A kind of biomass fuel and the technological process of processing this kind of biomass fuel

A technology of biomass fuel and process flow, applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve problems such as pollution and safety, achieve the effect of reducing transportation distance, reducing unlucky links, and convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

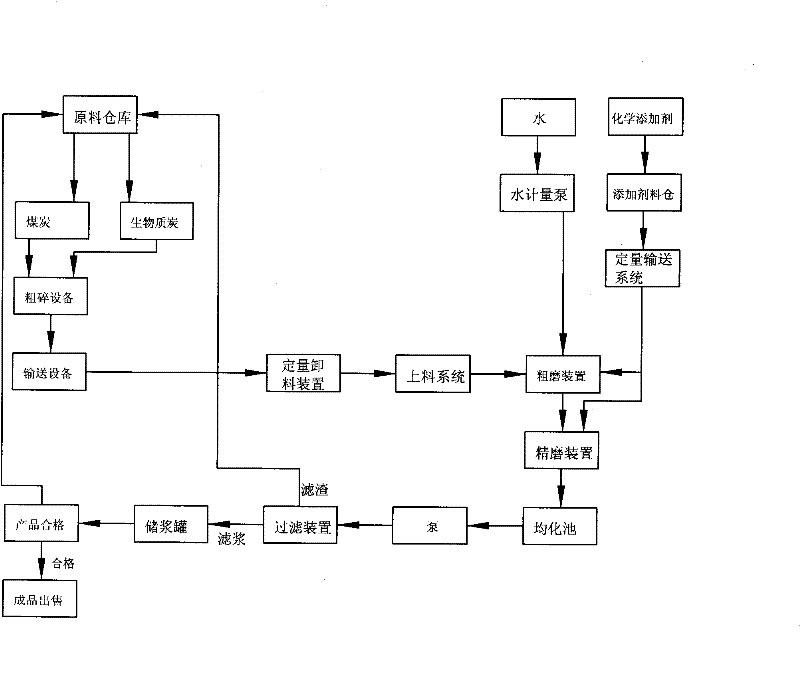

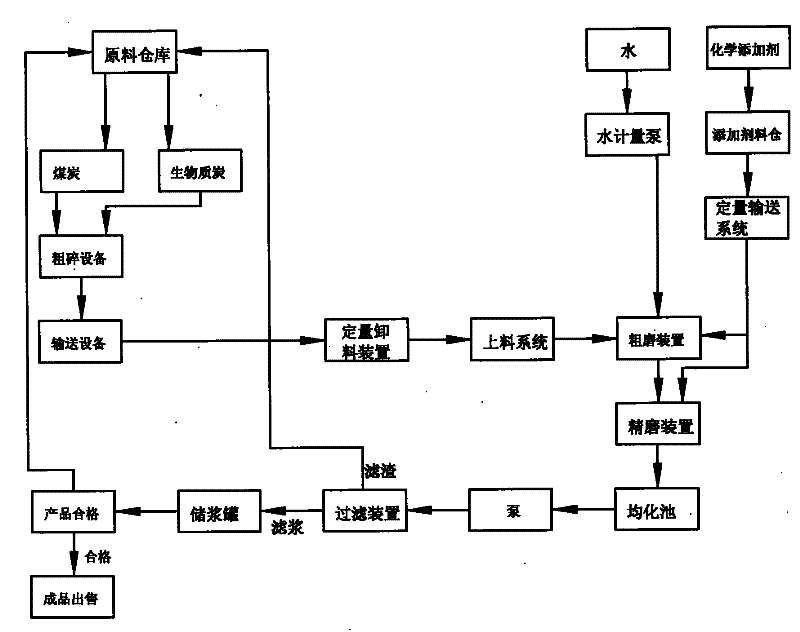

[0022] Please refer to figure 1 Shown, illustrate a kind of biomass fuel below in conjunction with specific embodiment, the quality of its component comprises the biomass carbon of 30% to 50%, the chemical additive of 0.3% to 0.5%, the coal of 18% to 20%; 31.8 % to 49.4% water.

[0023] In this embodiment, the mass proportion of the biochar is 40%; the mass proportion of the chemical additive is 0.3; the mass proportion of the coal is 20%; the mass proportion of the water is 39.7%.

[0024] The biochar is obtained by naturally decomposing chemical raw materials composed of multiple agricultural and forestry wastes as the main raw materials through a pyrolysis and dry distillation process for 6 to 8 hours under the condition of air isolation; the agricultural and forestry wastes Including straws, sawdust, rice husks, peanut husks, corn husks, branches and bagasse; said straws include rice stalks, wheat stalks, corn stalks, cotton and bean stalks. The biomass mentioned above r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com