Patents

Literature

47results about How to "Raise the ash melting point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Straw densification briquetting fuel preparation method for biomass power generation and boiler combustion

InactiveCN101768494ARaise the ash melting pointImprove combustion effectBiofuelsSolid fuelsSolid fuelPotassium ions

The invention provides a straw densification briquetting fuel (SDBF) preparation method for biomass power generation and boiler combustion, solving problems of low ash fusion point, easily coking, serious corrosion to boilers and the like of direct straw combustion. In the invention, straw is pre-processed through steam explosion or with diluted acid then is subjected to enzyme hydrolysis with cellulose, and the enzyme hydrolysis residue is briquetted to be used as fuel for biomass power generation or boiler combustion. The pre-processed and enzyme-hydrolysis straw can be briquetted easily; cellulose and hemicellulose in the pre-processed and enzyme-hydrolysis straw are removed basically, lignin content and calorific value increase, potassium ion, sodion and chloridion are removed, thereby improving ash fusion point of straw, reducing coking and boiler corrosion in combustion process, and improving combustion performance of straw. The straw solid fuel prepared by the invention can be used as fuel for common domestic boilers. Sugar produced by enzymolysis can be used as a fermentation carbon source for large-amount fermented products, so as to improve comprehensive utilization value of straw.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

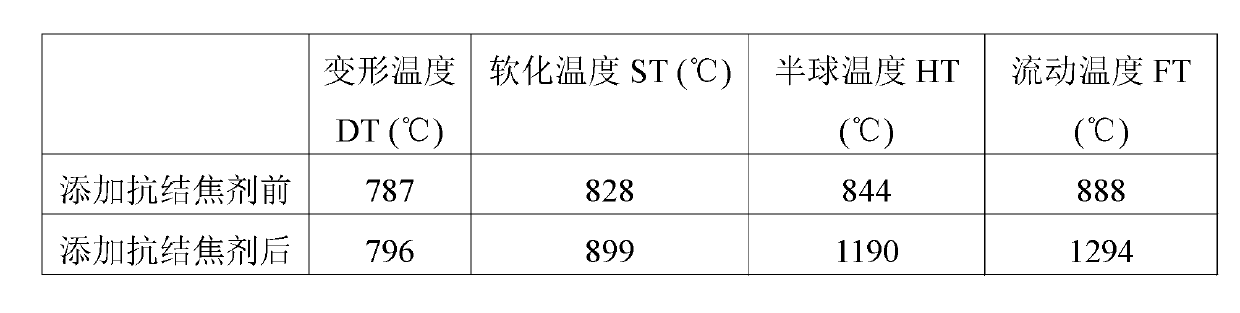

Industrial residue boiler anti-coking agent and application method thereof

InactiveCN103013617ARaise the ash melting temperatureAlleviate coking and slagging in the furnaceSolid fuelsFuel additivesPulverised fuel ashEngineering

The invention discloses an industrial residue boiler anti-coking agent and an application method thereof, belonging to the technical field of anti-coking additives. The industrial residue boiler anti-coking agent comprises the following components in percentage by mass: 30-60% of kaolin, 30-60% of CaO and 10-20% of fly ash. When in use, the industrial residue boiler anti-coking agent, accounting for 1-2% of the total mass of the industrial residue fuel, is added to the industrial residue fuel and evenly mixed. The industrial residue boiler anti-coking agent disclosed by the invention has high porosity, and the surface micropores have adsorbability; the industrial residue boiler anti-coking agent is simple to use, and the addition amount is only 1-2% of the total weight of the fuel, so that the invention does not influence the combustion characteristics of the fuel and the normal operation of the boiler, and does not need to modify the existing combustion equipment, thereby greatly lowering the investment cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

