Patents

Literature

35results about How to "Guaranteed to be filled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

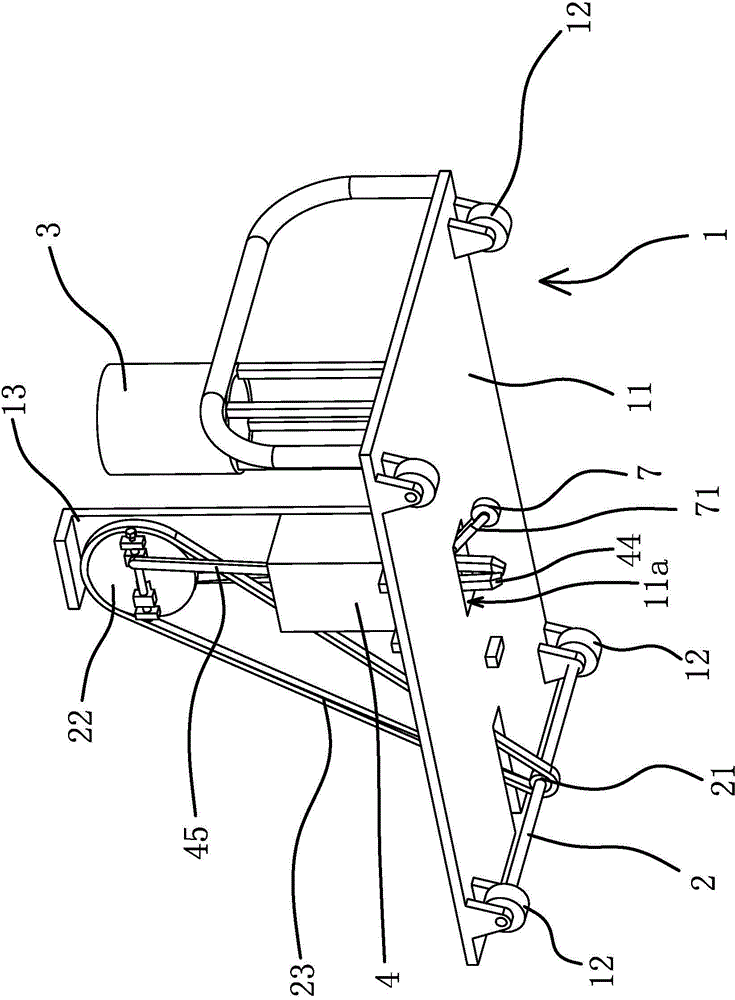

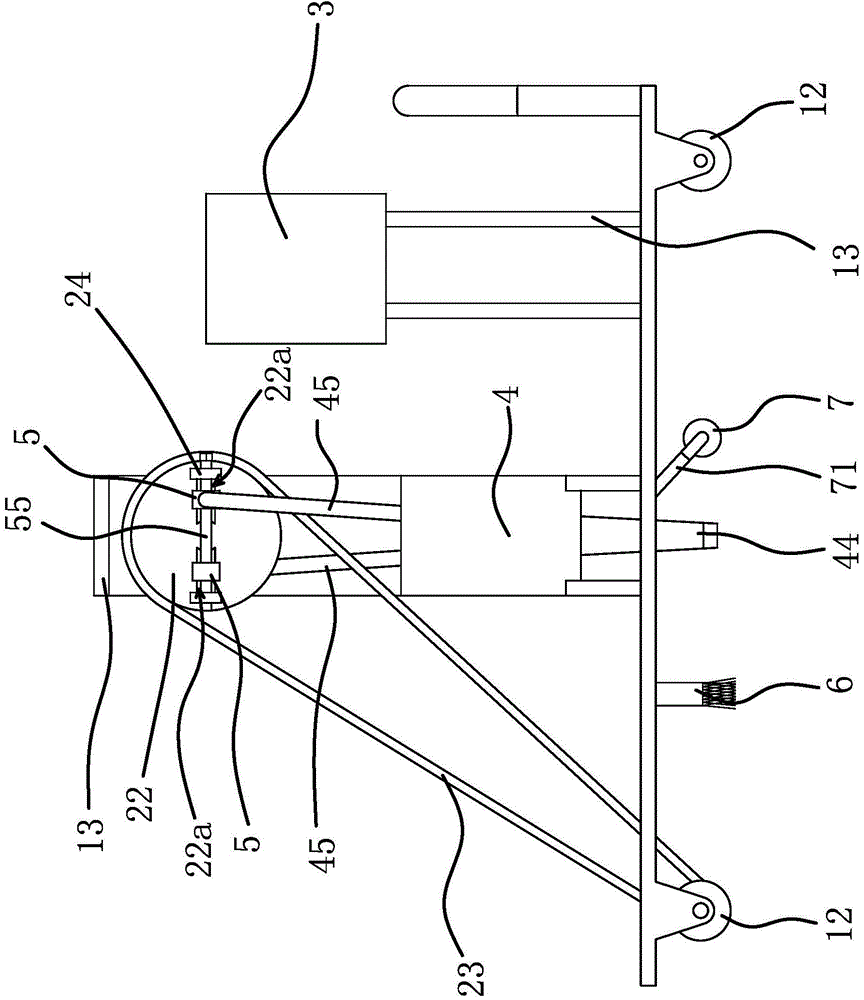

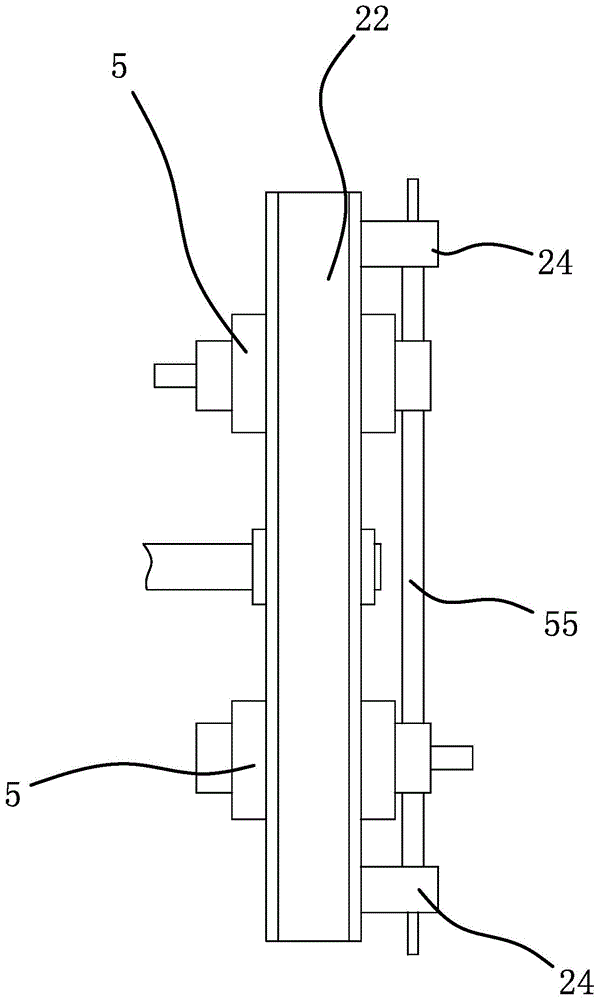

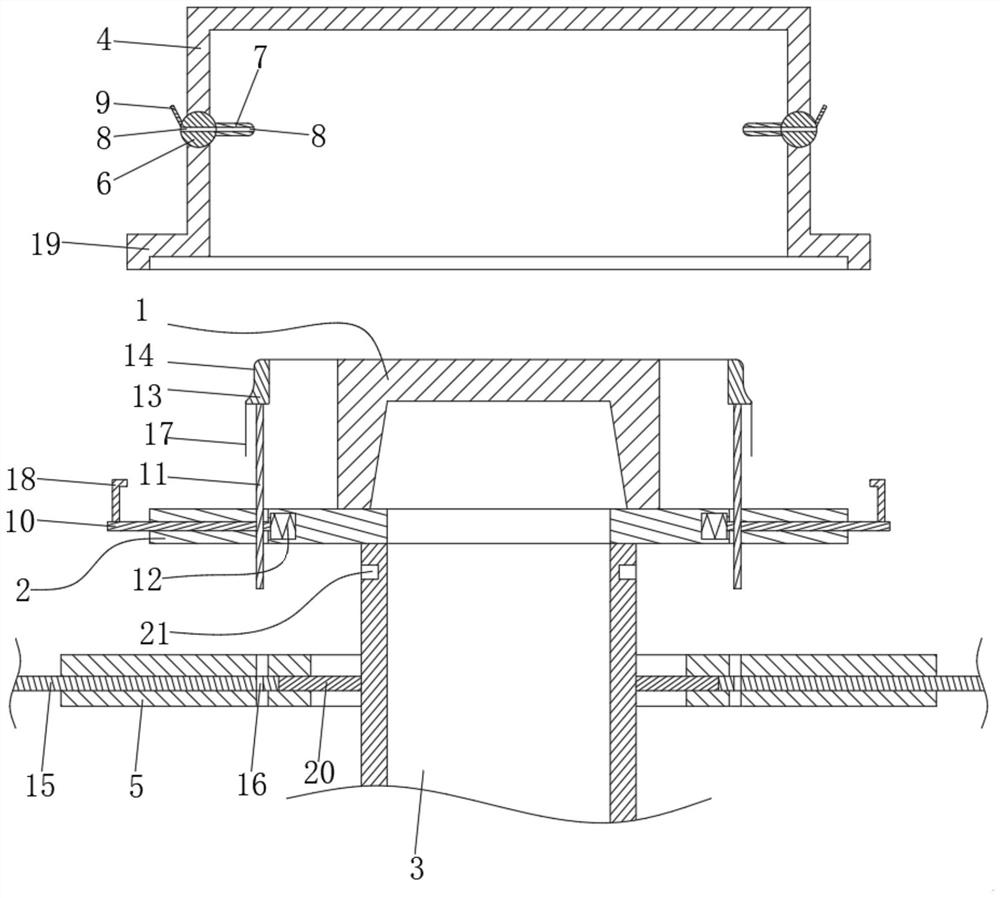

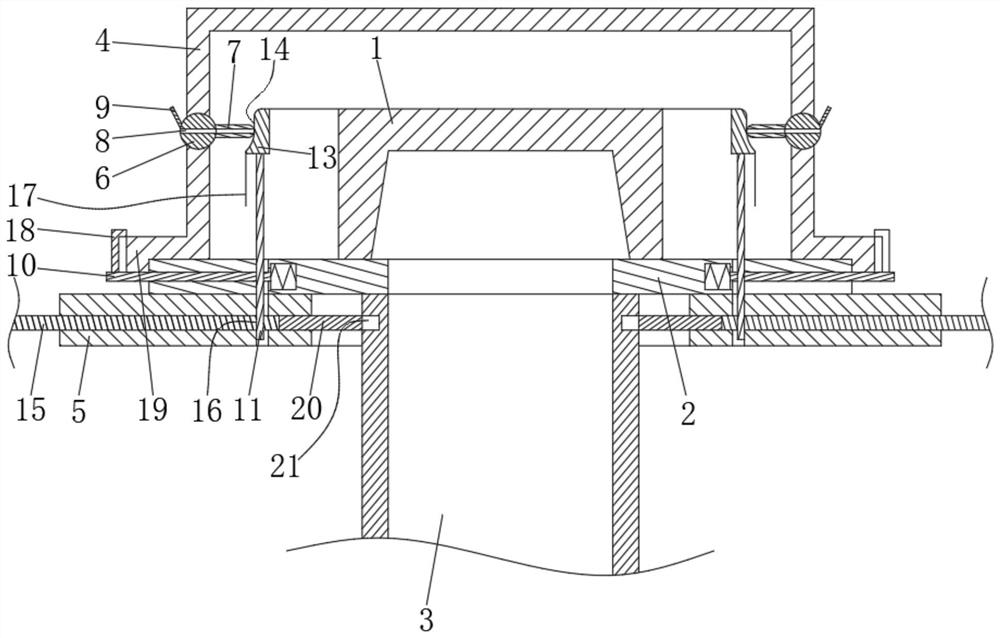

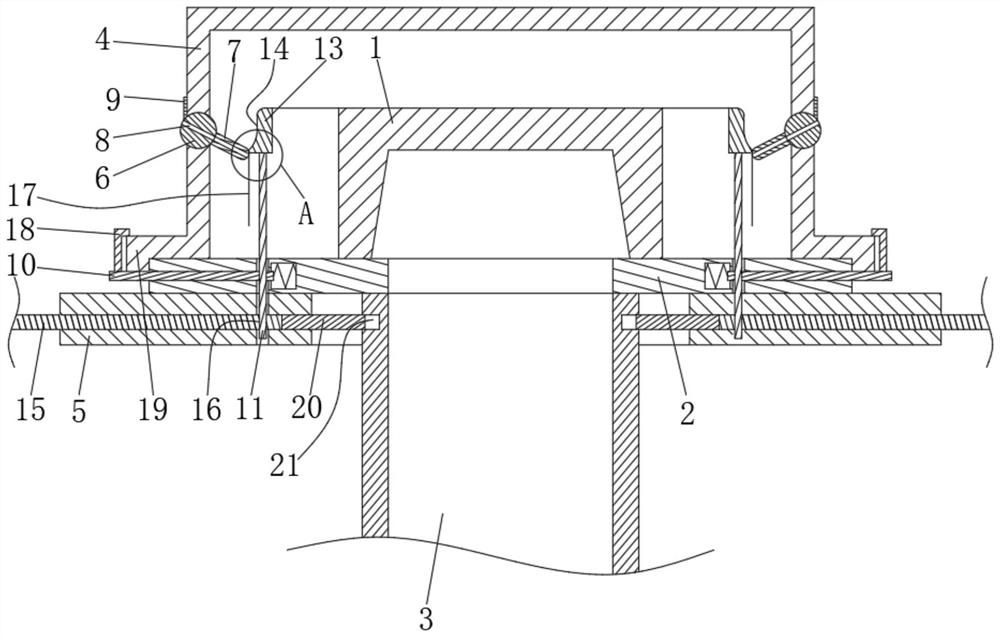

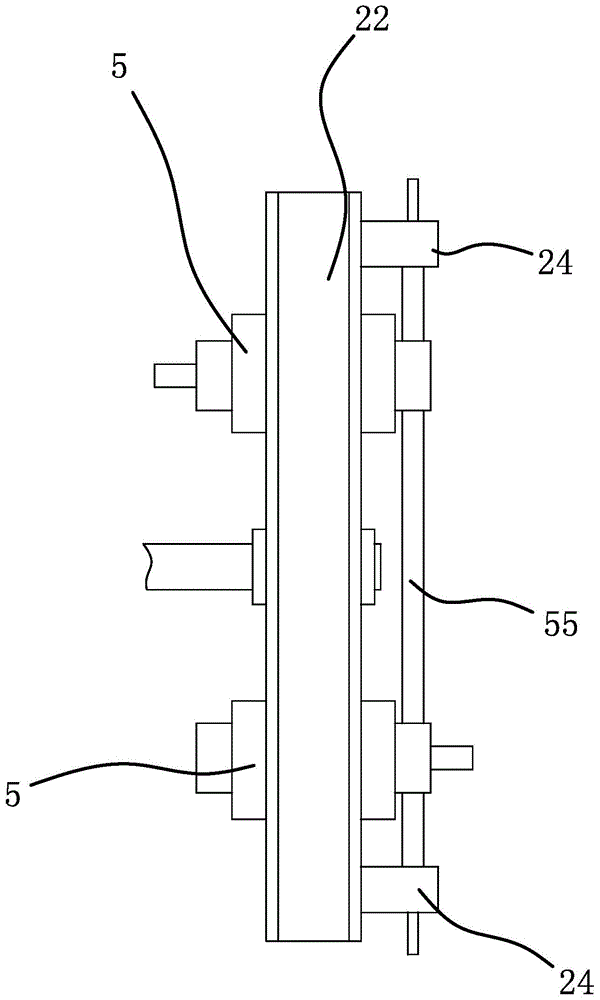

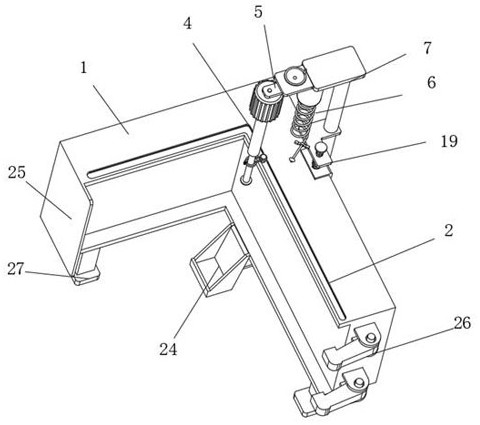

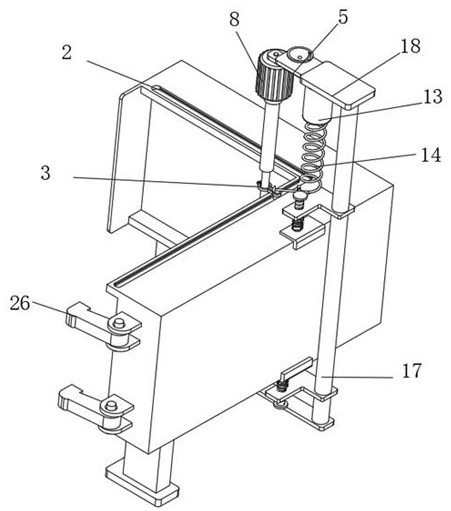

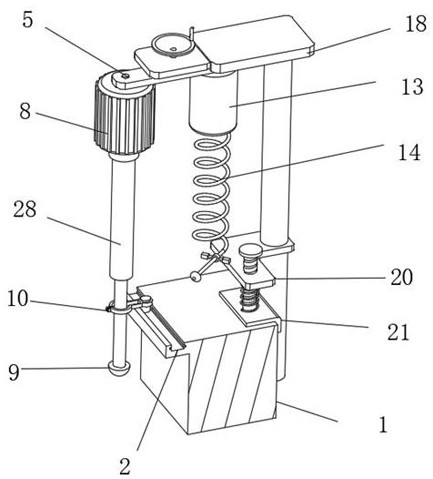

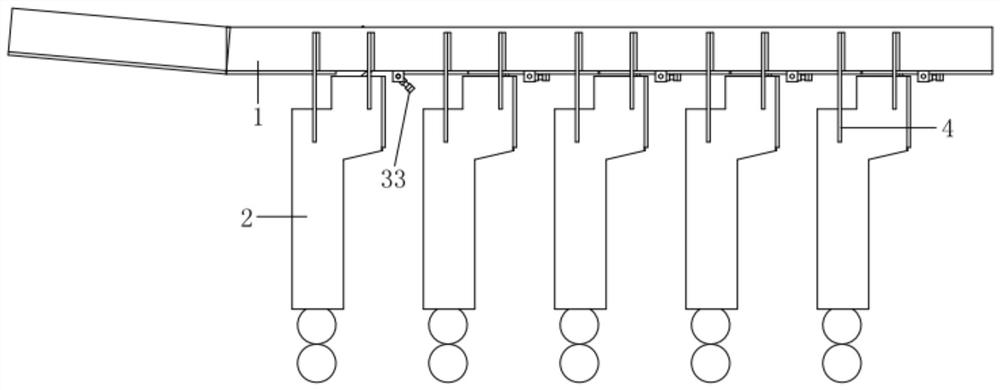

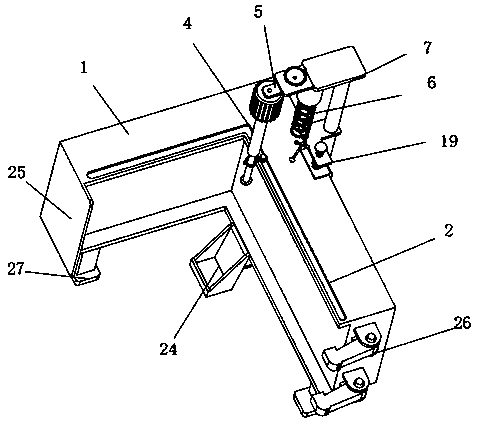

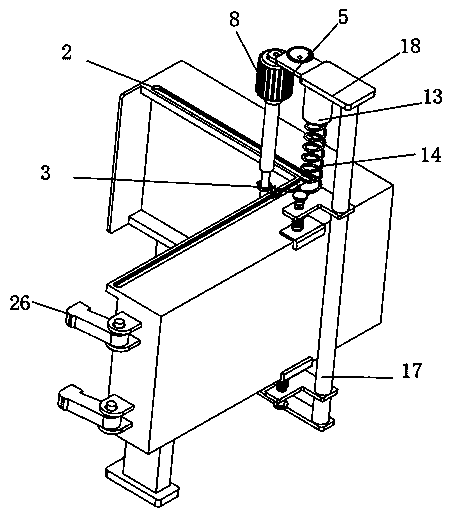

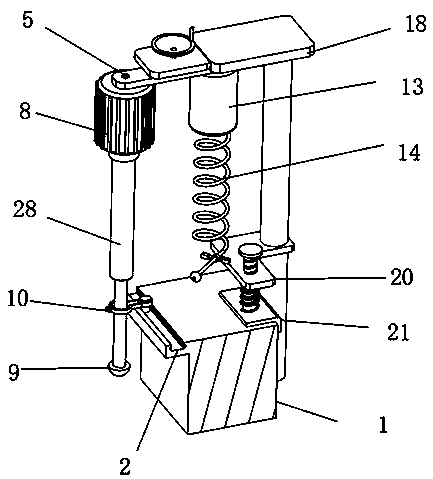

Multifunctional automatic gap filling machine

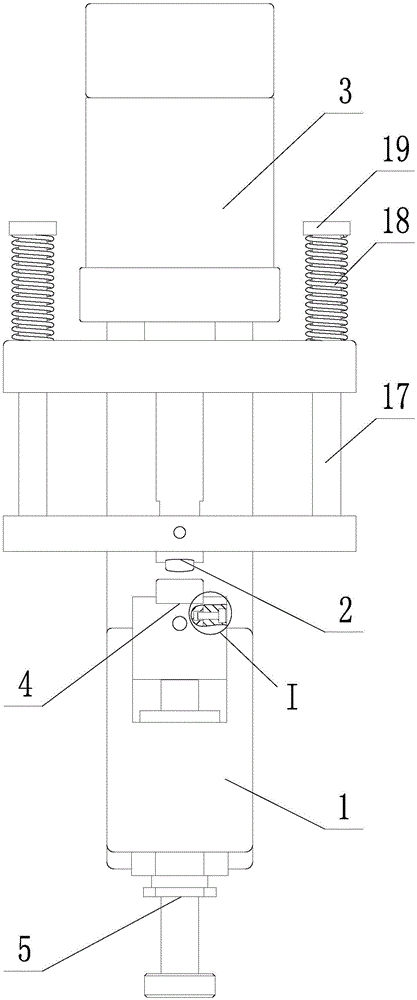

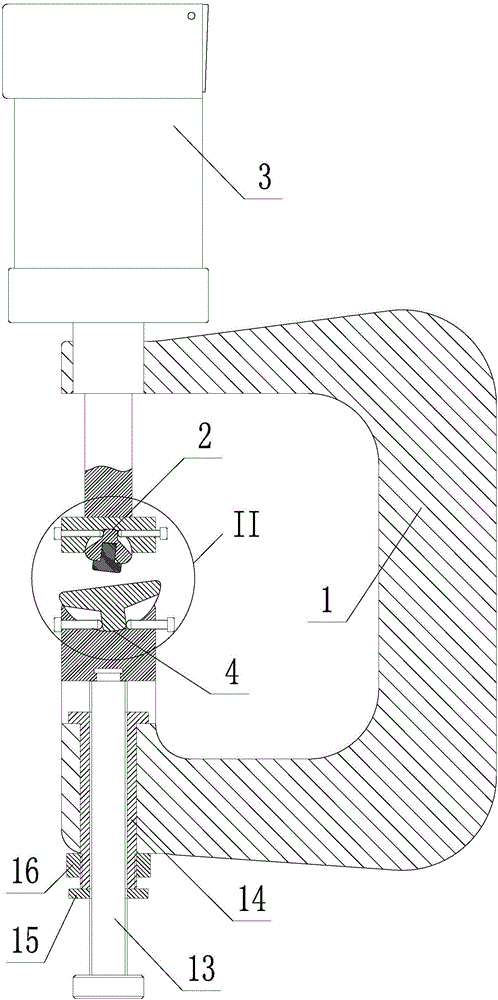

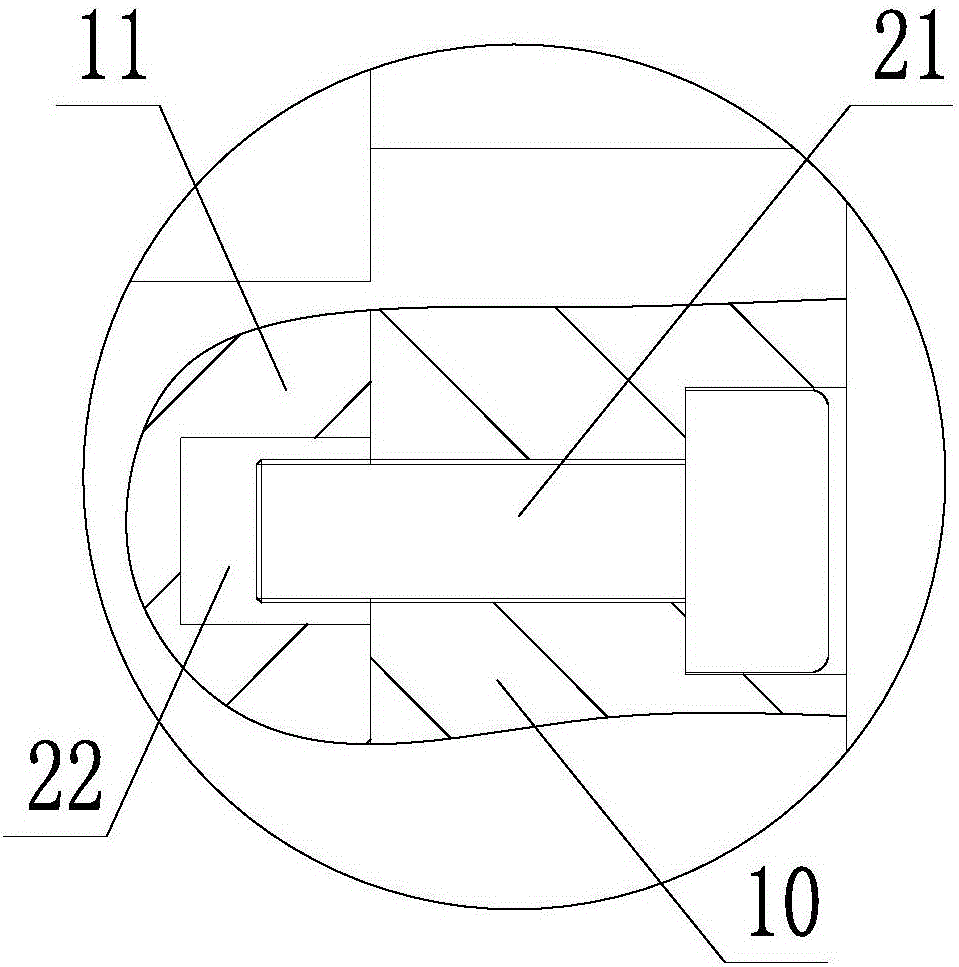

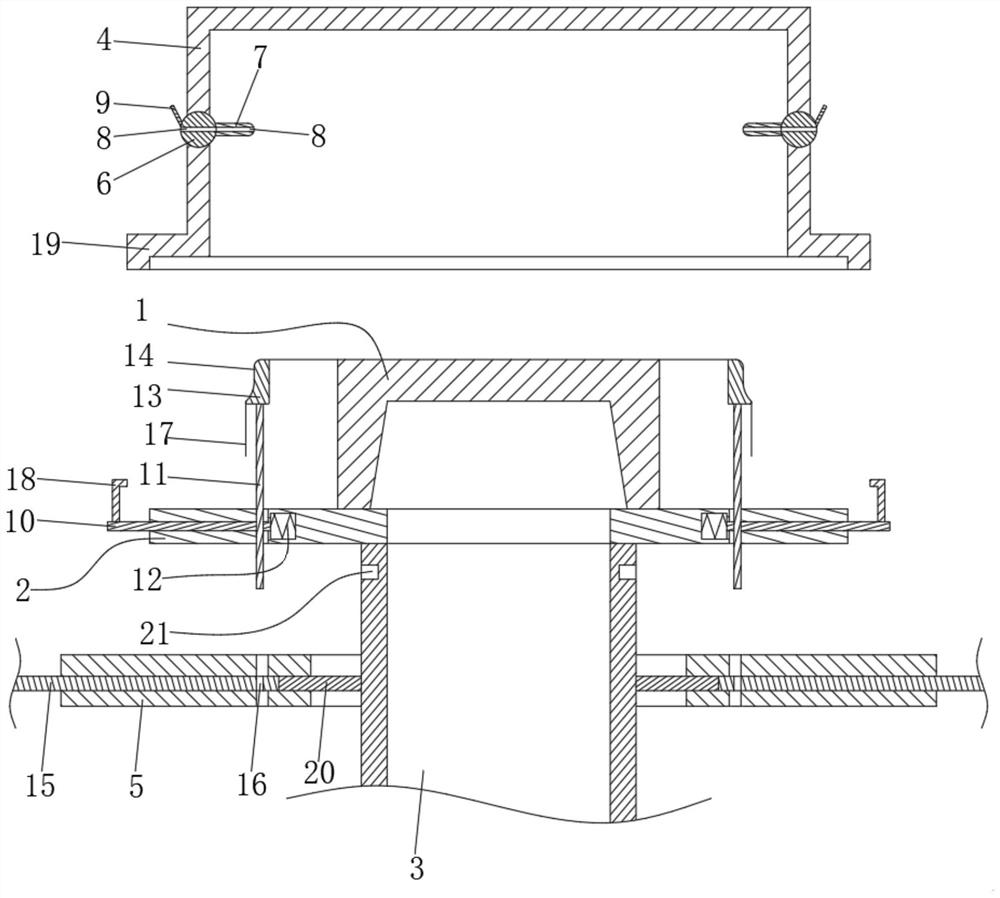

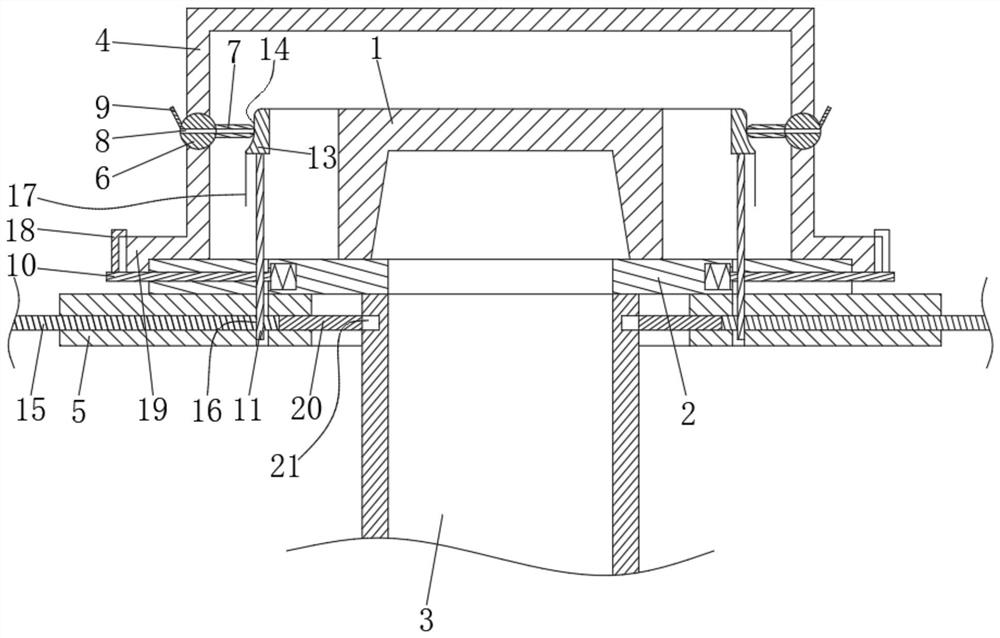

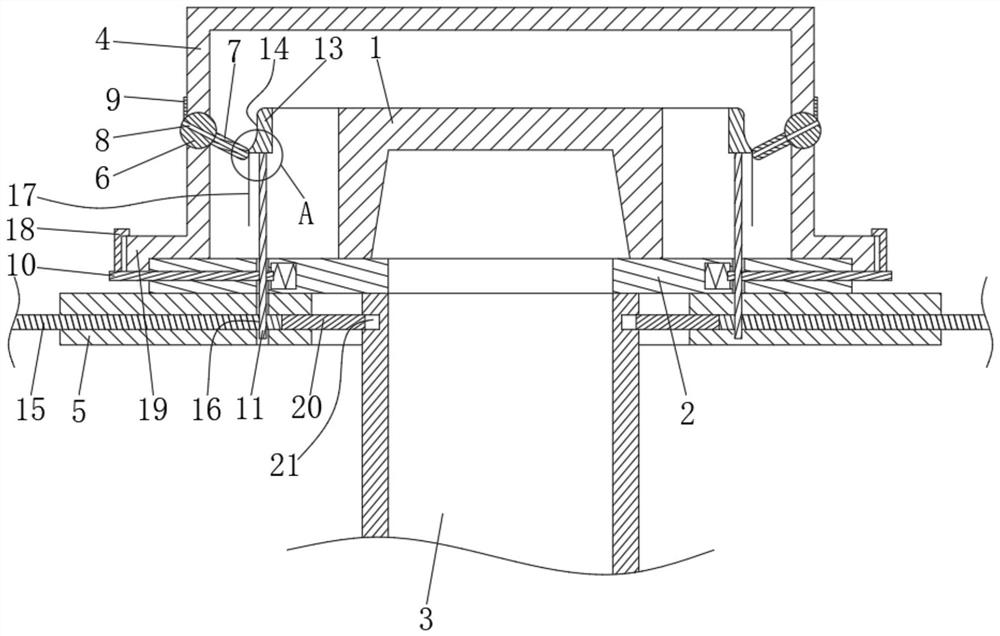

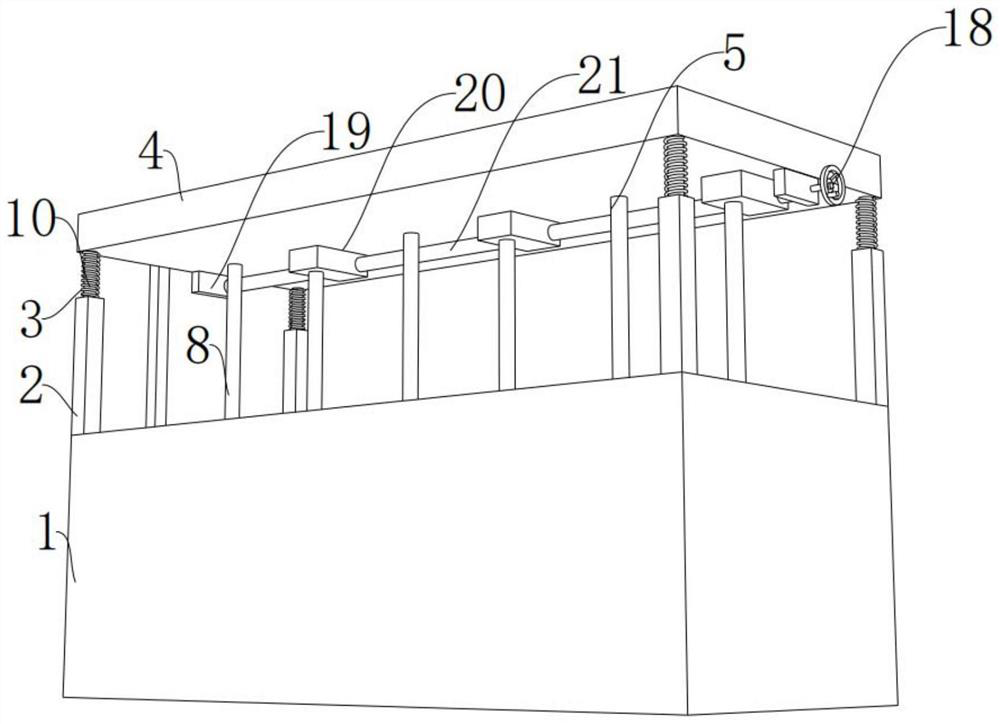

The invention provides a multifunctional automatic gap filling machine and belongs to the mechanical technical field. The multifunctional automatic gap filling machine solves the technical problems that an existing gap filling machine is complex in structure, difficult to operate and the like. The multifunctional automatic gap filling machine comprises a cart, a gap filling cylinder fixed on the cart and a storage barrel, wherein wheels of the car are connected with a rotary shaft; the rotary shaft is fixedly provided with a drive belt wheel; a driven belt wheel is rotationally connected to a fixing frame of the cart; the drive belt wheel can drive the driven belt wheel to rotate; the gap filling cylinder is vertically arranged under the drive belt wheel and comprises a cylinder body with two filling cavities and pistons arranged inside the filling cavities; the storage barrel is communicated with the two filling cavities; the lower end of the cylinder body is provided with two discharging nozzles communicated with the filling cavities respectively; through holes are formed in a bottom board of the cart; the discharging nozzles penetrate through the through holes; the two sides of the driven belt wheel are provided with push rods respectively; the hinged points of the two push rods and the driven belt wheel are symmetrically arranged along the center of the driven belt wheel; the lower ends of the two push rods are hinged to the two pistons respectively. The multifunctional automatic gap filling machine has the advantages of being simple in structure and high in construction speed.

Owner:台州普立德建筑科技有限公司

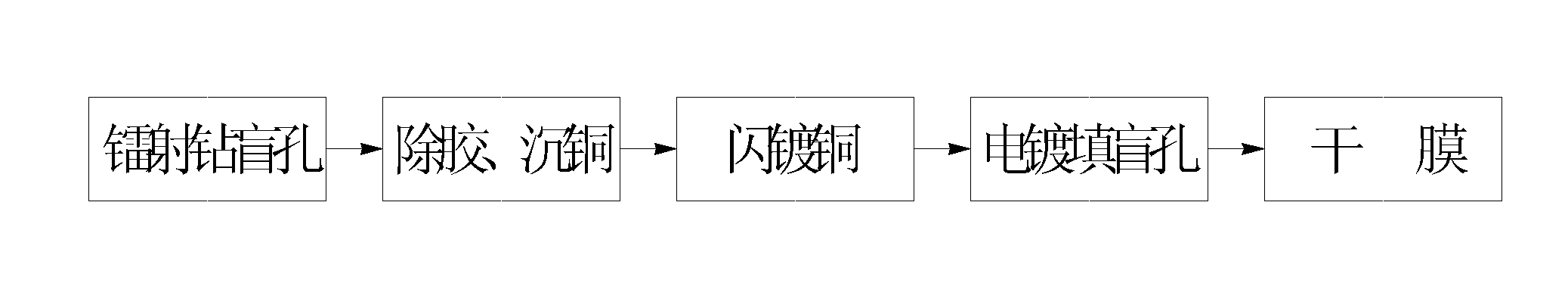

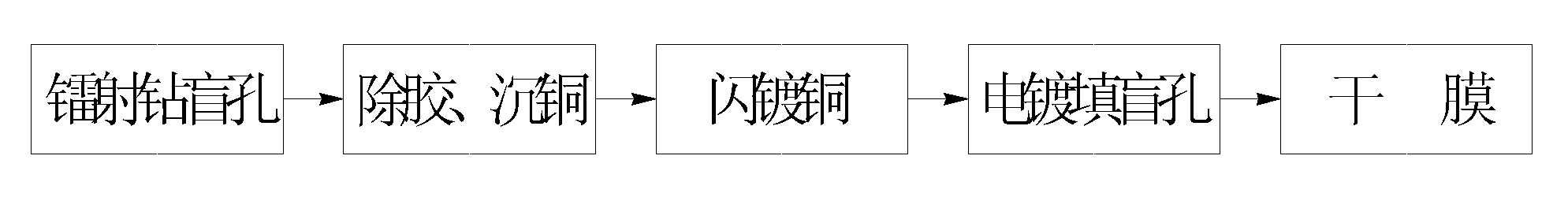

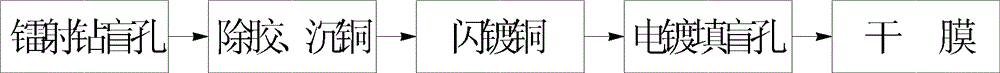

Blind via filling plating method using different current parameter combinations

ActiveCN102647862AShorten the timeIncrease productivityPrinted element electric connection formationAdhesiveSulfate

