Patents

Literature

64results about How to "Reliable abutment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

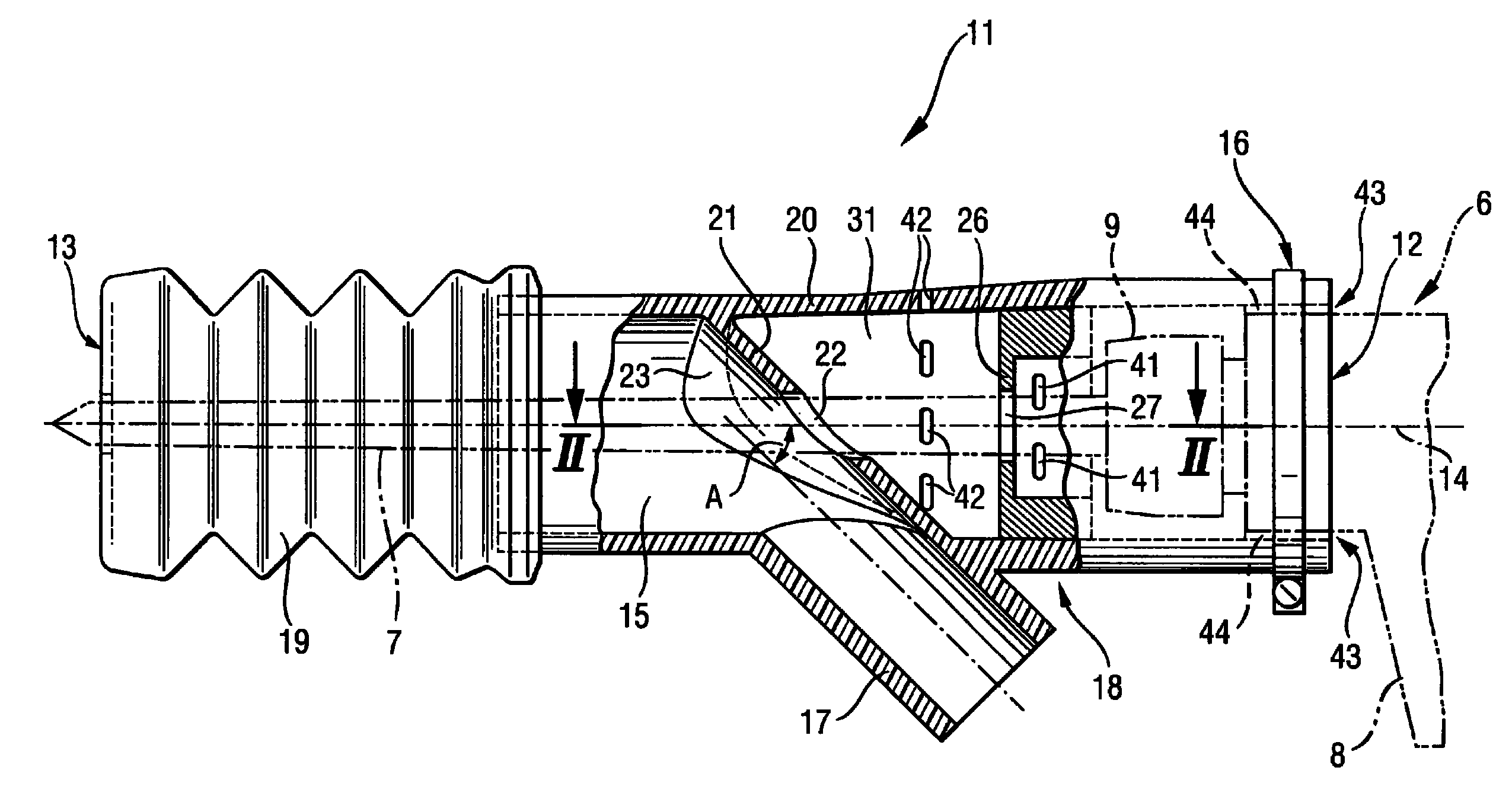

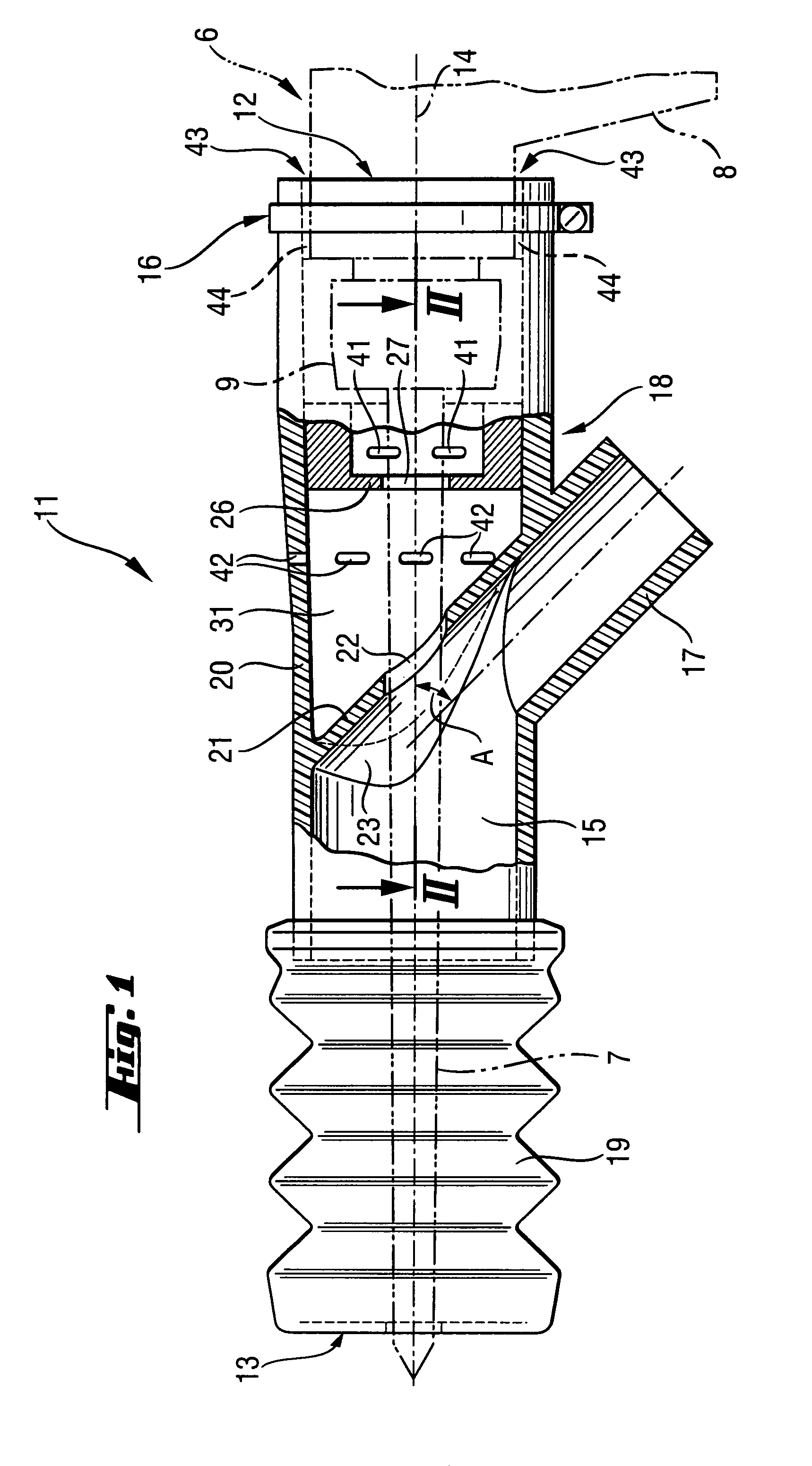

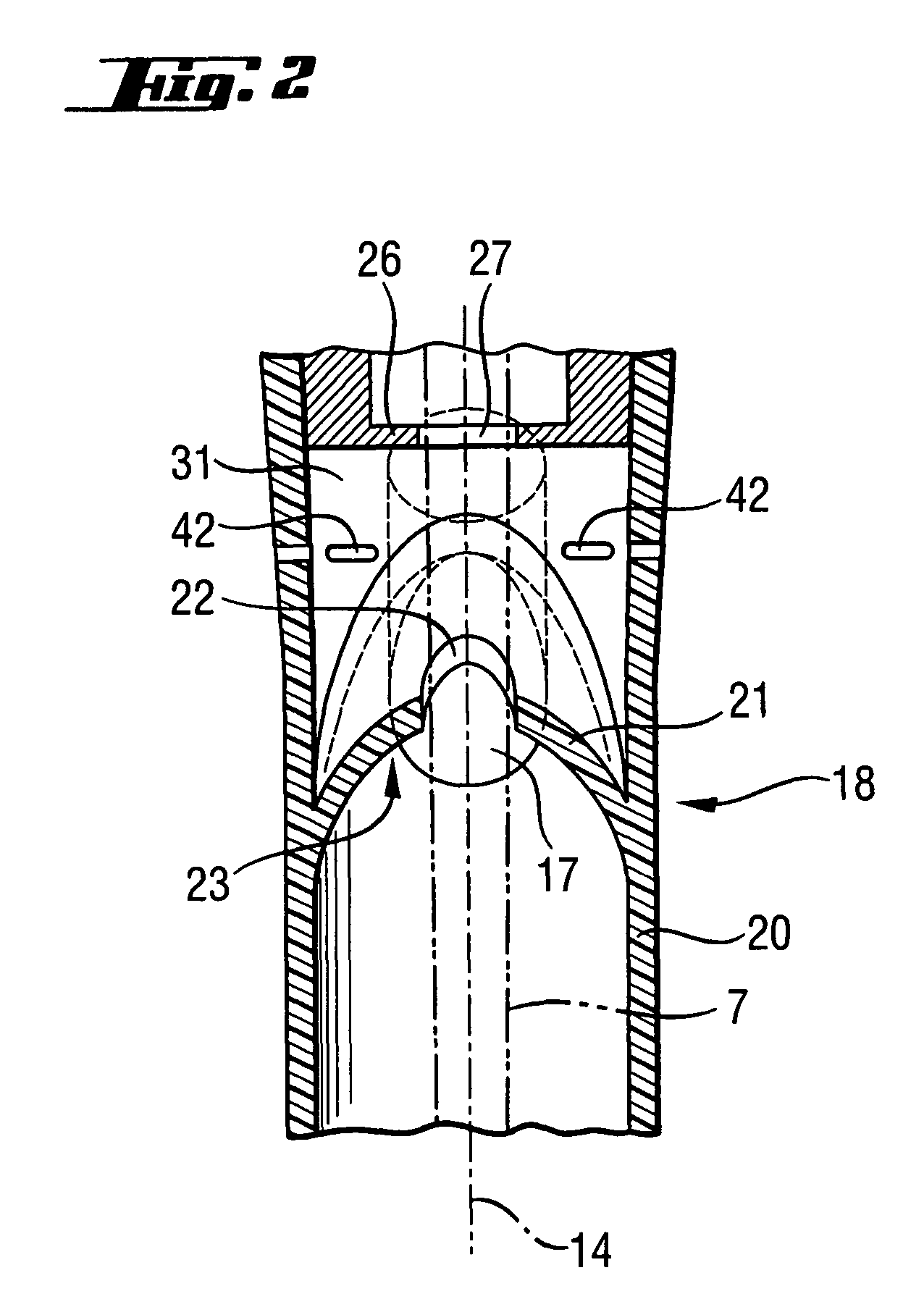

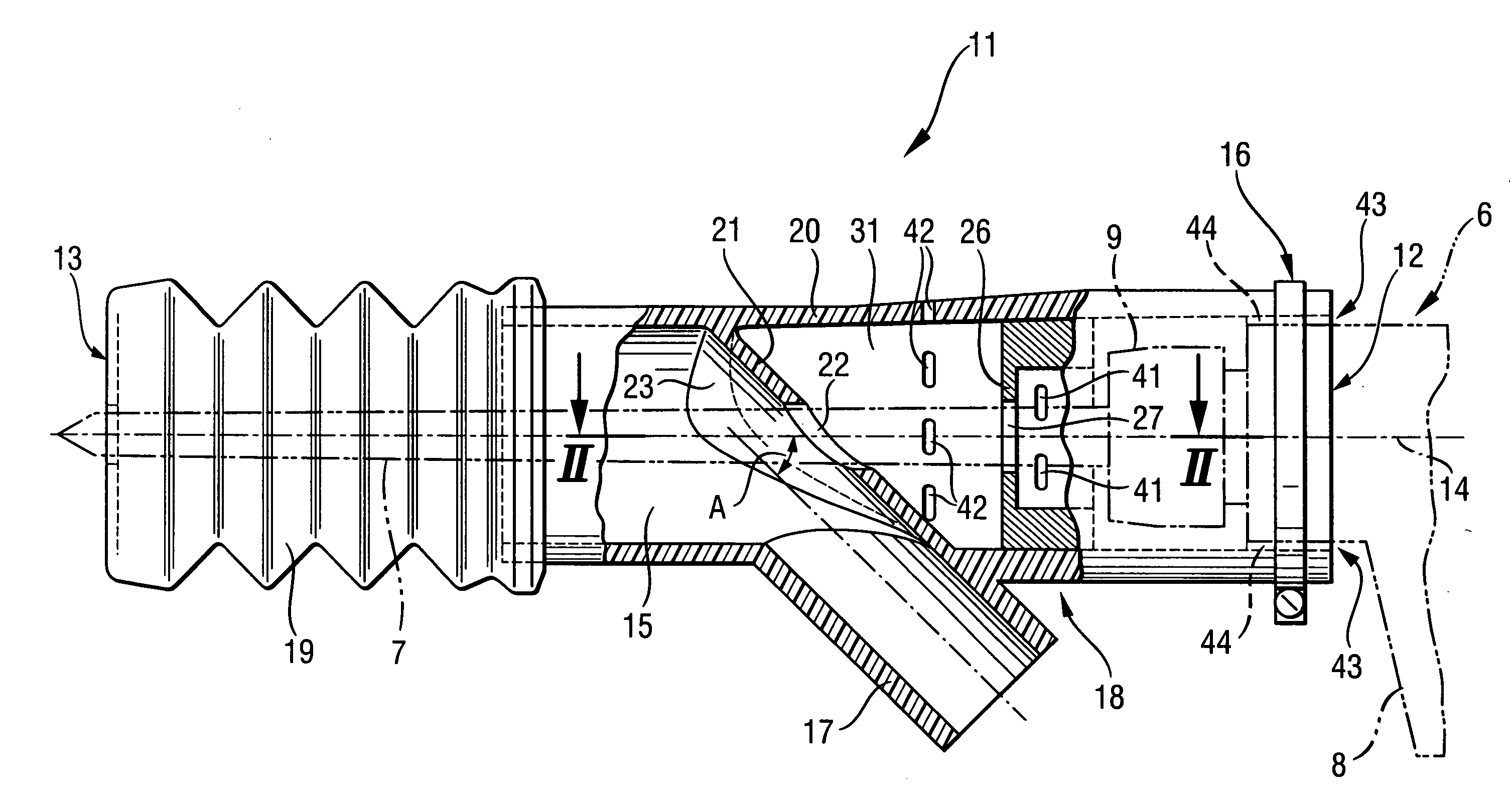

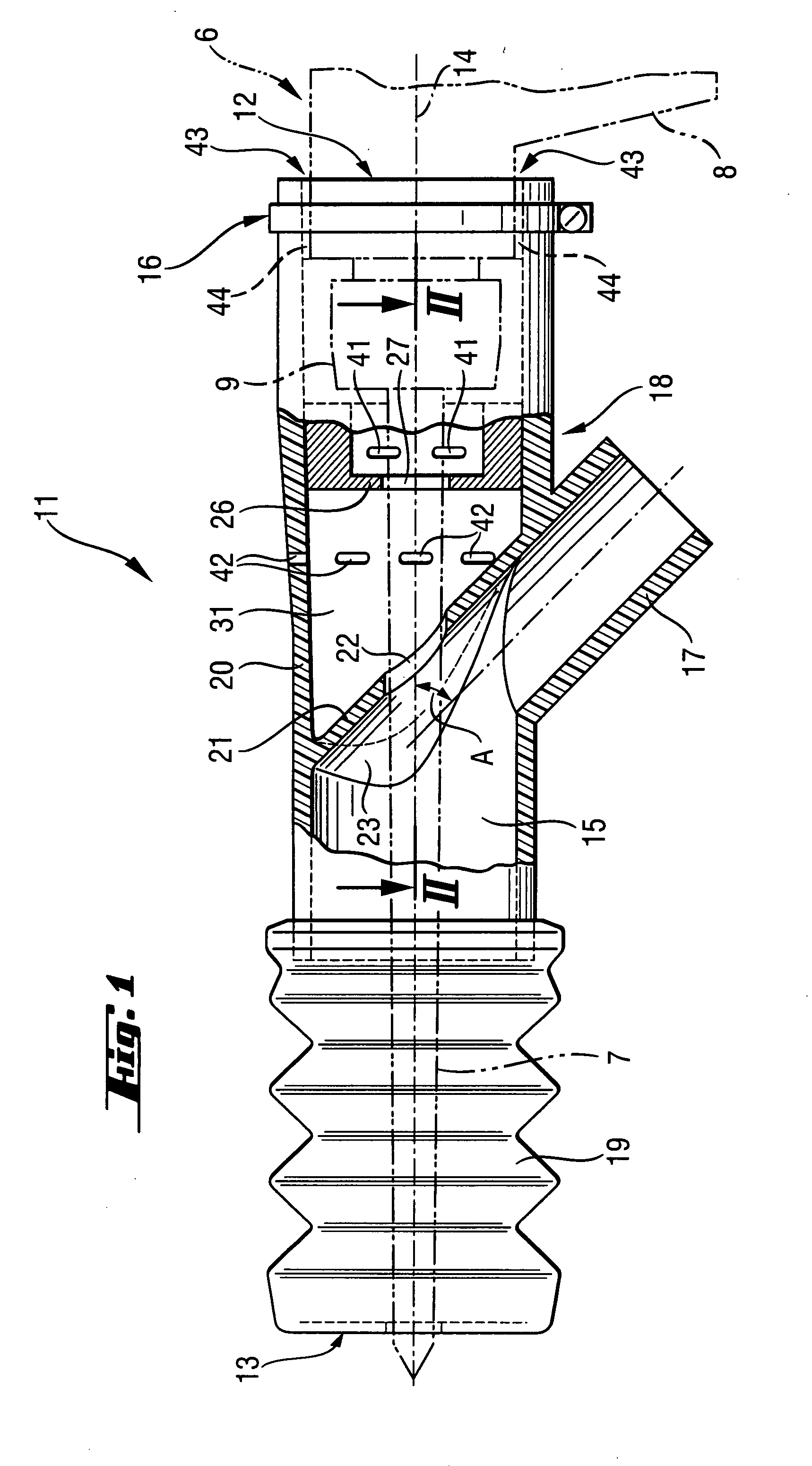

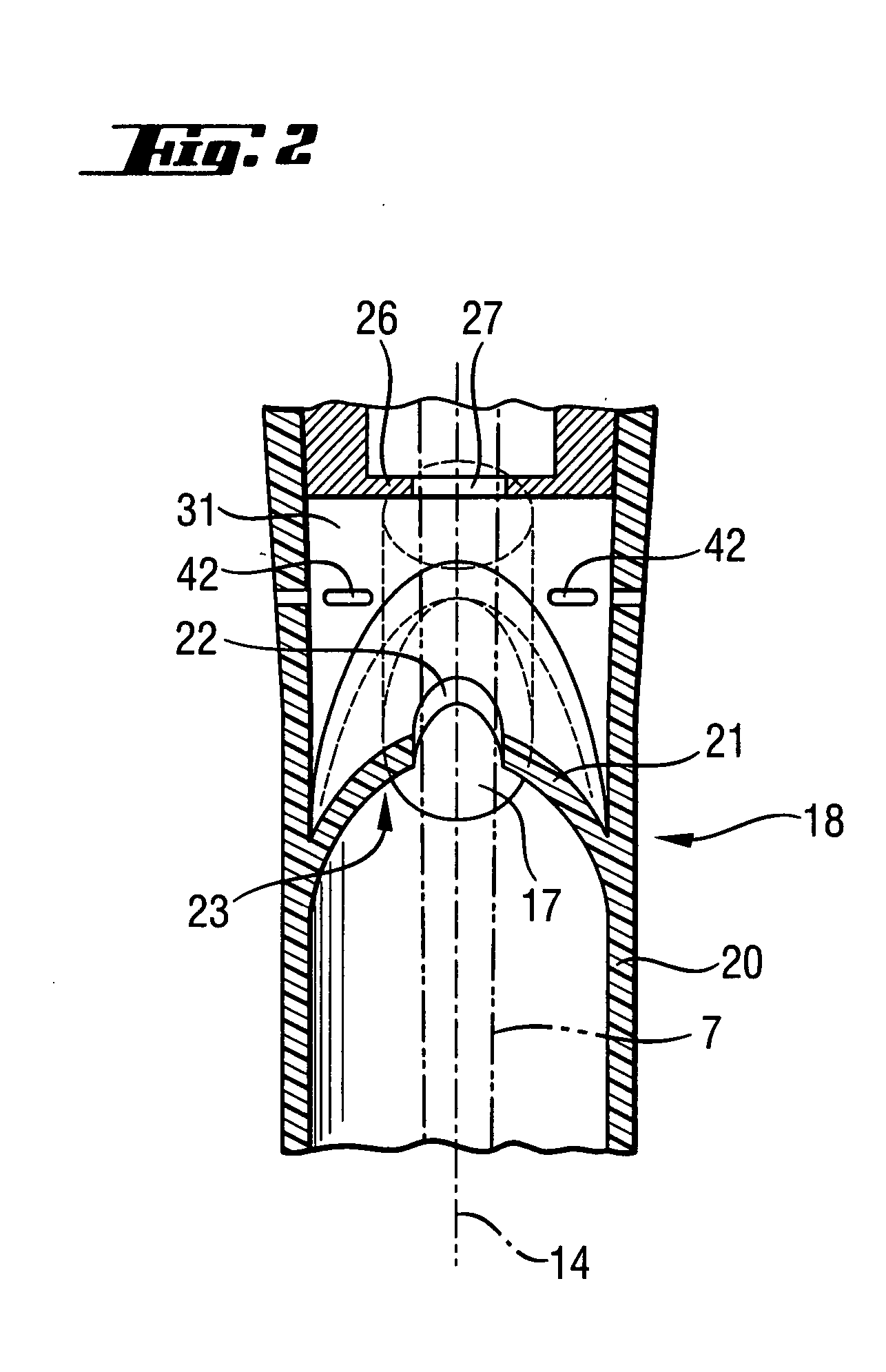

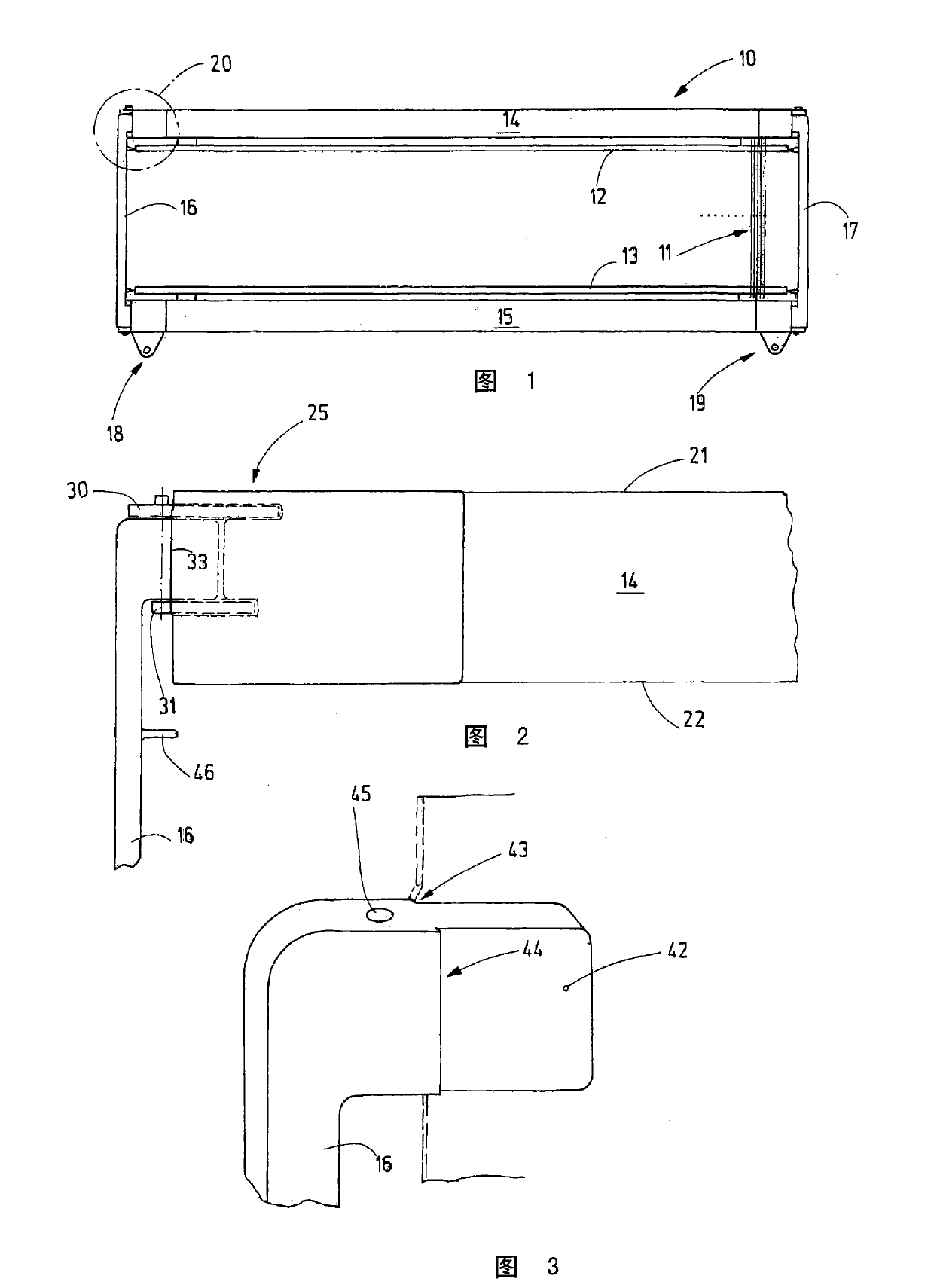

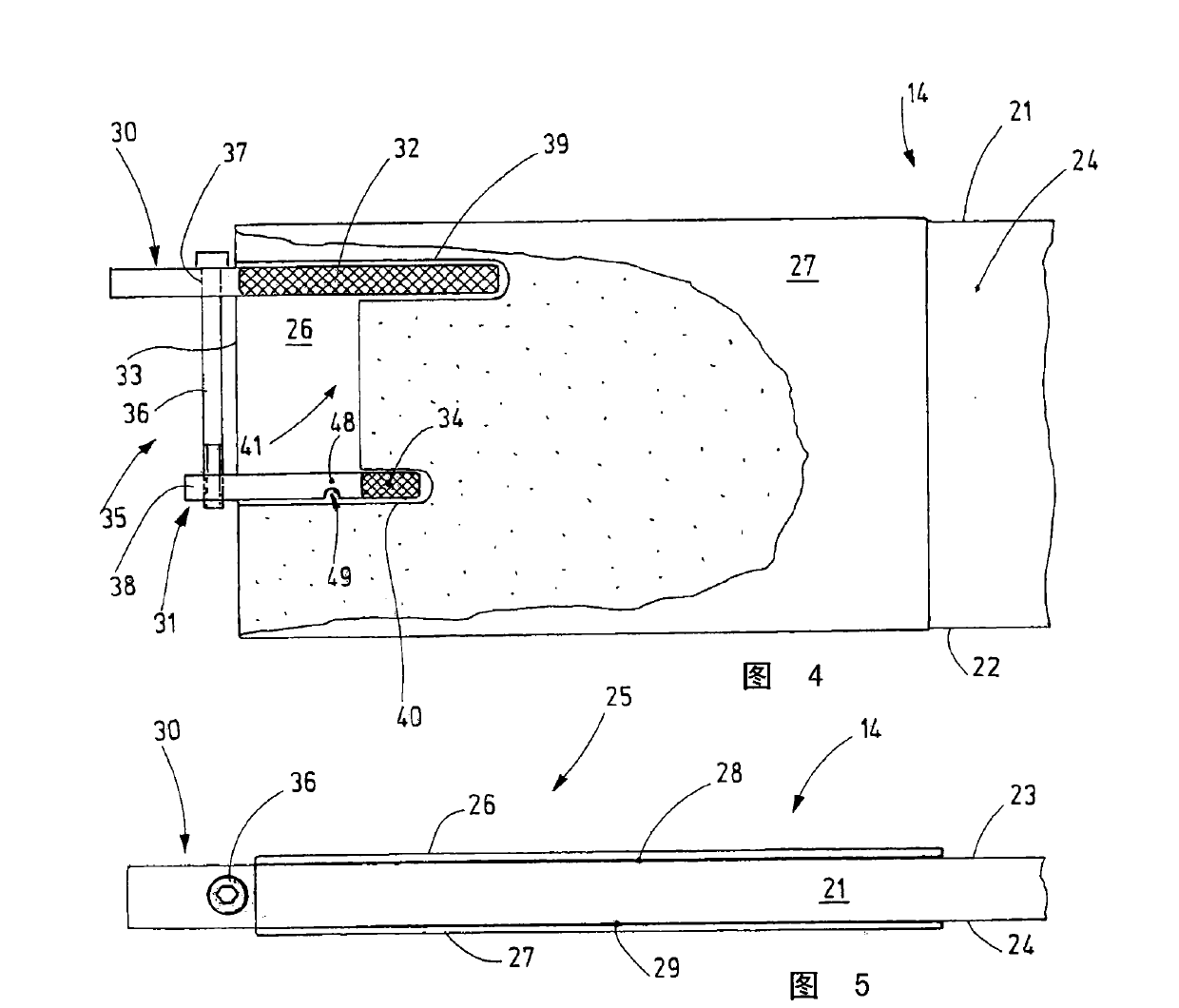

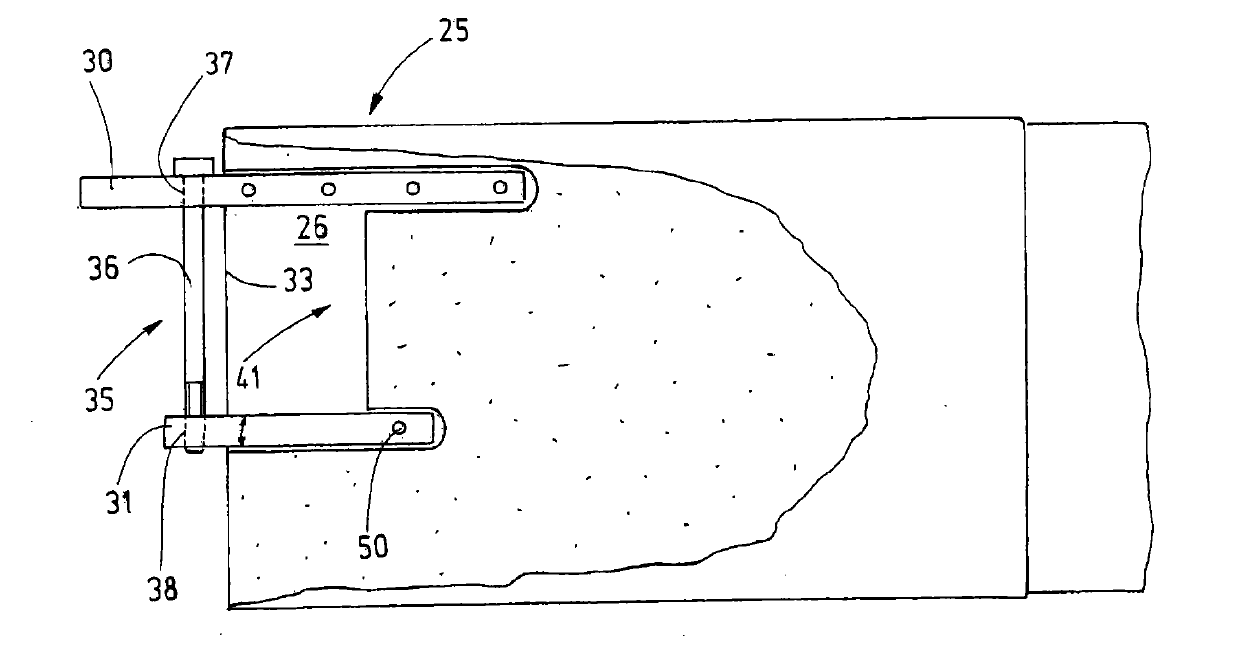

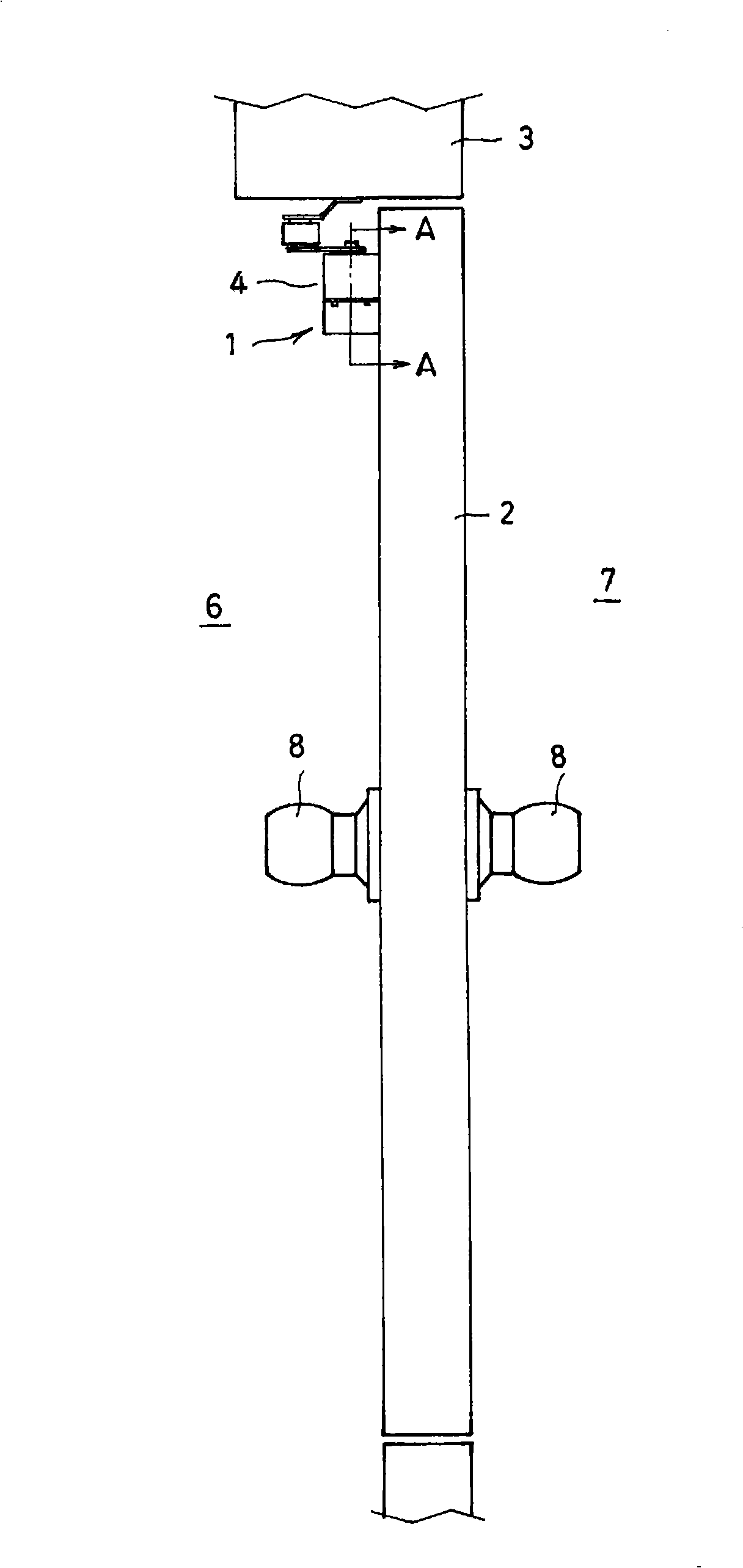

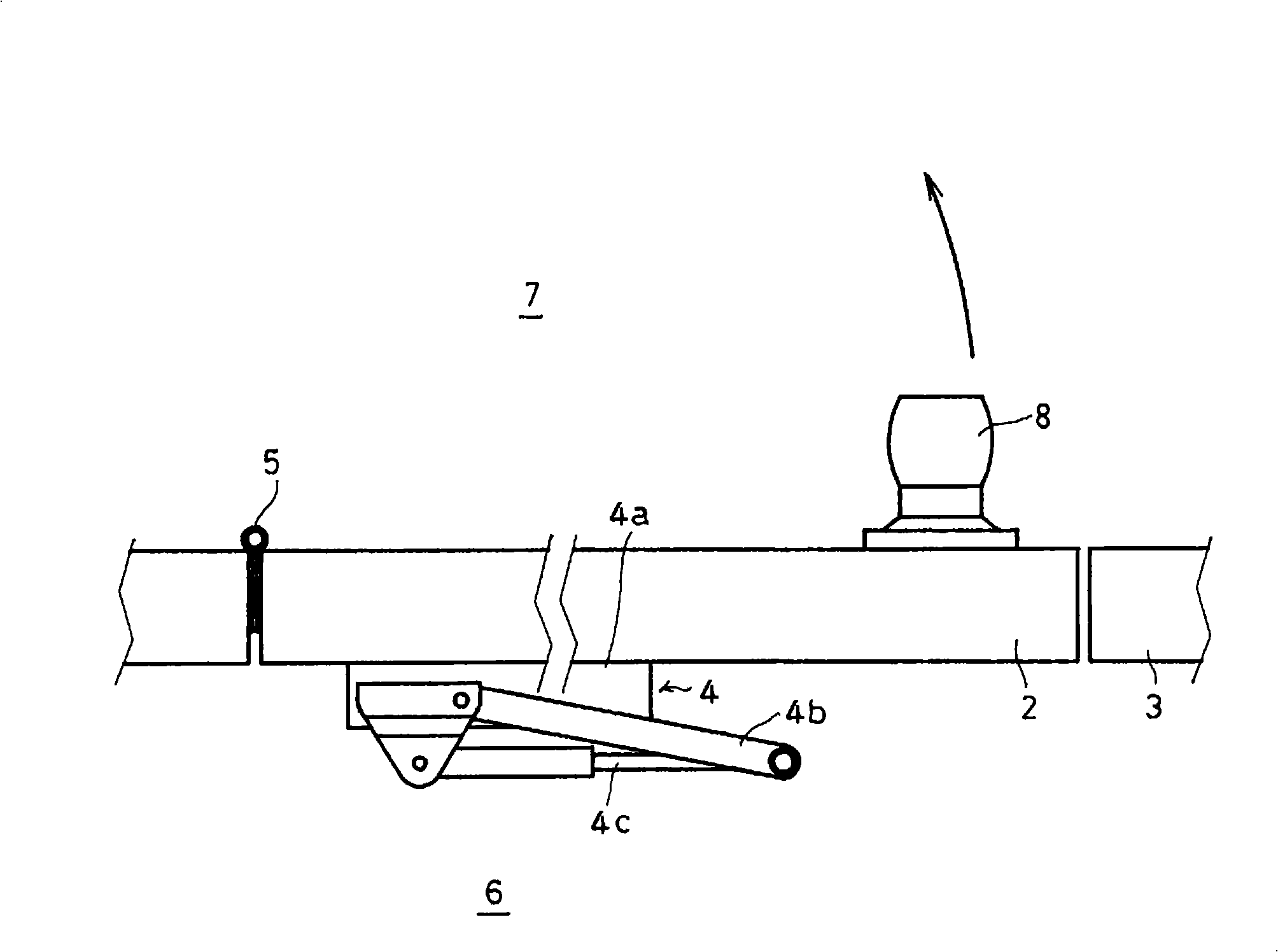

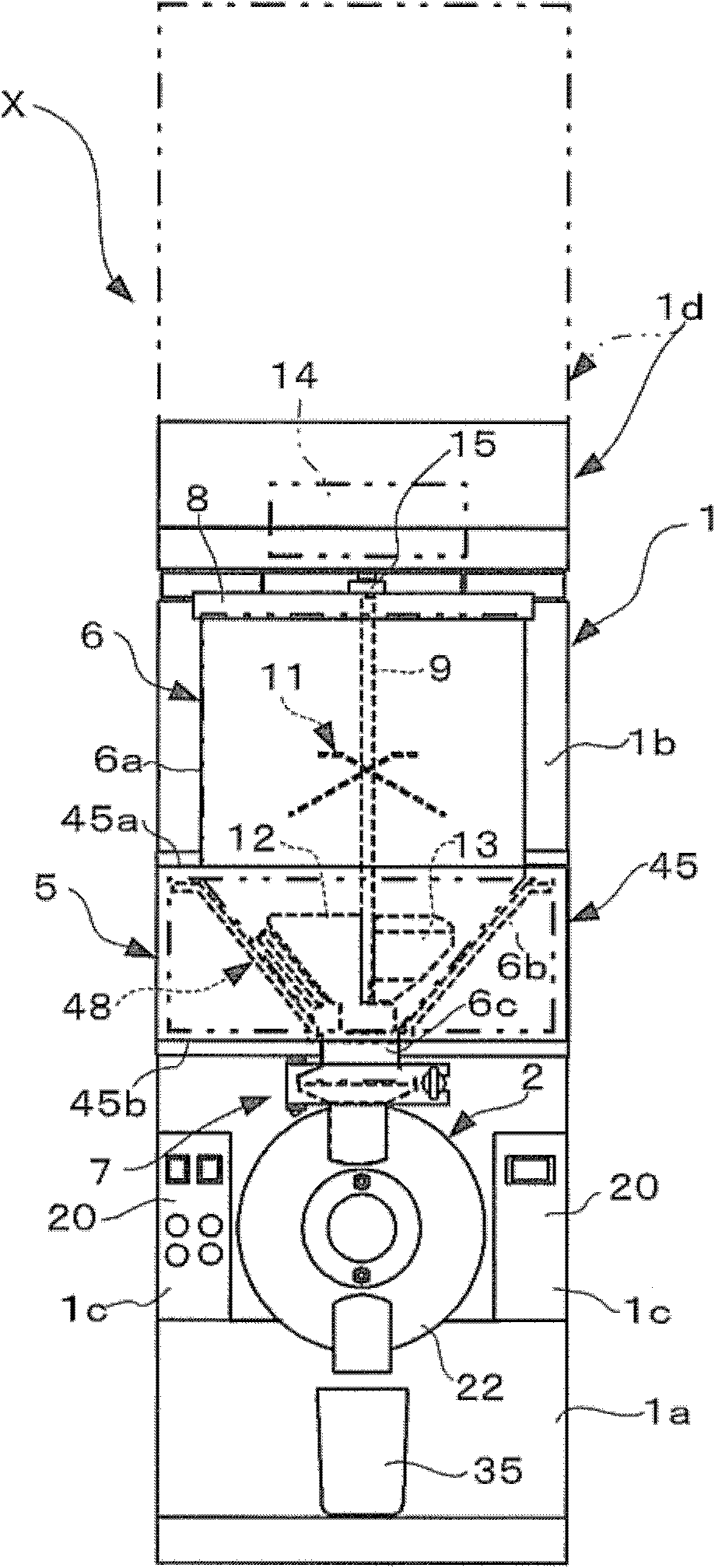

Suction device for pick power tool

A suction device for a pick power tool includes a securing device provided at the first axial end of the suction device for securing the suction device (11) on the pick power tool (6), a connection element (17) for a vacuum source inclined to the longitudinal axis (14) of the suction device (11), and a first baffle wall (21) and at least one further baffle wall (26) spaced from the first baffle wall (21), with the first baffle wall being located between the connection element (17) and the first end (12) of the suction device (11) and the at least one further baffle wall (21) being located between the first baffle wall and the first end (12), and the first baffle wall (21) and the second baffle wall (26) each having, respectively, a through-opening (22, 27) for the working tool (7) of the pick power tool (6).

