Patents

Literature

83 results about "Nail structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

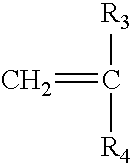

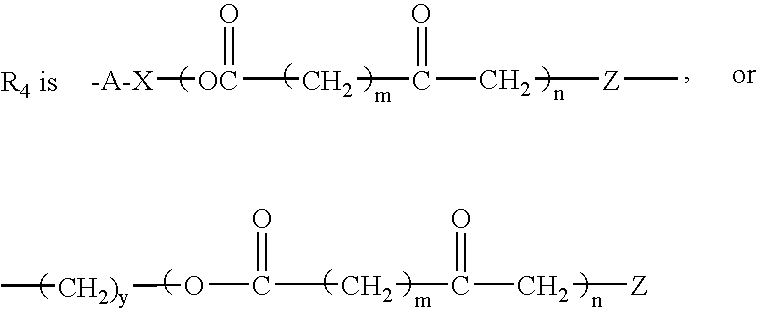

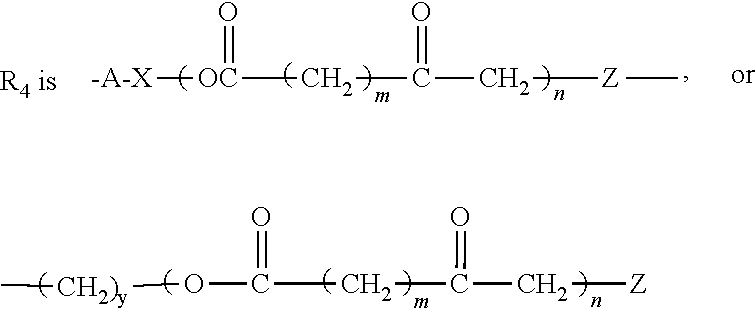

Artificial nail compositions and related methods

The invention comprises a polymerizable monomer composition for application to the nail surface and polymerization thereon to yield an artificial nail structure, comprising at least one multicarbonyl-vinyl containing monomer; a polymerized artificial nail structure having a thickness of about 10-60 mils, and a modulus of elasticity of about 550-800 N / m2, comprising a copolymer of at least one ethylenically unsaturated monomer and a multicarbonyl vinyl-containing monomer; a method for reducing, ameliorating, or eliminating delamination of an artificial nail structure from the natural nail surface; a method for improving adhesion of an artificial nail structure to the nail surface; and a method for reducing premature gelation of a liquid monomer composition.

Owner:CREATIVE NAIL DESIGN SYST INC

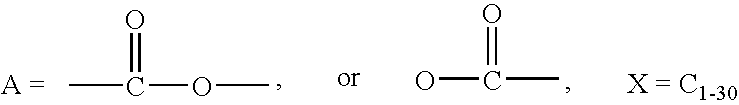

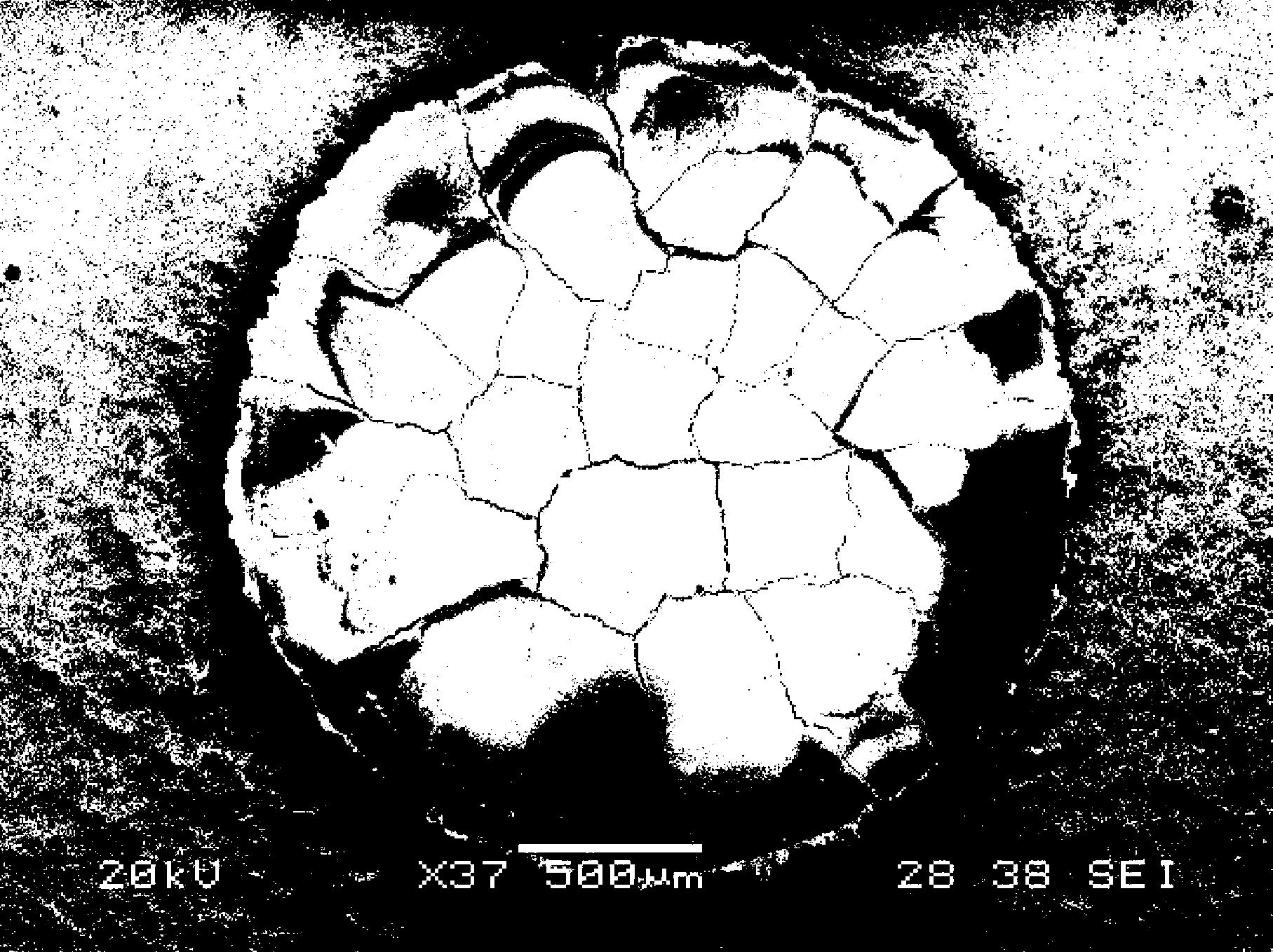

Laser surfacing modification method for thermal barrier coating

ActiveCN103266295AHigh bonding strengthImprove thermal fatigue lifeMolten spray coatingEfficient propulsion technologiesStress concentrationThermal fatigue

The invention relates to a laser surfacing modification method for a thermal barrier coating. The method comprises the following steps of: firstly, carrying out washing and sand blasting on the surface of a base body; then, preparing the thermal barrier coating in a thermal spraying state on the surface of the base body; then, designing shape, size, arrangement rule and distribution density of laser modification unit bodies in a pile nail structure to be prepared in the thermal barrier coating; then, adjusting the process parameters of a laser according to a design model; then, performing laser modification to the thermal barrier coating; and finally, performing the stress relief annealing treatment to the laser modified thermal barrier coating. With the adoption of the method for arranging discontinuous and dispersed intensifying unit bodies in the pile nail structure in the thermal barrier coating, the thermal barrier coating can not only generate characteristic of soft and hard alternate change, but also generate the 'pinning effect', thus not only relieving stress concentration at the crack tip of the coating and reducing the crack rate of the coating, but also extremely improving the bonding strength of the coatings, prolonging the thermal fatigue service life of the thermal barrier coating, improving the tissue structure of the coating and improving the compactness of the coating.

Owner:FOSHAN TAOYUAN INST OF ADVANCED MFG

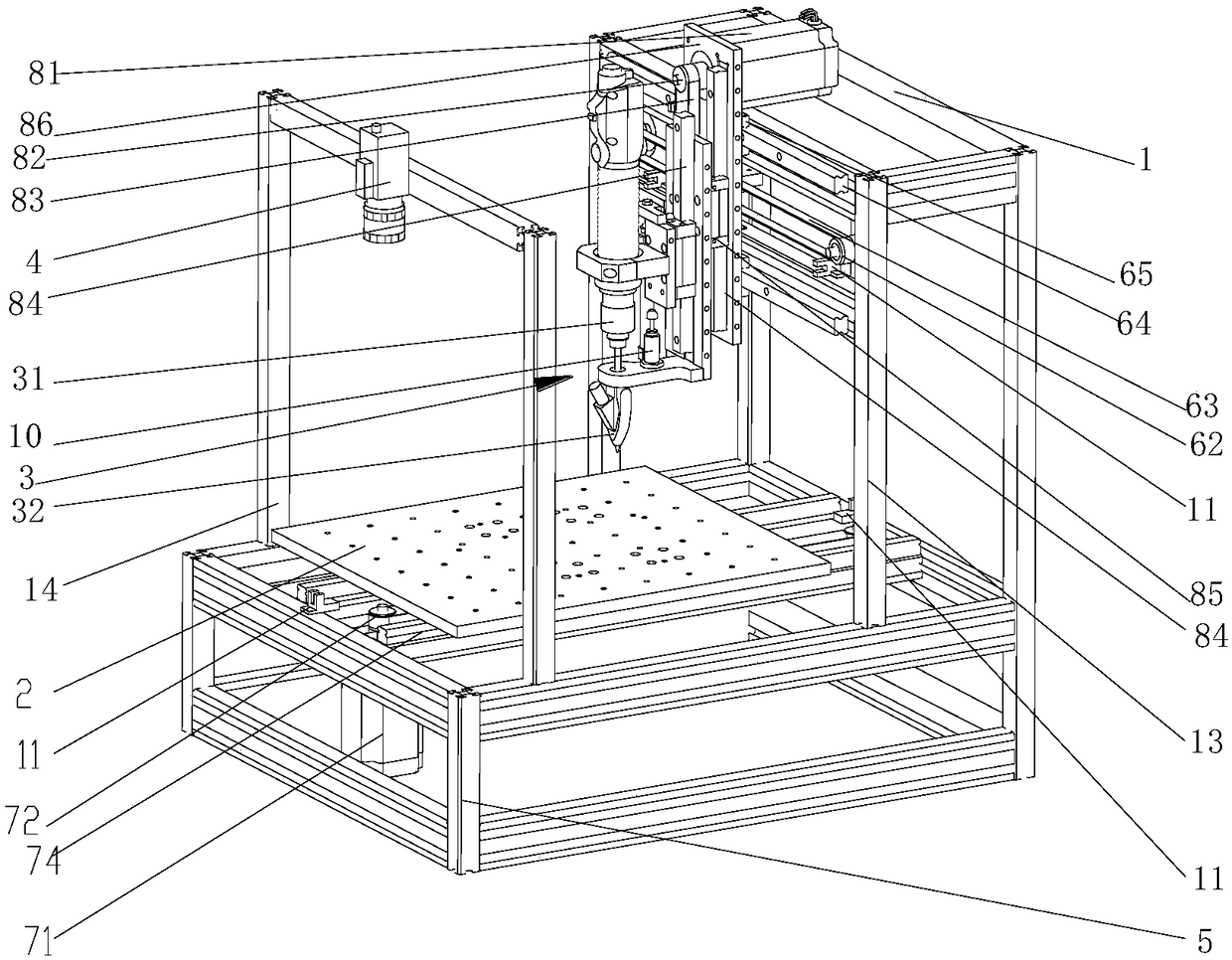

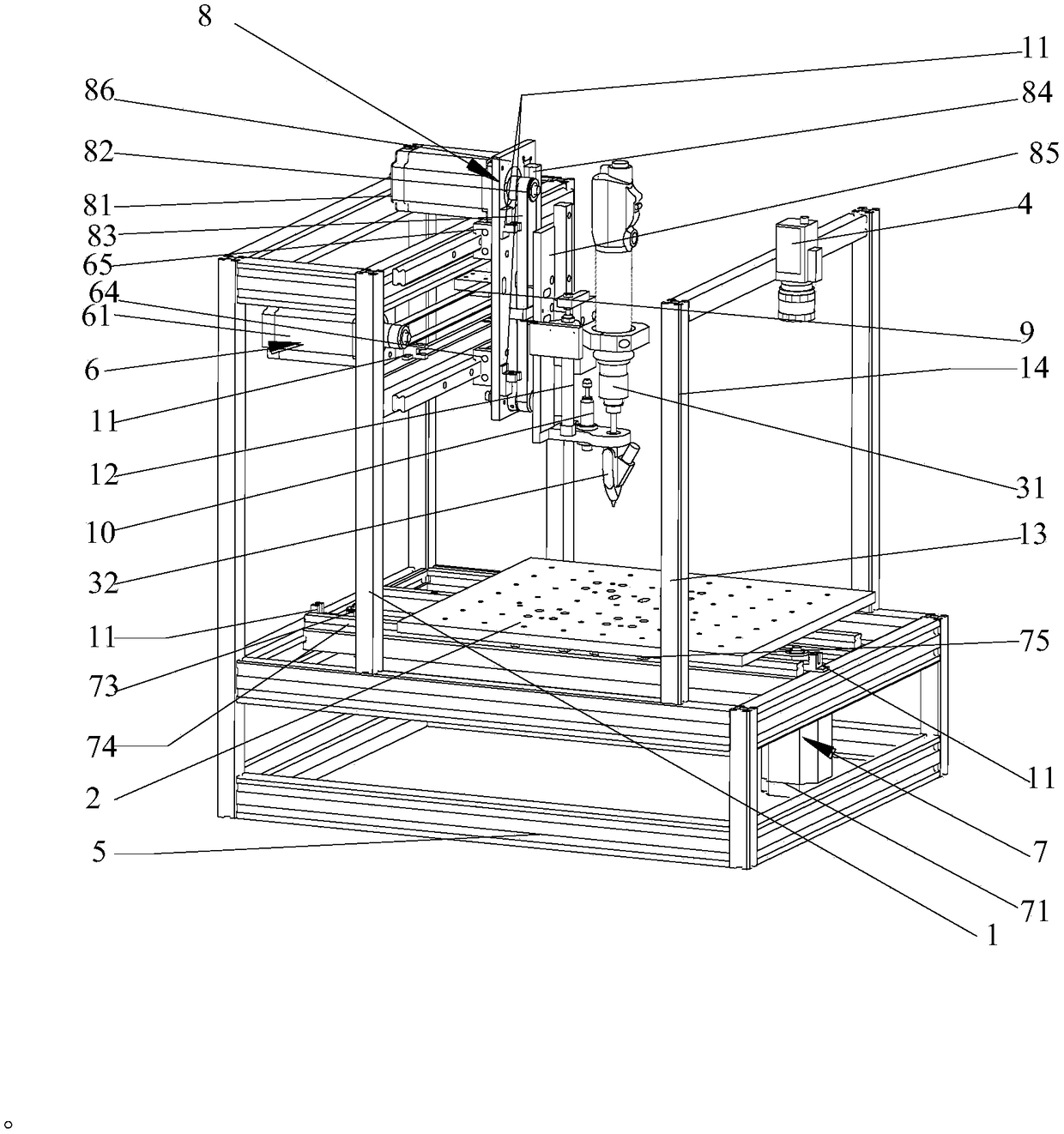

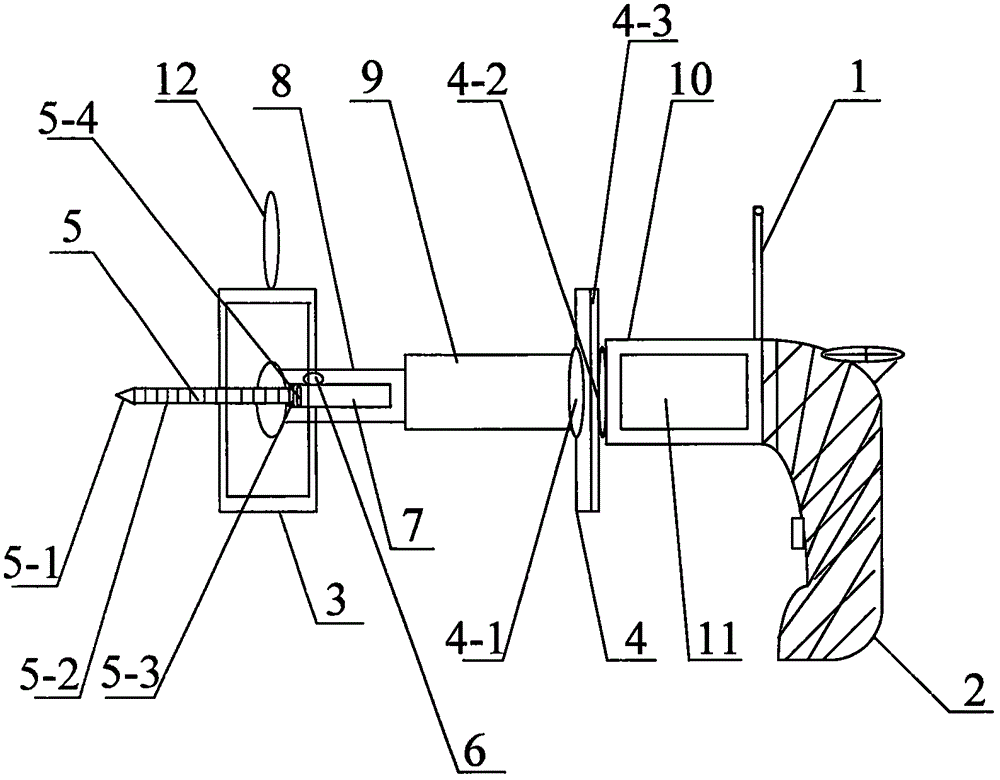

Automatic screw locking device

PendingCN108311877AReduce volumeImprove nailing efficiencyMetal working apparatusLocking mechanismEngineering

The invention discloses an automatic screw locking device, which comprises a machine body with a built-in programable logic controller (PLC), and a working platform arranged on the machine body. A screw locking mechanism and a camera arranged oppositely are arranged above the working platform; the working platform is fixed onto a base of the machine body through a Y-axis axial movement mechanism;a fixture mechanism is fixedly arranged on the working platform; and the screw locking mechanism is fixed onto the machine body through a Z-axis axial movement mechanism and an X-axis axial movement mechanism. According to the automatic screw locking device provided by the invention, by adopting the camera and a multisensory, and combining with an X-axis, Y-axis and Z-axis three-dimensional positioning technology, screw holes are accurately positioned, so that the inaccuracy in positioning the screw holes caused by deformation and deviation of the screw holes is avoided, and the screw lockingrate and the product qualification rate are improved; and the outer part of a screw clamp head is connected with a nail blowing mechanism, so that an effective space of the working platform is saved,meanwhile, an electric screwdriver has no need to move to an arrangement part of a screw nail structure back and forth so as to adsorb nails, and the nailing efficiency is improved.

Owner:WUYI UNIV

Spike nail structure

Owner:JOKER IND CO LTD

Method of treating onychomycosis

Owner:DUSA PHARMA INC

Artificial nail compositions and related methods

The invention comprises a polymerizable monomer composition for application to the nail surface and polymerization thereon to yield an artificial nail structure, comprising at least one multicarbonyl-vinyl containing monomer; a polymerized artificial nail structure having a thickness of about 10-60 mils, and a modulus of elasticity of about 550-800 N / m2, comprising a copolymer of at least one ethylenically unsaturated monomer and a multicarbonyl vinyl-containing monomer; a method for reducing, ameliorating, or eliminating delamination of an artificial nail structure from the natural nail surface; a method for improving adhesion of an artificial nail structure to the nail surface; and a method for reducing premature gelation of a liquid monomer composition.

