Patents

Literature

449results about How to "Reduce the probability of cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

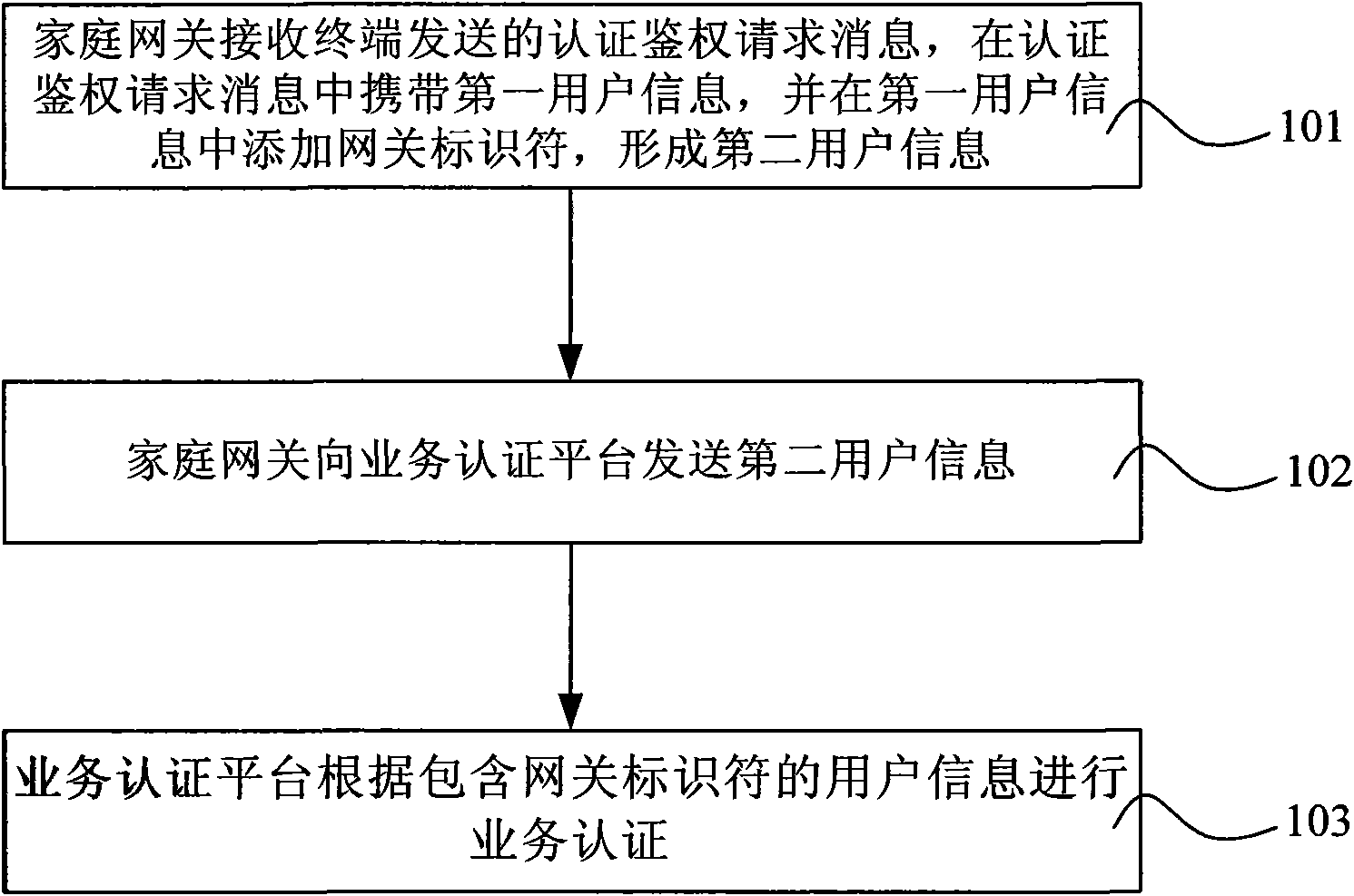

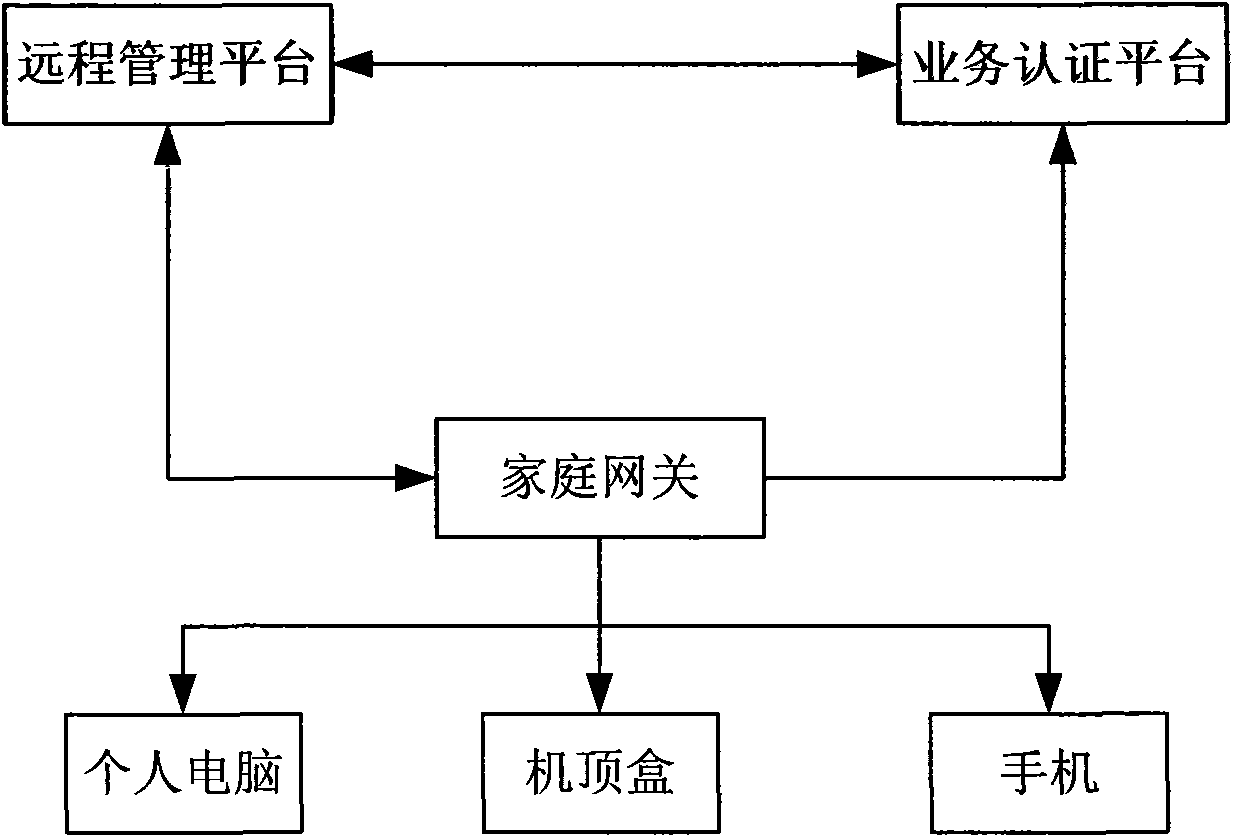

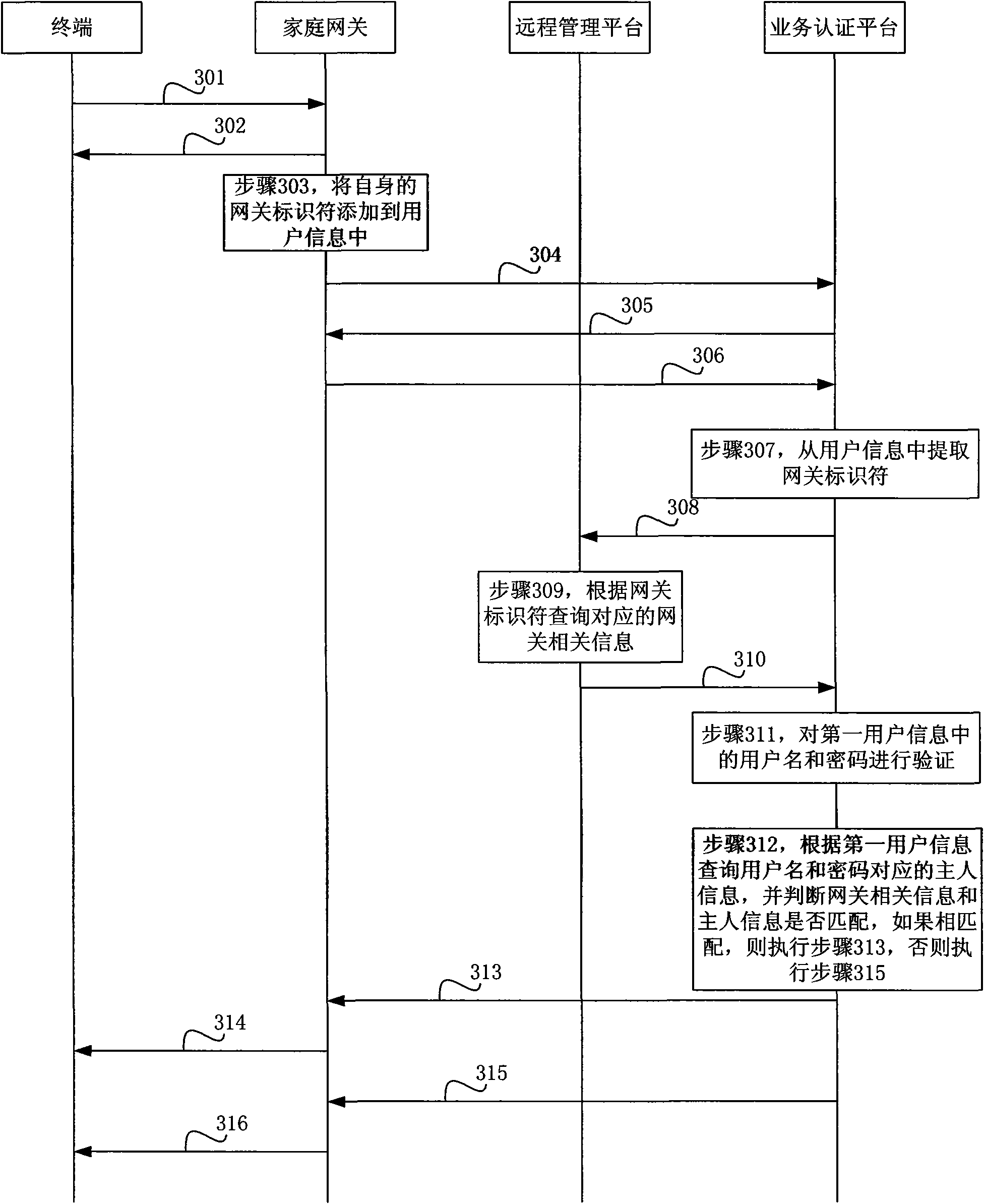

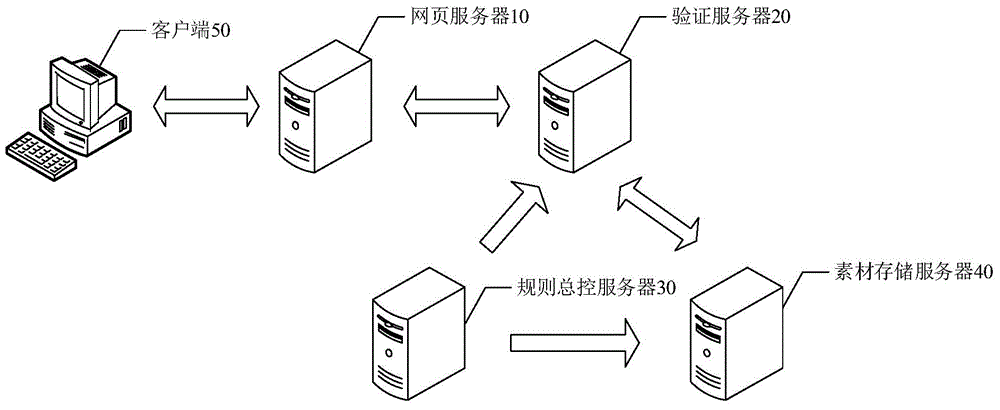

Service authentication method and system

The invention discloses a service authentication method and system, the method comprises that: a household gateway receives an authentication request message transmitted by a terminal, carries a first user information in the authentication request message, and add a gateway identification character of the household gateway per se in the first user information to form a second user information; the household gateway transmits the second user information to a service authentication platform; the service authentication platform performs the service authentication according to the second user information. The system comprises a household gateway and a service authentication platform, wherein, the household gateway comprises a message receiving module, an information adding module and an information transmitting module. The invention reduces the probability for decoding the user information, prevents the economic loss caused by the decoding the user information and improves the safety of the household network, meanwhile the user need not execute extra large quantities of operations.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Overall-bamboo anti-cracking processing method

InactiveCN101927516AReduce the probability of crackingHigh strengthWood treatment detailsCork treatment detailsAcetic acidWeather resistance

The invention discloses an overall-bamboo anti-cracking stewing, stewing and filling, and drying method. The method comprises the following steps of: stewing a bamboo section in mixed solution of sodium chloride and acetic acid at the temperature of 100 DEG C under normal pressure, wherein bamboo green is removed from the bamboo section and a hole is punched on a bamboo joint or a bamboo wall; stewing and filling the bamboo section in the mixed solution of alum and polyethylene glycol at the temperature of 100 to 200 DEG C and under the pressure of 0.1 to 1.6 MPa; performing low-temperature drying on the bamboo section in a wood steam drying kiln; hydrofuging the drying kiln until the moisture content of the bamboo section reaches 5 to 20 percent; and unloading an overall-bamboo after slowly reducing the temperature of the kiln to indoor normal temperature. After the treatment, the overall-bamboo has the characteristics of better dryness and anti-cracking effect, improved stability, weather resistance and strength, and prolonged service life.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

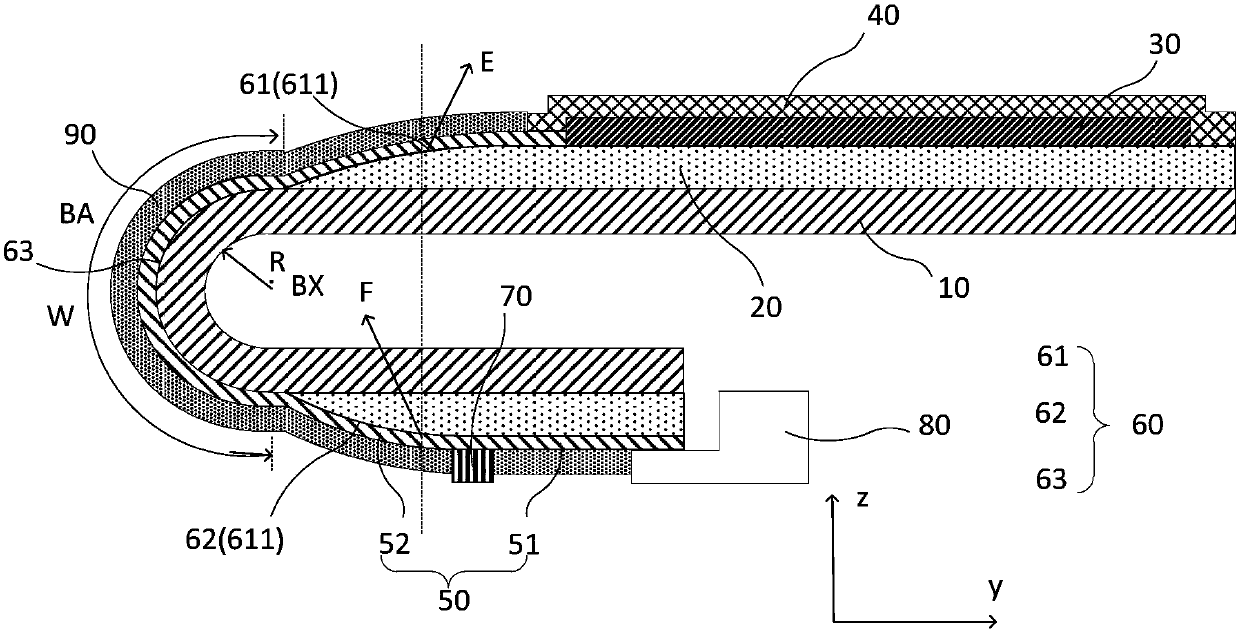

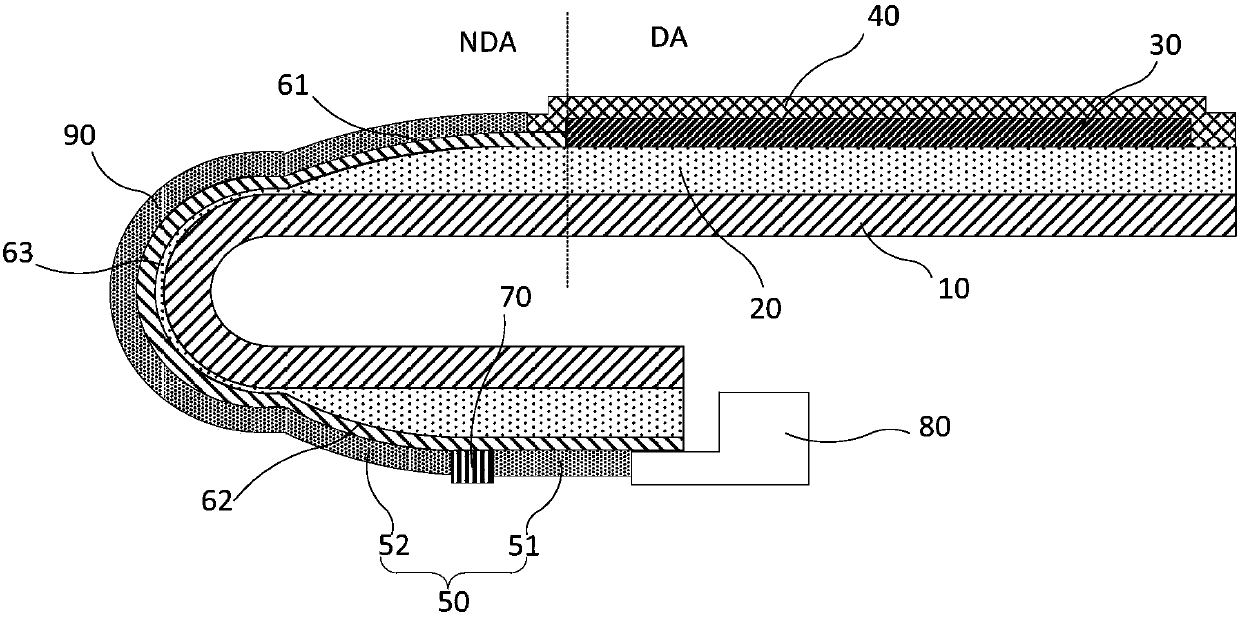

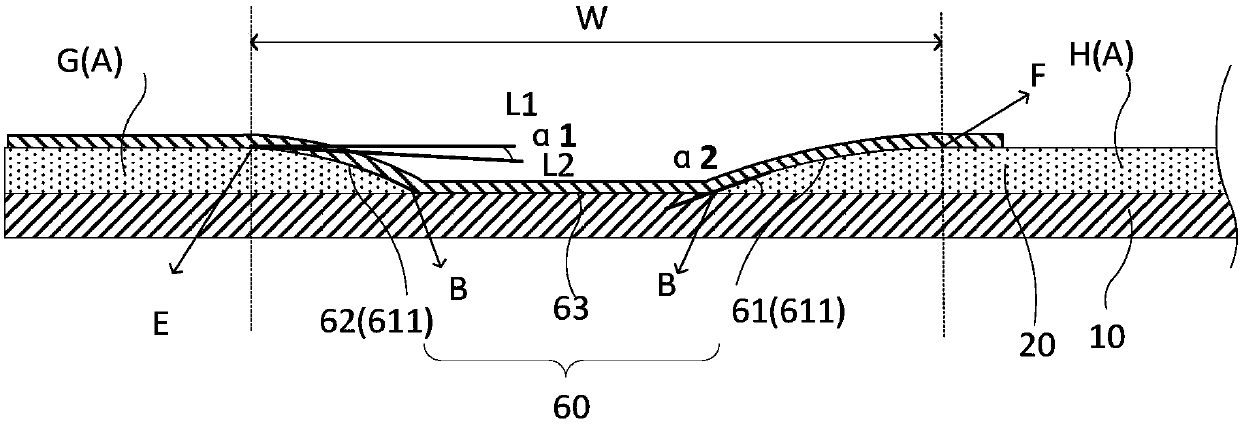

Flexible display device

ActiveCN108054188AReduce thicknessReduce bending stressSemiconductor/solid-state device detailsSolid-state devicesEngineeringFlexible display

The invention relates to a flexible display device which comprises a flexible substrate comprising a bending region and an insulating layer formed on the flexible substrate, wherein the insulating layer in the bending region comprises at least one notch; a plurality of wiring lines which are arranged in the bending region along the surface shape of the insulating layer. The notch comprises an inclined side wall, and the inclined side wall is provided with a convex shape which is opposite to the flexible substrate, so that the problem of short circuit or disconnection of the wiring in the bending area can be effectively solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

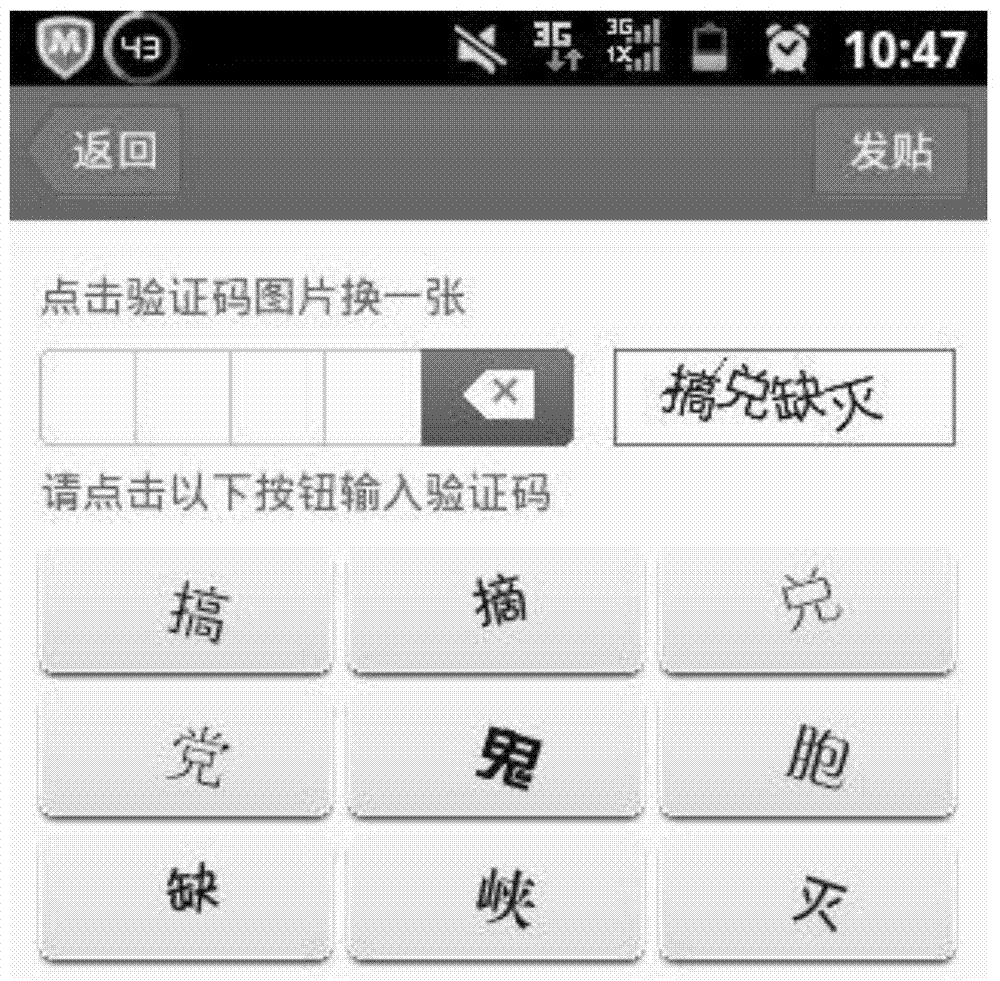

Safety verification method and device

ActiveCN105323065AReduce crack rateImprove securityUser identity/authority verificationDigital data authenticationColor processingCAPTCHA

Provided is a safety verification method. The method comprises that a request for drawing a CAPTCHA is received, an original picture is obtained, the original picture is processed into a preset color to generate a first picture, and multiple second pictures are cut from the original picture; the jigsaw CAPTCHA is generated according to the first and second pictures; the CAPTCHA is returned to a sender of the request; a jigsaw picture, which is completed by a user and sent by the sender, is received, and the degree that the jigsaw picture conforms to the original picture is determined; and whether the user passes safety verification is further determined. The invention also provides a safety verification device. The safety verification method and device can greatly reduce the declassification rate of an automatic machine under the condition that the difficulty in identifying CAPTCHA is not increased.