Owner:HILTI AG

Suction device for pick power tool

A suction device for a pick power tool includes a securing device provided at the first axial end of the suction device for securing the suction device (11) on the pick power tool (6), a connection element(17) for a vacuum source inclined to the longitudinal axis (14) of the suction device (11), and a first baffle wall (21) and at least one further baffle wall (26) spaced from the first baffle wall (21), with the first baffle wall being located between the connection element (17) and the first end (12) of the suction device (11) and the at least one further baffle wall (21) being located between the first baffle wall and the first end (12), and the first baffle wall (21) and the second baffle wall (26) each having, respectively, a through-opening (22, 27) for the working tool (7) of the pick power tool (6).

Owner:HILTI AG

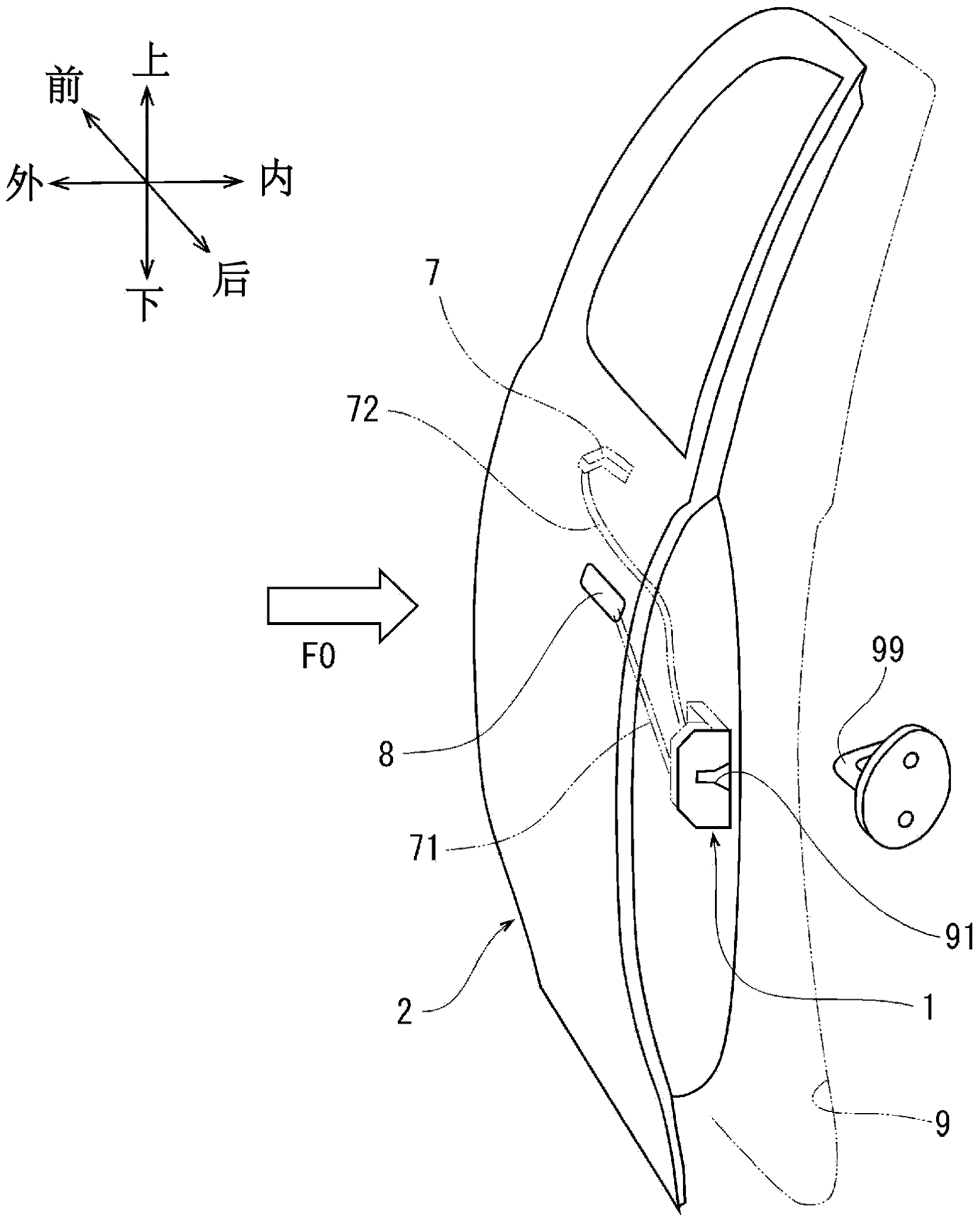

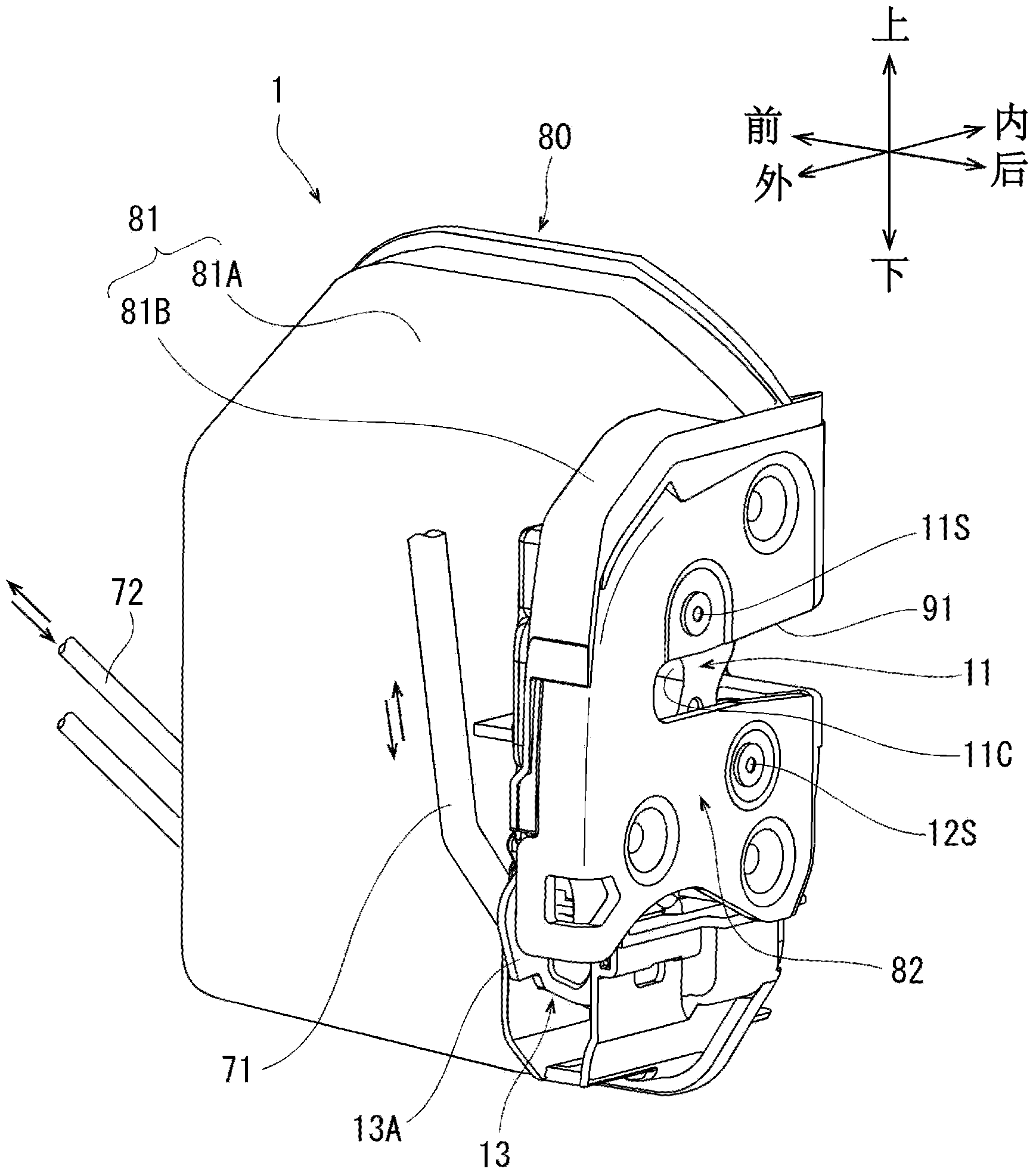

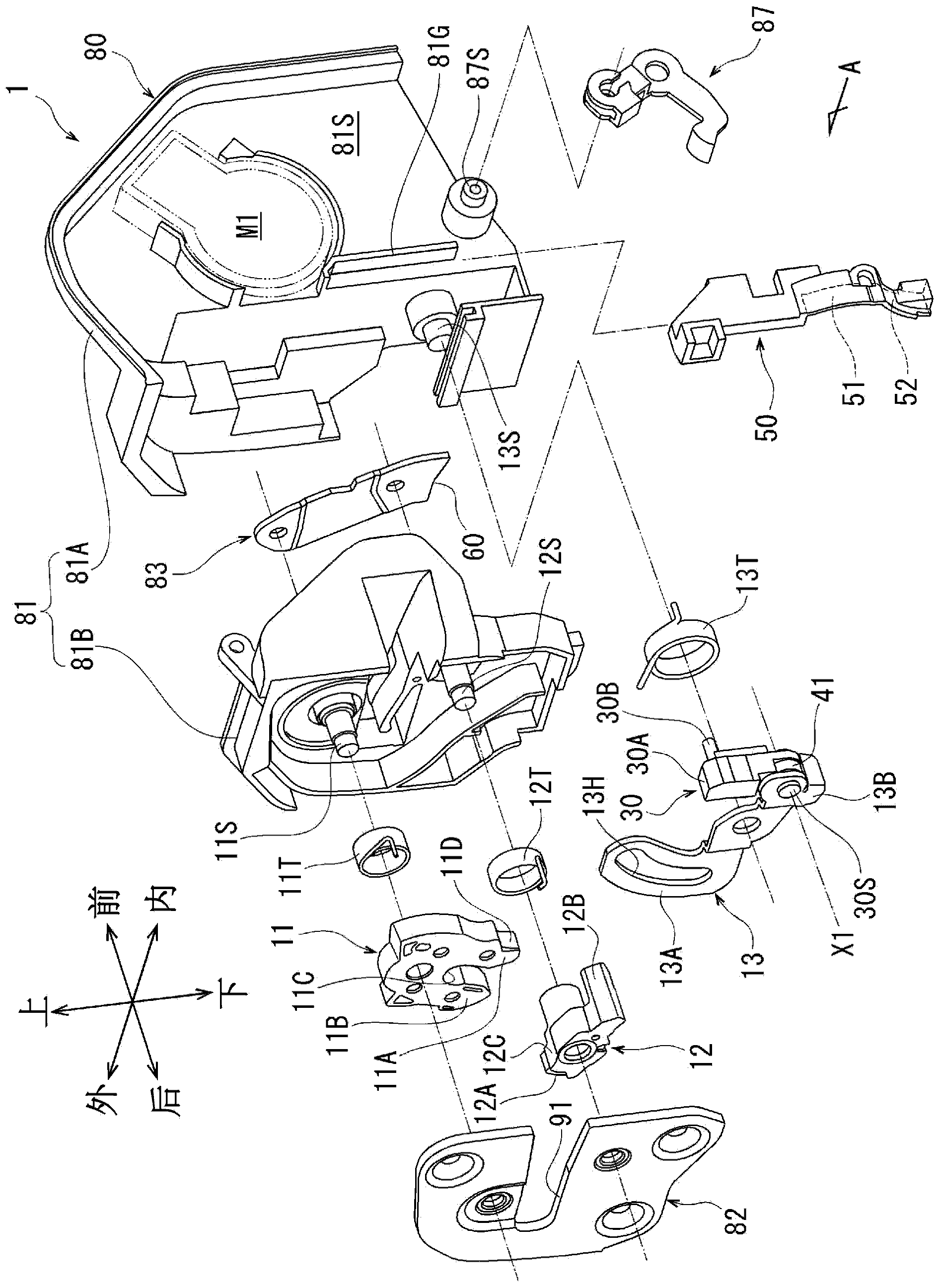

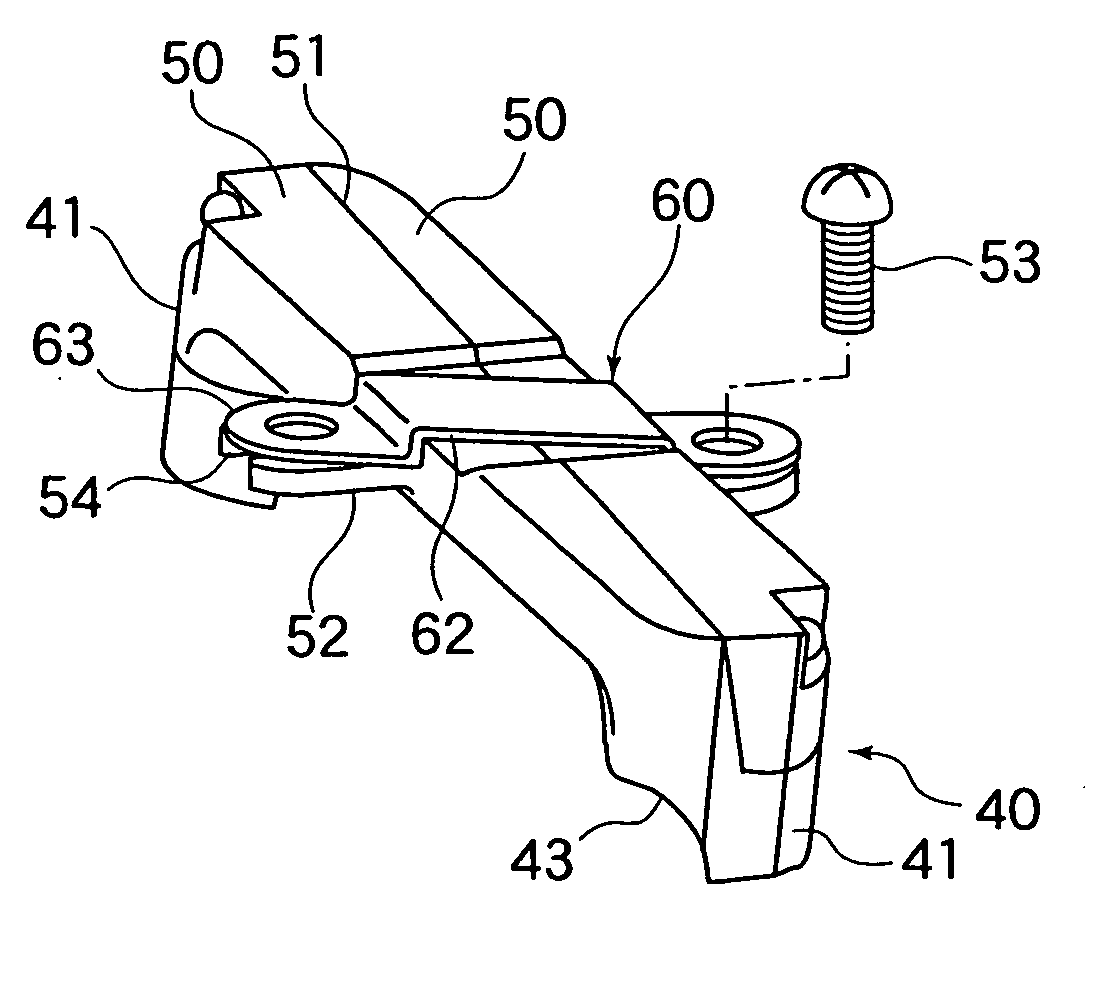

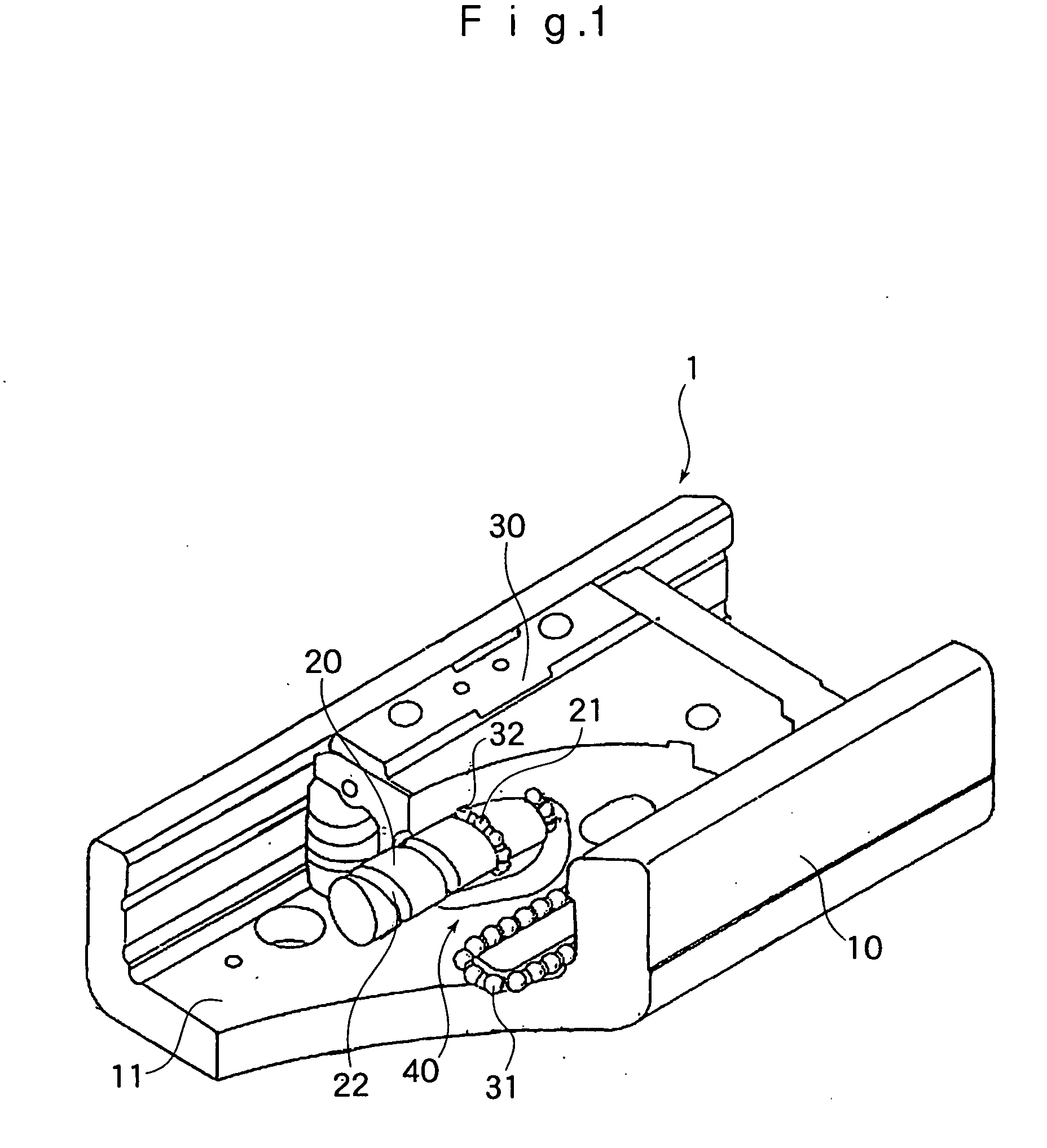

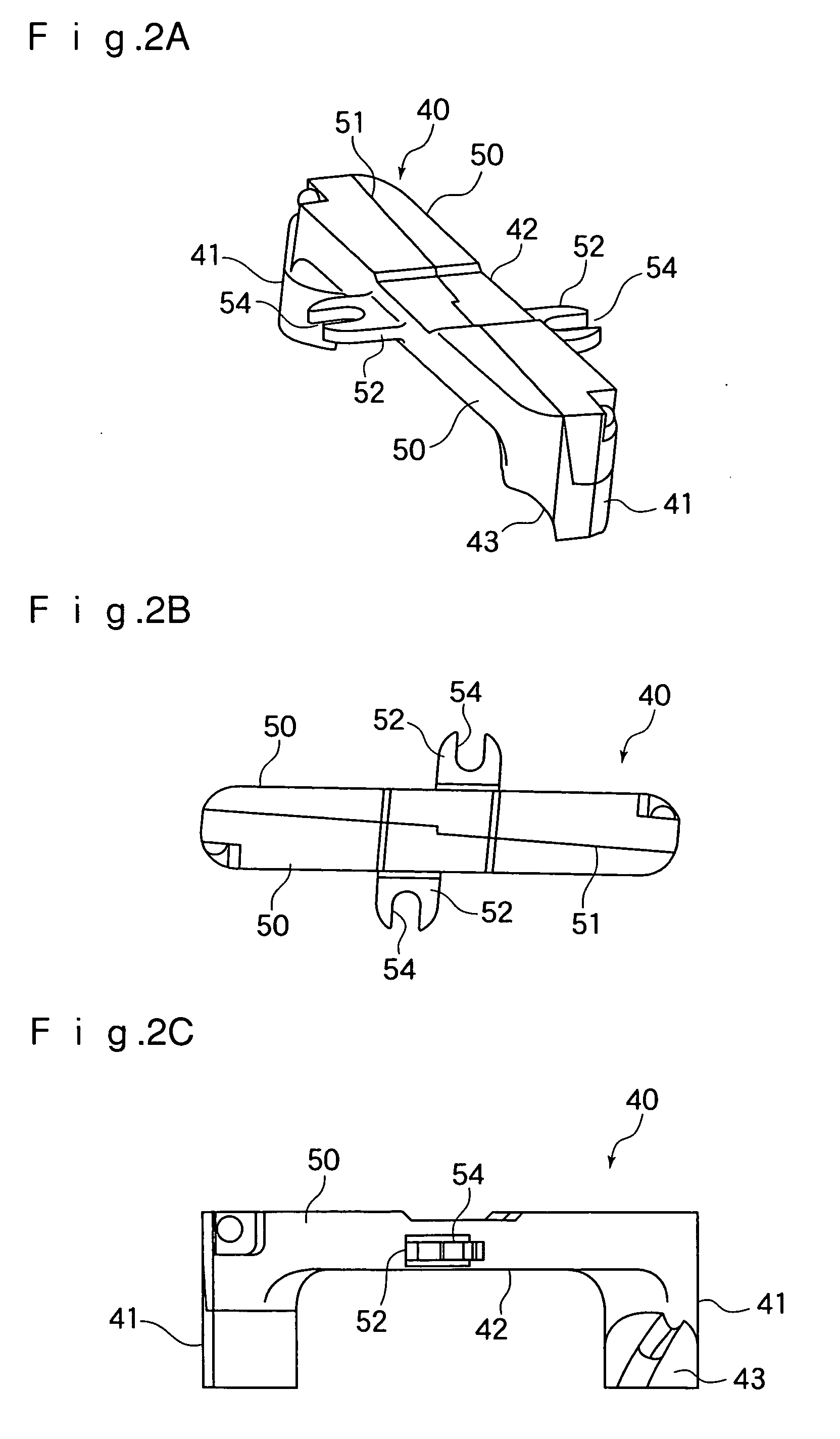

Door locking device for vehicle

ActiveCN103597155AReliable abutmentEasy to assembleAccident situation locksElectrical locking actuatorsEngineeringMechanical engineering

