Multi-sheet type fan tower and manufacturing method and transporting method thereof

A technology of manufacturing method and transportation method, which is applied in the directions of wind turbine transportation, wind turbine, and final product manufacturing, etc., can solve the problem of increasing the restraint degree and stress concentration of the tower structure, the difficulty of tower hoisting and transportation, and the large amount of tower welding. problems, to achieve the effect of fast and efficient on-site installation, avoid welding quality risks, and reduce welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

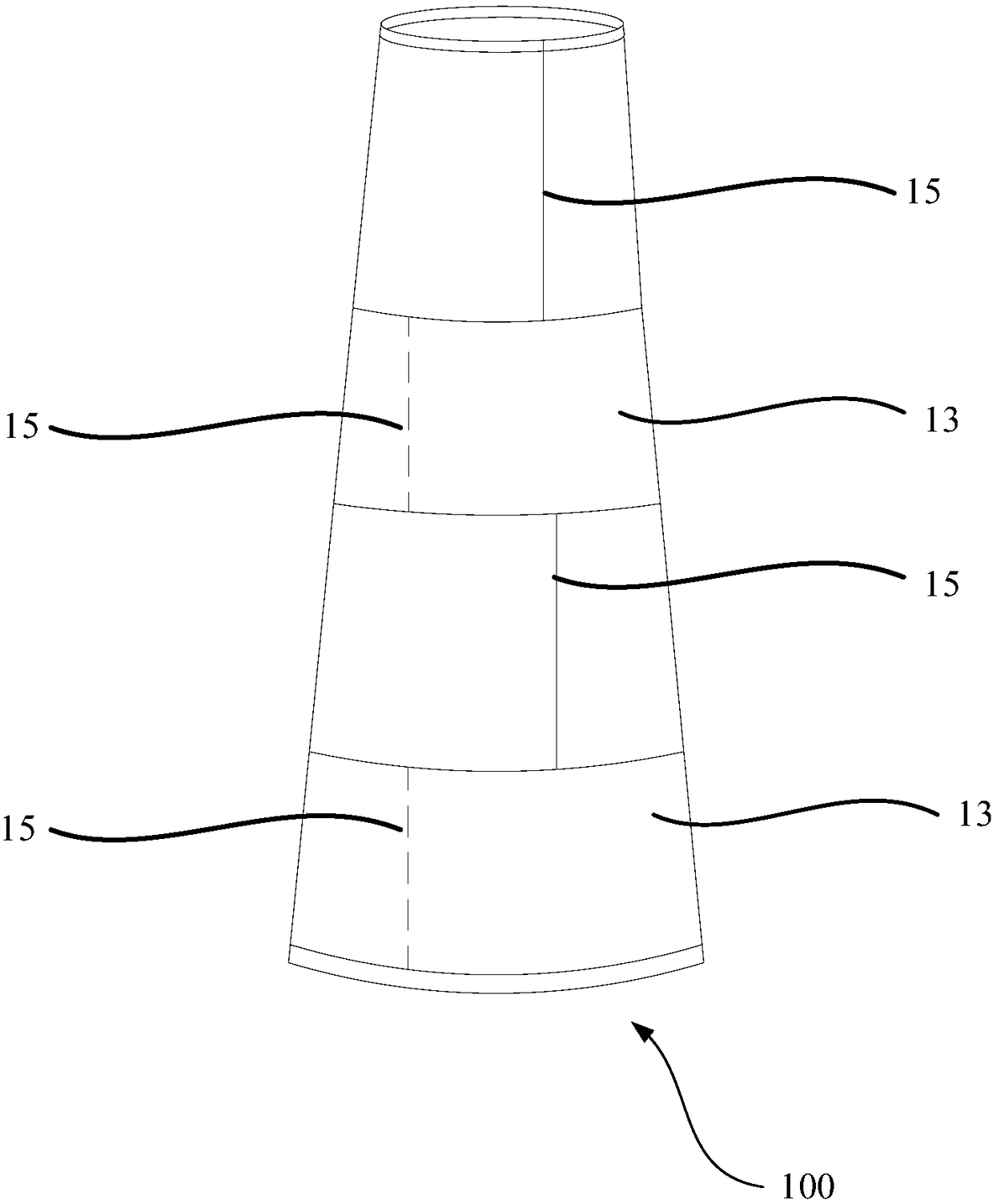

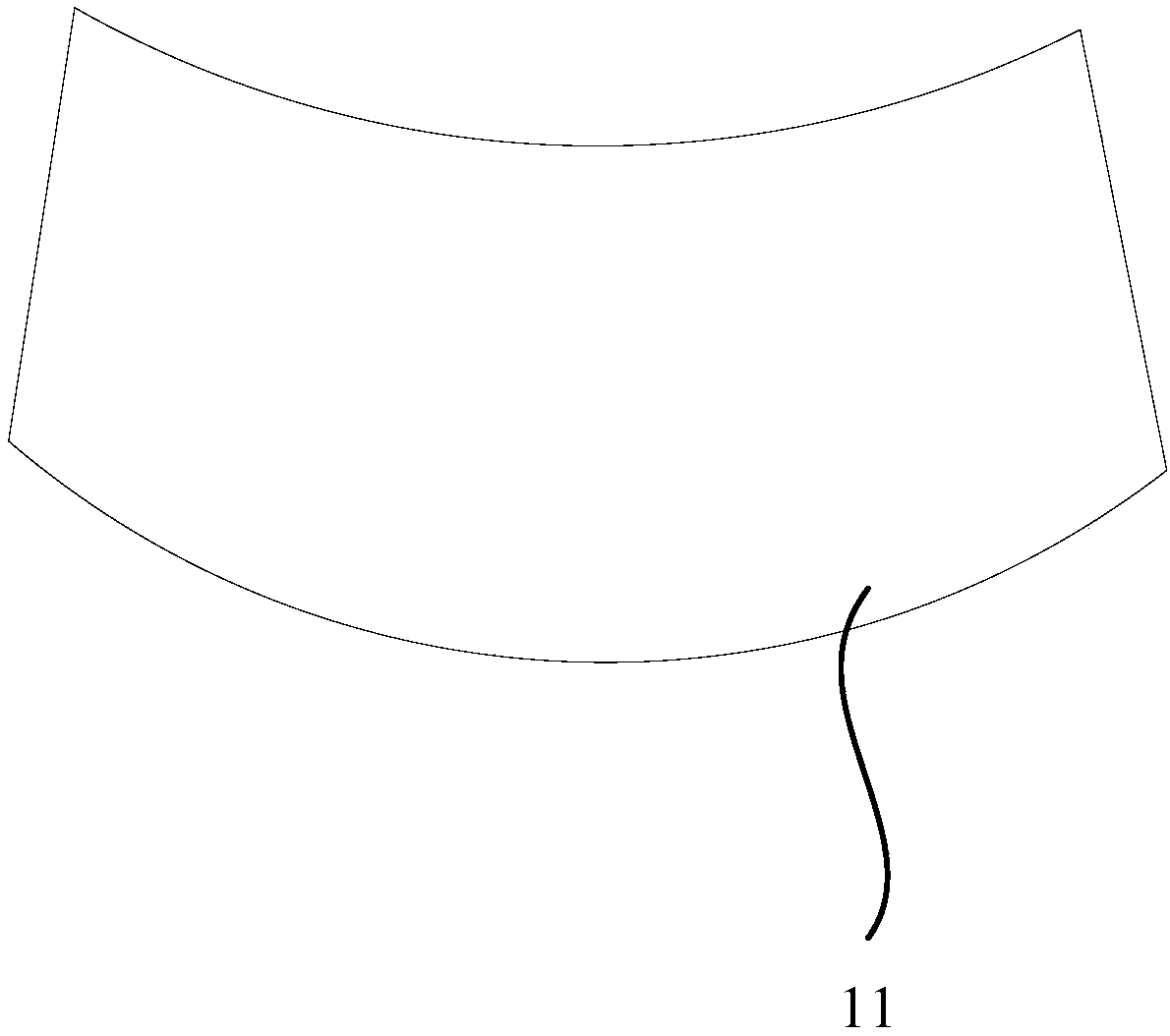

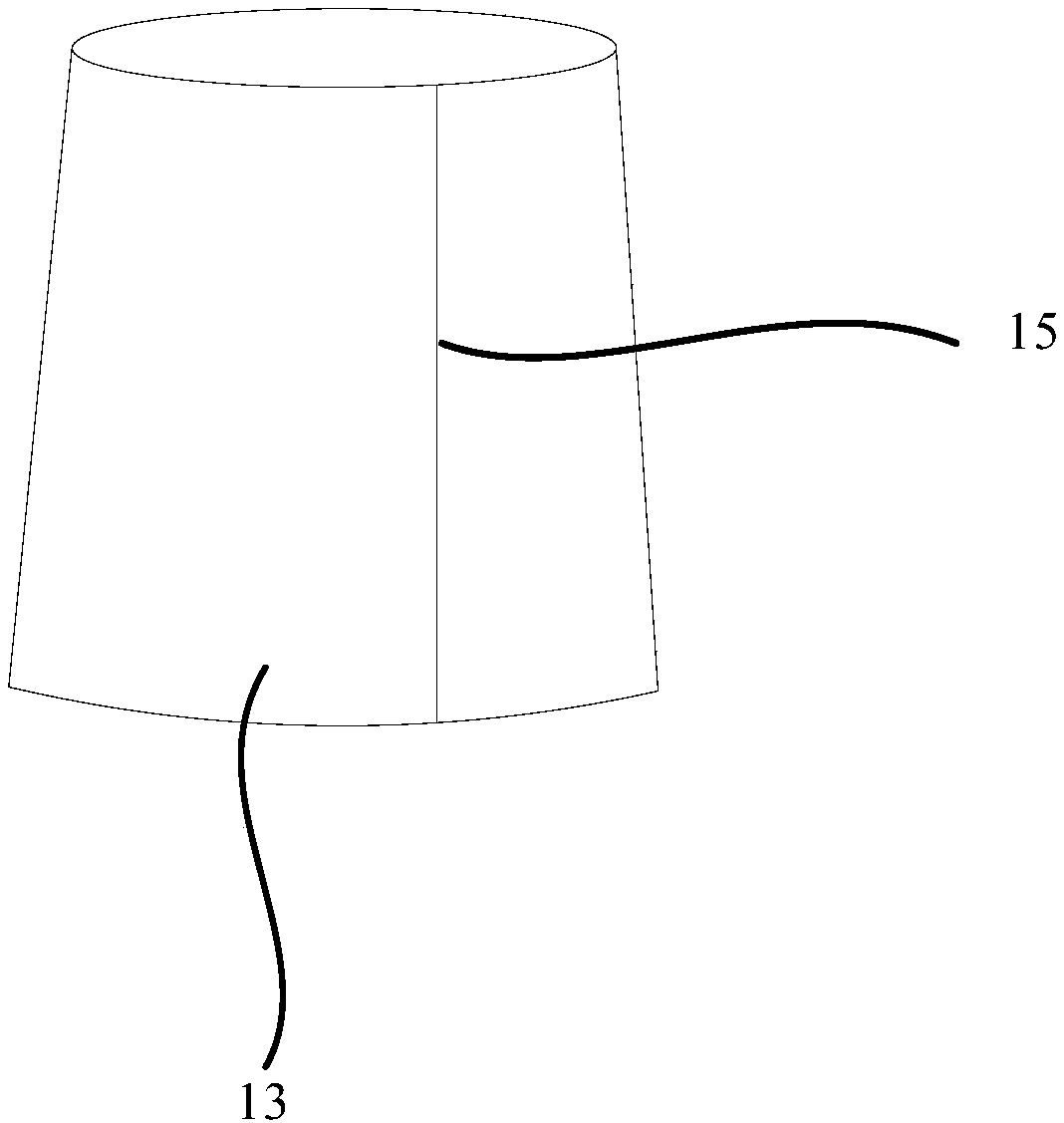

[0071] Such as Figure 4-6 It shows a schematic structural view of a sliced fan tower 200 of the present invention, as Figure 4 Shown is the segmented fan tower 200 of the first embodiment. Such as Figure 5 and as Figure 6 As shown, the sliced wind turbine tower 200 of the present embodiment 1 includes 4 longitudinal tower body pieces 22 of equal