Vapor deposition apparatus and vapor deposition method

A vapor deposition and equipment technology, applied in the field of vapor deposition equipment, can solve the problems of reducing deposition rate and material efficiency, and achieve the effect of reducing vapor flow and reducing the difference in deposition direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0033] (1) Structure of vapor deposition equipment

[0034] (2) Steps of vapor deposition method

[0035] (3) example

[0036] a. The cooling capacity of the substrate

[0037] b. Appearance and cross-sectional structure after deposition

[0038] 2. The second embodiment of the vapor deposition method

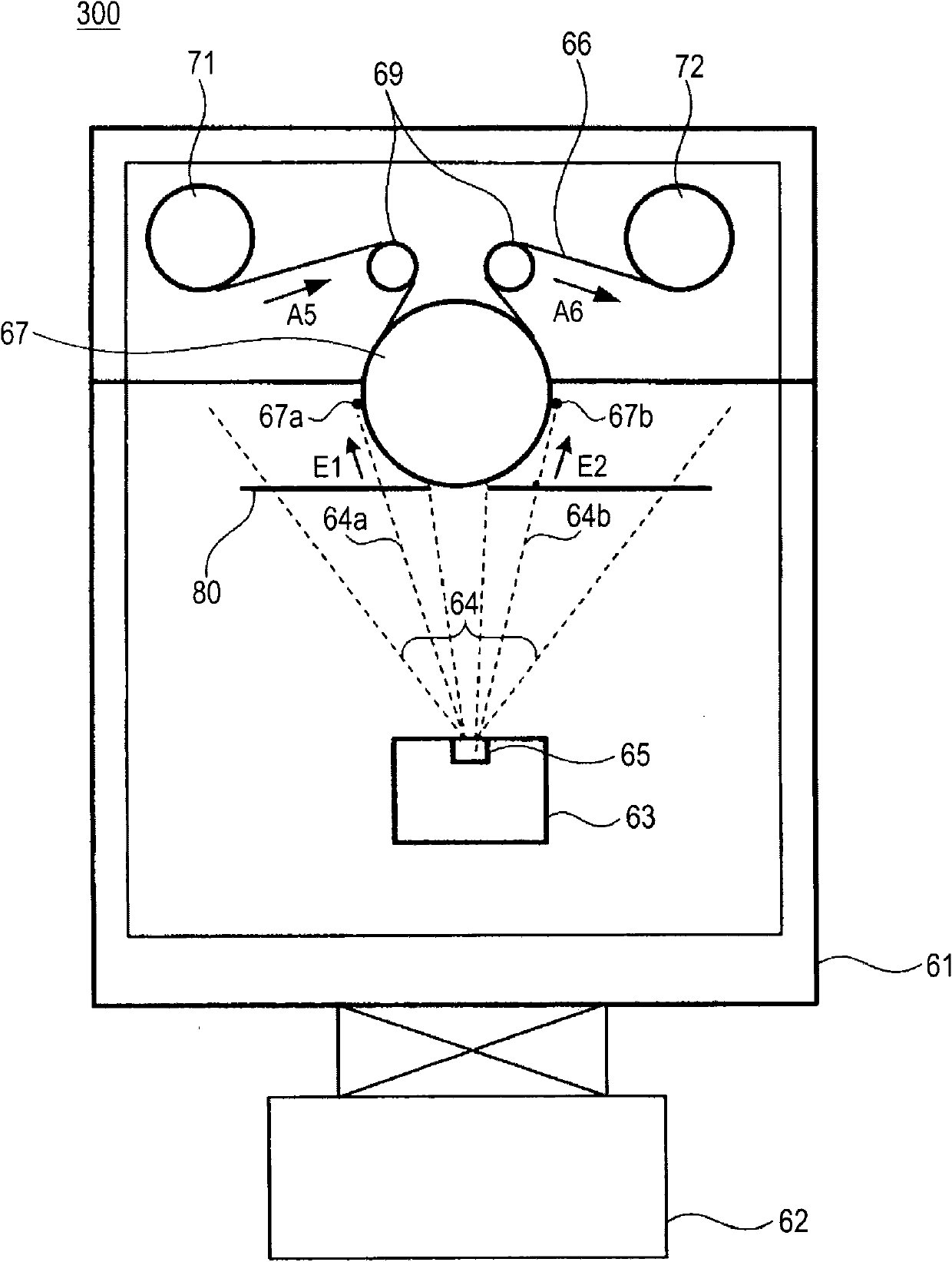

[0039] 3. The second embodiment of vapor deposition equipment

[0040] 1. The first embodiment of vapor deposition equipment and vapor deposition method