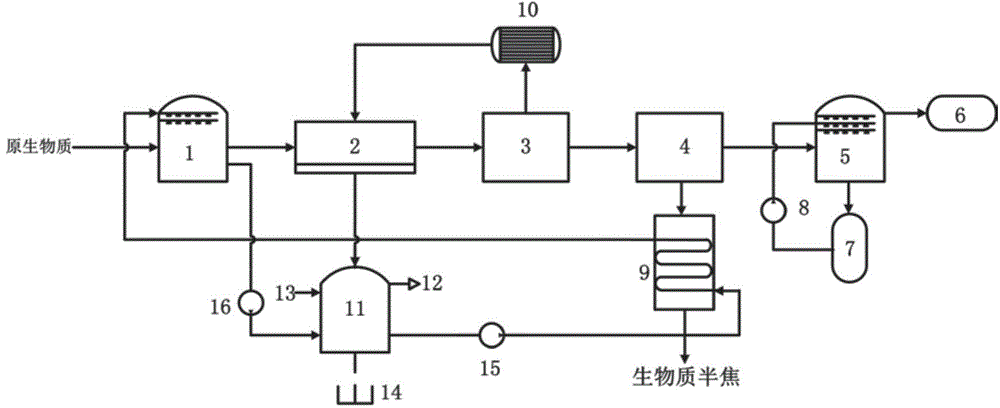

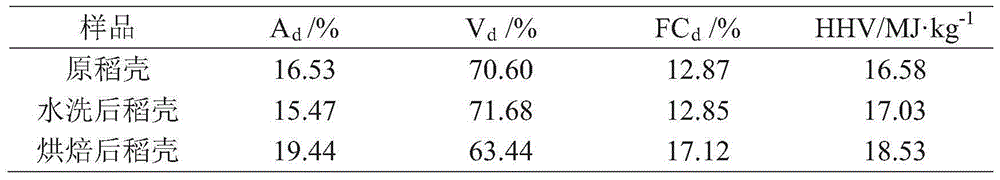

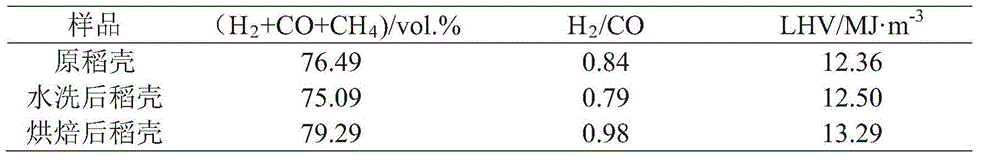

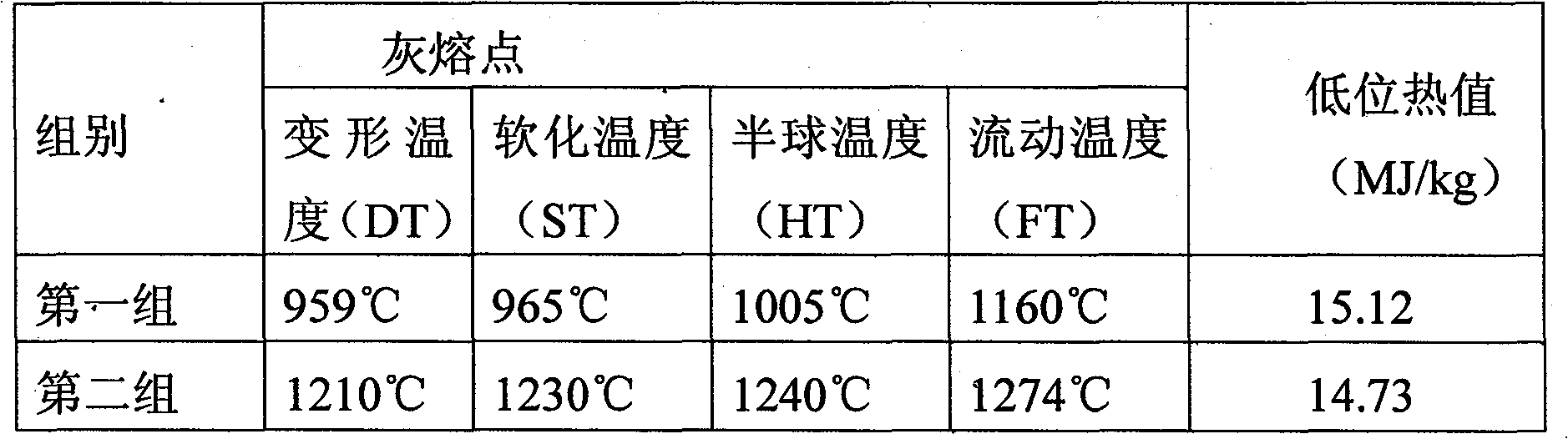

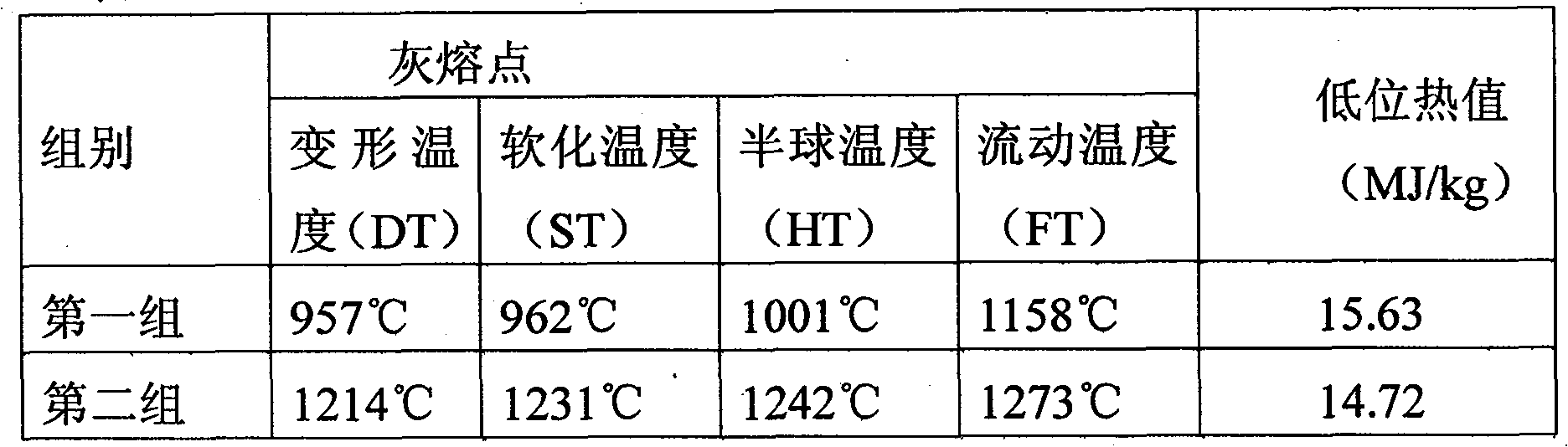

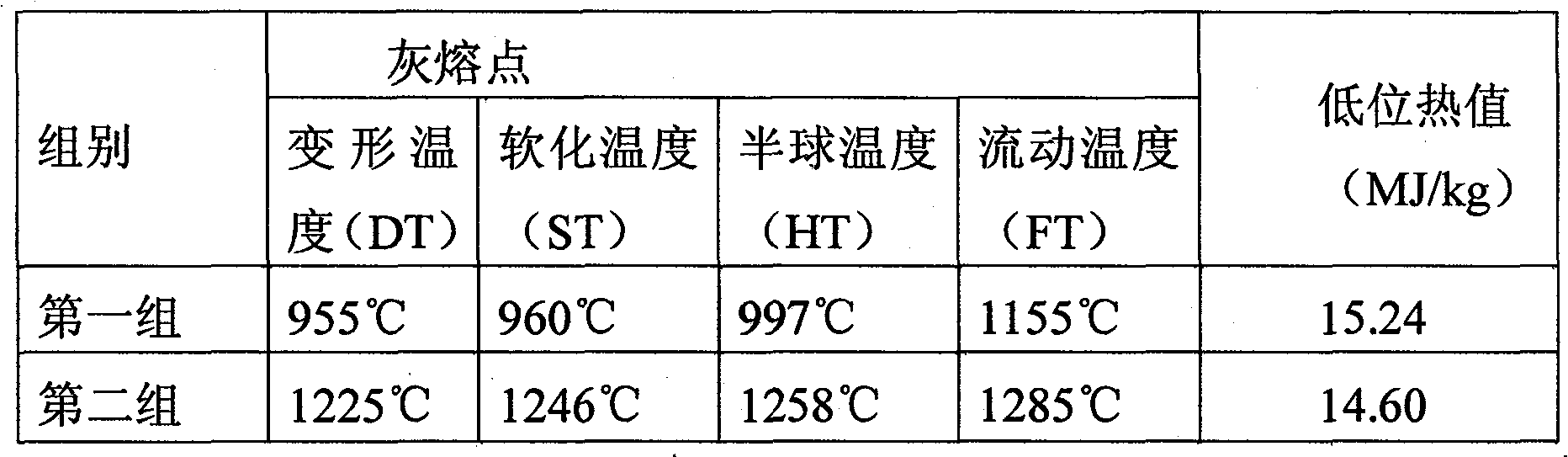

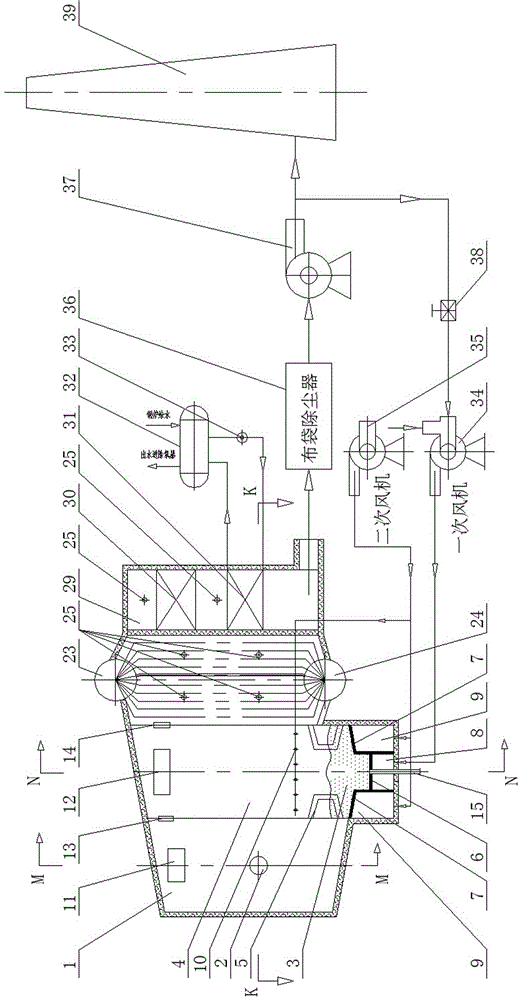

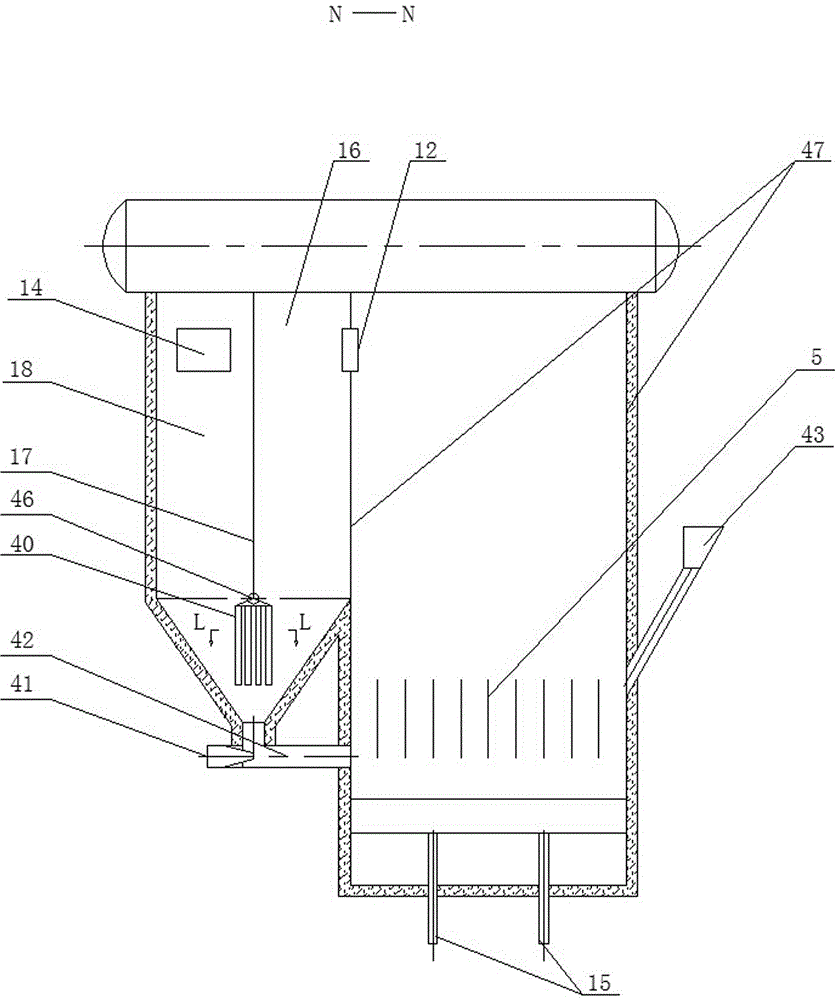

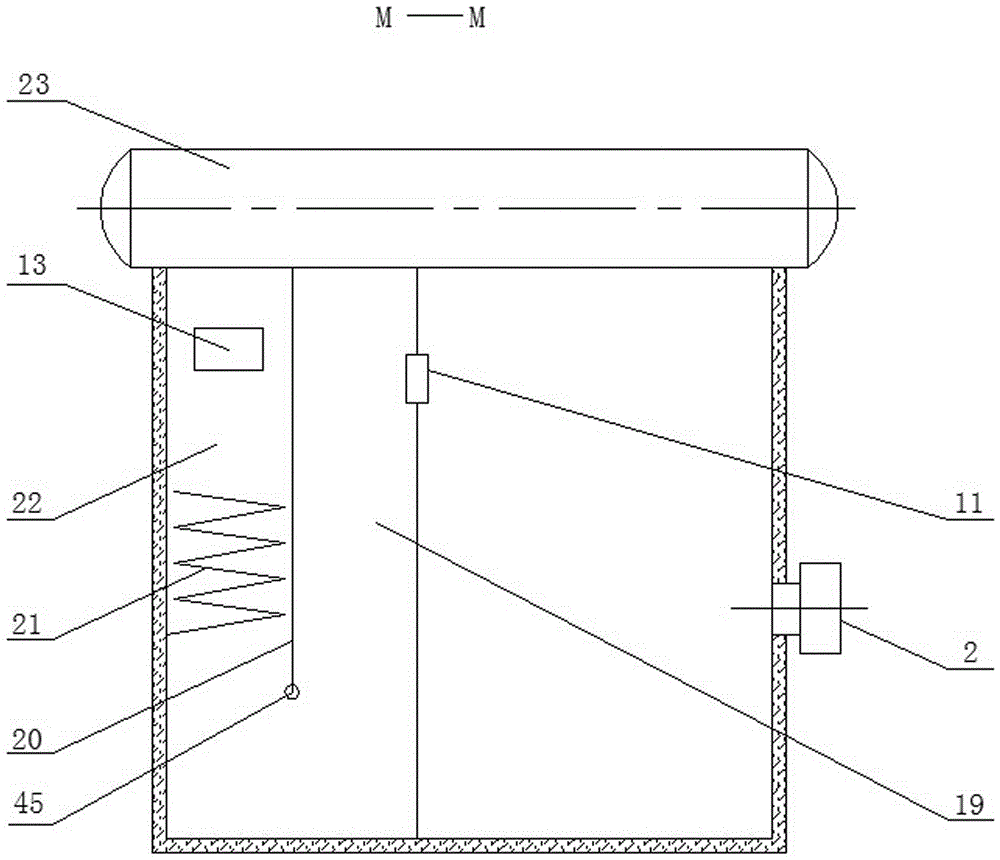

Systematic device and method for biomass microwave pyrolysis poly-generation by adopting combined washing and baking pretreatment

ActiveCN104673340AReduce moistureReduce stabilityBiofuelsSpecial form destructive distillationMoistureOperation safety

The invention discloses a systematic device and a method for biomass microwave pyrolysis poly-generation by adopting combined washing and baking pretreatment. The systematic device comprises a biomass washing-baking-pyrolysis system and a washing liquor circulatory system. According to the method, firstly, biomass raw materials are washed to remove part of alkali metal and impurities and then pre-dried, then large quantities of hemicellulose components are decomposed through baking pretreatment, the physical microstructure of biomass is improved, and the quality of a biomass microwave pyrolysis product after pretreatment is improved; the obtained biomass has high char calorific value and ash fusion point, low bio-oil water content and acidity, stable chemical composition, high syngas calorific value and great follow-up utilization potential. Energy of volatile matters is recovered and taken as a pre-drying heat source; meanwhile, the washing liquor circulatory system recovers sensible heat of pyrolysis char and moisture and latent heat in exhaust gas of flue gas after drying, the energy efficiency of the system is high, exhaust gas is not discharged in an operation process, operating parameters can be adjusted according to the biomass raw materials, the system operation safety is high, and the cost is low.

Owner:SOUTHEAST UNIV

Method for improving biomass ash fusion point

InactiveCN102041130ARaise the ash melting pointSimple processSolid fuelsFuel additivesSodium BentoniteProcess engineering

The invention discloses a method for improving biomass fuel ash fusion point, which is characterized in that the aim of improving the ash fusion point of biomass fuel is realized by mixing the compounding additives with the biomass fuel. By taking the mass of ash in the biomass fuel as 100 parts, the compounding additives contain the following components in parts by weight: 5-20 parts of kaolin, 0-15 parts of acid clay, 0-15 parts of diatomite, 0-10 parts of bentonite, 0-20 parts of coal, and 0-25 parts of coal gangue. The biomass fuel and the compounding additives are crashed, and are mixed uniformly by adopting a direct mixing method, The ash fusing point Ts (softening temperature) of the biomass fuel can be improved greatly, the range improved can reach 200-300 DEG C. The method has the characteristics of simple operation and low cost, and can be widely used for improving the ash fusing point of various biomass fuels.

Owner:EAST CHINA UNIV OF SCI & TECH

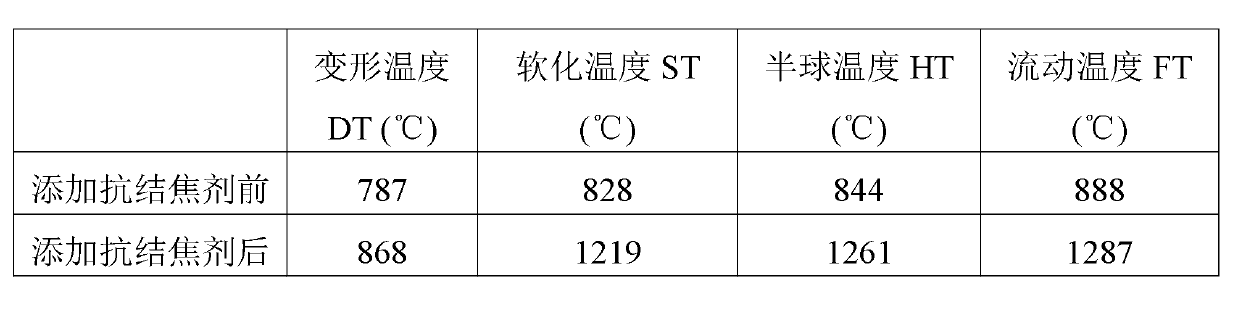

Additive inhibiting biomass boiler coking and using method thereof

ActiveCN105238494AWill not affect normal operationDoes not affect combustion characteristicsBiofuelsSolid fuelsChemical reactionSlag

The invention discloses an additive inhibiting biomass boiler coking. The additive is prepared from, by mass, 35-65% of kaolin, 30-60% of CaO and 5-35% of Mg(OH)2. When the additive is used, the addition proportion accounts for 0.5-2% of the total mass of biomass fuel. The additive can be directly mixed with biomass uniformly, then enters a combustion furnace by means of a feeding system of the boiler, and can be sprayed into a hearth uniformly along with an air inlet system, use is easy, and operation is easy. The additive has large porosity, the reaction area of the additive and the biomass fuel can be increased, pores in the surface of the additive have adsorption performance, alkali metal such as K and Na can be adsorbed to the surface of the additive effectively, the chemical reaction is carried out so that a high-melting-point substance can be generated, and ash deposition and slag bonding of the heated face are reduced; the amount of the adopted additive is small, efficiency is high, the coking resistant effect is remarkable, and the ash fusion point of the biomass can be remarkably increased.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Environmentally-friendly biomass granule fuel

The invention discloses an environmentally-friendly biomass granule fuel. The environmentally-friendly biomass granule fuel comprises sawdust, crop straw, anthracite smalls, sludge garbage, tea leaf residues, rice hull powder, attapulgite clay, montmorillonite and red mud. According to the environmentally-friendly biomass granule fuel, treatment of the sludge garbage is more environmentally friendly and economical, and the cost of the environmentally-friendly biomass granule fuel is low; compared with biomass granule fuels of the same type which are not compatible with the sludge garbage, theenvironmentally-friendly biomass granule fuel has higher heat value; moreover, the environmentally-friendly biomass granule fuel overcomes the phenomenon of slag-bonding, and discharging of harmful air is greatly reduced.

Owner:安徽盛昌生物能源科技开发有限公司

Blast furnace blowing semi-coke additive and preparation and use method thereof

The invention discloses a blast furnace injection semi-coke additive as well as a preparation method and a use method thereof, and belongs to the technical field of blast furnace coal injection. The additive comprises the following components in percentage by mass: 0.1-0.25% of a grinding aid, 58-80% of a composite waste residue type catalyst, 18-40% of a composite compound type catalyst and 1-4%of a dispersing agent. By adding the additive, the grindability and the ash melting point of semi-coke can be improved, the combustion effect is good, the injection amount of the semi-coke in a blastfurnace is greatly increased, the additive is suitable for large-scale popularization and application of blast furnace injection semi-coke, and a good foundation is laid for finally achieving completereplacement of coal with the semi-coke and achieving coal removal in a blast furnace injection system.