Owner:TENCENT TECH (SHENZHEN) CO LTD

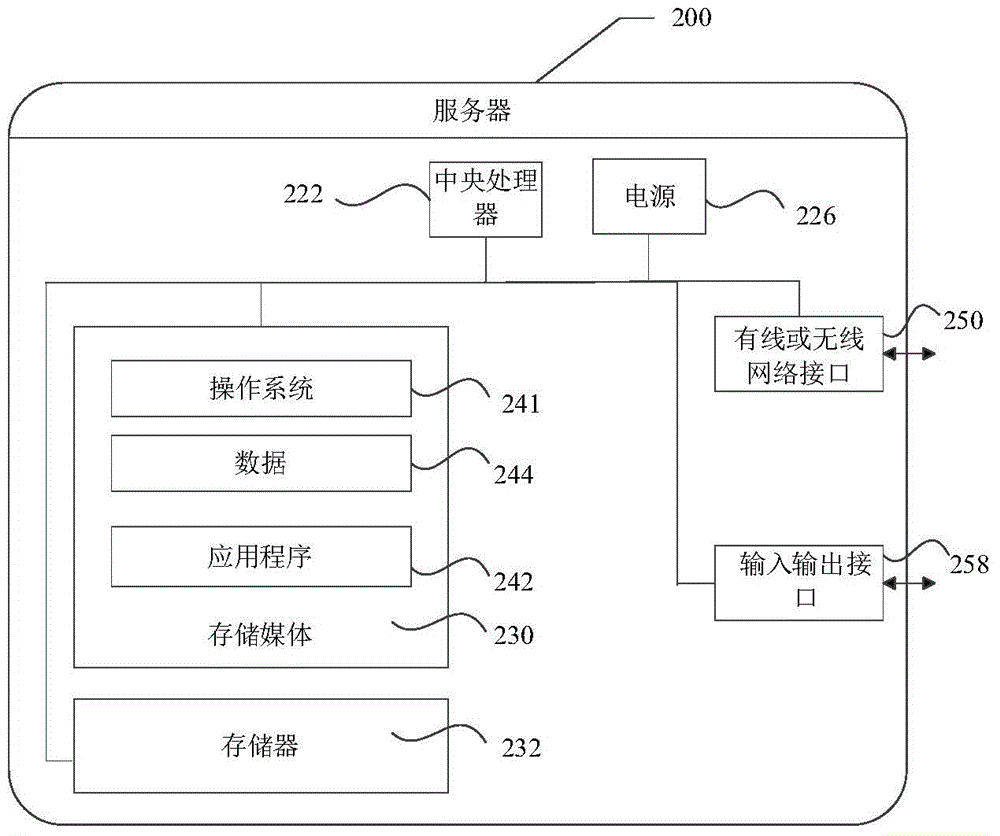

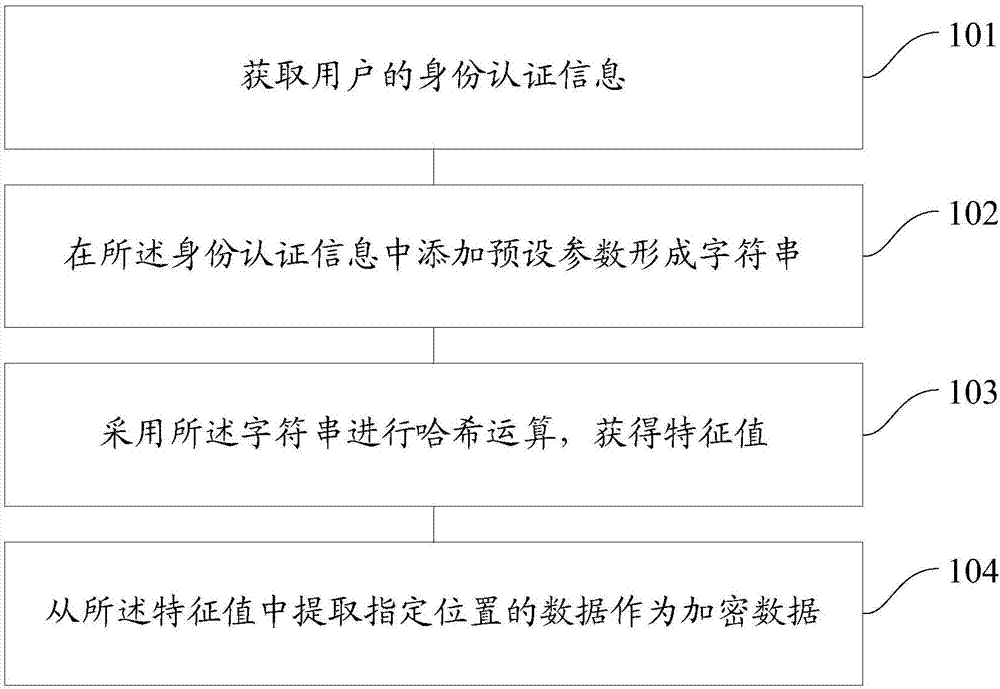

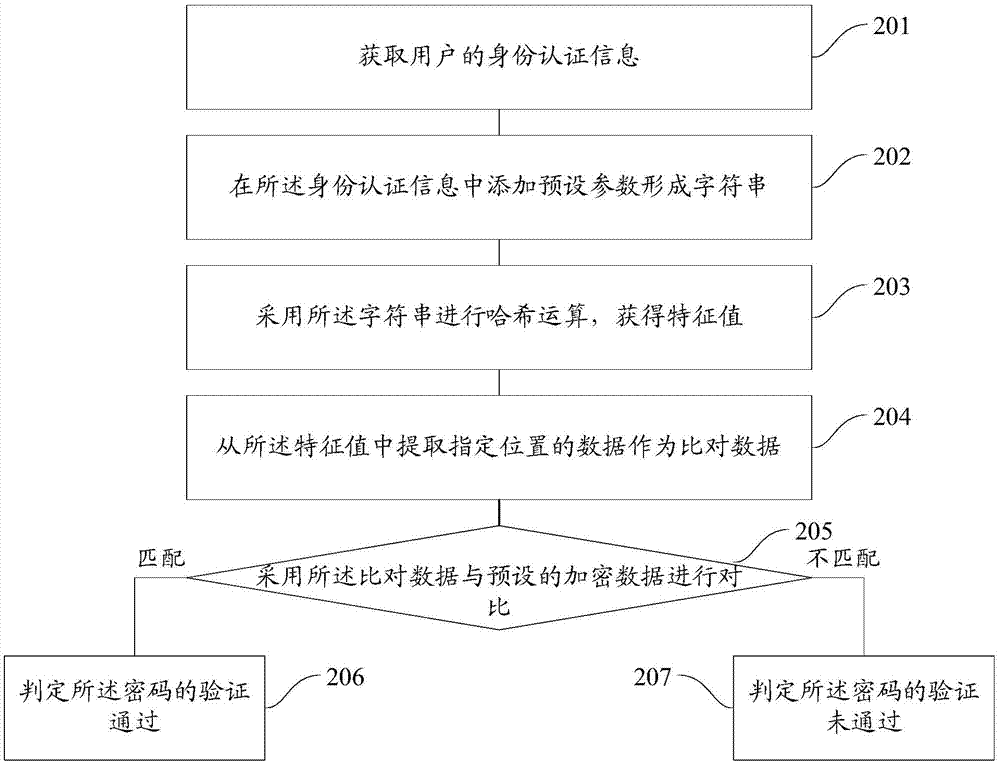

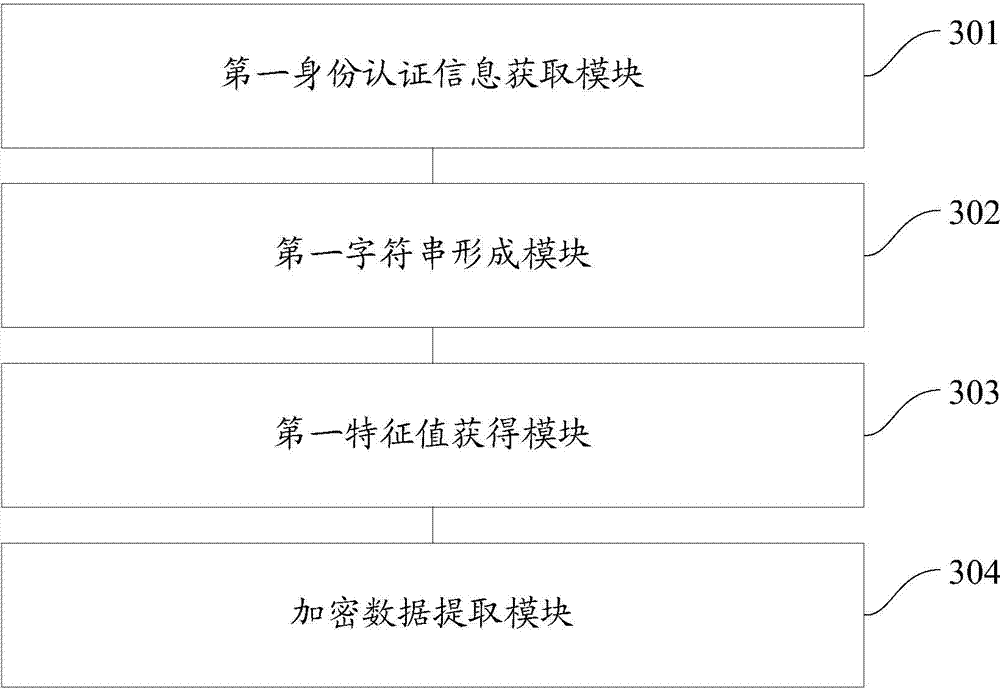

Password storing and verifying method and password storing and verifying device

InactiveCN104281794AIncreased complexityReduce the probability of crackingDigital data protectionDigital data authenticationPasswordAuthentication information

An embodiment of the invention provides a password storing and verifying method and a password storing and verifying device. The method comprises the following steps of acquiring identity authentication information of a user; adding preset parameters in the identity authentication information to obtain a character string; performing Hash operation by using the character string to obtain a characteristic value; and extracting data at an appointed position as enciphered data from the characteristic value. By the password storing and verifying method and the password storing and verifying device, the complexity of passwords of a user can be improved, the defense capability of the passwords of the user can also be improved, Hash collision is avoided or reduced, so that the crack probability of the passwords is reduced, and the passwords of the user are prevented from leaking.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

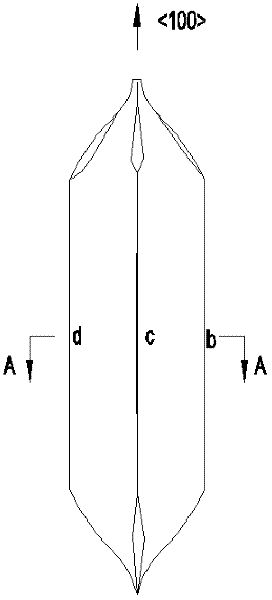

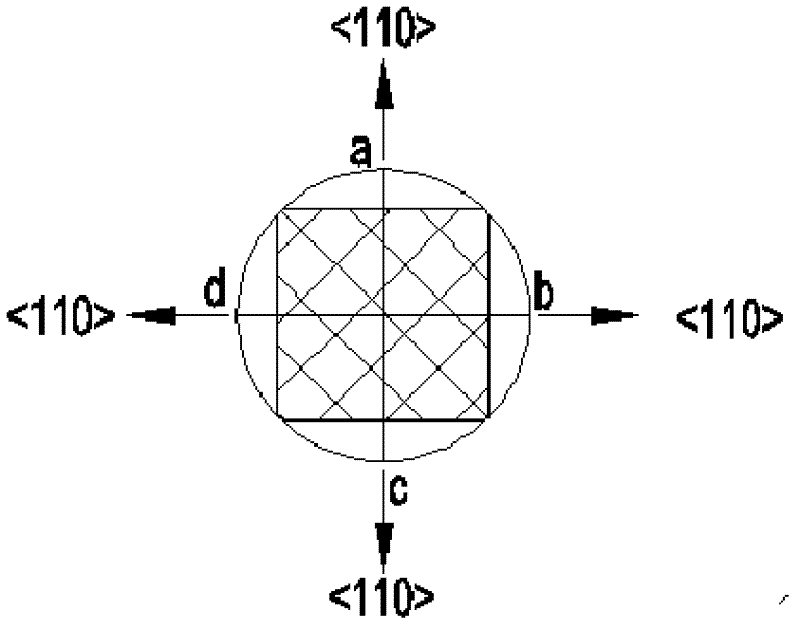

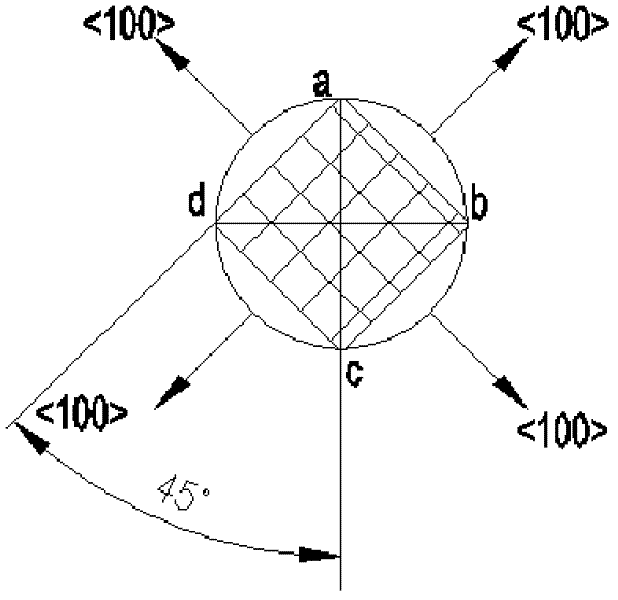

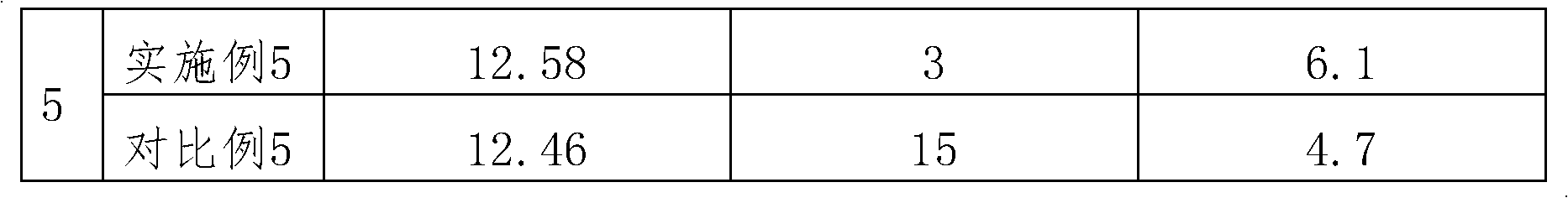

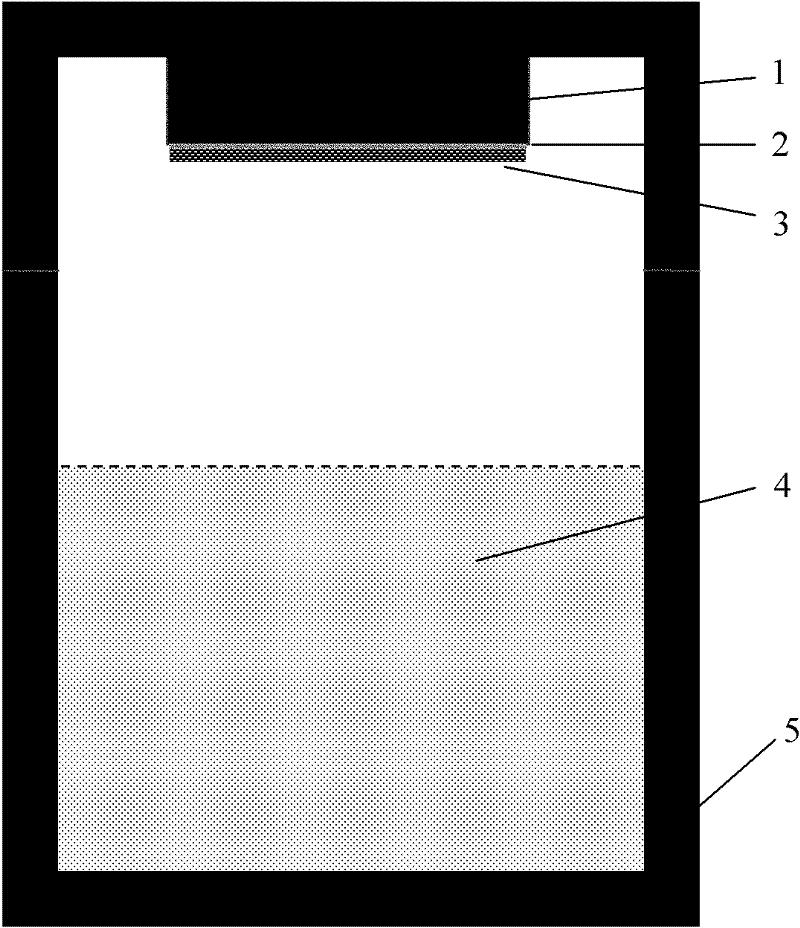

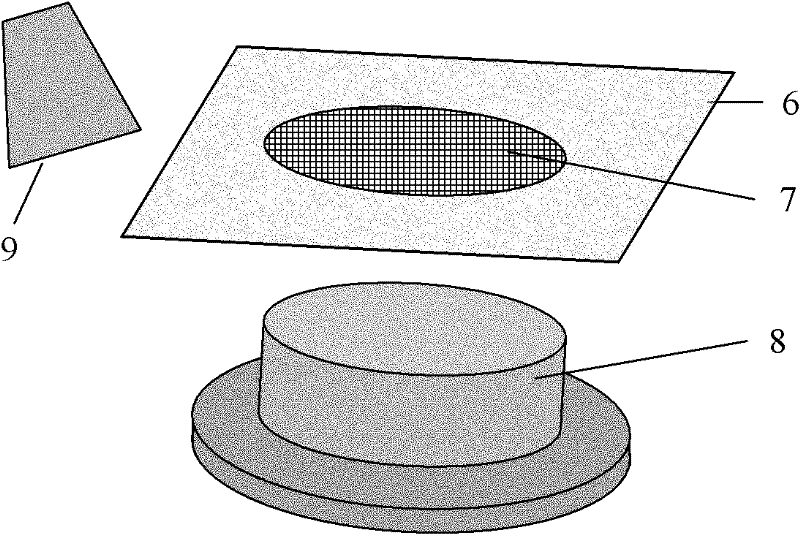

Production method of solar energy level polysilicon ingot with crystalline grains arranged regularly

InactiveCN102392300AImprove productivityReduce the probability of crackingPolycrystalline material growthFinal product manufactureSeed crystalProduction rate

The invention discloses a production method of solar energy level polysilicon ingot with crystalline grains arranged regularly, which comprises the following steps: a seed crystal layer is arranged on a plane at the bottom of a flat-bottom crucible in advance, then silicon melt is arranged in the flat-bottom crucible, or silicon raw material arranged in the flat-bottom crucible is heated and melted to form the silicon melt, and the polysilicon ingot is prepared by the inducing of the seed crystal layer, wherein the seed crystal layer is formed by tightly arranging nine or more than nine rectangular seed crystals, the seed crystals are arranged along the crystal direction (100) of the normal direction of the plane at the bottom of the flat-bottom crucible, and the included angle of the two adjacent seed crystals along the crystal direction of the normal direction of the spicing surface is 30-60 degrees. In the production method, the special seed crystal layer is adopted, so that the productivity of the silicon ingot is increased, the possibility of breakage of the silicon ingot is reduced, the minority carrier lifetime of the silicon ingot also can be prolonged, and the quality of the silicon crystal can be improved.

Owner:GREENERGY CRYSTAL TECH

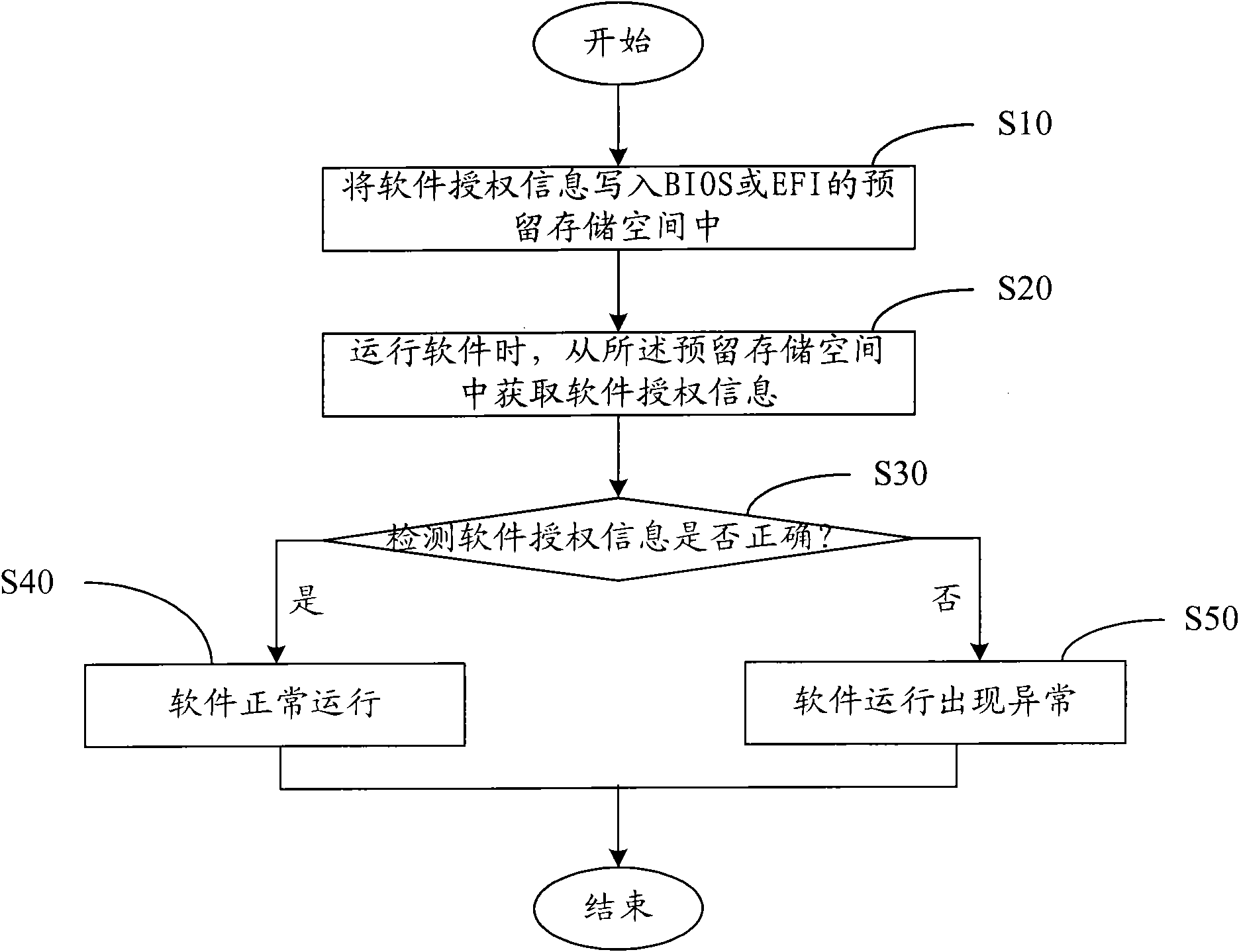

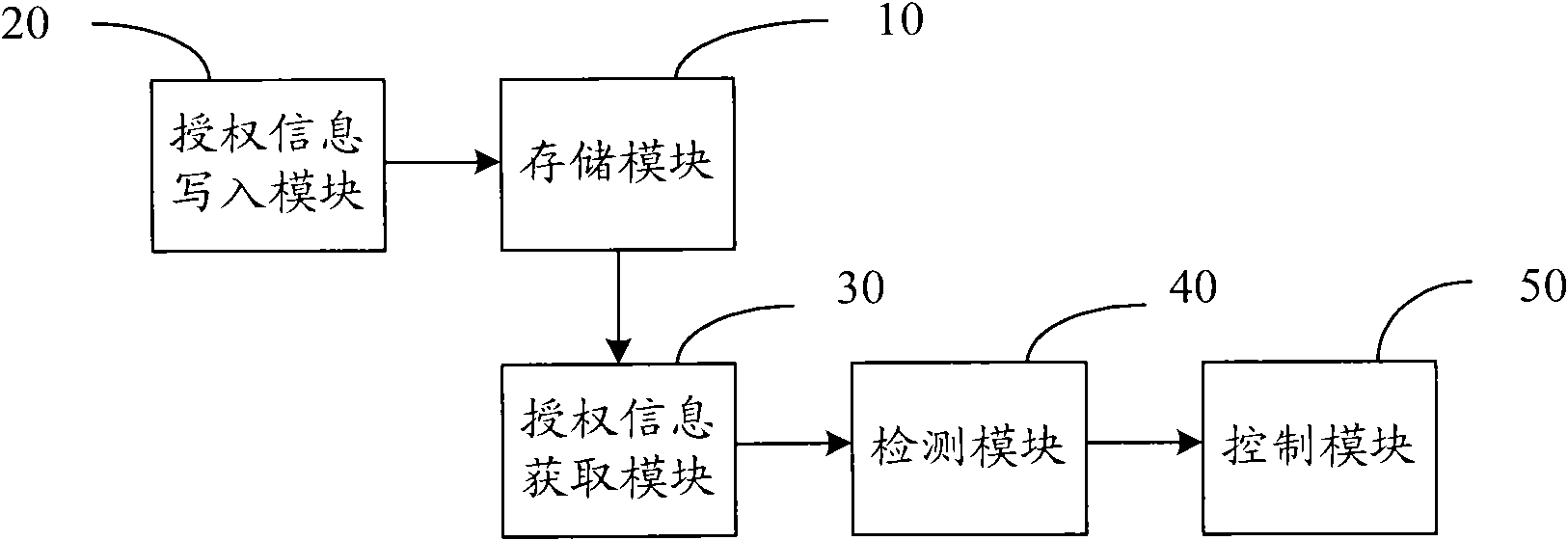

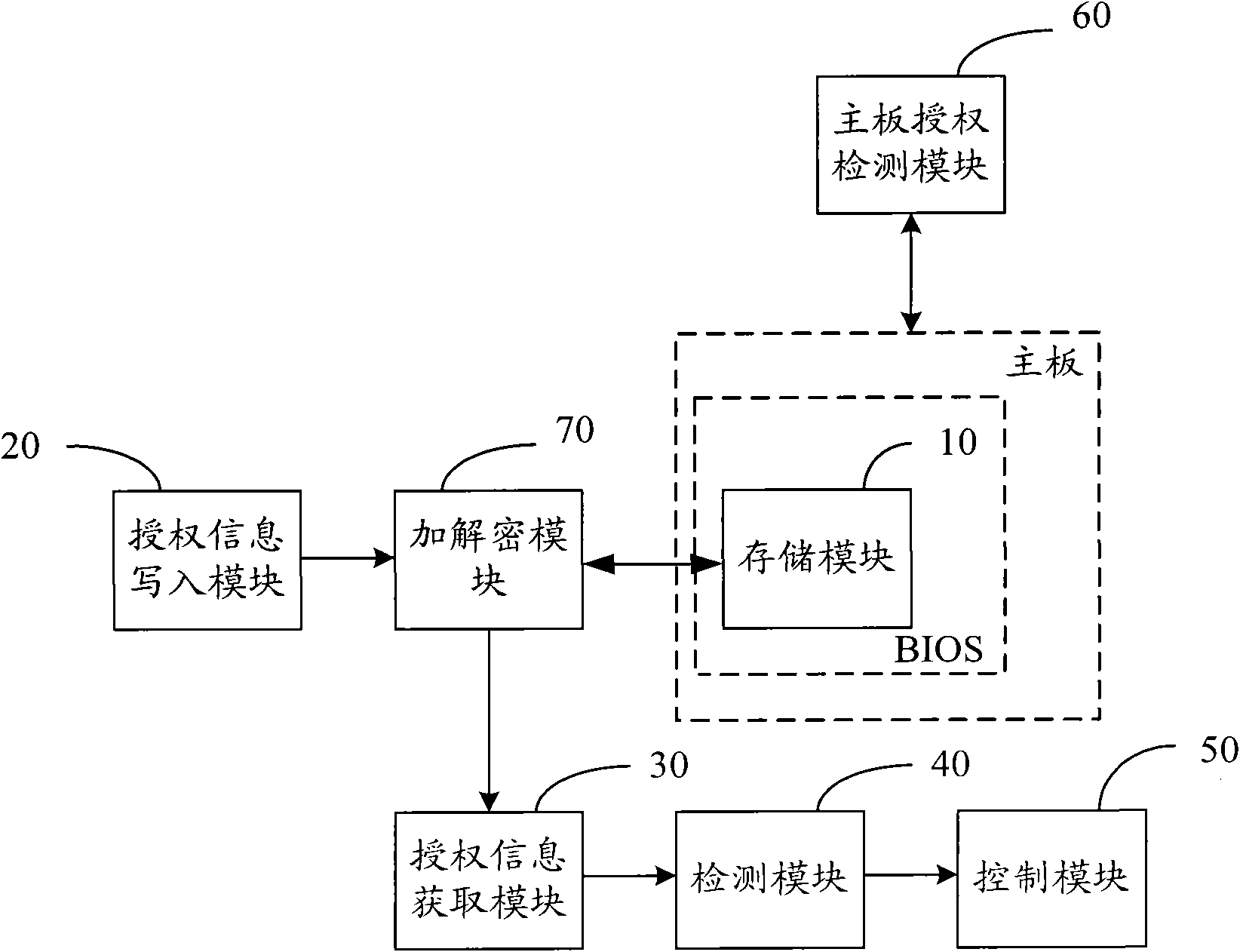

Method and system for encrypting software

ActiveCN102385671AReduce the probability of crackingImprove securityProgram/content distribution protectionSoftware engineeringApplication software

The invention provides a method and a system for encrypting software. The method comprises the following steps: writing software licensing information into the preserved storage space of a basic input / output system (BIOS) or an extensible firmware interface (EFI); when the software runs, obtaining the software licensing information from the preserved storage space; and detecting whether the software licensing information is right or not through the application program of the software; and if the software licensing information is right, the software normally runs, and otherwise, the software abnormally runs. By adopting the method and the system for encrypting the software, the software cannot be easy to crack, and the software encrypting safety is improved.

