Patents

Literature

363results about How to "Reduce the amount of welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

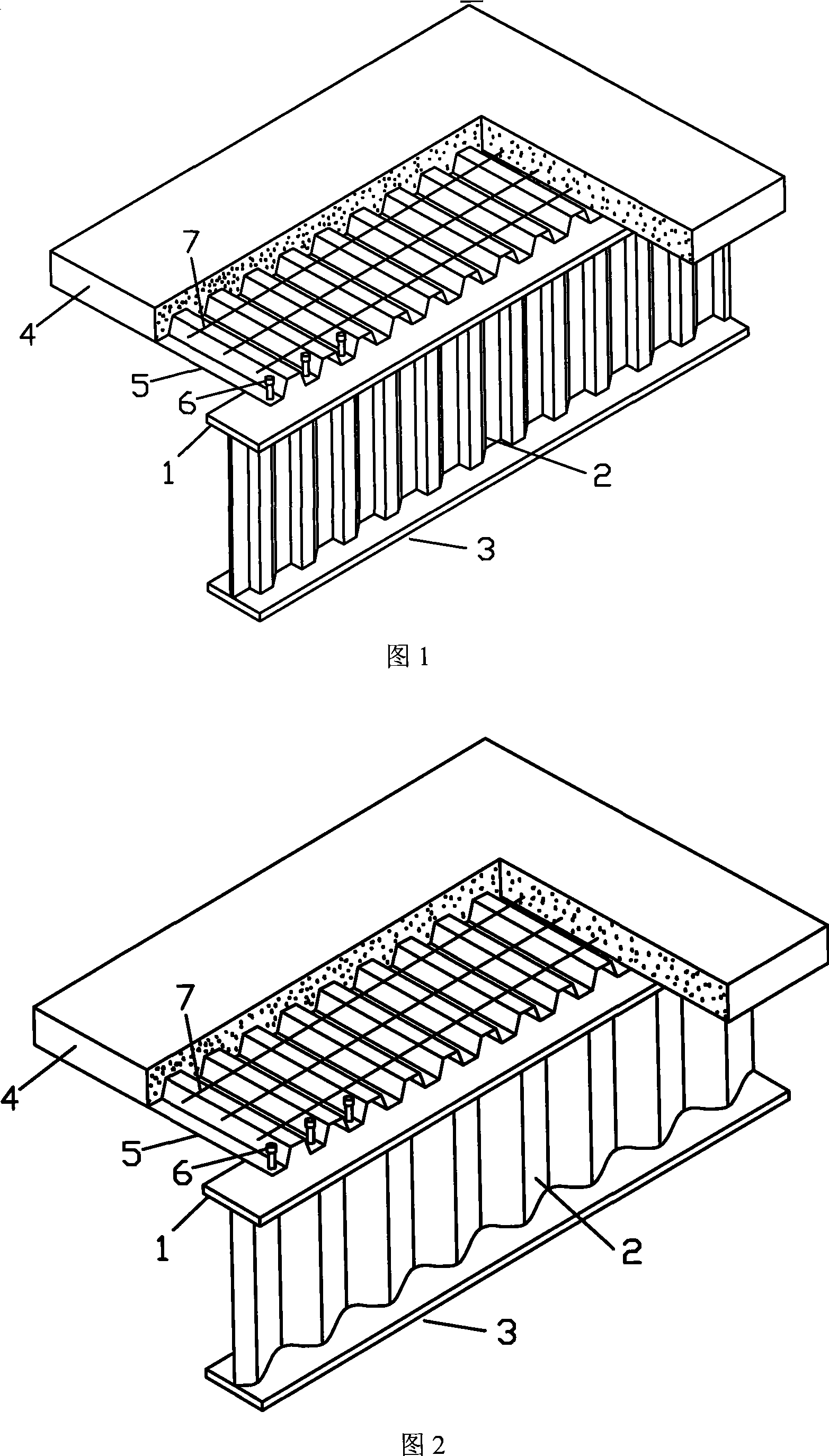

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

Integrated face frame used for panel television (TV) set and manufacturing method of integrated face frame

InactiveCN103139516ASimple structureReduce the amount of weldingTelevision system detailsColor television detailsEngineeringCable television

Owner:四川长虹技佳精工有限公司

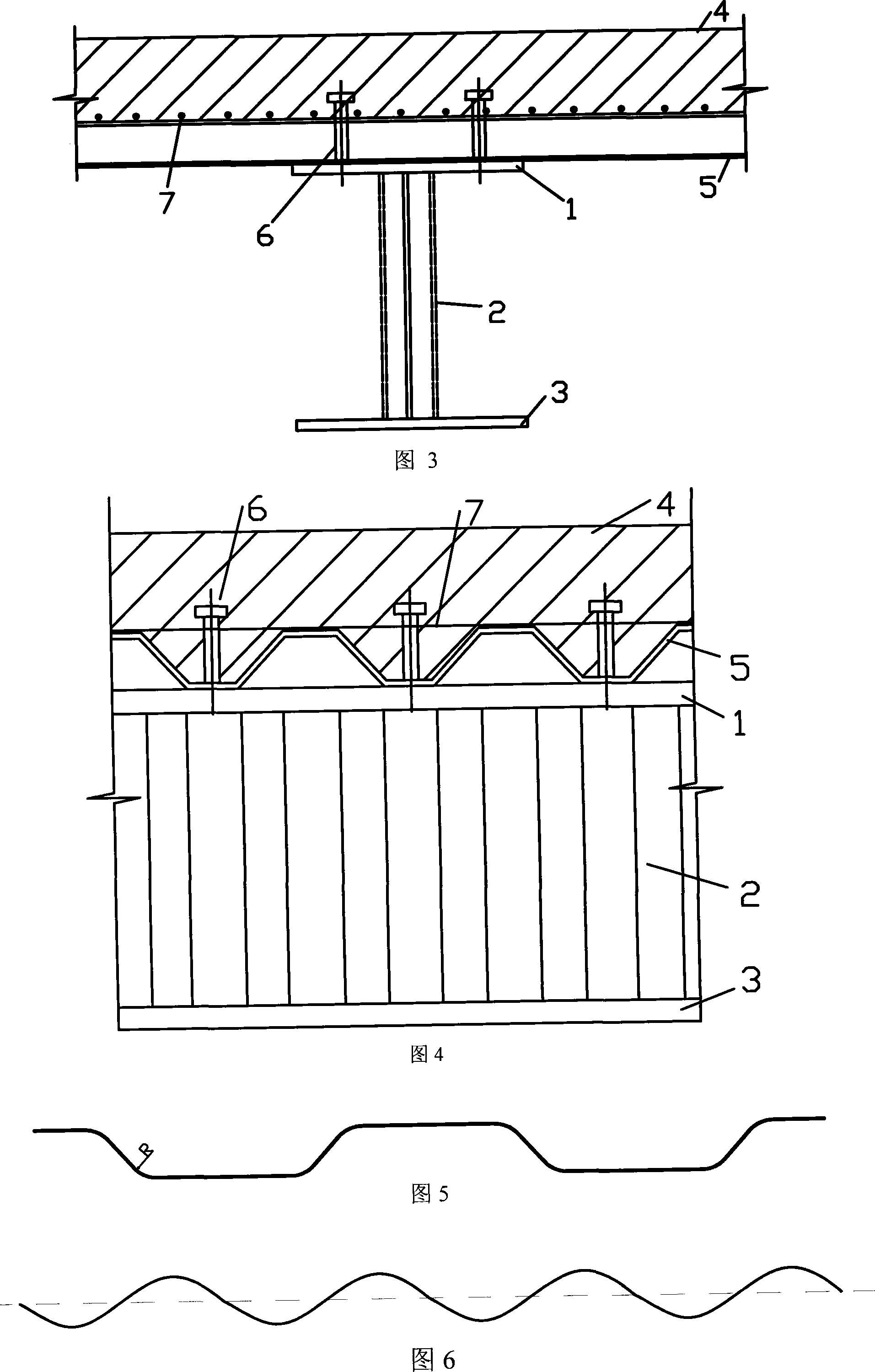

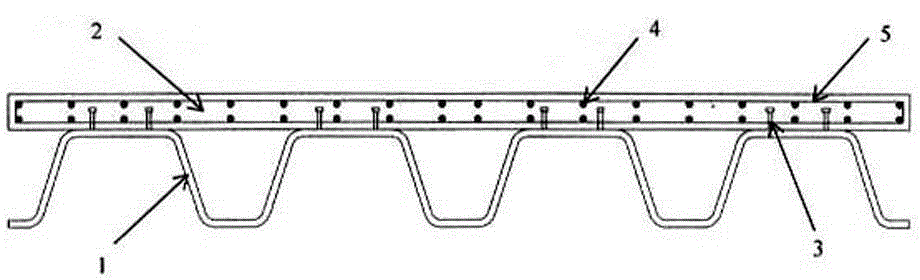

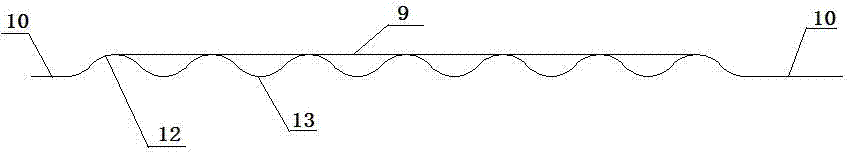

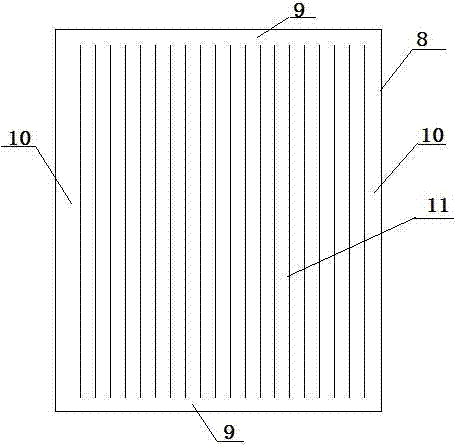

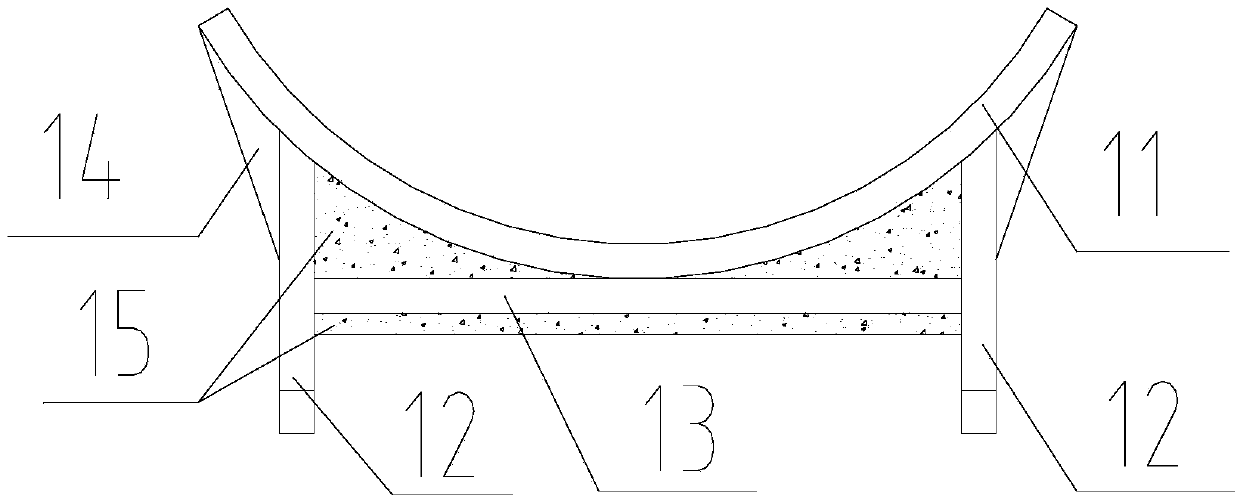

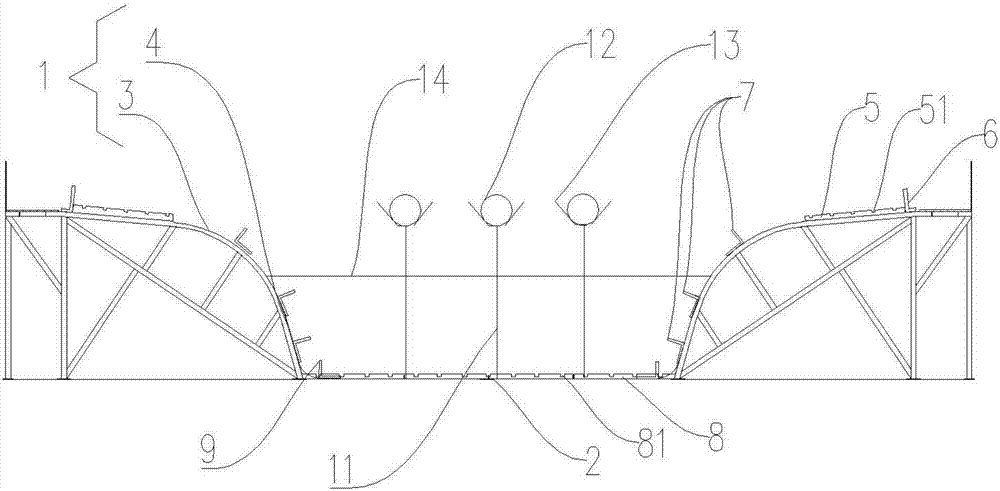

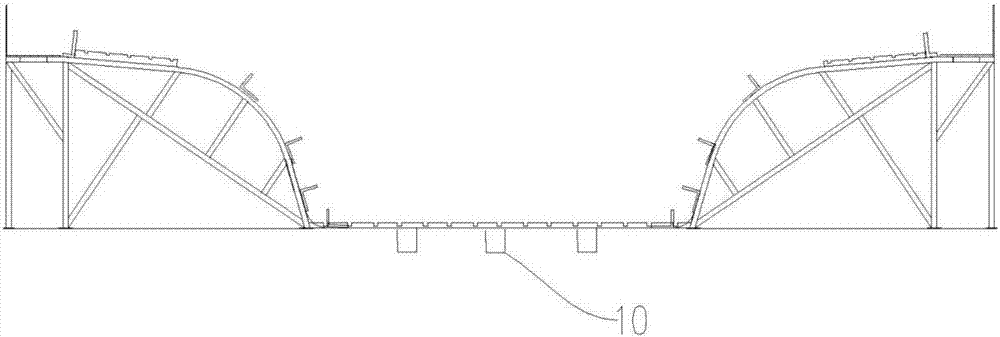

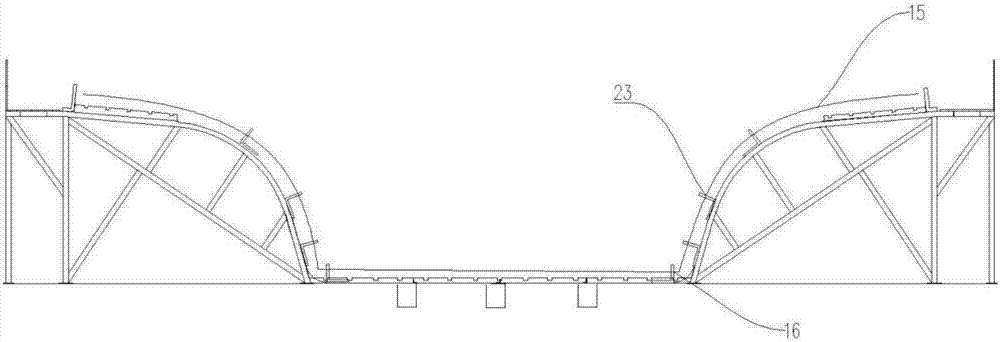

Composite bridge deck applied to long-span bridges and city bridges

ActiveCN104594194ALow costEase of large-scale standardized productionBridge structural detailsWater-setting substance layered productBridge deckWeld seam

The invention discloses a composite bridge deck applied to long-span bridges and city bridges. The composite bridge deck comprises a bridge deck body, wherein the bridge deck body is formed through combining a lower wave-shaped steel plate and an upper concrete slab; shear connectors which are symmetrically welded to wave crests of the wave-shaped steel plate upwards extend into the concrete slab; reinforcing steel bars and annular hoop reinforcements which are used for bundling up the reinforcing steel bars are arranged at the middle part of the concrete slab in a balanced manner. According to the composite bridge deck, the characteristics of the wave-shaped steel plate and the characteristics of the concrete slab are combined together, properties of materials are fully utilized, the flexural bearing capacity is enough under heavy loads, the deformation is small enough under the action of concentrated loads, and too-large secondary stress resulting from weld seams can be avoided; a top plate of a steel bridge deck is replaced with the concrete slab, so that the construction cost of a bridge floor system can be reduced; the quantity of welding is very small, so that the damage to the bridge deck caused by defects of a welding process can be reduced; due to the wrinkling effect of the wave-shaped steel plate, the problem that the deformation of the steel plate and the deformation of concrete are non-synchronous can be greatly solved, and the cracking of the transverse bridge direction of the bridge deck is avoided.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Welding joint and technique for longitudinal seam and circumferential seam of medium-thick plate

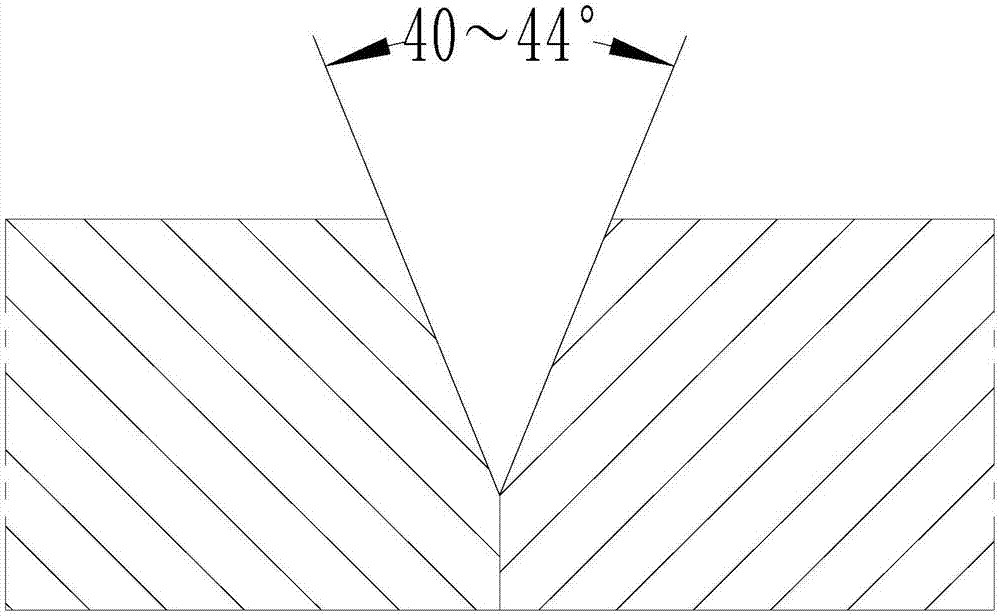

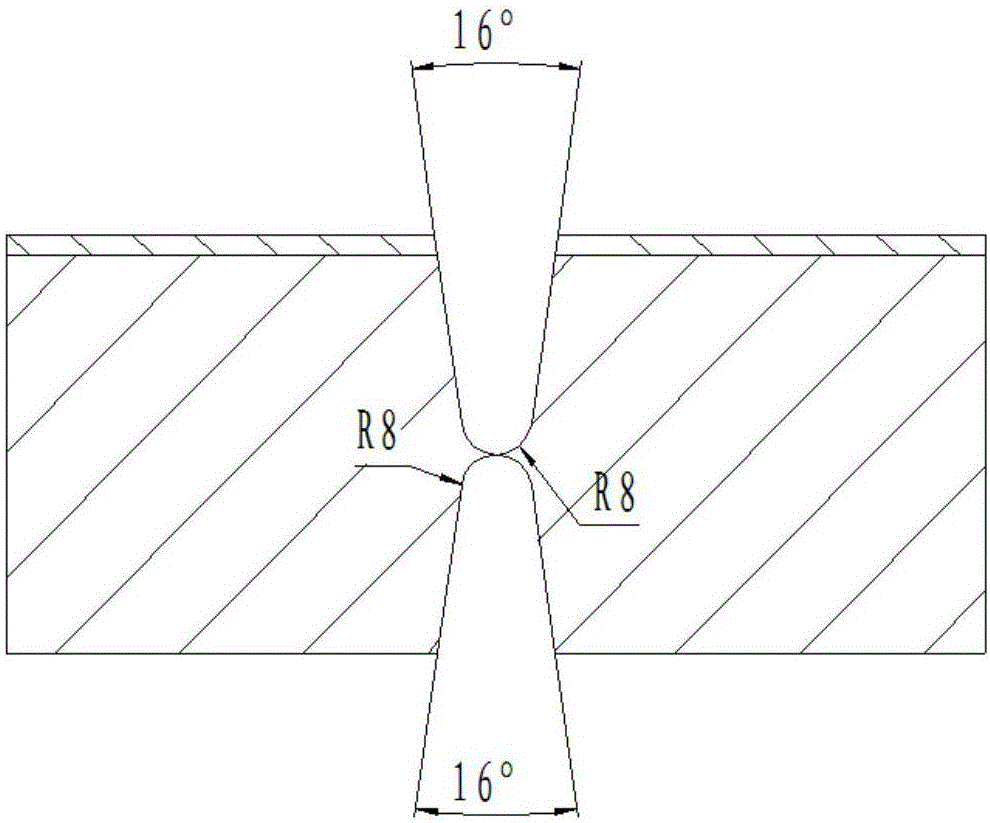

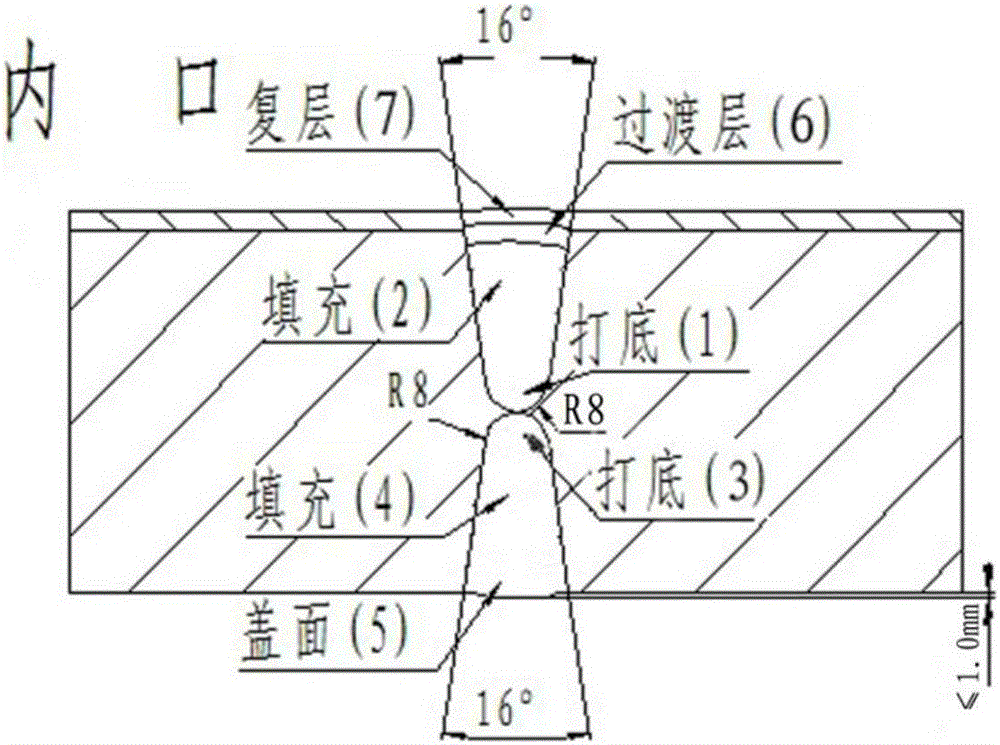

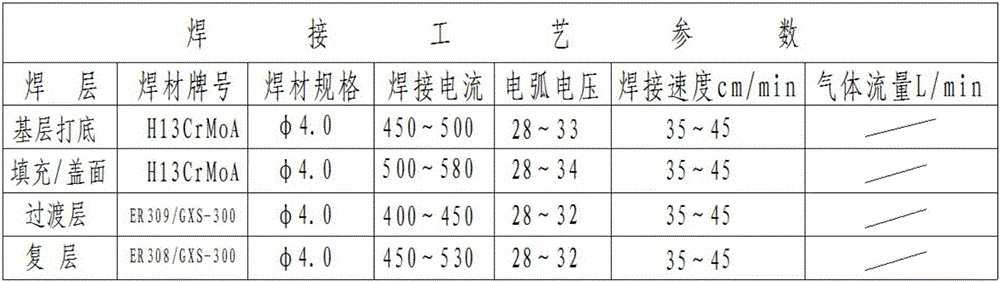

InactiveCN107442891AReduce fillingReduce the amount of weldingWorkpiece edge portionsWelding accessoriesThick plateEngineering

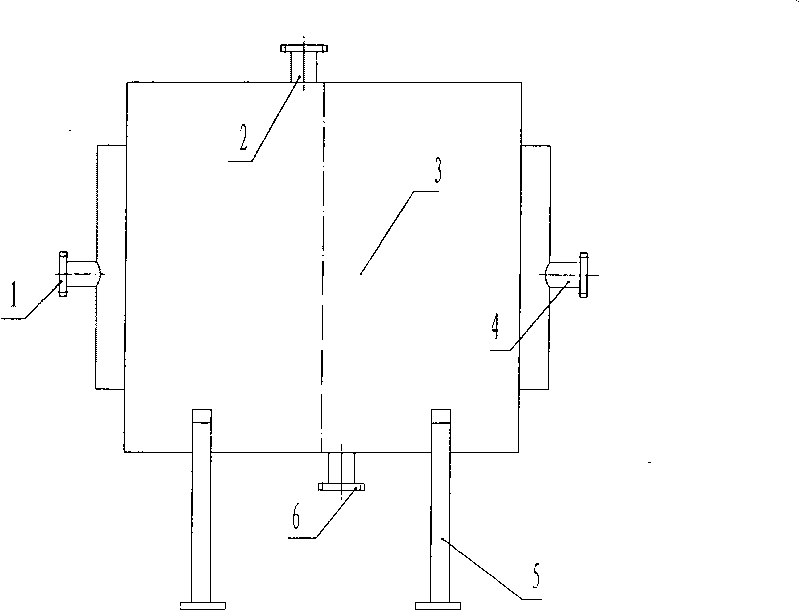

The invention discloses a welding joint and technique for a longitudinal seam and a circumferential seam of a medium-thick plate. The welding technique for the longitudinal seam and the circumferential seam of the medium-thick plate comprises the following steps that a groove inside the plate is machined; then, the surface and the two sides of the groove are cleaned; a priming layer, a filling layer and a surface covering layer of the internal groove are welded in a submerged-arc welding mode; then mechanical back chipping is conducted, and the back-chipped groove is detected nondestructively; and finally, a priming layer, a filling layer and a surface covering layer of an external groove are welded in a submerged-arc welding mode. By optimizing the groove type, the welding material filling amount is decreased, and the welding efficiency is improved; groove machining and welded seam back chipping are conducted through mechanical back chipping, base material hardening caused by rapid heating and cooling through carbon arc air gouging back chipping is avoided, the carburization phenomenon on the two sides of the groove of a stainless steel material is avoided, secondary polishing caused by using of a polishing machine is avoided, the back chipping efficiency is improved by about 50%, the labor intensity of workers is greatly reduced, the air environment is improved, and the welding quality of a cylinder is improved.