Owner:NANJING IRON & STEEL CO LTD

Biomass solid forming fuel additive

A biomass solid forming fuel additive relates to a biomass fuel additive. The invention settles the problems of easy slag bonding, easy ash accumulation, inadequate burning, low fuel usage factor, lowcombustion efficiency and serious corrosion of combustion device by the flue gas generated in burning, which are caused by low ash fusion point of biomass solid forming fuel that is produced by usingstalk as raw material. The additive of the invention is prepared by mixing Al2O2, Fe2O3 and kaolinum. The biomass solid forming fuel additive according to the invention can effectively increase the ash fusion point of stalk. The biomass solid forming fuel using the biomass solid forming fuel additive according to the invention is not easily generated with in-furnace slag bonding and ash accumulation in combustion process. The usage factor of biomass solid forming fuel is effectively increased for more sufficiently burning the biomass solid forming fuel.

Owner:HEILONGJIANG HUARUI BIO ENERGY TECH

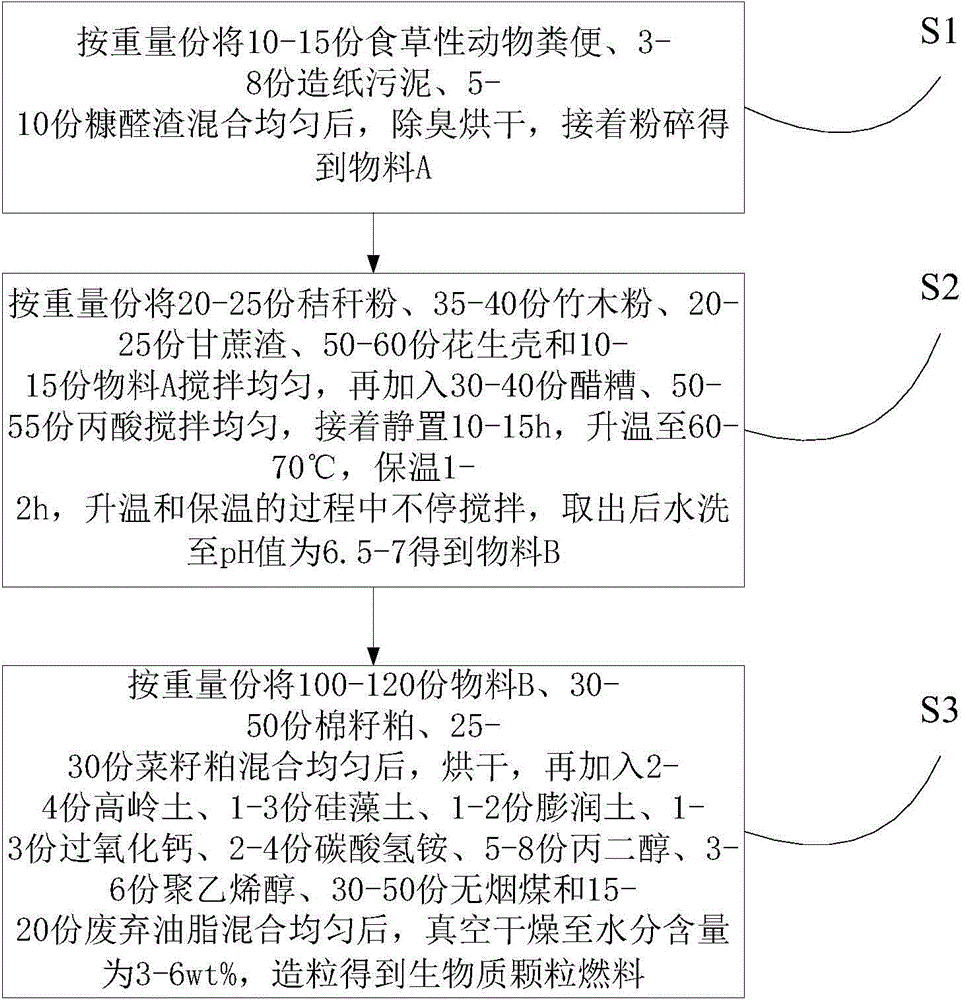

Preparation method for biomass granular fuel

InactiveCN104893779AReduce carbon contentReduce slagging rateBiofuelsSolid fuelsPolyvinyl alcoholPropylene glycol

The invention discloses a preparation method for biomass granular fuel. The preparation method comprises the following steps of: after uniformly mixing herbivorous animal waste, paper mill sludge and furfural residue, deodorizing and drying the mixture and then crushing the mixture to obtain a material A; uniformly stirring straw powder, bamboo powder, bagasse, peanut shells and the material A, then adding vinegar residues and propionic acid to uniformly stir the mixture, then leaving to stand for 10-15 hours, raising the temperature to 60-70 DEG C, insulating the mixture for 1-2 hours, ceaselessly stirring the mixture in the temperature raising and insulating processes, taking out the mixture and washing the mixture till the pH value is 6.5-7 to obtain a material B; and after uniformly mixing the material B, cottonseed meal and rapeseed meal, drying the mixture, then adding kaolin, diatomite, bentonite, calcium peroxide, aluminum hydroxide, propylene glycol, polyvinyl alcohol, anthracite and waste grease to uniformly mix the mixture, drying the mixture in vacuum till the water content of the mixture is 3-6wt% and granulating the mixture to obtain the biomass granular fuel.