radian; Side edge; the adjacent longitudinal tower body pieces are fixedly connected by the connecting piece, and the fixed connecting piece in this embodiment is a bolt set. In the sliced fan tower of the present invention, when the longitudinal tower body pieces are n pieces, the radian of each of the longitudinal tower body pieces is 360° / n, that is, in this embodiment, the longitudinal tower body When there are 4 pieces, the arc of each longitudinal tower body piece is 90°.

[0072] Further, the shape of the segmented fan tower is a cylinder, or the shape of the segmented fan tower is a cone. Such as Figure 4-6 As...

Embodiment 2

[0074] In Embodiment 2 of the present invention, the sliced fan tower in Embodiment 2 is similarly consistent with n pieces of the longitudinal tower body, and the arc of each longitudinal tower body is 360° / n. condition. In Embodiment 2 of the present invention, the n of the longitudinal tower body pieces 22 is 3 pieces, so the radian of each of the longitudinal tower body pieces is 120°, except that different tower body pieces 22 are used, other The structures of the sliced fan towers 200 in Embodiment 1 of the invention are basically the same.

Embodiment 3

[0076] Such as Figure 7-10 The manufacturing method of the sliced fan tower is shown. Such as Figure 7 Shown, the manufacturing method of described sliced fan tower, it comprises the following steps:

[0077] Step 300, steel plate rolling: roll the steel plate circumferentially into a tower body section, and fix the vertical connection seam on the tower body section by spot welding to form a vertical weld line;

[0078] Step 301, stacking tower body sections: stacking several tower body sections vertically, taking the vertical weld line of adjacent tower body sections as a reference, and the angle between adjacent tower body sections is k×360° / n;

[0079] Among them, k is an integer, 0, 1, 2, 3...

[0080] And, if the longitudinal tower body slices of the sliced fan tower are designed as n slices, the arc of each slice is 360° / n;

[0081] Step 302, flange installation: install flanges on the top of the stacked top tower body section and the bottom end of the stac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com