Owner:LUXI IND EQUIP

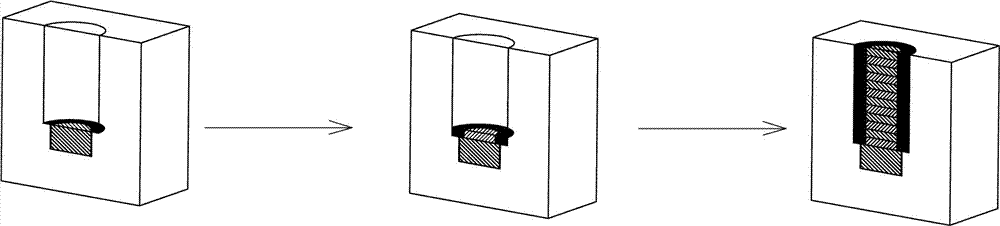

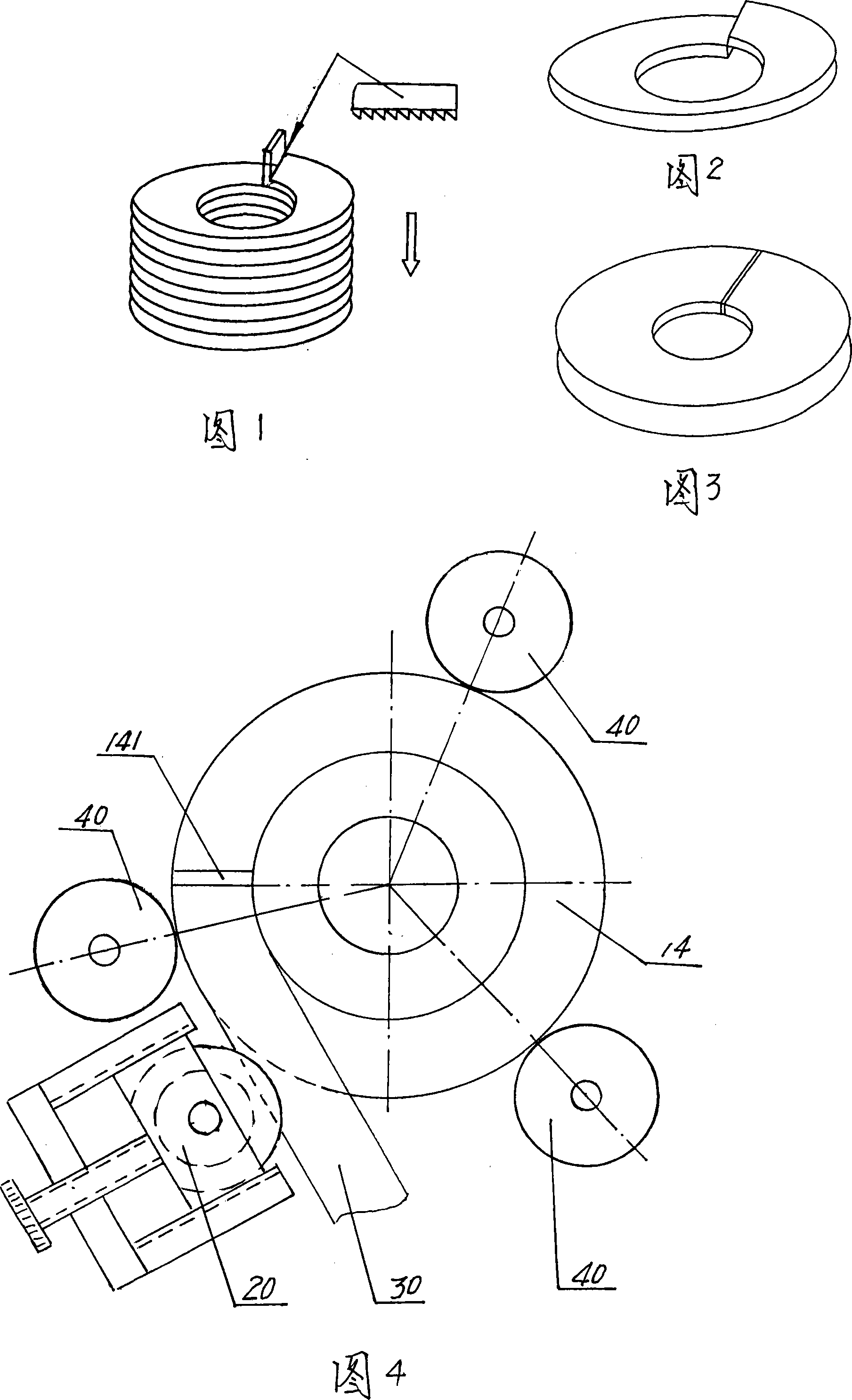

Electroslag fusion casting manufacturing method for annular plate of hydraulic generator

ActiveCN102416463AAchieve the purpose of near-net shape in melting and castingHigh dimensional accuracyManufacturing technologySlag

The invention discloses an electroslag fusion casting manufacturing method for an annular plate of a hydraulic generator. The method is characterized by comprising the following steps of: 1) controlling slag systems and slag amount; 2) igniting; 3) selecting a crystallizer; 4) rotating the crystallizer by using a control system; 5) selecting power supply parameters; 6) controlling casting alloy components after fusion casting; and 7) selecting a casting thermal processing process. A near-net-shape forming annular plate manufacturing technology is provided for producing annular anti-tear steel plates for hydraulic generator seat rings, top covers and bottom rings at present; a rotatable crystallizer is used for electroslag fusion casting formation, so that technical requirements on production of the annular plate are met; and the produced annular plate has high laminated tearing resistance, higher fatigue resistance and higher crack generation and expansion resistance, and the quality and the performance of the annular plate are not lower than those of a specially-forged product which is made of the same material as that of the annular plate.

Owner:沈阳市盛华特种铸造有限公司

Threaded hole welding and repairing process

ActiveCN107498262AImprove repair efficiency and qualityReduce welding height and welding volumeSheet steelSurface finishing

The invention provides a threaded hole welding and repairing process. The threaded hole welding and repairing process comprises the following steps of material preparation, chambering, welding, surface treatment, drilling and tapping. According to the process, circular steel sheets are laid in an inner hole subjected to chambering to replace the bead welding quantity, bead welding in the small diameter of a thread is replaced with the circular sheets, the welding quality of the large diameter of the thread and the small diameter of the thread is guaranteed, and meanwhile it is guaranteed that the small diameter of the thread is filled with the circular steel sheets, so that positioning and construction are performed conveniently when redrilling is performed. By means of the process, the quality and efficiency of repair of a threaded hole can be improved, meanwhile welding deformation is lowered, and the threaded hole welding and repairing process is particularly suitable for welding and repairing of the deep threaded hole.

Owner:中国船舶重工集团柴油机有限公司

Novel plate type air preheater

ActiveCN103759288AAvoid disadvantagesImprove heat transfer efficiencyCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention relates to a novel plate type air preheater, and belongs to the field of heat exchangers. The novel plate type air preheater comprises a heat exchange core with corrugated plates, an air preheater shell, flue gas inlet and outlet pipelines and air inlet and outlet pipelines. A plurality of groups of plate bundles are stacked up in a certain manner to form the heat exchange core with the corrugated plates. Two corrugated plates are welded together in a plane zone to form each plate bundle, flue gas elliptical tubular channels are formed by the plate bundles, the plate bundles are stacked up in the planar zones and then are welded to form air shell-side channels, and heat can be exchanged between two types of media in a cross-flow manner. The novel plate type air preheater has the advantages that the novel plate type air preheater is compact in structure, high in heat transfer efficiency, long in service life, convenient to machine and low in cost, and is high-temperature-resistant and high-pressure-resistant; air flue of the novel plate type air preheater flows through the elliptical straight channels and is low in flowing resistance as compared with a tubular air preheater and a finned tube air preheater; the novel plate type air preheater cannot be contaminated by dust, and the dust can be easily cleaned even of the novel plate type air preheater is contaminated by the dust.

Owner:MECS CHEM PLANTS EQUIP SHANGHAI

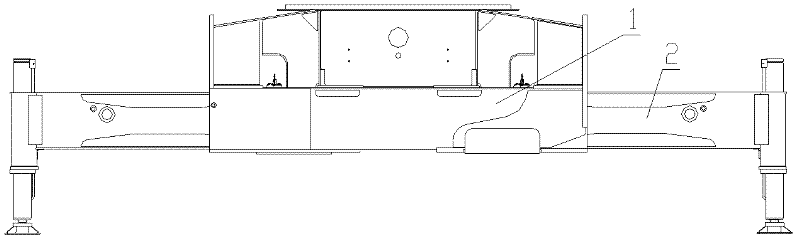

Super high-rise core tube internal and external hanging tower crane support beam structure and construction method thereof

InactiveCN103264968AFull utilization of hoisting rangeReduce the number of jackingsCranesSupporting systemTower crane

The invention relates to a super high-rise core tube internal and external hanging tower crane support beam structure and a construction method thereof. Two parallel horizontal tower crane support girders are arranged, the sections form box shapes, a root part of each girder is connected with a core tube embedded part through a girder ear plate, inclined supports are circular pipes, one end of the inclined support is supported and connected to a core tube, the other end is connected with the vertical tail end of the corresponding girder, one end of a horizontal pull rod is connected to the core tube in an inclined manner, the other end is connected with the horizontal tail end of the corresponding girder, and the two girders are connected by a horizontal connection rod to form a main body frame support system. According to the super high-rise core tube internal and external hanging tower crane support beam structure and the construction method, the structure is simple, a tower crane is externally hung on the outside of the core tube so that influence of structural construction in the core tube is greatly reduced and utilization of the hanging scope of the tower crane is sufficient, the construction is simple, and the cycle is shortened.

Owner:CHINA CONSTR FIRST DIV STEEL STRUCTUREENG

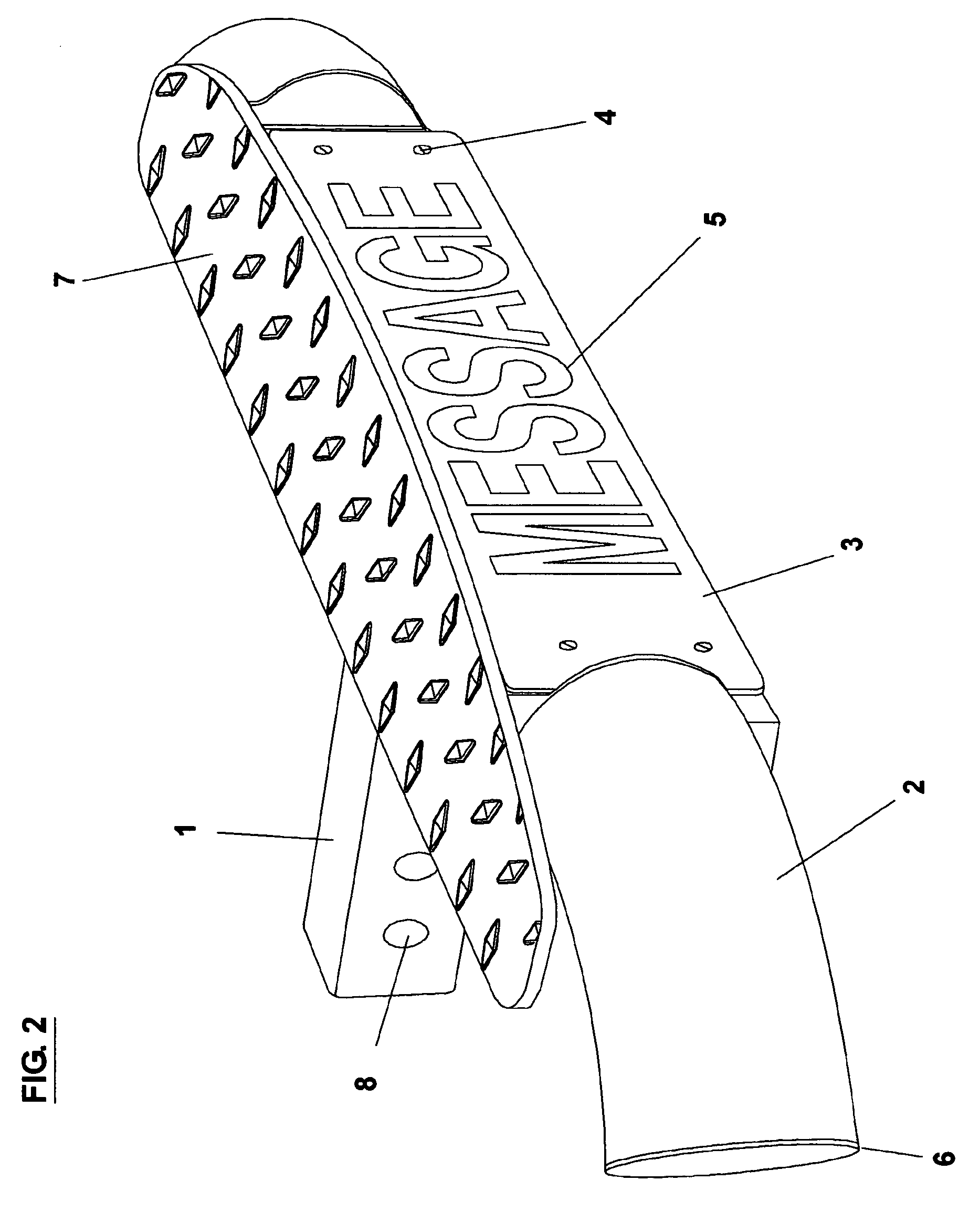

Modular trailer hitch accessory with decorative and interchangeable elements

InactiveUS20050286257A1Saving can be considerableImprove personalizationVehicle interior lightingOptical signallingModularityElectrical and Electronics engineering

The previous invention of decorative accessories which are designed to be placed in a trailer hitch receiver, function as hitch steps, have permanent decorative elements and also have the capacity to hold a display placards are the base concept for the present invention. The present invention is an improvement of the previous inventions, to which such improvements include provisions to further enhance the capacity to individualize the hitch receiver apparatus. The current invention consists of a decorative trailer hitch insert that is capable of holding a display placard and has the further provision for interchangeable decorative elements such as step plates, end tubes, various componential additions and various surface treatments.

Owner:TRIMMER THOMAS DAVIS +1

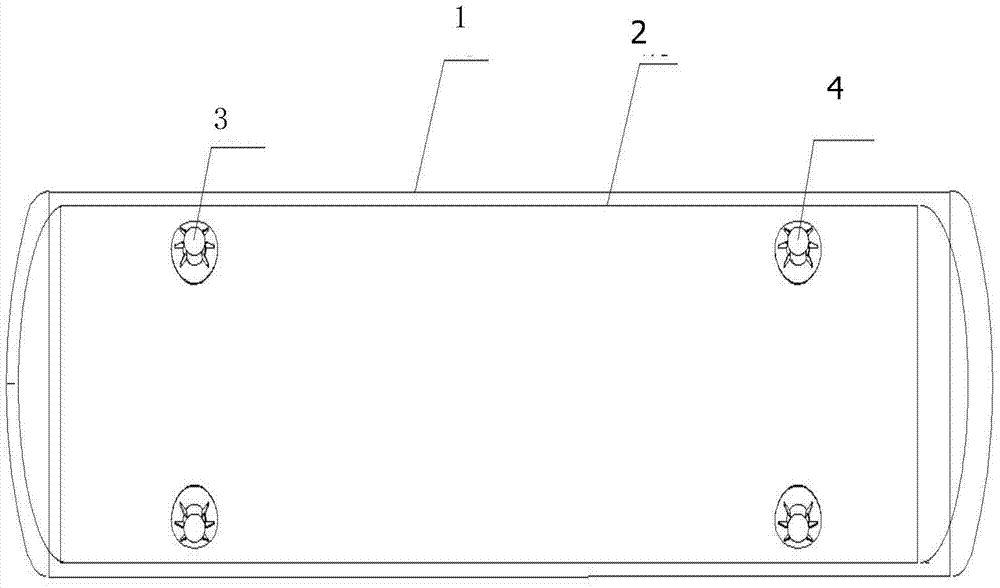

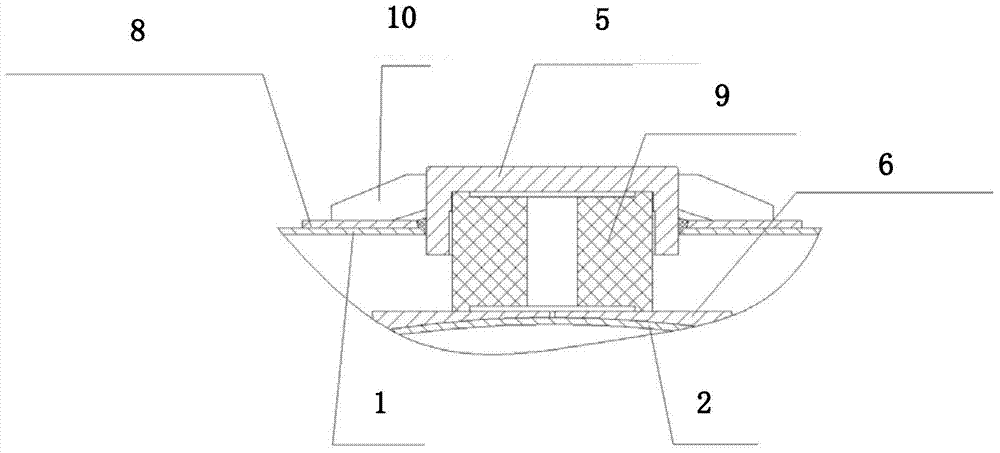

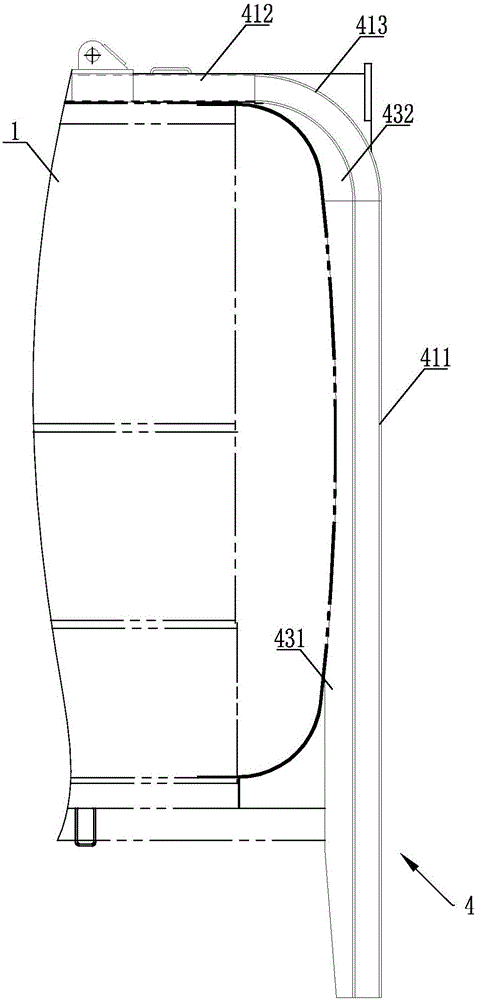

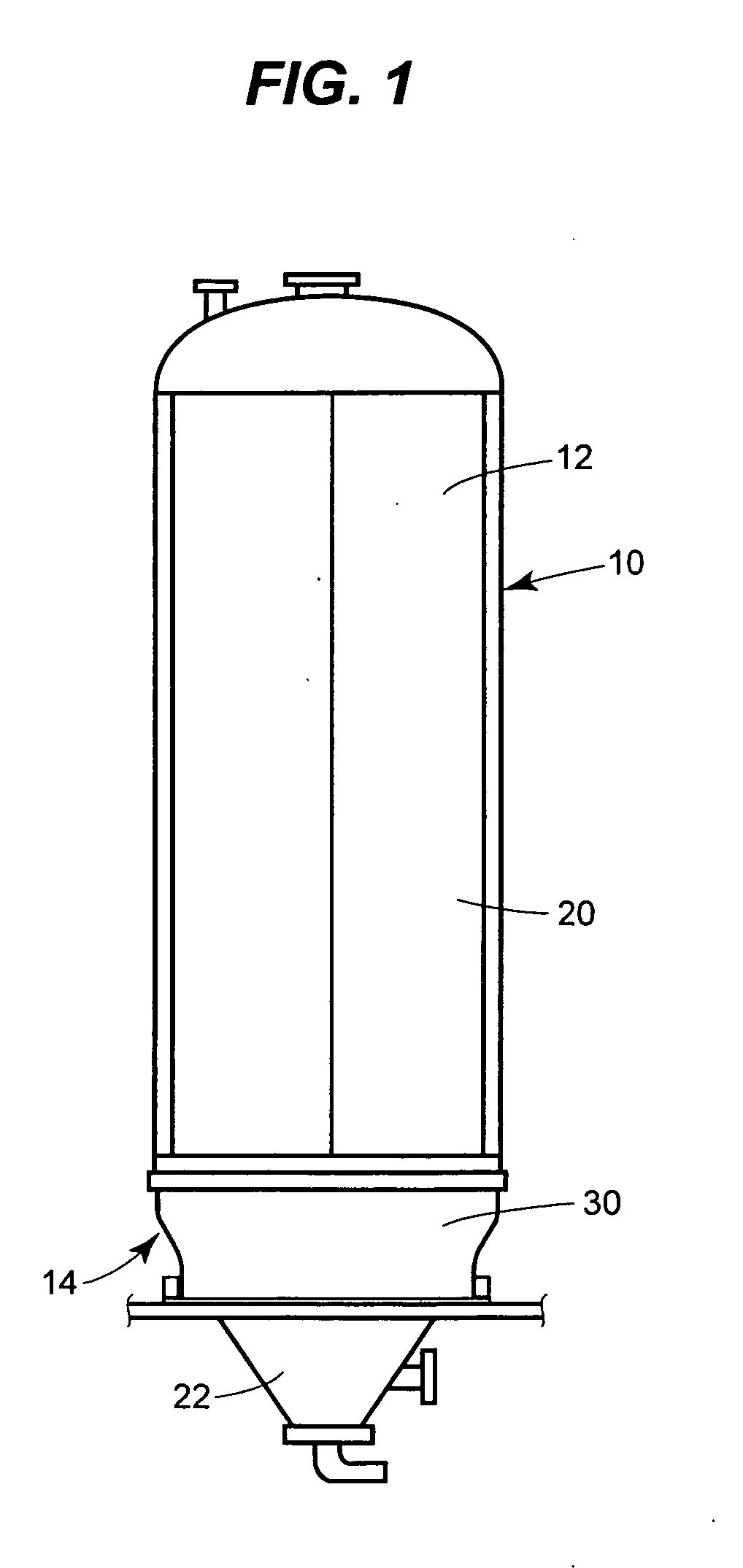

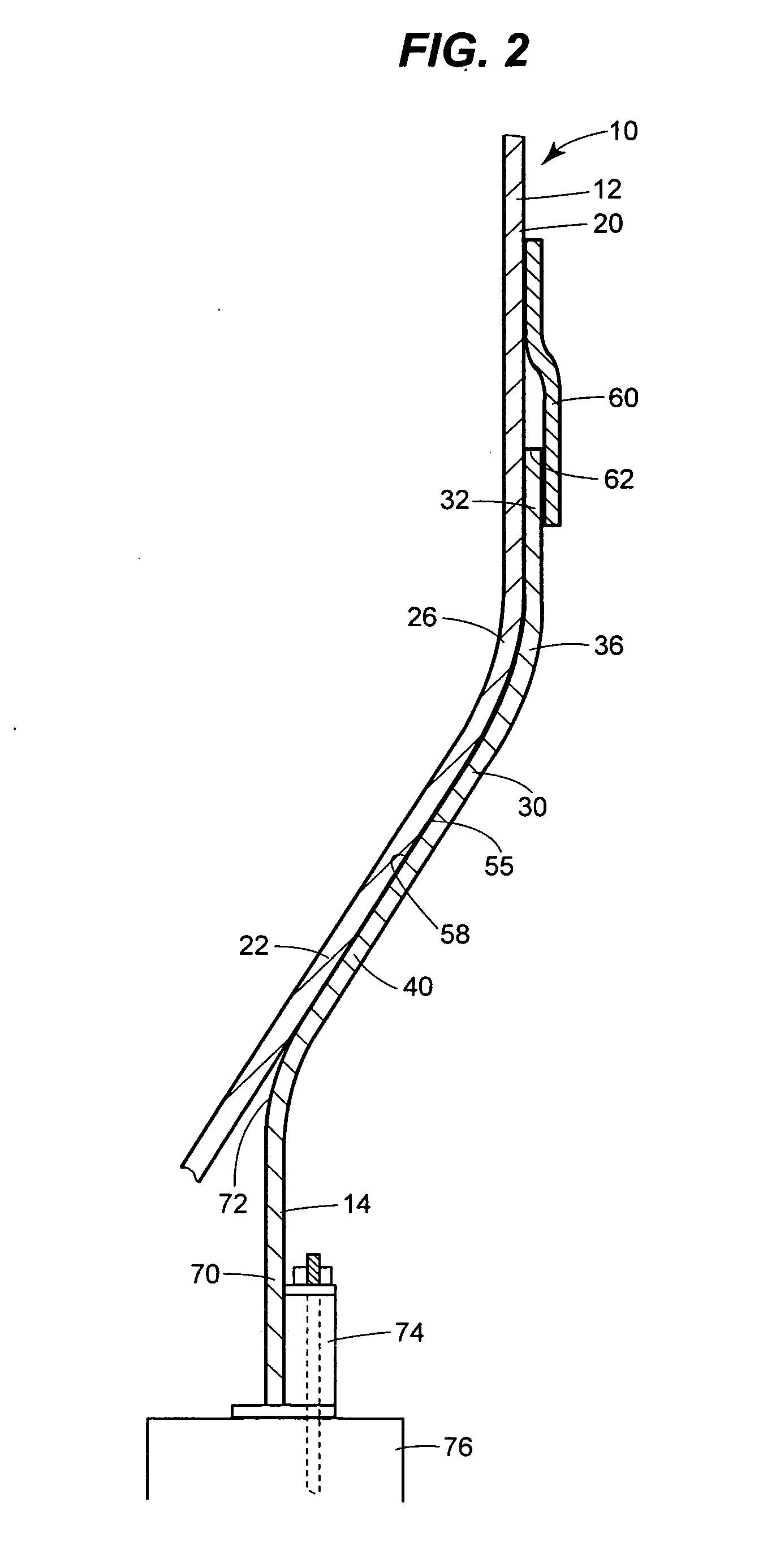

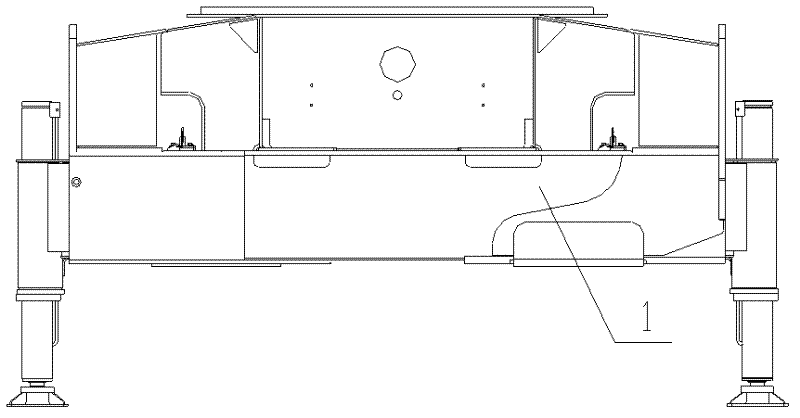

Inner tank and outer tank structural support

The invention relates to an inner tank and outer tank structural support comprising a sliding support component and a fixing support component between the inner tank and the outer tank. The sliding support component comprises an outer tank support cover arranged on the outer tank, an inner tank sliding support arranged on the inner tank, and a glass fiber reinforced plastics support used for connecting the outer tank support cover and the inner tank sliding support; the fixing support component comprises an outer tank support cover arranged on the outer tank, an inner tank fixing support arranged on the inner tank and a glass fiber reinforced plastics support used for connecting the outer tank support cover and the inner tank fixing support; an outer tank support cover stiffening ring and rib plate sets are arranged on the outer tank, and the rib plate sets are respectively connected with the outer tank support cover stiffening ring and the outer tank support cover. The inner tank and outer tank structural support is capable of reducing welding quantity, improving reliability and increasing braced force.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