Owner:深圳市研祥智慧科技股份有限公司

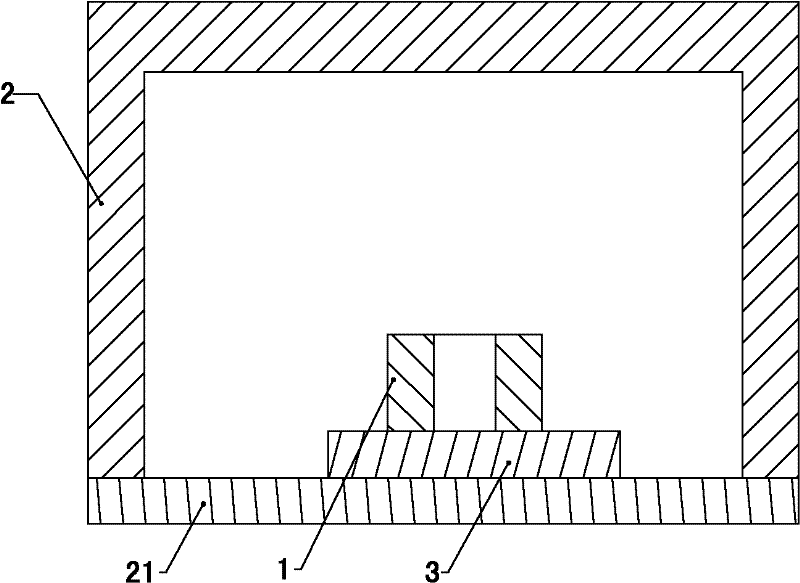

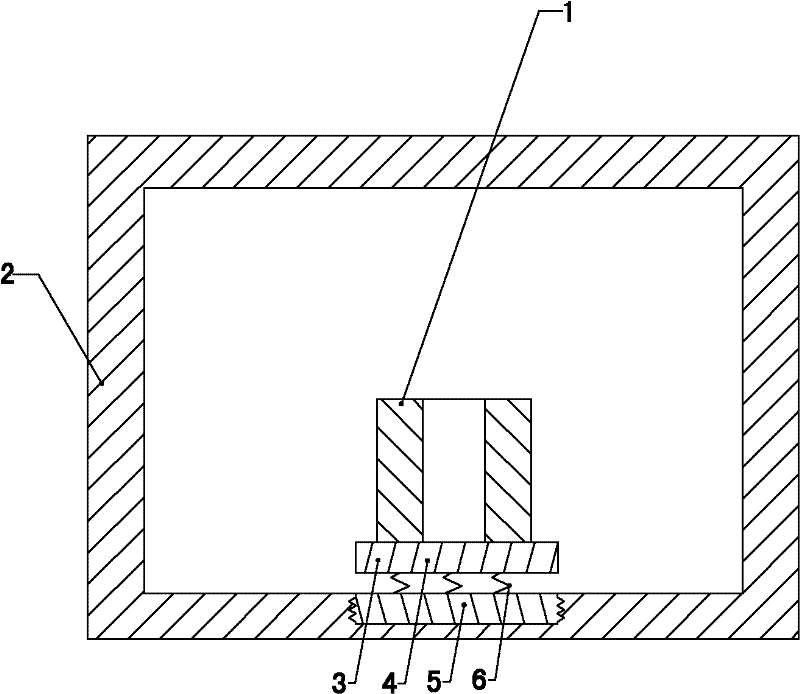

Filter

InactiveCN102222811AMinimize thermal expansion differencesReduce crackingWaveguide type devicesThermal expansionEngineering

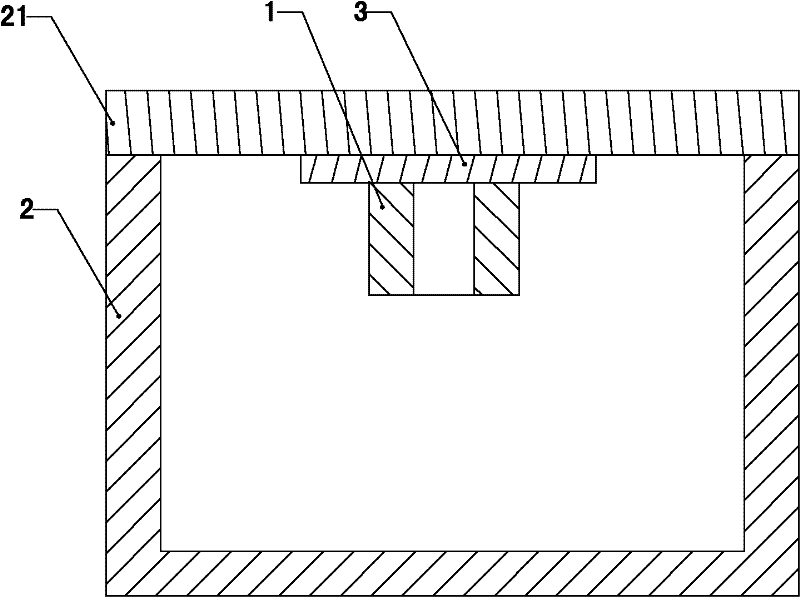

The invention discloses a filter relating to the field of communication equipment. The filter can reduce the possibility that a welding spot of a medium resonator is cracked owning to the difference of thermal expansion coefficient. The filter provided by the embodiment of the invention comprises a medium resonator, a chamber body and a connecting piece, wherein the medium resonator is arranged in the chamber body; the medium resonator is welded on the connecting piece that is connected with the chamber body together; the medium resonator is not directly contacted with the chamber body; the difference of the thermal expansion coefficient of the connecting piece and the thermal expansion coefficient of the medium resonator is less than that of the thermal expansion coefficient of the chamber body and the thermal expansion coefficient of the medium resonator, and / or the connecting piece is a deformation damping structural part with the elastic deformation capability higher than that of the chamber body. The filter is applied to the design concept on a novel filter and is mainly applied to a novel comb-shaped linear medium resonation mode.

Owner:HUAWEI MACHINERY

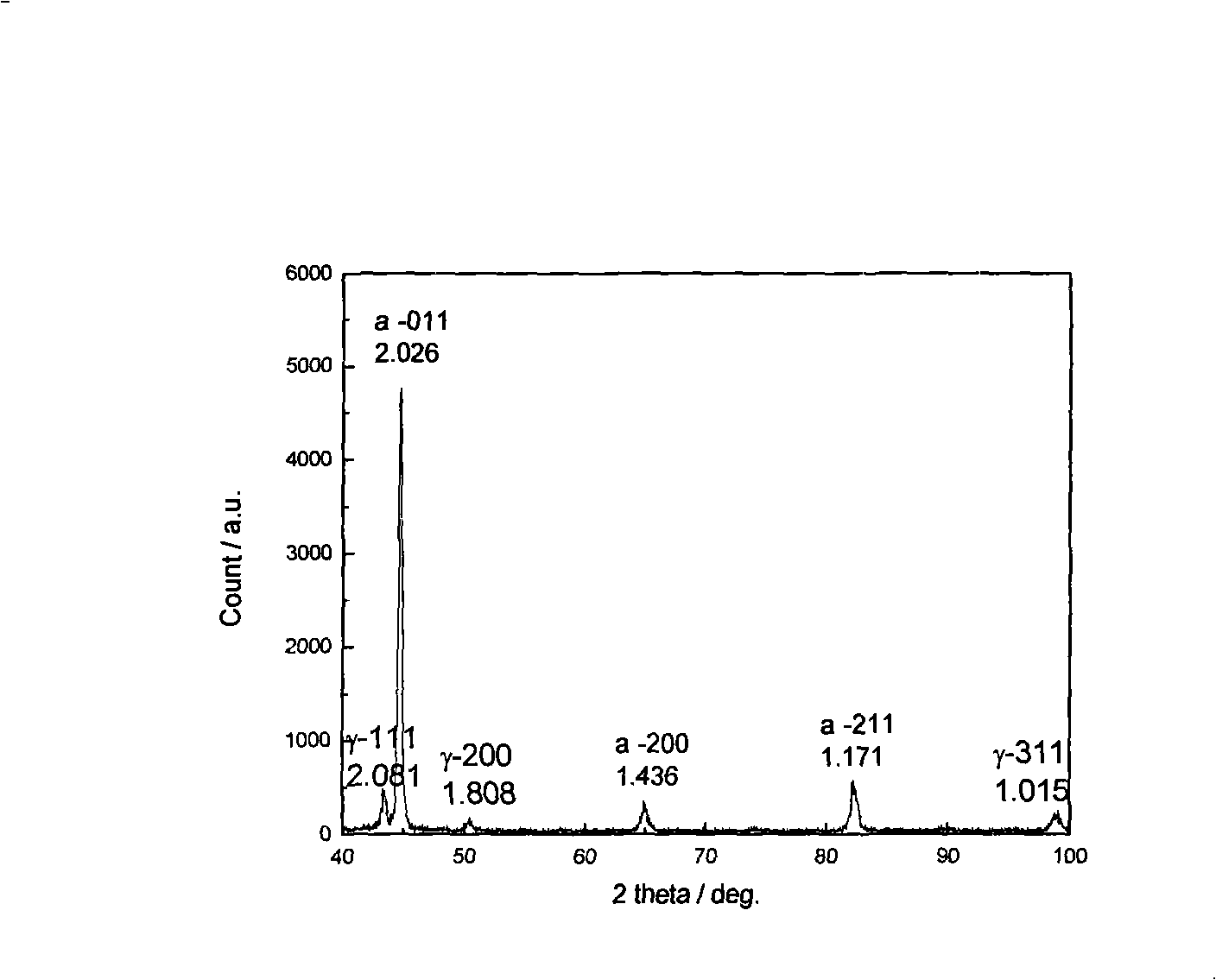

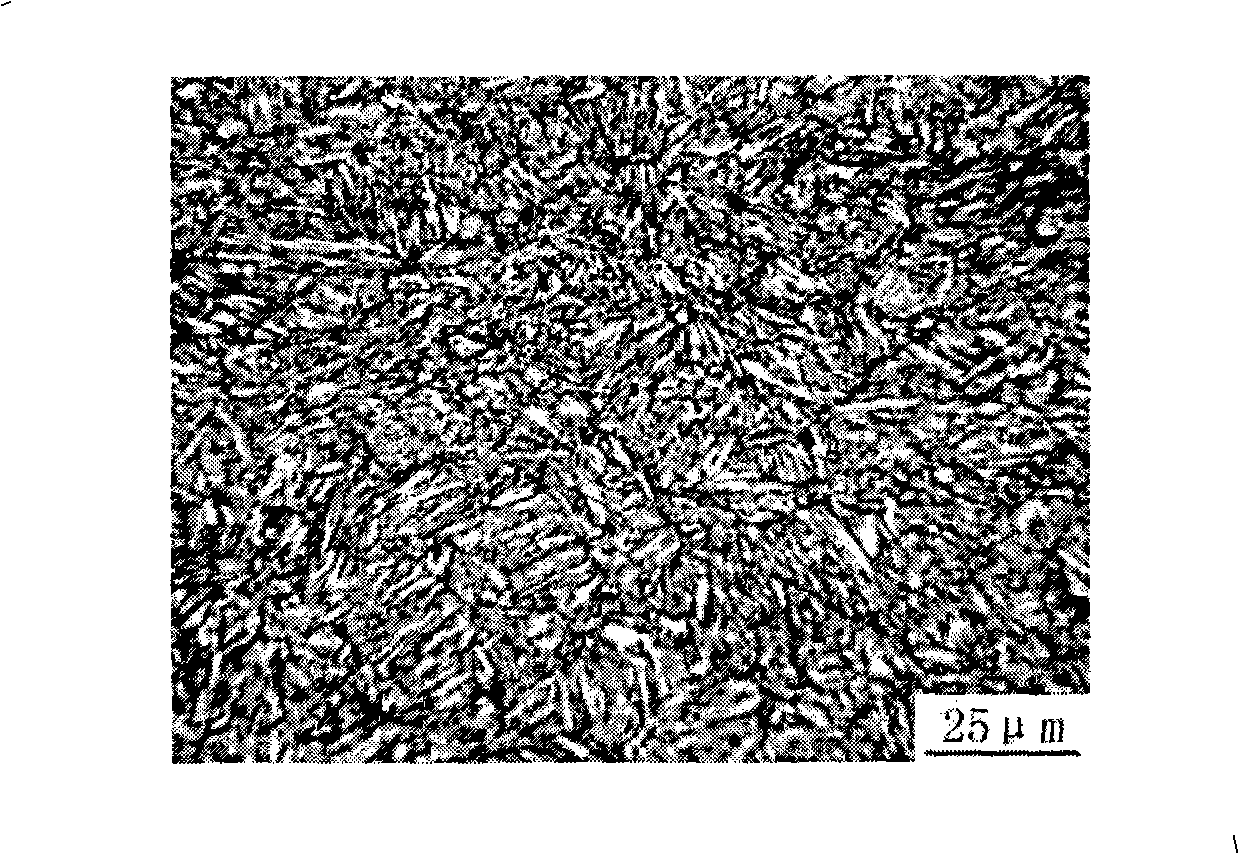

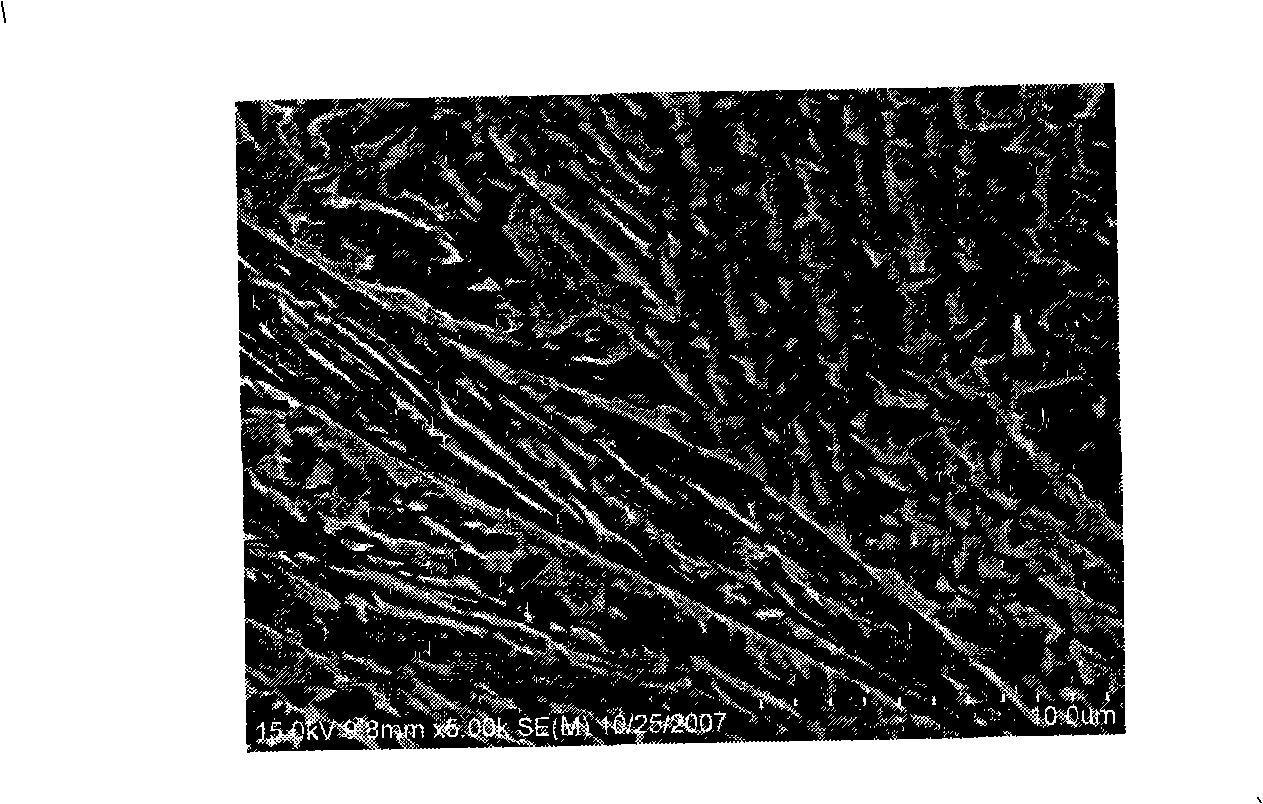

Carbides-free bainite wear resistant steel plate and production process thereof

ActiveCN101338399AImprove hardenabilityHigh strengthTemperature control deviceProduction lineWear resistant

The invention relates to a steel and a production technique thereof, in particular to a non-carbide bainite wear-resistant steel plate and a production technique thereof; the component weight percentages are: 0.15 to 0.25 percent of C, 1.50 to 2.00 percent of Mn, 0 to 0.015 percent of P, 0 to 0.006 percent of S, 1.30 to 2.00 percent of Si, 0.20 to 0.60 percent of Al, 0.60 to 1.00 percent of Cr, 0.25 to 0.50 percent of Mo, 0.010 to 0.035 percent of Nb and the rest is Fe. The production technique is carried out according to the following working procedures: (1) feeding a continuous casting plate to a heating furnace for heating; (2) feeding the continuous casting plate after being heated into a hot rolling production line to carry out the rolling of controlled rolling and controlled cooling; (3) carrying out middle-low temperature drawing temper on a rolling steel plate after the rolling is finished. The non-carbide bainite wear-resistant steel plate can be produced by the working procedures without carrying out online or offline hardening and tempering thermal processing which not only can simplify the working procedures of production, but also can improve the performance and the quality of a product as well as obtain the bainite wear-resistant steel with high intensity and high toughness.

Owner:NANJING IRON & STEEL CO LTD

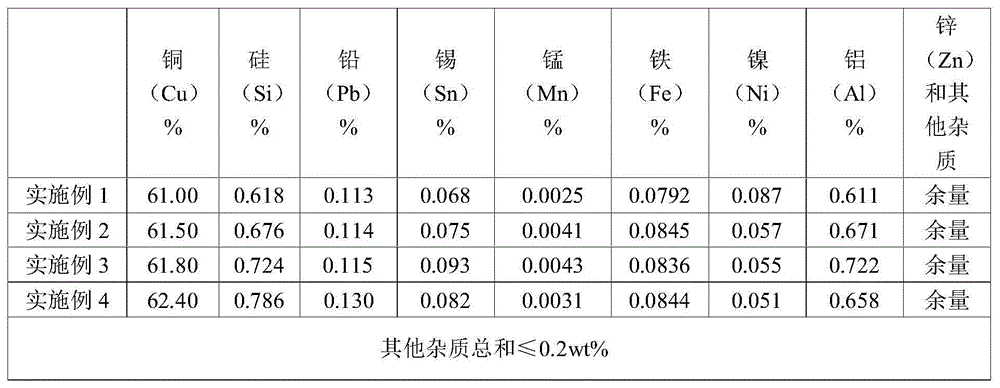

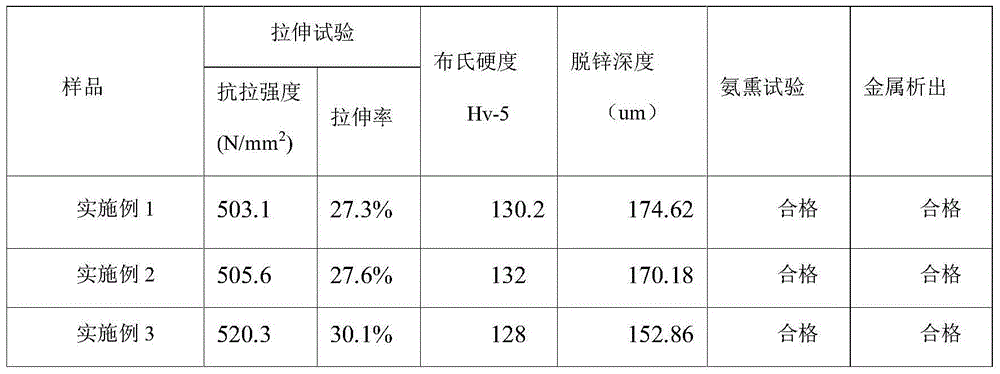

Easily processed silicon brass alloy and preparation method thereof

The invention discloses an easily processed silicon brass alloy. The alloy comprises the following components in percentage by weight: 60-63% of copper (Cu), 0.50-0.90% of silicon (Si), 0.50-0.80% of aluminum (Al), 0.10-0.20% of lead (Pb), less than 0.3% of other elements, and the balance of zinc (Zn) and inevitable impurities, wherein the sum of copper, silicon, aluminum and zinc is more than 99.60%, and other elements are a combination of tin (Sn), manganese (Mn), ferrum (Fe) and nickel (Ni). The invention further comprises a preparation method of the silicon brass alloy. The prepared silicon brass alloy is obviously higher than common lead brass in the performances of tensile strength, elongation rate, hardness and anti-zinc removal, the casting processability is good, practical production and application demands can be met, the precipitation of metals can meet the standard requirements, and the easily processed silicon brass alloy can be widely applied to water heating, valves and other various industries having limit on the precipitation of metal pollutants.

