Additive for alleviating coking feature of Xinjiang Zhundong high alkali coal and preparation and application method of additive

A high-alkali coal and additive technology, which is applied in fuel additives, petroleum industry, solid fuel, etc., can solve problems such as coking and serious boilers, and achieve the effects of simple preparation process, simple application and operation, and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

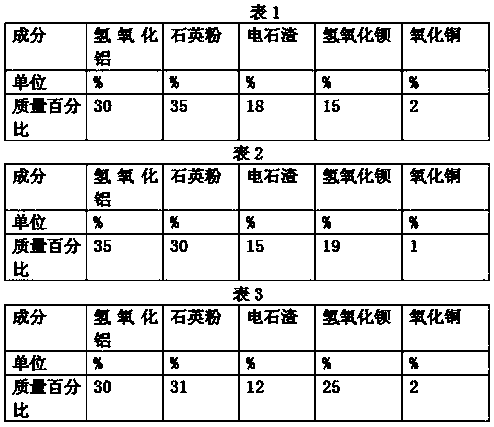

Embodiment 1

[0018] Embodiment 1, the additive used to alleviate the coking characteristics of high-alkali coal in Zhundong, Xinjiang, is characterized in that the raw materials include 30 to 40 parts by weight of aluminum hydroxide, 25 to 35 parts of quartz powder, and 12 to 35 parts of calcium carbide slag. 20 parts, barium hydroxide 15 to 25 parts, copper oxide 1 to 2 parts. The mass content of silicon dioxide in quartz powder can be 90% to 95%, and its melting point is above 1400 degrees Celsius. Aluminum hydroxide, quartz powder, barium hydroxide and other ingredients can effectively reduce the alkali-acid ratio. Barium hydroxide and quartz powder can promote the conversion of low melting point sulfuric acid compound sodium salt compounds in coking into high melting point silicic acid compound sodium salts. Quartz Powder and carbide slag can effectively increase the melting point of coal ash. The additive for alleviating the coking characteristics of Xinjiang Zhundong high-alkali coa...

Embodiment 2

[0019] Embodiment 2, the additive used to alleviate the coking characteristics of high-alkali coal in Zhundong, Xinjiang, is characterized in that the raw materials include 30 or 40 parts by weight of aluminum hydroxide, 25 or 35 parts of quartz powder, 12 or 35 parts of calcium carbide slag 20 parts, 15 or 25 parts of barium hydroxide, 1 or 2 parts of copper oxide.

Embodiment 3

[0020] Example 3, the additive used to alleviate the coking characteristics of Xinjiang Zhundong high-alkaline coal is obtained by the following preparation method: the required amount of aluminum hydroxide, quartz powder, carbide slag, barium hydroxide and copper oxide are mixed uniformly, The additive used to alleviate the coking characteristics of Xinjiang Zhundong high-alkaline coal was obtained. The content of silicon dioxide in quartz powder can be 90% to 95%. The preparation process of the invention is simple and the input cost is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com