Surface deburring device for small revolving body part

A rotary body and deburring technology, which is applied to surface polishing machine tools, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of poor deburring effect, low work efficiency, time-consuming and laborious, etc., and achieve the deburring effect Good, structurally complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

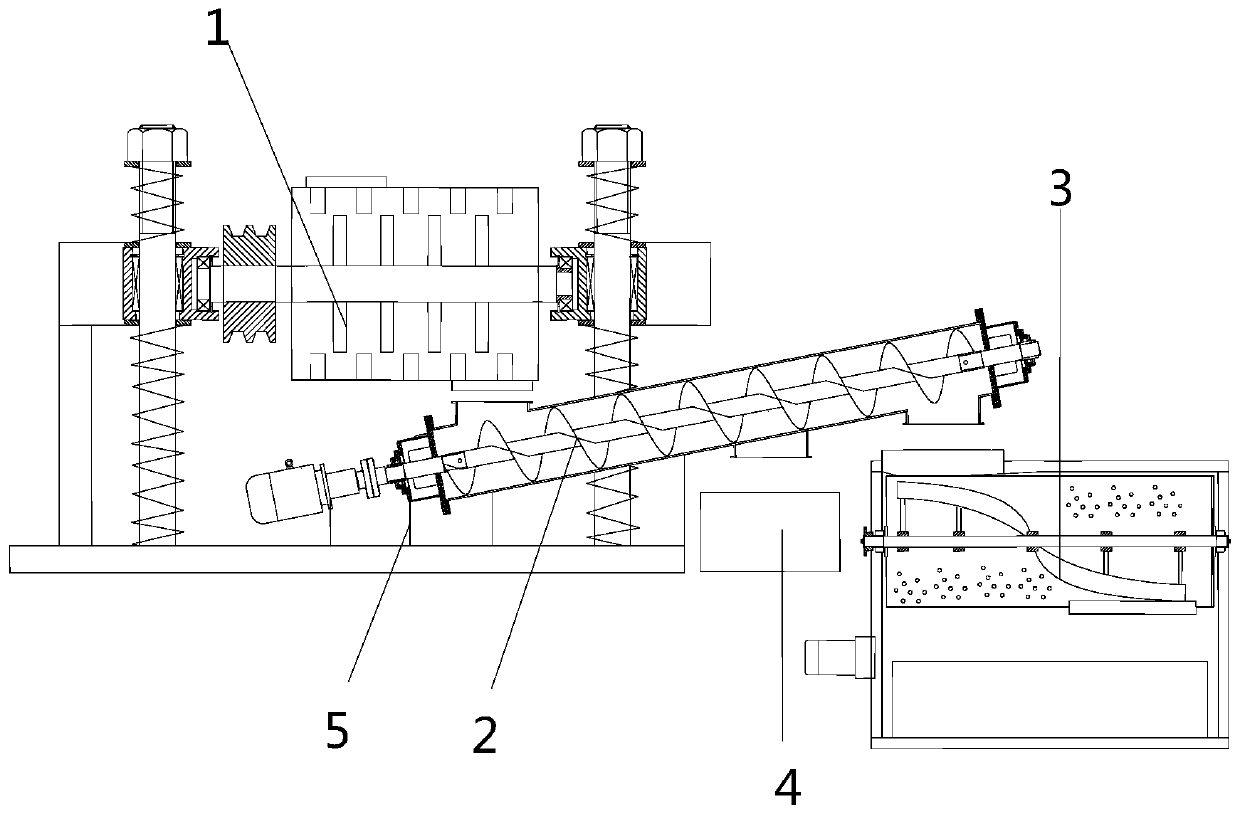

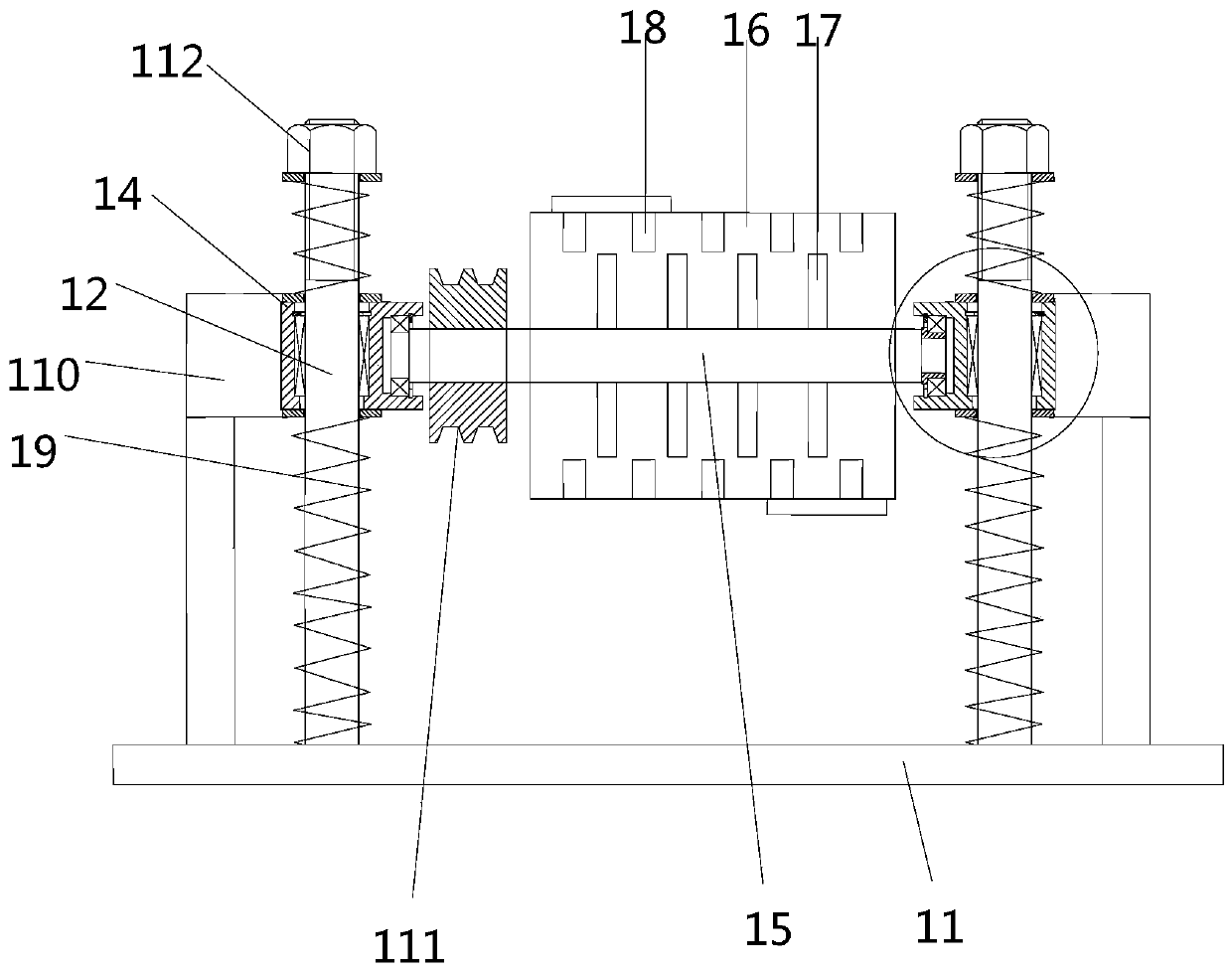

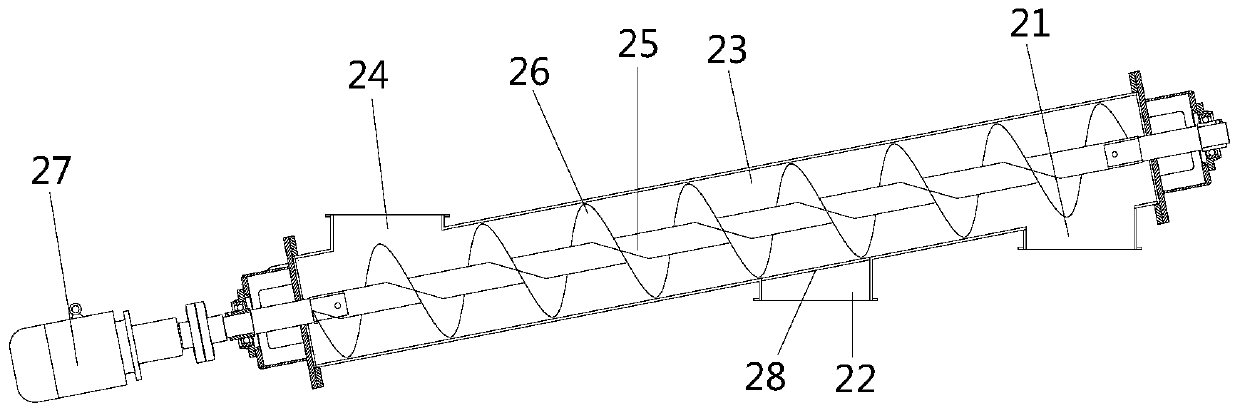

[0021] Embodiment: a kind of surface deburring device of small revolving body part, structure such as Figure 1 to Figure 5 As shown, it includes a drum deburring mechanism 1, the discharge port of the drum deburring mechanism 1 is connected with a screw conveying mechanism 2, and the lower side of the end section of the screw conveying mechanism 2 is respectively provided with a first discharge port 21 and a second discharge port 22. The first discharge port 21 is connected to the abrasive separation mechanism 3, and the first abrasive recovery box 4 is provided below the second discharge port 22; the drum deburring mechanism 1 includes a base 11, and a pair of columns 12 are arranged on the base 11 , a pair of columns 12 are provided with a slider 14 with a built-in sliding sleeve 13, a bearing seat is provided on the slider 14, a rotating shaft 15 is arranged through the bearing seat, and a roller 16 fixed with the rotating shaft 15 is arranged on the rotating shaft 15, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com