Novel flame resistant cable

A fire-resistant cable, a new type of technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of insufficient adhesion between conductors and mica tapes, low fire resistance, shortened service life, etc., so as to avoid insufficient tape tension and enhance adhesion. , easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

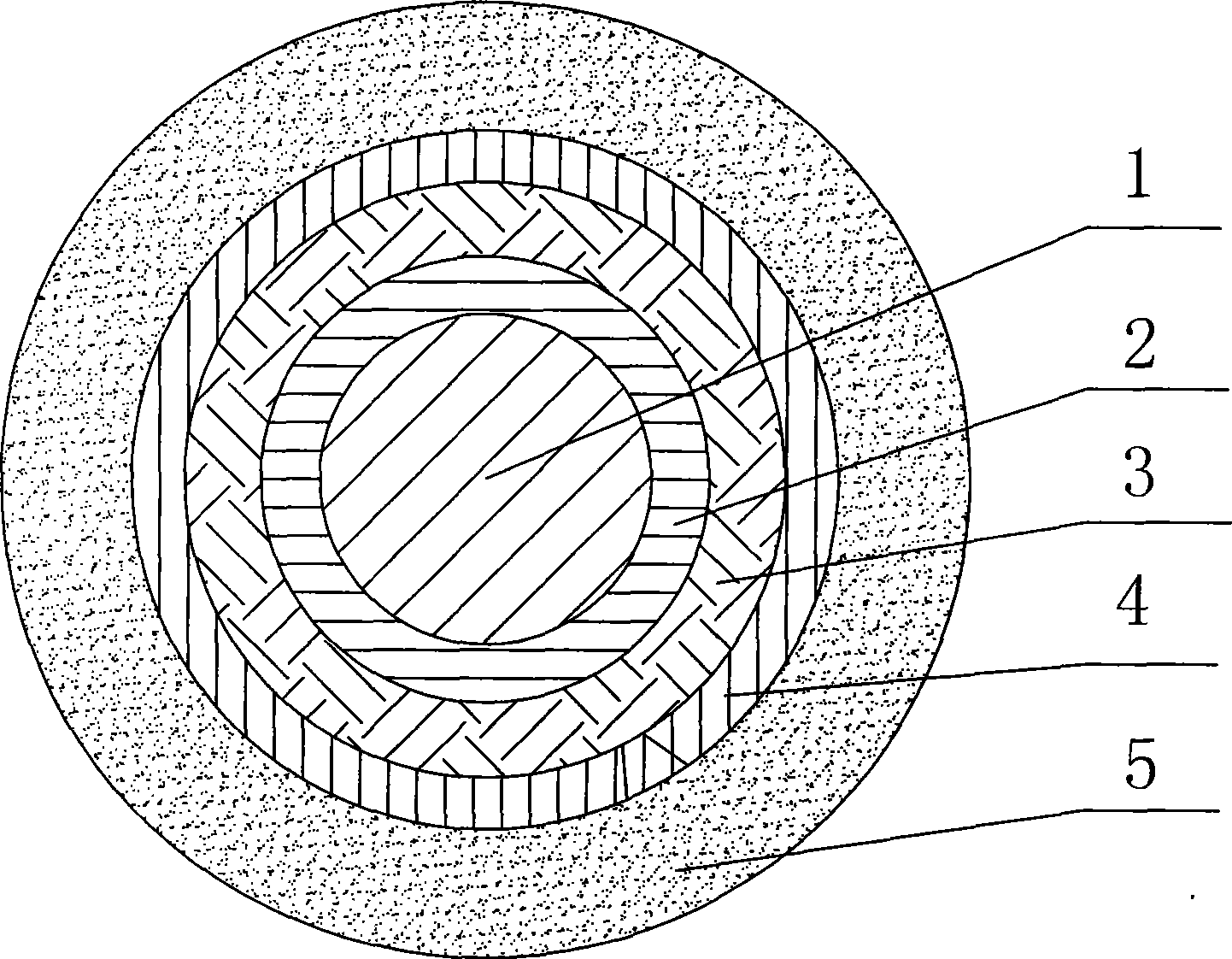

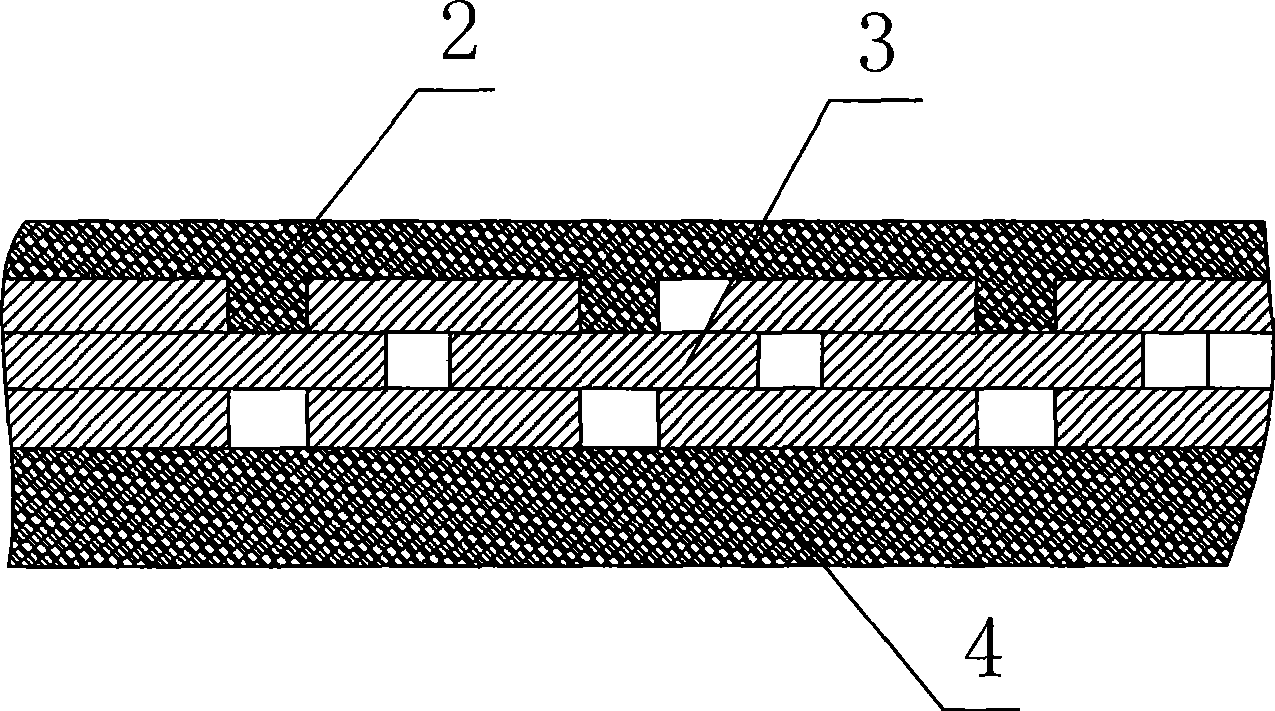

[0011] The inorganic insulating powder layer 2 is adhered on the mica-bearing side of the mica tape with a silicone adhesive, and the weight per square meter of the inorganic insulating powder layer is 0.1-0.5 g. The material of the inorganic insulating powder layer is silicon or aluminum oxide or calcium carbonate or aluminum hydroxide or glass or magnesium hydroxide, which can be any one of them, or a mixture of two or more of them, the particle size of the material The diameter is 1 nm to 100 nm. The substrate surface of the mica tape 3 is also bonded with inorganic insulating powder 4, and the mica tape is wrapped vertically on the conductor 1, and the side of the mica with the mica and inorganic insulating powder layers is inwardly in contact with the conductor 1, and the mica tape is covered with glass Extrude the insulating layer 5, the outer sheath after the ribbon is tied tightly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Particle size diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com