Owner:广德县新杭镇聚源新型材料压膜厂

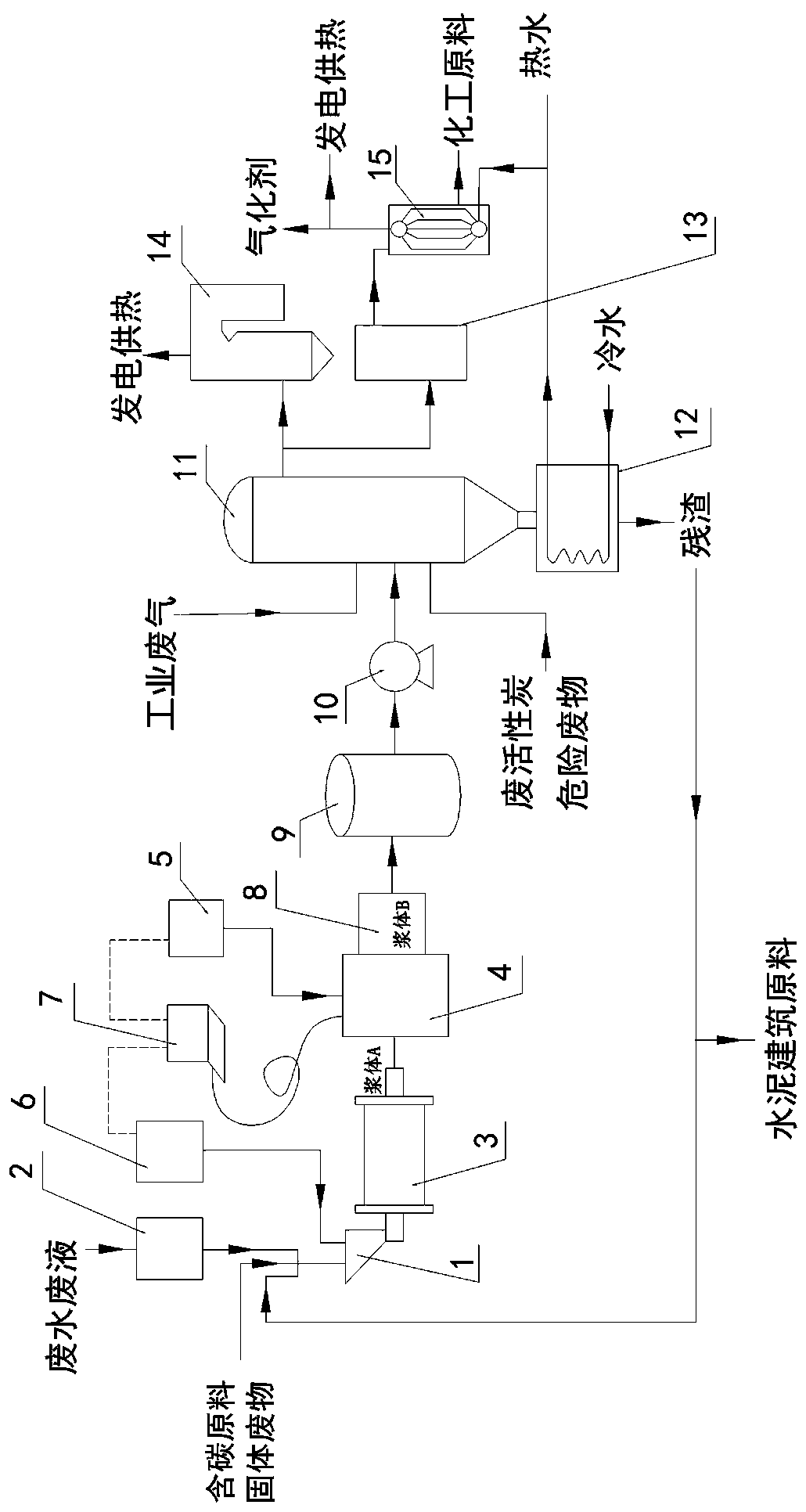

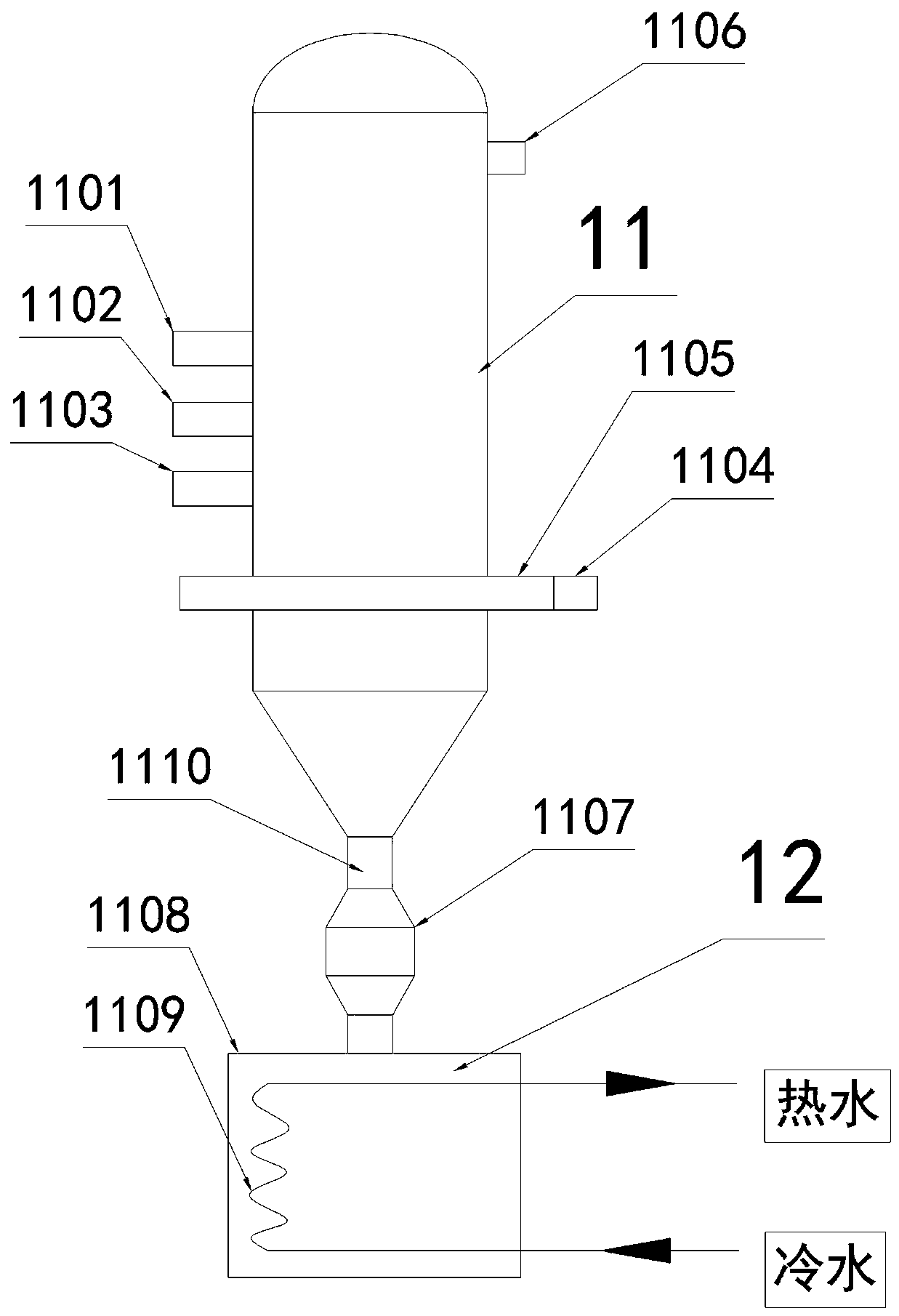

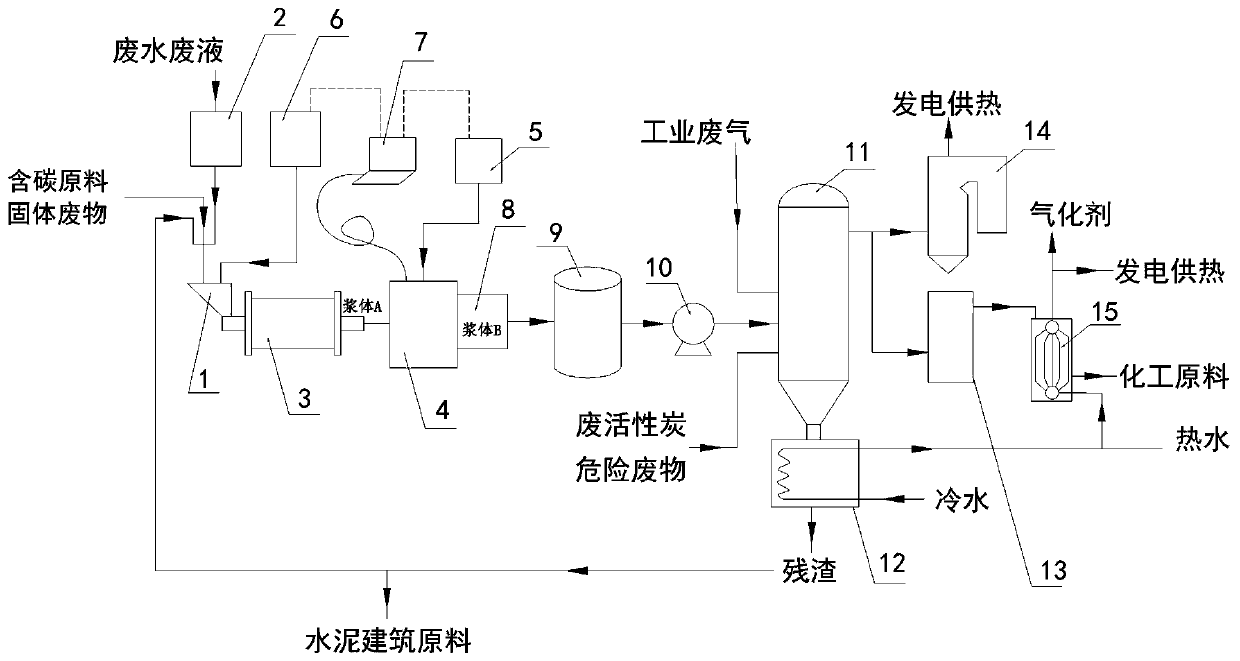

Gas-liquid-solid waste comprehensive treatment and resource utilization system

PendingCN110016368ARealize resource utilizationReduce high costGasification processes detailsCombustible gas productionLiquid wasteGuidance system

The invention relates to a gas-liquid-solid waste comprehensive treatment and resource utilization system, which comprises a grinding device, a pulping device and a gasification device. The grinding device comprises a feeding device and a mill. The feeding device is fed with carbon-containing raw material solid waste, waste water liquid and additives, and a formed mixture is sent to the mill for grinding to form a slurry A, and the slurry A is sent to the pulping device; the pulping device comprises a pulping body, a mixing pulping intelligent guidance system and a modifying conditioning device, wherein the mixing pulping intelligent guidance system guides the modifying conditioning device to perform conditioning treatment and ultrasonic treatment on the slurry A passing into the pulping body to generate a slurry B. The gasification device comprises a gasification furnace, wherein the gasification furnace is fed with the slurry B, which is prepared from the carbon-containing raw material solid waste and the waste water liquid by the front grinding device and pulping device, for pyrolysis and gasification to generate usable gas. The system provided by the invention is a system for comprehensive treatment of solid waste, waste liquid and waste gas.

Owner:浙江百能科技有限公司 +1

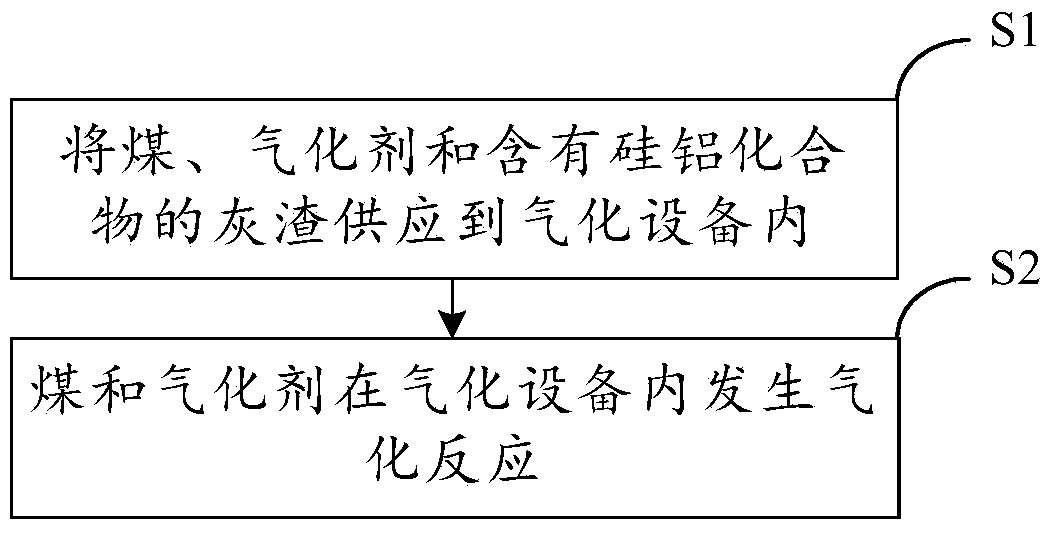

Coal gasification method

ActiveCN103992821ARaise the ash melting pointIncrease the content of silicon and aluminumGranular/pulverulent flues gasificationSlagProcess engineering

The invention discloses a coal gasification method and relates to the technical field of coal gasification. The coal gasification method can avoid scorification in a gasification method to ensure continuous and stable operation in the gasification process and expand the coal type application range of the gasification process. The coal gasification method disclosed by the invention comprises the following steps: supplying coal, a gasifying agent and slag containing silicoaluminate to gasifying equipment; and carrying out a gasification reaction on coal and the gasifying agent in the gasifying equipment. The coal gasification method disclosed by the invention is suitable for the coal gasification process.

Owner:ENN SCI & TECH DEV

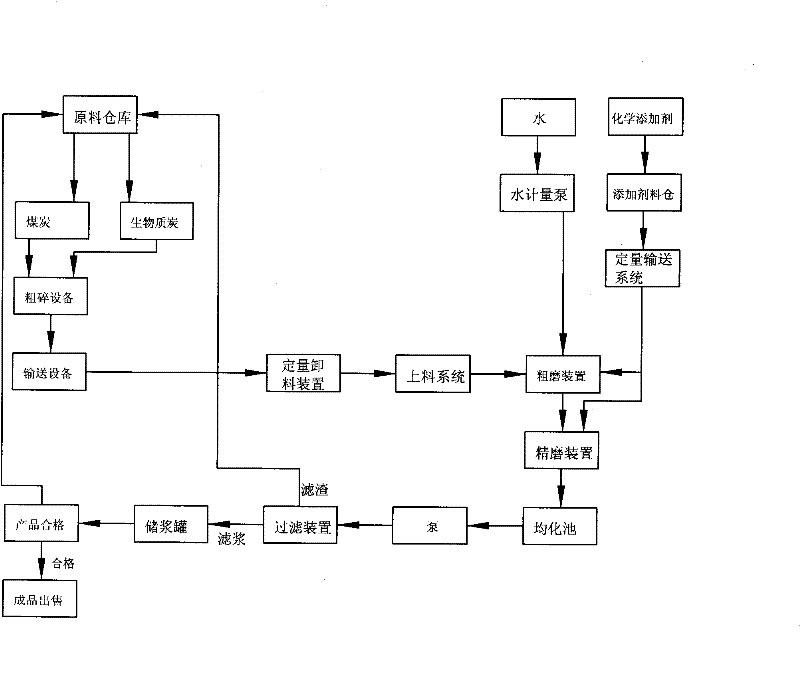

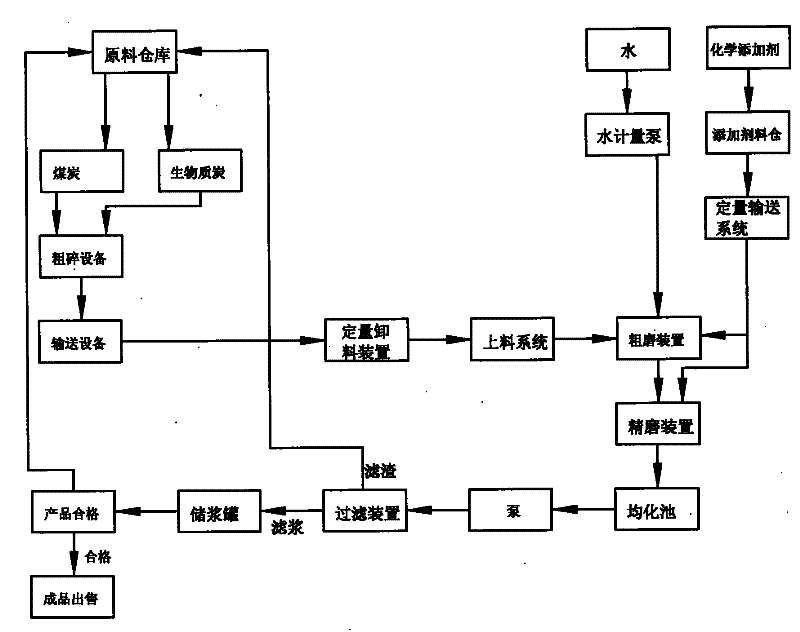

A kind of biomass fuel and the technological process of processing this kind of biomass fuel

InactiveCN102268306AEasy to collectEasy to get materialsLiquid carbonaceous fuelsBiomass carbonCombustion

The invention relates to a biomass fuel, which comprises 30% to 50% of biomass carbon, 0.3% to 0.5% of chemical additives, 18% to 20% of coal and 31.8% to 49.4% of water. When burning, coal can supplement or increase the calorific value required to be set in the boiler or kiln, so that the ash melting point of the fuel in the boiler or kiln can be increased, and unsafe hidden dangers can be avoided. Due to the convenience of coal collection, it has the beneficial technical effect of convenient material collection. In addition, the present invention also has the purpose of environmental protection. And because of the reasonable technological process and equipment configuration and the selection of new, efficient and energy-saving equipment, it is possible to reduce the reverse transportation link and transportation distance of materials. And because the coarse mill and the fine mill are equipped with frequency conversion control, the equipment can have sufficient starting torque, which meets the maximum requirement of the mill loading capacity, ensures normal process control requirements, and achieves the extension of the mill and motor. service life and the purpose of reducing maintenance.

