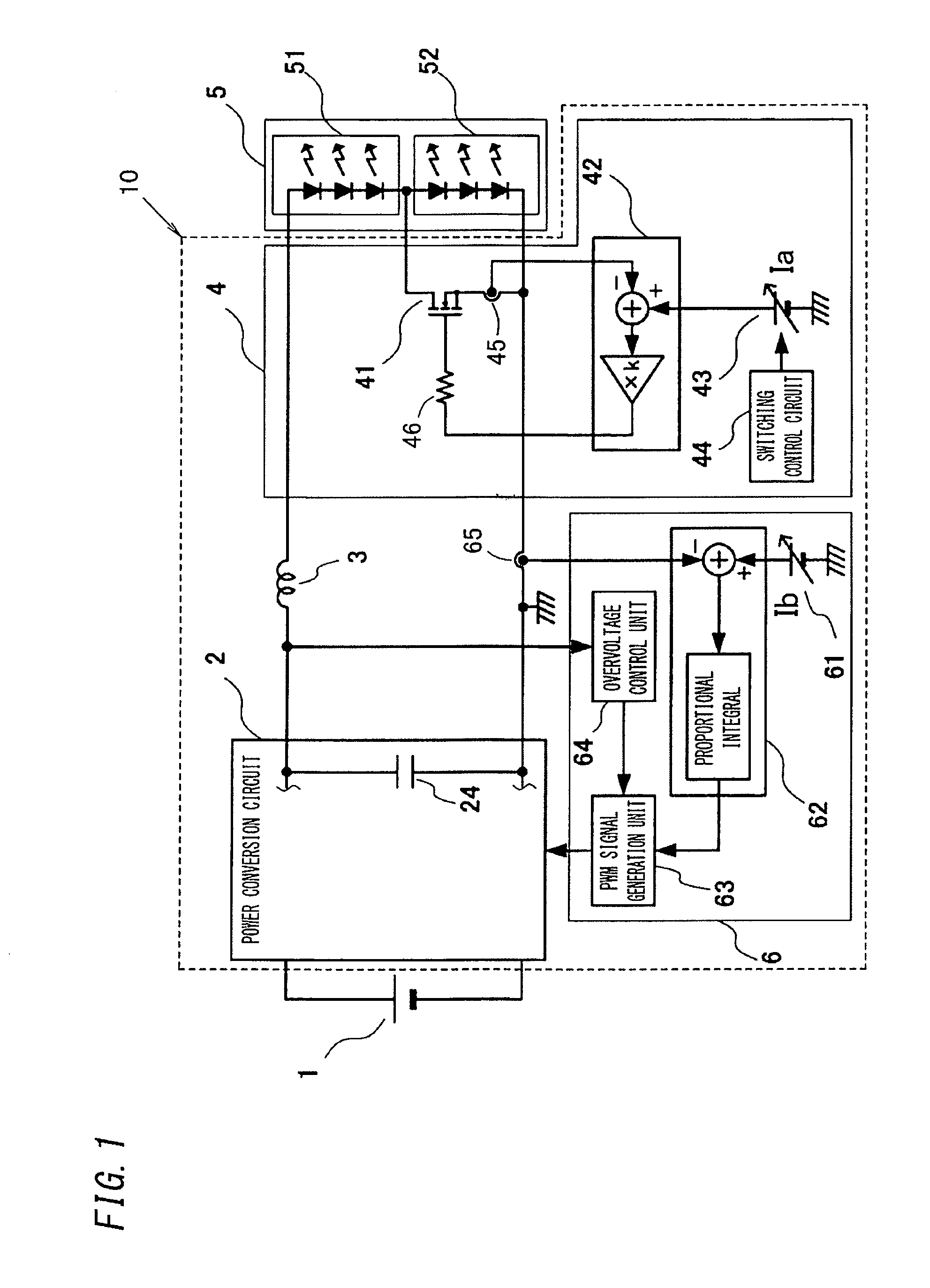

Lighting device and vehicle headlamp

ActiveUS20130320850A1Suppression delayImpedance variesVehicle headlampsElectrical apparatusPower flowControl signal

A switching circuit includes an active element connected in parallel to a second light source block and having an impedance that varies in accordance with a control signal input into a control terminal, and switches the second light source block between a lit condition and an extinguished condition by switching the active element ON and OFF. The switching circuit adjusts the impedance of the active element so that a current flowing to the active element matches a target value set by a switching control circuit. When the active element is to be switched ON, the switching control circuit varies the target value gradually over time, and therefore an excessive load current can be prevented from flowing while the active element shifts from an OFF condition to an ON condition.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Vehicle operation assisting system

InactiveUS7778753B2Reduce stepsStabilizing the vehicle behaviorDigital data processing detailsAnti-collision systemsVehicle behaviorDriver/operator

A vehicle operation assist system includes as assist yaw rate calculator which calculates a necessary moving amount to avoid an obstacle based on a detection result of the obstacle by a radar device, and a vehicle movement controller controls lateral movement of the vehicle based on the calculated moving amount. When an avoiding operation detector determines initiation of an obstacle avoiding operation by the driver, the vehicle movement controller operates a braking device to control the lateral movement of the vehicle, so that the obstacle can be reliably avoided. When a restoring operation detector determines initiation of a restoring operation, the vehicle movement controller operates a power steering device to control the lateral movement of the vehicle, so that delay in the steering operation by the driver, and excessive restoring operation of the steering handle to compensate for the delay are suppressed, thus stabilizing vehicle behavior.

