Stacked steel plate conveying system and hot rolled plate continuous heat treatment method

A transportation system and steel plate technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as low production efficiency, high investment costs, and impact on production capacity, so as to reduce equipment investment costs, reduce floor space, and increase production The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

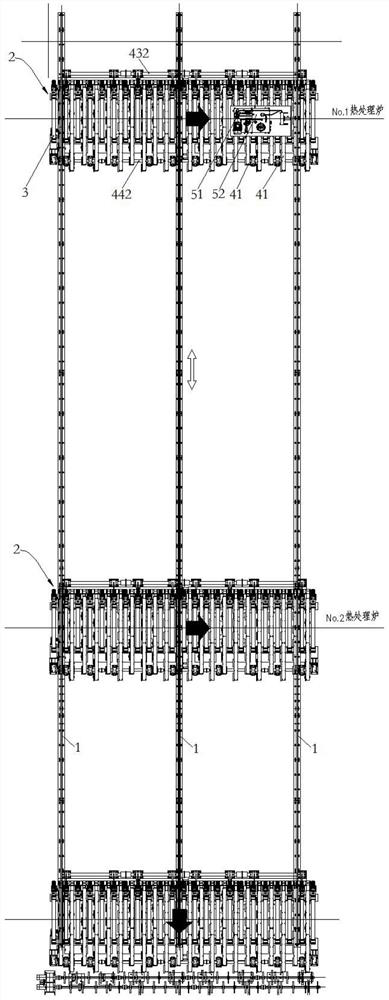

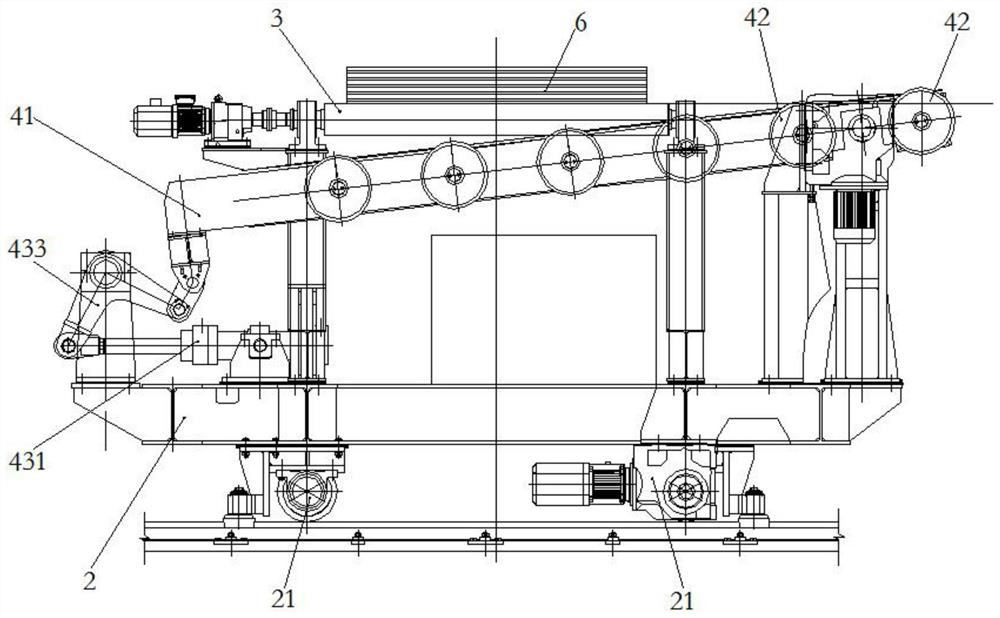

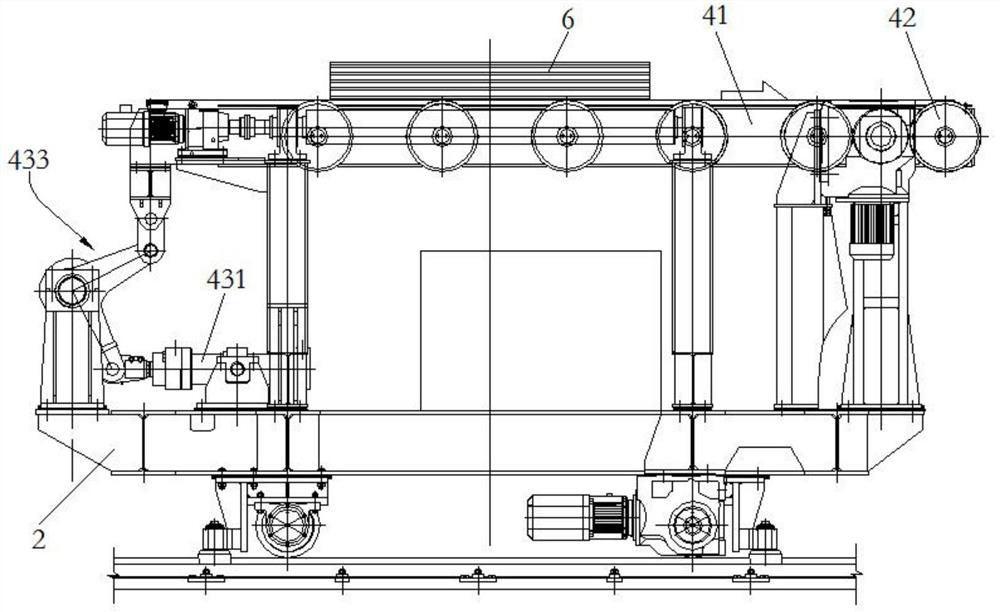

[0029] Such as figure 1 , the embodiment of the present invention provides a stacking steel plate transportation system, including a traversing track 1 and a steel plate transport vehicle 2 running on the traversing track 1; the guiding stroke of the traversing track 1 covers the heat treatment process position; the steel plate transport vehicle 2 is equipped with a side-by-side unloading roller table 3 suitable for carrying steel plate piles 6, and the conveying direction of the side-by-side unloading roller table 3 is perpendicular to the guiding direction of the traversing track 1.

[0030] The steel plate transportation system provided in this embodiment is mainly used in a continuous heat treatment production line for hot-rolled plates, and corresponding heat treatment equipment, such as heat treatment furnaces such as annealing furnaces / tempering furnaces, are arranged at the above heat treatment stations. When there are multiple heat treatment stations, each heat treatm...

Embodiment 2

[0049] Such as Figure 4-Figure 6 The embodiment of the present invention provides a steel plate transport vehicle 2 with a side guide eccentricity compensation function, which can be used as the steel plate transport vehicle 2 in the first embodiment above, including a vehicle body and multiple sets of walking mechanisms arranged at the bottom of the vehicle body, Described walking mechanism comprises traveling wheel 21 and side guide unit 23, and described side guide unit 23 comprises side guide frame 232, is located at the guide wheel shaft 233 on described side guide frame 232 and is rotatably installed on described guide wheel shaft 233 The side guide wheel 231 on the top, the distance between the axis of the guide wheel shaft 233 and the axis of the guide wheel shaft hole on the side guide frame 232 is adjustable, so that the side guide wheel 231 remains against the side of the wheel rail 11 catch.

[0050] Generally, the above-mentioned traveling mechanism includes a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com