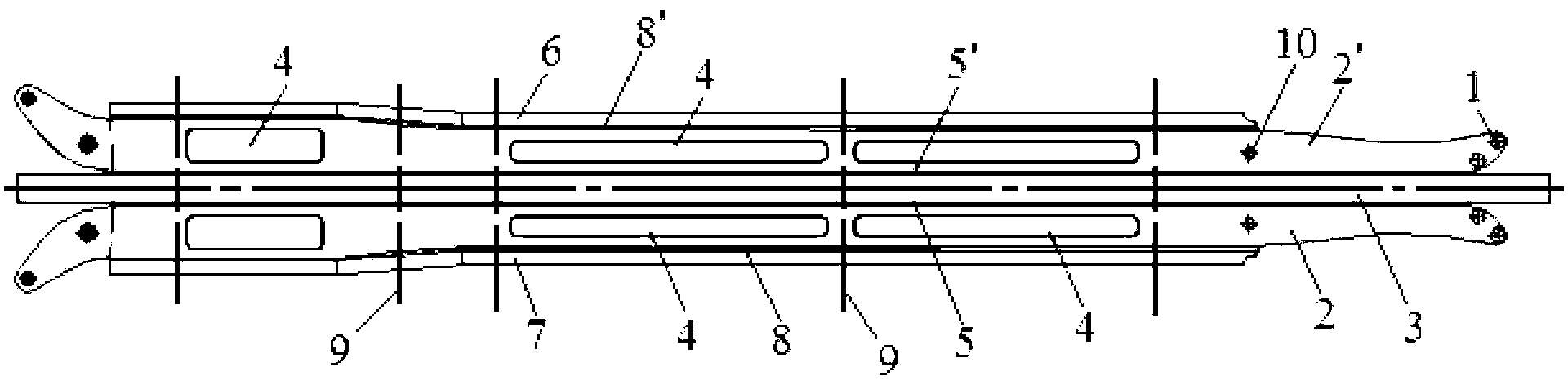

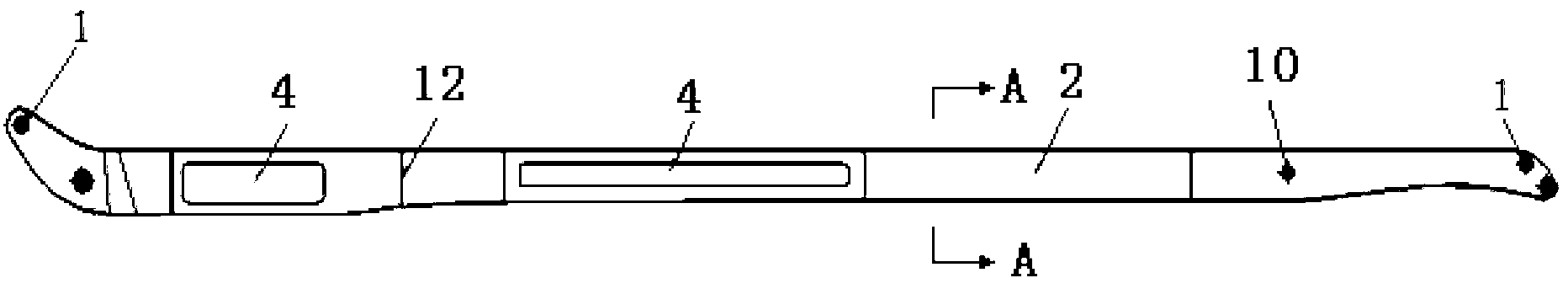

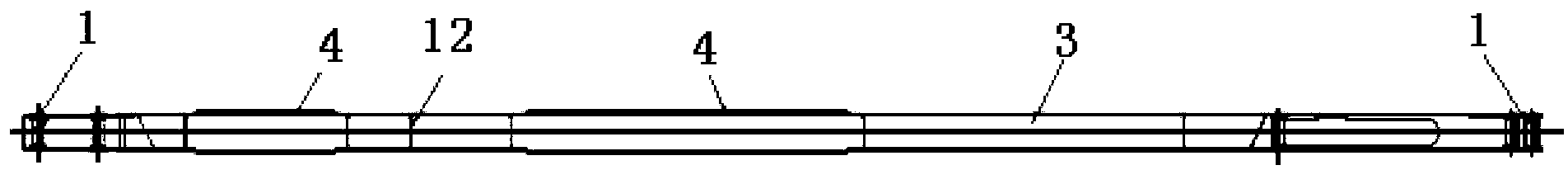

Processing method of box-shaped arm section, box-shaped arm section and concrete pump truck arm frame

A processing method and jib section technology, which is applied in the fields of construction, building structure, and building material processing, can solve the problems of increasing processing costs, difficulty in assembling, and increasing web damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

[0048] In the following specific embodiments, in order to facilitate the understanding of those skilled in the art, the box-shaped boom section processing method of the present invention is mainly illustrated by taking the box-shaped boom section of the concrete pump truck boom as an example, but for those skilled in the art, it is easy to think of Yes, the technical concept of the box-shaped jib processing method of the present invention can also be applied to the processing of box-shaped jib sections adopted by other engineering machinery, such as the processing of box-shaped jib sections of the boom of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com