Owner:HONDA MOTOR CO LTD

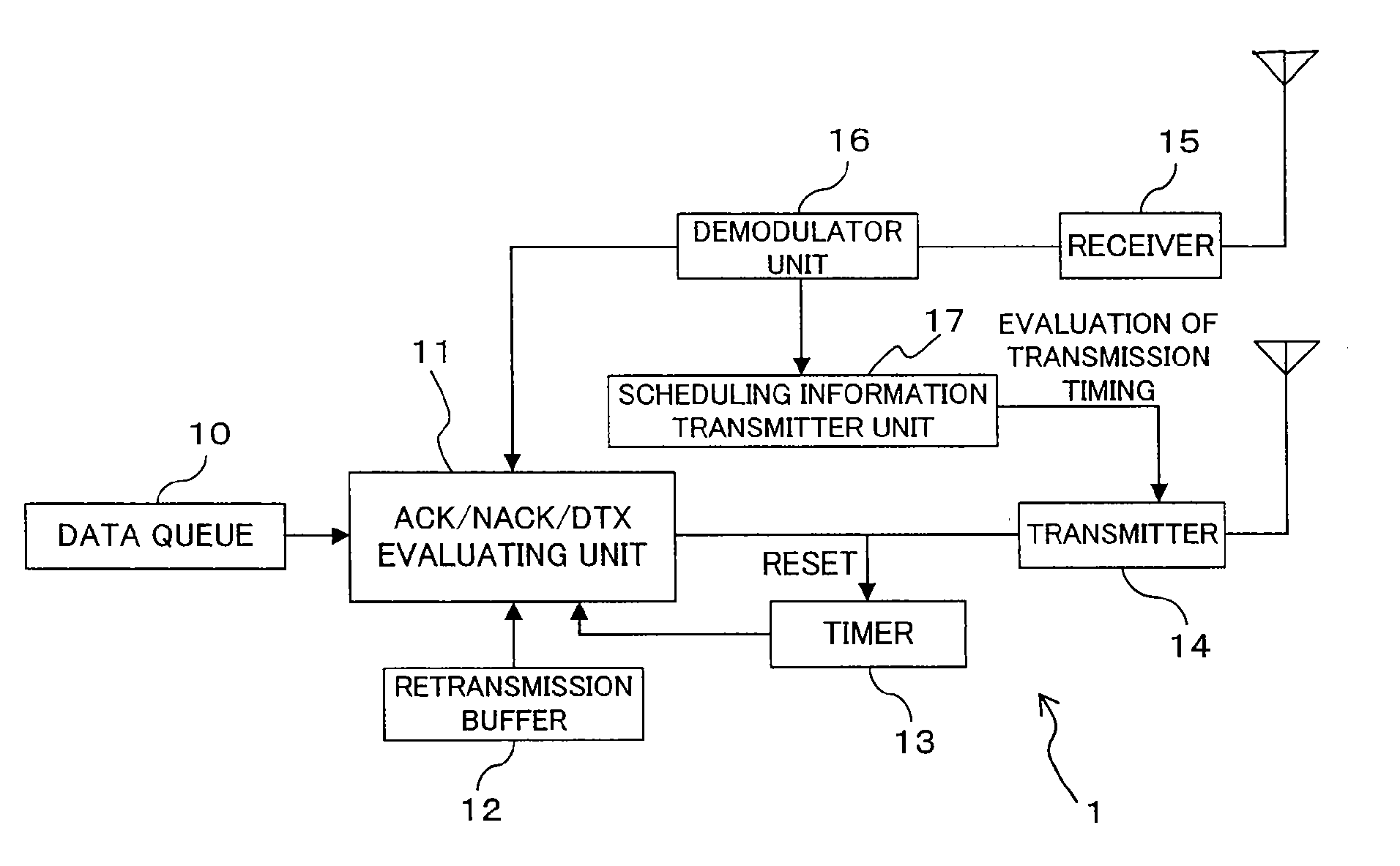

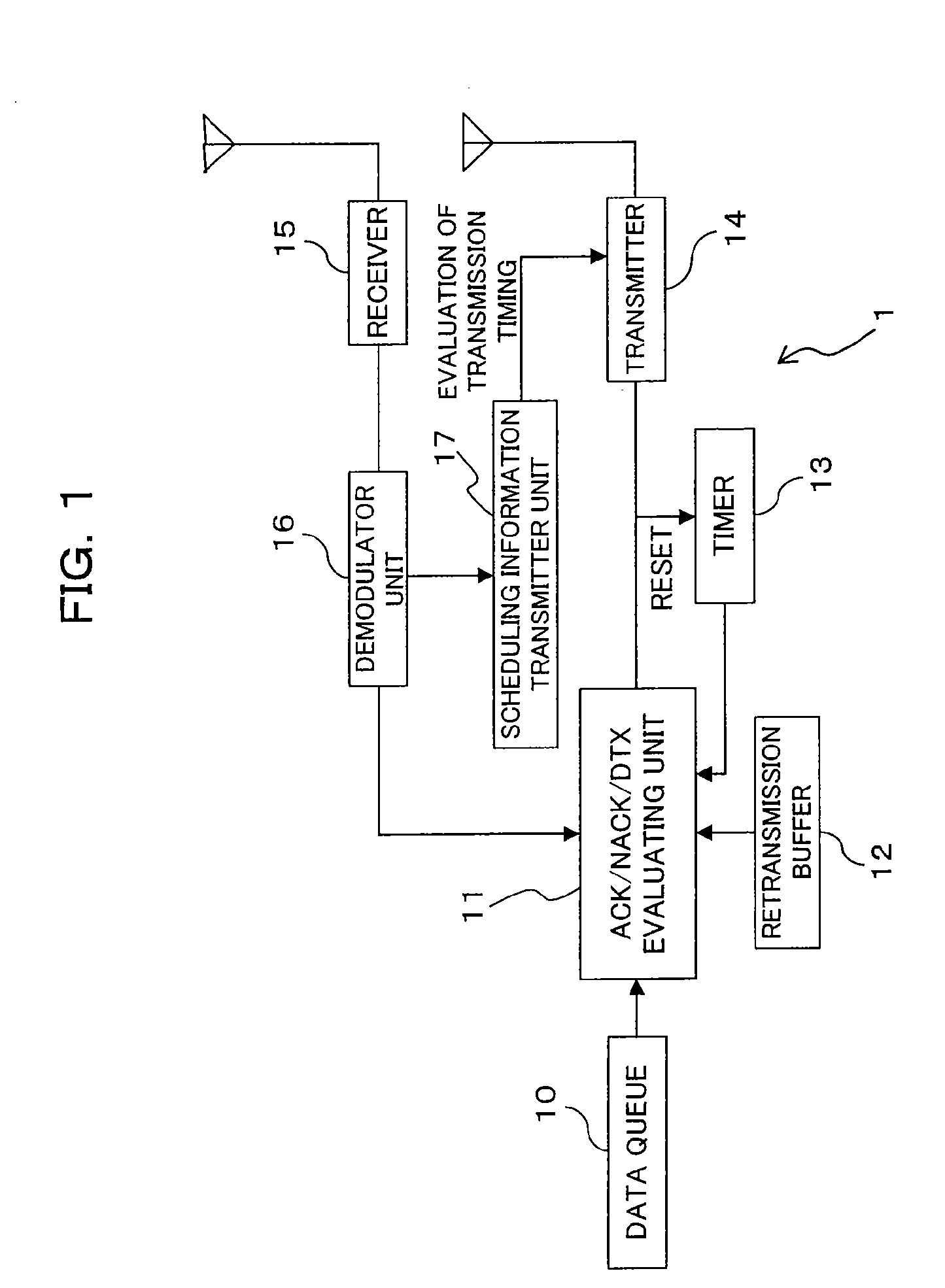

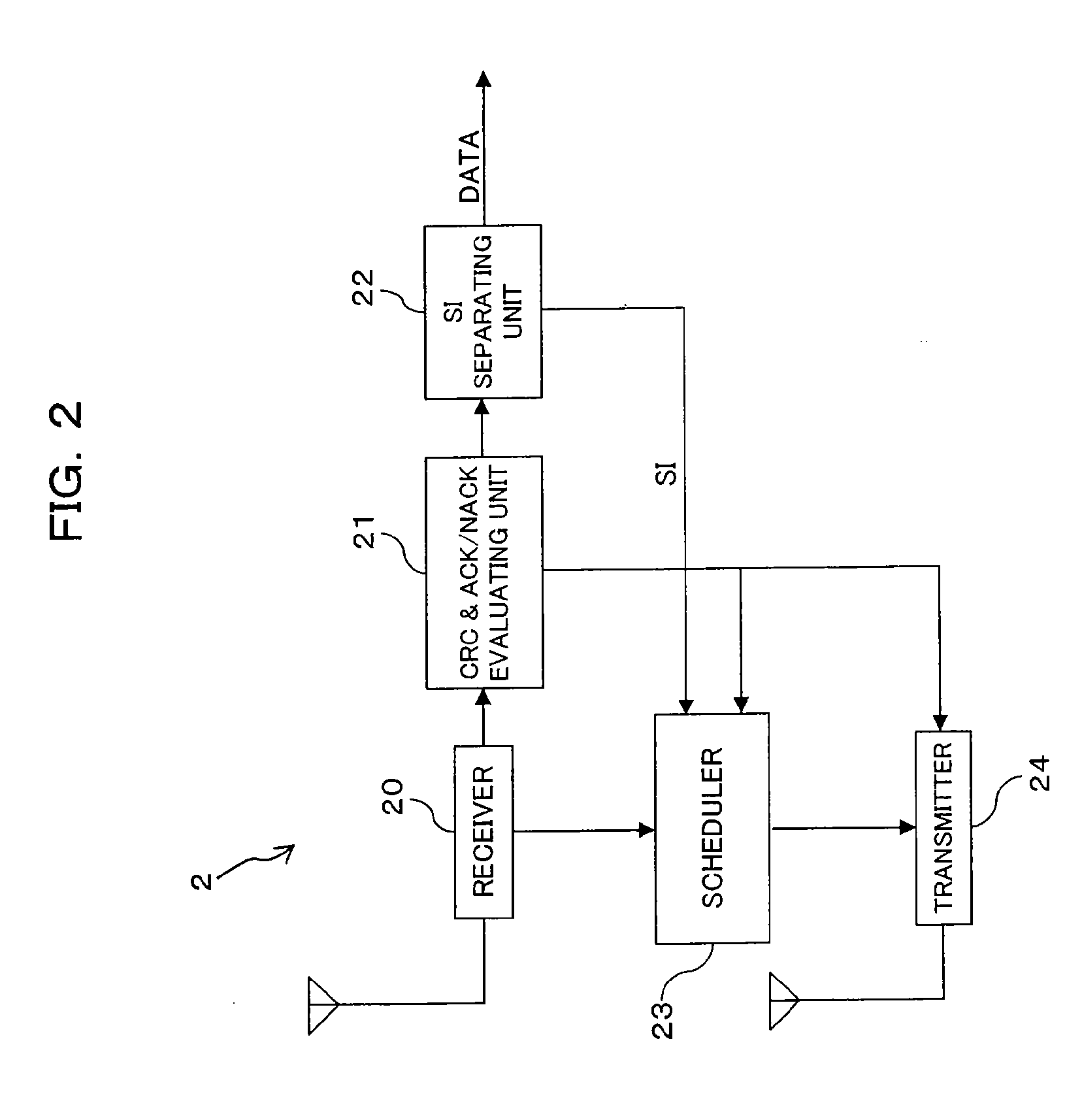

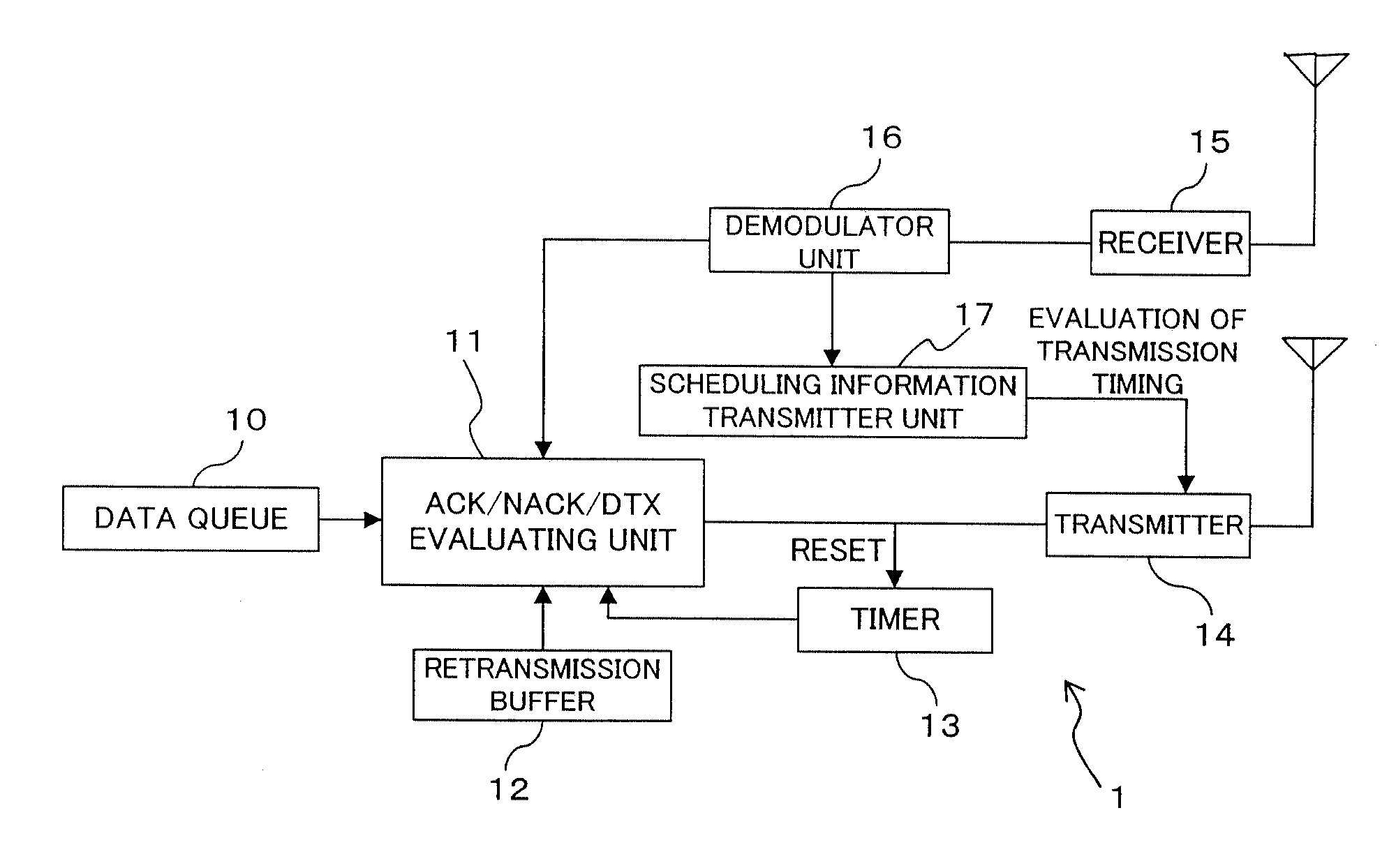

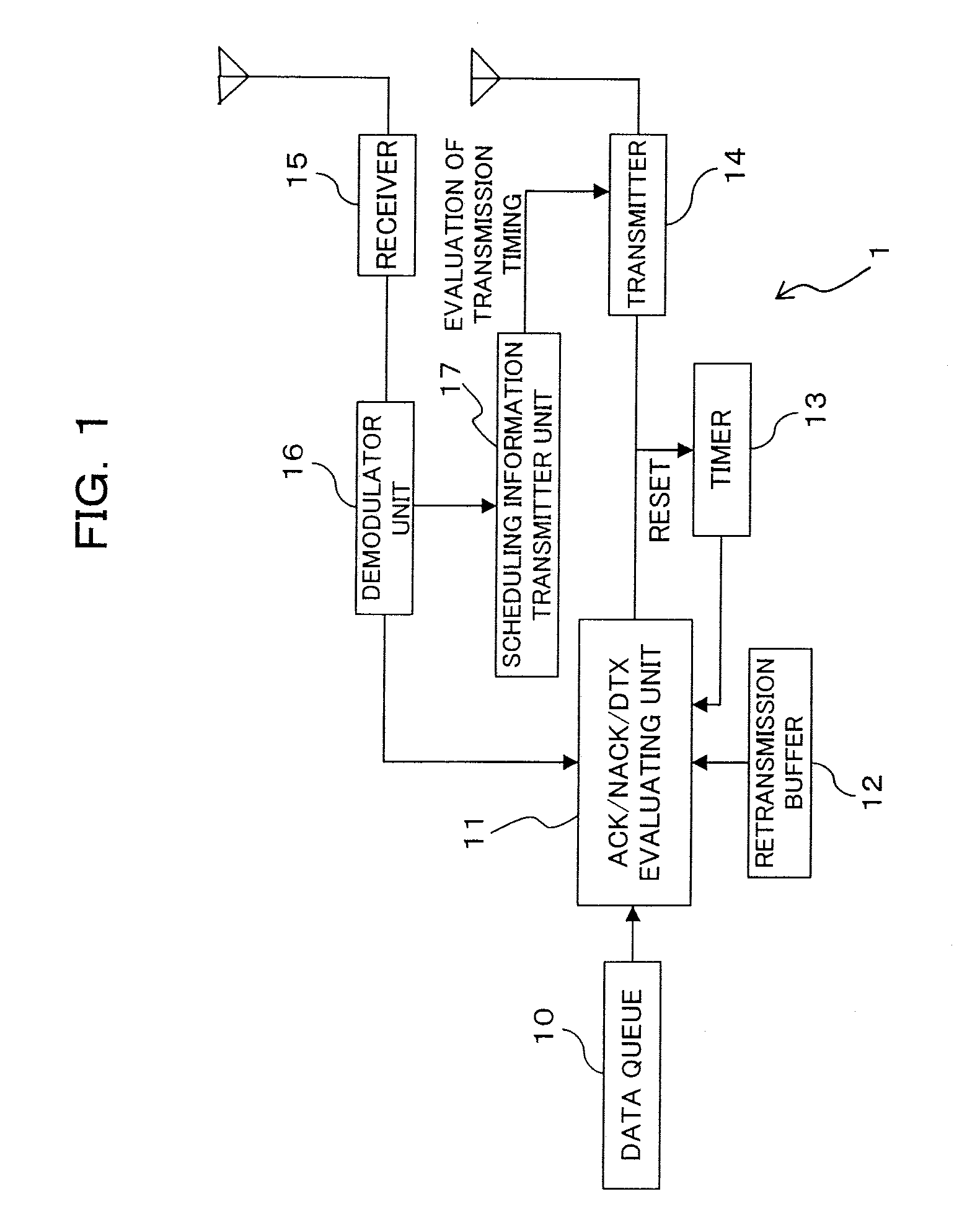

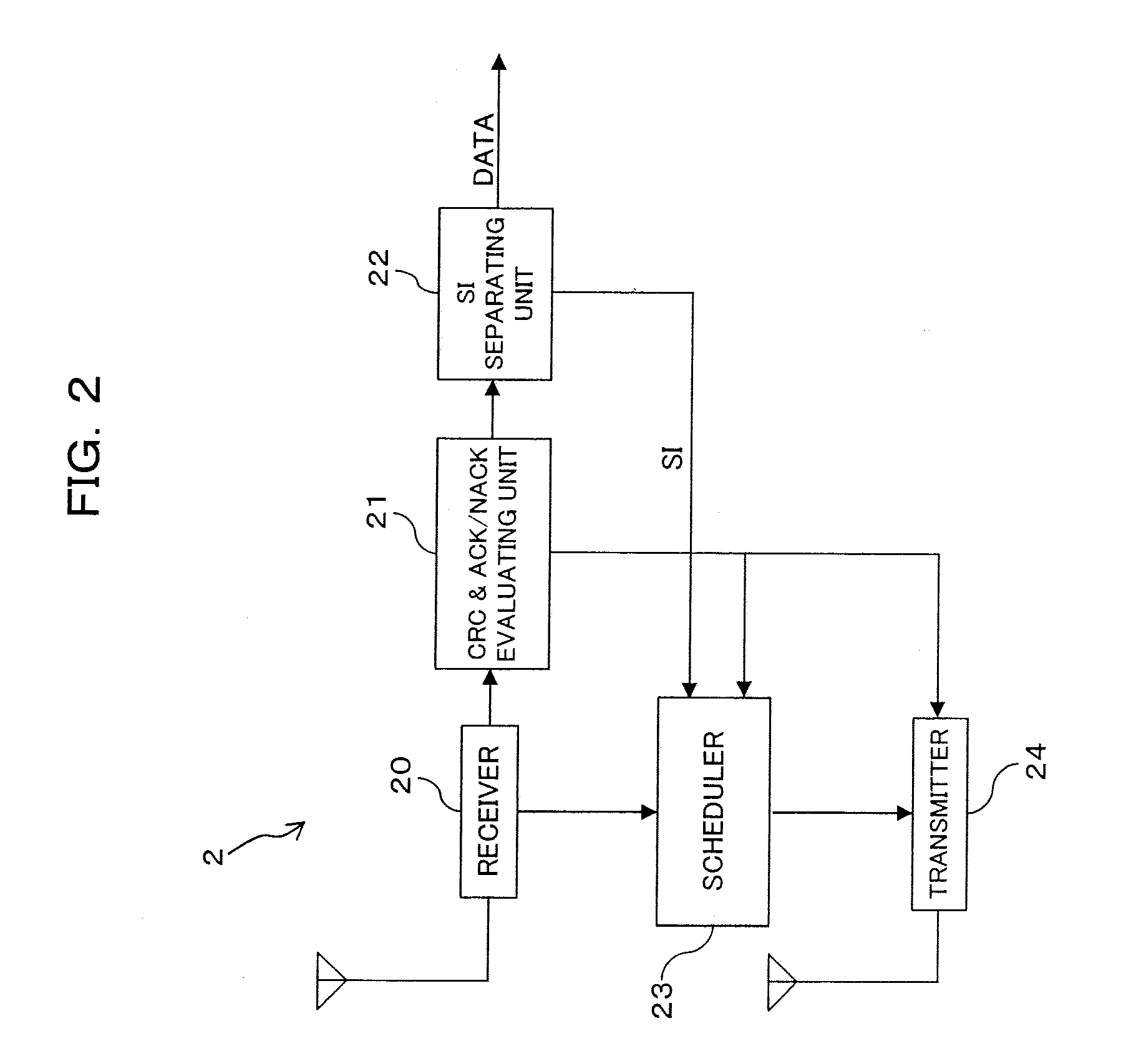

Communication Method In Mobile Communication System, And Mobile Station And Base Station In The Same System

ActiveUS20100284362A1Improve throughputSuppression delayNetwork topologiesTransmission monitoringPresent methodMobile station

Owner:FUJITSU LTD

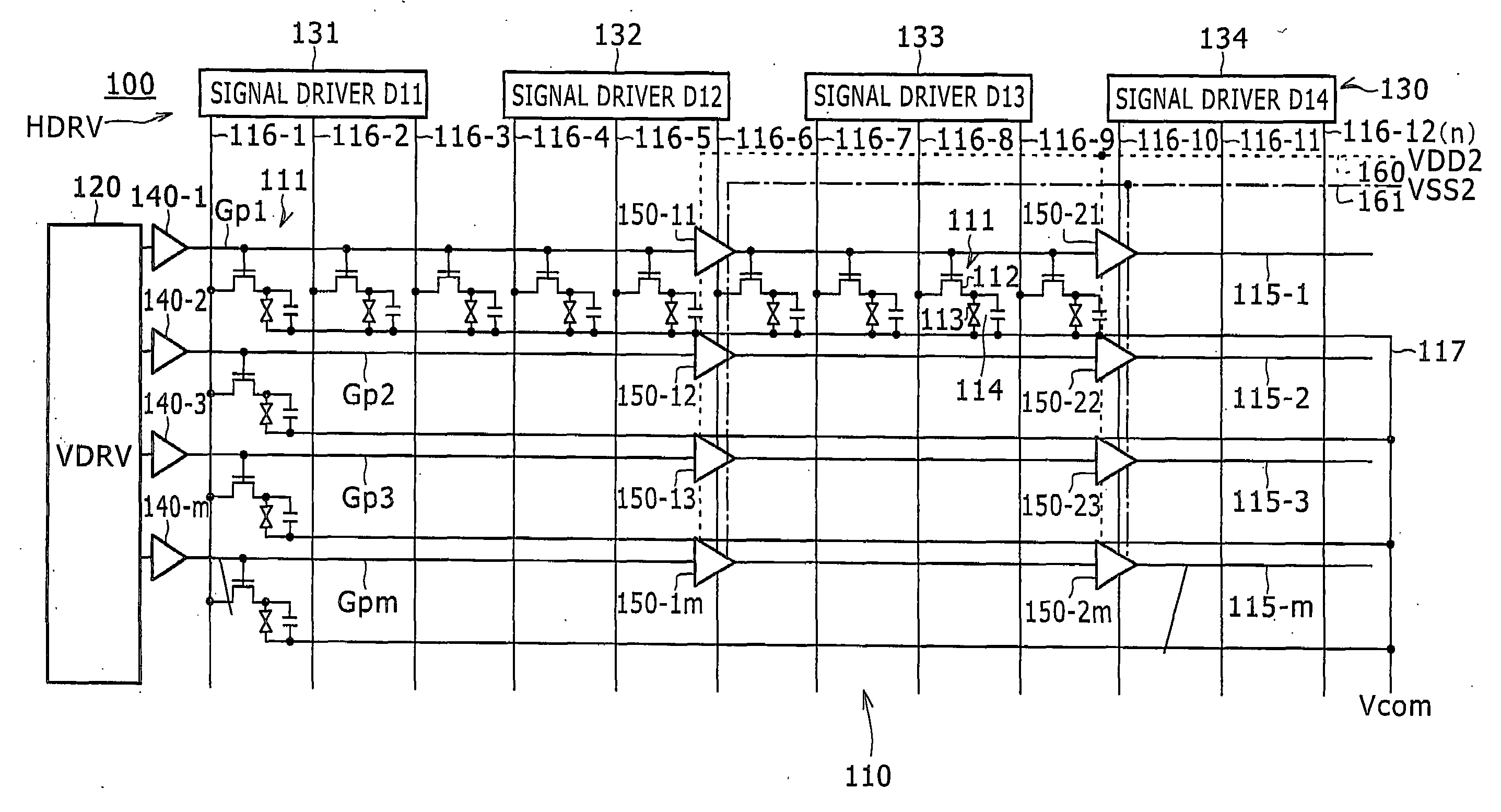

Display apparatus, driving method for display apparatus and electronic apparatus

InactiveUS20090046085A1Decrease in transmission factorIncrease powerCathode-ray tube indicatorsInput/output processes for data processingEngineeringDriving circuit

Disclosed herein is a display apparatus, including, a pixel section, a plurality of scanning lines, a plurality of signal lines, and a driving circuit.

