Threaded hole welding and repairing process

A welding repair and threaded hole technology, applied in the field of welding repair technology, can solve the problems of difficult construction, affecting the processing and assembly of threaded holes, and lack of fusion, so as to improve the repair efficiency and quality, and reduce the welding height and welding volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

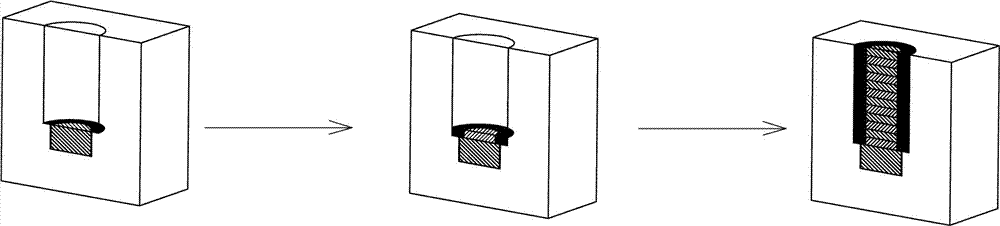

[0023] This embodiment takes 64-M80 115 / 150 threaded hole as an example for illustration. The diameter of the threaded hole is 80mm, the thread height is 115mm, and the depth of the threaded hole is 150mm. The specific implementation process is as follows, refer to figure 1 :

[0024] 1. Material preparation: prepare multiple round steel plates according to the height of the threaded holes. The first layer of round steel plates has a specification of ø78x30mm, the other round steel plates have a specification of ø65X10mm, and the quantity is 12 pieces.

[0025] 2. Reaming: Expand the diameter of the threaded hole to an inner hole with a diameter of 100mm and a depth of 120mm.

[0026] 3. Welding: Put the first layer of circular steel plate to the bottom of the threaded hole, and weld a circle around it. The welding method is metal arc welding, the welding wire type is ER70S-6, and the shielding gas is CO 2 , the welding current is 180A, the welding voltage is 21V, the welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com