The invention discloses a blind via filling plating method using different current parameter combinations, which belongs to the field of circuit board plating technology. The blind via filling plating method comprises the steps of (1) removing adhesive, chemically depositing copper and flash-plating copper; (2) filling a blind via and plating; (3) drying film. The step (2) specifically includes regulating a plating solution to a solution containing high copper sulfate and low sulfuric acid content; and conducting plating for three periods of time using different current densities, wherein the plating operation is conducted for 30 minutes at the first period of time using a current density of 1.5 to 2.5 A / dm<2>, for 23 to 35 minutes at the second period of time using a current density of 1.2A / dm<2>, and for 10 to 20 minutes at the third period of time using a current density of 1.5 to 2.5A / dm<2>, respectively. The blind via filling plating method provided by the invention has high processing efficiency, low cost, and high processing quality, and is used for plating and blind via filling of circuit boards.

Owner:BOMIN ELECTRONICS CO LTD +1

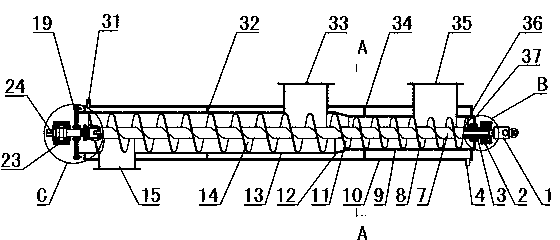

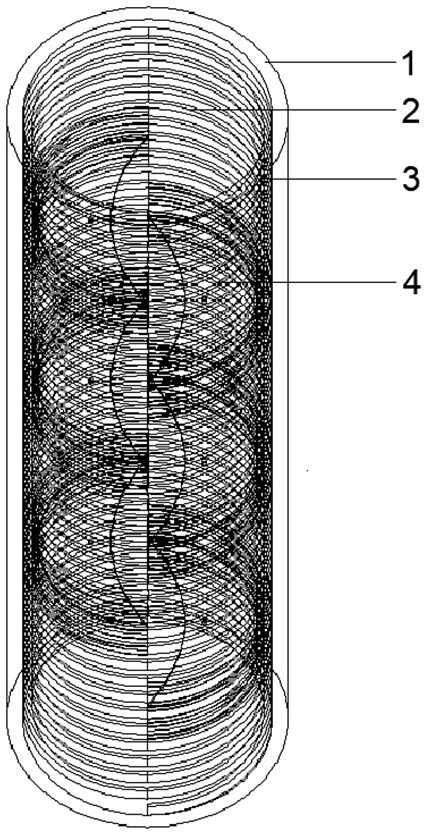

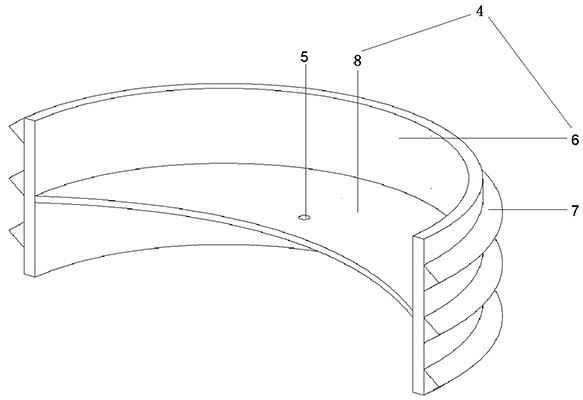

Semi coke waste heat recovery type spiral conveyer

ActiveCN104355071AAvoid dangerous accidentsTo achieve the purpose of full material deliveryStationary tubular conduit assembliesPackagingEngineeringCircular surface

The invention discloses a semi coke waste heat recovery type spiral conveyer, and belongs to the field of semi coke processing equipment. An inner cylinder body includes two or more inner cylinder body sections, a feeding port is communicated with the upper side at the conveying starting end of each inner cylinder body section, and a discharging port (15) is communicated with the lower side at the tail end of the last inner cylinder body section; the volume defined by a pitch screw blade of the N+1th inner cylinder body section, the external circular surface of a spiral base tube (7) and the internal circular surface of the N+1th inner cylinder body section is (N+1) / N plus or minus 1 / 5N times of the volume defined by a pitch screw blade inside the Nth inner cylinder body section, the external circular surface of the spiral base tube (7) and the internal circular surface of the Nth inner cylinder body section, wherein the N is an integer not smaller than 1 and not greater than 5. According to the invention, the fact that after semi coke inside the inner cylinder body section on the front side enters the inner cylinder body section on the rear side, semi coke at the feeding port of the inner cylinder body section on the rear side enters the inner cylinder body section on the rear side, and all the inner cylinder body sections are filled with material exactly is guaranteed, so that filled conveying is realized, and danger of gas leakage can be effectively avoided.