Owner:JAPAN DISPLAY INC

Plasma display panel and manufacturing method therefor

InactiveUS20080157673A1Large secondary electron emission coefficientLaunch evenlyAlternating current plasma display panelsCold-cathode tubesLow voltageSpace charge

“Discharge delay” and “dependence of discharge delay on temperatures” are solved by improving a protective layer, thus a PDP can be driven at a low voltage. Furthermore, the PDP can display excellent images by suppressing “dependence of discharge delay on space charges.” Liquid-phase magnesium alkoxide(Mg(OR)2) or acetylacetone magnesium ate whose purity is 99.95% and over is prepared, and is hydrolyzed by adding a small amount of acids to the solution. Thus, a gel of magnesium hydroxide that is a magnesium oxide precursor is formed. Burning the gel in atmosphere at 700° C. and over produces powder containing MgO particles 16a-16d having the NaCl crystal structure with (100) and (111) crystal faces or with (100), (110) and (111) crystal faces. By pasting the powder on a dielectric layer 7 or a surface layer 8, the MgO powder 16 is formed so as to serve as the protective layer.

Owner:PANASONIC CORP

Communication Method In Mobile Communication System, And Mobile Station And Base Station In The Same System

ActiveUS20090296667A1Improve throughputSuppression delayError preventionFrequency-division multiplex detailsMobile communication systemsMobile station

A scheduling method for transmitting an uplink signal from a mobile station to a base station comprises transmitting the uplink signal in a first scheduling mode in which the mobile station can transmit the uplink data without permission of the base station if an uplink communication state between the base station and the mobile station is higher than or equal to a predetermined quality; and transmitting the uplink signal in a second scheduling mode in which the permission is necessary for the mobile station transmitting the uplink data if the uplink communication state is lower than the predetermined quality.

