Polarizing plate

A technology of polarizers and polarizers, applied in the field of polarizers, can solve problems such as polarizers that have not yet been developed, achieve excellent thermal shock durability, and reduce the probability of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

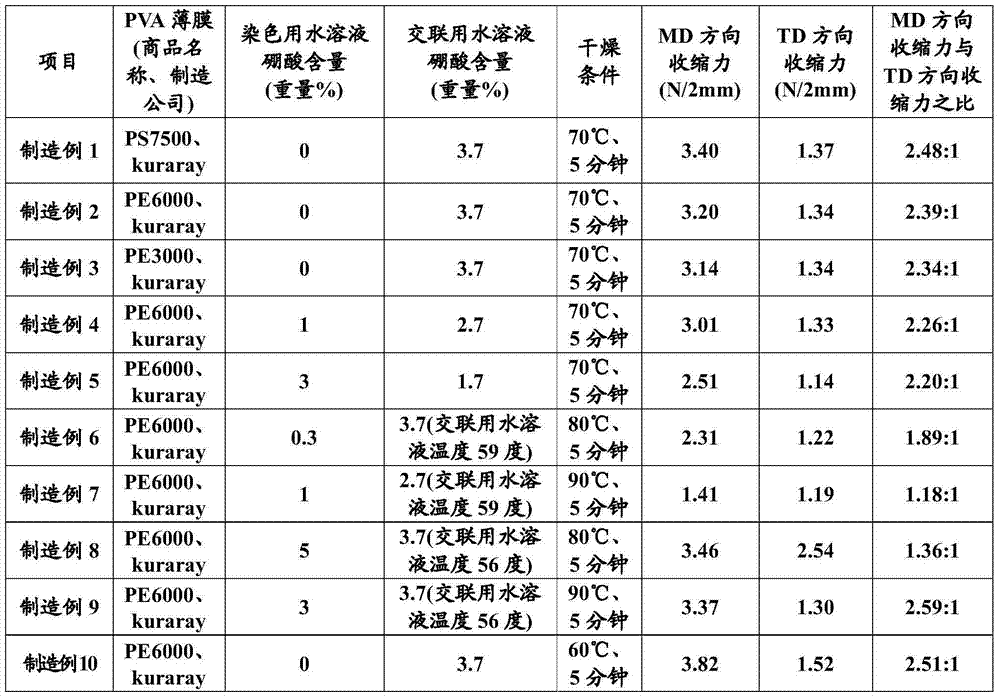

[0072] [production example, production of polarizer]

[0073] After soaking a polyvinyl alcohol film (PS 7500, Kuraray Co., Ltd.) with an average degree of polymerization of 2400, a degree of saponification of 99.9% or more, and a thickness of 75 μm in water (deionized water) at 30° C. for 2 minutes to swell, the It was dipped for 4 minutes in a 30° C. dyeing aqueous solution containing 3.5 mmol / L iodine and 2% by weight of potassium iodide to dye. Thereafter, it was dipped for 2 minutes in an aqueous solution for crosslinking at 53° C. to which 2% by weight of potassium iodide and 3.7% by weight of boric acid had been added to be crosslinked.

[0074] Thereafter, it was washed with distilled water at 25° C. for 20 seconds.

[0075] The cumulative draw ratio in each step of expansion / dyeing / crosslinking / water washing was 5.5 times, followed by heat treatment at 70° C. for 5 minutes to manufacture a polarizer (Manufacture Example 1).

[0076] Except for the conditions describ...