Owner:SHANDONG UNIV OF TECH

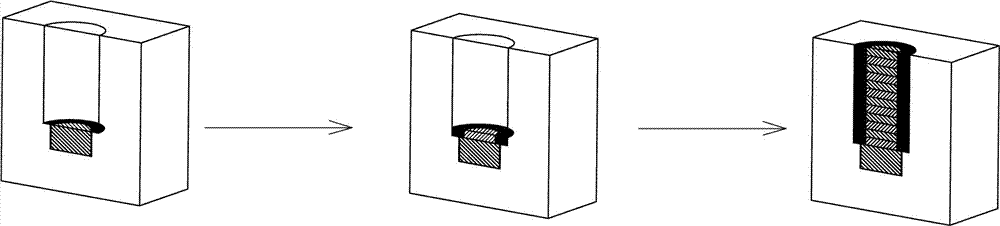

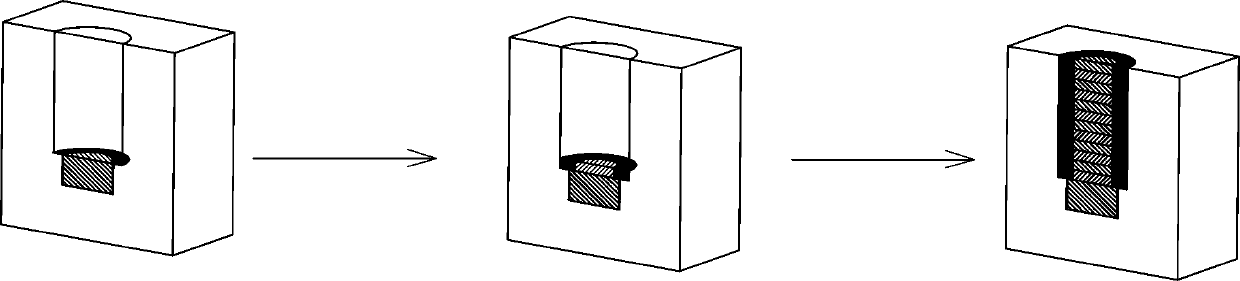

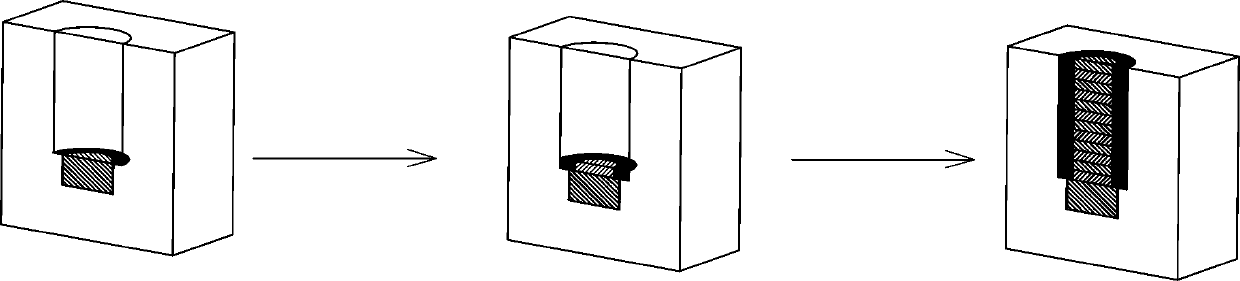

Threaded hole welding and repairing process

ActiveCN107498262AImprove repair efficiency and qualityReduce welding height and welding volumeSheet steelSurface finishing

The invention provides a threaded hole welding and repairing process. The threaded hole welding and repairing process comprises the following steps of material preparation, chambering, welding, surface treatment, drilling and tapping. According to the process, circular steel sheets are laid in an inner hole subjected to chambering to replace the bead welding quantity, bead welding in the small diameter of a thread is replaced with the circular sheets, the welding quality of the large diameter of the thread and the small diameter of the thread is guaranteed, and meanwhile it is guaranteed that the small diameter of the thread is filled with the circular steel sheets, so that positioning and construction are performed conveniently when redrilling is performed. By means of the process, the quality and efficiency of repair of a threaded hole can be improved, meanwhile welding deformation is lowered, and the threaded hole welding and repairing process is particularly suitable for welding and repairing of the deep threaded hole.

Owner:中国船舶重工集团柴油机有限公司

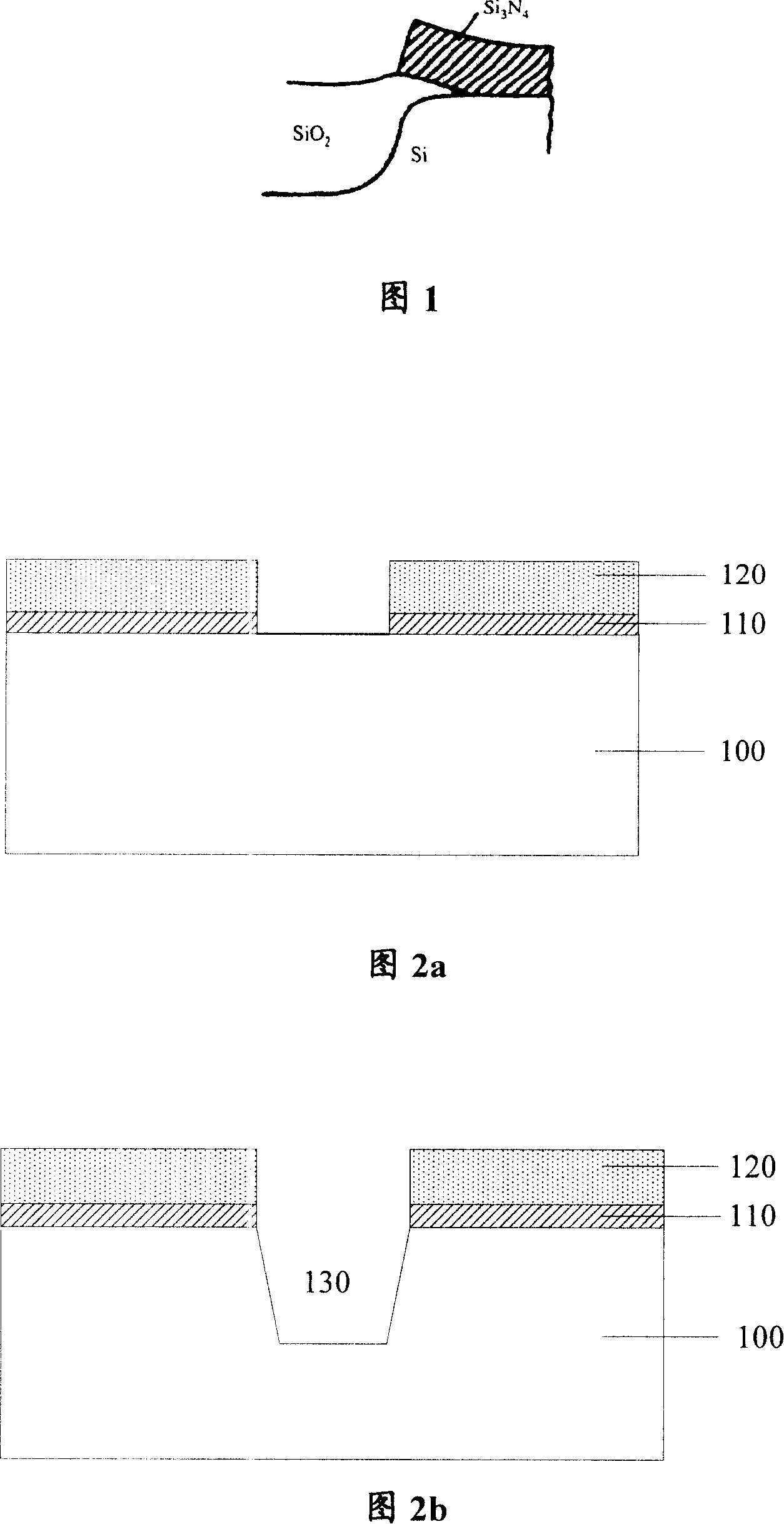

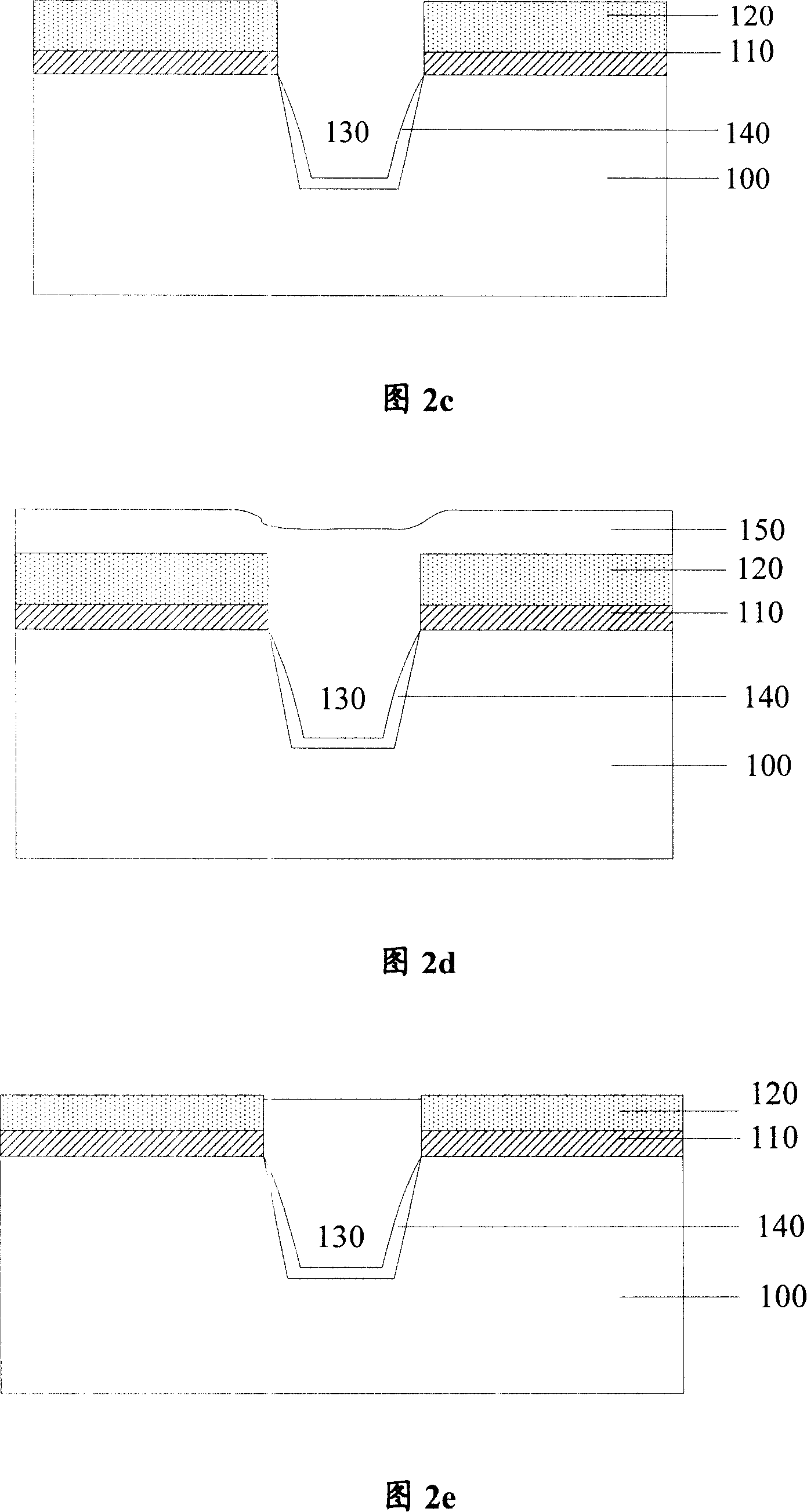

Method for forming isolation structure of shallow plough groove

InactiveCN101154616AOvercoming the pitfallsGuaranteed to be filledSemiconductor/solid-state device manufacturingSemiconductorCorrosion

A formation method for shallow groove isolation structure comprises the following steps that: a pad oxide layer and a corrosion barrier layer are orderly formed on a semiconductor basal plate, and the corrosion barrier layer, the pad oxide layer and the semiconductor basal plate are orderly defined to form a groove; a liner oxide layer is formed on the surface of the groove; an isolation oxide layer filling up the groove and covering the sidewalls of the pad oxide layer and the corrosion barrier layer is formed; the isolation oxide layer is flattened until the surface of the corrosion barrier layer is exposed; the corrosion barrier layer and the pad oxide layer are orderly removed; a rotary oxide layer is formed on the semiconductor basal plate and the isolation oxide layer to fill up the groove sidewall depressions of an isolation structure; the rotary oxide layer is removed until the semiconductor basal plate and the isolation oxide layer are exposed. The present invention avoids the defect of forming the depressions of the groove sidewall.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

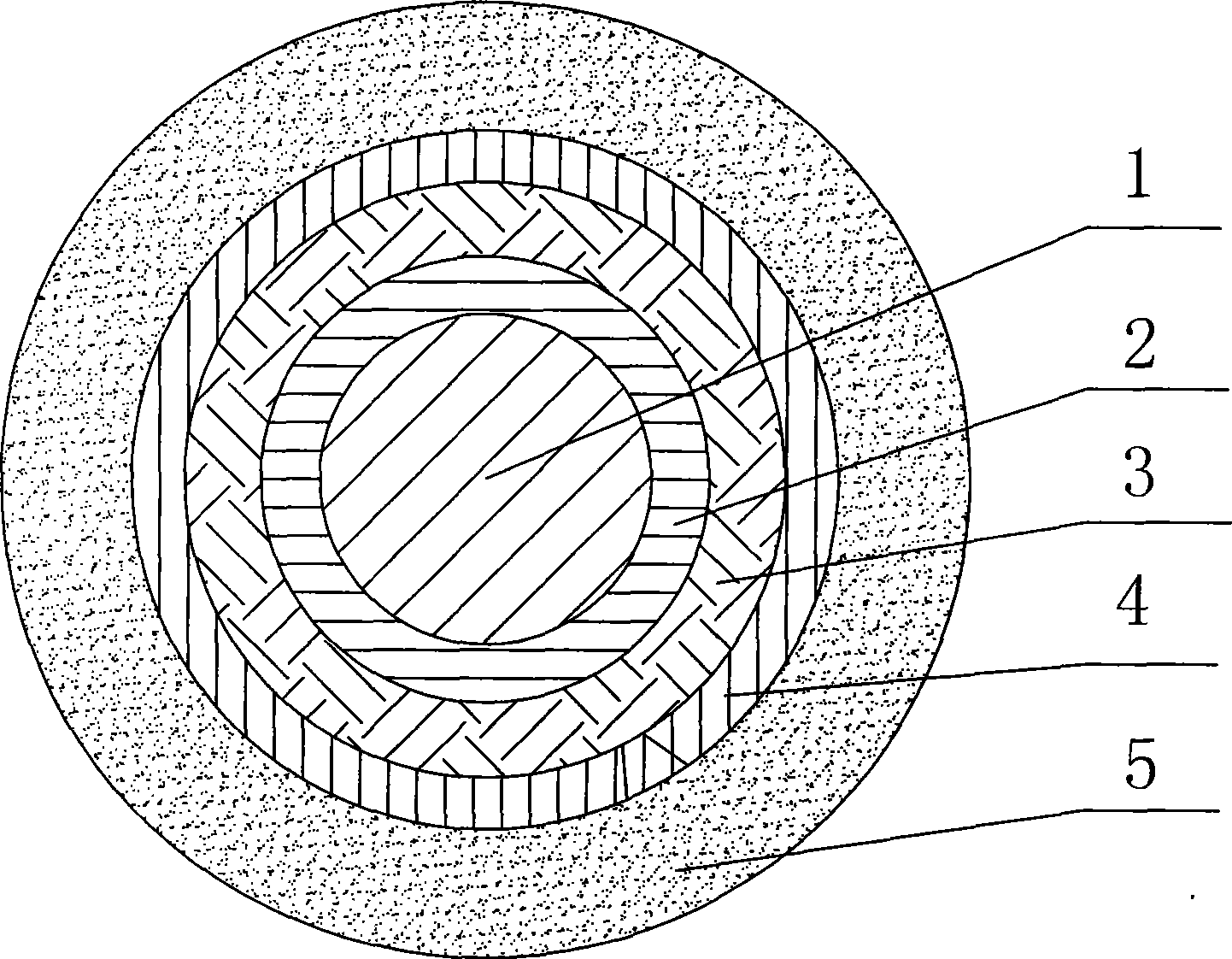

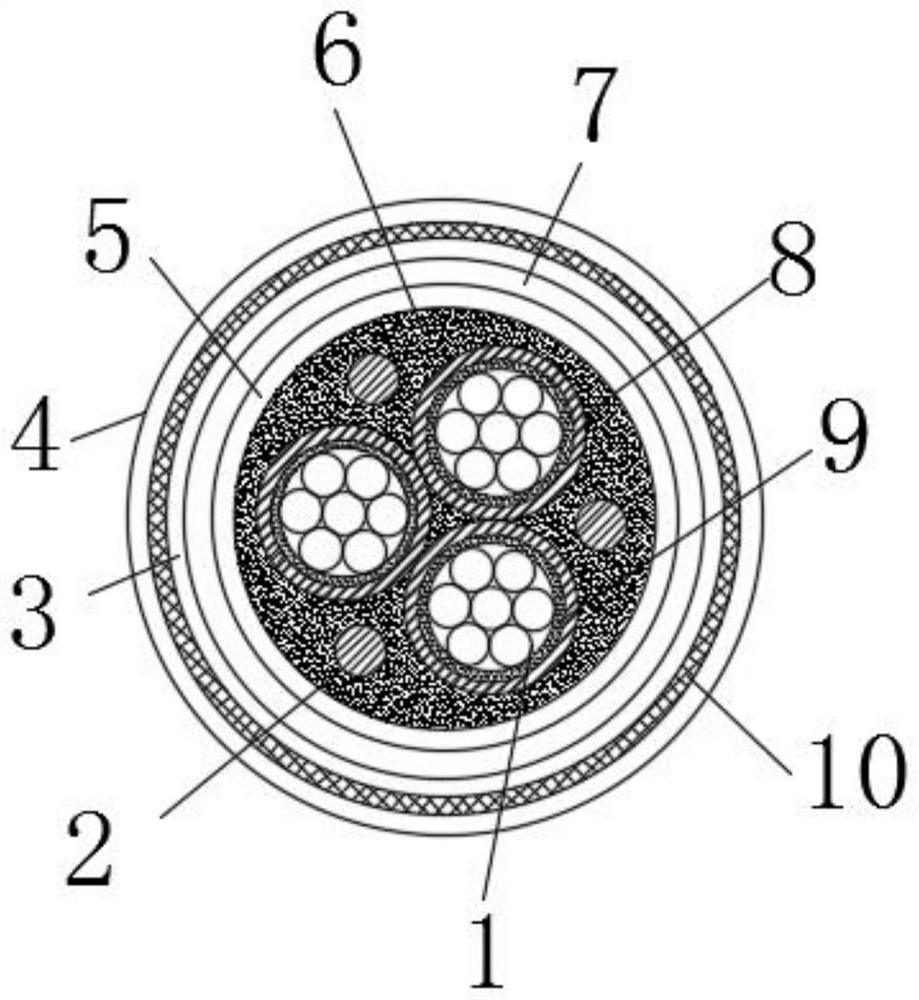

Novel flame resistant cable

InactiveCN101447252AScientific and reasonable structureSimple and compactInsulated cablesInsulated conductorsMicaElectrical conductor

The invention relates to a novel flame resistant cable, and belongs to the technical field of cables. The novel flame resistant cable comprises a conductor and a mica tape longitudinally wrapped on the conductor, an insulating layer extruded and wrapped and an outer sheath. The novel flame resistant cable is characterized in that a glass tape for tightening the mica tape is arranged on the mica tape; an inorganic insulating powder layer is arranged between the conductor and the mica tape; and the insulating layer is extruded and wrapped on the mica tape tightened. The invention has the advantages of scientific and reasonable structure, simpleness and compactness, easy production and manufacture and improved product quality, fire resistance rating, service performance and service life. The adhesion force between the conductor and the mica tape is improved under the condition that the tensile force of a covering machine is not increased, therefore, the phenomenon that the end surface of the cable is exposed from the conductor is avoided. Inorganic insulating powder is attached to the mica tape by an organic silicon biding agent and filled in the dish of the mica tape, so that the contact area between the conductor and the mica tape is enlarged and the adhesion force is enhanced. The inorganic insulating powder is also attached to the backing material surface of the mica tape; the insulating layer is extruded and wrapped after the glass tape is tightened on the mica tape, so that the contact area between of the mica tape and the insulating layer is enlarged.

