A pulverized coal burner and boiler

A pulverized coal burner and pulverized coal technology are applied to burners, burners that burn powder fuels, and combustion using multiple fuels, etc., which can solve the problems of powder accumulation and slagging, and solve the problems of powder accumulation and slagging, The effect of reducing wall temperature and preventing slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

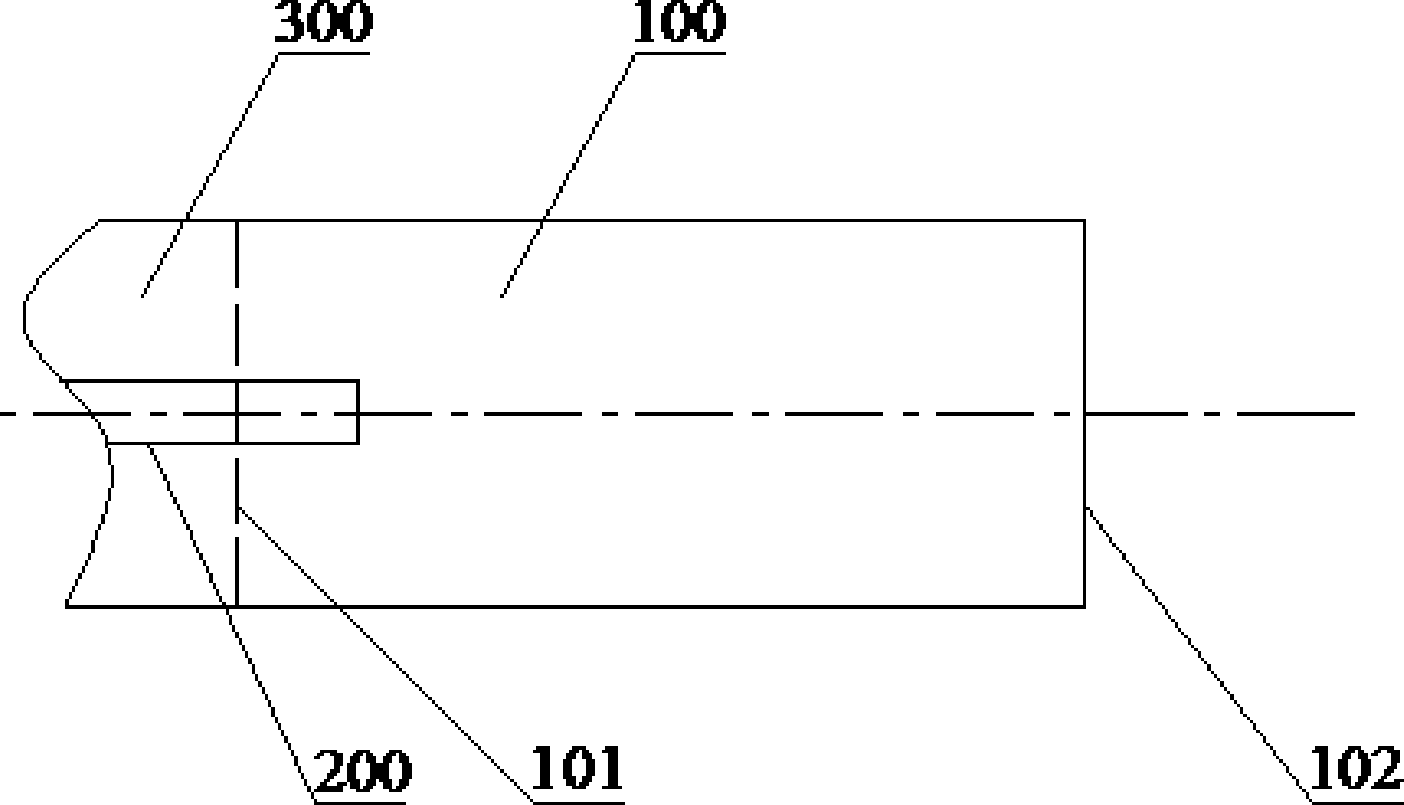

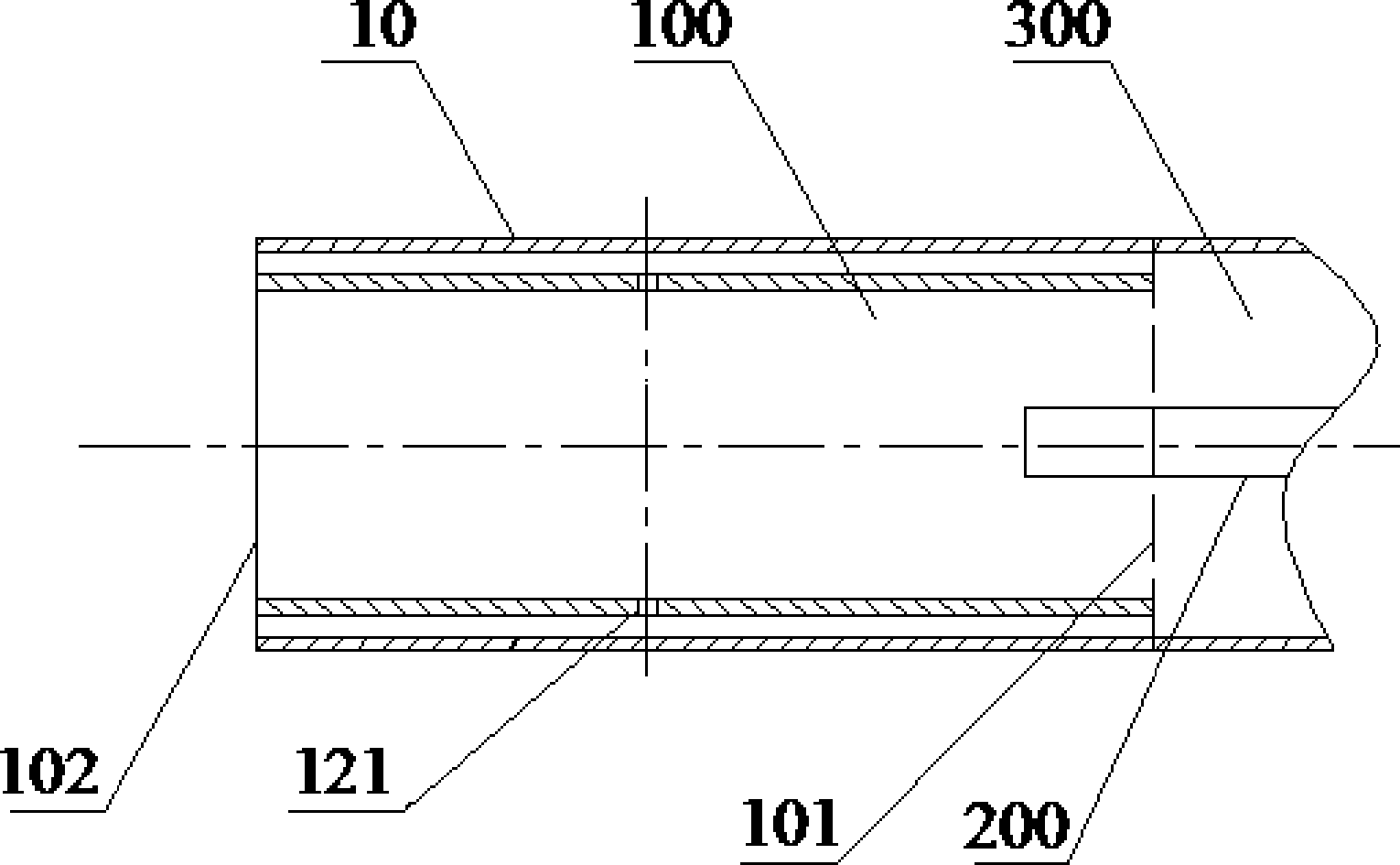

[0037] Please refer to figure 2 , which is a longitudinal structural view of the pulverized coal burner provided in Embodiment 1 of the present invention.

[0038] For the convenience of description, figure 2 The air inlet pipe 300 is also shown in the figure; the fire source 200 extends into the internal combustion chamber 100 from the air inlet pipe 300 , and the air inlet pipe 300 communicates with the inlet 101 . The heat source is a continuous heat source to continuously ignite the pulverized coal.

[0039] The pulverized coal burner provided in Embodiment 1 of the present invention is a double-layer sleeve structure of the outer cylinder 10 and the inner cylinder 100, and the pulverized coal burner includes a heat source 200 and an internal combustion chamber. The inner tube 100 serves as the internal combustion chamber.

[0040] The heat source 200 is located in the internal combustion chamber, and the internal combustion chamber has an inlet and an outlet; the hea...