Owner:JOMOO KITCHEN & BATHROOM

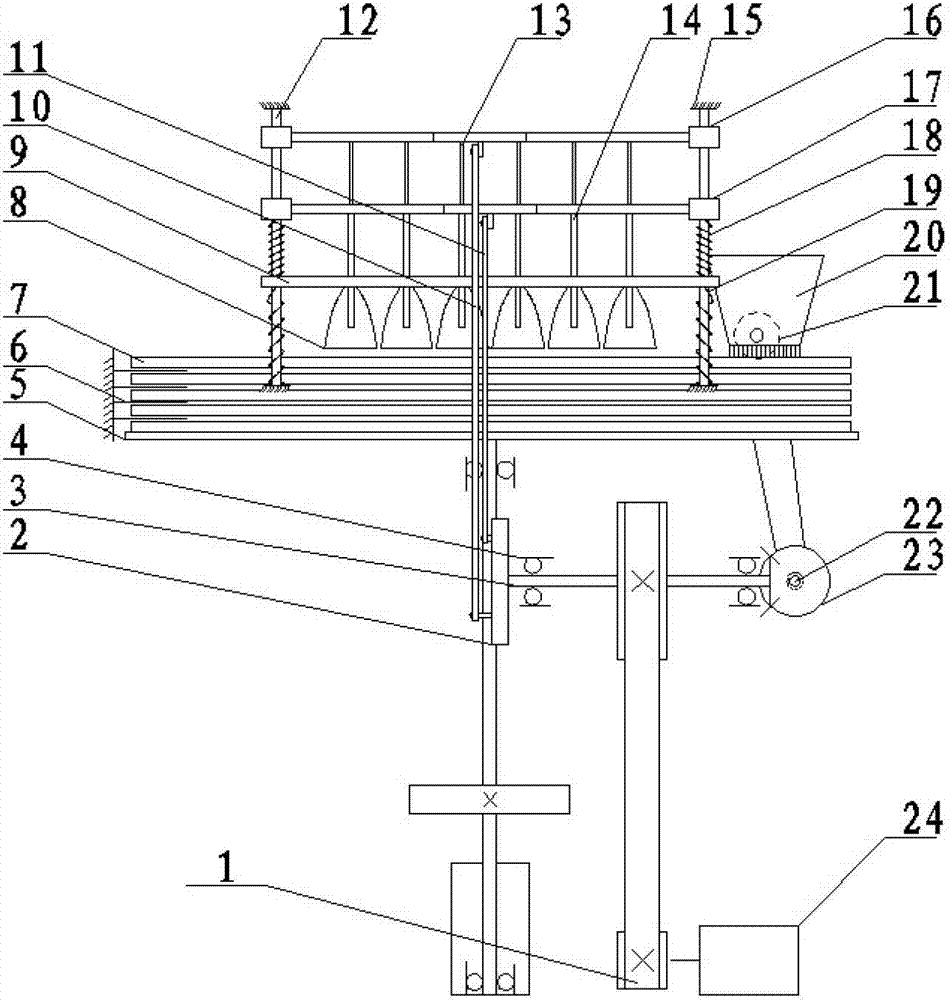

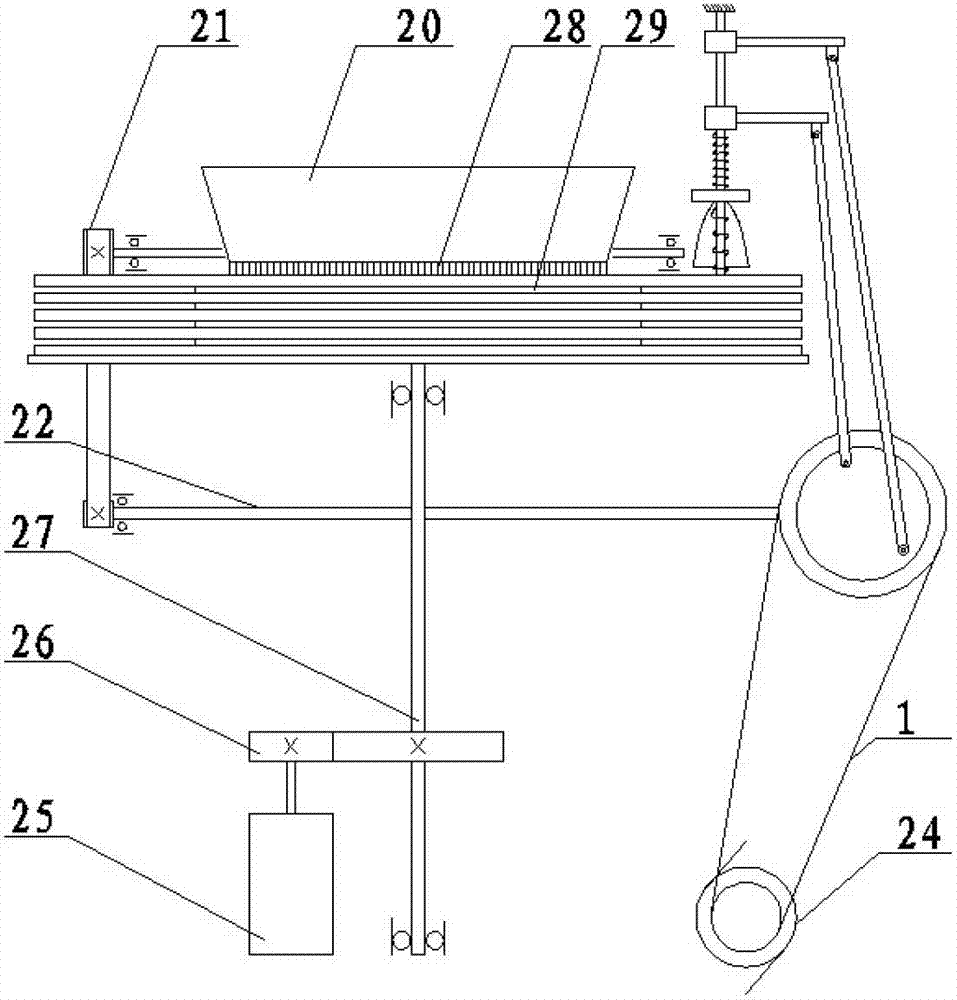

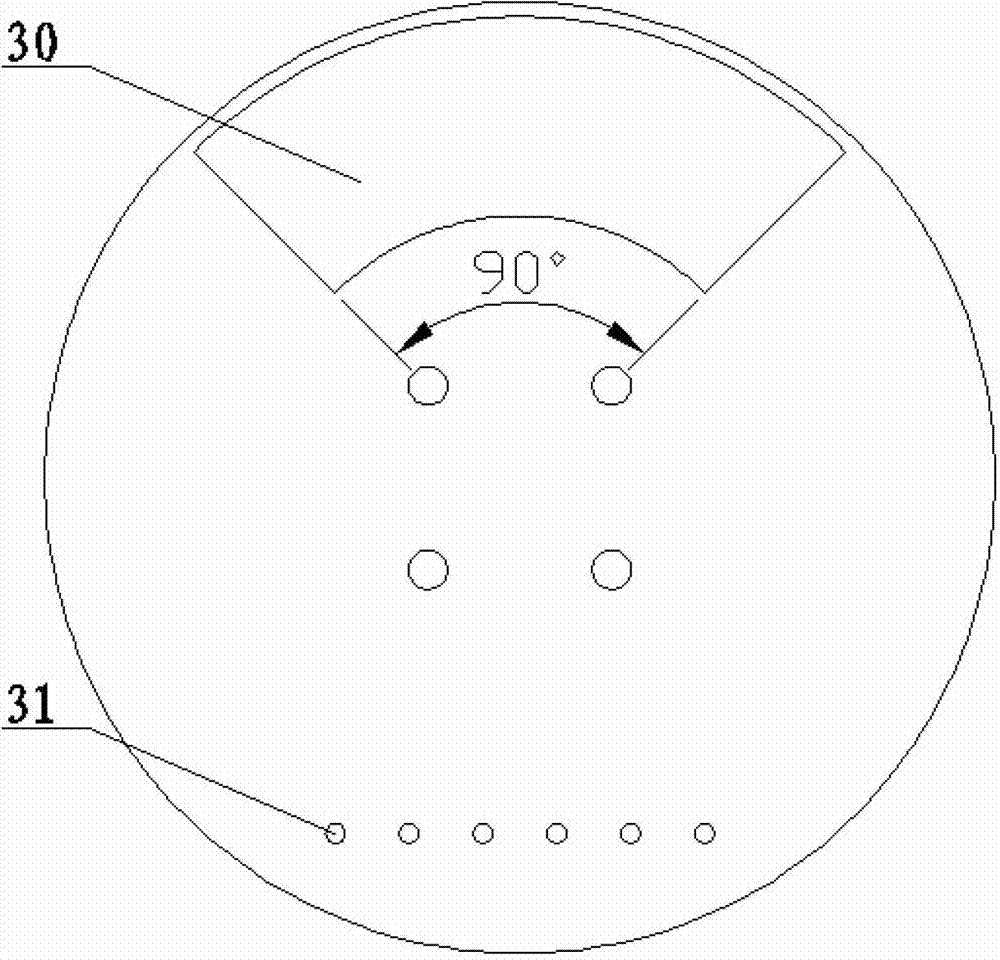

Full-automatic Chinese-date vertical type date pit removing and slicing all-in-one machine

InactiveCN103082378ASimple structureLow crack rateFruit stoningMetal working apparatusEngineeringFissure

A full-automatic Chinese-date vertical type date pit removing and slicing all-in-one machine comprises an actuating unit, a feed mechanism, a date pit removing mechanism, a slicing mechanism and a blanking mechanism. The feed mechanism can guarantee that Chinese-dates can be loaded automatically, each Chinese-date can be vertically arranged in each Chinese-date hole, and every Chinese-date hole can contain one Chinese-date. According to the date pit removing mechanism, the date pit can be removed by adopting of a packing leather type flexibility positioning centralizer mechanism and a step of inserting the date pit at first and ejecting the date pit at last, fissure rate of removing the date pit is low, and the date pit can be fast separated from date flesh. According to the slicing mechanism, a method that a cutter does not move and a rotating plate rotates is adopted, the Chinese-date can be fast and transversely cut into a ring piece shape and the low slicing breaking ratio is guaranteed. The blanking mechanism can guarantee that cut date slices can smoothly enter a material collecting groove. The actuating mechanism guarantees that four actions of feeding, date pit removing, slicing and blanking can be finished smoothly. According to the full-automatic Chinese-date vertical type date pit removing and slicing all-in-one machine, integration of Chinese-date orientation and vertical type date pit removing and vertical type slicing is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

High-manganese medium-carbon peritectic steel continuous casting crystallizer casting powder and preparation method thereof

ActiveCN103121090AReduced infrared transmission performanceReduced radiative heat transfer performanceLiquid slagManganese

The invention discloses high-manganese medium-carbon peritectic steel continuous casting crystallizer casting powder and a preparation method thereof. 2%-8% of MnO is added into the casting powder, infrared transmitting performance of the casting powder is obviously reduced, infrared light transmittance of the casting powder is reduced, radiant heat transfer performance of the casting powder is reduced, the cracking rate can be reduced and can be effectively controlled under 0.8%, and therefore production cost is greatly reduced. Through effective control on crystallization performance of the casting powder, the condition that crystallization occurs in liquid flux films can be effectively avoided, and therefore the production accidents such as bonding and even bleed-out can be effectively avoided.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Wood material drying method

InactiveCN106403519AReduce the chance of crackingReduce stressDrying gas arrangementsWood dampingAfter treatmentDrying time

The invention discloses a wood material drying method and belongs to the technical field of wood processing. The wood material drying method specifically comprises the following steps: (1) pre-treating a wood material; (2) pre-drying the wood material; (3) deeply drying the wood material; and (4) performing after treatment after the wood material is dried. The method disclosed by the invention can commendably prevent phenomena of deformation, cracking and flexure of the wood material in a drying process and can also shorten the drying time by 30% to 35%; the cracking probability of the wood material is reduced by more than two times; and the surface of the dried wood material is smoother, so the wood material drying method has quite good promotion and application values.

Owner:阜南县环宇柳木工艺制品有限公司

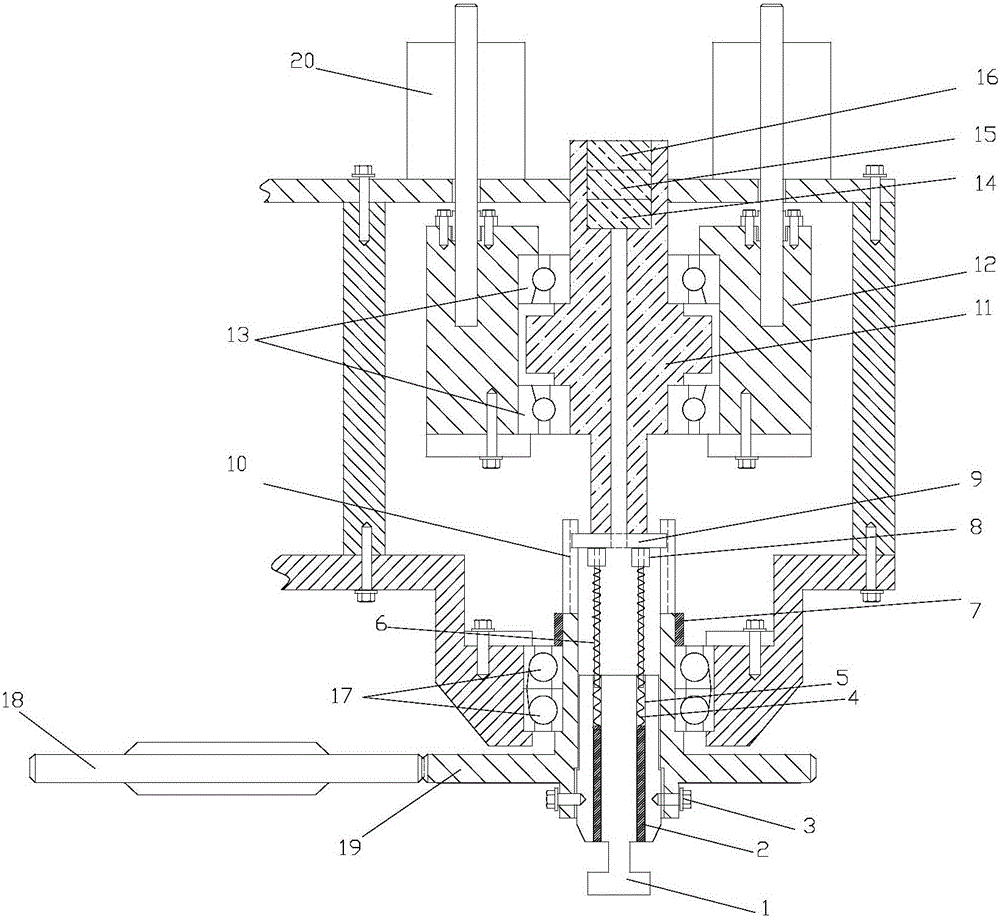

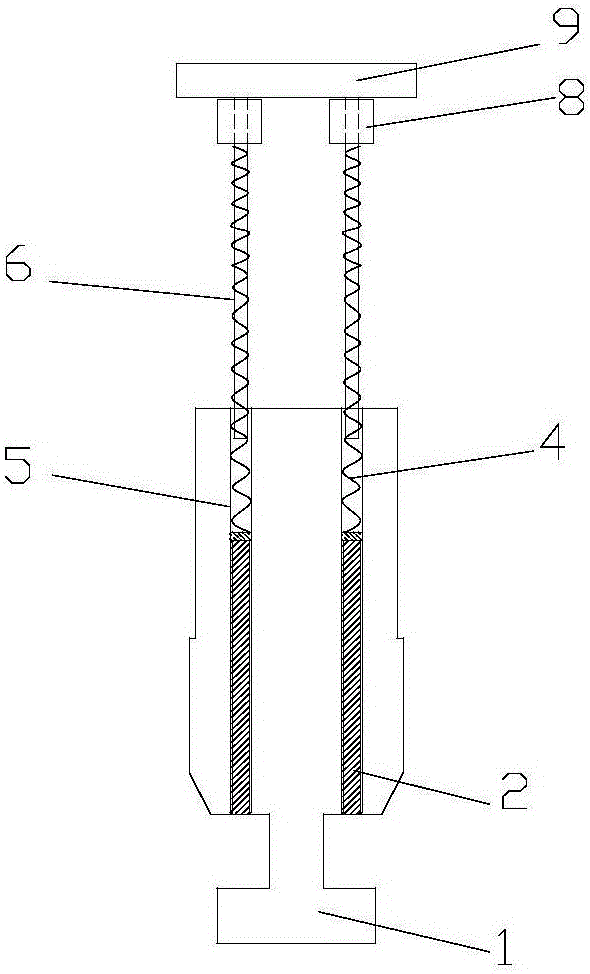

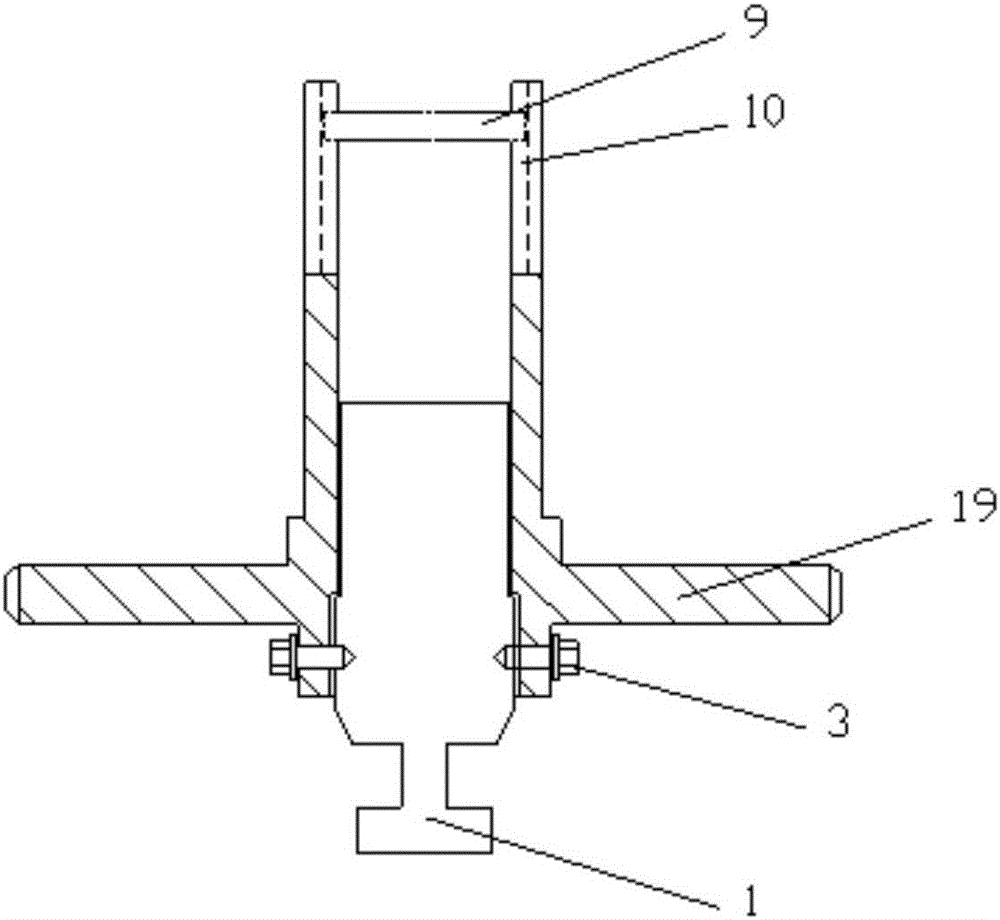

Friction stirring device with adjustable filling pressure and welding method

ActiveCN105921877AUniform and moderate strengthControl thrustNon-electric welding apparatusLinear motorWelding defect

The invention discloses a friction stirring device with adjustable filling pressure and a welding device. The friction stirring device comprises a framework, wherein two linear motors are mounted on the framework; each linear motor is connected with a slider; a pair of first bearings is mounted in each slider; a push rod is clamped between each pair of the first bearings; the lower end of each push rod is fixedly connected with a support plate; each support plate is fixedly connected with a material guide bar; the lower part of the framework is fixedly connected with a support frame; second bearings are nested in the support frame and arranged on a rotary device in a sleeving manner; the rotary device is fixedly connected with a stirring head body; material guide holes are formed in the stirring head body; a metal filling bar and one of the material guide bars are sequentially arranged in each material guide hole; and a spring and a pressure sensor are arranged on each material guide bar in a sleeving manner. The invention solves the problem that welding defects are caused by metal loss of conventional friction stirring heads; the pushing forces of the linear motors can be controlled to ensure that the filling pressure of the metal filling bars can be controlled according to actual demands; and the propulsion is more scientifically selected to guarantee moderate and appropriate metal filling.