Owner:CREATIVE NAIL DESIGN SYST INC

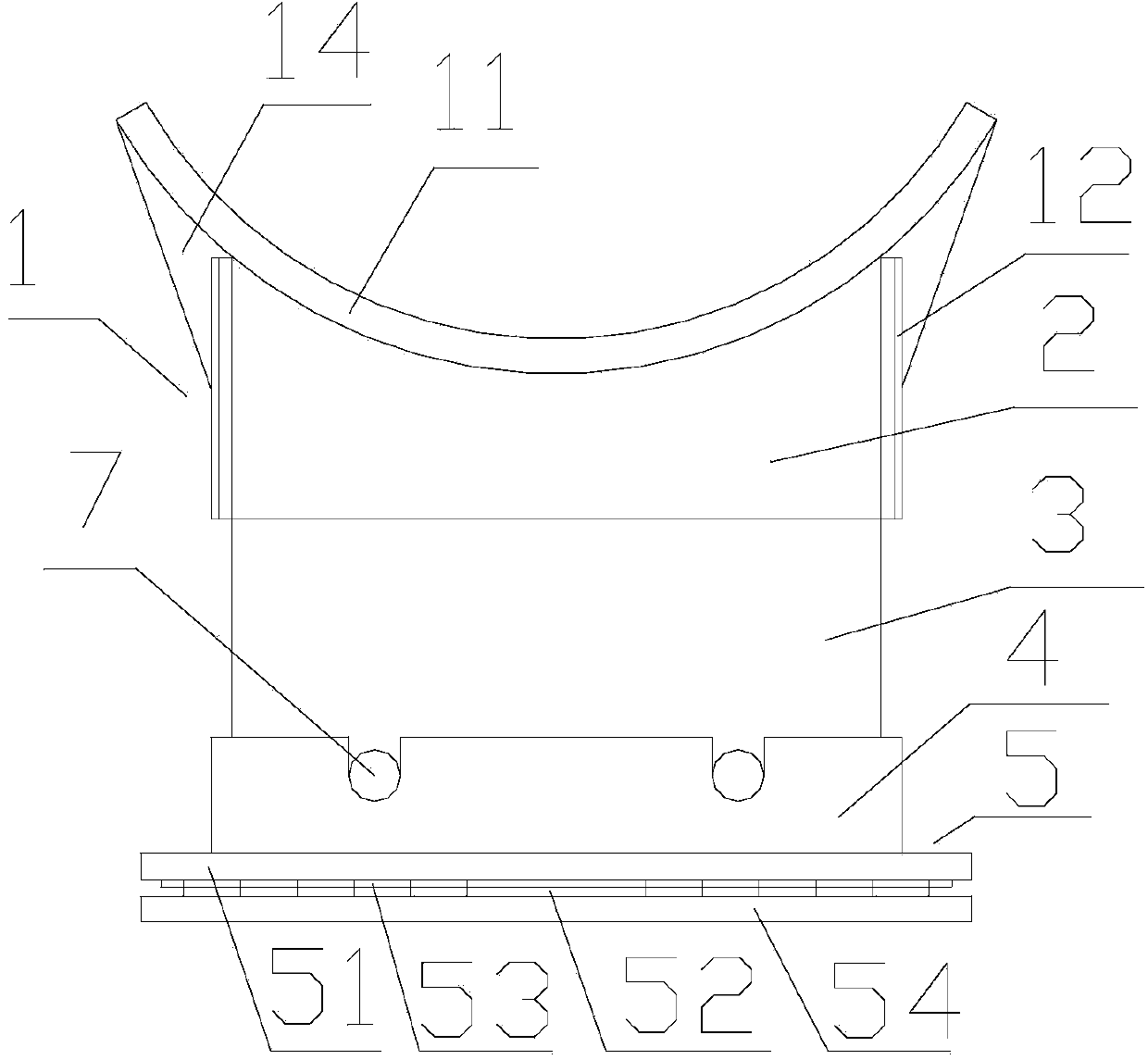

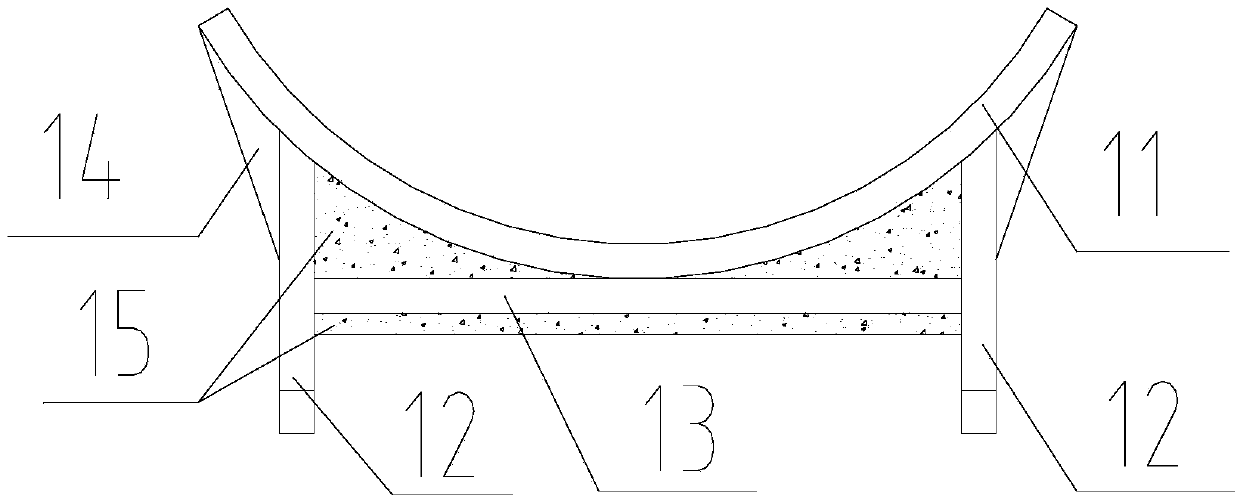

High-temperature pipeline heat insulation support

ActiveCN103807570AMeet strength requirementsReduce usagePipe supportsThermal insulationEngineeringPetrochemical

The invention relates to a matched product of a petrochemical pipeline, in particular to a high-temperature pipeline heat insulation support. The high-temperature pipeline heat insulation support comprises a pipeline connection component, a heat insulation block, a base connection component and a base and is characterized in that a pipeline is lifted by the upper end of the pipeline connection component; the lower end of the pipeline connection component is connected with the top end of the heat insulation block; the lower end of the heat insulation block is fixed on the base by the base connection component. The high-temperature pipeline heat insulation support has the following advantages: 1, a heat insulation material is used as a component of a pipe holder supporting component, so that not only the requirement on intensity of a pipe holder, but also the requirement on a heat insulation effect of the pipe holder are met, and the effective heat insulation thickness is effectively increased; 2, in the working process, the axial thrust of the pipeline can be balanced out by a baffle and compared with a conventional anchoring nail structure, the high-temperature pipeline heat insulation support can bear a larger axial force; 3, the size of the heat insulation block assembly is not restrained by the sizes of the pipeline connection component and the base connection component, modular production can be carried out, universality is improved, and cost is reduced; 4, the use amount of steels is reduced, the welding quantity is small, and the workload of production is reduced.

Owner:中申(上海)管道工程股份有限公司

Cut-tobacco drier frying cylinder

InactiveCN103431511AImprove loose efficiencyImprove uniformityTobacco preparationNail structureNozzle

The invention discloses a cut-tobacco drier frying cylinder which comprises a cylinder body, wherein a plurality of sets of target nail structures are arranged on the cylinder walls of the inlet end and the outlet end of the cylinder body respectively, and a plurality of sets of turning plate structures are arranged on the cylinder wall of the middle of the cylinder body. Each turning plate structure comprises a bottom plate, wherein two sets of vertical plats are arranged on each bottom plate at intervals, and the bottom of each vertical plate is provided with a cocked arc bent plate. The inlet end and the outlet end of the cylinder body are provided with a water adding spraying nozzle and a material adding spraying nozzle respectively. According to the cut-tobacco drier frying cylinder, tobacco loosening efficiency is improved, the loosening rate reaches 99.9%, evenness of material adding is improved obviously, process technological index requirements are met, and a prospective effect is achieved.

Owner:SUZHOU YEMING PLASTIC PRODS FACTORY

Enclosure connecting structure

The invention discloses an enclosure connecting structure, which comprises a connecting pair constituted by a main connecting part and an auxiliary connecting part, wherein the back ends of the main connecting part and the auxiliary connecting part are fixed with an enclosure, pin holes are arranged at the front end of the main connecting part and the front end of the auxiliary connecting part, a pin shaft penetrates the pin holes for hinging the main connecting part and the auxiliary connecting part together, the bottom end of the pin shaft adopts a tooth nail structure and extends out of the pin hole, and a fastening head is fixed at the top end of the pin hole. On the basis of the hinged enclosure connecting structure, the bottom end of the pin shaft adopts a tooth nail structure and extends out of the pin hole, and a tooth nail can be conveniently and firmly embedded in the mounting surface, so that the enclosure connecting structure is not only easy to fix but also less prone to deformation; furthermore, the fastening head is fixed at the top end of the pin hole, so that a pin is less prone to shedding, and detachment is also convenient; after the fastening head is detached, a layer of the enclosure can also be superimposed, and only the tooth nail on an upper-layer enclosure connecting part needs to be inserted into the top end of the pin hole, so that the structure is simple and the connection is convenient.

Owner:ZHEJIANG YUANSENTAI FURNITURE

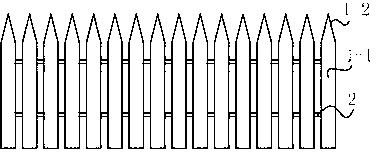

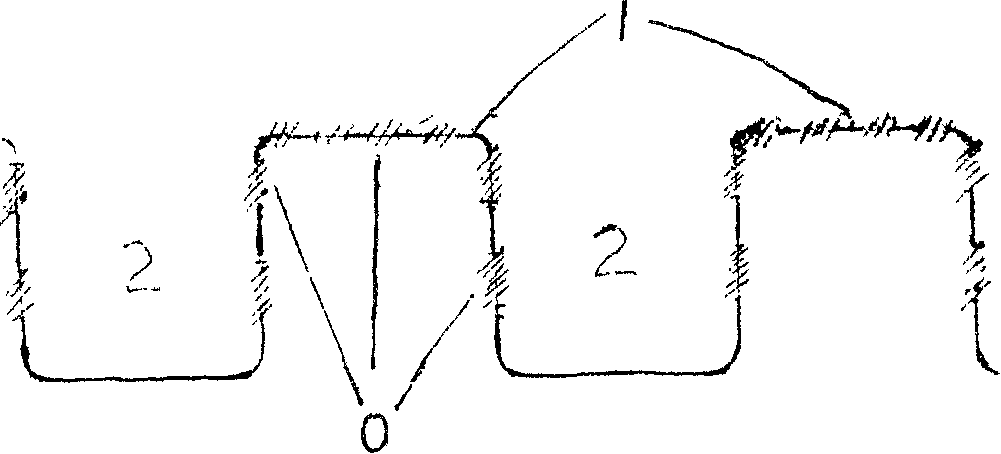

Preparation method of high-molecular composite material strip nail

InactiveCN103254615AHigh strengthReduce weightStaplesNailsInjection molding machineInjection moulding

The invention relates to a preparation method of high-molecular composite material strip nail. Strength and toughness of plastic nails prepared by present methods are not high enough. The method provided by the invention comprises the following steps: firstly uniformly mixing nylon resin, glass fibre, a toughening modifier, a filler, a coupling agent, an anti-oxidant and a lubricant in proportion, and carrying out melt extrusion for pelleting; drying pellets, and forming by injection moulding in an injection machine to form a strip nail structure which comprises a plurality of individual nail bodies which are arranged in parallel, wherein two adjacent individual nail bodies are connected with each other through a connecting rod and a sidewall of each nail body part is provided with an elongated groove; and dipping and drying the injection-moulded material by the use of a silicone oil acetone solution, so as to obtain the high-molecular composite material strip nail. The high-molecular composite material strip nail prepared by the method has characteristics of high strength, light weight, rust resistance, corrosion resistance, antistatic performance, colorable performance and stable performance, and is convenient for secondary processing.

Owner:HANGZHOU HAIXUE TECH

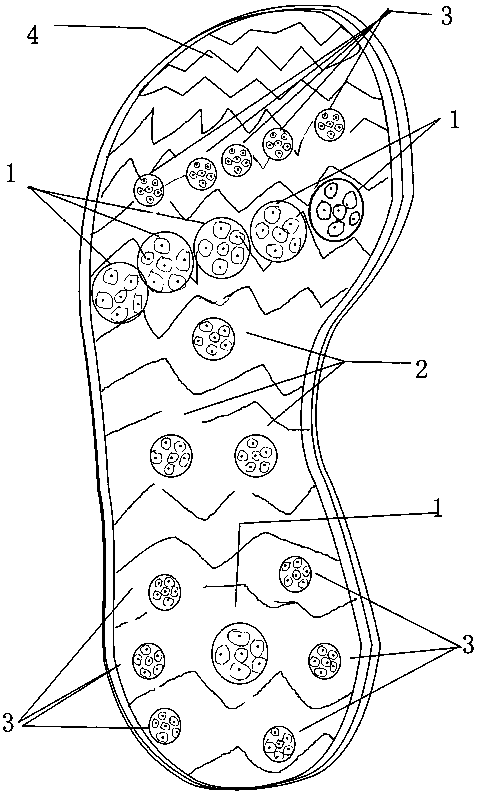

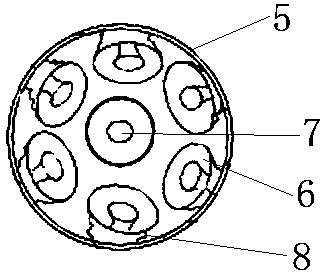

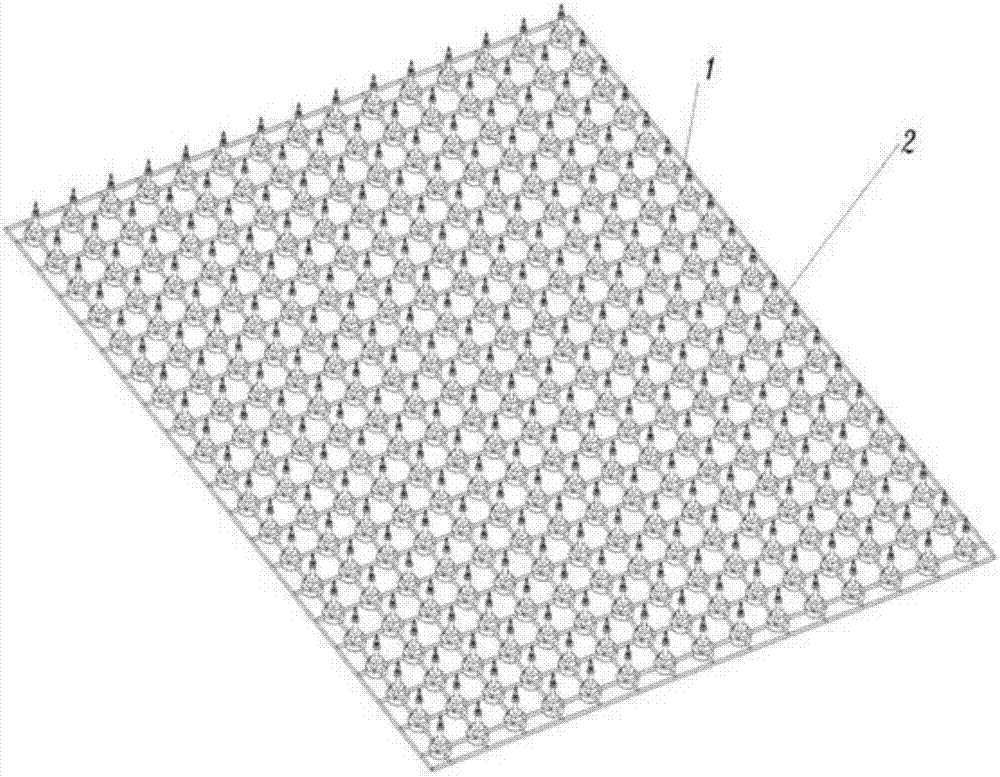

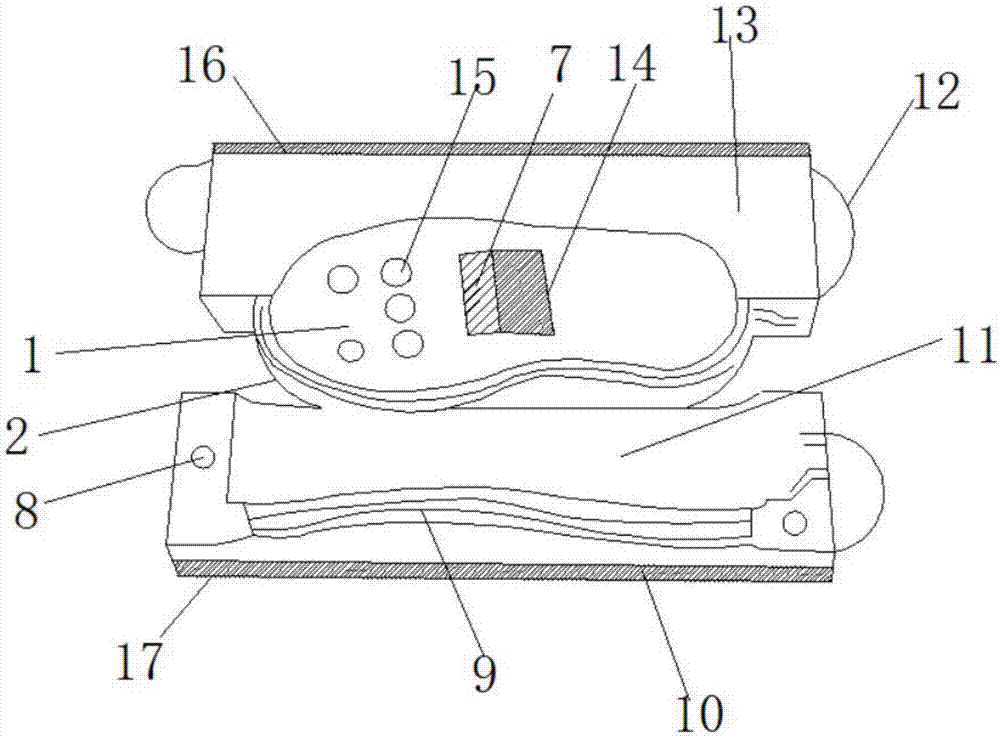

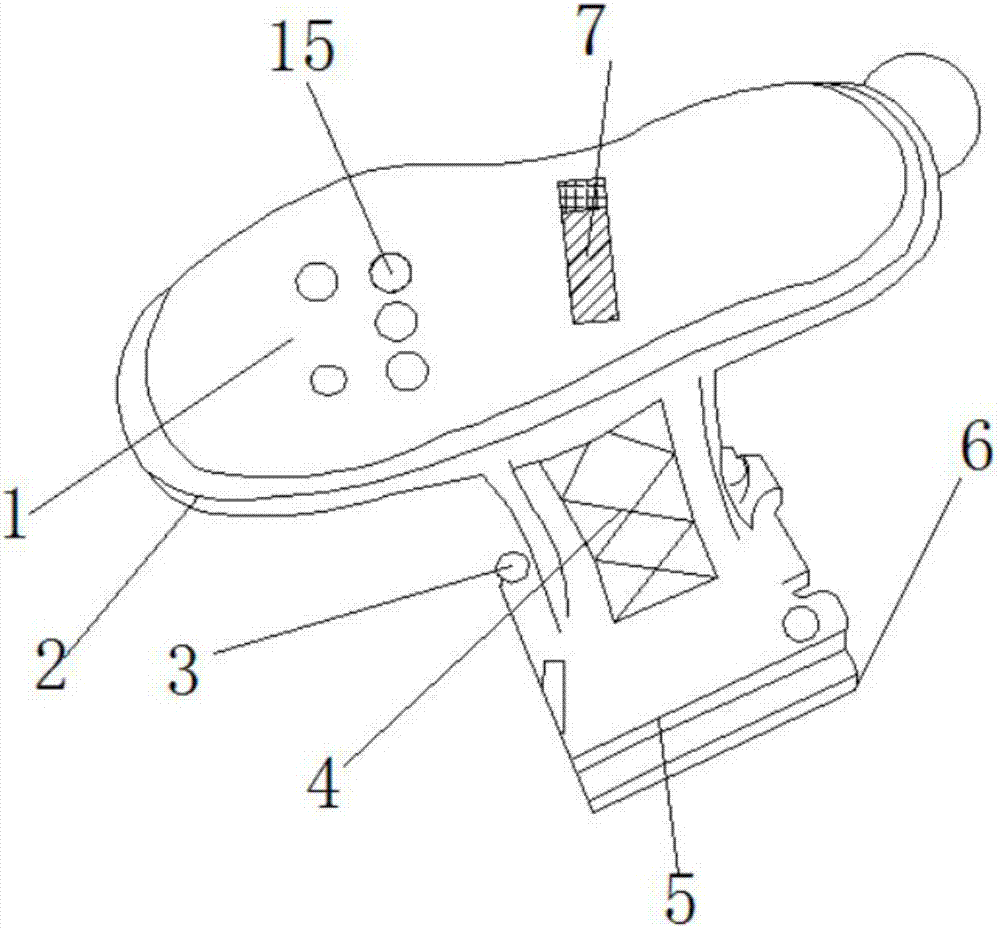

Rotary anti-skid shoe sole for children

ActiveCN107802054AImprove skid resistanceSolesTextile/flexible product manufactureFoot solesClassical mechanics

The invention relates to a rotary anti-skid shoe sole for children. A plurality of protruding rotatable circular anti-skid nail structures different in size are designed on the shoe sole to form a step-by-step anti-skid system. The rotatable anti-skid structures can change directions on the uneven ground to achieve a multidirectional anti-skid function. A plurality of micro-adsorption structures in the shoe sole can form a plurality of miniature closed spaces in different directions, so that the adsorption performance is enhanced, and the multidirectional anti-skid effect is achieved. The anti-skid nails different in size are arranged according to foot sole mechanical paths and pressure distribution areas in the walking process of children, so that each area of the foot soles of children can provide strong anti-skid performance in each stage of the walking process. In addition, the anti-skid nails of the shoe sole are connected by inclined patterns so that friction force can be increased to achieve the secondary anti-skid effect.

