Road roller with good pavement leveling effect

A road roller and leveling technology, applied in the field of road rollers, can solve the problems affecting the rolling effect and the inability to adjust the water spray rate, etc., to achieve the effect of improving the effect, increasing the stability, and improving the smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

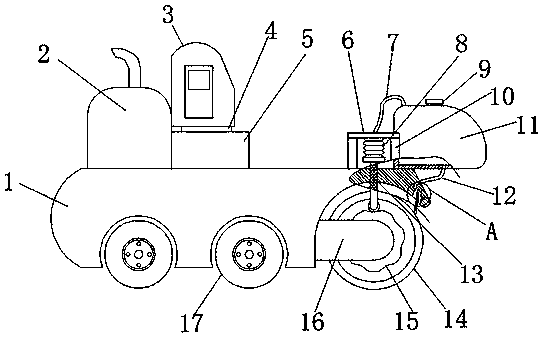

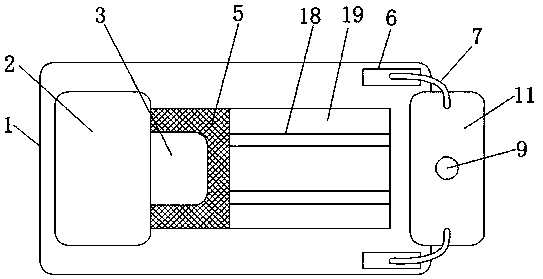

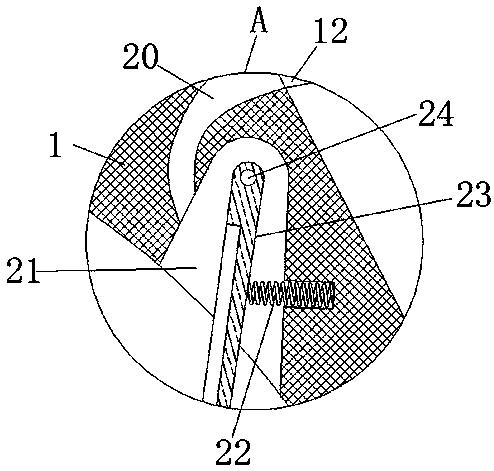

[0030] refer to Figure 1-5 , a road roller with good road surface leveling effect, comprising a bracket 1, two connecting bodies 16 are welded on one side of the bracket 1, and a cam 15 is rotatably connected to the side of the two connecting bodies 16 that are close to each other, and between the two cams 15 The working wheel 14 is welded, the two cams 15 will rotate together with the working wheel 14, two circular through holes are opened on one side of the top end of the bracket 1, and the bracket 1 is provided with a moving rod 13 at the circular through hole, and the moving rod 13 The bracket 1 is penetrated at the circular through hole, the bottom end of the moving rod 13 is rotatably connected with a roller, the top of the moving rod 13 is provided with an air pump 8, the top of the air pump 8 is provided with an air delivery pipe 7, and one side of the support 1 is provided with an air pump 8. In the water tank 11, the other end of the gas transmission pipe 7 is conne...

Embodiment 2

[0043] refer to Figure 6-7 In this embodiment, compared with Embodiment 1, in order to increase the practicability of the device, the device scrapes off the asphalt when adsorbing asphalt, and automatically increases the amount of water sprayed, the bottom end of the bracket 1 is provided with a third groove, and the bracket 1 A scraper 34 is rotatably connected between the two inner walls of the third groove. The bracket 1 is provided with a pressure sensor 35 on one inner wall of the third groove. One side of the scraper 34 is in contact with the pressure sensor 35. The water tank 11 The bottom end of the solenoid valve 33 is provided with a solenoid valve 33, the bottom end of the solenoid valve 33 is connected with the water pipe 12 by threads, and the solenoid valve 33 and the pressure sensor 35 are electrically connected. When the working wheel 14 occupies asphalt, the asphalt will be scraped by the scraper. 34 is scraped off, and the asphalt will rotate the scraper 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com