Owner:FUJITSU LTD

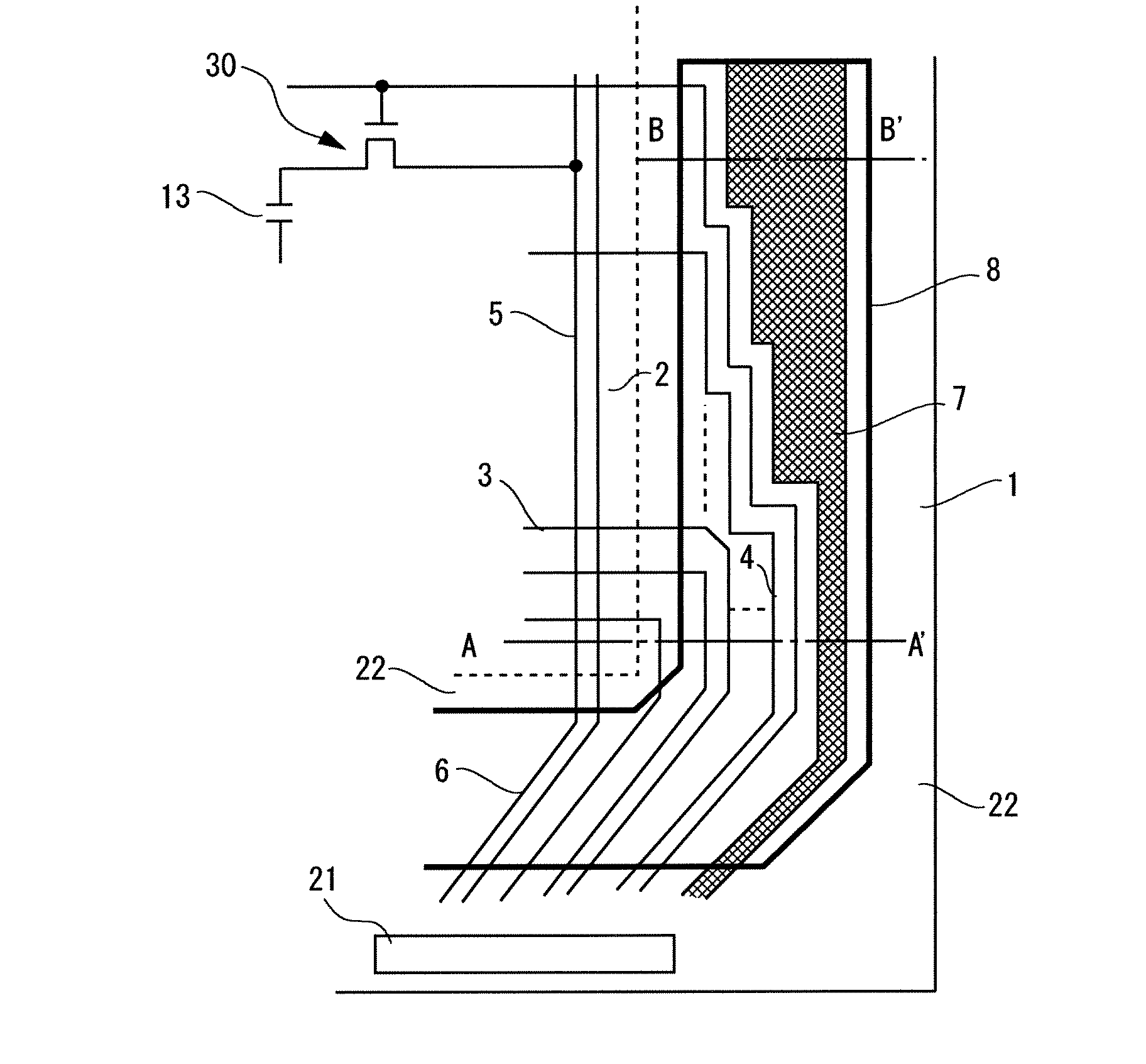

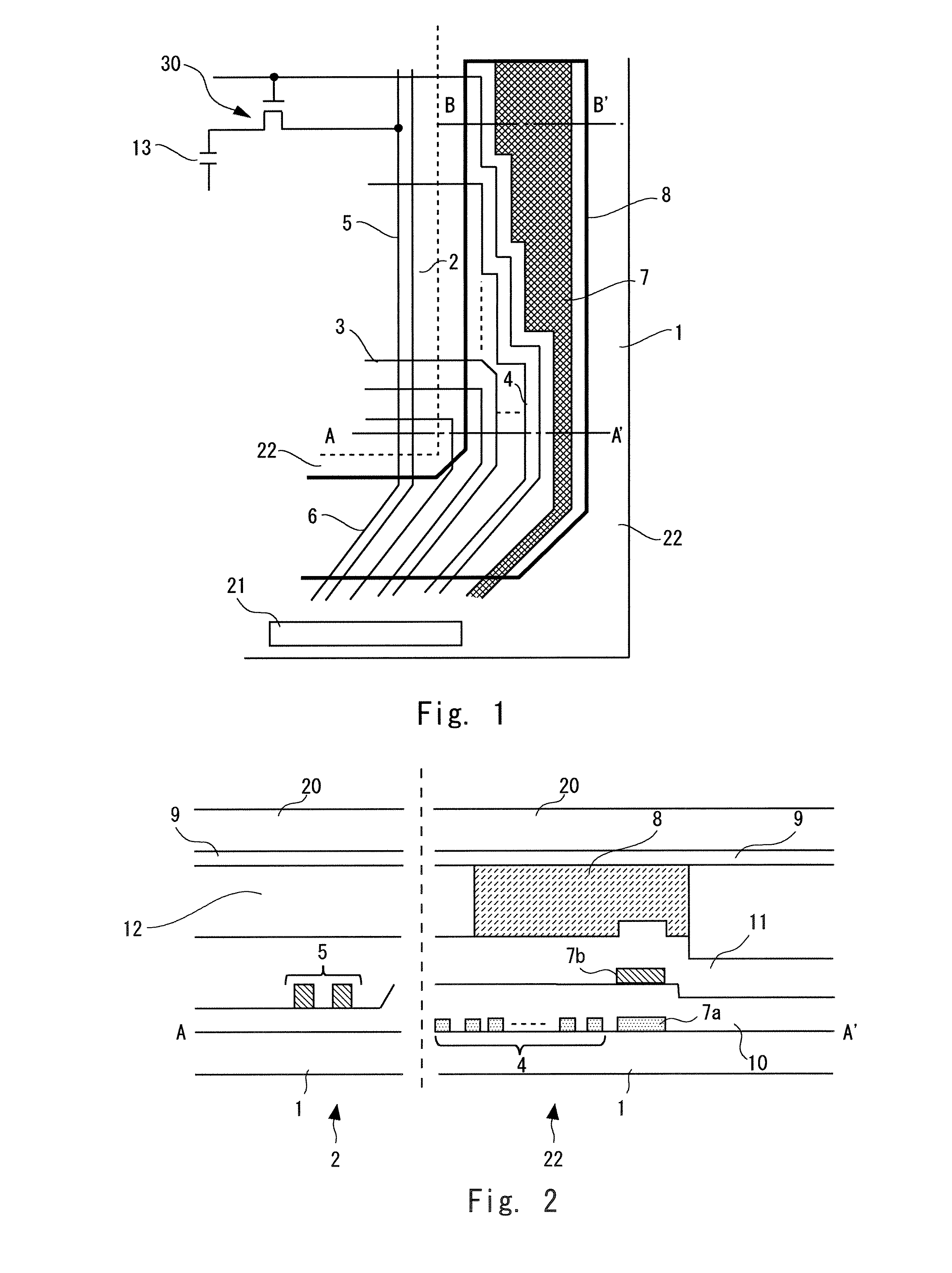

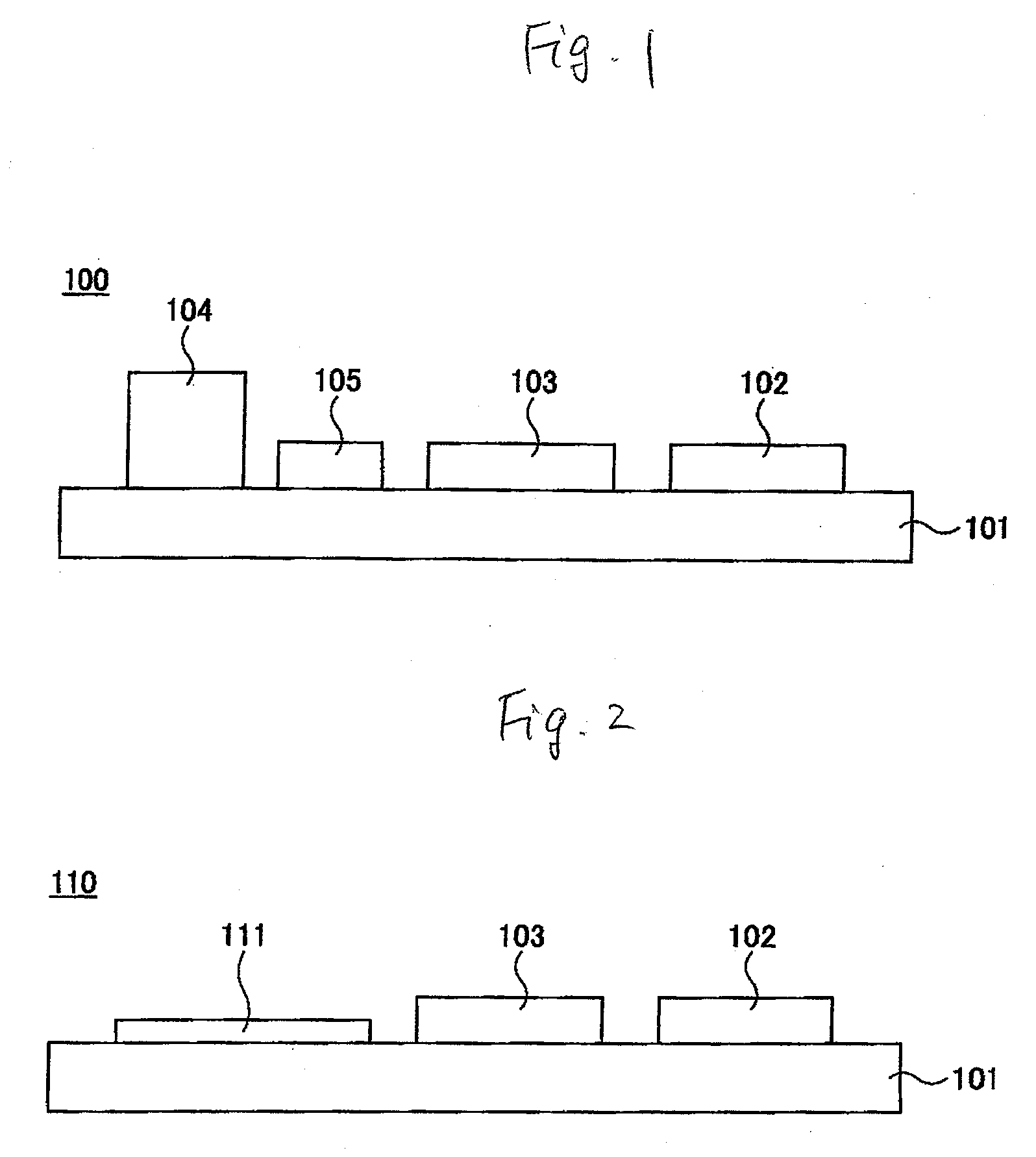

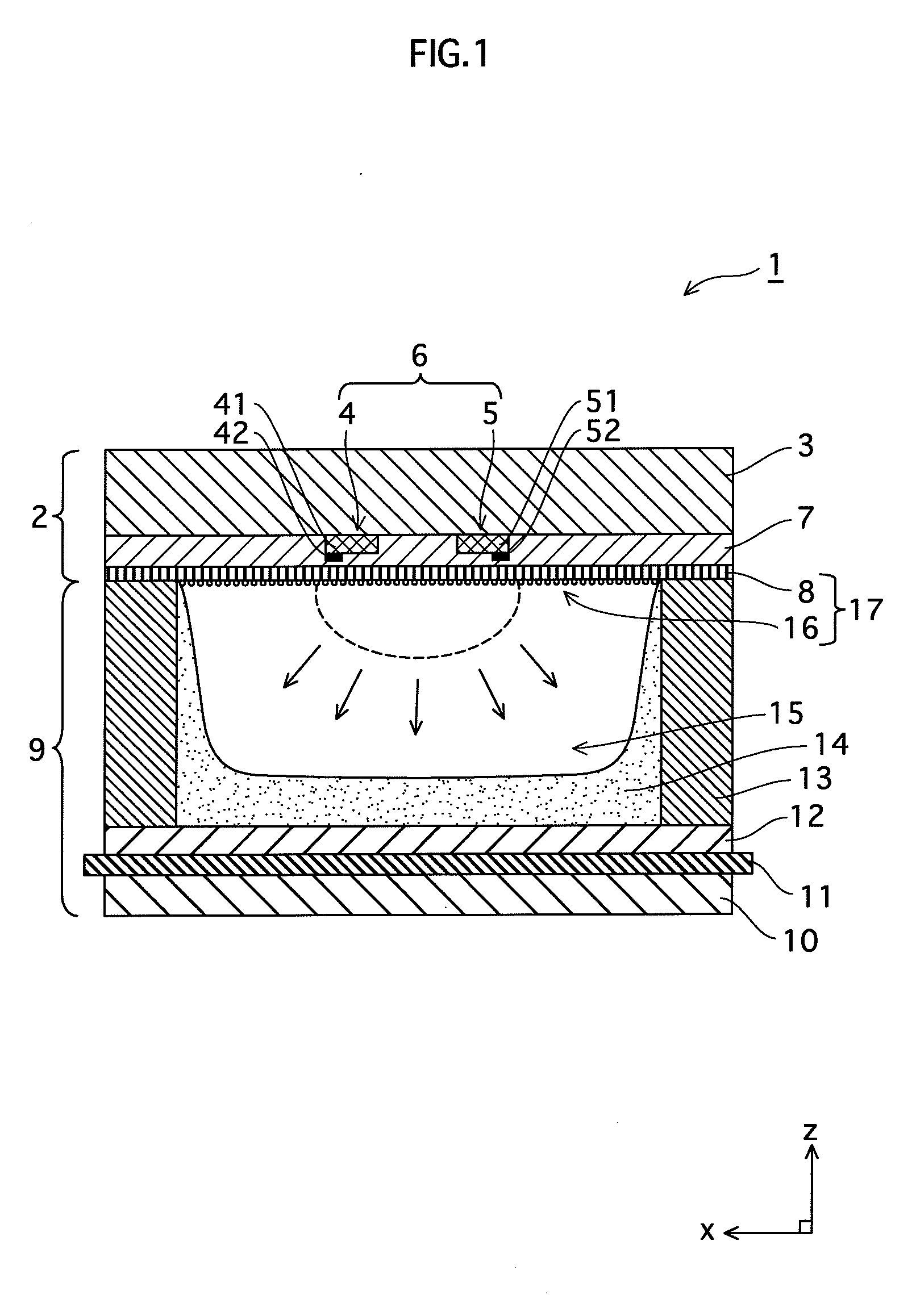

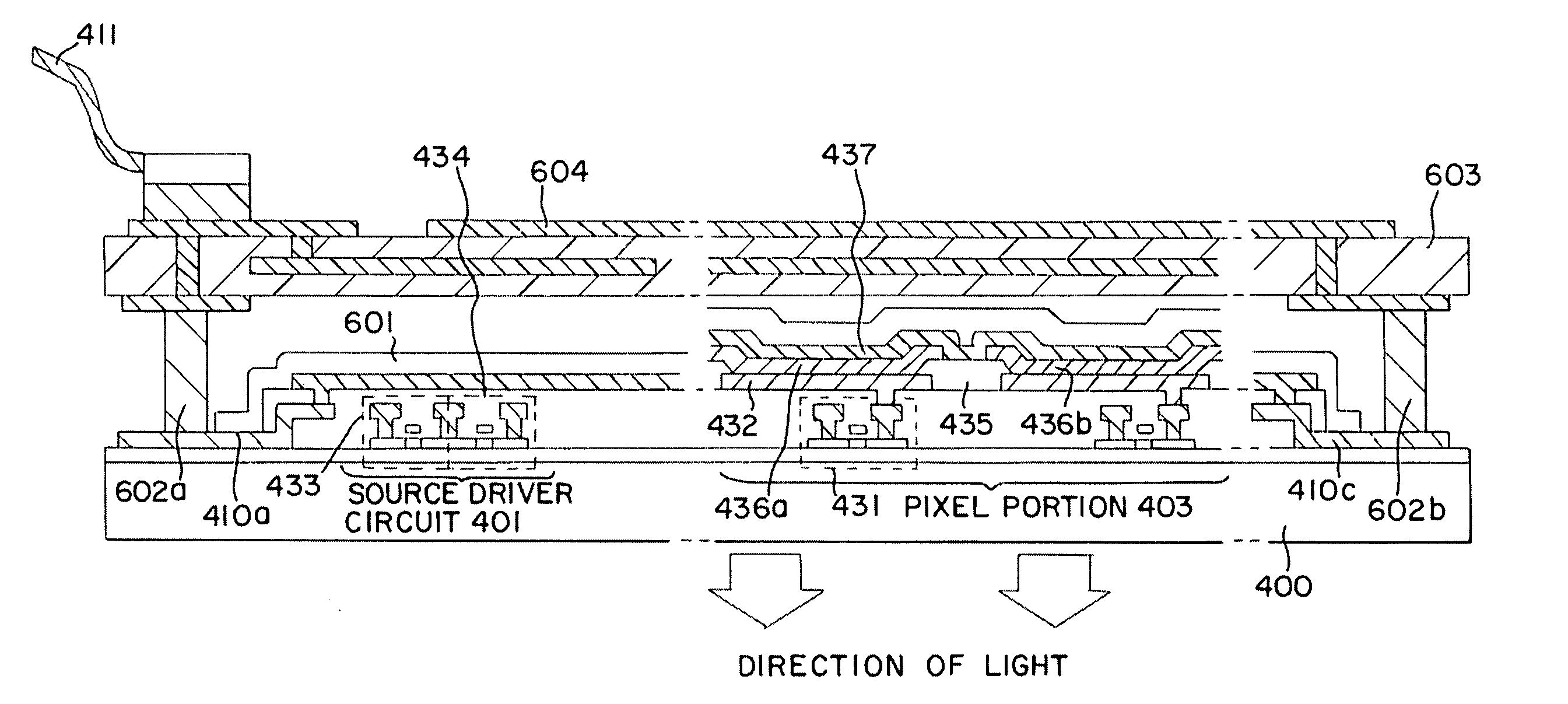

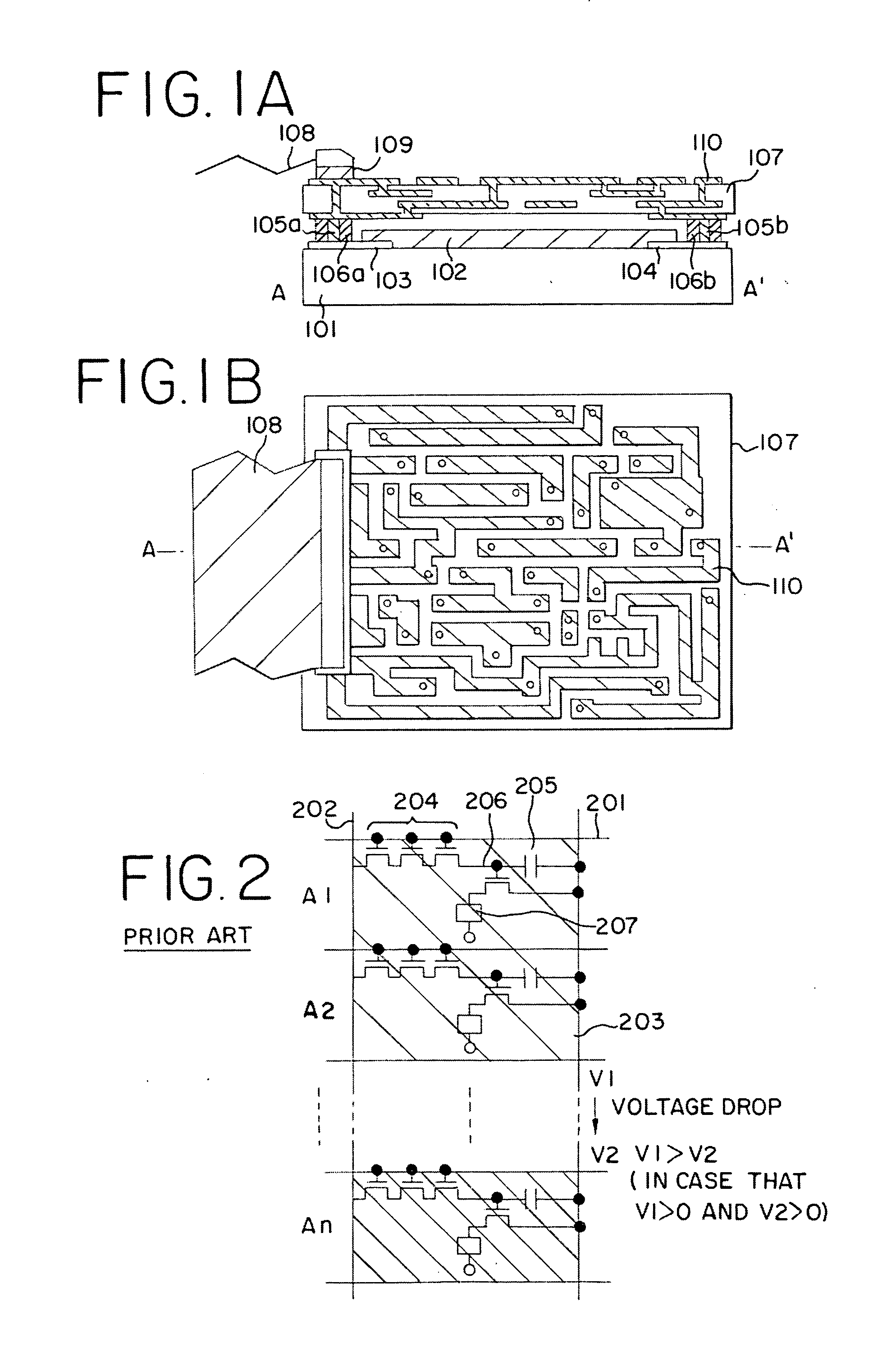

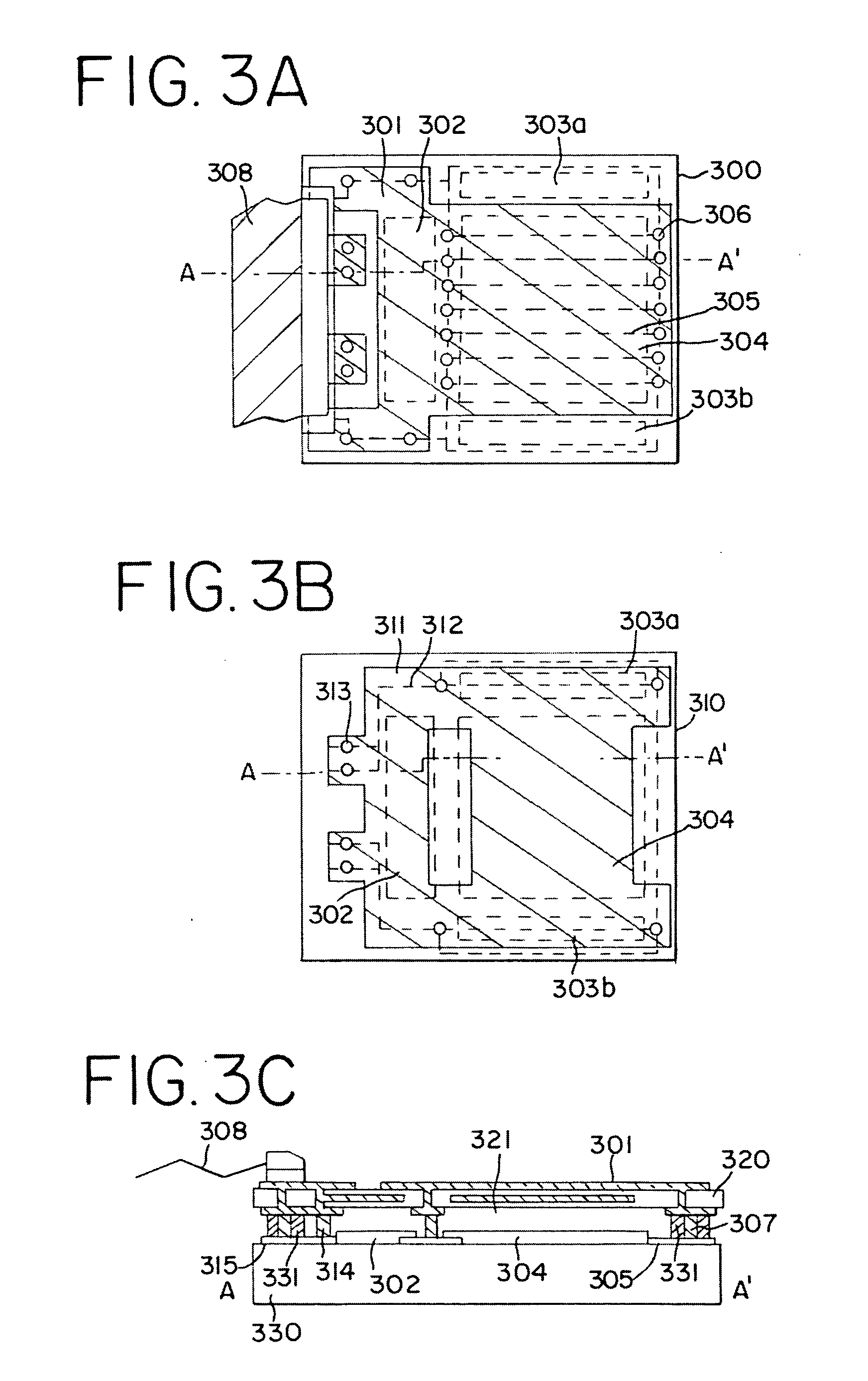

Light-emitting device

InactiveUS20050156509A1Suppression delayHigh speedTelevision system detailsFinal product manufactureDriver circuitAnisotropic conductive film

A light-emitting device having the quality of an image high in homogeneity is provided. A printed wiring board (second substrate) (107) is provided facing a substrate (first substrate) (101) that has a luminous element (102) formed thereon. A PWB side wiring (second group of wirings) (110) on the printed wiring board (107) is electrically connected to element side wirings (first group of wirings) (103, 104) by anisotropic conductive films (105a, 105b). At this point, because a low resistant copper foil is used to form the PWB side wiring (110), a voltage drop of the element side wirings (103, 104) and a delay of a signal can be reduced. Accordingly, the homogeneity of the quality of an image is improved, and the operating speed of a driver circuit portion is enhanced.