Owner:BAOSHENG SCI & TECH INNOVATION

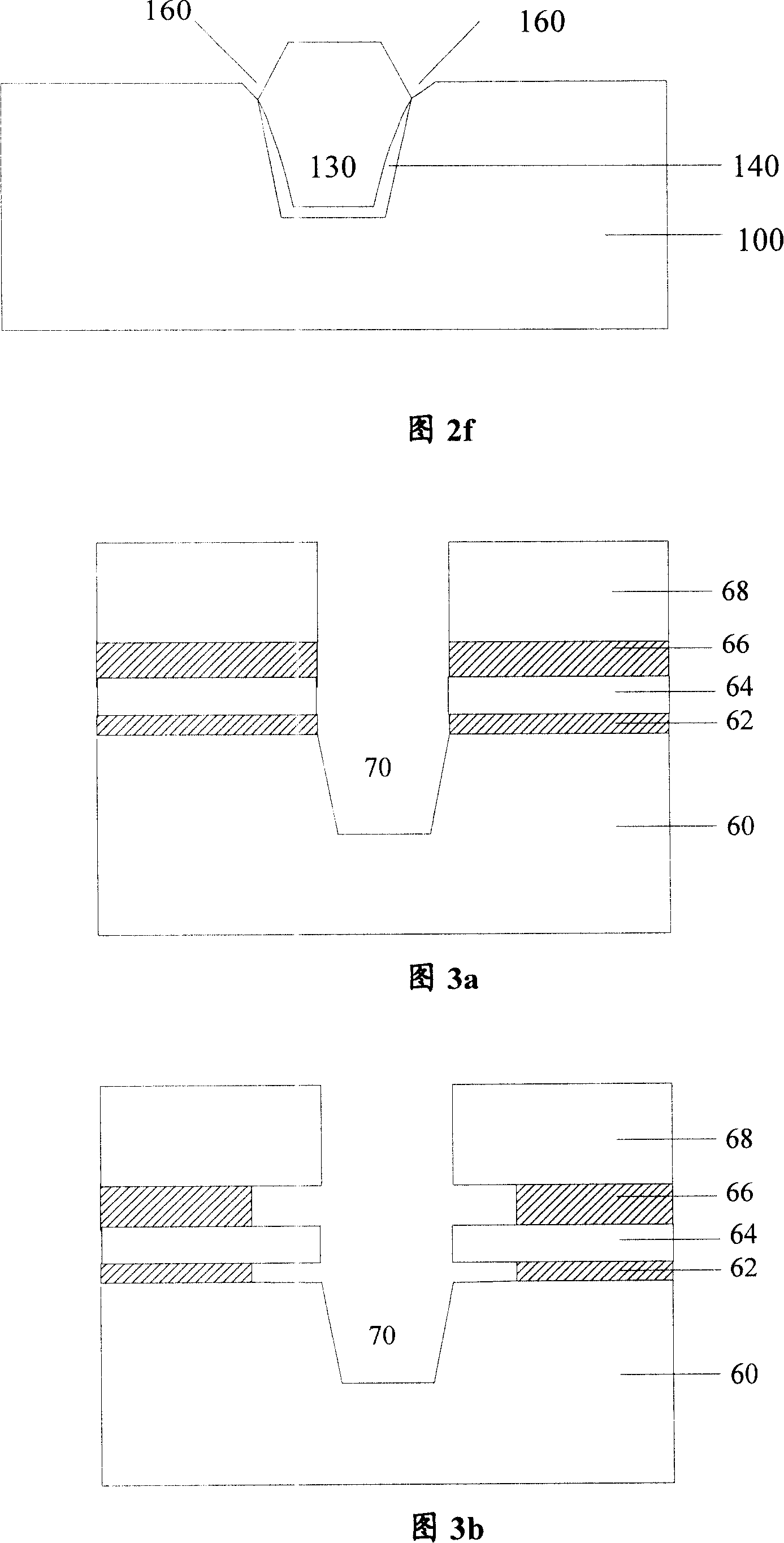

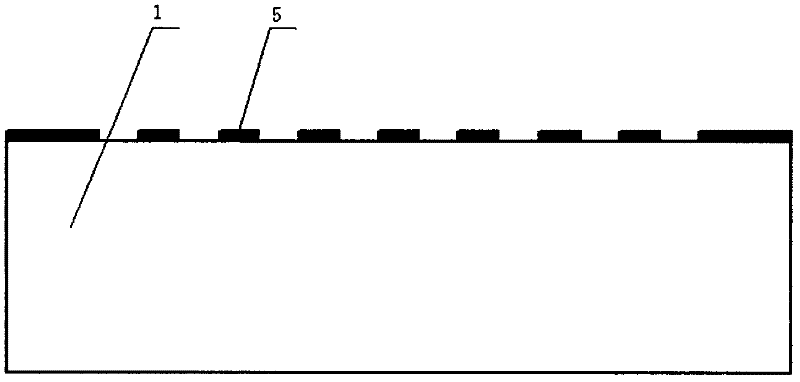

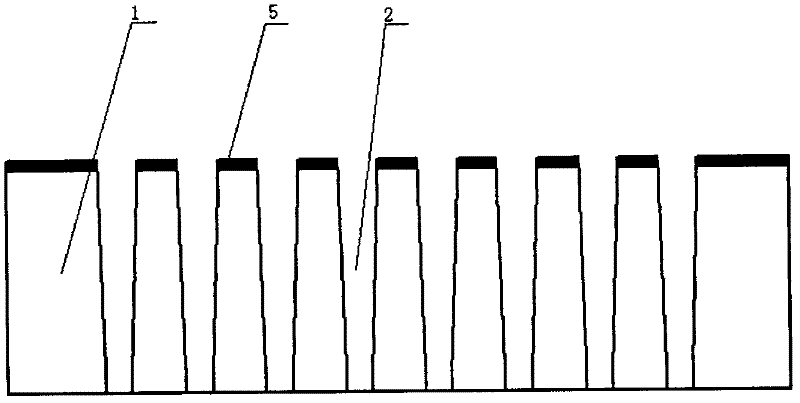

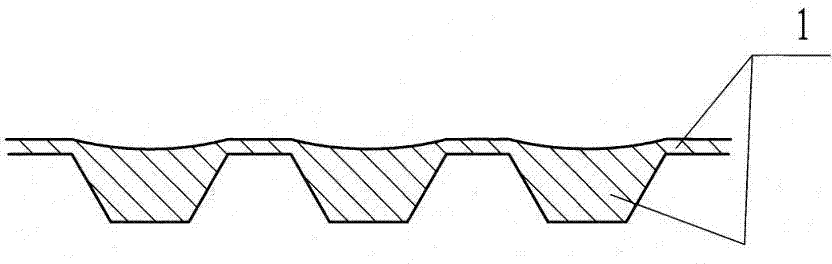

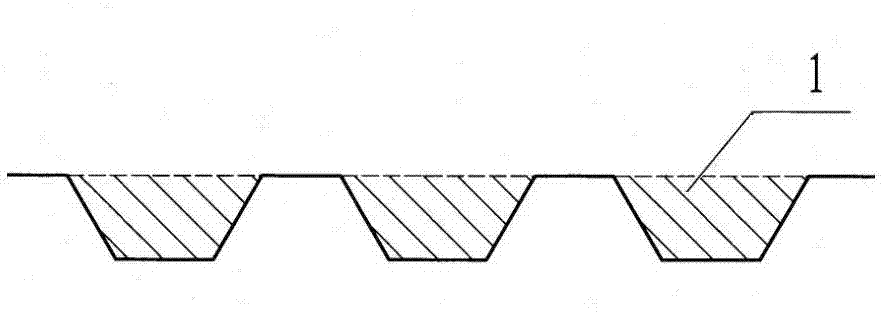

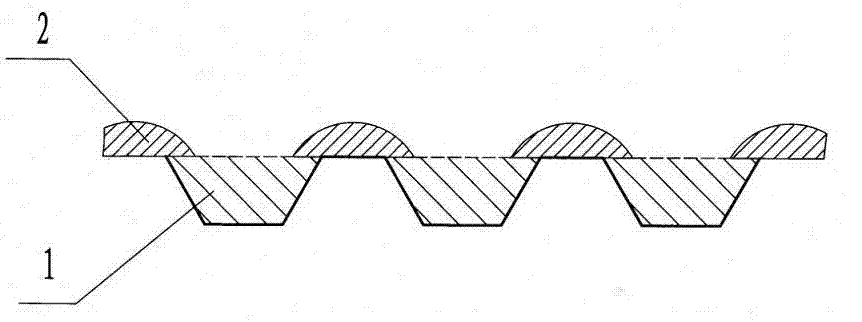

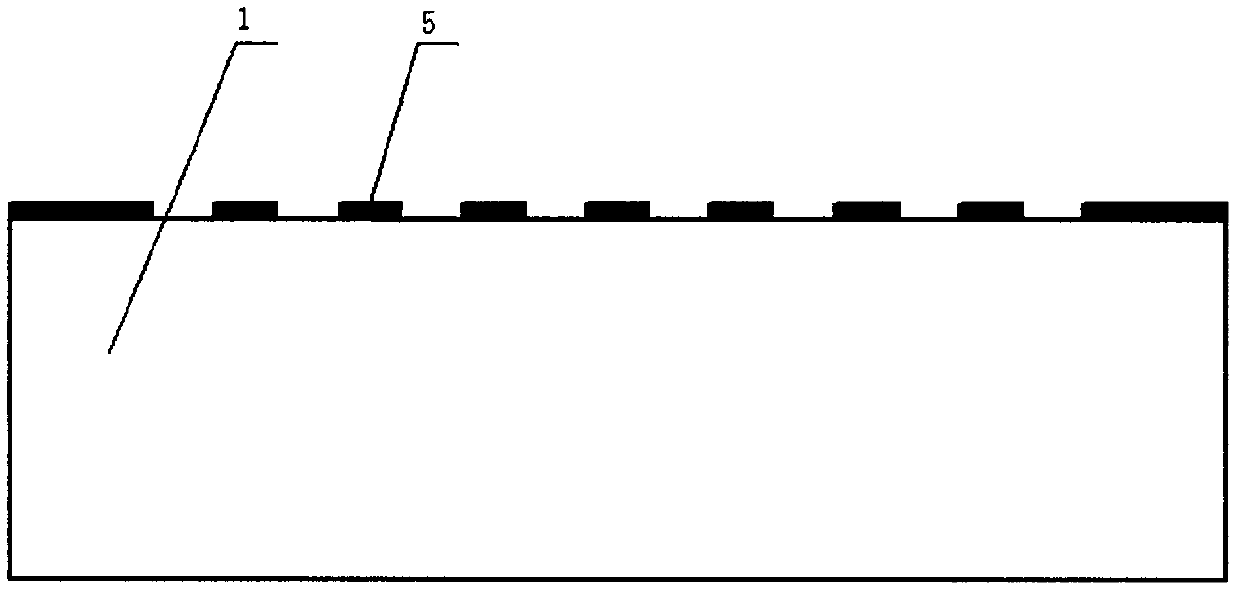

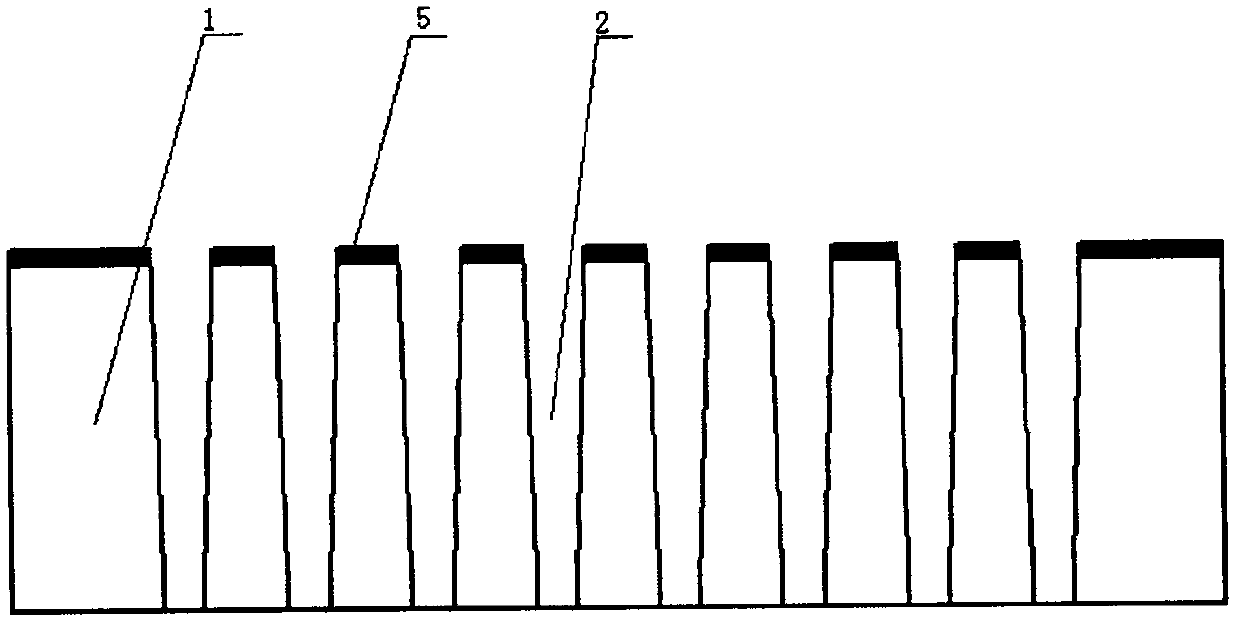

Preparation method for deep trench isolation channel

InactiveCN102344114AGuaranteed to be filledAvoid Notching PhenomenonDecorative surface effectsChemical vapor deposition coatingIsosceles trapezoidOxygen

The invention discloses a preparation method for a deep trench isolation channel, aiming at the requirements of mechanical connection but electrical insulation in MEMS (Micro Electro Mechanical System) technology. The method comprises the following steps of: polishing a silicon wafer; photo-etching; performing DRIE (Deep Reactive Ion Etching) to form a deep channel 2, wherein the deep channel 2 has an inverted isosceles trapezoid shape, and an included angle theta between a side wall of the channel and vertical direction is greater than or equal to 1 degree and is less than or equal to 5 degrees; cleaning with oxygen; generating a silicon dioxide insulating layer 3 on the surface of the side wall of the deep channel 2 and the surface of the silicon wafer; and filling a polycrystalline silicon layer 4. The preparation method has the beneficial effects that: the silicon wafer is etched into the inverted trapezoidal deep trench isolation channel by using DRIE; Notching phenomenon in isotropic etching is avoided; and the filling of the bottom of the deep channel can be guaranteed. Since the deep channel has the inverted trapezoid shape, an open part is still larger than the middle part of the channel, and the situation of a gap caused by blockage of the open part is also avoided during deposition of polycrystalline silicon. Since the included angle between the side wall of an oblique channel and the vertical direction is smaller, insulating characteristic and mechanical strength of the isolation channel are not influenced, and packaging air-tightness and insulation requirement can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

