Method for coiling directly metal flange using with strip steel and its coiled equipment

A flange and metal technology, which is applied in the field of methods and rolling equipment, can solve the problems of large machining allowance, undisclosed rolling die structure, complicated process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

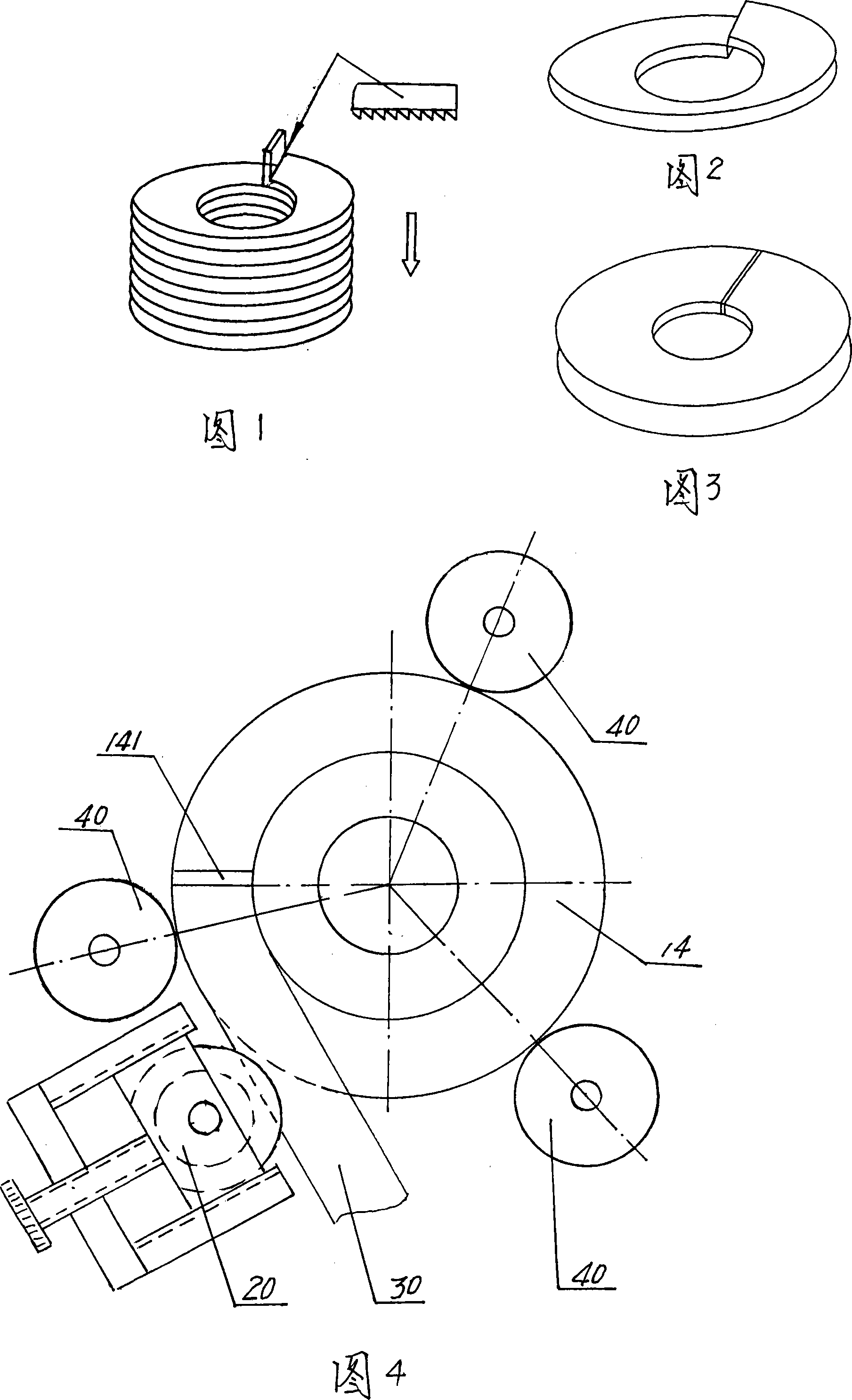

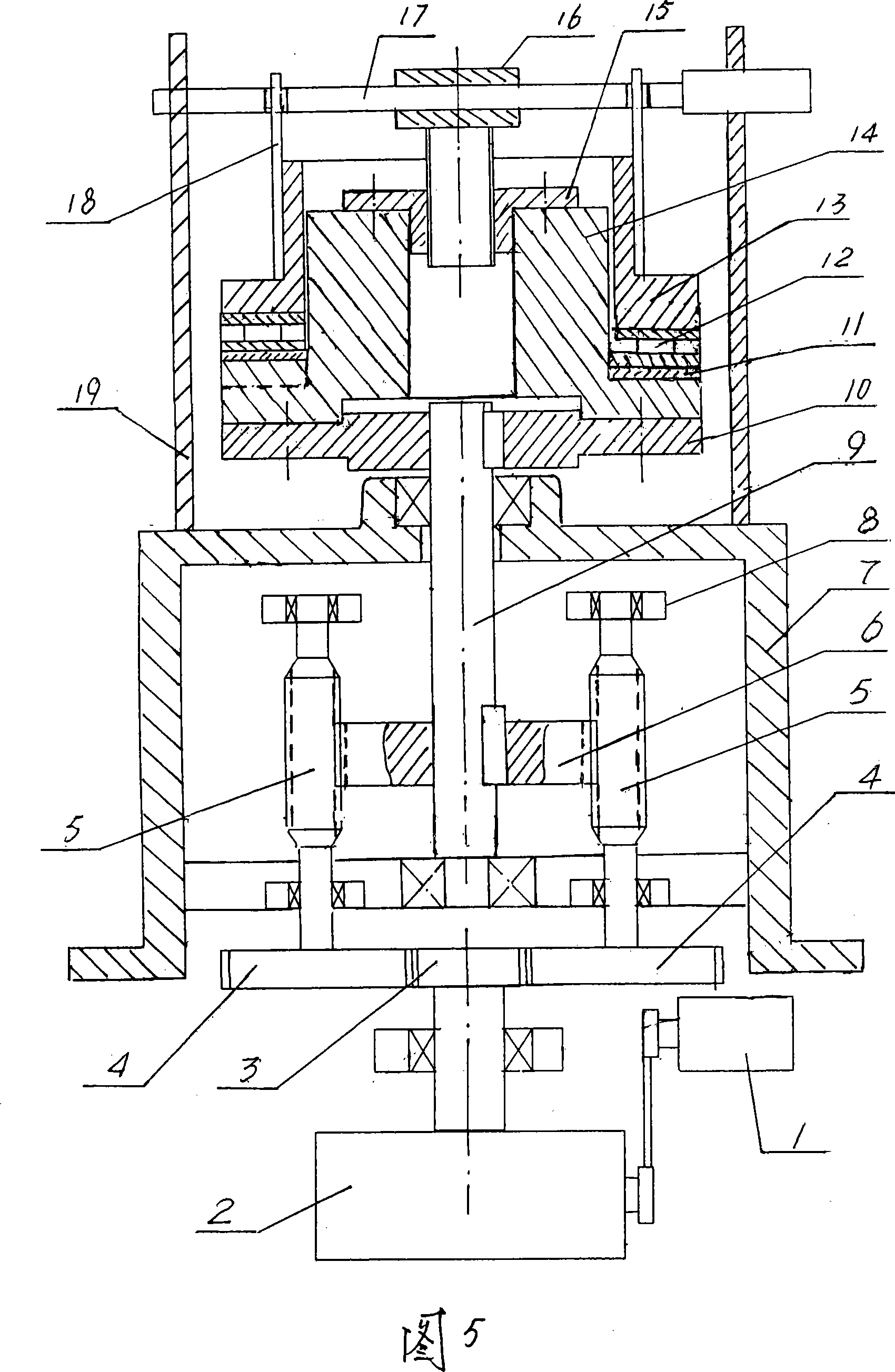

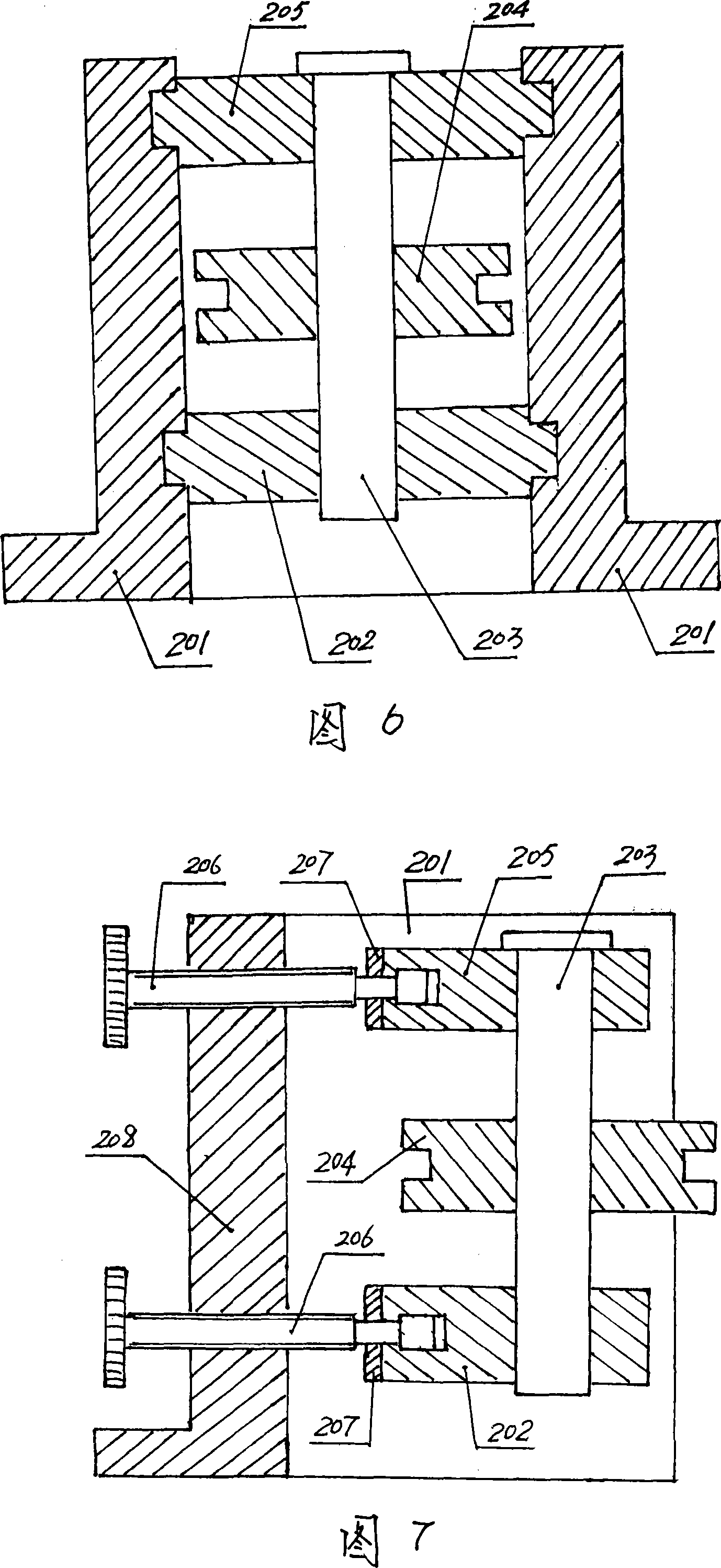

[0039] Taking a six-hole flange with an outer diameter of 460mm, an inner diameter of 360mm, and a thickness of 5mm as an example, the specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings:

[0040] The rolling method is as follows:

[0041] ①Select a strip steel with a width of 50mm and a thickness of 5mm;

[0042] ② Bend the starting end of the strip steel into a 90° elbow under normal temperature conditions, and the size of the elbow is 5-6mm

[0043] ③Insert the strip steel elbow into the notch 141 of the end face of the rolling mold core 14 in the special rolling equipment for metal flanges, and roll it into a spiral ring cylinder by the special rolling equipment for metal flanges, as shown in Figure 1;

[0044] ④ Carry out radial cutting along the bending head at the starting end of the lowest roll, remove the bending head at the starting end, and obtain several open flange blanks, as shown in Figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com