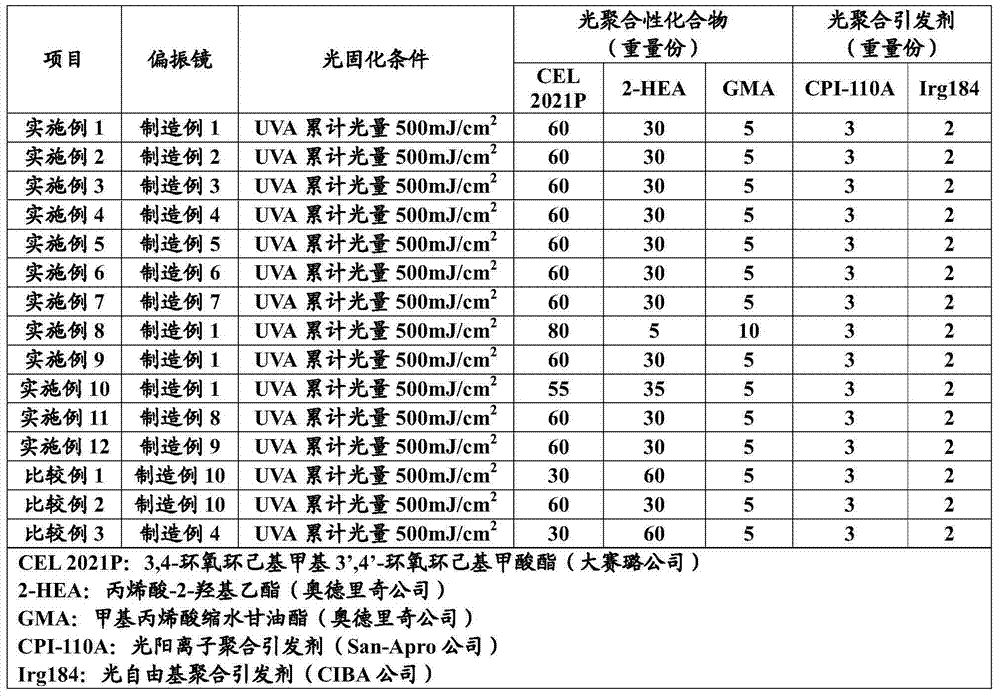

experiment example

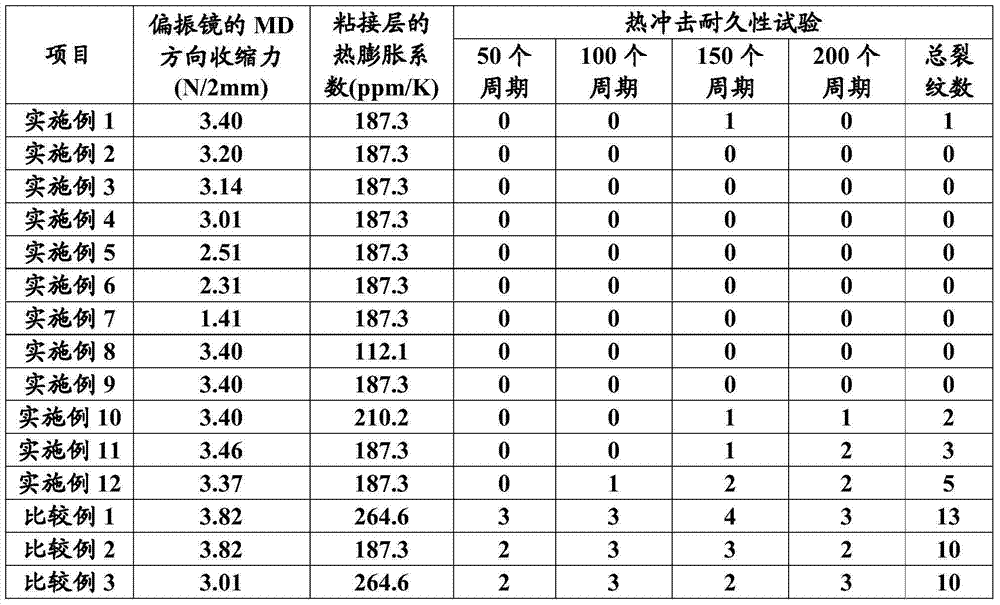

[0087] (1) Coefficient of thermal expansion (CTE) of the adhesive layer

[0088] On a non-corona-treated cycloolefin polymer (COP) film (Zeon Corporation), the adhesive composition of the above-mentioned Table 2 was coated with a thickness of 30 μm by bar coating, and then a high-pressure mercury lamp ( The cumulative UVA light intensity is 500mJ / cm 2 ×4 times) for UV curing.

[0089] Next, after peeling off a 30 μm adhesive layer from the COP film and cutting it into a size of 8.0mm×4.0mm, the coefficient of thermal expansion was measured using TMA (TA Company) (the temperature was increased from 30°C to 10°C per minute under the measurement conditions). After reaching 70°C, the coefficient of thermal expansion was confirmed using the slope up to 70°C).

[0090] (2) Thermal shock durability test

[0091] After cutting the polarizers produced in Examples and Comparative Examples into a size of 15.0 cm (MD)×11 cm (TD), the polarizers were bonded to glass using an acrylic adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com