Owner:深圳市赛尔勒环保科技有限公司

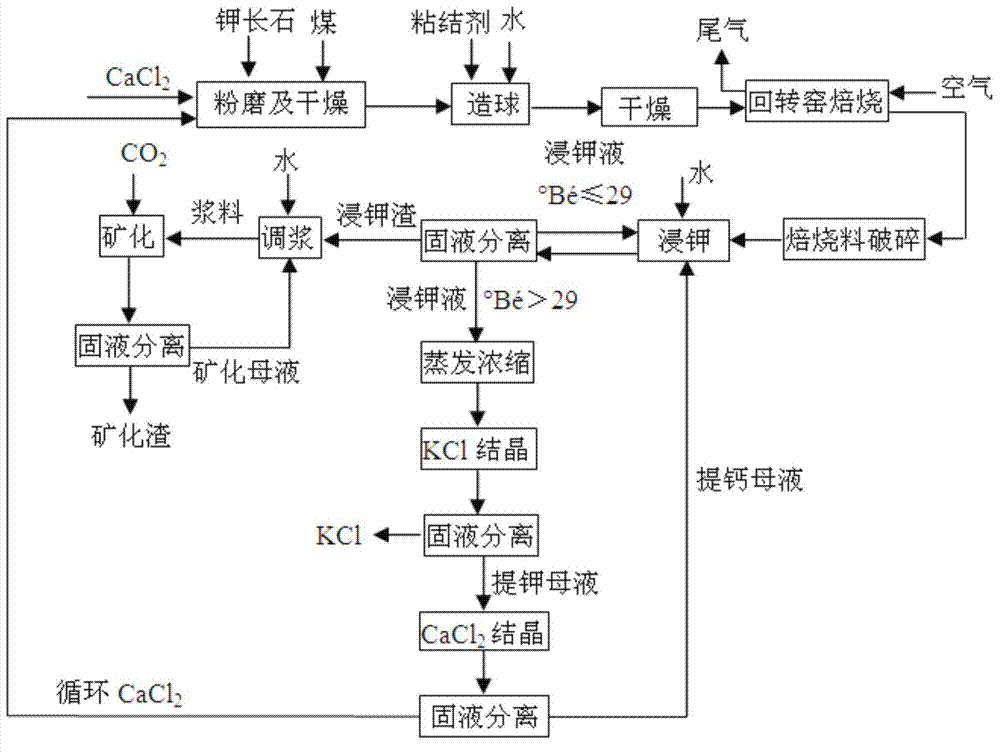

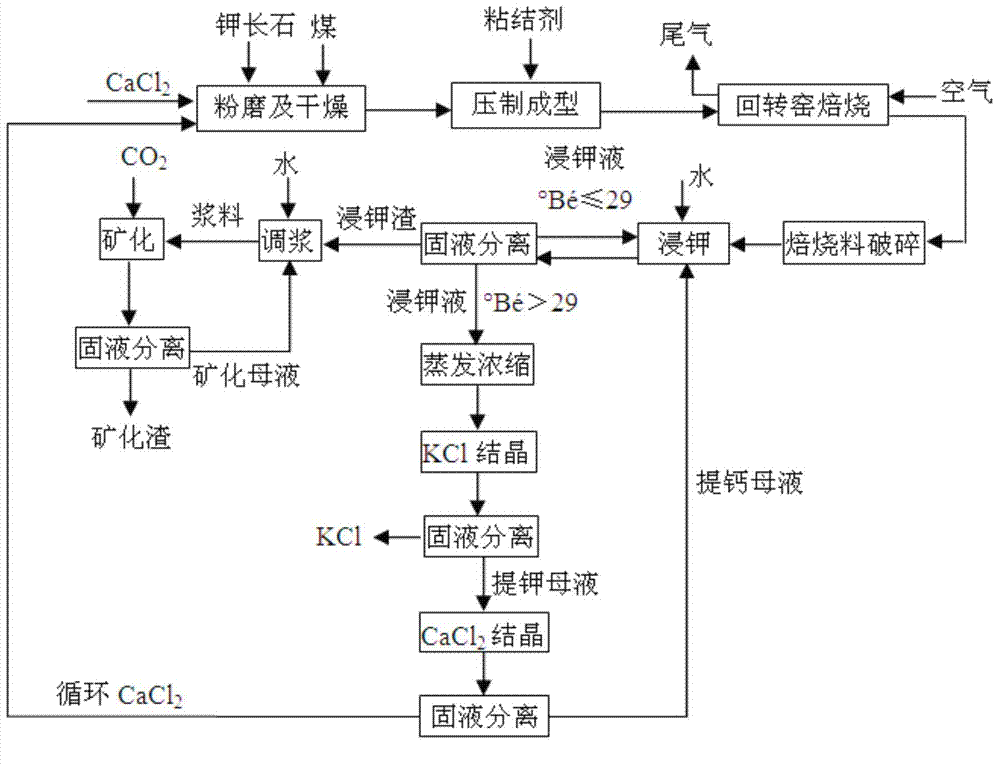

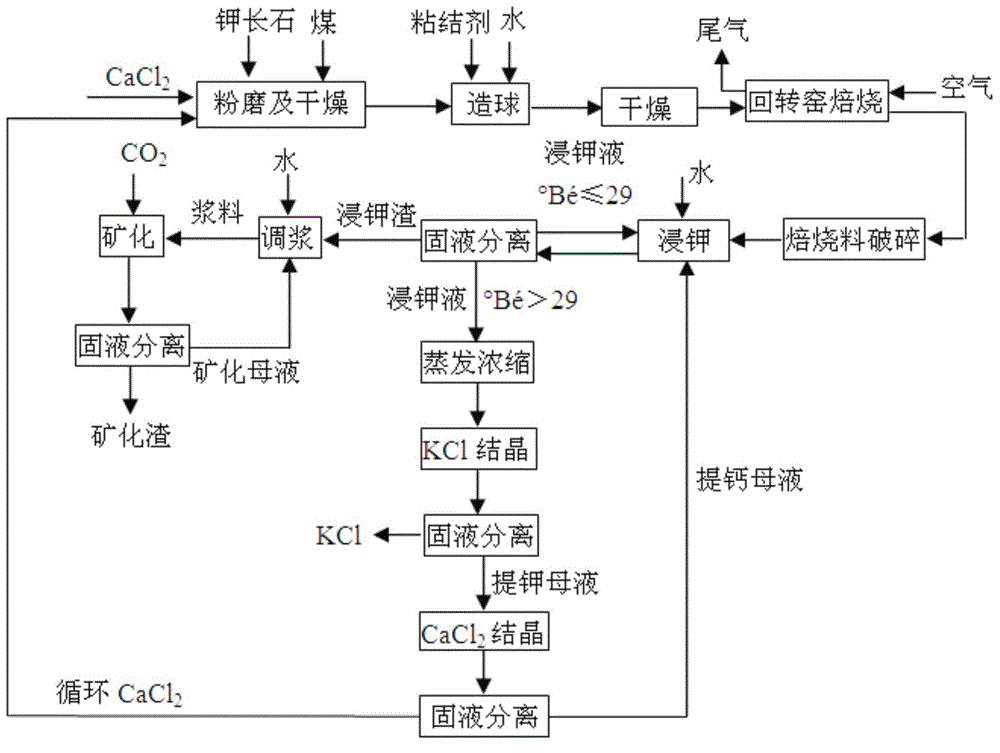

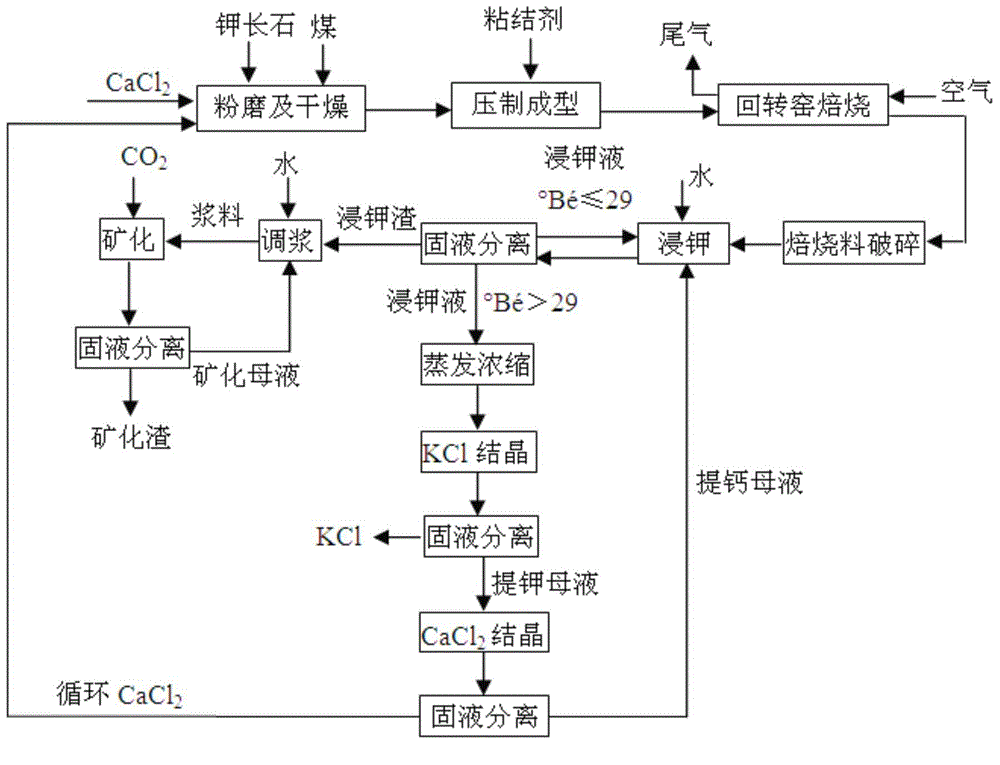

Method for concurrent production of potassium chloride and mineralization fixation of CO2

InactiveCN103693659ARaise the ash melting pointHigh melting pointDispersed particle separationAlkali metal chloridesEvaporationPotassium

The invention belongs to the comprehensive field of potassium fertilizer production and CO2 emission reduction, and provides a method for concurrent production of potassium chloride and mineralization fixation of CO2. The process steps comprise: (1) adopting potassium feldspar, calcium chloride and coal as raw materials, preparing materials, carrying out ball milling, and carrying out pressing molding or pelletizing; (2) conveying the molded material or the material balls into a rotary kiln from the kiln tail, conveying air into the rotary kiln from the kiln head, and controlling a residence time of the molded material or the material balls at a temperature range of 800-1000 DEG C to 20-40 min; (3) crushing the calcinated material, and adding water to carry out potassium leaching through the water; (4) adding water to the potassium leaching residue to carry out pulp conditioning, and introducing CO2 to carry out a mineralization reaction; (5) carrying out returning of the potassium leaching solution so as to be used for leaching of potassium from the calcinated material when the Baume degree of the potassium leaching solution is less than or equal to 29, and carrying out evaporation concentration on the potassium leaching solution to achieve the Baume degree of 42-42.5 when the Baume degree of the potassium leaching solution is more than 29, and cooling to carry out potassium chloride crystallization; and (6) cooling the potassium extraction mother liquor to carry out calcium chloride crystallization, and carrying out solid-liquid separation to obtain calcium chloride and the calcium extraction mother liquor.

Owner:SICHUAN UNIV

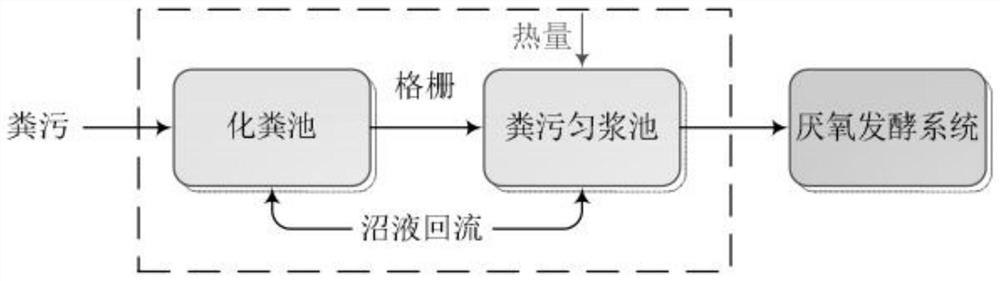

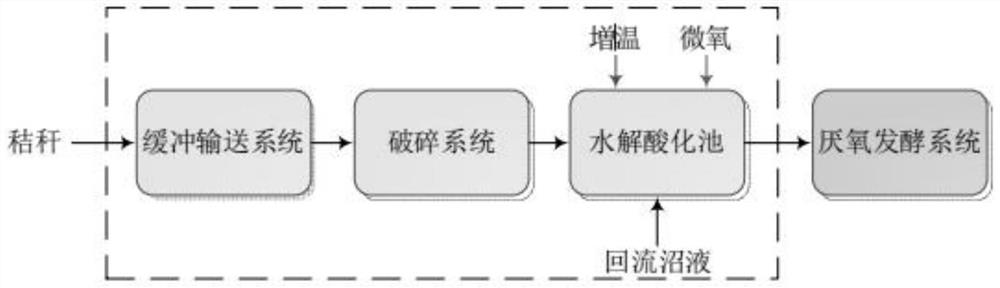

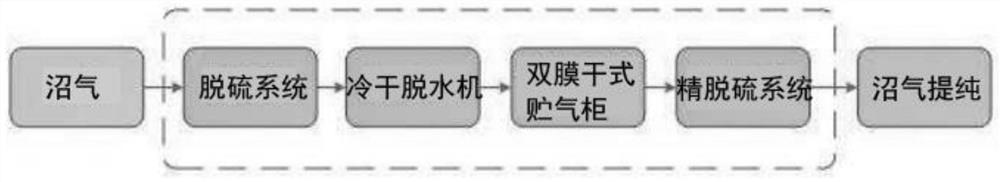

Poly-generation method employing coupling of biomass with livestock and poultry manure

InactiveCN112830821AReduce energy consumptionIncrease soil volatile organic carbon contentCarbon compoundsDrying solid materials without heatBiogasBiomass

The invention belongs to the technical field of comprehensive utilization of biomass and livestock and poultry manure, and particularly relates to a poly-generation method employing coupling of biomass with livestock and poultry manure. The poly-generation method comprises the following steps: burning straws to generate power so as to provide heat, pretreating the straws and the livestock and poultry manure, respectively hydrolyzing and acidifying the straws and livestock and poultry manure, feeding the straws and livestock and poultry manure having been hydrolyzed and acidified into a CSTR anaerobic fermentation tank, allowing the hydrolyzed and acidified straw and livestock and poultry manure to undergo medium-temperature anaerobic fermentation in the CSTR anaerobic fermentation tank so as to obtain biogas and biogas slurry, subjecting the biogas slurry to solid-liquid separation before preparation of an organic fertilizer from the biogas slurry, and subjecting the biogas to drying, gas-water separation, desulfurization and filtration before preparation of natural gas from the biogas. According to the invention, the straw and the livestock and poultry manure are coupled and recycled to generate electricity, heat, cold, biogas and organic fertilizer, so harmless utilization of resources is realized.