Owner:ANSEI CORP

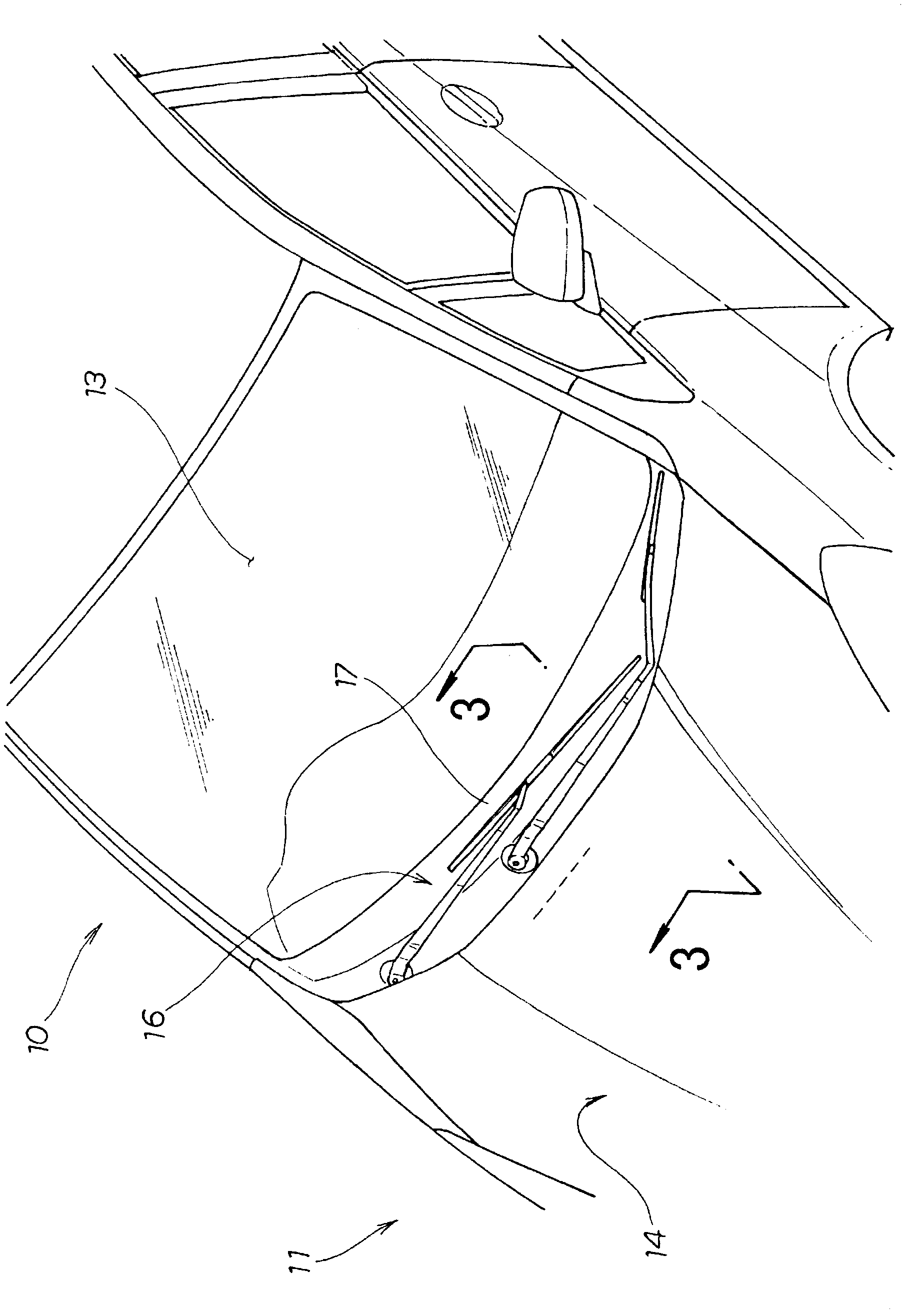

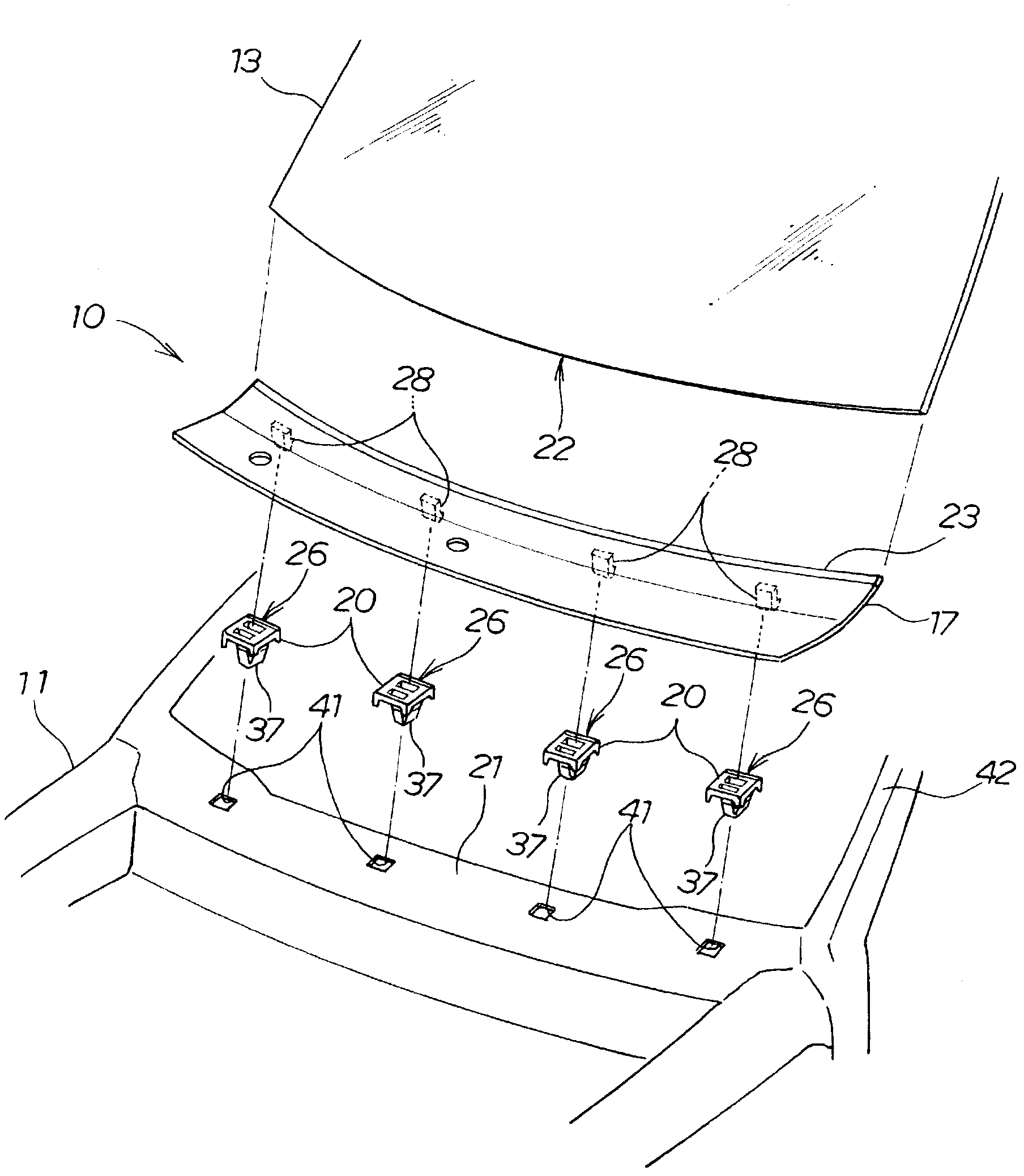

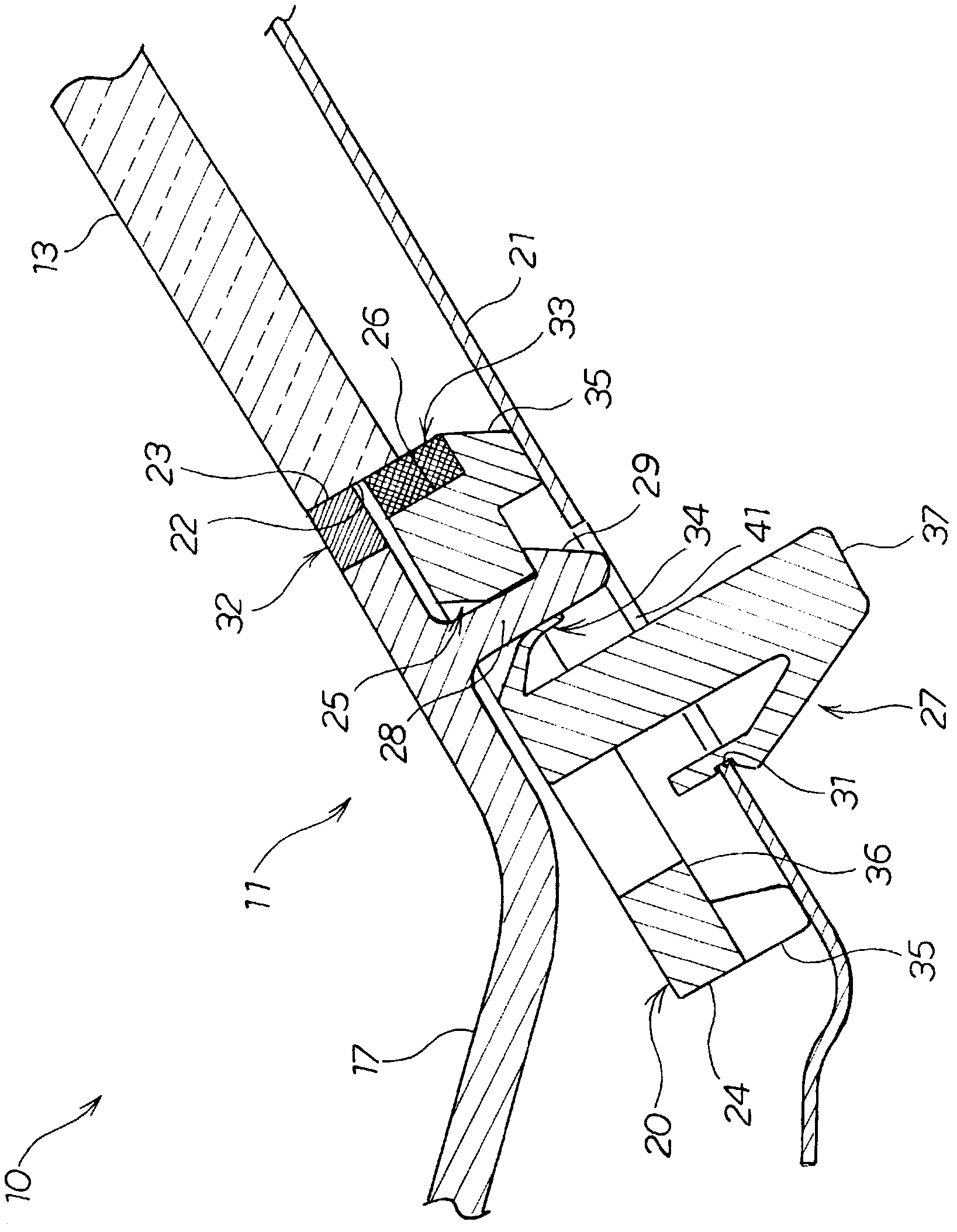

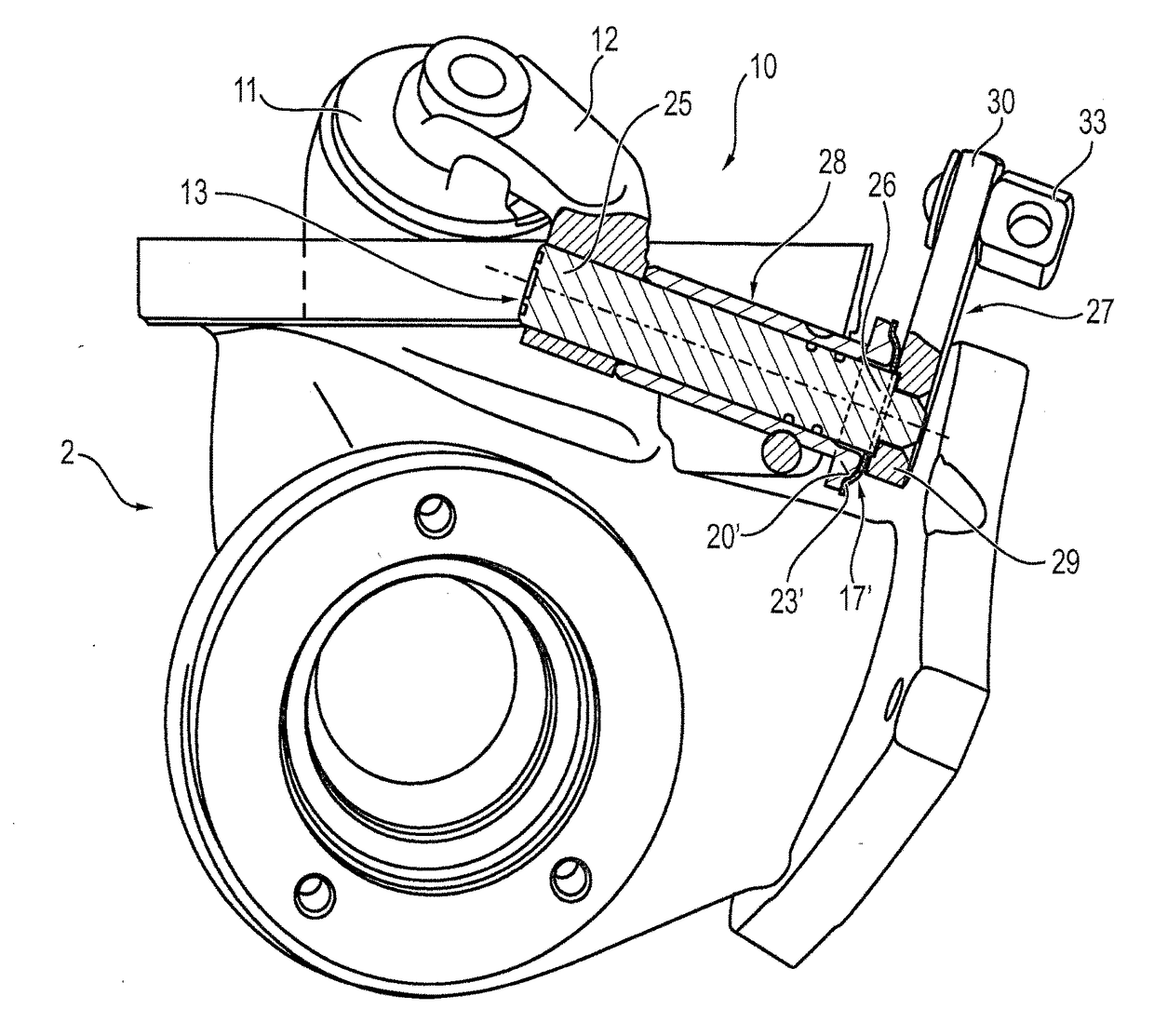

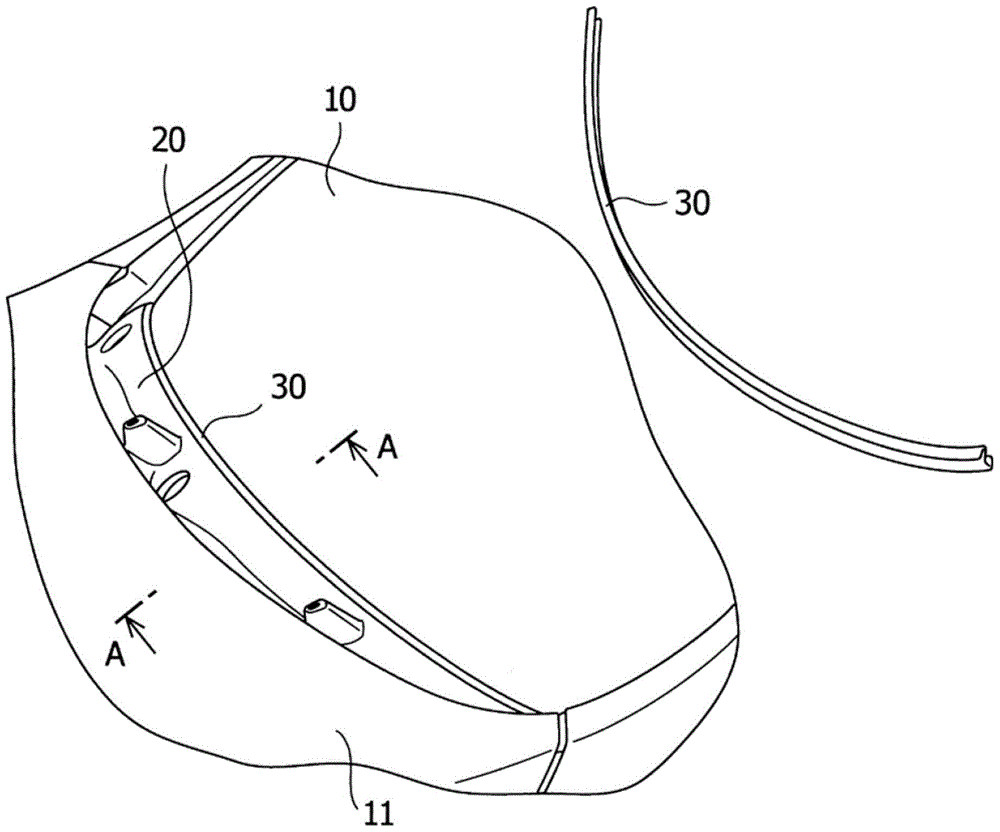

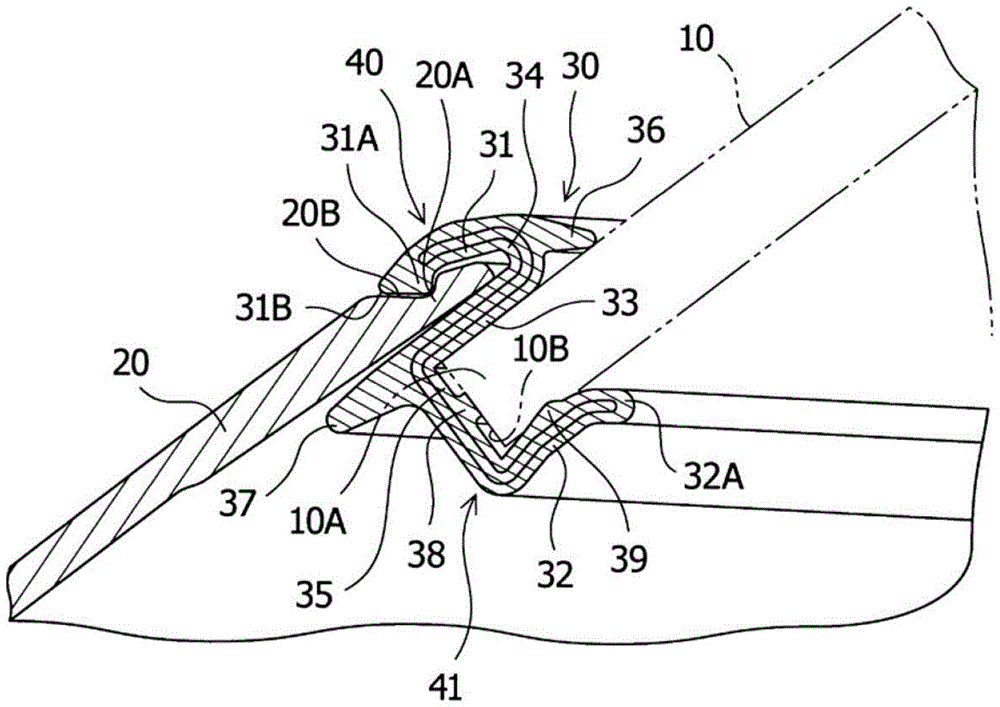

Structure for positioning cowl top for vehicle

ActiveCN103153760AInhibition of entry of foreign matterImprove appearanceWindowsWindscreensEngineeringForce generation

Disclosed is a cowl top positioning structure for determining the relative positions of a windshield (13) and a front cowl top (17) by means of a clip (20). The clip (20) has: a cowl top mounting section (25) to which the front cowl top (17) is mounted; a windshield facing section (26) facing the lower end surface (22) of the windshield (13); and a reaction force generation section (27) for generating a reaction force acting against a pushing force with which the lower end surface (22) of the windshield (13) pushes the windshield facing section (26) toward the front of the vehicle body (11). The relative positions of the windshield (13) and the front cowl top (17) are determined by causing, by means of the reaction force generated by the reaction force generation section (27), the rear end surface (23) of the front cowl top (17) to abut against the lower end surface (22) of the windshield (13).

Owner:HONDA MOTOR CO LTD

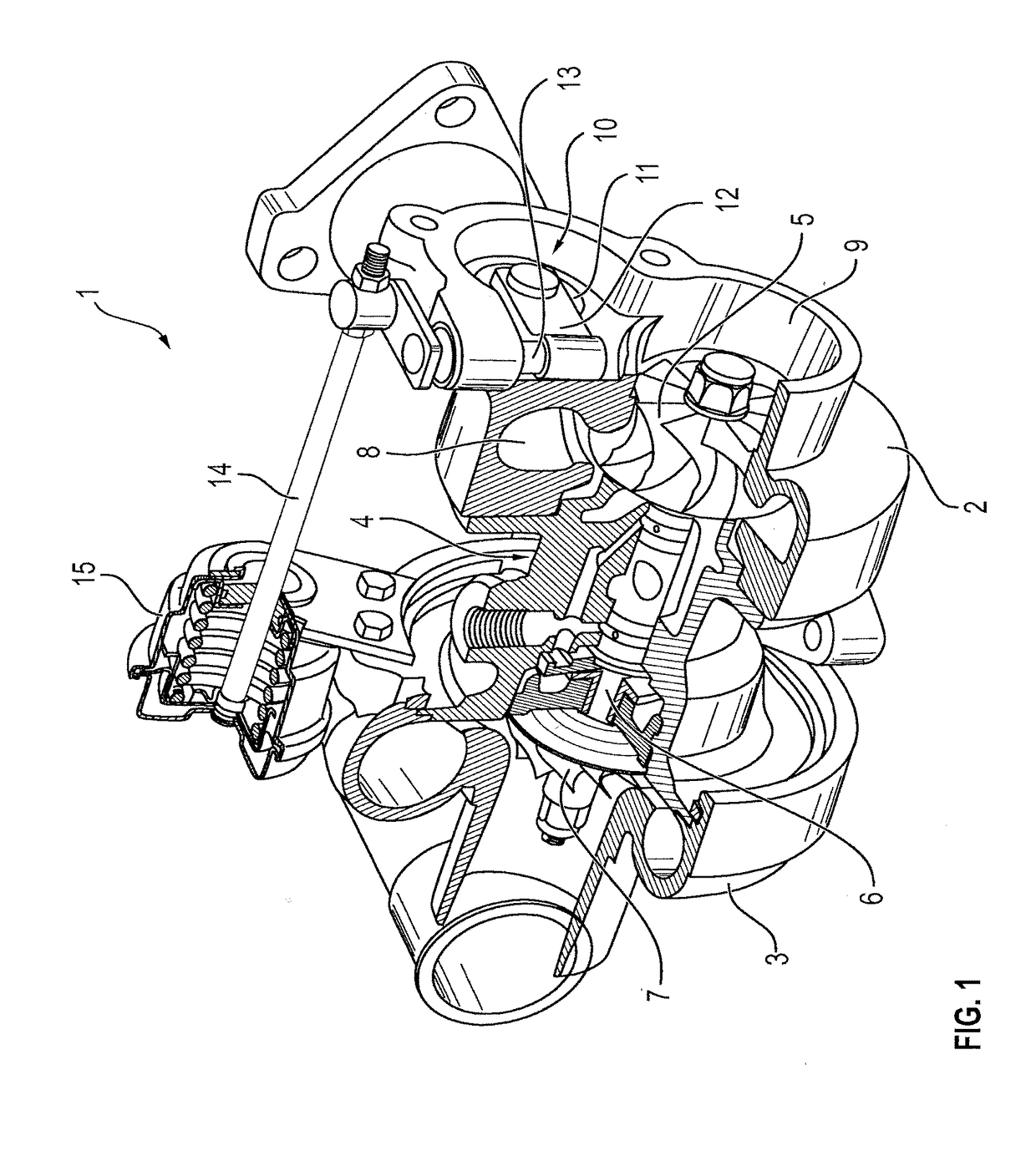

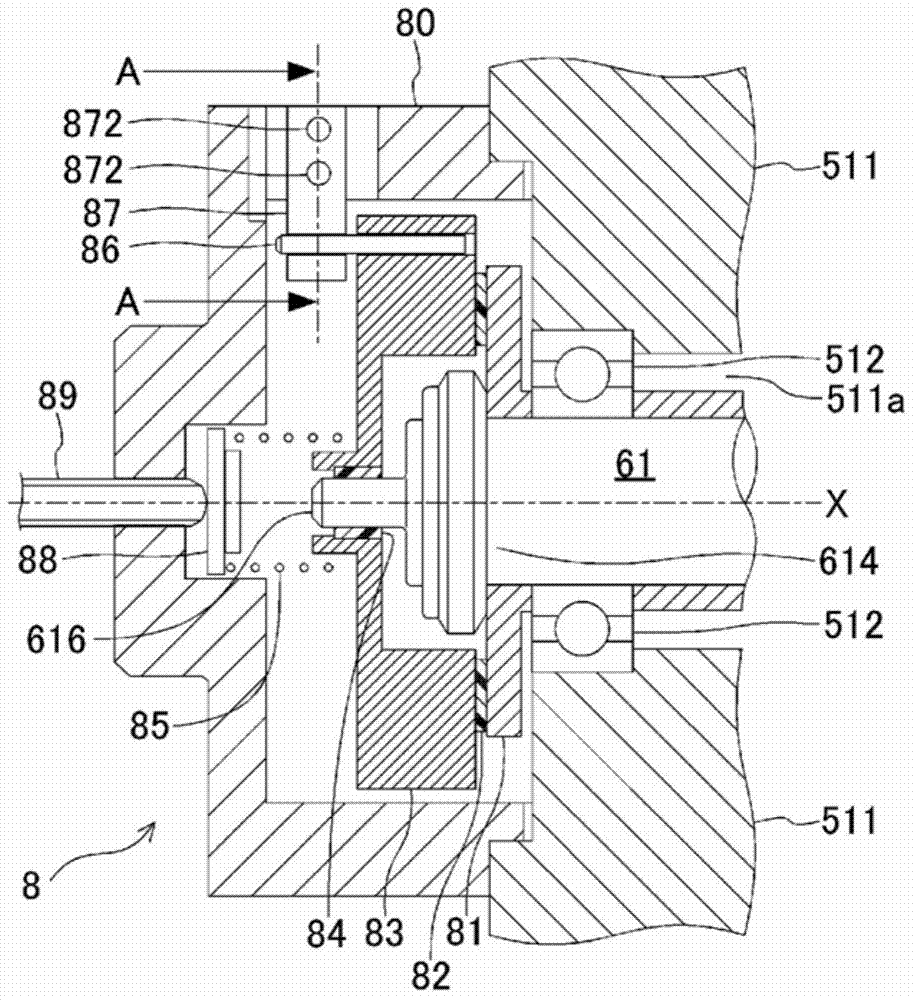

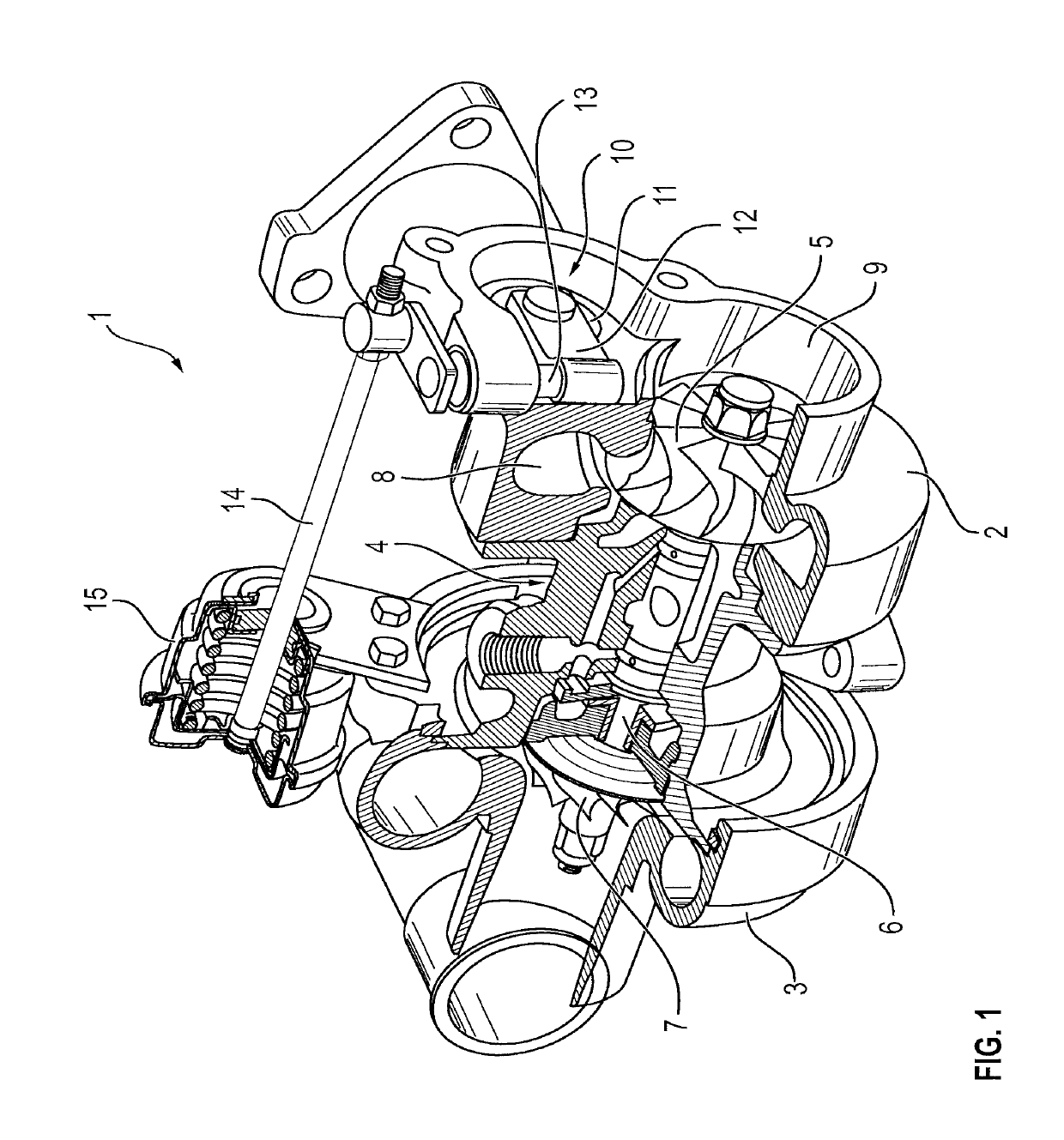

Exhaust-gas turbocharger

ActiveUS20180073425A1Vibration damping of the flap plate in the open position can be attainedReliable abutmentInternal combustion piston enginesGas turbine plantsCircular discWastegate

An exhaust-gas turbocharger (1), with a turbine housing (2) which has a turbine housing inlet (8) and a turbine housing outlet (9) for exhaust gas, and which has a wastegate duct (45) between the turbine housing inlet (8) and the turbine housing outlet (9), and a flap arrangement (33) comprising a pivotable flap lever (35), a flap plate (34), which is connected to the flap lever (35), for opening and closing the wastegate duct, and having a spring element (37) which is arranged between the flap lever (35) and a disc (36) fastened to the flap plate (34). The spring element (17) has an outer circumferential region (23) which is supported on a sliding contact surface (42), which is of curved form, of the disc (36).

