Composite bridge deck applied to long-span bridges and city bridges

A combined bridge and long-span technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of pure steel bridge deck structure corrosion, heavy concrete slab weight, poor torsion resistance, etc., and reduce deformation asynchronous. , Small amount of welding, the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

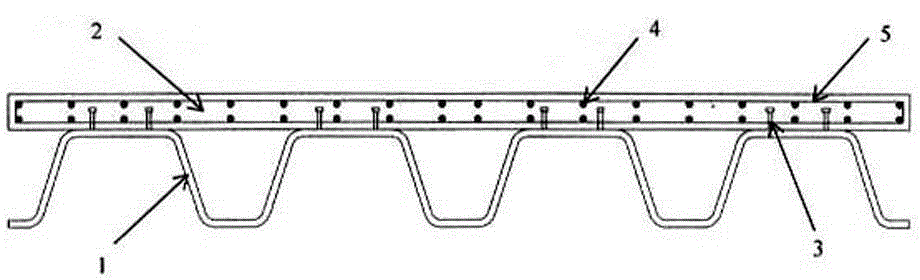

[0021] Such as figure 1 As shown, the composite bridge deck applied to long-span bridges and urban bridges according to the present invention includes a bridge deck body composed of a lower corrugated steel plate 1 (bottom plate) and an upper concrete plate 2 (top plate): The shear connector 3 symmetrically welded on the crest of the corrugated steel plate 1 extends upwards into the concrete slab 2; in the middle of the concrete slab 2, a reinforcing steel bar 4 is evenly arranged along the length of the bridge, and the circular stirrup 5 of the reinforcing steel bar is bundled After being connected to form a whole; the annular stirrup 5 and the shear connector 3 are connected to each other to ensure sufficient shear rigidity between the corrugated steel plate 1 and the concrete slab 2 .

[0022] In actual use, the shear connector 3 can be a stud, section steel or perforated plate structure; according to the section structure and the force analysis of the bridge deck, the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com