Owner:SHAANXI UNIV OF SCI & TECH

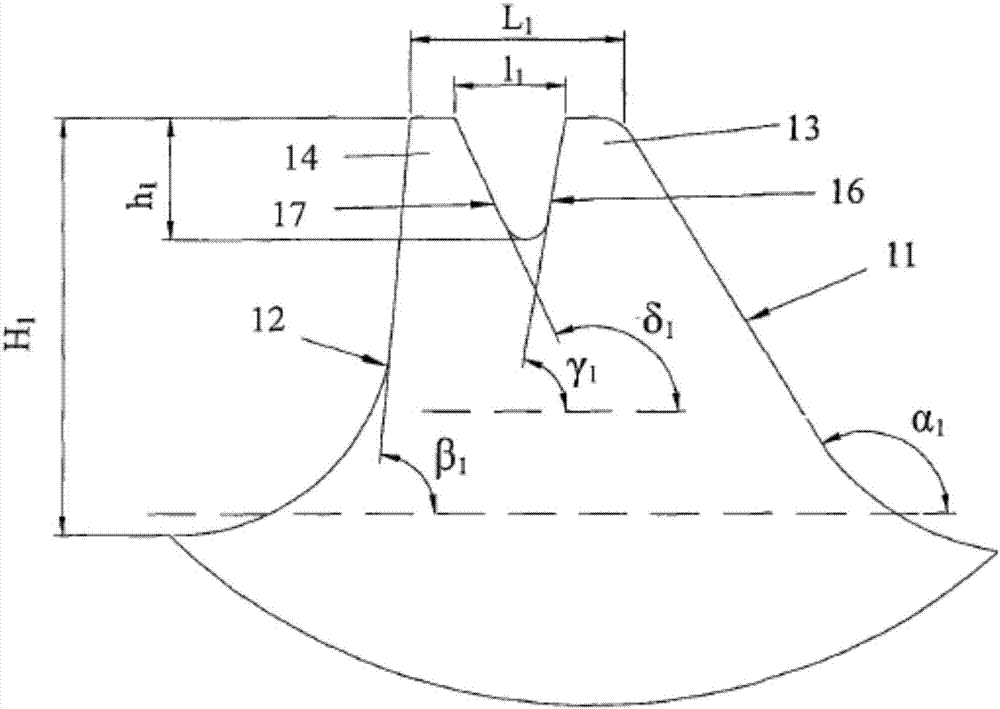

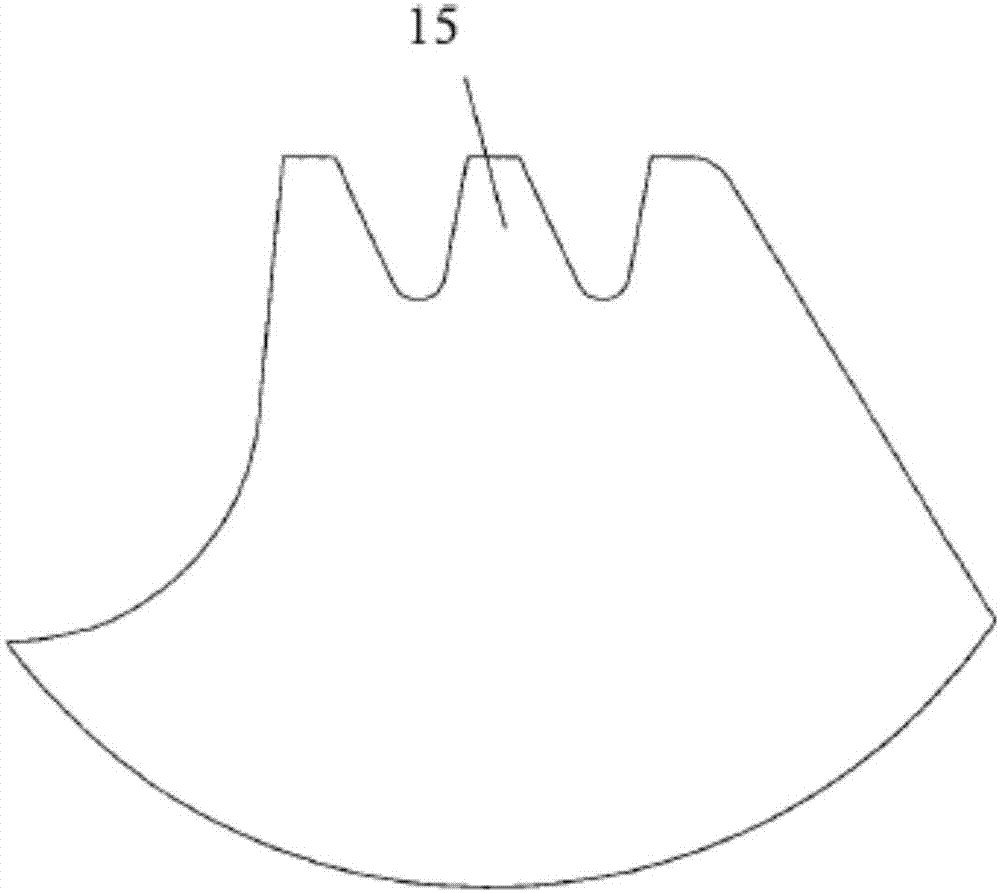

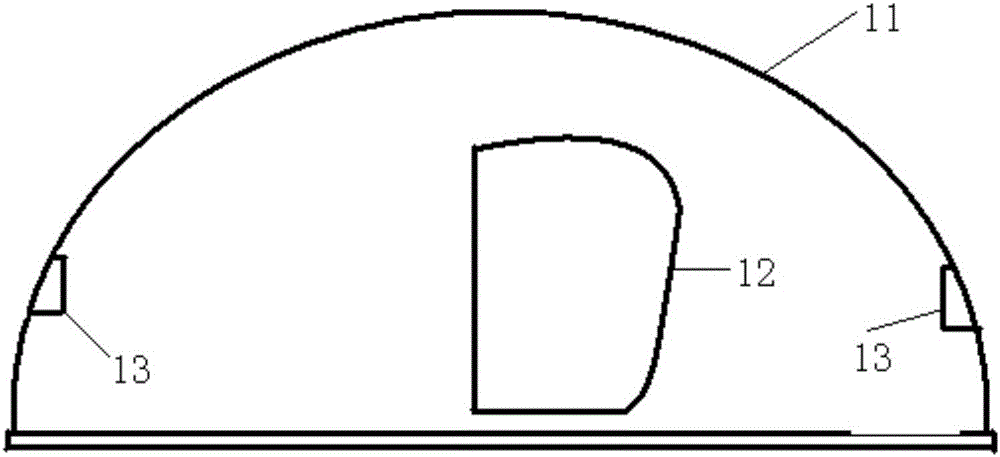

Medical cranium nail structure

InactiveCN107280756ADoes not reduce inner diameterIncreased contact surface areaFastenersDefect repairMolecular materials

The invention discloses a medical cranium nail structure. The cranium nail structure includes first threads with first front surfaces, first rear surfaces and crests, second threads which include second front surfaces and second rear surfaces are formed on at least part of the crests of the first threads, the shapes of sections, in the cross section of the axis of a bolt, of at least part of the second threads are changeable, the mode of change includes gradual change, sudden change and the combination of the gradual change and the sudden change, the first threads include conical thread root diameters, and the thread pitches of the second threads are changeable; a penetrating-through cavity is formed in the middle of a cranium nail, the upper end portion of the cavity is provided with a hexagonal groove segment, the bottom of the hexagonal groove segment and the bottom of the cavity are both provided with plugs, and the cranium nail is prepared by the adoption of a medical polyether-ether-ketone macromolecular material. The medical cranium nail structure is simple in structure and convenient to use; by the adoption of the medical cranium nail structure and a preparation method thereof, surgical effects are good, standardized convenient preparation can be achieved, and the effect on a cranium defect repair is good.

Owner:KONTOURXIANMEDICAL TECH CO LTD

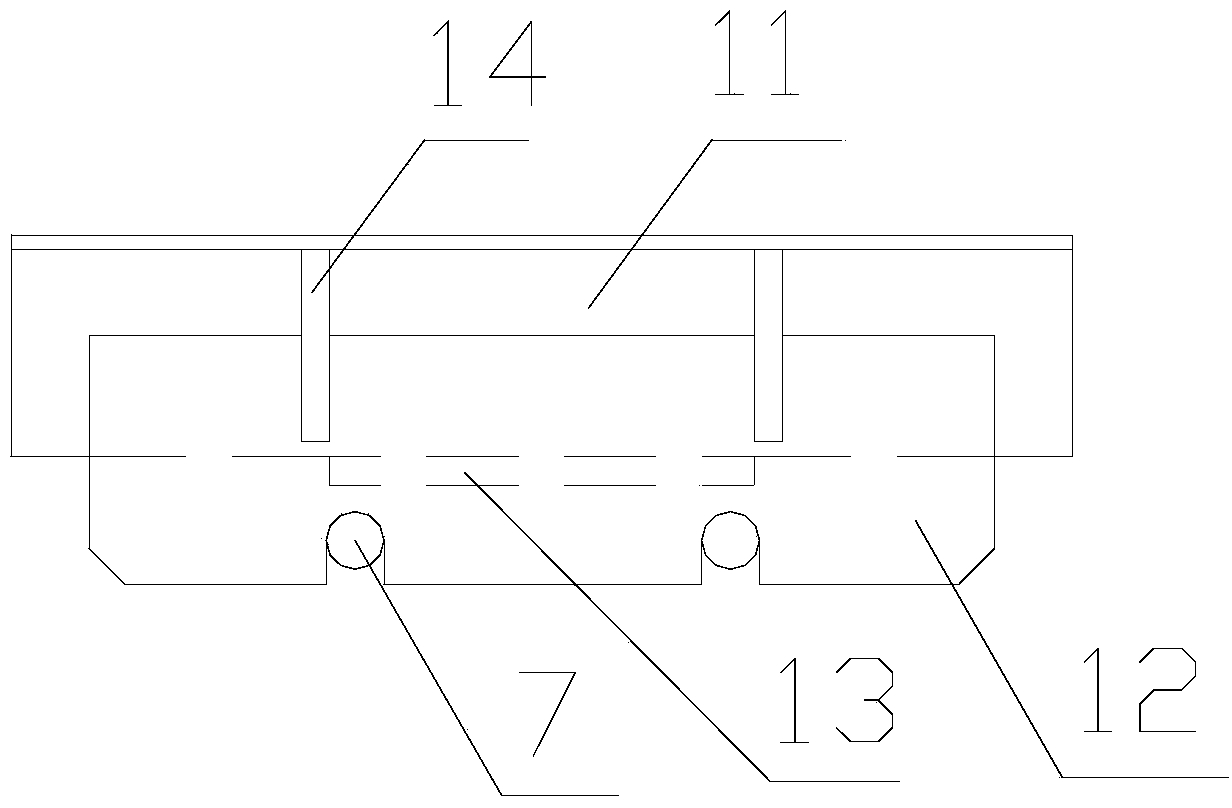

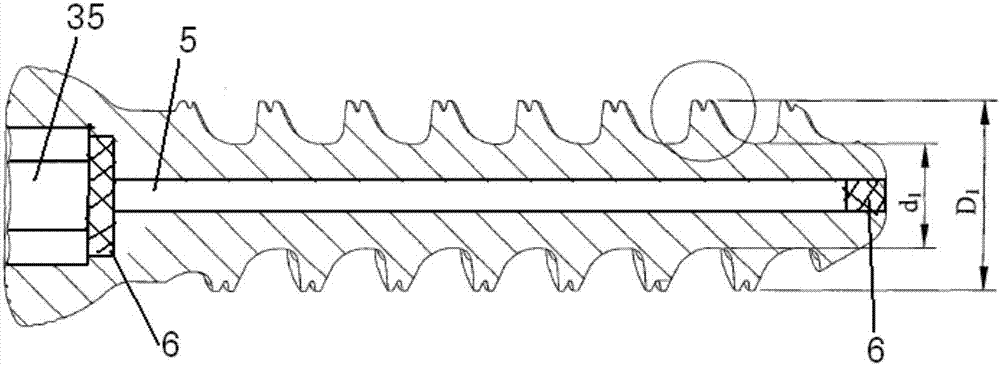

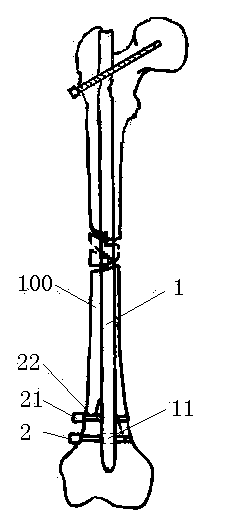

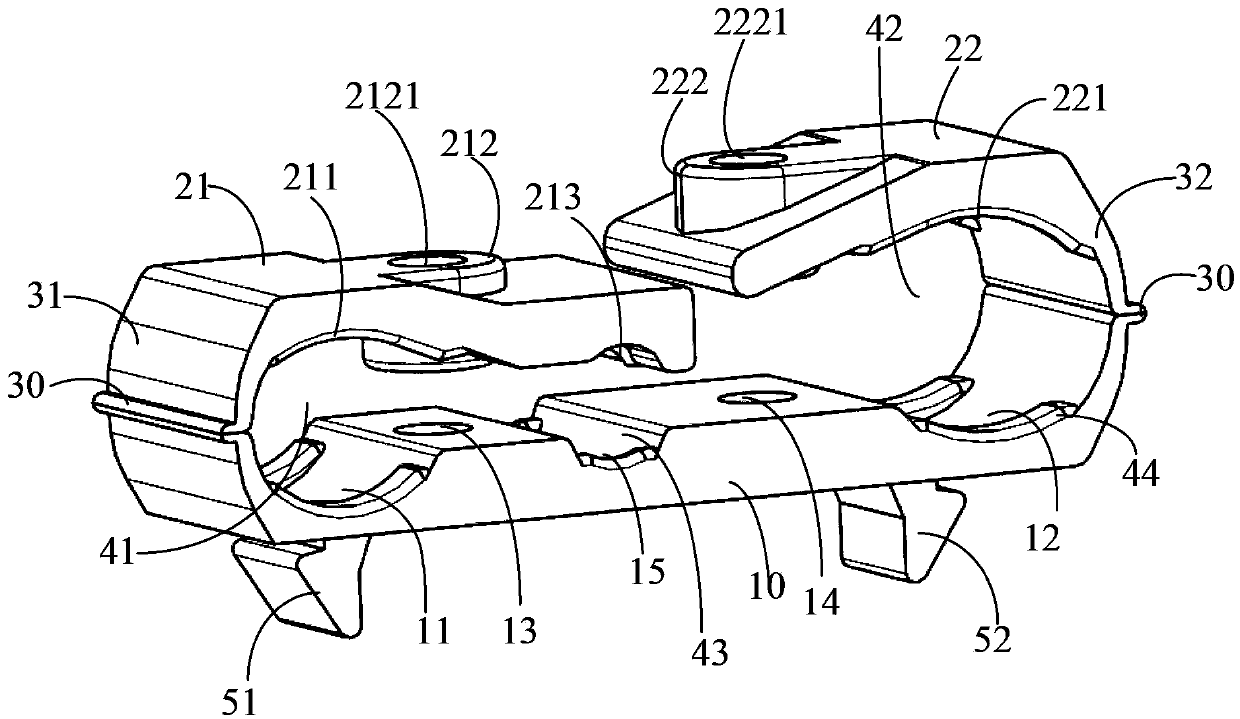

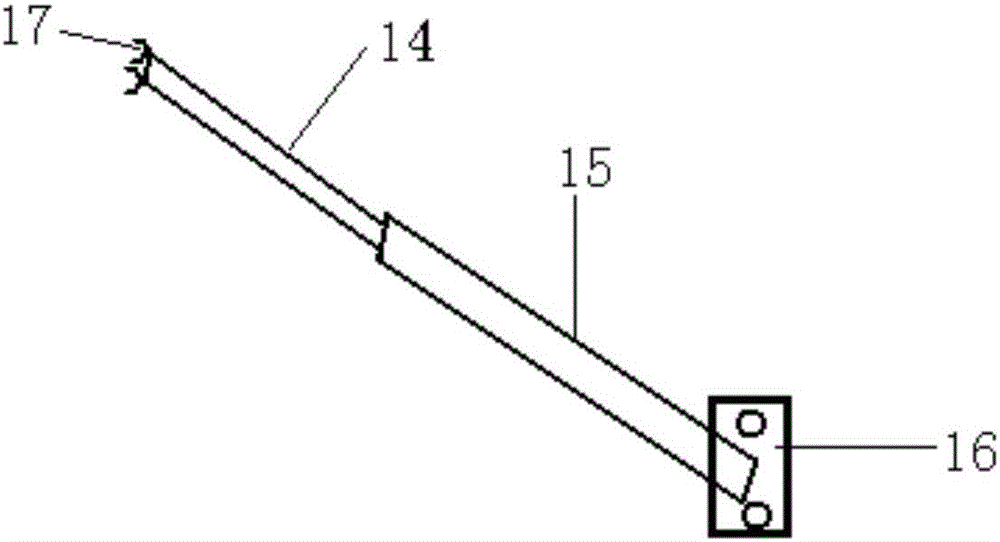

Double-locking intramedullary nail structure

InactiveCN103800064APromote healingAvoid shakingInternal osteosythesisBiomedical engineeringNail structure

The invention discloses a double-locking intramedullary nail structure. The intramedullary nail structure comprises an intramedullary nail rod and a screw used for being fixedly connected with the intramedullary nail rod, a hole is formed in the close end or the far end of the intramedullary nail rod and used for being connected with the screw, and a locking structure is arranged at the position of the hole and used for locking a screw rod inserted into the hole. The double-locking intramedullary nail structure facilitates operation in surgery, the end, located outside the long bone, of the screw can be connected with long bone threads in a locked mode, and the end, located inside the long bone, of the screw can be locked with the intramedullary nail rod, so that double-locking connection between the intramedullary nail rod and the screw is achieved, and the intramedullary nail rod is prevented from waggling or shifting in the long bone, which is beneficial to knitting.