Owner:国能生物发电集团有限公司

Biomass granular fuel

InactiveCN107739638AEmission reductionCompatibility is reasonableBiofuelsSolid fuelsRed mudEnvironmental engineering

The invention discloses biomass granular fuel, which is prepared from the following components: sawdust, crop straw, a corncob, rice hull powder, attapulgite clay, montmorillonite and red mud. The biomass granular fuel provided by the invention is reasonable in componential compatibility; the slagging phenomenon of a present biomass granular fuel is greatly ameliorated; the emission of pollution gas is greatly reduced and the combustion rate of the biomass granular fuel is improved.

Owner:安徽盛昌生物能源科技开发有限公司

Chemical method

InactiveCN103421574ARaise the ash melting pointReduce dust accumulationSolid fuelsHigh sodiumCompound (substance)

The invention provides a chemical method. The chemical method can reduce adverse effects of active sodium-containing components in high-sodium coal on a boiler and other devices in a high-temperature environment, and comprises the following steps: step 1, pretreatment, namely uniformly spraying a certain amount of a silica sol solution containing silica onto the high-sodium coal or soaking the high-sodium coal in the silica sol solution for a period of time to obtain high-sodium coal completely subjected to pretreatment; step 2, drying, namely drying the high-sodium coal completely subjected to pretreatment to obtain dried high-sodium coal; step 3, conveying the dried high-sodium coal to the high-temperature environment for use, wherein in the process, the silica and active sodium-containing components react to generate a sodium-containing substance which is high in melting point and insusceptible to volatilization.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Industry fire coal additive agent

The invention discloses a novel industrial coal additive prepared from solid ketene dimmer residue and auxiliary materials. The additive comprises the following components by weight percentage: 70wt%-90wt% of solid ketene dimmer residue, 2wt%-10wt% of quicklime, 3wt%-10wt% of potassium permanganate and 5wt%-10wt% of kaolin. The additive has the advantages that (1) the heating value of the additive per se is not lower than 4,000KCaL / Kg, and the coal can be saved by adopting the additive itself; (2) the additive allows the fuel to burn more sufficiently and even completely, reduces carbon monoxide in the fume, and controls the discharge of the black smoke, thus achieving the coal-saving effect; (3) the additive allows the ash fusion point of the clinker to increase, so as to ensure that the cinder turns to be crisp without generating coke residue, and the additive also reduces the carbon content of the cinder, thus achieving the coal-saving effect; and (4) the raw material of the additive is derived from the industrial waste so as to solve the industrial pollution problem during the process of producing diketene, and the additive is applicable to various industrial boilers based on various coals.

Owner:南通宏信化工有限公司

Environment-friendly and inflammable fuel rod and manufacturing process thereof

InactiveCN105950250ARaise the ash melting pointEfficient removalBiofuelsSolid fuelsFiberVegetable oil

The invention discloses an environment-friendly and inflammable fuel rod and a manufacturing process thereof. According to a formula, the environment-friendly and inflammable fuel rod is prepared from, in percentage by weight, 20%-40% of elm sawdust, 10%-30% of elm bark, 5%-12% of waste carbon powder, 2%-6% of an alkaline paper pulp waste liquid, 15%-40% of dewatered sludge, 3%-10% of waste paper pulp, 2%-6% of vegetable oil sediments and 4%-12% of furnace slag. Compared with the prior art, the environment-friendly and inflammable fuel rod and the manufacturing method have the advantages as follows: substance structures in the elm bark can be effectively improved, carbon elements are kept, fiber structures of the fuel rod can be softened, and the fuel rod can be easily processed and formed; the main raw materials are elm sawdust and bark, the sulfur content is lower than 0.1%, the content of ash is lower and ranges from 1.6%-3.2%, burning is easy, the burning time is long, the fuel rod is environment-friendly, and the operation cost is reduced by about 40% while compared with that by adopting conventional fuel.

Owner:安徽省珍云生物能源有限公司

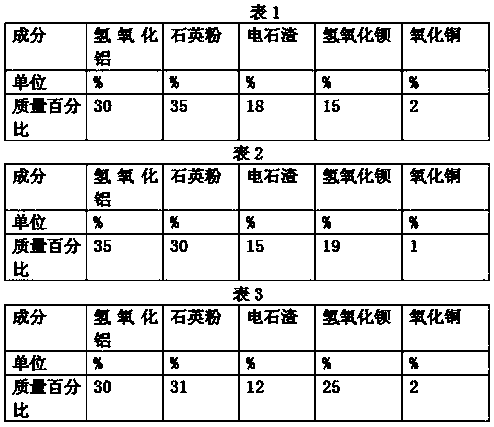

Additive for alleviating coking feature of Xinjiang Zhundong high alkali coal and preparation and application method of additive

InactiveCN108359512AReduced coking characteristicsRaise the ash melting pointSolid fuelsFuel additivesCombustionSlag

The invention relates to the technical field of an additive for alleviating the coking feature of high alkali coal, and relates to an additive for alleviating the coking feature of Xinjiang Zhundong high alkali coal as well as a preparation and application method. The additive is prepared by adopting the following method: uniformly mixing a needed amount of aluminum hydroxide, quartz powder, carbide slag, barium hydroxide and copper oxide, and thus obtaining the additive for alleviating the coking feature of the Xinjiang Zhundong high alkali coal. The additive for alleviating the coking feature of the Xinjiang Zhundong high alkali coal is added into Zhundong high alkali coal to be combusted, in the case of blowing the ash one time every six hours, the combustion feature of the coal with the additive is proved to be consistent with that of the coal which is uneasy to coke when in combustion, a boiler is basically free from coking, an ash fusion point of a combustion substance can be effectively increased, and the coking feature of the Xinjiang Zhundong high alkali coal can be reduced. The preparation process provided by the invention is simple, the investment cost is low, the application operation is simple, and the requirement for the equipment for preparing the additive is low.

Owner:ELECTRIC POWER SCI RES INST OF STATE GRID XINJIANG ELECTRIC POWER +1

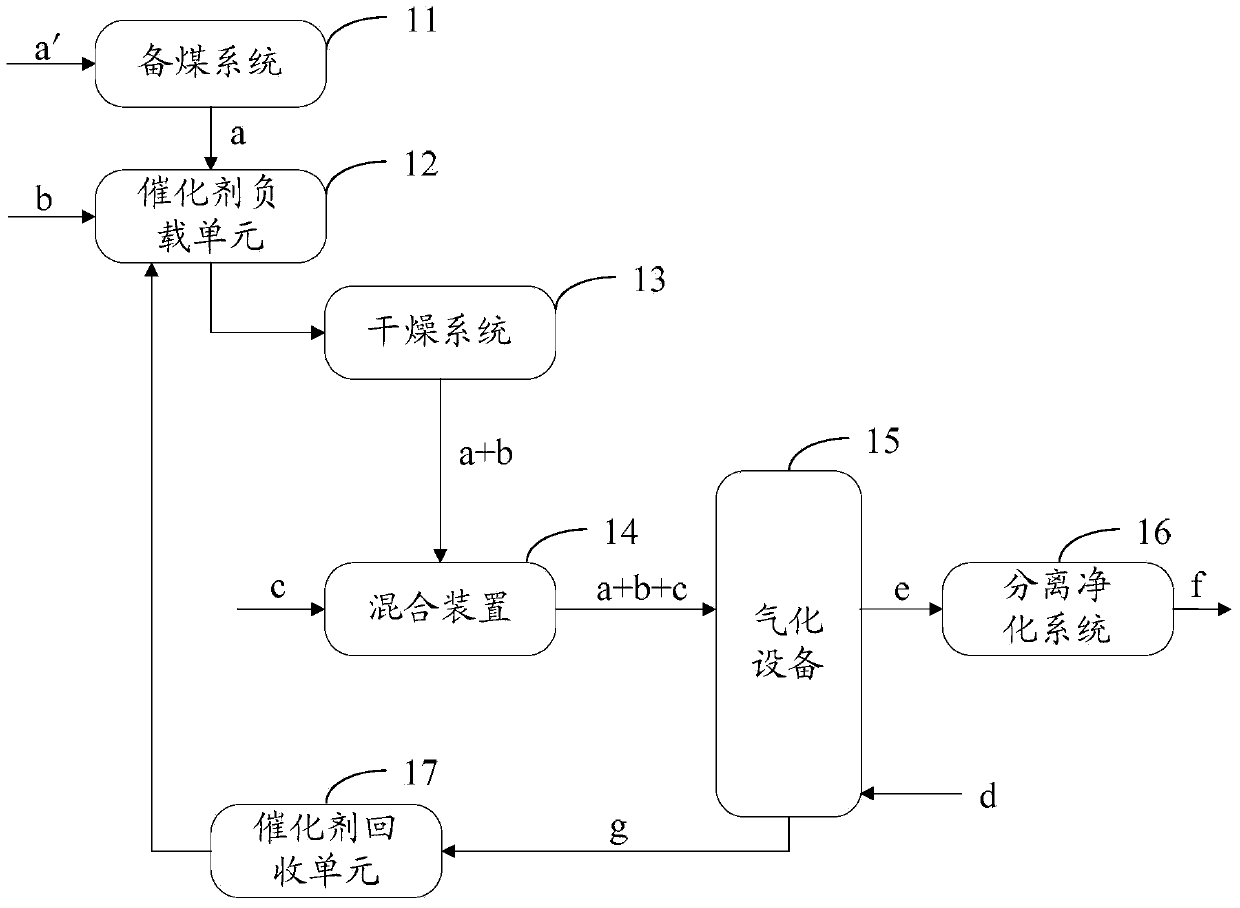

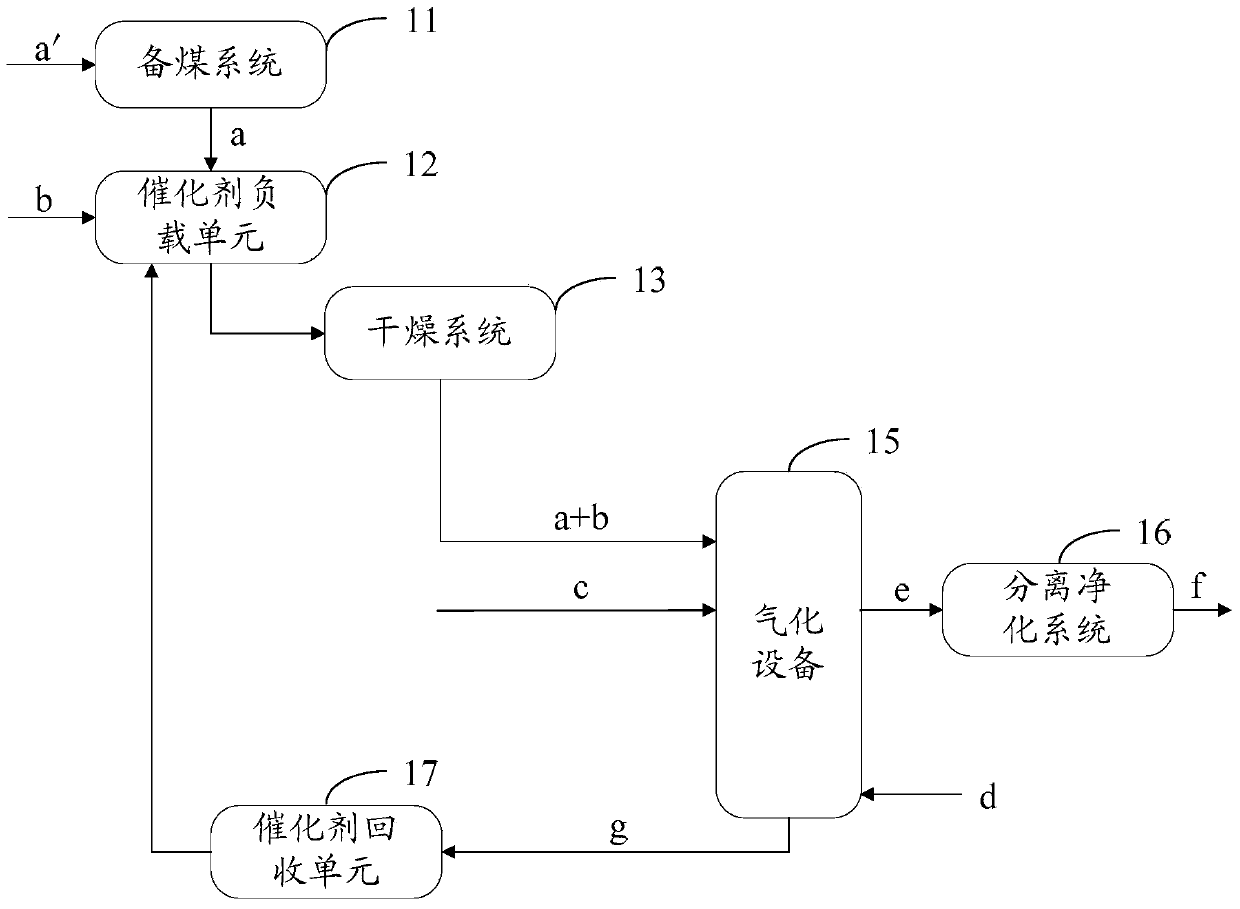

Pretreatment method of high-alkali coal

ActiveCN106010727ARaise the ash melting pointHigh catalytic activitySolid fuelsPretreatment methodPhysical chemistry

The invention relates to the field of catalytic coal gasification, in particular to a pretreatment method of high-alkali coal. The method can make the alkali metal in high-alkali coal exist in the form of an alkali metal salt with catalytic activity so as to improve the catalytic activity of catalytic high-alkali coal gasification, and also can reduce slagging. The pretreatment method of high-alkali coal provided by an embodiment of the invention includes: stirring high-alkali coal in the presence of calcium ions existing in the form of calcium-oxygen bond and water, carrying out ion exchange reaction on the oxygen-containing functional group on the surface of the high-alkali coal and the calcium ions existing in the form of calcium-oxygen bond, then carrying out ion exchange reaction on calcium ions exchanged to the surface of the high-alkali coal and alkali metal ions in the high-alkali coal, and performing drying to obtain the treated high-alkali coal with the surface rich in K-O-C active intermediate. The embodiment of the invention can be applied to pretreatment of high-alkali coal.

