Semi coke waste heat recovery type spiral conveyer

A technology of screw conveyor and waste heat recovery, which is applied to the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc. It can solve the problems that the coke quenching system of the semi-coke furnace cannot be applied, the U-shaped box cannot be filled with materials, and the Problems such as gas material seal, achieve compact structure, overcome uncompact structure, and prevent gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

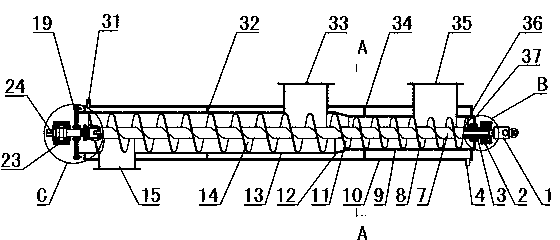

[0043] refer to Figure 1~2 , the inner cylinder in this embodiment has two inner cylinder sections, which are the first inner cylinder section 9 and the second inner cylinder section 13 along the conveying direction, and the corresponding helical blades include the first helical blade 8 and the second helical blade. Two helical blades 14, the first helical blade 8 is located in the first inner cylinder section 9, the second helical blade 14 is located in the second inner cylinder section 13, and in this embodiment the inner diameter of the second inner cylinder section 13 is greater than The inner diameter of the first inner cylinder section 9, and the pitch of the second helical blade 14 is greater than the pitch of the first helical blade 8, the combination of the two makes the second helical blade 14 of a pitch and the outer surface of the helical base pipe 7 The volume enclosed by the circular surface and the inner circular surface of the second inner cylinder section 13 ...

Embodiment 2

[0052] refer to Figure 5 , The difference between this embodiment and Embodiment 1 is that the water-cooled housing and the water-cooled rotating body are coaxially arranged, and the axis is inclined upward along the conveying direction, and the inclined setting can firstly increase the height of the discharge port 15 to achieve the purpose of lifting materials , so as to increase the installation space, it is convenient to install a scraper or a belt conveyor under the semi-coke waste heat recovery screw conveyor, which is convenient for the transformation of the existing semi-coke furnace quenching system, and the inclined setting can further ensure that the semi-coke is filled In the inner cylinder, the purpose of material sealing is achieved to avoid gas leakage. Preferably, the inclination angle is 5°, and the inclination angle can be selected from 3° to 15°.

[0053] Both the upper ends of the first feeding port 35 and the second feeding port 33 are fixed with flange p...

Embodiment 3

[0055] refer to Figure 6 In this embodiment, the inner diameters of the first inner cylinder section 9 and the second inner cylinder section 13 are the same, that is, the inner cylinder is a straight cylinder, and the pitch of the second helical blade 14 is the pitch of the first helical blade 8 In this way, the volume enclosed by the second helical blade 14 of one pitch, the outer circular surface of the helical base pipe 7, and the inner circular surface of the second inner cylinder section 13 can be the first pitch of one pitch. A helical blade 8, the outer circular surface of the helical base pipe 7, and the inner circular surface of the first inner cylinder section 9 double the volume, and the processing of the inner cylinder and the helical blade is simple. Of course, the cross-sectional area of the annular cavity between the second inner cylinder section 13 and the spiral base pipe 7 can also be made to be twice the cross-sectional area of the annular cavity betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com