Owner:SEMICON ENERGY LAB CO LTD

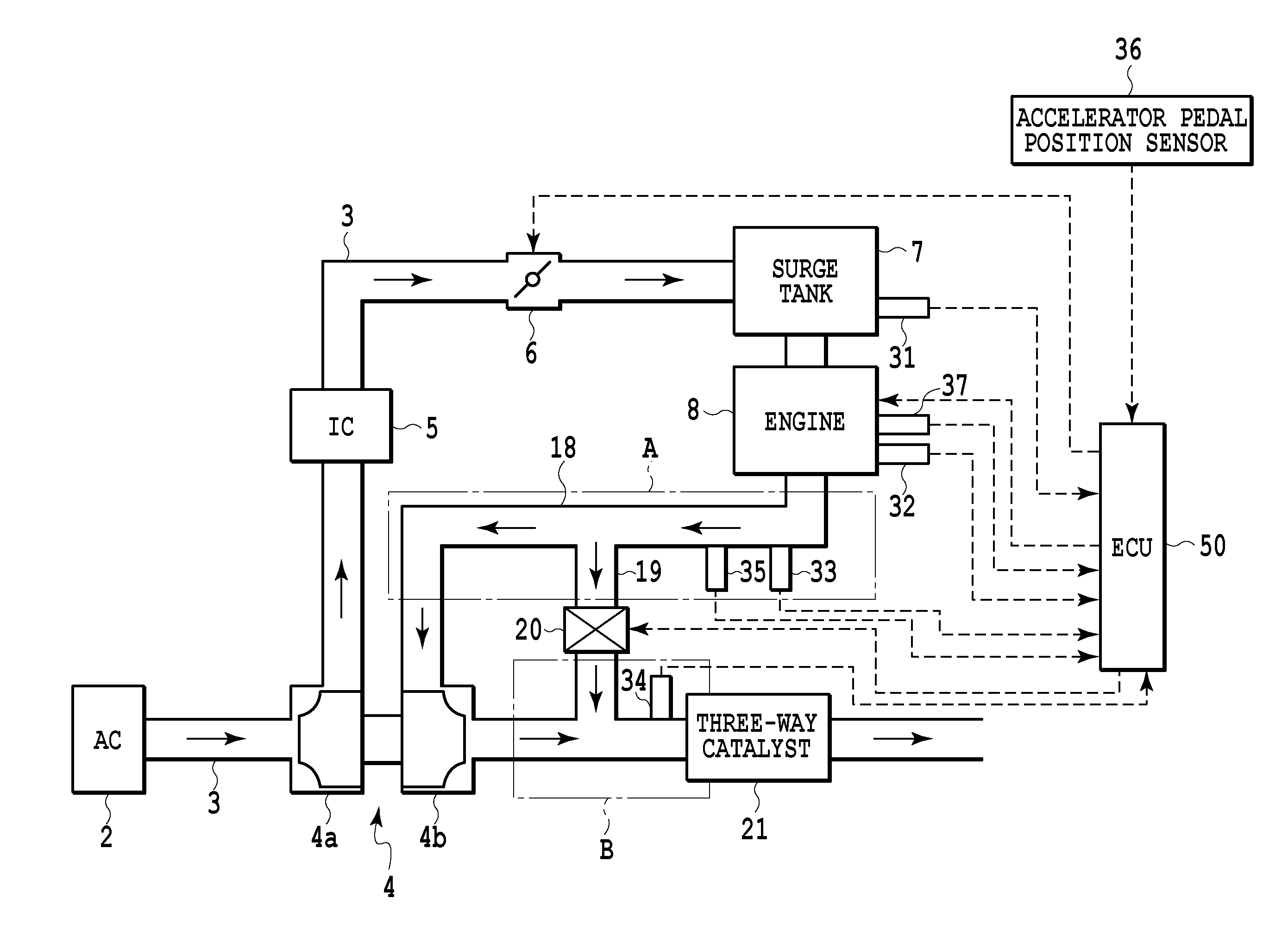

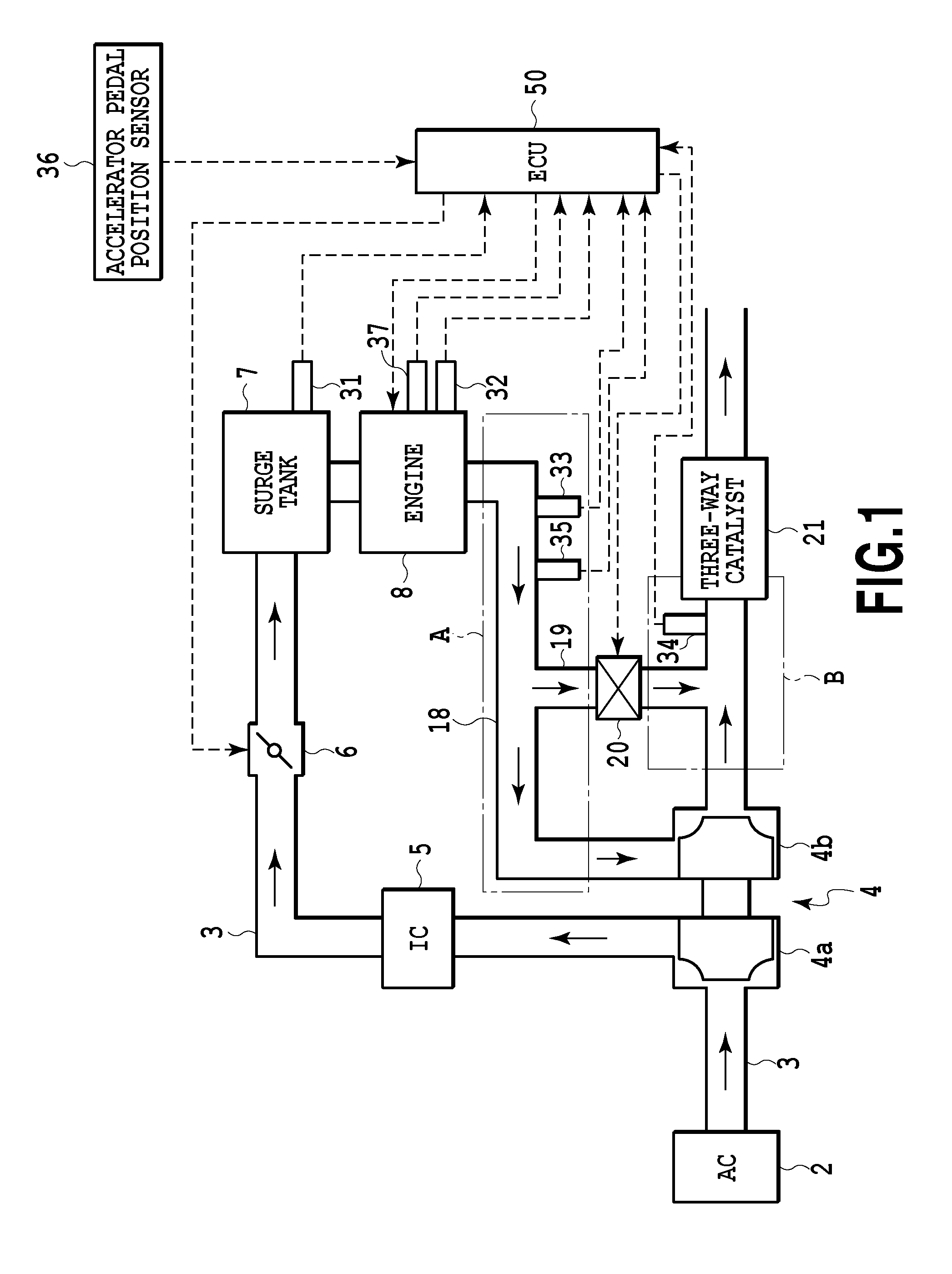

Apparatus for controlling an internal combustion engine

InactiveUS20150300245A1Simple measureSuppression delayElectrical controlInternal combustion piston enginesLean combustionEngineering

A control apparatus for an internal combustion engine is provided. The control apparatus includes a turbocharger, a bypass passage, a wastegate valve, a catalyst device and a controller. The controller sets the wastegate valve to a closed state in a case where a warm-up execution condition is established, and performs A / F oscillation for increasing or decreasing the fuel injection amount so that lean combustion and rich combustion are alternately performed in a case where the temperature in the exhaust passage upstream of the turbocharger is beyond a predetermined reference value.

