Patents

Literature

146results about How to "Shorten the conveying distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

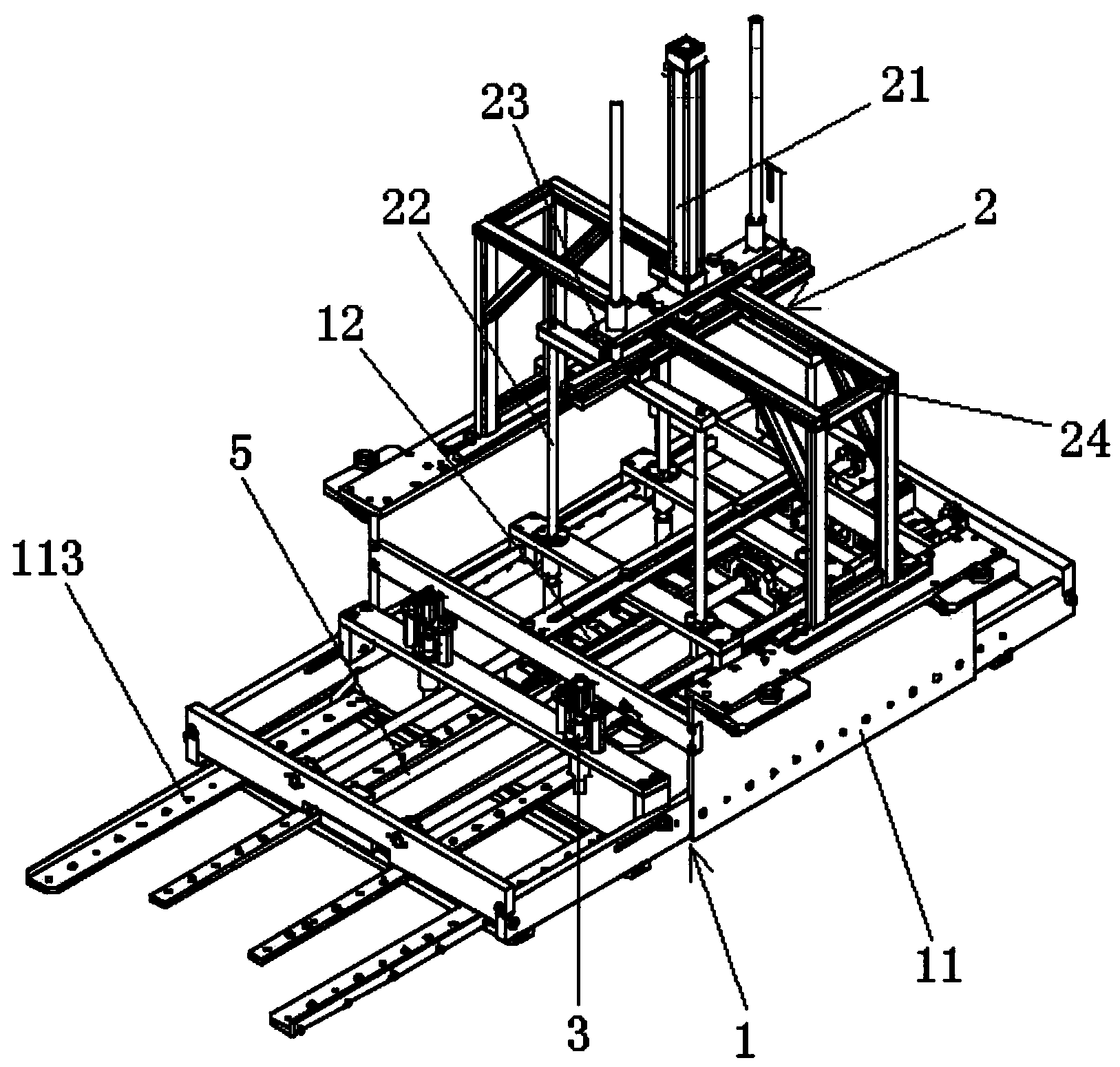

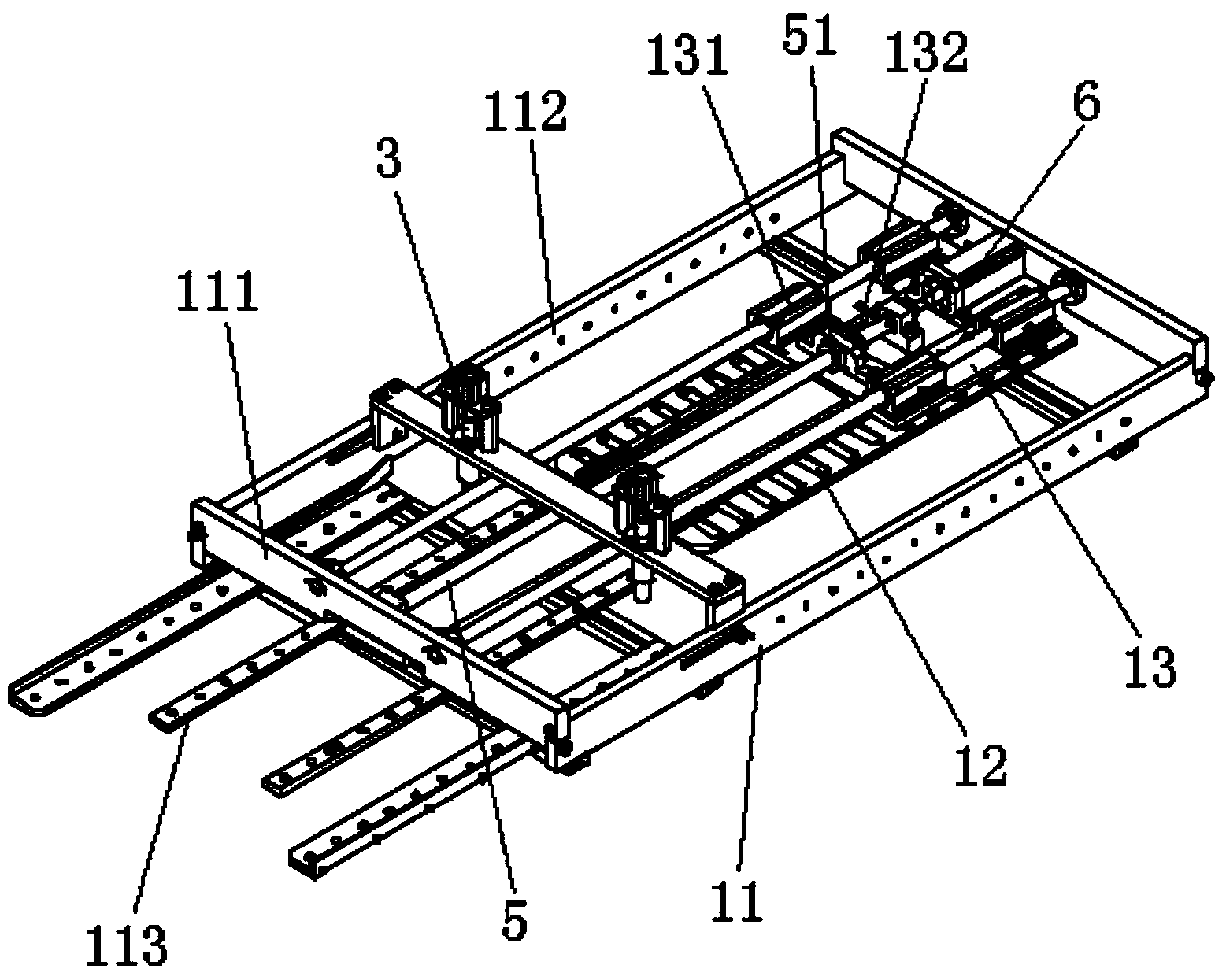

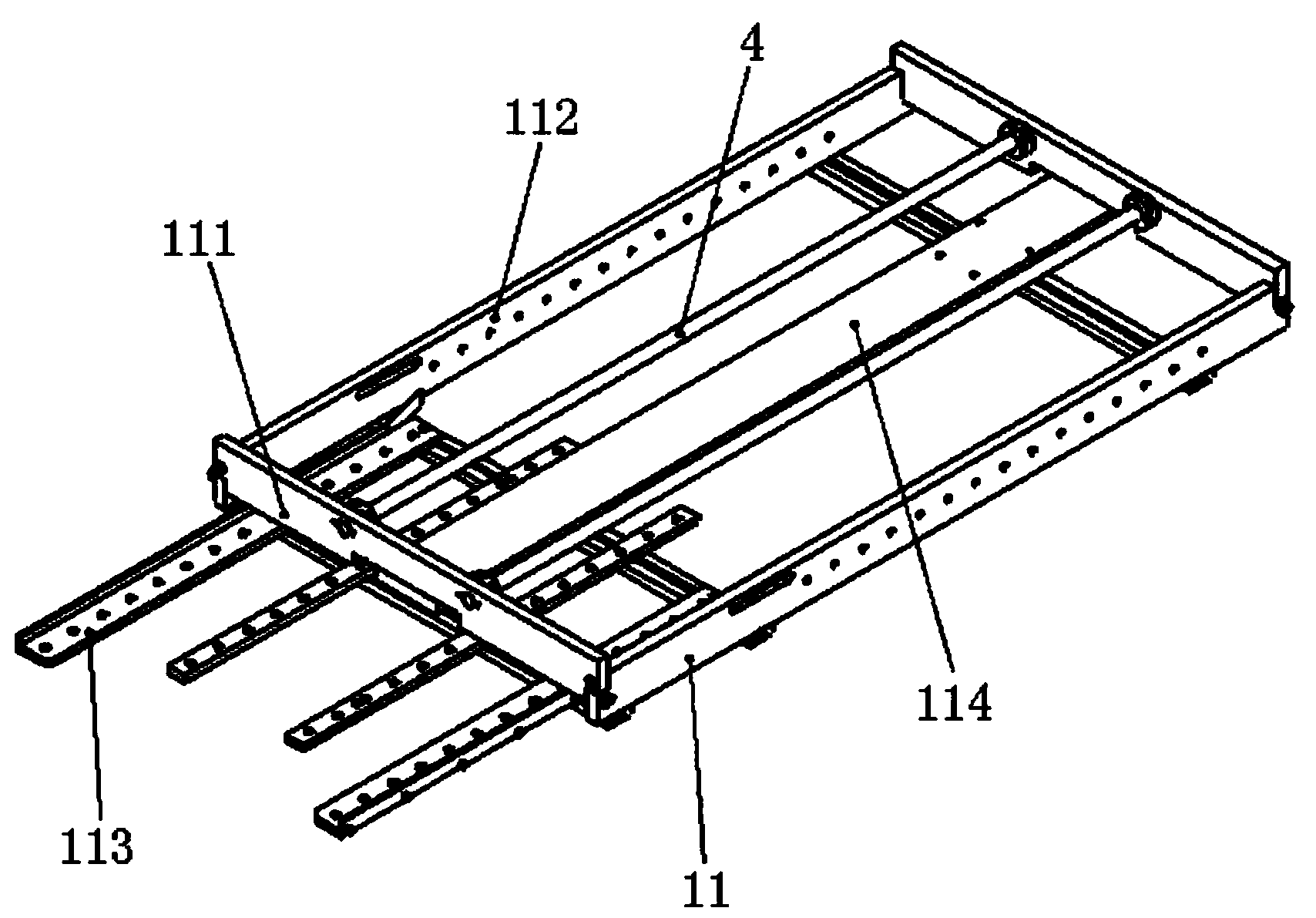

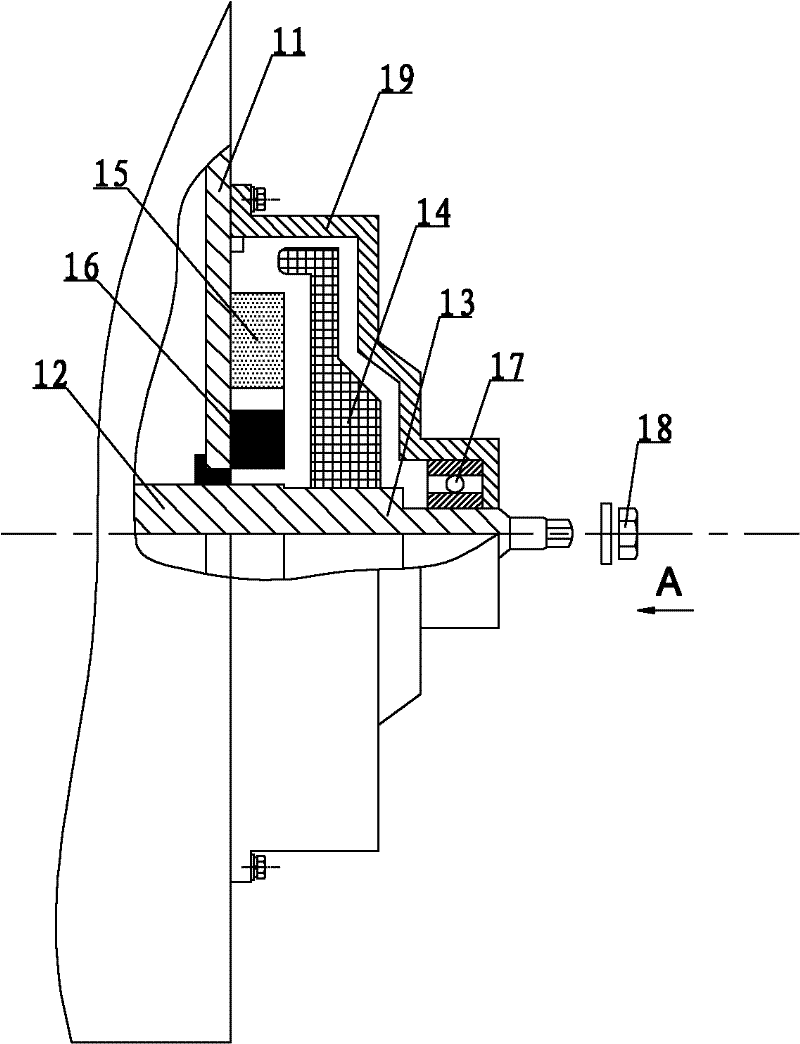

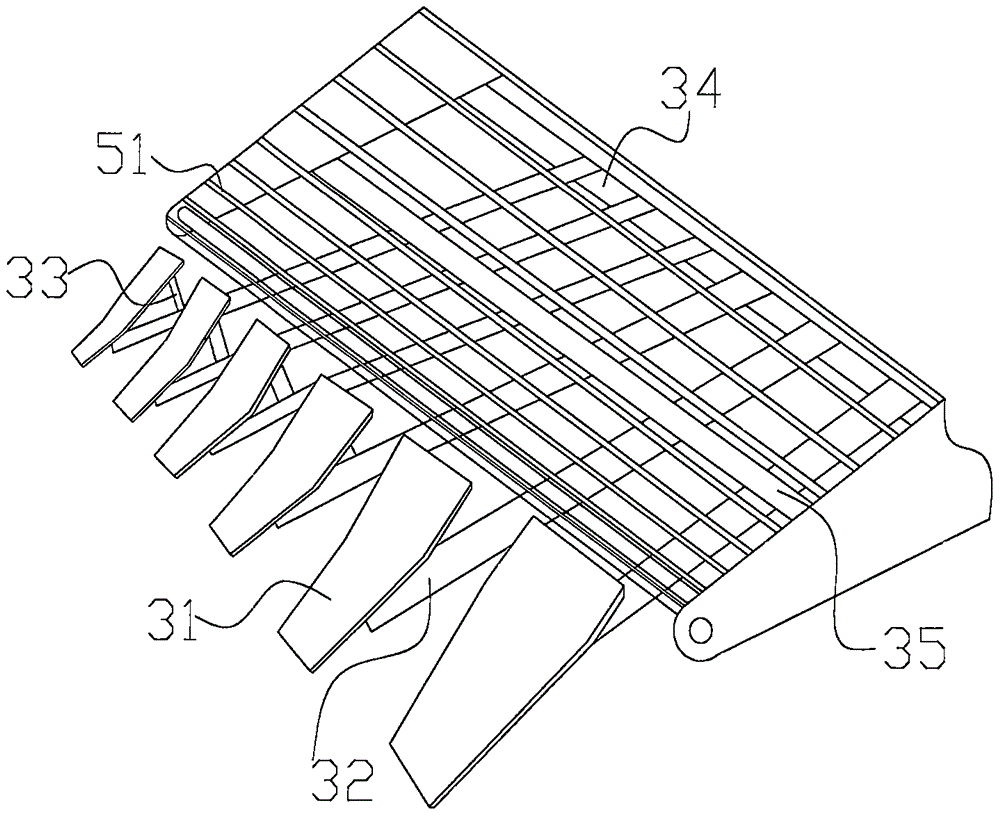

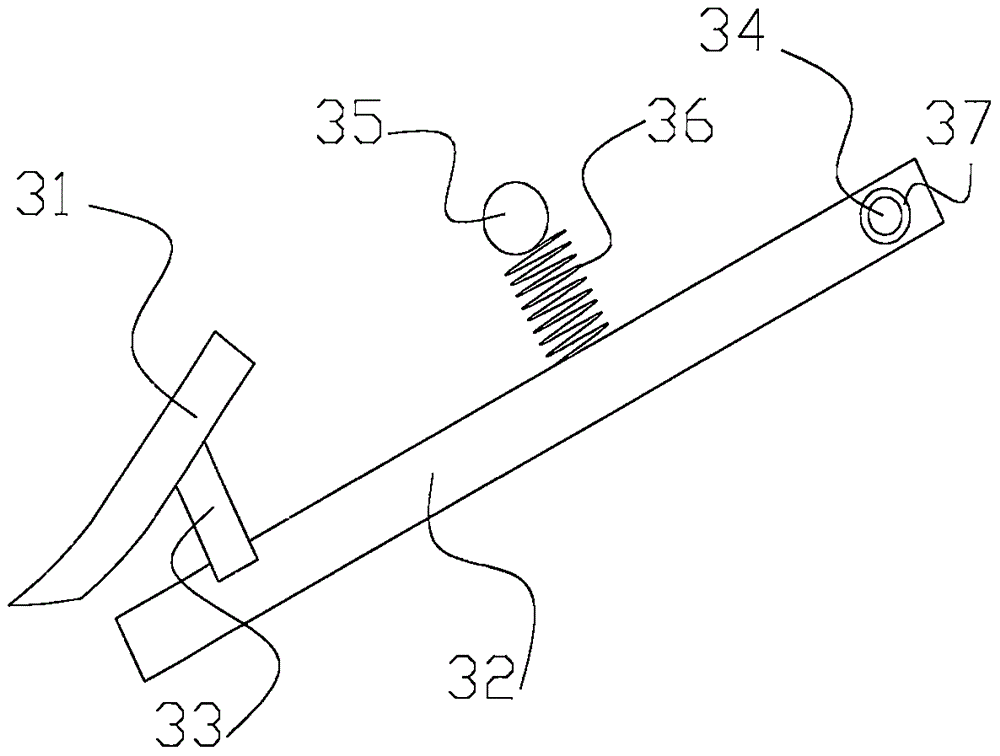

Automatic material feeding mechanism

ActiveCN103848194AReduce work stepsEliminate hazardsMetal-working feeding devicesPositioning devicesPunchingStops device

The invention provides an automatic material feeding mechanism. The automatic material feeding mechanism comprises a material sucking device and a material feeding mechanism, the material feeding mechanism comprises a material feeding platform, a power device, a material stopping device, a pushing plate and a guide device, a guide rod and a transmission device are installed on the material feeding plate, the transmission device is rotatably connected with the power device, the pushing plate is installed on the material feeding platform and is fixedly connected with the guide device, and the guide device is respectively and movably connected with the transmission device and the guide rod and can slide along the guide rod; pushing pins which can swing up and down are installed at the front end of the pushing plate; the material stopping device is installed on the material feeding platform and is used for stopping material sheets from moving back. The automatic material feeding mechanism has the advantages that the conveying distance from the automatic material feeding mechanism to a punching machine is shortened and the area occupied by the machine is reduced; the automatic material feeding mechanism is suitable for producing various material sheets with different sizes; the feeding stability is improved and the production efficiency and the production safety of the machine are also improved.