[0041] (1) Structure of vapor deposition equipment

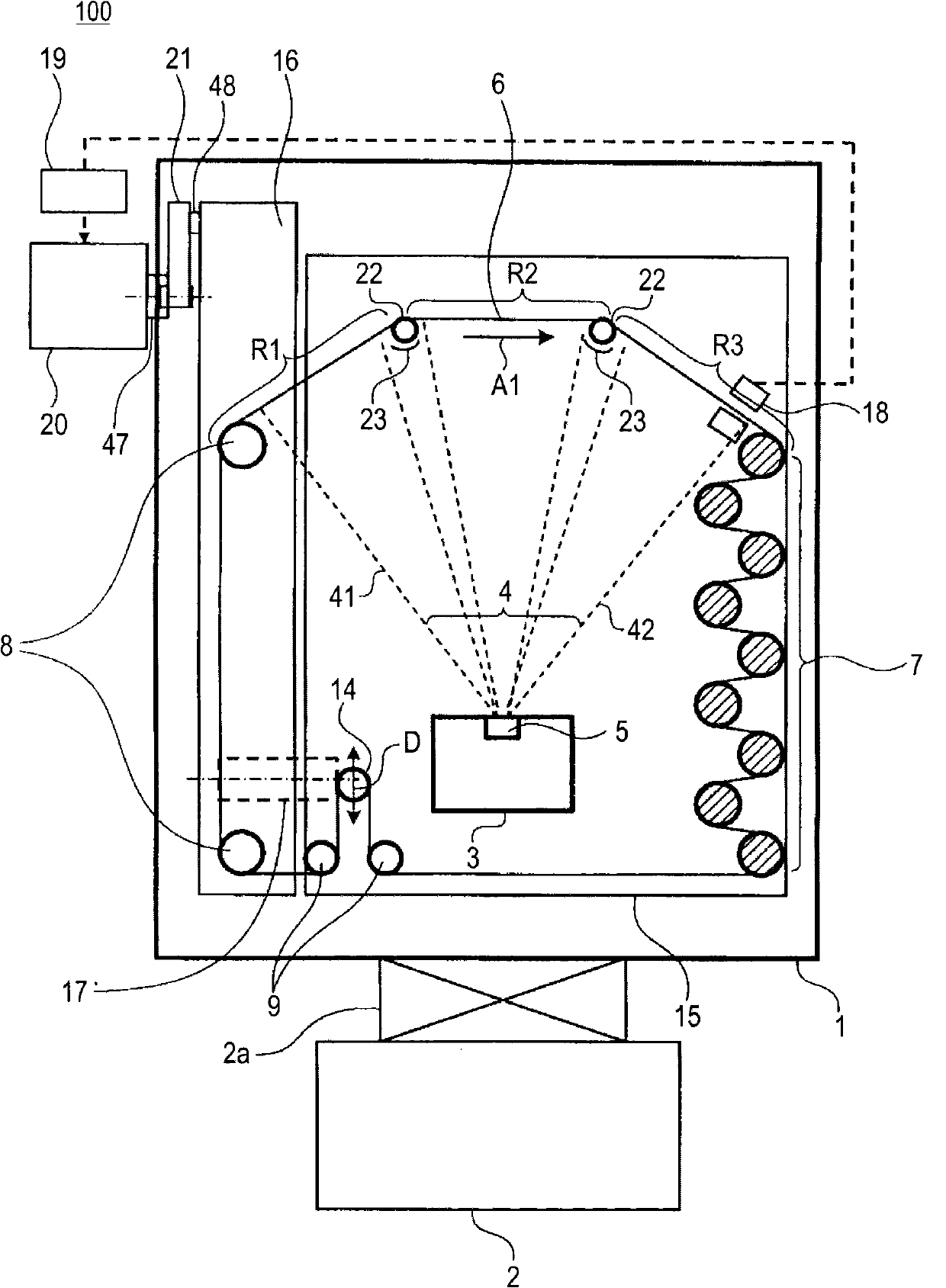

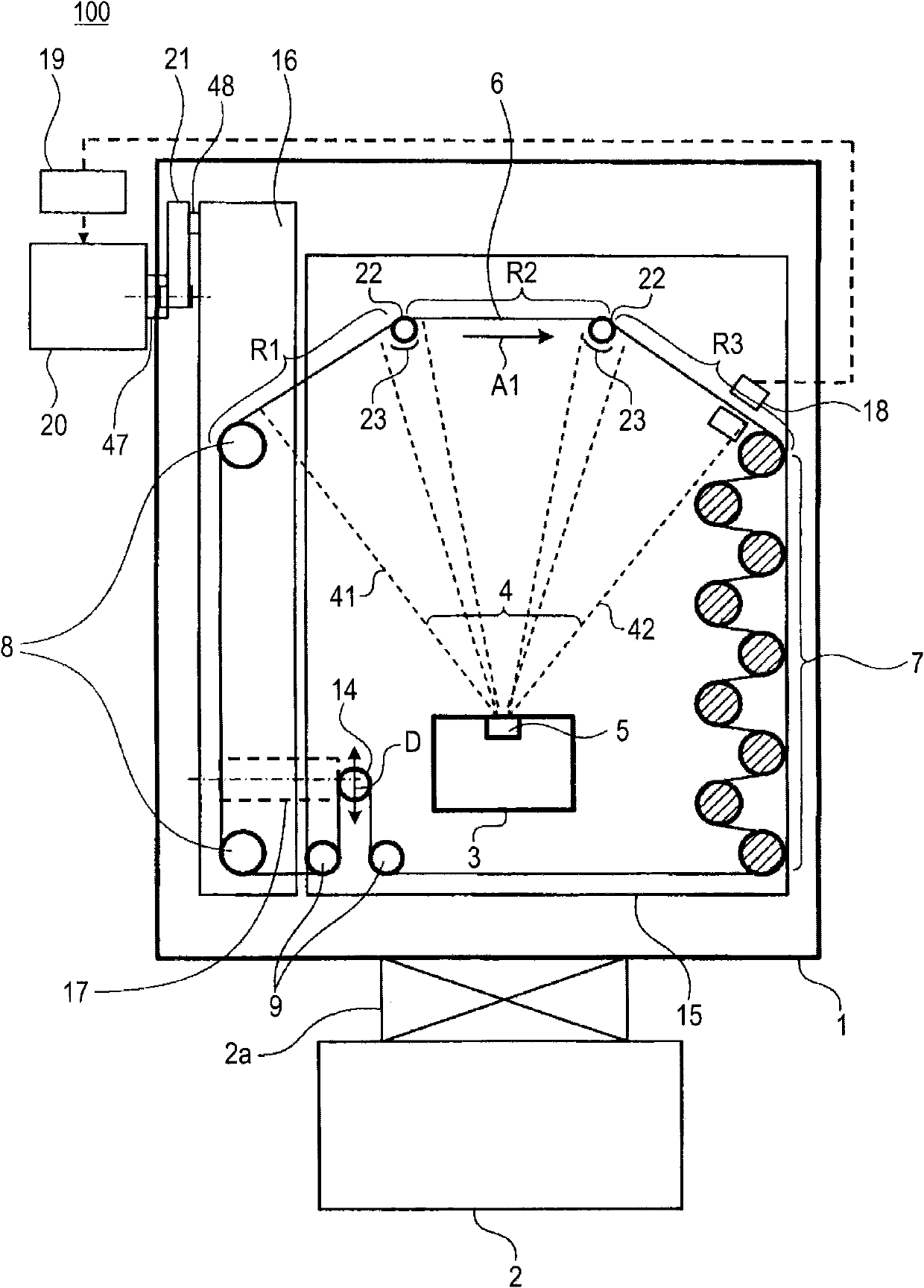

[0042] figure 1 is a schematic configuration diagram of the vapor deposition apparatus 100 according to the first embodiment. The vapor deposition apparatus 100 according to the embodiment has a vacuum tank 1 and a vacuum pump 2 that evacuates the inside of the vacuum tank 1 as an exhaust section. The vacuum tank 1 is evacuated to, for example, 10 by a vacuum pump 2 connected thereto via a valve 2a. -2 to 10 -4 Pa.

[0043] The rollers 22 define a concave travel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com