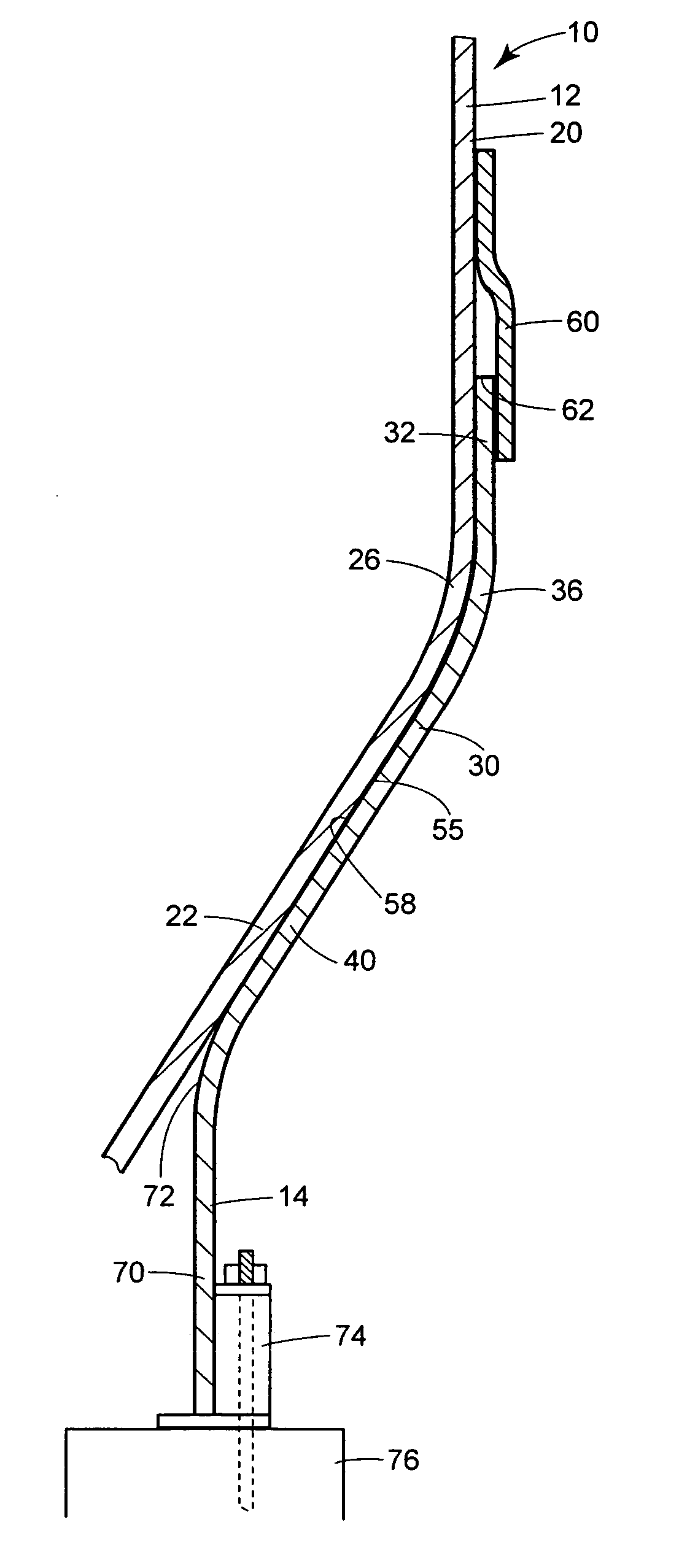

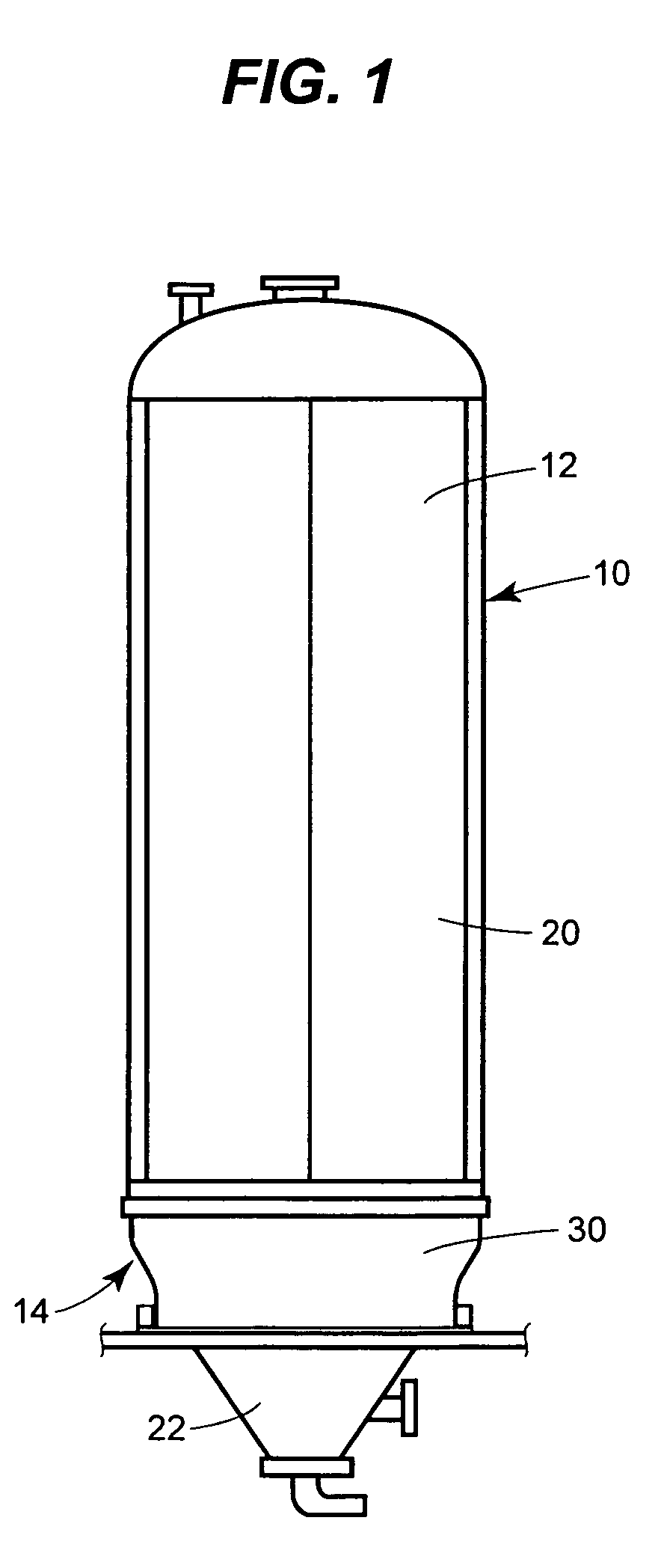

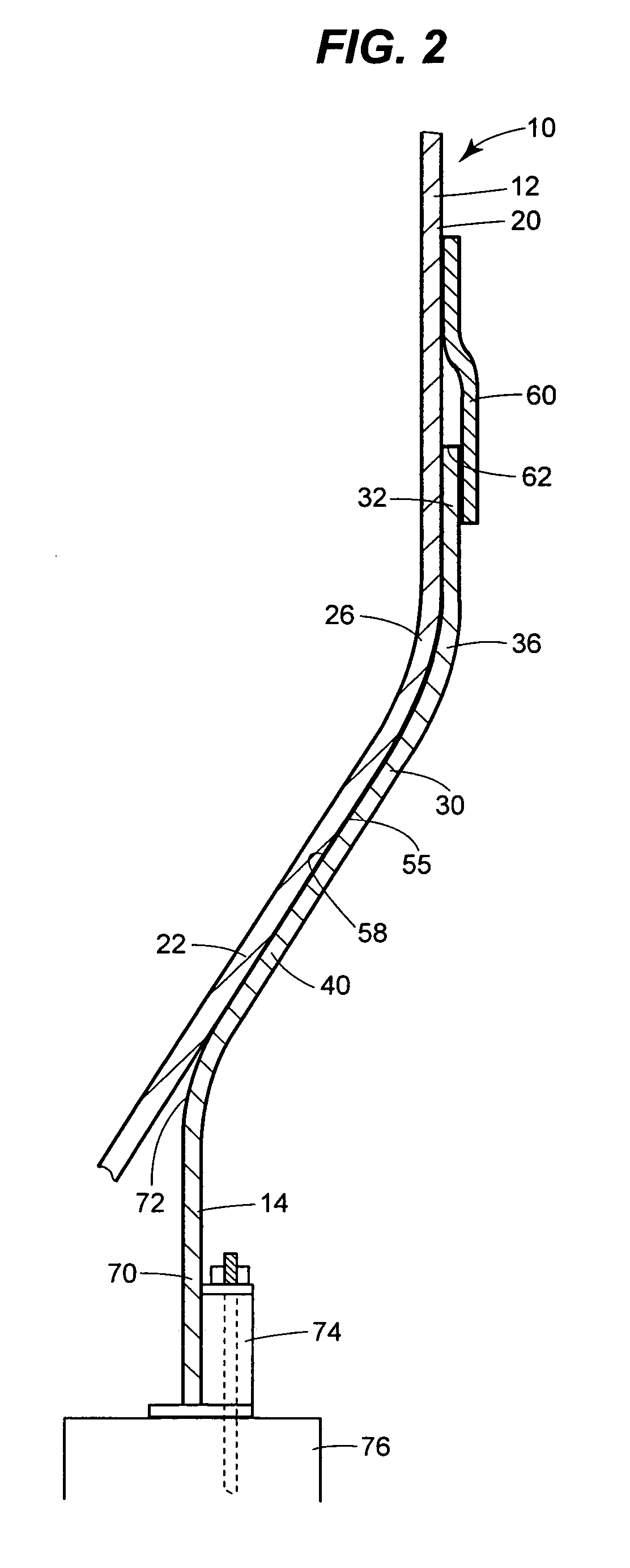

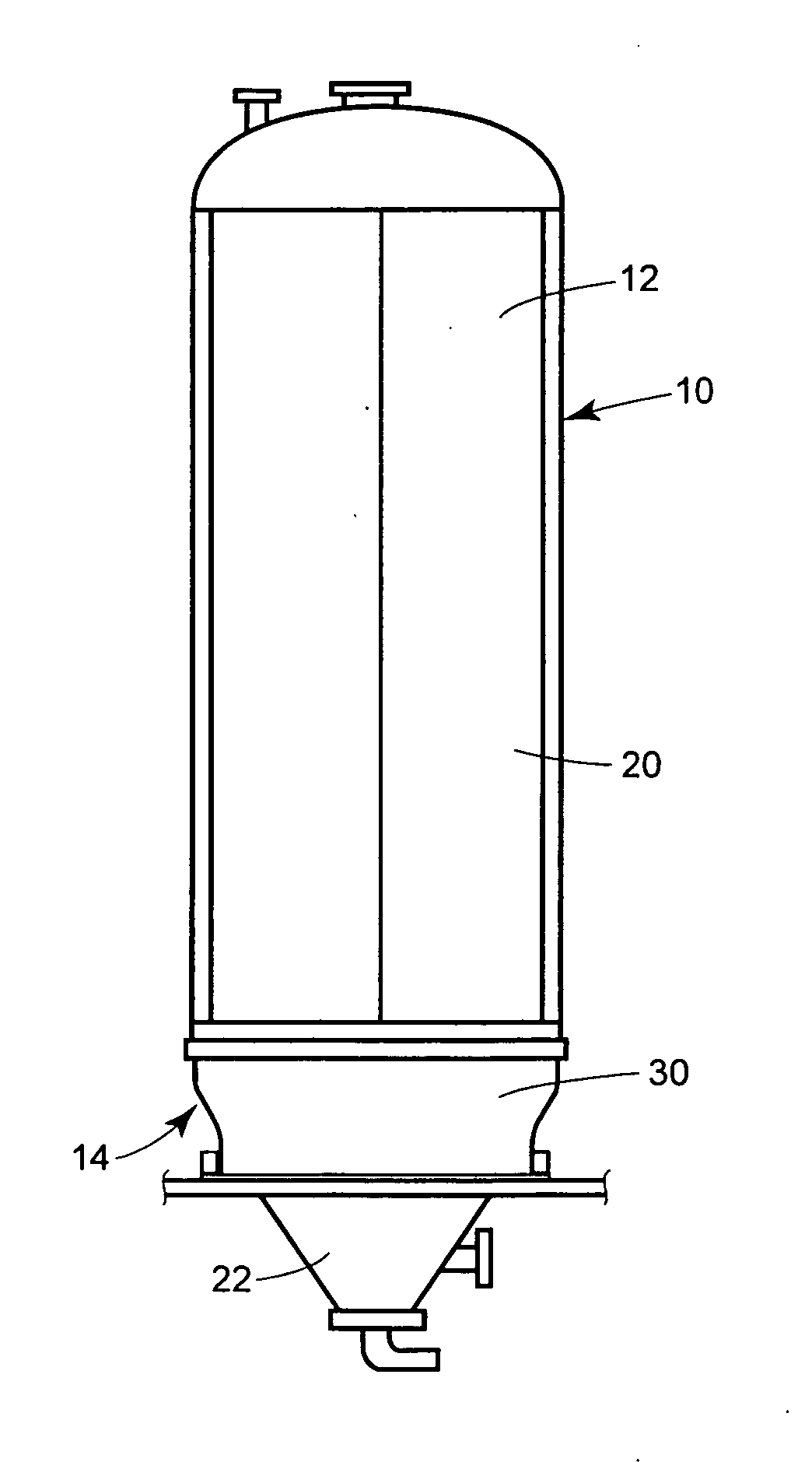

Structure for extreme thermal cycling

ActiveUS7666279B2Reduce the amount of weldingFlexible connectionMechanical conveying coke ovensCharging-discharging device combinationsPre stressPre stressing

A structure for extreme thermal cycling has a support element that supports a vessel primarily by bearing and frictional forces rather than by welds. The support element has a bearing portion that tapers inwardly beneath a knuckle that separates a cylindrical section of the vessel from a sloped lower section. The bearing portion of the support element follows that slope, providing an extended area of contact between the support element and the vessel. An annular section of the support element can be heated and expanded before placing it around the cylindrical section of the vessel to provide pre-stressing. If required, a strap may extend downwardly from the vessel over an upper edge of the support element.

Owner:CB&I STS DELAWARE LLC

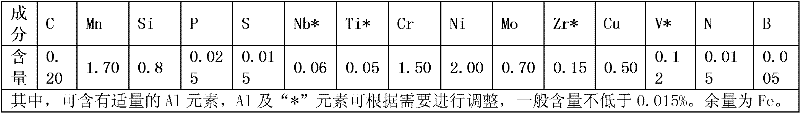

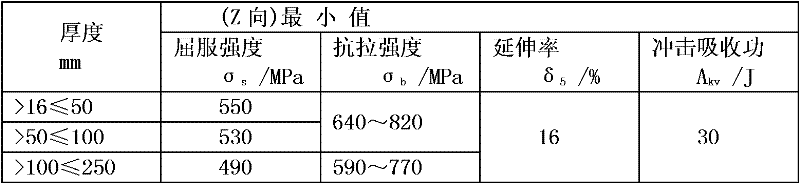

Automatic submerged arc welding method for pearlitic heat-resistant steel composite board

ActiveCN105665898AReduce fillingReduce the amount of weldingArc welding apparatusWelding/soldering/cutting articlesWeld seamEngineering

The invention discloses an automatic submerged arc welding method for a pearlitic heat-resistant steel composite board. The significant advantages are achieved by changing the welding method and the groove type and adjusting the welding sequence. The automatic submerged arc welding method has the significant advantages that by optimizing the groove type, the welding material filling quantity is reduced, and the welding efficiency is improved; a mechanical mode is adopted to conduct groove machining and welding seam back chipping, parent metal hardening caused by rapid heating and rapid cooling of thermal cutting or carbon arc air gouging is effectively avoided, and the rolling machining and welding quality of a barrel is improved; outer edge back chipping is conducted immediately after inner edge base layer welding is completed, welding stagnation and reheating in the middle can be effectively avoided, and the welding quality is guaranteed; transition layer welding is conducted immediately after base layer welding is completed, composited layer welding is conducted after crack detection is qualified, repeated preheating and transition layer welding which are conducted after nondestructive detection of previous base layer welding is completed and qualified can be effectively avoided, and the composited layer welding quality is improved.

Owner:LUXI IND EQUIP

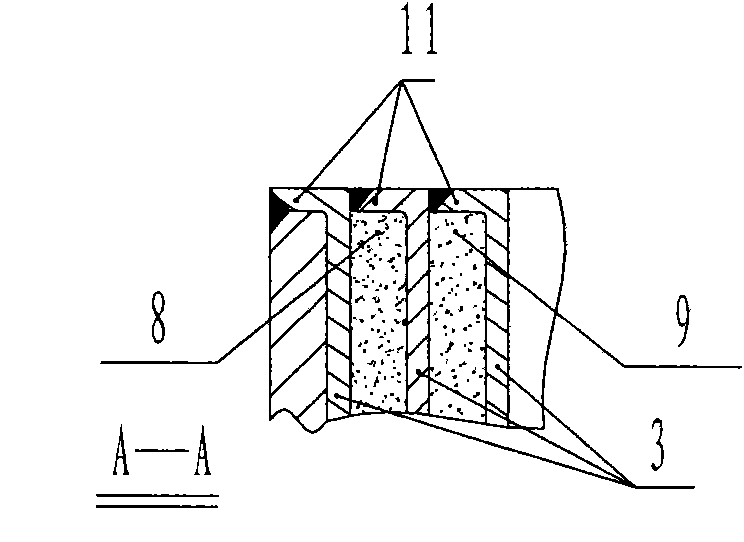

Spiral plate heat exchanger and production method thereof

InactiveCN101749972AFirmly connectedReduce the amount of weldingStationary plate conduit assembliesPlate heat exchangerEngineering

The invention relates to a spiral plate heat exchanger made of two steel plates through coiling and a production method thereof. The spiral plate heat exchanger is designed to mainly solve the problem of the existing spiral plate heat exchanger that the welding amount is large and the leakage points are in a large quantity. The upper edge and the lower edge of the two spiral plates for forming a spiral body are respectively bended outward and lapped on the end face of the adjacent spiral plate and then welded and sealed, and a strengthening seal angle is additionally arranged at the angle part between the spiral plate and a division plate. The production method comprises the following steps: coiling two pieces of steel plates into a spiral body, forming two uniform spiral channels, arranging a division plate in the middle of the spiral body, respectively welding and sealing the two edges of the division plate with the inner ends of the two spiral plates, bending the upper edge and the lower edge of the spiral plate of each channel of the spiral body outward and lapping the edges to the end surface of the adjacent spiral plate to be welded and sealed, and arranging a bracket under the spiral body. The spiral plate heat exchanger and the production method have the advantages that the welding amount is small, the leakage points are in a small quantity, and the production cost is low.

Owner:付涛

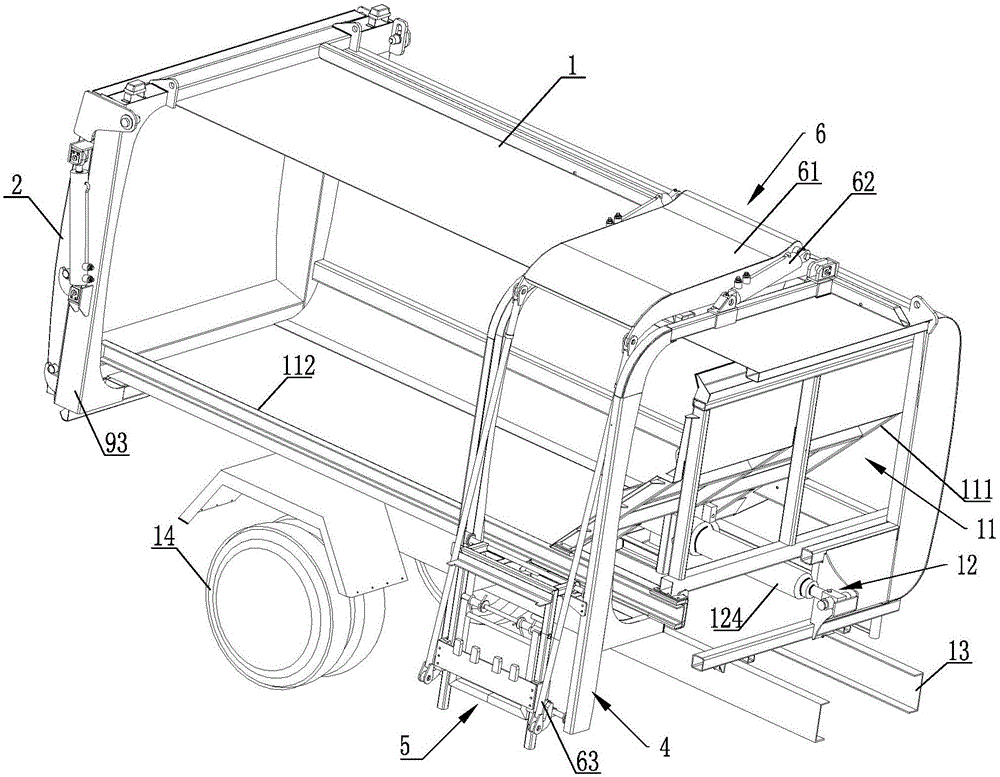

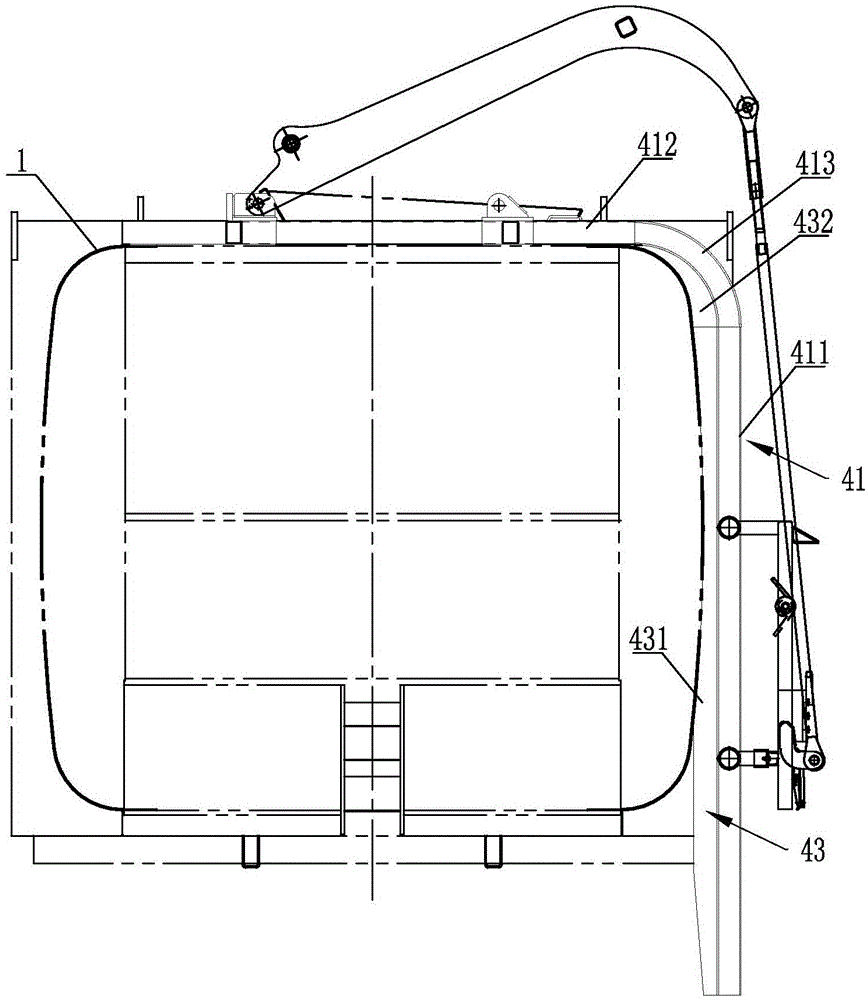

Push plate type side loading and unloading sanitation vehicle

The invention discloses a push plate type side loading and unloading sanitation vehicle. The push plate type side loading and unloading sanitation vehicle comprises a tank with a rear-end tank opening, wherein a garbage dumping opening is formed in the top of the tank; a tank rear baffle plate is hinged to the rear-end tank opening of the tank; a garbage can elevating guiding device is fixedly arranged on the side wall of the tank; a can lifting device is arranged on the top of the tank and is connected to a can hanging device; the can hanging device is arranged in the garbage can elevating guiding device in a rolling manner; a garbage pushing device is arranged in the tank in a sliding manner and is connected to a pushing control device extending to the outer side of the tank; the pushing control device is arranged on a vehicle body of the sanitation vehicle; wheels are arranged at the bottom of the vehicle body; and the front end of the vehicle body is connected to a cab. The friction between the garbage can and the tank is avoided, the realization of protection of the garbage can and the tank is facilitated, the garbage pushing device and the pushing control device can also avoid secondary pollution and prevent a driver from getting off the vehicle to perform operation, and therefore, the push plate type side loading and unloading sanitation vehicle is labor-saving in use and convenient to operate.