Owner:桐乡市华杰工业自动化科技有限公司

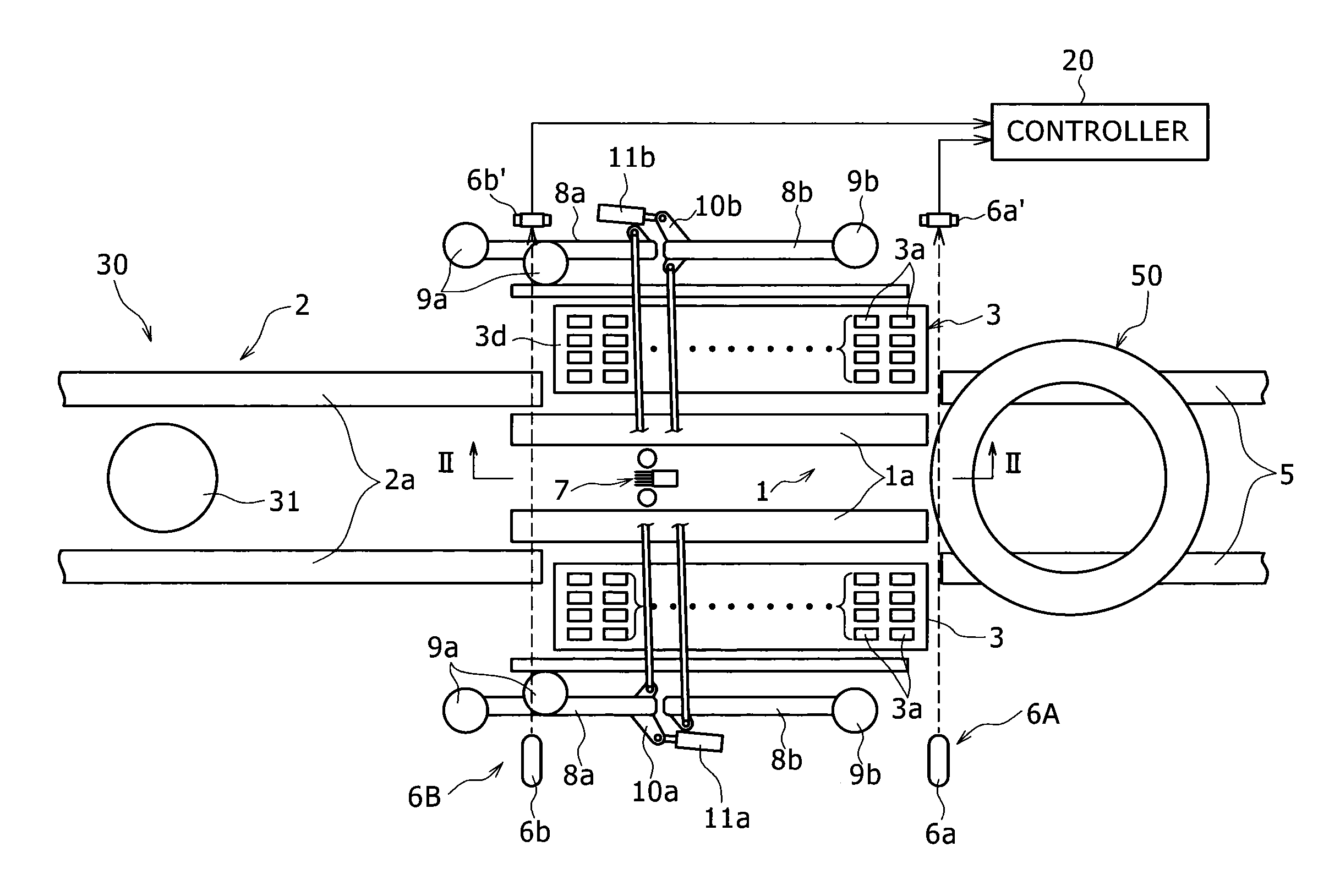

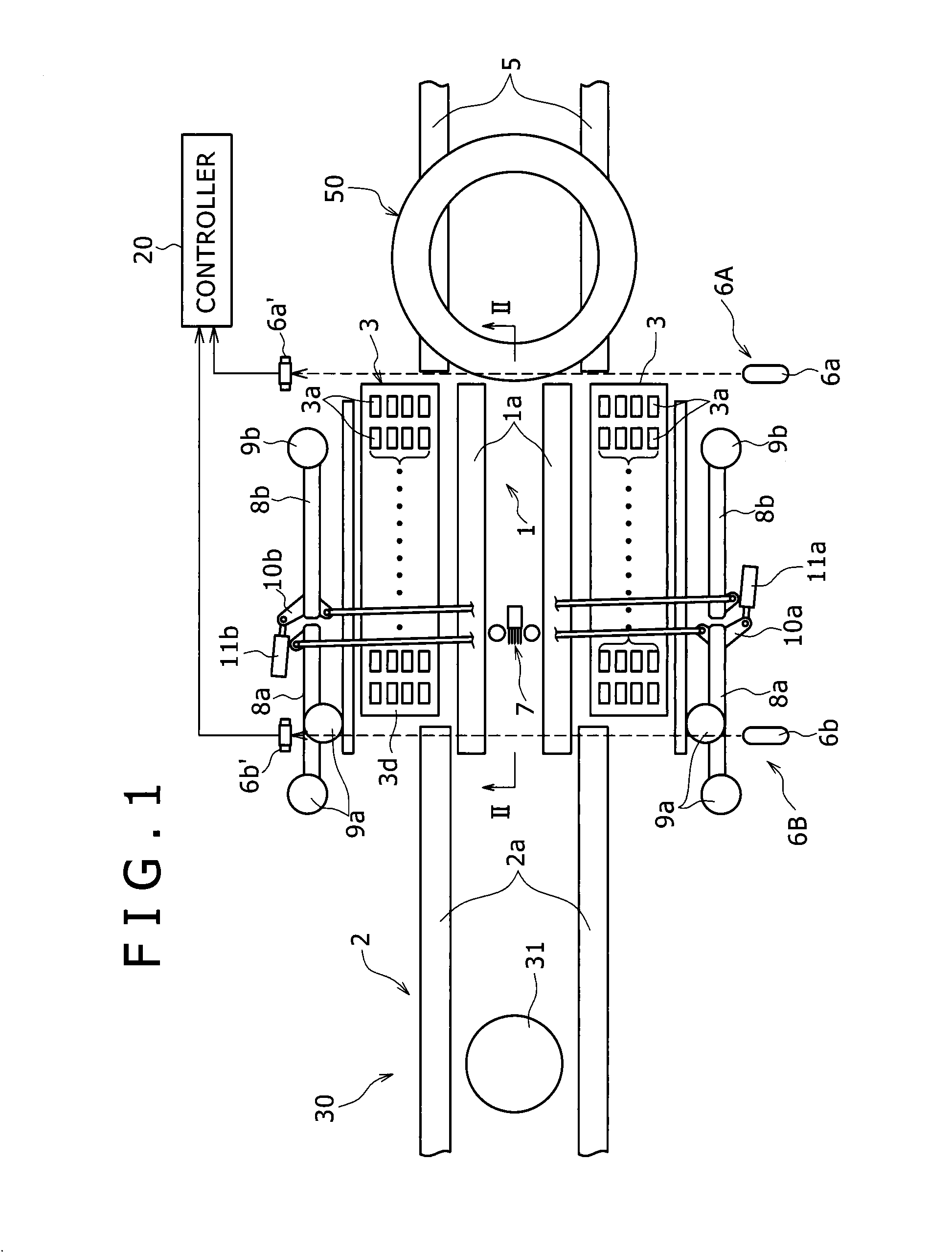

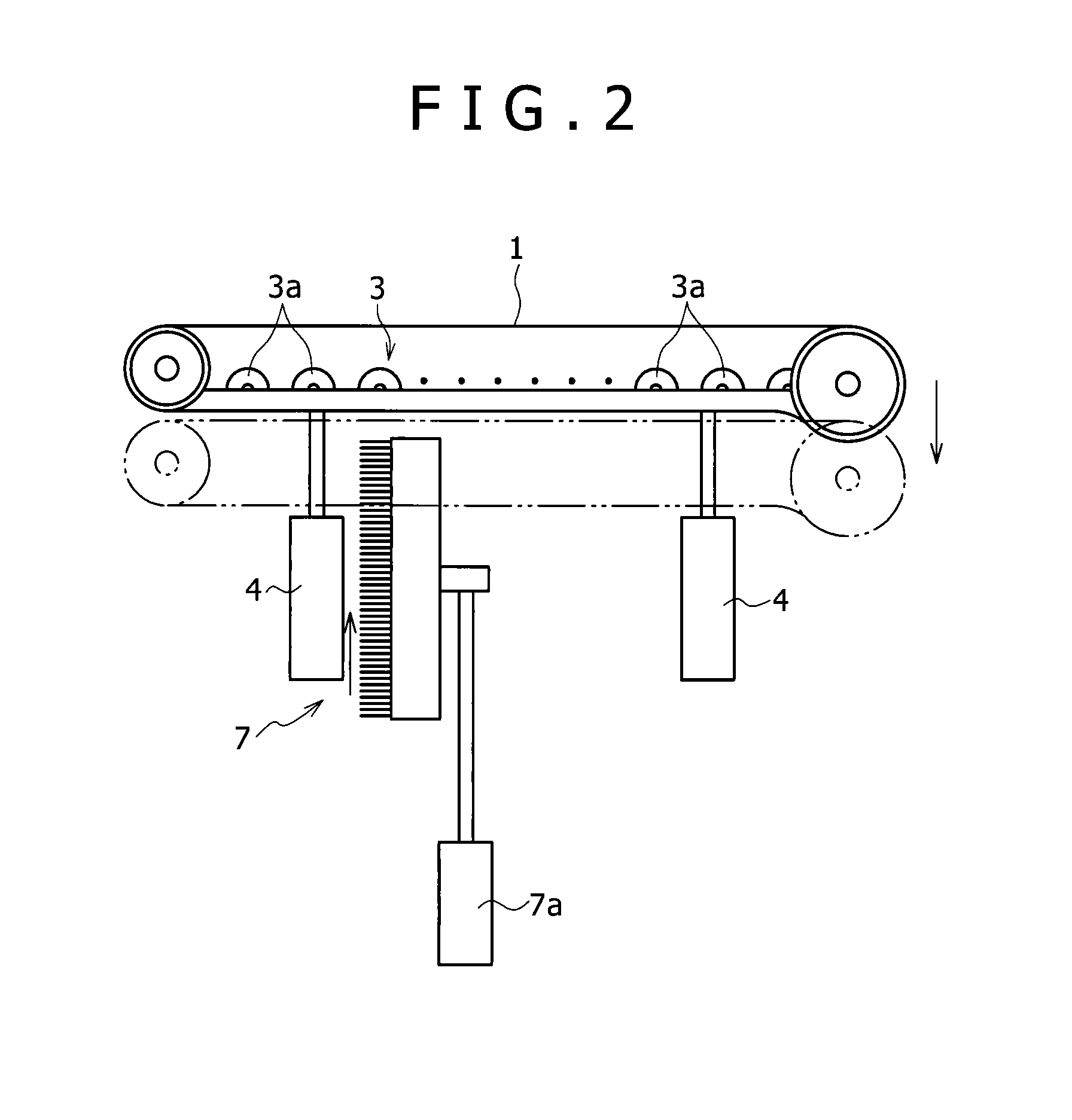

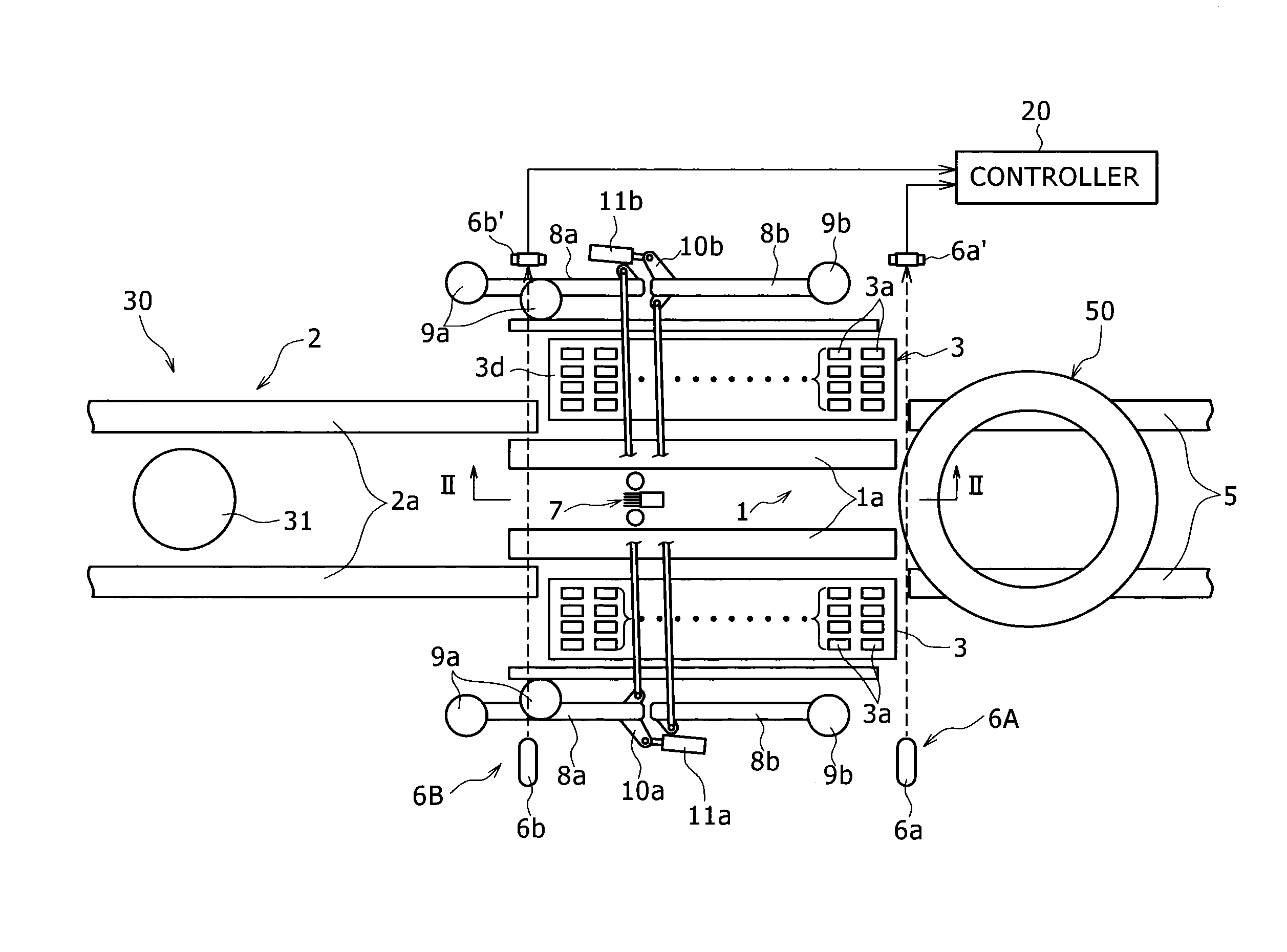

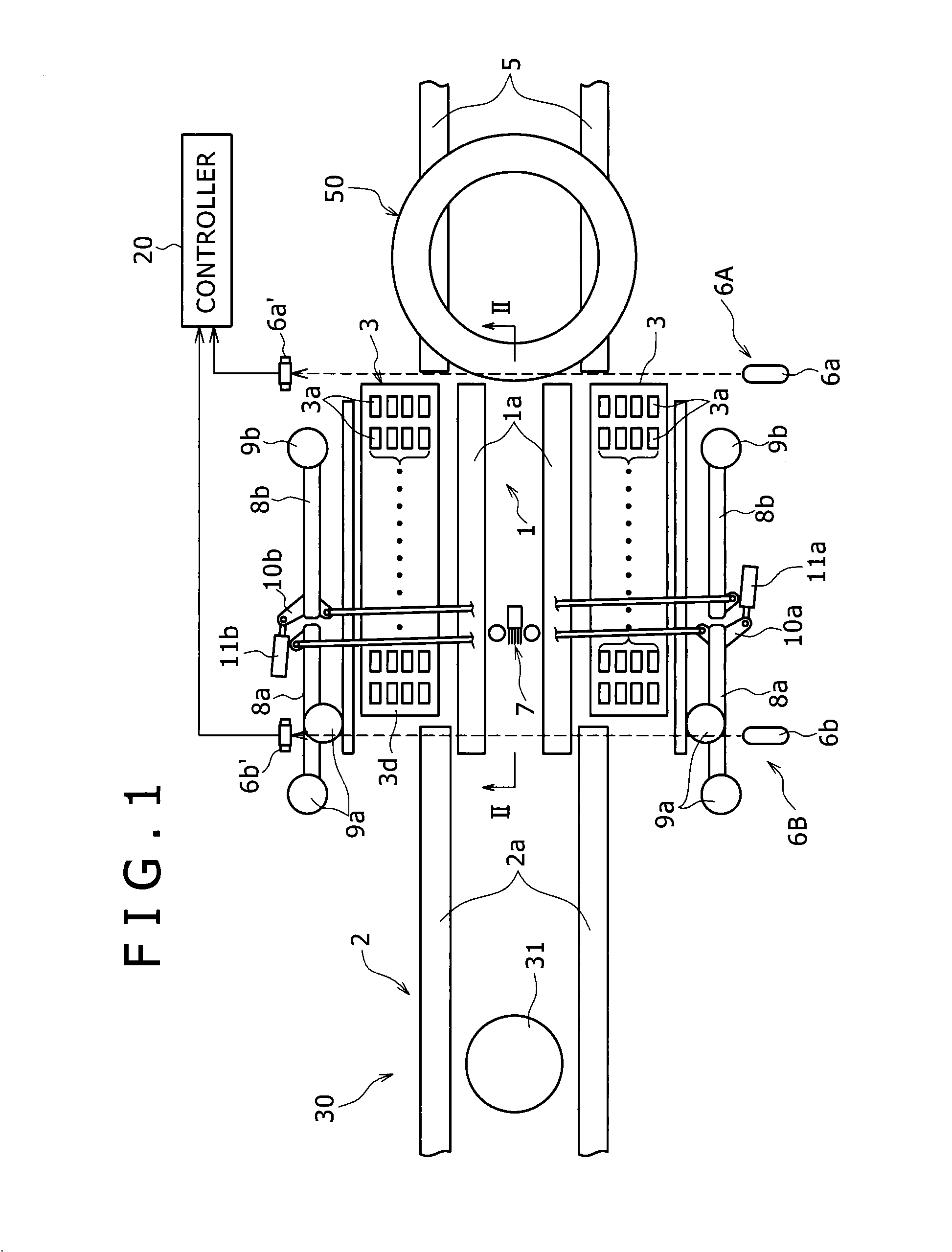

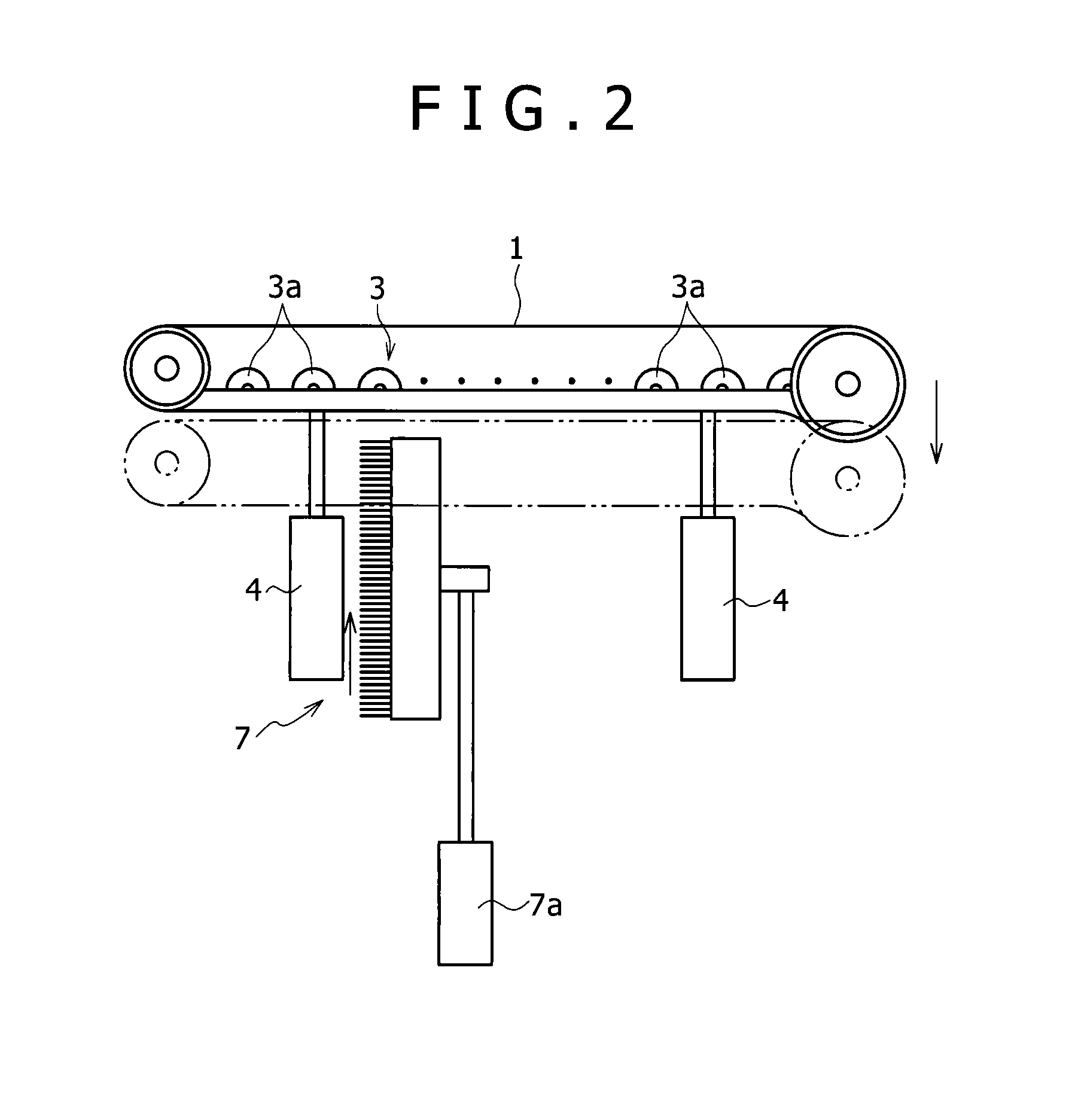

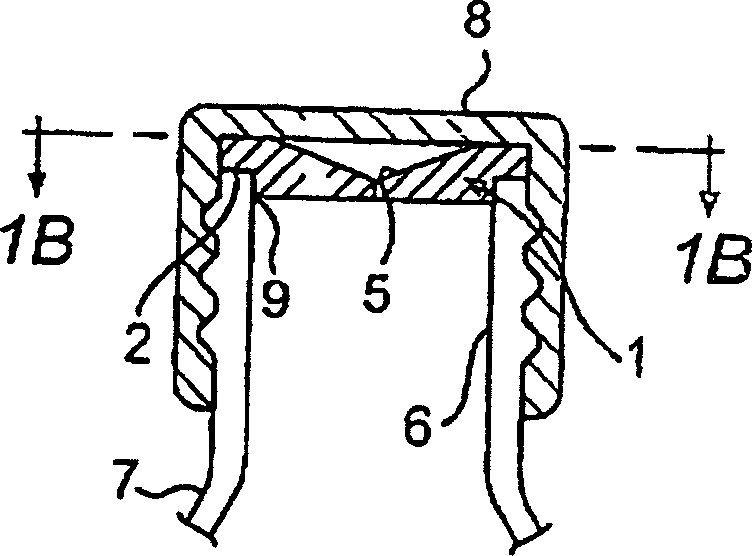

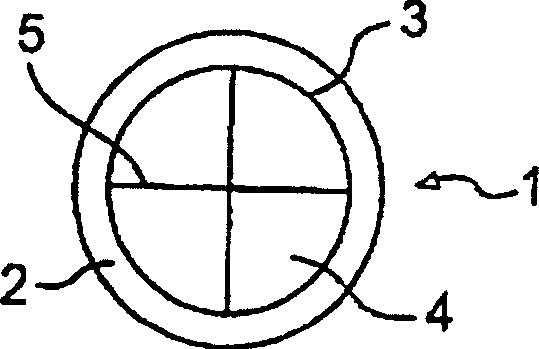

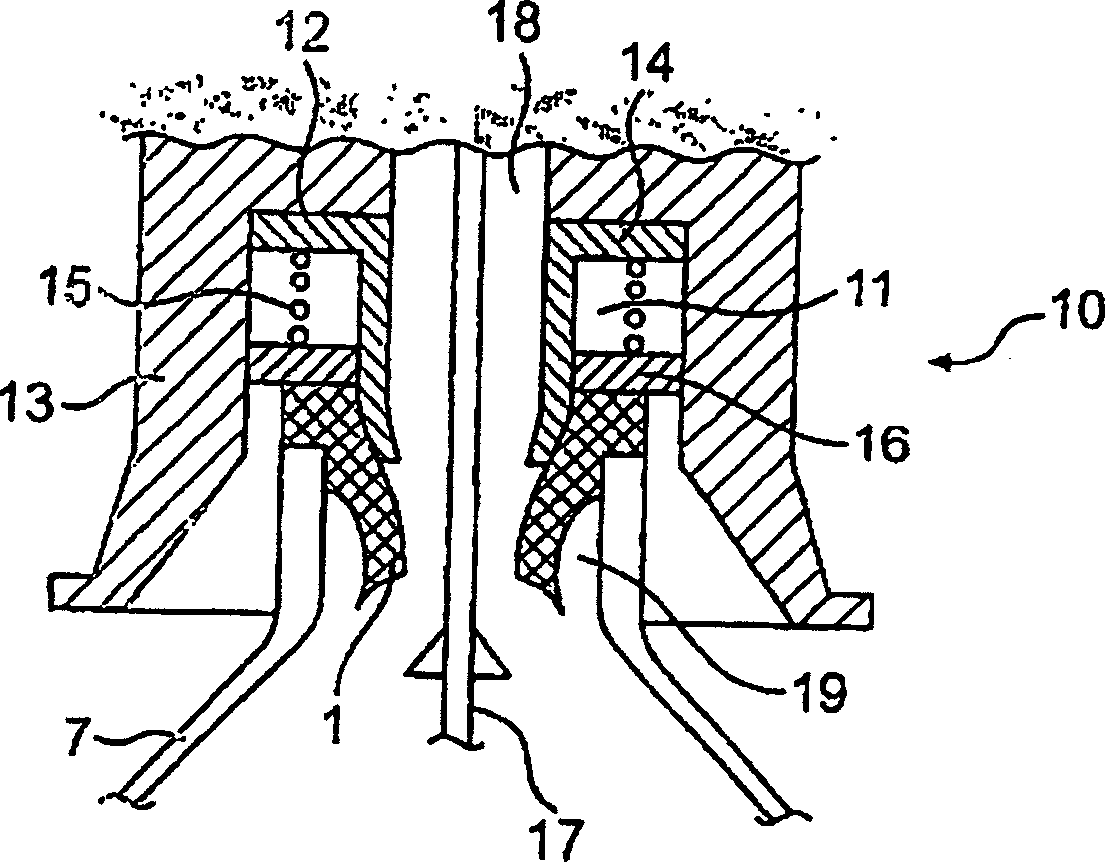

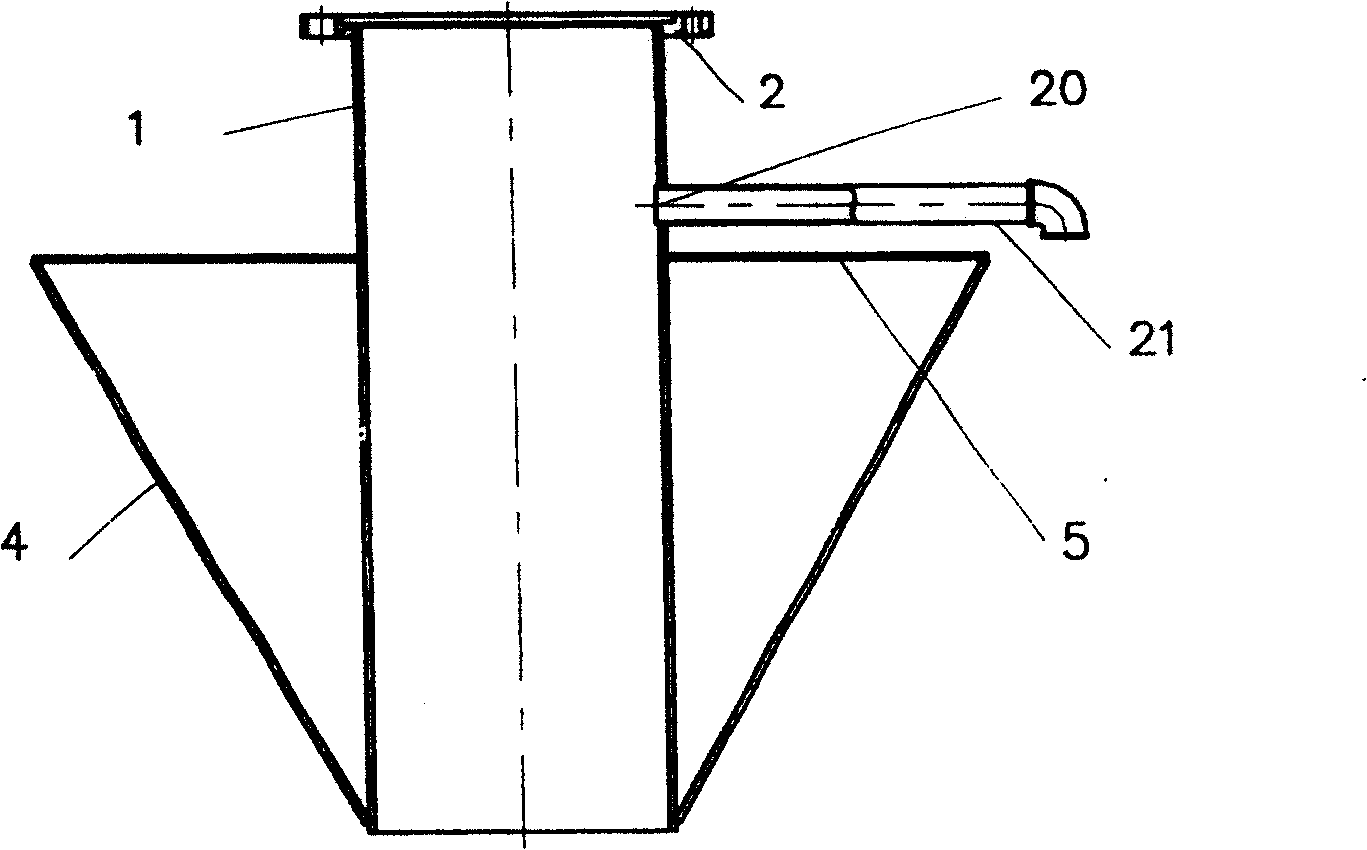

Loading device for tire testing machine

InactiveUS20130333615A1Reduce the necessary timeIncrease delivery speedTyre partsLiquid surface applicatorsCycle timeTesting position

Provided is a loading device that is provided in a tire testing machine including a testing station (30) provided with a spindle (31) attached with a tire (50) to be tested and feeds the tire (50) from a predetermined standby position to a testing position where the center of the spindle matches the center of the tire (50) in the testing station (30). The loading device includes: conveyors (1, 2) that convey the tire (50) from the standby position toward the testing position in a direction perpendicular to the axial direction of the tire; and positioning devices (6B, 20) that position the tire to be tested to a position, in which a front end of the tire in the feeding direction matches a point separated from the spindle by a predetermined distance, as the standby position. Setting of the standby position based on the position of the front end of the tire (50) in the feeding direction shortens the feeding distance and the feeding time and hence shortens the testing cycle time.