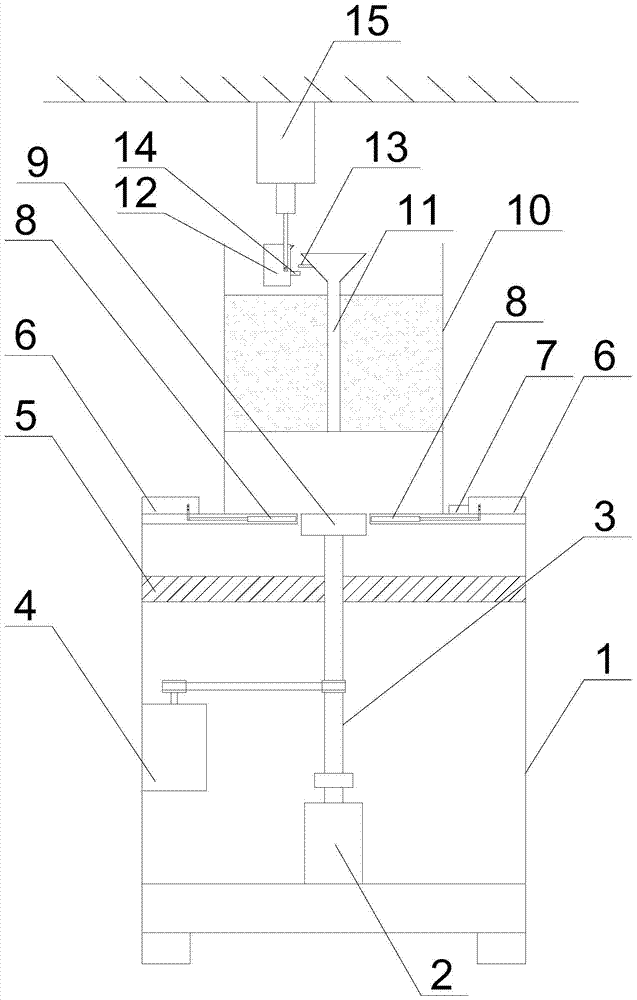

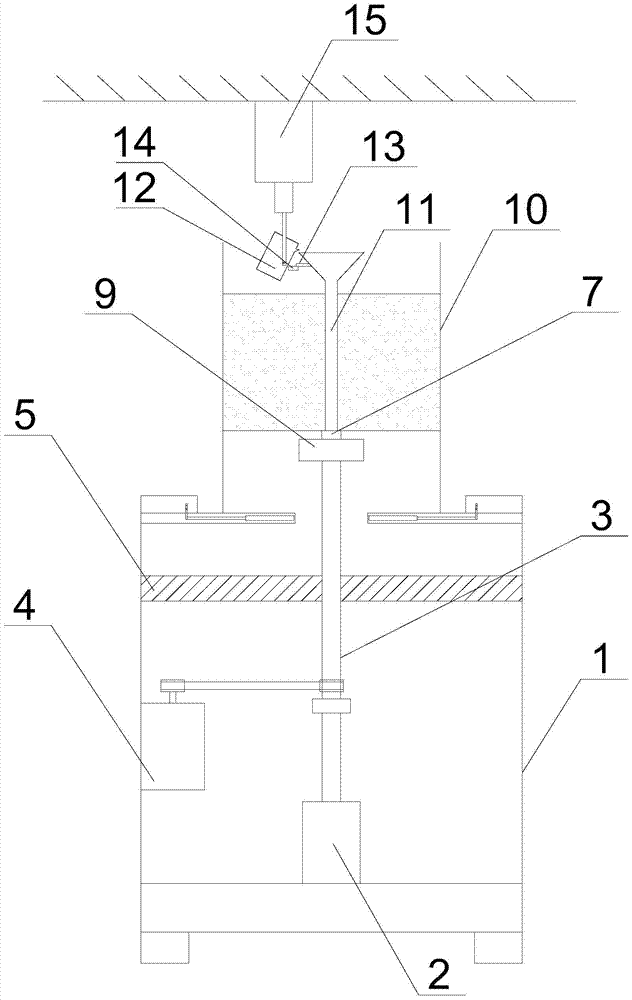

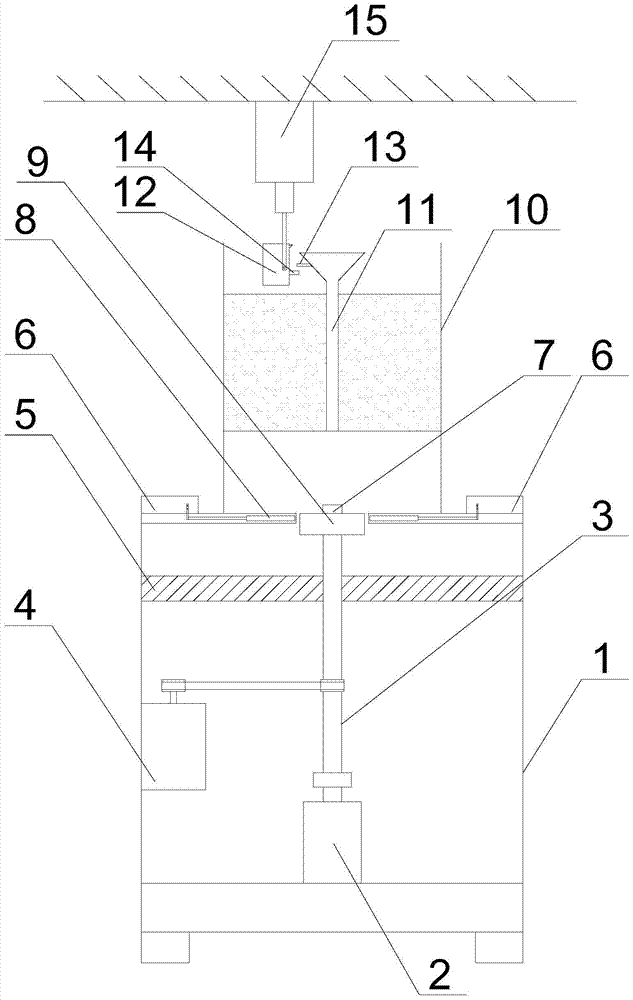

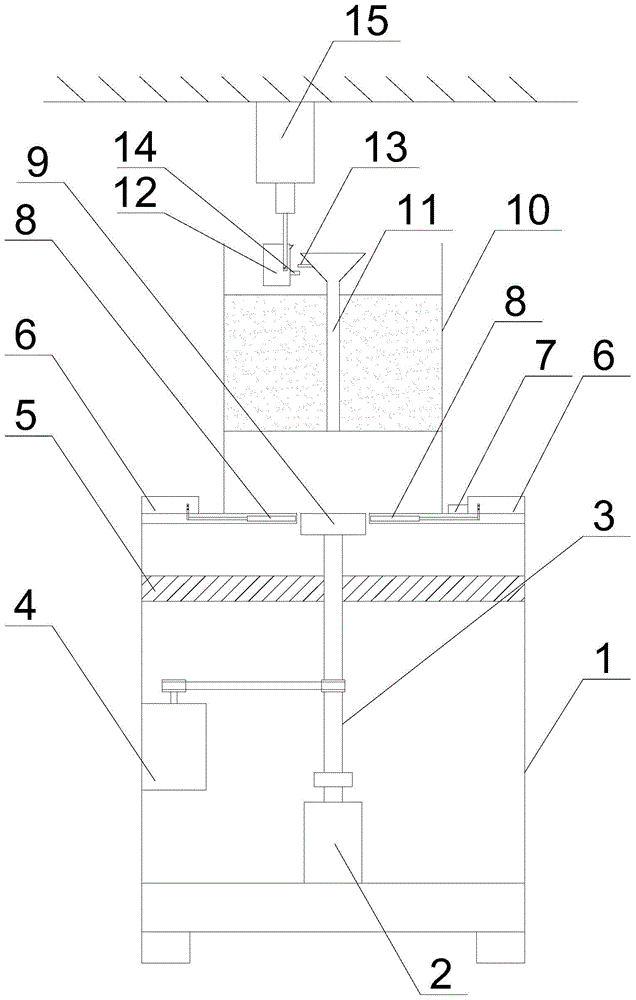

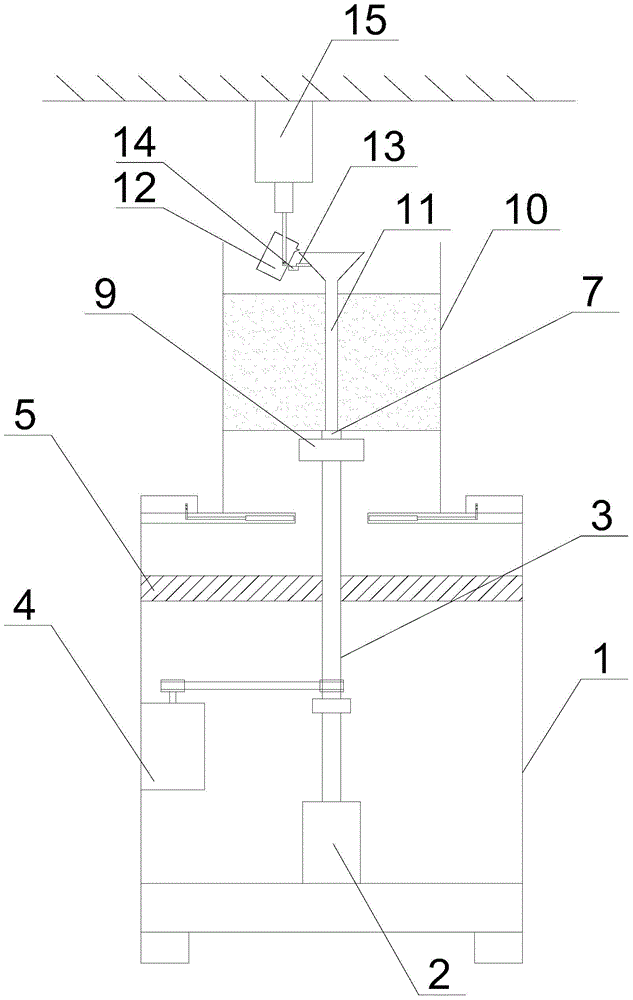

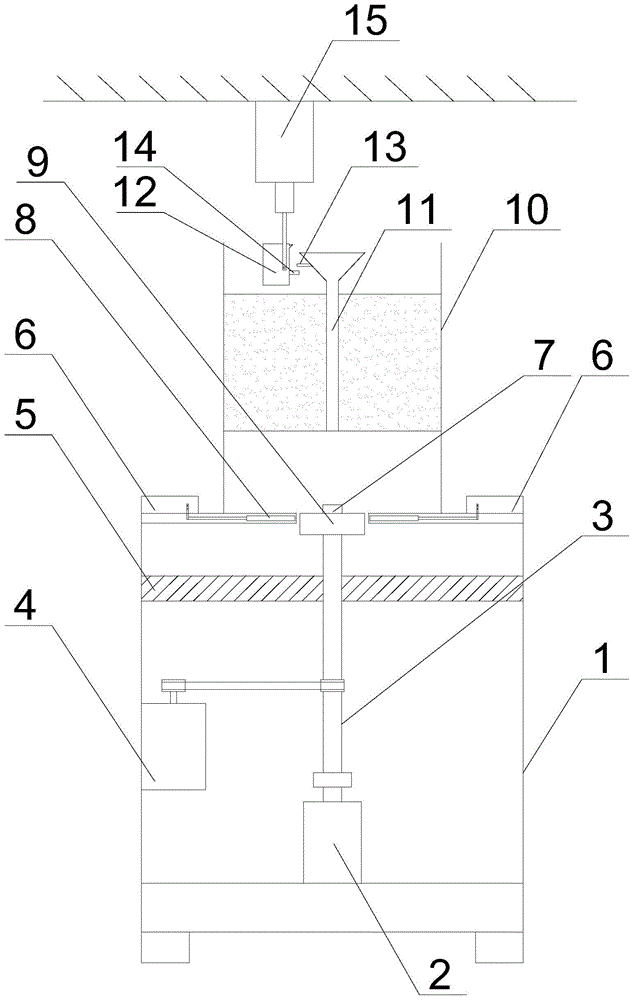

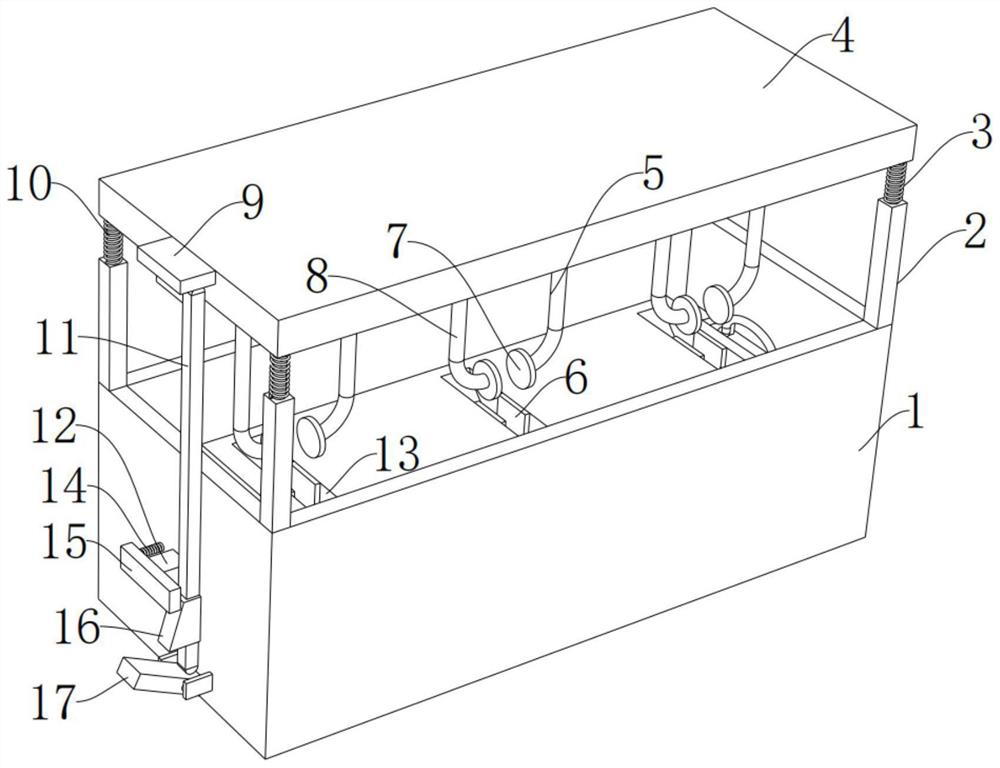

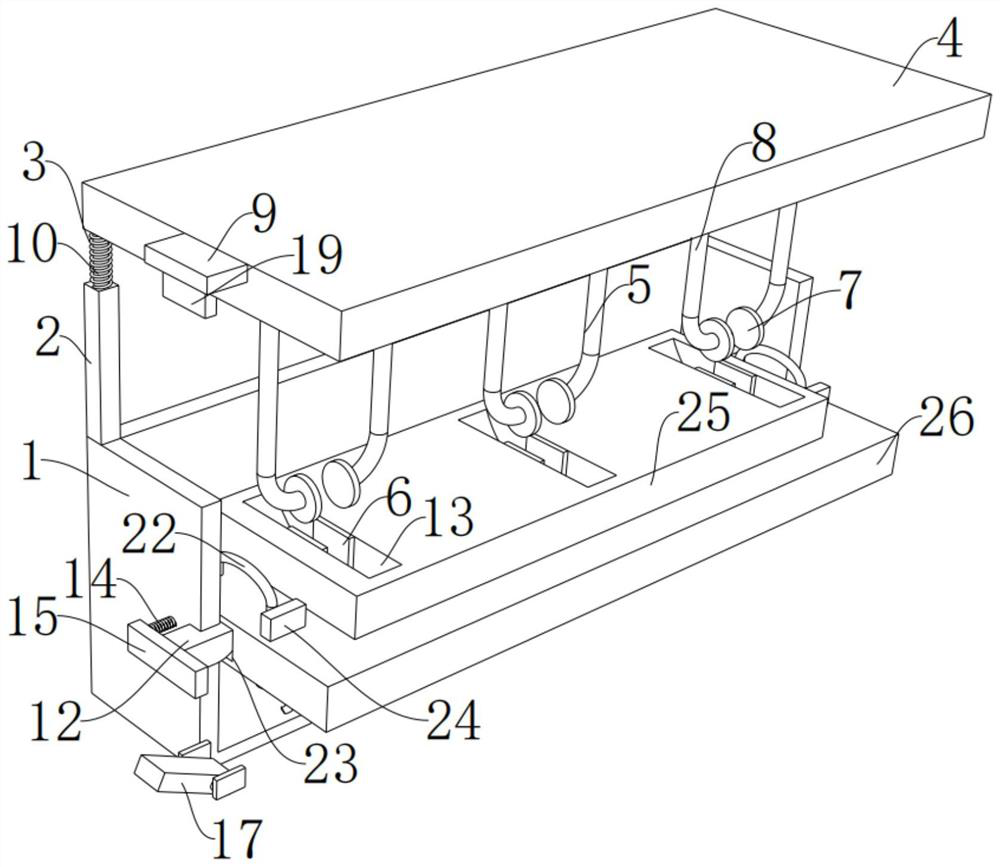

a casting equipment

ActiveCN104588626BImprove casting effectImprove operational flexibilityMolten metal conveying equipmentsCastingInertia

The invention discloses a casting method and casting equipment for implementing the casting method. The method comprises the steps of S1, pouring casting liquid into a mold through a pouring gate arranged on the mold; S2, enabling the casting liquid to fully fill a casting cavity of the mold through movement of the mold; S3, cooling and solidifying the casting liquid to form a casting blank. The equipment comprises a mold, a pouring device and a movement device, wherein the mold is provided with a casting cavity and a pouring gate and the casting cavity is communicated with the pouring gate; the pouring device is used for preparing casting liquid and pouring the casting liquid into the pouring gate; the mold is installed on the movement device, the movement device is driven by a movement drive mechanism to drive the mold to move, and the casting liquid in the casting cavity fully fills the casting cavity through inertia thereof. The casting method and the casting equipment for implementing the casting method have the beneficial effects that the casting liquid in the casting cavity fully fills the entire casting cavity under the effect of inertial force through the movement of the mold under the drive of the movement device and the casting effect is good.

Owner:山西建邦集团铸造有限公司

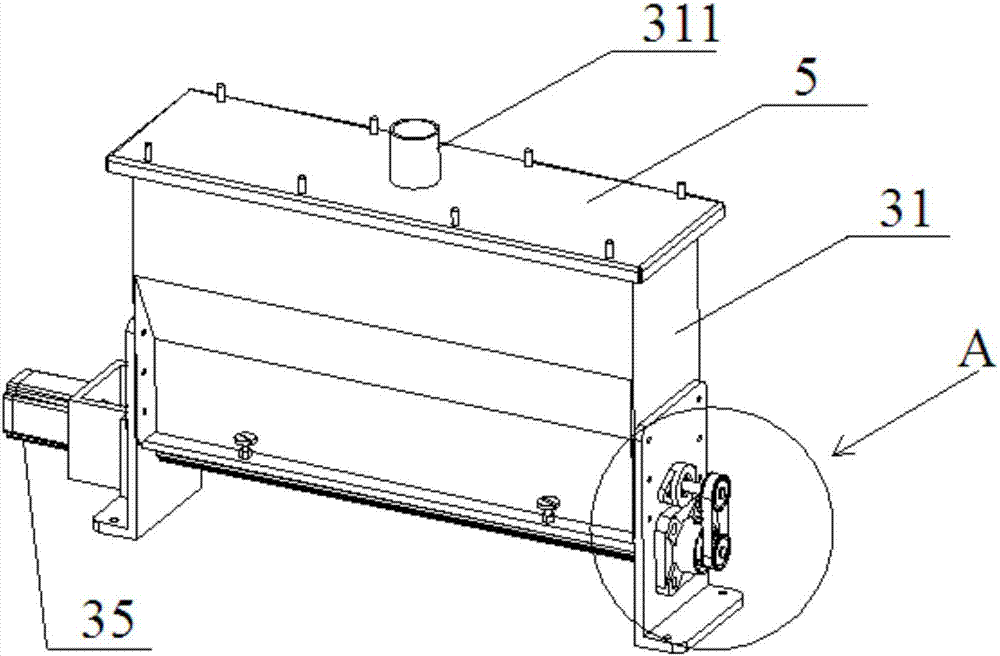

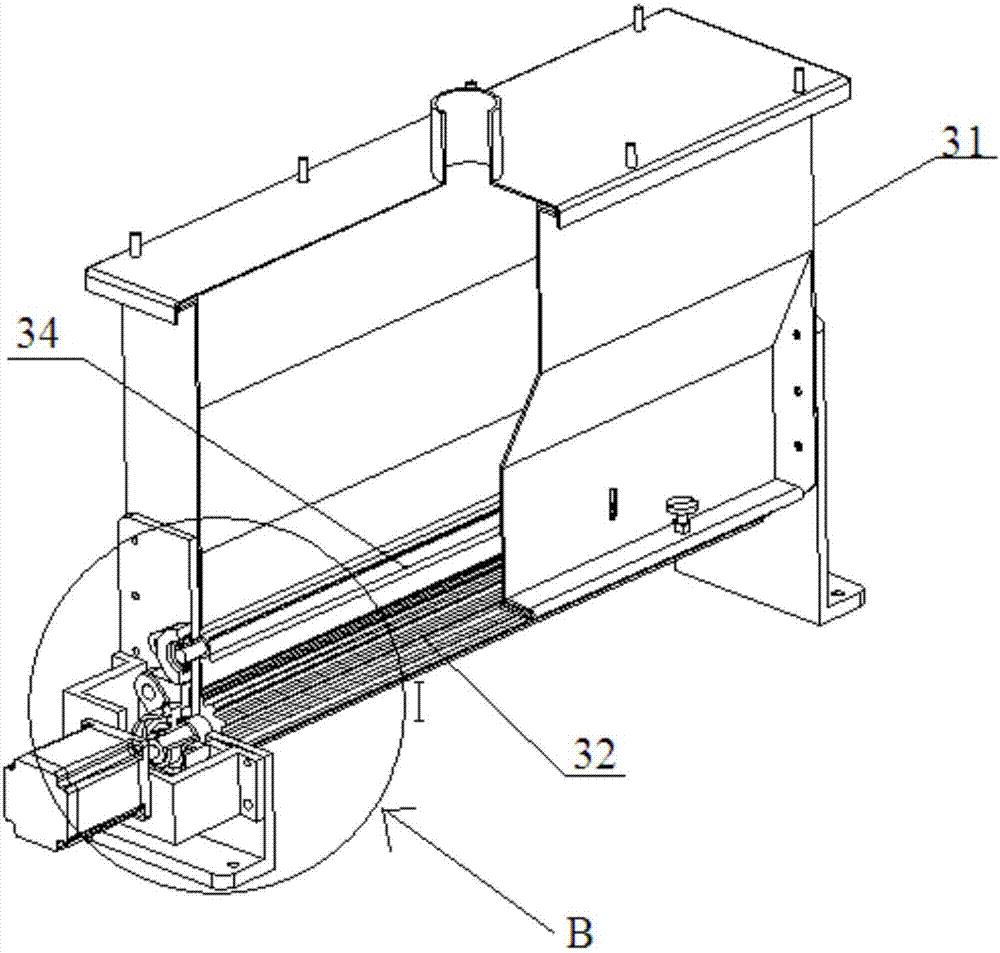

Equipment for manufacturing three-dimensional object and powder feeding device thereof

ActiveCN107952955AEnsure powder feeding stabilitySmooth entryAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgy

The invention provides equipment for manufacturing a three-dimensional object and a powder feeding device thereof. The powder feeding device comprises a powder feeding box provided with a bottom opening, a powder driver, a roller provided with a plurality of grooves and a driving mechanism for driving the roller to move rotatably, wherein the powder driver is arranged in the powder feeding box, the roller is arranged at the bottom opening of the powder feeding box, and powder in the powder feeding box falls from a groove of the roller under the action of the powder driver as the roller is tightly matched with the bottom opening of the powder feeding box so as to feed powder. Under the action of the powder driver, the mobility of the powder is enhanced, and an effect of applying pressure downward is achieved. Therefore, the powder can fall into the groove of the roller more continuously, so that the it is further ensured that the groove is filled with powder, and therefore, the powder feeding stability is guaranteed by means of the equipment for manufacturing the three-dimensional object and the powder feeding device thereof.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Casting method and casting equipment for implementing casting method

ActiveCN104588626AImprove casting effectImprove operational flexibilityMolten metal conveying equipmentsCastingInertia

The invention discloses a casting method and casting equipment for implementing the casting method. The method comprises the steps of S1, pouring casting liquid into a mold through a pouring gate arranged on the mold; S2, enabling the casting liquid to fully fill a casting cavity of the mold through movement of the mold; S3, cooling and solidifying the casting liquid to form a casting blank. The equipment comprises a mold, a pouring device and a movement device, wherein the mold is provided with a casting cavity and a pouring gate and the casting cavity is communicated with the pouring gate; the pouring device is used for preparing casting liquid and pouring the casting liquid into the pouring gate; the mold is installed on the movement device, the movement device is driven by a movement drive mechanism to drive the mold to move, and the casting liquid in the casting cavity fully fills the casting cavity through inertia thereof. The casting method and the casting equipment for implementing the casting method have the beneficial effects that the casting liquid in the casting cavity fully fills the entire casting cavity under the effect of inertial force through the movement of the mold under the drive of the movement device and the casting effect is good.

Owner:山西建邦集团铸造有限公司

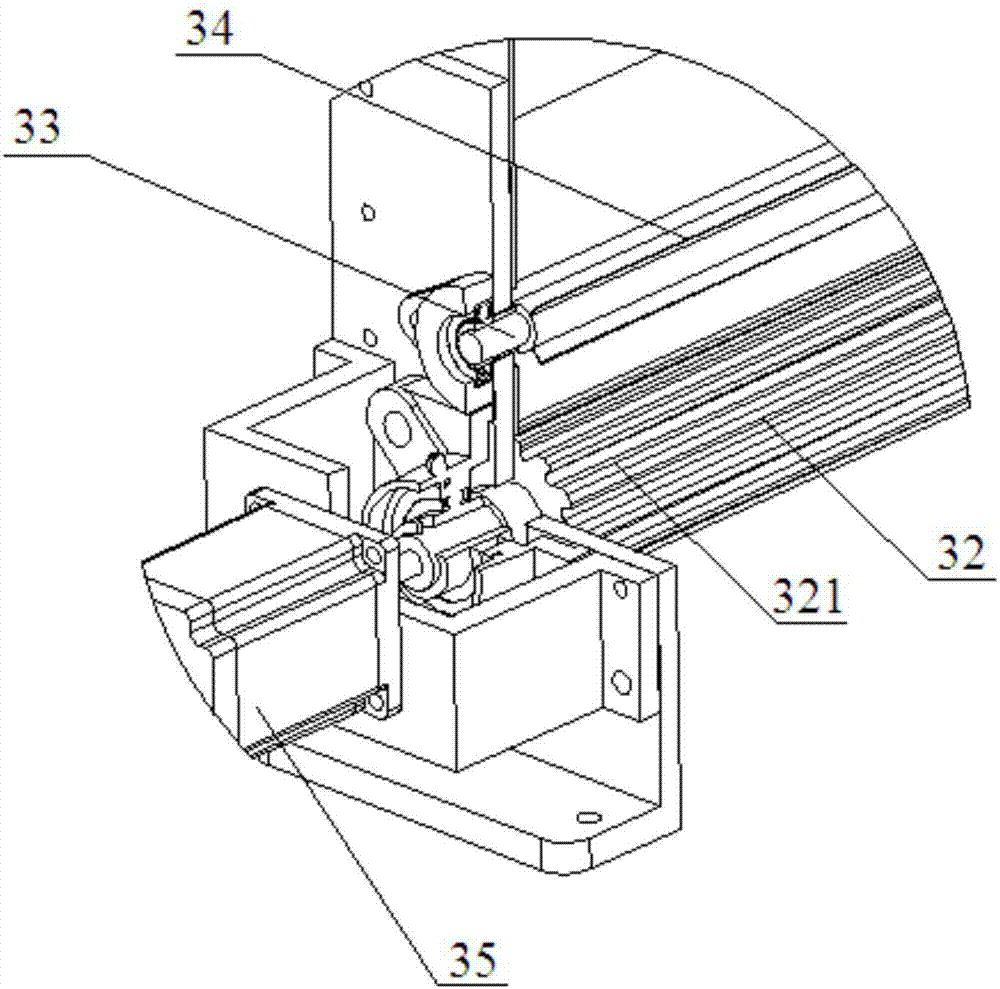

Wedge-shaped part press-riveting device and method

The invention discloses a wedge-shaped part press-riveting device and method. An upper pressure head assembly and a lower pressure head assembly of the press-riveting device are mounted on an arch-shaped frame from top to bottom; the upper pressure head assembly comprises an angle self-adaptive upper pressure head mechanism and a pressing cylinder; the pressing cylinder is vertically and fixedly arranged on the arch-shaped frame; the angle self-adaptive pressure head mechanism is arranged at the bottom end of a piston rod of the pressing cylinder; the lower pressure head assembly comprises an angle self-adaptive lower pressure head mechanism and a lower pressure head height adjusting mechanism; the lower pressure head height adjusting mechanism is arranged on the arch-shaped frame; and the angle self-adaptive lower pressure head mechanism is arranged at the top end of the lower pressure head height adjusting mechanism. The wedge-shaped part press-riveting method comprises the following steps of: loosening an upper pressure head positioning bolt and a lower pressure head positioning bolt; starting the pressing cylinder, and enabling the piston rod to descend to the maximal stroke position; putting a wedge-shaped part, enabling the lower pressure head to rotate in a self-adaptive mode, and enabling the upper surface of the lower pressure head to be in tight fit with the lower surface of the wedge-shaped part; lifting the lower pressure head, and enabling the upper surface of the wedge-shaped part to be in tight fit with the lower surface of the upper pressure head; screwing up the upper pressure head positioning bolt and the lower pressure head positioning bolt; returning the piston rod of the pressing cylinder to the initial position; mounting rivets; and starting the pressing cylinder to apply pressure to the rivets, thereby completing riveting.