Owner:WUZHENG

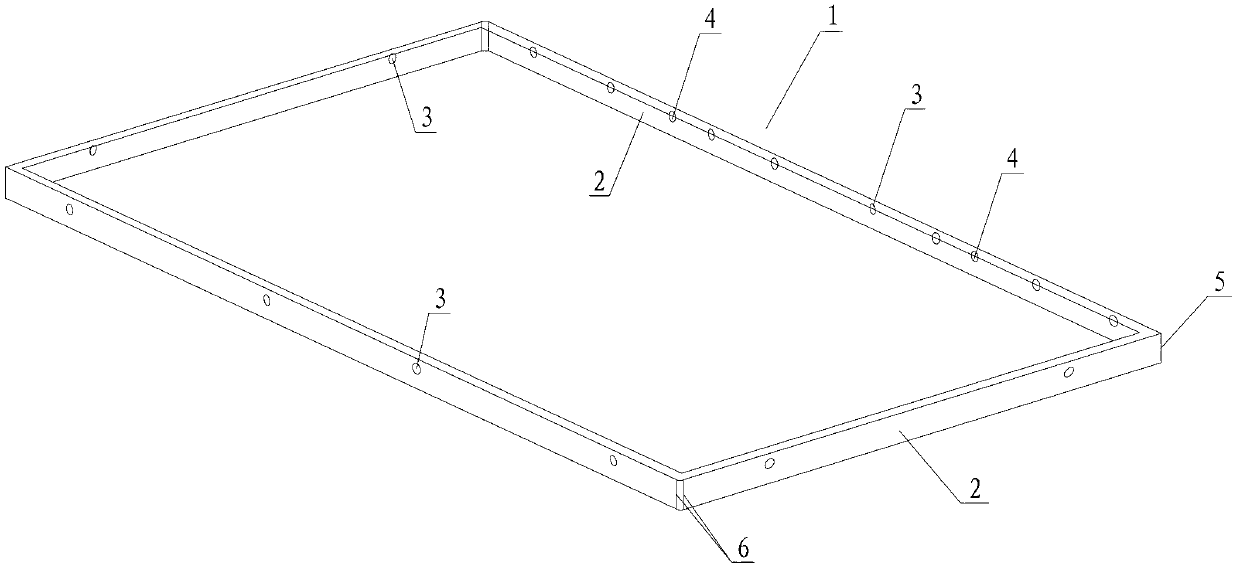

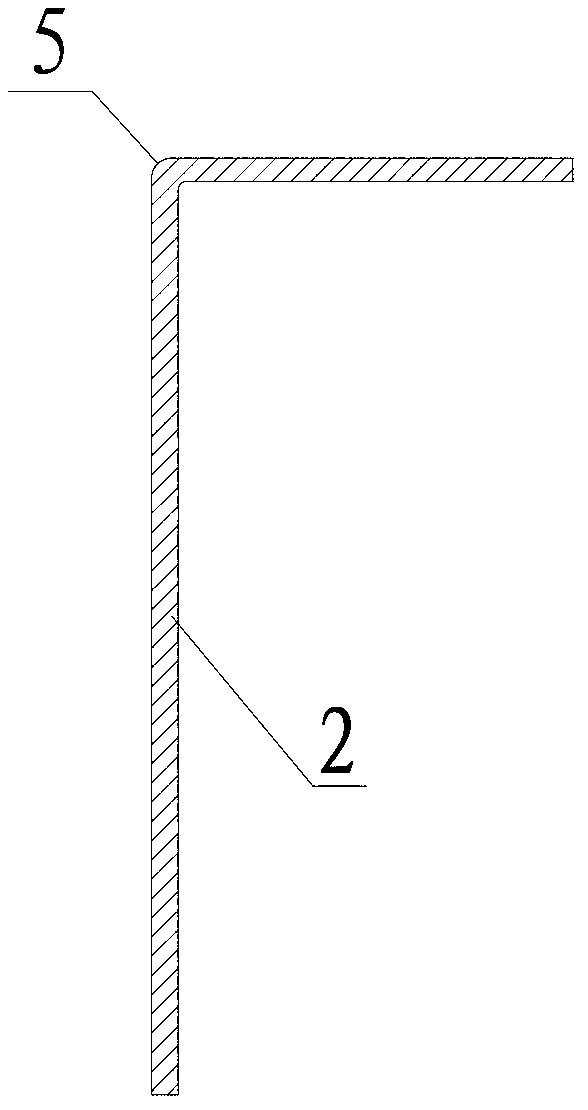

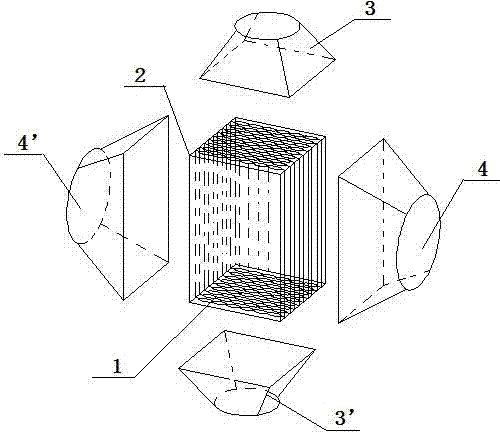

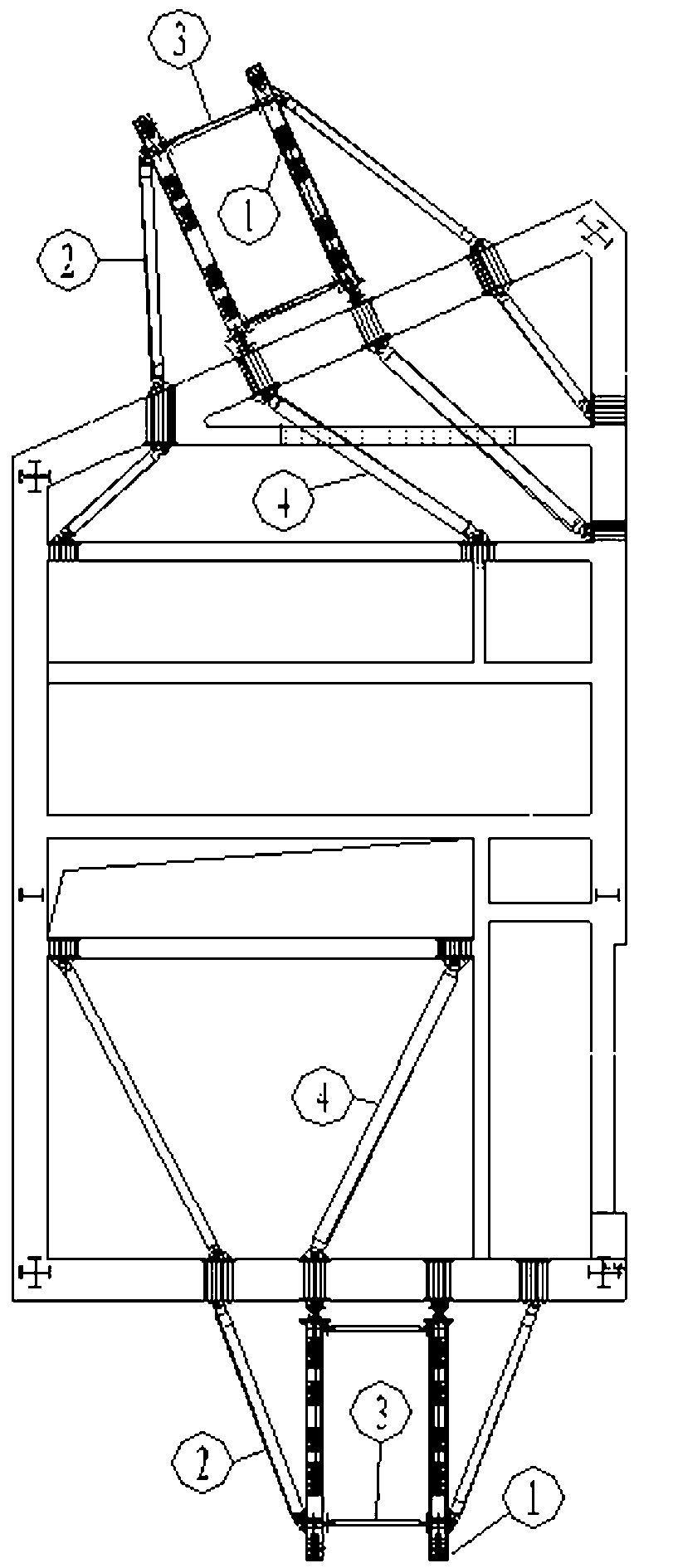

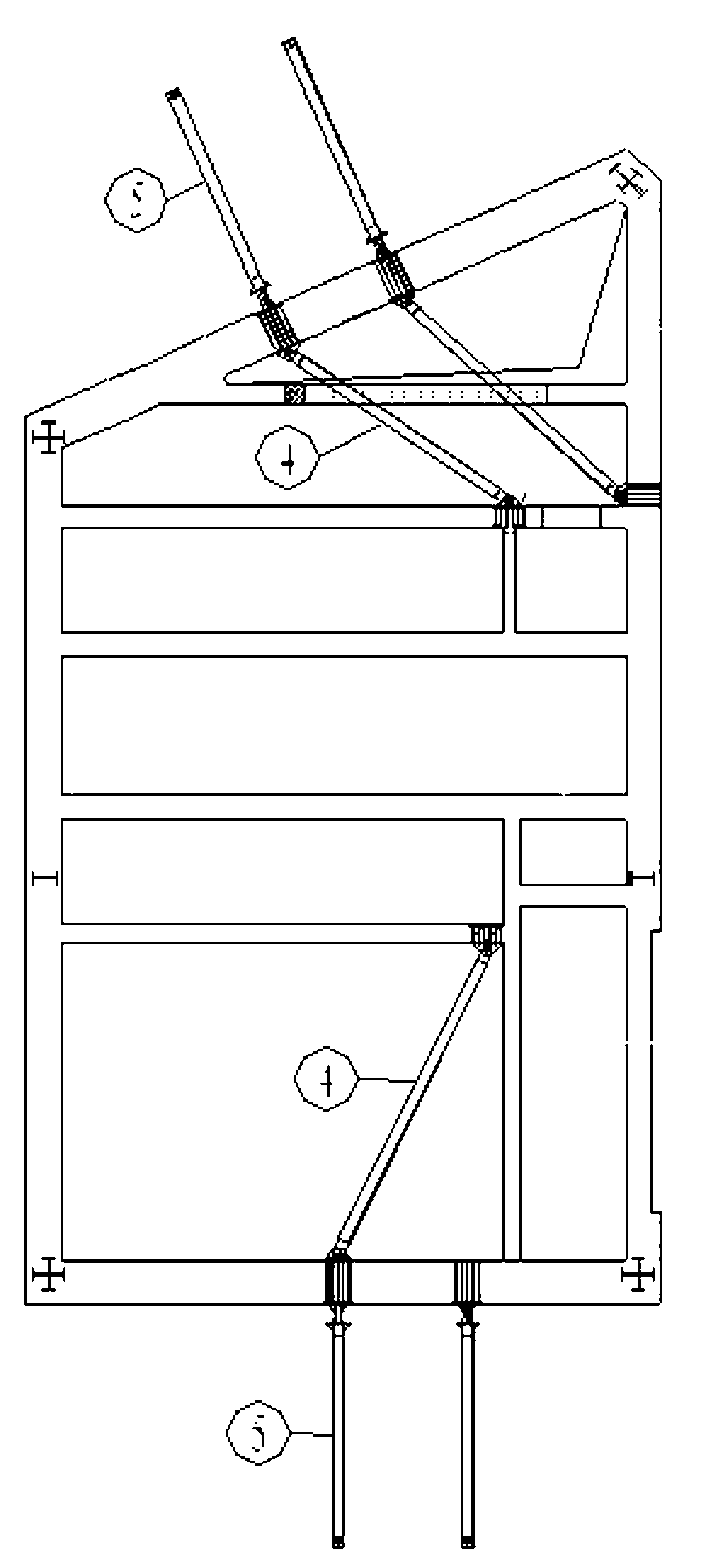

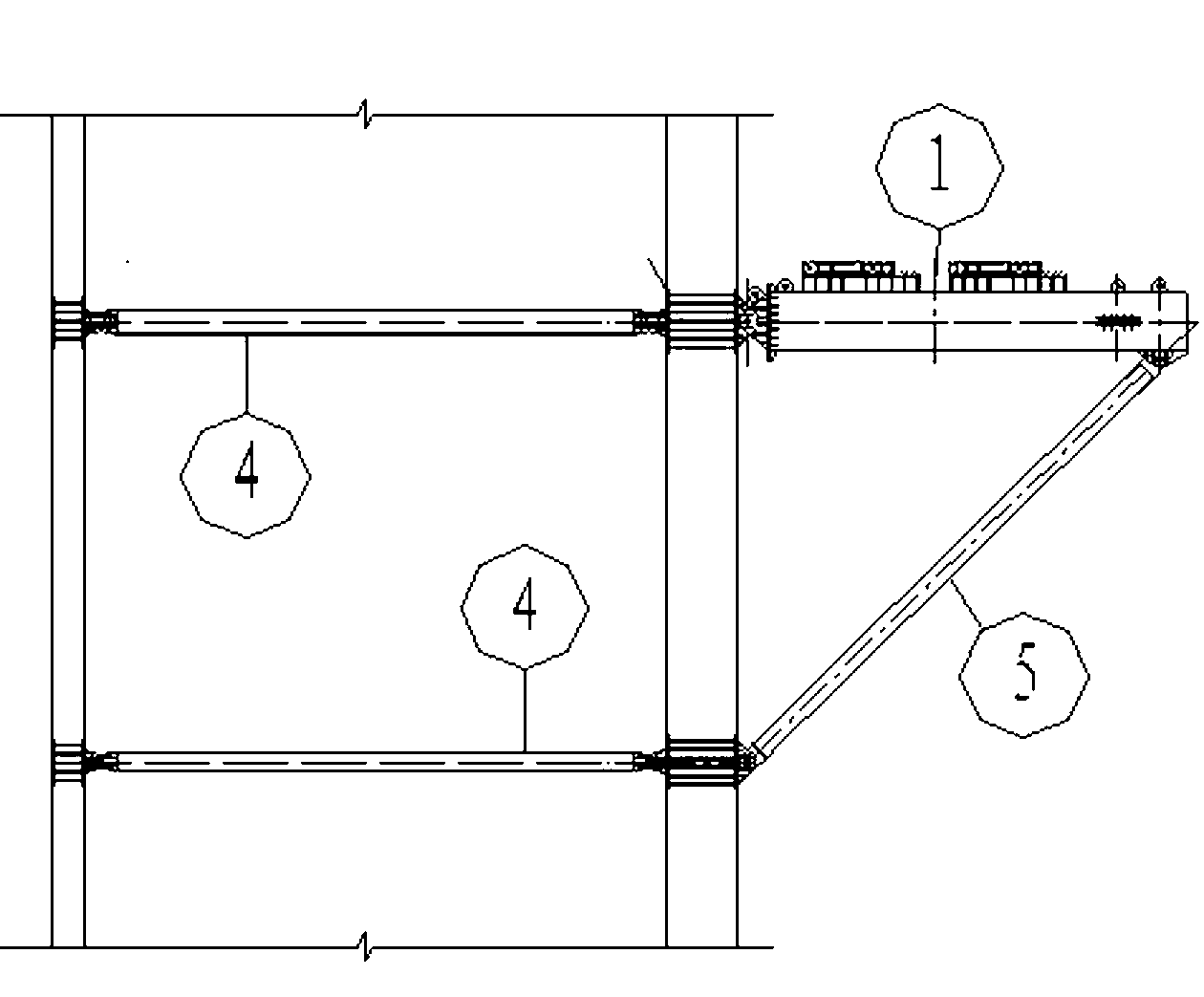

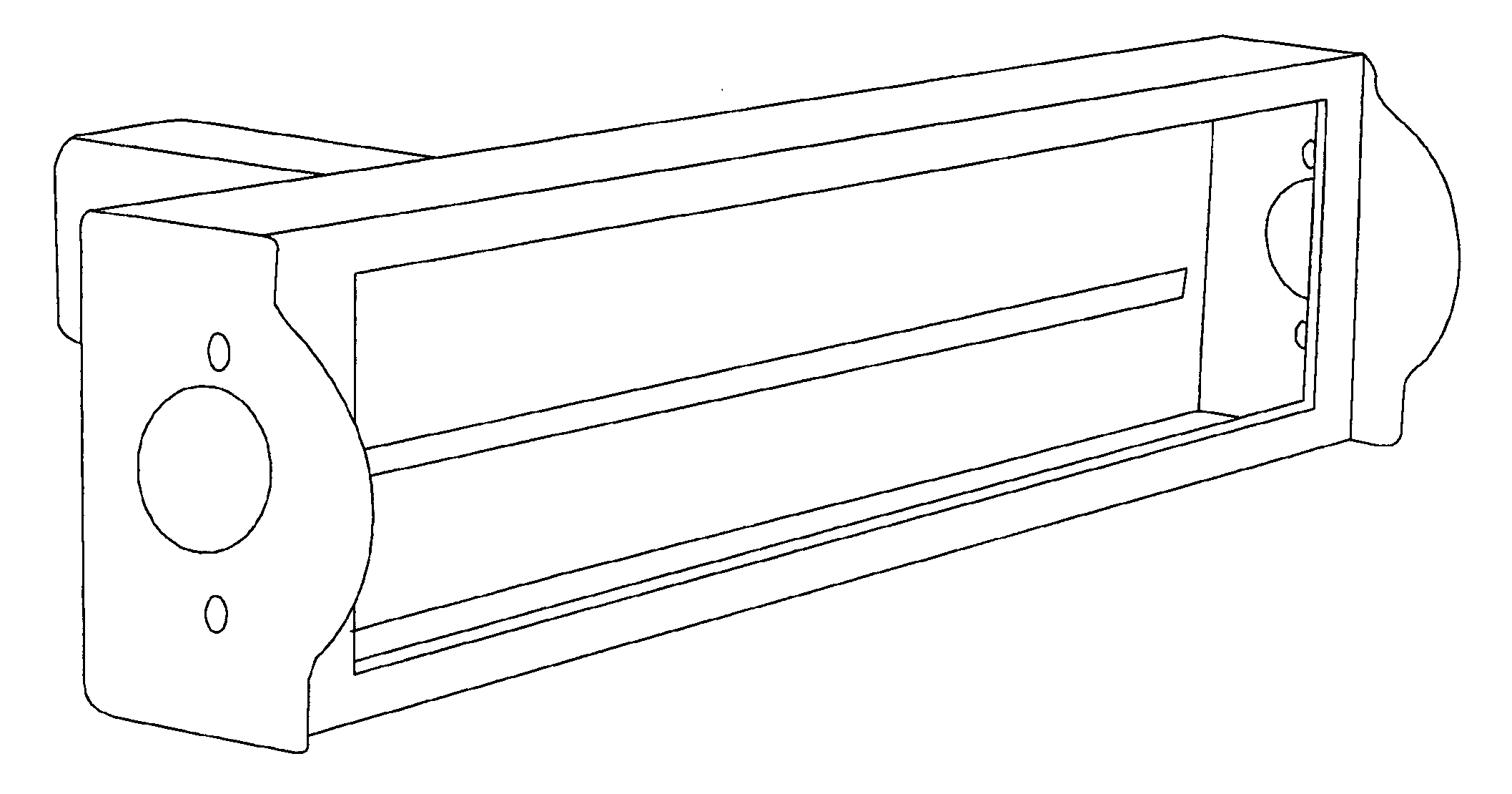

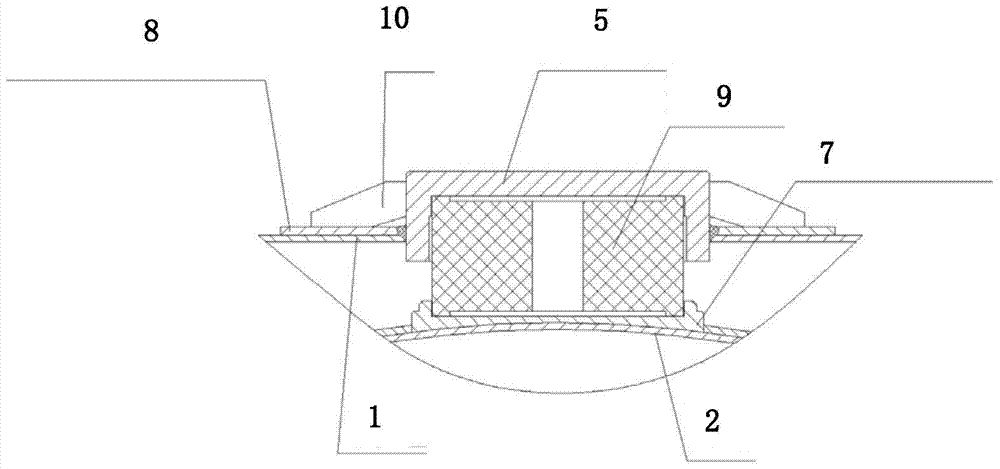

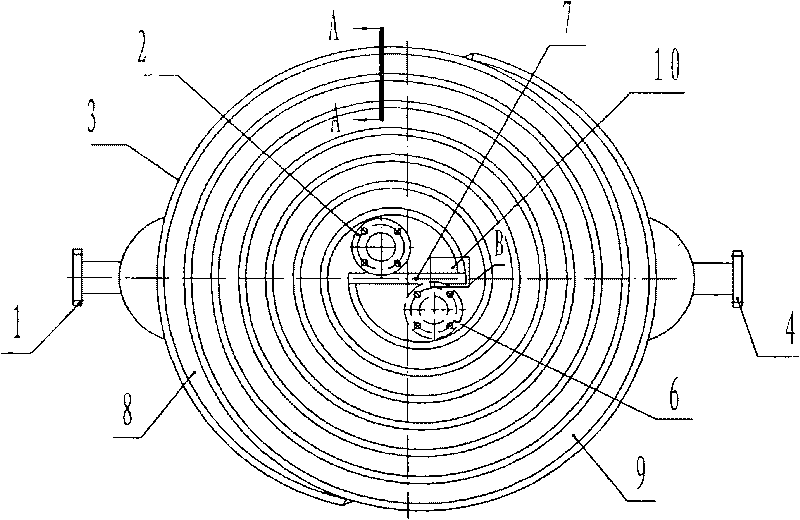

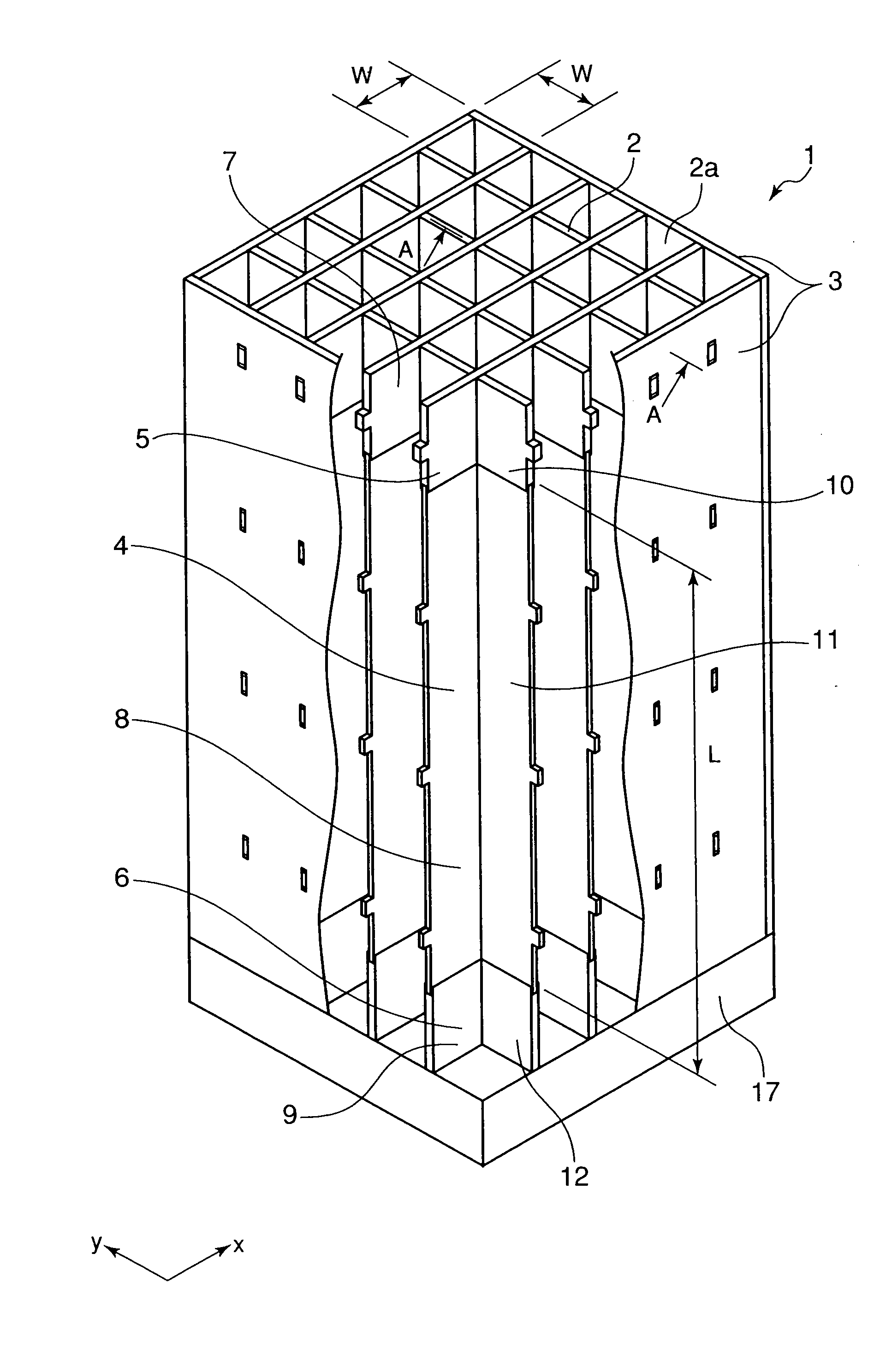

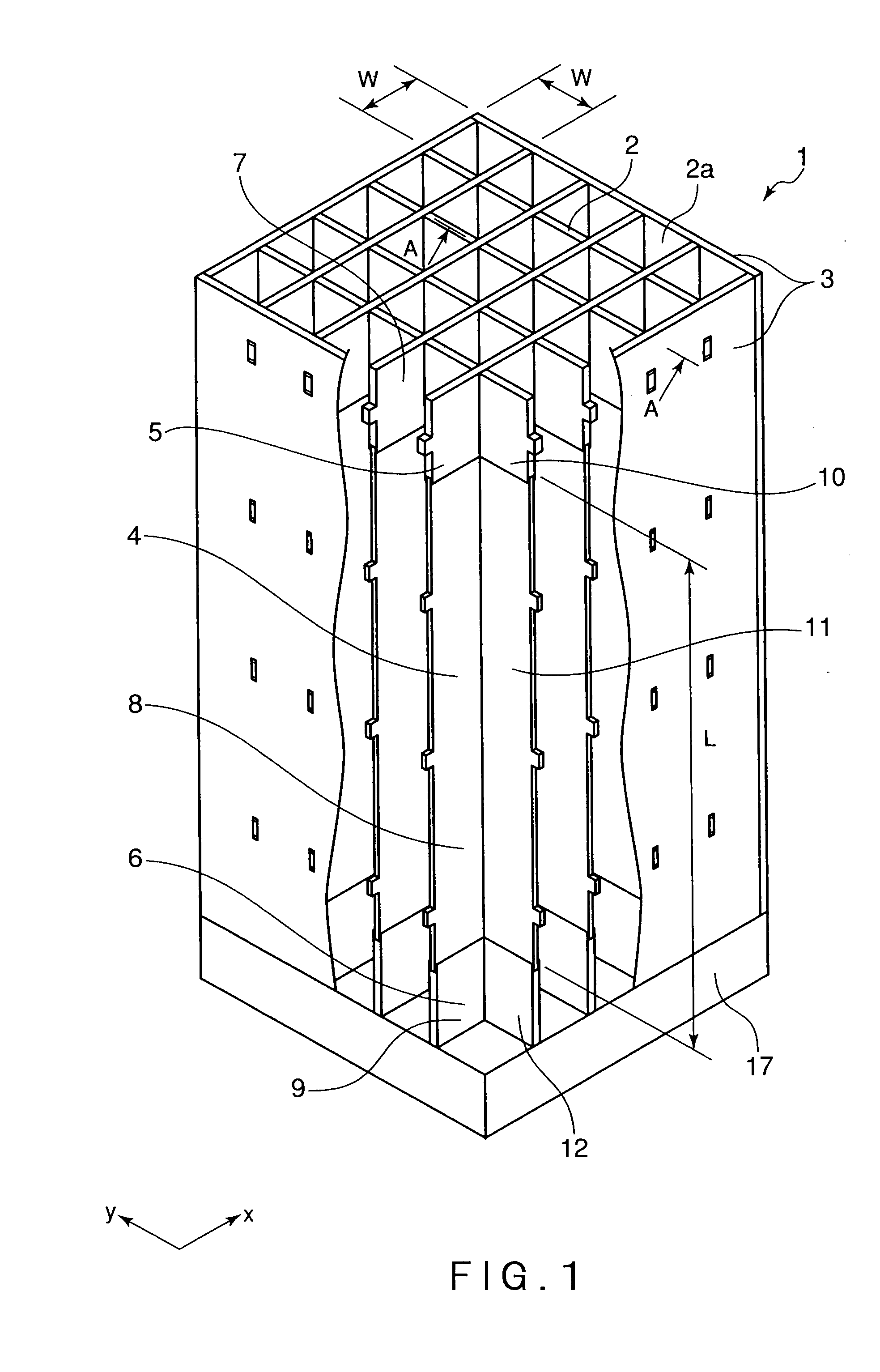

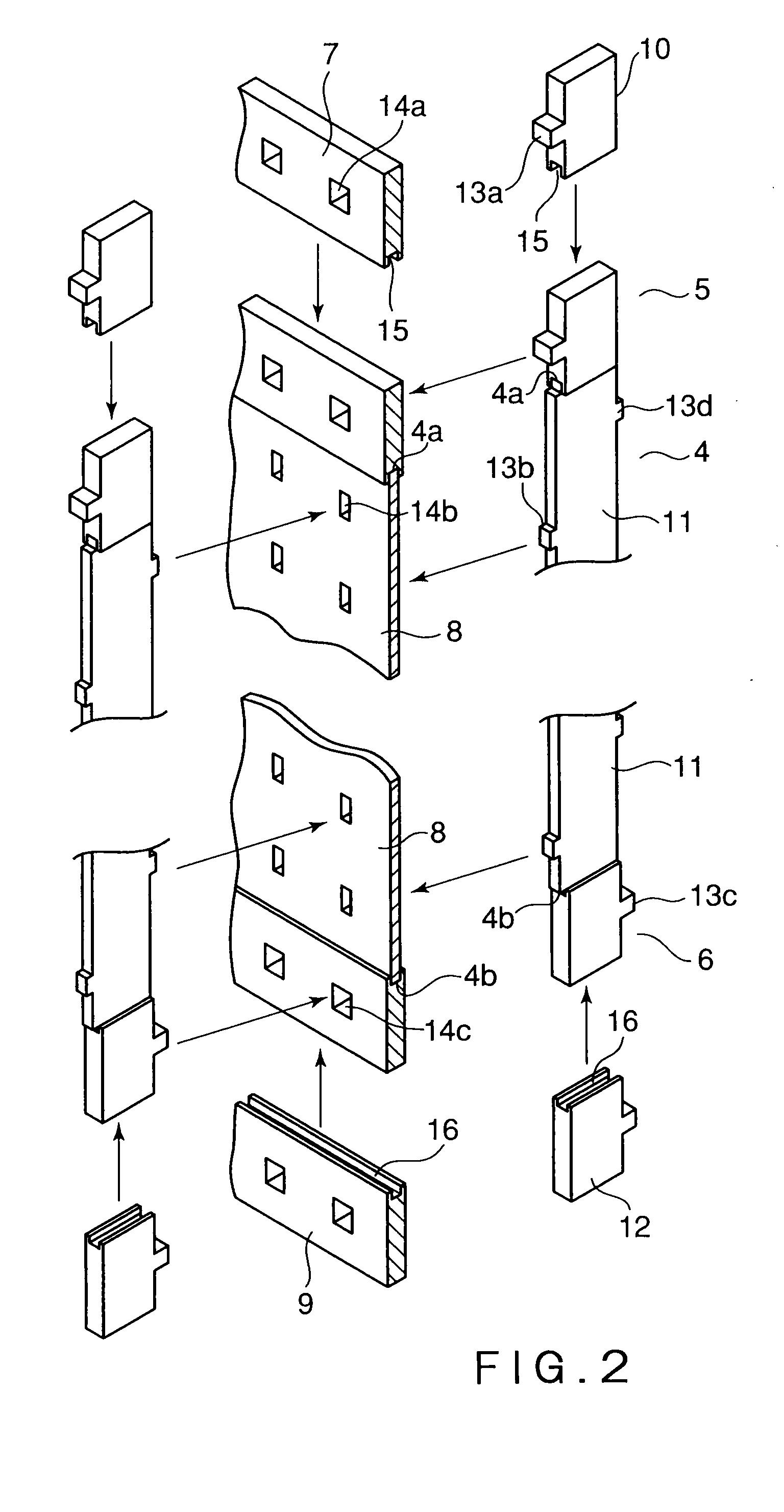

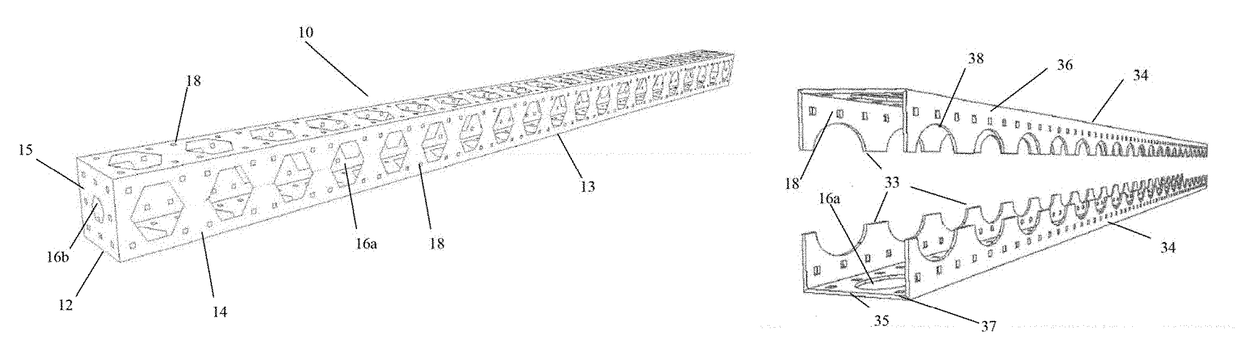