Owner:KOBE STEEL LTD

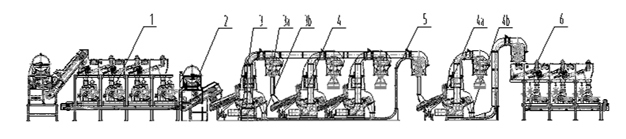

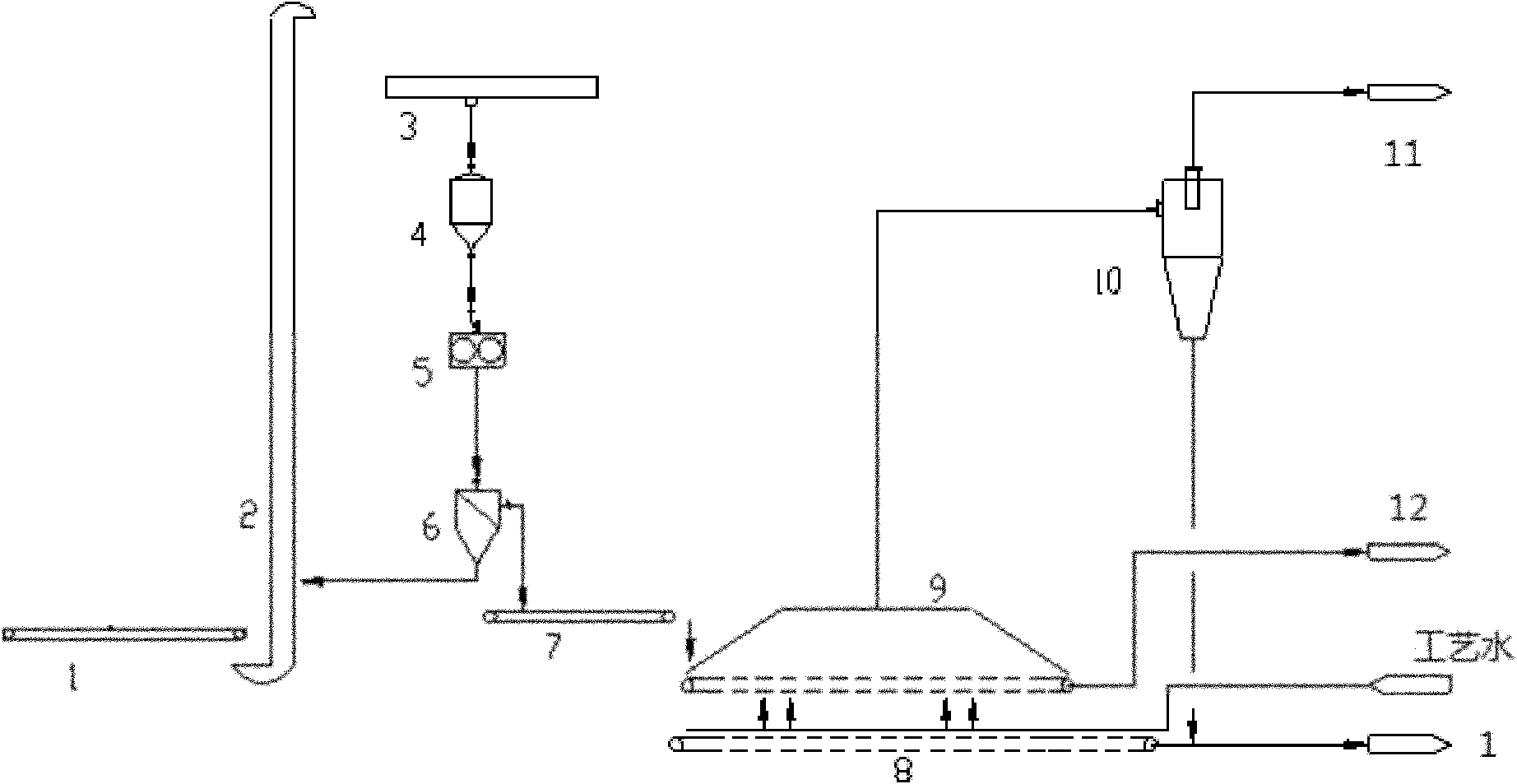

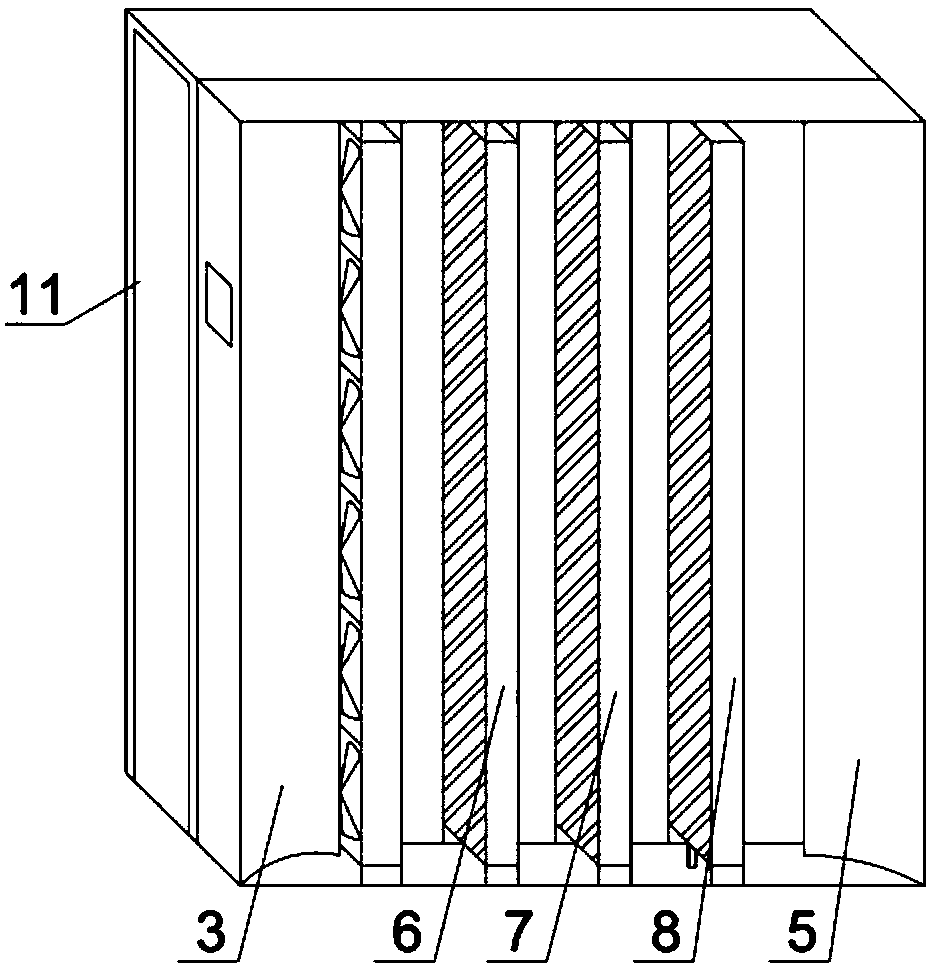

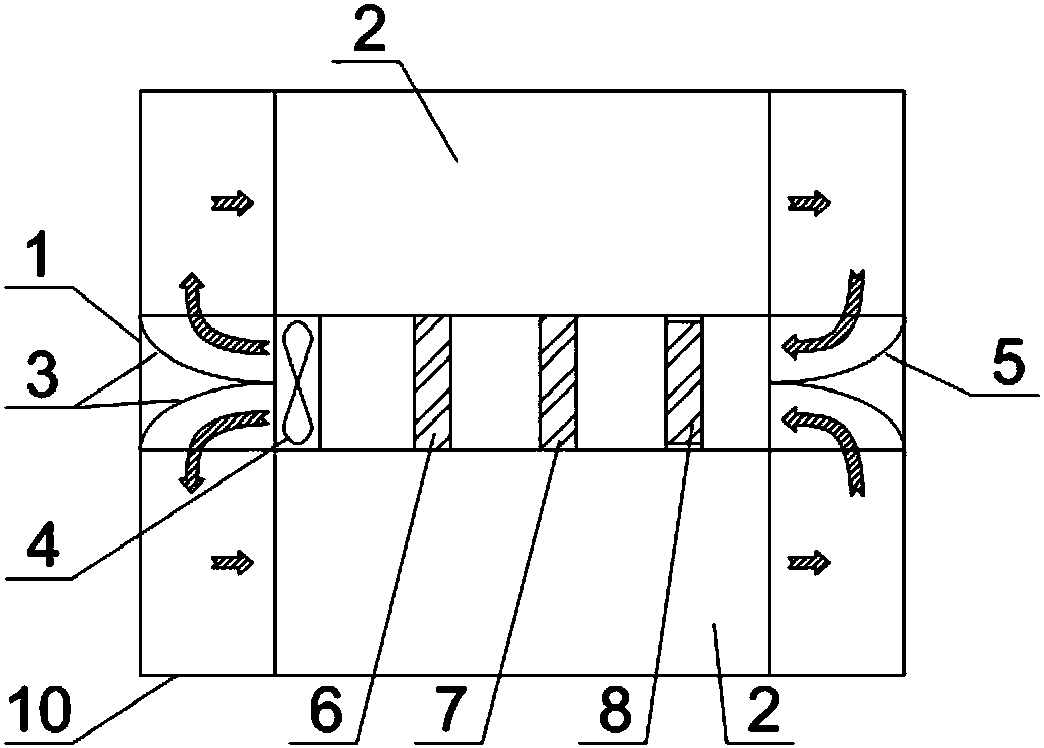

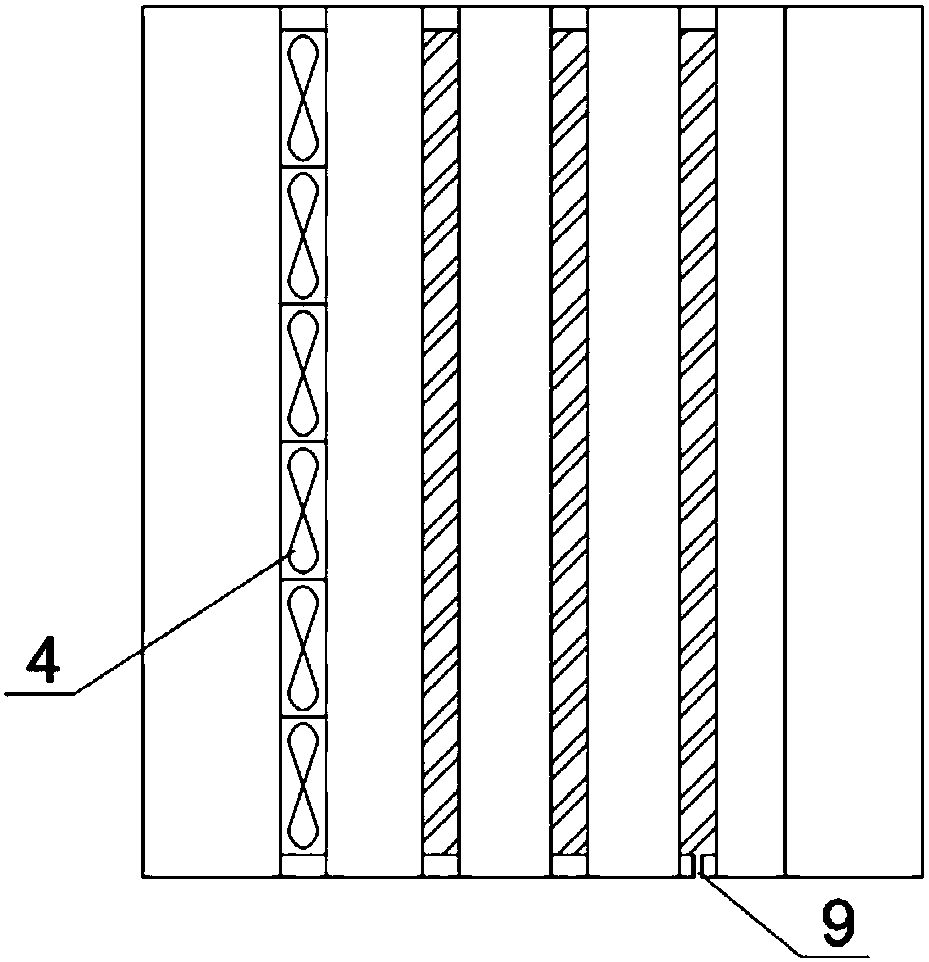

Divided winnowing method and system for tobacco leaf threshing

ActiveCN102048237AShorten delivery timeShorten the conveying distanceTobacco preparationProcess engineeringMutual influence

The invention relates to a divided winnowing method and system for tobacco leaf threshing. The winnowing system consists of a leaf threshing machine (1), a primary-selection winnowing unit (3), a multi-stage fine-selection air distributing unit (4) and a secondary leaf threshing machine (6) that are sequentially arranged, wherein the leaf threshing machine and the primary-selection winnowing unitare connected via auxiliary communicated conveying equipment (2), a blanking hole (3a) of a blanking device of the primary-selection winnowing unit is arranged above a feeding device of the multi-stage fine-selection air distributing unit, and the part between the discharge hole (3b) of the primary-selection winnowing unit and the secondary leaf threshing machine is connected with a collecting air blowing pipeline (5) or a conveyor. By virtue of the winnowing system, materials obtained after leaves are threshed can be reasonably divided and winnowed, lighter materials and heavier materials are effectively separated so as to avoid the mutual influence caused by mixing different materials during winnowing, the load entering a winnowing classifier is reduced, the winnowing precision of the fine-selection air distributing unit is improved, the stalk-content index in leaves is reduced, the leaf threshing effect is enhanced, the breakage of tobacco leaves is lowered, and the resource waste is reduced.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

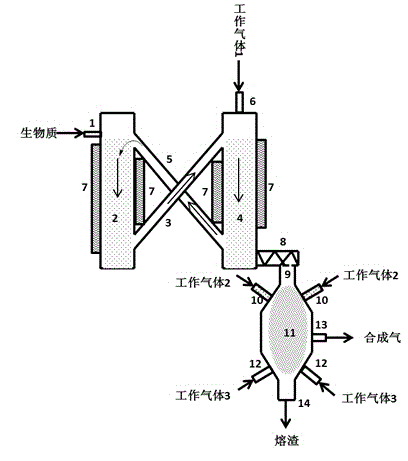

Biomass pyrolysis gasification method

ActiveCN105586091ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas productionMicrowave pyrolysisTar

The invention discloses a biomass pyrolysis gasification method which includes the following steps: 1) feeding a biomass raw material into a microwave pyrolysis reaction section to perform pyrolysis under microwave to generate gas, tar and semicoke as pyrolysis products; 2) respectively feeding the pyrolysis products and a first working gas into a microwave oriented gasification section to perform a gasification reaction to obtain a gasification product; 3) in the gasification product, separating gasified semicoke into two parts, wherein one part is spirally transported to the upper part of a microwave pyrolysis reaction section from the bottom of the microwave oriented gasification section so that this part of semicoke is mixed with the biomass raw material to perform microwave pyrolysis, and the other part of the semicoke is spirally transported to a plasma reaction section with a gas-phase volatile component in the gasification product; 4) performing a plasma gasification reaction to the material fed into the plasma reaction section to obtain high-quality synthetic gas which then is discharged out from a gas outlet while solid residues are discharged from the bottom of the plasma reaction section. The method is high in biomass gasification rate and carbon conversion rate. The synthetic gas is high in quality, can satisfy demand on synthetic liquid fuels and has excellent application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

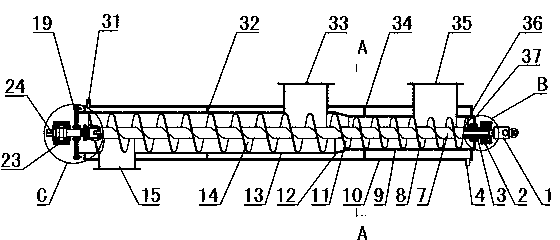

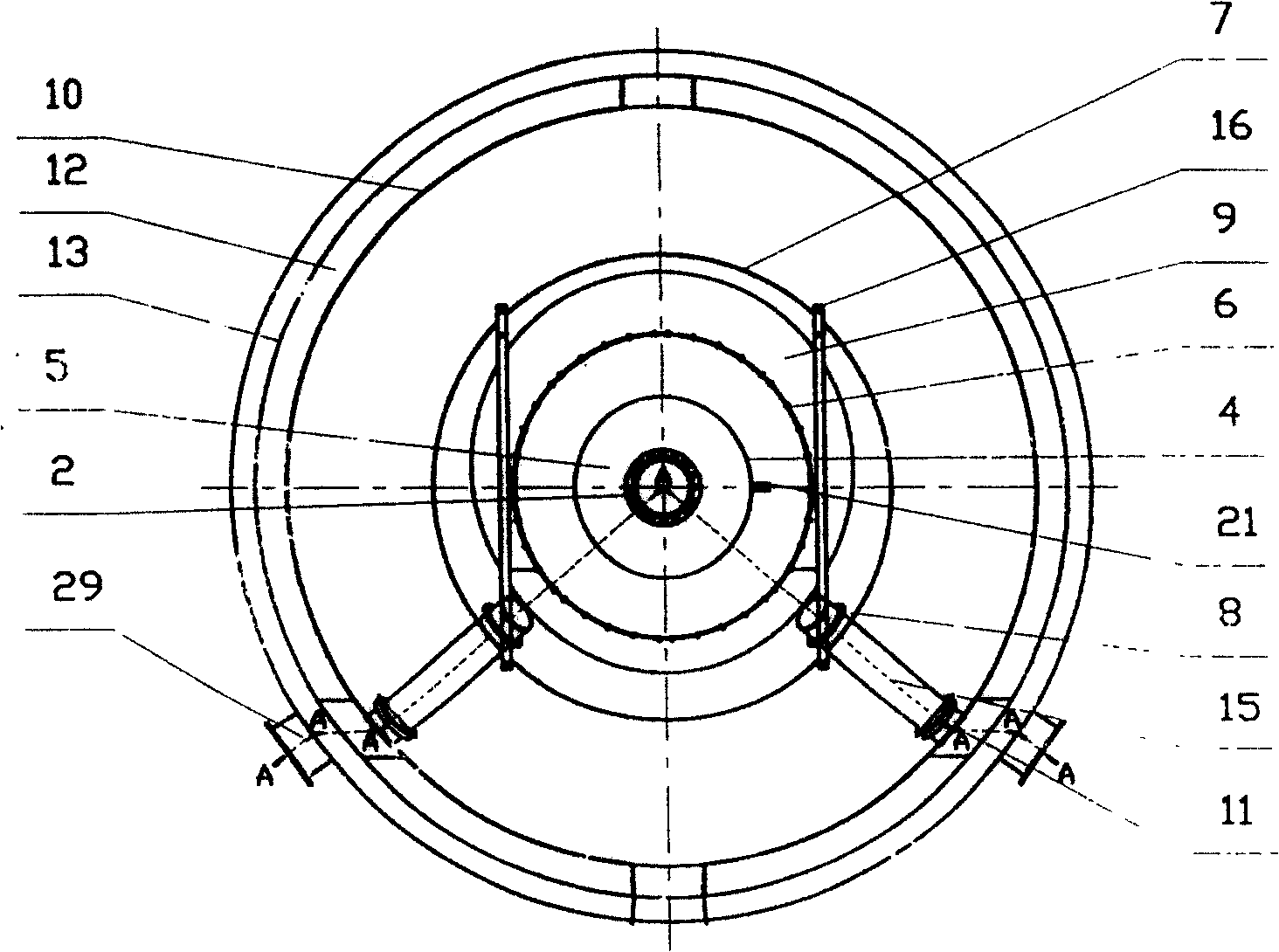

Semi coke waste heat recovery type spiral conveyer

ActiveCN104355071AAvoid dangerous accidentsTo achieve the purpose of full material deliveryStationary tubular conduit assembliesPackagingEngineeringCircular surface

The invention discloses a semi coke waste heat recovery type spiral conveyer, and belongs to the field of semi coke processing equipment. An inner cylinder body includes two or more inner cylinder body sections, a feeding port is communicated with the upper side at the conveying starting end of each inner cylinder body section, and a discharging port (15) is communicated with the lower side at the tail end of the last inner cylinder body section; the volume defined by a pitch screw blade of the N+1th inner cylinder body section, the external circular surface of a spiral base tube (7) and the internal circular surface of the N+1th inner cylinder body section is (N+1) / N plus or minus 1 / 5N times of the volume defined by a pitch screw blade inside the Nth inner cylinder body section, the external circular surface of the spiral base tube (7) and the internal circular surface of the Nth inner cylinder body section, wherein the N is an integer not smaller than 1 and not greater than 5. According to the invention, the fact that after semi coke inside the inner cylinder body section on the front side enters the inner cylinder body section on the rear side, semi coke at the feeding port of the inner cylinder body section on the rear side enters the inner cylinder body section on the rear side, and all the inner cylinder body sections are filled with material exactly is guaranteed, so that filled conveying is realized, and danger of gas leakage can be effectively avoided.

Owner:SHANDONG UNIV OF TECH

Loading device for tire testing machine

InactiveUS8950250B2Reduce the necessary timeIncrease delivery speedTyre partsLiquid surface applicatorsCycle timeTesting position

Provided is a loading device that is provided in a tire testing machine including a testing station (30) provided with a spindle (31) attached with a tire (50) to be tested and feeds the tire (50) from a predetermined standby position to a testing position where the center of the spindle matches the center of the tire (50) in the testing station (30). The loading device includes: conveyors (1, 2) that convey the tire (50) from the standby position toward the testing position in a direction perpendicular to the axial direction of the tire; and positioning devices (6B, 20) that position the tire to be tested to a position, in which a front end of the tire in the feeding direction matches a point separated from the spindle by a predetermined distance, as the standby position. Setting of the standby position based on the position of the front end of the tire (50) in the feeding direction shortens the feeding distance and the feeding time and hence shortens the testing cycle time.