Owner:BORGWARNER INC

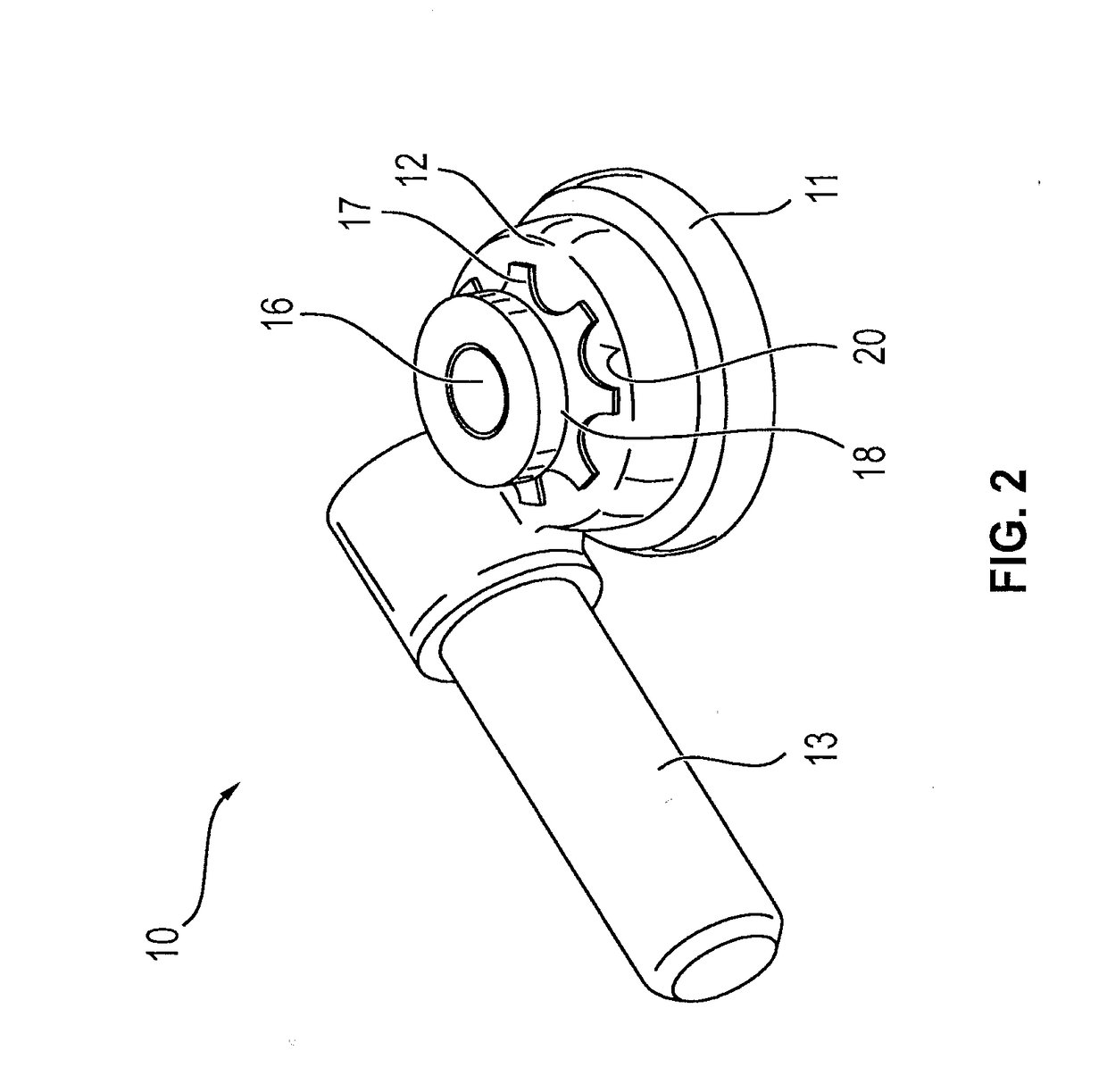

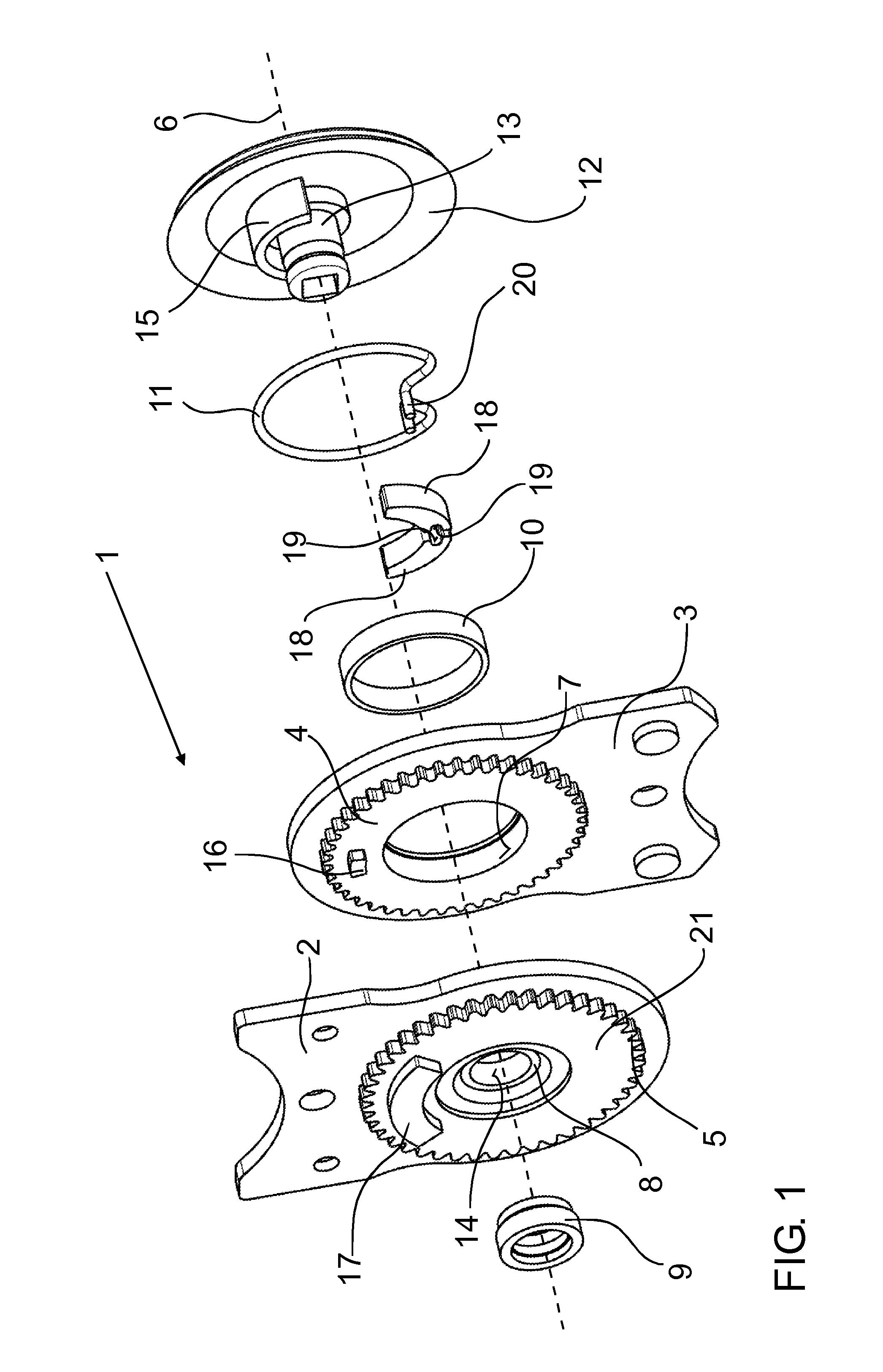

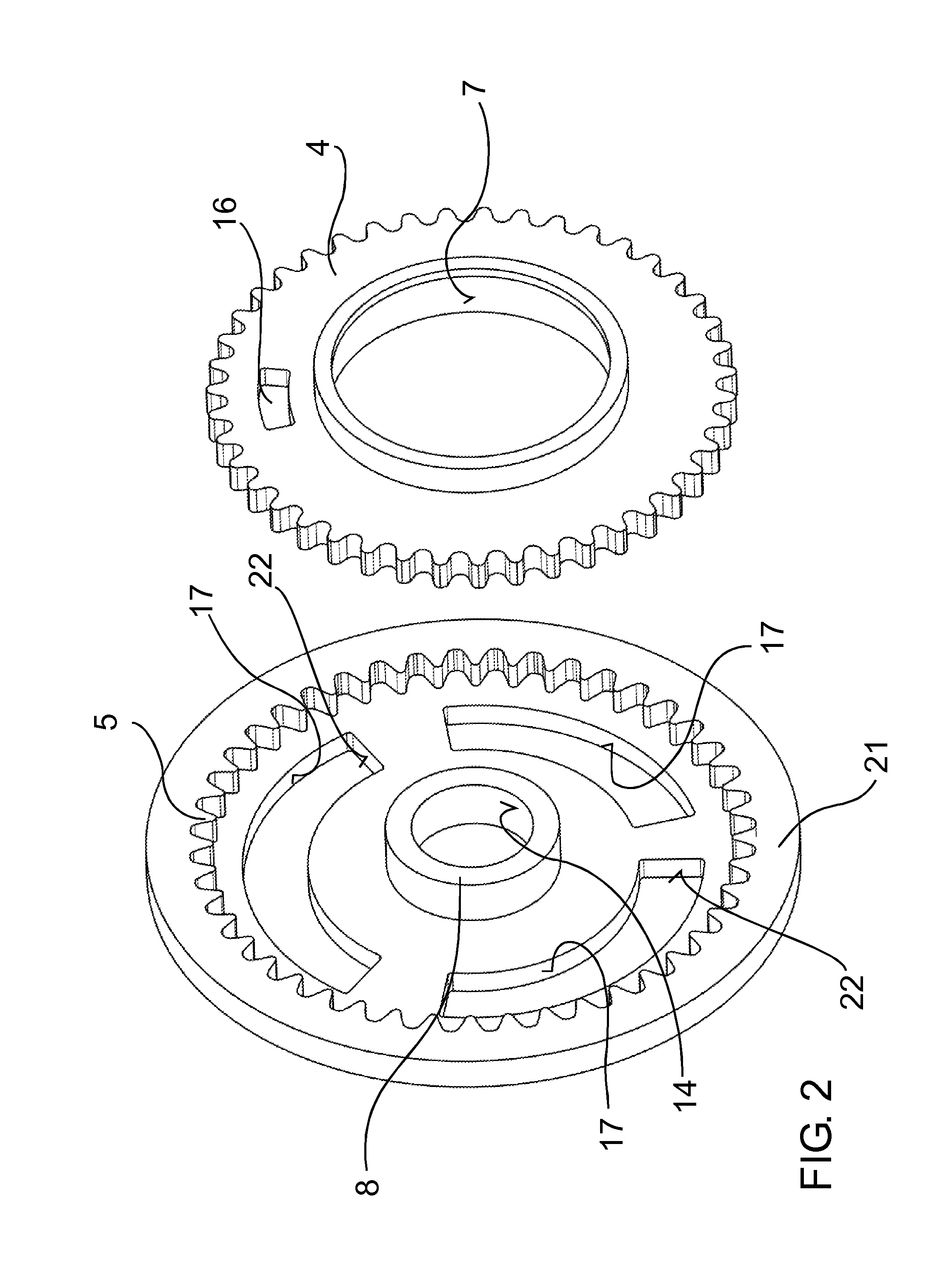

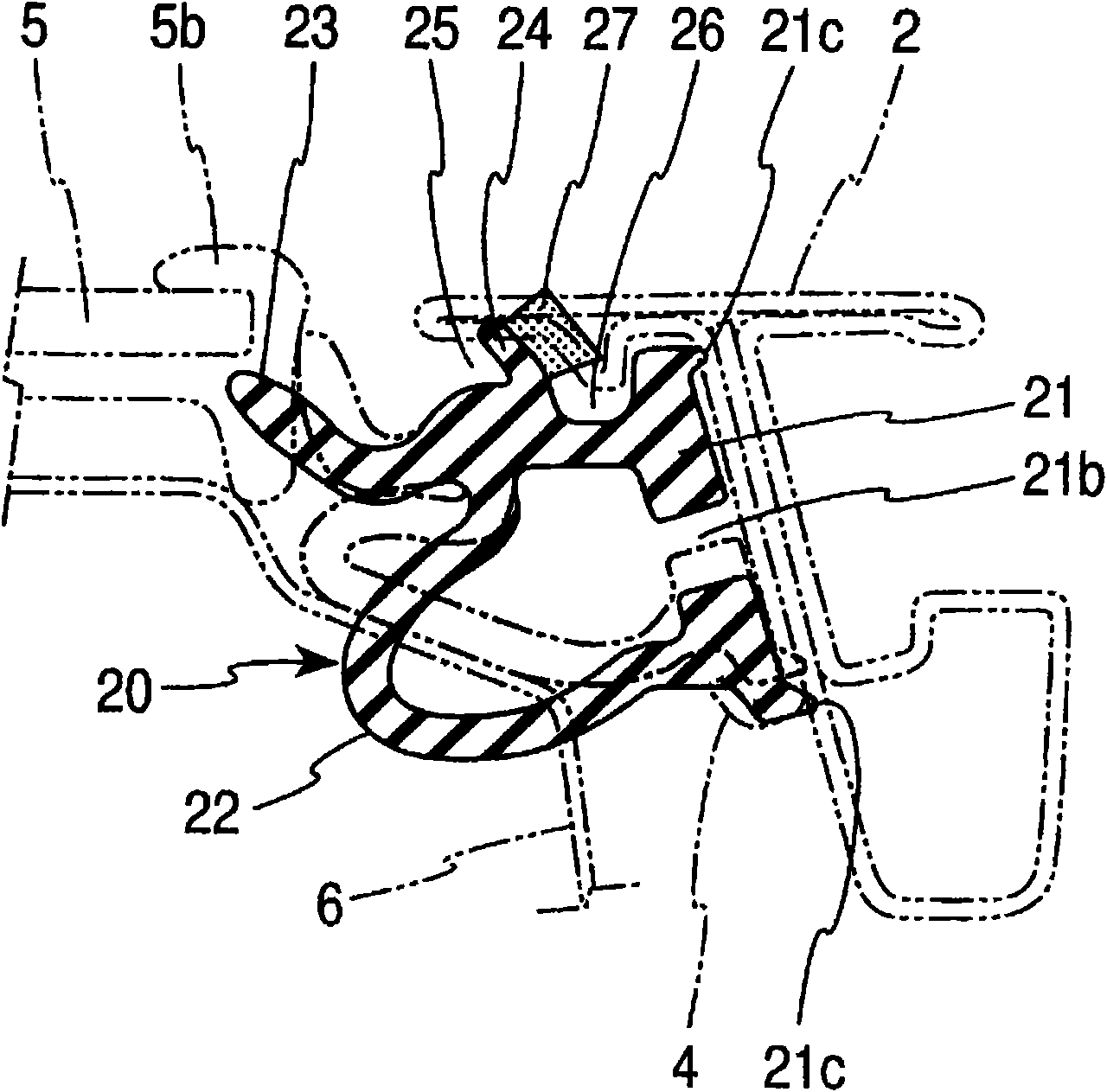

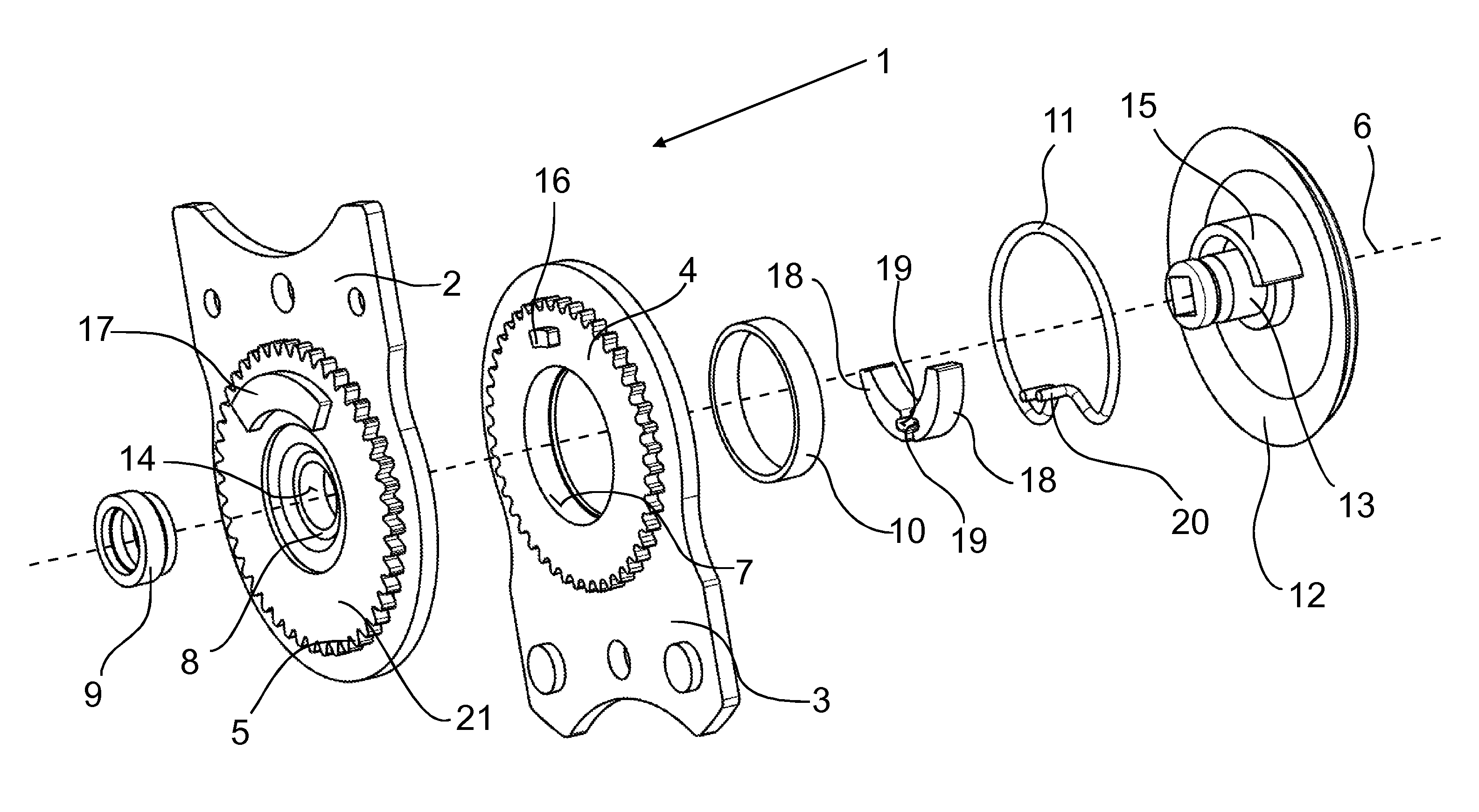

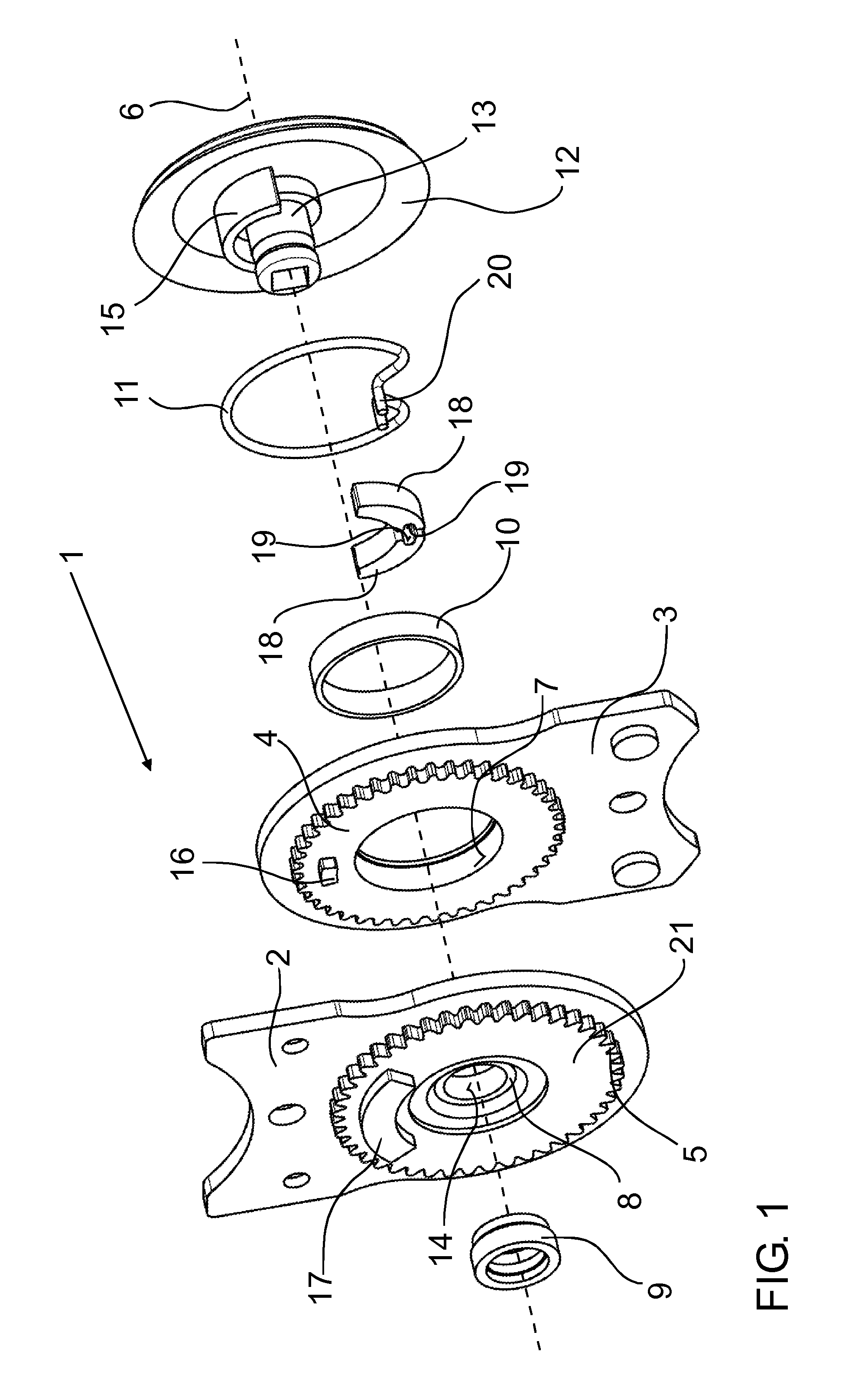

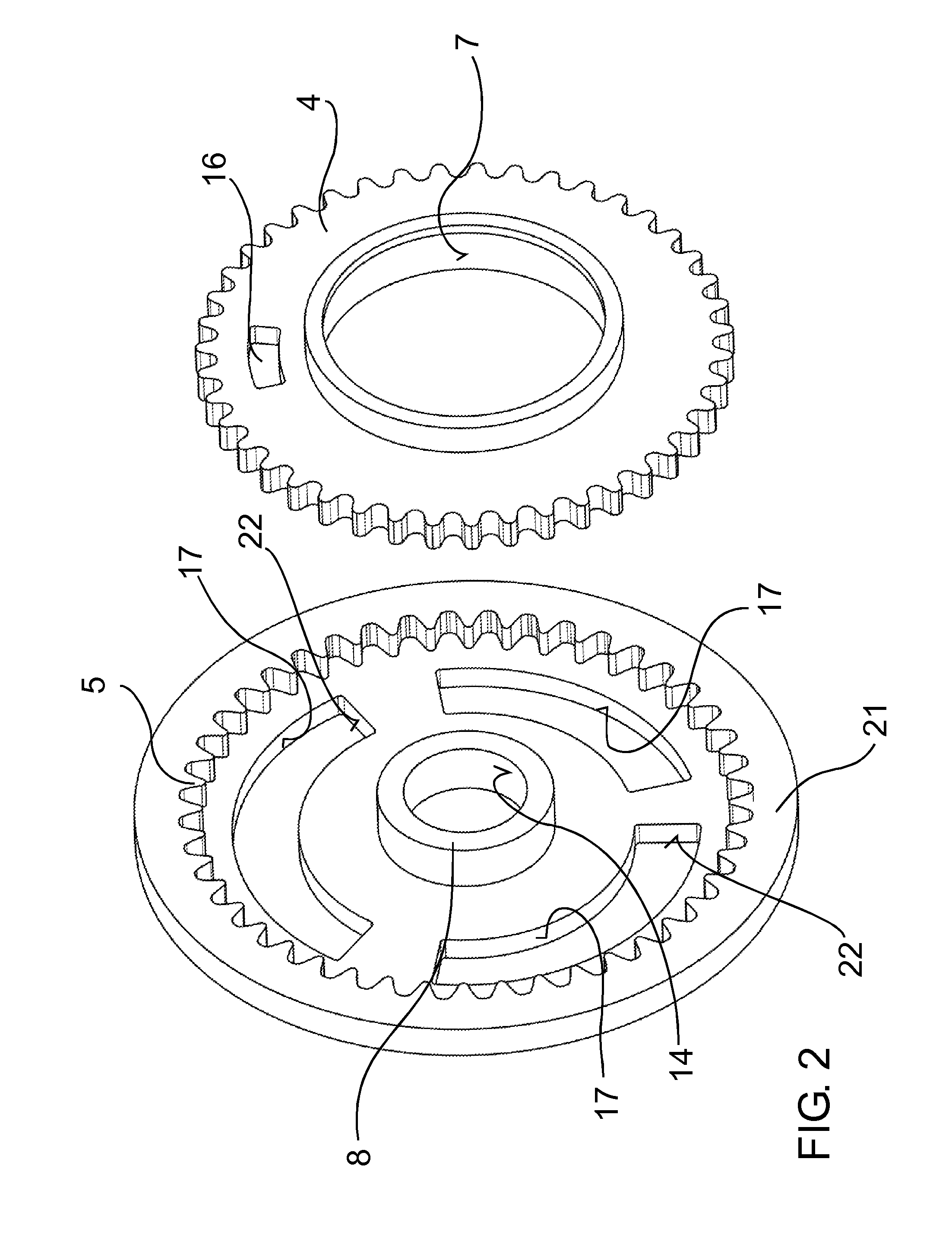

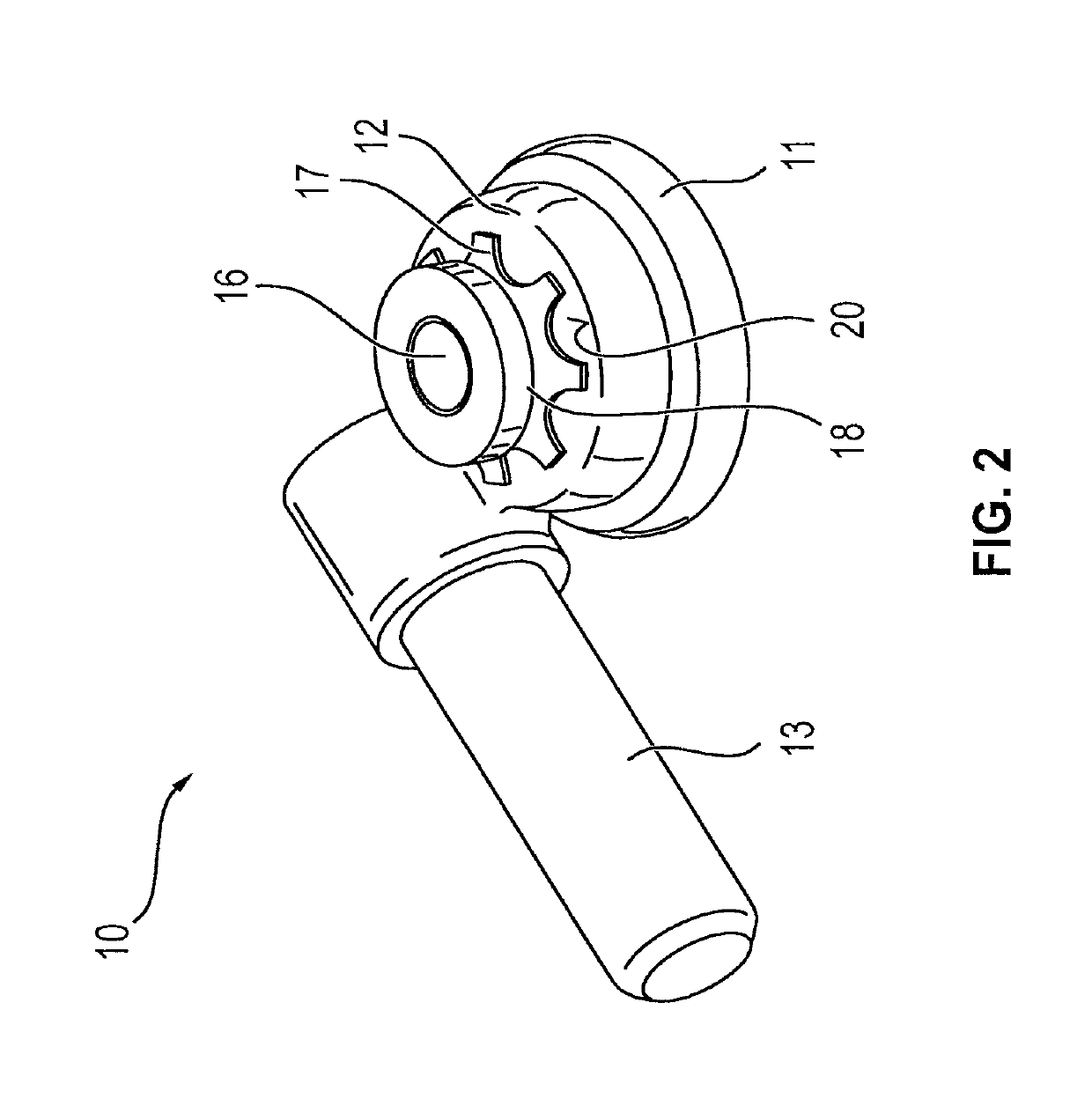

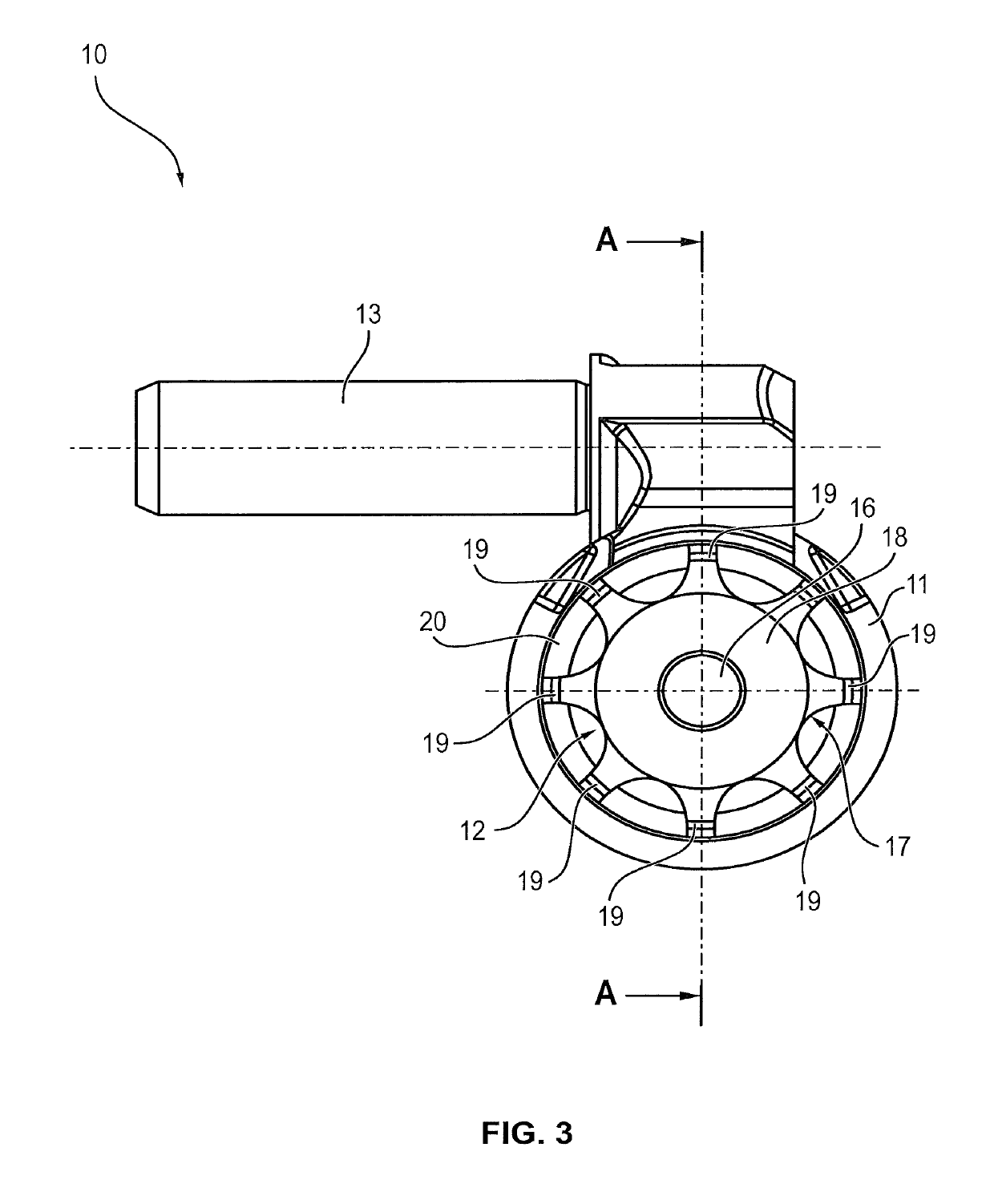

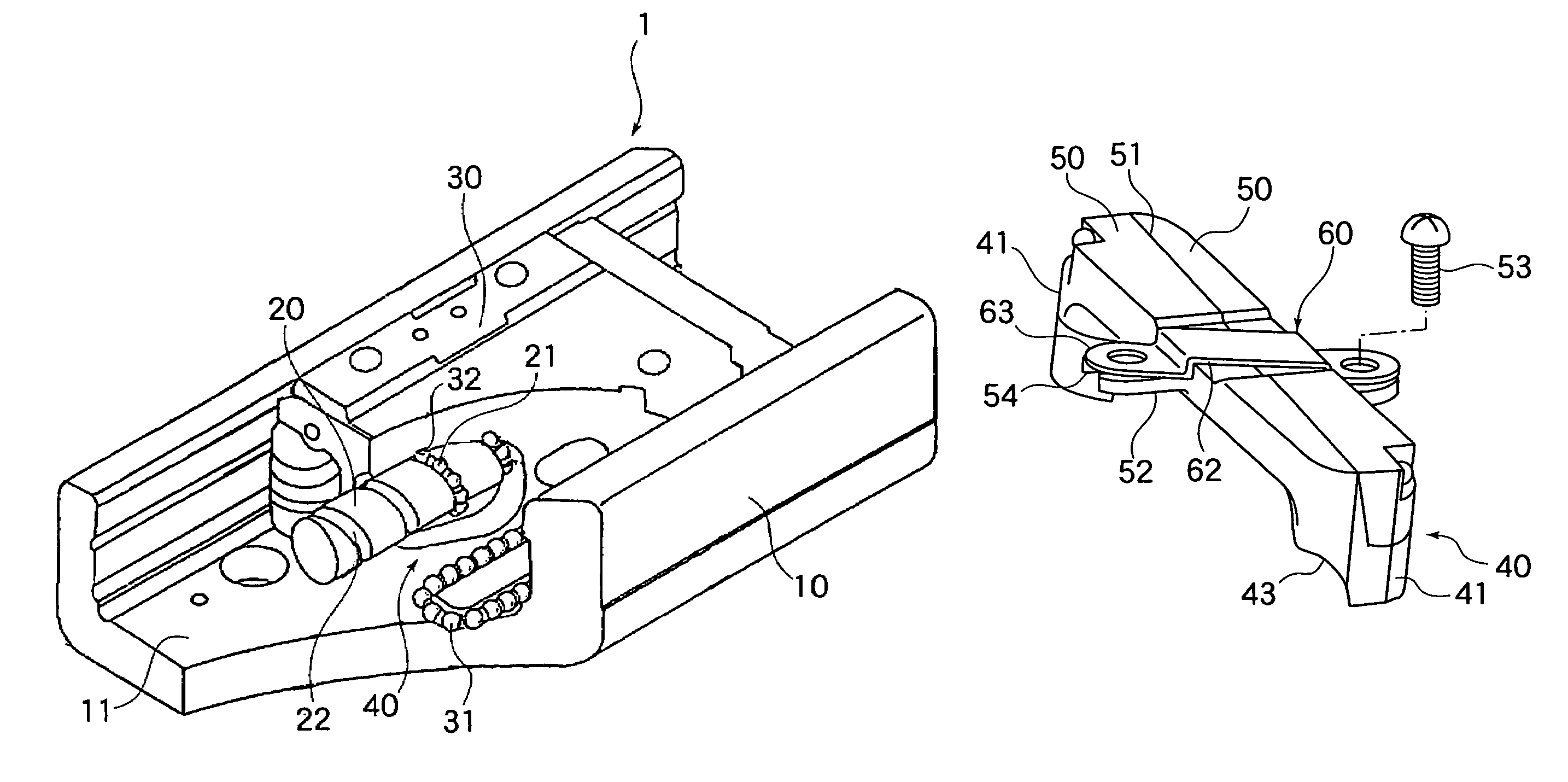

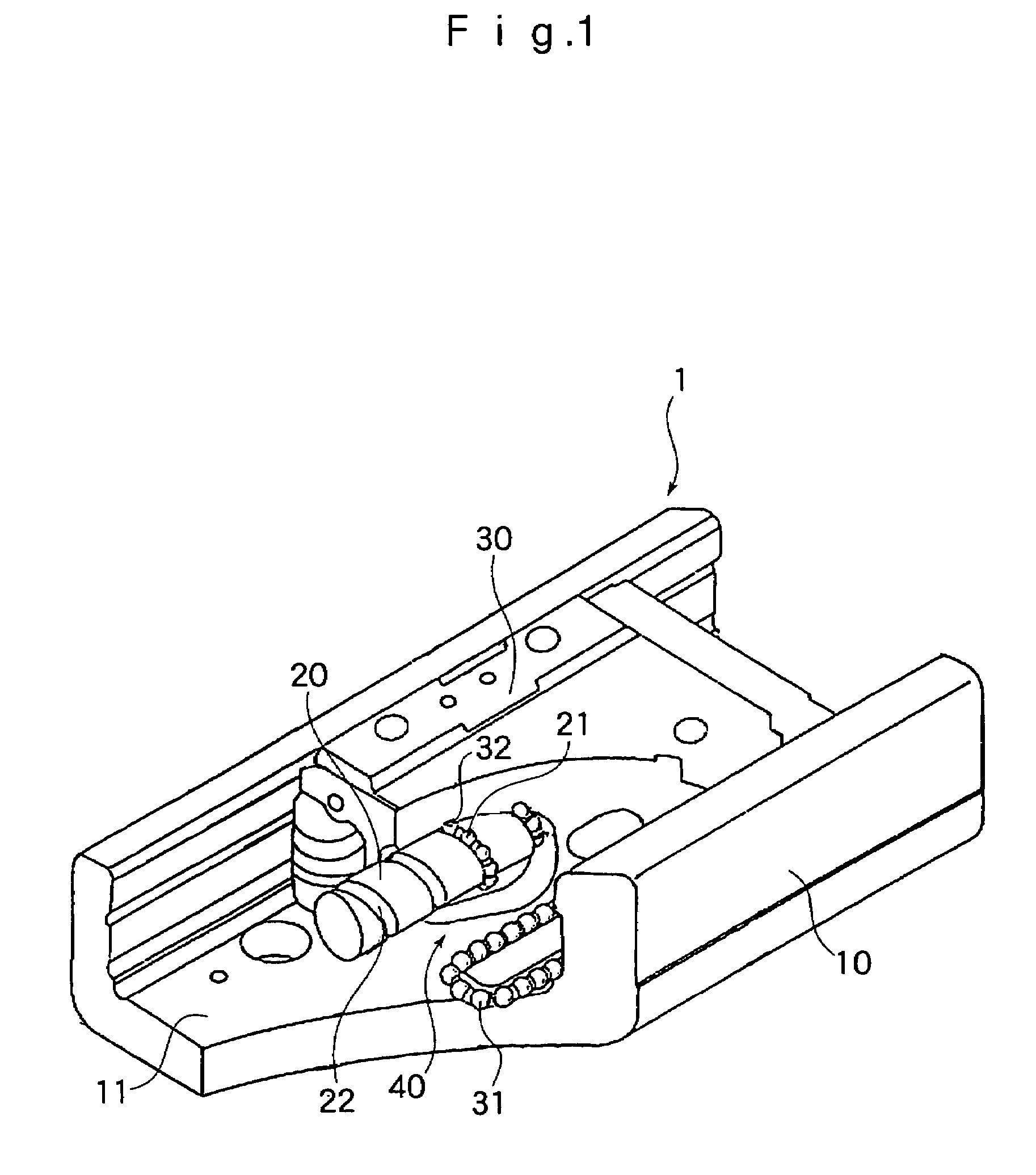

Seat fitting for a motor vehicle seat

ActiveUS20140162827A1Preventing seizingCost effective productionVehicle seatsToothed gearingsMotor vehicle partDrive shaft

A motor vehicle seat fitting includes a fitting top part with a ring gear (21) having internal toothing, a fitting bottom part with a gear wheel (4), having external toothing and which is in engagement with the ring gear, an eccentric arranged rotatably in a bore (7) of the bottom part running axially to the gear wheel, for rolling adjustment of the gear wheel relative to the hollow gear, and a drive shaft, which drives the eccentric and extends axially to the ring gear. A cam receptacle (17) is arranged on one of the gear wheel or the ring gear (21) and a stop cam (16), that engages in the cam receptacle, is arranged on the other of the gear wheel or ring gear, in a ring portion between the external toothing and the bore and on the ring gear in a zone which may overlap the ring portion.

Owner:ADIENT US LLC

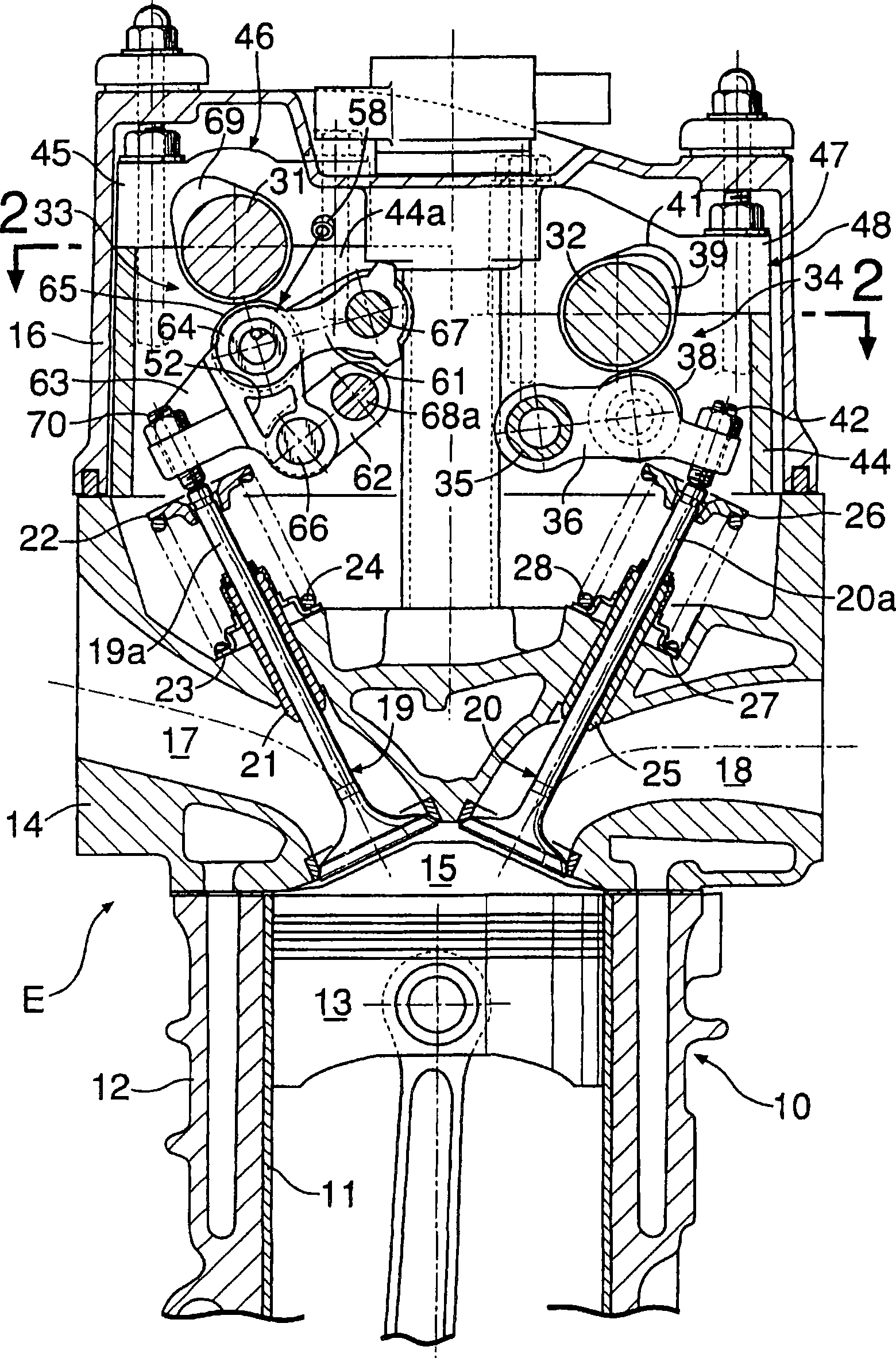

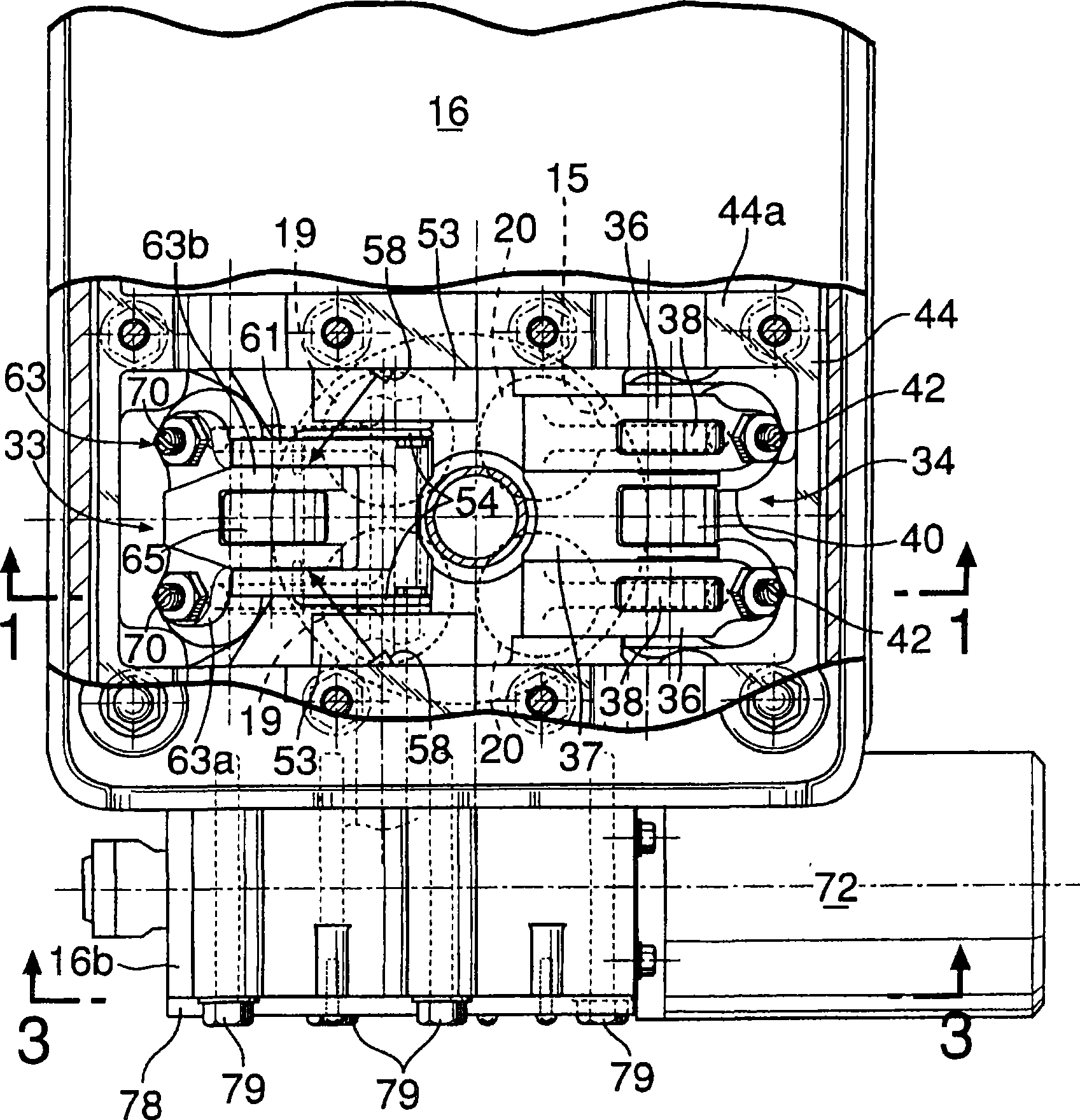

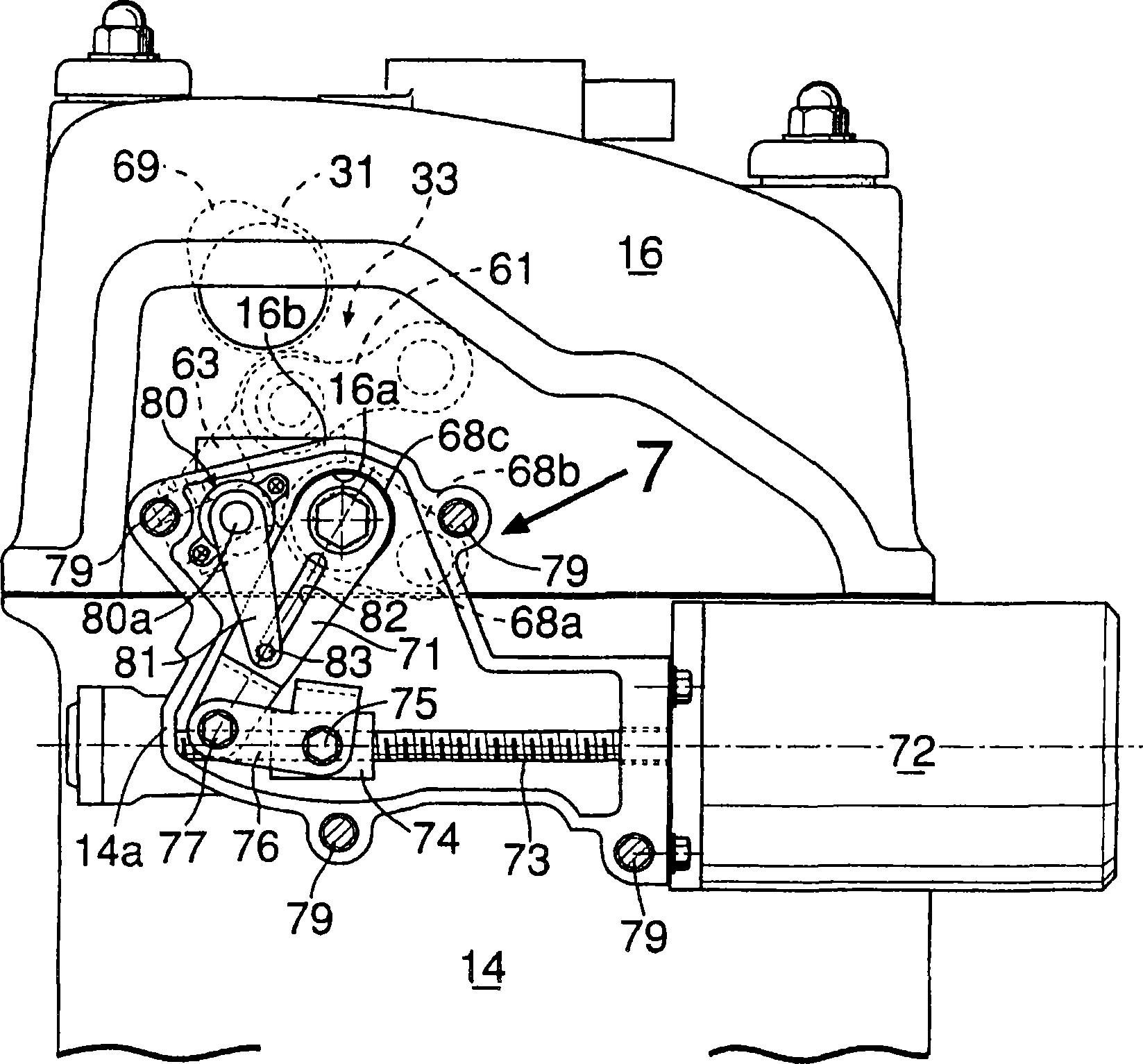

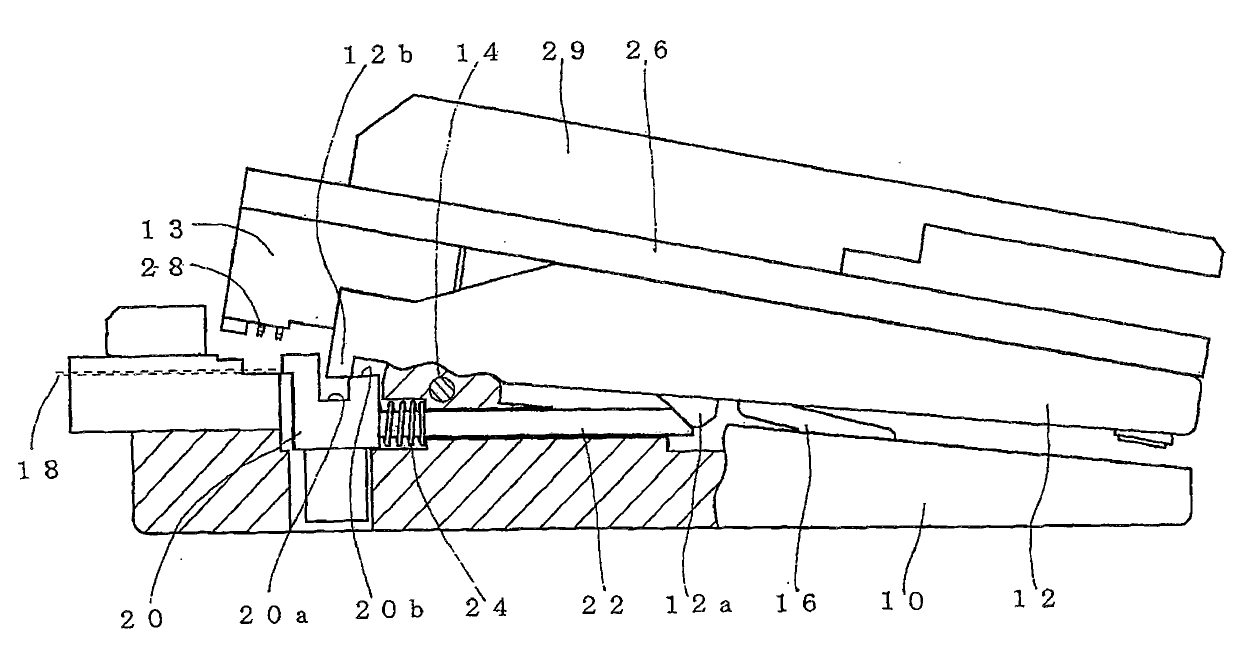

Valve operating device for engine

InactiveCN1910349AReduce widthMiniaturizationValve arrangementsMachines/enginesEngineeringEngine valve

A rocker arm (63) is provided with a valve connecting portion (63a) into which tappet screws (70) abutting against a pair of engine valves (19) are screwed so that their advance / retract positions can be adjusted, and the rocker arm (63) has a cam abutting portion (65) which abuts against a valve operating cam (69) and is interlocked and connected to the engine valves (19). The rocker arm (63) turnably connects to one end of a first link arm (61) turnably supported at a fixed position of an engine body and to one end of a second link arm turnably supported by a displaceable movable support shaft (68a). The rocker arm (63) is formed so that the valve connecting portion (63a) has a larger width in a direction along a rotating axis of the valve operating cam (69) than in the remaining part. This enables the lift amount of the engine valves to be continuously varied. It is also possible to reduce the size of the system, while ensuring follow-up ability of the opening / closing operations.