Owner:SHENYANG AEROSPACE UNIVERSITY

Packaging mechanism for pressure sensor chip packaging test, and packaging method thereof

ActiveCN111855076AAchieve electrical connectionTo achieve a fixed connectionElectronic circuit testingFluid pressure measurementSilicone GelsSilica gel

The invention discloses a packaging mechanism for a pressure sensor chip packaging test, and a packaging method thereof. According to the packaging mechanism, two injection molding pieces are arrangedon the surface of a cover plate; the d packaging mechanism further comprises a first linkage part, a second linkage part and a third linkage part; through the injection molding pieces, under the action of the first linkage part, a sensor chip is driven to be electrically connected with PCB; through the injection molding pieces, under the combined action of the first linkage part and the second linage part, the cover plate and a substrate are driven to be fixedly connected; and through the injection molding pieces, under the combined action of the first linkage part and the third linage part,a copper nut and the PCB are driven to be fixedly connected. According to the invention, by pulling two limiting columns upwards, a pressure sensor chip can be packaged, so that the packaging is convenient and fast; and a silica gel can be injected into a cover plate through an injection molding channel to fill the periphery of a sensor chip, so that the sealing protection effect on the sensor chip is achieved, and it is guaranteed that the inner cavity of the cover plate can be filled with the silica gel.

Owner:南京东芯电子科技有限公司

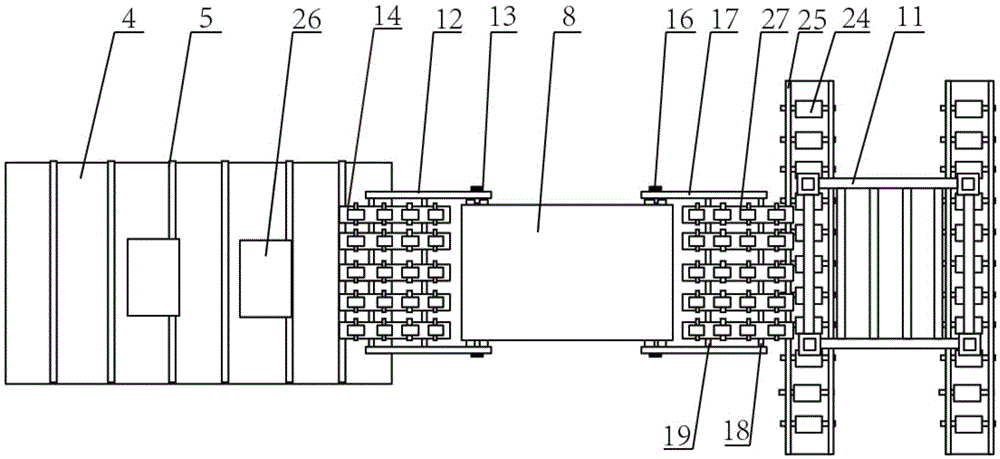

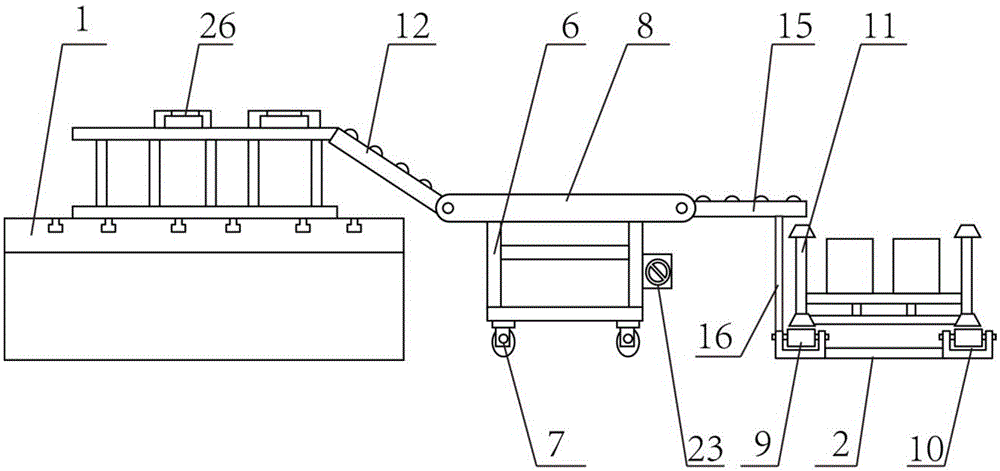

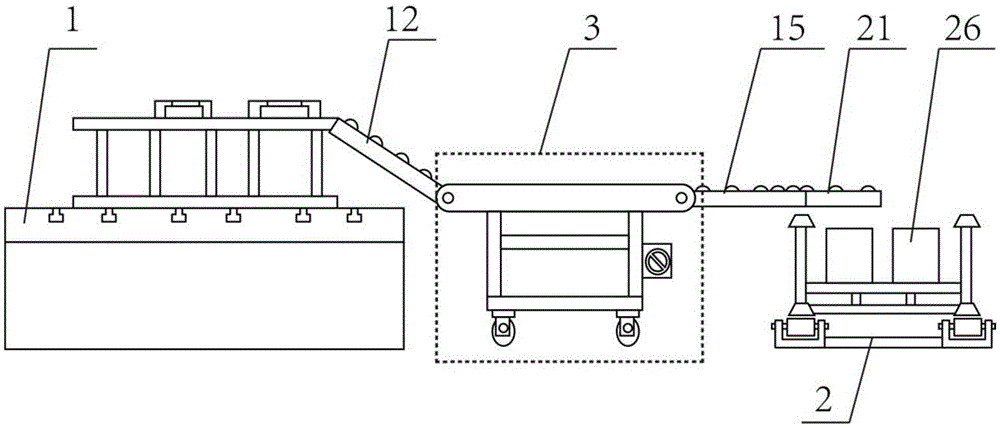

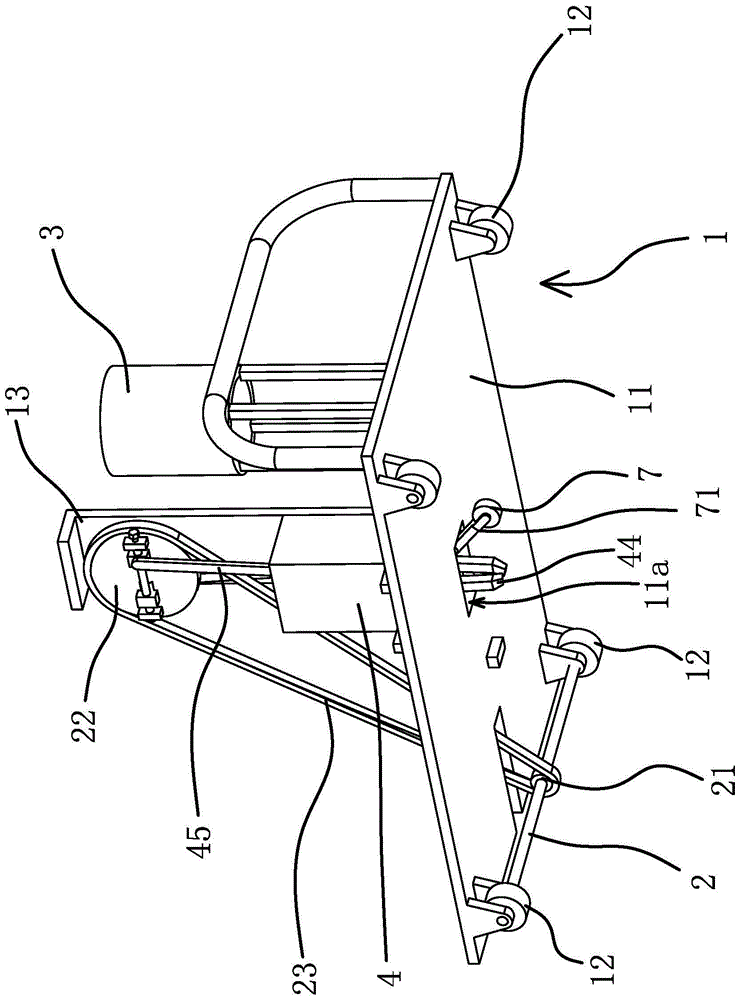

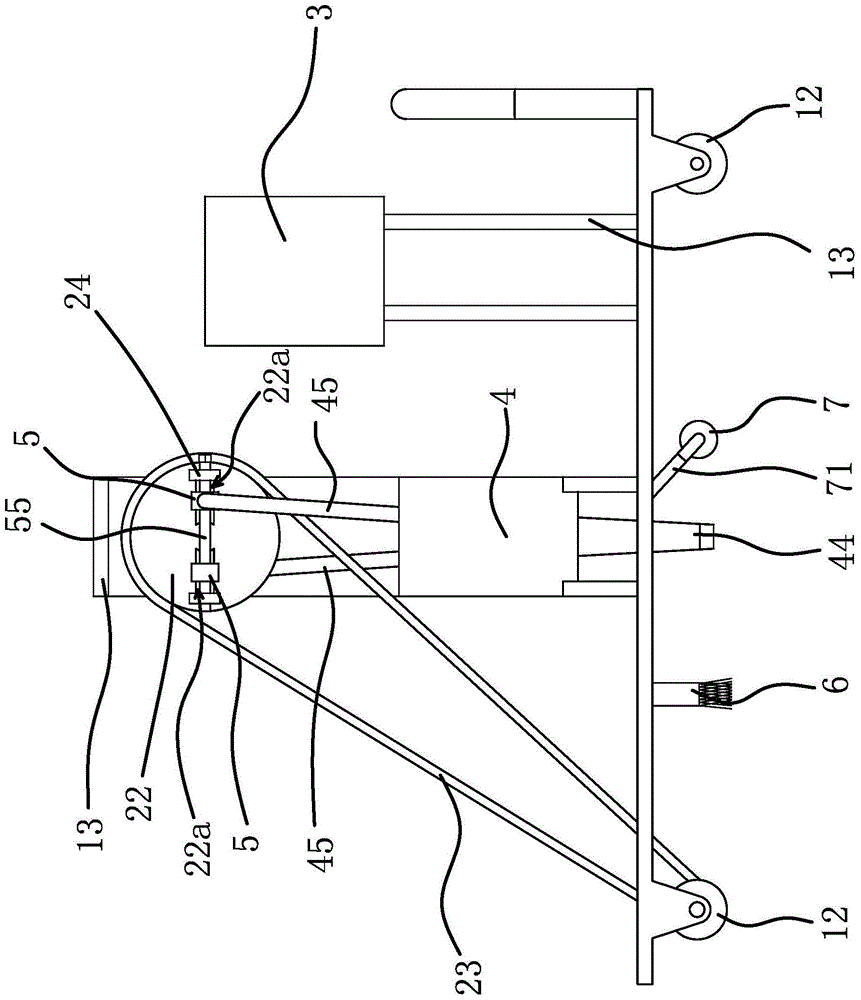

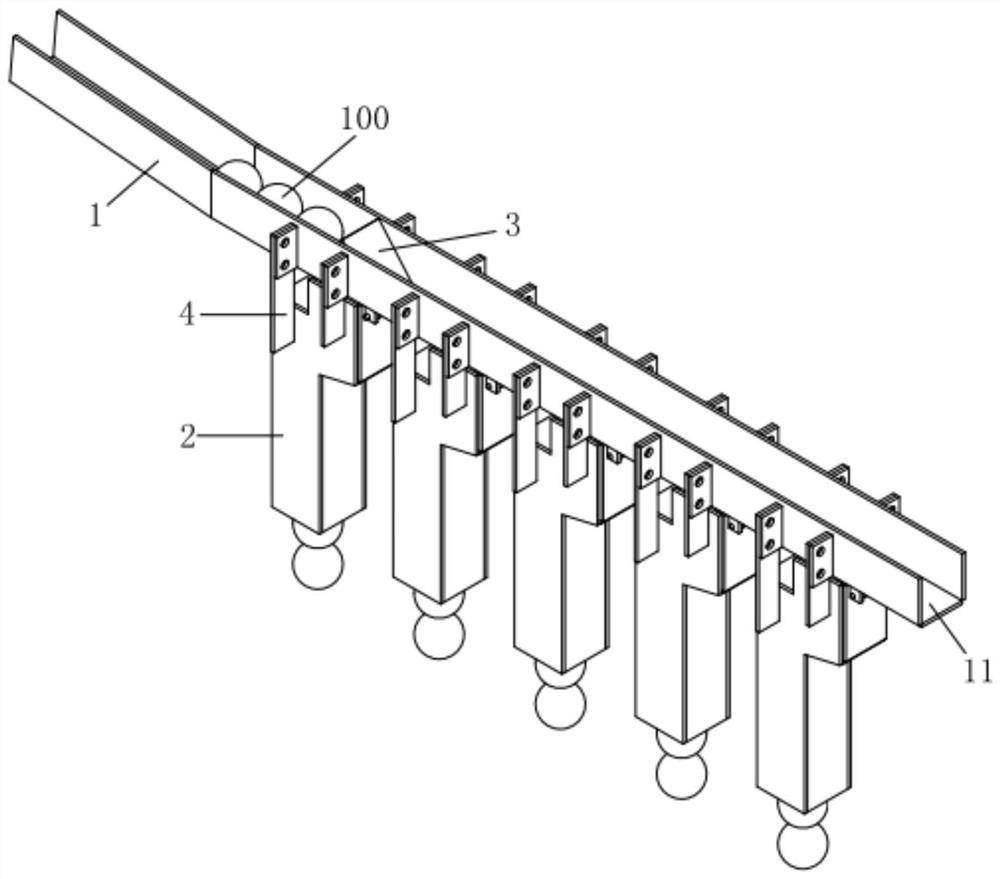

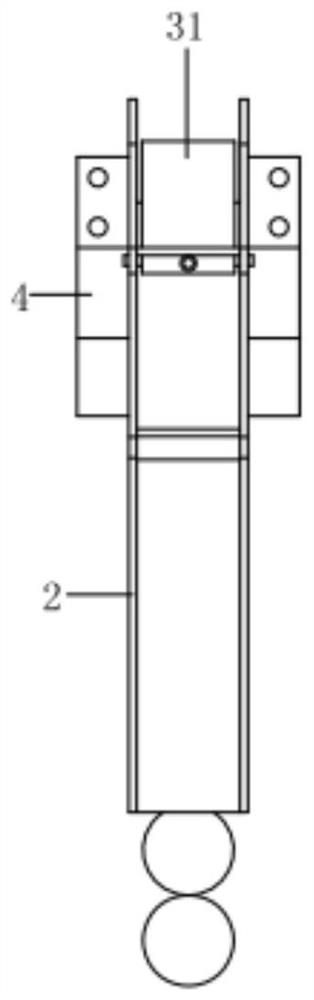

Discharging and conveying device of punching production line

ActiveCN105540189ARealize seamless dockingGuaranteed to be filledSupporting framesMechanical conveyorsProduction linePunching

The invention discloses a discharging and conveying device of a punching production line. The discharging and conveying device comprises a discharging platform and a conveying rail. The discharging and conveying device further comprises a conveying trolley. The discharging platform comprises a supporting table and rollers I arranged on the supporting table. Two rows of rollers, namely rollers II and rollers III, are arranged on the conveying rail. A movable platform I is arranged between the discharging platform and the conveying trolley. The left end of the movable platform I is lapped on the discharging platform, and the right end of the movable platform I is connected with the conveying trolley through fixing bolts I. A plurality of rows of conveying shafts I are arranged on the movable platform I. A movable platform II is arranged between the conveying trolley and the conveying rail. The left end of the movable platform II is connected with the conveying trolley through fixing bolts II, and the right end of the movable platform II is located above the rollers II. According to the discharging and conveying device, the conveying trolley is additionally arranged and located between the discharging platform and the conveying rail, and seamless butt joint of the discharging platform and the conveying rail is achieved.

Owner:TIANJIN HENGXING MECHANICAL EQUIP

Packaging mechanism and packaging method for pressure sensor chip packaging and testing

ActiveCN111855076BAchieve electrical connectionTo achieve a fixed connectionElectronic circuit testingFluid pressure measurementSilicone GelsElectrical connection

The invention discloses a packaging mechanism and a packaging method for the packaging and testing of pressure sensor chips. Two injection molded parts are arranged on the surface of the cover plate, and linkage part 1, linkage part 2 and linkage part 3 are also included. Under the action of linkage part 1, the electrical connection between the sensor chip and the PCB board is driven, through the injection molded part, and under the joint action of linkage part 1 and linkage part 2, the fixed connection between the cover plate and the substrate is driven, and through the injection molded part, And under the joint action of the linkage part 1 and the linkage part 3, the fixed connection between the copper nut and the PCB board is driven. The present invention has the effect that the pressure sensor chip can be packaged by moving the two limit posts upwards, and the package is convenient and fast. At the same time, the silicone gel can be injected into the cover plate through the injection molding channel to fill the sensor chip. The four sides of the sensor chip are sealed and protected, and the silicone gel can fill the inner cavity of the cover plate.

Owner:南京东芯电子科技有限公司

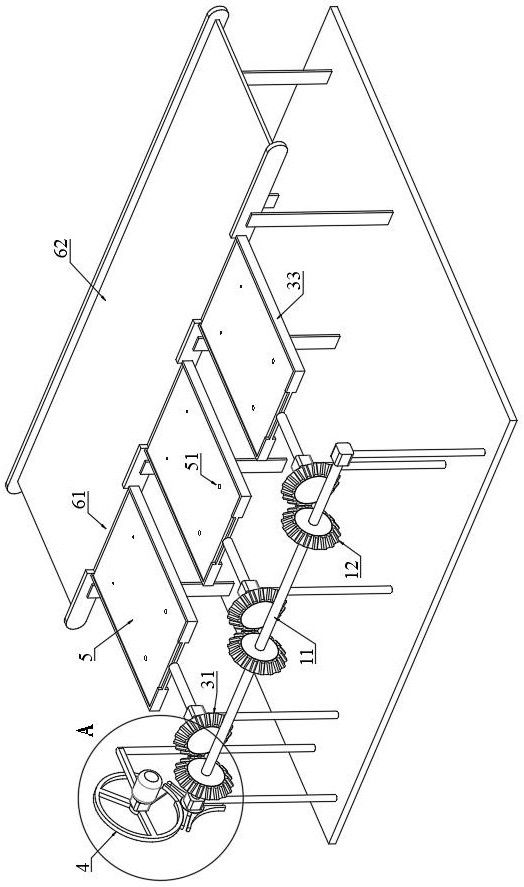

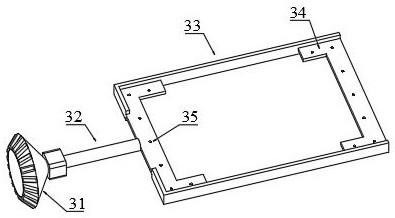

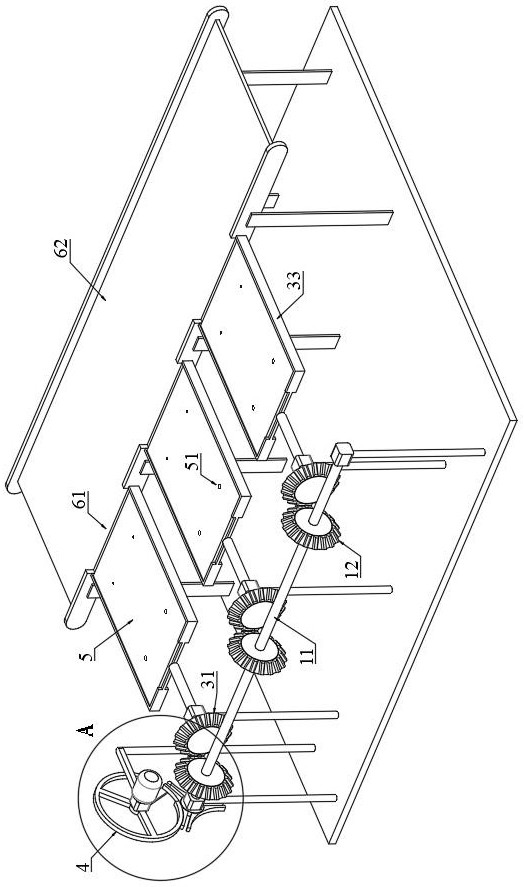

Resin hole plugging device and method for double-sided back drilling printed circuit board

ActiveCN114364140AGuaranteed to be filledAvoid voidsPrinted circuit manufactureComposite materialDrill hole

The invention discloses a resin hole plugging device and method for a double-sided back drilling printed circuit board. The resin hole plugging device comprises a turnover mechanism, a vacuum resin hole plugging machine and a plurality of bearing mechanisms arranged in a horizontal array mode, each bearing mechanism comprises a first bevel gear, a horizontal rod and a bearing frame which are sequentially connected, the horizontal rods are connected to the supporting rods through bearings, clamping grooves are formed in the top faces and the bottom faces of the bearing frames, and vacuum adsorption hole plates are arranged on the clamping grooves. The turnover mechanism is connected with the first bevel gears and used for rotating all the first bevel gears at the same time. The vacuum resin hole plugging machine comprises a resin injection assembly located above the bearing frame and an air pump air exhaust assembly located below the bearing frame. The resin hole plugging device can turn over the printed circuit board, and the back drilling holes in the two faces of the printed circuit board are filled with resin, so that cavities are avoided.

Owner:四川英创力电子科技股份有限公司

Processing technology for manufacturing spectacle lens from PLA (polylactic acid) particles

PendingCN114228207AExtended drying timeImprove work efficiencyDrying gas arrangementsOptical articlesEngineeringEye lens

The invention belongs to the field of spectacle lenses, particularly relates to a processing technology for manufacturing spectacle lenses by using PLA (polylactic acid) particles, and provides the following scheme aiming at the problems that the existing technology for manufacturing the spectacle lenses by using the PLA particles is not available, the original spectacle lenses are discarded and replaced by the spectacle lenses with degrees after a spectacle frame is selected by a spectacle matching person, and the discarded spectacle lenses cause pollution and are very not environment-friendly. The preparation method comprises the following steps: S1, preheating and drying; S11, putting PLA particles into a stirrer or a vibration box; s12, water in the PLA particles is dried through a dryer, the drying time is properly prolonged, the time needed for dissolving the PLA particles can be shortened, and the working efficiency is improved. The spectacle lens made of the PLA particles can be degraded, the degradation speed is high, the situation that waste is accumulated due to the fact that the spectacle lens cannot be degraded for a long time is avoided, pollution is small, the environment is further protected, and the production cost is reduced. The manufacturing effect is good, the success rate is high, and unqualified lenses are not prone to occurring.