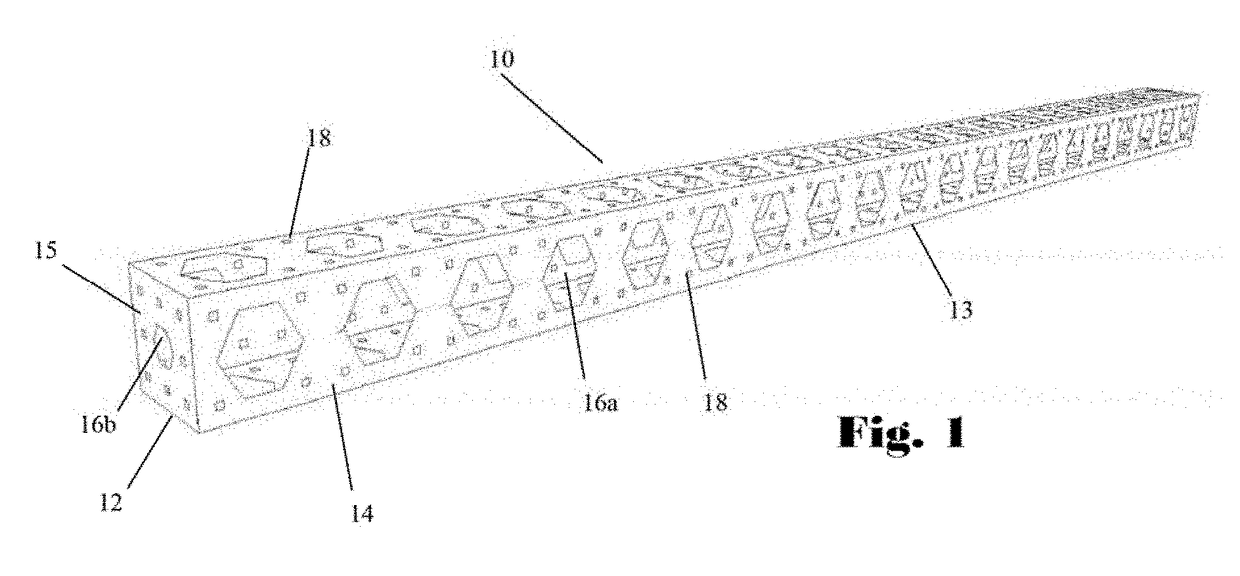

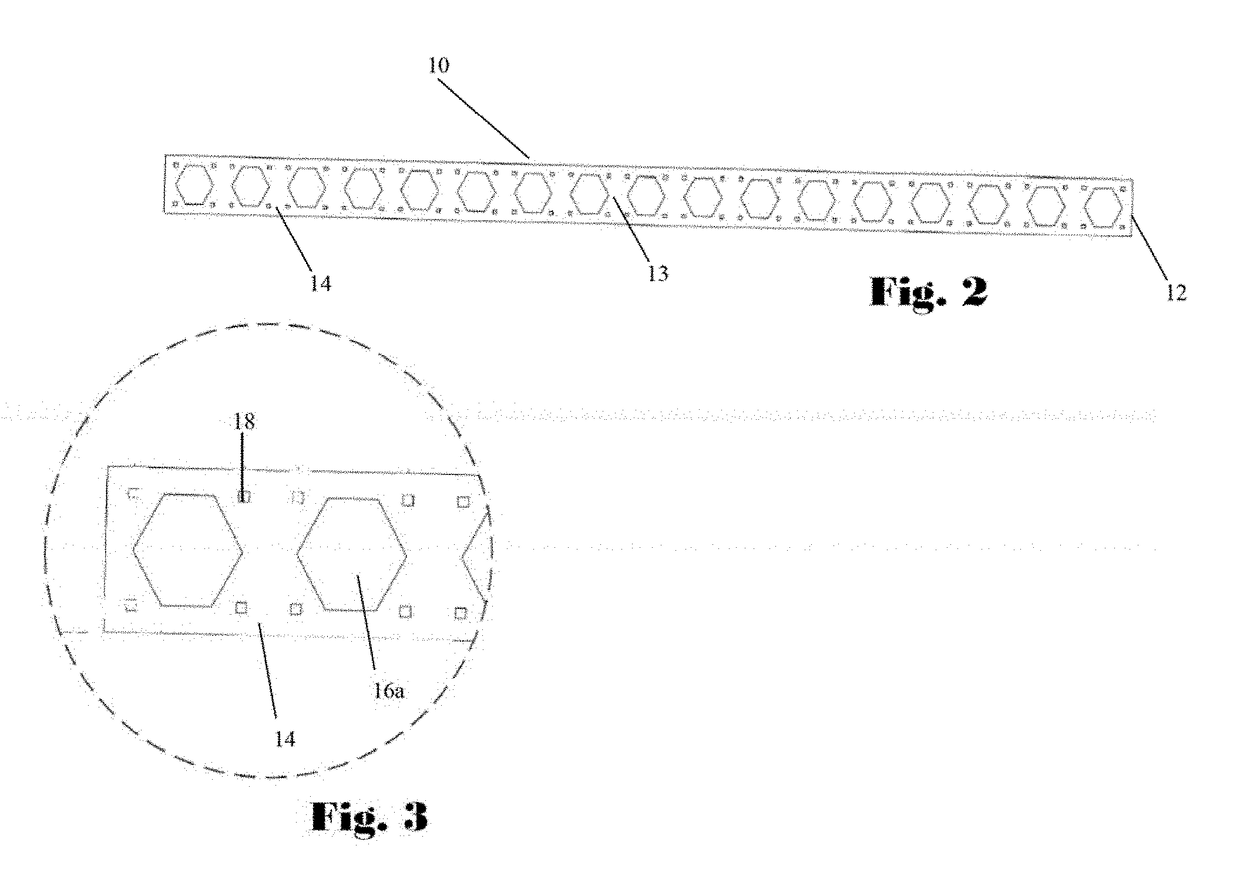

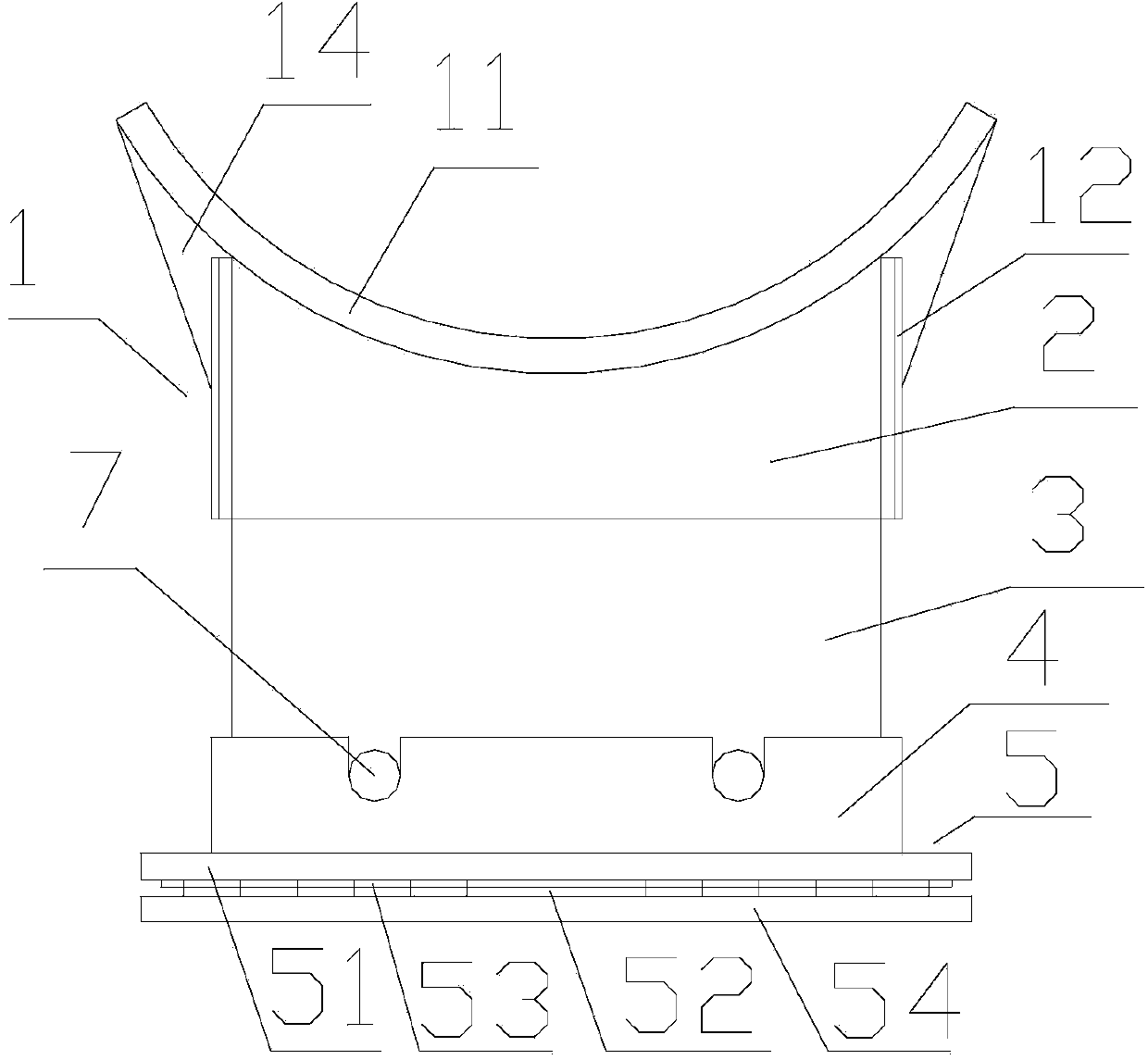

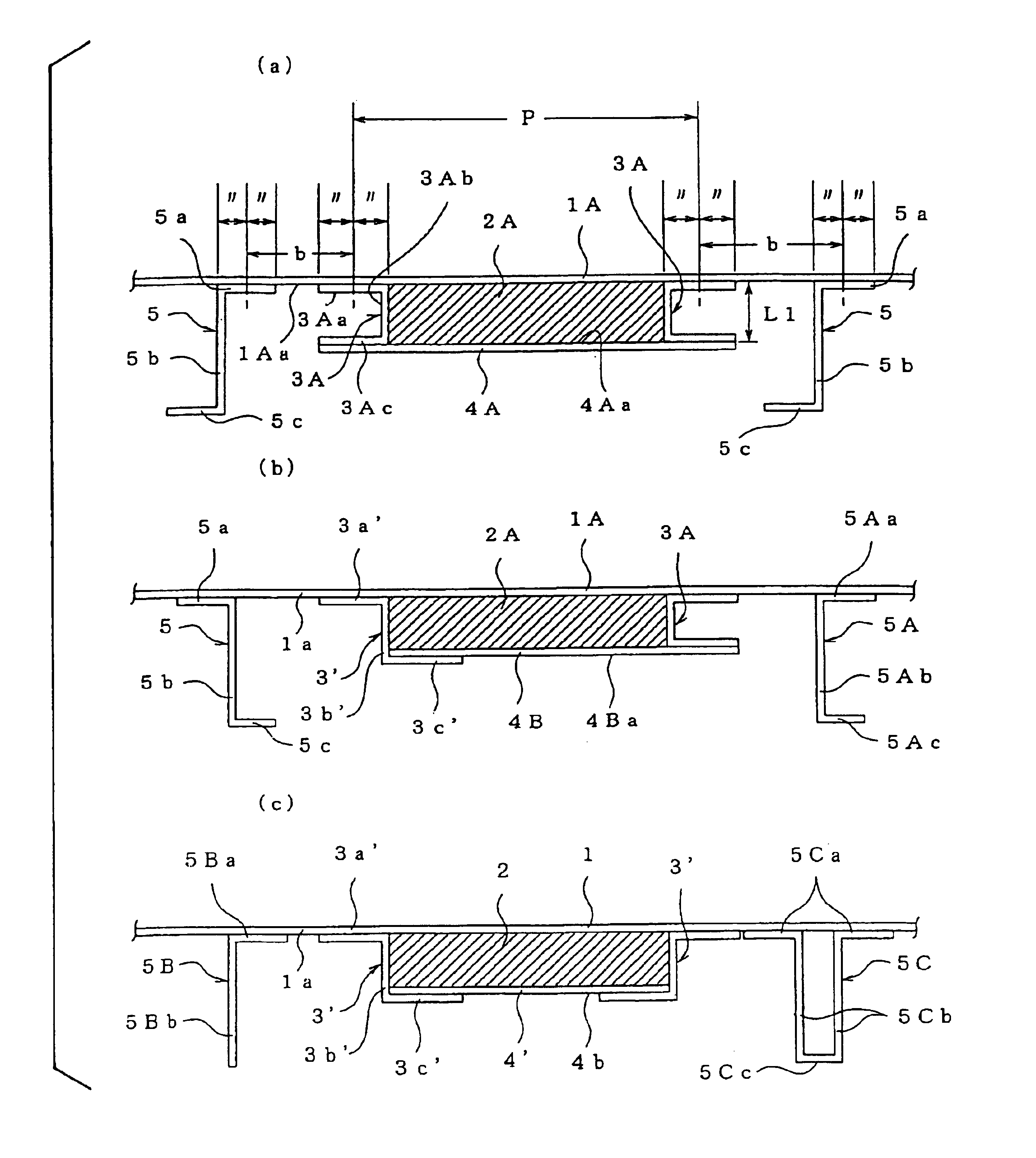

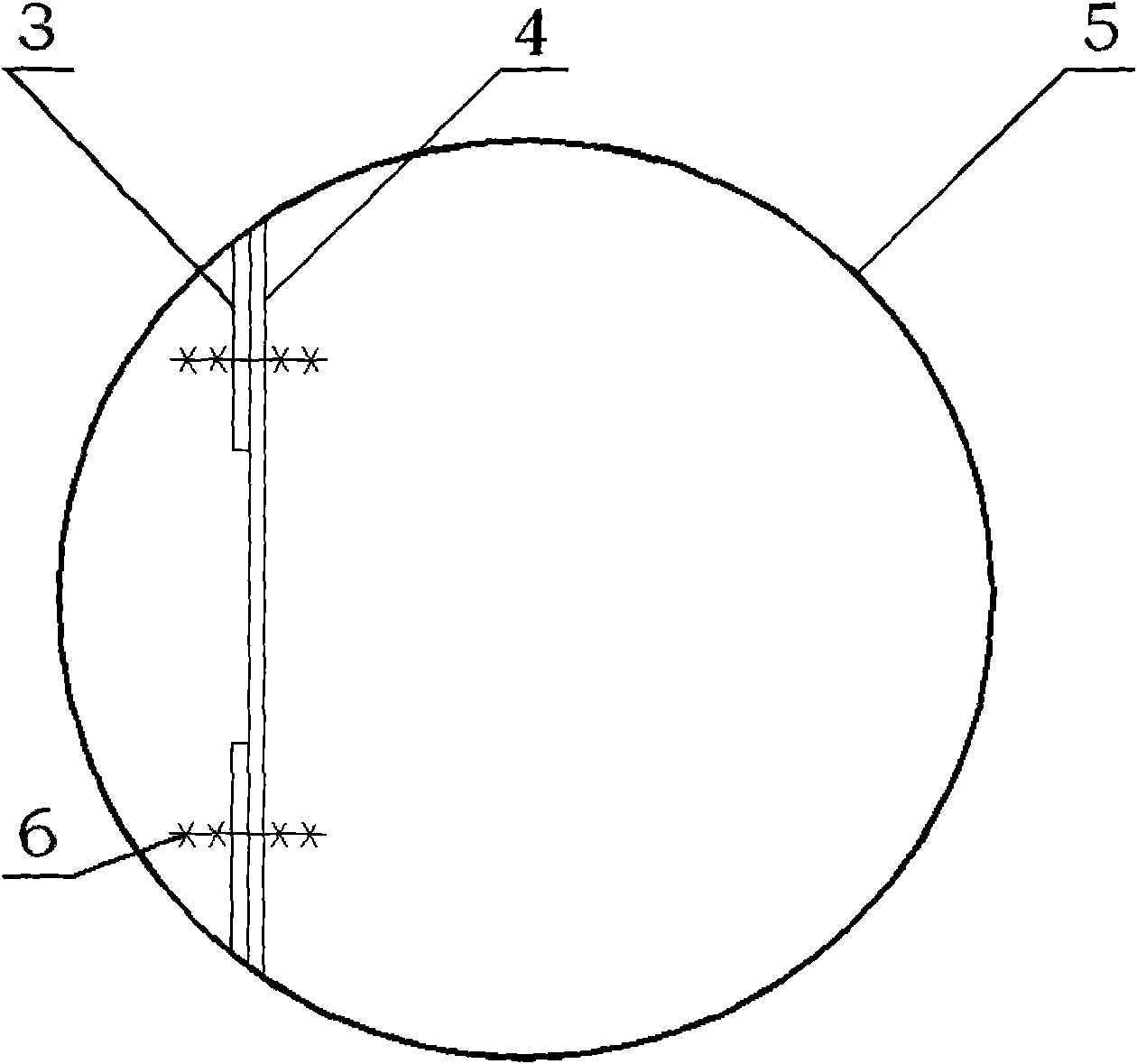

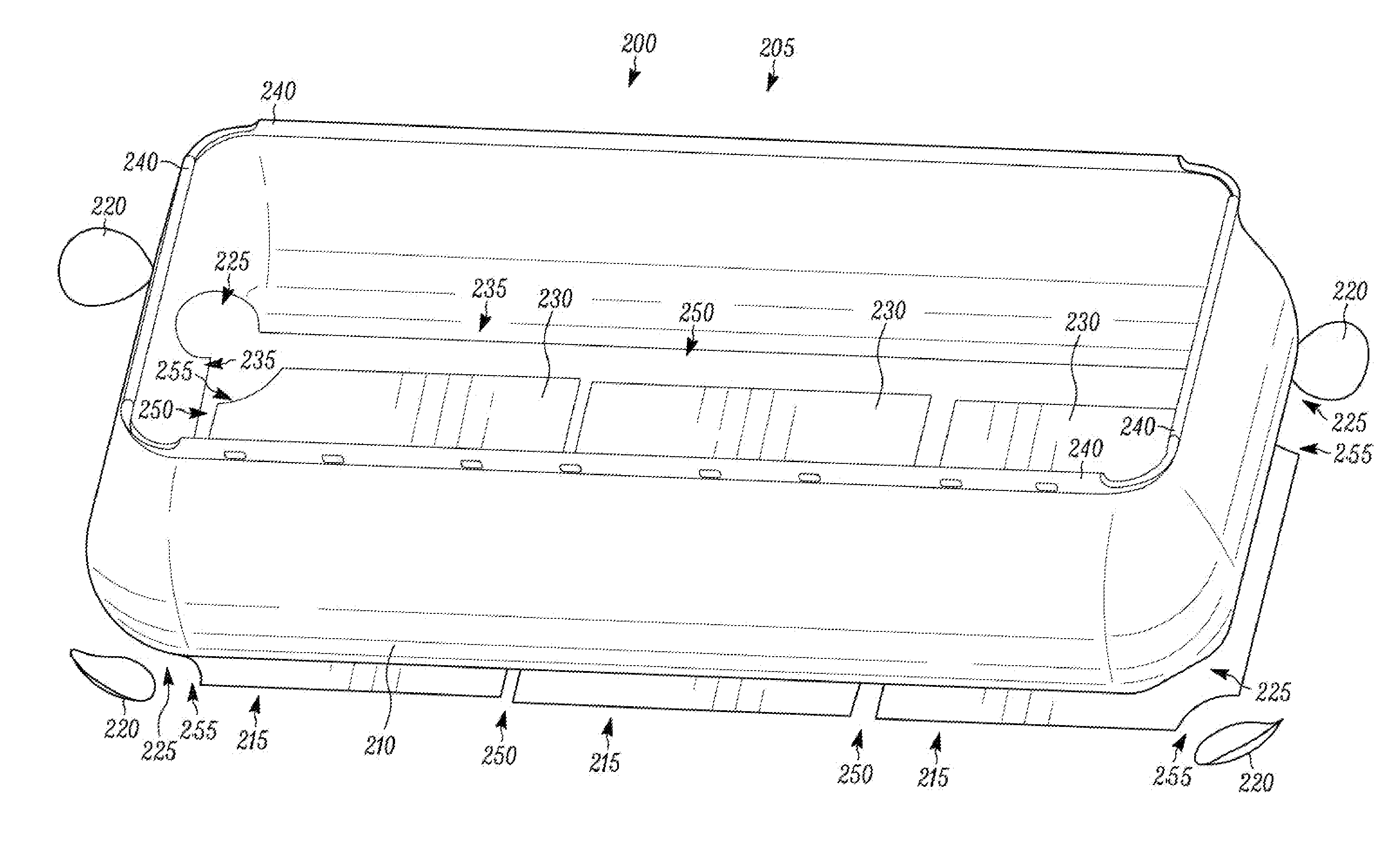

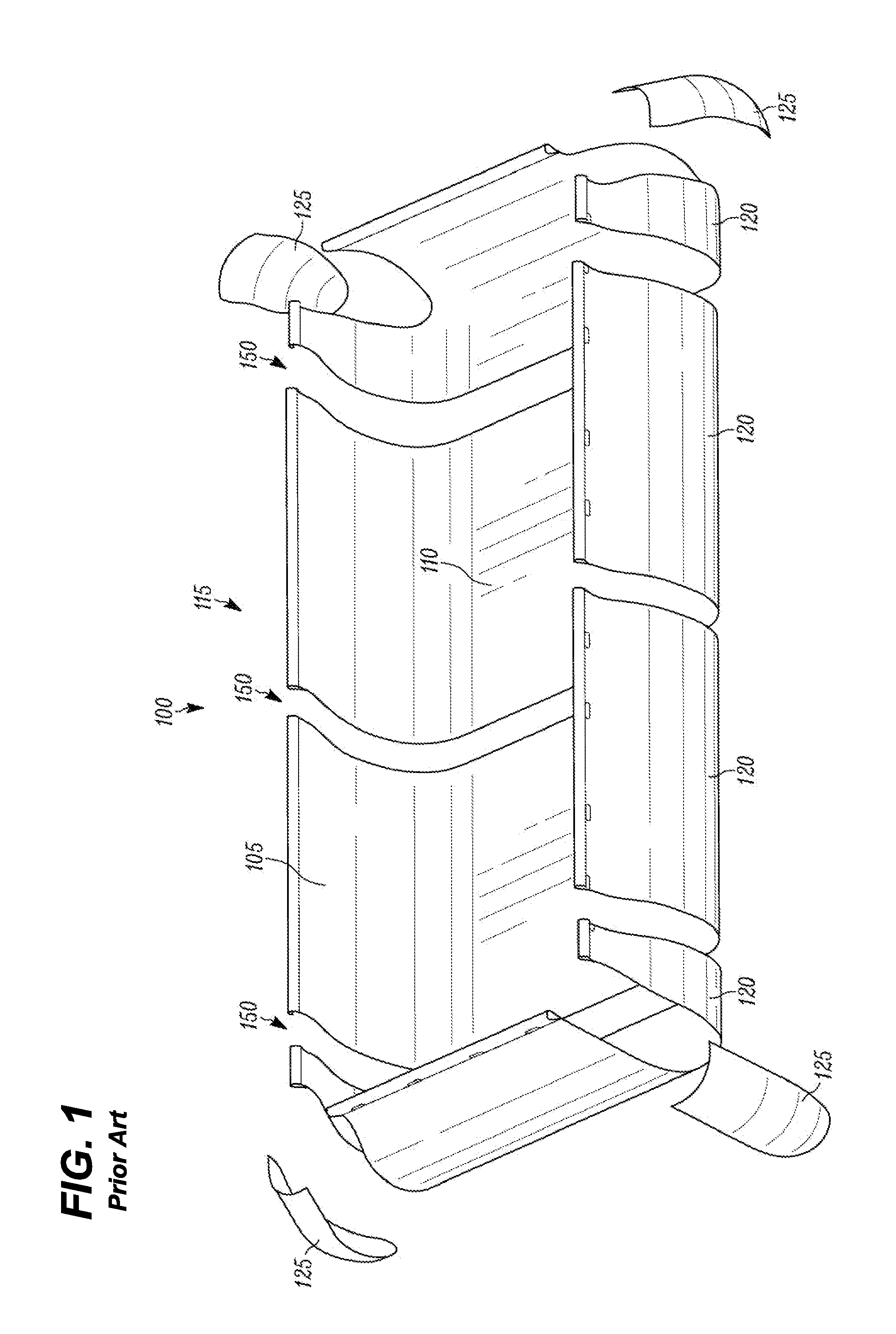

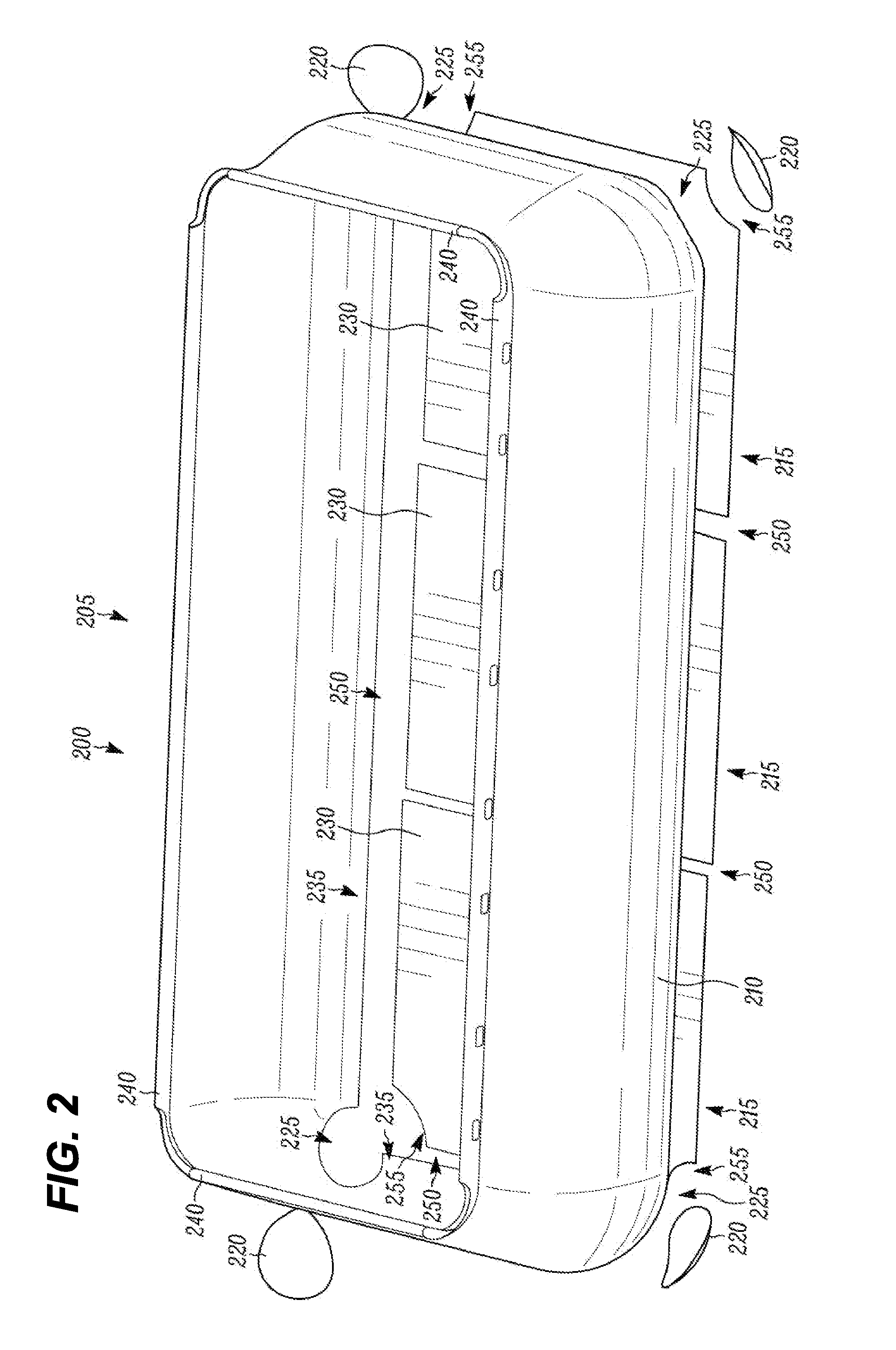

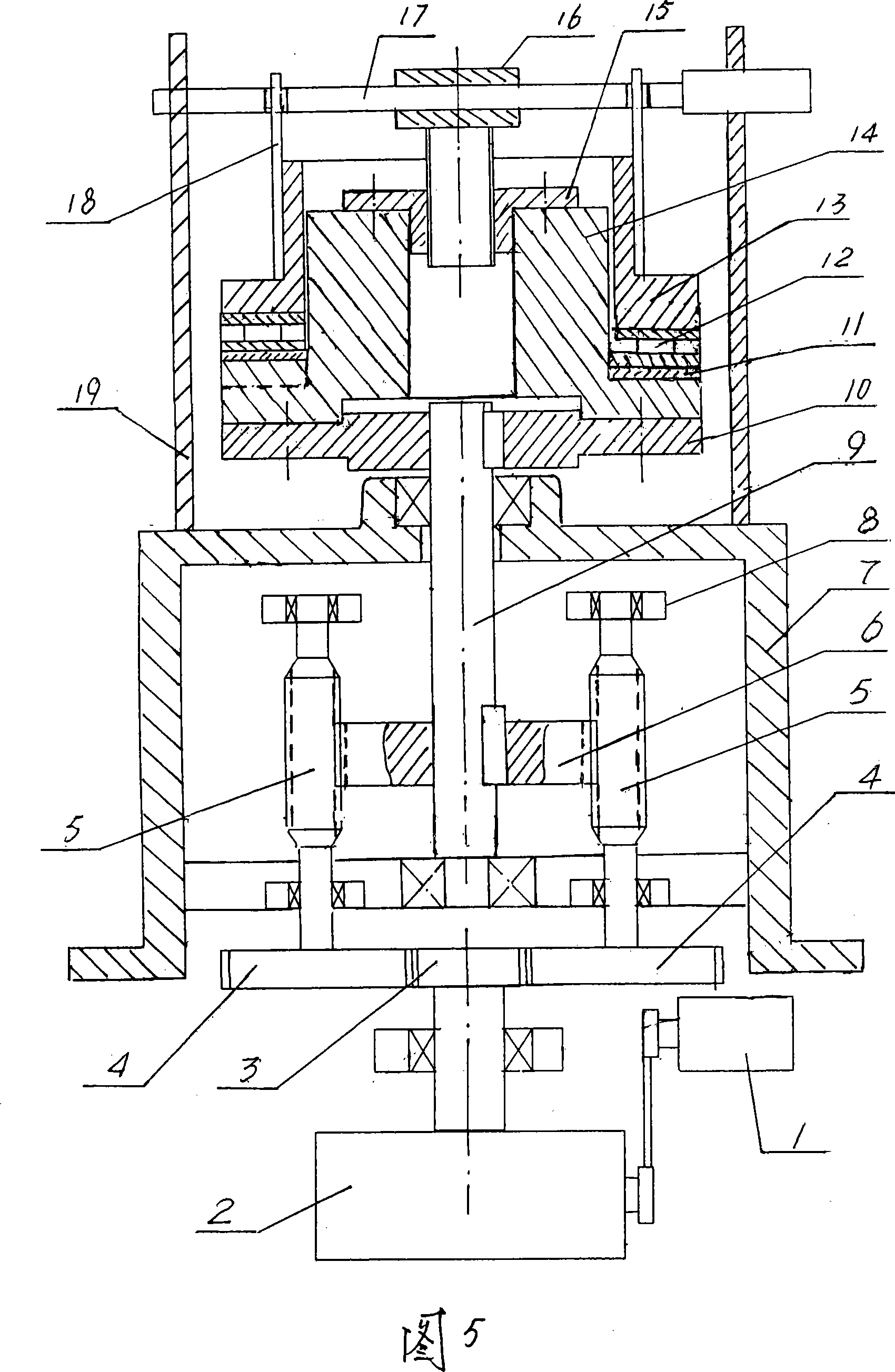

Spent fuel storage rack

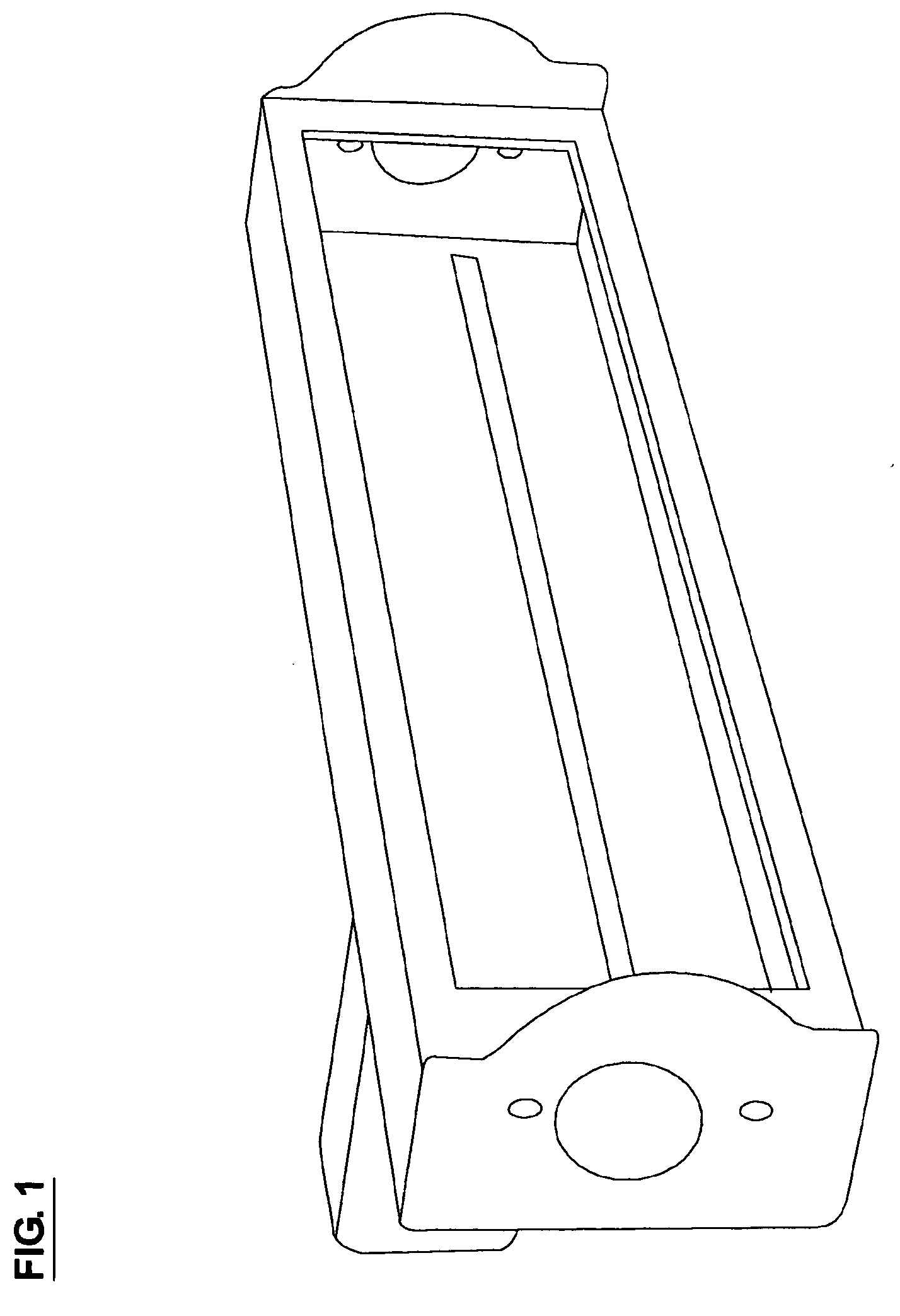

ActiveUS20090207962A1Sufficient ability to absorbReduce the amount of weldingNuclear energy generationNuclear engineering problemsEngineeringBoron