Owner:KOBE STEEL LTD

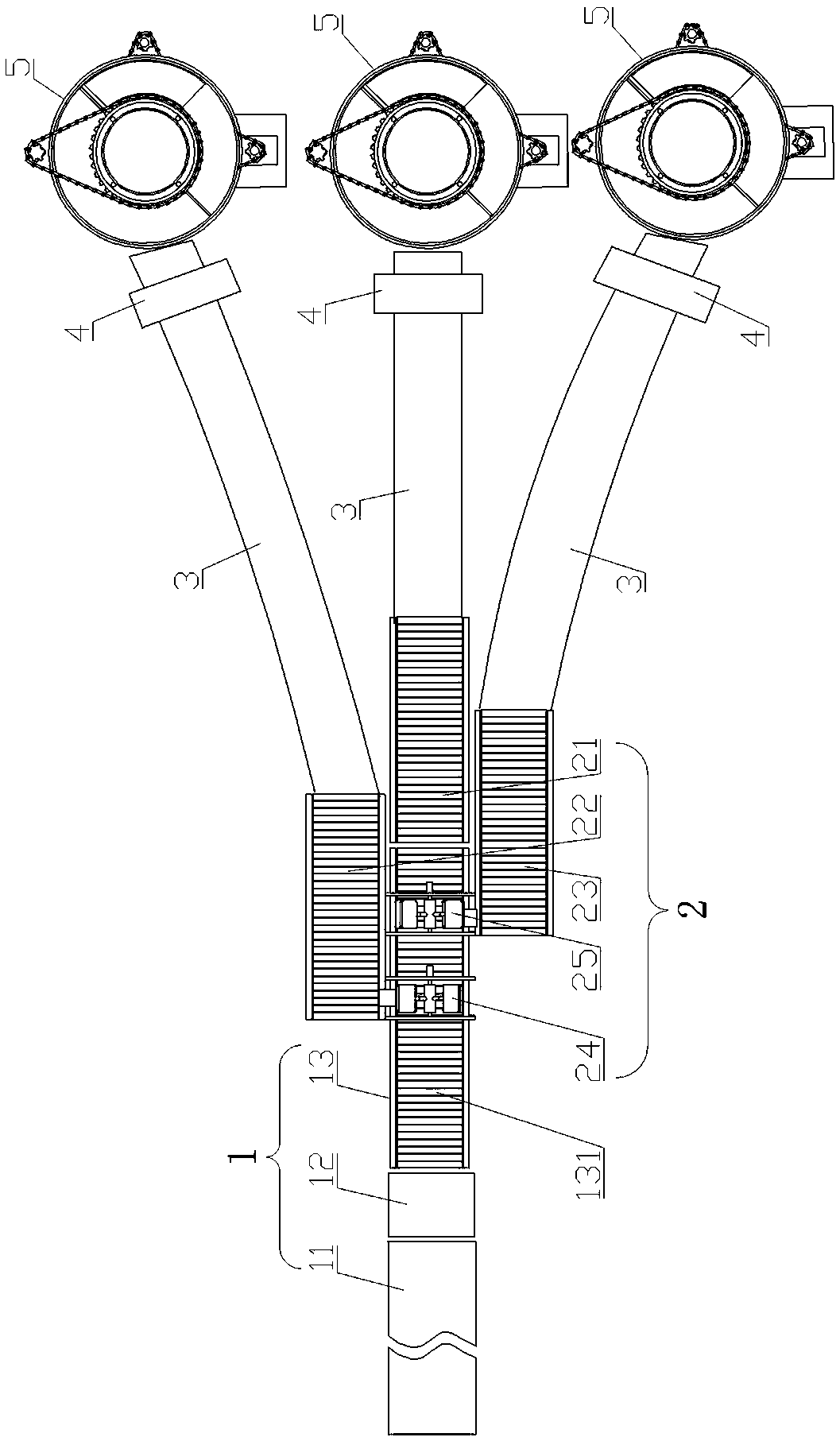

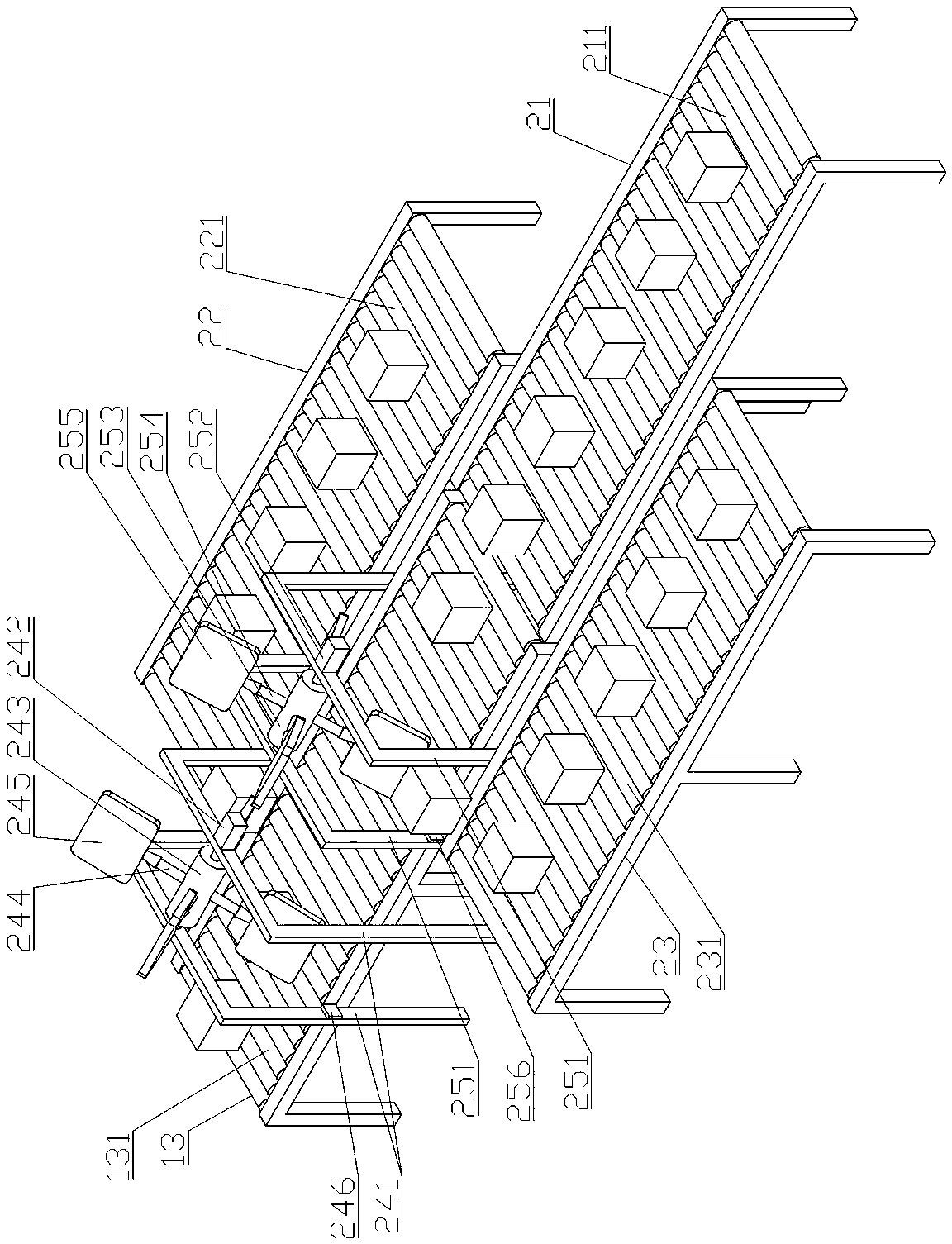

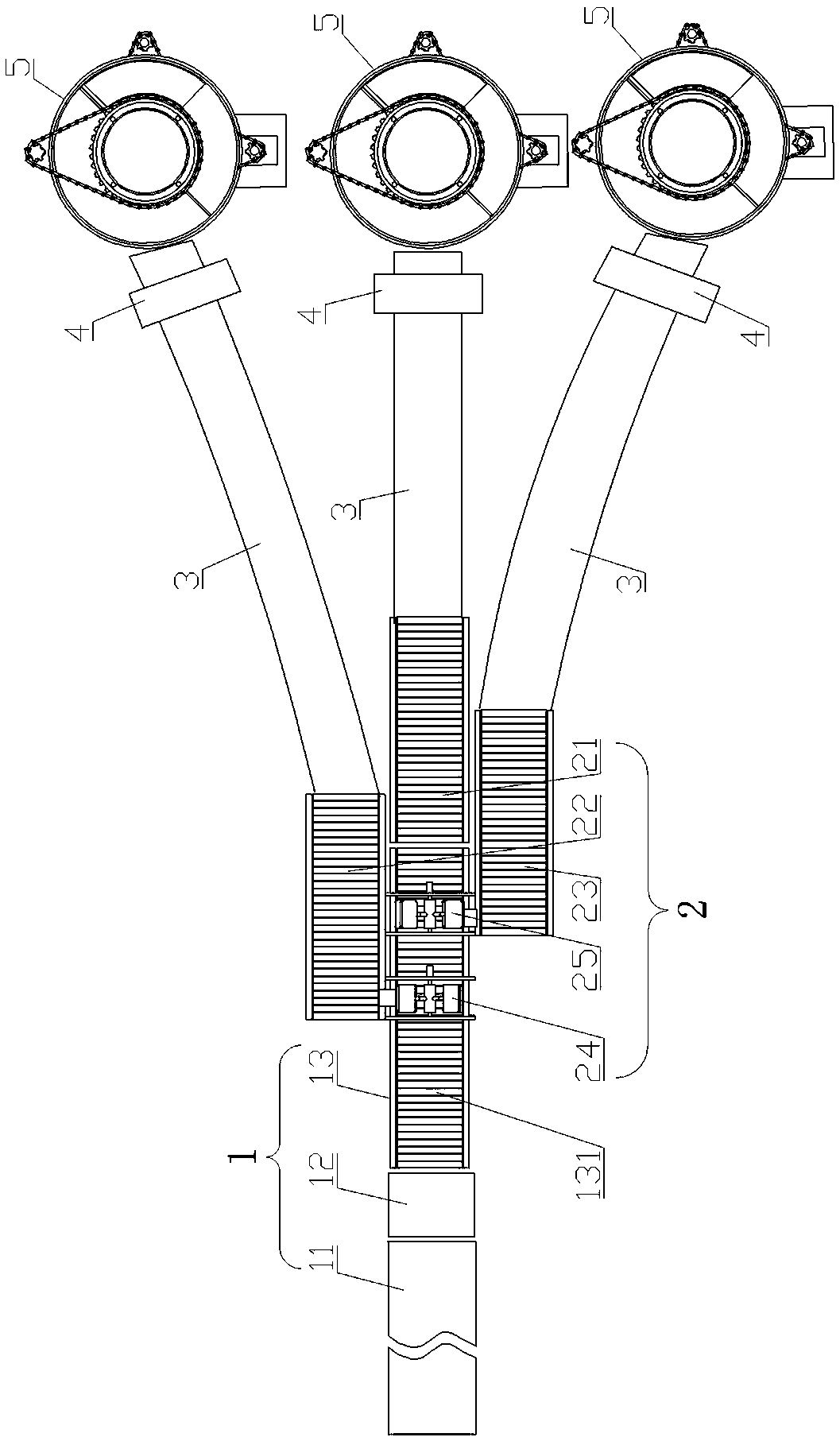

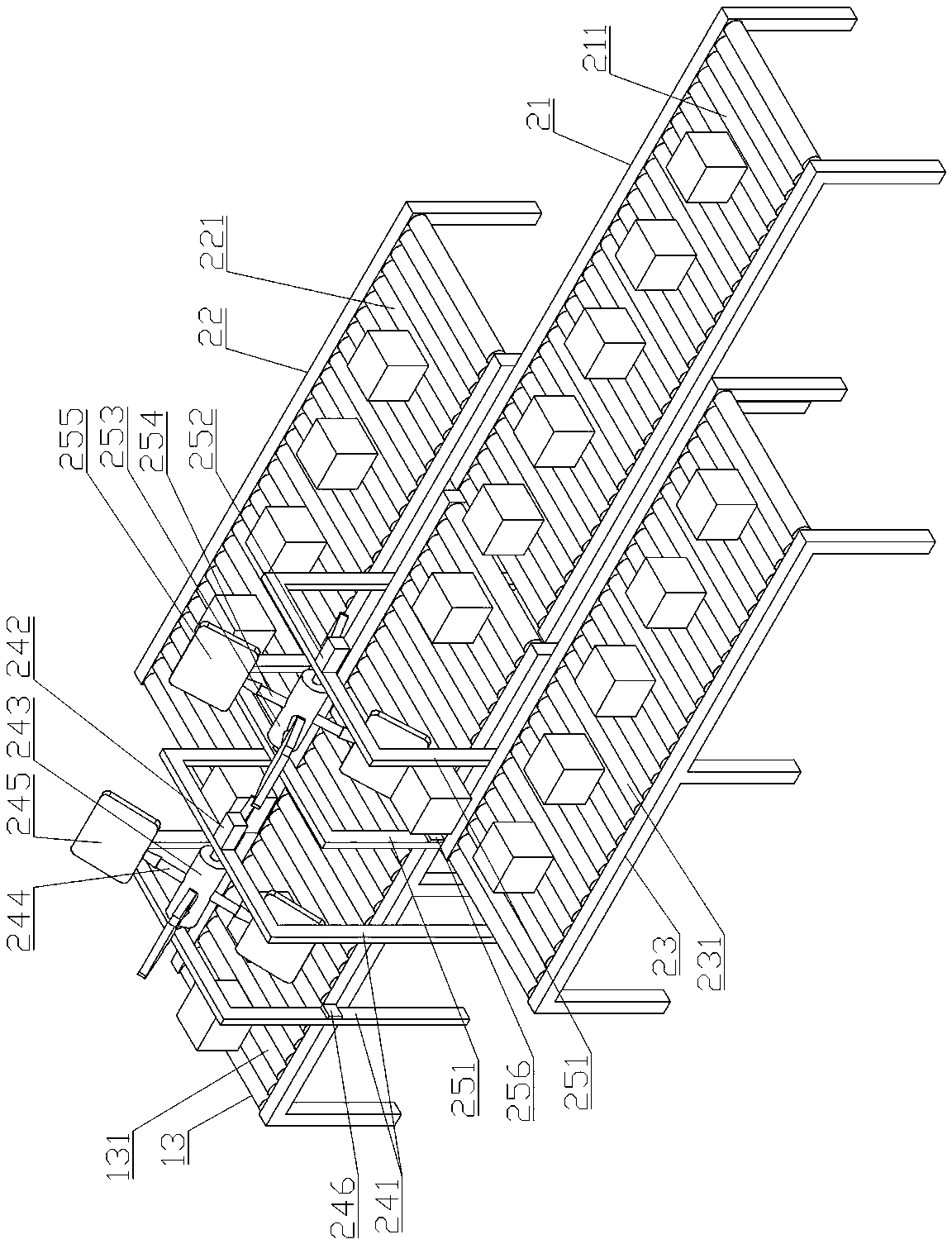

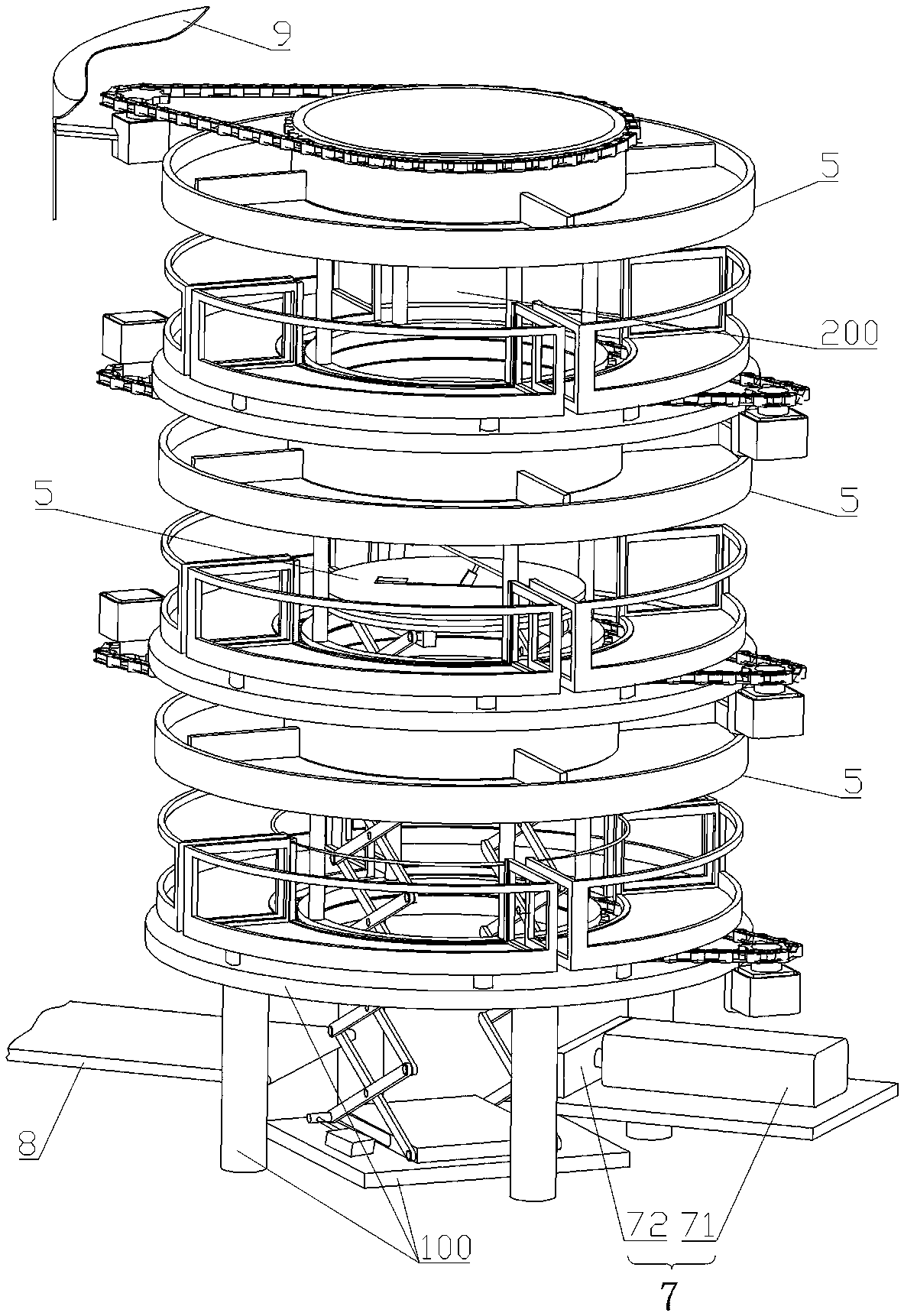

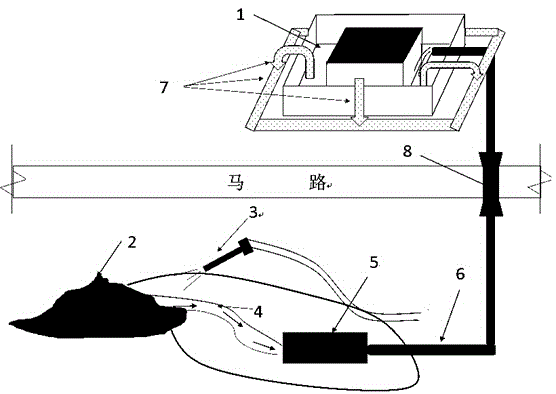

Code-scanning rear-mounted logistics sorting system

ActiveCN108499884AReduce the probability of misalignmentShorten the conveying distanceSortingLogistics managementTower

A code-scanning rear-mounted logistics sorting system comprises a seeking separator, a three-dimension divider, dividing conveyors, a scanning device and tower sorting devices; the seeking separator comprises a conveyor A, a smooth separator plate and a roller conveying device which are sequentially adjacently arranged from front to back; the three-dimension divider comprises a middle roller conveying device, a left roller conveying device, a right roller conveying device, a front swing mechanism and a rear swing mechanism; the quantity of the dividing conveyors is three, and the dividing conveyors are respectively arranged at the rear ends of the middle roller conveying device, the left roller conveying device and the right roller conveying device; the quantity of the tower sorting devices is three, and the tower sorting devices are respectively arranged the rear ends of the three dividing conveyors; and every tower sorting device comprises a sorter, a package taking device, a pusher,a conveyor B, an outer cover and a pedestal. An independent address code scanning device is arranged at the near front end of every tower sorting device, so a conveying distance between address codescanning and the sorters is reduced, the dislocation probability between the code scanning address and the address of a package, caused by dropping of the package, is reduced, and the sorting accuracyis improved.

Owner:NANHUA UNIV

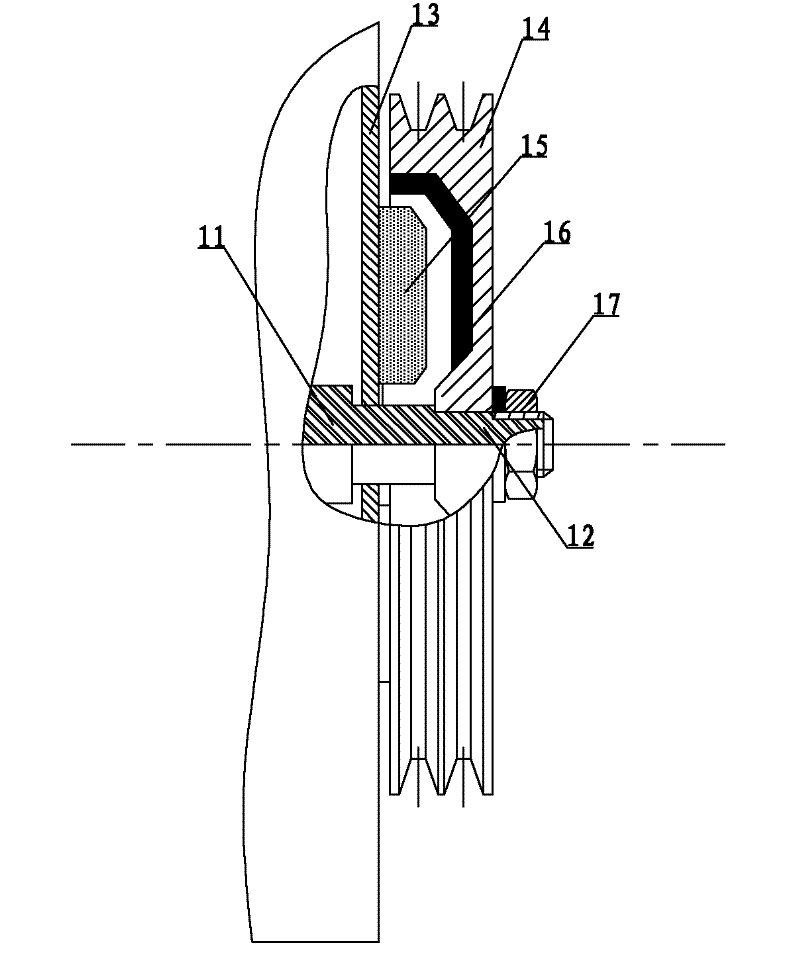

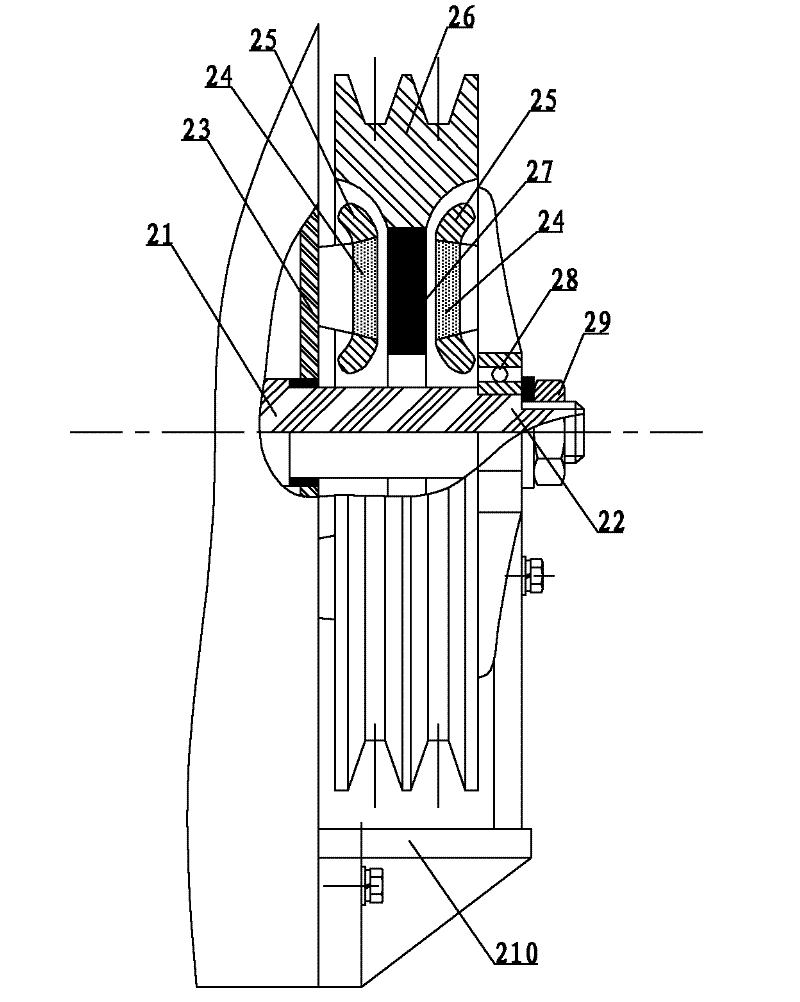

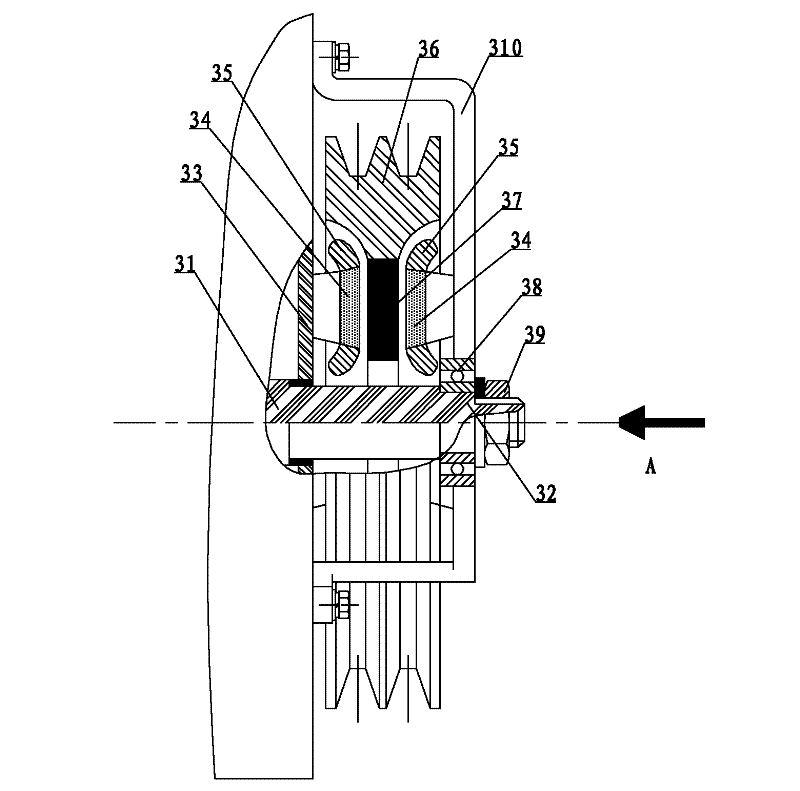

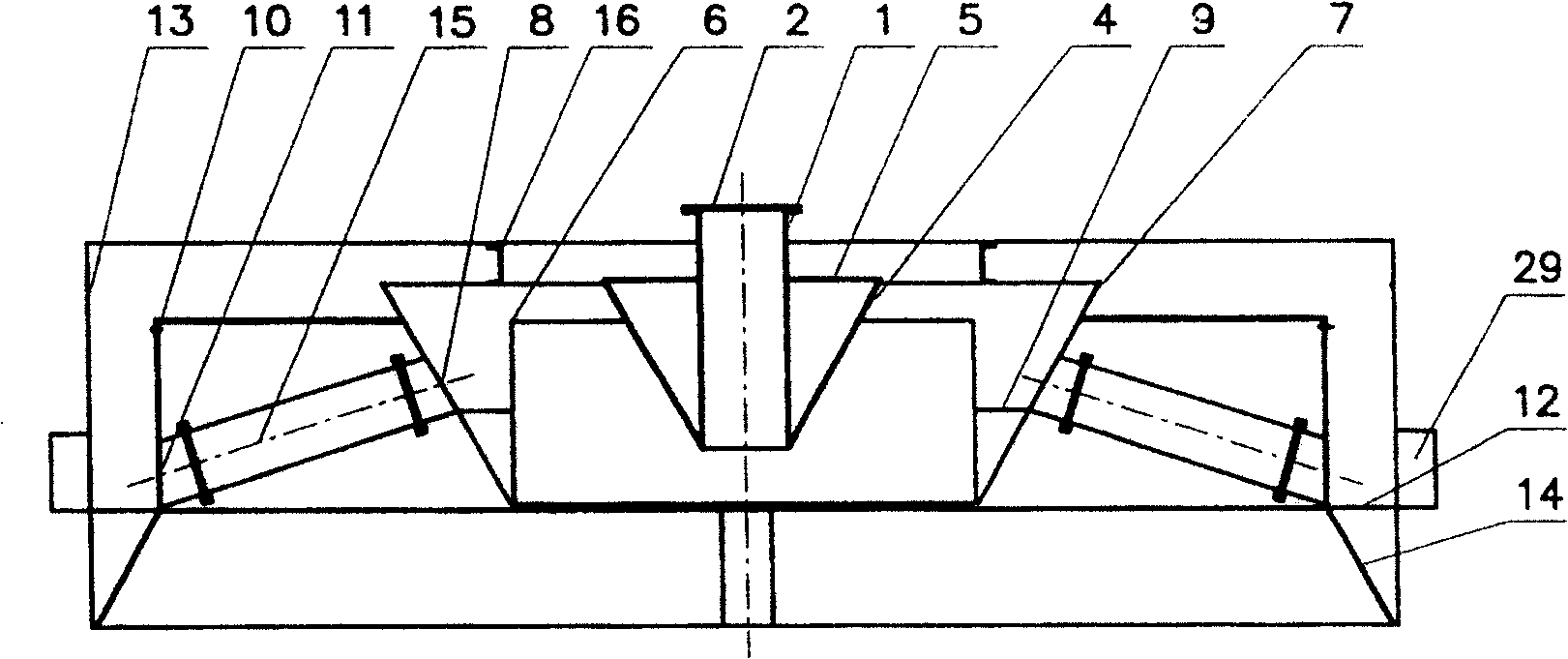

Foam pushing device of floatation machine

InactiveCN1931438AShorten the conveying distanceImprove flotation indexFlotationNon-ferrous metalEngineering

The present invention relates to floatation equipment for separating non-ferrous metal mineral, ferrous metal mineral and non-metal mineral, and is especially foam pushing device for large floatation machine. The foam pushing device is one double foam pushing cone structure comprising an inner foam pushing cone, an inner foam channel, outer foam pushing cone and outer foam channel. The foam pushing device separates the foams inside the floatation tank into two parts, the marginal part exhausted through the outer foam channel and the middle part exhausted through the inner foam channel, and the shortened foam conveying distance ensures the fluent exhaustion of floatation foam and is favorable to the floatation process.