Embodiment 3

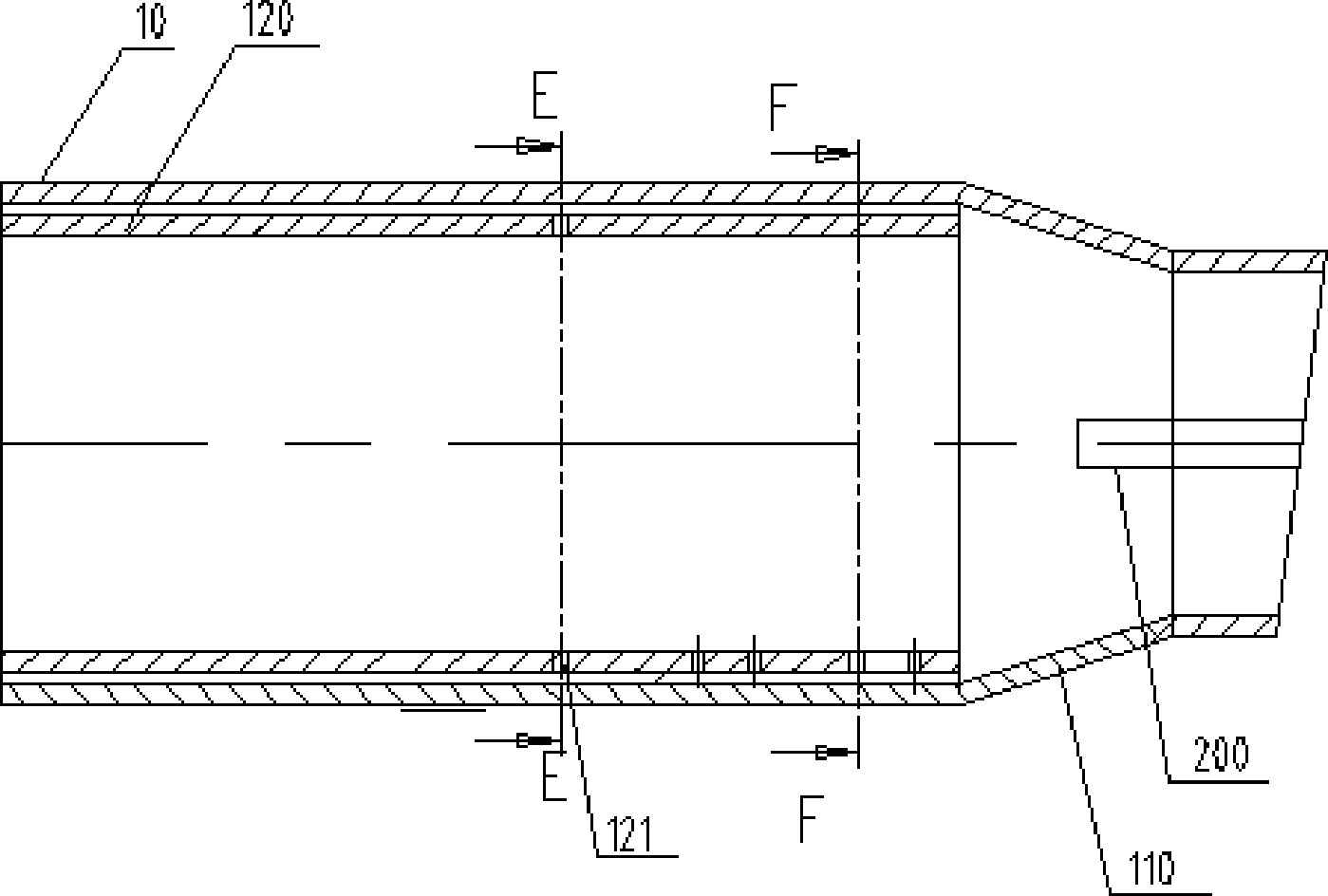

[0056] see Figure 6 to Figure 9 , Figure 6 The sectional structure diagram of the pulverized coal burner provided for the second embodiment of the present invention; Figure 7 for Figure 6 The B-B direction sectional view shown; Figure 8 for Figure 6 The C-C sectional view shown; Figure 9 for Figure 6 The D-D direction sectional view is shown.

[0057] When the pulverized coal airflow ignited in the internal combustion chamber 100 is drawn out through the outlet and introduced into the boiler furnace, in order to make the drawn high-temperature pulverized coal combustion flame have higher rigidity and adapt to the overall combustion organization needs of the boiler furnace, internal combustion can also be used. The chamber 100 is provided with an accelerated exit section. Such as Figure 6 As shown, the pulverized coal burner also has an acceleration outlet section 130 connected to the rear end of the combustion chamber 120 .

[0058] The through hole 121 may o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com