Structure for positioning cowl top for vehicle

A technology for a cowl top cover and a vehicle, which is applied in the directions of the upper structure, vehicle components, and upper structure sub-assemblies, can solve problems such as unfavorable vehicle appearance, unfavorable foreign matter intrusion, etc., so as to improve the appearance and inhibit the entry of foreign matter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

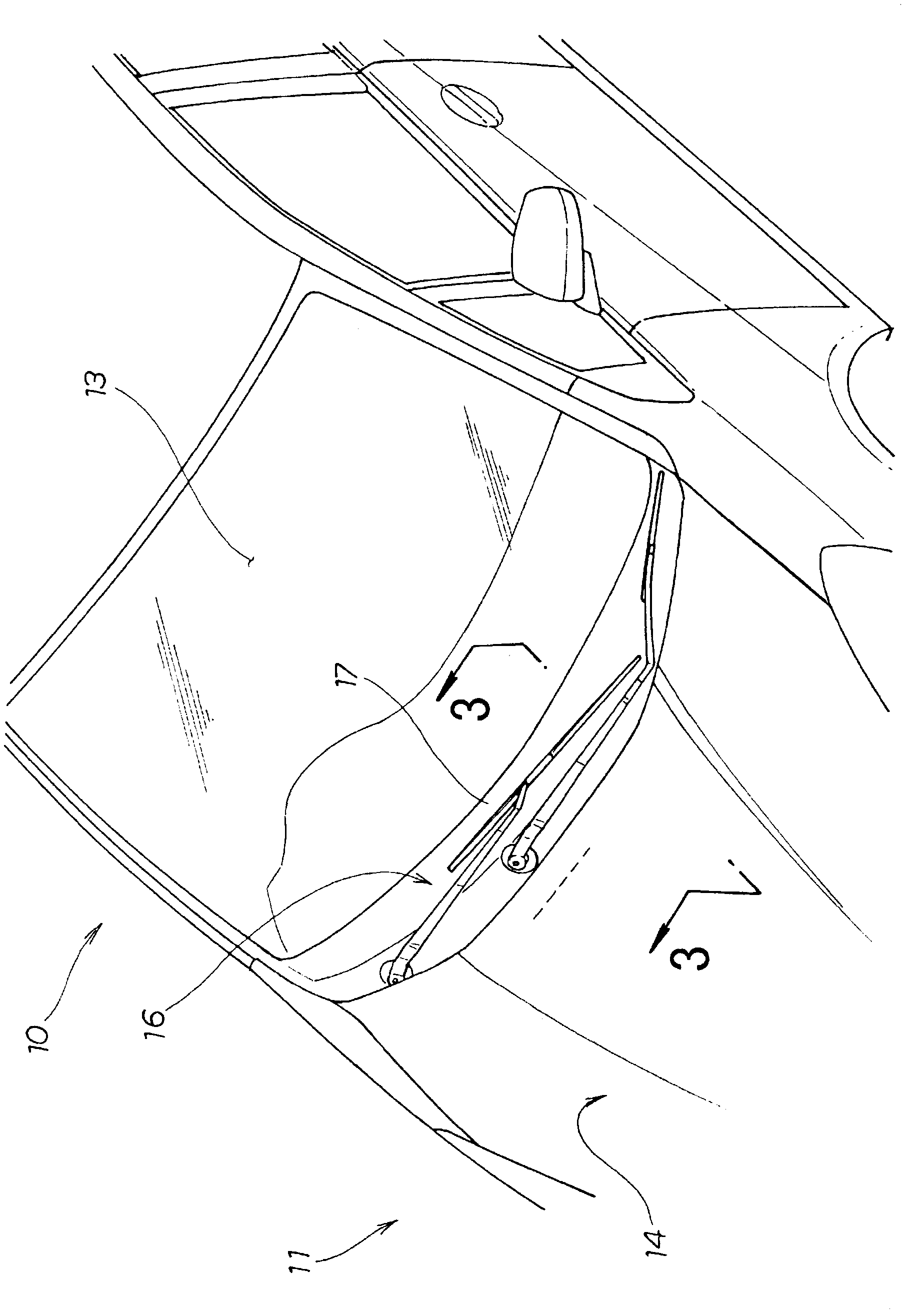

[0033] Such as figure 1 As shown, in the vehicle 10 , a cowl top 17 is arranged at the front of the vehicle body 11 and between the lower end of the windshield 13 and the rear end of the hood 14 . The hood 14 is a front-opening hood, and the left and right sides of the rear end are openably and closably attached to the vehicle body 11 , and the front portion can be locked to the vehicle body 11 by a hood locking member (not shown).