Owner:JIANGSU UNIV OF SCI & TECH

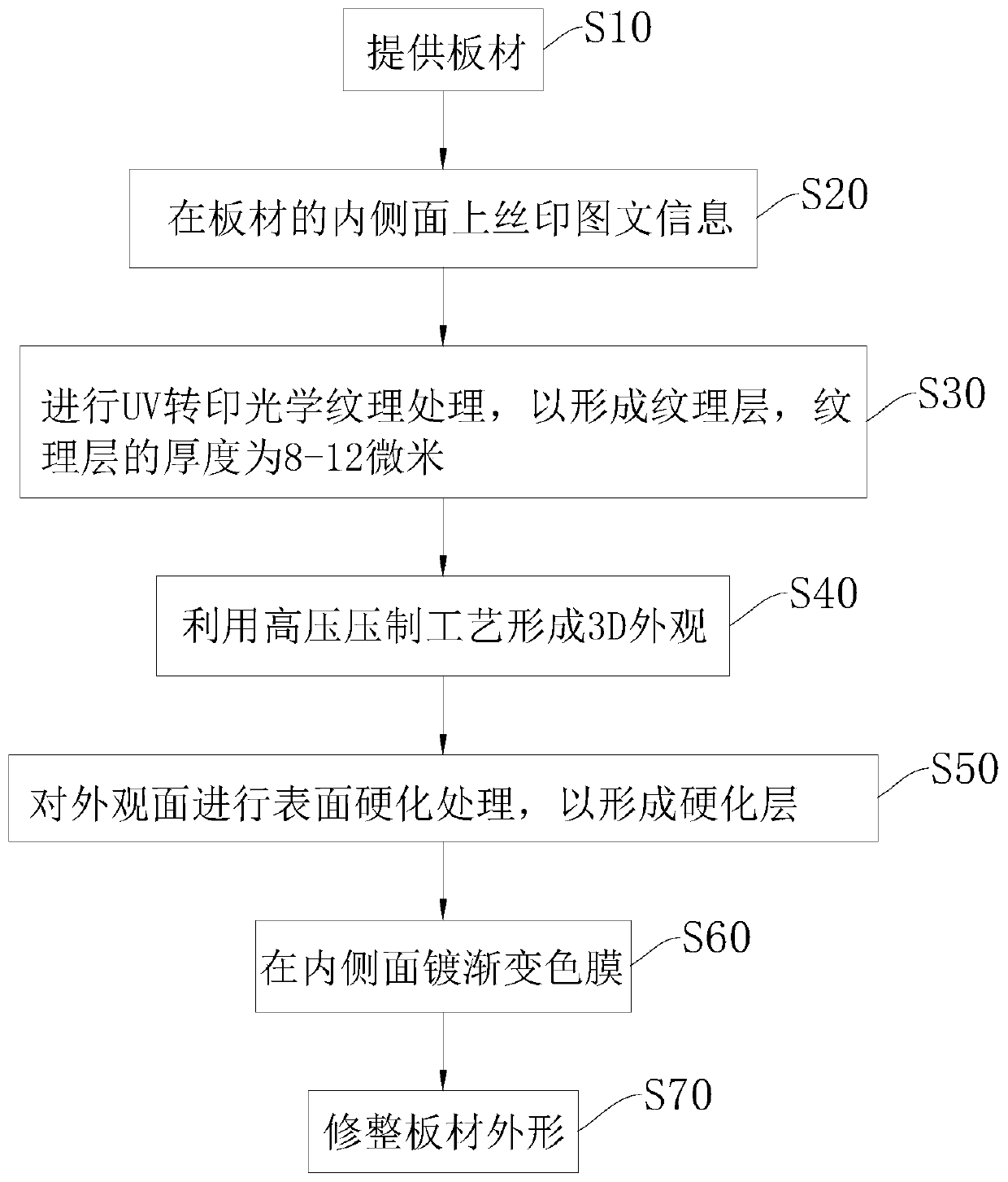

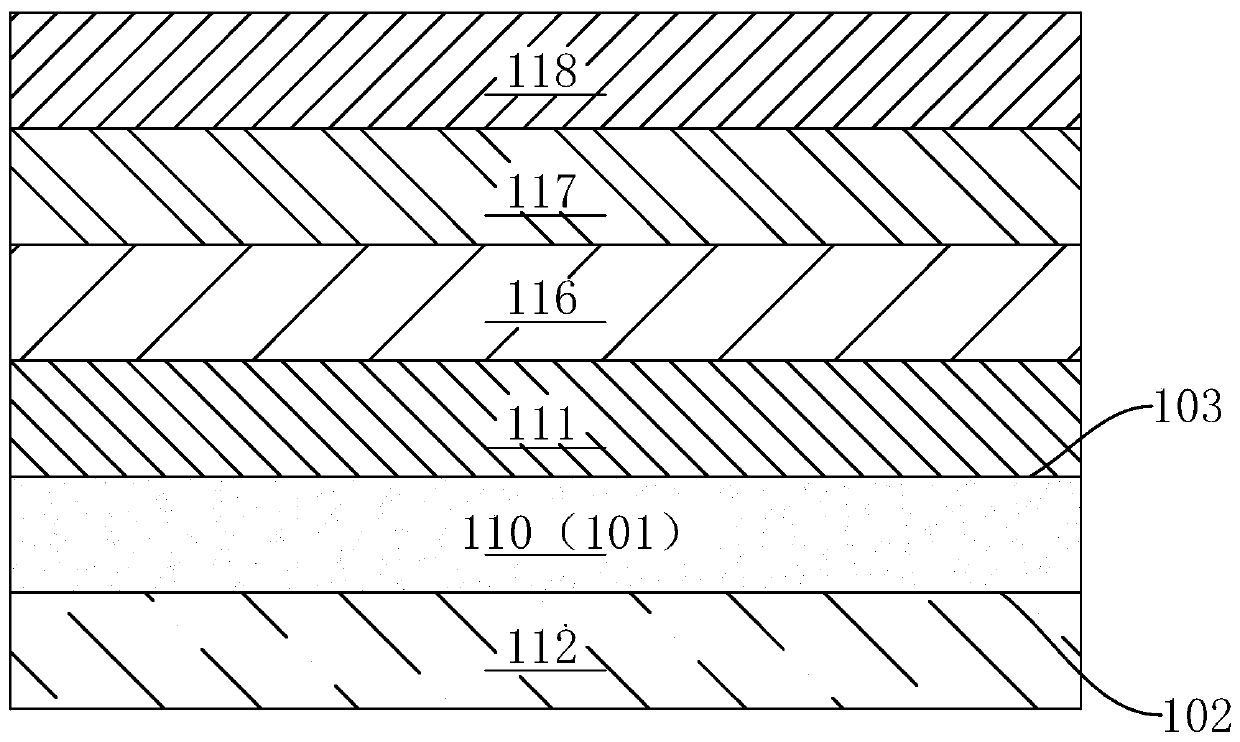

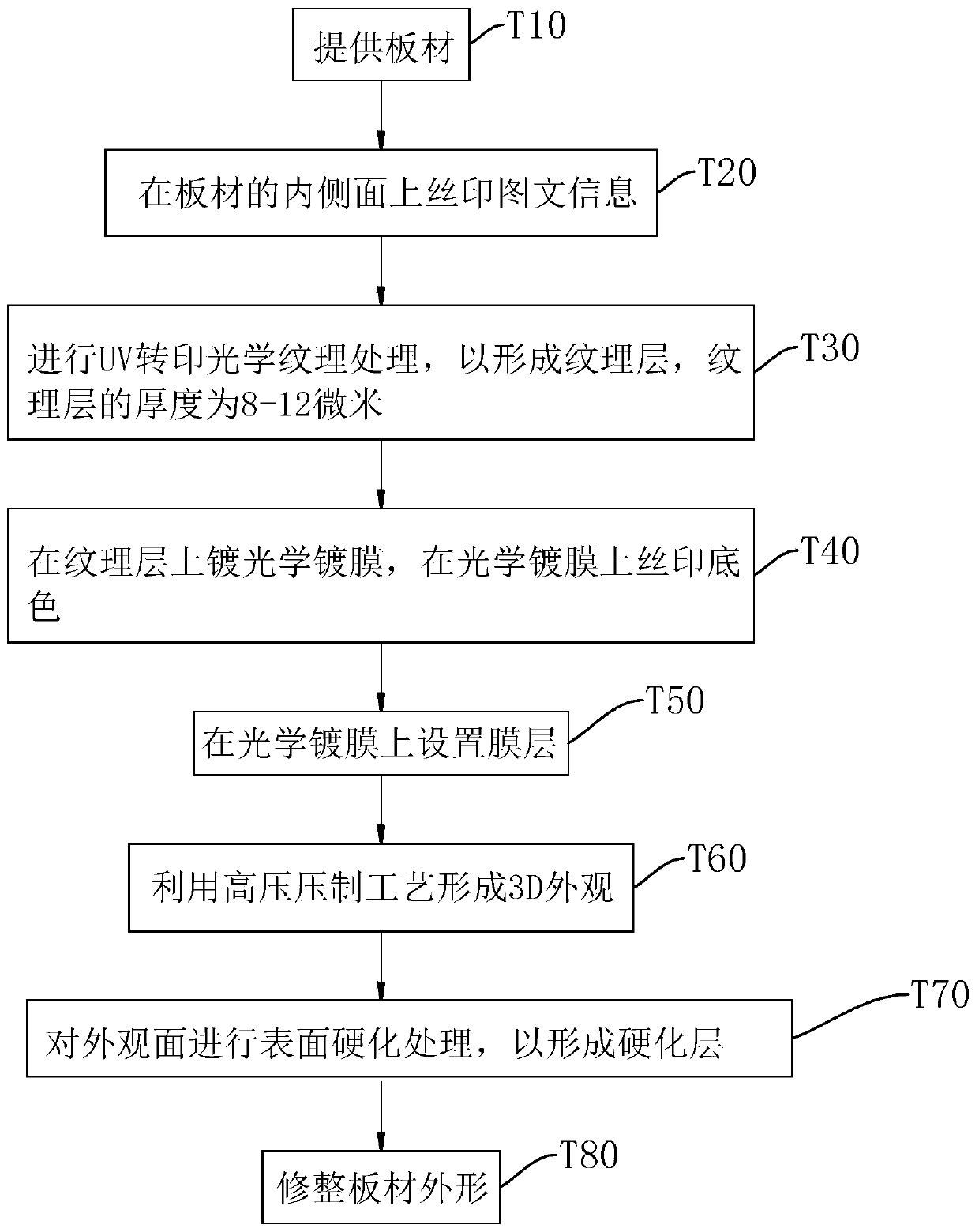

Electronic device, shell assembly and processing method thereof

InactiveCN109890156AImproved drop resistanceStrong structural strengthOrnamental structuresCasings/cabinets/drawers detailsMaterials scienceElectronic equipment

The invention discloses an electronic device, a shell assembly and a processing method thereof. The processing method comprises the following steps: providing a plate; performing UV transfer optical texture treatment on the inner side surface of the plate to form a texture layer, wherein the thickness of the texture layer is 8-12 um; forming a 3D appearance by using a pressing process; performingsurface hardening treatment on the appearance surface to form a hardened layer; and finishing the appearance of the plate. According to the processing method of the shell assembly, the texture layer with a thickness of 8-12 um is combined with the hardened layer, so that the anti-falling characteristic of the plate can be improved, the processed shell assembly has high structural strength, and theprobability of cracking of the shell assembly in the using process or falling process is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Casting defect eliminating method

The invention discloses a casting defect eliminating method which belongs to the field of casting treatment. The casting defect eliminating method provided by the invention comprises five steps: defect cleanup, bevel preparation, weld preheating, welding repair and postweld treatment, wherein the defect cleanup refers to eliminating common surface defects by grinding, and common crack defects andgreats defects are subjected to a next step; the bevel preparation refers to forming a U-shaped bevel in the defected position and the bevel surface is a smooth curved surface; the weld preheating refers to carrying out local preheating to the common defects and integral preheating to the great defects; the welding repair refers to carrying out 1-2 layers of resurfacing welding along the side surface of a bevel, further fully welding the concave part in the resurfacing welding position and repeating the step until the whole bevel is welded to be full completely; and the postweld treatment refers to carrying out dehydrogenation treatment to the common defects after being welded and annealing treatment to the great defects after being welded. By improving the welding method and optimizing the process parameters when repairing different defects, the invention greatly reduces the probability of adverse influencing factors occurring in defect repair process, saves the time spent in defect repair and achieves the effect of cost saving while ensuring the qualified rate of casting repair.

Owner:ANHUI MAGANG HEAVY MASCH MFG CO LTD

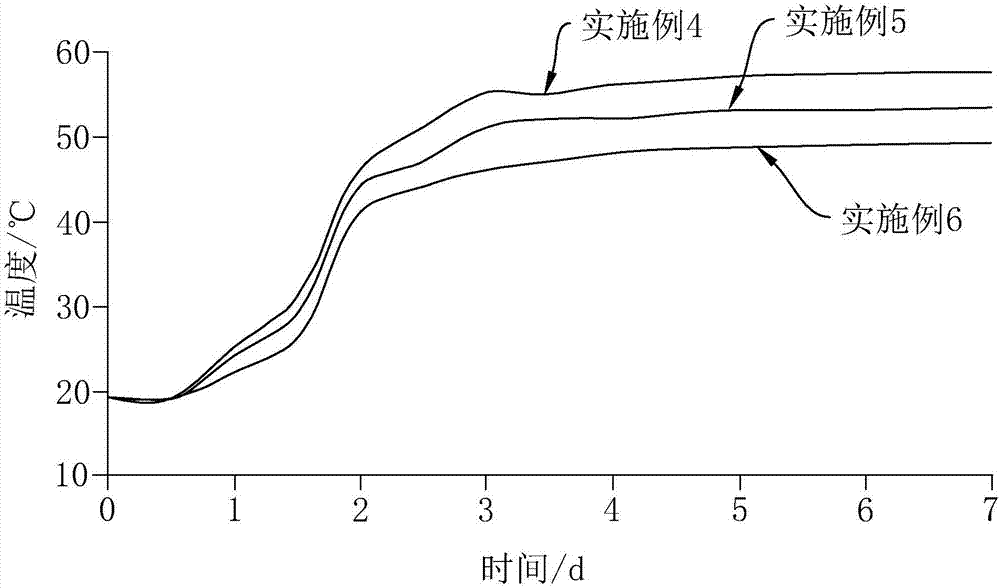

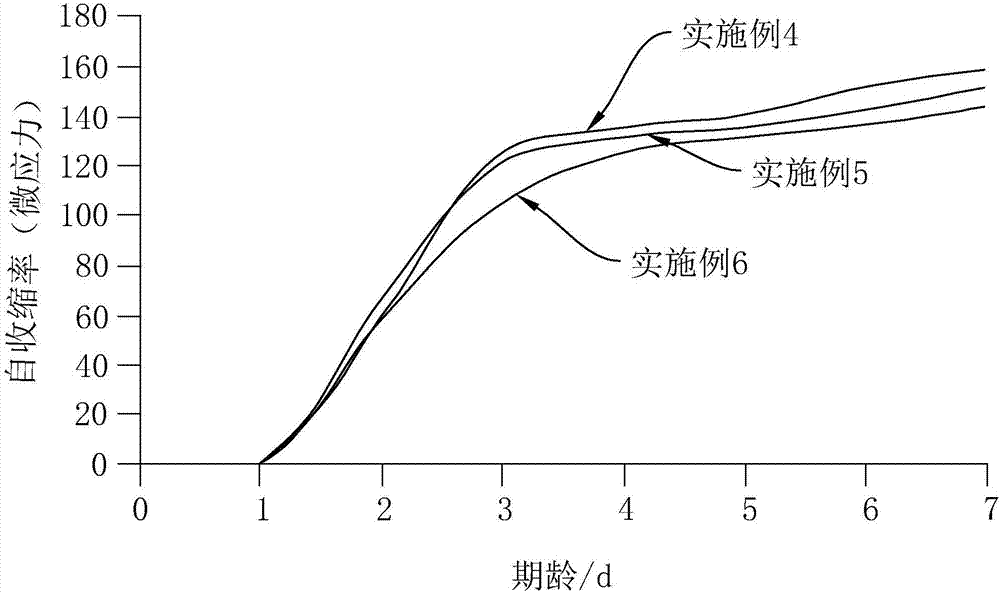

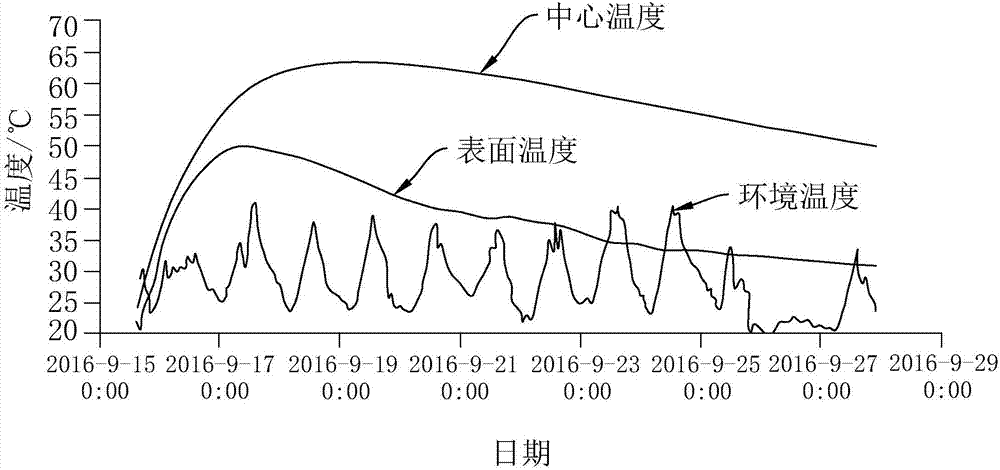

Concrete mixture for large volume concrete construction in autumn period and construction method of poured walls thereof

InactiveCN107382214AReduce heat of hydrationReduce absolute temperature riseWallsBuilding material handlingMass ratioSlag

The invention relates to a concrete mixture for large volume concrete construction in autumn period and a construction method of poured walls thereof. The concrete mixture comprises the following raw materials in parts by weight: 182-218 parts of cement, 775 parts of medium sand, 1048 parts of cobblestones, 170 parts of water, 145-181 parts of a mineral admixture, and 7.8 parts of an additive. The mineral admixture comprises coal ash and slag powder, the usage amount of the coal ash is 39-40% of the usage amount of a gelling material, the gelling material comprises cement and the mineral admixture, the additive comprises a water reducer, a water-proofing agent, and an expanding agent, and the mass ratio of the water reducer to the water-proofing agent to the expanding agent is 5:2:3. The construction method comprises the following steps: preparation before construction, weighing of raw materials, stirring of raw materials, pouring, vibrating and maintenance. Under the prerequisite that concrete strength is guaranteed, double mixing technology is employed, in order to reduce the usage amount of the total gelling material, reduce the absolute usage amount of cement, and improve the usage amount of the admixture; the usage amount of the coal ash in the admixture is improved, in order to reduce hydration heat and adiabatic temperature rise of the concrete, and reduce cracking risk of the concrete.

Owner:北京铁建永泰新型建材有限公司

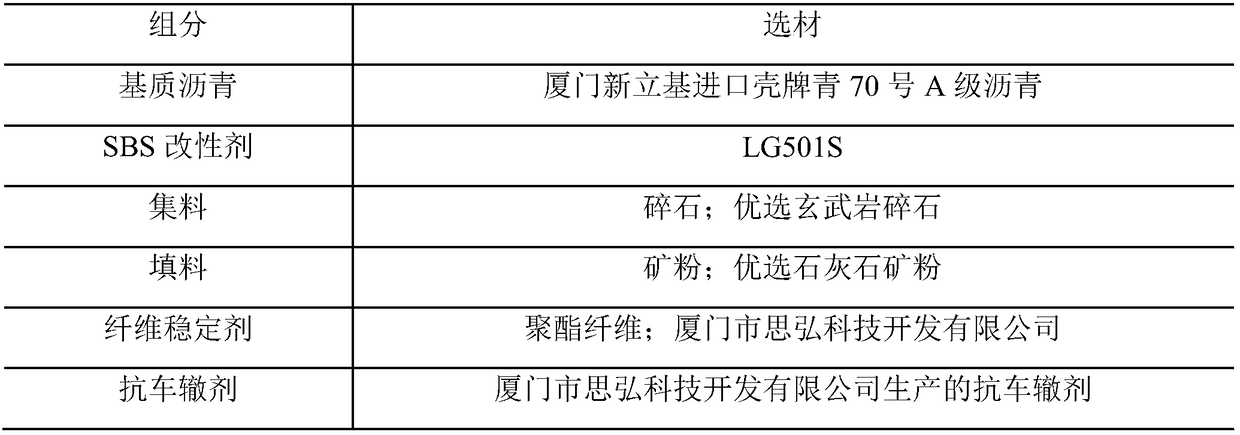

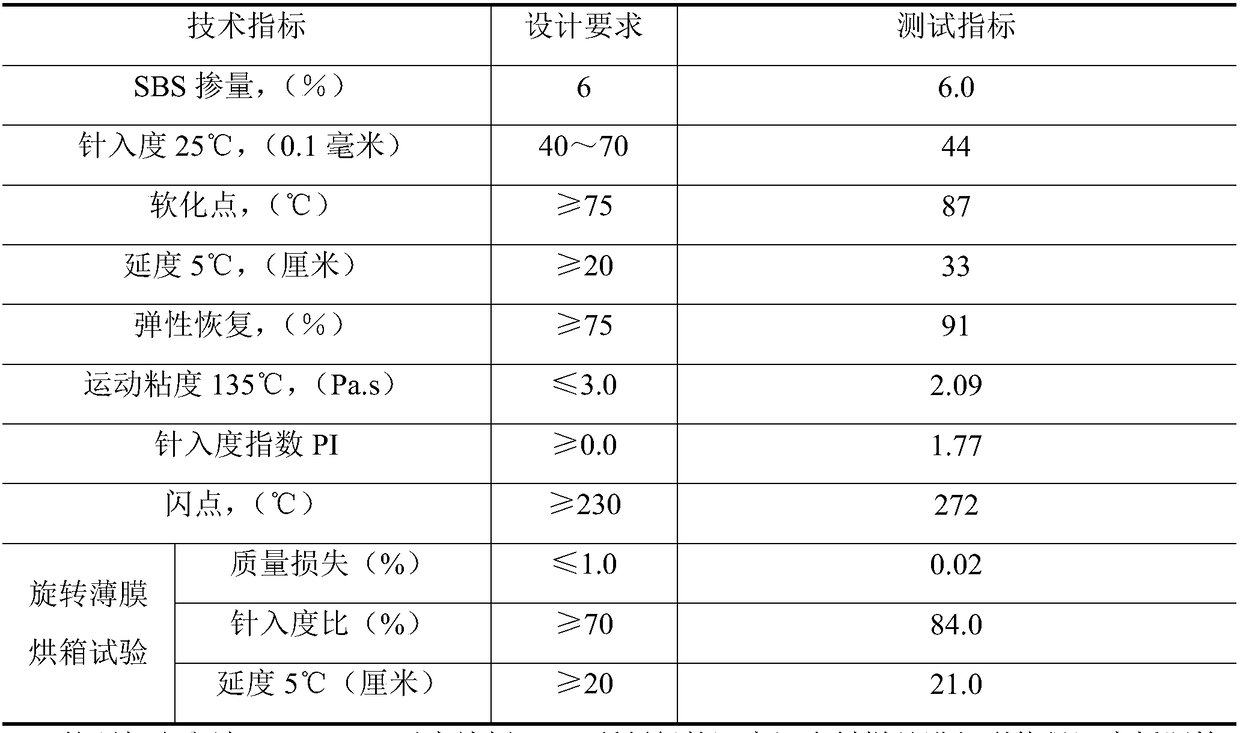

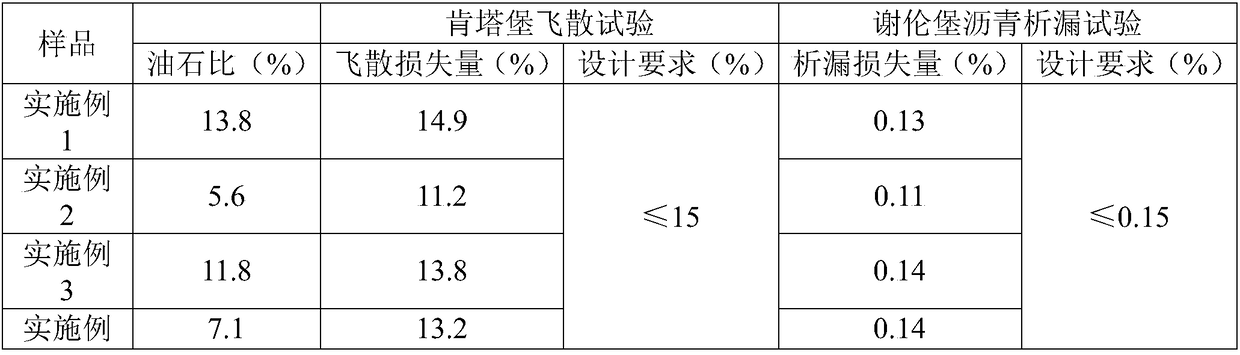

Asphalt mixture and production method thereof

ActiveCN109180077AImproves rutting resistanceImprove stress resistanceBuilding insulationsAsphaltPolymer chemistry

The invention discloses an asphalt mixture and a production method thereof and relates to the field of building materials. The asphalt mixture solves the problem that the existing asphalt mixture forthe airport runway has poor stability and anti-rutting ability, and comprises 4 to 12 wt% of modified asphalt, 72 to 88 wt% of aggregate, 5 to 10 wt% of a filler, 0.5 to 3 wt% of a fiber stabilizer and 0.5 to 3 wt% of an anti-rutting agent and has an asphalt-aggregate ratio of 5.6 to 14%. The modified asphalt comprises matrix asphalt and SBS and the weight of the SBS is 5-8 wt% that of the matrixasphalt. The asphalt mixture has the advantages of high dynamic stability, high temperature stability, strong rutting resistance and good water stability, and is suitable for airport runways.