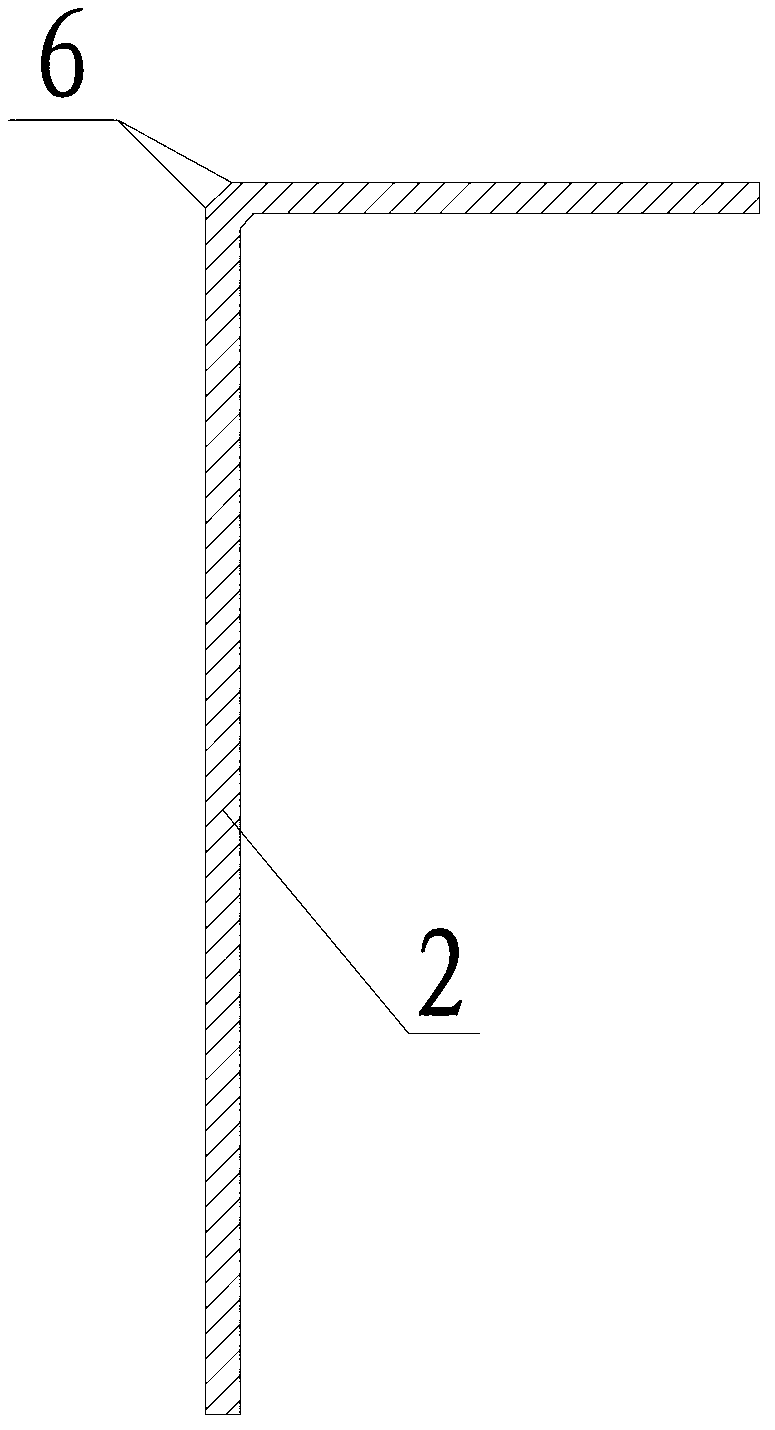

A spent fuel storage rack 1 according to the present invention is installed in a fuel storage pool of a nuclear facility, and has a rectangular parallelepiped shape forming a plurality of lattice-like cells 2a that are configured to separately accommodate a plurality of fuel assemblies in a matrix of rows and columns. As shown in FIG. 1, the spent fuel storage rack 1 includes: a base 17 configured to support lower parts of fuel assemblies, the base 17 forming a bottom surface of the spent fuel storage rack 1; an outer frame 3 located above the base 17, the outer frame 3 forming an outermost periphery of the spent fuel storage rack 1; and a lattice body 2 disposed inside the outer frame 3, the lattice body 2 forming the lattice-like cells 2a. The lattice body 2 includes: a main lattice 4 having a height equivalent to an active length of the fuel assembly; an upper lattice 5 disposed above the main lattice 4 so as to be fitted to an upper end of the main lattice 4; and a lower lattice 6 disposed between the base 17 and the main lattice 4 so as to be fitted to a lower end of the main lattice 4. Thus, the main lattice 4 can be formed without welding, whereby the main lattice 4 can be made of a boron-added stainless steel to which a sufficient amount of boron is added to absorb neutrons.

Owner:KK TOSHIBA

Lightweight semi-permanent truss system

Owner:PELTIER CARL

Structure for extreme thermal cycling

ActiveUS20070215452A1Reduce fatigueImprove fatigue resistanceMechanical conveying coke ovensCharging-discharging device combinationsPre stressPre stressing

A structure for extreme thermal cycling has a support element that supports a vessel primarily by bearing and frictional forces rather than by welds. The support element has a bearing portion that tapers inwardly beneath a knuckle that separates a cylindrical section of the vessel from a sloped lower section. The bearing portion of the support element follows that slope, providing an extended area of contact between the support element and the vessel. An annular section of the support element can be heated and expanded before placing it around the cylindrical section of the vessel to provide pre-stressing. If required, a strap may extend downwardly from the vessel over an upper edge of the support element.

Owner:CHICAGO BRIDGE & IRON CO

High-temperature pipeline heat insulation support

ActiveCN103807570AMeet strength requirementsReduce usagePipe supportsThermal insulationEngineeringPetrochemical

The invention relates to a matched product of a petrochemical pipeline, in particular to a high-temperature pipeline heat insulation support. The high-temperature pipeline heat insulation support comprises a pipeline connection component, a heat insulation block, a base connection component and a base and is characterized in that a pipeline is lifted by the upper end of the pipeline connection component; the lower end of the pipeline connection component is connected with the top end of the heat insulation block; the lower end of the heat insulation block is fixed on the base by the base connection component. The high-temperature pipeline heat insulation support has the following advantages: 1, a heat insulation material is used as a component of a pipe holder supporting component, so that not only the requirement on intensity of a pipe holder, but also the requirement on a heat insulation effect of the pipe holder are met, and the effective heat insulation thickness is effectively increased; 2, in the working process, the axial thrust of the pipeline can be balanced out by a baffle and compared with a conventional anchoring nail structure, the high-temperature pipeline heat insulation support can bear a larger axial force; 3, the size of the heat insulation block assembly is not restrained by the sizes of the pipeline connection component and the base connection component, modular production can be carried out, universality is improved, and cost is reduced; 4, the use amount of steels is reduced, the welding quantity is small, and the workload of production is reduced.

Owner:中申(上海)管道工程股份有限公司

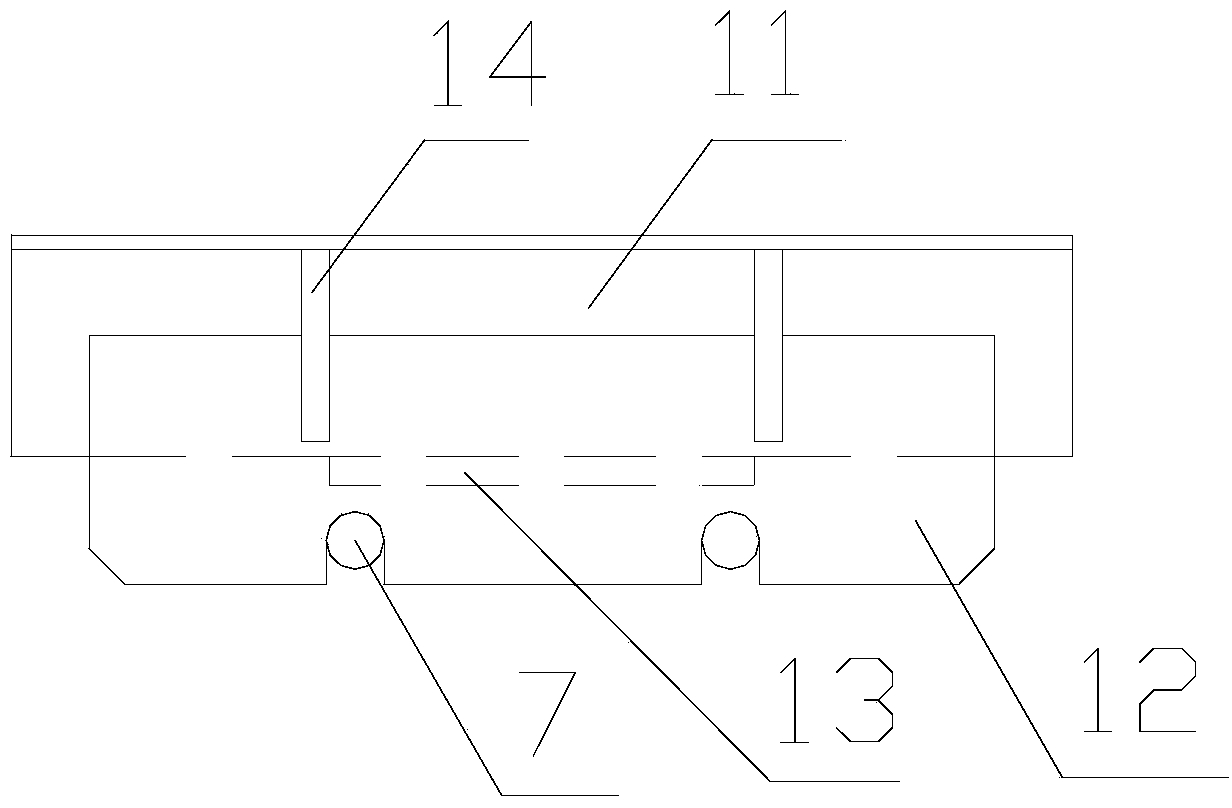

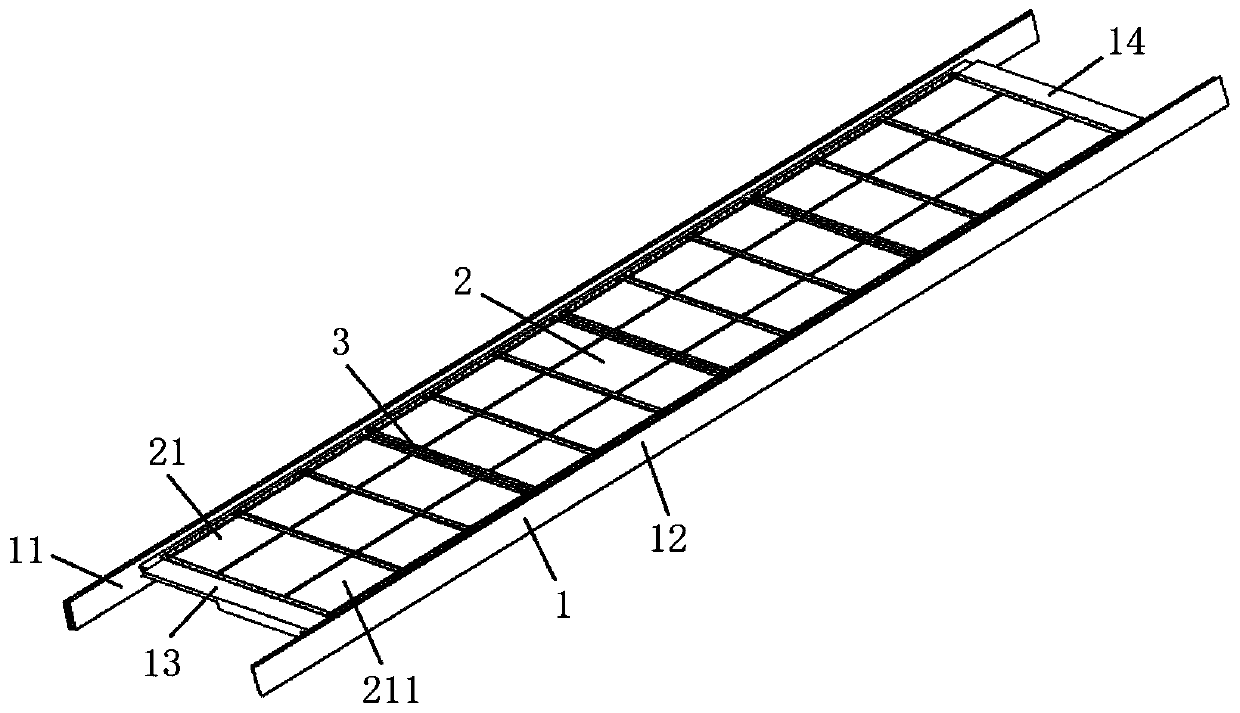

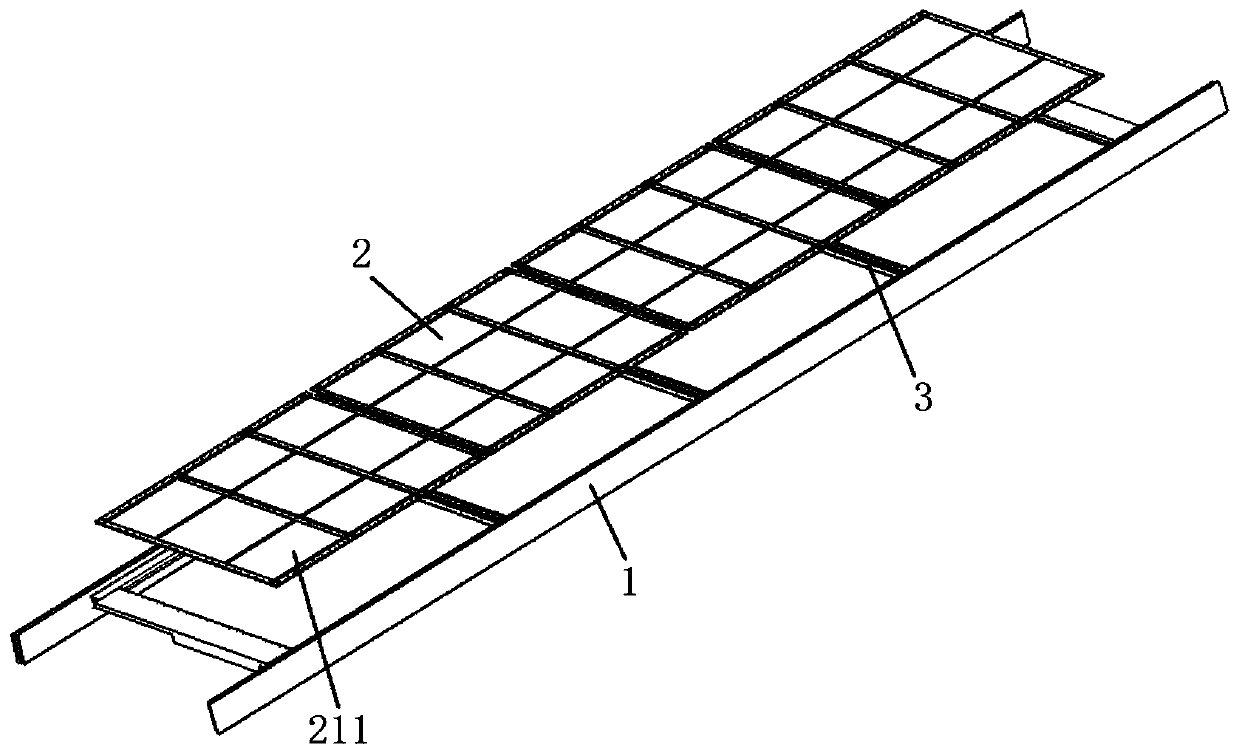

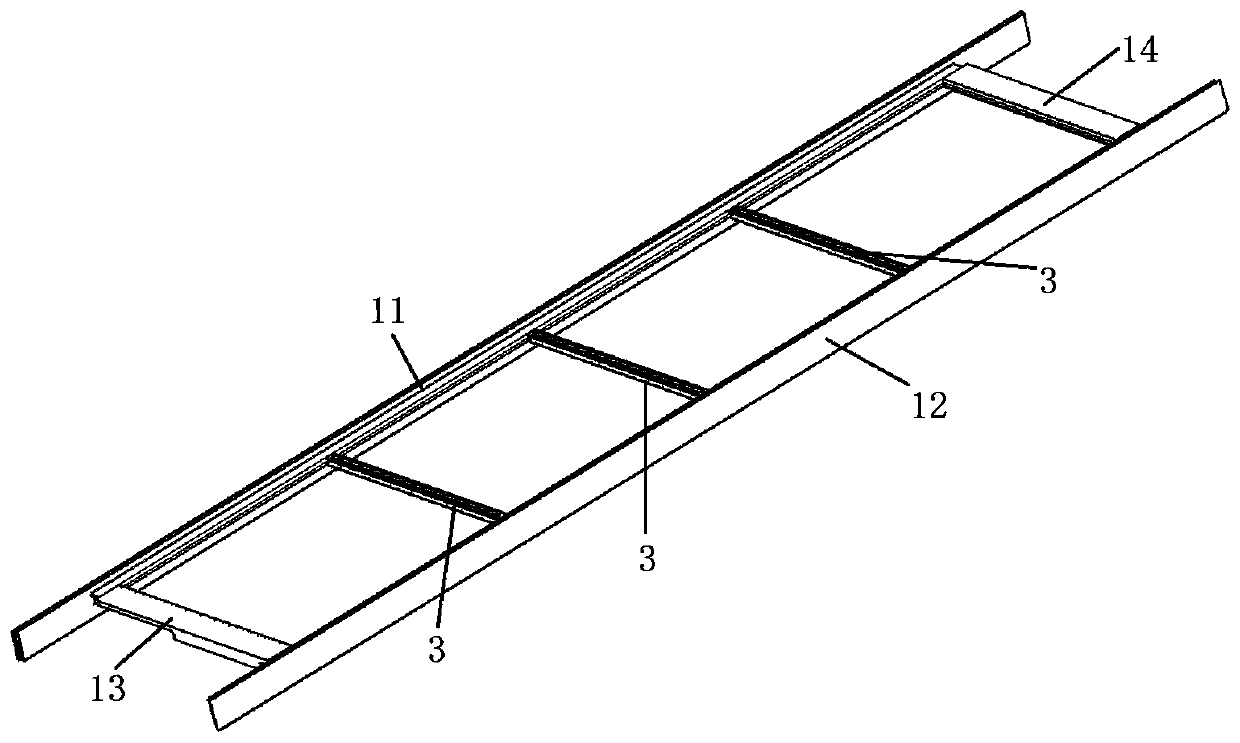

Vehicle body floor structure and railway vehicle with vehicle body floor structure

InactiveCN110116736AStable supportReduce usageAxle-box lubricationRailway bodiesAutomotive engineering

The invention relates to the technical field of railway vehicles, and discloses a vehicle body floor structure and a railway vehicle with the vehicle body floor structure. The vehicle floor structurecomprises a floor frame, a floor body, and a plurality of support beams, wherein the floor body is detachably mounted on the floor frame, the floor body comprises a plurality of floor units, and adjacent floor units are detachably connected; each of the support beams is arranged on the floor frame and used for supporting the floor body, wherein one of the support beams is arranged between every two of the floor units. The vehicle body floor structure has the advantages of being modularized, detachable, light in weight, and low in welding quantity.

Owner:CRRC QINGDAO SIFANG CO LTD

Steel bar integrated binding mold of prefabricated box girder and use method of steel bar integrated binding mold

InactiveCN107009510AReduce material consumptionReduce investmentCeramic shaping apparatusEngineeringRebar

The invention discloses a steel bar integrated binding mold of a prefabricated box girder and a use method of the steel bar integrated binding mold. The steel bar integrated binding mold of the prefabricated box girder comprises an outer mold frame and an inner mold frame, wherein the outer mold frame comprises two side formworks and a bottom formwork, the side formworks include an upper side formwork and a lower side formwork which are integrally formed, the upper side formwork is provided with a plurality of first plate bodies at intervals in the longitudinal direction, the upper side formwork is provided with at least one second plate body, the lower side formwork is provided with a plurality of third plate bodies at intervals from bottom to top, the bottom formwork is provided with a plurality of fourth plate bodies at intervals in the longitudinal direction, and the two ends, in the transverse direction, of the bottom formwork are each provided with at least one fifth plate body; and the inner mold frame comprises a plurality of lines of top plate steel bar binding supporting sleeves, a plurality of top plate longitudinal shaping steel pipe supporting pipes and a plurality of top plate longitudinal shaping steel pipes all of which are arranged at intervals in the transverse direction. The steel bar integrated binding mold of the prefabricated box girder is small in investment in use, low in cost, high in adaptive capacity, easy to construct, rapid and high in safety.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 2ND ENG

