Silver paste composition and solar cell using same

A solar cell and silver paste technology, applied to conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve problems such as inability to ensure the uniformity of printed patterns, and achieve improved stability and uniformity, Less residue, less curling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

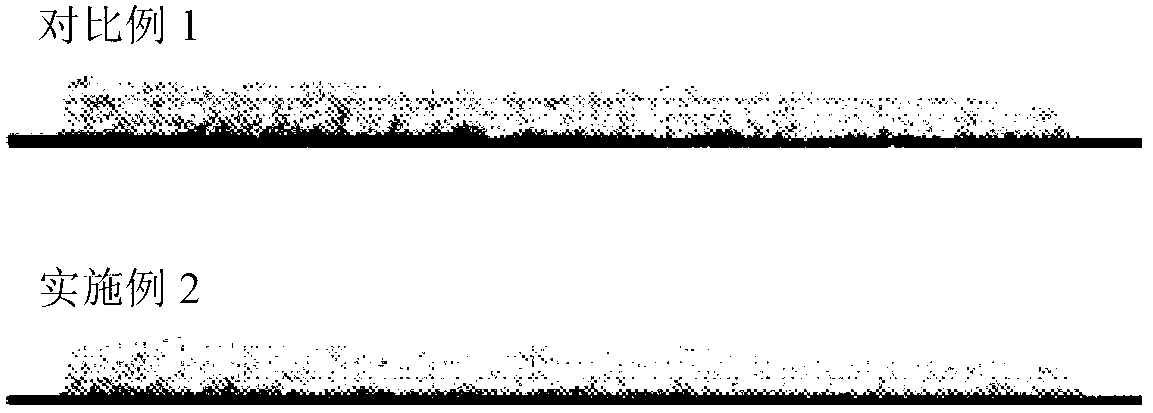

Embodiment 1~7 and comparative example 1

[0055] By mixing silver powder, glass powder, organic binder (ethyl cellulose) and additives (plasticizer, wetting agent and thixotropic agent) according to the composition (unit: weight %) shown in Table 1 below, and then using 3 Each silver paste composition was prepared by uniformly dispersing with a roll mill.

[0056] In Table 1, the plasticizer in Examples 1 to 4 is dipropylene glycol dibenzoate (DPD), the plasticizer in Example 5 is dioctyl phthalate (DOP), and in Example 6 The plasticizer in Example 7 is dioctyl adipate (DOA), and the plasticizer in Example 7 is tricresyl phosphate (TCP).

[0057] Table 1

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com