Owner:BEIJING GENERAL RES INSITUTE OF MINING & METALLURGY GUAN MACHINERY +1

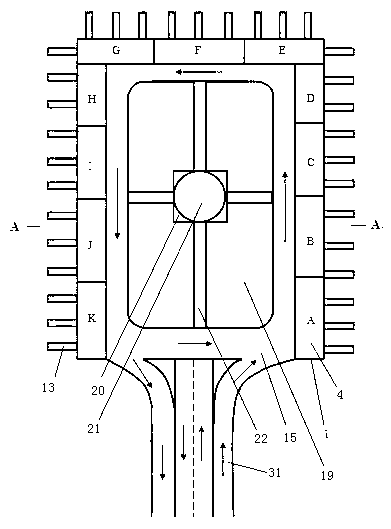

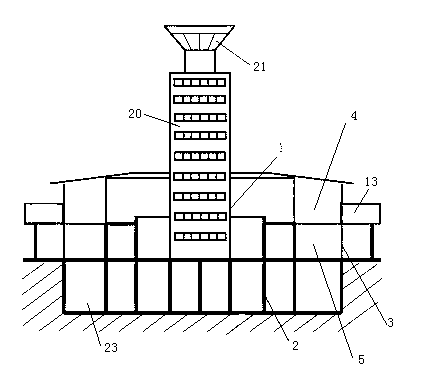

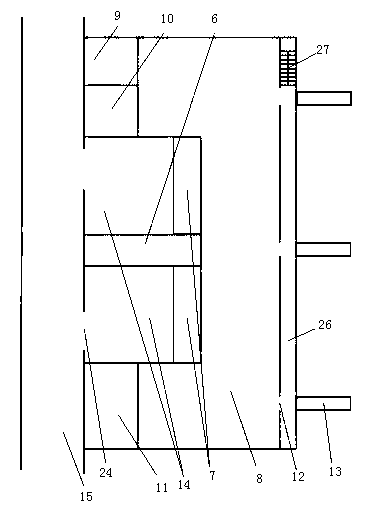

Ring-shaped terminal building of airport

InactiveCN102839830ANot cause congestionReduce operating pressurePublic buildingsJet aeroplaneEngineering

The invention relates to a ring-shaped terminal building of an airport. A main building body (1) of the ring-shaped terminal building comprises an underground layer (2) and at least more than two ground layers (3), wherein each ground layer (3) at least comprises an upstairs starting layer (4) and a downstairs arriving layer (5), and the upstairs starting layer (4) and the downstairs arriving layer (5) are both of plane structures which are ring-shaped structural bodies with one sides opened or provided with door openings; the ring-shaped structural body of the upstairs starting layer (4) is provided with a plurality of subareas, an outer ring of the ring-shaped structural body is provided with a walkway (26), the outer ring of the walkway (26) is radially provided with aerobridges which lead to airplanes or upstairs passages (13) which lead to ferry vehicles, and an inner ring of the walkway (26) is a starting layer ring-shaped lane (15); the outer ring of the ring-shaped structural body of the downstairs arriving layer (5) is radially provided with door access passages (17), the ring-shaped structural body of the downstairs arriving layer (5) is provided with a plurality of subareas, and the inner ring of the ring-shaped structural body is an arriving layer ring-shaped lane (18); the area inside the arriving layer ring-shaped lane (18) is provided with a ground parking lot (19) and an office building (20); a flight command control tower (21) is arranged on the top of the office building (20); the underground layer (2) is provided with an underground parking lot (23); and an outer lane (31) is respectively connected with the starting layer ring-shaped lane (15) and the arriving layer ring-shaped lane (18) through openings. The ring-shaped terminal building disclosed by the invention is reasonable in structure and capable of shortening the time of passengers entering and leaving a port, increasing the operation efficiency of the airport and decreasing the potential safety hazards of the airport.

Owner:罗富强

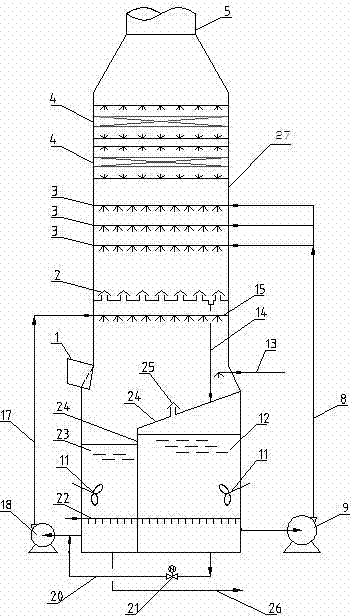

Absorption tower for wet desulfurization by calcium method

The invention discloses an absorption tower for wet desulfurization by a calcium method. The absorption tower comprises a tower body. A slurry pond, a gas cap layer, a plurality of main spray absorption layers and a plurality of demister layers are sequentially arranged inside the tower body from bottom to top; a flue gas outlet is formed in the top of the tower body, and a flue gas inlet is formed in space between the slurry pond and the gas cap layer; the slurry pond is divided into a thin slurry pond and a thick slurry pond by a partition plate, and the thin slurry pond is closed; a cooling concentration spray layer is arranged between the slurry pond and the gas cap layer, and a sprayer on the cooling concentration spray layer is communicated with the thick slurry pond via a cooling concentration circulating outlet pipeline; a gypsum slurry discharge outlet is formed in the thick slurry pond; the thin slurry pond is connected with sprayers of the main spray absorption layers via a main absorption circulating outlet pipeline; the gas cap layer is connected with the thin slurry pond by a connecting pipe. The absorption tower has the advantages that the absorption tower is quite favorable for absorbing sulfur dioxide of flue gas, the desulfurization efficiency can be greatly improved, a designed liquid-gas ratio can be greatly reduced under the same condition, and accordingly running power consumption of a circulating pump can be reduced.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

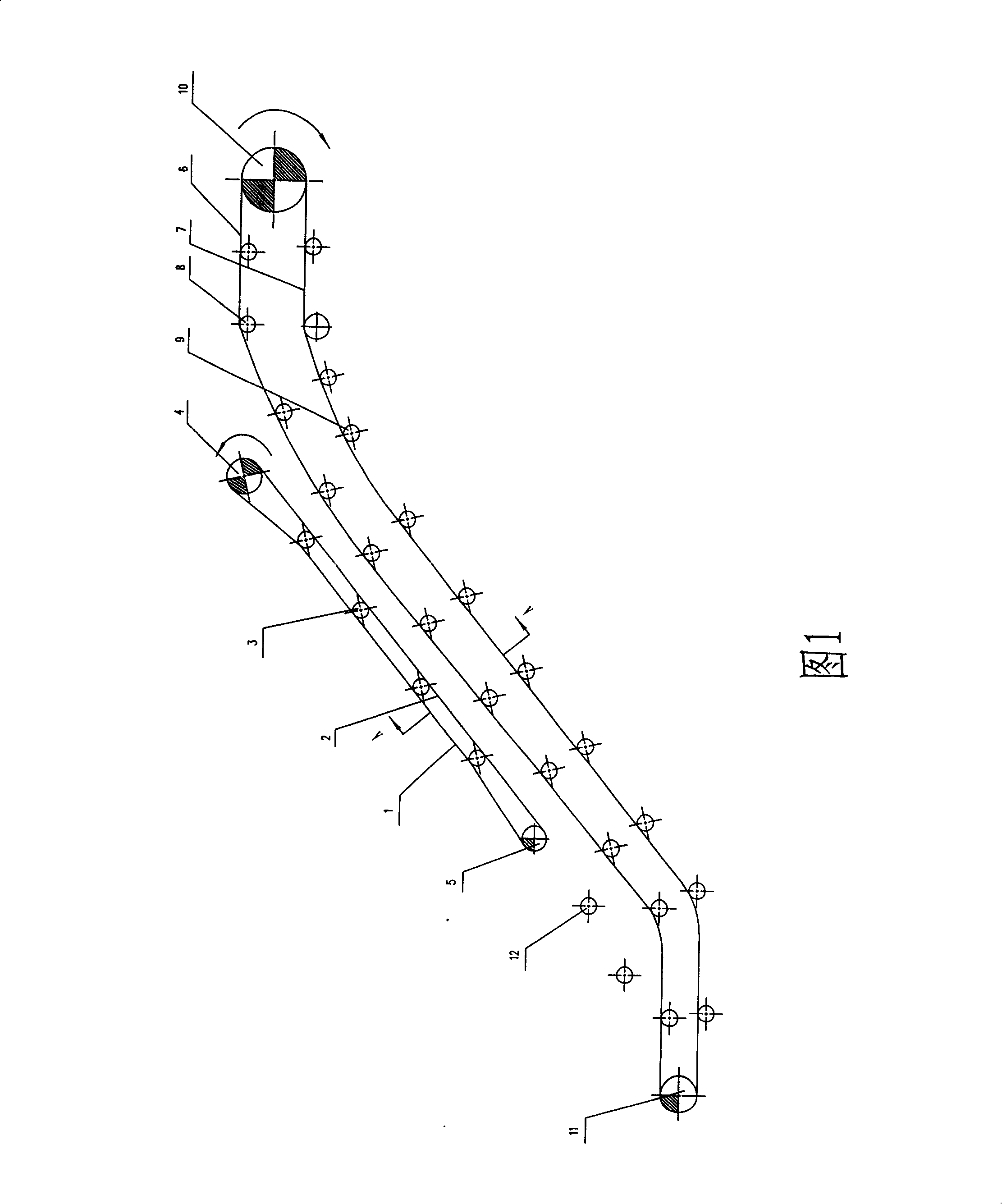

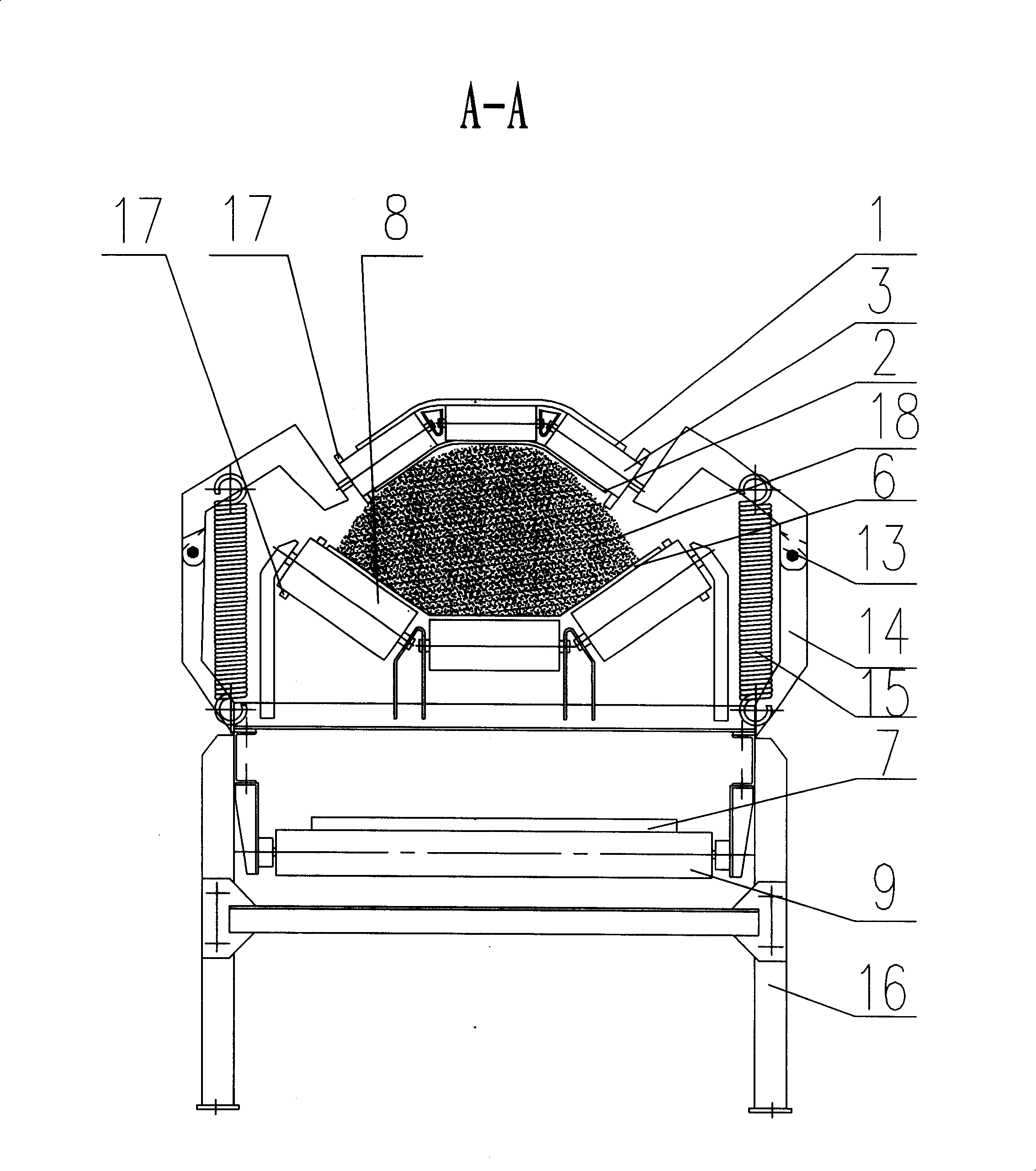

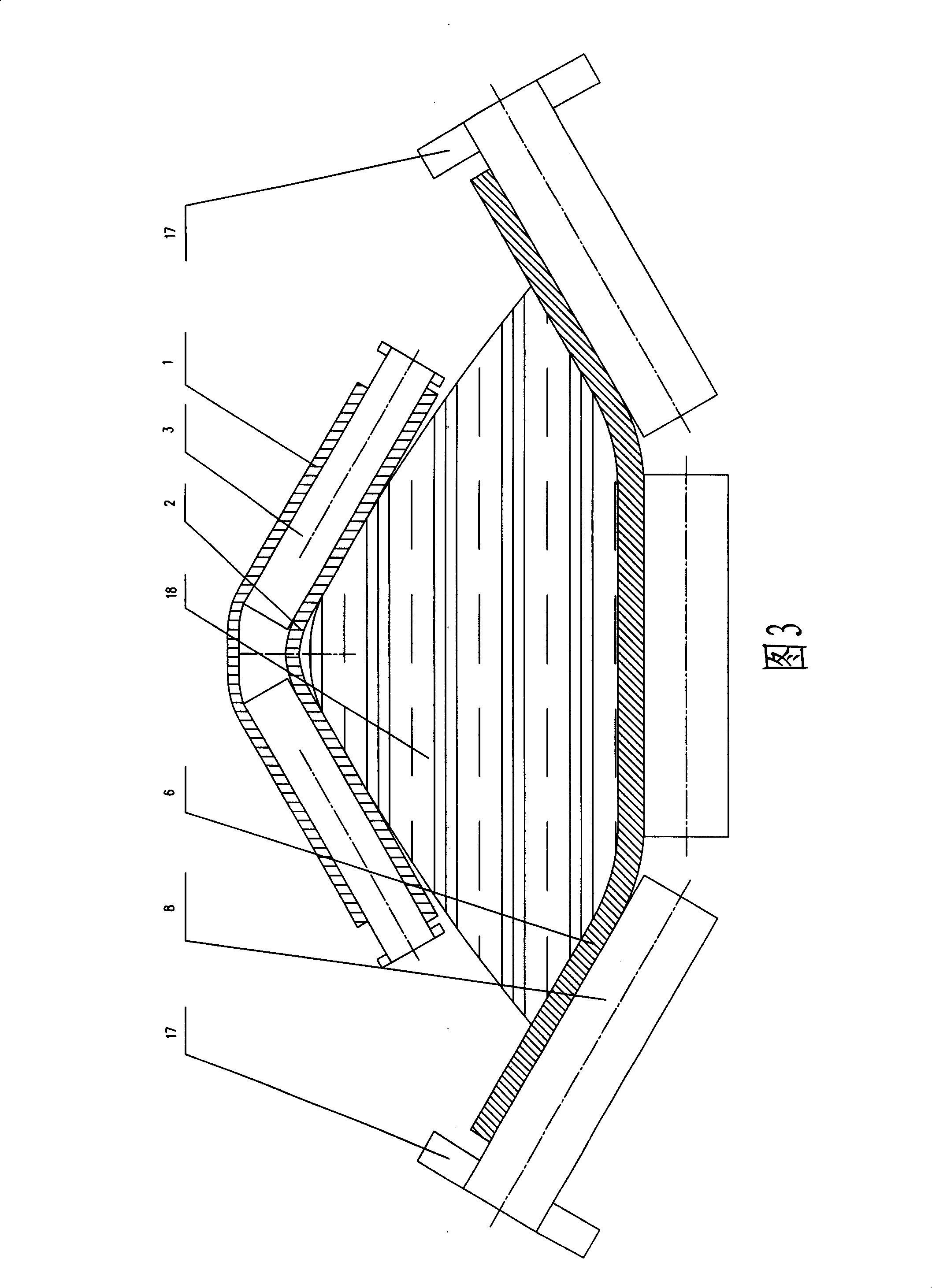

Rising large inclination angle belt conveyor of common rubber belt

The invention discloses a belt conveyor with a large inclined angle for upward transporting of a regular belt, comprising a belt conveyor consisting of a driving roller of the conveyor (10), a direction changing roller (11), a flute profile roller of the conveyor (8), a flat profile roller of the conveyor (9) and a material loading belt of inclined angle arrangement of upward transporting on the conveyor (6); a pressure belt mechanism which is parallel with the material loading belt of inclined angle arrangement of upward transporting on the conveyor (6) and of the same belt speed and the same running direction is arranged above the belt conveyor; the pressure belt mechanism comprises a driving roller (4) and a directional changing roller (5) of pressure belts, a roller (3) supporting the pressure belts, and pressure belts (1 and 2). The invention has the advantages of that the flute profile angle (generally 30 to 45 degrees) of the former belt conveyor is kept unchanged; retaining-side belts with clapboards are not required; the transportation capacity is not reduced; the belt speed is not decreased, and the upward transporting of large inclined angle is reached. In addition, the invention can greatly reduce the transportation distance, shorten the project construction period, reduce the area occupation, effectively decrease project and device cost, guarantee the transportation efficiency, and present significant effects of energy conservation and consumption reduction.

Owner:孙明昭

System and method for aseptic filling of packages with liquid products

InactiveCN1750993AIncrease profitImprove adaptabilitySterilising/aseptic filling operationsLiquid productAir atmosphere

The invention includes aseptics packages (7) and methods and systems allowing aseptic filling on a conventional filling line, with relatively small and inexpensive equipment modifications. The invention allows avoidance of the conventional need to encase all or part of the filling equipment in a sterile air atmosphere. The invention includes a package (7), fitted with a flexible membrane (1), wich can trap and carry its own sterility through the filling steps, whereby the membrane finally becomes part of the cap (8) of the package. The invention reduces product risk, operator specialisation and the costs of aseptic filling.

Owner:THE COCA-COLA CO

Independent address scanning sorter-based package sorting method

ActiveCN108499883AReduce the probability of misalignmentShorten the conveying distanceSortingLogistics managementBarcode

An independent address scanning sorter-based package sorting method is applied to a scanning rear-set logistics system. The package sorting method comprises the following steps: 1, packages input in adistantly unordered manner are output in an equidistant array manner; 2, the packages are divided into three division conveyors in an ordered manner; 3, barcode information of the packages on the division conveyors are scanned by a scanning device; 4, the packages are sorted and enter corresponding collecting boxes; 5, the collecting boxes bind off collecting bags reaching bind-off standards; 6,the bound collecting bags are transferred to an objective table; 7, one of the collecting bags is distracted after the collecting bag is transferred; and 8, the collecting bags on the objective tableare transferred to the conveyor B through a pusher. An independent address code scanning link is arranged at the near front end of every sorting link, so a conveying distance between address code scanning and sorters is reduced, the dislocation probability between the code scanning address and the address of a package, caused by dropping of the package, is reduced, and the sorting accuracy is improved.

Owner:NANHUA UNIV

Process and system thereof for forming upgraded lignite

ActiveCN101914403ALower the placement heightReduce the overall heightSolid fuelsWater contentBriquette

The invention relates to a process and a system thereof for forming upgraded lignite, solving the problems of inflammability, explosiveness, environment pollution, low forming rate, poor system stability, low safety performance and the like existing in the forming process of the upgraded lignite. The invention can save the construction cost, reduces the safety risk, decreases the coal dust pollution of a finished product conveying system and has the characteristics of safety, energy saving, environmental protection, high efficiency and stability. The method comprises the following steps of: (1) feeding the formed lignite which is subjected to drying and dehydration and upgrading treatment and meets the requirements for water content, the temperature and the granularity; (2) pressing the lignite into the molded lignite by using a molding device, screening the molded lignite and feeding the qualified molded lignite into next step and turning the unqualified molded lignite into the step (1); (3) air cooling the qualified molded lignite by adopting air with water fog, feeding the cooled molded lignite into a finished bin and feeding lignite powder / granules generated by cooling back tothe step (1); and (4) collecting waste gas generated by cooling, removing dust and emptying or recycling to other proper work sections and feeding the lignite power collected by a dust removing device into the step (1).