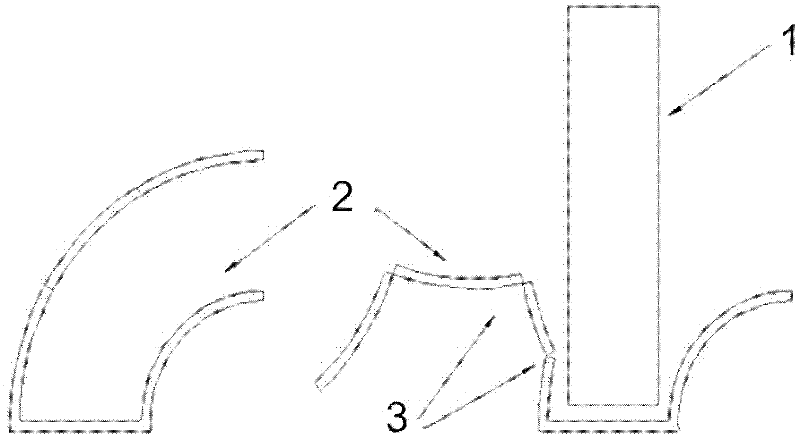

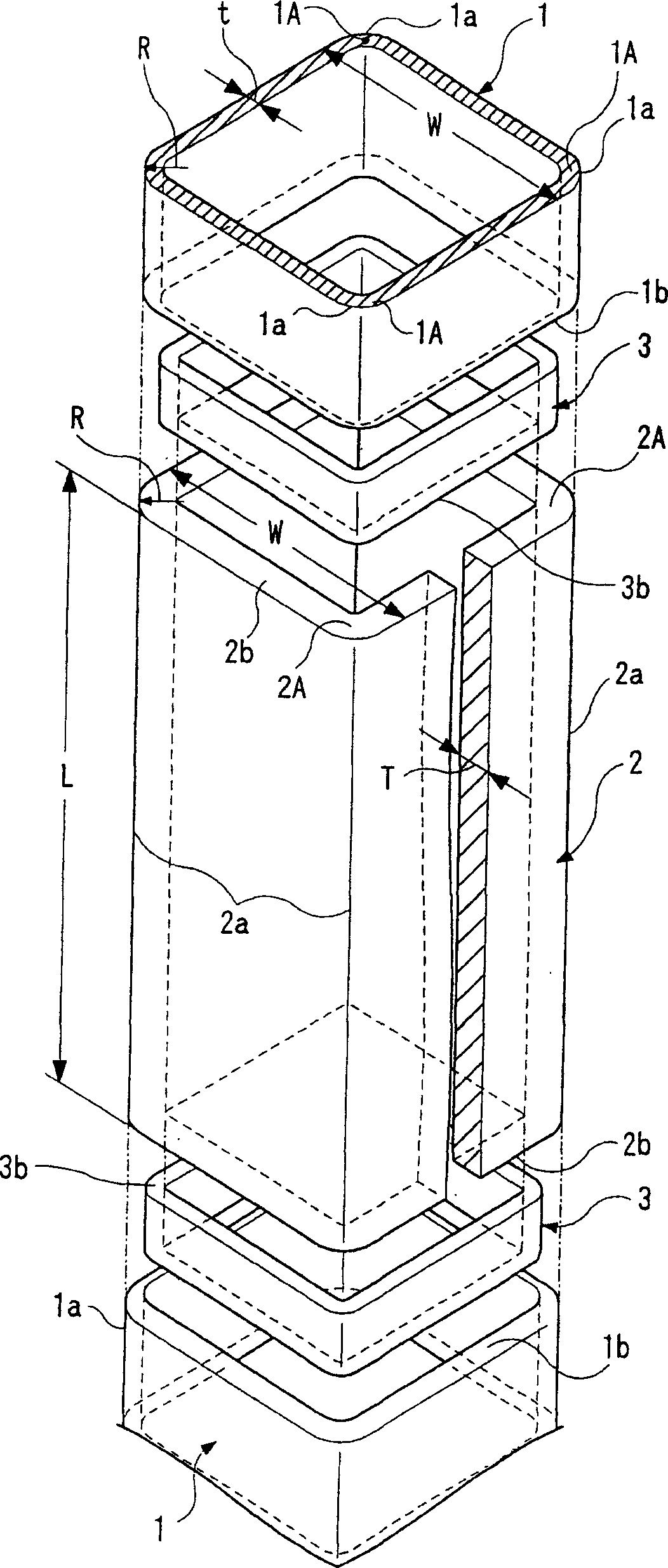

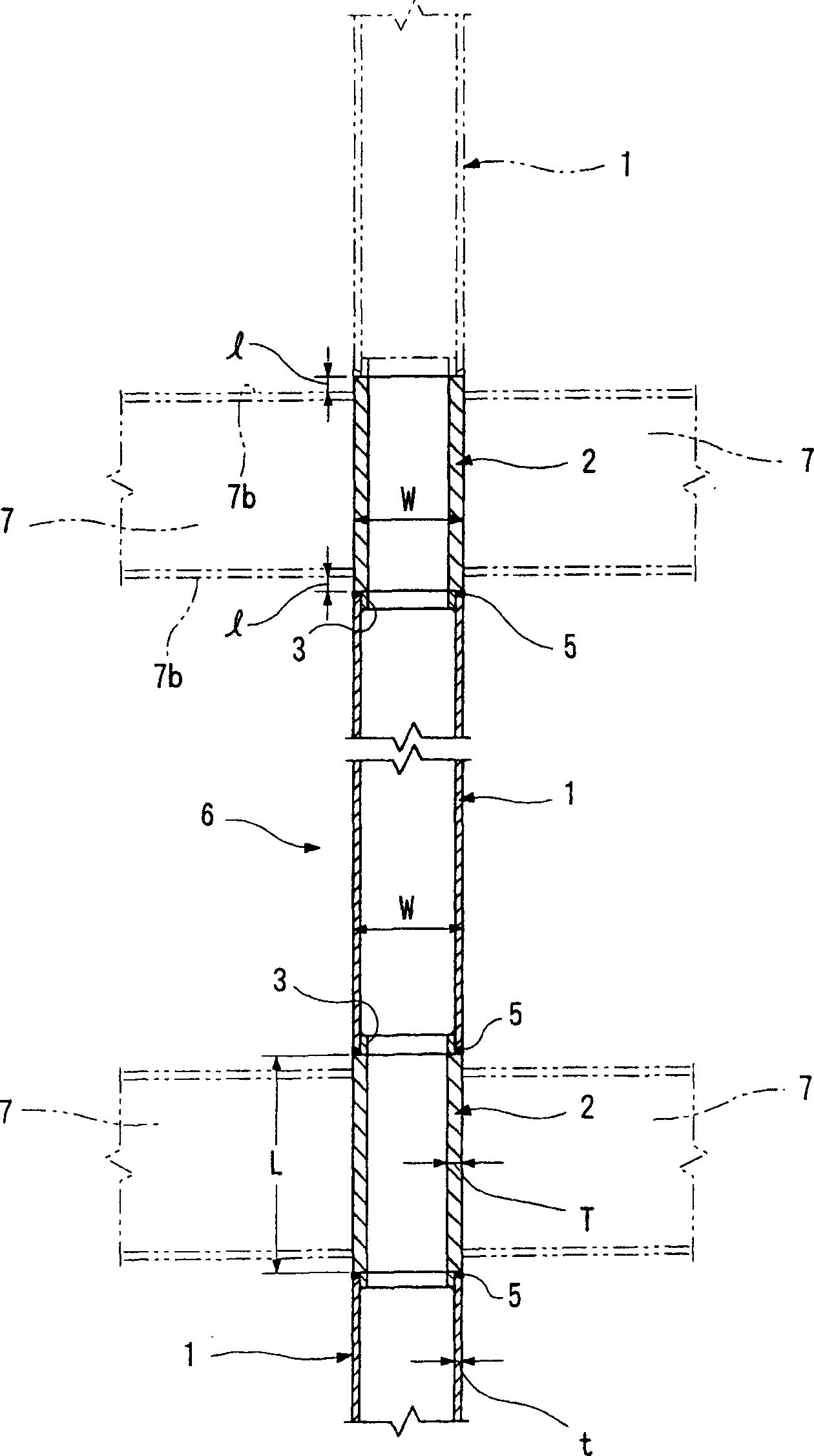

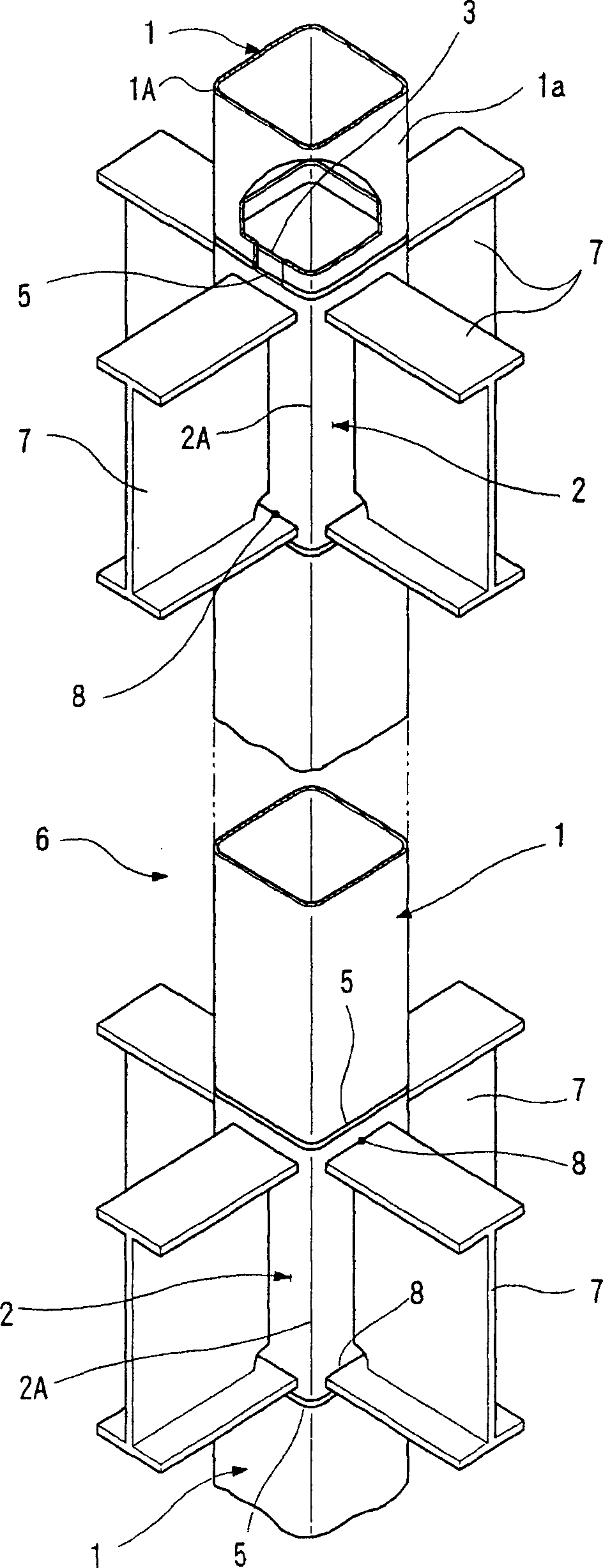

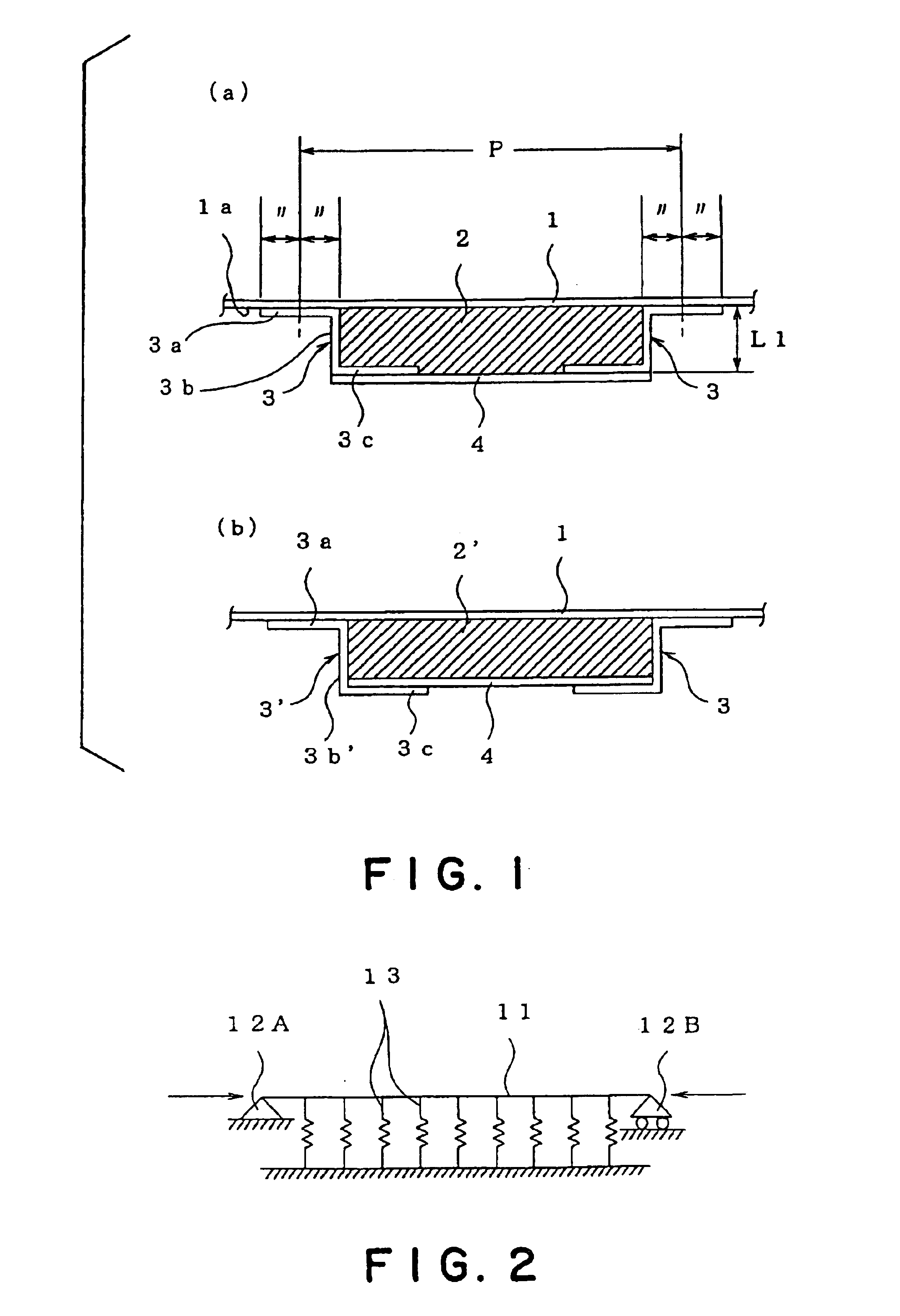

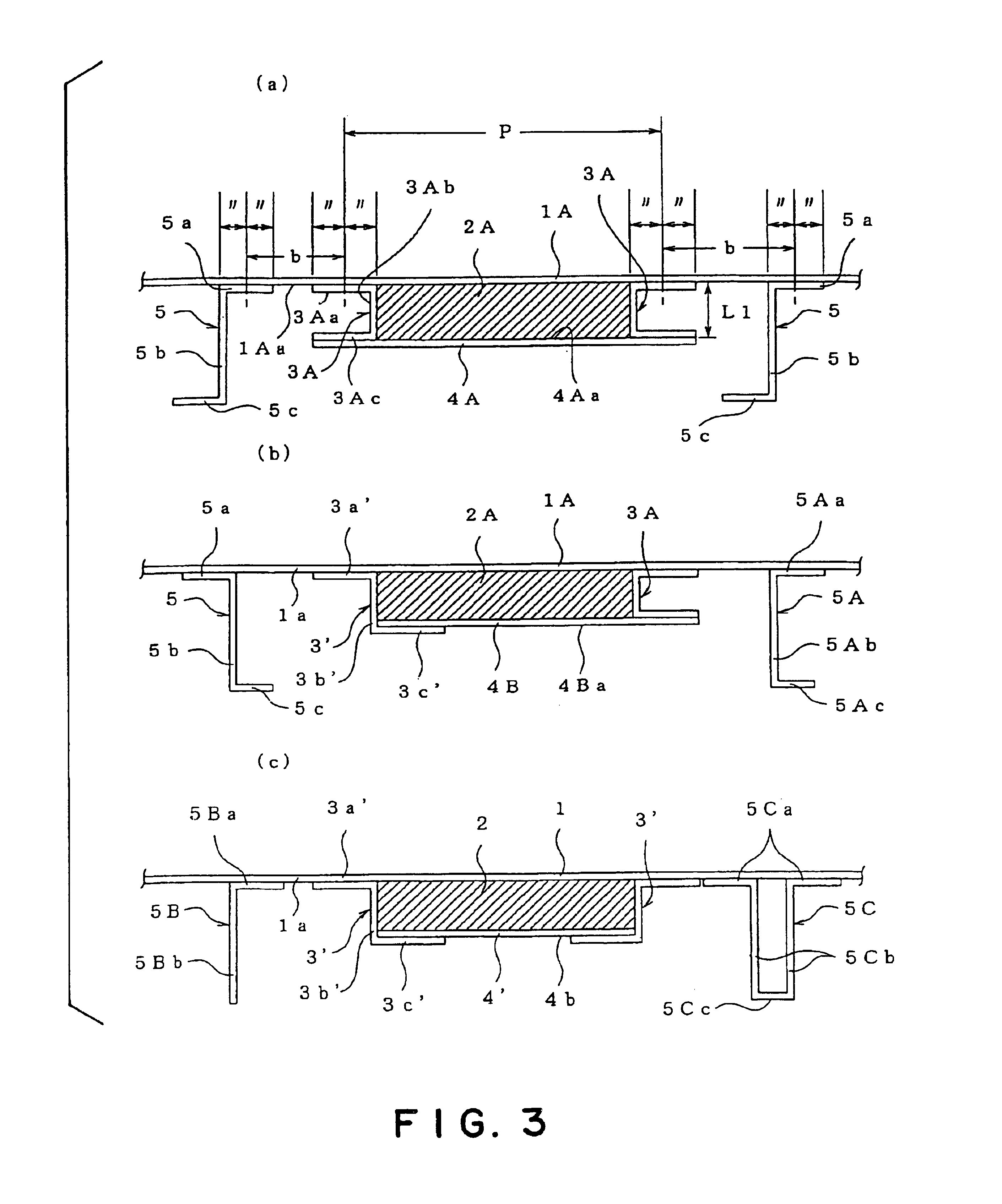

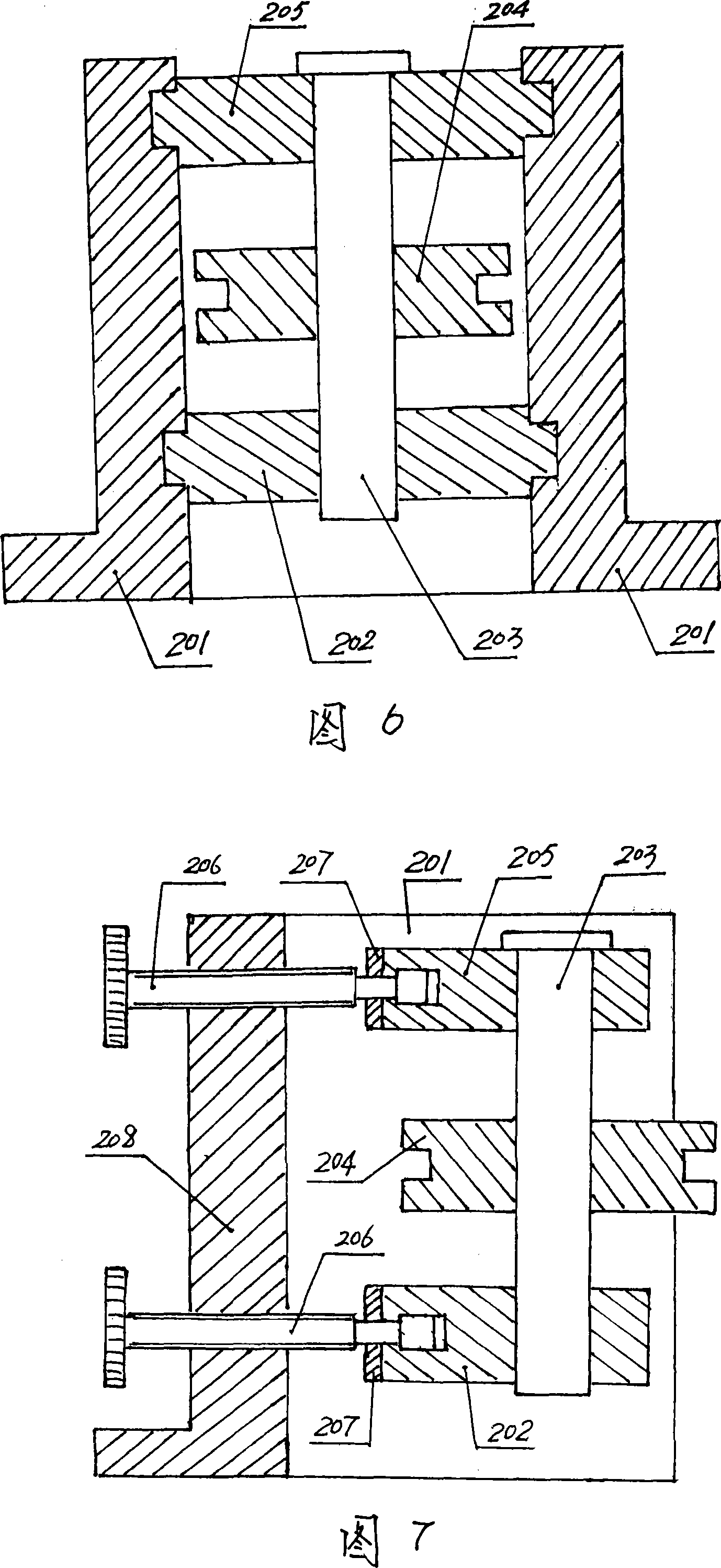

A welded joint construction for a steel pipe column

InactiveCN1467349AImprove stress transferShorten production timeStrutsArc welding apparatusSteel tubeEngineering

A joint construction for a column of steel pipes comprises a long steel pipe 1 of a first thickness t and a second steel pipe 2 of a second thickness T which is greater than that of the first. The steel pipes 1,2 are formed by either cold or hot forming to have the same outer shape and diameter, and they are welded together from the outside in an arrangement in which an end surface of the long pipe 1 is opposed to an end surface of the short pipe 2 which has no bevelled portion. An inner collar 3 can be included in the joint construction and may be positioned inside the long pipe 1 so that it can be abutted against the end surface of the short pipe 2. The pipes 1,2 may either be quadrangular or cylindrical.

Owner:NAKAJIMA STEEL PIPE CO LTD

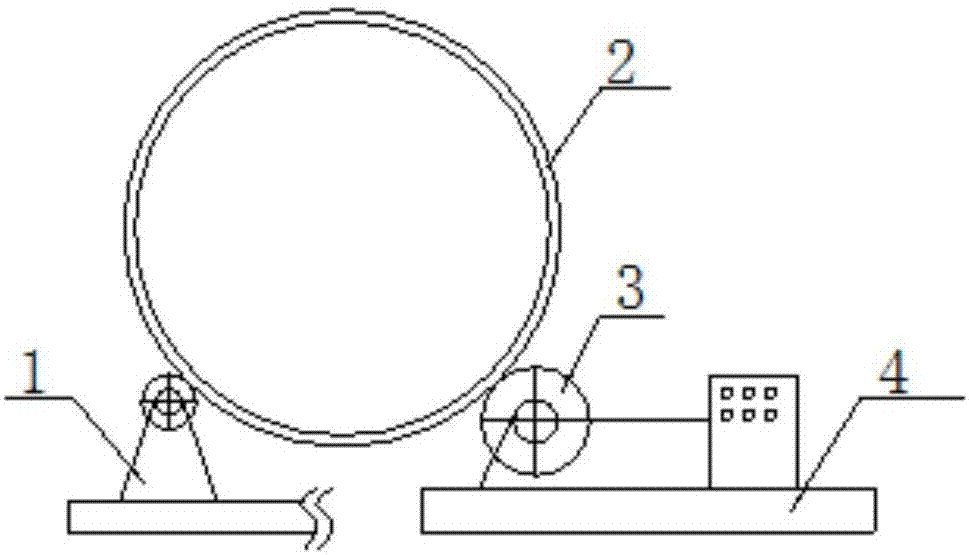

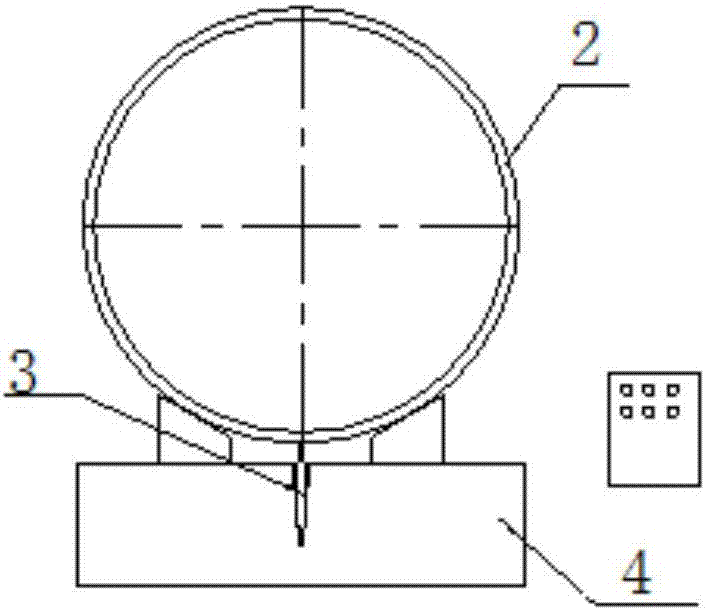

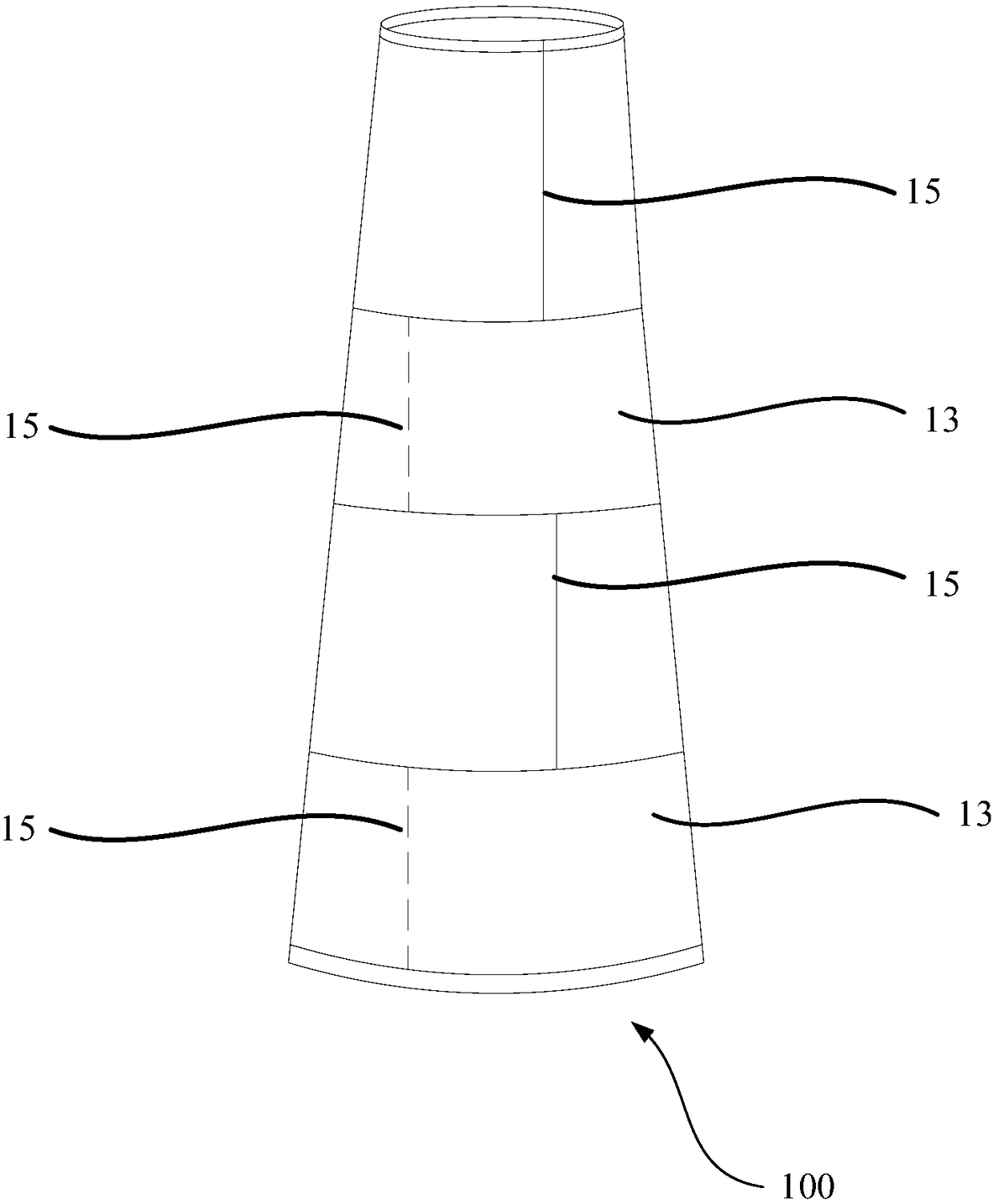

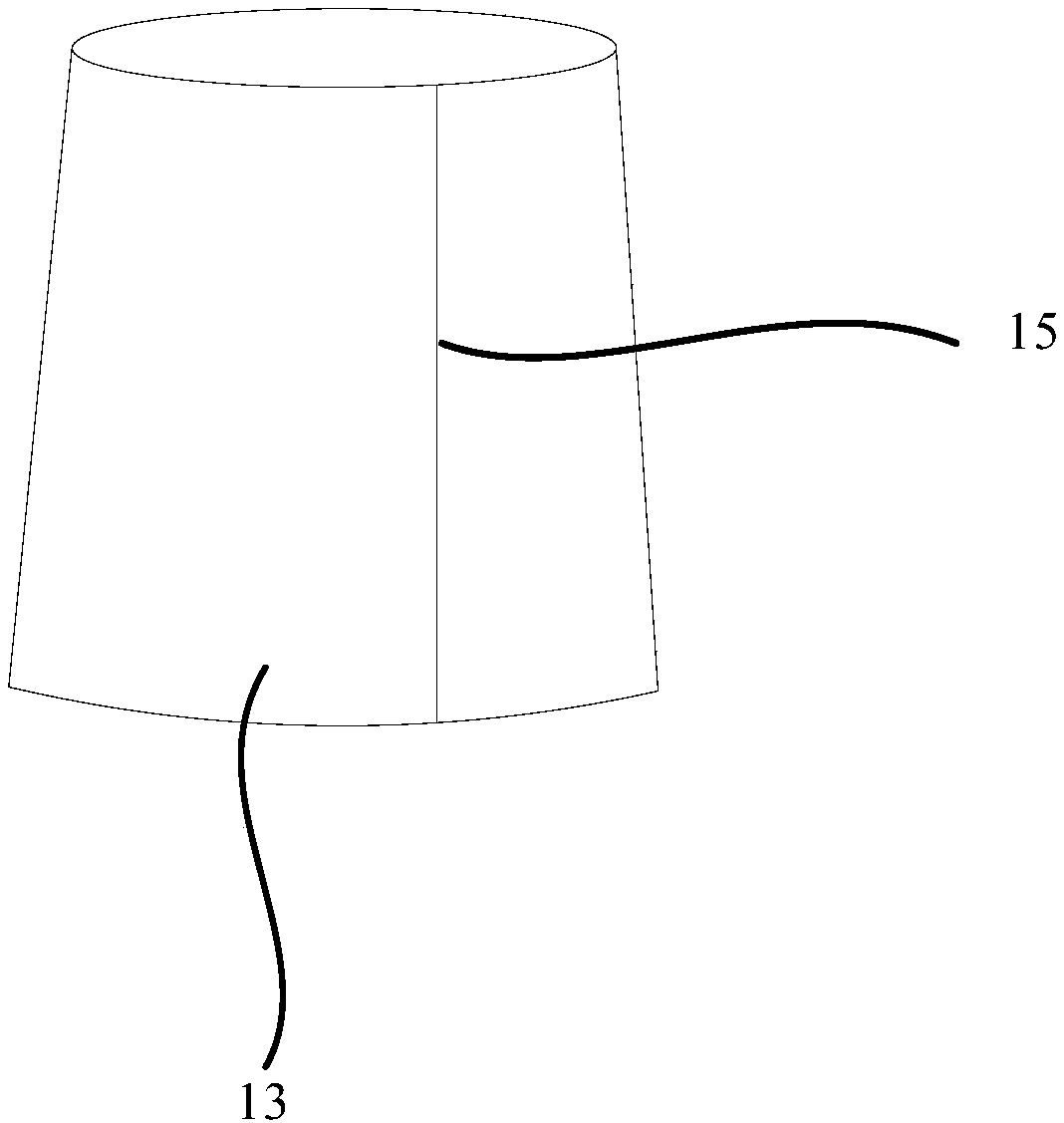

Multi-sheet type fan tower and manufacturing method and transporting method thereof

ActiveCN108301982AReduce the amount of weldingReduce welding stressFinal product manufactureWind motor supports/mountsNondestructive testingRadian

The invention discloses a multi-sheet type fan tower and a manufacturing method and a transporting method thereof. The multi-sheet type fan tower comprises a plurality of longitudinal tower body sheets equal in radian and a plurality of connecting pieces which are fixedly arranged at the end edges of two sides of the longitudinal tower body sheets, wherein the adjacent longitudinal tower body sheets are fixedly connected through the connecting pieces. The radian of each of the n longitudinal tower body sheets is 360 degrees / n. The invention also discloses a manufacturing method and a transporting method of the multi-sheet type fan tower. According to the multi-sheet type fan tower, the welding workload is reduced, the non-destructive testing cost is lowered, and the welding quality risk isavoided; moreover, the butt weld quantity of the tower is reduced, and the damage of restraint intensity and stress concentration of the tower structure is alleviated, so that the service life of thetower is prolonged. In addition, the multi-sheet type structure brings hoisting and transporting convenience.

Owner:SHANGHAI TAISHENG WIND POWER EQUIP

Structural element and body structure including the same

InactiveUS6871903B2Reduce weightReduce in quantitySuperstructure subunitsAxle-box lubricationWindow openingEngineering

A side structure included in a railroad car is provided with an window opening, and door openings formed on the longitudinally opposite sides of the window opening, respectively. The side structure excluding parts corresponding to the window opening and the door openings are divided into a plurality of sections. A first section extends vertically between the window opening and the door opening, a second section extends vertically between the window opening and the door opening, and a third section of a width substantially equal to that of the window opening extends under the window opening. Each of the sections has a core attached to the inner surface of an outer panel, and rim members having a substantially Z-shaped cross section and surround the core. An inner panel is attached to the core and the rim members so as to cover the inner surface of the core.

