Rotary electric machine

A technology for rotating motors and separating components, which is applied in the direction of electrical components, electromechanical devices, and electric components. It can solve the problems of reduced dimensional accuracy of rectification structures, dimensional changes, and difficulty in obtaining sufficient rectification effects, etc., to achieve improved cooling effects, reliable positioning, The effect of preventing positional misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

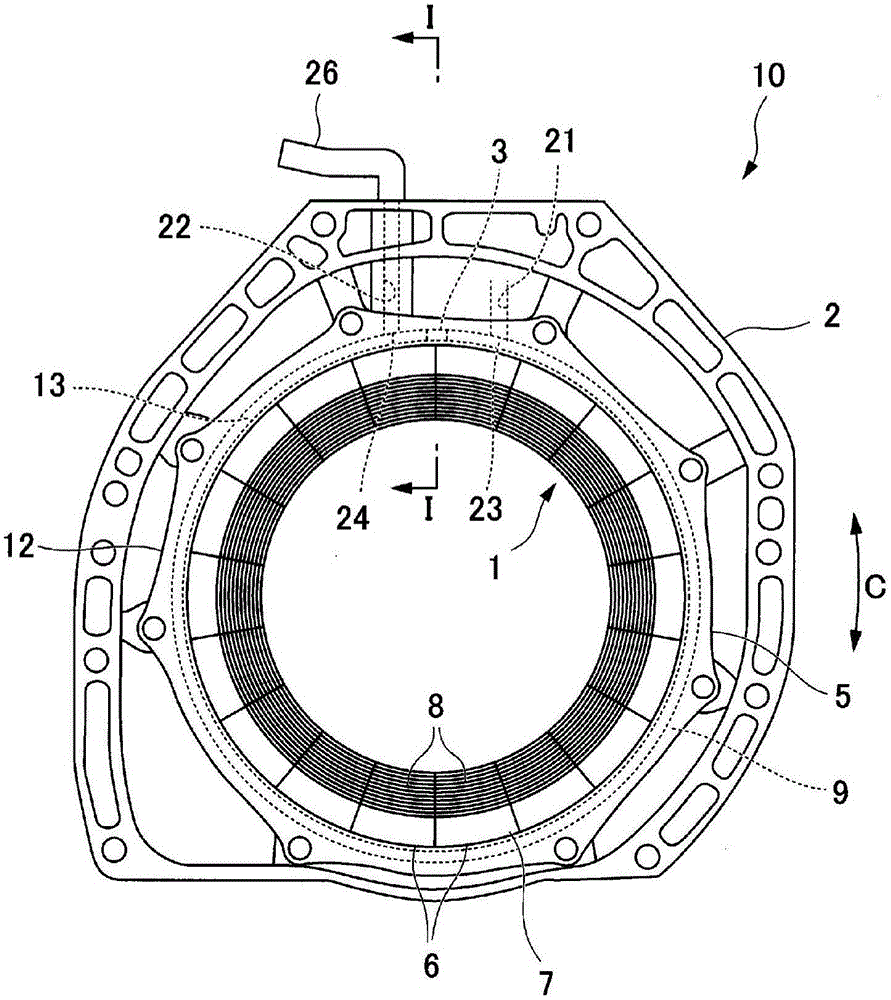

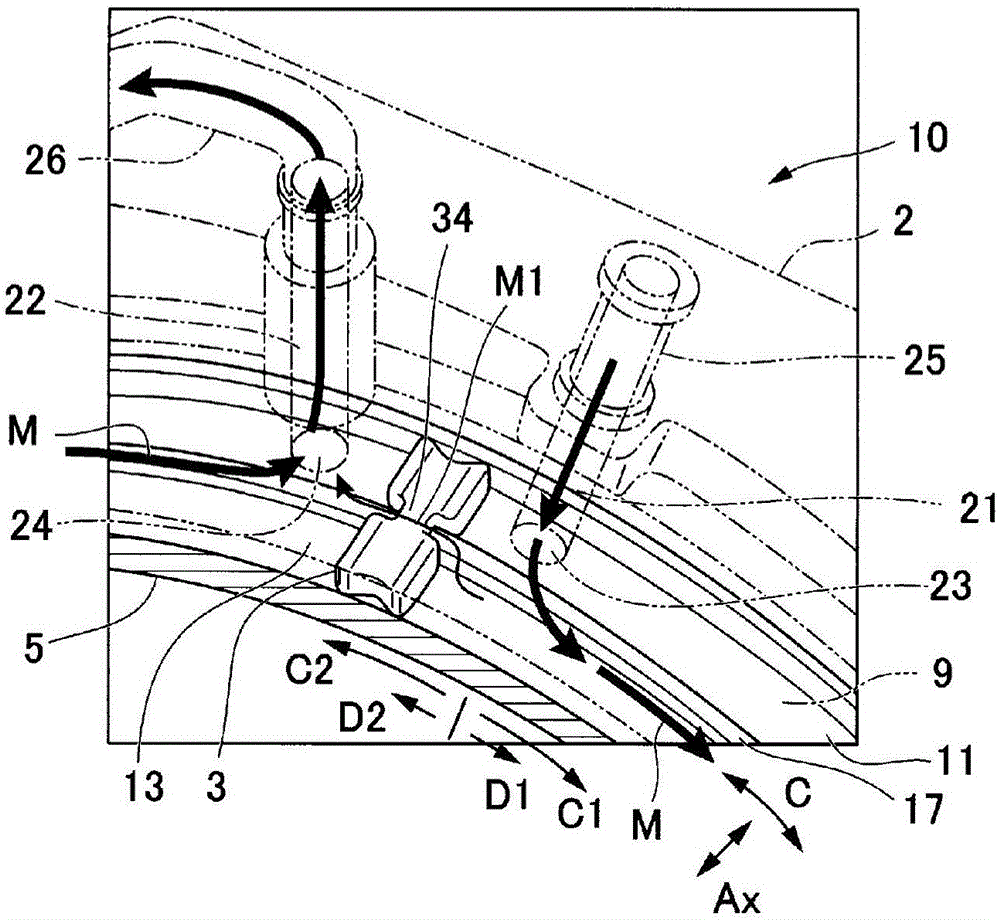

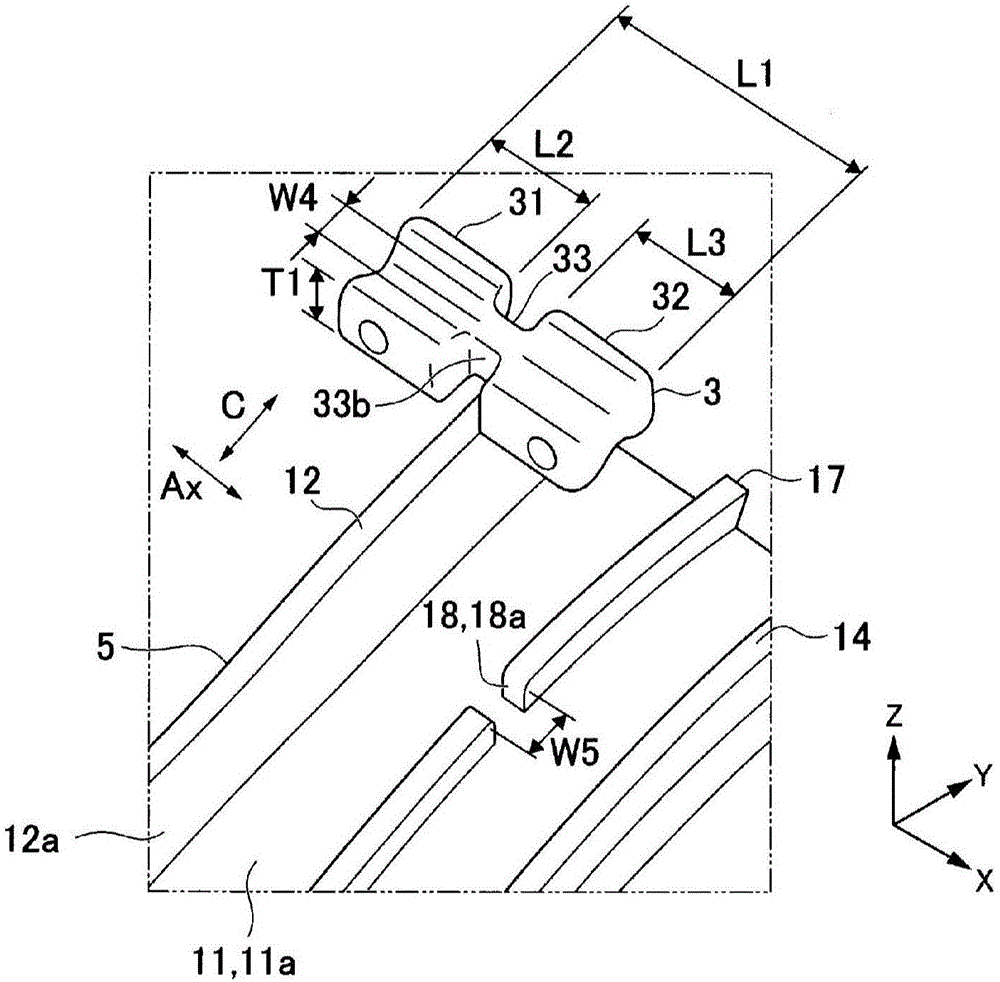

[0057] figure 1 It is a front view of the rotating electric machine 10 of embodiment. figure 2 It is a perspective view showing a part of the stator bracket 5 and the housing 2 . image 3 It is a perspective view showing the stator bracket 5 and the partition member 3 . Figure 4 It is a sectional view showing a part of the stator bracket 5 and the housing 2 . Figure 5 ~ Figure 9 It is a figure which shows the stator holder 5 and the partition member 3. Arrow Ax indicates a direction along the axis of the stator 1 . Arrow R indicates the radial direction of the stator 1 . Arrow C indicates a direction around the axis of the stator 1 (circumferential direction).

[0058] The rotary electric machine 10 can be used for vehicle drive and regenerative power generation of, for example, an electric vehicle, a hybrid vehicle, and the like. Inside the stator 1, a rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com