Heald shaft with lightweight shaft rod

A technology of heald frame rod and heald frame, which is applied in the directions of heald wire, textile, textile and paper making, etc., can solve problems such as the difficulty of plastic heald frame rod and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

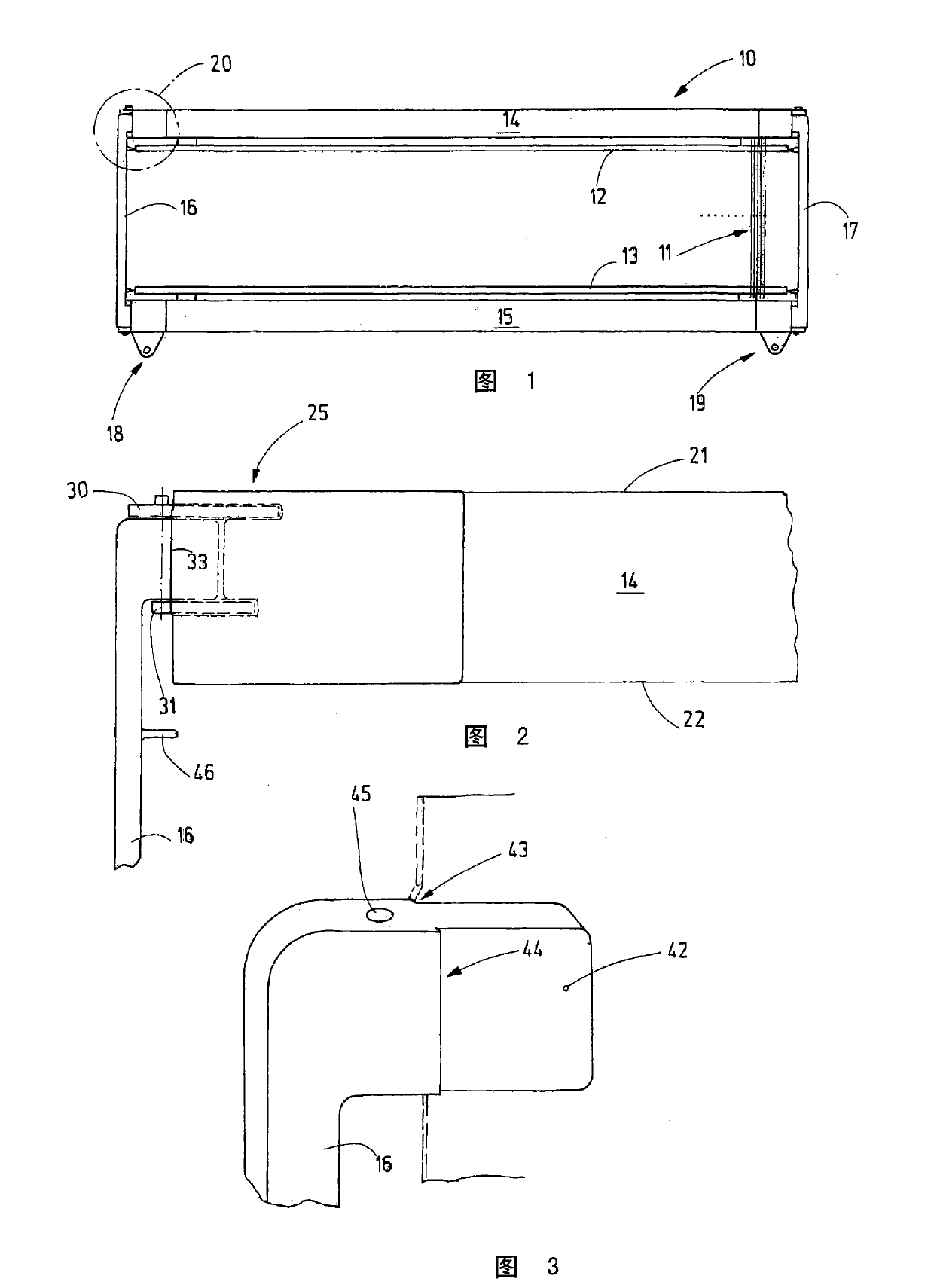

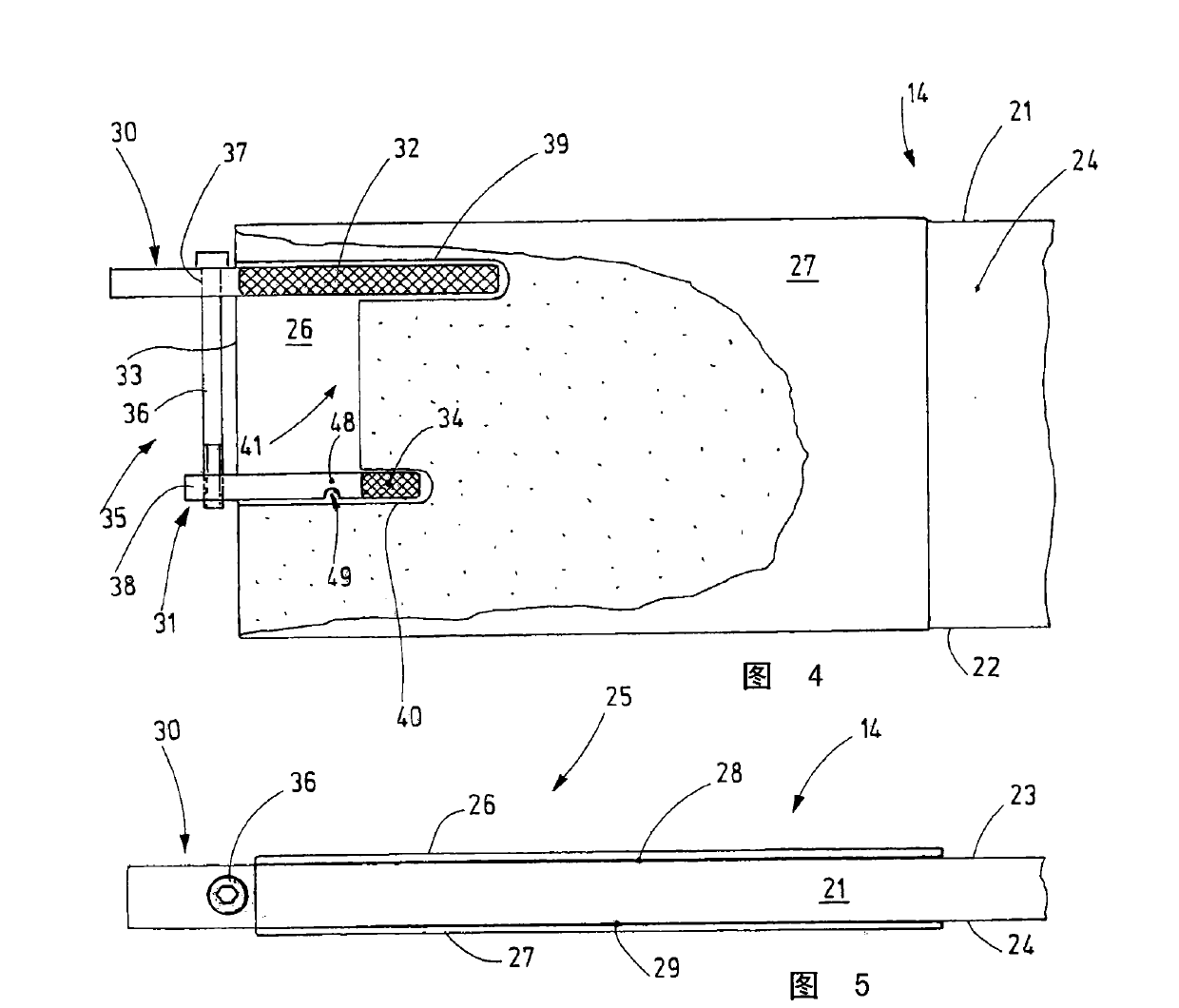

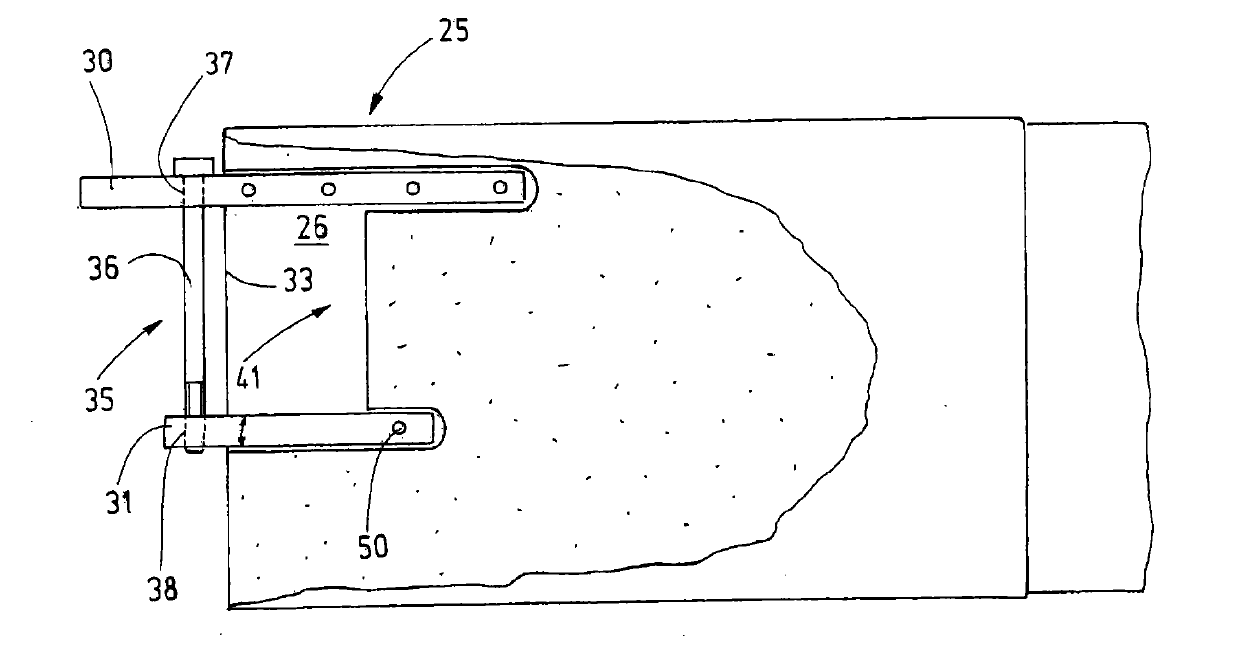

[0031] figure 1A heald frame 10 is shown, which is a part of a loom which is not particularly shown. The heald frame represents a rectangular frame in which the individual heddles 11 are arranged. Healds are provided for guiding warp threads, not shown in particular, during the weaving process. The heald 11 is arranged on the heald support rails 12 and 13, and the heald support rails 12 and 13 are horizontally arranged with a certain vertical distance therebetween. The upper heald support rail 12 is held on the upper heald frame rod 14 . The lower heald support rail 13 is held on the lower heald frame rod 15 . Each of the upper and lower heald shaft rods 14, 15 is constructed of a suitable lightweight material, such as fiber reinforced plastic, honeycomb reinforced sheet metal, thin wall extruded aluminum profiles or the like. Lateral supports 16 , 17 are connected to the ends of the heald frame rods 14 , 15 so as to form a rectangular frame with the heald frame rods 14 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com