Owner:TOYOTA JIDOSHA KK

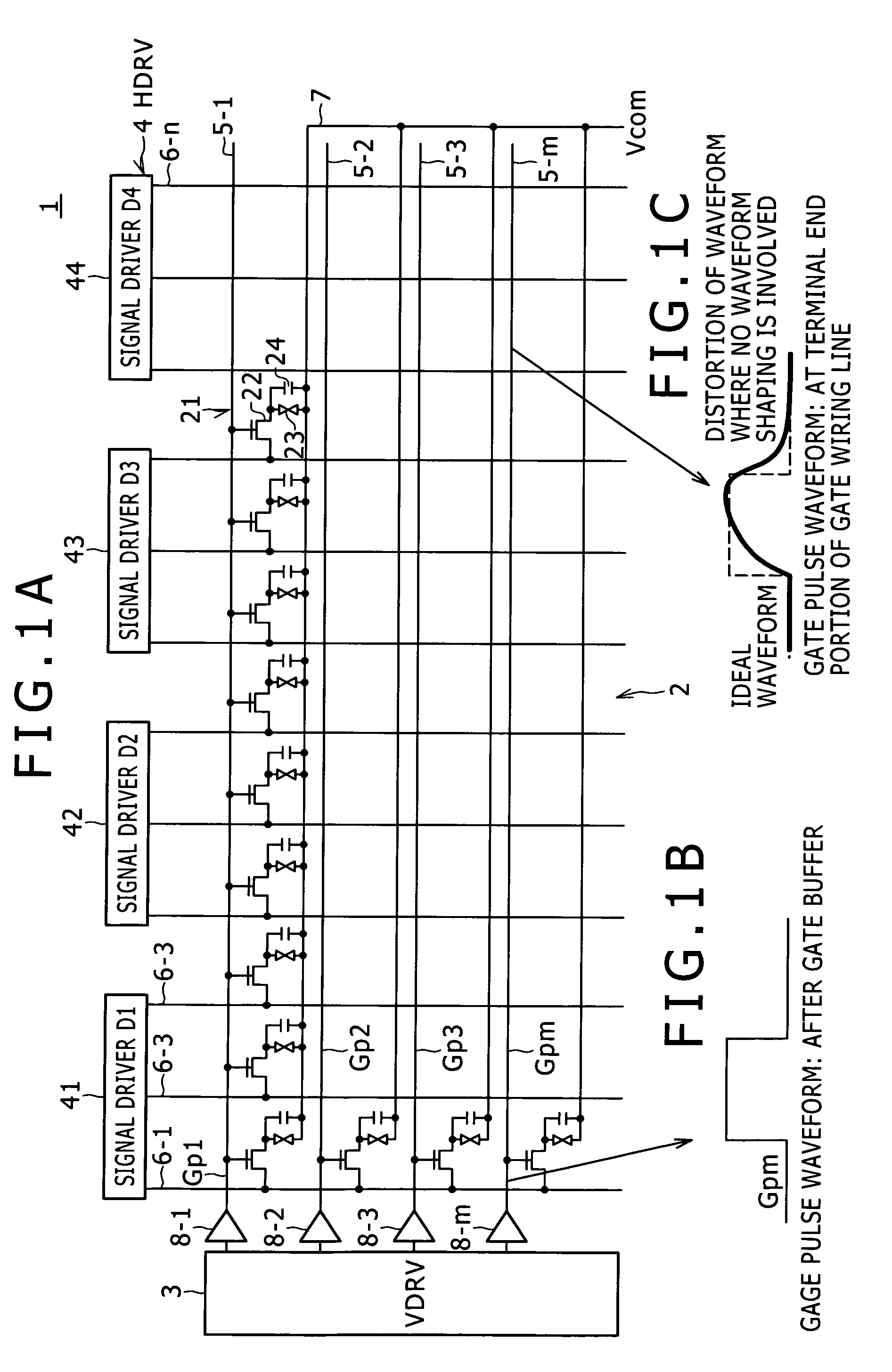

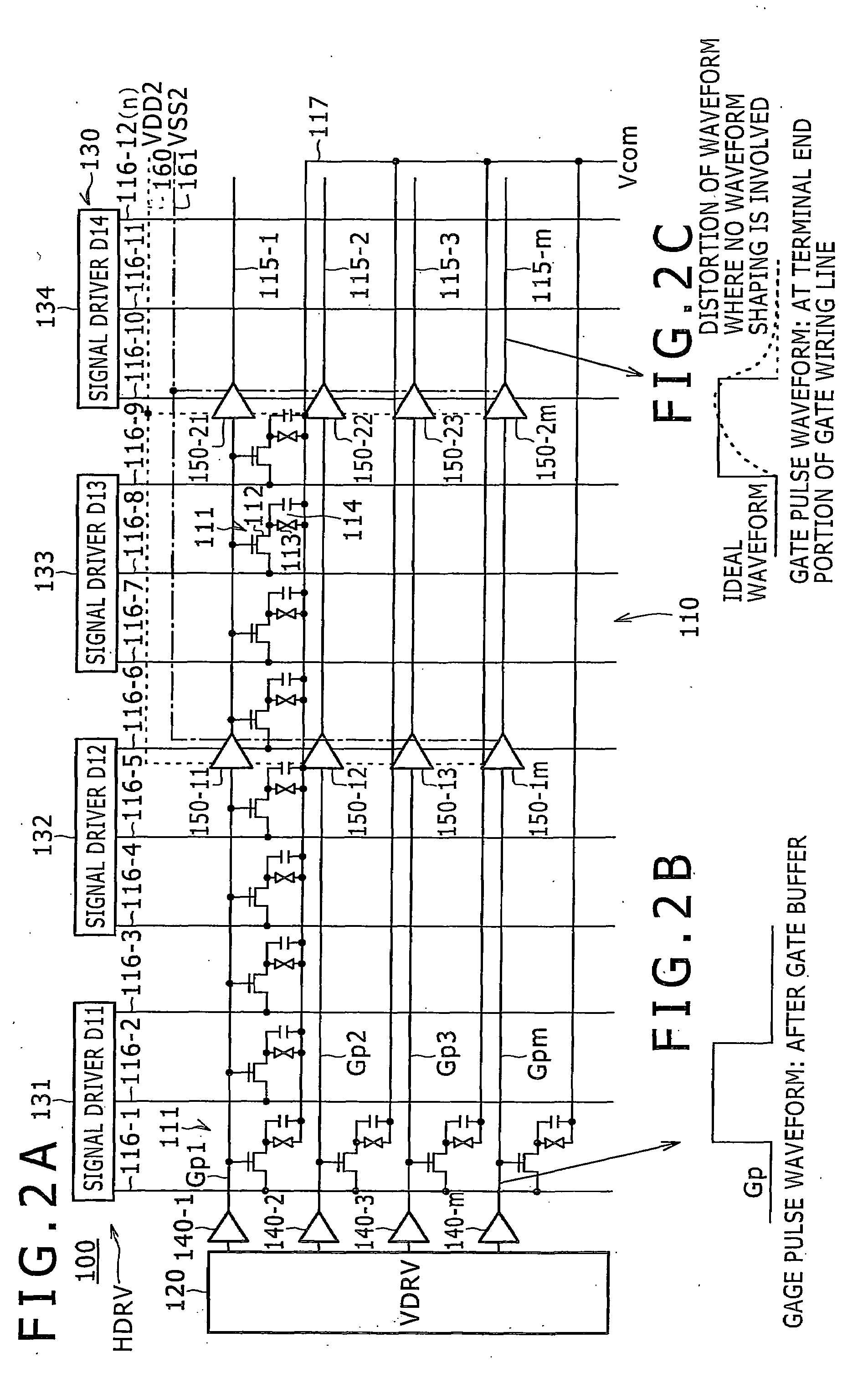

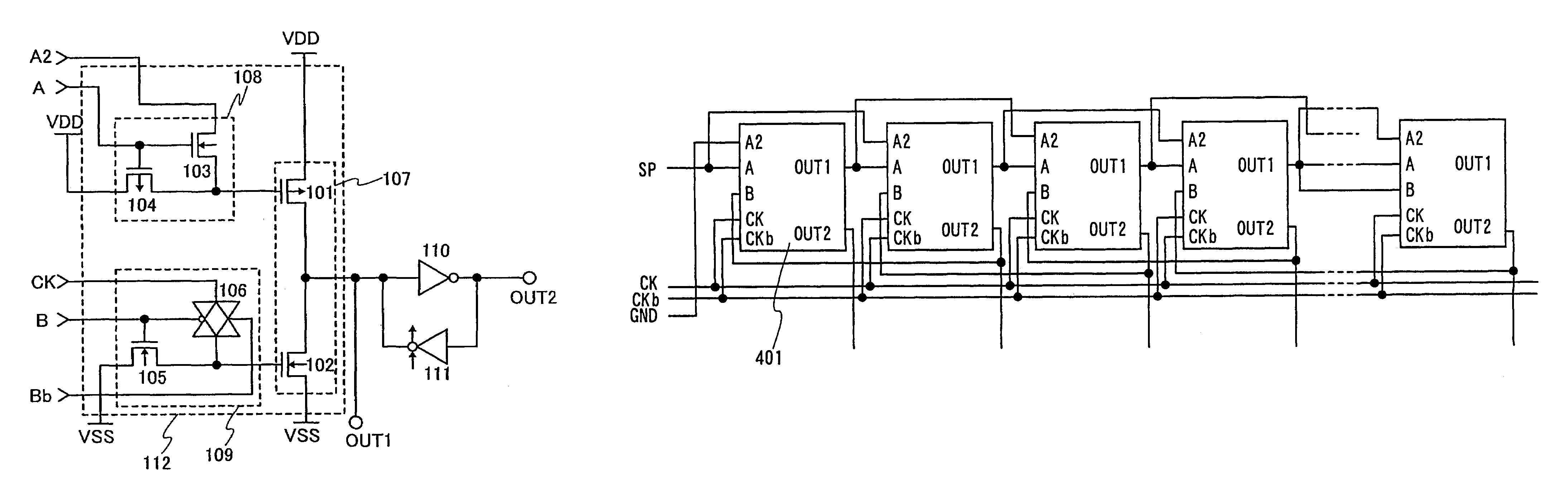

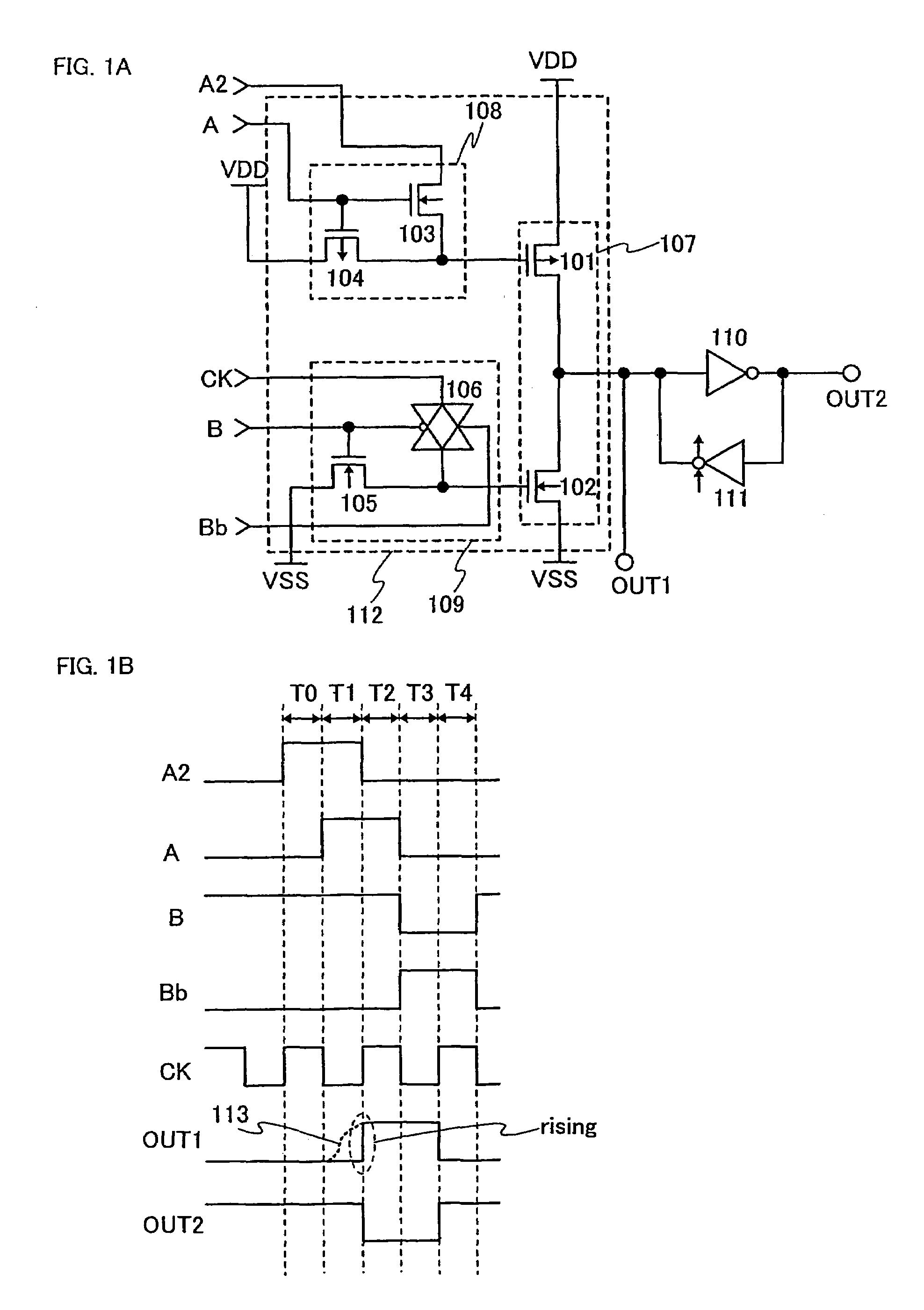

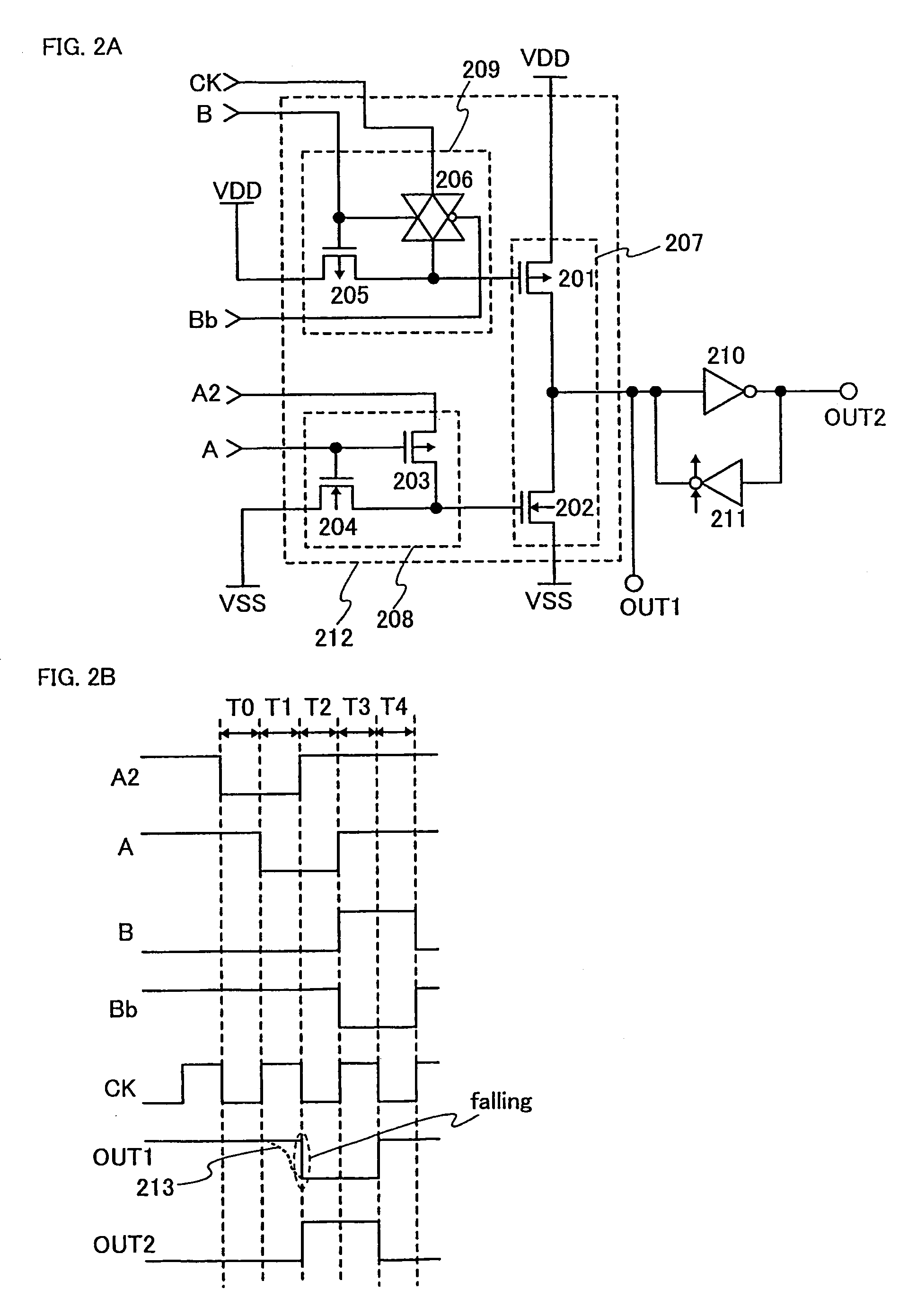

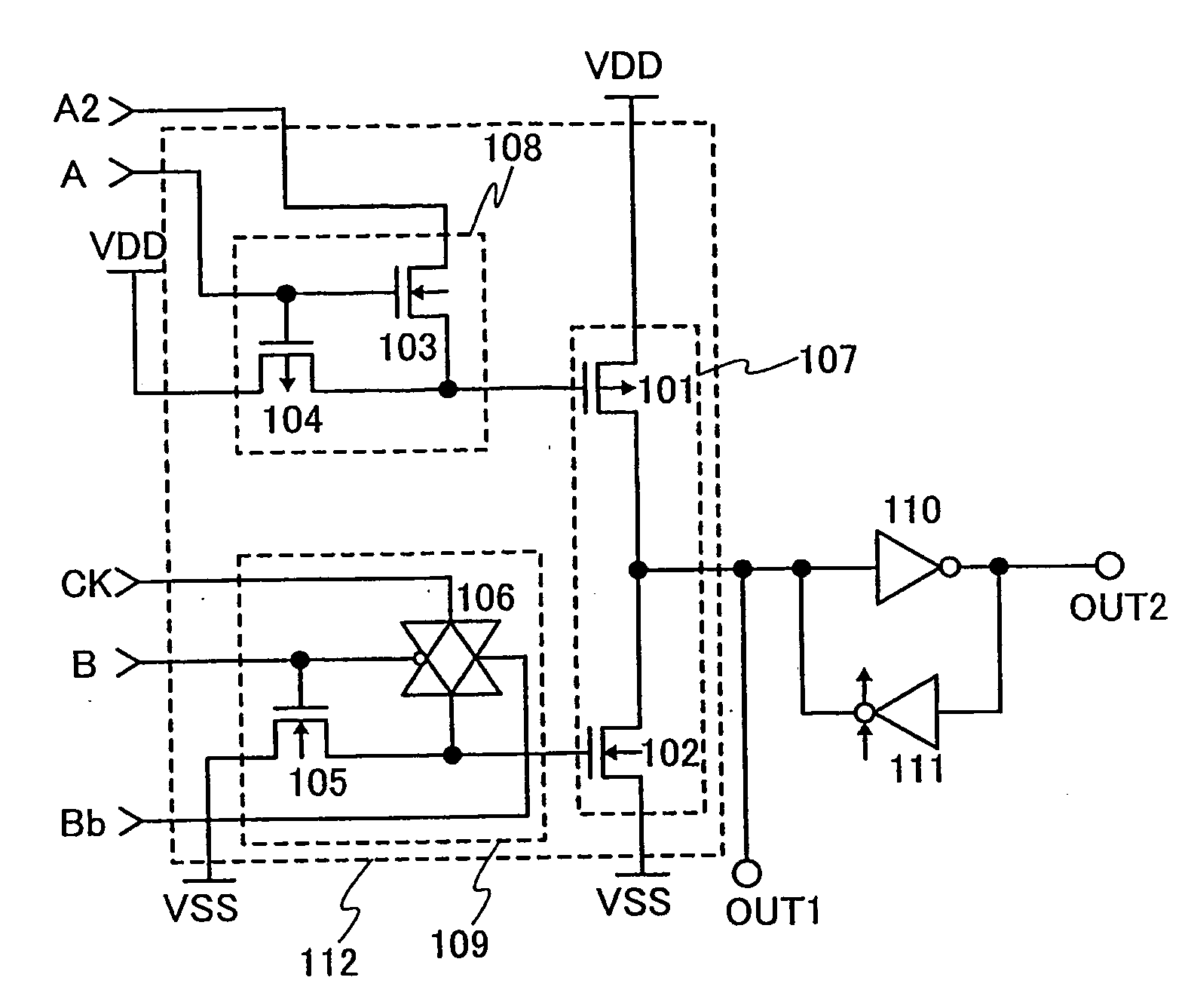

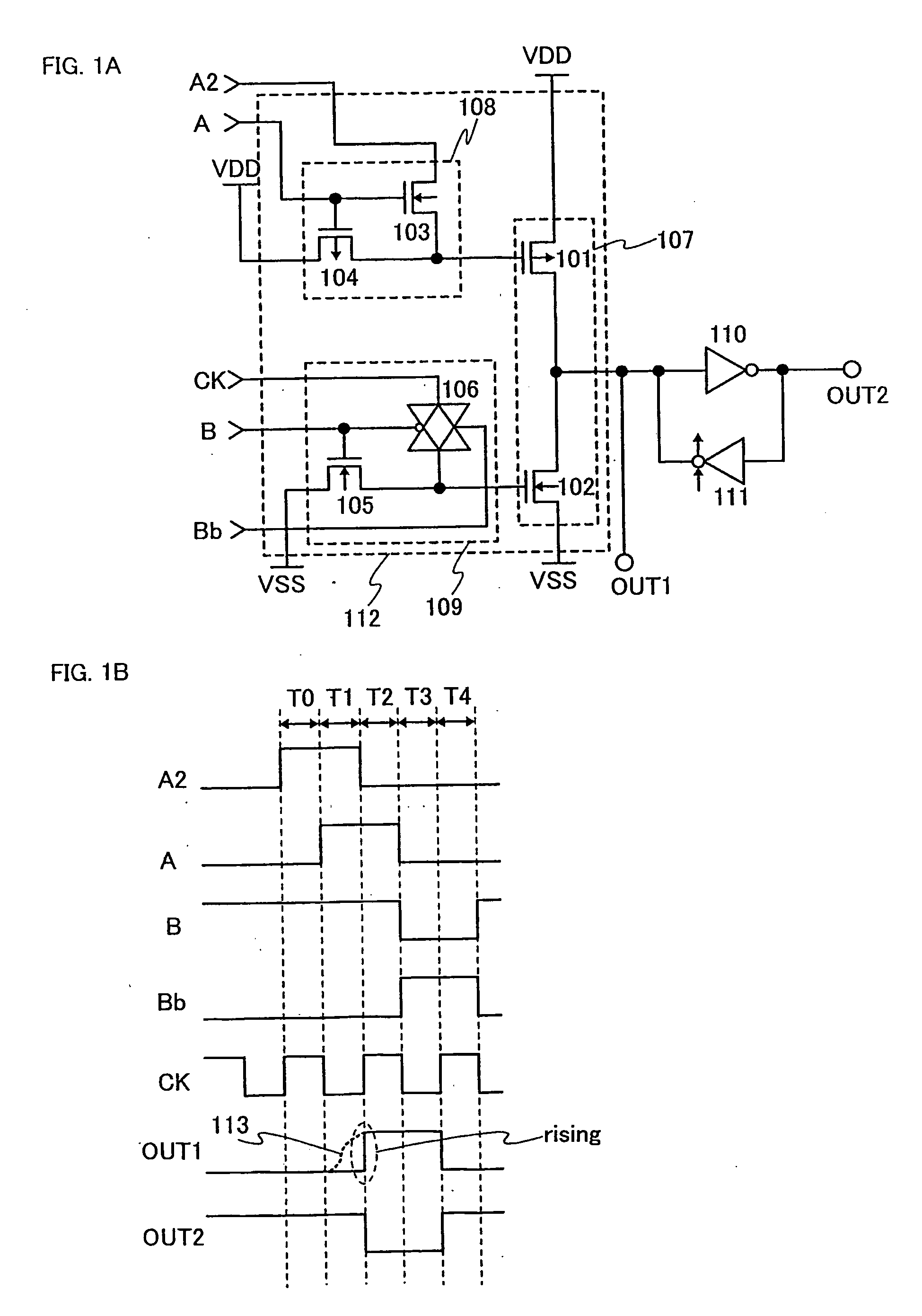

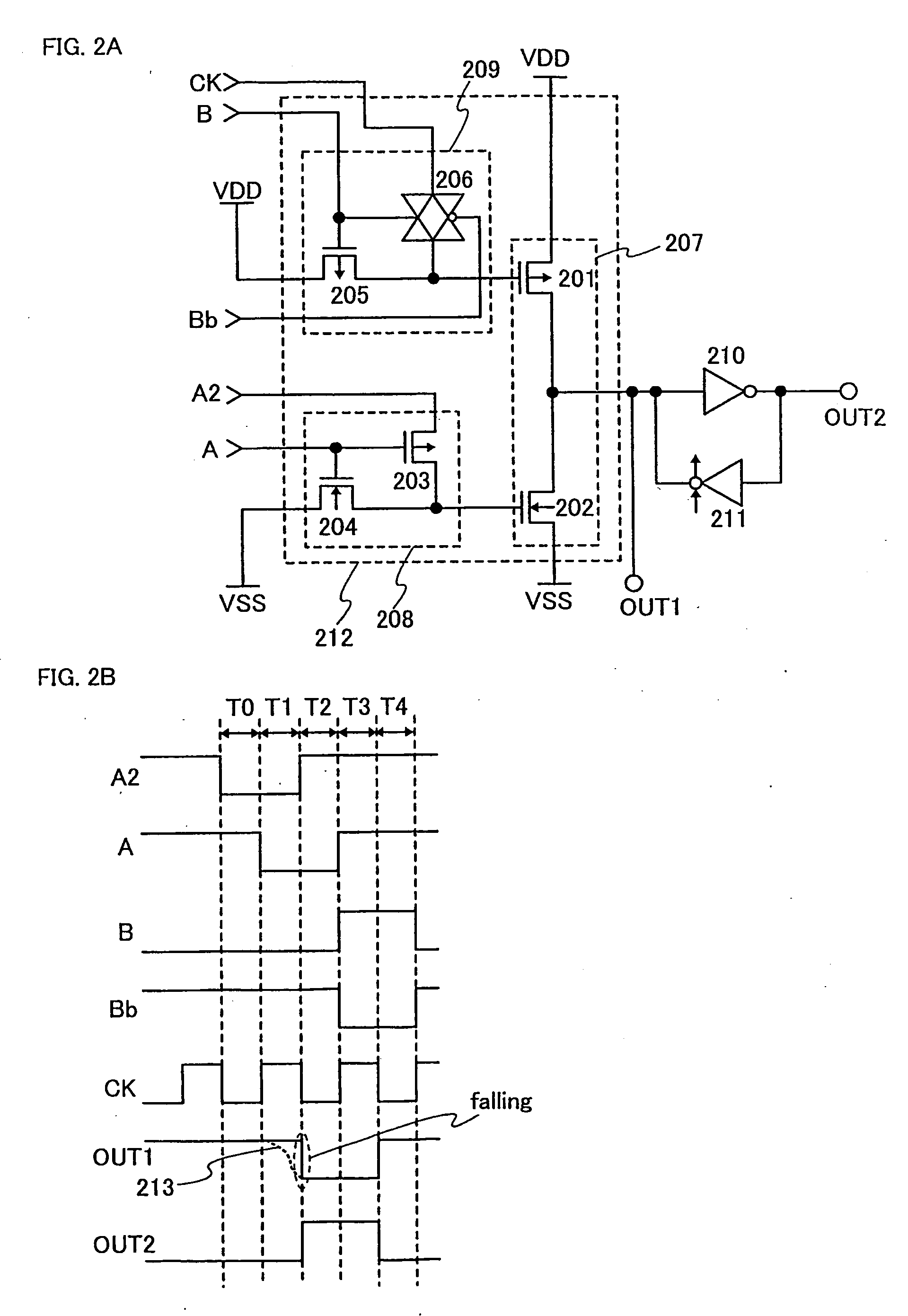

Shift register and semiconductor display device

ActiveUS7602215B2Reduce sizeSuppress signal delayStatic indicating devicesCounting chain pulse countersShift registerPower inverter

The invention provides a shift register which can operate normally while suppressing a delay of signal and a rounding of waveform. The shift register of the invention includes a plurality of stages of flip-flop circuits each of which includes a clocked inverter. The clocked inverter includes a first transistor and a second transistor which are connected in series, a first compensation circuit including a third transistor and a fourth transistor which are connected in series, and a second compensation circuit including a fifth transistor and a transmission gate. According to the first compensation circuit, a timing at which a signal outputted from the flip-flop circuit rises or falls can be controlled in synchronization with an output of two stages before. The second compensation circuit can control a clock signal input can be controlled.

Owner:SEMICON ENERGY LAB CO LTD

Shift Register and Semiconductor Display Device

ActiveUS20080273004A1Stable in free energyImprove lattice distortionStatic indicating devicesCounting chain pulse countersShift registerTransmission gate

The invention provides a shift register which can operate normally while suppressing a delay of signal and a rounding of waveform. The shift register of the invention includes a plurality of stages of flip-flop circuits each of which includes a clocked inverter. The clocked inverter includes a first transistor and a second transistor which are connected in series, a first compensation circuit including a third transistor and a fourth transistor which are connected in series, and a second compensation circuit including a fifth transistor and a transmission gate. According to the first compensation circuit, a timing at which a signal outputted from the flip-flop circuit rises or falls can be controlled in synchronization with an output of two stages before. The second compensation circuit can control a clock signal input can be controlled.

