Filter

A filter and dielectric resonator technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of high filter failure risk, high long-term reliability risk, small thermal expansion coefficient, etc., and achieve the goal of reducing cracking phenomenon Probability, guaranteed reliability, and the effect of improving the life of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

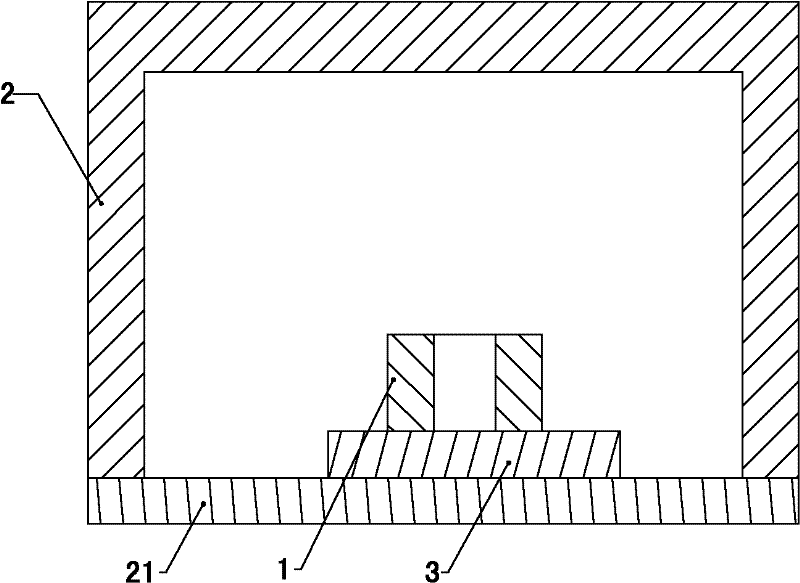

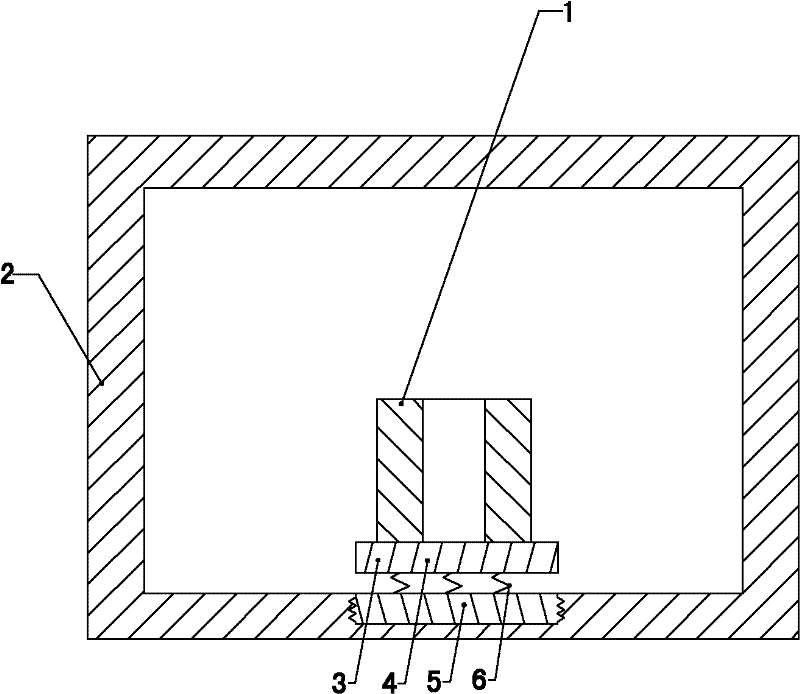

[0027] See figure 1 , The filter of the embodiment of the present invention includes a dielectric resonator 1, a cavity 2 and a connector 3. The dielectric resonator 1 is installed in the cavity 2, and the dielectric resonator 1 is welded to the connector 3 and connected The part 3 is connected to the cavity 2 and the dielectric resonator 1 is not in direct contact with the cavity 2; in this way, the connection between the dielectric resonator 1 and the cavity 2 through the connector 3 is formed. The design of the connector 3 can be as follows One or two of the solutions:

[0028] First, the difference between the thermal expansion coefficient of the connecting piece 3 and the thermal expansion coefficient of the dielectric resonator is smaller than the difference between the thermal expansion coefficient of the cavity 2 and the thermal expansion coefficient of the dielectric resonator.