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

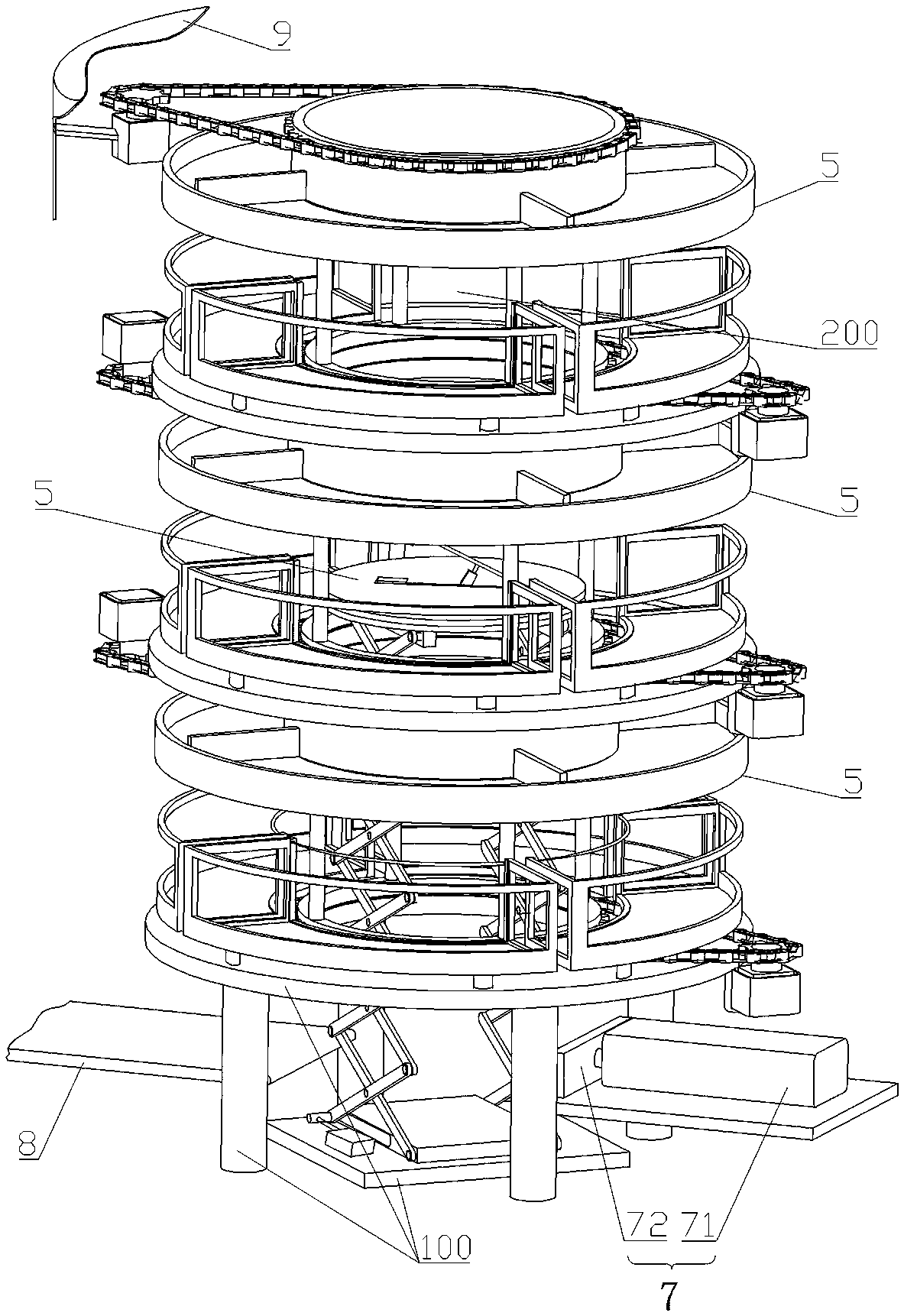

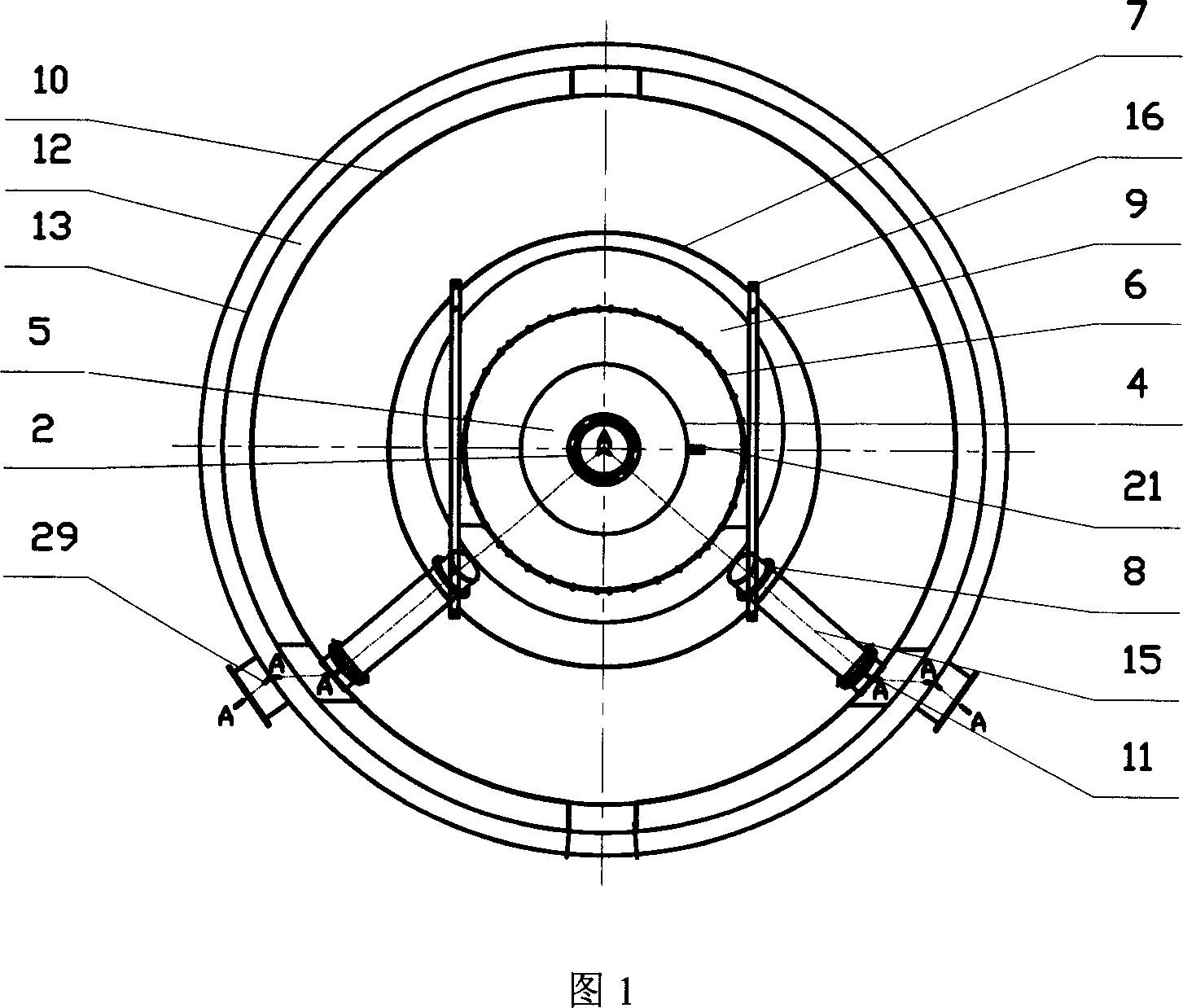

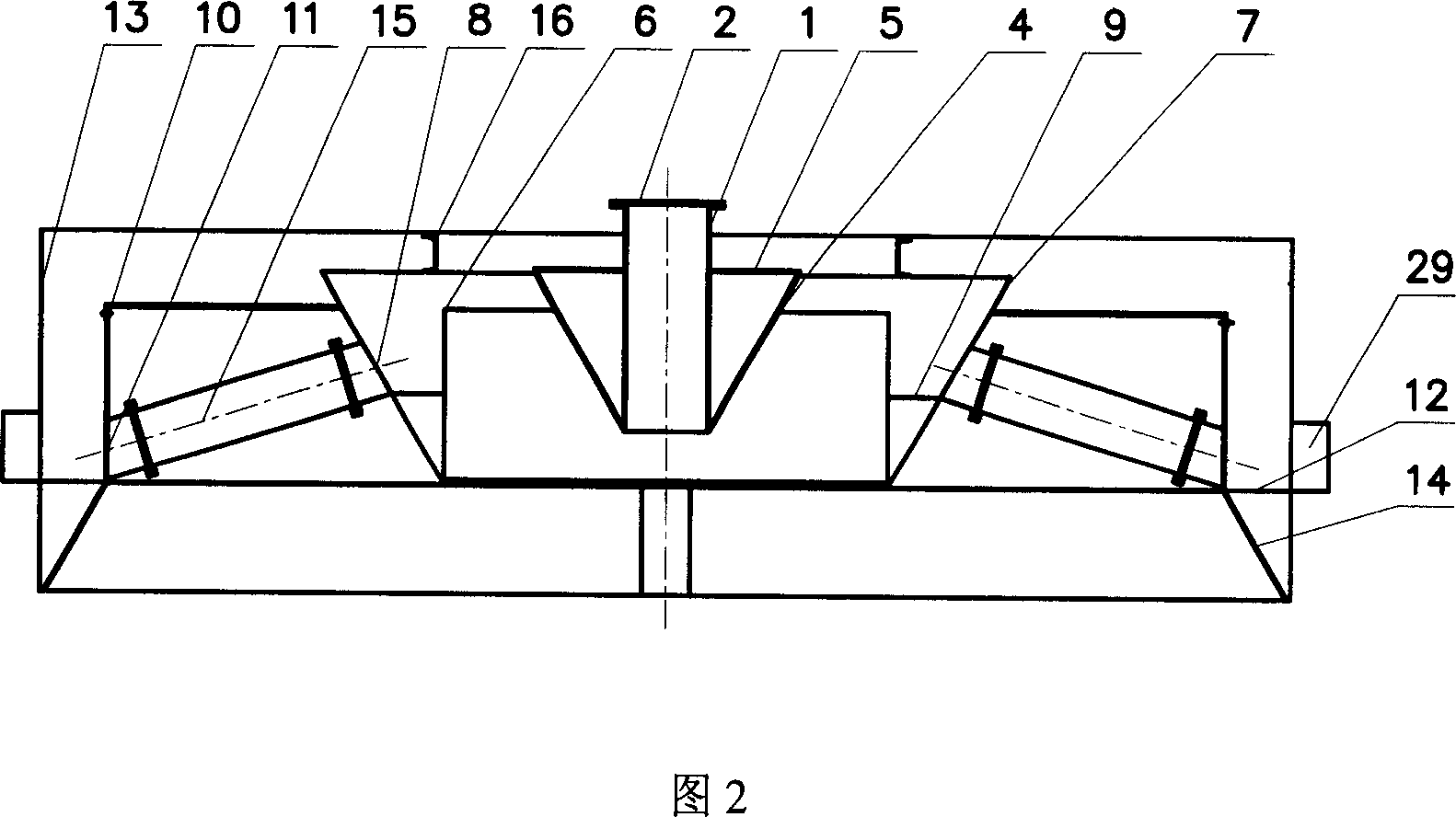

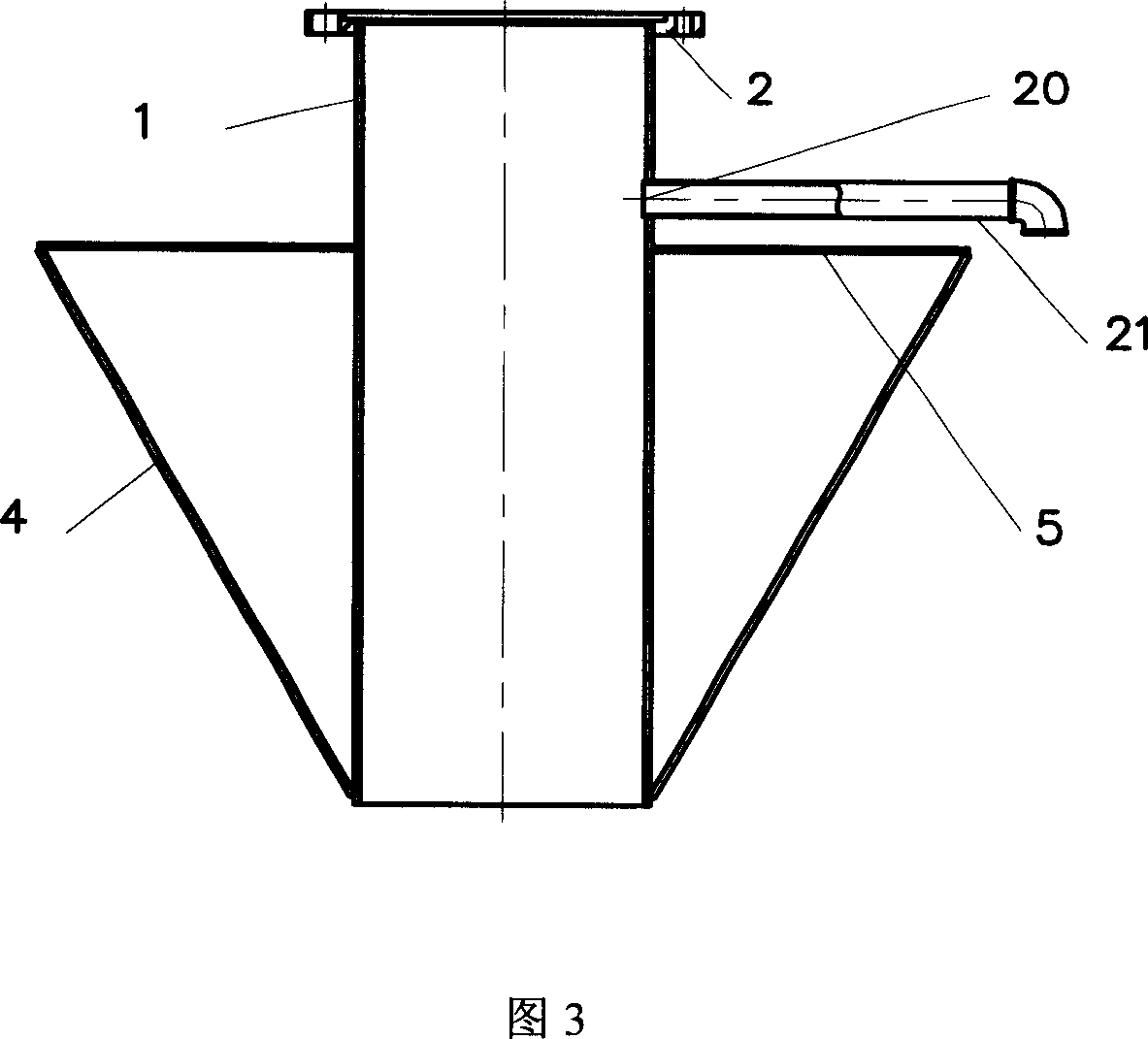

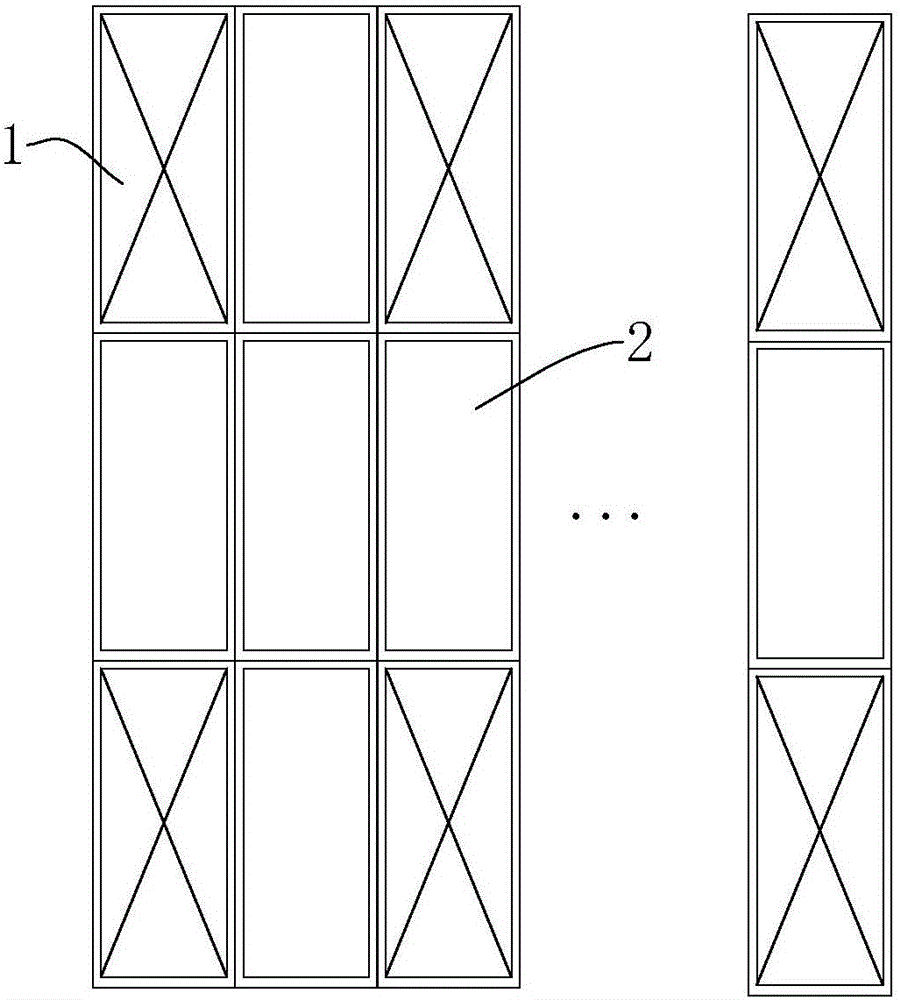

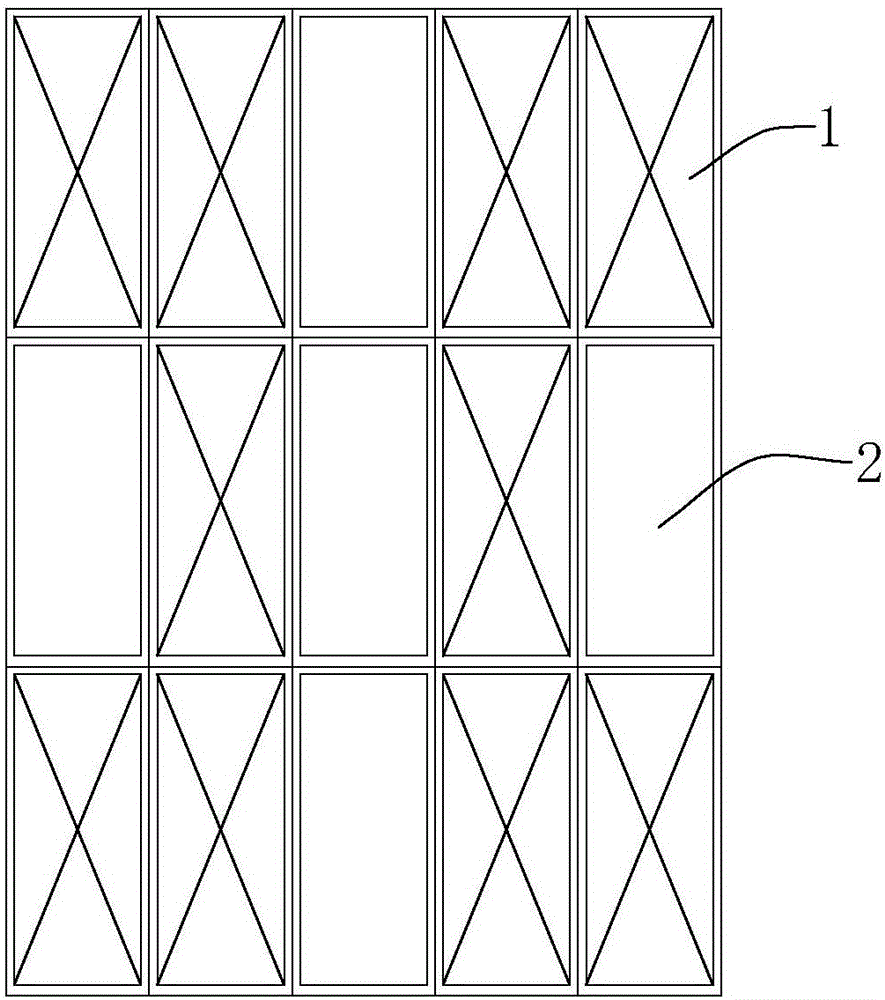

Stereoscopic garage and control system thereof

ActiveCN106567580AImprove stabilityShorten the conveying distanceParkingsControl systemMechanical engineering

The invention discloses a stereoscopic garage and a control system of the stereoscopic garage. The stereoscopic garage aims to achieve the effects that reverse automobile search can be rapid and accurate, the automobile finding time is short, and parking and picking up are convenient and rapid. The stereoscopic garage is technically characterized in that multiple lifting mechanisms and multiple automobile carrying plates are arranged, a user can make an appointment to pick up the automobile, multiple inlets are arranged for parking, multiple outlets are arranged for picking up, the picking-up efficiency is improved, and the timing charge efficiency is high.

Owner:洪浩

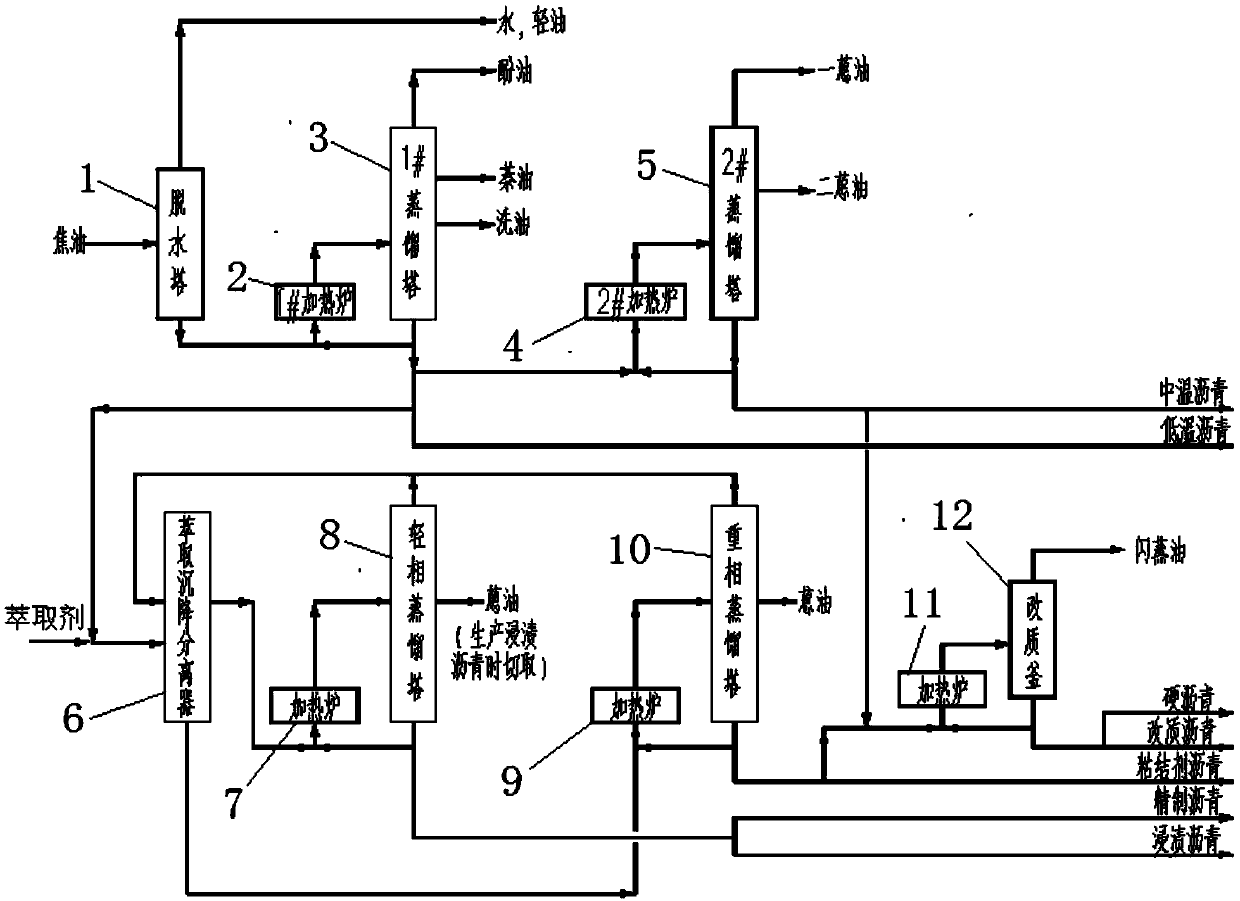

Process and device for producing various asphalt products by combining distillation and extraction

PendingCN109517614AMeet needsSolve the problem of low single added valueWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionDistillationTar

The invention relates to a process and a device for producing various asphalt products by combining distillation and extraction. The device comprises a dehydration tower, a distillation system, an extraction system and an asphalt modification system. Coal tar is used as a raw material to produce low-temperature asphalt, medium-temperature asphalt, modified asphalt, low-quinoline insoluble refinedasphalt, impregnated asphalt, hard asphalt, binder asphalt and other products by using a combined production process of distillation, extraction and asphalt modification. A variety of high value-addedasphalt products can be produced simultaneously with a set of production device, the utilization of the device is maximized, and the process and the device are adaptive to the needs of large-scale tar processing.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