Owner:SEMICON ENERGY LAB CO LTD

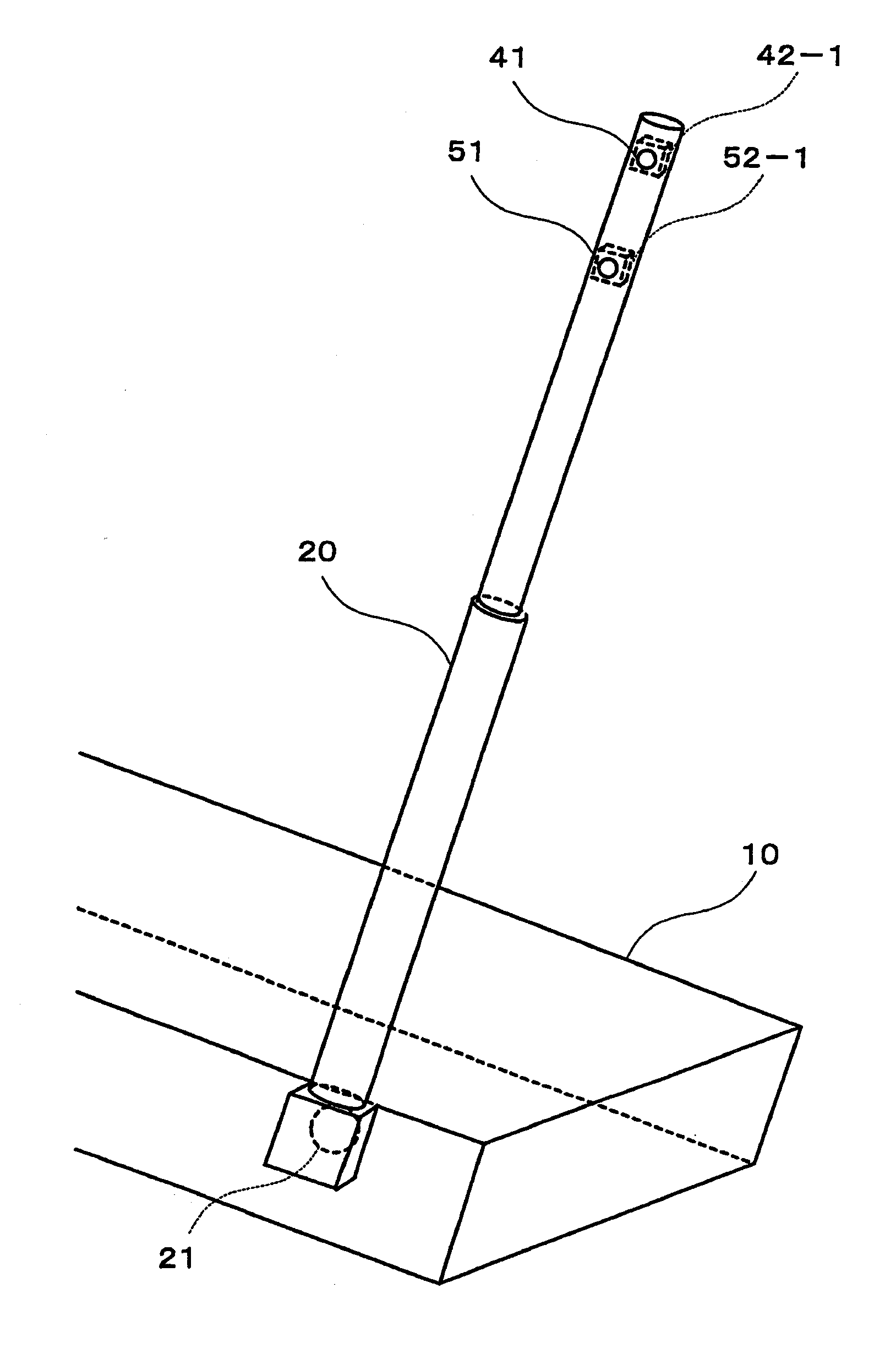

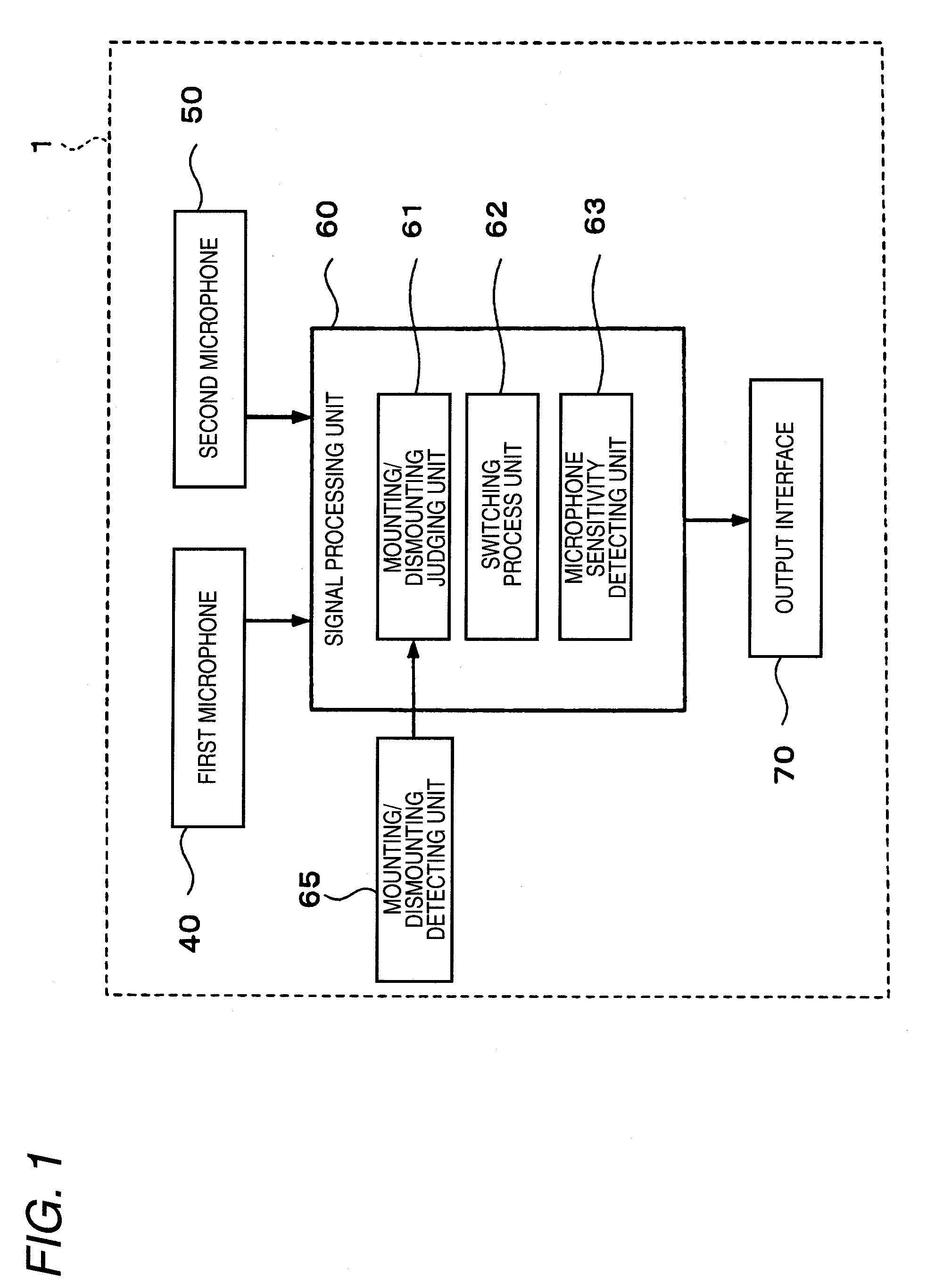

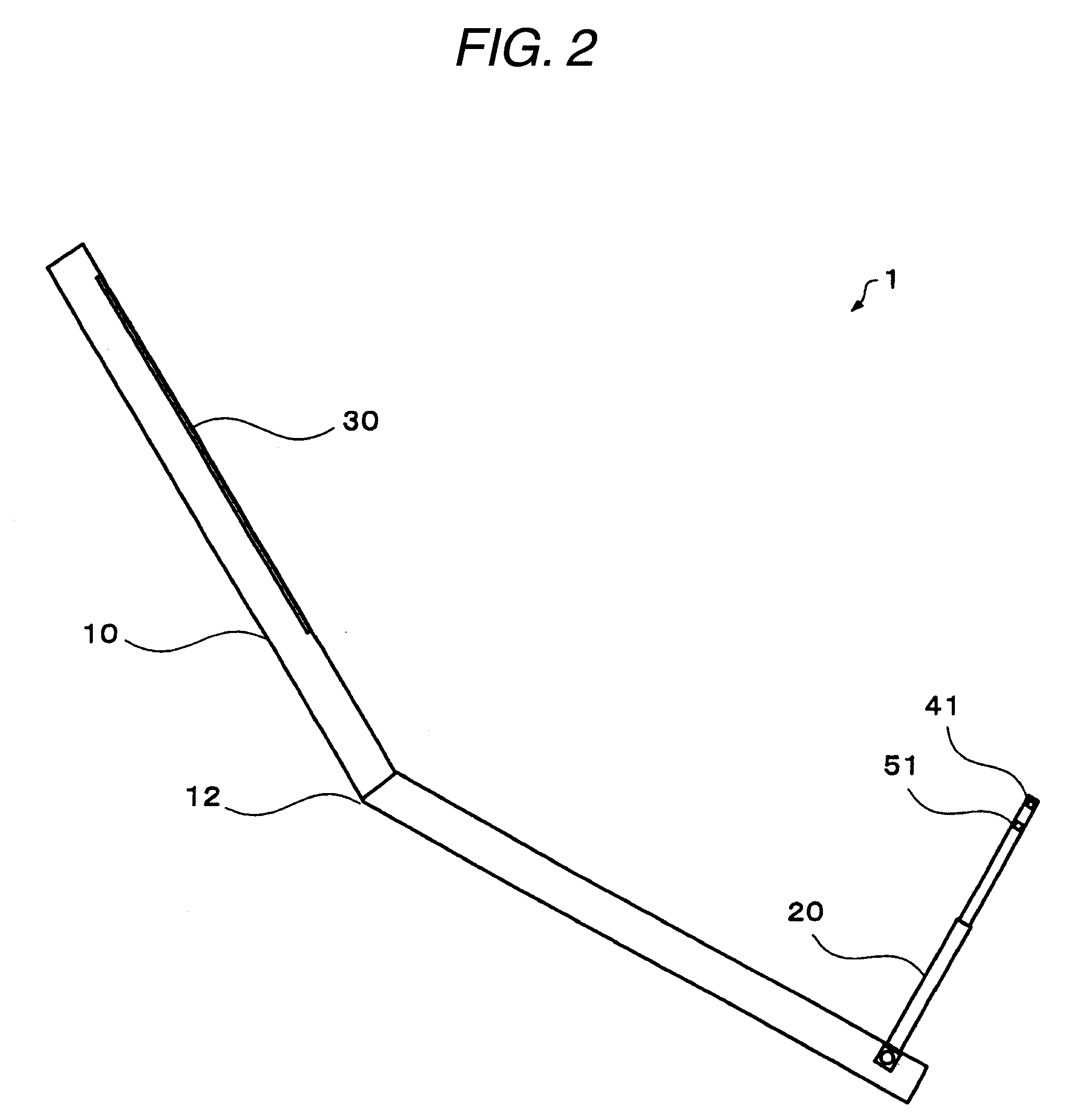

Voice sound input apparatus

InactiveUS20090310811A1Suppression problemSuppression delayPiezoelectric/electrostrictive microphonesMicrophonesSound sourcesComputer science

A voice sound input apparatus, adapted to be inputted a sound and configured to output sound data, includes: a display unit; a first microphone, related to a first sound hole; a second microphone, related to a second sound hole; a signal processing unit; and a microphone holding unit, formed with the first sound hole, and adapted to extend toward a sound source predicted position; wherein a distance between the first sound hole and the second sound hole is a distance that a phase component of a sound strength ratio is lower than or equal to 0 dB, the sound strength ratio being a ratio between a strength of a sound component contained in differential sound pressure of sounds entered to the first sound hole and the second sound hole and a strength of sound pressure of the sound entered to the first sound hole.

Owner:ONPA TECH

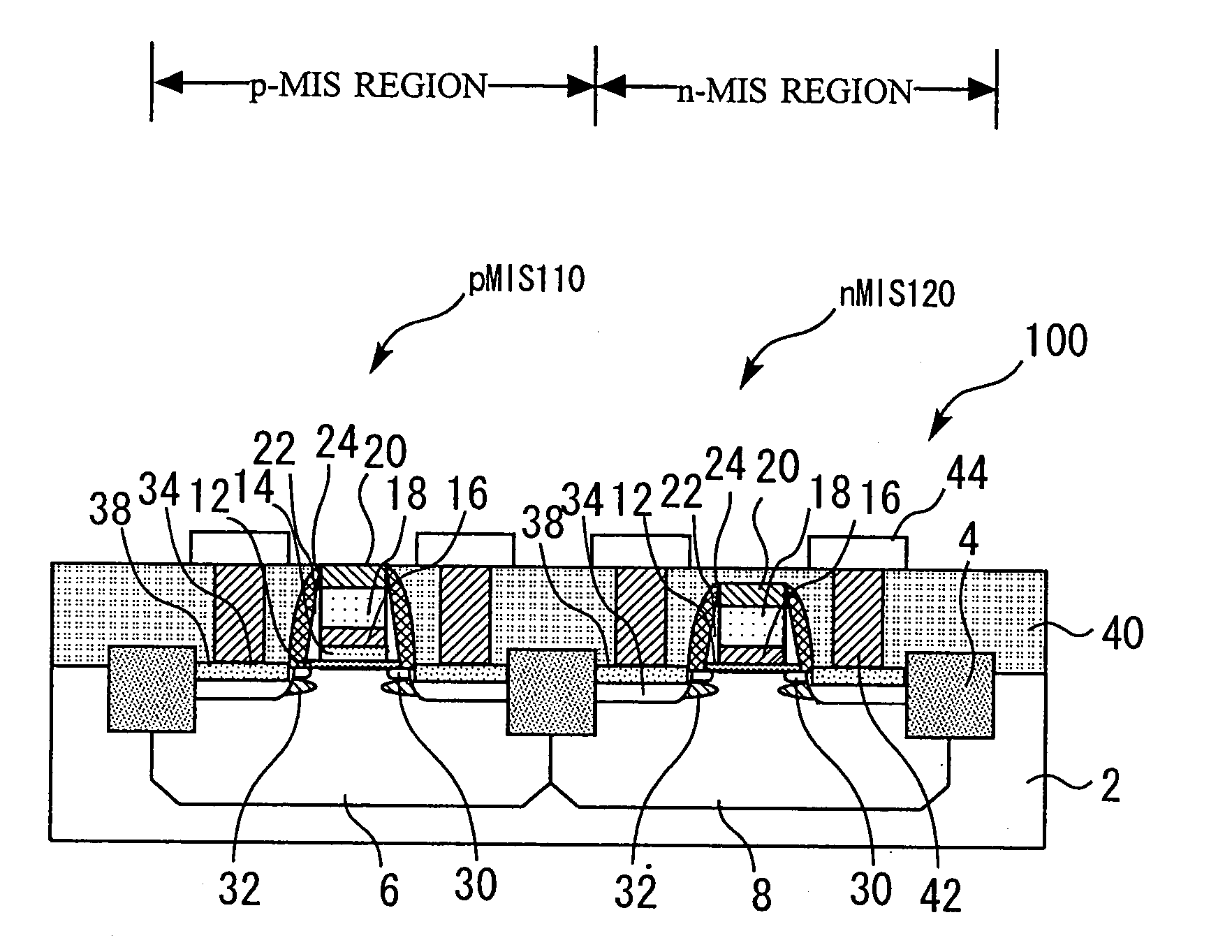

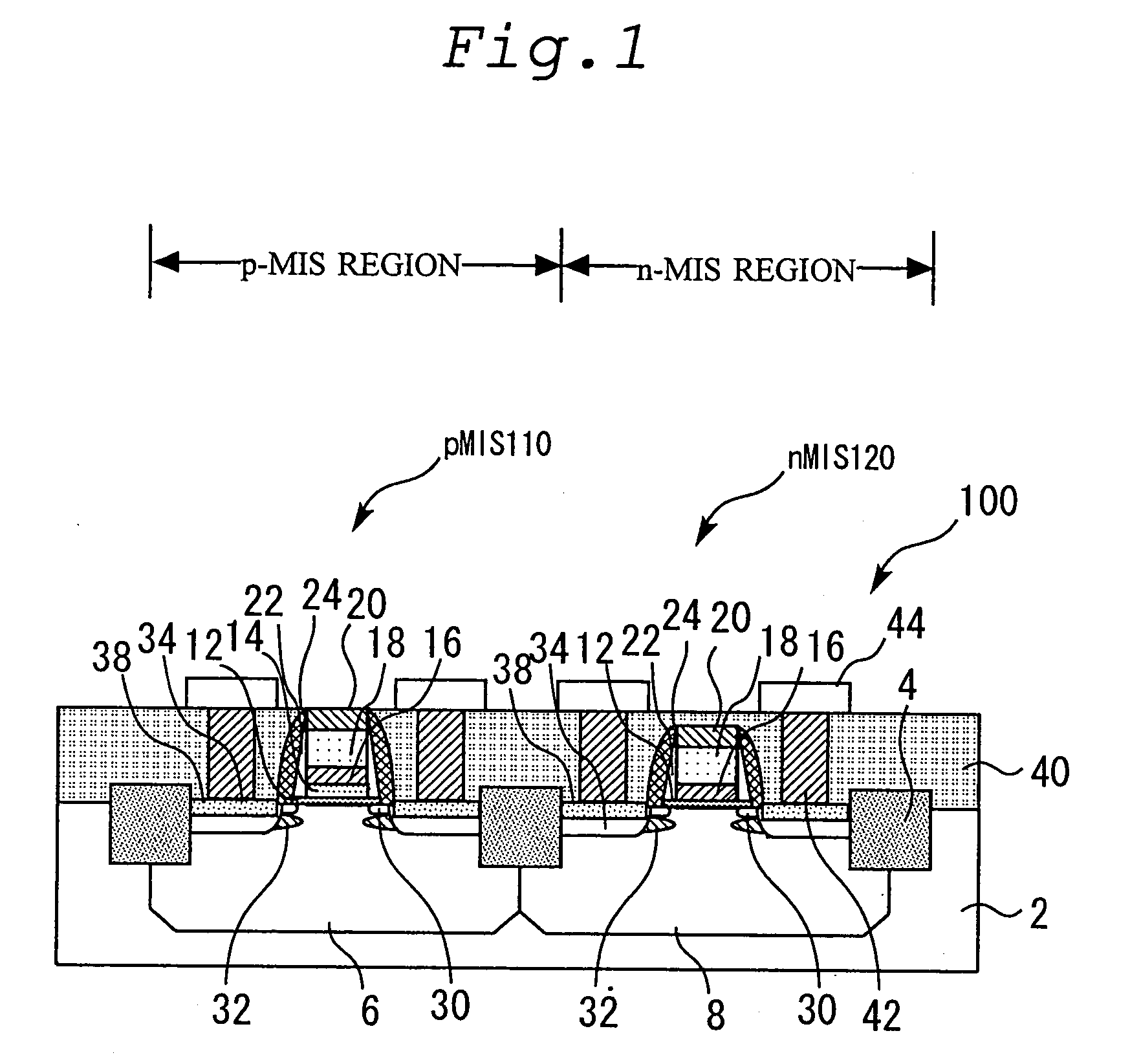

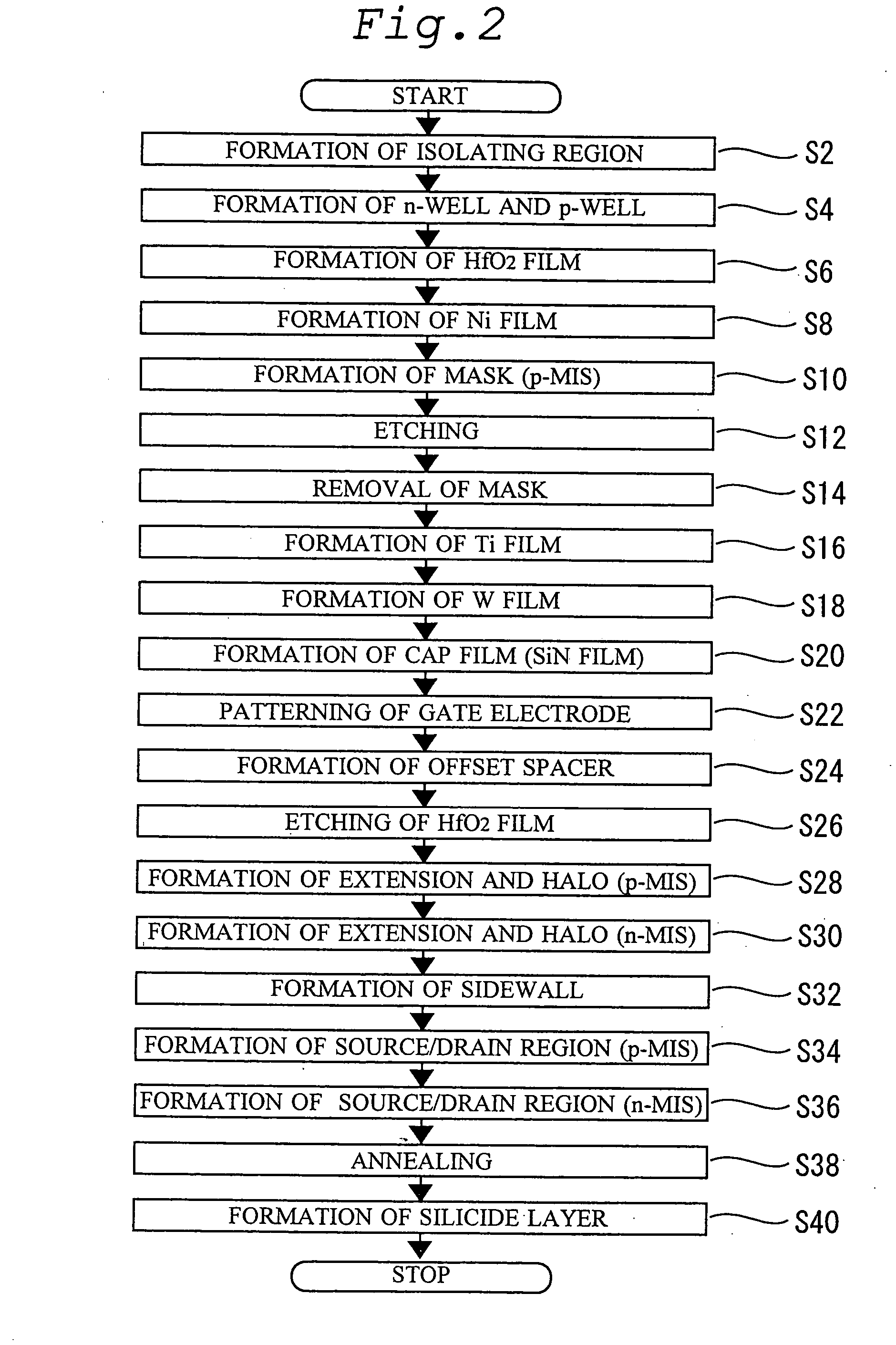

Semiconductor device and method for manufacturing semiconductor device

InactiveUS20050082605A1Avoid consumptionSuppress RC delaySemiconductor/solid-state device manufacturingSemiconductor devicesImpurity diffusionDevice material

A gate insulating film is formed in a first region and a second region of a substrate, a first metallic film is formed on the gate insulating film in one of the first region or the second region, and a second metallic film is formed on each of the first and second regions. Furthermore, a protective film is formed on the second metallic film, and the protective film and the metallic film are patterned to the pattern of the gate electrode. Next, a first sidewall is formed on the side of a gate electrode. Then, impurities producing first and second conductivity types are implanted into the surface of the substrate in respective regions, using the first sidewalls and the gate electrodes as masks to form a first impurity-diffused region, and impurities producing second and first conductivity types are implanted to form an impurity diffusion preventing layer. Thereafter, a second sidewall is formed on the side of the first sidewall, and an impurity is implanted into the surface of the substrate using the second sidewalls and the gate electrodes as masks to form a second impurity-diffused region.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com