High-temperature pipeline heat insulation support

A pipeline and high-temperature technology, which is applied in the field of high-temperature pipeline heat insulation supports, can solve the problems of reducing the effective thickness of the heat insulation layer, reducing the heat insulation effect, and large welding volume, etc., and achieves increasing the effective heat insulation thickness, improving versatility, and welding Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described now in conjunction with accompanying drawing.

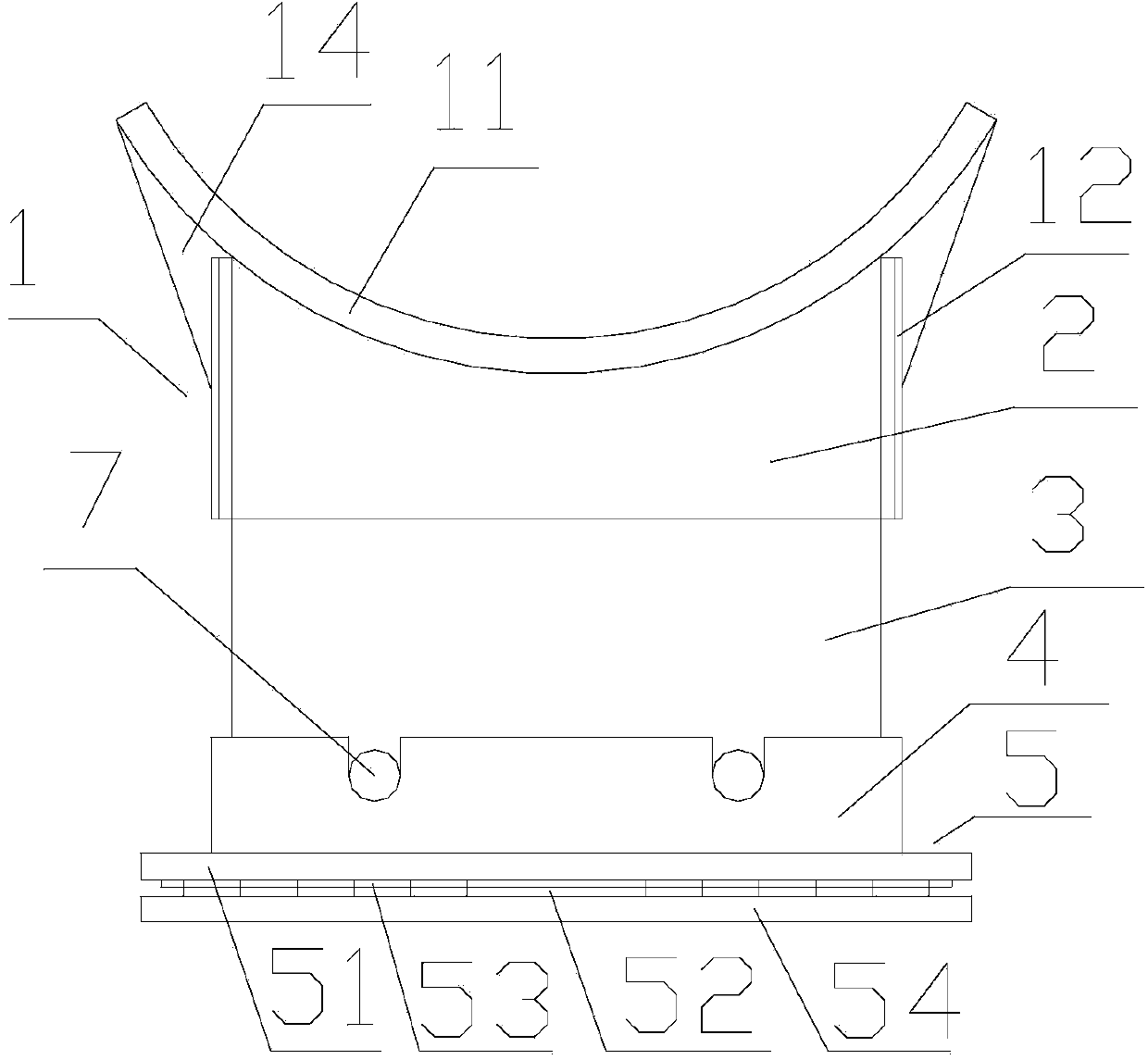

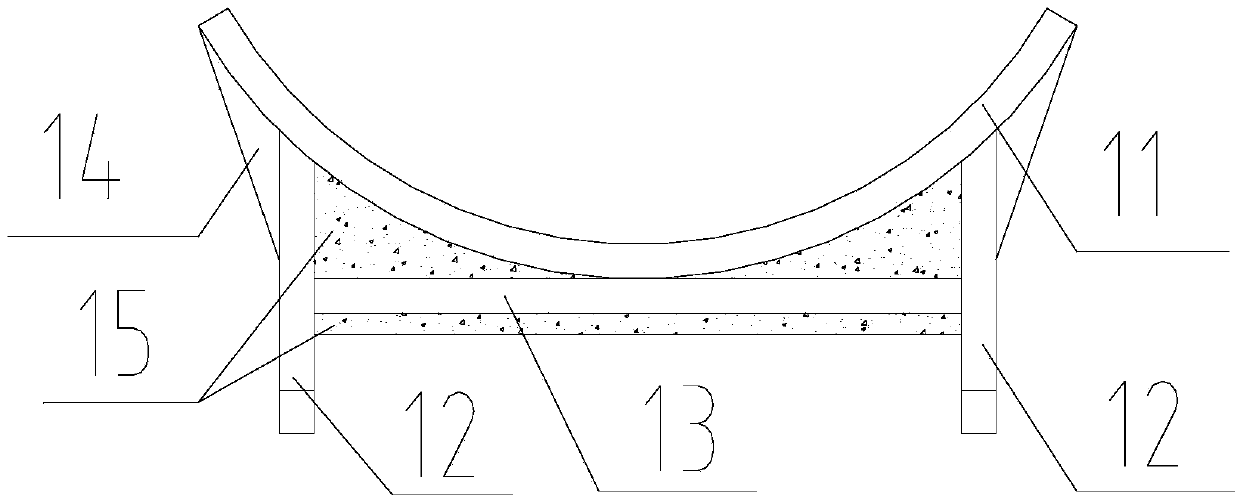

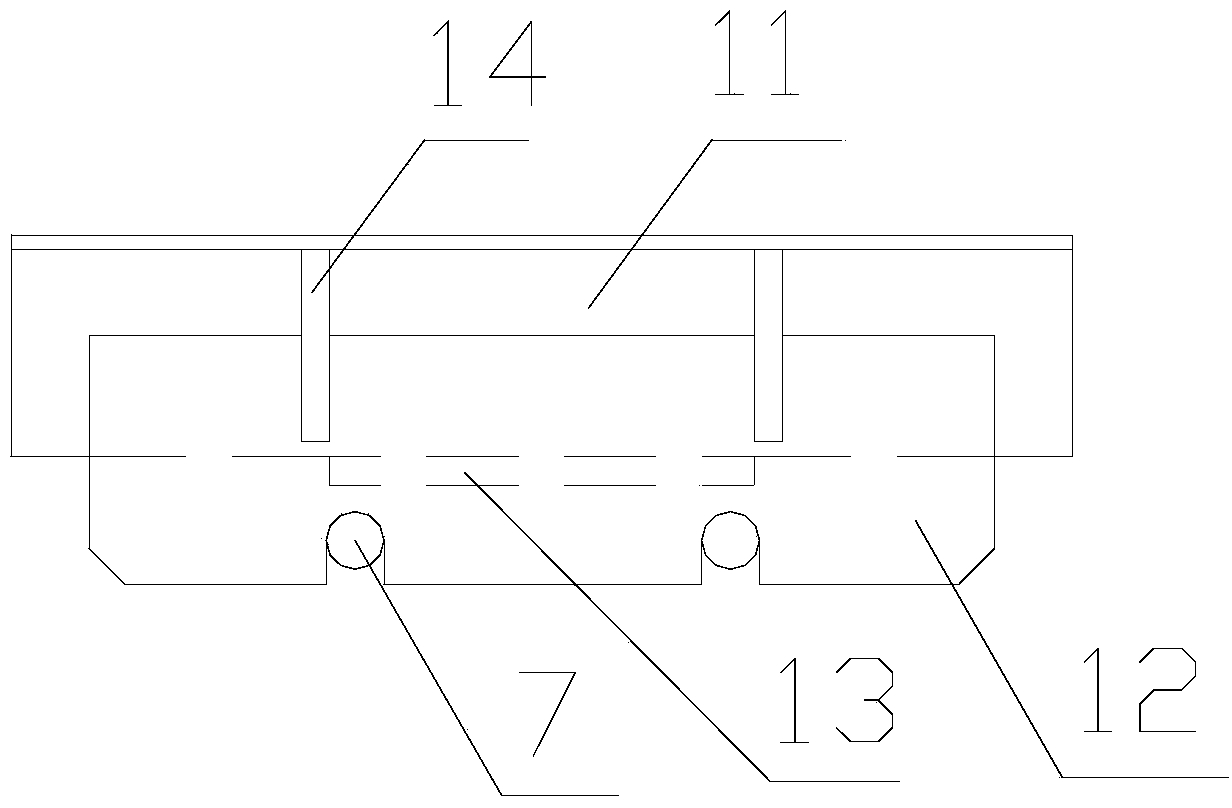

[0024] see Figure 1 to Figure 3 , shows an embodiment of the present invention, the nominal diameter is DN400 (mm), the service temperature is 200°C to 800°C, and the elevation of the pipe bottom is 200mm, specifically including the pipe connecting member 1, the heat insulating block 3, and the base connecting member 4 and the base 5, the upper end of the pipe connecting member 1 lifts the pipe, and its lower end is connected to the top of the heat insulating block 3; the lower end of the heat insulating block 3 is fixed on the base 5 through the base connecting member 4.

[0025] The pipe connection member 1 includes an arc plate 11 with an upward opening, two vertical plates 12 arranged in the axial direction, a baffle plate 2 and a horizontal horizontal plate 13; The right sides are connected, and the lower end of the vertical plate 12 is connected to the top of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com