Method for preparing dense diffusion barrier of limiting current type oxygen sensor with co-permeation method

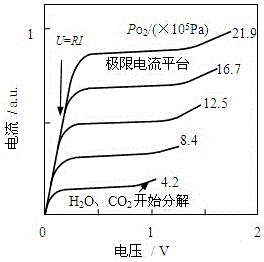

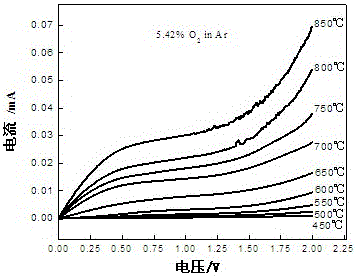

A limiting current type, oxygen sensor technology, applied in the field of sensors, can solve the problems of long cycle, cumbersome preparation process, unevenness, etc., and achieve the effects of short production cycle, high sensitivity, and low thermal expansion difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for preparing the dense diffusion barrier layer of the limiting current type oxygen sensor according to the present embodiment is carried out according to the following steps:

[0027] (1) According to La 0.8 Sr 0.2 Ga 0.83 Mg 0.17 O 2.815 (LSGM) stoichiometric ratio, weighed La 2 O 3 , SrCO 3 , Ga 2 O 3 And MgO, fully grinded to a particle size ≤100μm, then compressed into tablets, kept at 1000°C for 20h, then crushed after natural cooling, re-grinded and pressed into tablets, kept at 1200°C for 20h, again naturally cooled and then crushed for the third time. Press the tablet after the second grinding and keep it at 1450℃ for 20h;

[0028] (2) The La 0.8 Sr 0.2 Ga 0.83 Mg 0.17 O 2.815 The sheet is placed in the lower part of the forming mold, and the upper part of the forming mold is filled with Fe 2 O 3 The powder is kept under a pressure of 10MPa for 10 minutes, and then sintered at 1450°C for 20 hours. Fe diffuses into the LSGM at high temperature to form a den...

Embodiment 2

[0030] The method for preparing the dense diffusion barrier layer of the limiting current type oxygen sensor according to the present embodiment is carried out according to the following steps:

[0031] (1) According to La 0.8 Sr 0.2 Ga 0.83 Mg 0.17 O 2.815 (LSGM) stoichiometric ratio, weighed La 2 O 3 , SrCO 3 , Ga 2 O 3 And MgO, fully grinded to a particle size ≤100μm, then compressed into tablets, kept at 1000°C for 20h, then crushed after natural cooling, re-grinded and pressed into tablets, kept at 1200°C for 20h, again naturally cooled and then crushed for the third time. Press the tablet after the second grinding and keep it at 1450℃ for 20h;

[0032] (2) The La 0.8 Sr 0.2 Ga 0.83 Mg 0.17 O 2.815 The sheet is placed in the lower part of the forming mold, and the upper part of the forming mold is filled with Co 3 O 4 The powder is kept under pressure of 10MPa for 10 minutes, and then sintered at 1550°C for 5 hours. Co diffuses into LSGM at high temperature to form a dense diff...

Embodiment 3

[0035] The method for preparing the dense diffusion barrier layer of the limiting current type oxygen sensor according to the present embodiment is carried out according to the following steps:

[0036] (1) According to La 0.8 Sr 0.2 Ga 0.83 Mg 0.17 O 2.815 (LSGM) stoichiometric ratio, weighed La 2 O 3 , SrCO 3 , Ga 2 O 3 And MgO, fully grinded to a particle size ≤100μm, then compressed into tablets, kept at 1000°C for 20h, then crushed after natural cooling, re-grinded and pressed into tablets, kept at 1200°C for 20h, again naturally cooled and then crushed for the third time. Press the tablet after the second grinding and keep it at 1450℃ for 20h;

[0037] (2) The La 0.8 Sr 0.2 Ga 0.83 Mg 0.17 O 2.815 The sheet is placed in the lower part of the forming mold, and the upper part of the forming mold is filled with NiO powder. The pressure is maintained at a pressure of 6MPa for 8 minutes, and then sintered at 1600°C for 30 hours. Ni diffuses into the LSGM at high temperature to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com