Honeycomb hydrophobic molecular sieve adsorbent as well as preparation method and application thereof

A molecular sieve and hydrophobic technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of high internal cracking rate, cumbersome operation, and long production cycle, and achieve reduced cracking rate, simple preparation method, The effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

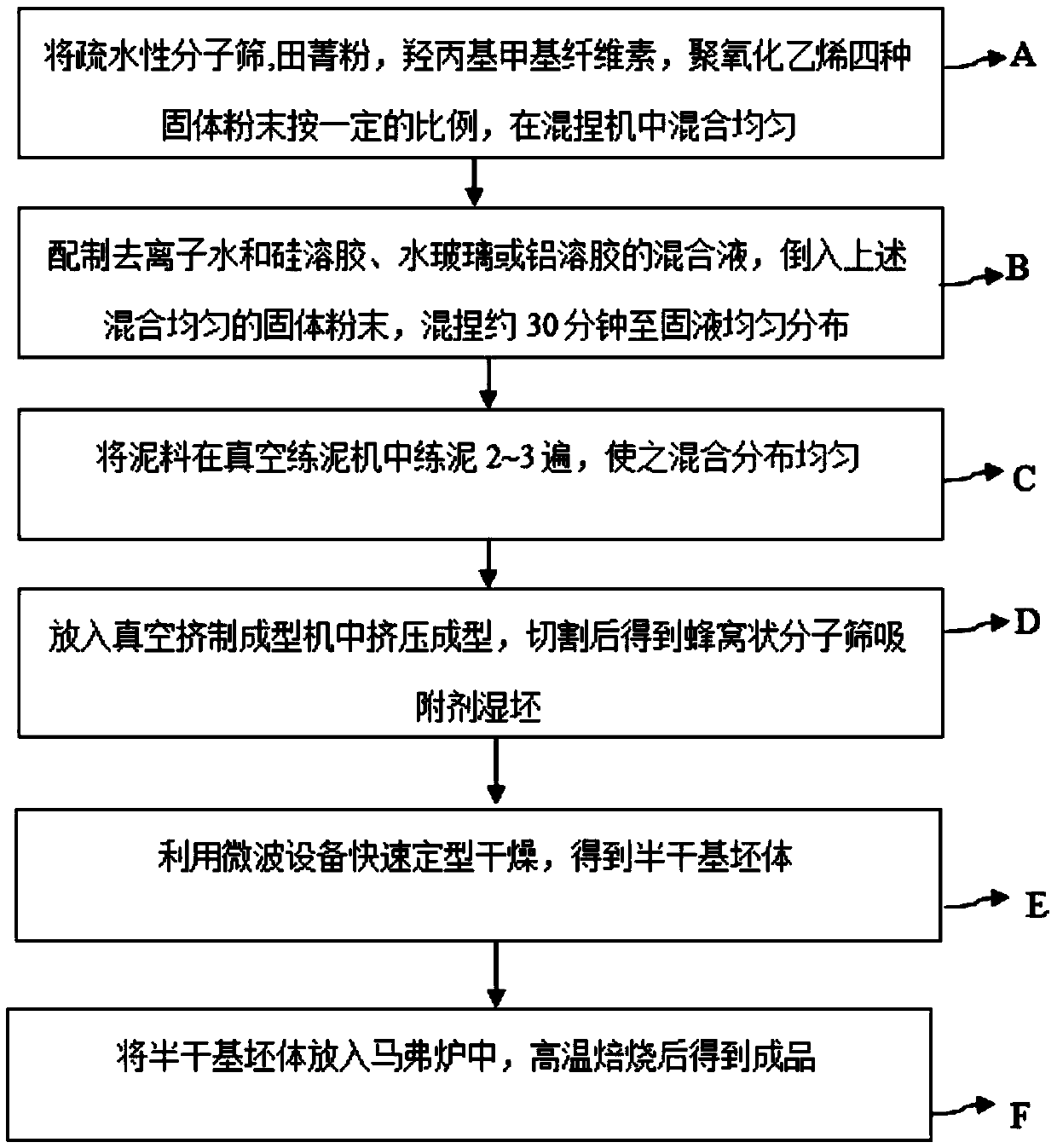

[0044] A kind of honeycomb hydrophobic molecular sieve adsorbent, the specific preparation process is as follows (flow chart sees figure 1 ):

[0045] (1) Sieving: pass the highly hydrophobic ZSM-5 (silicon to aluminum ratio greater than 300) molecular sieve powder through a 100-mesh sieve, and obtain powdered molecular sieves with uniformly dispersed particle sizes after sieving.

[0046] (2) Drying: The sieved powder was dried in an oven at 80 degrees for 6 hours, and then sealed in a vacuum desiccator for use.

[0047] (3) Mixing: Weigh 300g ZSM-5 molecular sieve powder, 25g squid powder, 35g hydroxypropyl methylcellulose, and 1.5g polyethylene oxide, mix them and add them to the kneader and stir for about 20-35 minutes. The mud temperature is controlled at 20-35°C.

[0048] (4) Kneading: 320 g of 30% alkaline silica sol is slowly poured into a kneader to fully mix the two. After it is completely added, continue kneading for about 20 minutes, and the temperature is contr...

Embodiment 2

[0054] A honeycomb hydrophobic molecular sieve adsorbent, the difference from Example 1 is that the molecular sieve powder used is SBA-15.

Embodiment 3

[0056] A kind of honeycomb hydrophobic molecular sieve adsorbent, with step (1)~(2) and (5)~(8) in example 1, difference is the selection of molecular sieve, used molecular sieve powder is 13X molecular sieve.

[0057](3) Mixing: Weigh 300g of 13X molecular sieve powder, 25g of asparagus powder, 35g of hydroxypropyl methylcellulose, and 1.5g of polyethylene oxide, mix them and add them to the kneader and stir for about 30 minutes, and set the temperature to 30 ℃.

[0058] (4) Kneading: 320 g of 30% alkaline silica sol and 20 g of deionized water are slowly poured into a kneader to fully mix the two. After the addition is complete, continue kneading for about 25 minutes, and the temperature is controlled at 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com