Owner:SUZHOU UNIV

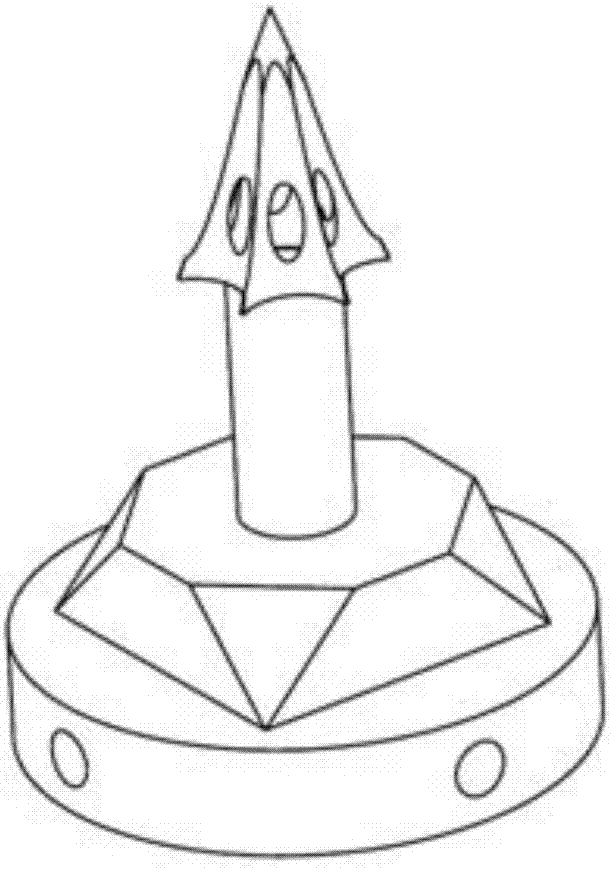

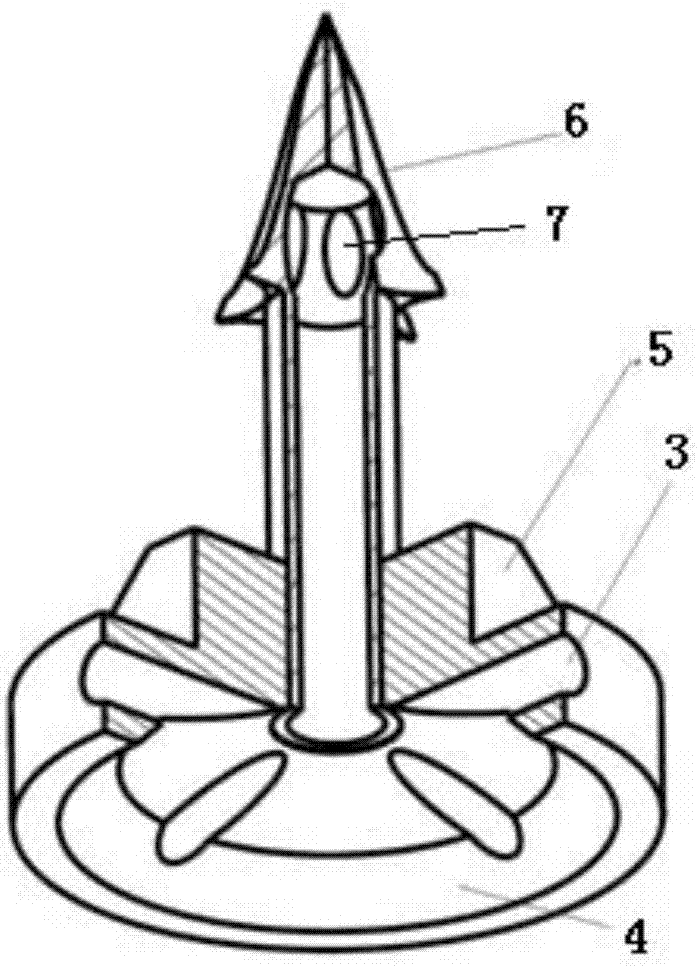

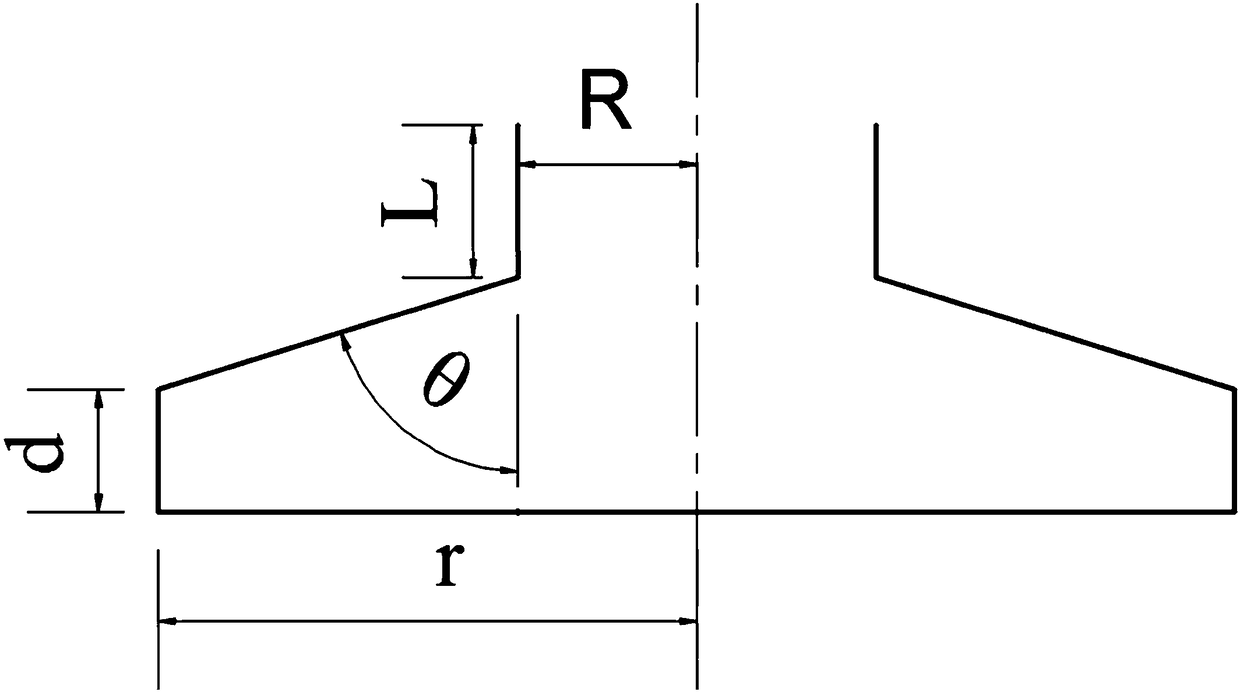

Tire puncturing nail structure of net type tire puncturing stopper

InactiveCN107288065ATo facilitate the execution of official dutiesQuick lockTraffic restrictionsEngineeringCarbon steel

The invention discloses a tire puncturing nail structure of a net type tire puncturing stopper. The tire puncturing nail structure comprises a tire puncturing nail single body, the tire puncturing nail single body comprises a base and a tire puncturing nail, the upper portion of the base is of a round cake shaped top structure made of a cast iron material, a quadruple rim chamfering structure is arranged at the top of the base, the bottom of the base is of a round boss structure, mutually perpendicular connecting holes are formed in the side face of the bottom of the base, and are used for allowing aromatic polyamide fiber to penetrate through to achieve that a net body and the tire puncturing nail single body are mutually fixed, a conical air leakage cavity is arranged in the bottom of the base, and is communicated with the connecting holes, the tire puncturing nail single body is of a columnar structure made of medium carbon steel, the inside of the columnar structure is hollow, the top of the tire puncturing nail single body is of a pentagonal rim structure, air leaking holes are formed in the side face of the tire puncturing nail single body, and the hollow part of the bottom of the tire puncturing nail single body is communicated with the air leaking cavity. The tire puncturing nail structure of the net type tire puncturing stopper is simple in structure, convenient to manufacture and high in practicability.

Owner:GUIZHOU UNIV

Wire nail structure

The invention discloses a wire nail structure. The wire nail structure comprises an upper wall and a lower wall which are arranged correspondingly and side walls for connecting the upper wall and the lower wall, wherein a height difference exists between the upper wall and the lower wall; a plurality of accommodating spaces for accommodating a plurality of electric wires are arranged between the upper wall and the lower wall; each side wall is provided with one or more deformation parts capable of enabling the corresponding side wall to be deformed; an upper wall mounting hole and a lower wall mounting hole are further formed in the upper wall and the lower wall, and are used for fixing the upper wall and the lower wall. The electric wires with different functions are fixed in different accommodating spaces so as to ensure that the electric wires can be clamped in the accommodating spaces through the deformation difference on the deformation part on the wire nail, so that the design is more targeted, and meanwhile different wire diameters are also suitable for use.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

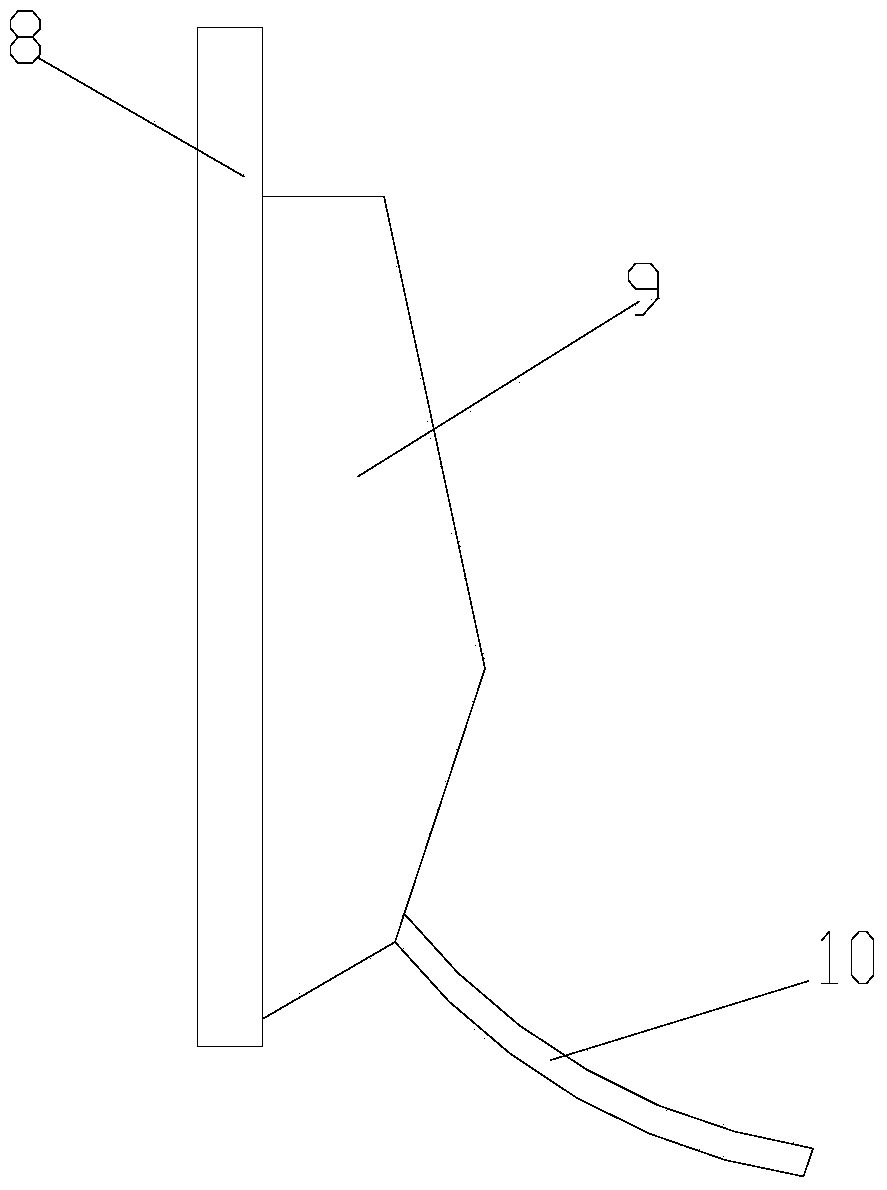

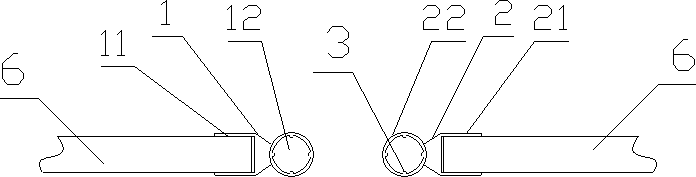

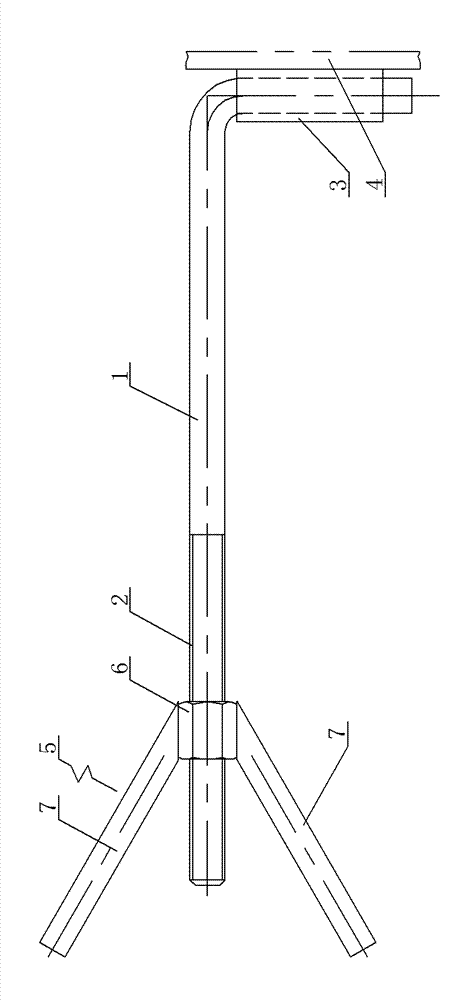

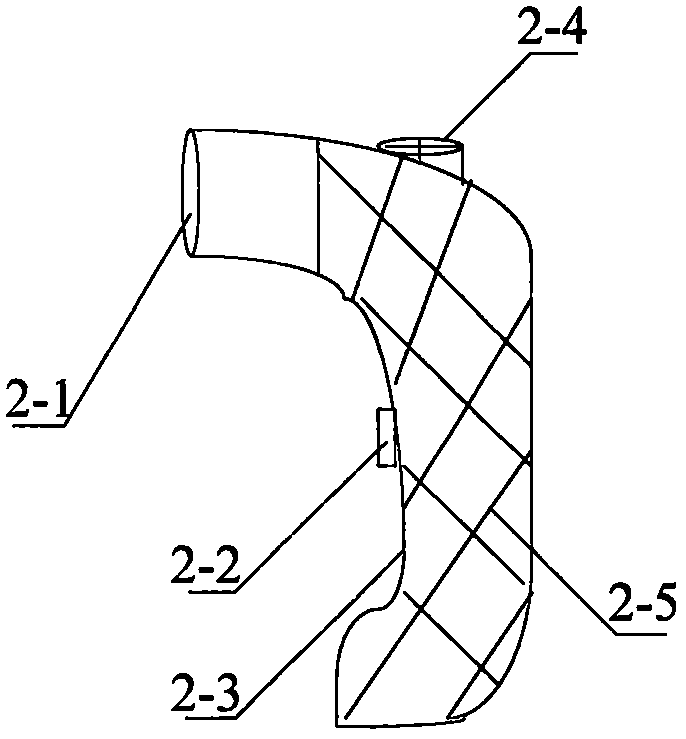

Adjustable Y-type furnace wall grasping nail structure

The invention provides an adjustable Y-type furnace wall grasping nail structure. Due to the structure, the length of Y-type furnace wall grasping nails can be adjusted according to the thickness of refractory materials, then the Y-type furnace wall grasping nails are high in generality, the design and production workload is reduced, and working efficiency is improved. The adjustable Y-type furnace wall grasping nail structure comprises a V-type head structure and an L-type force arm structure and is characterized in that the connection position of the V-type head structure is concretely of a nut structure, the outer walls on the two sides of the nut structure are respectively connected with a metal rod in a welded mode, the metal rods on the two sides are combined to form the V-type structure and are located in the same plane, one end of the L-type force arm structure is machined to be of an external thread structure, and the nut structure is in threaded connection with the external thread structure.

Owner:WUXI HUAGUANG BOILER

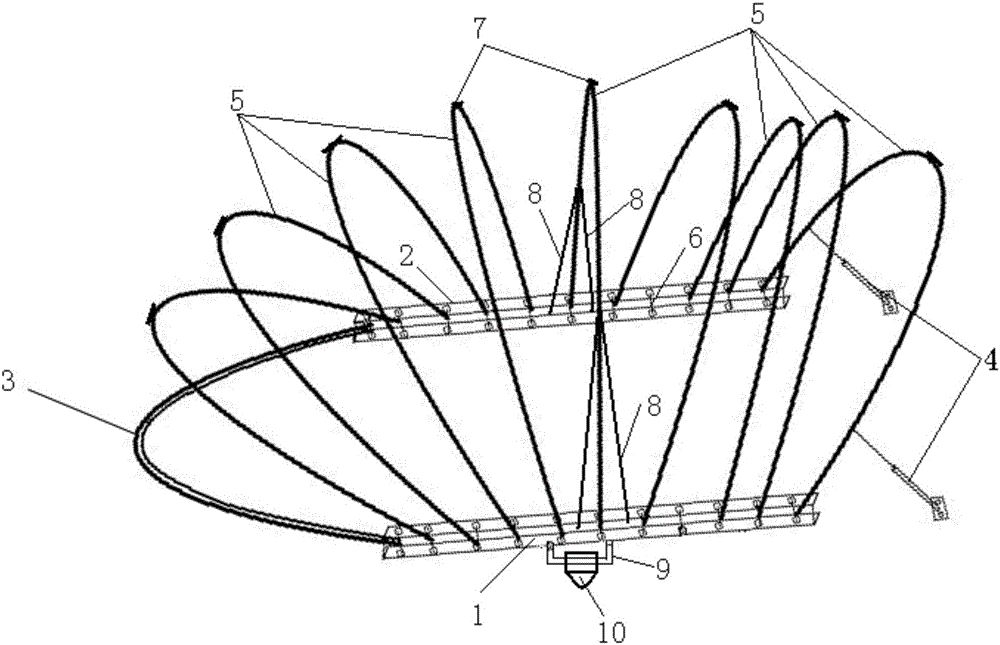

Energy saving type folding mobile storehouse

The invention belongs to the technical field of an energy saving garage, and relates to an energy saving type folding mobile storehouse. More than three rotating shafts of rotatable structures are arranged on a left support seat and a right support seat which are in parallel arrangement; a circular arc-shaped fixed supporting frame or a supporting frame of the same structure is arranged on each rotating shaft; the supporting frame positioned at the outermost side is fixed by a fixing seat to form a stable and firm storehouse framework; paulin with good waterproof and ventilation performance is cladded at the outer part of the storehouse framework through hook-loop adhesive tapes; a zipper door and visual windows are arranged on the paulin, so that great convenience is brought for the use of the storehouse by people; during building or dismounting, the building or dismounting of the whole storehouse can be realized by only screwing or unscrewing steel nail structures arranged on the fixing seat and screw structures arranged on the rotating shafts and sequentially mounting or dismounting the fixed supporting frame, the supporting frame and fixing seat. The energy saving type folding mobile storehouse has the advantages that the whole structure is simple; the design is scientific; the stability is high; the building is convenient; the dismounting is easy; the visual performance is good; the safety is high; the environment-friendly effect is achieved.