Owner:江西科强光学有限公司

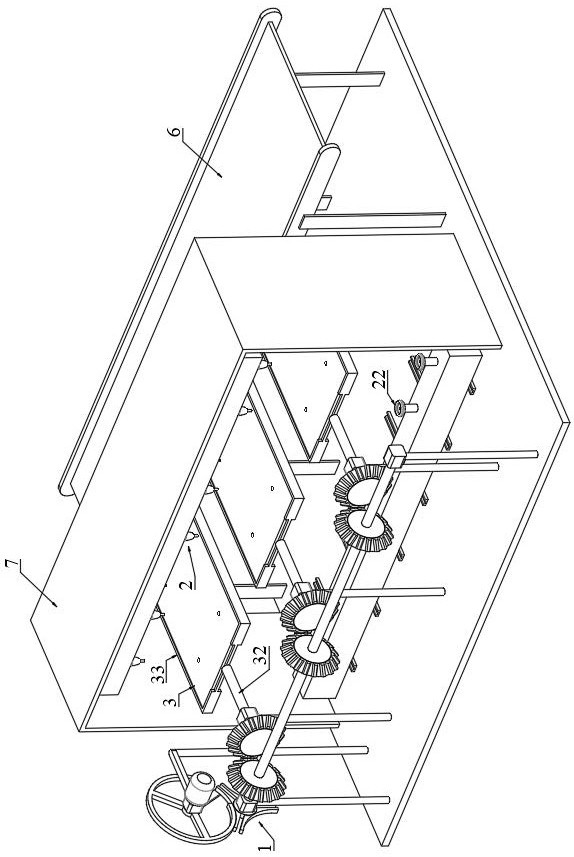

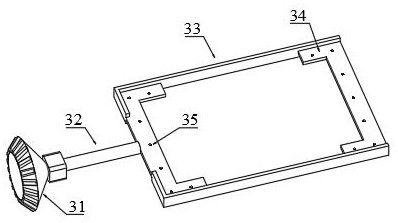

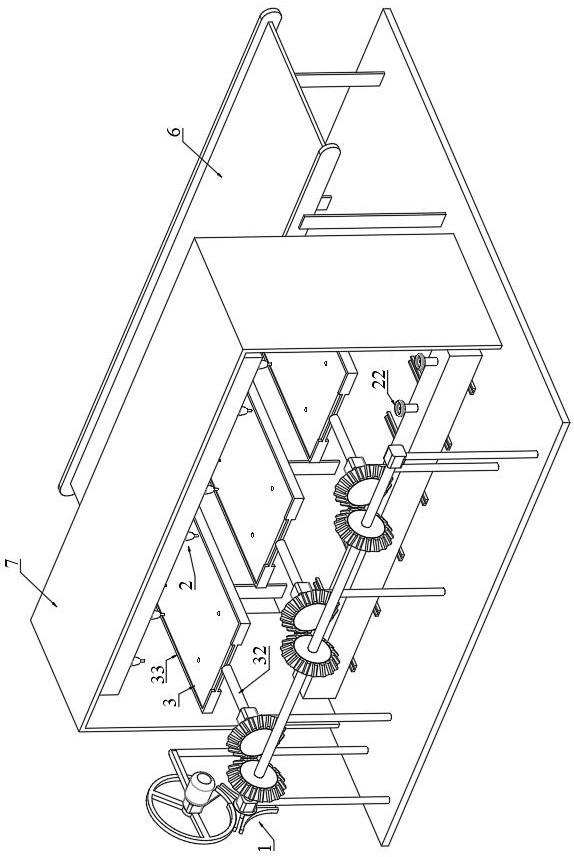

A multifunctional automatic caulking machine

ActiveCN104831946BAchieve seamless connectionGuaranteed to be filledBuilding repairsFixed frameEngineering

The invention provides a multifunctional automatic gap filling machine and belongs to the mechanical technical field. The multifunctional automatic gap filling machine solves the technical problems that an existing gap filling machine is complex in structure, difficult to operate and the like. The multifunctional automatic gap filling machine comprises a cart, a gap filling cylinder fixed on the cart and a storage barrel, wherein wheels of the car are connected with a rotary shaft; the rotary shaft is fixedly provided with a drive belt wheel; a driven belt wheel is rotationally connected to a fixing frame of the cart; the drive belt wheel can drive the driven belt wheel to rotate; the gap filling cylinder is vertically arranged under the drive belt wheel and comprises a cylinder body with two filling cavities and pistons arranged inside the filling cavities; the storage barrel is communicated with the two filling cavities; the lower end of the cylinder body is provided with two discharging nozzles communicated with the filling cavities respectively; through holes are formed in a bottom board of the cart; the discharging nozzles penetrate through the through holes; the two sides of the driven belt wheel are provided with push rods respectively; the hinged points of the two push rods and the driven belt wheel are symmetrically arranged along the center of the driven belt wheel; the lower ends of the two push rods are hinged to the two pistons respectively. The multifunctional automatic gap filling machine has the advantages of being simple in structure and high in construction speed.

Owner:台州普立德建筑科技有限公司

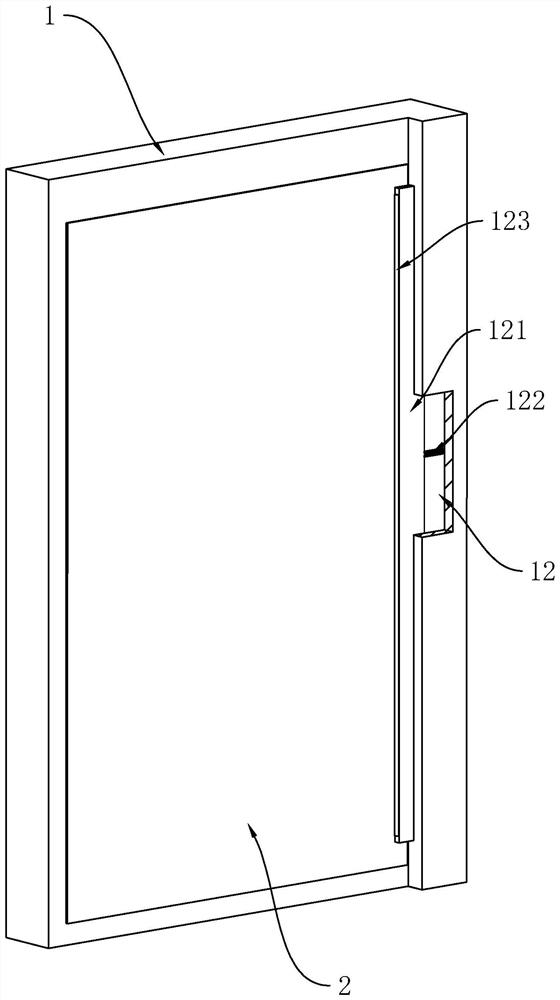

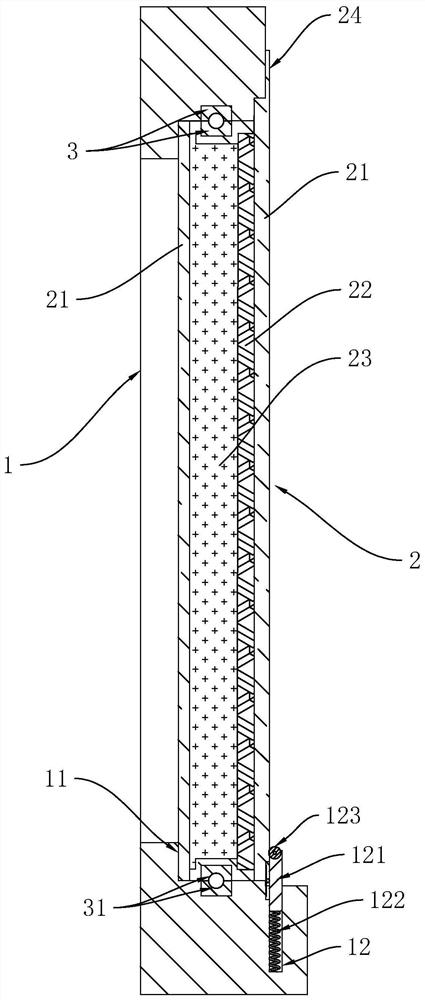

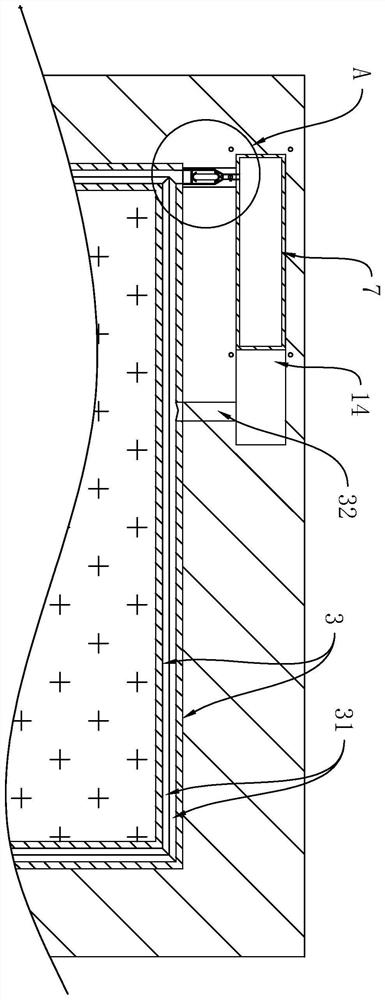

Fire escape door and its manufacturing process

ActiveCN111677421BGuaranteed to be filledIsolation leakFireproof doorsSealing arrangementsStructural engineeringFire prevention

The invention relates to a fire-proof passage door and its manufacturing process. The invention comprises a door frame, one side of the door frame is provided with a container, and a door leaf is placed in the container, and the door leaf is hinged to the door frame; The sealing strips are all provided with ring grooves, and the ring grooves of the two fireproof expansion sealing strips are spliced with each other to form a water channel; there is a water tank inside the door frame, and a water pipe connected to the ring groove is arranged on the upper side of the door frame, and a hollow support plate is horizontally arranged in the middle of the water pipe. The upper end of the water pipe is provided with a necking tube, and the upper end of the water pipe is also provided with a plug, the diameter of which is smaller than the diameter of the water pipe, and the hollow support plate and the plug are provided with a temperature-sensitive glass bulb that can push, block and close the necking tube under normal conditions. ; The water outlet of the water tank is communicated with the necking pipe. The present invention has the effect of preventing the penetration of dense smoke while effectively achieving the effect of fire prevention.

