Systematic device and method for biomass microwave pyrolysis poly-generation by adopting combined washing and baking pretreatment

A technology for pretreatment of biomass and water washing equipment, which is applied in the fields of biofuel, special dry distillation, petroleum industry, etc., and can solve the problems of reduced calorific value of pyrolysis synthesis gas, poor stability of bio-oil, and reduced yield of bio-oil, etc. , to achieve the effect of increasing calorific value and ash melting point, improving quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

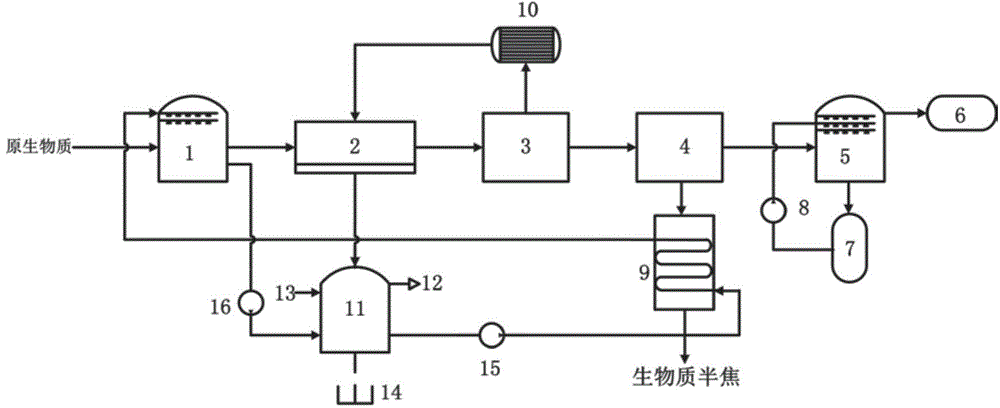

[0013] The present invention will be further explained below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, a combined water washing-baking pretreatment biomass microwave pyrolysis polygeneration device includes a water washing tower 1, a flue gas convection drying bed 2, a low-power microwave baking furnace 3, a high-power microwave pyrolysis furnace 4, spray Shower condenser 5, gas storage tank 6, oil storage tank 7, oil pump 8, liquid-solid heat exchanger 9, low calorific value gas porous media burner 10, water storage tank 11, circulation pump 15, water pump 16. The outlet of the water washing tower 1 is connected to the inlet of the flue gas convection drying bed 2, the outlet of the flue gas convection drying bed 2 is connected to the inlet of the low-power microwave oven 3, and the outlet of the low-power microwave oven 3 The port is connected to the feed port of the high-power microwave pyrolysis furnace 4, and the flue gas outlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com