Foam pushing device of floatation machine

A flotation machine and a set of technology, applied in the direction of flotation, solid separation, etc., can solve the problems of easy flow of foam, easy stagnation of foam, falling off of foam particles, etc., to improve the flotation index, shorten the conveying distance, and achieve good flotation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

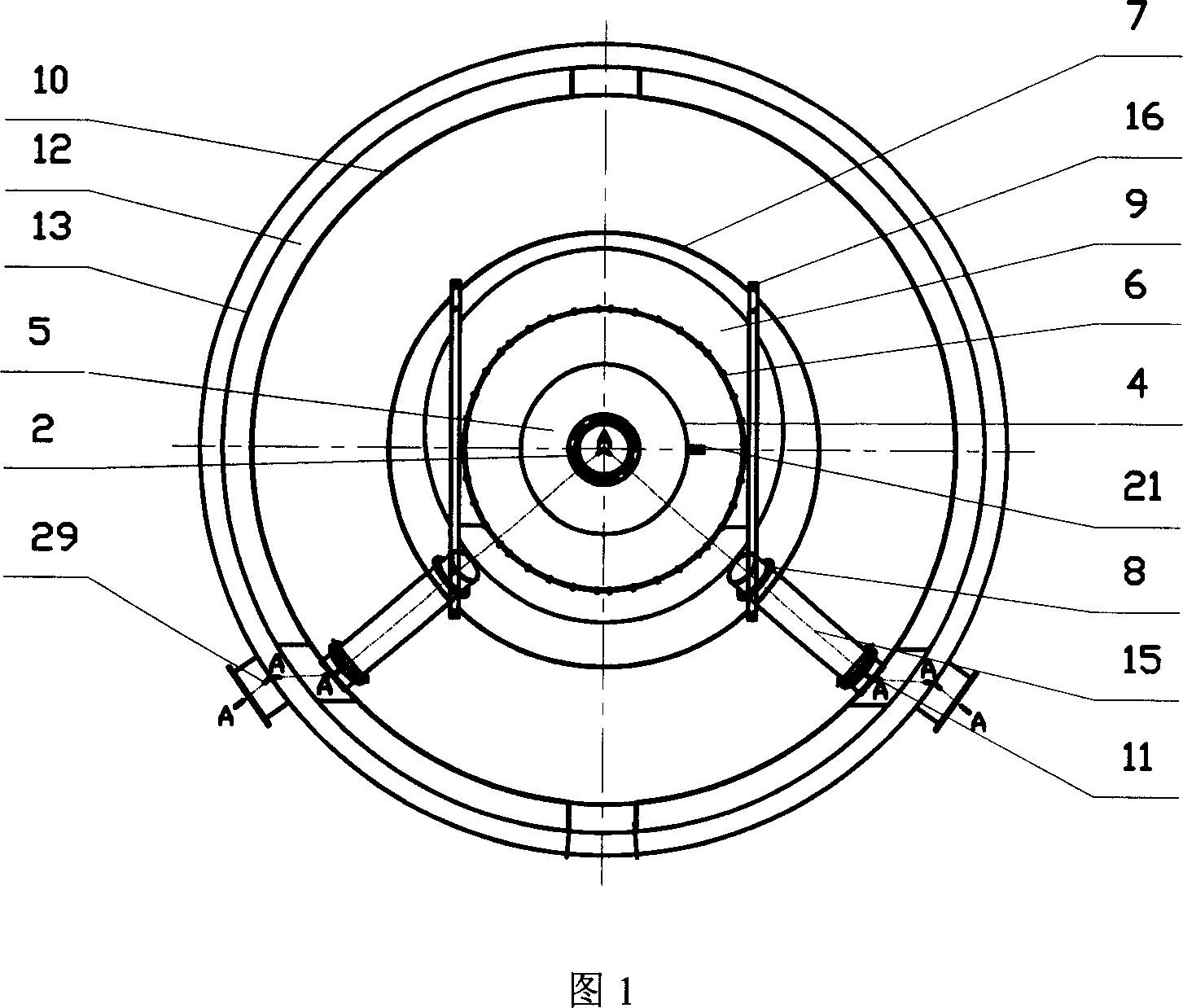

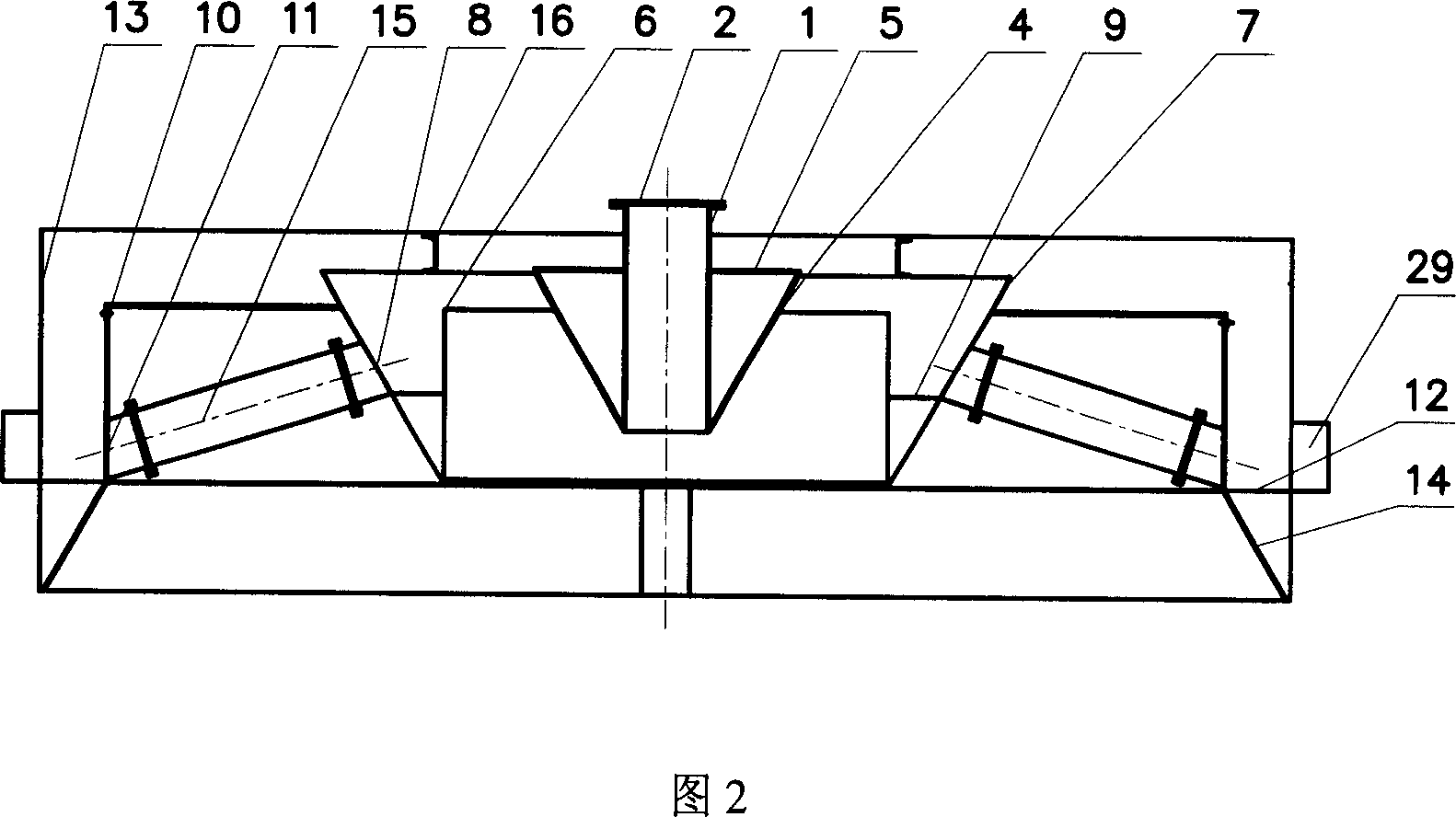

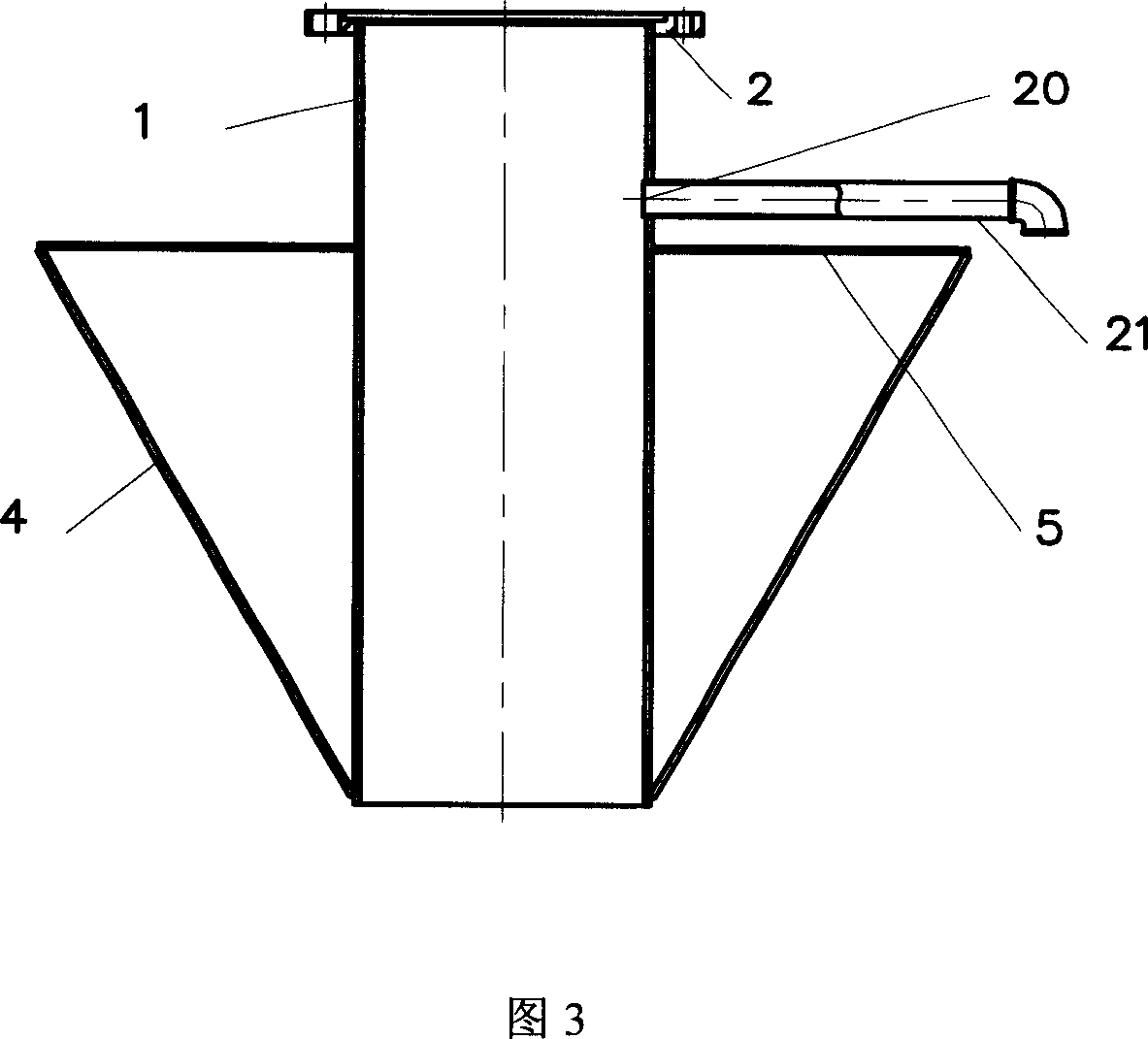

[0036] A foam pushing device of a flotation machine, the foam pushing device is a double foam pushing cone structure composed of an inner foam pushing cone, an inner foam groove, an outer foam cone complex, and an outer foam groove; wherein the structure of the inner foam pushing cone Including: connecting pipe 1-the connecting pipe is a tube-shaped structure that is fitted on the hollow main shaft of the flotation machine with a coaxial gap, and the upper end is fixed on the bearing body 3 at the upper end of the main shaft through the flange 2; the inner push bubble cone panel 4- The cone panel is an annular truncated cone plate, and the bottom ring edge of the truncated cone is fixedly connected to the bottom edge of the connecting pipe; the angle between the truncated cone plate and the connecting pipe surface is 25°~45°; the horizontal sealing plate 5-the sealing plate is horizontal Ring plate; its inner ring edge is fixedly connected to the wall of the connecting pipe, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com