Owner:ENN SCI & TECH DEV

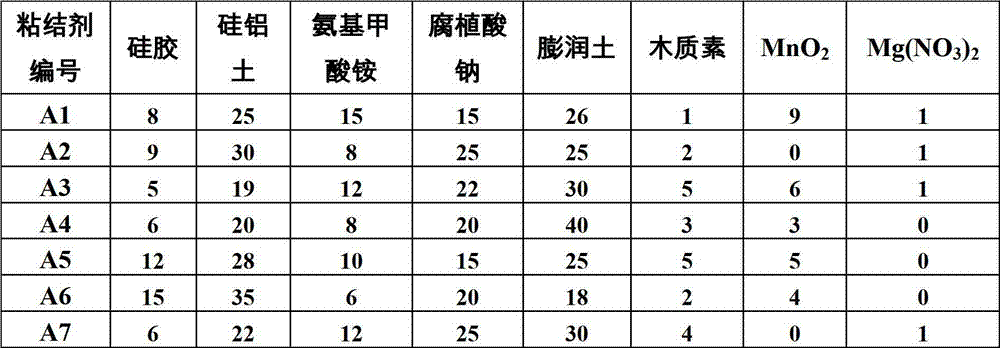

Binder for pressure gasification briquettes

The invention relates to a binder for pressure gasification briquettes, in particular to a pressurized fixed bed gas making briquette binder comprising silica gel, siallitic soil, ammonium carbamate and an auxiliary binder. The invention also relates to the briquettes comprising the briquette binder and a preparation method thereof.

Owner:山西潞安环保能源开发股份有限责任公司 +1

High-combustion-value fuel rod and manufacturing process thereof

The invention discloses a high-combustion-value fuel rod and a manufacturing process thereof. A formula of the high-combustion-value fuel rod adopts the following weight percentage: 20 to 40% of paulownia saw dust, 10 to 30% of paulownia bark, 5 to 12% of waster carbon powder, 2 to 6% of acidic pulp mill waste liquor, 15 to 40% of food sludge, 3 to 10% of waste paper pulp, 2 to 6% of glass cement and 4 to 12% of calcium oxide. Compared with the prior art, the high-combustion-value fuel rod and the manufacturing process thereof, which are disclosed by the invention, have the following advantages that: in the invention, by performing a reaction on the paulownia bark and the acidic pulp mill waste liquor under a certain conditions, the material structure in the paulownia bark is improved, combustible components in the high-combustion-value fuel rod are kept, and active components in the high-combustion-value fuel rodare increased, so that the fuel rod can be sufficiently burnt; macromolecular substances in the high-combustion-value fuel rod are degraded into low molecular weight organic matter, so that not only is a raw material easy to form, but also an adhesion degree of the fuel rod can be reinforced, and residues and offcut in the machining process are reduced; combustion heat of the fuel rod reaches about 4,600 Kcal / kg; the fuel rod can be used for equipment or processes with high requirements for heat.

Owner:安徽省珍云生物能源有限公司

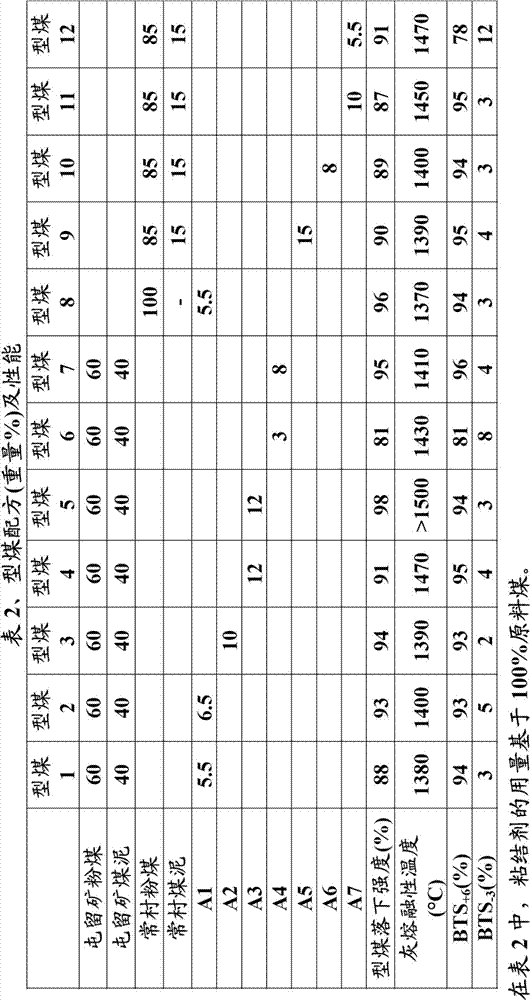

Method for concurrent production of potassium chloride and mineralization fixation of CO2

InactiveCN103693659BRaise the ash melting pointHigh melting pointDispersed particle separationAlkali metal chloridesEvaporationPotassium

The invention belongs to the comprehensive field of potassium fertilizer production and CO2 emission reduction, and provides a method for concurrent production of potassium chloride and mineralization fixation of CO2. The process steps comprise: (1) adopting potassium feldspar, calcium chloride and coal as raw materials, preparing materials, carrying out ball milling, and carrying out pressing molding or pelletizing; (2) conveying the molded material or the material balls into a rotary kiln from the kiln tail, conveying air into the rotary kiln from the kiln head, and controlling a residence time of the molded material or the material balls at a temperature range of 800-1000 DEG C to 20-40 min; (3) crushing the calcinated material, and adding water to carry out potassium leaching through the water; (4) adding water to the potassium leaching residue to carry out pulp conditioning, and introducing CO2 to carry out a mineralization reaction; (5) carrying out returning of the potassium leaching solution so as to be used for leaching of potassium from the calcinated material when the Baume degree of the potassium leaching solution is less than or equal to 29, and carrying out evaporation concentration on the potassium leaching solution to achieve the Baume degree of 42-42.5 when the Baume degree of the potassium leaching solution is more than 29, and cooling to carry out potassium chloride crystallization; and (6) cooling the potassium extraction mother liquor to carry out calcium chloride crystallization, and carrying out solid-liquid separation to obtain calcium chloride and the calcium extraction mother liquor.

Owner:SICHUAN UNIV

Compound biomass granular fuel

The invention discloses a compound biomass granular fuel. The compound biomass granular fuel comprises the following components: sawdust, crop straws, anthracite powder, corncobs, rice hull powder, attapulgite clay, montmorillonite and red mud. The biomass granular fuel provided by the invention is reasonable in component compatibility, the current slag-bonding phenomenon of the biomass granular fuel is greatly improved, the emission of polluted gas is greatly reduced, the combustion ratio of the biomass granular fuel is improved, and the combustion value and combustion time of the biomass granular fuel are greatly improved.

Owner:安徽盛昌生物能源科技开发有限公司

A kind of preparation method of novel biomass industrial fuel

InactiveCN105505508BImprove combustion performanceNot easy to fall apartBiofuelsSolid fuelsPolyethylene oxideRoom temperature

The invention discloses a preparation method of a novel biomass industrial fuel. The preparation method comprises: pulverizing raw materials, mixing them with polyethylene oxide, raising the temperature and drying the mixture until the water content reaches 5-20%, and extruding at room temperature After molding and cooling, the biomass industrial fuel of the present invention can be obtained. The preparation method is simple, and the obtained fuel has excellent water seepage resistance, good combustion effect, no overall deformation, no easy to fall apart, high ash melting point, no slagging and ash accumulation, and is suitable for industrial production.

Owner:JILIN YONGTUO NEW ENERGY TECH CO LTD

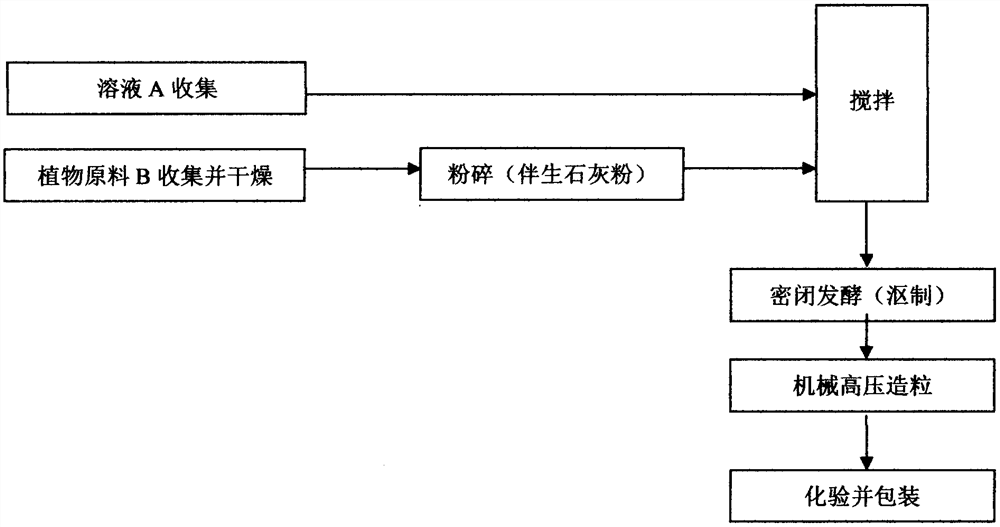

Biomass organic fertilizer and preparation method thereof

InactiveCN113501731AHigh calorific valueReduce energy consumptionCalcareous fertilisersBio-organic fraction processingBiogasLivestock

The invention belongs to the technical field of comprehensive utilization of biomass organic fertilizers, and particularly relates to a biomass organic fertilizer which is prepared by processing a solution A obtained by taking an animal manure protogenetic solution such as human or livestock, a plant raw material B obtained by collecting stems, stems or leaves of plants such as rice, wheat, sugarcane and corn, and a proper amount of quick lime, and the weight ratio of the solution A to the plant raw material B to the quick lime is 65: 30: 5. According to the invention, not only is recycling of the straws and the livestock and poultry manure realized, but also the straws and the livestock and poultry manure can be used for producing electricity, heat, cold, biogas and organic fertilizers after being treated, so that the resource utilization of the straws and the livestock and poultry manure is improved. Internal circulation of electric power and heat energy is achieved, comprehensive benefits and economic benefits of environmental protection can be greatly improved, and recycling and harmless utilization of straw is achieved. Through biomass energy electric heating cold air fertilizer poly-generation integration, a terminal product with large market potential and demand is formed, a biomass industry chain is expanded, and green and healthy development of the biomass industry is promoted.

Owner:周德昌

A kind of semi-coke additive for blast furnace injection and its preparation and use method

ActiveCN110982578BImprove hard-to-grind situationsIncrease usageSolid fuelsBlast furnace detailsPtru catalystCombustion

The invention discloses a semi-coke additive for blast furnace injection and methods for preparing and using the same, and belongs to the technical field of blast furnace coal injection. The composition of the additive contains 0.1-0.25% of grinding aid, 58-80% of composite waste residue type catalyst, 18-40% of composite compound type catalyst and 1-4% of dispersant in terms of mass percentage. By adding this additive, the grindability and ash melting point of semi-coke can be improved, and the combustion effect can be improved, which greatly increases the amount of semi-coke injected in the blast furnace, and is suitable for large-scale popularization and application of semi-coke injected into blast furnaces. In the blast furnace injection system, semi-coke can be completely replaced by coal, which lays a good foundation for de-coalization.

Owner:NANJING IRON & STEEL CO LTD

Fuel oil or natural gas and tobacco stem integrated boiler and pollutant control method

InactiveCN105180156BPrevent slaggingAvoid serious dust accumulationFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberCooling chamber

The invention relates to an oil-burning or natural-gas-burning and tobacco-stem-burning integrated boiler and a contaminant control method and belongs to the field of oil-burning or natural-gas-burning and tobacco-stem-waste-burning boilers. The problems that slagging and coking exist when fuel oil or natural gas and tobacco stems are burnt together in a fluidized bed boiler are solved. A first smoke outlet of an oil-burning or natural-gas-burning combustor is sequentially communicated with a first oil-burning or natural-gas-burning combustor cooling chamber and a second oil-burning or natural-gas-burning combustor cooling chamber which are located behind the first smoke outlet. An outlet of a fluidized bed combustor is communicated with a first fluidized bed combustor cooling chamber and a second fluidized bed combustor cooling chamber which are located behind the outlet. The first fluidized bed combustor cooling chamber is separated from the second fluidized bed combustor cooling chamber through a first membrane panel separation wall. The lower end of the first cooling chamber membrane panel separation wall is connected with a U-shaped groove separator. The second fluidized bed combustor cooling chamber is communicated with a second smoke outlet of the second oil-burning or natural-gas-burning combustor cooling chamber. An outlet window of the second fluidized bed combustor cooling chamber is communicated with a first convection exhaust pipe and a second convection exhaust pipe. The second convection exhaust pipe is communicated with a coal economizer and an energy saver. The boiler is used for burning fuel oil or natural gas and tobacco stem waste.