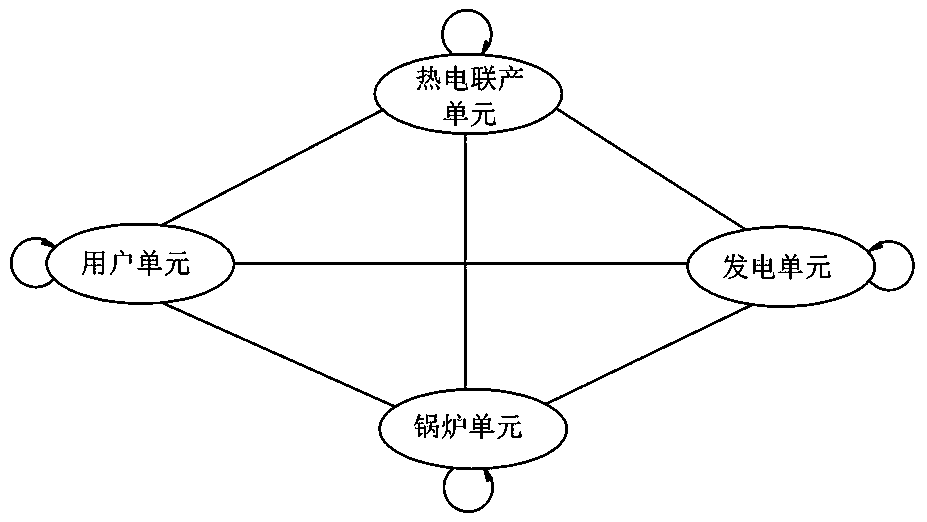

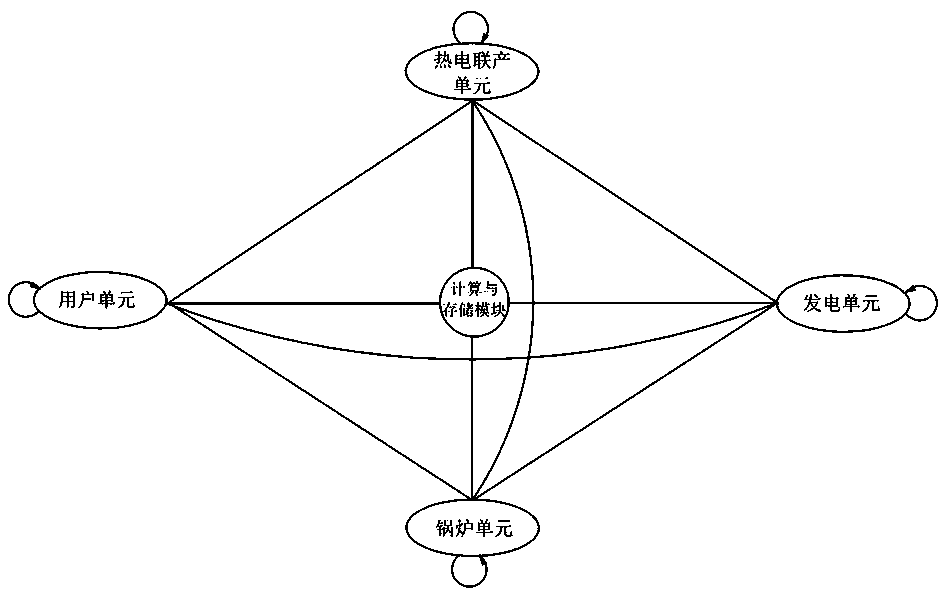

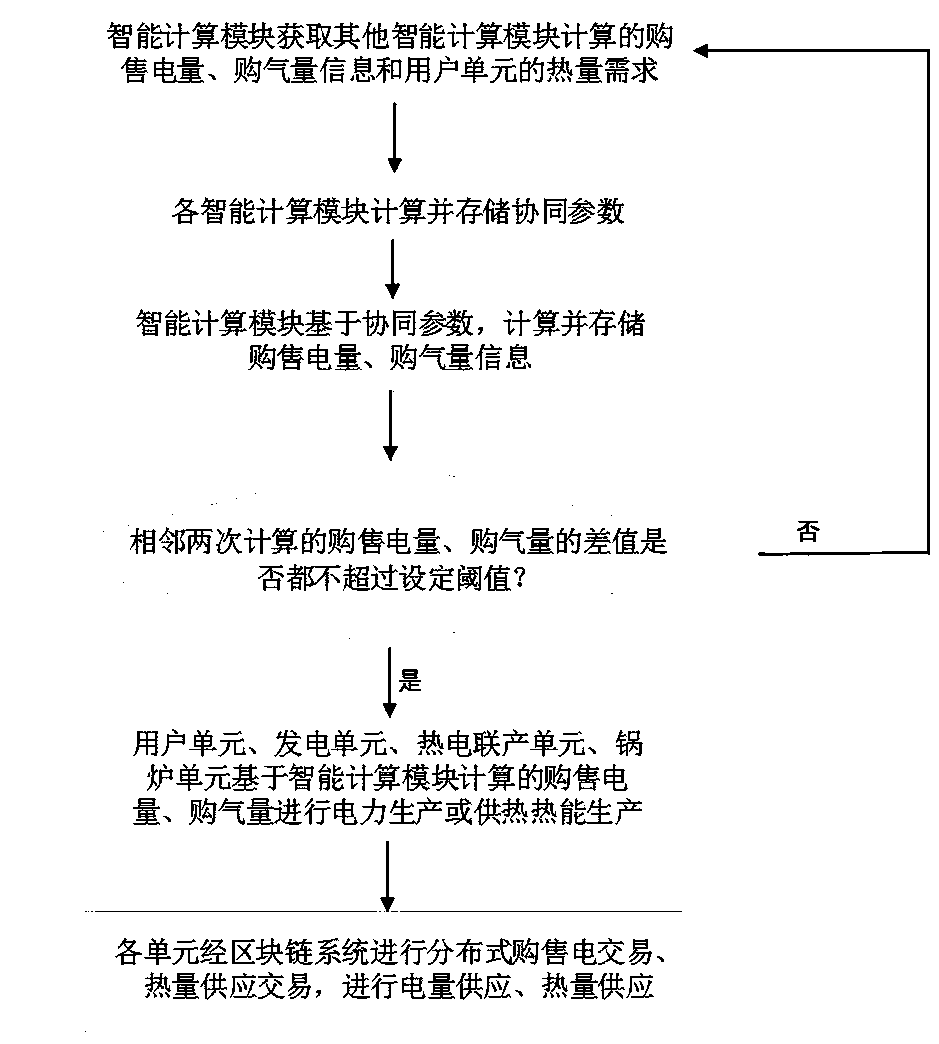

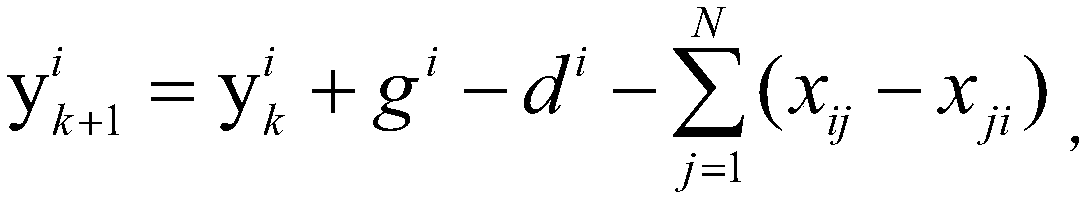

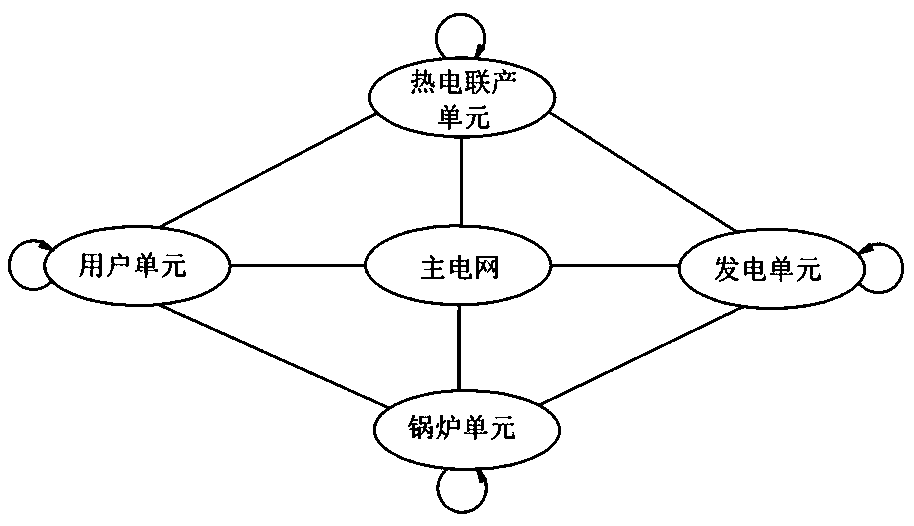

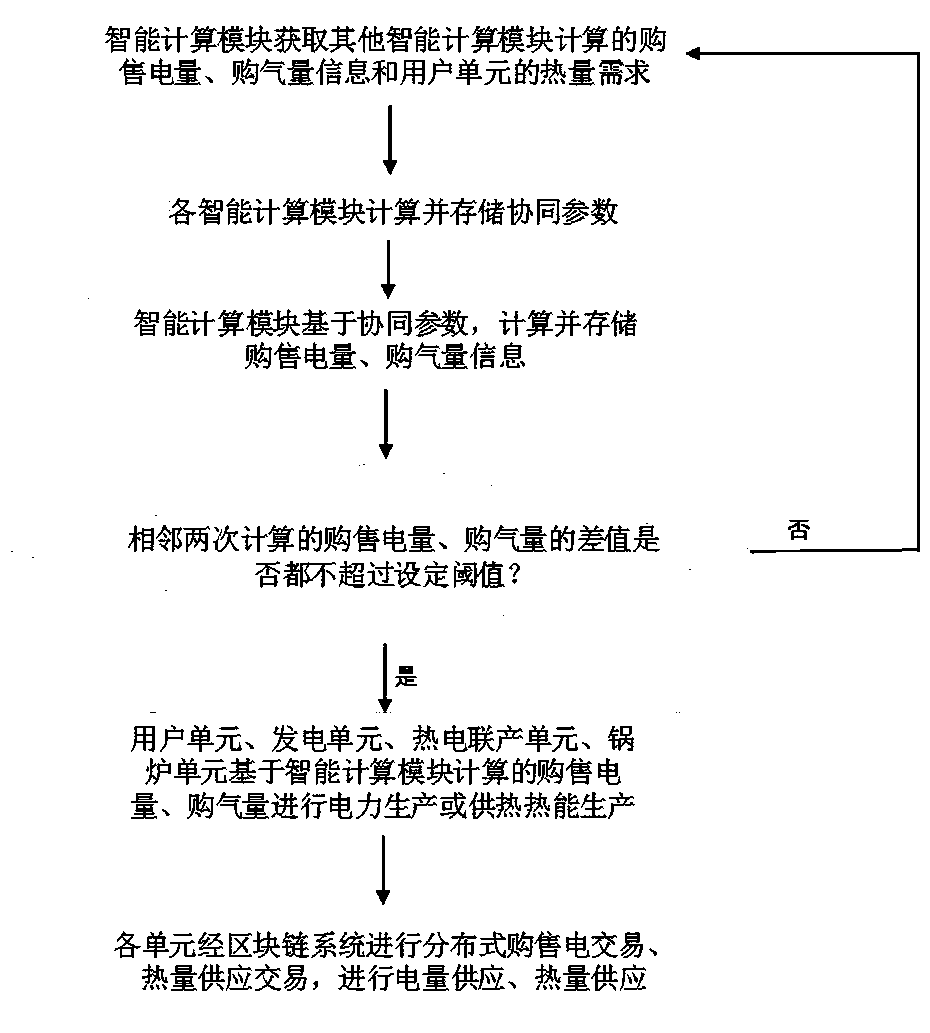

An island micro-grid intelligent scheduling system and scheduling method

ActiveCN109598429AImprove reliabilityEasy to sendResourcesInformation technology support systemChain systemCogeneration

The island microgrid intelligent scheduling system comprises a plurality of user units, a plurality of power generation units, a plurality of combined heat and power generation units and a plurality of boiler units, The user unit comprises electric equipment or electric appliances, a photovoltaic power generation module, a wind power generation module and an electric automobile; The combined heatand power generation unit takes natural gas as a raw material and outputs electric energy to the outside and supplies heat to the outside, and heat supply and power supply of the combined heat and power generation unit are located in a feasible working interval; The boiler unit uses natural gas as a raw material to supply heat to the outside. The invention further provides a scheduling method, theintelligent calculation module selects the user unit, the power generation unit, the combined heat and power generation unit and the boiler unit to purchase, sell and purchase gas strategies throughan intelligent acceleration algorithm, and each unit performs distributed electricity purchase, sell and transaction and heat supply transaction through the block chain system. According to the invention, a price driving and exciting mechanism is set, and the consumption of new energy power generation is promoted. And power generation and power utilization are only transacted in the island, so that the power transmission and heat transmission cost is reduced.

Owner:CHINA YANGTZE POWER

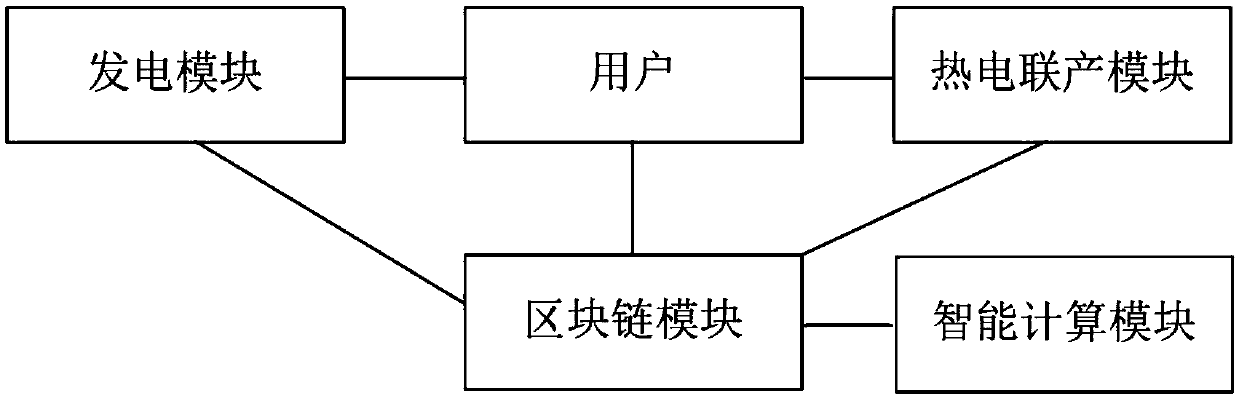

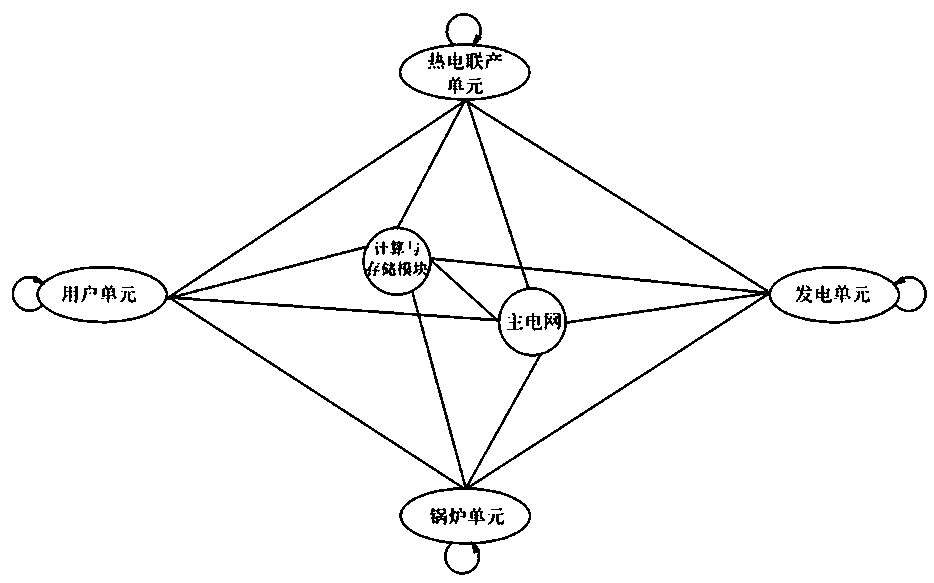

An intelligent power grid monitoring system based on regional internal transactions and a control method thereof

The invention discloses an intelligent power grid monitoring system based on regional internal transactions and a control method of the intelligent power grid monitoring system. The system comprises ablock chain module and an intelligent calculation module, All users, all power generation modules and all combined heat and power generation modules in the area are independent of a main power grid,and heat energy and electric energy are exchanged and consumed in the area; The block chain module is used for acquiring the power demand and the heat supply demand of each user in the region, the power generation amount of each power generation module and the gas demand, the power generation amount and the heat generation amount of each heat and power cogeneration module; And the intelligent calculation module is used for obtaining the electricity purchase quantity and heat purchase quantity of each user, the electricity sale quantity of each power generation module and the gas purchase quantity, the electricity sale quantity and the heat sale quantity of each heat and power cogeneration module by using the information of the block chain module and taking the maximum economic benefit of the intelligent power grid monitoring system as the purpose. The method is reliable in operation, user privacy leakage is avoided, and local consumption of new energy power generation is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

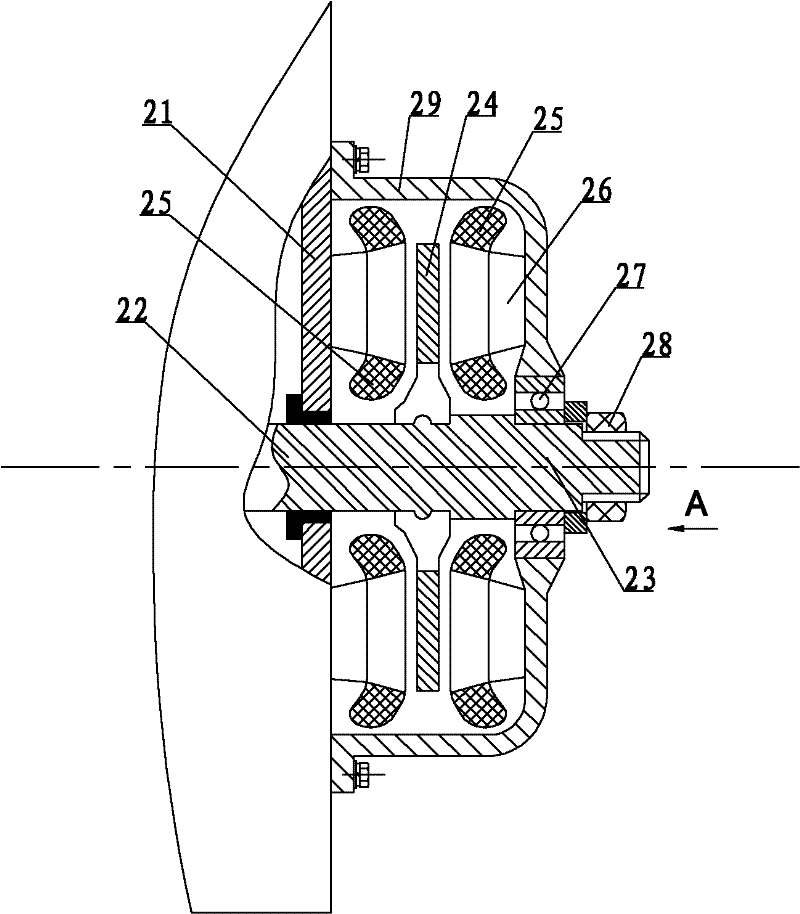

Generator set for electric compressor of automotive air conditioner

InactiveCN102678298AShorten the lengthShorten the conveying distanceMachines/enginesMechanical energy handlingDynamoStator

A generator set for an electric compressor of an automotive air conditioner comprises a body and a crankshaft, and is characterized by further comprising an air conditioner generator. The air conditioner generator comprises a stator and a rotor and is disposed at the front end of an automotive engine and driven by a crankshaft of the automotive engine. A drive shaft of the air conditioner generator and the crankshaft of the engine are integral drive shafts formed by one-step machining. Therefore, accessories of the internal combustion engine and the generator are few, the internal combustion engine and the generator are simple and compact in structure, longitudinal mounting dimension is shortened evidently, belt drive is not needed, mechanical loss is reduced, transmission efficiency is improved, and overall structural layout of a vehicular air conditioning system is facilitated.

Owner:HUNAN VAQOUNG ELECTRIC +1

An intelligent grid dispatching system and a dispatching method based on user requirements

ActiveCN109544016AImprove reliabilityEasy to sendDigital data protectionPayment architectureNew energyCogeneration

The invention discloses an intelligent grid dispatching system based on user requirements, which comprises a plurality of user units, a plurality of power generation units, a plurality of cogenerationunits, a plurality of boiler units and a main grid. The subscriber unit comprises an electric equipment or an electric appliance, a photovoltaic power generation module, a wind power generation module and an electric vehicle; Cogeneration unit takes natural gas as raw material, outputs electric energy and provides heat to the outside, and the heating and power supply of Cogeneration unit are in feasible working range. The boiler unit uses natural gas as raw material and provides heat to the outside world. The invention also provides a dispatching method, wherein an intelligent calculation module selects a subscriber unit, a power generation unit, a cogeneration unit, a boiler unit, a purchase and sale electricity and a purchase gas strategy of a main power network through an accelerated intelligent algorithm, and each unit, the main power network, carries out a distributed purchase and sale electricity transaction and a heat supply transaction through a block chain system. The invention sets a price driving mechanism, promotes the consumption of new energy power generation, and effectively improves the reliability of grid operation.

Owner:CHINA YANGTZE POWER

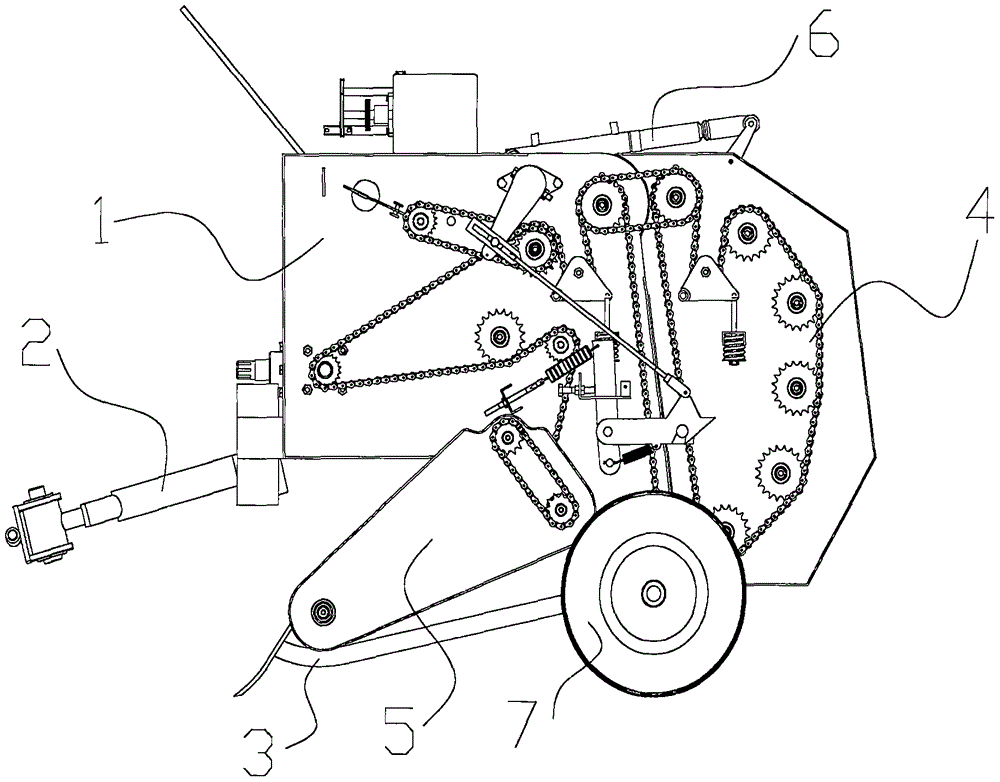

Film residue picker

InactiveCN106068710AHigh strengthExpand the scope of workHarvestersGatherer machinesEngineeringSurface conditions

The invention discloses a film residue picker, comprising a tractive device, a film lifting device, a bundling device, a chain elevating device, a film discharging device and a travelling device; the film lifting device comprises a lifting shovel, a first cross beam and a second cross beam, a cylindrical auxiliary lifting shovel is hinged to the first cross beam, one end of the auxiliary lifting shovel far away from the cross beam is connected with the lifting shovel, the middle of the auxiliary lifting shovel is also connected with a spring, the auxiliary lifting shovel is connected with the second cross beam through a spring, the chain elevating device comprises an elevating chain that arranged in upward inclination, the bundling device comprises a bundling roller, the chain elevating device also comprises fixed side plates arranged at two ends of the elevating chain and a fixed cross beam arranged on the upper portions of the fixed side plates, and vibrating springs are connected between the fixed cross beam and the fixed side plates; the lifting shovels of a bundling unit are connected with a cross beam of a frame through springs, the lifting shovels can automatically adjust shoveling thickness according to surface conditions and can prevent excess soil on the surface to be shoveled up, and blockage of the chain elevating mechanism and the lifting shovels from being blocked.

Owner:GANSU AGRI UNIV

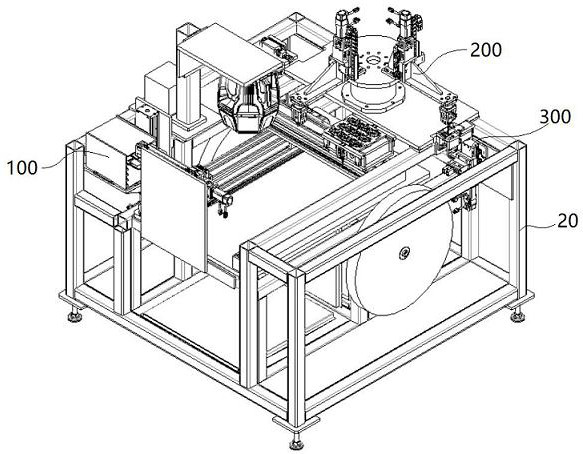

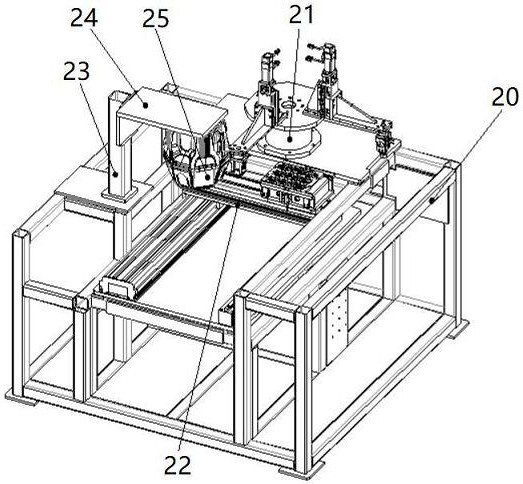

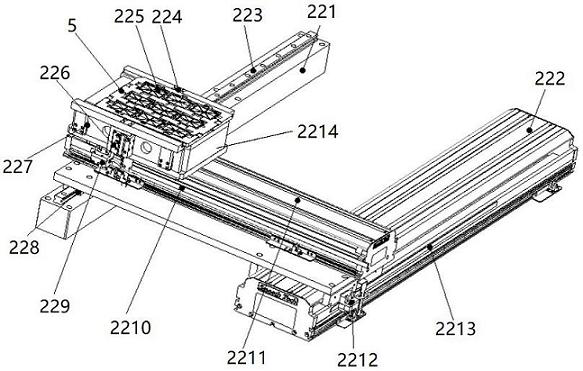

Automatic pin inserting machine of IGBT module

ActiveCN112117223AEasy to operateWork fasterSemiconductor/solid-state device manufacturingConveyor partsComputer hardwareMechanical engineering

The invention discloses an automatic pin inserting machine of an IGBT module. The machine comprises a rack, an automatic tray feeding device, a pin feeding device and a pin inserting device. The pin inserting device comprises a rotary pin inserting assembly, a tray moving module and a camera detection assembly, and the rotary pin inserting assembly is fixedly arranged on one side, opposite to theautomatic tray feeding device, of the rack; the tray moving module is fixedly arranged on the rack and drives a material tray to move between the automatic tray feeding device and the rotary pin inserting assembly; the camera detection assembly is arranged on the other side, adjacent to the automatic tray feeding device, of the rack and located above the tray moving module. The automatic pin inserting machine is compact in design, high in pin inserting operation speed, suitable for disc-mounted pin feeding, capable of carrying out pin taking and pin inserting actions at the same time and capable of being used for two kinds of pins of different specifications; the camera detection assembly can accurately detect the position of the pin sleeve and the height of the pin, and can detect the position of the pin and the quality after the pin is inserted in real time, thereby achieving the complete automation of the pin insertion operation of the IGBT module.

