Recyclable integral honeycomb molecular sieve adsorbent and preparation method thereof

A recycling and molecular sieve technology, which is applied in separation methods, filter regeneration, combustible gas purification, etc., can solve the problems of inability to realize material recycling, cost increase, etc., and achieve short preparation cycle, low defective rate and stable product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

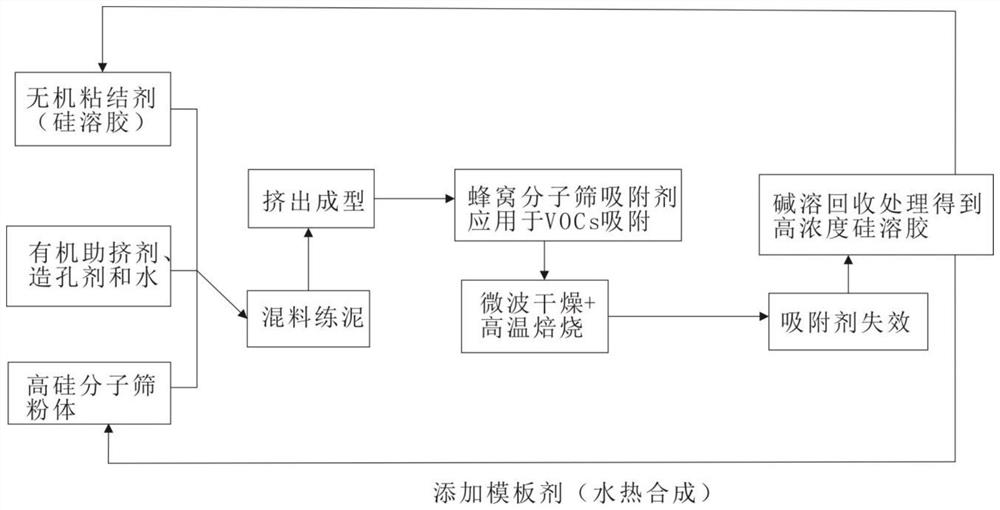

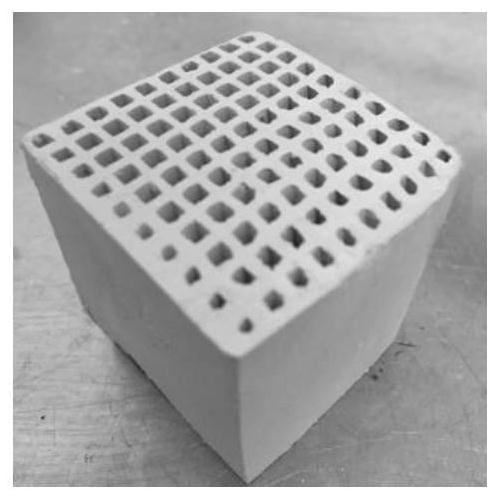

[0034] see in conjunction figure 1 As shown, a method for preparing a recyclable monolithic hydrophobic honeycomb molecular sieve VOCs adsorbent (hereinafter referred to as honeycomb molecular sieve adsorbent or honeycomb molecular sieve adsorbent or honeycomb molecular sieve) specifically includes the following steps:

[0035]1) Mixing mud: Mix 300g of high-silicon (silicon-aluminum ratio greater than 300) hydrophobic ZSM-5 molecular sieve powder, 50g of 40% alkaline silica sol, 30g of hydroxypropyl methylcellulose, and 20g of squid powder. Finally, add water to adjust the humidity to 50%, then slowly pour it into the kneader and knead (30min); put the above-mentioned uniformly mixed wet material in a vacuum mud refining machine and repeatedly mix and extrude it for 3 times, and control the mud during the mud refining process. The temperature is 25°C and the vacuum is 10KPa.

[0036] 2) Extrusion molding and drying and roasting: Put the mud after refining mud into a vacuum e...

Embodiment 2

[0039] A method for preparing a recyclable monolithic hydrophobic honeycomb molecular sieve VOCs adsorbent (hereinafter referred to as honeycomb molecular sieve adsorbent or honeycomb molecular sieve adsorbent or honeycomb molecular sieve), specifically comprises the following steps:

[0040] 1) Mixing mud: After mixing 200g of high-silicon (silicon-aluminum ratio about 100) hydrophobic Y molecular sieve powder, 40g of 40% alkaline silica sol, 25g of hydroxypropyl methylcellulose, and 10g of squash powder, Then add water to adjust the humidity to 60%, then slowly pour into the kneader and knead (30min); put the above-mentioned uniformly mixed wet material in a vacuum mud refining machine and repeatedly mix and extrude it for 3 times, and control the temperature of the mud during the mud refining process The temperature is 25°C, and the vacuum degree is 10KPa.

[0041] 2) Extrusion molding and drying and roasting: Put the mud after refining mud into a vacuum extrusion molding m...

Embodiment 3

[0044] A method for preparing a recyclable monolithic hydrophobic honeycomb molecular sieve VOCs adsorbent (hereinafter referred to as honeycomb molecular sieve adsorbent or honeycomb molecular sieve adsorbent or honeycomb molecular sieve), specifically comprises the following steps:

[0045] 1) Mixing mud: Mix 200g of high-silicon (silicon-aluminum ratio greater than 300) hydrophobic ZSM-5 molecular sieve powder, 30g of 40% alkaline silica sol, 20g of hydroxypropyl methylcellulose, and 10g of squid powder. Finally, add water to adjust the humidity to 60% and then slowly pour it into the kneader for kneading (15min); put the above-mentioned uniformly mixed wet material in a vacuum mud mill and repeatedly mix and extrude it for 3 times, and control the mud during the mud refining process. The temperature is 25°C and the vacuum is 10KPa.

[0046] 2) Extrusion molding and drying and roasting: Put the mud after refining mud into a vacuum extrusion molding machine for extrusion mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com