[0034] The cowl top 17 is a plate-shaped member that covers the gap between the lower end of the windshield 13 and the rear end of the hood 14 . A wiper device 16 for wiping off rainwater on the glass surface of the windshield glass 13 is arranged at the portion of the cowl top 17 (hereinafter simply referred to as "dash top 17").

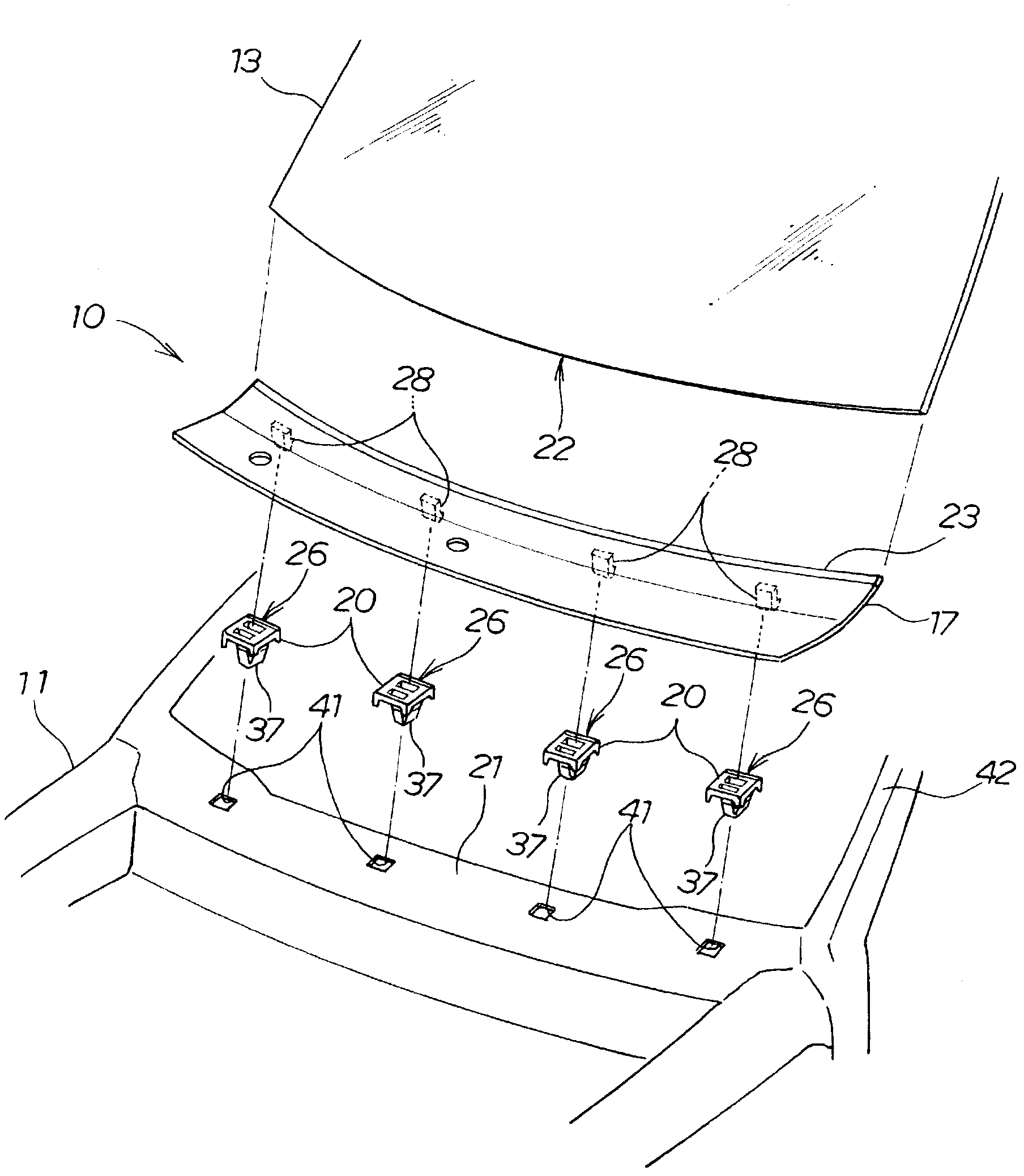

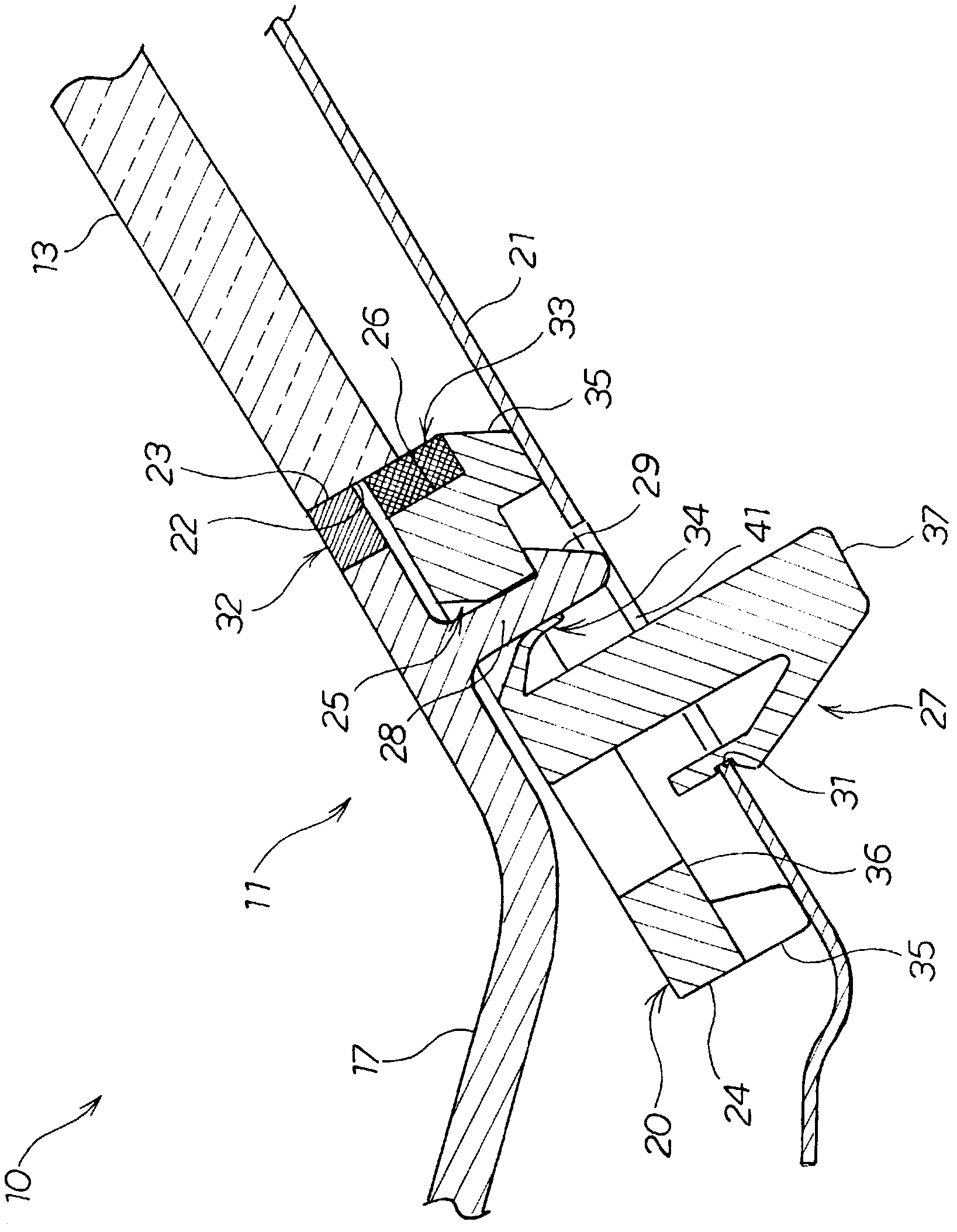

[0035] Such as figure 2 and image 3 As shown, the cowl top 17 is mounted so as to be positioned on a windshield lower 21 of the vehicle body 11 by a plurality of clips 20 arranged in the vehicle width direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com