Owner:HONDA MOTOR CO LTD

Heald shaft with lightweight shaft rod

Owner:GROZ BECKERT KG

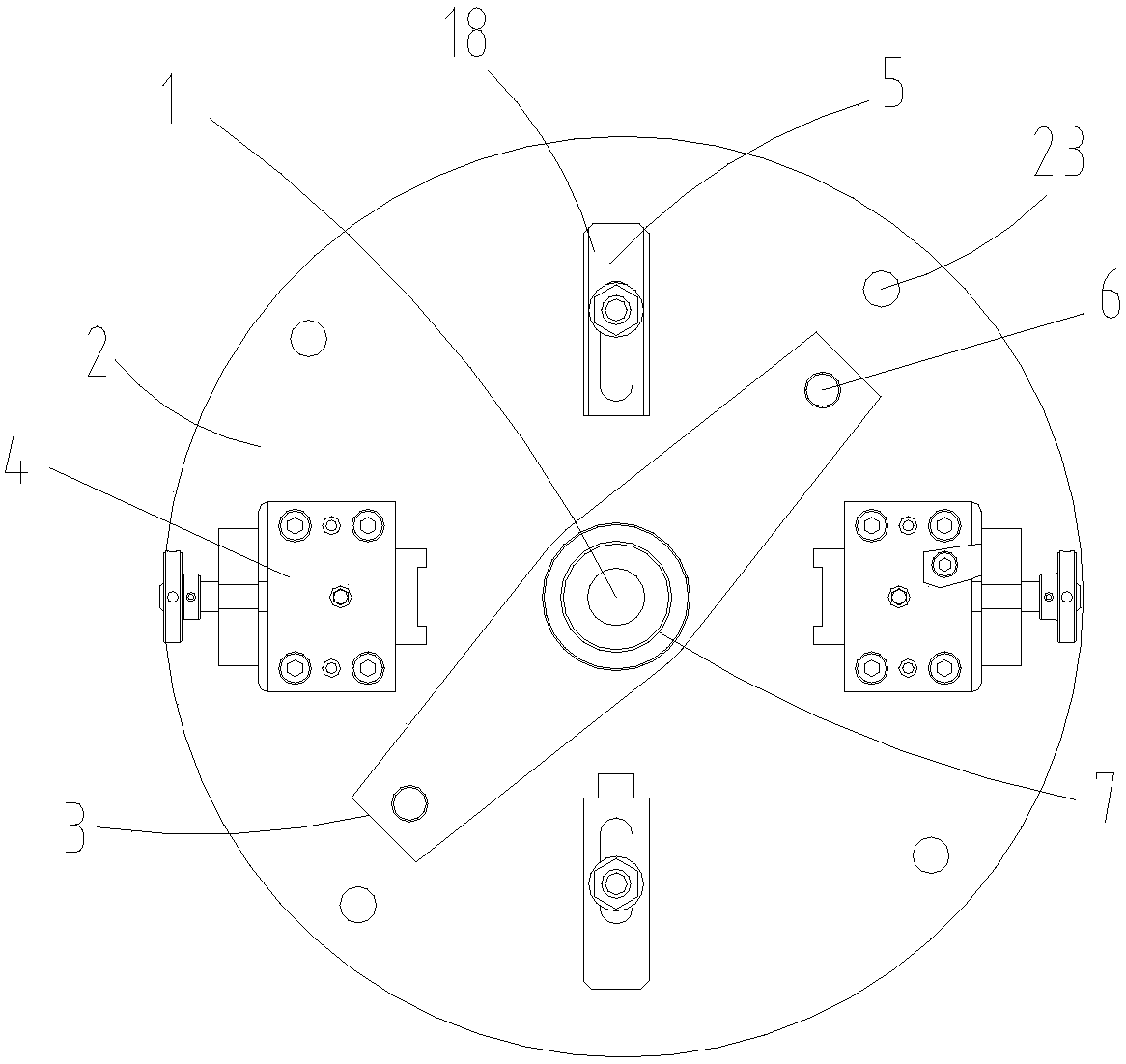

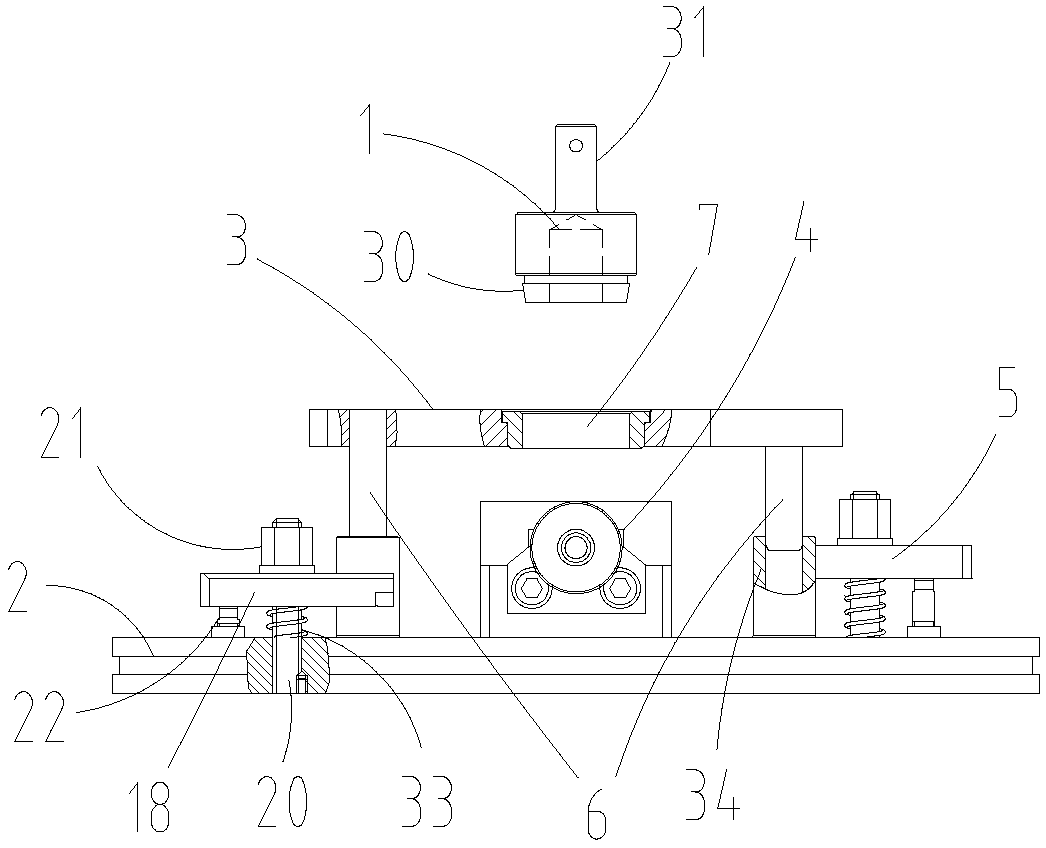

Efficient numerical control vehicle clamp and clamp installation method

PendingCN108032106AThere will be no concave and convex phenomenonPrecise positioningPositioning apparatusMetal-working holdersNumerical controlMachine tool

The invention discloses an efficient numerical control vehicle clamp and a clamp installation method. The clamp comprises a correction core shaft and a face plate, the face plate is provided with a mounting hole, a guide sleeve, two clamping mechanisms and two pressing mechanisms, wherein the clamping mechanisms are distributed in axis symmetry about the face plate, the pressing mechanisms are distributed in axis symmetry about the face plate, a correction plate is arranged above the face plate and is connected with the guide sleeve through a guide rod, the correction plate is provided with acorrection hole coaxial to the face plate, and the correction hole coincides with the correction core shaft; the clamping mechanisms comprise fixing blocks connected with the face plate, each fixing block is provided with a guide hole, the guide hole is internally provided with a movable block, protrusions are arranged at the two sides of the end, close to the core part of the face plate, of the movable block, a through hole is formed in the end, away from the core part of the face plate, of the movable block and is internally provided with a ball head, and a screw is connected to the ball head and penetrates through one side of the movable block and is connected with the fixing block through a supporting plate. A machining tool for an end cover vehicle has the advantages of being high inefficiency and high in surface machining quality.

Owner:AVIC LIYUAN HYDRAULIC

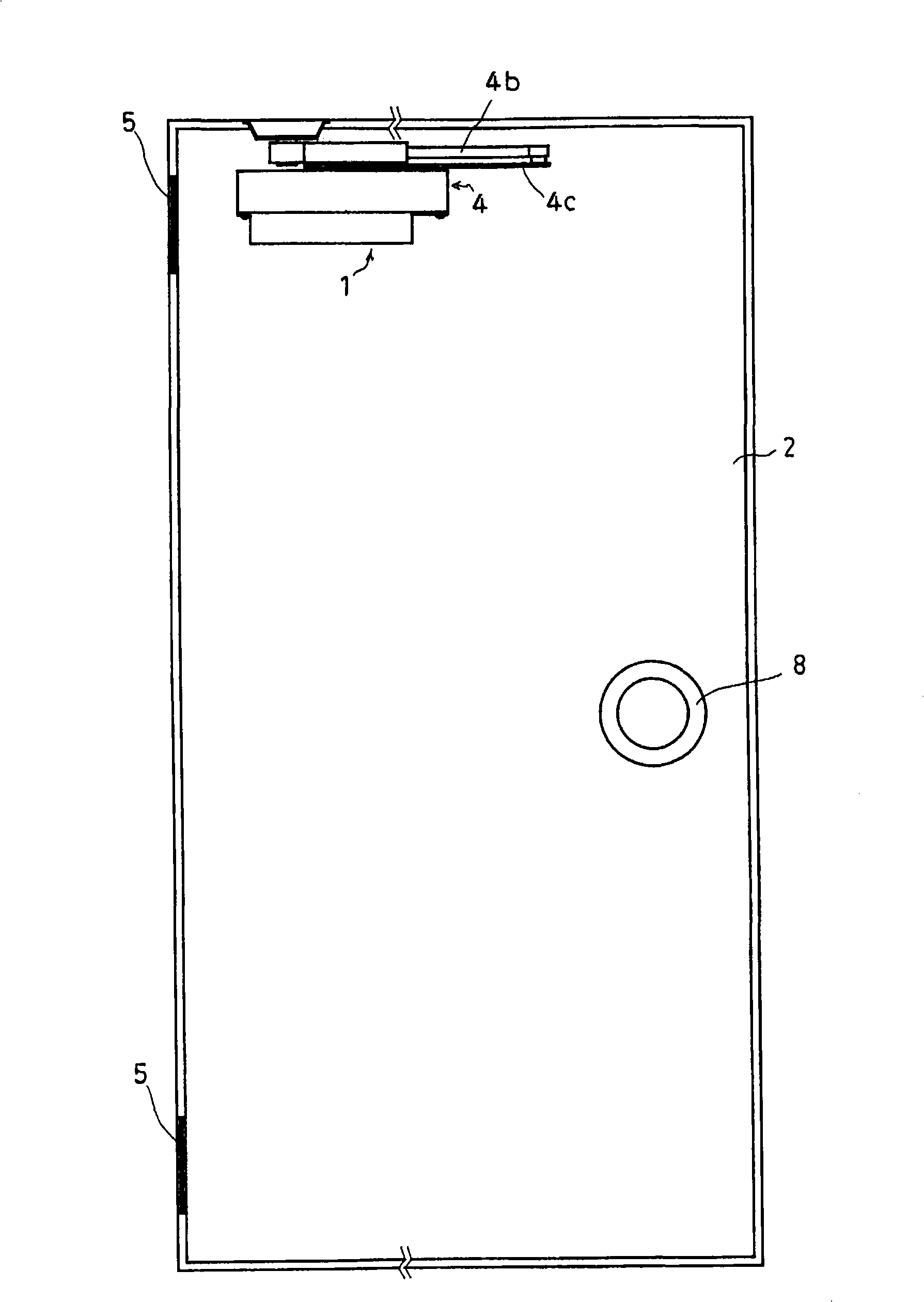

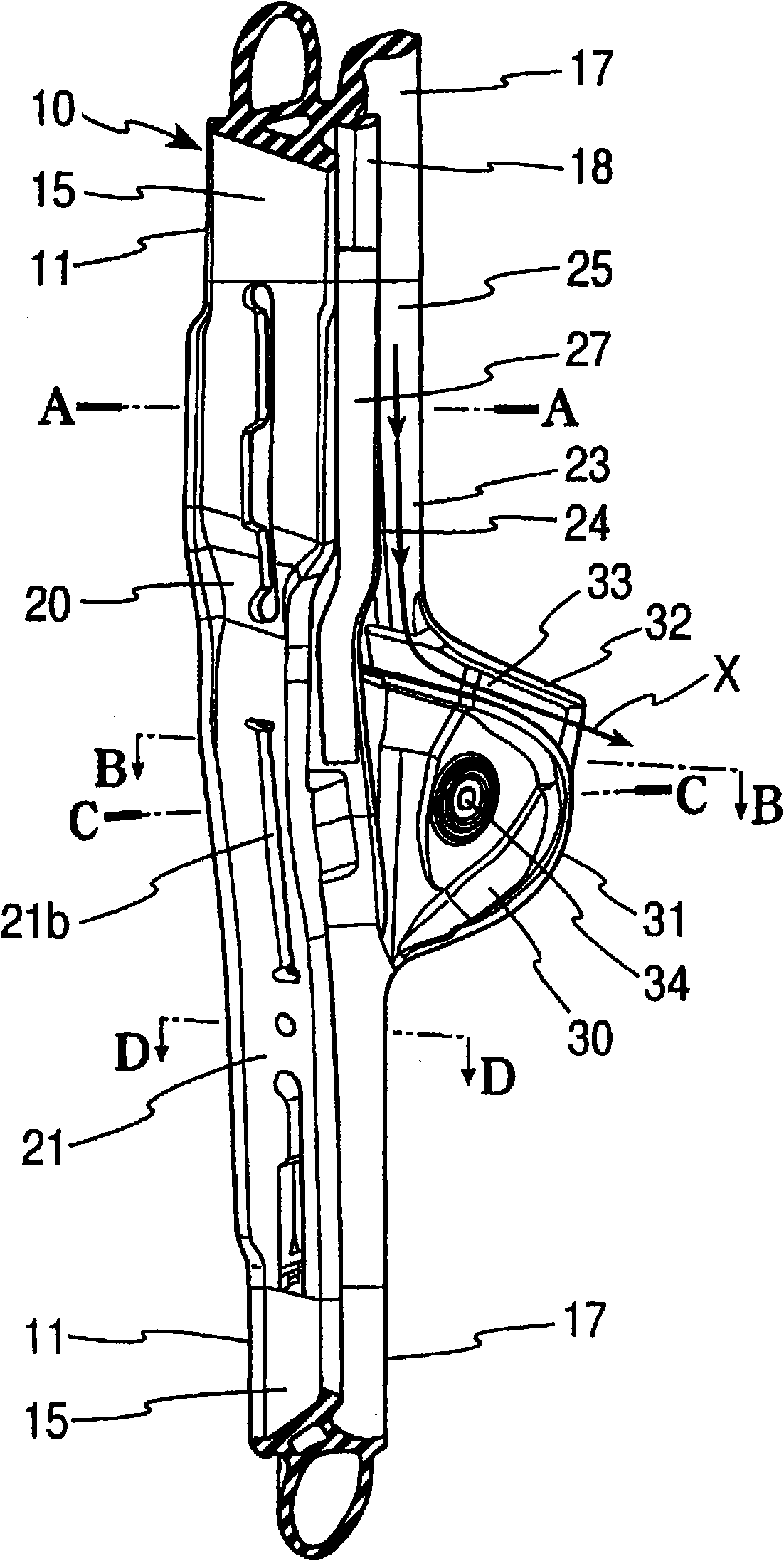

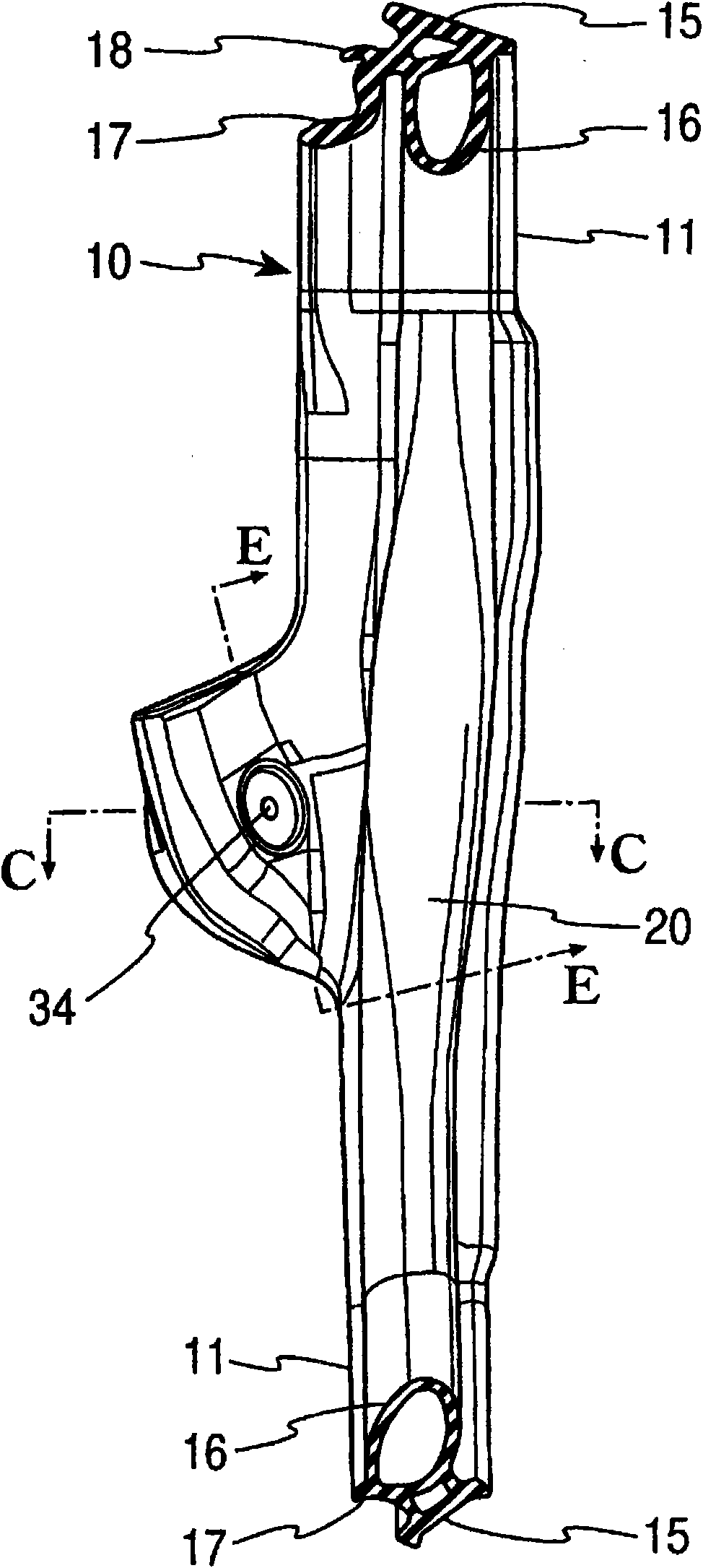

Auxiliary door-opening apparatus

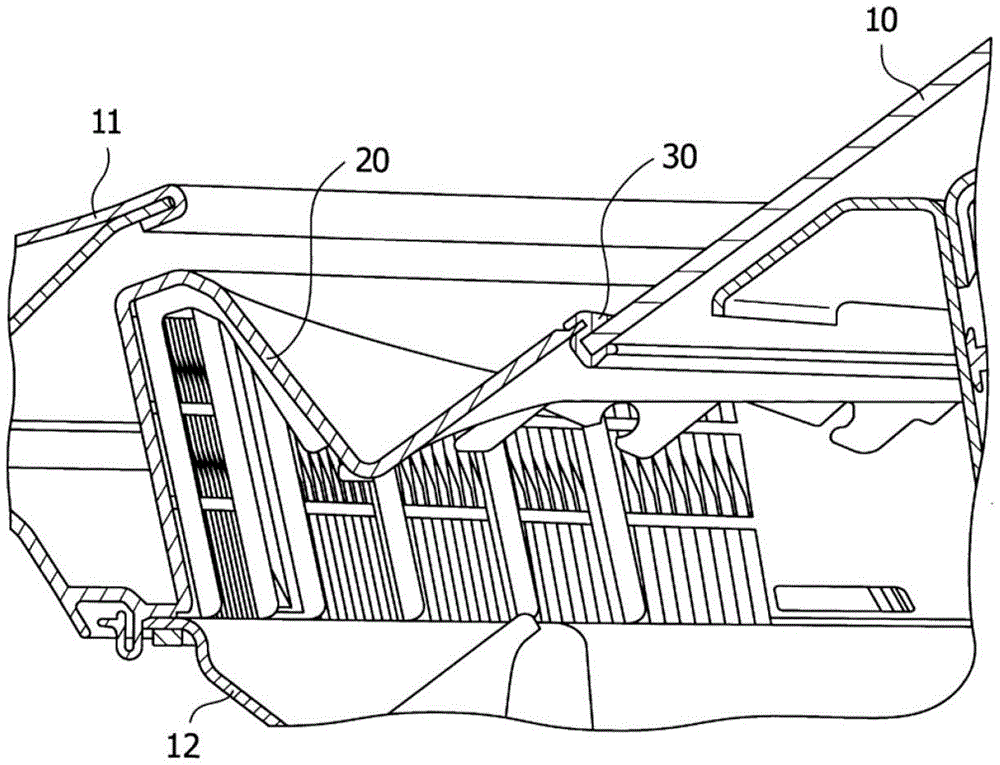

InactiveCN101305149APrevent appearance deteriorationReduce operating forceBuilding braking devicesWing accessoriesOperabilityElectrical and Electronics engineering

A door opening assisting device that has a simple structure not requiring a dedicated operation member for assisting opening of a door and whose operability and reliability when it operates in synchronous with door opening operation are enhanced. The door opening assisting device is constructed as follows. With opening and closing of the door, a passive member (20) connected to a door closer for rotatingly urging the door in the closing direction is rotated in the normal and reverse direction, and the rotation of the door closer causes transmission members (30, 31) to reciprocate in the direction corresponding to the opening and closing of the door.; In this process, the opening of the door causes an opening spring (51) to urge and move the transmission member (30) in the door opening direction, and after opening force is accumulated in the spring (51) by the movement of the transmission member (31), the spring (51) is locked with the opening force accumulated in it. In the construction above, when the passive member is rotated in a predetermined angle region in the initial stage of door opening operation, this causes the opening spring to exert opening force and also causes the spring to accumulate opening force and then to be locked with the opening force accumulated in it.

Owner:NHK SPRING CO LTD

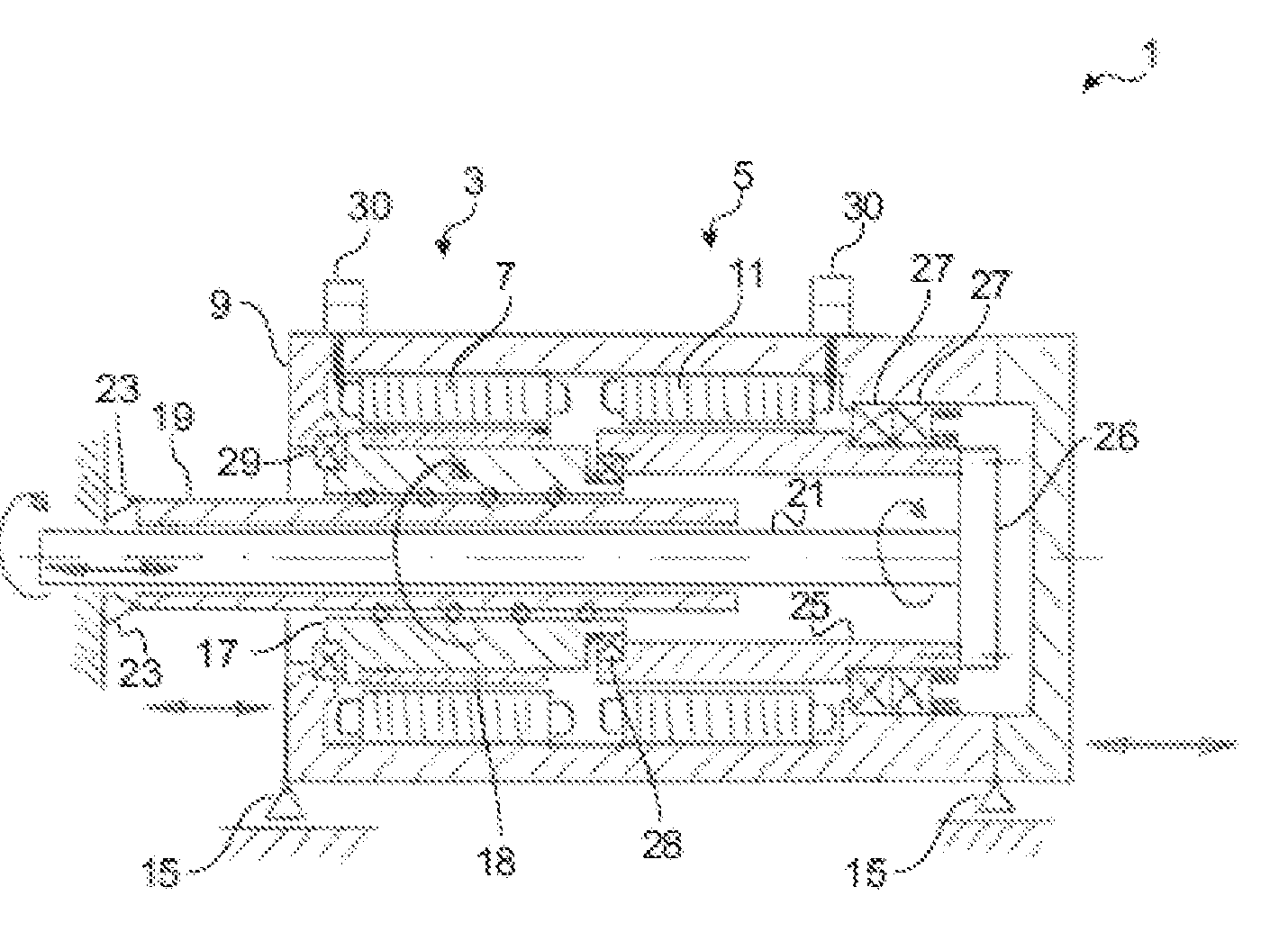

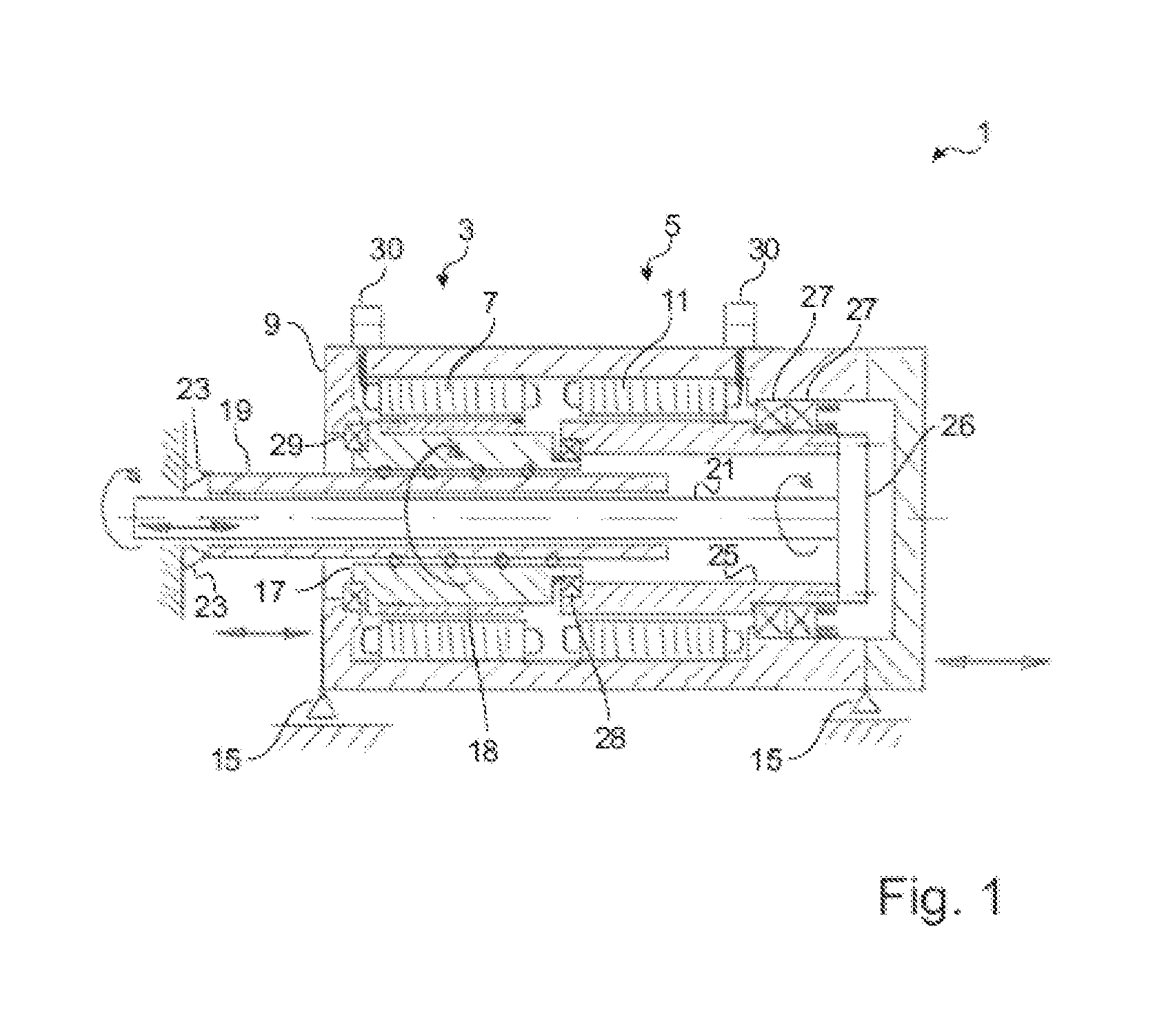

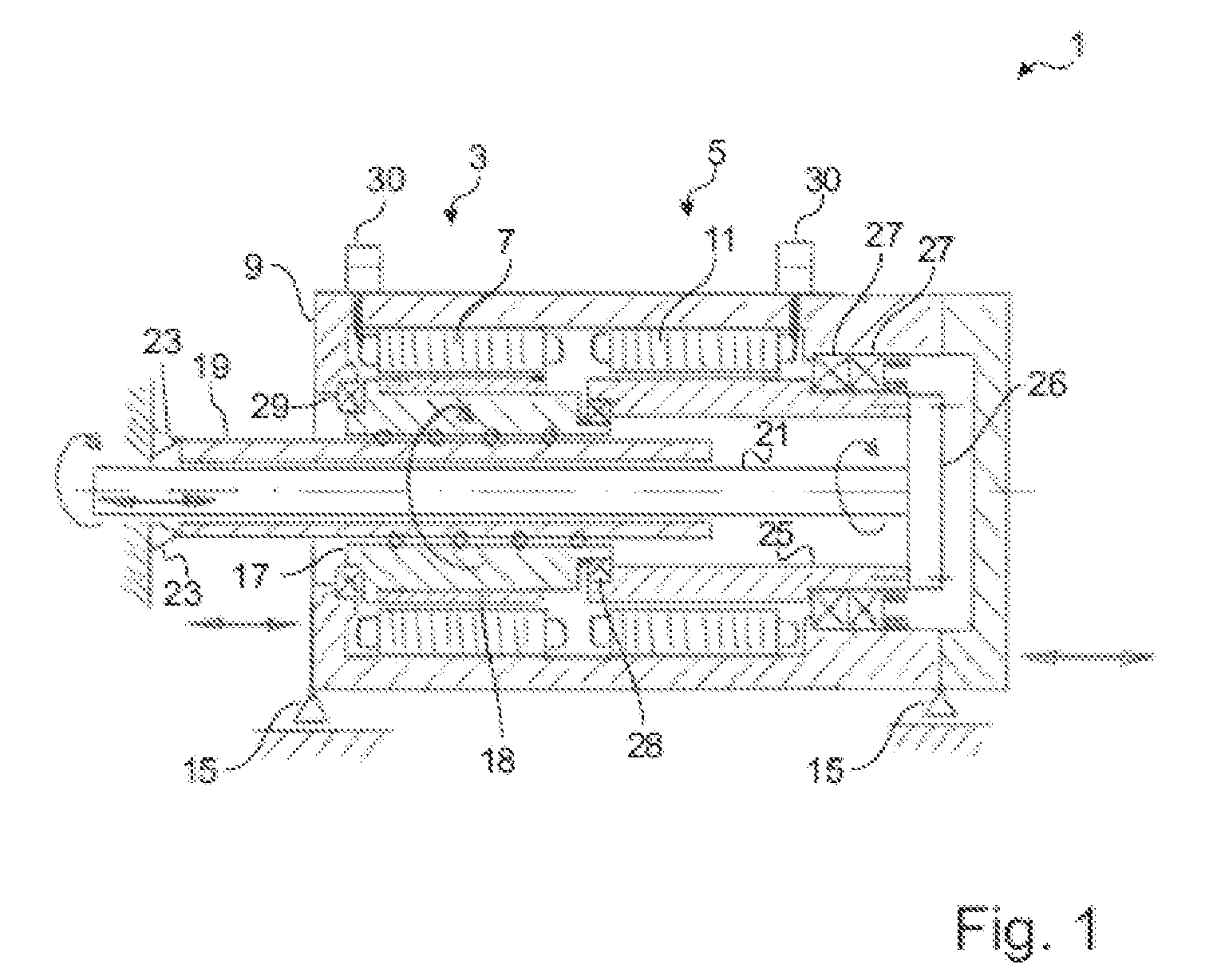

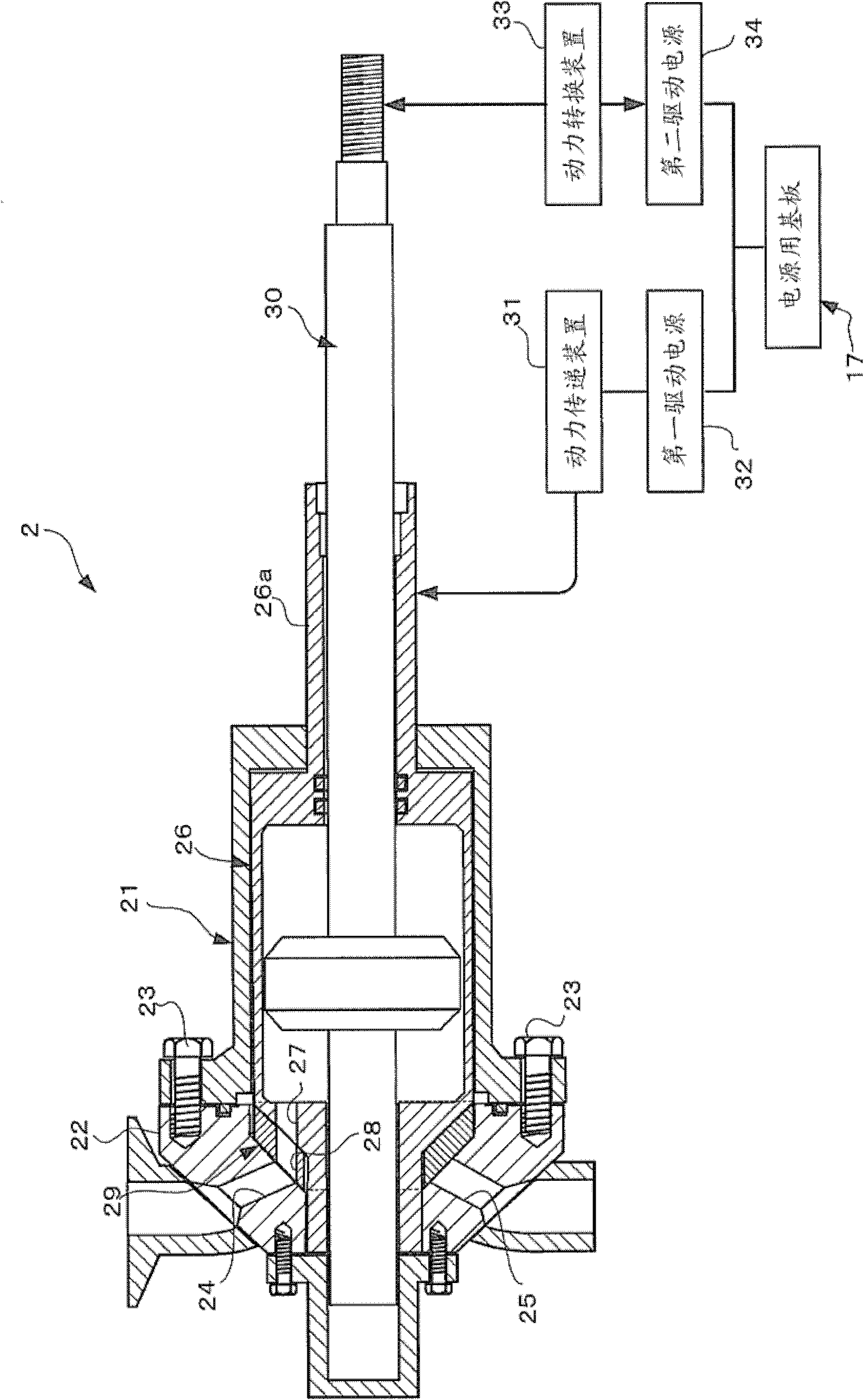

Drive apparatus

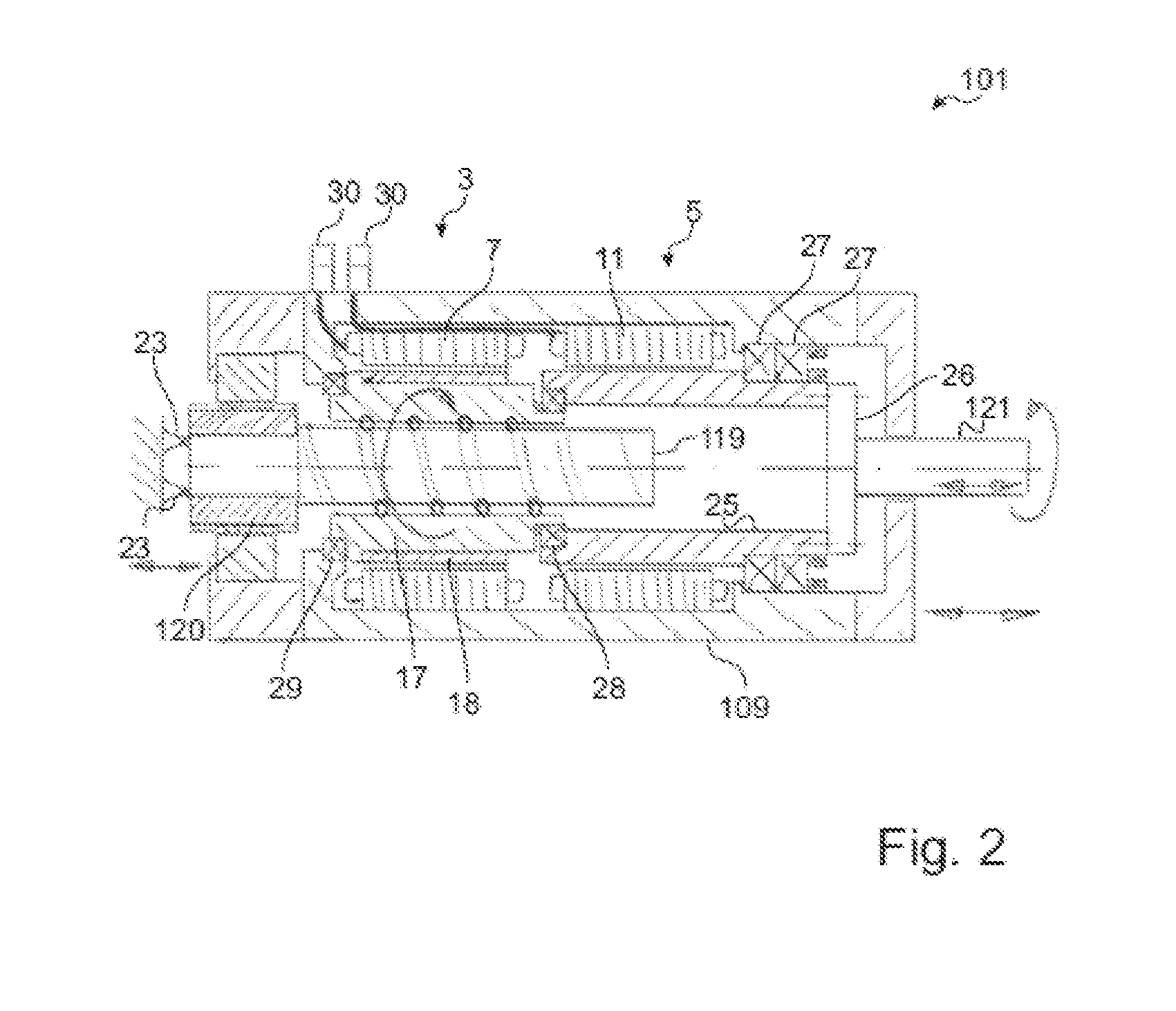

ActiveUS20150013483A1Improve rigidityMinimize risk of failureFriction gearingsEngineeringInjection molding machine

Drive apparatus (1, 101), in particular for driving a worm of an injection molding machine, which worm is arranged coaxially with respect to an injection molding cylinder, having a housing (9, 109) which is mounted such that it can be displaced in an axial direction of the housing (9, 109) and is fixed rotationally, an output shaft (21, 121) which is mounted non-displaceably and rotatably in the housing (9, 109), a rotational drive (5) which is arranged in the housing (9, 109) for the rotational drive of the output shaft (21, 121), and a translatory drive (3) which is arranged in the housing (9, 109) for the translatory drive of the housing (9, 109).