Owner:王丰波

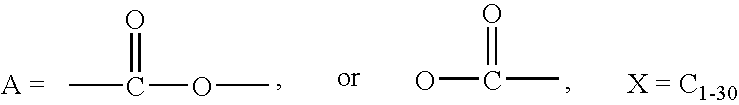

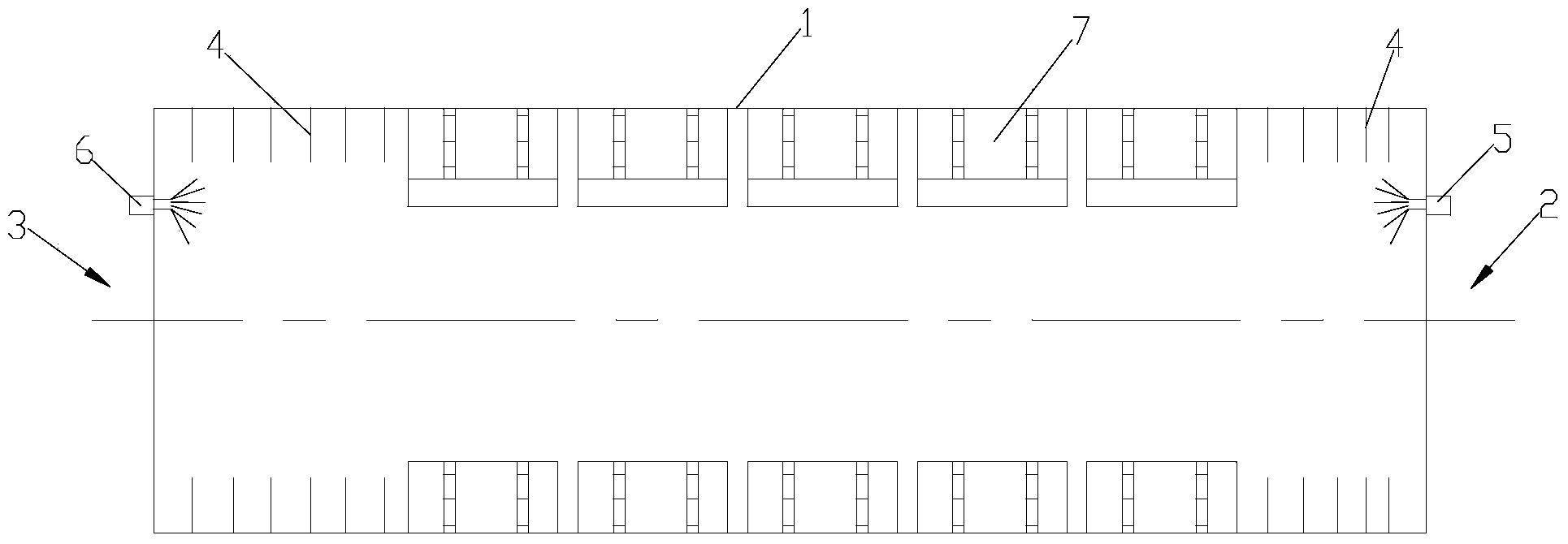

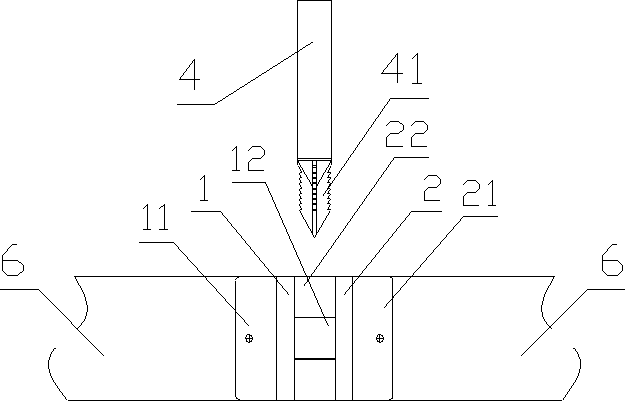

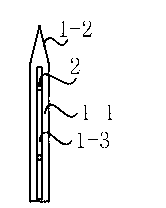

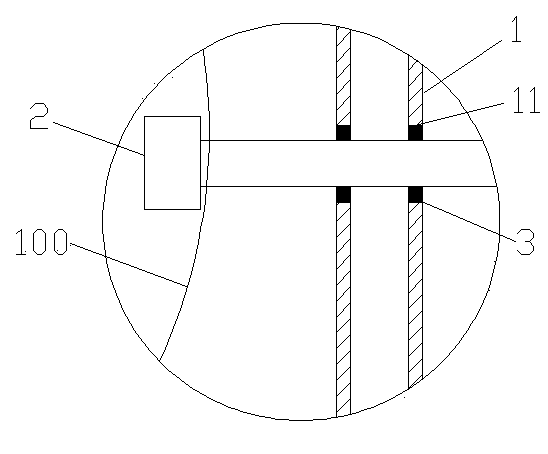

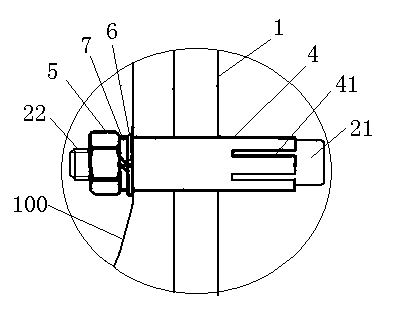

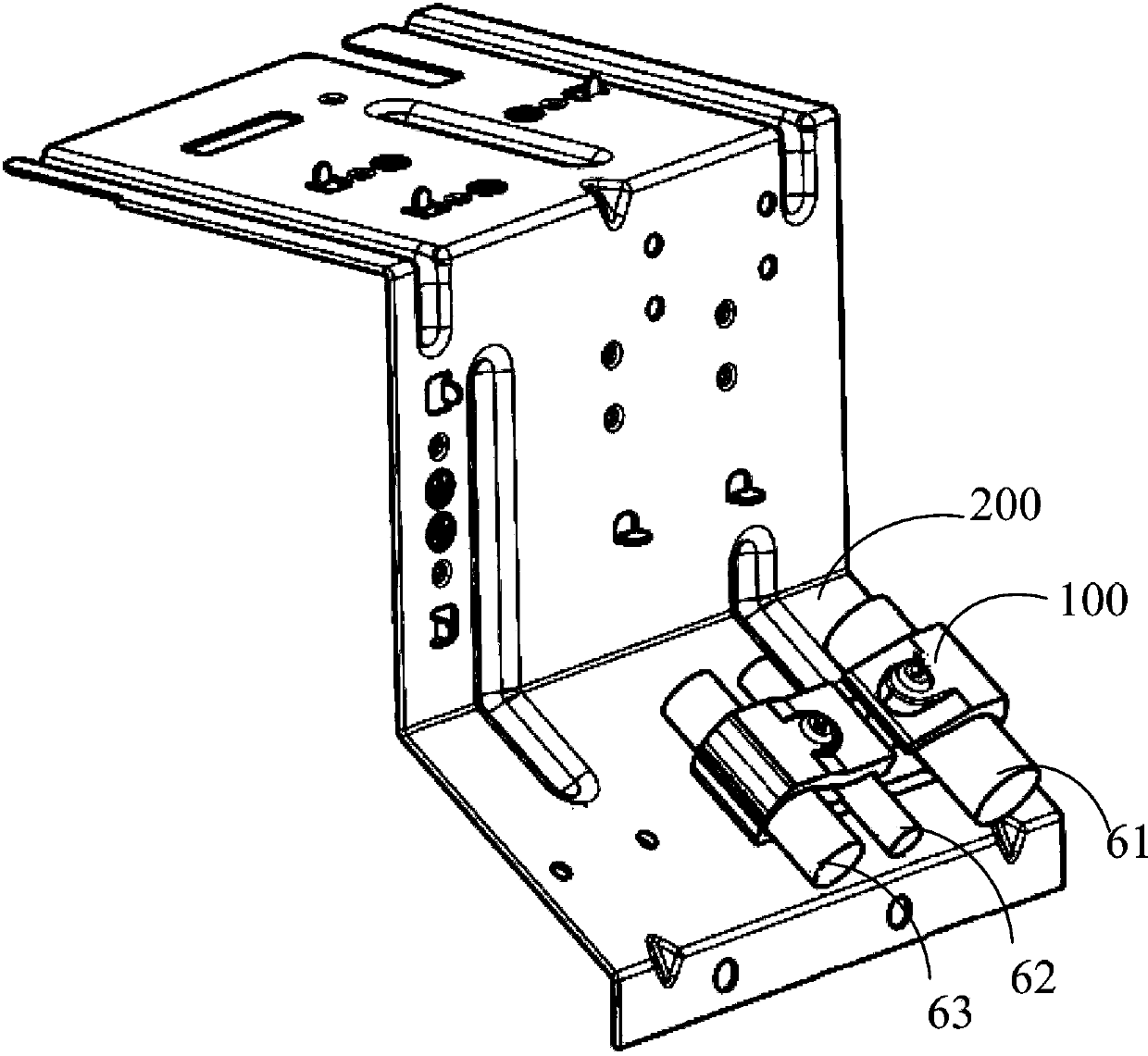

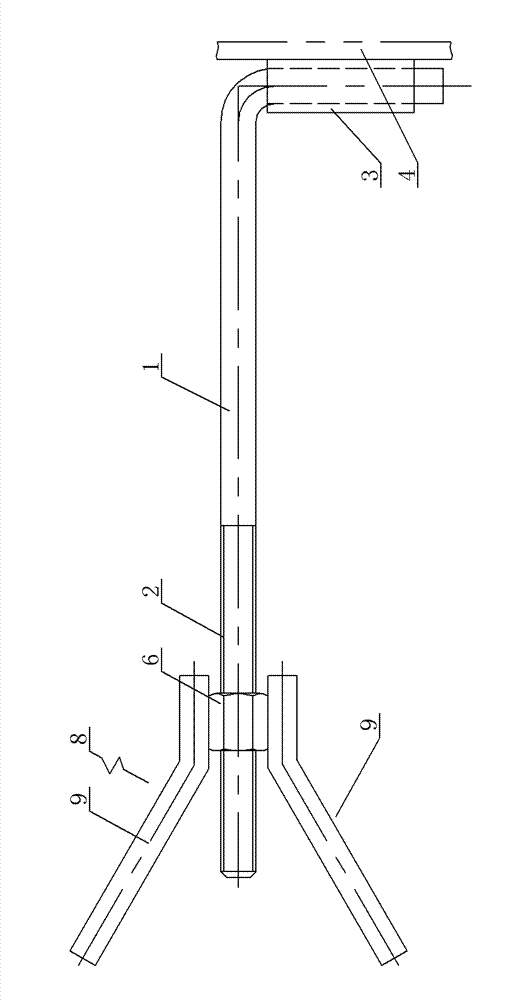

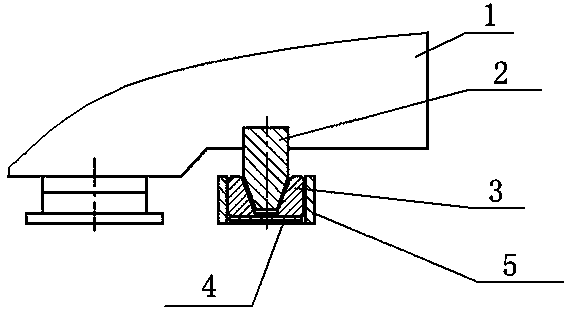

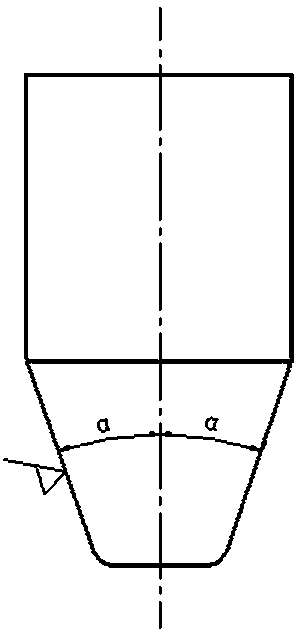

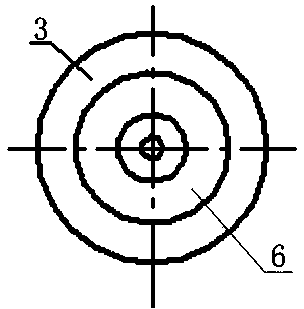

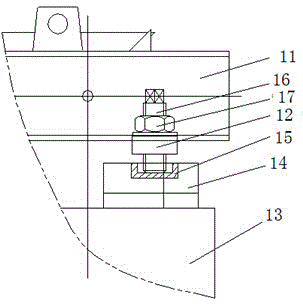

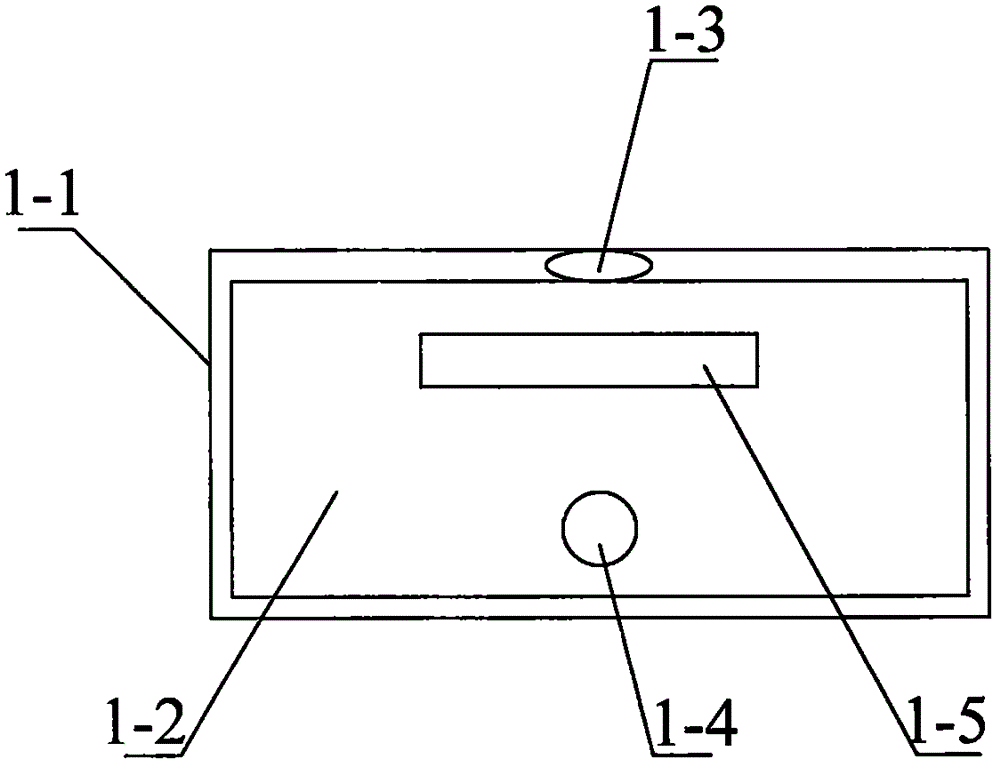

Bucket type oil tank positioning nail structure and positioning method of transformer

InactiveCN103779060AReduce in quantityReduce the number of weldsInductances/transformers/magnets manufactureFuel tankEngineering

The invention relates to a bucket type oil tank positioning nail structure and a positioning method of a transformer, and belongs to the technical field of transformers. The invention adopts the technical scheme as follows, the bucket type oil tank positioning nail structure comprises an iron core lower clamp web (1), a positioning nail (2), a base sleeve (3), an insulating paper board (4) and a seamless steel tube (5), wherein the positioning nail is welded on the iron core lower clamp web (1); a section of seamless steel tube is welded at the bottom of a transformer oil tank; the base sleeve is arranged inside the seamless steel tube; the base sleeve is matched with the positioning nail; the base sleeve is a polyurethane base sleeve which is elastic and convenient to adjust and matched with the positioning nail. The bucket type oil tank positioning nail structure has the positive effects that polyurethane base sleeves of three different models are equipped, the size of the positioning nail is measured, the errors are strictly controlled, proper base sleeves are selected, the workload is alleviated, the working efficiency is improved, and the cost of the transformer is lowered; the oil tank positioning nail structure is simplified, the number of components and the welding times are reduced, and the positioning nail is not required to be cast, so that the working intensity is alleviated, and hanging and checking are convenient to perform.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

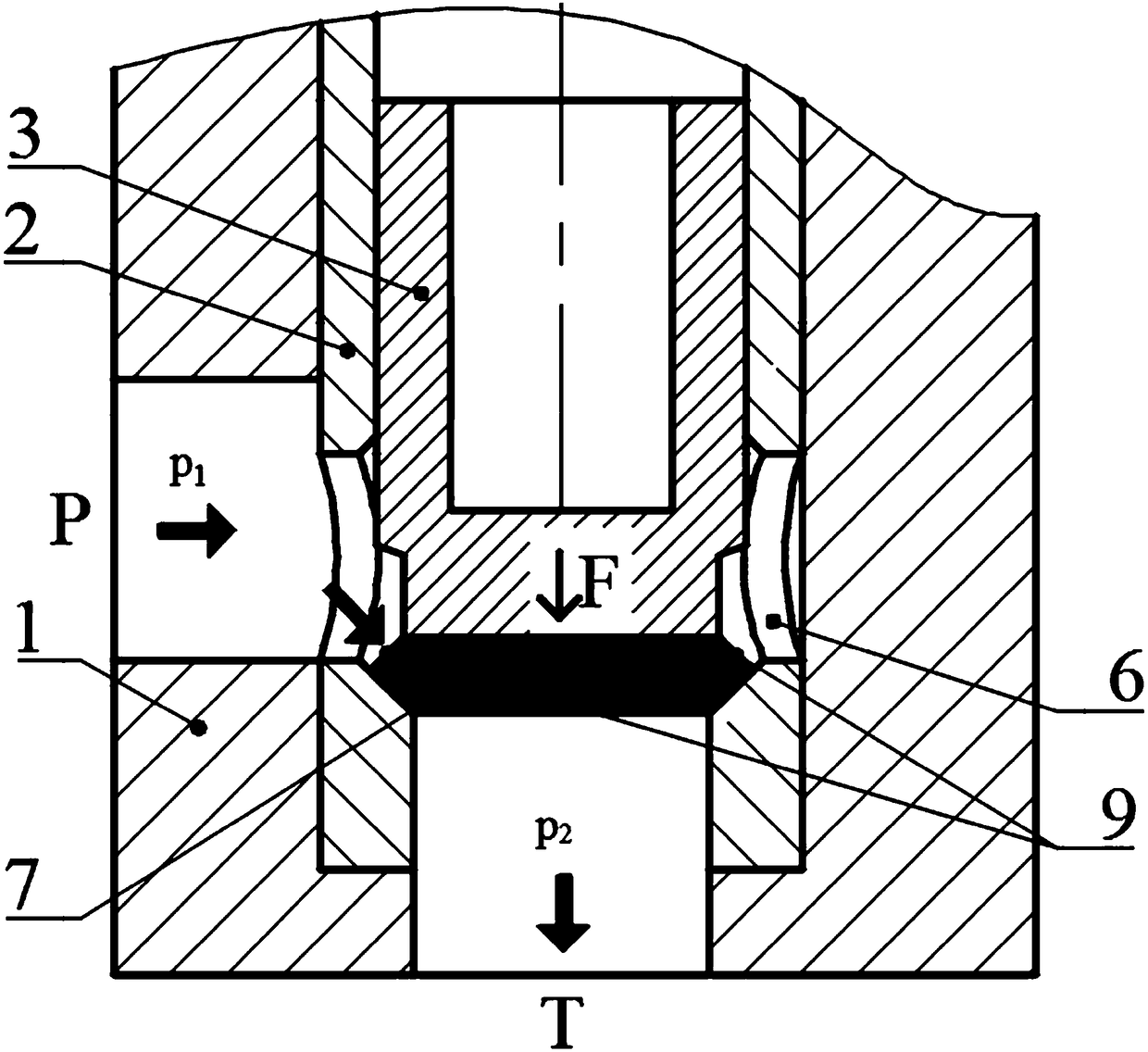

Pressure stabilizing nail structure for compensating flow force in closing direction of internal flow type cartridge valve

InactiveCN108167459AWork status controlEasy to controlValve members for absorbing fluid energyLift valveEngineeringNail structure

The invention discloses a pressure stabilizing nail structure for compensating a flow force in the closing direction of an internal flow type cartridge valve. A plurality of throttle holes which are uniformly formed in a spaced manner circumferentially are formed in the periphery of the bottom of a valve sleeve of the cartridge valve; a chamfer is arranged at the inner edge of the inner end surface, close to an oil return port, of the valve sleeve; the chamber is matched with the outer edge of the bottom end surface of a valve element, close to the oil return port, and the pressure stabilizingnail structure is arranged on the bottom end surface of the valve element; the pressure stabilizing nail structure comprises a connecting rod of a pressure stabilizing nail and a tail boss of the pressure stabilizing nail, wherein one end of the connecting rod of the pressure stabilizing nail is fixed to the center of the bottom end surface of the valve element while the other end of the connecting rod of the pressure stabilizing nail is fixedly connected to the center of the small end surface of the tail boss of the pressure stabilizing nail, the large end surface of the tail boss of the pressure stabilizing nail faces downward and is parallel to the bottom end surface of the valve element, and the connecting rod of the pressure stabilizing nail, the tail boss of the pressure stabilizingnail and the valve element are arranged coaxially. The pressure stabilizing nail structure disclosed by the invention can compensate the flow force in the closing direction of the internal flow typecone valve, and can adjust the compensating degree of the flow force subjected to the valve element.

Owner:ZHEJIANG UNIV

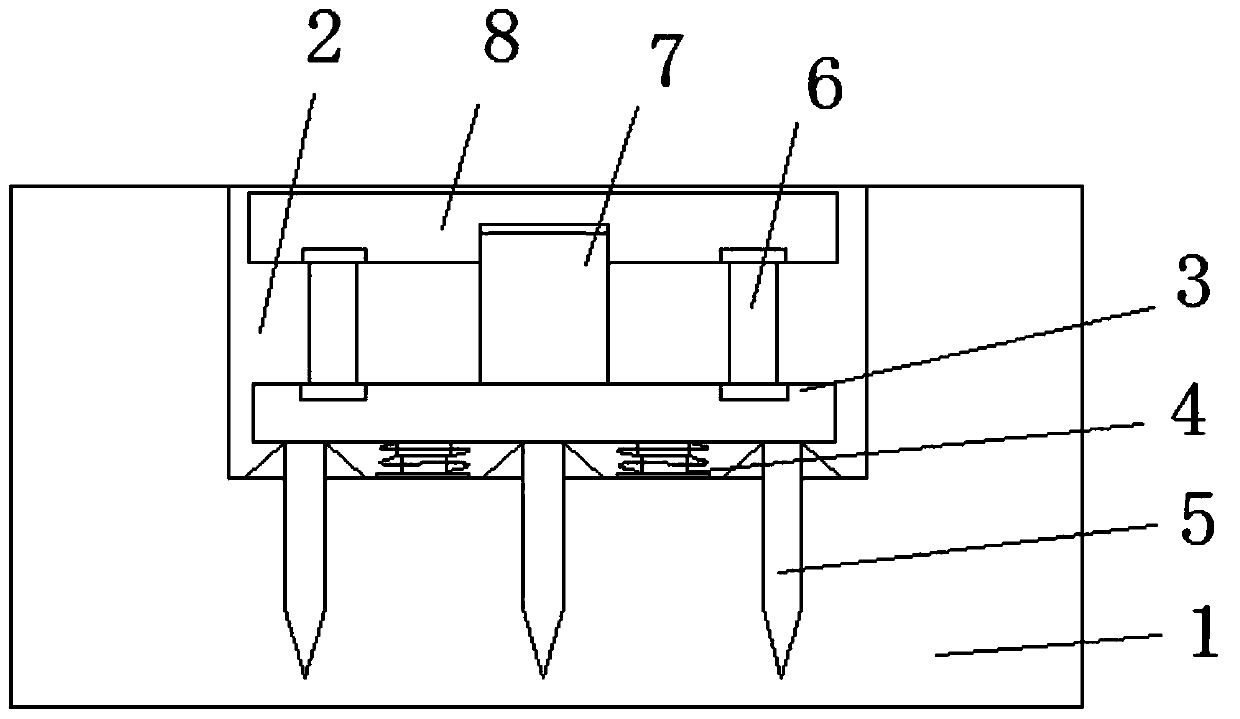

Foundation structure in house building construction

ActiveCN110761338AImprove stabilityImprove seismic performanceProtective foundationArchitectural engineeringHouse building

The invention discloses a foundation structure in house building construction. The foundation structure comprises an original soil layer, a foundation groove is formed in the top of the original soillayer, a first steel structure layer is mounted at the groove bottom in the foundation groove, a ground nail structure is inserted on the first steel structure layer in a penetrating mode, supportingcolumns are welded to the two sides of the top of the first steel structure layer correspondingly, a vertical column is further welded to the middle of the top of the first steel structure layer, a second steel structure layer is mounted at the tops of the vertical column and the supporting columns and comprises a bottom plate, a sliding rail is mounted at the top of the bottom plate, mounting plates are welded to the two ends of the sliding rail correspondingly, a first damping assembly is mounted on the inner side face of the mounting plate, sliding blocks are slidably connected to the two sides of the surface of the sliding rail, and a top plate is welded to the tops of the sliding blocks. The foundation structure is simple and reasonable in structural design, convenient to operate, good in structural stability, high in anti-seismic ability, safe and stable, capable of prolonging the service life, wide in application range, and beneficial to being promoted and popularized.