Owner:KAWASAKI HEAVY IND LTD

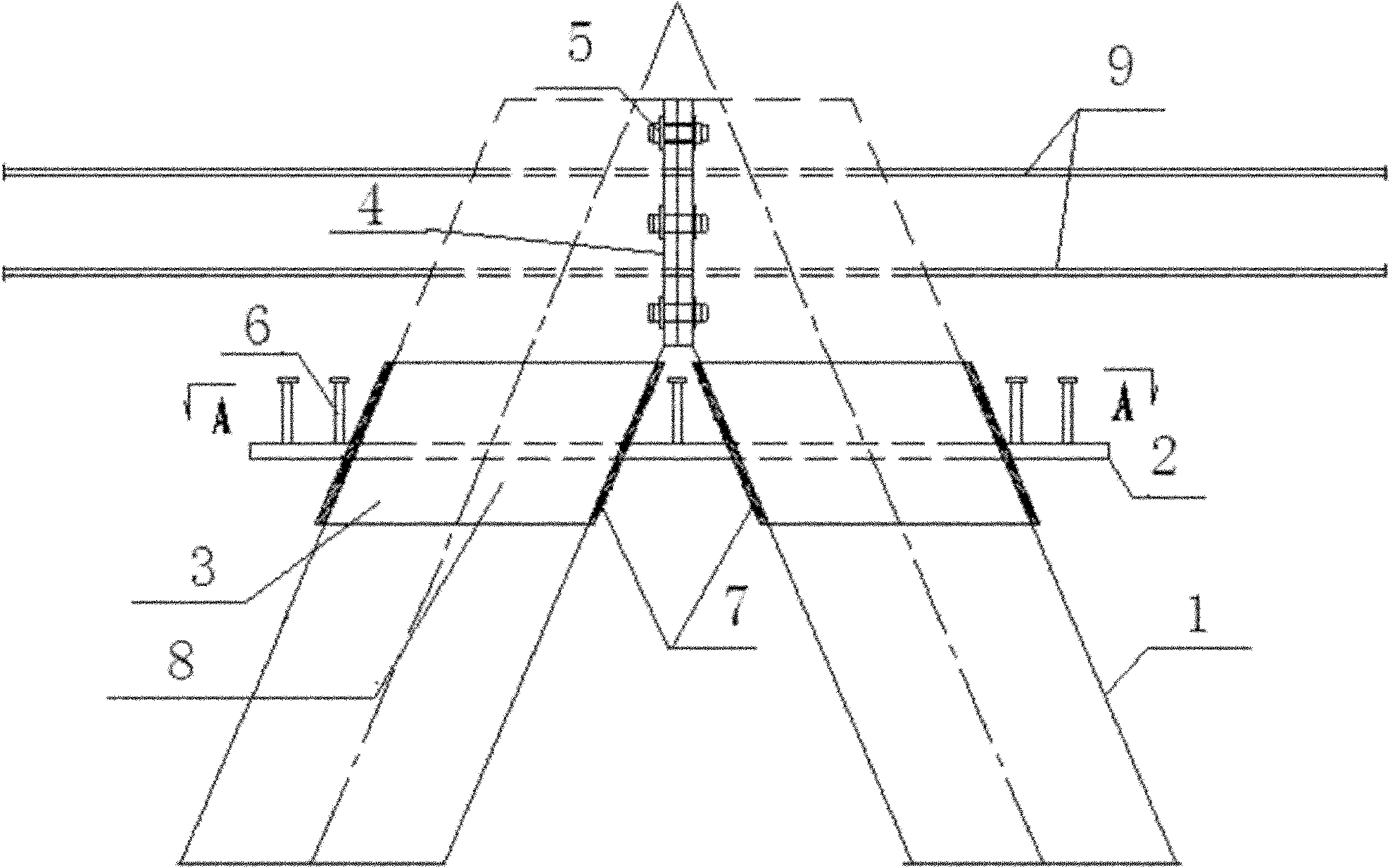

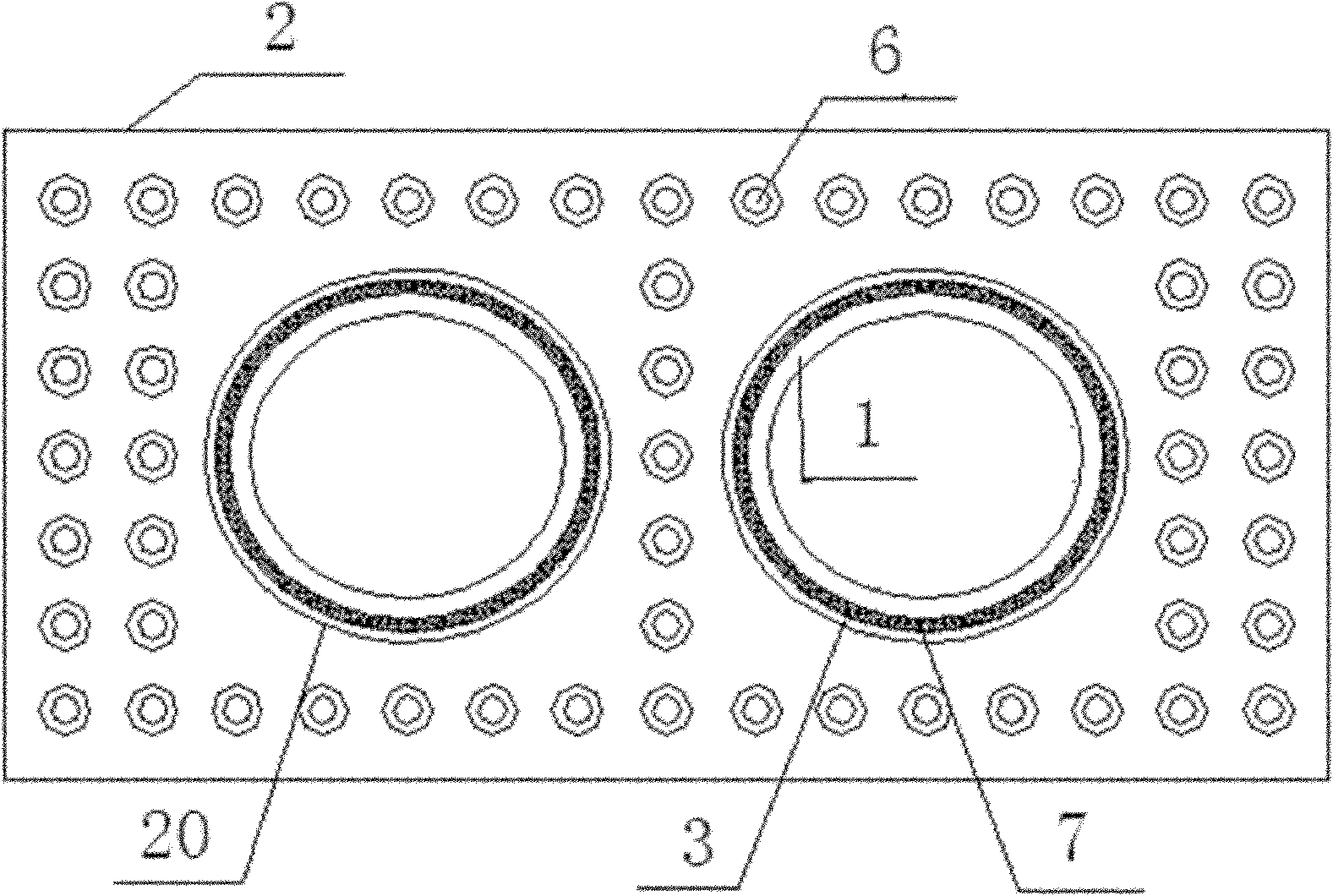

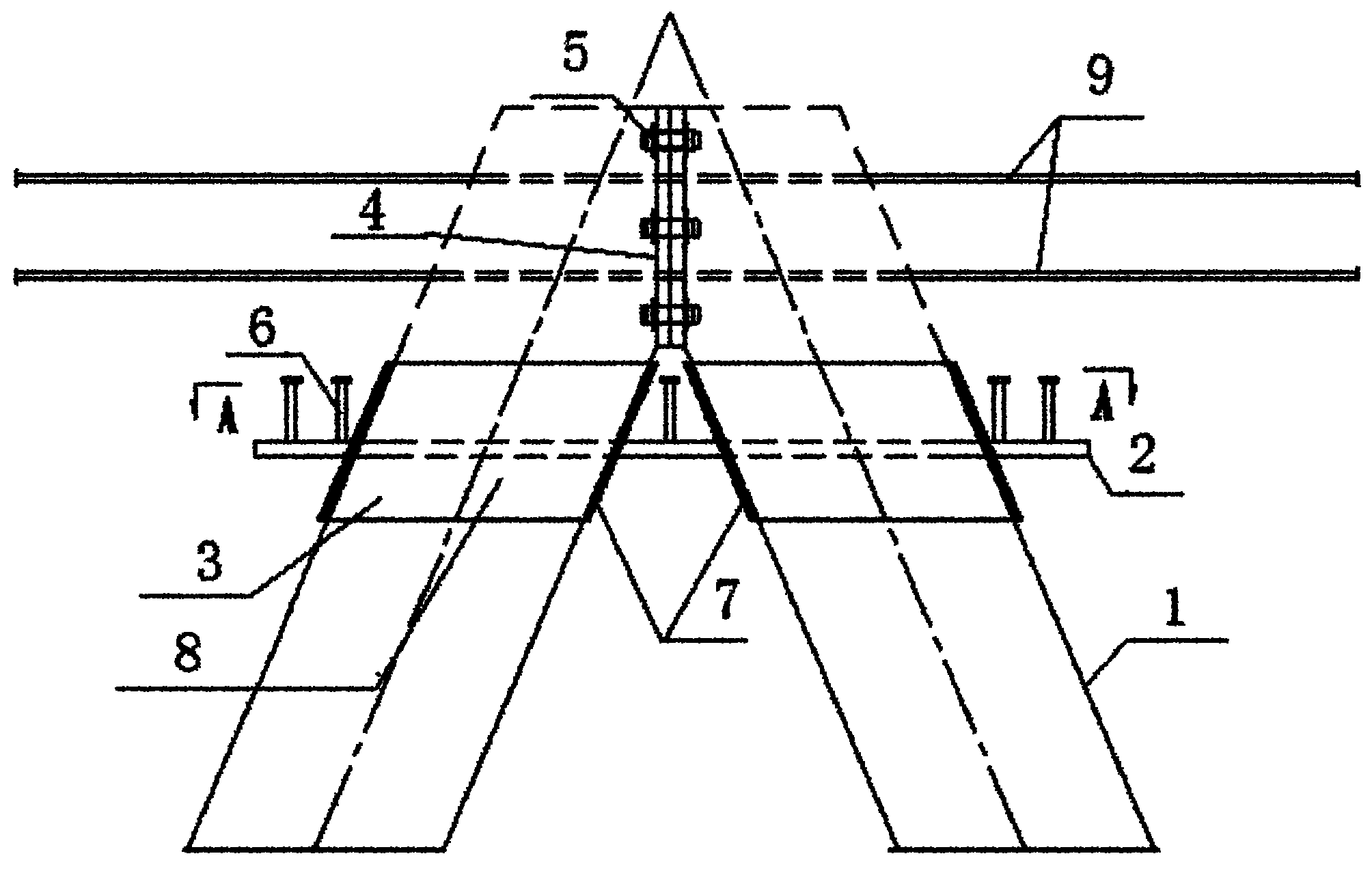

Steel sheath type steel truss web node structure

ActiveCN102061665AEfficient deliveryImprove bearing capacityBridge structural detailsRebarMechanical engineering

The invention discloses a steel sheath type steel truss web node structure. Two truss web steel tubes, a horizontal steel plate and slant steel sheaths are arranged on a node; the horizontal steel plate is parallel to a top plate or a bottom plate; two elliptic holes are formed on the horizontal steel plate; two slant steel sheaths are inserted and welded in the elliptic holes; the two truss web steel tubes are inserted into the slant steel sheaths respectively in the traverse direction; the two truss web steel tubes are inserted into the slant steel sheaths respectively opposite to each other in a herringbone form; intersection parts are vertically cut respectively; cut surfaces are welded with steel plates respectively to be sealed; bolt holes and through reinforcement holes are reserved on the steel plates; and the steel plates of the two steel tubes are riveted together through common bolts to ensure that the two truss web steel tubes are integrated in the traverse direction.

Owner:JSTI GRP CO LTD

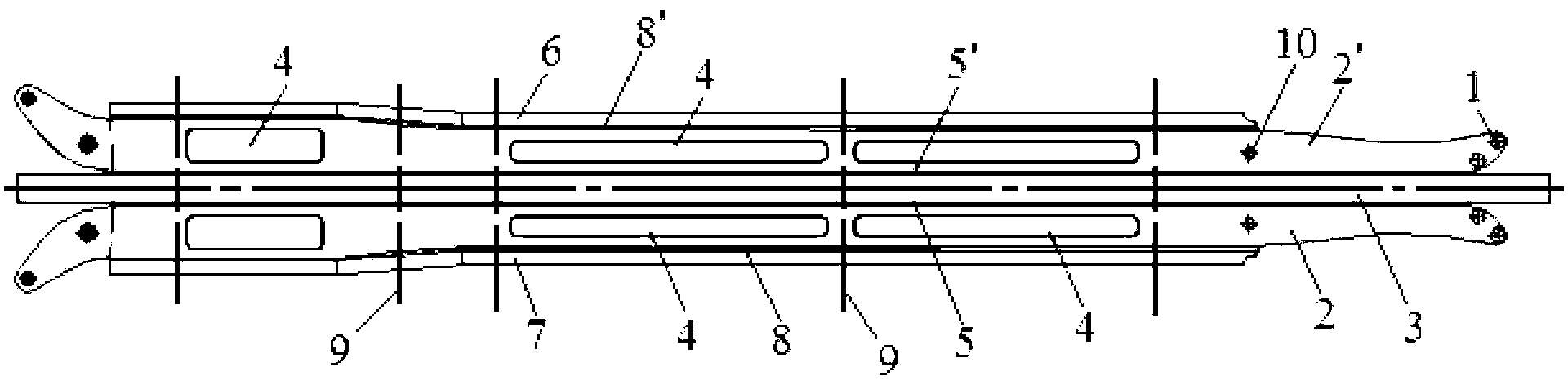

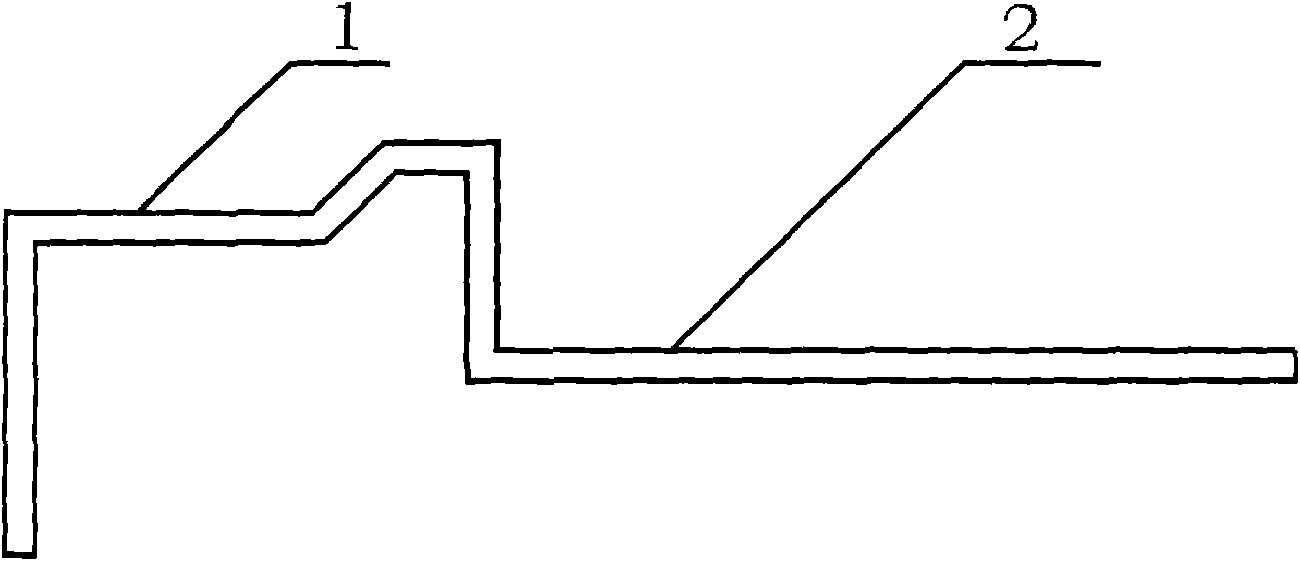

Processing method of box-shaped arm section, box-shaped arm section and concrete pump truck arm frame

ActiveCN103015726AExtended service lifeImprove structural strengthBuilding material handlingEngineeringConcrete pump

The invention discloses a processing method of a box-shaped arm section. The processing method comprises the following steps: a cutting forming step, a first bending step, a second bending step and a closed connection step, wherein in the cutting forming step: a sheet material is cut to form a cutting forming plate; in the first bending step: a first web forming part (2) and a second web forming part (2') are bent relative to a base plate forming part (3) of the cutting forming plate; in the second bending step: the edges of a first top plate forming part and a second top plate forming part are mutually contacted or are opposite through the first top plate forming part (6) and the second top plate forming part (7) of the bending cutting forming plate of the first web forming part and the second web forming part; and in the closed connection step: the edges of the first top plate forming part and the second top plate forming part are mutually connected, so as to form the box-shaped arm section. In addition, the invention also provides a box-shaped arm section and a concrete pump truck arm frame. The processing method of the box-shaped arm section is simple in process, and is convenient for guaranteeing the processing quality; the processing working procedures and the processing time are obviously reduced; and the working efficiency is improved.

Owner:ZOOMLION HEAVY IND CO LTD

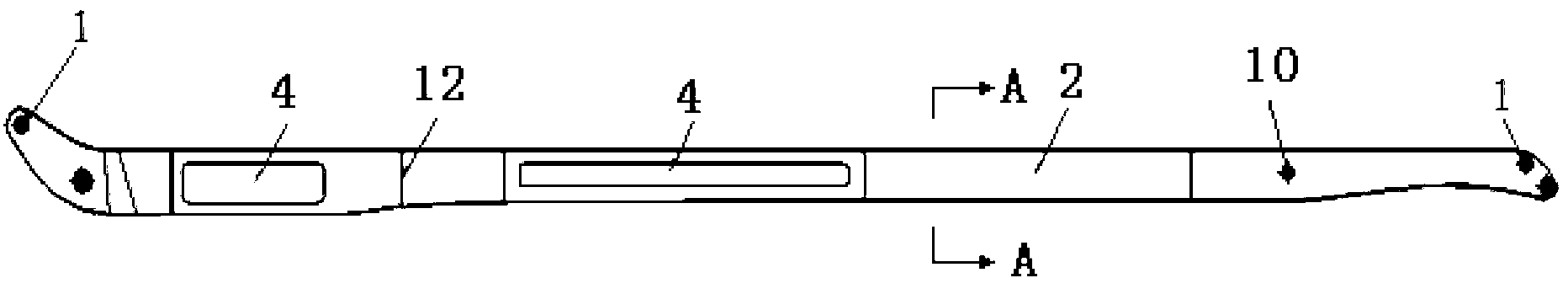

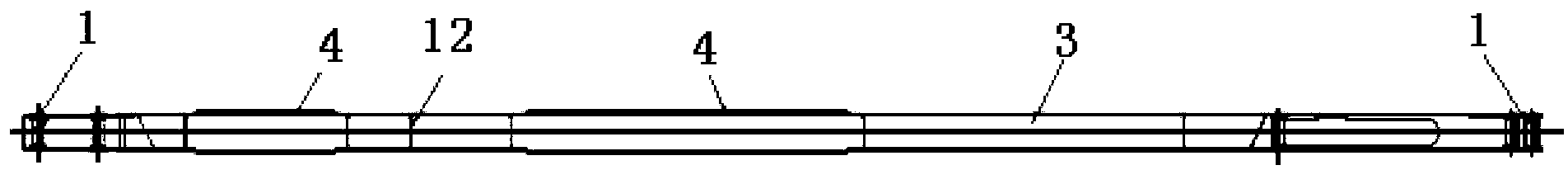

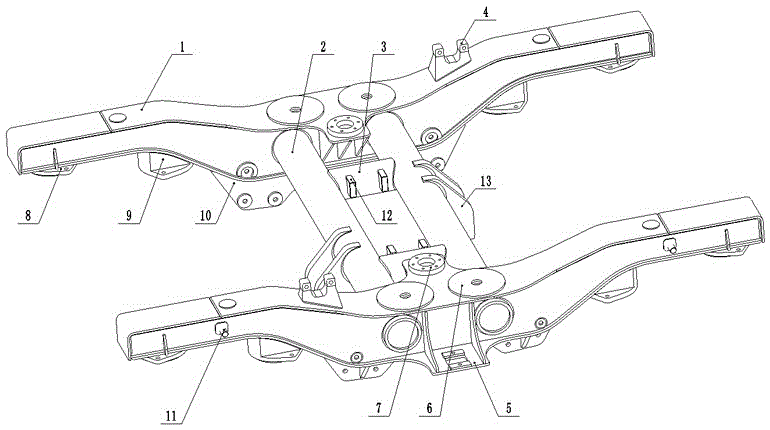

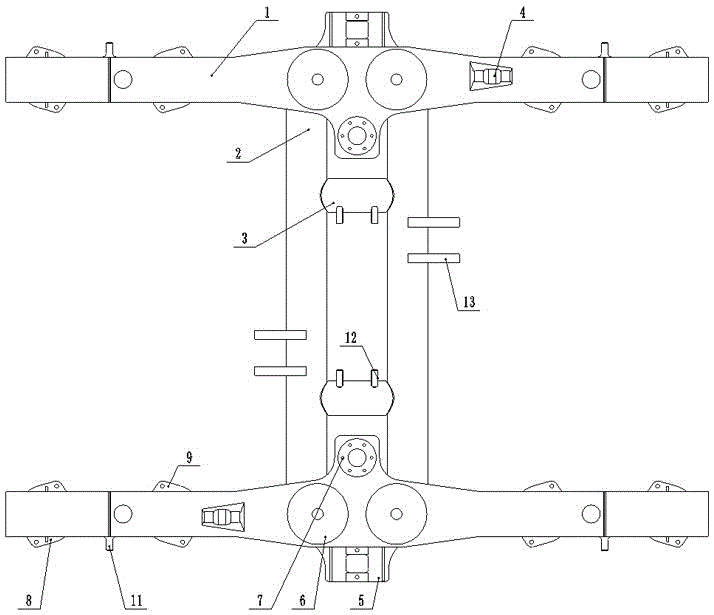

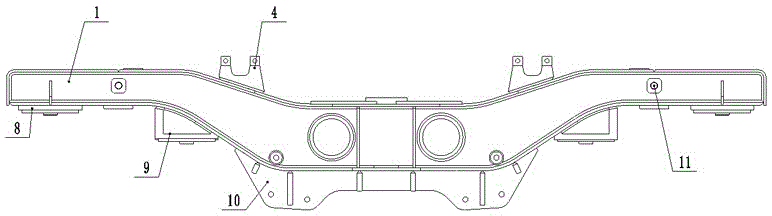

Engineering detection vehicle bogie frame

PendingCN107176179ARealize the purpose of lightweight designGuaranteed production costBogiesBogieBrake

The invention discloses an engineering detection vehicle bogie frame. The engineering detection vehicle bogie frame comprises an H-shaped frame body composed of two side beams of a box-shaped structure and two cross beams of a hollow structure. Hollow auxiliary beams are fixed between the inner sides of the two cross beams. The middles of the side beams are sunken to form sunken parts used for mounting secondary spring seats. The outer sides of the middles of lower cover plates of the side beams protrude outward to form vertical oil pressure shock absorber seats. According to the trailer engineering detection vehicle bogie frame suitable for tread brake, the side beams are of the box-shaped structure, the cross beams and the auxiliary beams all adopt hollow steel pipes, thus the whole weight of the frame is effectively decreased while strength is guaranteed, and the purpose that a vehicle body is lightweight is achieved.

Owner:CRRC LUOYANG CO LTD

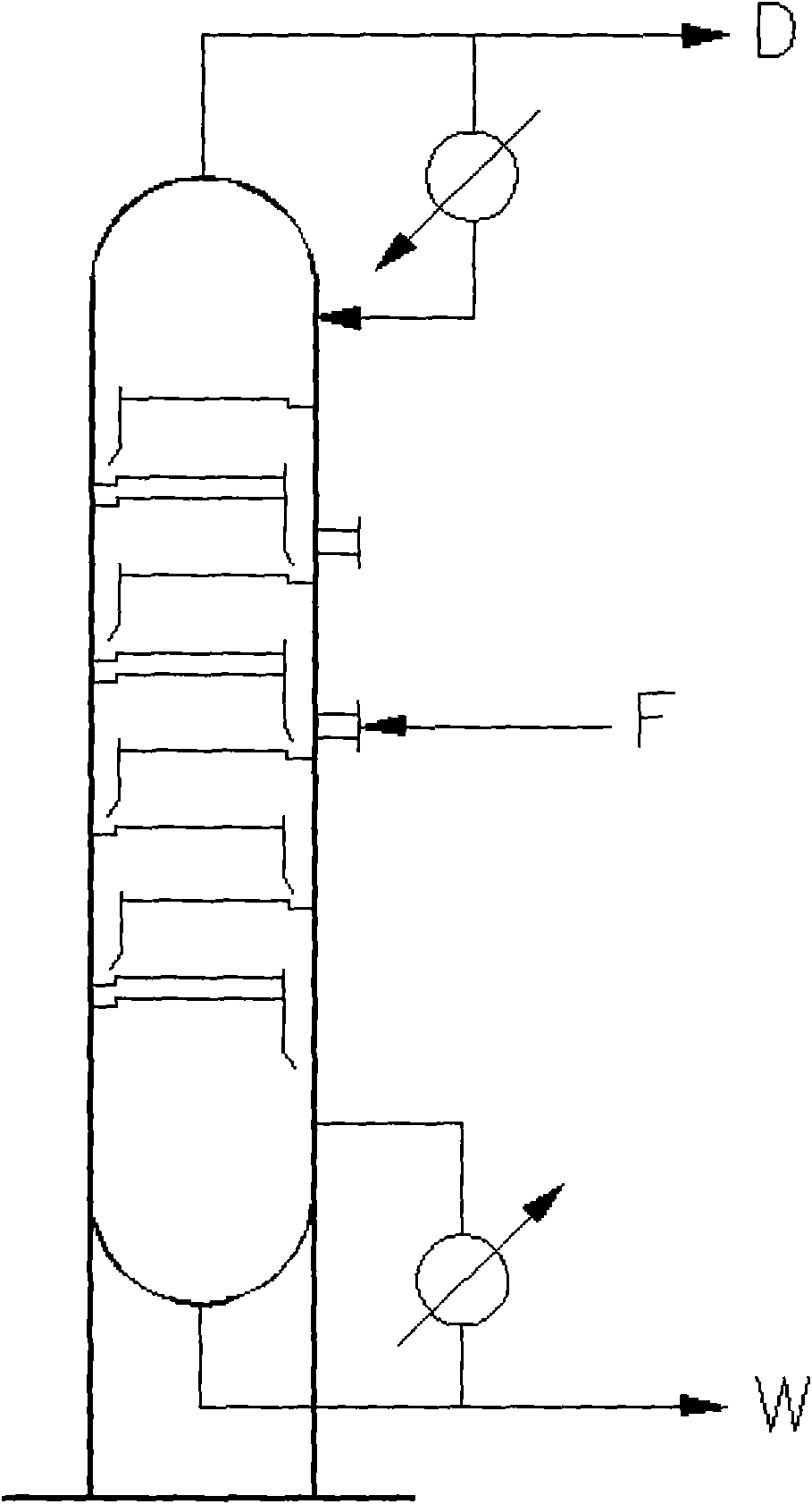

Novel tower equipment

ActiveCN101934158AImprove the level ofEasy to assembleFractional distillationPetrifactionChemical industry

The invention discloses novel tower equipment and relates to a mass transfer process in industrial processes, belonging to the field of gas-liquid mass transfer devices. In the tower equipment, supporting angle iron and a liquid receiving disk are manufactured into a piece, thus the processing efficiency and the levelness of a tower plate can be improved; a liquid downcomer plate and the liquid receiving disk are manufactured to be detachable so as to be convenient to assemble, maintain and clean the equipment; and a safety plate is arranged above each manhole, i.e. below a lowest tower plate on the part of the tower body for protecting workers while mounting and maintaining. The equipment can be used for the mass transfer process in industries of chemical industry, petrifaction, light industry, metallurgy, and the like and has the characteristics of simple structure, low manufacturing cost, obvious economic benefit, and the like.

Owner:北京先锋创新科技发展有限公司

Pool systems and methods for making and using same

ActiveUS20140157509A1Reduce the possibilityEasy and less-expensive to manufactureLamination ancillary operationsLaminationManufacturing engineering

Embodiments of the present invention provide an improved pool. Embodiments of the present invention also provide a method of making an improved pool. The pool can comprise an integrated sidewall joined to a floor portion. The integrated sidewall can be constructed from one piece of material, and can have fewer seams than traditional pools, thereby reducing the likelihood that that pool will rupture and leak. In some embodiments, since the pool has fewer seams than traditional pools, fewer manufacturing steps are required to make the pool. This can increase manufacturing speed and decrease cost.

Owner:POLYGROUP MACAU BVI

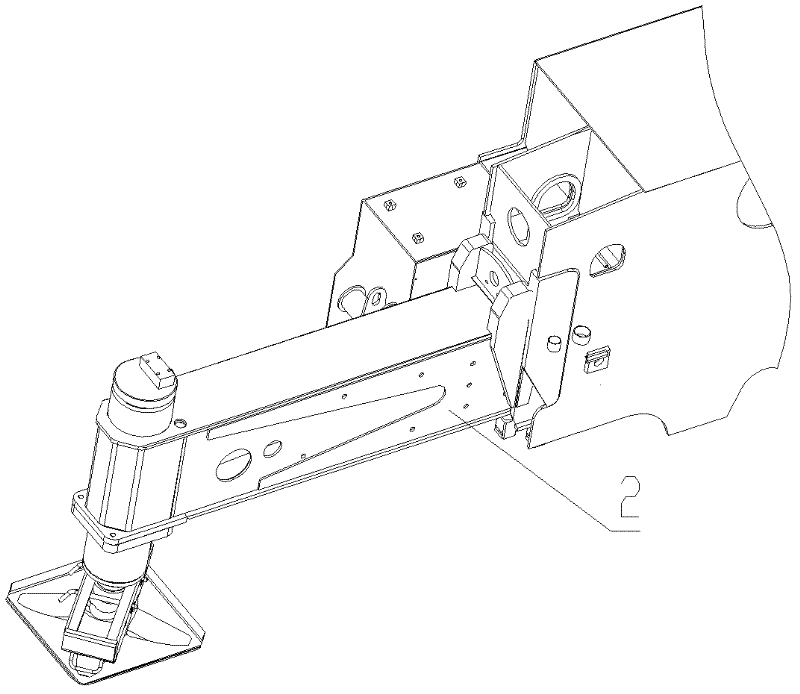

Supporting leg and applied crane thereof

ActiveCN102408062AReduce the amount of weldingBase supporting structuresBraking devices for hoisting equipmentsStress concentrationStress distribution

The invention discloses a supporting leg of crane, which comprises at least one movable supporting leg; the movable supporting leg is formed in a manner that a cover plate assembly, a left web plate assembly, a right web plate assembly and a bottom plate are assembled and welded; each plate assembly comprises a base plate and a reinforced plate respectively; the reinforced plate is greater in thickness than the corresponding base plate and is butted, assembled and welded with the corresponding base plate to form the plate assembly; and the base plate in the plate assembly is located outside the reinforced plate. The movable supporting leg is formed in a manner that a cover plate assembly, a left web plate assembly, a right web plate assembly and a bottom plate are assembled and welded, and the base plate and the reinforced plate are assembled and welded, so that welding quantity is reduced. Concentrated and larger stress is formed at overlap joint position when the movable supporting leg is extended out, the reinforced plate is located inside and the overlap joint position is located on the reinforced plate so that the reinforced plate can adapt stress distribution of the plate assembly. The supporting leg of such structure adapts stress distribution of the plate assembly and reduces welding quantity. The invention also discloses a crane comprising the supporting leg.

Owner:XUZHOU HEAVY MASCH CO LTD

Method for coiling directly metal flange using with strip steel and its coiled equipment

The invention discloses a method using band steel to directly coil a metallic flange, and also provides a coiling device exclusively for the metallic flange. The invention doesnot need to heat and proceed tempering or annealing process during the coiling process; in addition, the invention is able to successively carry out coiling process with the minimum welding quality. As is proved by actual production, the key technical indexes such as the dimension accuracy of the internal and external cycles and the planarity of the flange are able to reach level IT9; the utilizing rate of the band steel materials is up to 97 percent. The longer the band steel is, the higher the utilizing rate is. Only one person is able to operate ten coiling machines. The invention has not only simple and convenient operation, but also excellent safety and reliablity as well as high productivity as well as low cost.

Owner:柳锁兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com