Owner:常州科瑞尔科技有限公司

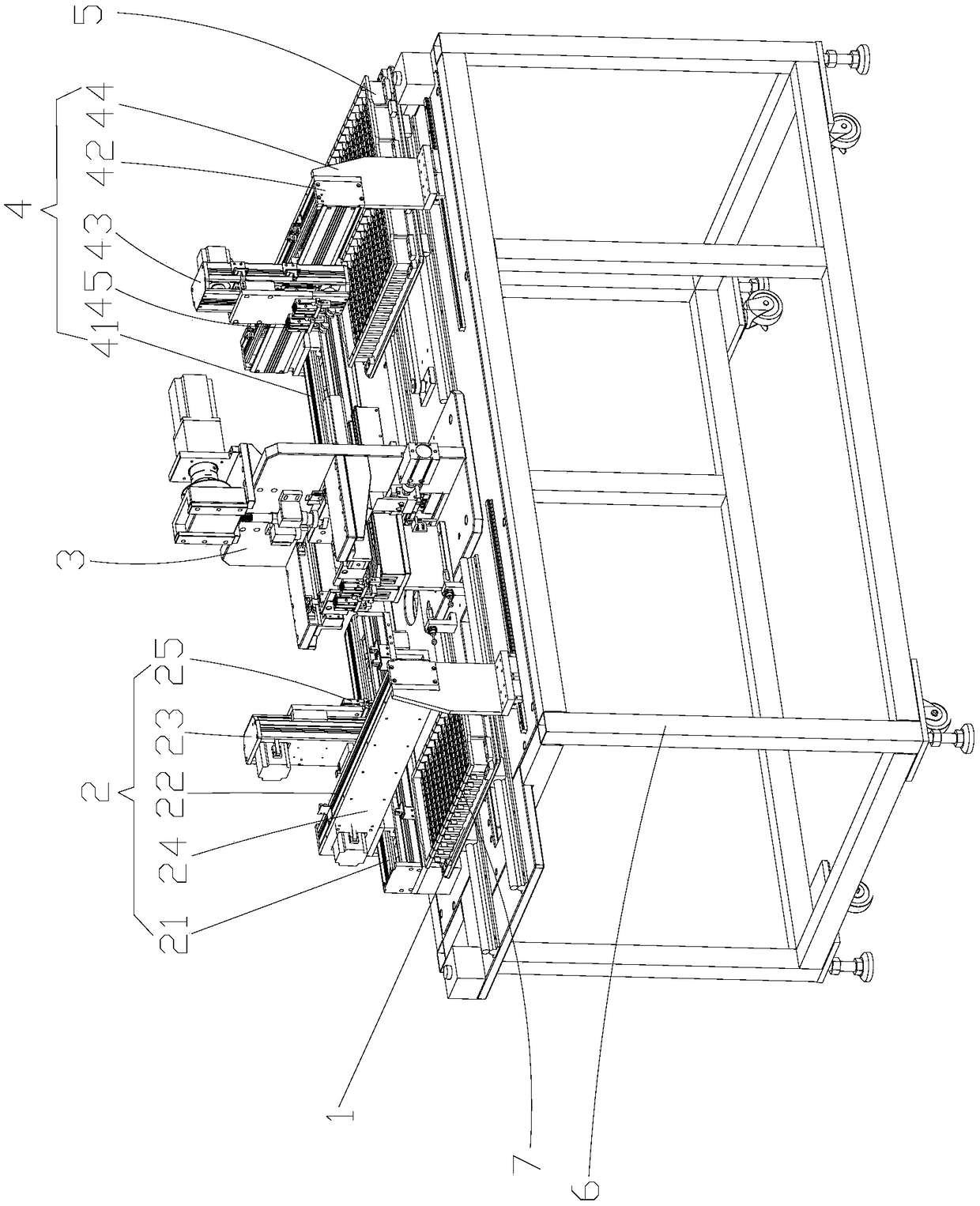

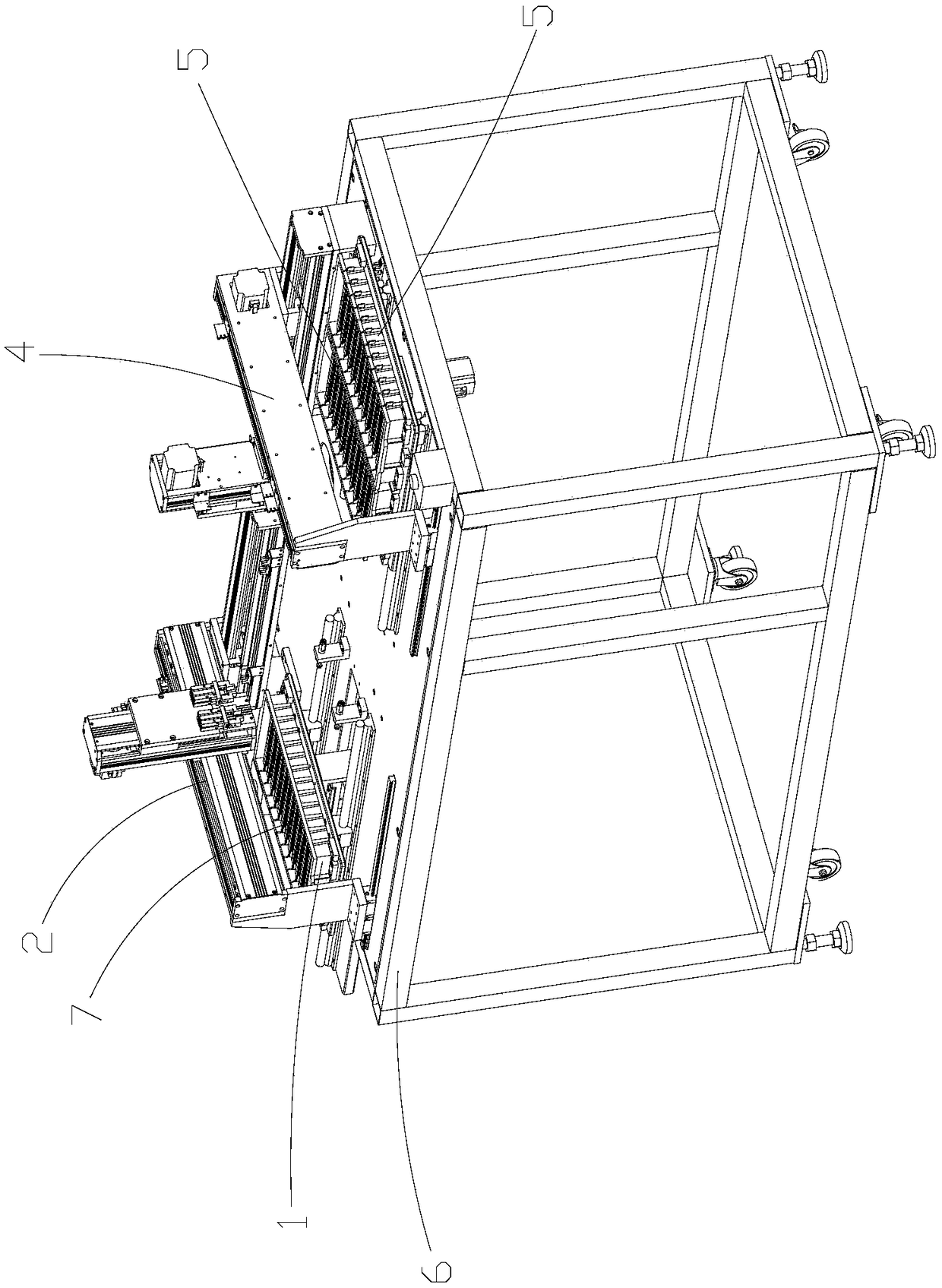

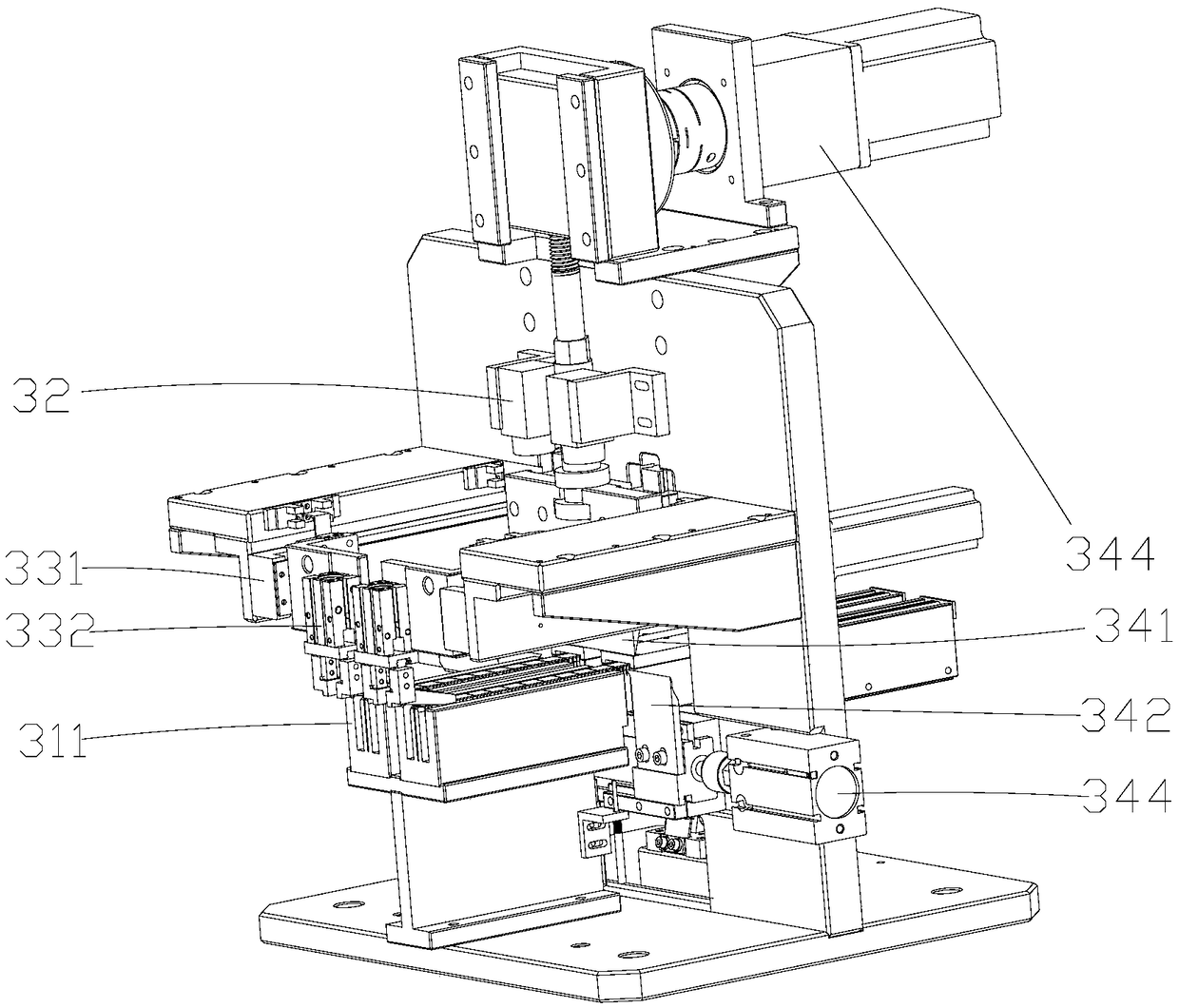

Automatic plate separation device for PCB plate single-strip connecting sheets

ActiveCN109262706AHigh speedQuality improvementPrinted circuit manufactureMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic plate separation device for PCB plate single-strip connecting sheets. The device comprises a connecting sheet tray, a feeding mechanism, a plate separation mechanism, a discharging mechanism and a finished product tray, wherein the PCB plate single-strip connecting sheets on the connecting sheet tray are conveyed to the plate separation mechanism through the feeding mechanism and subjected to cutting and plate separation through the plate separation mechanism, and then the discharging mechanism conveys a PCB plate finished product after cutting and plate separation to the finished product tray; the plate separation mechanism comprises plate separation platforms, image recognition assemblies, positioning assemblies and cutting assemblies, the feeding mechanism conveys and places the PCB plate single-strip connecting sheets on the plate separation platforms, and the positioning assemblies move to drive the PCB plate single-strip connecting sheets to move on the plate separation platforms. The automatic plate separation device for the PCB plate single-strip connecting sheets has the advantages that through the cooperation of the positioning assemblies and the image recognition assemblies, the V-CUT positions of the PCB plate single-strip connecting sheets are aligned with the cutting assemblies, the cutting assemblies conduct cutting and plateseparation, and the plate separation mechanism is provided with the two sets of plate separation platforms, the image recognition assemblies and the positioning assemblies to achieve simultaneous cutting and plate separation of double stations to improve the production efficiency.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD

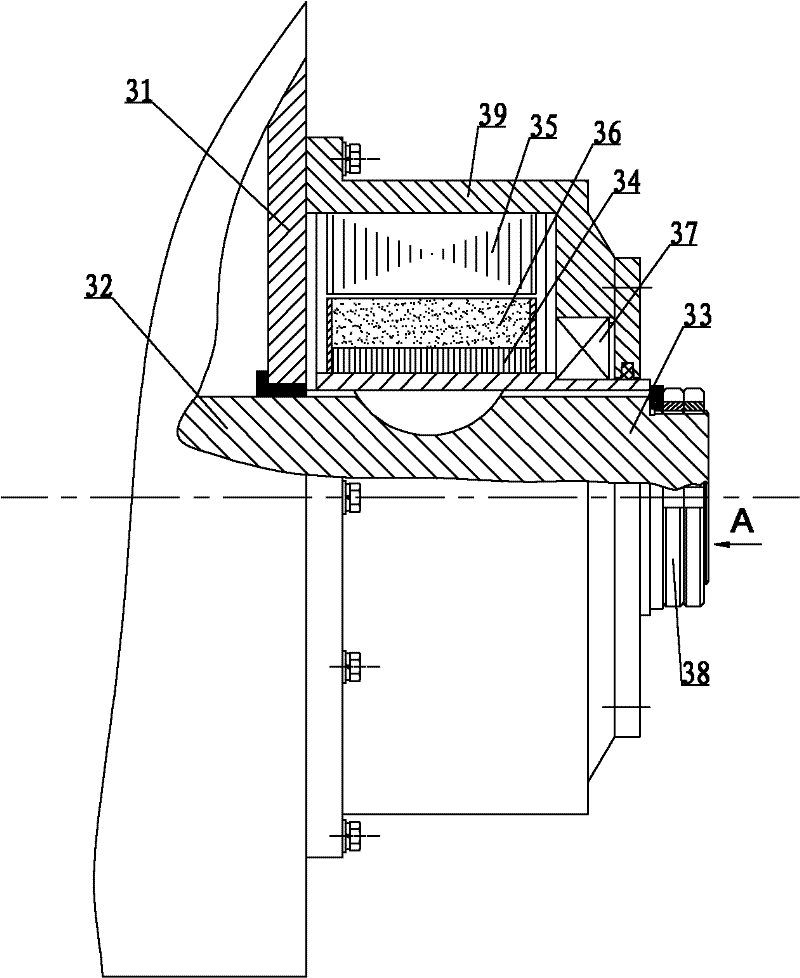

Power generator of motor compressor for automobile air conditioner

InactiveCN102684385AShorten the lengthShorten the conveying distanceMechanical energy handlingSupports/enclosures/casingsExternal combustion engineAutomobile air conditioning

The invention relates to a power generator of a motor compressor for an automobile air conditioner, which comprises a machine body and a crankshaft and is characterized by further comprising an air-conditioning power generator; a crankshaft belt pulley is arranged on the crankshaft and is installed at the front end of the automobile engine crankshaft; a connecting part of the front end of the automobile engine crankshaft and the crankshaft belt pulley is hollow; a rotor of the air-conditioning power generator is arranged on the inner wall of the hollow part of the crankshaft belt pulley; and a stator of the air-conditioning power generator is arranged at a hollow part at the front end of the automobile engine crankshaft and is arranged on an engine shell. Thus, the power generator has the advantages of fewer accessories between an internal combustion engine and the power generator, simple and compact structure, remarkably shortened longitudinal mounting size, no belt drive, reduced mechanical loss and improved transmission efficiency and is convenient for a vehicle-mounted air-conditioning system conveniently to adopt an overall arrangement structure.

Owner:HUNAN VAQOUNG ELECTRIC +1

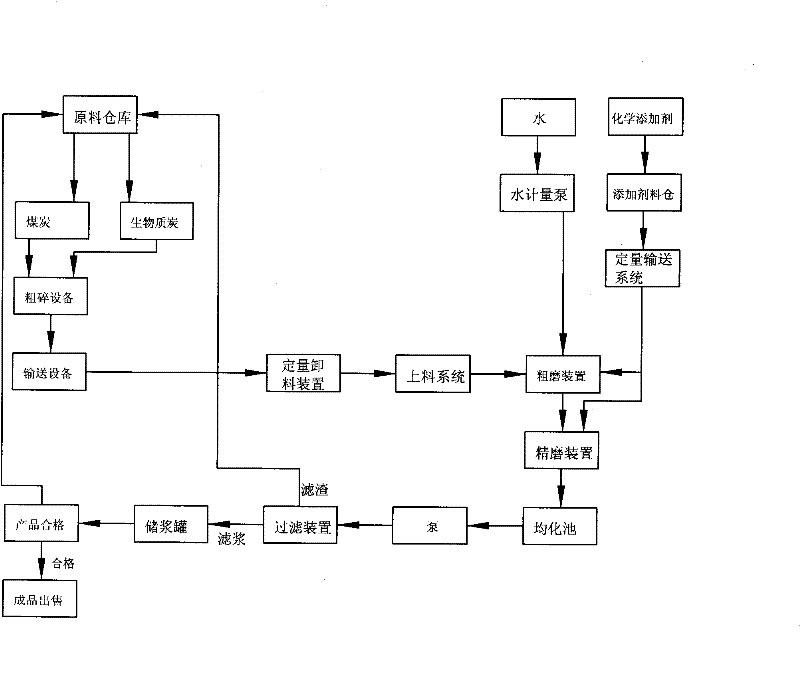

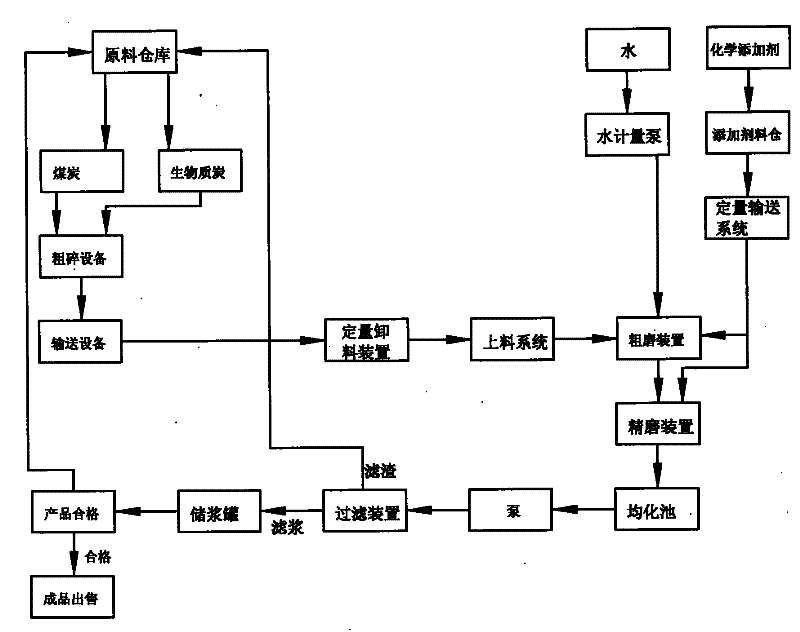

A kind of biomass fuel and the technological process of processing this kind of biomass fuel

InactiveCN102268306AEasy to collectEasy to get materialsLiquid carbonaceous fuelsBiomass carbonCombustion

The invention relates to a biomass fuel, which comprises 30% to 50% of biomass carbon, 0.3% to 0.5% of chemical additives, 18% to 20% of coal and 31.8% to 49.4% of water. When burning, coal can supplement or increase the calorific value required to be set in the boiler or kiln, so that the ash melting point of the fuel in the boiler or kiln can be increased, and unsafe hidden dangers can be avoided. Due to the convenience of coal collection, it has the beneficial technical effect of convenient material collection. In addition, the present invention also has the purpose of environmental protection. And because of the reasonable technological process and equipment configuration and the selection of new, efficient and energy-saving equipment, it is possible to reduce the reverse transportation link and transportation distance of materials. And because the coarse mill and the fine mill are equipped with frequency conversion control, the equipment can have sufficient starting torque, which meets the maximum requirement of the mill loading capacity, ensures normal process control requirements, and achieves the extension of the mill and motor. service life and the purpose of reducing maintenance.

Owner:深圳市赛尔勒环保科技有限公司

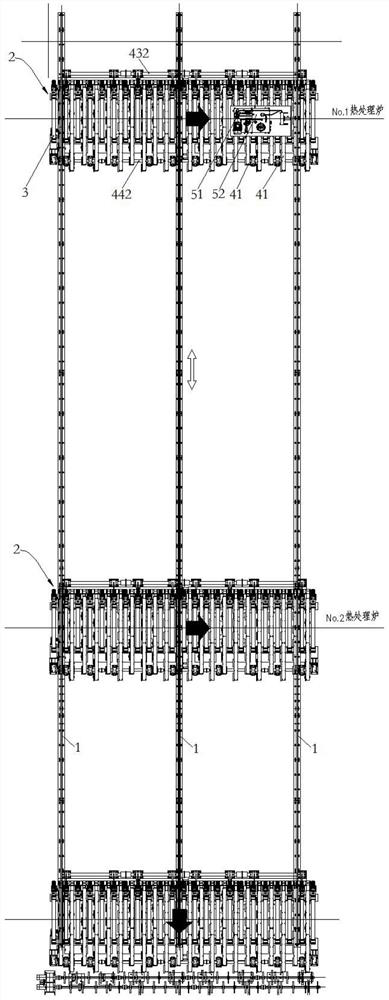

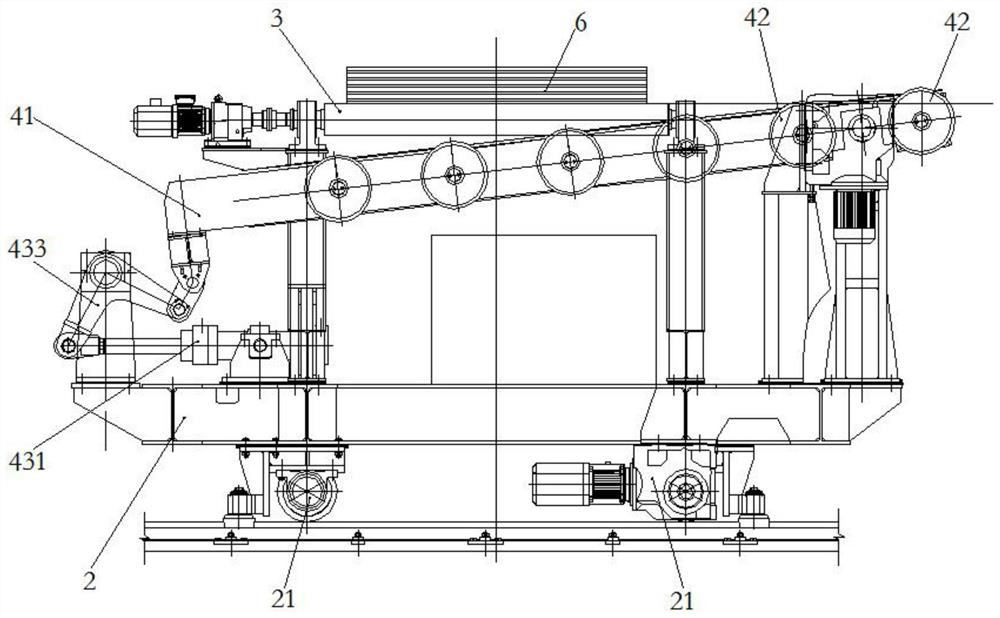

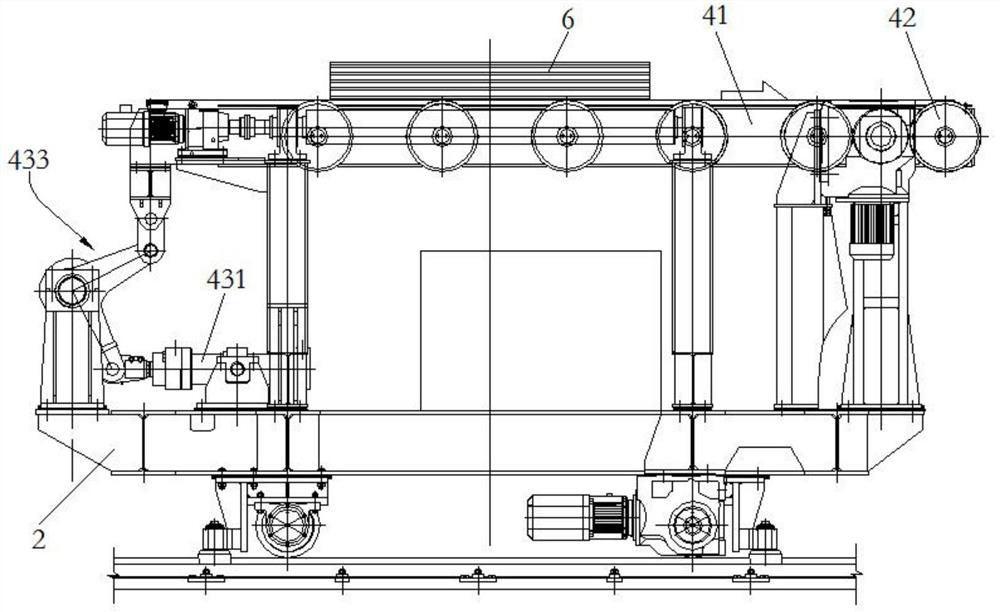

Stacked steel plate conveying system and hot rolled plate continuous heat treatment method

ActiveCN113981201AShorten the conveying distanceImprove stabilityFurnace typesProcess efficiency improvementTransit systemStructural engineering

The invention relates to a stacked steel plate conveying system which comprises a transverse moving rail and a steel plate conveying vehicle running on the transverse moving rail. The guide stroke of the transverse moving rail covers each matched heat treatment station; the steel plate conveying vehicle is provided with a side-moving lower vehicle roller way suitable for bearing steel plate stacks, and the conveying direction of the side-moving lower vehicle roller way is perpendicular to the guiding direction of the transverse moving rail. In addition, the invention further provides a hot rolled plate continuous heat treatment method. The method comprises the following steps: after continuously quenching a steel plate, performing fixed-length cutting and stacking; using the stacked steel plate conveying system for conveying the steel plate stacks formed by stacking a plurality of steel plates to a downstream heat treatment station. The steel plate conveying vehicle is adopted as steel plate conveying equipment, whole-pile transportation of steel plate stacks can be achieved, namely batch steel plate heat treatment is achieved, the steel plate conveying efficiency and the steel plate heat treatment efficiency can be remarkably improved, particularly in long-distance transportation, the steel plate transportation stability can be improved, and the equipment investment cost is obviously reduced.

Owner:WISDRI ENG & RES INC LTD

A method of heat dissipation and cooling for high heat density cabinets in data centers

ActiveCN106385784BShorten the conveying distanceTake away quicklyCooling/ventilation/heating modificationsControl systemData center

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Foam pushing device of floatation machine

Owner:BEIJING GENERAL RES INSITUTE OF MINING & METALLURGY GUAN MACHINERY +1

Construction method for backfilling of underground foundation pit excavation soil

ActiveCN104963349AGuaranteed compact qualityShorten the timeEmbankmentsSoil preservationSoil scienceStructural engineering

The invention relates to a construction method for backfilling of underground foundation pit excavation soil. According to the method, on a site of original deep foundation pit excavation, the temporary excavation soil is stacked on the ground nearby a deep foundation pit in a sorted mode, then a filling technology is adopted for returning the excavation soil into the original deep foundation pit in a slurry mode, in the backfilling process, soil is made compact after backfilling through drainage, balanced matching and appropriate regulation and control of the same layer of soil are achieved, and in this way, backfilling is performed in a layer-by-layer mode until a design control ground elevation is reached. The construction method has the advantages that in backfilling of the underground foundation pit excavation soil, excavation and filling time of the deep foundation pit can be greatly shortened, excavation and filling costs of the deep foundation pit can be greatly lowered, and backfill resetting can be rapidly guaranteed without ramming machines.

Owner:NANTONG INST OF TECH

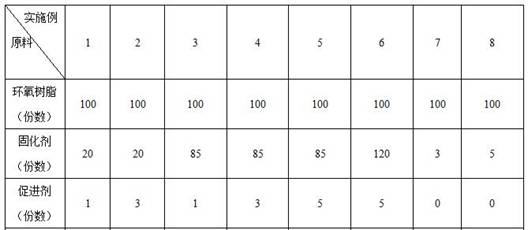

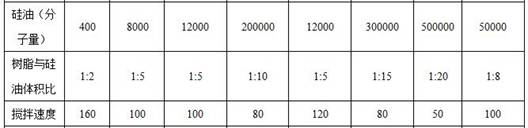

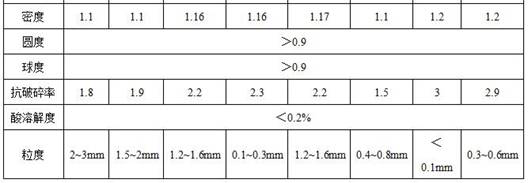

Epoxy resin fracturing propping agent and preparation method thereof

PendingCN112048294AHigh reactivityGood temperature resistanceFluid removalDrilling compositionPolymer chemistryFirming agent

The invention discloses an epoxy resin fracturing propping agent and a preparation method thereof, and belongs to the technical field of oil and gas exploitation. The preparation method comprises thefollowing steps: uniformly mixing epoxy resin, a curing agent and an accelerant according to the weight part ratio of 100: (3-120): (0-10) to obtain a dispersed phase; selecting one or a combination of more than two of silicone oil with the molecular weight of 400-500,000 as a continuous phase; adding the dispersed phase into the continuous phase, stirring, and controlling the stirring speed to be50-300 r / min and the temperature of the silicone oil medium to be 70-90 DEG C; and uniformly dispersing, heating to 130-160 DEG C, and curing to obtain the epoxy resin fracturing propping agent. Theepoxy resin fracturing propping agent meets the following indexes: the density is 1.0-1.1 g / cm <3>, the roundness is greater than or equal to 0.9, the sphericity is greater than or equal to 0.9, the crushing resistance is less than or equal to 3%, the acid solubility is less than or equal to 0.2%, and the size distribution range is 100-5000 [mu]m.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com