Owner:HANGZHOU BAOLI SPORTS FACILITIES ENG

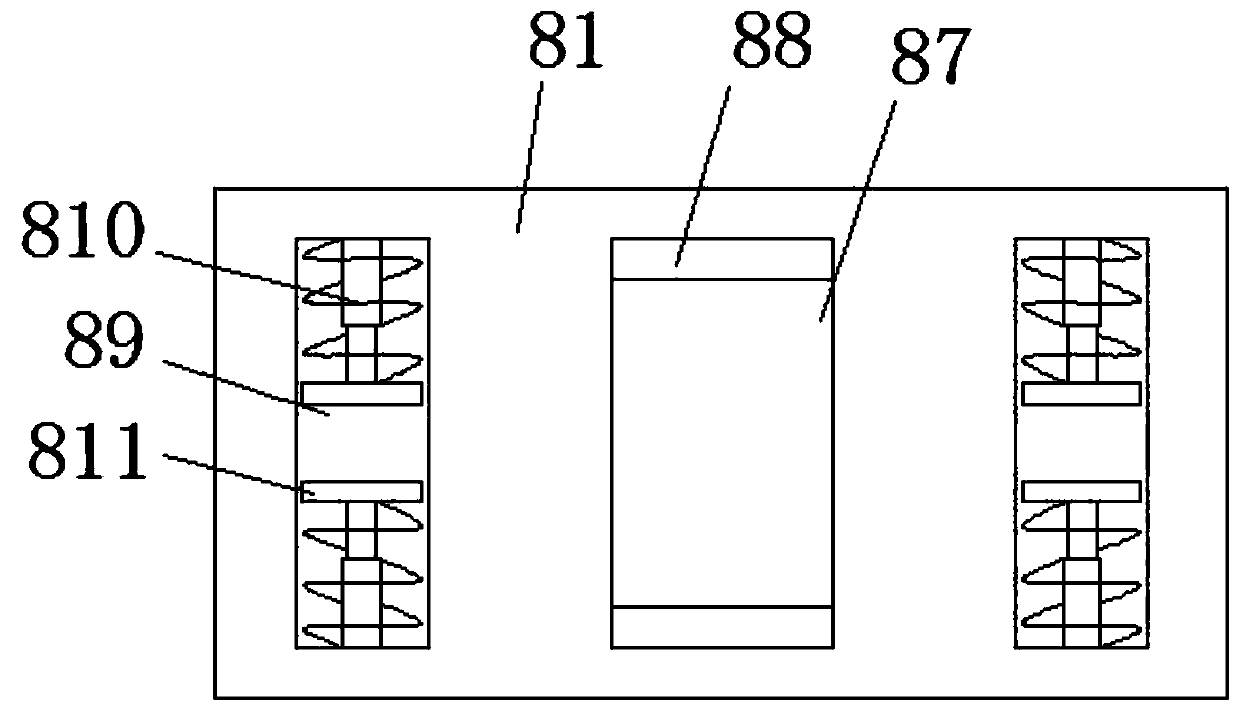

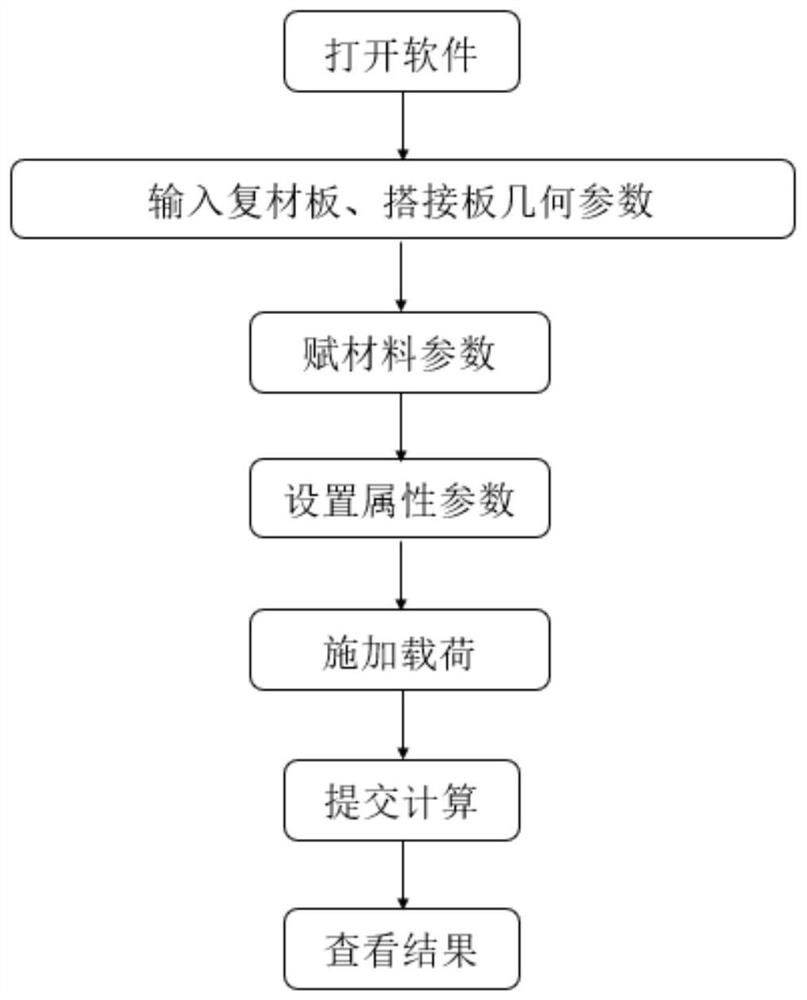

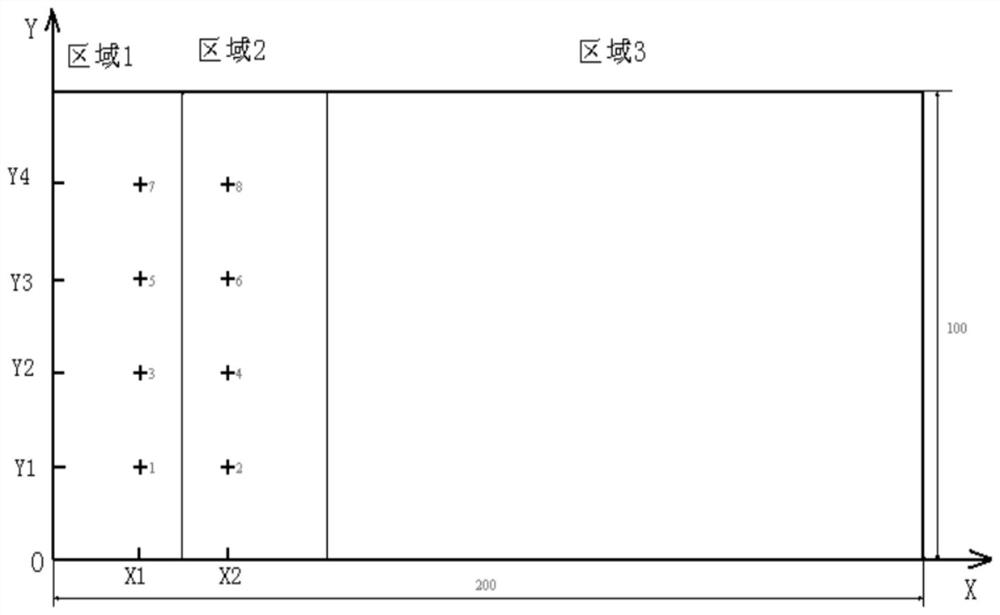

Rapid analysis system for composite material nail loads

InactiveCN112231864AQuick calculationEasy to operateGeometric CADSpecial data processing applicationsDimensional modelingMechanical engineering

The invention relates to the technical field of composite material mechanical connection structure load calculation, in particular to a rapid analysis system for composite material nail loads which directly calls PATRAN to perform modeling according to structure geometrical parameters, material parameters, attribute parameters, load parameters and the like input by a user and calls NASTRAN to perform calculation. Load size and the distribution proportion of each nail can be obtained. The load distribution proportion of the composite material nailing structure can be rapidly calculated, the complex modeling and analysis process is removed. The two-dimensional modeling method of mechanical connection is improved, the calculation accuracy is improved, and the modeling time is greatly saved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

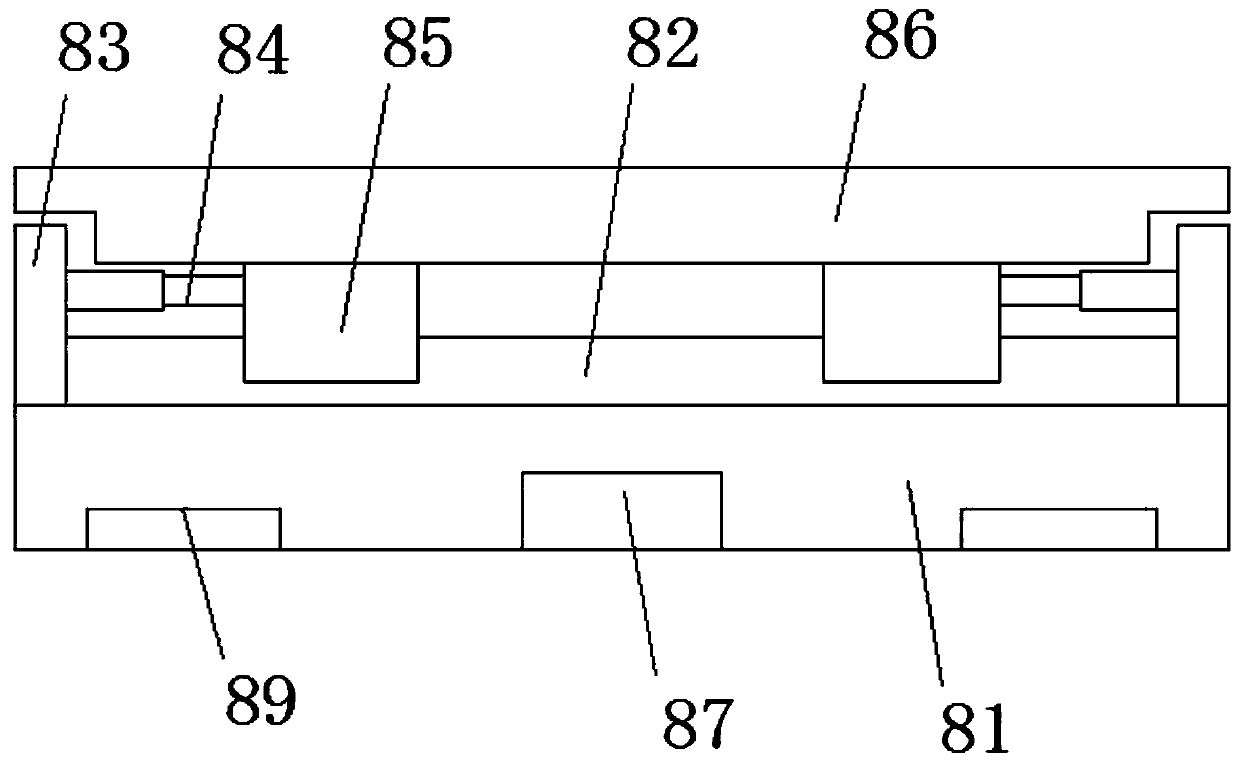

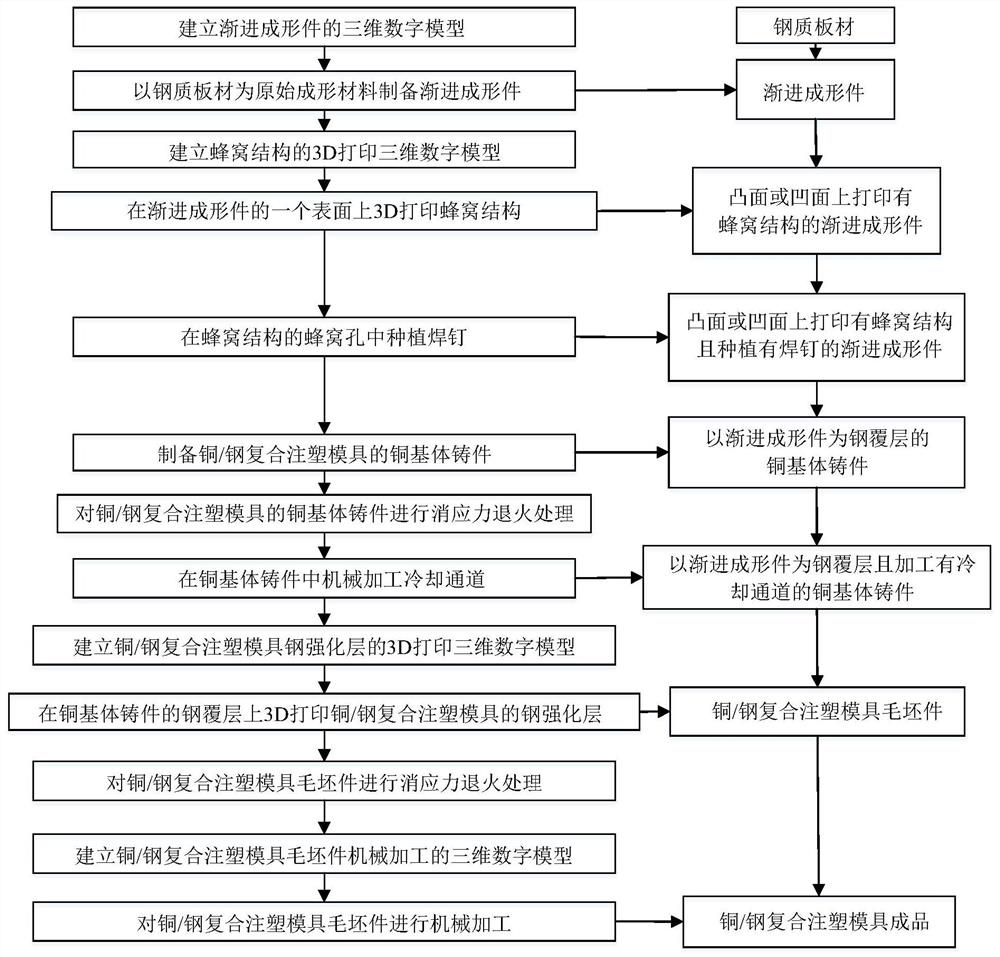

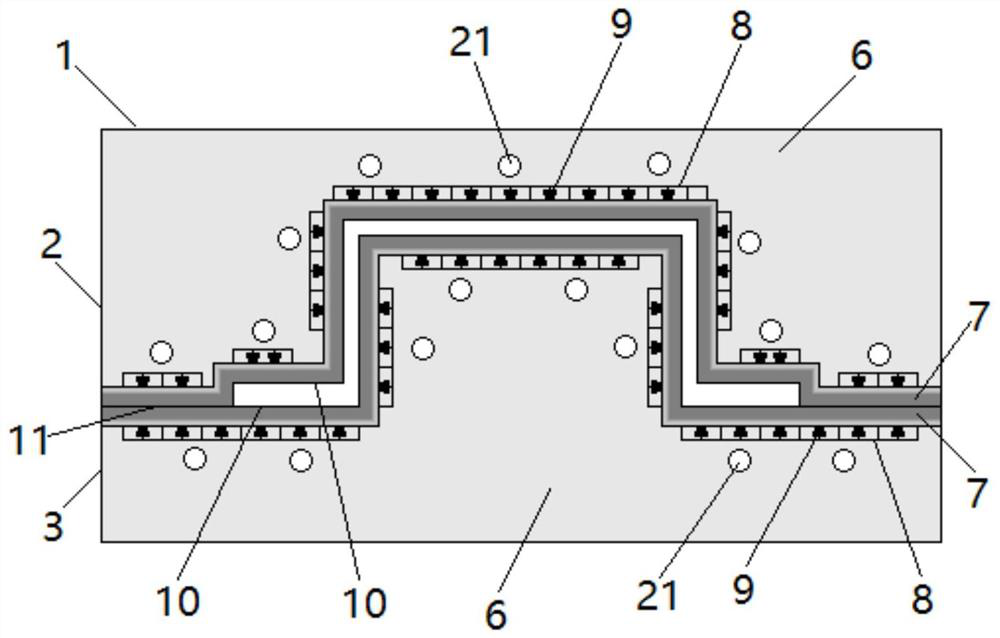

Manufacturing method of copper/steel combination injection mold with honeycomb and planted nail interface structure

ActiveCN111716084AIncrease binding areaReduce the impactAdditive manufacturing apparatusPlasma welding apparatusBond interfaceHoneycomb structure

The invention discloses a manufacturing method of a copper / steel combination injection mold with a honeycomb and planted nail interface structure. The manufacturing method comprises the following steps that a steel plate serves as a raw forming material, and a steel plate incremental forming part is manufactured according to an incremental forming method; then a honeycomb structure is arranged onone surface of the incremental forming part in a 3D printing mode; welding nails are planted in honeycomb holes; a copper substrate casting of the copper / steel combination injection mold is cast in amold-free mode; cooling channels are machined; and steel reinforcing layers of the copper / steel combination injection mold are formed on the surface of a steel coating of the copper substrate castingin a 3D printing mode. According to the manufacturing method, the interface bonding of a copper substrate and the steel reinforcing layers of the copper / steel combination injection mold is achieved through the honeycomb and planted nail structure in the manufacturing process, the outline of a bonding interface is similar to the curved surface of a mold cavity of the copper / steel combination injection mold, the whole manufacturing process is free of molds, and high-quality and low-cost rapid manufacturing of the copper / steel combination injection mold is achieved.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Method of treating onychomycosis

ActiveUS20140052049A1Organic active ingredientsElectrotherapyAmino-Levulinic AcidFungal nail infection

This application is directed to a method of treating onychomycosis by applying a phototherapeutic agent to a nail structure, waiting for a period of at least three days, and exposing the nail to light that causes an activation reaction. The phototherapeutic agent may be amino levulinic acid, alkylated derivatives of ALA, and their pharmaceutically acceptable salts.

Owner:DUSA PHARMA INC

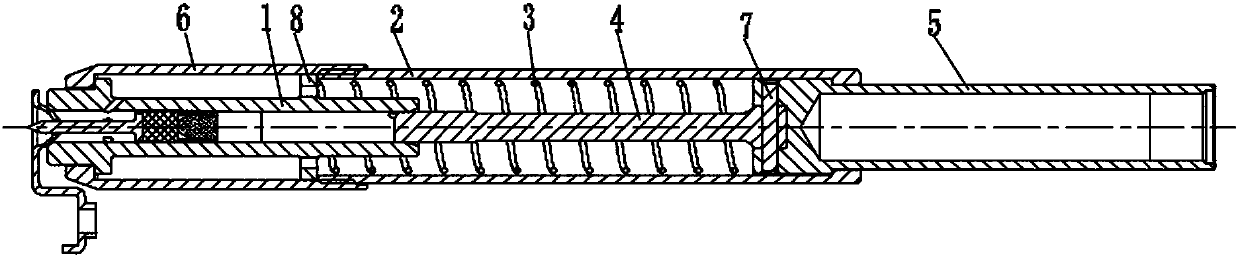

Nail shooting device without firing spring

The invention discloses a nail shooting device without a firing spring. The nail shooting device without the firing spring comprises a nail tube, a nail tube fixing sleeve, a nail tube pressure spring, a firing needle and a firing needle seat, wherein one end of the nail tube fixing sleeve is fixedly arranged on the nail tube in a sleeving manner while the other end of the nail tube fixing sleeveis movably arranged on the firing needle seat in a sleeving manner; one end of the firing needle is fixed on the firing needle seat while the other end of the firing needle is positioned in the nail tube; and one end of the nail tube pressure spring is arranged on the nail tube in a sleeving manner while the other end of the nail tube pressure spring is arranged on the firing needle in a sleevingmanner. A plurality of parts such as a firing pin, a firing pin pressure spring, a firing column, a firing plate and a firing column pressure spring in an existing pressing type nail shooting device are omitted, the structure of the nail shooting device is greatly simplified, and the manufacturing cost, the failure rate, the maintaining cost and the like are greatly reduced. Correspondingly, a to-be-fired state in a firing process is further omitted, the purposes of simplifying a firing processing, improving firing efficiency and the like are achieved, and furthermore, withdrawing of a shell case is facilitated.