Owner:厦门市政沥青工程有限公司 +2

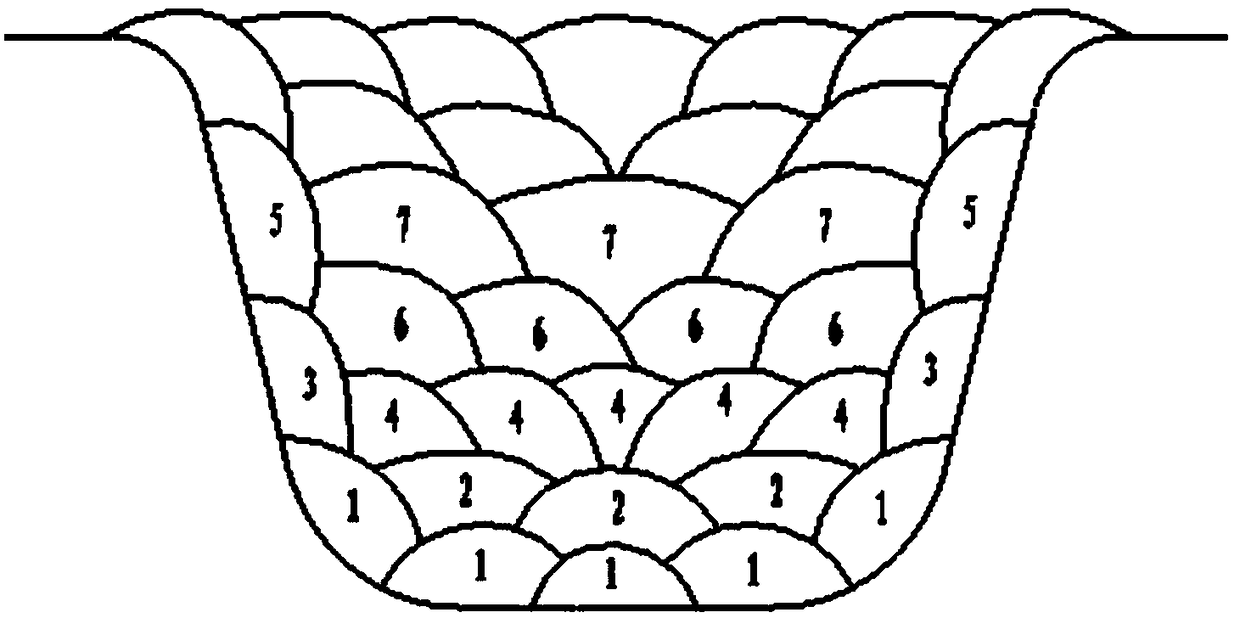

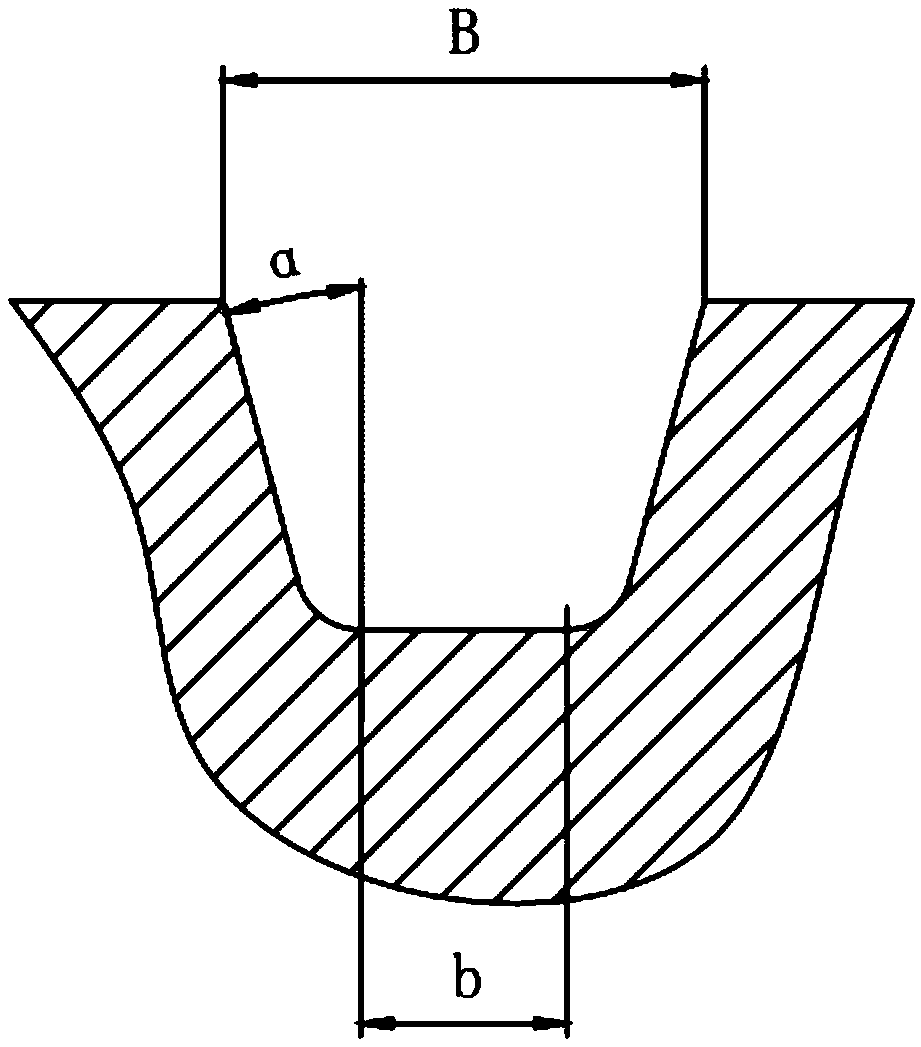

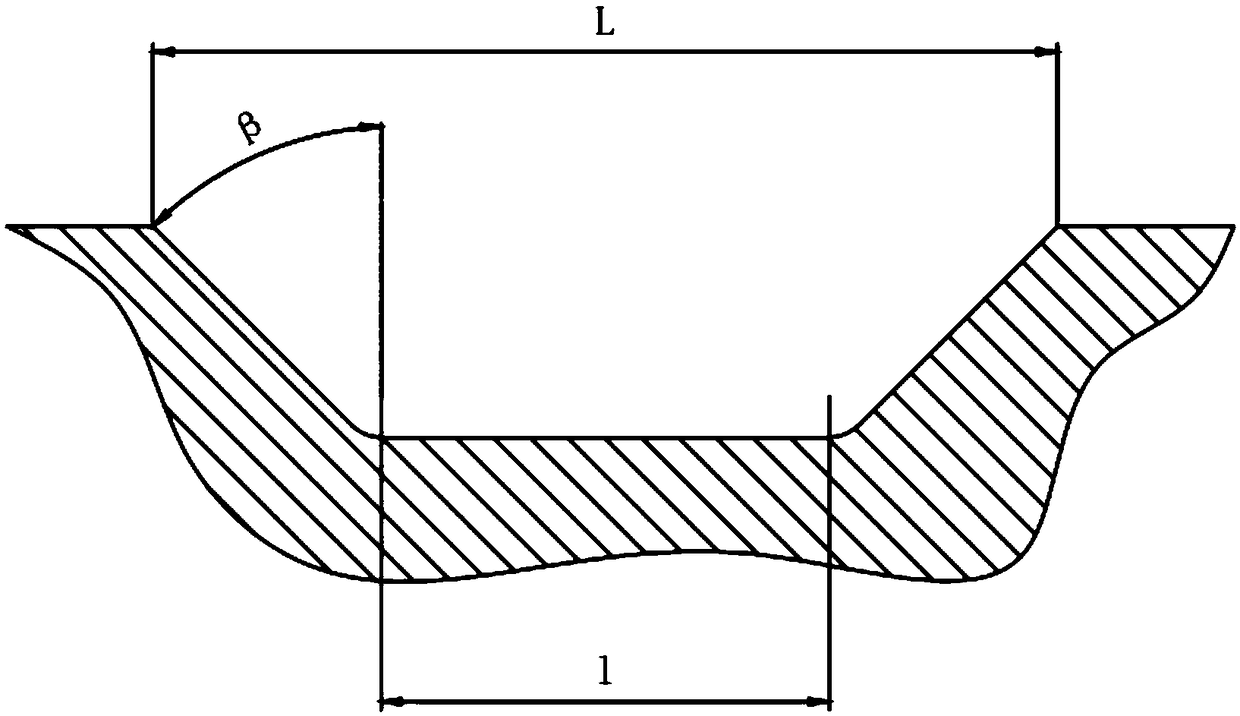

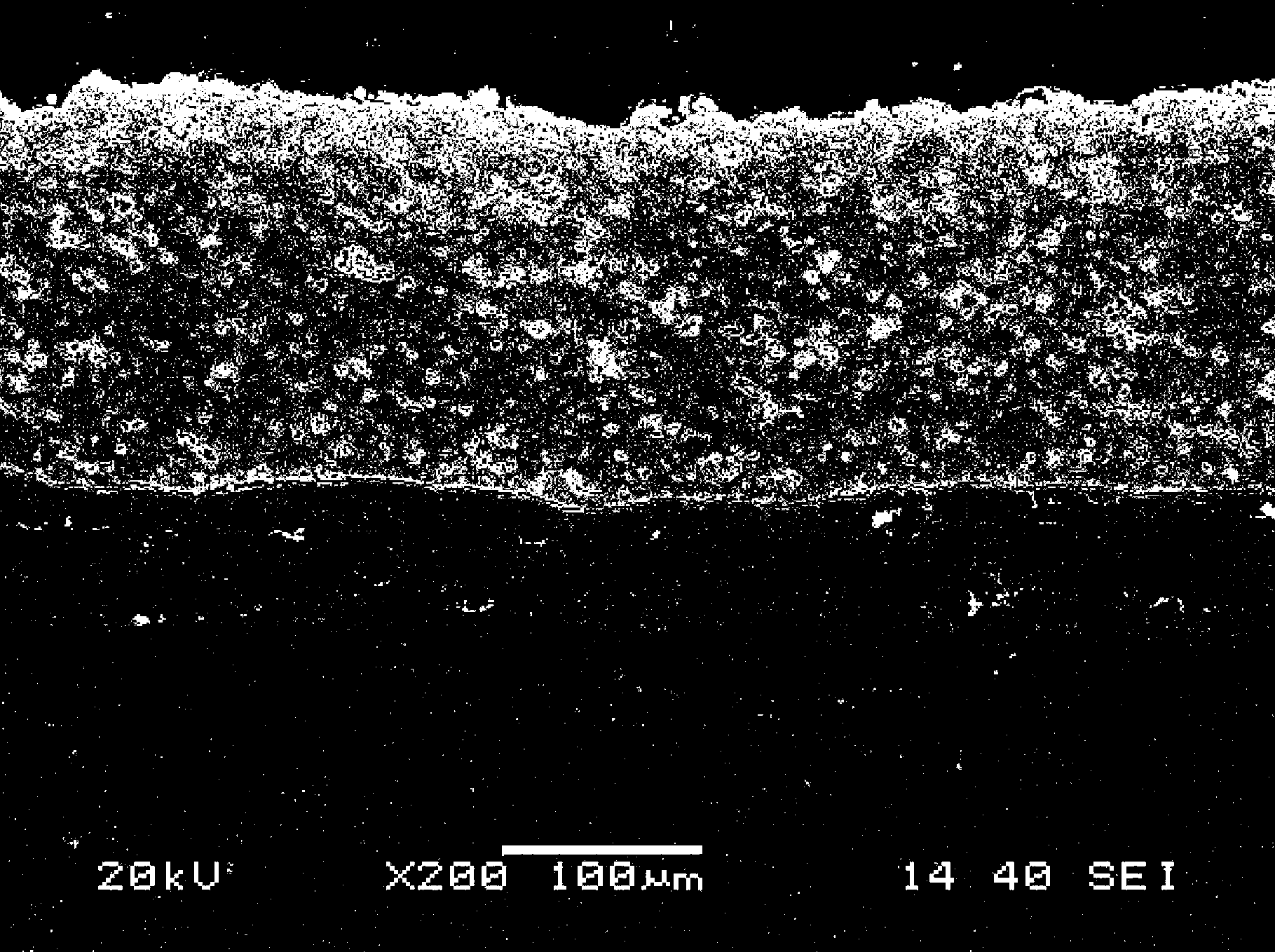

Laser surfacing modification method for thermal barrier coating

ActiveCN103266295AHigh bonding strengthImprove thermal fatigue lifeMolten spray coatingEfficient propulsion technologiesStress concentrationThermal fatigue

The invention relates to a laser surfacing modification method for a thermal barrier coating. The method comprises the following steps of: firstly, carrying out washing and sand blasting on the surface of a base body; then, preparing the thermal barrier coating in a thermal spraying state on the surface of the base body; then, designing shape, size, arrangement rule and distribution density of laser modification unit bodies in a pile nail structure to be prepared in the thermal barrier coating; then, adjusting the process parameters of a laser according to a design model; then, performing laser modification to the thermal barrier coating; and finally, performing the stress relief annealing treatment to the laser modified thermal barrier coating. With the adoption of the method for arranging discontinuous and dispersed intensifying unit bodies in the pile nail structure in the thermal barrier coating, the thermal barrier coating can not only generate characteristic of soft and hard alternate change, but also generate the 'pinning effect', thus not only relieving stress concentration at the crack tip of the coating and reducing the crack rate of the coating, but also extremely improving the bonding strength of the coatings, prolonging the thermal fatigue service life of the thermal barrier coating, improving the tissue structure of the coating and improving the compactness of the coating.

Owner:FOSHAN TAOYUAN INST OF ADVANCED MFG

Environmental protection material with insect expelling and purifying functions, and manufacturing method and application thereof

InactiveCN104693830AEasy to handleHas the function of repelling insects and purifyingCoatingsFiberEngineering

The invention relates to an environmental protection material with insect expelling and purifying functions, and a manufacturing method and an application thereof, and belongs to the field of the environmental protection material. The environmental protection material comprises the following components in percentage by mass: 10-15% of plant fiber, 30-40% of traditional Chinese medicine residue, 28-35% of glue and 18-25% of additive. The environmental protection material has the following beneficial effects: the raw materials of the environmental protection material are agricultural wastes and pharmaceutical wastes, the processing problem of the agricultural wastes is solved, and the processing problem of the pharmaceutical wastes is solved at the same time, the corruptible is transformed into mysterious life, the earth is protected and the environment is purified.

Owner:杨国桢 +2

Input validation method and device

InactiveCN103701600AImprove securityReduce the probability of crackingUser identity/authority verificationDigital data protectionValidation methodsData mining

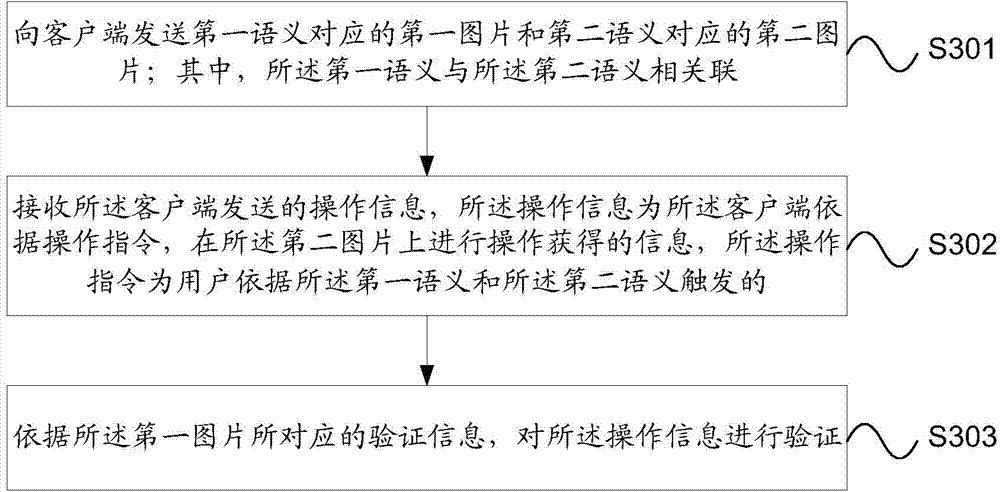

The embodiment of the invention provides an input validation method. The input validation method comprises the following steps: sending a first picture corresponding to a first semantic meaning and a second picture corresponding to a second semantic meaning to a client, wherein the first semantic meaning is associated with the second semantic meaning; receiving operation information sent by the client, wherein the operation information is information obtained by operating the second picture through the client according to an operation instruction, and the operation instruction is triggered by a user according to the first semantic meaning and the second semantic meaning; validating the operation information according to validation information corresponding to the first picture. The embodiment of the invention also provides an input validation device. According to the technical scheme provided by the embodiment of the invention, the safety of input validation is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

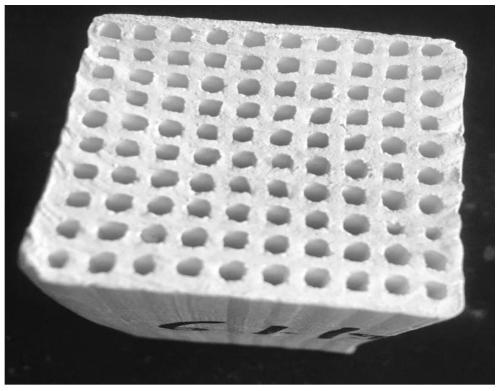

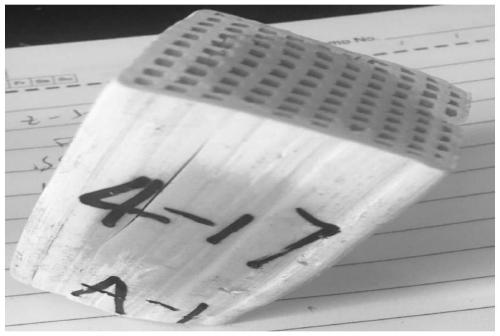

Honeycomb hydrophobic molecular sieve adsorbent as well as preparation method and application thereof

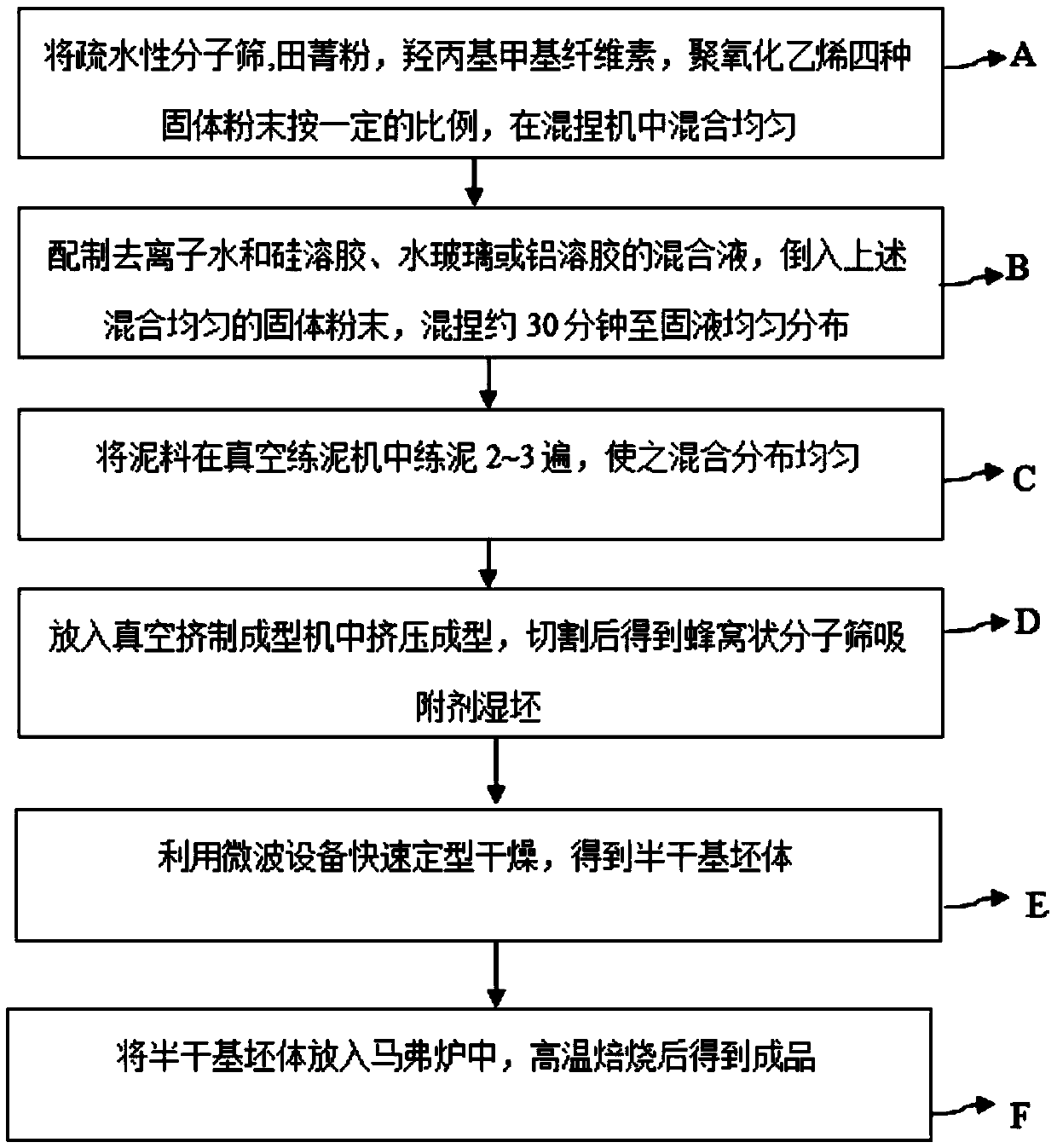

ActiveCN111203175ASolve the problem that it is not easy to form evenly dispersed mudReduce the probability of crackingGas treatmentOther chemical processesMolecular sieveAdhesive

The invention relates to the field of VOCs waste gas treatment, in particular to a honeycomb hydrophobic molecular sieve adsorbent and a preparation method and application thereof. Raw materials of the honeycomb hydrophobic molecular sieve adsorbent comprise a hydrophobic molecular sieve and an adhesive, the adhesive comprises an organic adhesive and an inorganic adhesive, and the inorganic adhesive is one of water glass and alkaline silica sol; and the mass ratio of the hydrophobic molecular sieve to the organic binder to the inorganic binder is 100:(40-110):(18-23). According to the invention, the problem that the high-hydrophobicity molecular sieve is not easy to form uniformly dispersed pug is solved, the cracking rate of the honeycomb hydrophobic molecular sieve adsorbent is greatly reduced, the preparation period is short, the preparation method is simple, and the application of the honeycomb-shaped hydrophobic molecular sieve adsorbent in the VOCs treatment industry is facilitated.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

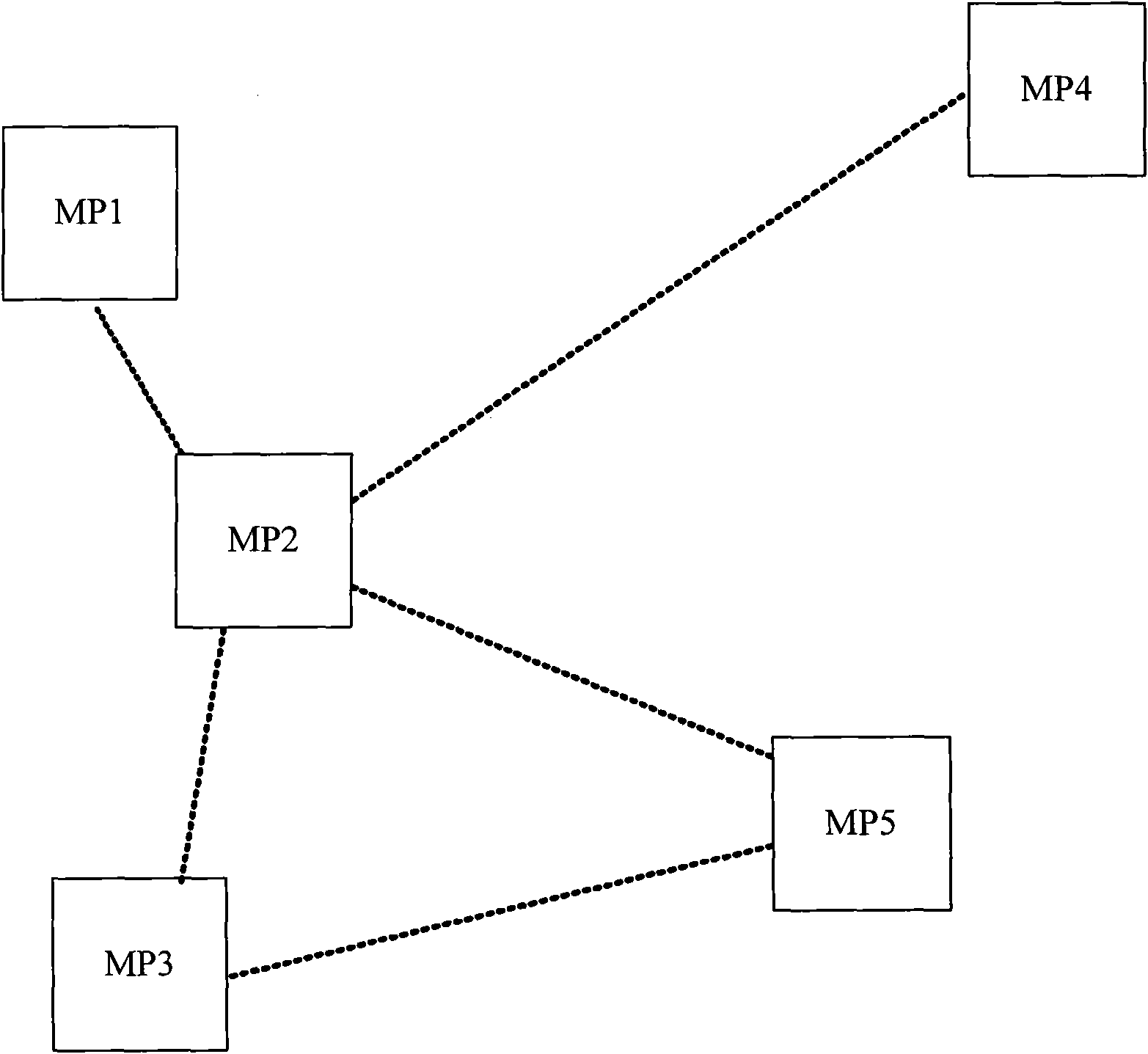

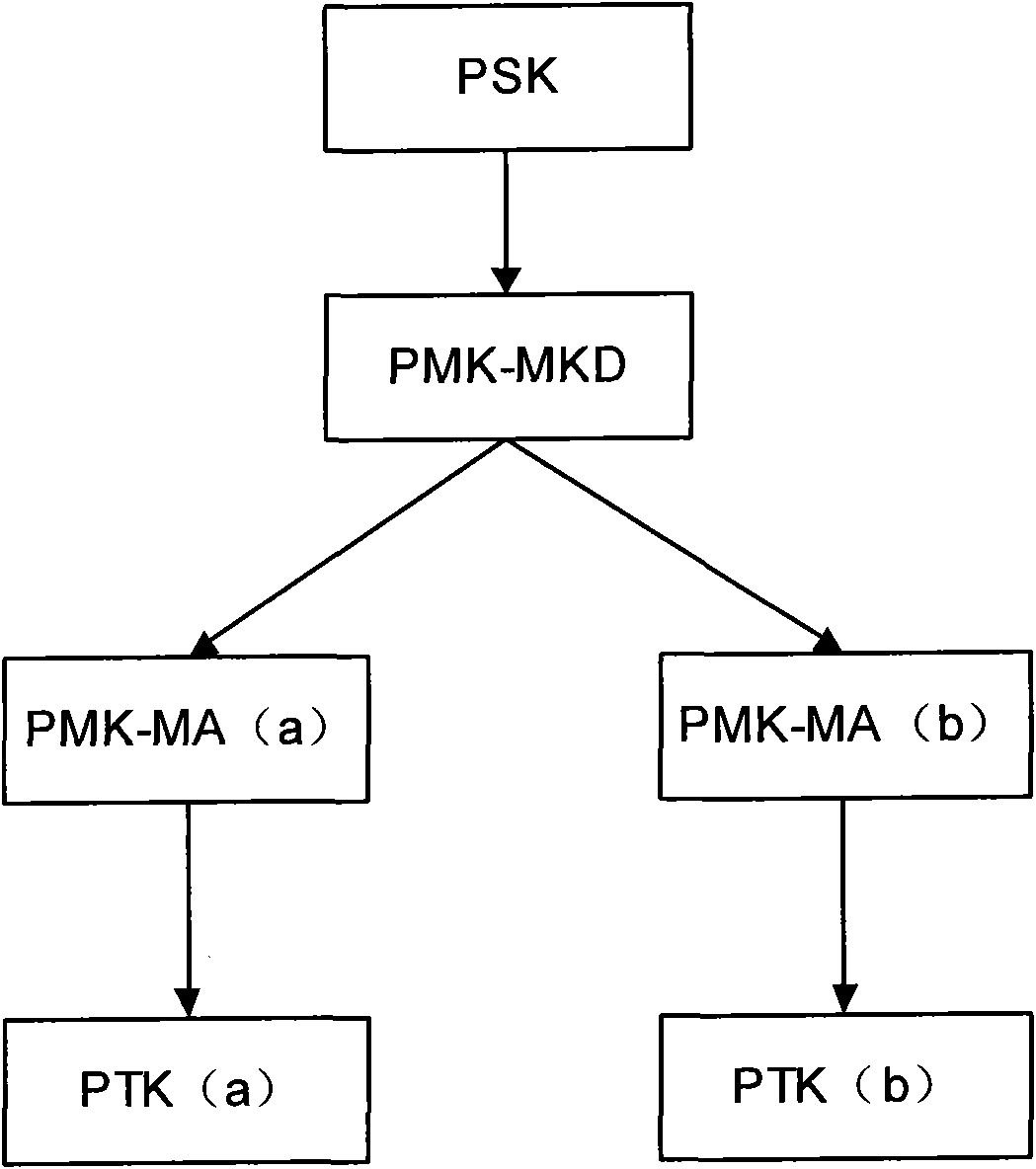

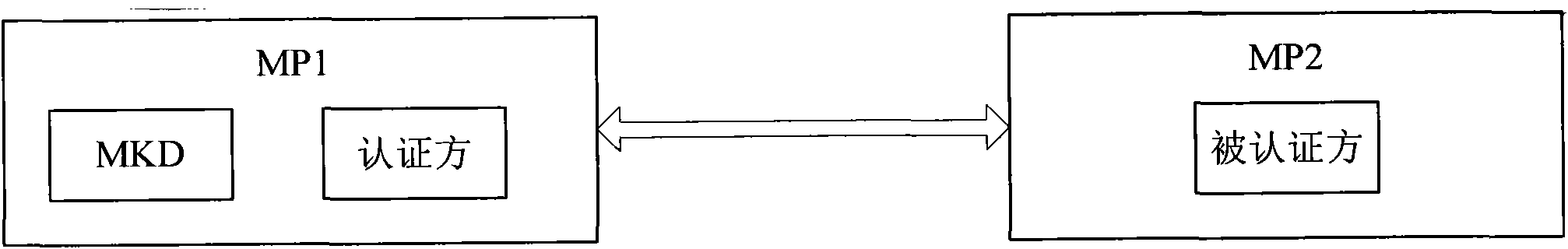

Distributed MESH network key management method and wireless access point device

InactiveCN102056163AReduce the probability of crackingImprove securityNetwork topologiesSecurity arrangementPasswordSecret code

The invention provides a distributed MESH network key management method which comprises the following steps: dividing a MESH network into a plurality of MKD areas by taking an authentication party as a center, taking an MP (mesh access point) as the authentication party as an MKD (MESHKey Distributor), forming an MKD area by the MP and all authenticated parties MP taking the MP as the authentication party, distributing MPTK-Anonce for the authenticated parties in the MKD area through the MKD in each MKD area and enabling the authenticated parties to negotiate a key on each layer according to the MPTK-Anonce distributed by the MKD in the MKD area. The invention also provides an MP. With the adoption of the distributed MESH network key management method and the MP, when any MP is added intodifferent MKD areas as the authenticated parties, a password is negotiated in the different MKD areas according to different MPTK-Anonce, so that the safety of the key management is increased.