Owner:湖南博茂节能环保科技有限公司 +1

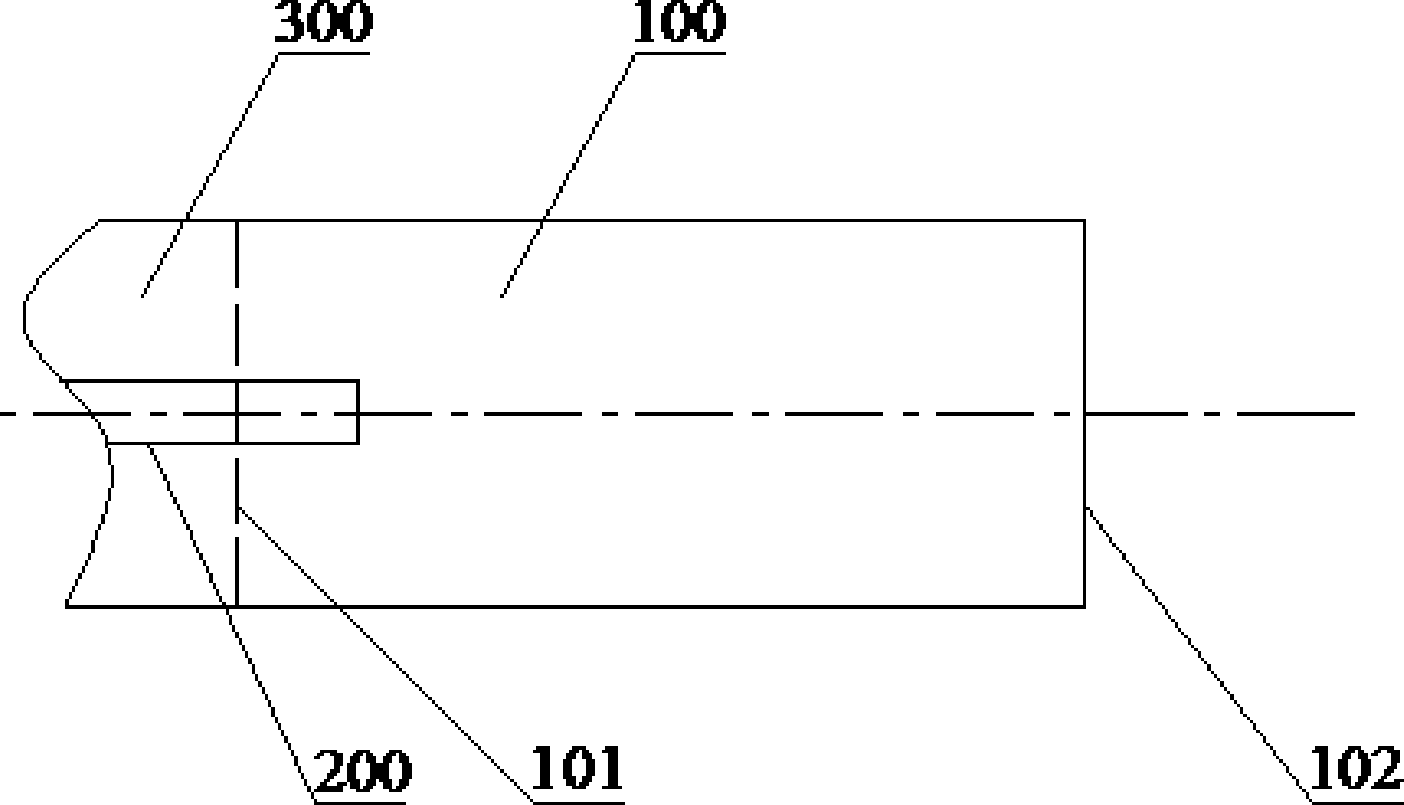

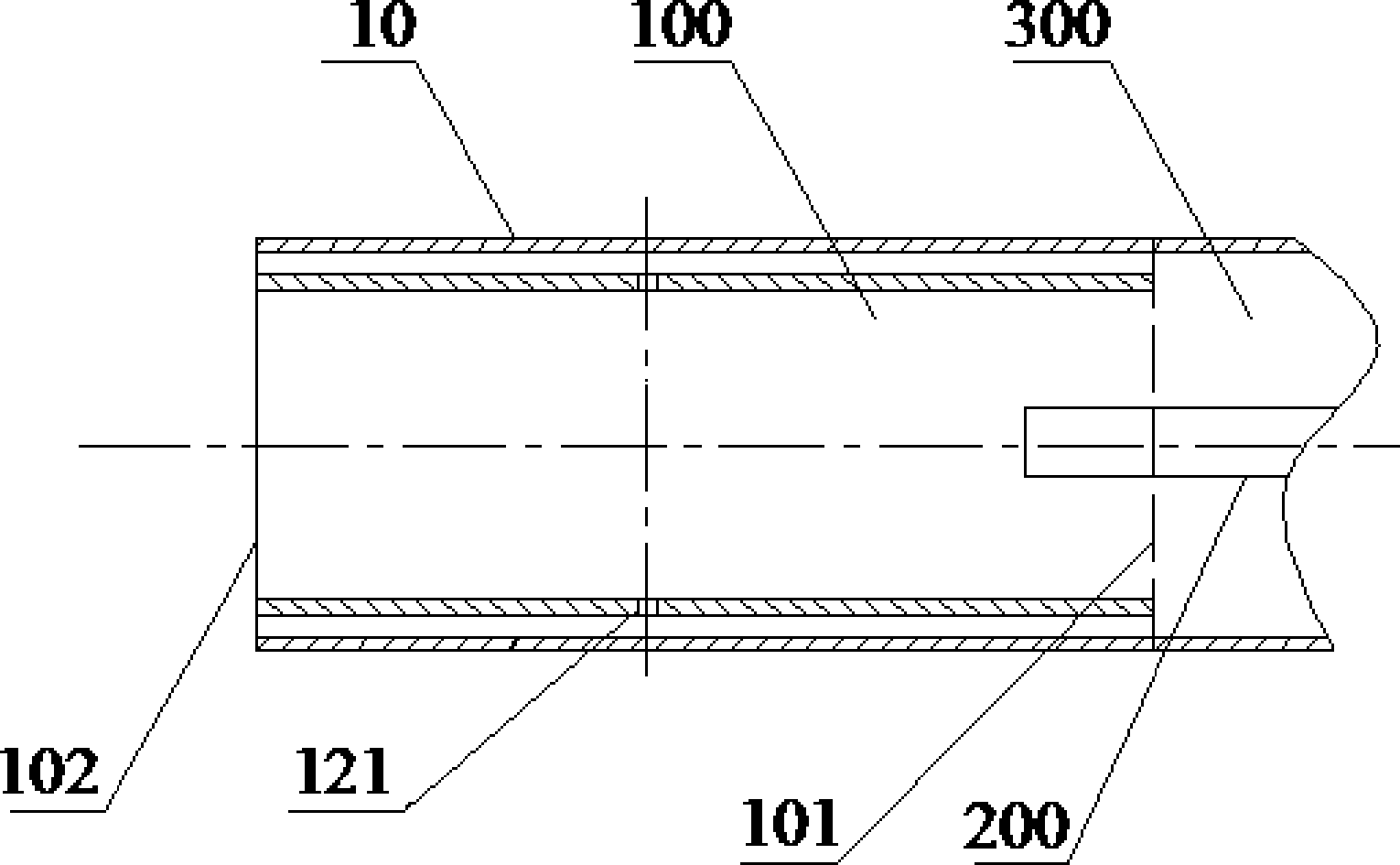

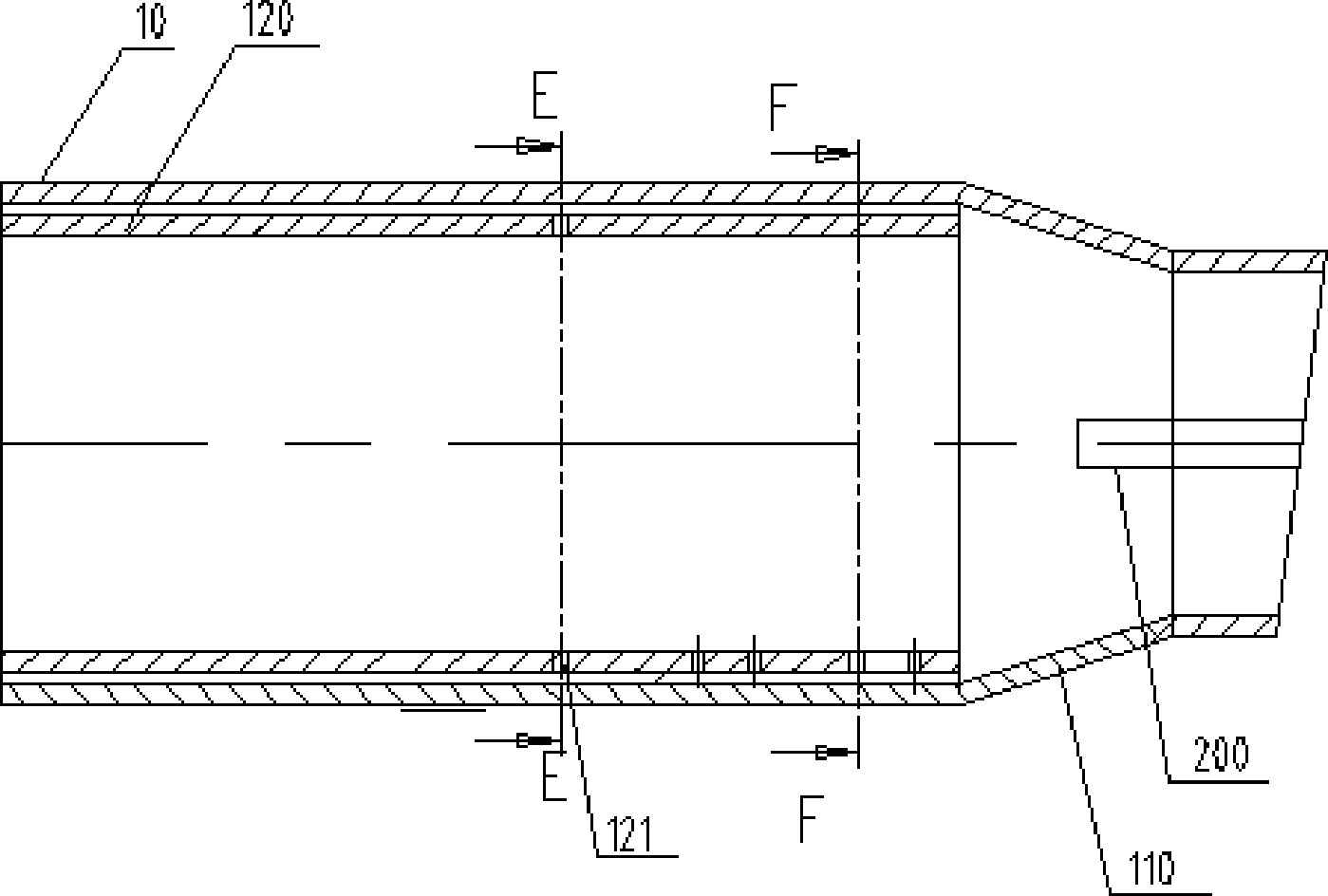

A pulverized coal burner and boiler

ActiveCN102454986BNot easy to depositSolve powder accumulationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCoal dust

Owner:YANTAI LONGYUAN POWER TECH

Novel method for preparing biomass industrial fuel

InactiveCN109749806AImprove combustion performanceNot easy to fall apartSolid fuelsWaste based fuelCombustionPolyethylene oxide

The invention discloses a novel method for preparing biomass industrial fuel. The novel method includes smashing raw materials; mixing the raw materials and polyethylene oxide with one another; heating and drying mixtures until the moisture content of the mixtures reaches 5-20%; carrying out normal-temperature extrusion forming; carrying out cooling to obtain the biomass industrial fuel. The novelmethod has the advantages that the novel method is simple, and the biomass industrial fuel prepared by the aid of the method is excellent in water seepage resistance; good combustion effects can be realized by the biomass industrial fuel, the biomass industrial fuel is integrally free of deformation and is difficult to fall apart, high in ash melting point and free of slag bonding or ash deposition, and the novel method is applicable to industrial production.

Owner:吕志敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com