Owner:SICHUAN DEYANG CITY LIXIE

Injection mould shoe insole for manufacturing bottom face anti-sliding protruding points and manufacturing method of injection mould shoe insole

InactiveCN107053724AEasy to disassembleGood flexibilitySolesDomestic footwearEngineeringNail structure

The invention discloses an injection mould shoe insole for manufacturing bottom face anti-sliding protruding points and a manufacturing method of the injection mould shoe insole. The injection mould shoe insole comprises a base and a lower die, a shock pad is fixedly installed at the upper end of the base, and the upper portion of the shock pad is provided with a fixing hole, a first horizontal working table, a second horizontal working table and a radiating guide sheet; a protruding nail structure is arranged on one side of a protruding groove, and the other side of the protruding groove is provided with a protruding groove and a rectangular groove; the bottom of the lower die is provided with an upper base, a lower base and a screw, a connecting plate is arranged at the upper end of the upper base, and the upper base is fixedly connected with the lower die through the connecting plate; and a lamp strip is fixedly installed on the upper surface of the second horizontal working table. By means of the injection mould shoe insole for manufacturing the bottom face anti-sliding protruding points and the manufacturing method of the injection mould shoe insole, the shock pad and the lamp strip are arranged, and therefore equipment operation convenience can be guaranteed, night operation can be carried out, skid resistance of the shoe insole is effectively achieved, the injection mould shoe insole is suitable for different working conditions, and the better using prospect is achieved.

Owner:东莞市鹏翼自动化科技有限公司

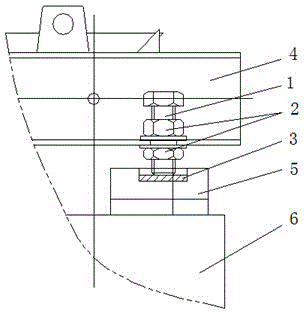

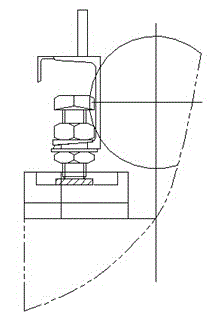

Press nail structure of epoxy cast dry-type transformer

InactiveCN104900386AAdjustable structureGuaranteed reliabilityTransformers/inductances coils/windings/connectionsCoils manufactureEpoxyTransformer

The invention discloses a press nail structure of an epoxy cast dry-type transformer. The press nail structure comprises a compression bolt, a locking nut and a press plate, the compression bolt is arranged in a through hole in the lower part of an upper clamp piece and firmly compresses the press plate, the press plate is arranged in a long slot hole in an upper cushion block, and the locking nut sleeves the compression bolt and is located at two sides of the through hole in the lower part of the upper clamp piece. The compression structure is easy to assemble and operate; the assembly reliability is fully guaranteed, and the production requirements are satisfied.

Owner:ZHENJIANG TIANLI TRANSFORMER

Wall nail with inner strips

A nail structure comprises a wall nail casing and a hammer nail capable of being beaten into the wall nail casing. A plurality of semi-round strips are axially installed on the through hole of the wall nail casing. Each strip is reduced from an opening of the central axial hole to the middle section of the wall nail casing for firmly securing the hammer nail. The hammer nail is positioned to an opening of the wall nail casing and resists against the strips. Thereby, the hammer nail is loosely fixed to the strips. The hammer nail is sold with a matched wall nail casing. When using, the hammer nail is not necessary to be detached from the wall nail casing so that the user can beat the hammer nail directly with the wall nail casing.

Owner:YEH MING TIEN

Novel orthopedic operation navigation system

The invention provides a novel orthopedic operation navigation system. An intelligent manipulation device is arranged at the top of a connecting control box, an operation electric drill is connected to the rear portion of the connecting control box, and a location scanning plate is arranged on the periphery of a fixed nail structure; an image obtaining module, a communication module, a data processing module, a display module, a power module and an output module are arranged in the intelligent manipulation device, the image obtaining module is connected with the data processing module through the communication module, the data processing module is connected with the display module and the output module, and the power module is connected with the data processing module. Virtual skeleton images of the operation portions of a patient and the concrete position, where an operation instrument enters, of the patient body are displayed through three-dimensional images, real-time guidance is carried out in the operation process, efficiency of operation of a doctor is improved greatly, and therefore the operation is completed more safely, accurately and efficiently.

Owner:鞠克丰

Tool for preventing thorn anesthesia

InactiveCN101164400AReduce chances of gettingIncrease Pepper Picking SpeedPicking devicesProtective garmentEngineeringKnife blades

The present invention relates to a prickle-proofing tool which can be used for picking prickly vegetables and fruits (prickly ash, jujube, tea leaf and others for preventing prickly from pricking human body. Said prickly-proofing tool includes two portions of glove and hook knife. Said glove is made up by using a flexible material whose texture is close, strong and pliable. Said glove includes the glove body with curved face structure and air permeable structure and finger covers, in which every finger cover end portion is equipped with a simulated nail structure. Said hook knife is formed from two knife blades with blade edge, said two knife blades can be opened and closed together for cutting prickly fruits.