Owner:NEW H3C TECH CO LTD

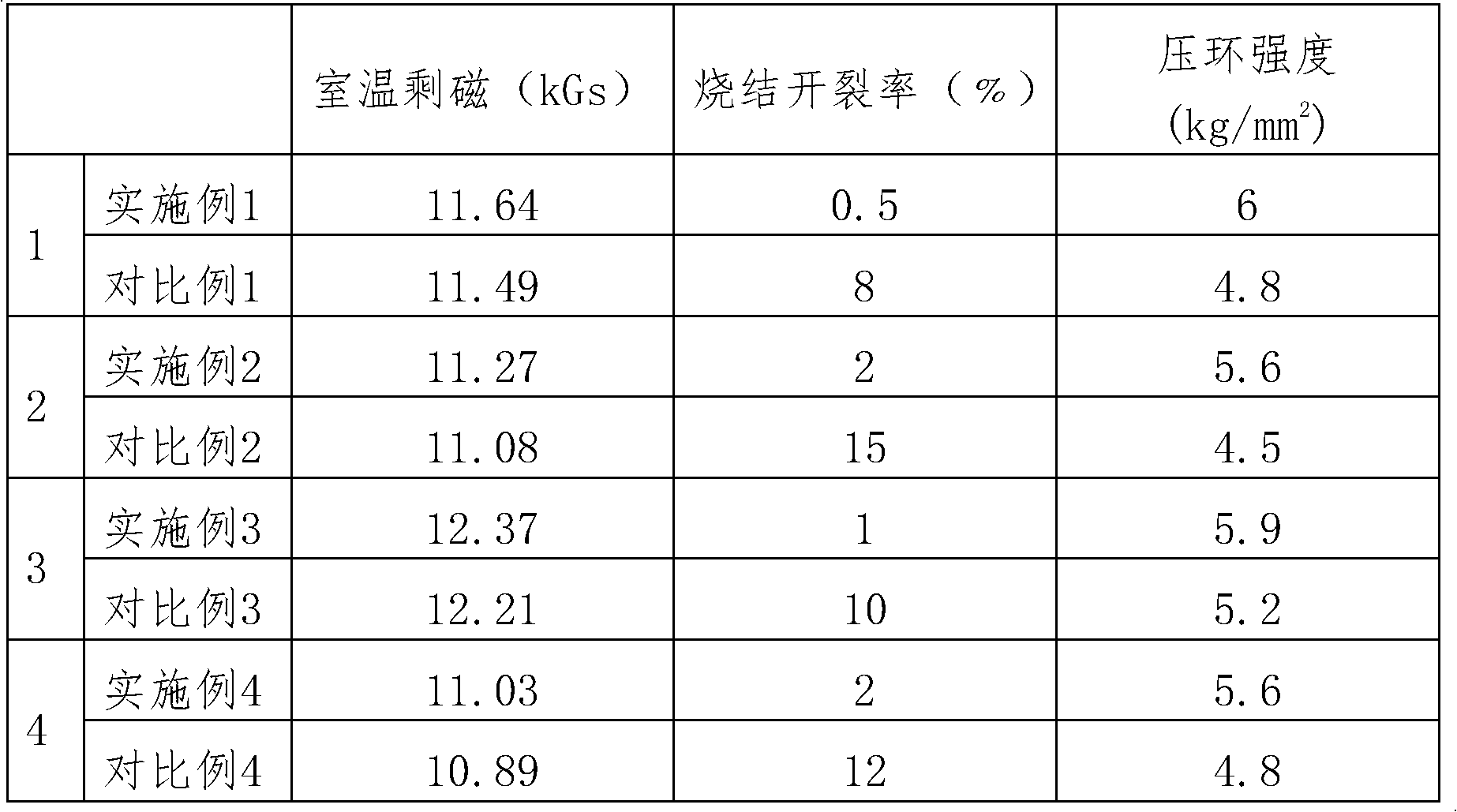

Heat treatment method of radiation or multi-pole orientation magnet ring

ActiveCN102601367AReduce the probability of crackingImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureUltimate tensile strengthAtmosphere

The invention relates to a heat treatment method of radiation or multi-pole orientation magnet ring. The heat treatment method is characterized by comprising the following steps: putting magnet ring sintering blanks into a feed box, which is uniformly distributed with a layer of sintering filler powder at the bottom; placing the feed box into a vacuum sintering furnace; deflating and processing the sintering blanks by atmosphere sintering. The improved heat treatment method can significantly improve the performance of radiation or multi-pole orientation magnet rings, especially thin-walled and polar anisotropy products, and significantly reduces the cracking rate of the magnet ring products, improves the strength thereof, ensures size consistency thereof and reduces operative difficulty of the subsequent processing.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Novel oxidizing-resistant nanometer copper soldering paste and preparation method and application thereof

InactiveCN107267938APrevent oxidationPrevent surface oxidationTransportation and packagingSemiconductor/solid-state device detailsOxidation resistantHigh temperature electronics

The invention relates to novel oxidizing-resistant nanometer copper soldering paste and a preparation method and application thereof. By adopting a magnetron sputtering process, the surface of nanometer copper powder is evenly coated with a metal film. Silver, gold and the like can be selected as the components of the metal film as required; then a traditional nanometer copper soldering paste formula continues to be used, a proper amount of forming auxiliaries are added; and finally, the novel oxidizing-resistant nanometer copper soldering paste resistant to oxidizing and cracks is prepared. Compared with the prior art, according to the novel nanometer copper soldering paste, mutual connection between a chip and a substrate can be achieved by means of a low-temperature sintering process or a pressurizing low-temperature sintering process, a traditional nanometer copper soldering paste function is achieved; and oxidizing resistance, crack initiation resistance and an extending performance are achieved at the same time, the novel oxidizing-resistant nanometer copper soldering paste can be used in large-power high-temperature electronic device packaging, and is especially suitable for packaging of third-generation semiconductor devices, after packaging, a connector is good in performance, fault-free service under high temperature can be achieved for a long time, and the novel nanometer copper soldering paste is matched with an existing lead-free solder packaging process.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

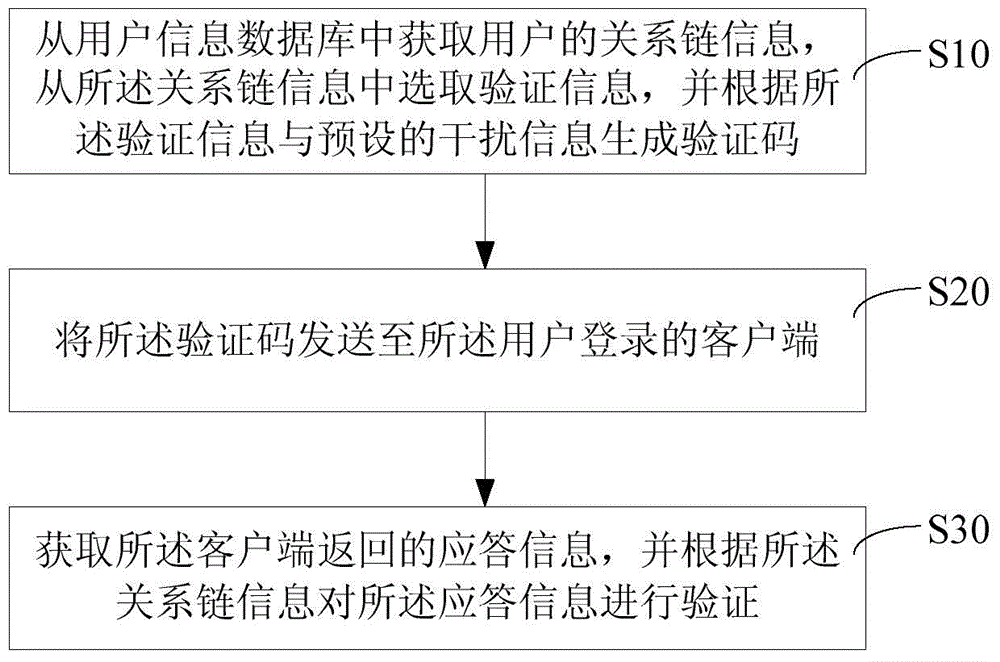

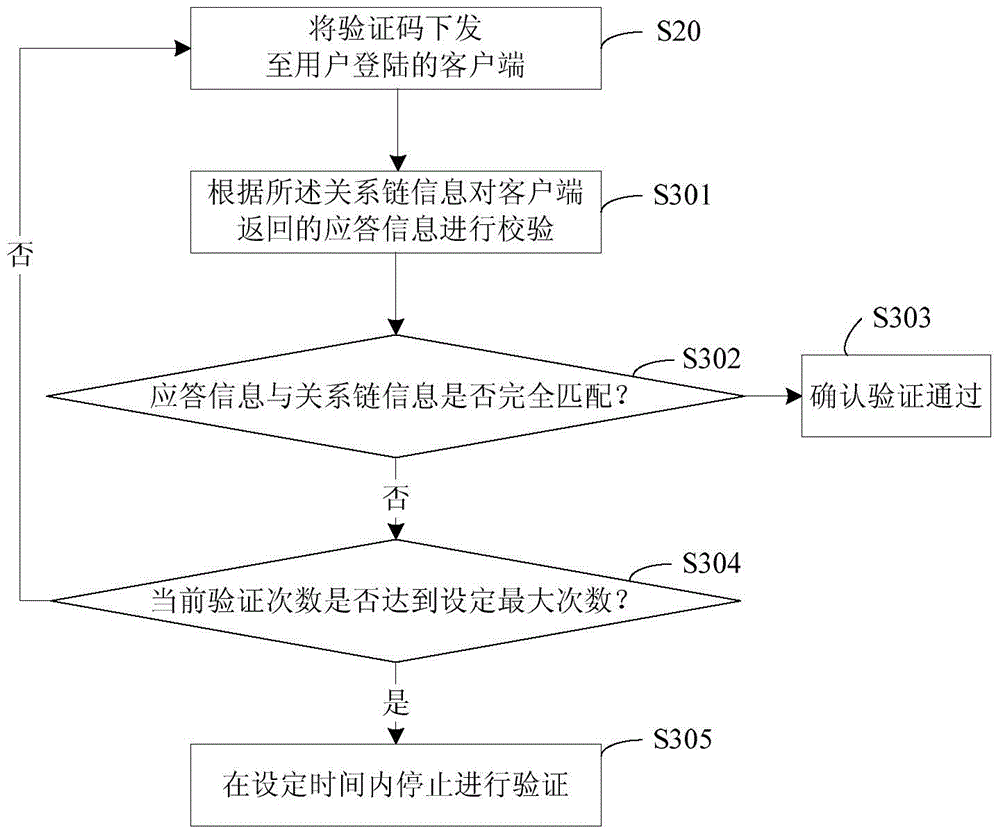

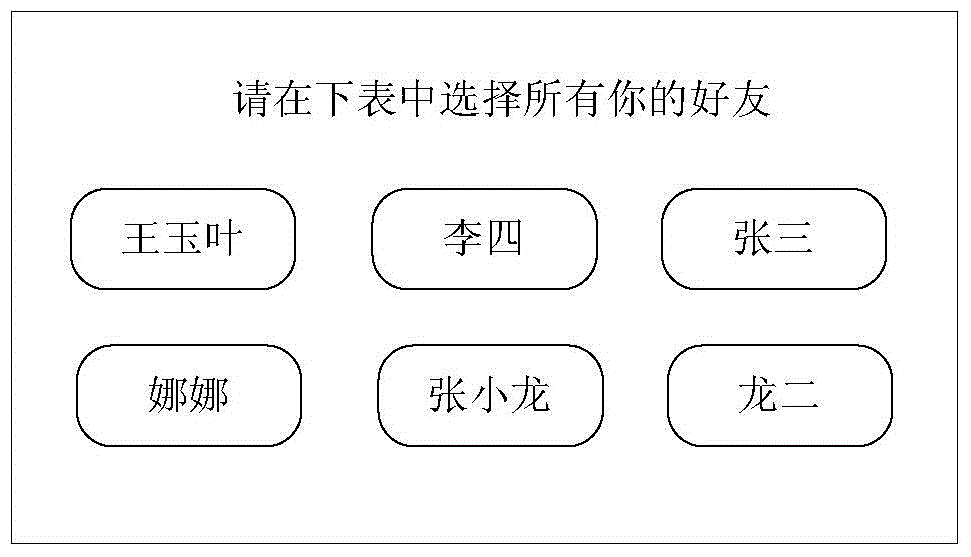

Method for verifying verification code and system thereof

ActiveCN104954131AAccurate answerReduce the probability of crackingUser identity/authority verificationValidation methodsData library

The present invention provides a method for verifying a verification code and a system thereof. The method comprises the a step of obtaining the relationship chain information of a user from a user information database and selecting verification information from the relationship chain information and generating a verification code according to the verification information and preset disturbance information, a step of sending the verification code to the client that a user logged, and a step of obtaining the response information returned by the client and verifying the response information according to the relationship chain information. According to the technical scheme, a low crack rate is ensured, artificial code can be effectively fought based a low user application threshold, and the artificial code problem is thoroughly solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

