Novel tower equipment

A technology of towers and equipment, applied in the field of mass transfer devices, can solve the problems of uneven liquid layer thickness, inconvenient movement, falling to the bottom of the tower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

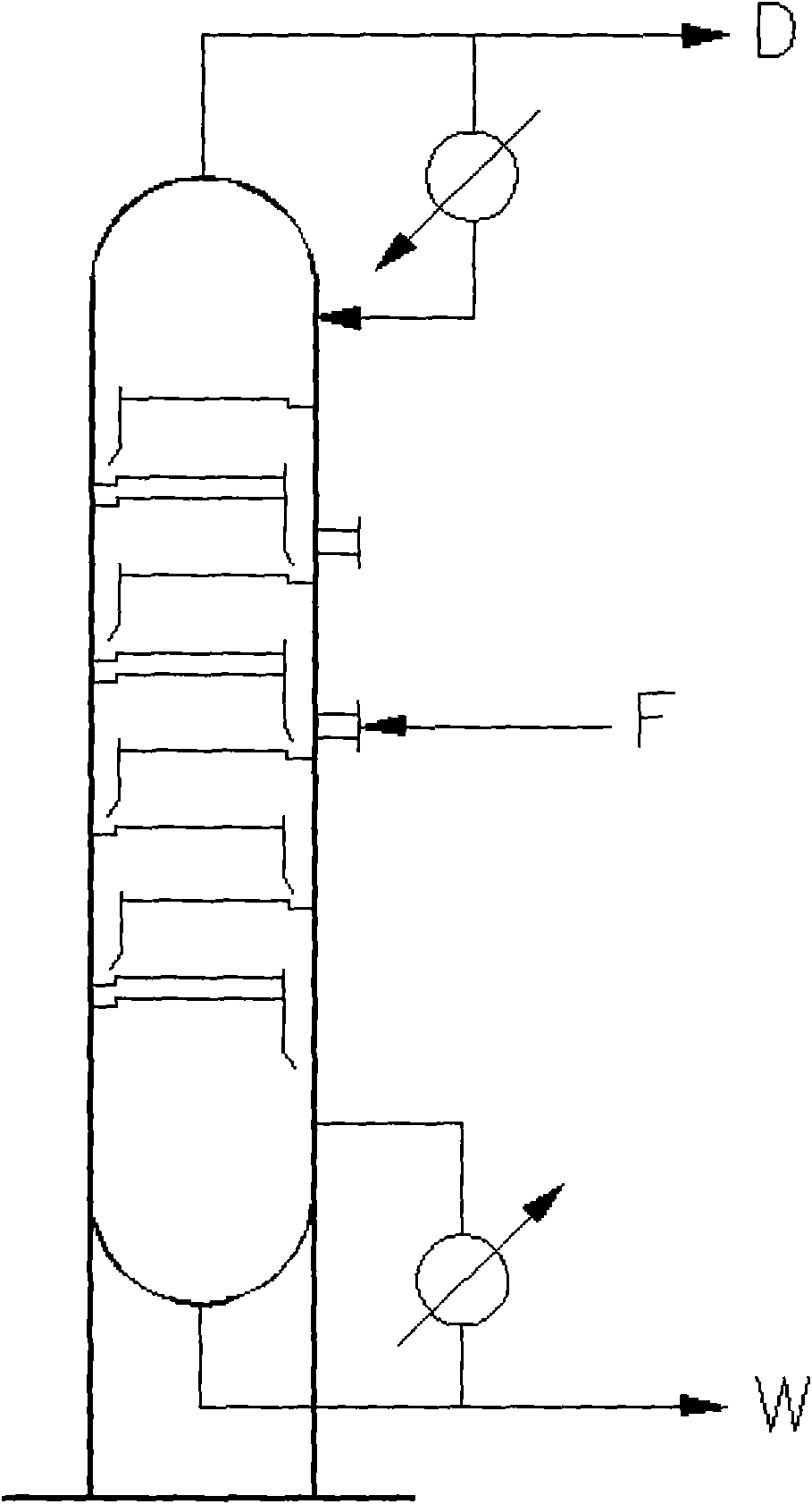

[0019] Implementation example: adopt the novel column device announced by the present invention to separate the vinyl chloride system, and the feed flow rate is 45m 3 / h, wherein vinyl chloride accounts for 90% (mass percentage, the same below), dichloroethane accounts for 3%, acetylene accounts for 2%, water accounts for 1%, and the rest are trace impurities. The tower height is 25m, the tower diameter is 2m, 40 trays, and the plate spacing is 400mm. After being treated by the novel tower equipment disclosed by the invention, the top vinyl chloride accounts for 85%, acetylene accounts for 14%, and the others are light impurities. At the bottom of the tower, vinyl chloride accounts for 95%, ethylene dichloride accounts for 3.2%, water accounts for 1.2%, and the rest are heavy impurities, which achieves a good separation effect. It takes about 2 to 3 days to complete the installation of the traditional tower with the same size, but the new tower equipment disclosed by the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com