[0029] Second, the connecting member 3 is a deformation buffer structure with an elastic defor...

Embodiment 2

[0042] The filter of the embodiment of the present invention may also adopt another design, as follows:

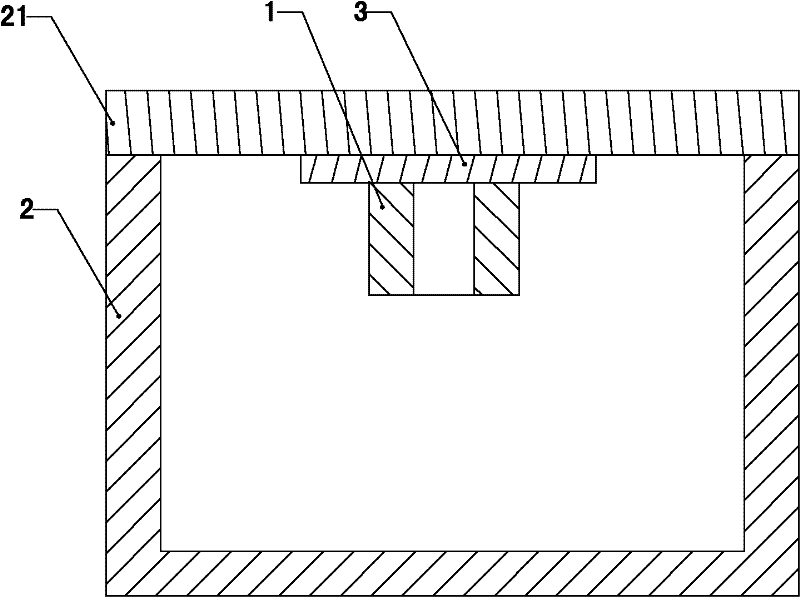

[0043] See Figure 5 , The filter of the embodiment of the present invention includes a dielectric resonator 1 and a cavity 2. The dielectric resonator 1 and the cavity 2 are welded together. The cavity 2 is a sheet metal part. The material of the cavity 2 is directly replaced. For sheet metal parts with a smaller thermal expansion coefficient, the CTE of the sheet metal parts is generally small, which is close to the ceramic material of the dielectric resonator 1. In this way, the reliability of the solder joints of the dielectric resonator can be guaranteed and the dielectric resonator 1 and the cavity can be reduced. The probability of body 2 cracking due to the difference in thermal expansion coefficient.

[0044] In the above design, in order to provide a specific design of sheet metal parts that can be implemented, the sheet metal parts in the filter of the present invent...

Embodiment 3

[0046] See Picture 10 , The filter of the embodiment of the present invention includes a dielectric resonator 1 and a cavity 2. The dielectric resonator 1 and the cavity 2 are welded together, and the weld 10 between the dielectric resonator 1 and the cavity 2 is provided with columnar reinforcement The two ends of the reinforcing member 11 are welded to the dielectric resonator 1 and the cavity 2 respectively, and the area where the reinforcing member 11 is not provided at the welding seam 10 is filled with the above-mentioned solder 12, so that the reinforcing member 11 can be installed Increasing the thickness of the welding seam 10 can increase the life of the welding joint to a certain extent, and ultimately reduce the probability that the dielectric resonator 1 and the cavity 2 will crack due to the difference in thermal expansion coefficient.

[0047] In the filter of the embodiment of the present invention, the columnar reinforcement 11 is provided with a plurality of hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com