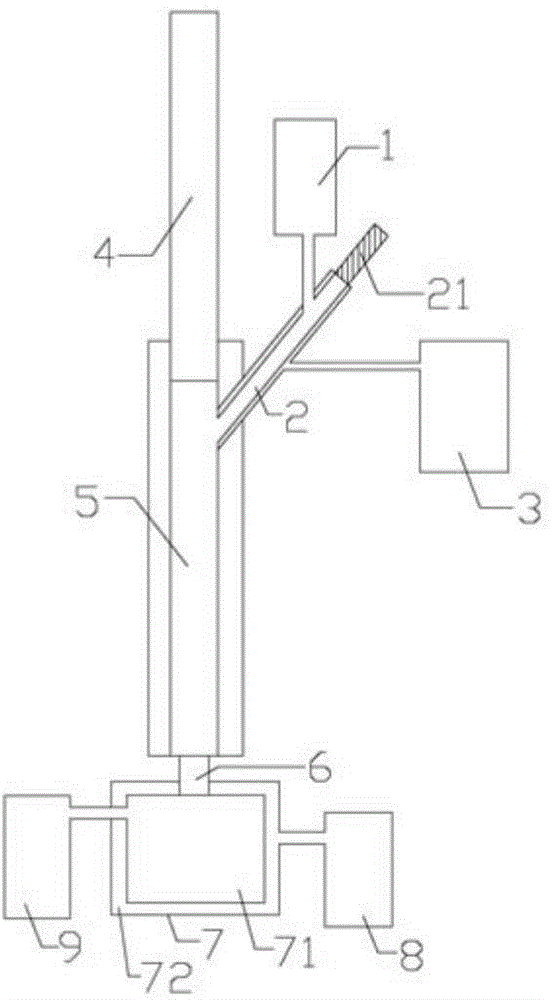

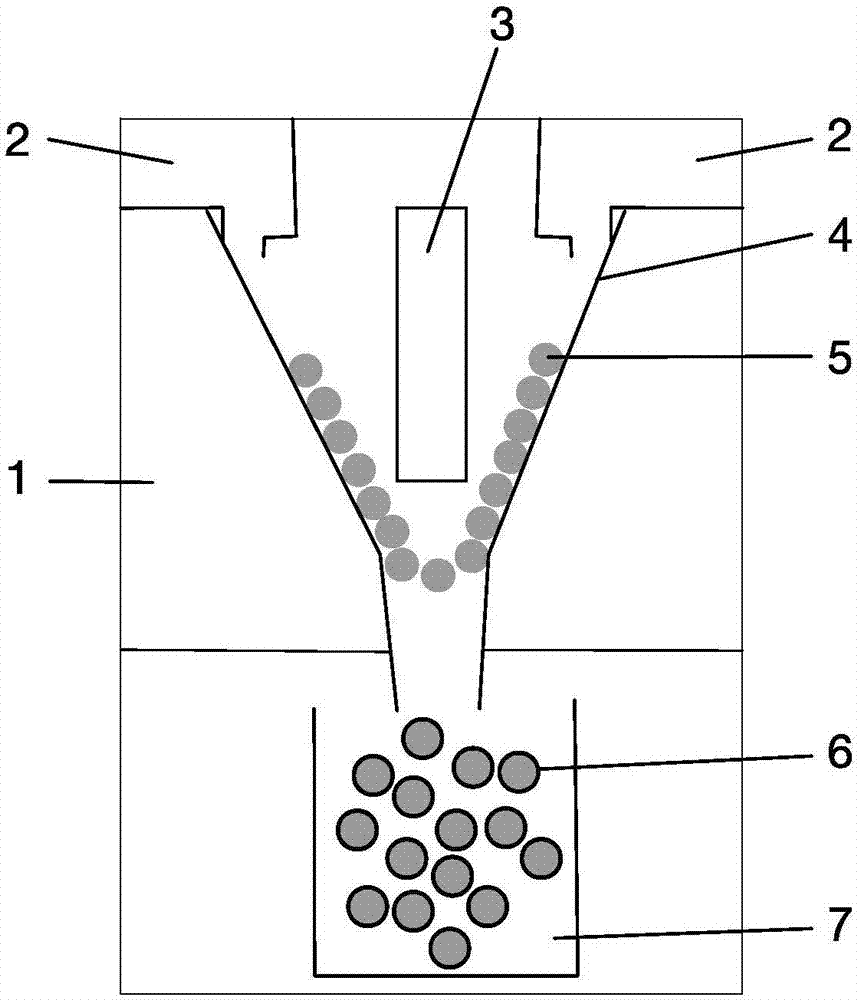

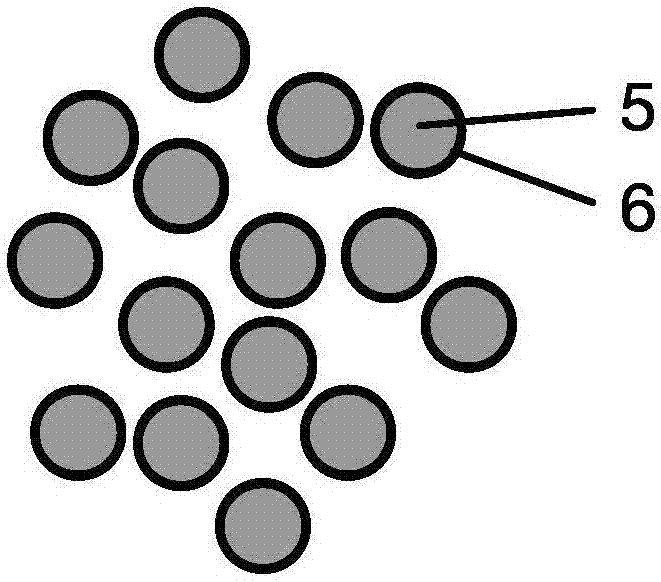

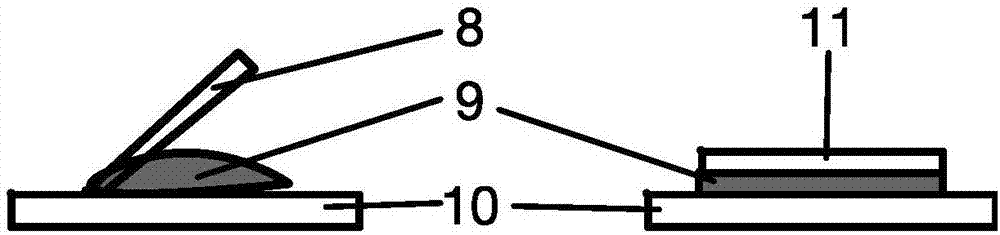

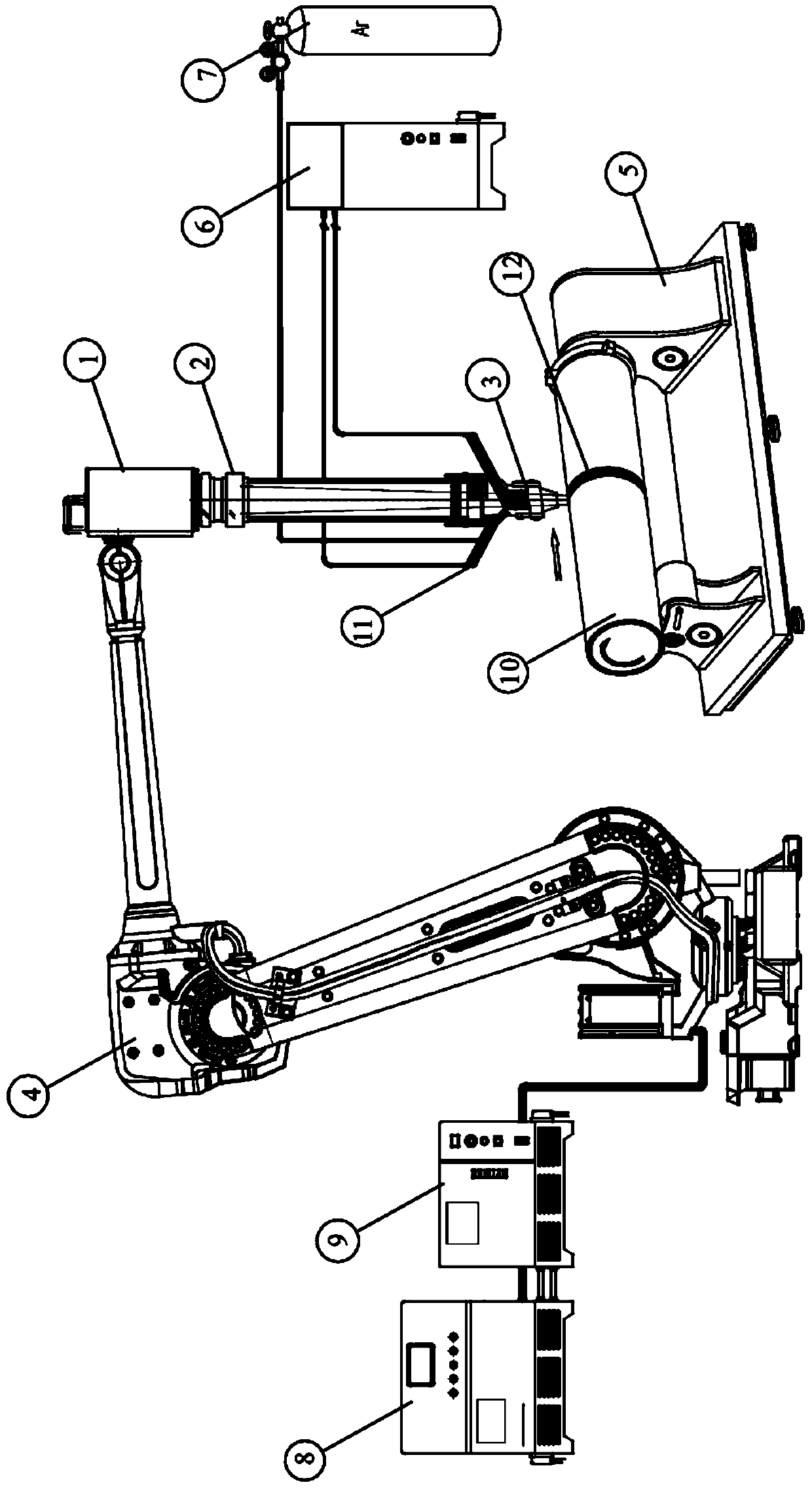

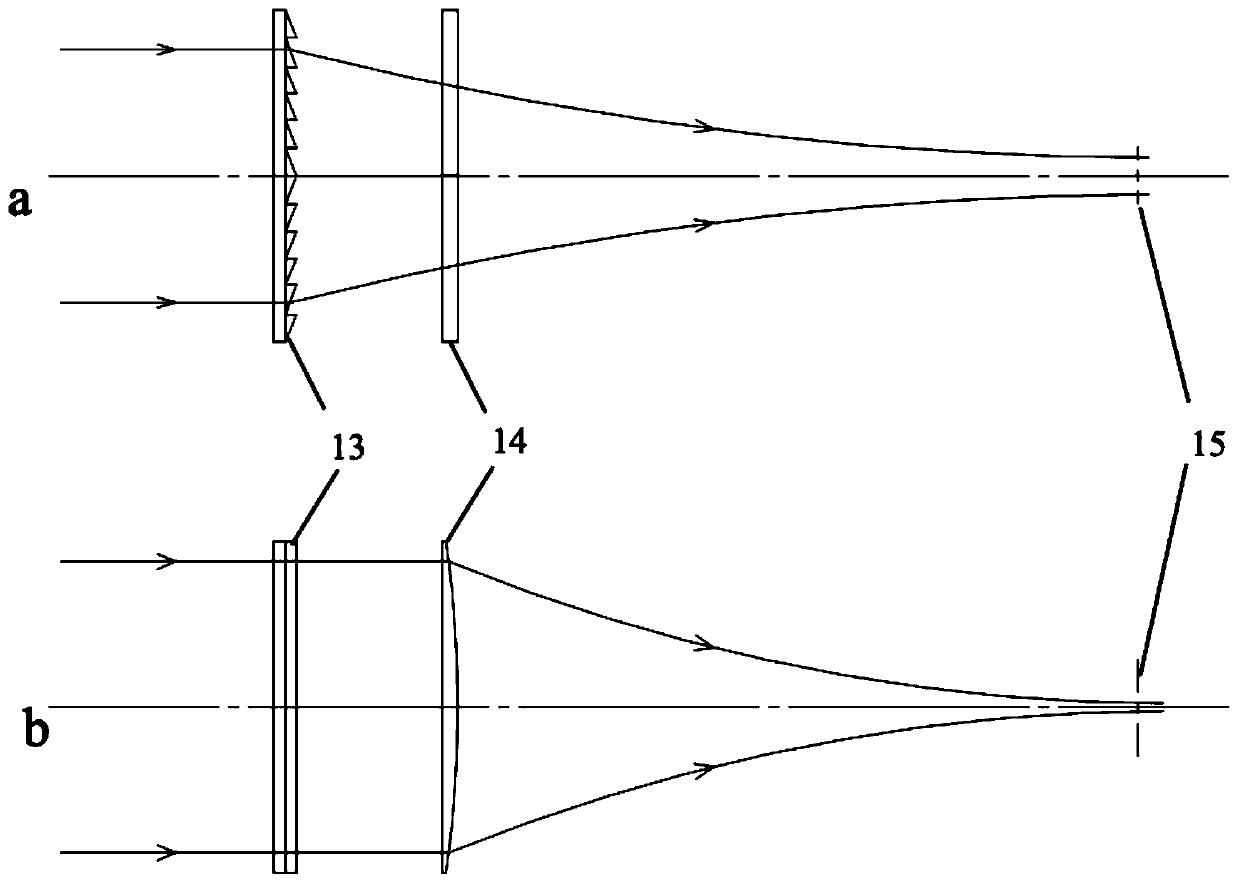

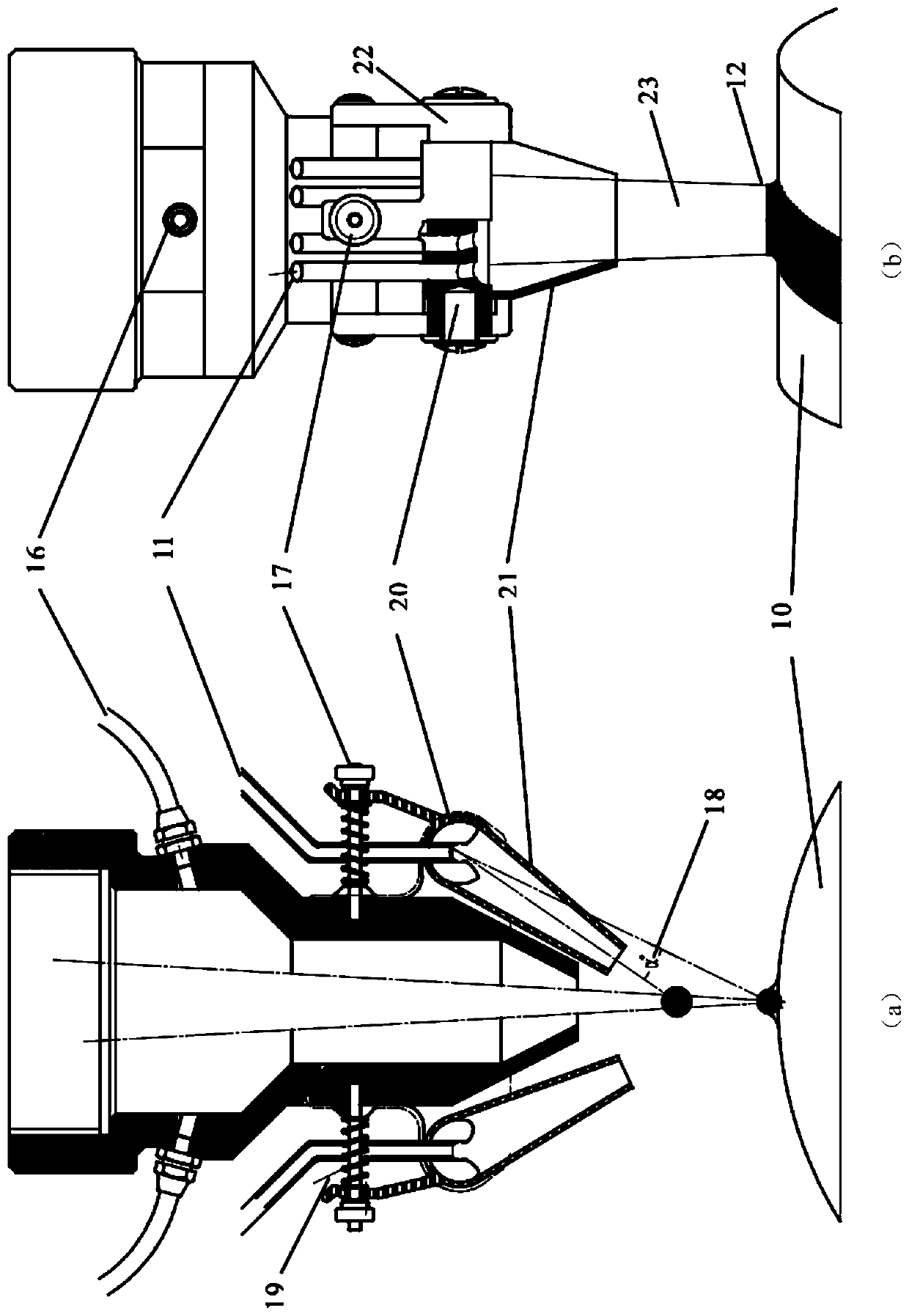

Fast and efficient semiconductor laser cladding device with wide light beam and adjustable powder feeding angle

ActiveCN110144583AIncrease single pass cladding areaReduce the burden of rotationMetallic material coating processesLaser lightSurface modification

The invention belongs to the technical field of laser surface modification, and discloses a fast and efficient semiconductor laser cladding device with a wide light beam and an adjustable powder feeding angle. The fast and efficient semiconductor laser cladding device with the wide light beam and the adjustable powder feeding angle comprises a semiconductor laser (1), a light beam shaping and Fresnel focusing system (2), an adjustable wide light band powder feeding head (3), a powder feeder (6), a high-speed machine tool (5), a six-axis linkage robot (4) and a central control system (9), wherein the light beam shaping and Fresnel focusing system (2) is used for shaping a laser light and focusing to form a wide-light-band laser light; the adjustable wide light band powder feeding head (3) is used for conveying powder and the wide-light-band laser light on the surface of a large-scale shaft type workpiece to be processed; and the diameter of a workpiece is larger than 1000mm, and the length of the workpiece is not lower than 10m. According to the fast and efficient semiconductor laser cladding device with the wide light beam and the adjustable powder feeding angle provided by the invention, through improving structures and arrangement manners of key components, outer surface strengthening and surface repairing can be carried out aiming at the large-scale shaft type workpieces such as petroleum pipelines, ocean facilities, natural gas conveying, mining and tunnel piercing, so that the wear resistance and the corrosion resistance of the surface are improved, and the service life is greatly prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

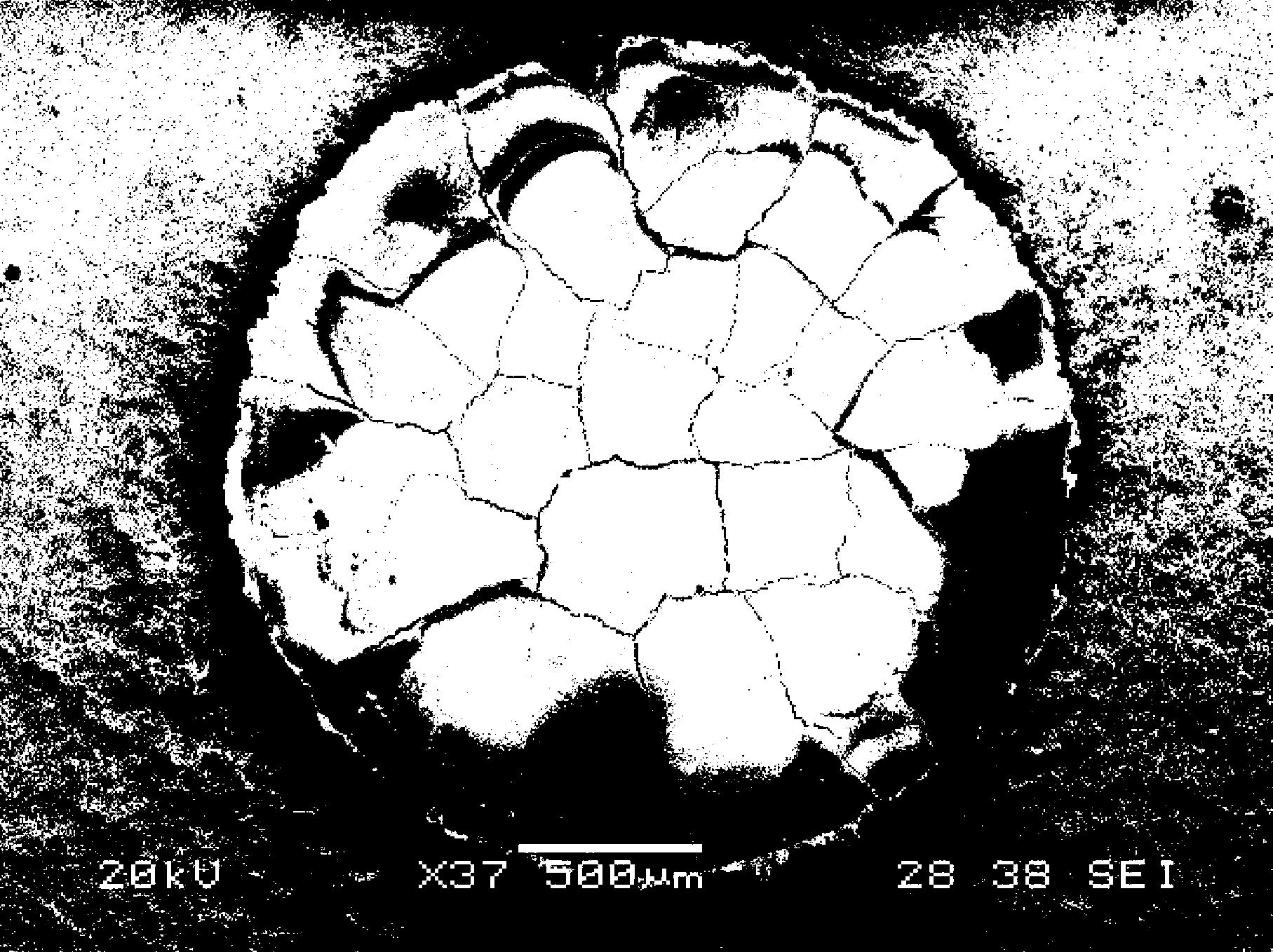

Seed crystal bonding method for growing SiC crystals

InactiveCN102534762AUniform growthQuality improvementPolycrystalline material growthFrom condensed vaporsCrystallographyAdhesive

The invention belongs to the field of crystal growth, and relates to a seed crystal bonding method for growing SiC crystals. The seed crystal bonding method for growing high-quality SiC crystal comprises the following steps of: (1) printing a silk screen; (2) bonding the seed crystals; and (3) curing an adhesive for bonding the seed crystals and a seed crystal support, wherein the thickness of the cured adhesive layer is 7-10 microns. The seed crystal bonding method for growing the high-quality SiC crystals provided by the invention can ensure uniform distribution of the thickness of the adhesive layer between the seed crystals and the seed crystal support and avoid cracking caused by non-uniform mechanical stress and heat stress; and meanwhile, the temperature gradient distribution of the seed crystals is uniform, thereby being beneficial to the uniform growth of the SiC crystals, and further improving the quality of the SiC crystals.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

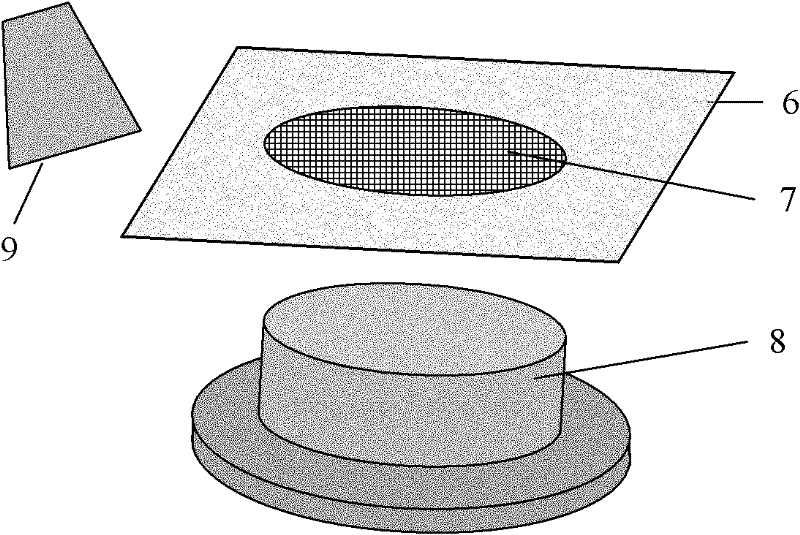

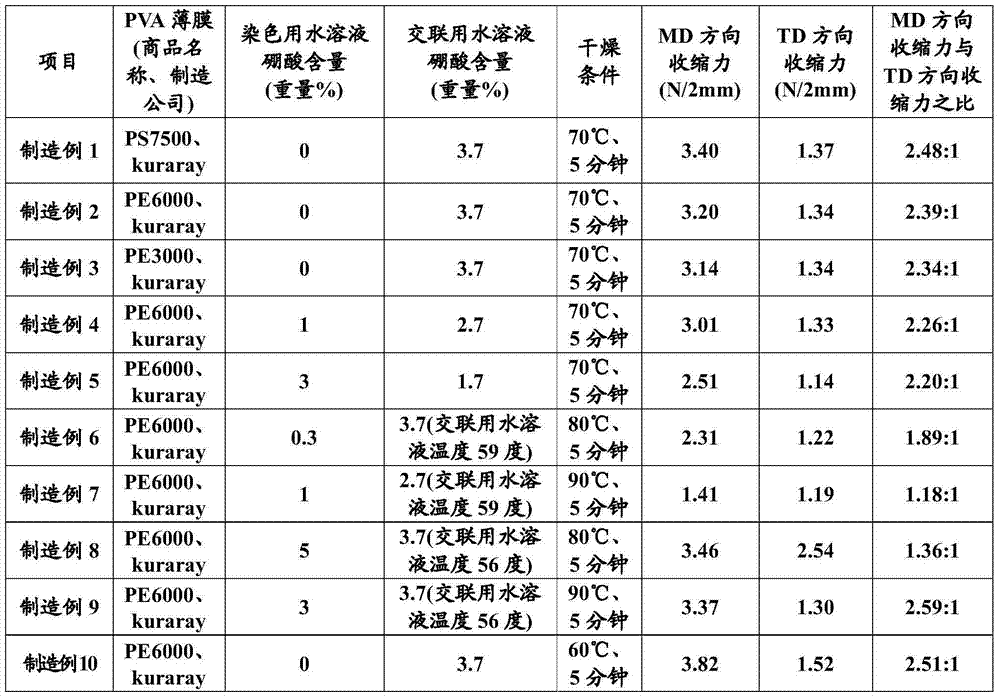

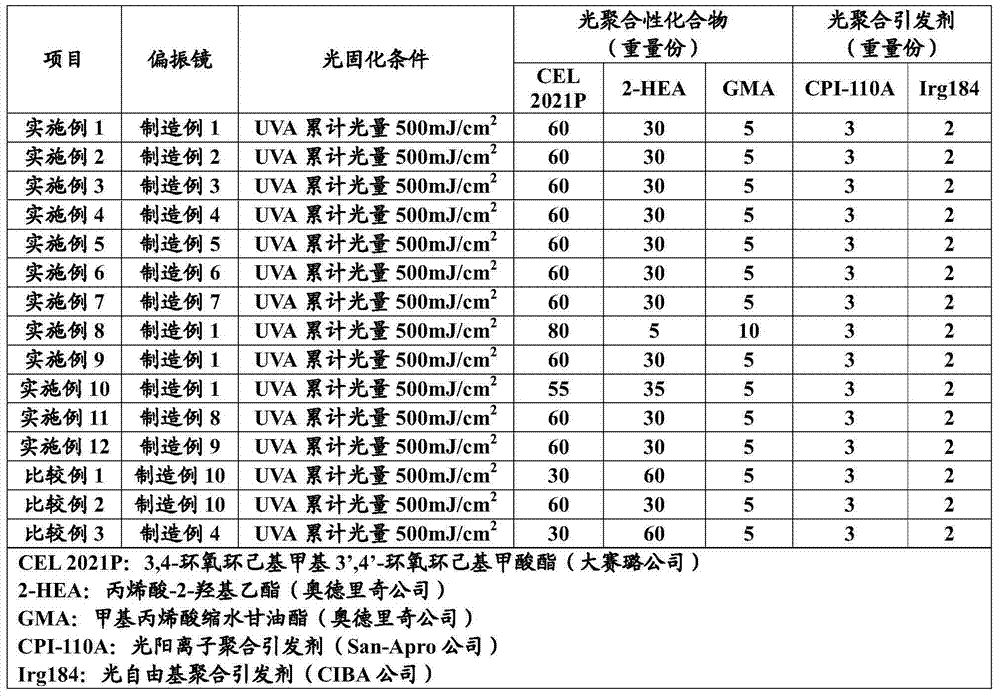

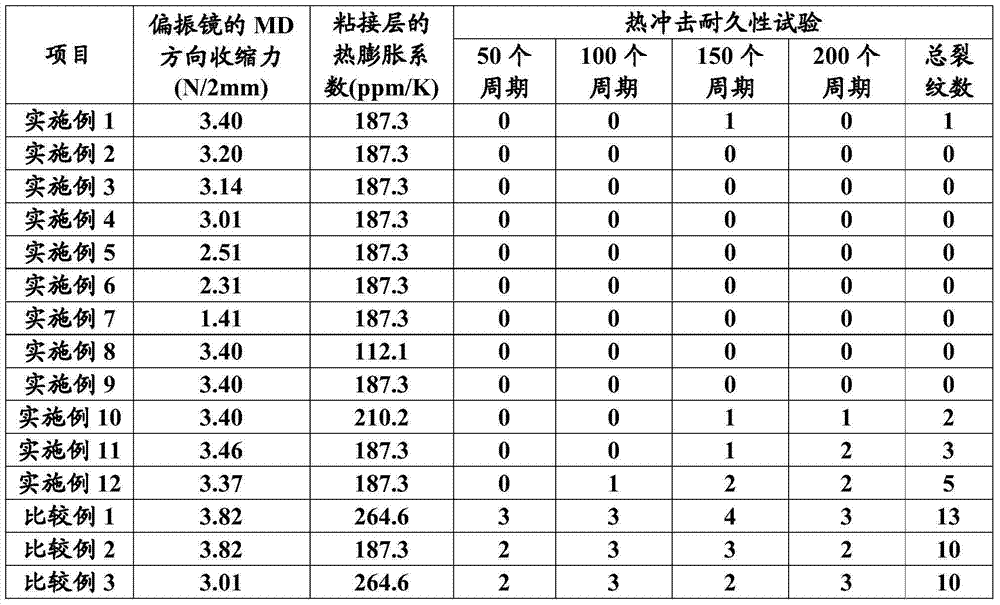

Polarizing plate

ActiveCN104777542AExcellent thermal shock durabilityReduce the probability of crackingLayered productsPolarising elementsOptoelectronicsPolarizer

The invention relates to a polarizing plate. The polarizing plate bonds a polarizer and a protective film through a bonding layer, the contraction force of the polarizer in the MD direction is lower than 3.5N / 2mm, and the thermal expansion coefficient of the bonding layer is lower than 250ppm / K, and is between that of the polarizer and that of the protective film. Thus, the polarizing plate has significant excellent thermal shock durability, and the probability of crack generation is greatly reduced, even if the polarizing plate is exposed in high temperature and low temperature environments.

Owner:DONGWOO FINE CHEM CO LTD

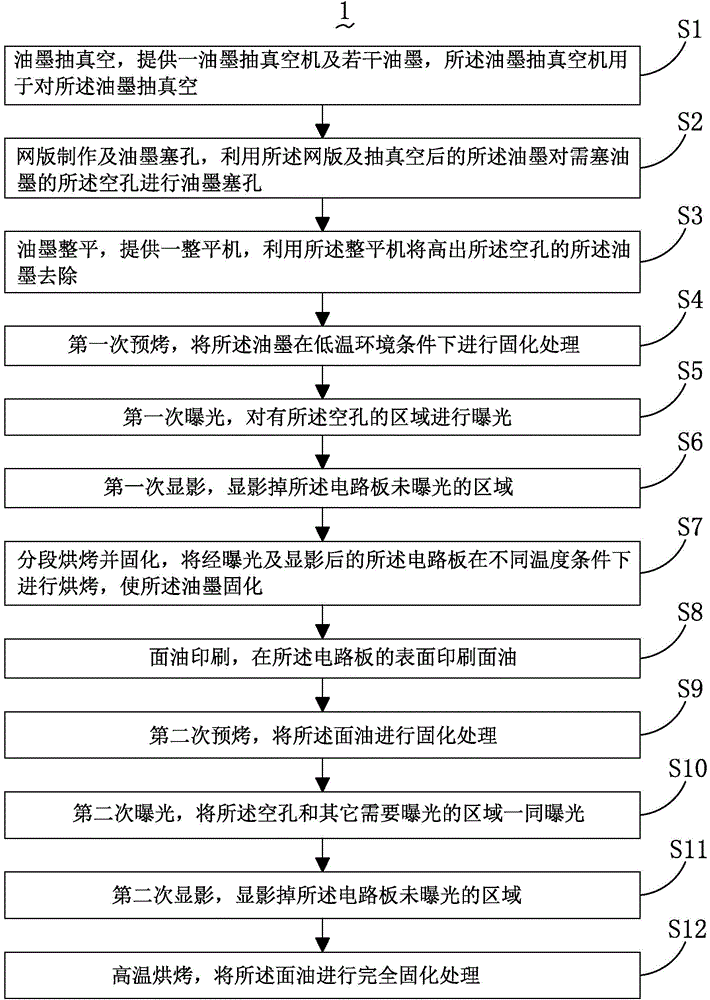

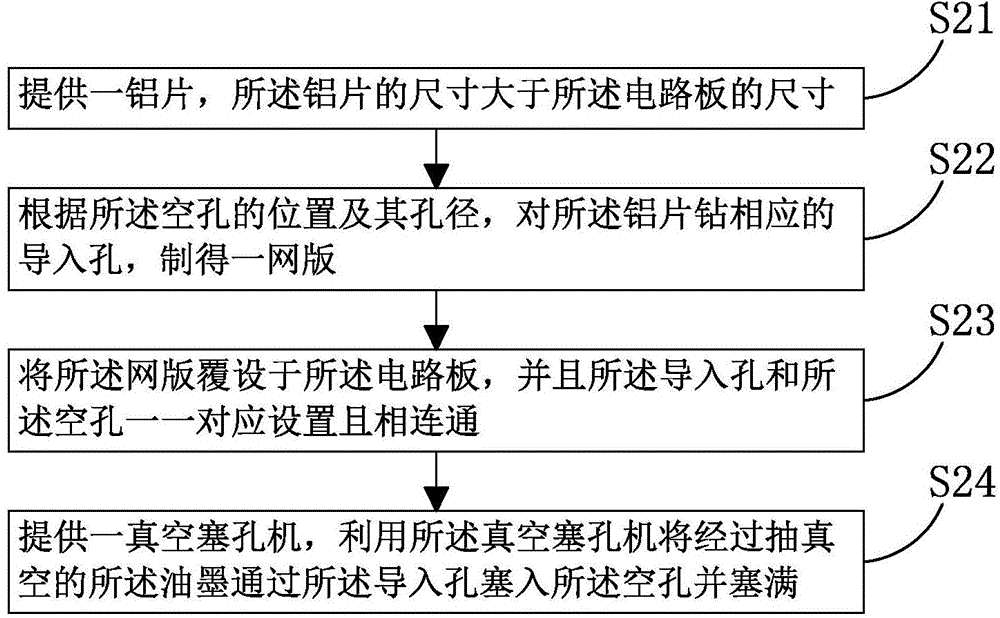

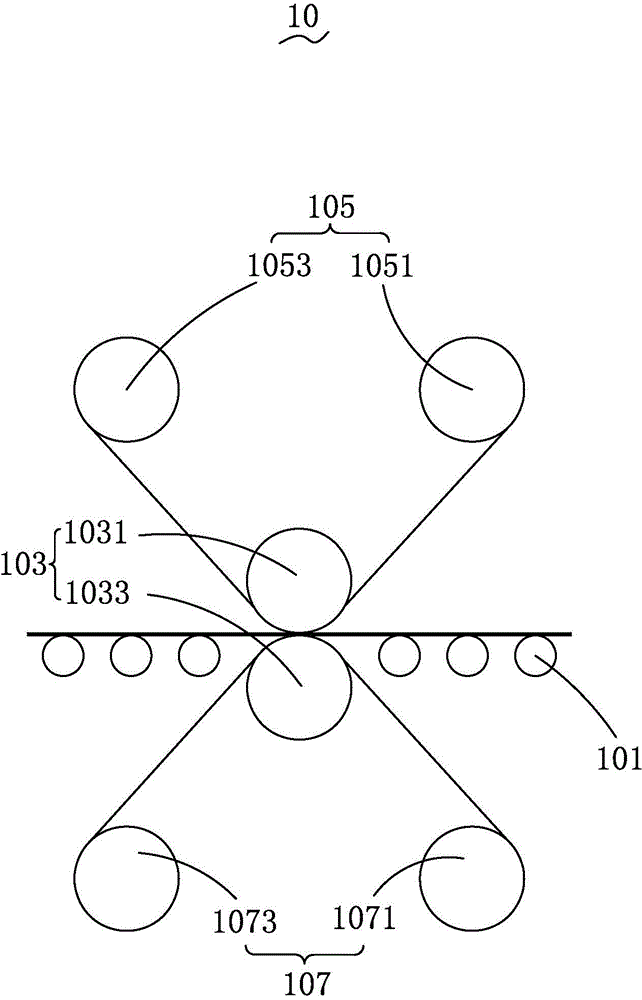

Printing ink hole plugging process method for circuit boards

InactiveCN104486913AImprove the effectReduce the difficulty of alignmentPrinted element electric connection formationPrinting inkEngineering

The invention provides a printing ink hole plugging process method for circuit boards. The printing ink hole plugging process method comprises the following steps: printing ink vacuumizing; screen printing plate production and printing ink hole plugging; printing ink leveling; pre-baking for the first time; exposing for the first time; developing for the first time; subsection baking and curing; surface oil printing; pre-baking for the second time; exposing for the second time; developing for the second time; high-temperature baking. The printing ink hole plugging process method reduces the probability that cracks exist in printing ink, improves the effect of printing ink hole plugging, and avoids the phenomenon that chemicals and humidity in the follow-up process can permeate into empty holes as the cracks exist in the cured printing ink.

Owner:SHENZHEN WUZHU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com