Owner:WITTENSTEIN SE

Car door sealing strip

ActiveCN101564982AImprove sealingEasy to installEngine sealsVehicle sealing arrangementsEngineeringFlange

The invention provides a car door sealing strip which can prevent rainwater from entering the car even in the case that steps are formed in the joint part of the door frame and the door panel. The car door sealing strip is characterized in: the connection part of the door sealing strip has a mounting base, a sealing lip part, an auxiliary sealing lip part and a hollow sealing part; also has a cover part covering the door frame and the joint portion between the door panels; the cover part has a sealing flange formed on the back; the front end of one side of the sealing flange is extended to the prolonged part of the sealing lip part or the auxiliary sealing lip part in order to block up the slot between the sealing lip part and the auxiliary sealing lip part on the connection portion; the front end of the other side is extended at least to the front of the cover part to discharge the water in the slot between the sealing lip part and the auxiliary sealing lip part outside the car.

Owner:TOYODA GOSEI CO LTD

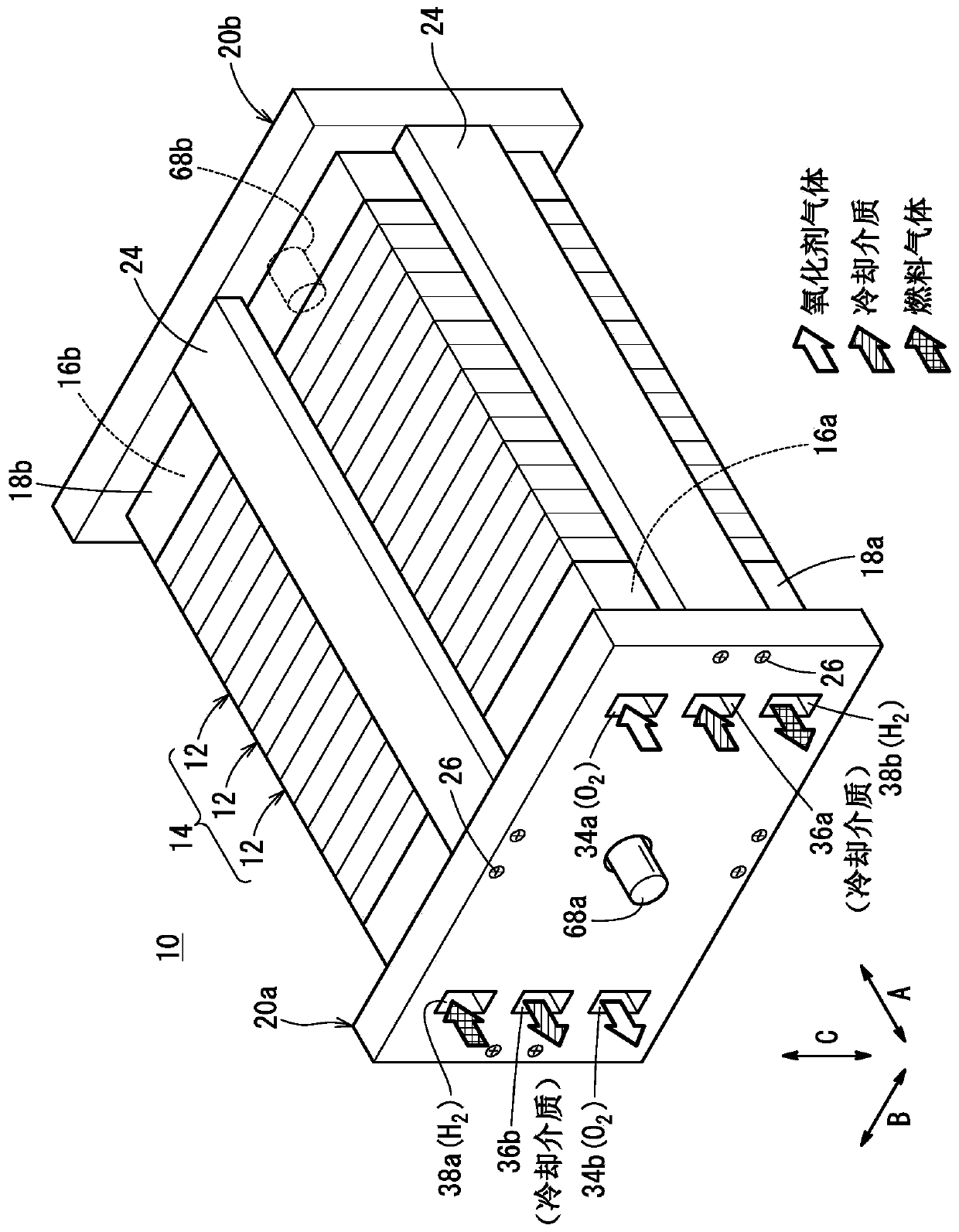

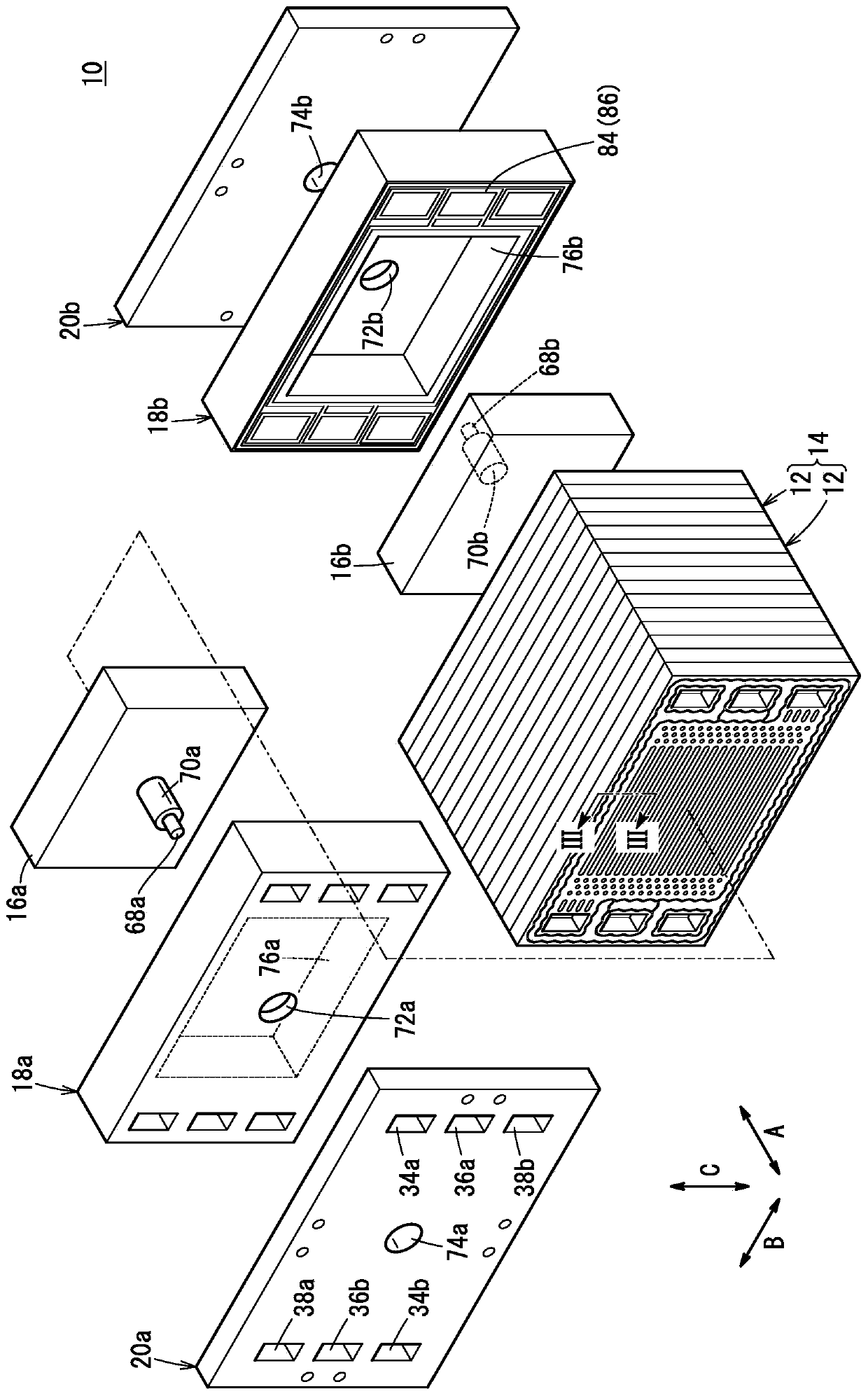

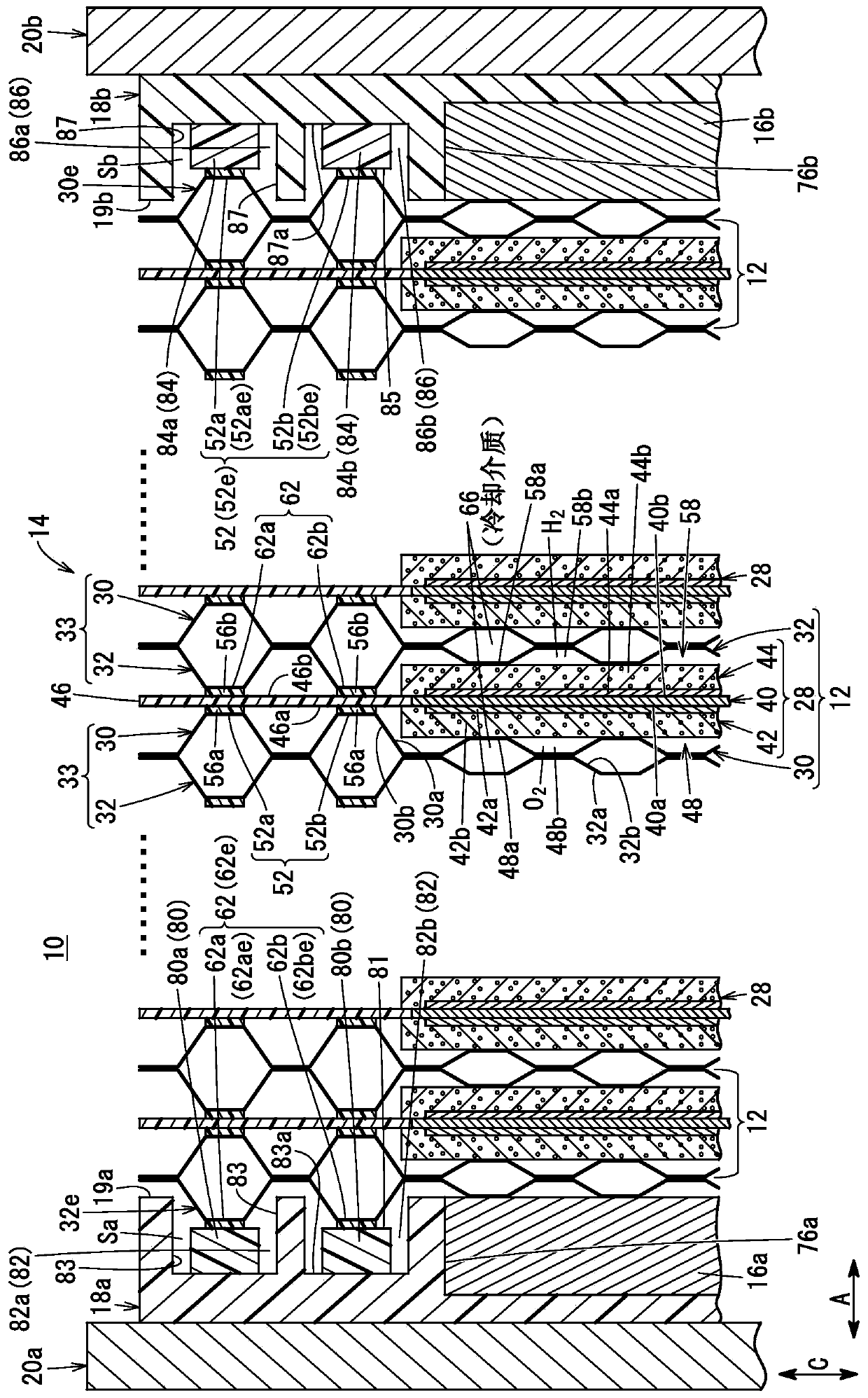

Fuel cell stack

ActiveCN110299545AReliable abutmentImprove sealingCollectors/separatorsFuel cellsMechanical engineering

The disclosure relates to a fuel cell stack (10) that includes a stack body (14) formed by stacking a plurality of power generation cells (12). A first seal line (52) of a first metal separator (30) and a second seal line (62) of a second metal separator (32) protrude in a stacking direction of the stack body (14) in a manner to contact a resin film (46). An insulator (18a) is provided with a first elastic seal member (80) which contacts a second end seal line (62e). The width (W2) of the first elastic seal member (80) is larger than the maximum width (W3) of the second end seal line (62e).

Owner:HONDA MOTOR CO LTD

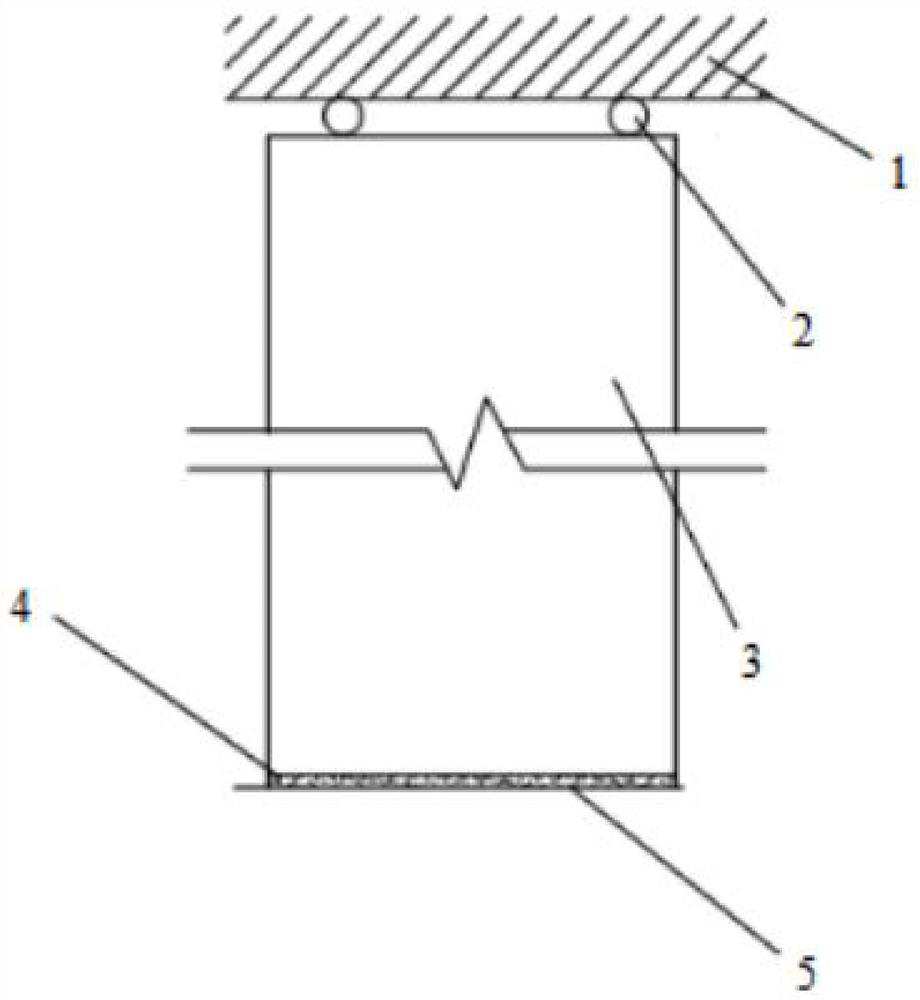

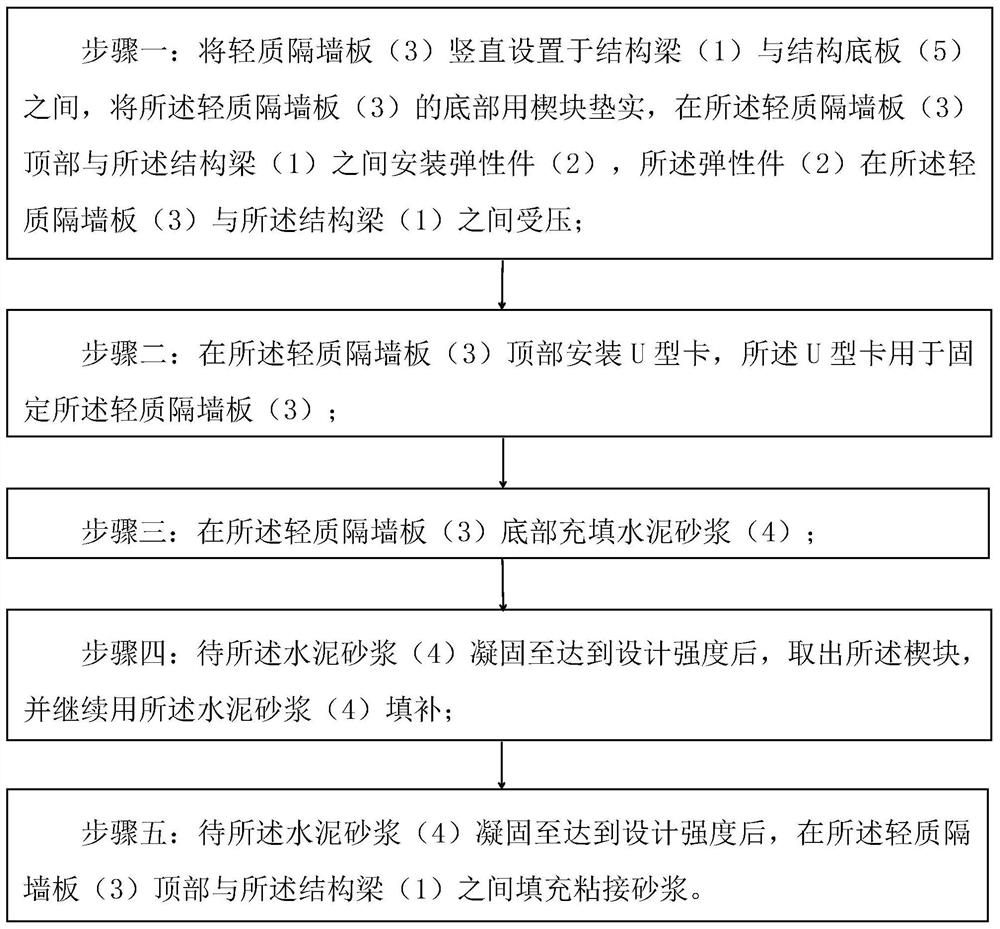

Light partition board mounting structure and mounting method

InactiveCN111734017ASolve the quality problem of transverse crackingLow costWallsEngineeringCement mortar

The invention relates to the technical field of housing construction, in particular to a light partition board mounting structure and a mounting method. The light partition board mounting structure comprises a light partition board, a structural beam located on the top of the light partition board and a structural bottom plate located at the bottom of the light partition board. An elastic part isfurther arranged between the light partition board and the structural beam, and the elastic part is pressed between the light partition board and the structural beam. The mounting method of the lightpartition board mounting structure comprises the following steps of S1, mounting the light partition board and the elastic part between the structural beam and the structural bottom plate in positionand cushioning the bottom of the light partition board with a wedge block; S2, mounting a U-shaped clip on the top of the light partition wall; S3, filling the bottom of the light partition board withcement mortar; S4, taking out the wedge block after the cement mortar is frozen to designed strength, and filling the wedge block continuously with cement mortar; and S5, filling the space between the top of the light partition board and the structural beam with bonding mortar after the cement mortar is frozen to designed strength.

Owner:中铁二十三局集团第四工程有限公司

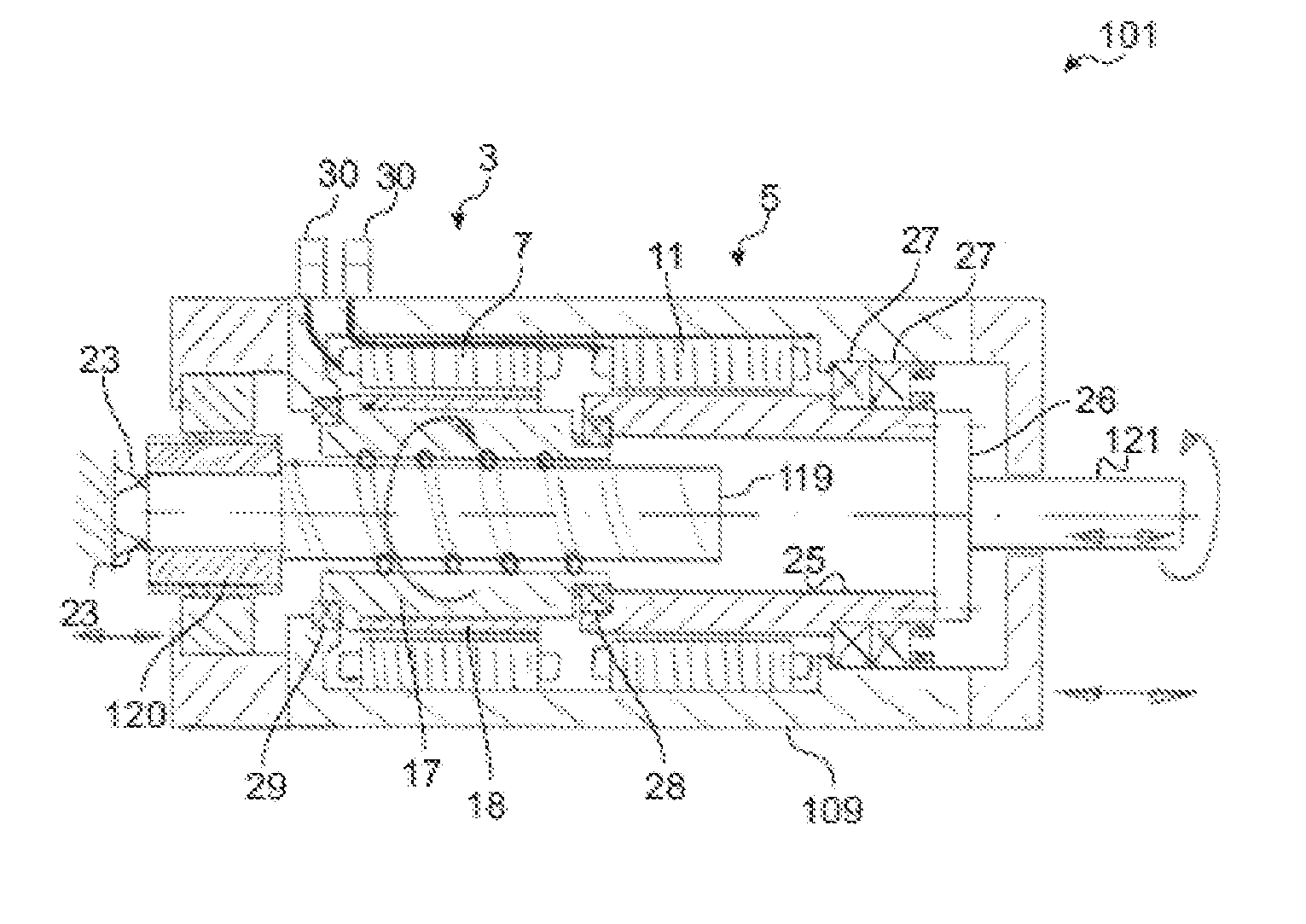

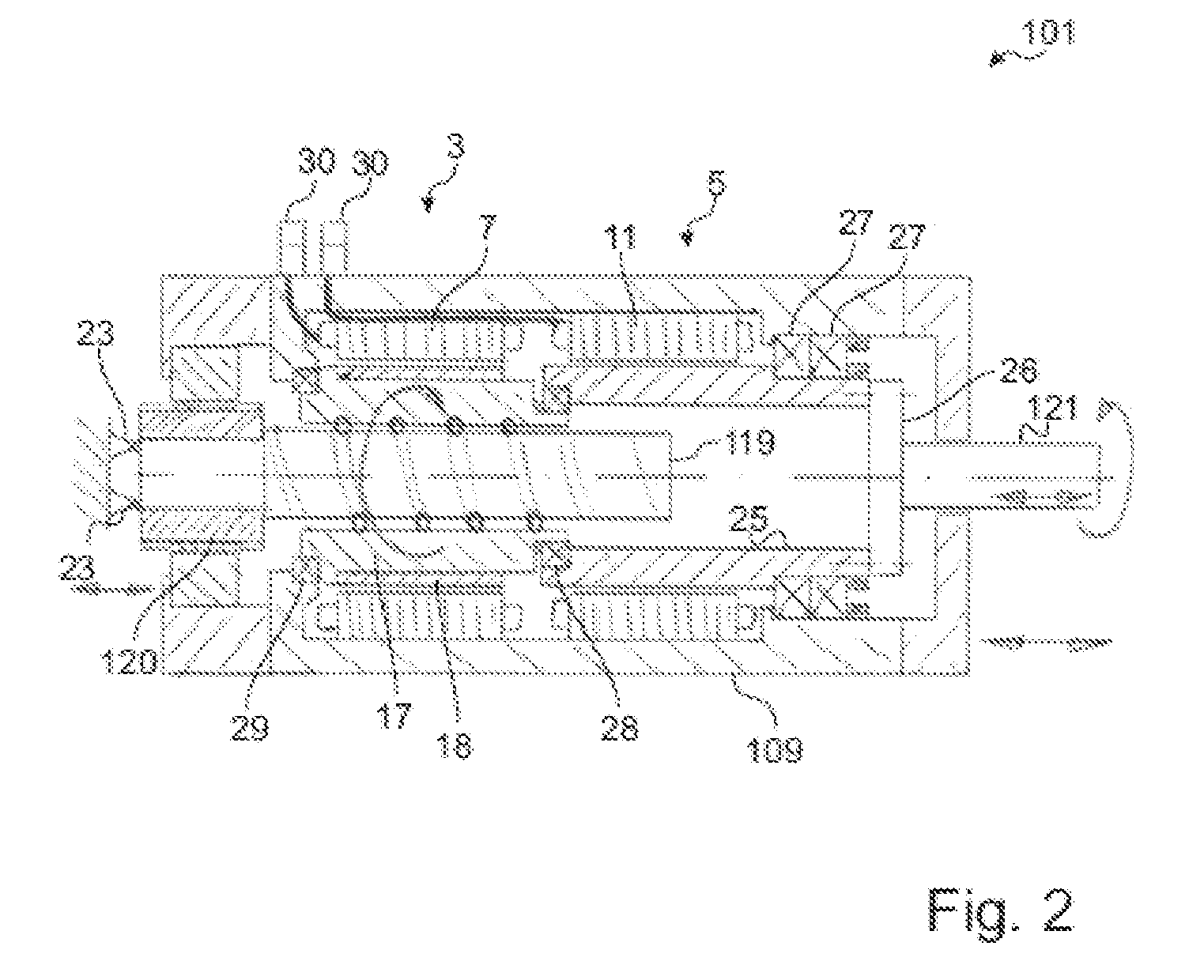

Drive apparatus for driving a worm of an injection molding machine

ActiveUS9080651B2Reliable abutmentRigid configurationFriction gearingsInjection mouldingInjection molding machine

Drive apparatus (1, 101), in particular for driving a worm of an injection molding machine, which worm is arranged coaxially with respect to an injection molding cylinder, having a housing (9, 109) which is mounted such that it can be displaced in an axial direction of the housing (9, 109) and is fixed rotationally, an output shaft (21, 121) which is mounted non-displaceably and rotatably in the housing (9, 109), a rotational drive (5) which is arranged in the housing (9, 109) for the rotational drive of the output shaft (21, 121), and a translatory drive (3) which is arranged in the housing (9, 109) for the translatory drive of the housing (9, 109).

Owner:WITTENSTEIN SE

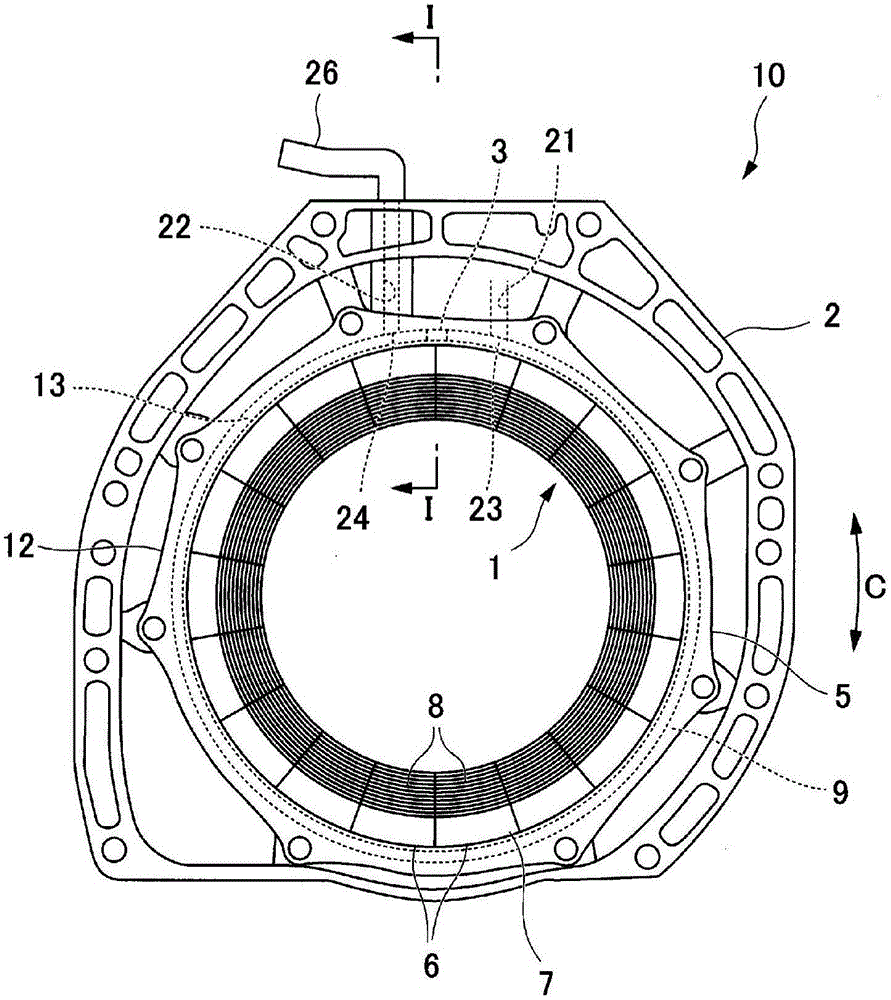

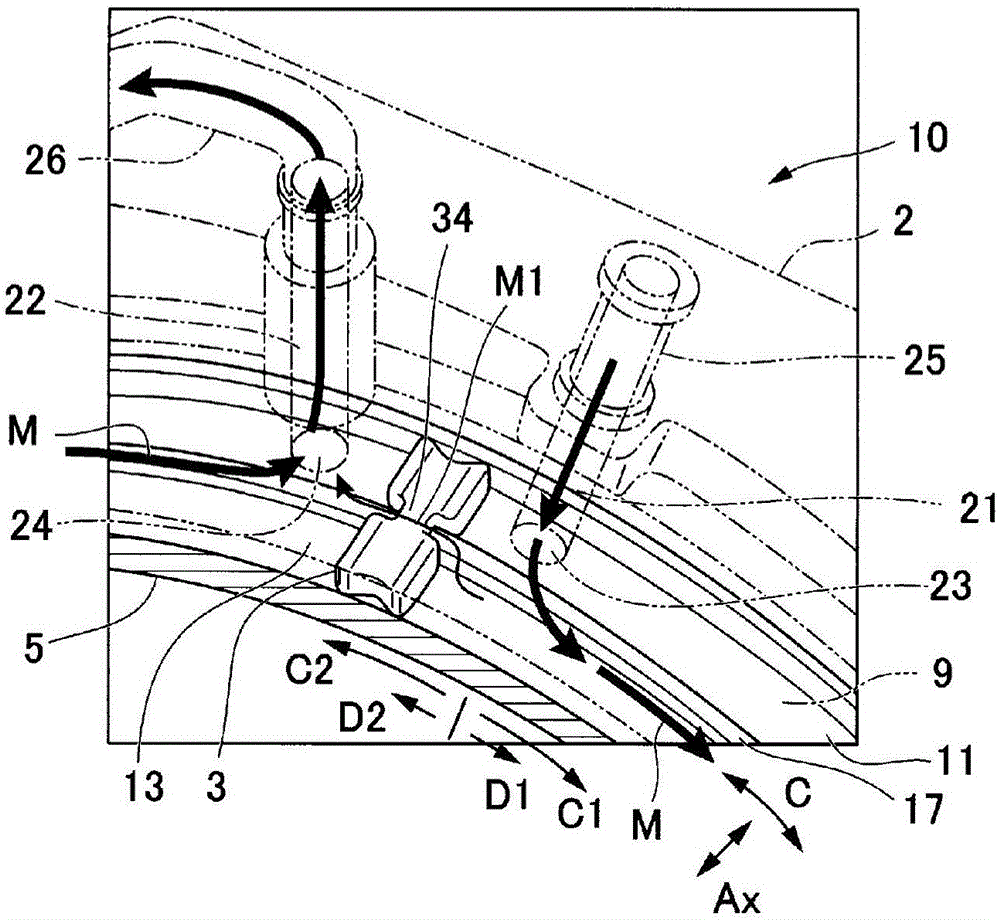

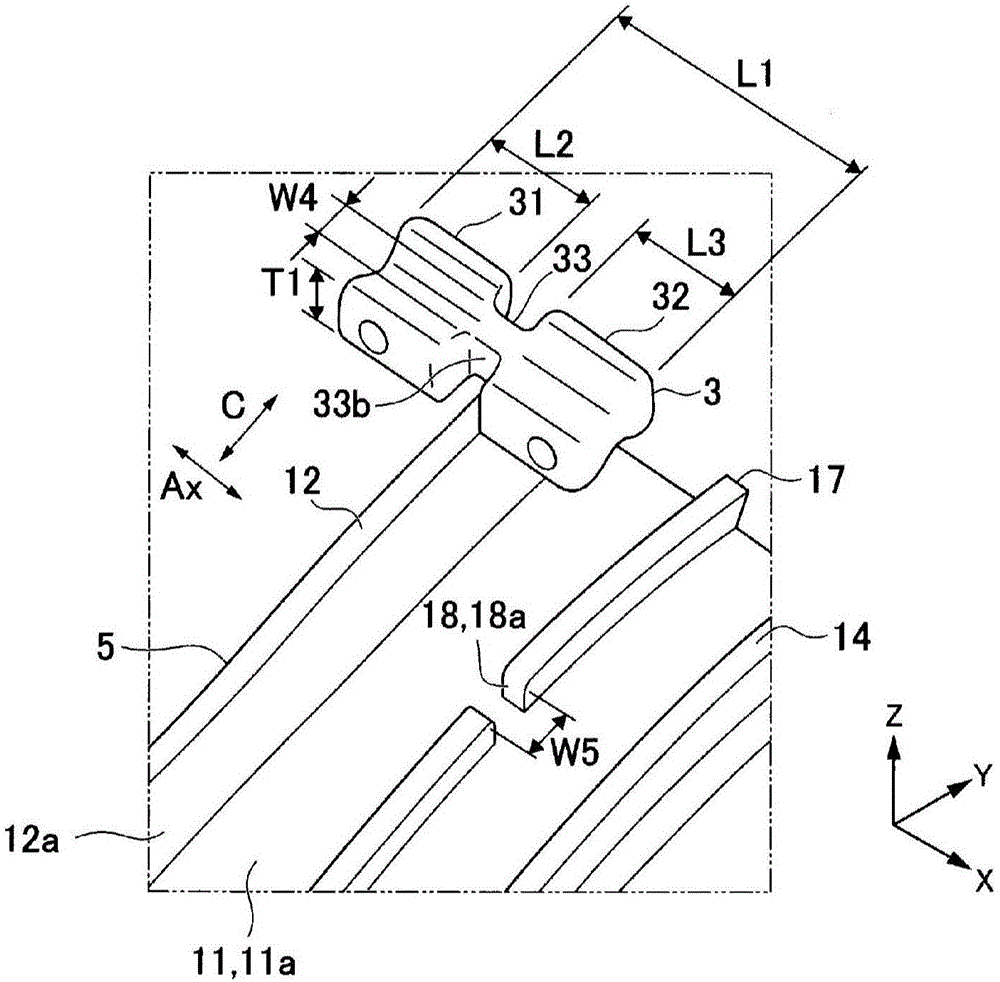

Rotary electric machine

ActiveCN107528424ANot easy to fall offNot easy to moveMagnetic circuit stationary partsCooling/ventillation arrangementElectric machineEngineering

The invention provides a rotary electric machine having full rectification, easy to manufacture and having excellent durableness. The rotary electric machine (10) includes a stator, a passage (13), an inlet opening (23), an outlet opening (24), and a partition (3). The stator has an outer periphery. The passage is provided around the outer periphery. A cooling medium (M) is to flow through the passage. The inlet opening (23) is connected to the passage. The cooling medium (M) is to be supplied to the passage via the inlet opening. The outlet opening (24) is connected to the passage. The cooling medium is to be discharged from the passage (13) via the outlet opening. The inlet opening and the outlet opening divide the passage into a longer passage and a shorter passage shorter than the longer passage. The partition (3) is provided in the shorter passage and comprises an elastic material to contact with an inner surface of the shorter passage (3) so as to restrict a flow of the cooling medium.

Owner:HONDA MOTOR CO LTD

Induction heating apparatus for soup and the like

InactiveCN102196751AReliable abutmentEfficient dischargeFood preparationVessels with intergral heatingEngineeringElectrical and Electronics engineering

An induction heating apparatus for a soup etc. for serving the soup in a given amount of servings, the apparatus having a body including a controlling section, pump and a driving source of the pump, and being affixed to the body is a circular supporting body which has, over an inner side of its circular conic wall for supporting a circular conic portion of a hopper, an induction heating coil for induction-heating the hopper. A through hole is formed in the circular conic wall, while fixing thereto, a supporting member for supporting a movable temperature sensor over the inner surface of the circular conic wall, and a forefront portion of the temperature sensor is being continuously biased via the through hole in a direction abutting toward an outer surface of the circular conic portion of the hopper by a spring member provided in the supporting member.