Owner:王秋绒

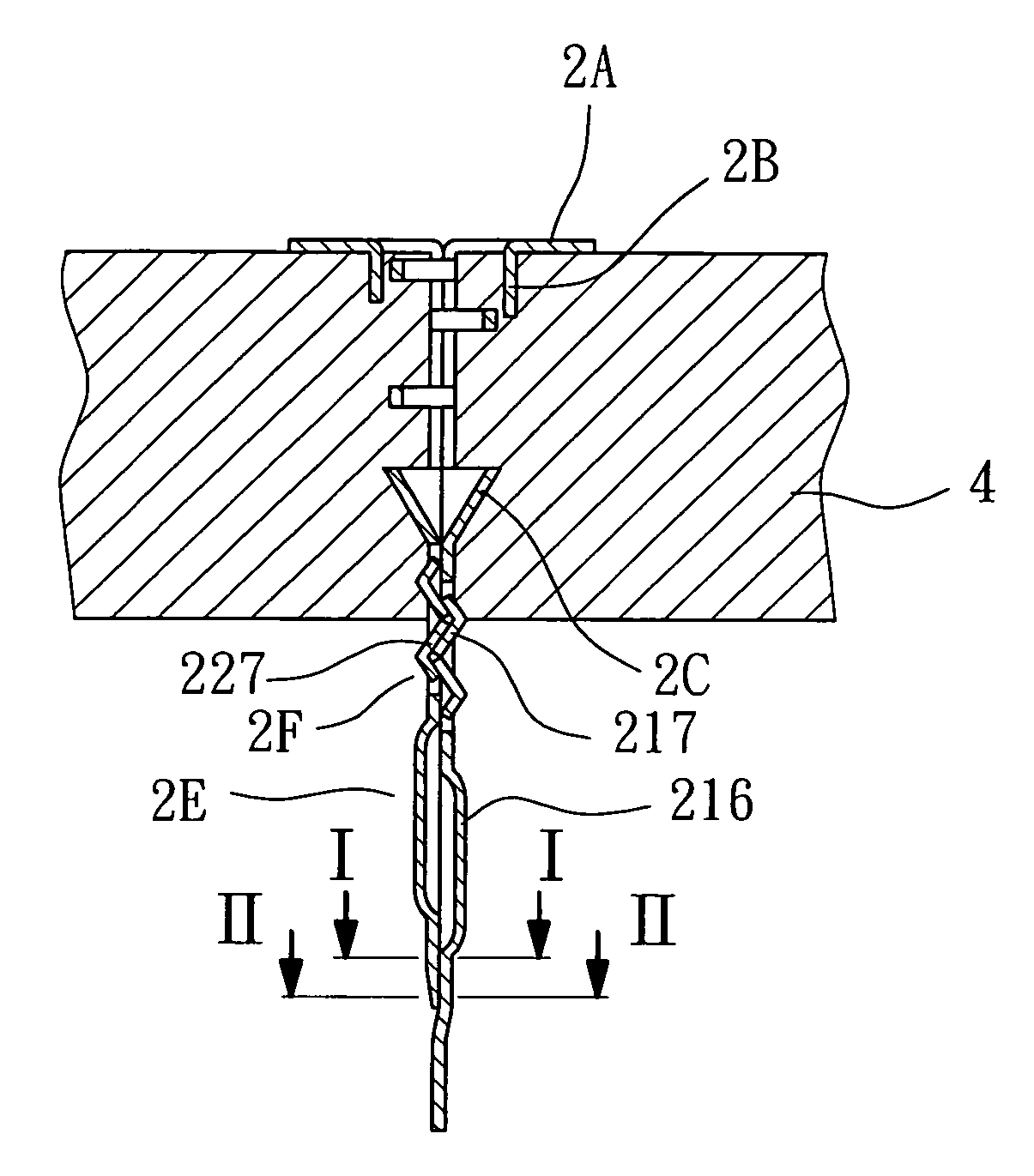

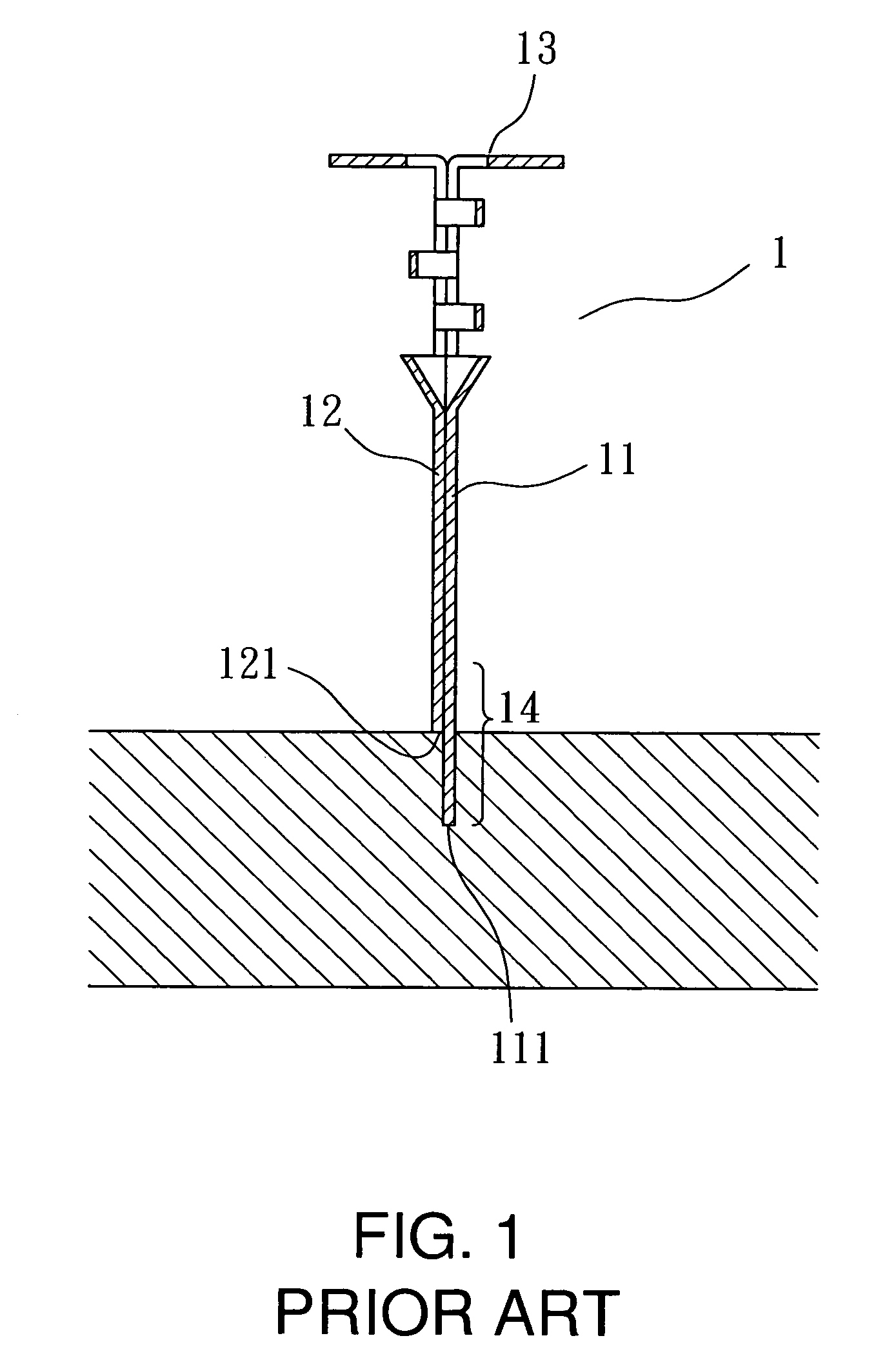

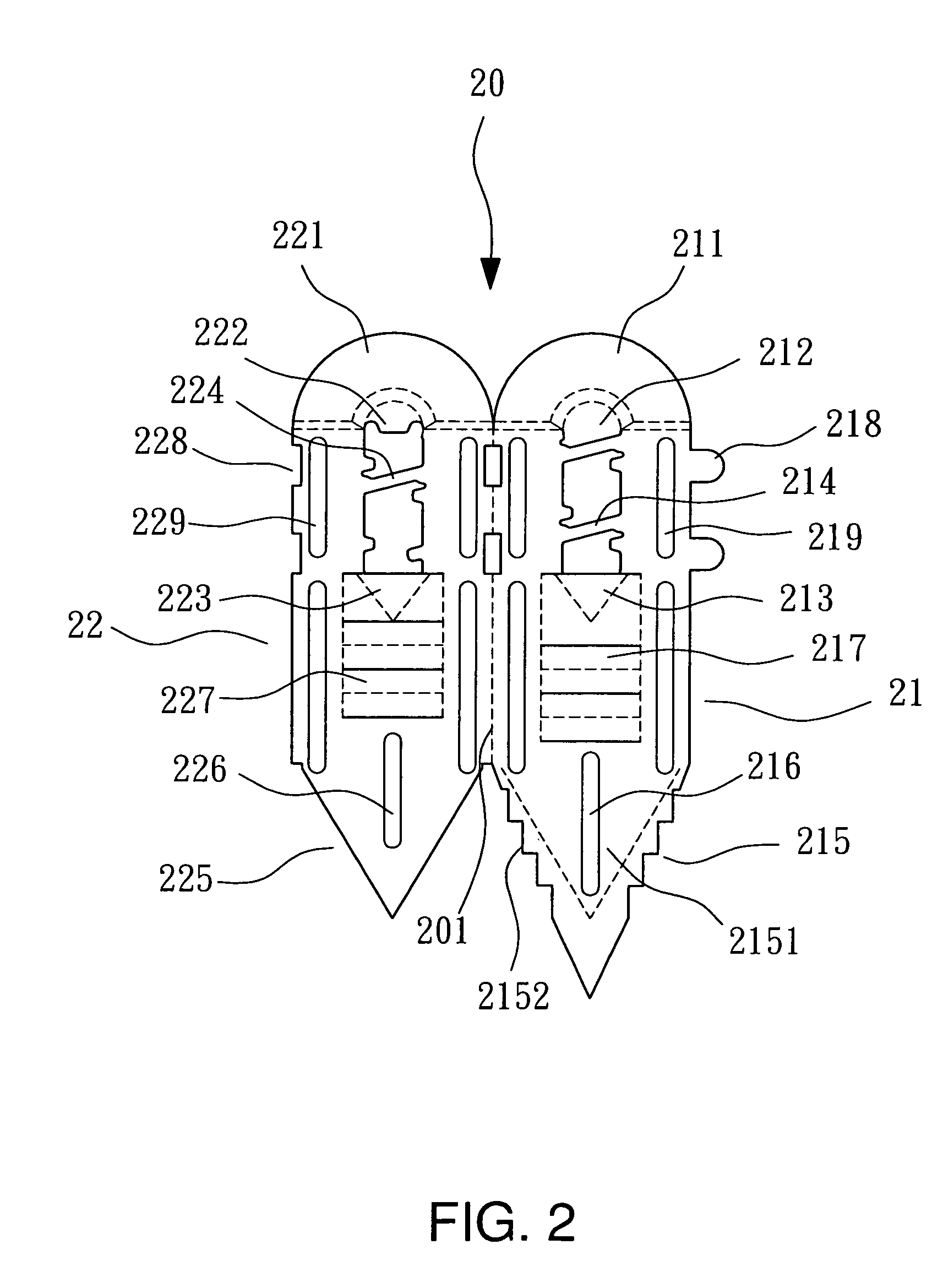

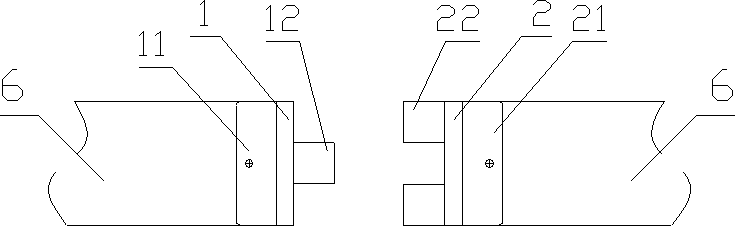

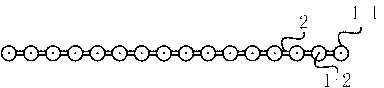

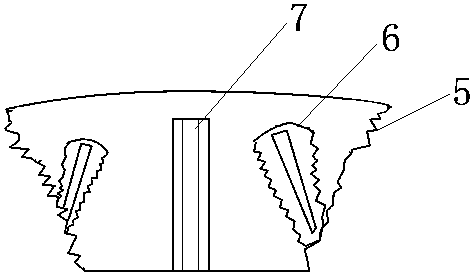

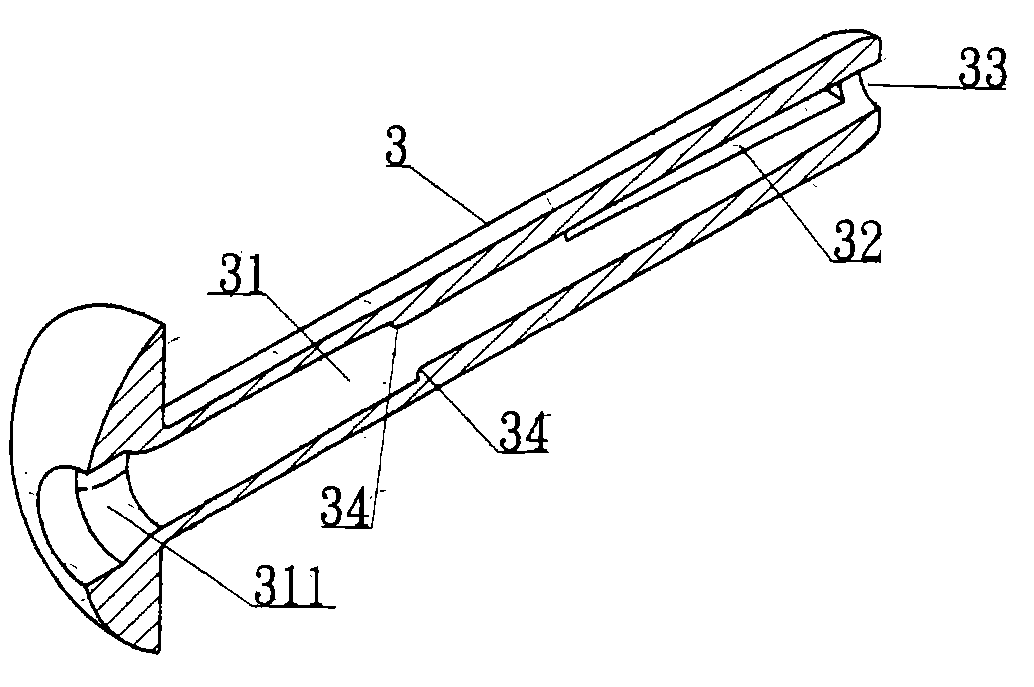

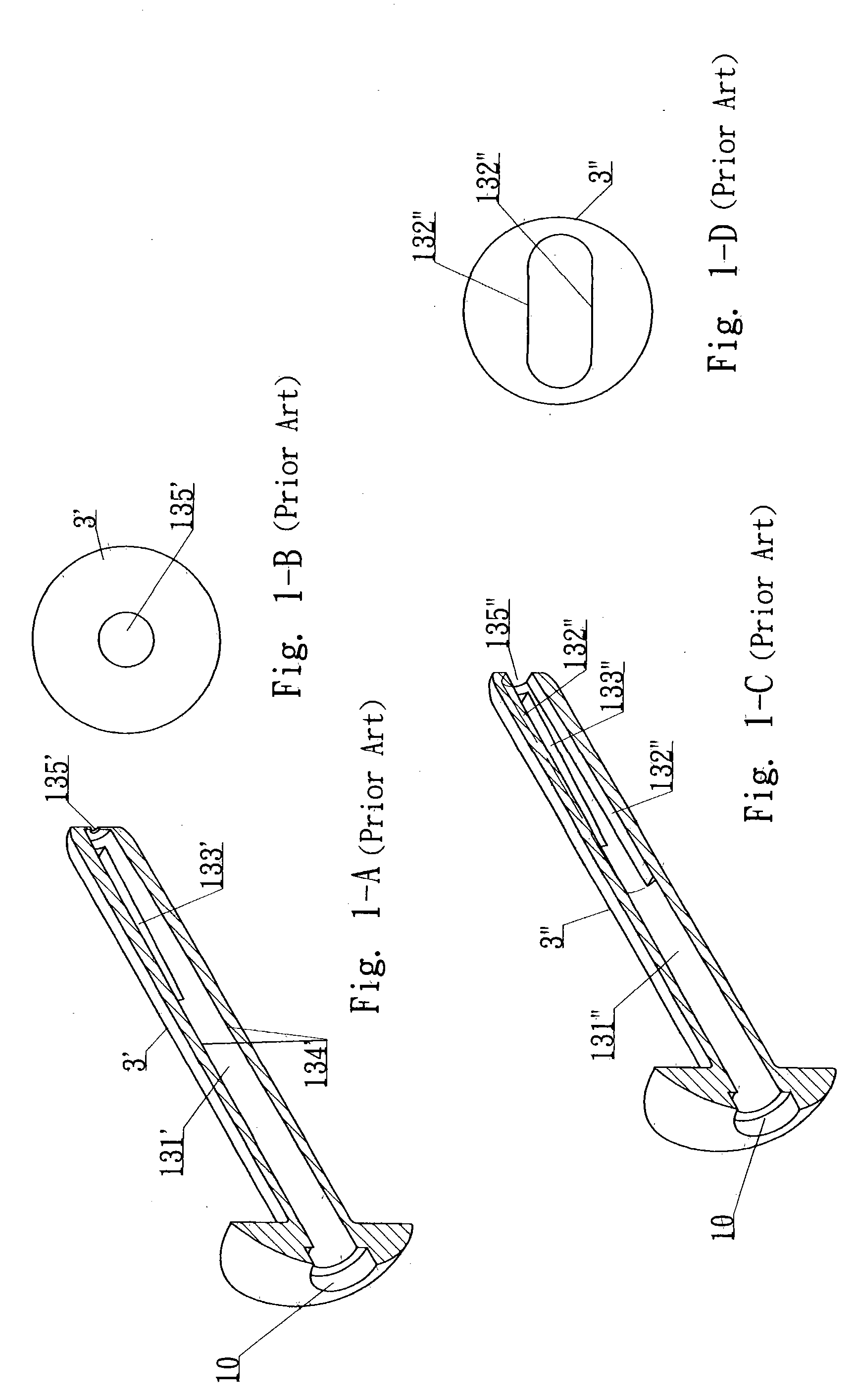

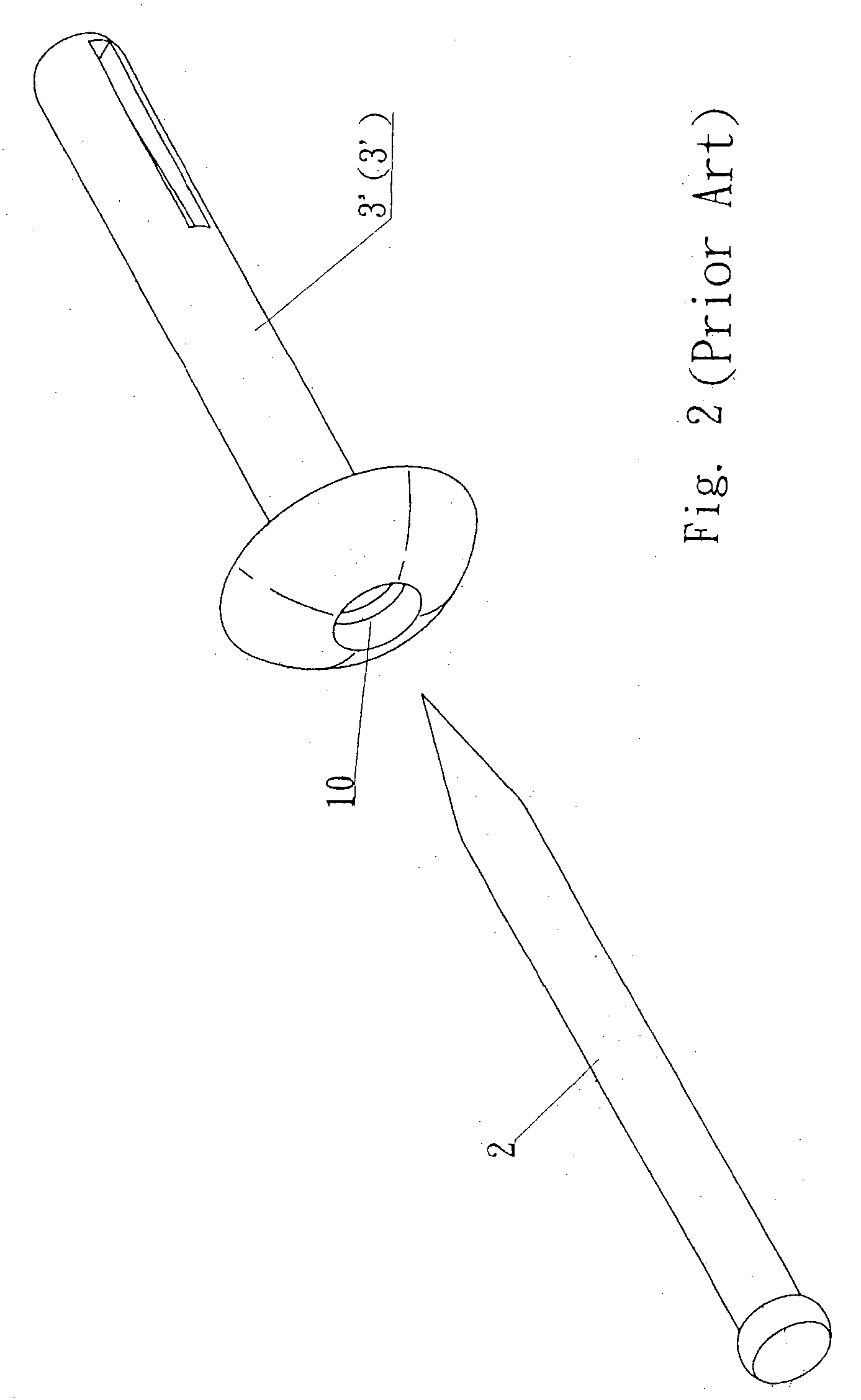

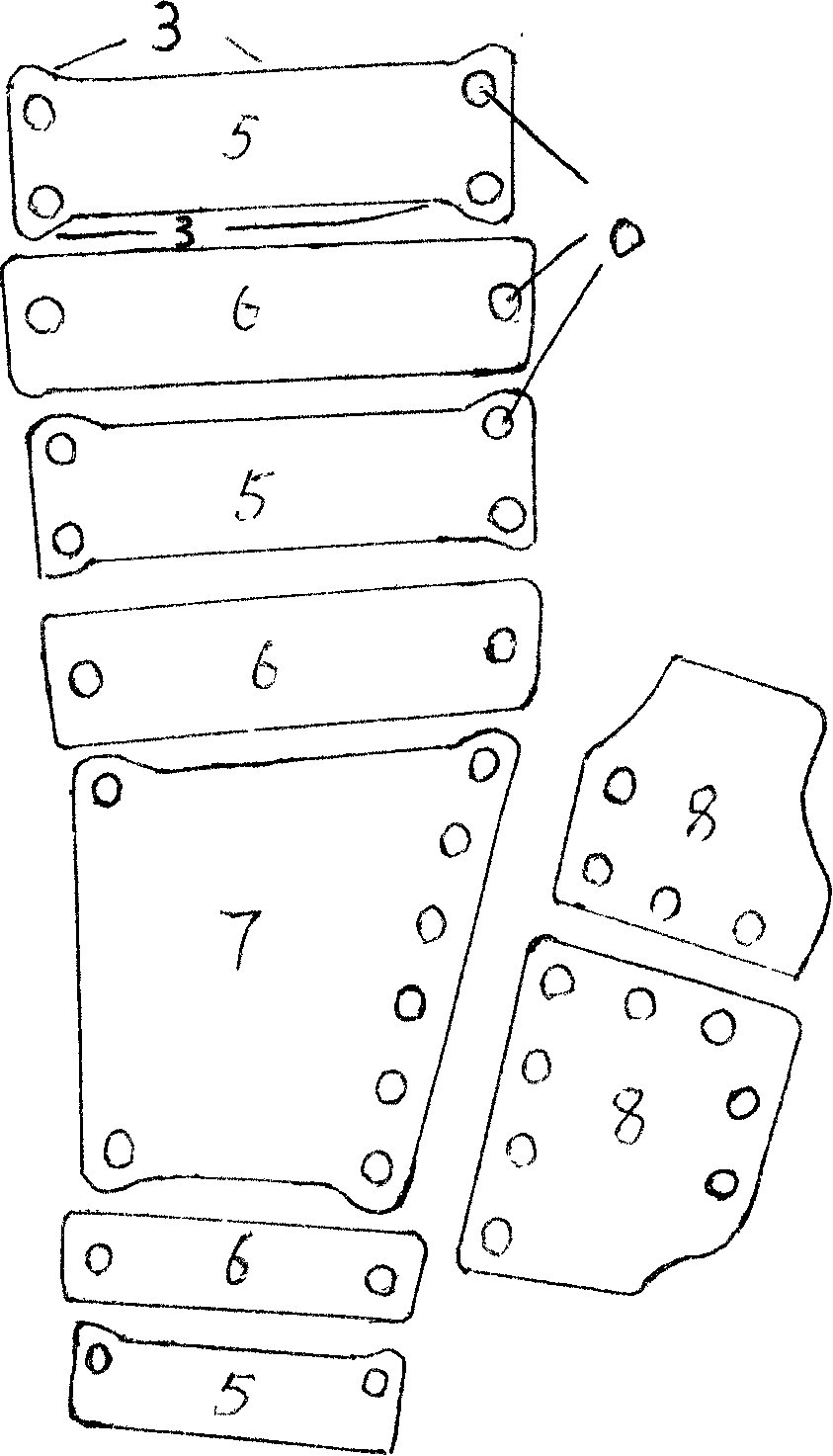

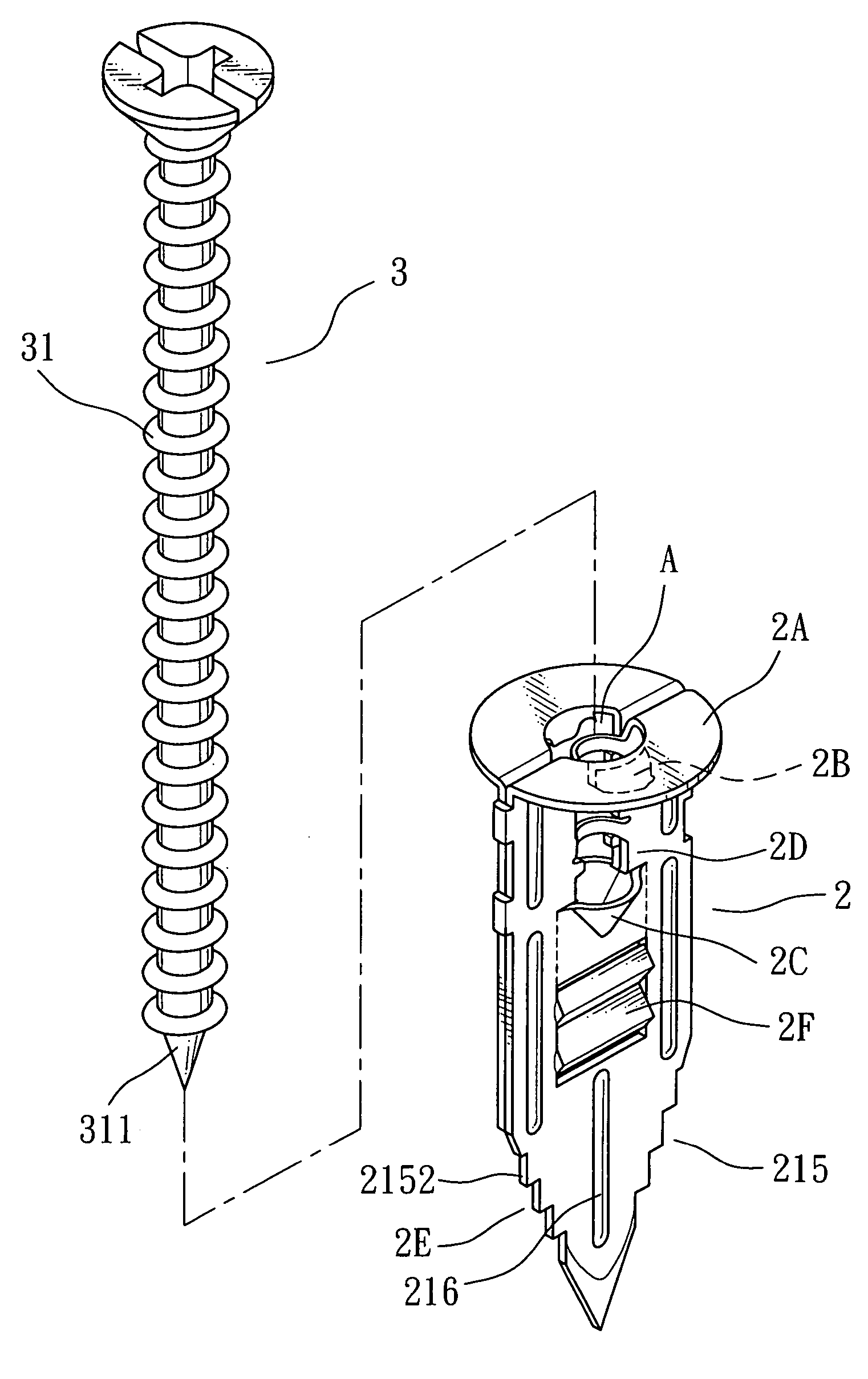

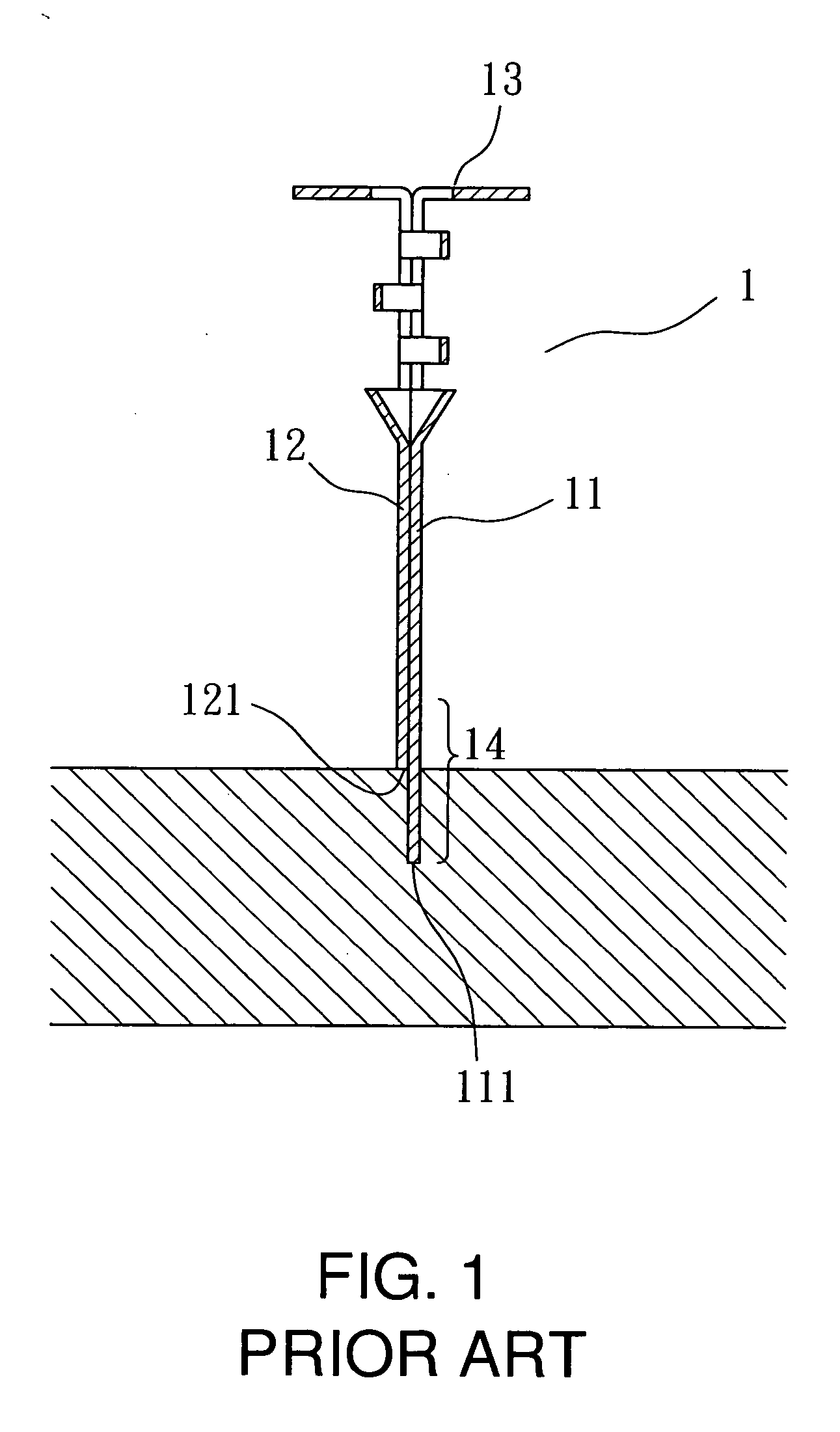

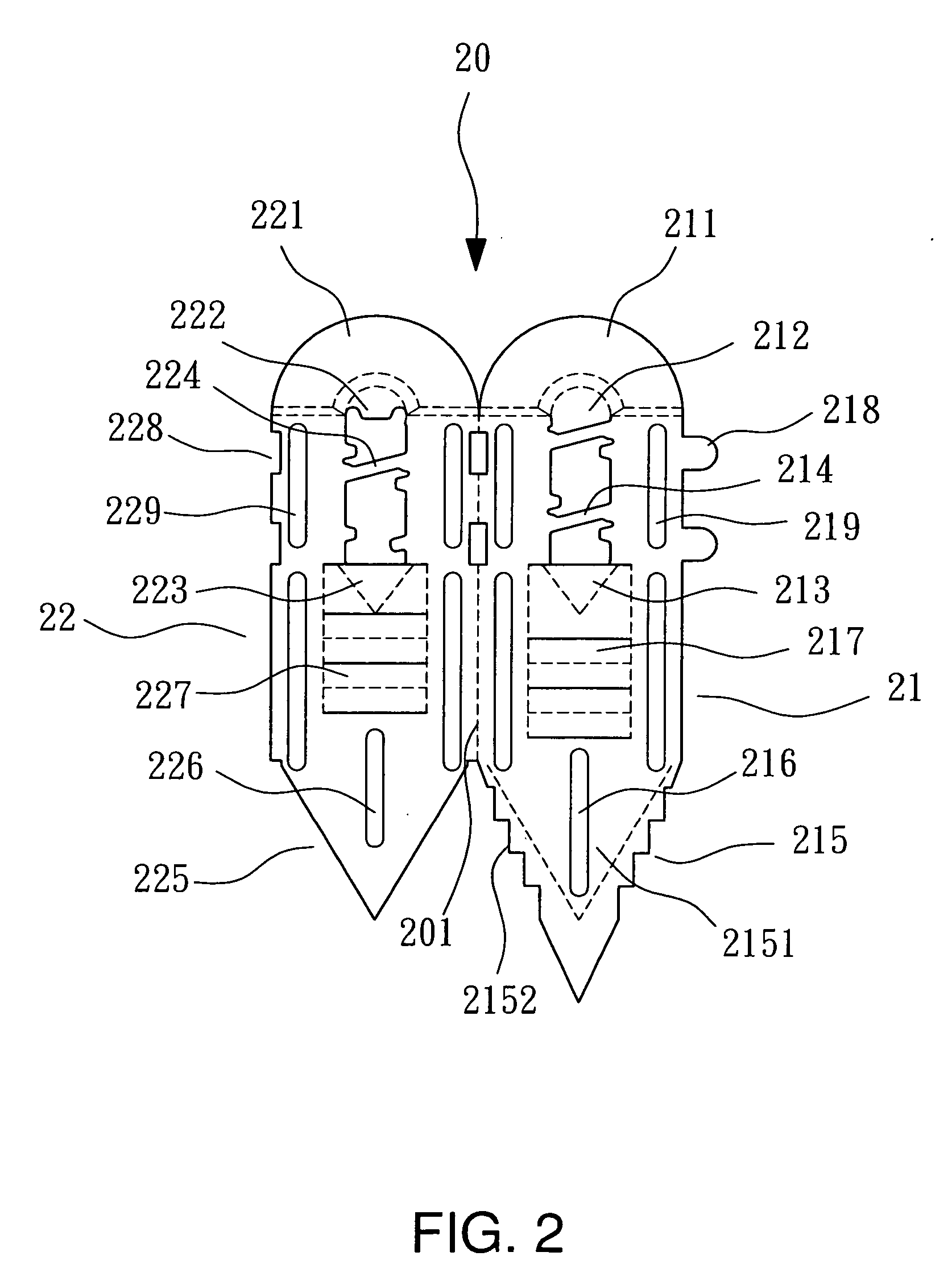

Spike nail structure

A spike nail for nailing in walls made of gypsum boards or fiber boards has a nail body which consists of a first blade and a second blade. The nail body includes a striking section, a upper guiding sleeve, a lower guiding sleeve, a screw thread guiding section and a nail point section. The spike nail thus constructed can be nailed into gypsum board or fiber board walls to facilitate hanging articles.

Owner:JOKER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com