Engineering detection vehicle bogie frame

A technology for engineering testing and bogies, applied in bogies, railway car body parts, transportation and packaging, etc., can solve problems such as unfavorable bogie lightweight design, high bogie manufacturing cost, and complex frame structure, and achieve simplified processing The effect of manufacturing technology, improving the economic benefits of the enterprise, and reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

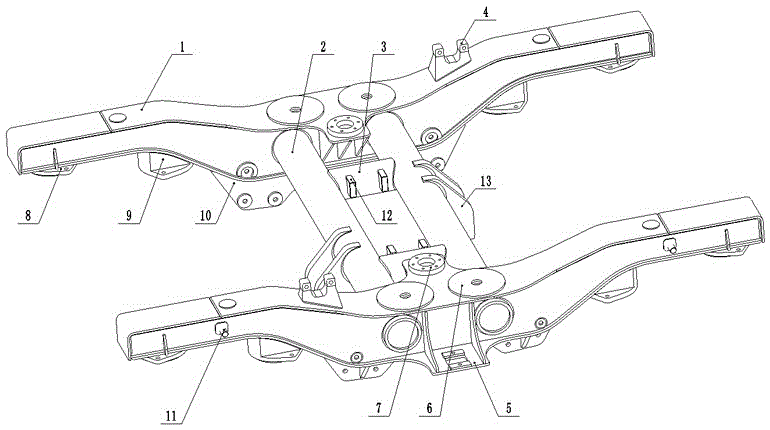

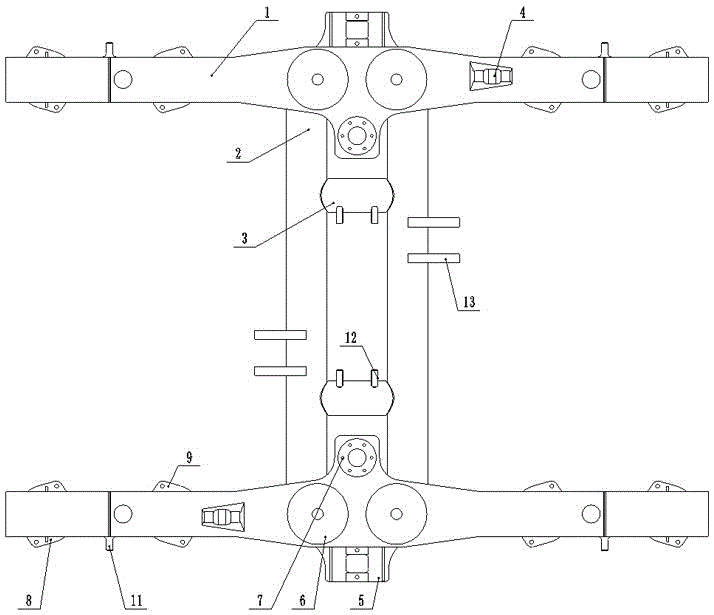

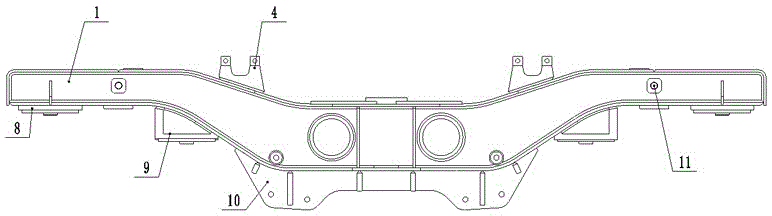

[0020] Embodiment 1: see Figure 1 to Figure 3 , a bogie frame of an engineering testing vehicle, comprising two box-shaped side beams 1 and two cross beams 2, the two side beams 1 and two cross beams 2 are fixedly connected to each other to form an H-shaped frame body, The crossbeams 2 are hollow structures, and an auxiliary beam 3 is fixed between the inner sides of the two crossbeams 2, which meets the strength and rigidity requirements of the framework and realizes the lightweight design requirements. The middle part of the side beam is concaved to form a concave part for installing the secondary spring seat, which reduces the distance between the upper plane of the secondary spring group and the rail surface, and reduces the height of the center of gravity of the vehicle.

[0021] The auxiliary beam adopts a hollow steel pipe, on which the fixing seat 12 used for the limitation of the traction beam when the bogie is hoisted as a whole is welded and installed. superior. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com