Light partition board mounting structure and mounting method

A light-weight partition wall panel and installation structure technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problem of affecting the quality of decoration, the adhesion of the upper part of the lightweight partition wall panel to the bottom of the structural beam or the bottom of the structural slab, High cracking rate and other problems, to achieve good economic benefits, low cost, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

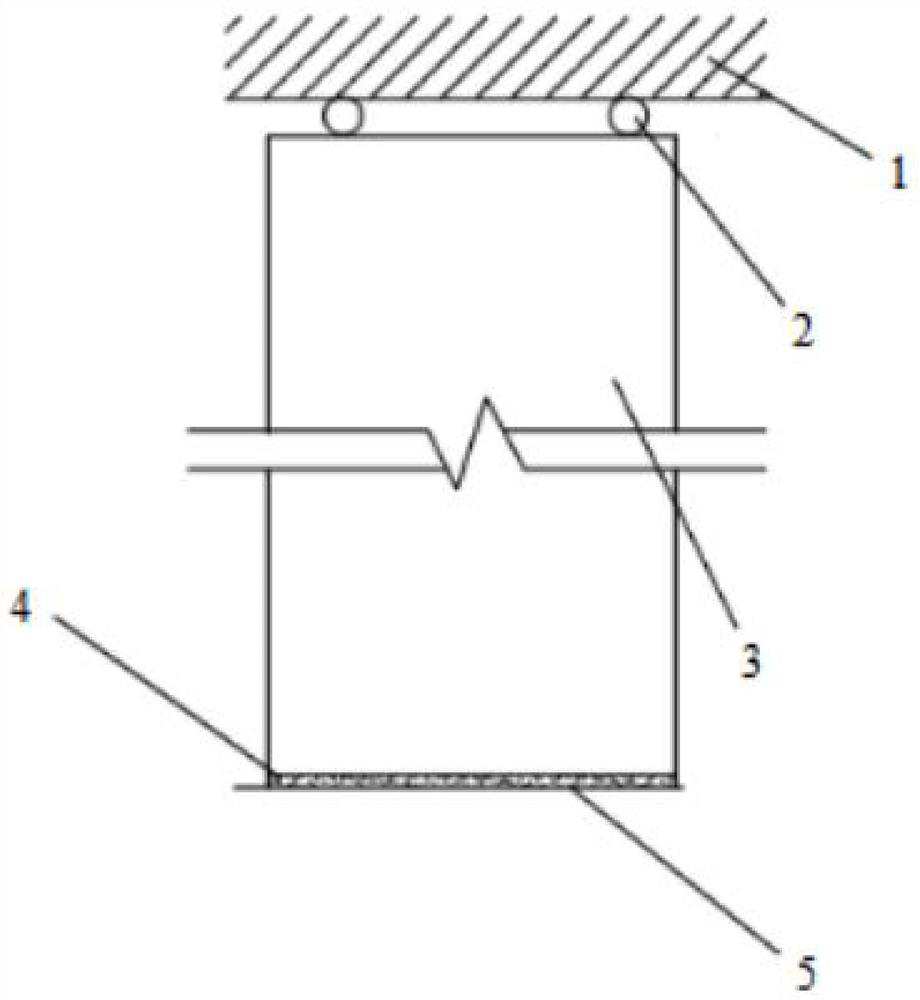

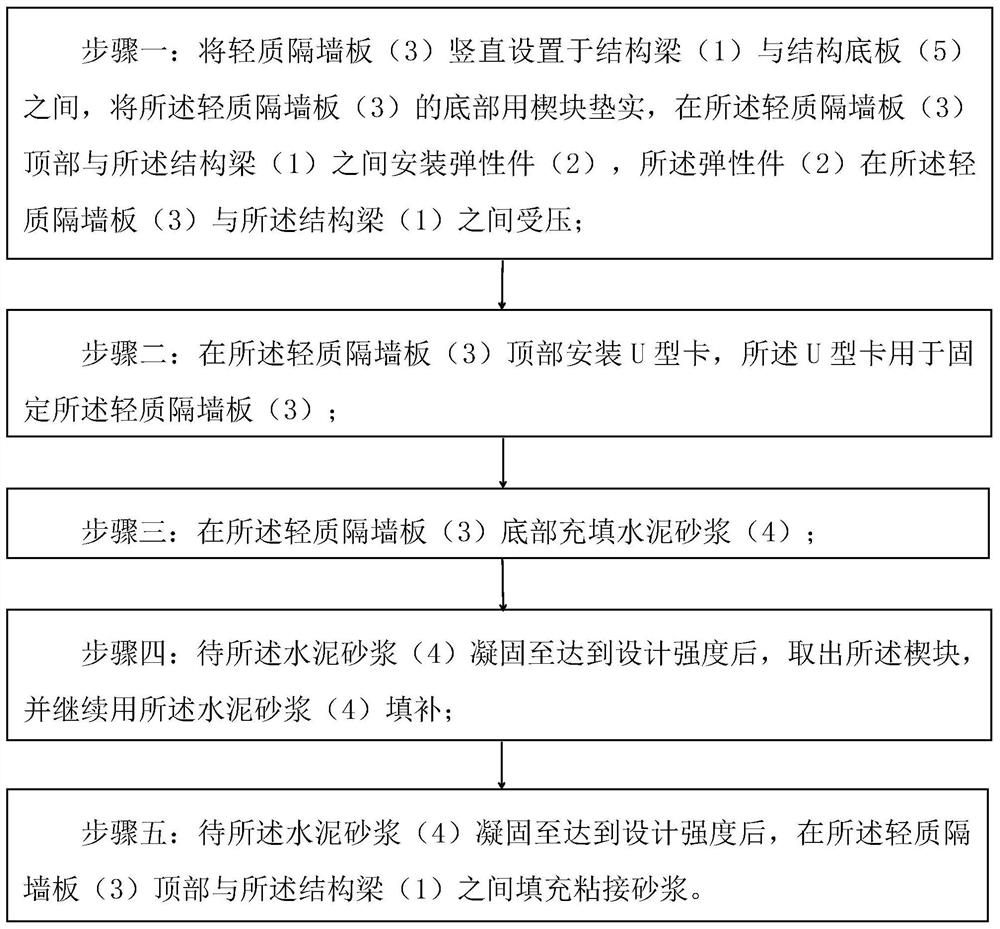

[0039] Such as Figure 1-Figure 2 As shown, the installation method of lightweight partition wall panels includes the following steps:

[0040]Step 1: Install the lightweight partition wall panel 3 vertically between the structural beam 1 and the structural bottom plate 5, pad the bottom of the lightweight partition wall panel 3 with wooden wedges, and place the lightweight partition wall panel 3 An elastic member 2 is installed between the top and the structural beam 1, specifically, the elastic member 2 is two PVC pipes, and the two PVC pipes are symmetrically arranged at both ends of the top of the lightweight partition wall panel 3 10cm, the PVC pipe is compressed between the lightweight partition wall board 3 and the structural beam 1, the length of the PVC pipe is equal to the thickness of the lightweight partition wall board 3, according to the Install the PVC pipe in such a way that the length direction of the PVC pipe is perpendicular to the surface of the lightweigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com