Owner:HANGZHOU KANG AN FIRE EQUIP

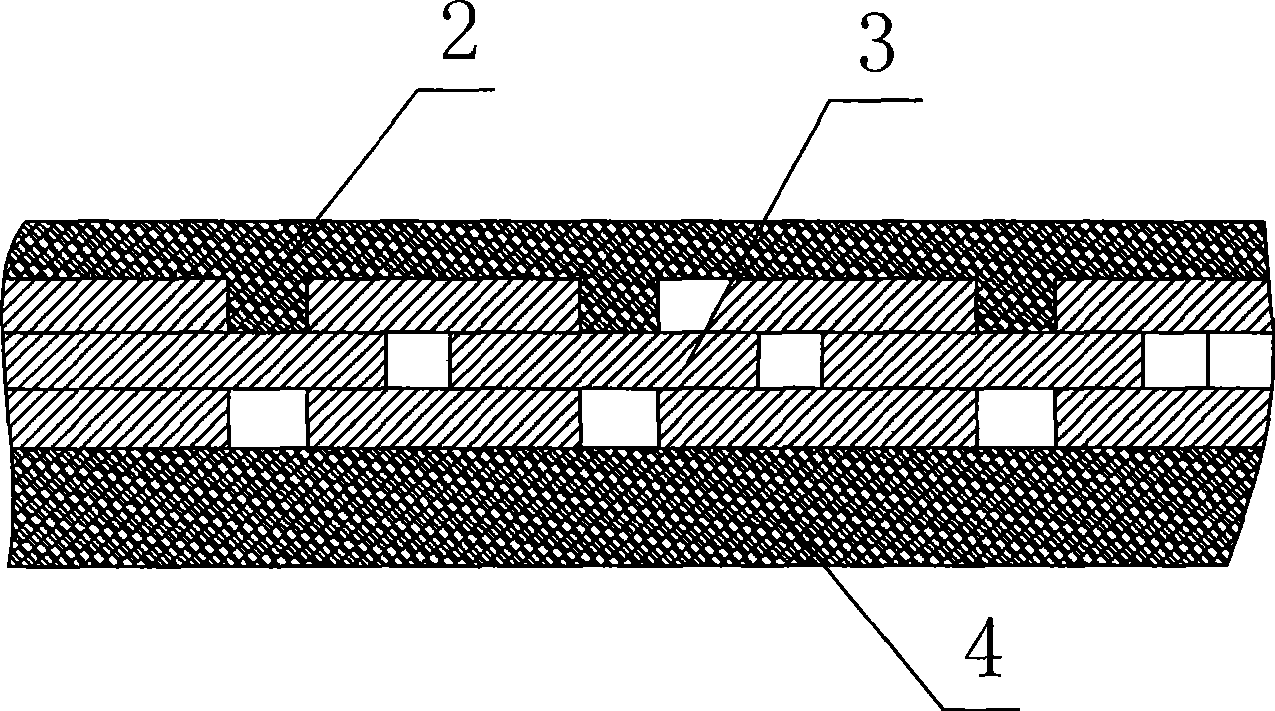

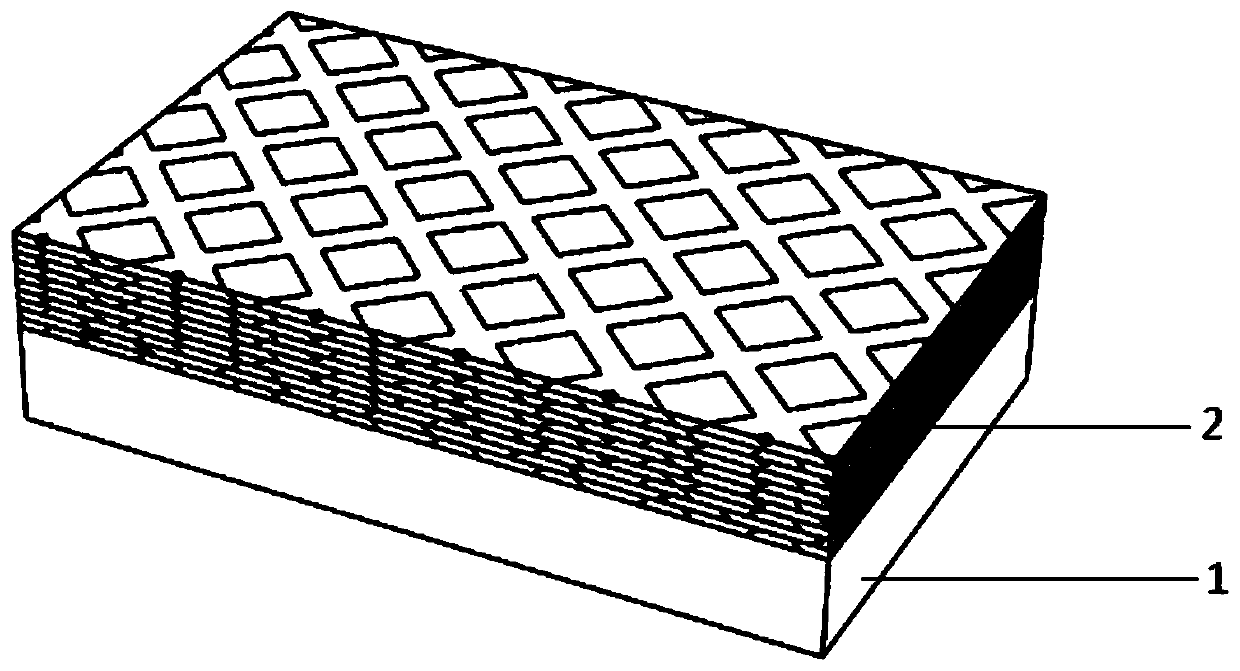

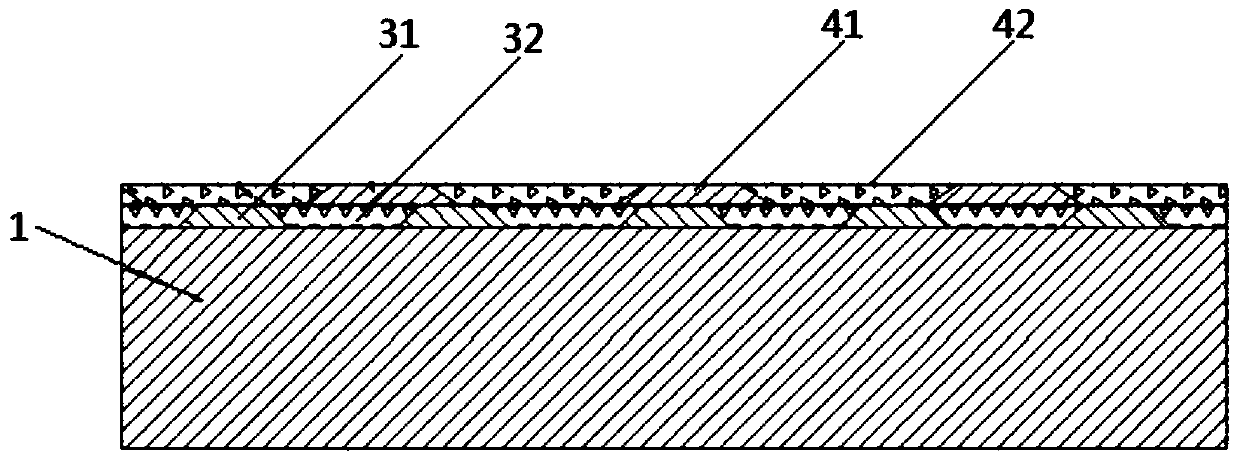

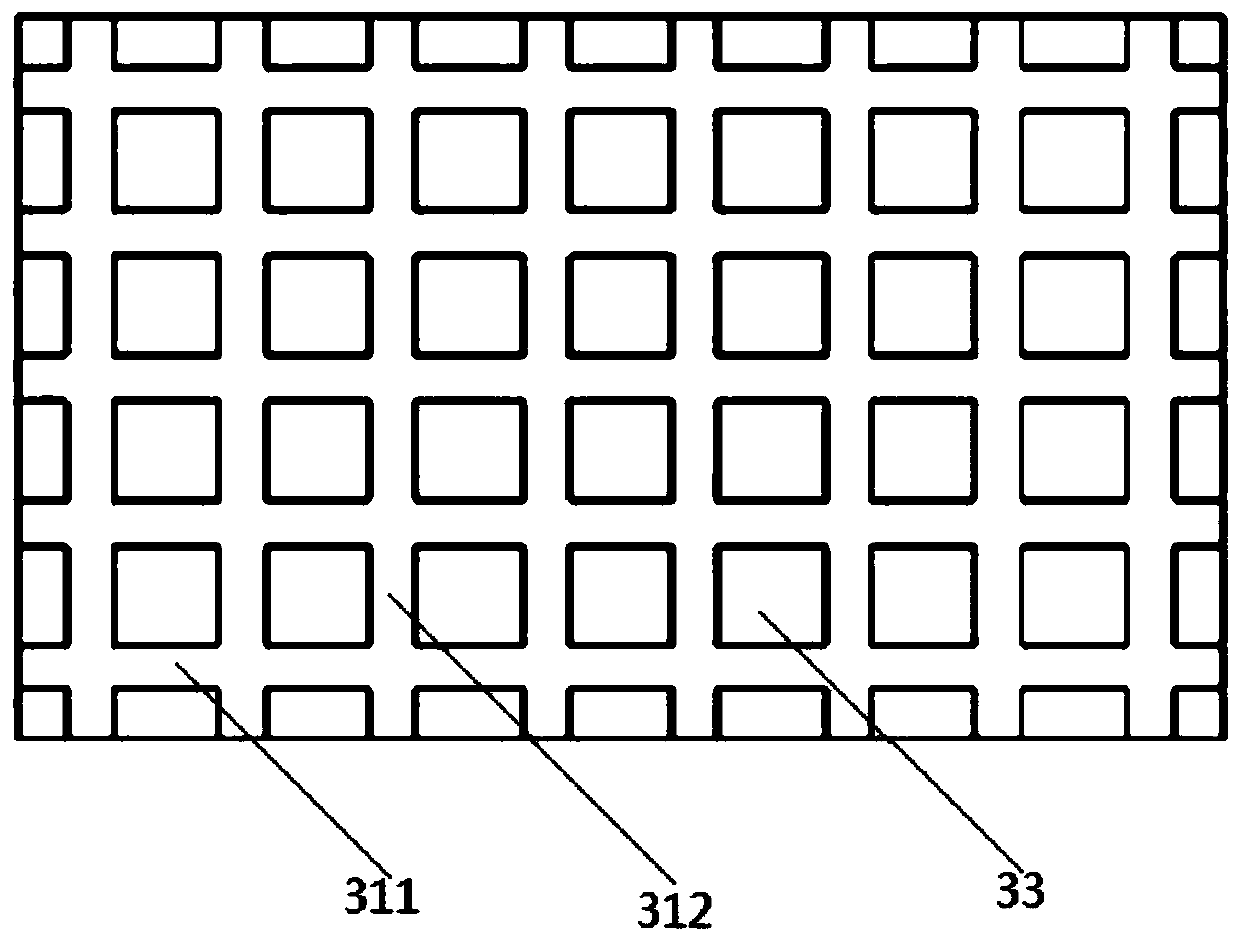

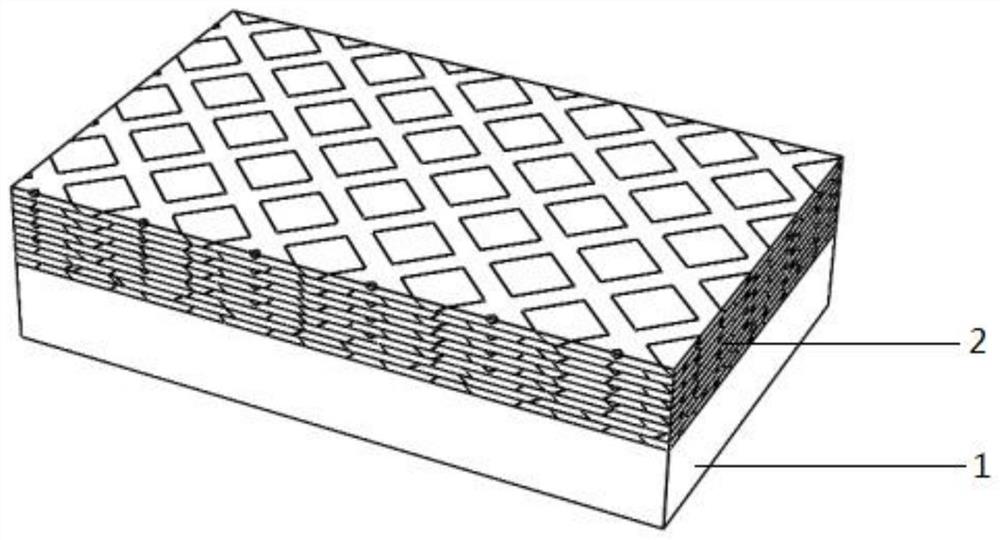

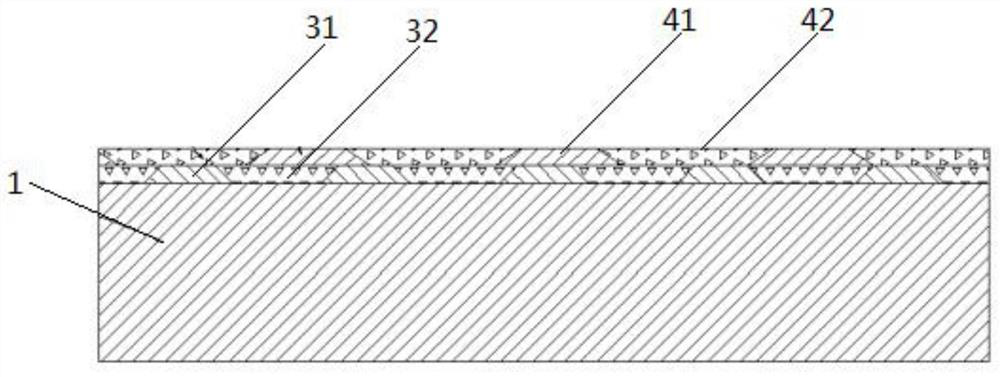

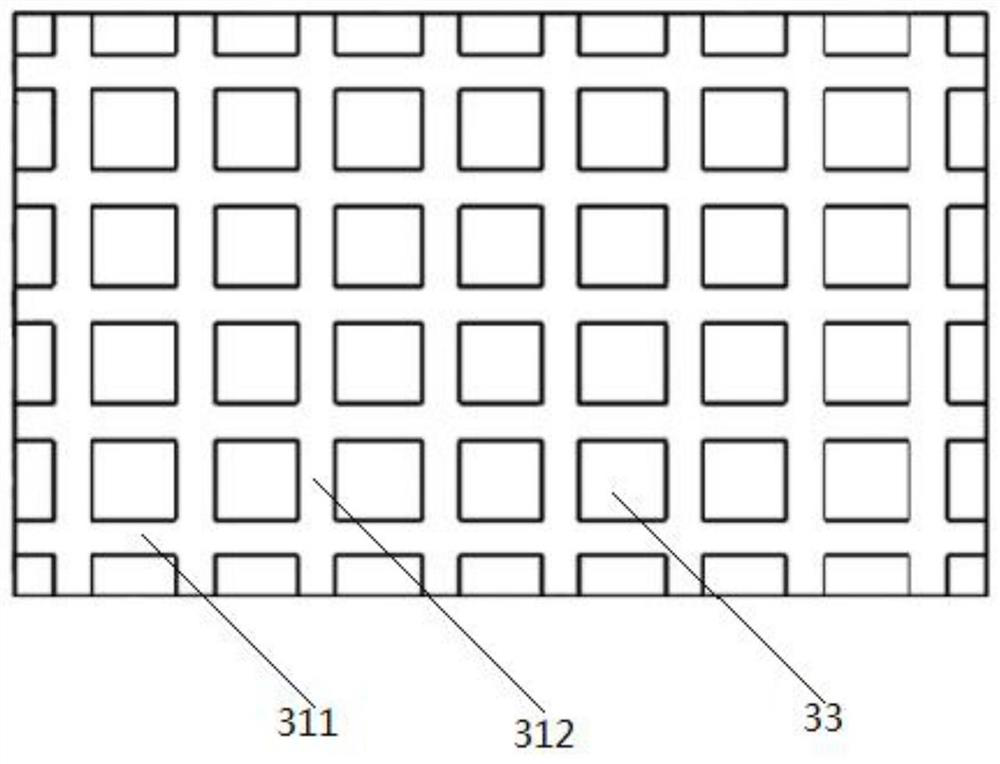

Composite lining plate and manufacturing method thereof

ActiveCN111559126AImprove wear resistanceImprove impact resistanceMetal layered productsStructural engineeringMechanical engineering

The invention discloses a composite lining plate and a manufacturing method thereof. The composite lining plate comprises a base body and a wear-resisting plate, the lower end of the wear-resisting plate is fixed to the upper end face of the base, the wear-resisting plate comprises a plurality of first wear-resisting layers and a plurality of second wear-resisting layers, the first wear-resistinglayers and the second wear-resisting layers are alternately arranged up and down, each first wear-resisting layer comprises a first impact-resistant net-shaped layer and first wear-resisting blocks, aplurality of first through holes are uniformly formed in the first impact-resistant net-shaped layers, the first through holes penetrate through the first impact-resistant net-shaped layers in the direction perpendicular to the upper end surface of the base body, one first through hole is correspondingly filled and fixed with one first wear-resisting block, the first wear-resisting block corresponds to the through hole in shape, each second wear-resisting layer comprises a second impact-resistant net-shaped layer and second wear-resisting blocks, a plurality of second through holes are formedin the second wear-resisting layer, the second through holes penetrate through the second impact-resistant net-shaped layer in the direction perpendicular to the upper end face of the base body, onesecond through hole is correspondingly filled with one second wear-resisting block in a fixed mode. The composite lining plate is resistant to wear and impact and long in service life.

Owner:NANCHANG HANGKONG UNIVERSITY

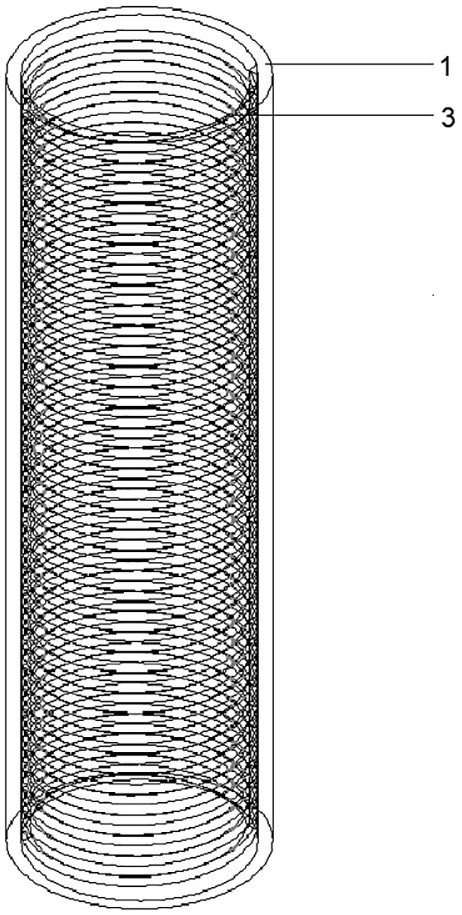

Solvent-based insulating glue, round net fetal membrane using the same and preparation method thereof

ActiveCN102432981BGuaranteed to be filledGuaranteed fluencyScreen printersPretreated surfacesElectrolysisContinuous use

The invention discloses a solvent-based insulating glue, a round net fetal membrane using the same and a preparation method thereof, wherein the solvent-based insulating glue comprises a main component and a diluting solvent; and the insulating glue is filled in the round net fetal membrane. The invention has the following advantages that: a glue layer has uniform thickness and smoothness after the insulating glue is coated; the insulating glue has strong metallic cohesion, high insulating property and lower than 1% of shrinkage rate during curing and solidifying, and is resistant to high temperature, acid, oxidation and electrolytic corrosion; as the embedded insulating glue of the round net fetal membrane, the insulating glue not only satisfies the required insulation effect completely, but also guarantees quality of the round net and ensures the printing smooth and the printing effect excellent; repeated use of the round net fetal membrane is more than 200 times, continuous usage time is as long as more than 60 hours, shear strength is reached to 395 KGF / cm<2>, insulating and voltage-resistant performance is 25 KV / mm, and coefficient of thermal expansion is less than 4.5*10<-5>cm / degree centigrade.

Owner:山东同大镍网有限公司

A threaded hole welding repair process

The invention provides a threaded hole welding and repairing process. The threaded hole welding and repairing process comprises the following steps of material preparation, chambering, welding, surface treatment, drilling and tapping. According to the process, circular steel sheets are laid in an inner hole subjected to chambering to replace the bead welding quantity, bead welding in the small diameter of a thread is replaced with the circular sheets, the welding quality of the large diameter of the thread and the small diameter of the thread is guaranteed, and meanwhile it is guaranteed that the small diameter of the thread is filled with the circular steel sheets, so that positioning and construction are performed conveniently when redrilling is performed. By means of the process, the quality and efficiency of repair of a threaded hole can be improved, meanwhile welding deformation is lowered, and the threaded hole welding and repairing process is particularly suitable for welding and repairing of the deep threaded hole.

Owner:中船发动机有限公司

A steel tube concrete column

The invention discloses a steel pipe concrete column, which relates to the field of structural engineering and includes steel pipes, concrete and stiffeners. The inner wall of the steel pipe is provided with internal threads for the installation of the stiffeners. Filled with concrete. The outer side wall of the side reinforcing plate has an external thread, the stiffening plate has a through hole, and the position of the stiffening rib can be adjusted along the internal thread. The internal thread improves the bonding force between the steel pipe and the concrete, and the stiffening plate can prevent the relative slippage of the concrete and effectively restrain the cracking of the concrete. The stiffeners are easy to install, and the stiffeners strengthen the clamping effect of the steel pipe to prevent buckling and deformation of the steel pipe; increase the critical force of the steel pipe, thereby increasing the bearing capacity of the steel pipe; debonding phenomenon.

Owner:FUZHOU UNIV

Device and method for resin plugging hole of double-sided back-drilled printed circuit board

The invention discloses a double-sided back-drilling printed circuit board resin plug hole device and method. The resin plugging device includes a turning mechanism, a vacuum resin plugging machine and several bearing mechanisms arranged in a horizontal array. Each bearing mechanism includes a first bevel gear connected in sequence, a horizontal rod and a bearing frame. The horizontal rod is connected to the support rod through a bearing. , the top and bottom surfaces of the bearing frame are provided with card slots, and the card slots are provided with vacuum adsorption orifice plates; the turning mechanism is connected to the first bevel gears, and is used to rotate all the first bevel gears at the same time; the vacuum resin plugging machine includes The upper resin injection assembly and the air pump air extraction assembly are located below the carrier frame. The resin plugging device can turn the printed circuit board over and fill the back-drilled holes on both sides of the printed circuit board with resin respectively, without voids.

Owner:四川英创力电子科技股份有限公司

Composite lining board and its manufacturing method

ActiveCN111559126BImprove wear resistanceImprove impact resistanceMetal layered productsMechanical engineeringComposite liner

The invention discloses a composite lining board and a manufacturing method thereof, comprising a base body and a wear-resistant plate, the lower end of the wear-resistant plate is fixed on the upper end surface of the base body, and the wear-resistant plate includes several first wear-resistant layers and several second wear-resistant layers. Wear-resistant layer, the first wear-resistant layer and the second wear-resistant layer are alternately arranged up and down, the first wear-resistant layer includes the first impact-resistant mesh layer and the first wear-resistant block, and the first impact-resistant mesh layer is evenly arranged A plurality of first through holes, the first through holes penetrate the first impact-resistant mesh layer in the direction perpendicular to the upper end surface of the base body, one first through hole corresponds to filling and fixing a first wear-resistant block, and the first wear-resistant block Corresponding to the shape of the through hole, the second wear-resistant layer includes a second impact-resistant mesh layer and a second wear-resistant block. The second wear-resistant layer is provided with a plurality of second through holes, and the second through holes are perpendicular to the substrate. The direction of the end face penetrates through the second impact-resistant mesh layer, and a second through hole is correspondingly filled and fixed with a second wear-resistant block. The composite liner is wear-resistant and impact-resistant, and has a long service life.

Owner:NANCHANG HANGKONG UNIVERSITY

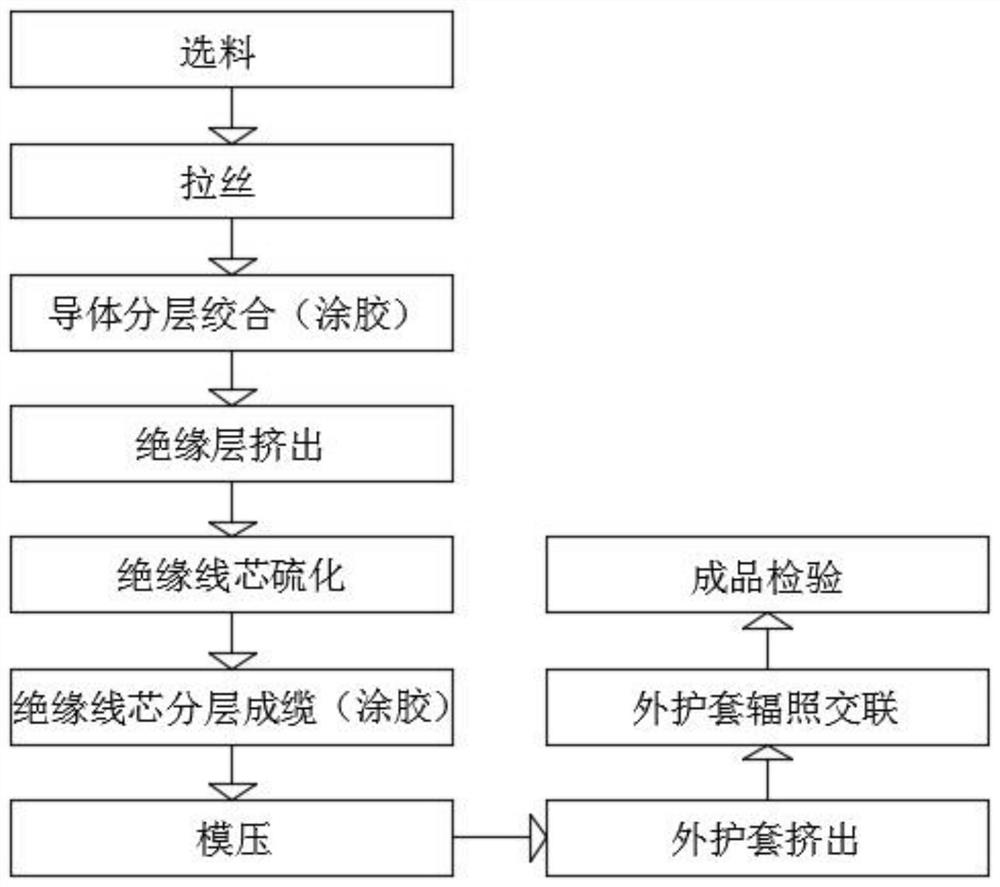

Manufacturing method of watertight cable special for deep diving equipment

PendingCN111640532AImprove water tightnessImprove air tightnessRubber insulatorsPlastic/resin/waxes insulatorsTinningProduct inspection

The invention discloses a manufacturing method of a watertight cable special for deep diving equipment. The manufacturing method of the watertight cable specifically comprises the following steps of wire drawing, wherein tinned copper single wires are manufactured through copper large drawing, medium drawing, small drawing and annealing tinning; conductor layered twisting and gluing, wherein layered twisting is performed on a conductor by adopting a special twisting mold; extrusion of an insulating layer, wherein an extrusion type mold is adopted; vulcanization of an insulating wire core, wherein steam vulcanization is performed on an insulating layer by adopting steam vulcanization under the steam pressure of 1.0-1.2 MPa; core layered cabling and gluing of the insulating wire; mold pressing, wherein the cable core is pressed by using a special pressing mold; outer sheath extruding; outer sheath irradiation cross-linking; and finished product inspection. According to the invention, thewatertight cable has the advantages of high watertight performance, high airtight performance, high seawater resistance, high marine organism corrosion resistance, wear resistance, no leakage and excellent halogen-free flame-retardant environment-friendly performance, and meets the requirements of watertight cables for deep diving equipment in China.

Owner:ANHUI HUAYU CABLE GRP

A device for treating the surface of a turning wall notch

The invention discloses a surface treatment device for a turning wall notch, which comprises a chute on the top of the turning wall placement frame, a positioning piece connected inside the chute, a grinding power piece on the top of the positioning piece, and a grinding power The output end of the part passes through the positioning part, the top of the grinding power part is connected with a fixed plate, the end of the fixed plate far away from the grinding power part is connected with a filling part, one side of the fixed plate is connected with a support part, and the support part is connected to the crutch One side of the wall placement frame is connected, and the invention grinds the surface of the gap through the grinding power part, which reduces the hand-holding phenomenon of manual grinding of small turning wall parts, and at the same time avoids the gap between the worker's palm and the gap due to hand slipping during the grinding process. At the same time, after the grinding is completed, the gap is filled with the set filler, which is conducive to ensuring the complete filling of the gap of the turning wall. At the same time, the filling and grinding of the gap are in the same position, which is beneficial It is beneficial to ensure the accuracy of the surface treatment of the notch.

Owner:JIANGBEI HONGSHENG HIGH VOLTAGE ELECTRIC APPLIANCE HYDRAULIC MACHINERY NINGBO CITY

Device and method for adding copper balls or tin balls in electroplating line of printed board

The invention discloses an adding device and adding method for copper balls or solder balls in a printed board plating line, and the adding device comprises a lead-in wire groove for leading in the copper balls or the solder balls, a plurality of adding grooves which are arranged at the lower end of the lead-in wire groove at intervals and are sequentially arranged from front to back, and a plurality of plate turning mechanisms which are correspondingly arranged at the rear sides of the adding grooves one by one, a through hole for a copper ball or a tin ball to penetrate through up and down is formed in the adding groove in a penetrating mode, an opening communicated with the through hole is formed in the position, corresponding to the adding groove, of the lead-in wire groove, and the turning plate mechanism is used for closing or opening the opening. According to the adding device, automatic adding of the copper balls or the tin balls is achieved, the situation that the whole bag of copper balls or tin balls need to be manually carried to corresponding groove bodies of a production line each time during adding is avoided, the labor intensity of workers is reduced, and the adding efficiency is improved.

Owner:DALIAN CHONGDA CIRCUIT

Preparation method for deep trench isolation channel

InactiveCN102344114BGuaranteed to be filledAvoid Notching PhenomenonDecorative surface effectsSemiconductor/solid-state device manufacturingIsosceles trapezoidEngineering

The invention discloses a preparation method for a deep trench isolation channel, aiming at the requirements of mechanical connection but electrical insulation in MEMS (Micro Electro Mechanical System) technology. The method comprises the following steps of: polishing a silicon wafer; photo-etching; performing DRIE (Deep Reactive Ion Etching) to form a deep channel 2, wherein the deep channel 2 has an inverted isosceles trapezoid shape, and an included angle theta between a side wall of the channel and vertical direction is greater than or equal to 1 degree and is less than or equal to 5 degrees; cleaning with oxygen; generating a silicon dioxide insulating layer 3 on the surface of the side wall of the deep channel 2 and the surface of the silicon wafer; and filling a polycrystalline silicon layer 4. The preparation method has the beneficial effects that: the silicon wafer is etched into the inverted trapezoidal deep trench isolation channel by using DRIE; Notching phenomenon in isotropic etching is avoided; and the filling of the bottom of the deep channel can be guaranteed. Since the deep channel has the inverted trapezoid shape, an open part is still larger than the middle part of the channel, and the situation of a gap caused by blockage of the open part is also avoided during deposition of polycrystalline silicon. Since the included angle between the side wall of an oblique channel and the vertical direction is smaller, insulating characteristic and mechanical strength of the isolation channel are not influenced, and packaging air-tightness and insulation requirement can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Blind via filling plating method using different current parameter combinations

ActiveCN102647862BShorten the timeIncrease productivityPrinted element electric connection formationSulfateAdhesive

The invention discloses a blind via filling plating method using different current parameter combinations, which belongs to the field of circuit board plating technology. The blind via filling plating method comprises the steps of (1) removing adhesive, chemically depositing copper and flash-plating copper; (2) filling a blind via and plating; (3) drying film. The step (2) specifically includes regulating a plating solution to a solution containing high copper sulfate and low sulfuric acid content; and conducting plating for three periods of time using different current densities, wherein the plating operation is conducted for 30 minutes at the first period of time using a current density of 1.5 to 2.5 A / dm<2>, for 23 to 35 minutes at the second period of time using a current density of 1.2A / dm<2>, and for 10 to 20 minutes at the third period of time using a current density of 1.5 to 2.5A / dm<2>, respectively. The blind via filling plating method provided by the invention has high processing efficiency, low cost, and high processing quality, and is used for plating and blind via filling of circuit boards.

Owner:BOMIN ELECTRONICS CO LTD +1

Treatment device for surface of gap of turning wall

The invention discloses a treatment device for the surface of a gap of a turning wall. The device comprises a slide groove formed in the top of a turning wall placement rack. A positioning part is connected into the slide groove, a polishing power part is arranged on the top of the positioning part, and an output end of the polishing power part penetrates through the positioning part. A fixing plate is connected to the top of the polishing power part, a filling part is connected to the end, away from the polishing power part, of the fixing plate, and a supporting part is connected to one sideof the fixing plate and connected with one side of the turning wall placement rack. According to the treatment device, the arranged polishing power part polishes the surface of the gap, the phenomenonthat a worker holds the small-sized turning wall part by hand when polishing the part is reduced, and the phenomenon that the palm of the worker is scratched by the wall of the gap due to slip of thehand during polishing is avoided. After polishing is ended, the filling part is used for filling the gap, which helps to guarantee that the gap of the turning wall is completely filled. Filling and polishing are performed on the same part of the gap, which helps to guarantee the accuracy of treating the surface of the gap.

Owner:JIANGBEI HONGSHENG HIGH VOLTAGE ELECTRIC APPLIANCE HYDRAULIC MACHINERY NINGBO CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com