Owner:生田 尚之

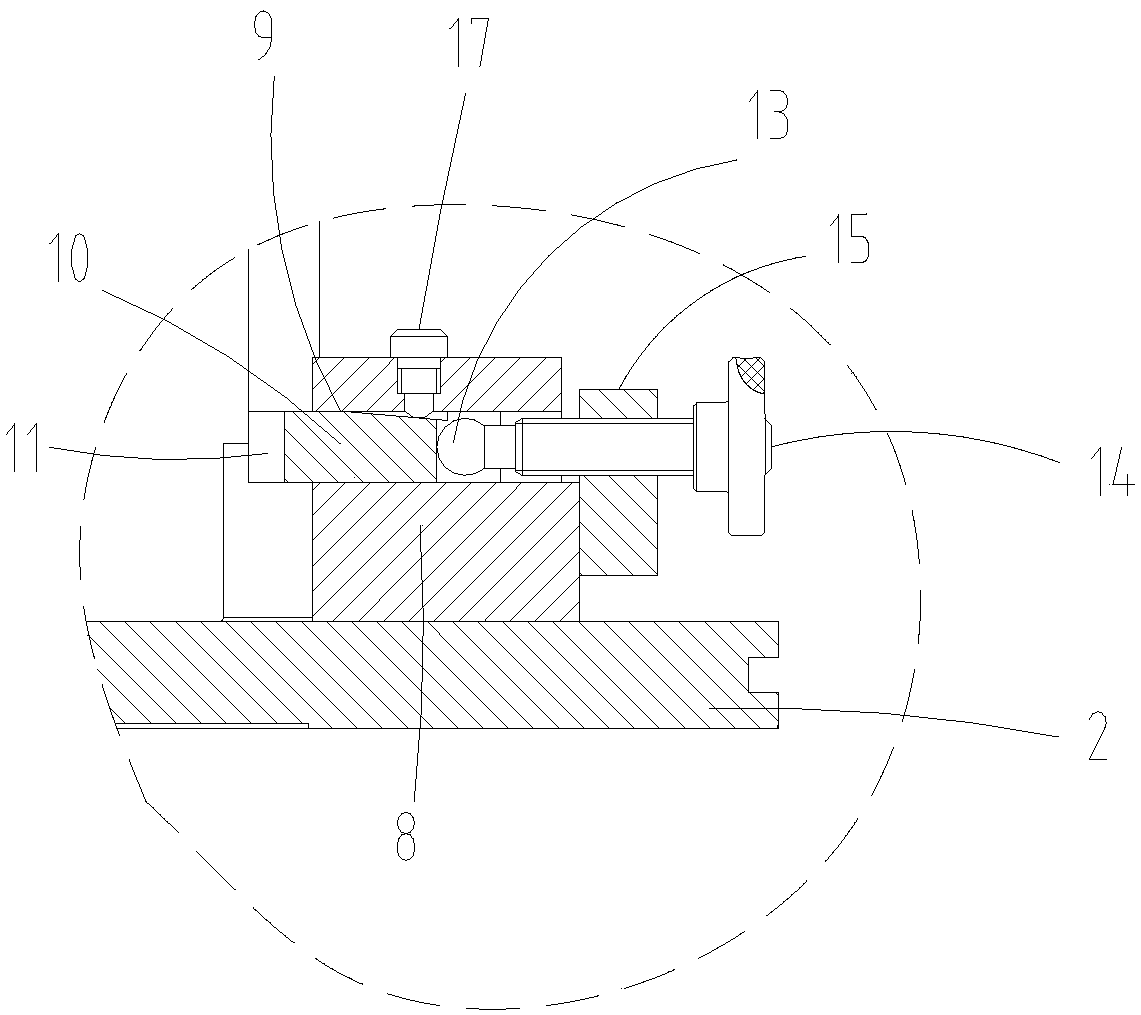

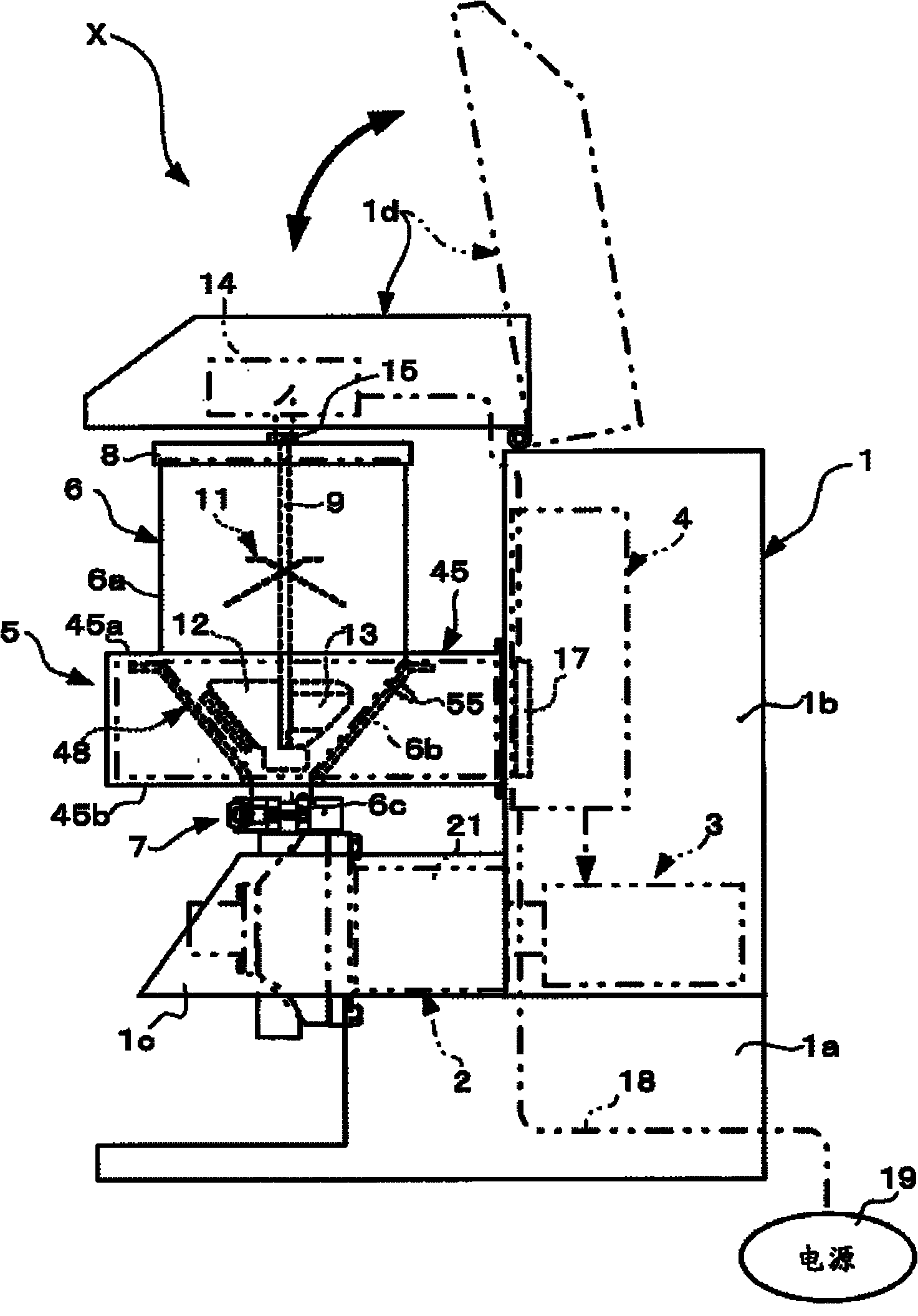

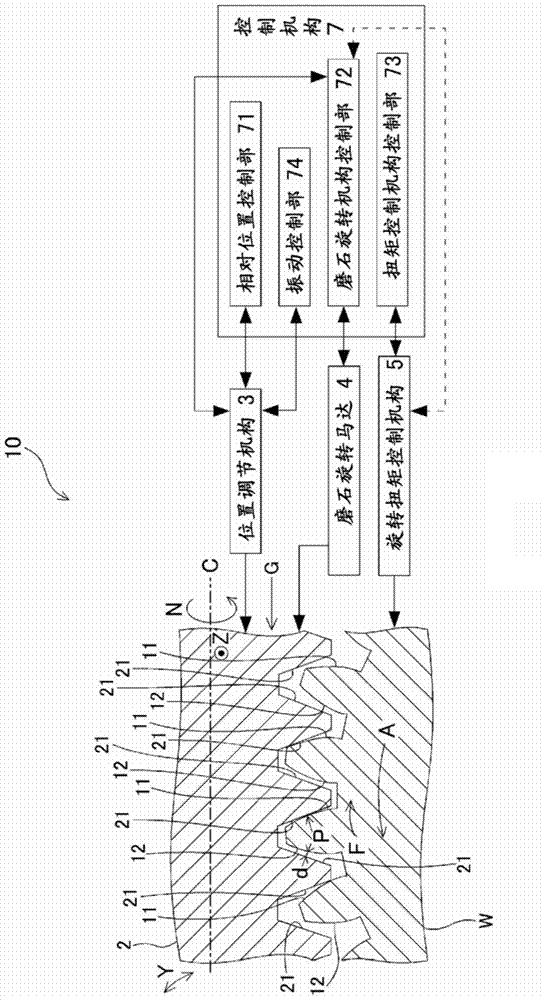

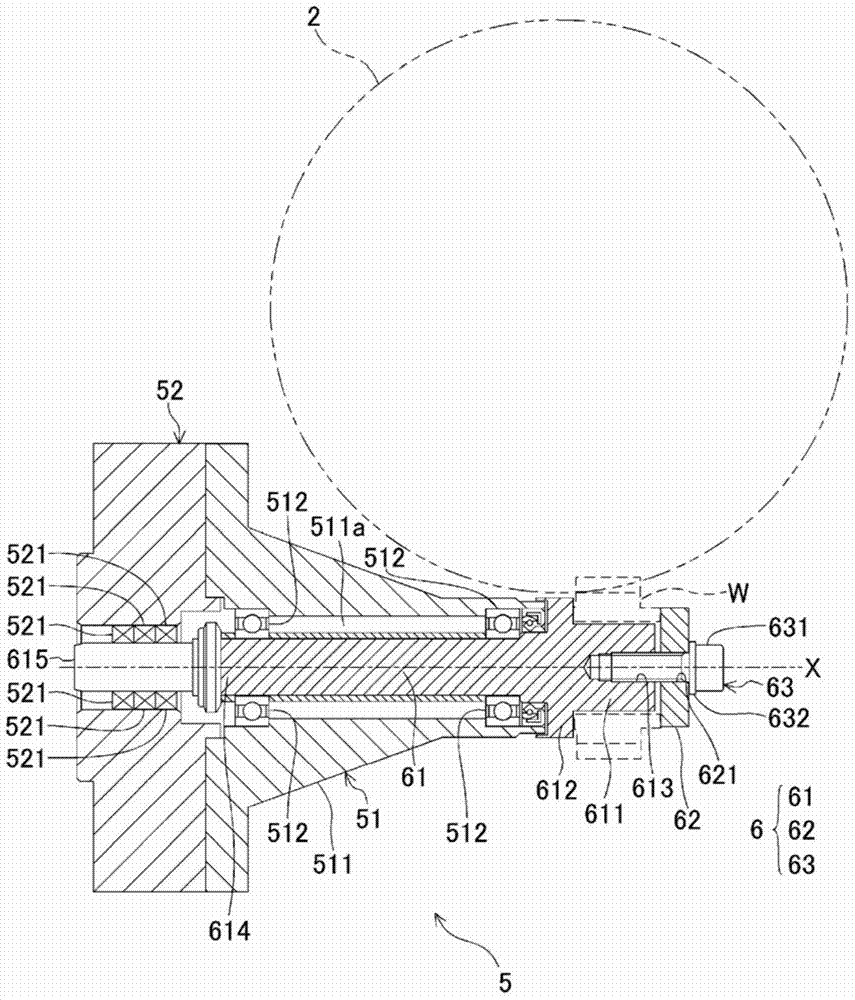

Gear tooth surface processing device and gear manufacturing method

ActiveCN104507613AAvoid Grinding BurnsImprove surface roughnessGrinding feed controlBonded abrasive wheelsGrindstoneGear manufacturing

A gear tooth surface processing device and a gear manufacturing method are provided which are capable of adjusting processing pressure for the purpose of improving the surface roughness of high-hardness gears and the like. The gear tooth processing device (10) has: a helical grindstone (2); a position adjusting means (3) which is capable of moving the relative positions of a rotary axis (C) of the helical grindstone (2) and a rotary axis (X) of a gear to be processed (W); and a control means (7). The control means (7) includes: a position control unit (71) which operates the position adjusting means (3) so as to adjust the relative positions of the rotary axis (C) of the helical grindstone (2) and the rotary axis (X) of the gear to be processed (W) to cause only one of the tooth surfaces to be processed (11), from among the gear tooth surfaces that form a single tooth of the gear to be processed (W), to make contact with a grindstone tooth surface (21) of the helical grindstone (2) such that the helical grindstone (2) and the gear to be processed (W) are engaged; a grindstone rotation means control unit (72) for operating a grindstone rotation means (4); and a torque control means control unit (73) for operating a rotation torque control means (5) so as to adjust the rotation torque within a predetermined range.

Owner:AISIN AI CO LTD +1

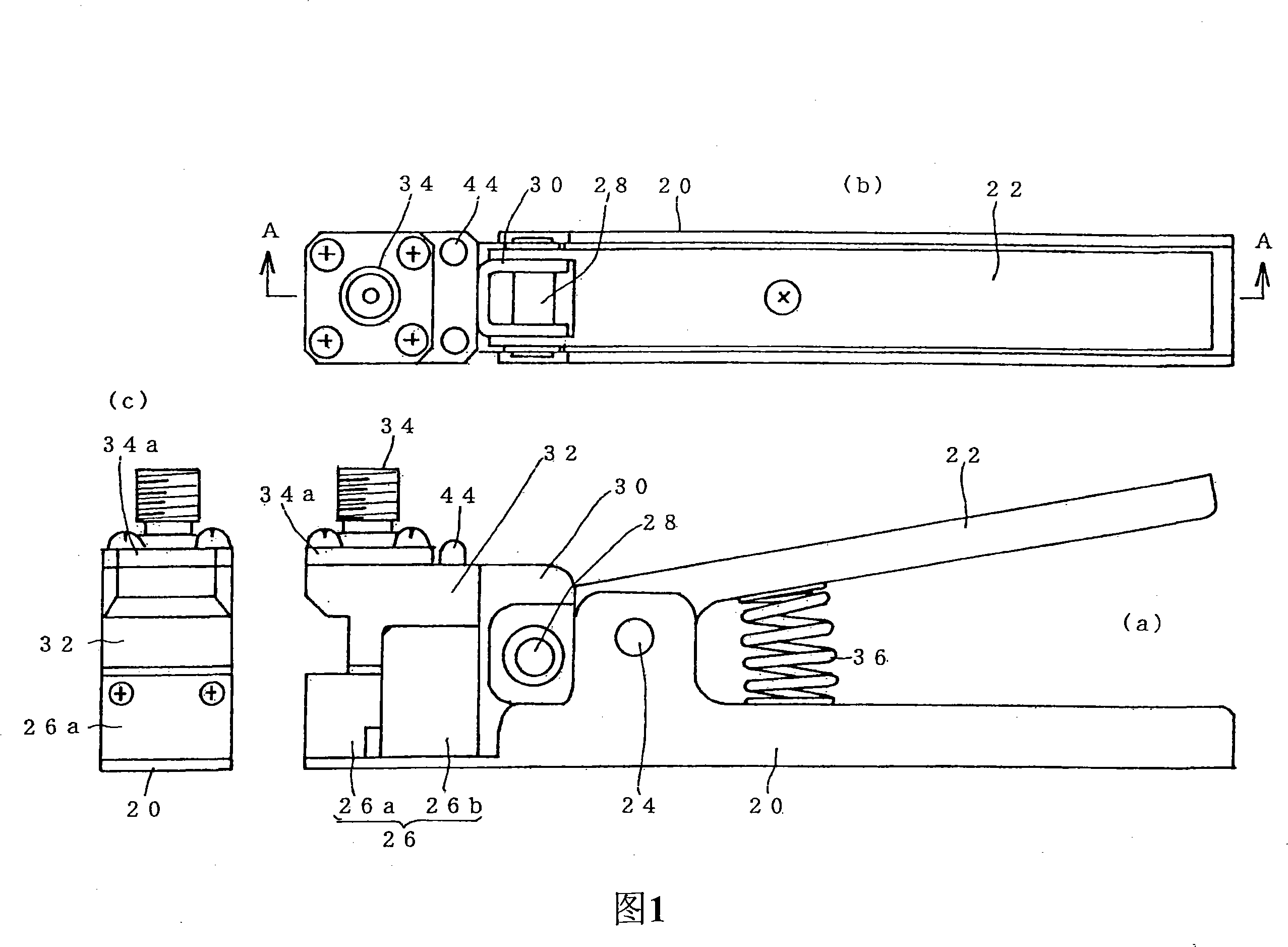

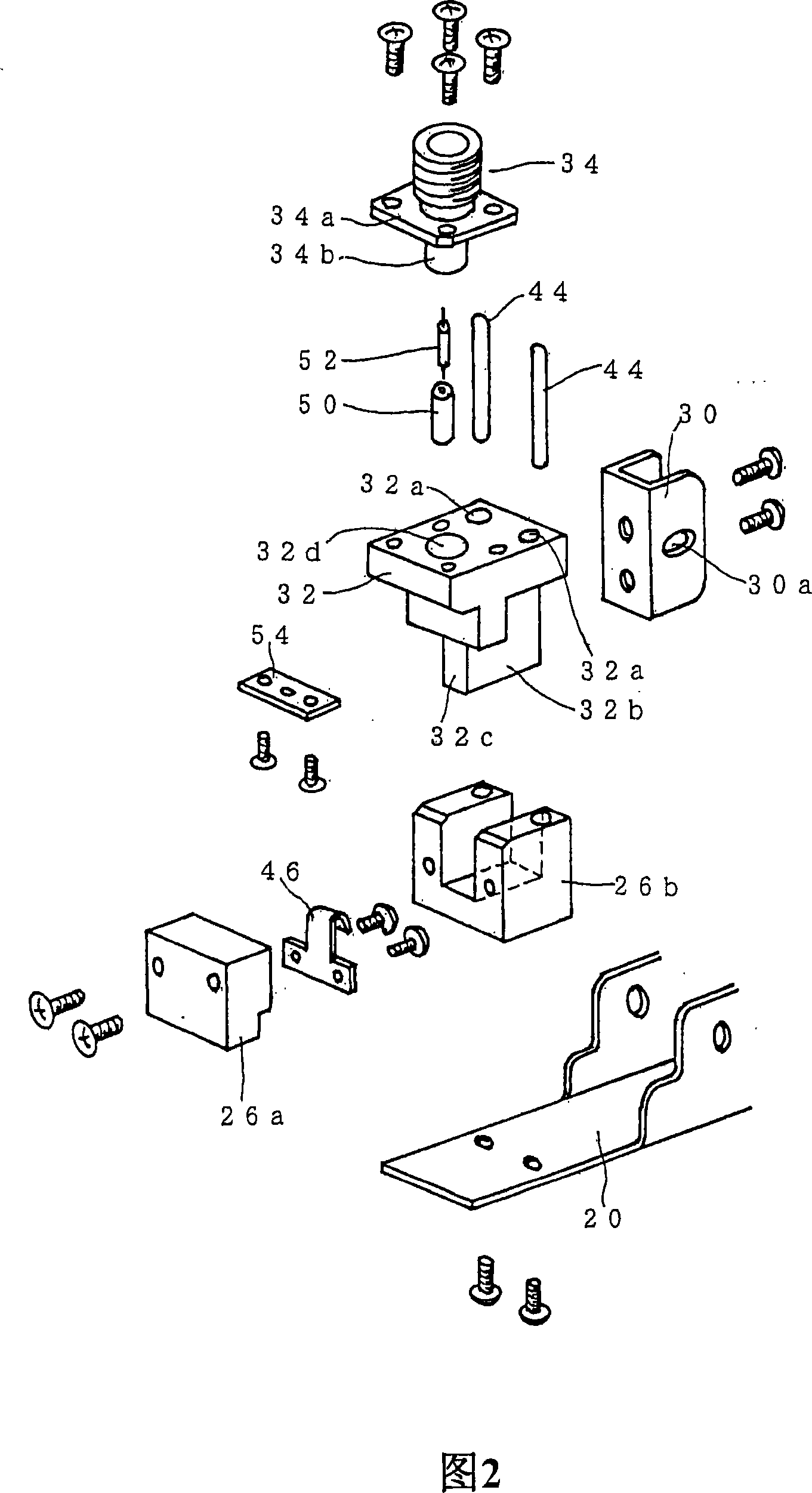

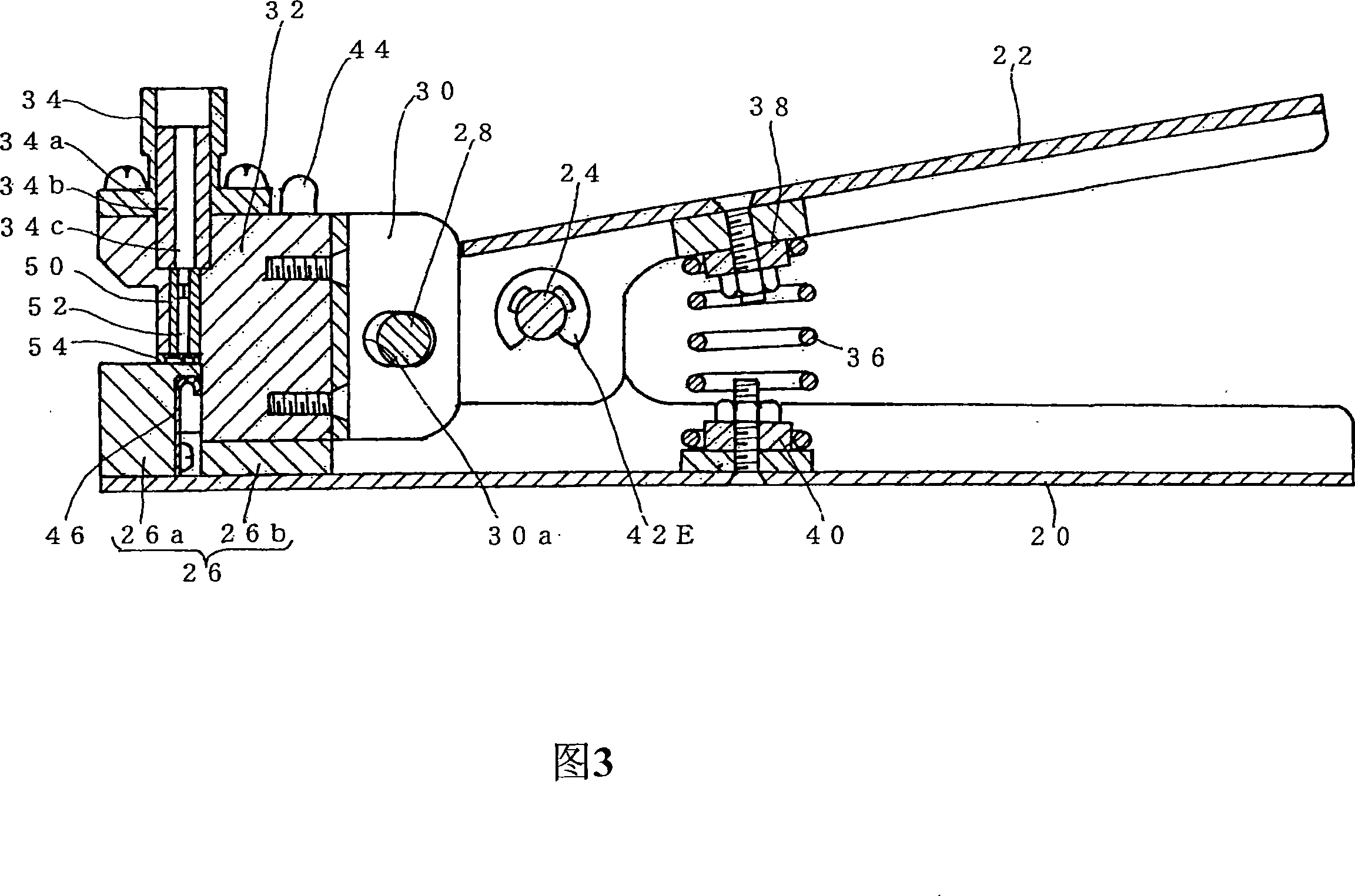

Relay connector

InactiveCN101197487AOvercoming elasticityFirmly connectedLine/current collector detailsElectrically conductive connectionsConductive materialsEngineering

The invention relates to a relay connector which can electrically connect a coaxial connector (34) onto or off a substrate (10), with small-scale and simple operation. A first operating lever and a second operating lever (20 and 22) can sewing so that the substrate GND block (26) and the outer shell GND block (32) made of conductive materials and positioned at one end side of the first operating lever and a second operating lever (20 and 22) can sewing towards to the approaching and separating direction. The coaxial connector (34) is fixed on the outer shell GND block (32). An insulation tube (50) is inserted into a through hole (32d) positioned on the outer shell GND block (32), as well as an inserting core (34c) and a probe (52), wherein, one end of the probe (52) is resisted with the inserting core (34c). an insulation pressing component (54) is arranged on the outer shell GND block (32) in such a way of outstanding the post plug positioned at the other end side while ensuring the probe (52) is unable to be pulled out. The substrate GND block (26) is electrically connected with the outer shell GND block (32). The substrate (10) is clamped by the substrate GND block (26) and the outer shell GND block (32).

Owner:YOKOWO CO LTD

Rolling body screw device

ActiveUS20060169080A1Reliable abutmentAvoid generatingToothed gearingsPortable liftingPipingEngineering

A return pipe is constituted by combining a pair of return pipe halves split along a non-load passage. A pipe hold down member is fixed to a nut member so as to be astride the return pipe, fixing the return pipe to the nut member. A flange portion is formed on each of the return pipe halves, while a pair of fixing leg portions covering the flange portion of each return pipe half is formed on the pipe hold down member. Fastening members pass through the fixing leg portions of the pipe hold down member and the flange portion of the return pipe halves and are fastened to the nut member. When the fixing leg portions of the pipe hold down member are fixed to the nut member by the fastening members, an engagement portion of the pipe hold down member is configured to tighten the pair of the return pipe halves in the direction where split faces of the return pipe halves abut against each other.

Owner:THK CO LTD

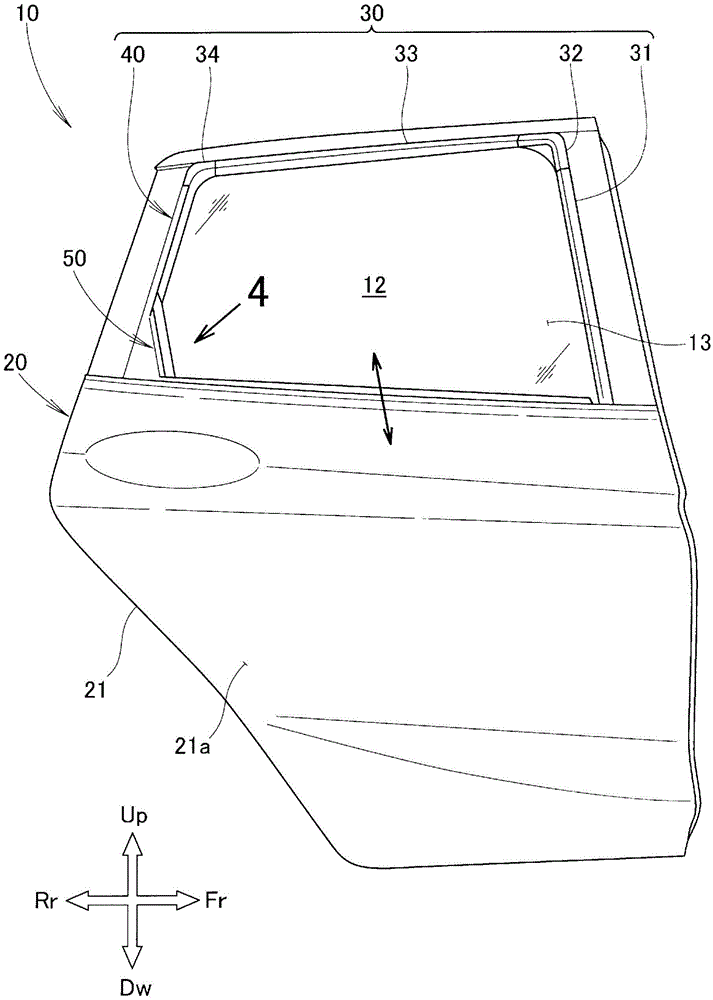

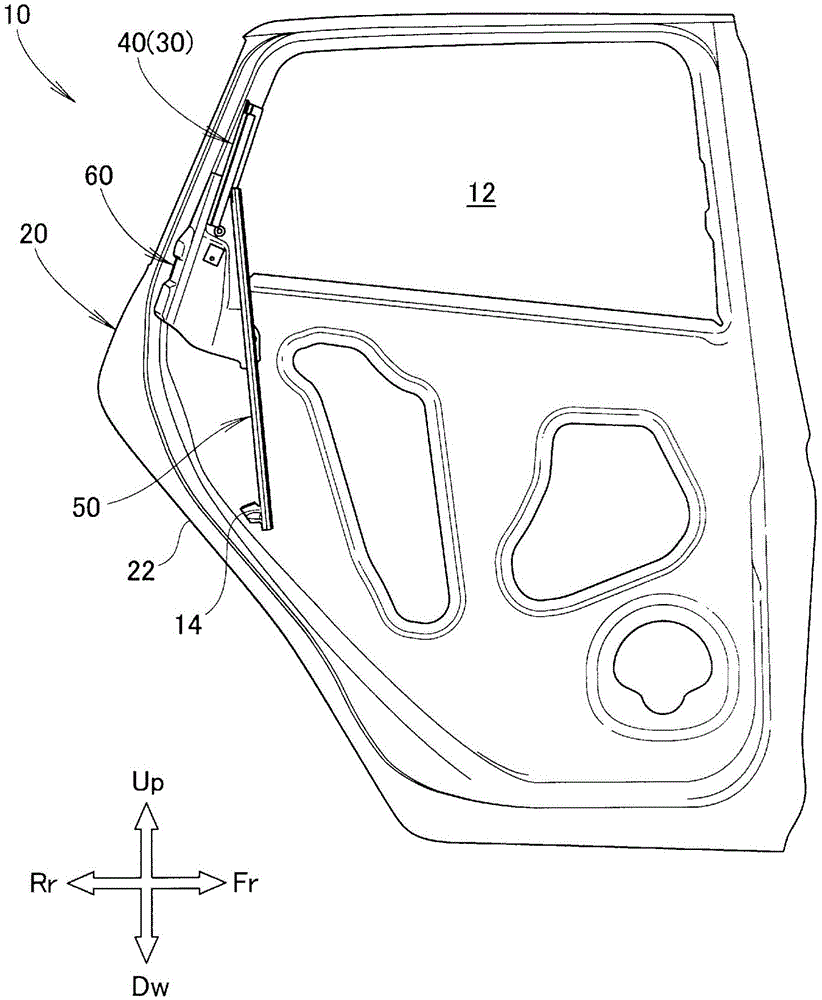

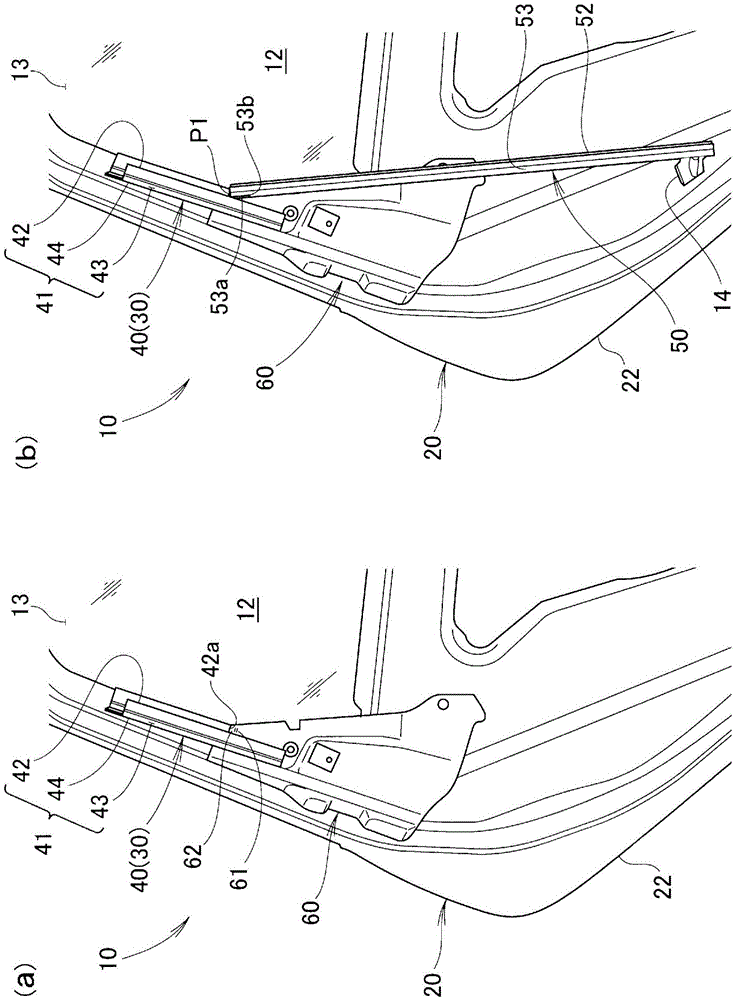

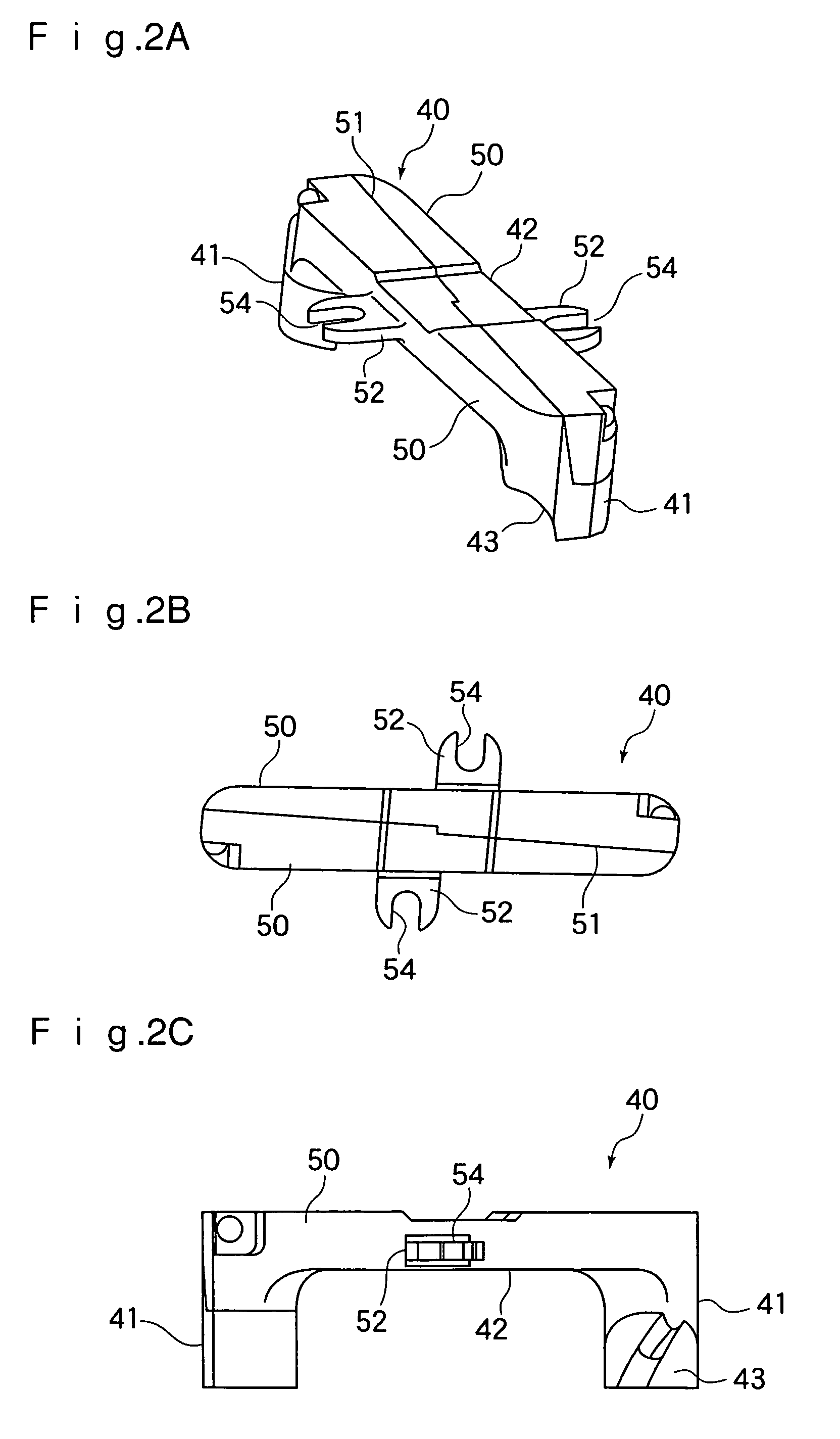

Vehicle door

This vehicle door (10) is provided with: a main sash (30) that is disposed above a door main body (20) and that encircles a window opening; and an auxiliary sash (50) of which the upper end abuts the main sash (30). The auxiliary sash (50) is provided with: a second vehicle interior wall (52) abutting a first vehicle interior wall (42) of the main sash (30); a second vehicle exterior wall (53) abutting the a first vehicle exterior wall (43); and a second bottom wall (54) coupling the second vehicle interior wall (52) and the second vehicle exterior wall (53). A notch (53a) that is notched alongside the first vehicle exterior wall (43) is formed solely at the second vehicle exterior wall (53). The bottom end (53b) of the notch (53a) is disposed below the top side (54b) of the second bottom wall (54) and the top side (52b) of the second vehicle interior wall (52) formed contiguously.

Owner:HONDA MOTOR CO LTD

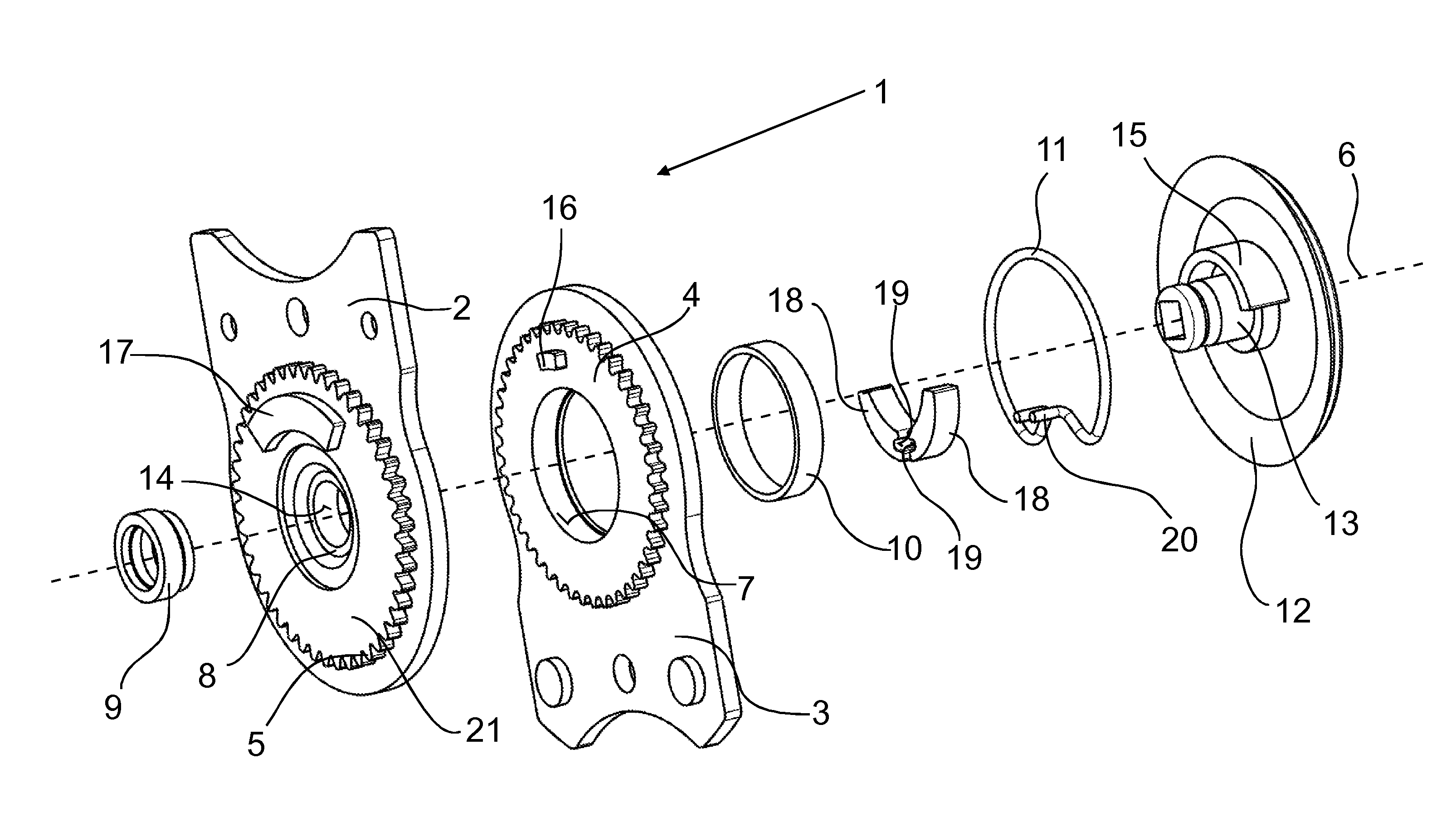

Seat fitting for a motor vehicle seat

ActiveUS9315122B2Small spacingSimple and cost-effective mannerVehicle seatsToothed gearingsDrive shaftGear wheel

A motor vehicle seat fitting includes a fitting top part with a ring gear (21) having internal toothing, a fitting bottom part with a gear wheel (4), having external toothing and which is in engagement with the ring gear, an eccentric arranged rotatably in a bore (7) of the bottom part running axially to the gear wheel, for rolling adjustment of the gear wheel relative to the hollow gear, and a drive shaft, which drives the eccentric and extends axially to the ring gear. A cam receptacle (17) is arranged on one of the gear wheel or the ring gear (21) and a stop cam (16), that engages in the cam receptacle, is arranged on the other of the gear wheel or ring gear, in a ring portion between the external toothing and the bore and on the ring gear in a zone which may overlap the ring portion.

Owner:ADIENT US LLC

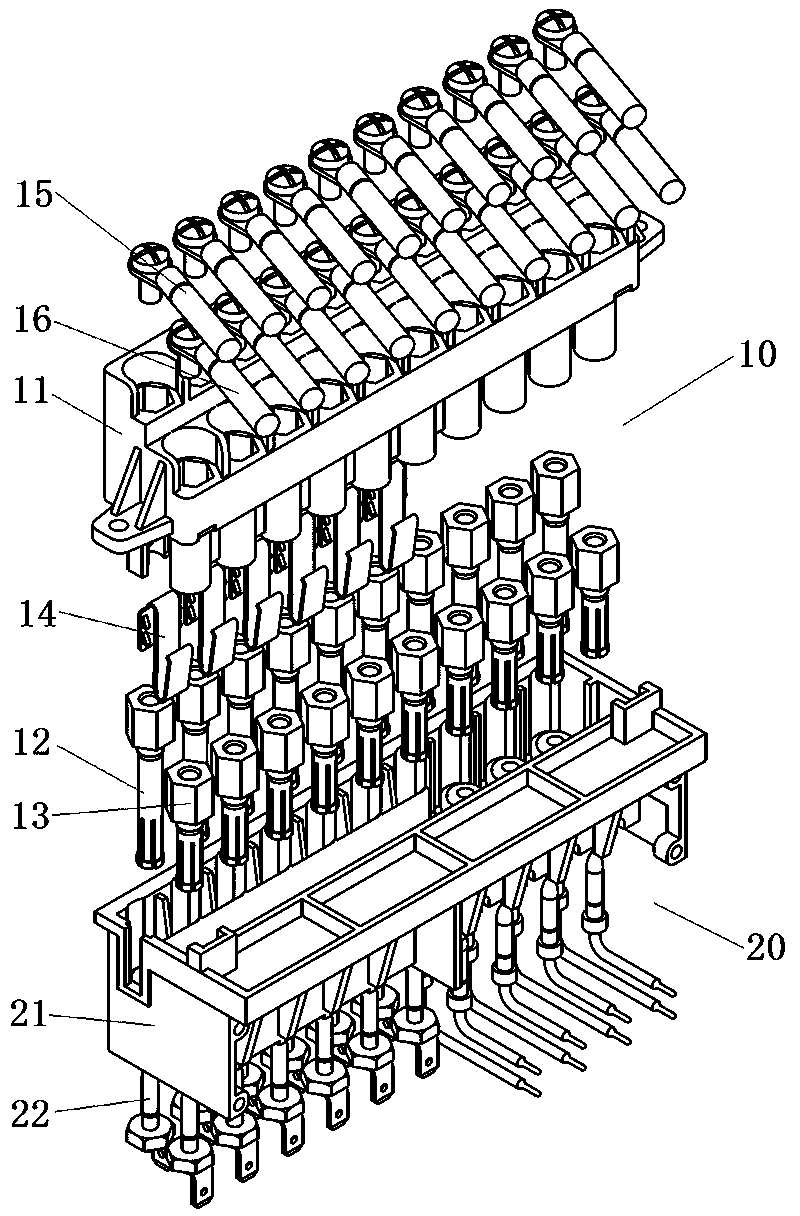

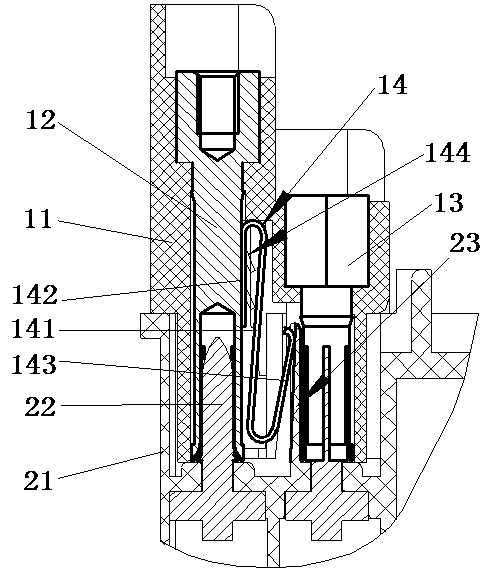

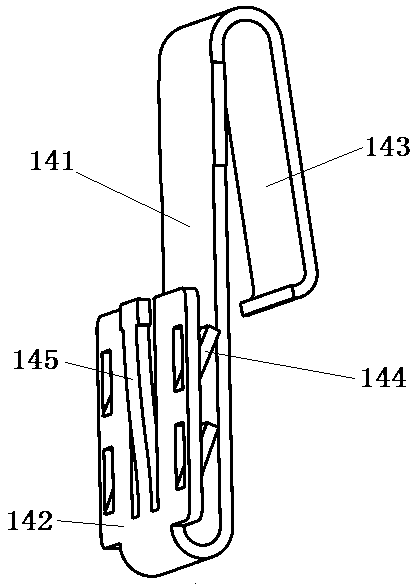

Self-short-circuit connector

PendingCN111129894AAchieve short circuitRealize self-short circuit functionCoupling contact membersEngineeringStructural engineering

The invention relates to a self-short-circuit connector which can solve the problems that in the prior art, a self-short-circuit connector is large in number of parts and complex in structure. The self-short-circuit connector comprises: a shell; contact members arranged in pairs within the housing; a short circuit piece which is arranged in the shell and is positioned between the two contact members in the contact piece pair, wherein the short-circuit piece comprises a first end and a second end, the first end is in contact with one of the contact pieces in the contact piece pair, the second end is of an elastic arm structure formed by bending and elastically abuts against the other contact piece, and the second end and the abutted contact member form a flaring structure at one side facingthe plugging direction, so that the insulator of the adaptive connector can be inserted into the flaring structure in use to insulate and isolate the second end of the short circuit sheet from the contact member.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

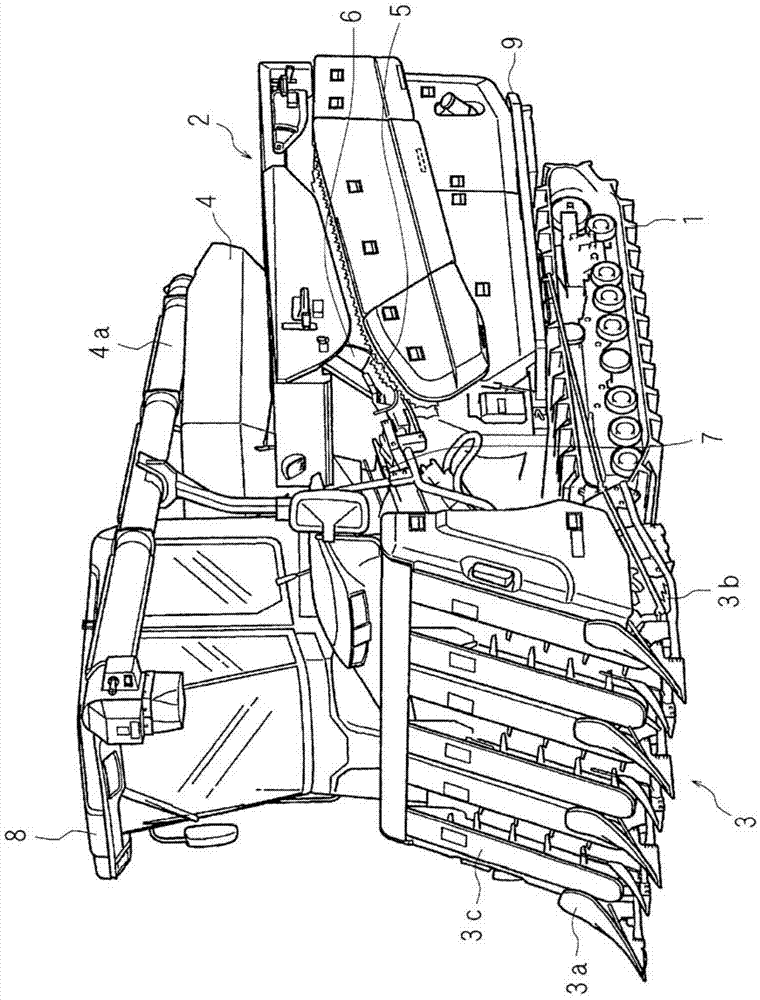

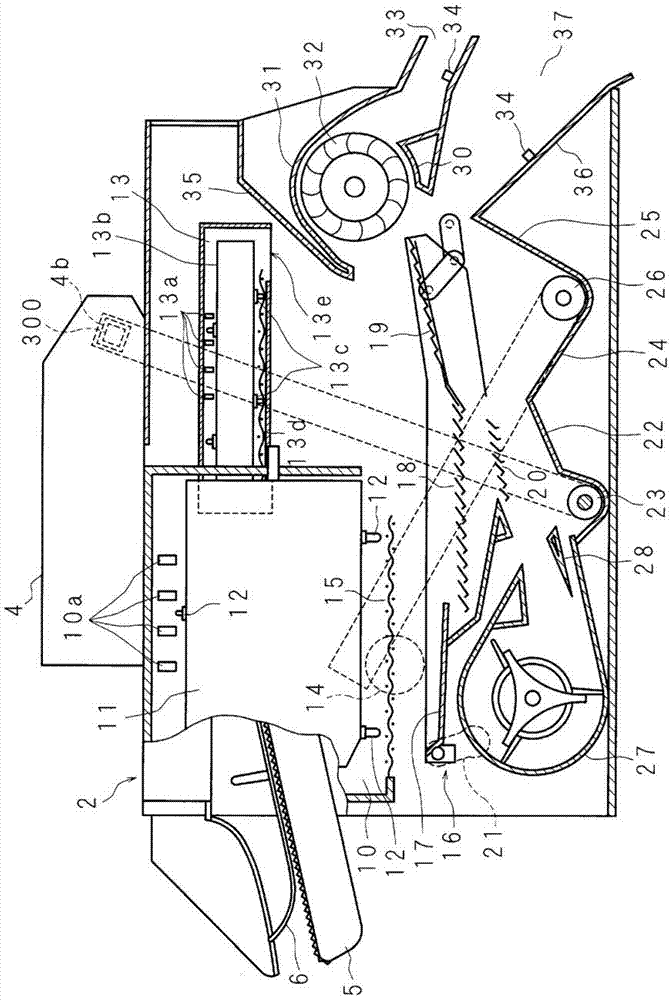

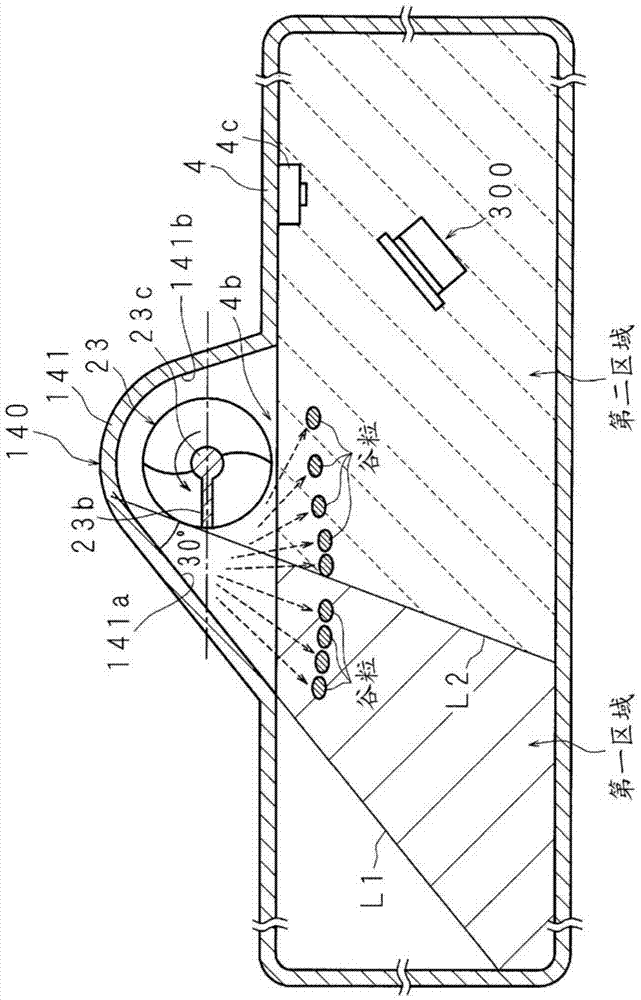

Combine

The objective of the present invention is to provide a combine that can eliminate the effect of disturbance from grain quantity detection values, even during a period of contact in which grain contacts a sensor. The impact force detected by a discharging opening sensor is compared with a pre-set threshold (a). On the basis of the comparison results, it is determined whether or not the impact force is included in the subject of calculation. For example, if the impact force is less than the threshold (a), the impact force is removed from being a subject of calculation. As a result, particularly when a small quantity of grain is being conveyed (for example, in the case of harvesting work being performed at a low speed or the case of a hand-threshing mode), it is possible to improve the calculation precision of the amount of grain. If the amount of grain conveyed is small, the effect of disturbance on the calculated amount of grain is larger than when the amount of grain conveyed is large.

Owner:YANMAR POWER TECHNOLOGY CO LTD

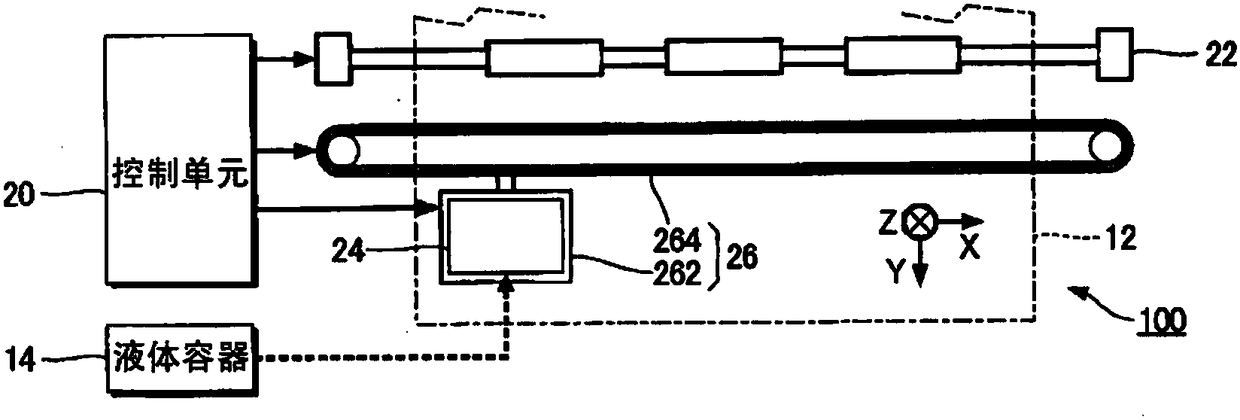

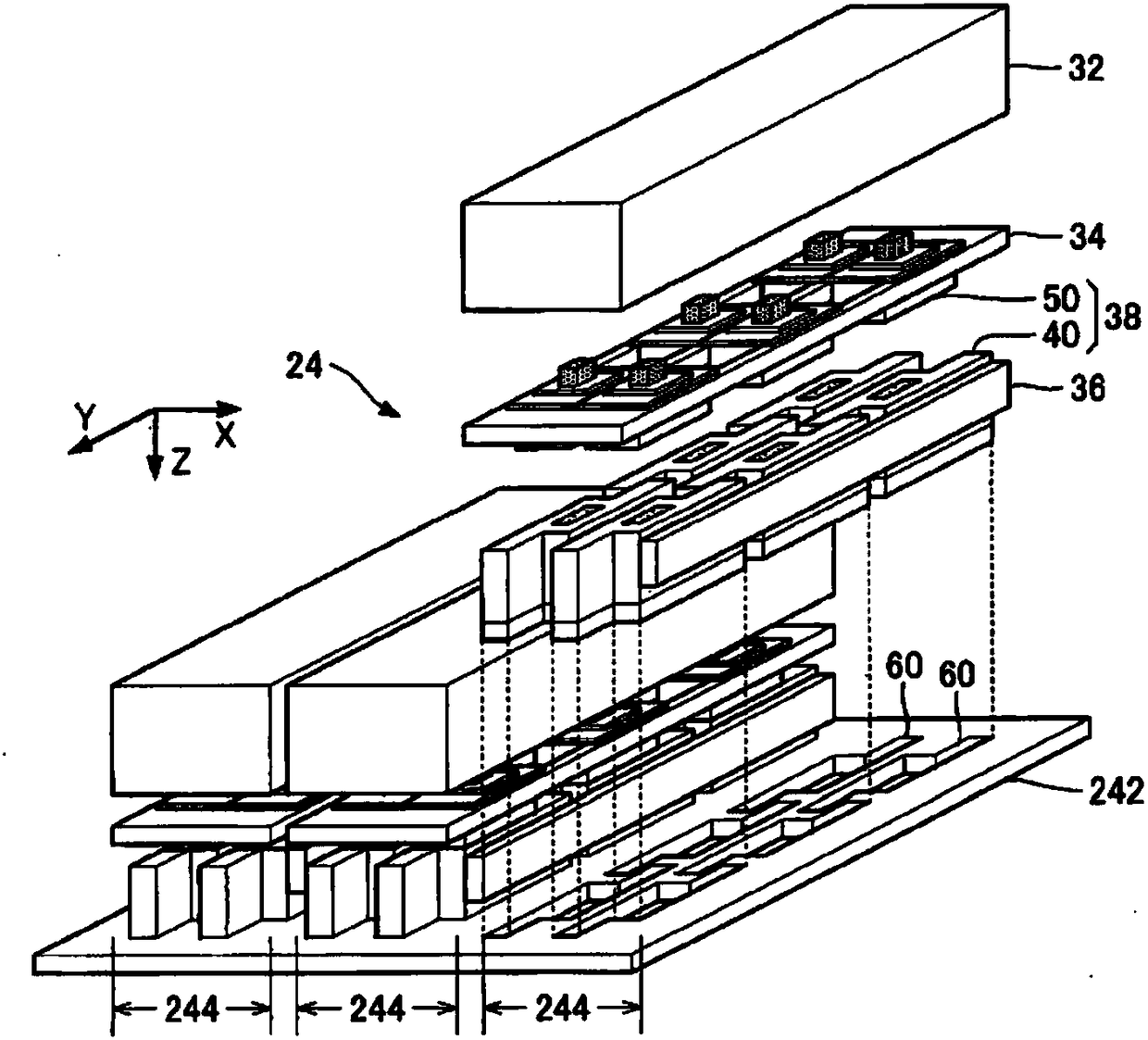

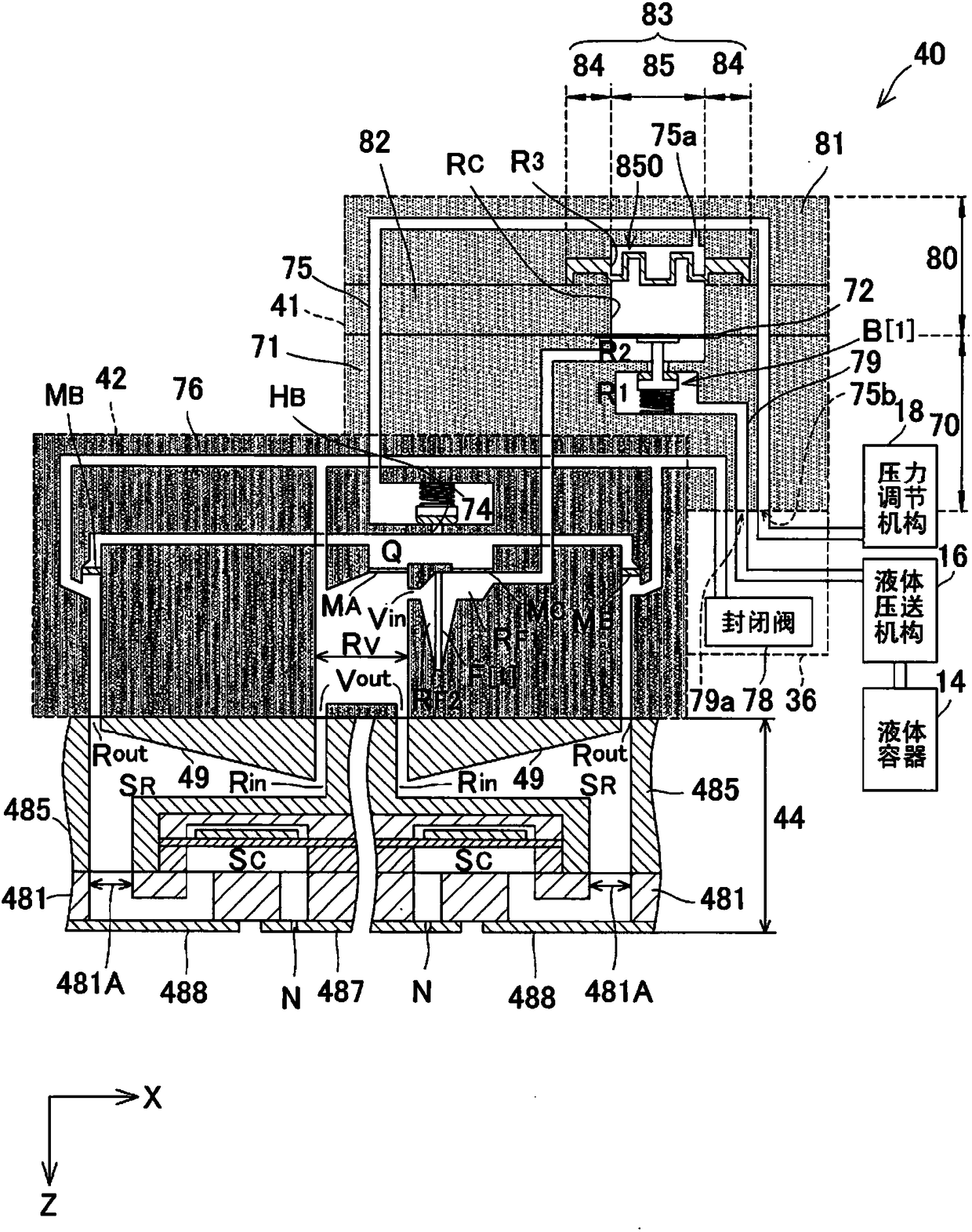

Flexible membrane mechanism, flow path member, liquid ejecting apparatus, and control method

Owner:SEIKO EPSON CORP

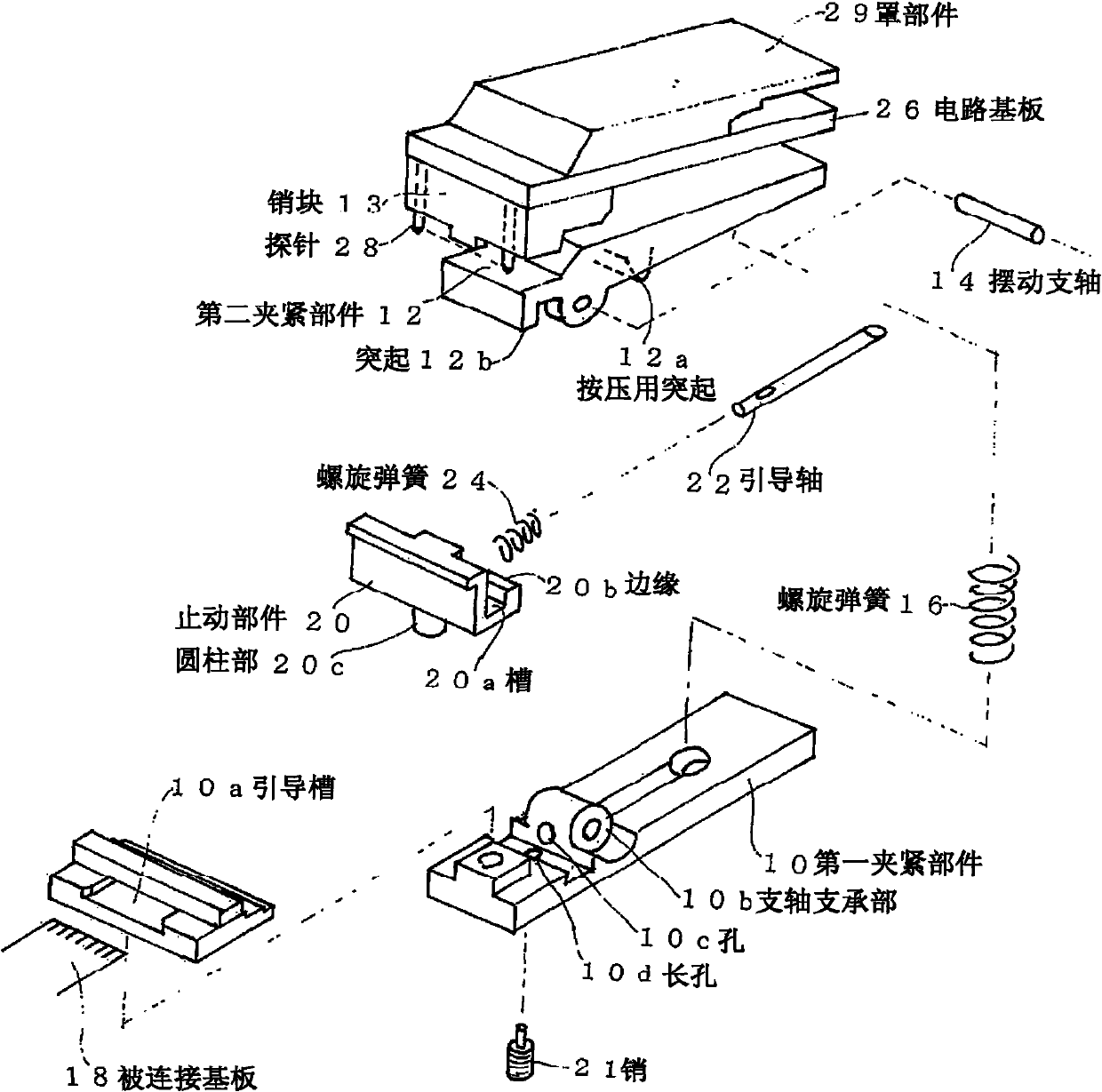

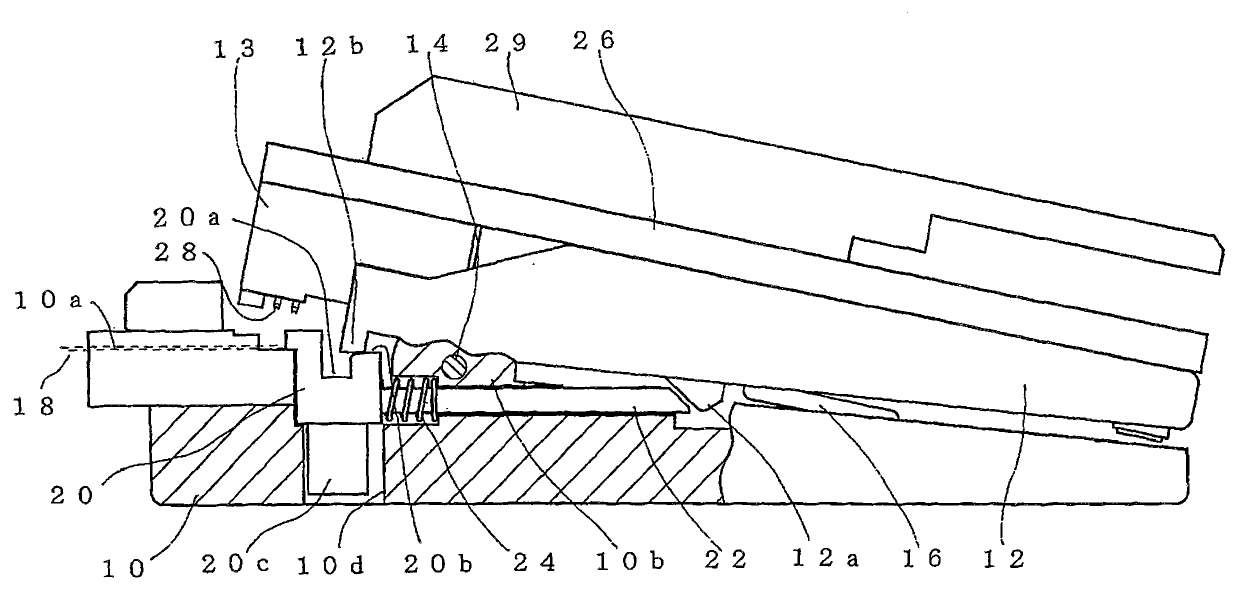

Relay connector

InactiveCN102170071AReliable abutmentWon't hurtCoupling device detailsReciprocating motionCoil spring

The invention provides a relay connector. When a connected substrate is inserted in an appropriate position, the front sides of a first clamping component and a second clamping component are closed, and a probe can abut against the terminal of the connected substrate. In this case, first and the second clamping components can freely swing, and the front sides are closed through the elastic force application of a helical spring (16). The front side of the first clamping component is provided with a stop component in a manner of smooth reciprocating motion in a regulated range. An elastic force is applied to the front of the stop component through another helical spring (24). When being disposed in the front, the stop component abuts against the boss on the second clamping component to limit the front side closing, and removes the abutting when moving backwardly to close the front side. When the stop component moves backwardly by overcoming the elastic force of the helical spring (24) through the insertion of the connected substrate, the abutting of the boss can be removed. The probe on the second clamping component abuts against the terminal of the connected substrate.

Owner:YOKOWO CO LTD

Exhaust-gas turbocharger

ActiveUS10280835B2Vibration damping of the flap plate in the open position can be attainedReliable abutmentInternal combustion piston enginesGas turbine plantsWastegateSliding contact

An exhaust-gas turbocharger (1), with a turbine housing (2) which has a turbine housing inlet (8) and a turbine housing outlet (9) for exhaust gas, and which has a wastegate duct (45) between the turbine housing inlet (8) and the turbine housing outlet (9), and a flap arrangement (33) comprising a pivotable flap lever (35), a flap plate (34), which is connected to the flap lever (35), for opening and closing the wastegate duct, and having a spring element (37) which is arranged between the flap lever (35) and a disc (36) fastened to the flap plate (34). The spring element (17) has an outer circumferential region (23) which is supported on a sliding contact surface (42), which is of curved form, of the disc (36).

Owner:BORGWARNER INC

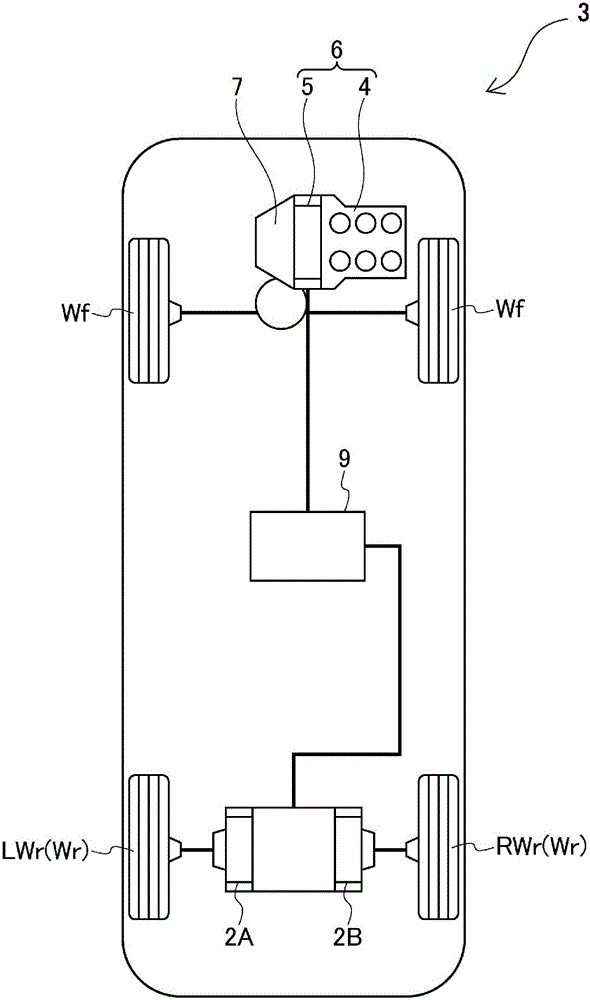

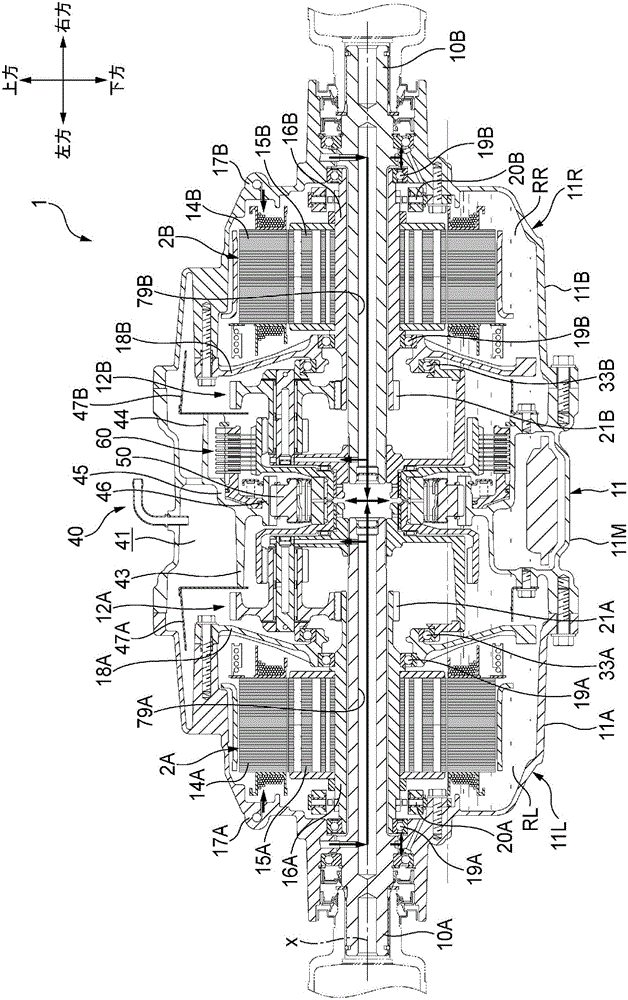

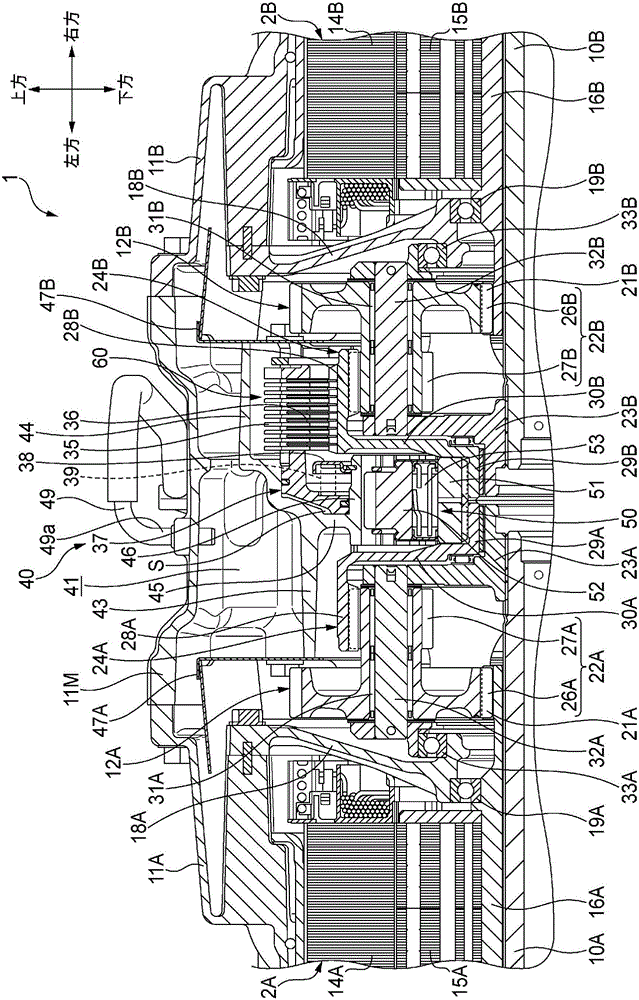

Vehicle

ActiveCN105793082AImprove rigidityImprove securityHybrid vehiclesElectric propulsion mountingVehicle frameEngineering

A vehicle (3) comprises a rear wheel drive device (1) which is supported on a subframe (13) by a bracket (81A, 81B) and a support unit (82A, 82B). The rear wheel drive device (1) comprises an extending portion (93A, 93B) which, from the rear wheel drive device (1), extends at an inclination to the vertical direction or extends in the horizontal direction, and which is formed such that, when an external force of at least a prescribed magnitude acts on said rear wheel drive device (1) and displaces an object mounted on said rear wheel drive device (1) by at least a prescribed amount, said extending portion (93A, 93B) contacts the upper surface (13f) of a joining flange (13e) on the subframe (13).

Owner:HONDA MOTOR CO LTD

The installation structure of the molding

InactiveCN104648090BExcellent adhesionImprove the sense of rhythmWindowsWindscreensEngineeringMechanical engineering

Owner:SUZUKI MOTOR CORP

Rolling body screw device

ActiveUS7461572B2Reliable abutmentAvoid it happening againPortable liftingToothed gearingsEngineeringFlange

A return pipe is constituted by combining a pair of return pipe halves split along a non-load passage. A pipe hold down member is fixed to a nut member so as to be astride the return pipe, fixing the return pipe to the nut member. A flange portion is formed on each of the return pipe halves, while a pair of fixing leg portions covering the flange portion of each return pipe half is formed on the pipe hold down member. Fastening members pass through the fixing leg portions of the pipe hold down member and the flange portion of the return pipe halves and are fastened to the nut member. When the fixing leg portions of the pipe hold down member are fixed to the nut member by the fastening members, an engagement portion of the pipe hold down member is configured to tighten the pair of the return pipe halves in the direction where split faces of the return pipe halves abut against each other.

Owner:THK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com