In-line plasma CVD device

A technology of chemical vapor deposition and plasma, which is applied in gaseous chemical plating, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve problems such as scattering of accumulations, increase of resistance on the inner wall of the chamber, and unstable generation of plasma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

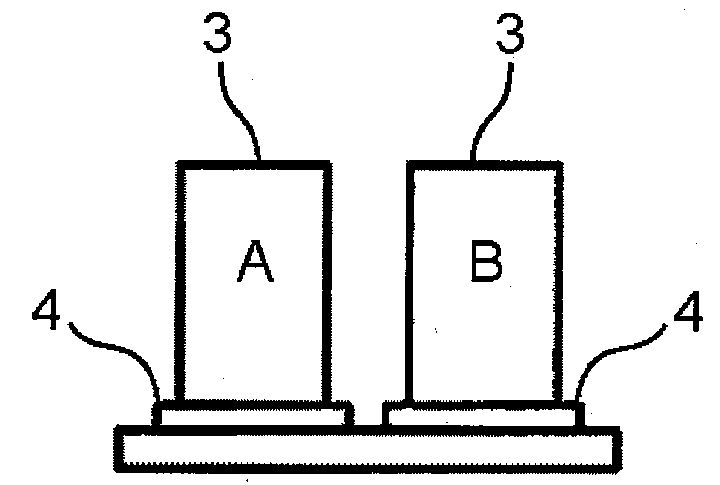

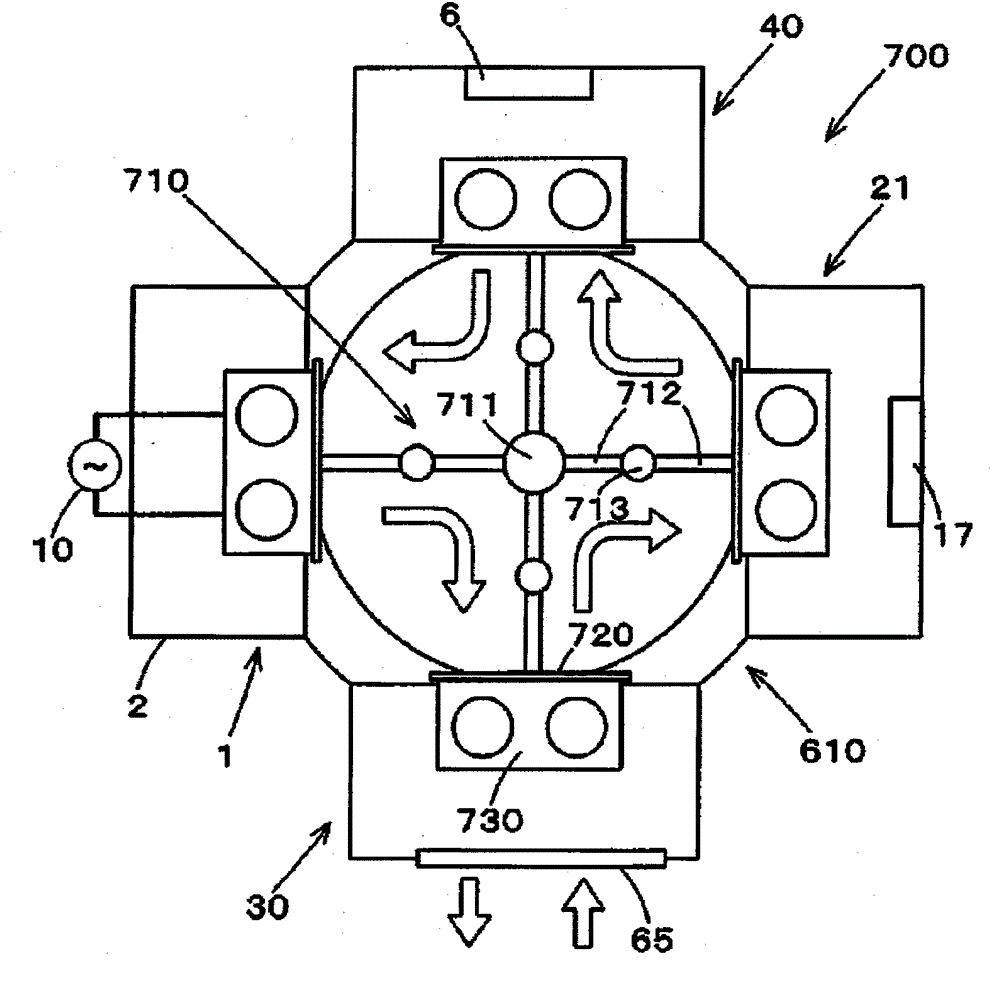

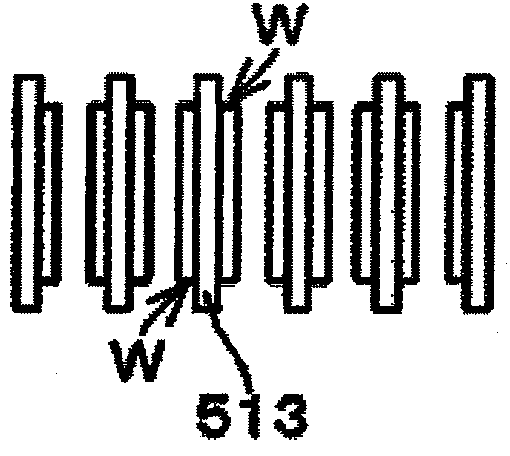

[0036] figure 1 It is a perspective view showing the overall structure of the plasma chemical vapor deposition apparatus 100 according to the first embodiment of the present invention, figure 2 is its top view.

[0037] The plasma chemical vapor deposition apparatus 100 includes a film forming chamber 1 having a plasma chemical vapor deposition mechanism, a load-lock vacuum chamber 20 as a separate compartment arranged on the upstream side of the film forming chamber 1, and a film forming chamber 20 arranged on the film forming chamber. A load-lock vacuum chamber (compartment) 30 as a separate compartment on the downstream side of the chamber 1 . The upstream and downstream described here refer to the direction in which the substrate W is transported. An isolation valve 41 is arranged at the entrance of the load-lock vacuum chamber 20, an isolation valve 42 is arranged between the outlet of the load-lock vacuum chamber 20 and the entrance of the film forming chamber 1, and ...

no. 2 Embodiment approach

[0103] Below, yes Figure 5A ~ Figure 5D The plasma chemical vapor deposition apparatus 200 according to the second embodiment of the present invention will be described. The plasma chemical vapor deposition apparatus 200 of the second embodiment is different from the plasma chemical vapor deposition apparatus 100 of the above-mentioned first embodiment in the arrangement of the substrate W on the substrate stage. Other than that, it is the same as that of the first embodiment, so the description will not be repeated here about the part that overlaps with the above description.

[0104] Figure 5A The plasma chemical vapor deposition apparatus 200 of the second embodiment is shown. Should Figure 5A corresponds to Figure 4A .

[0105] Such as Figure 5A As shown, the plasma chemical vapor deposition apparatus 200 includes: a chamber having a vacuum chamber 202 as a film forming chamber 201 including a plasma chemical vapor deposition mechanism; a load-lock vacuum chambe...

no. 3 Embodiment approach

[0109] Below, yes Figure 6A The plasma chemical vapor deposition apparatus 300 according to the third embodiment of the present invention shown will be described. This plasma chemical vapor deposition apparatus 300 is different from the plasma chemical vapor deposition apparatus 100 of the above-mentioned first embodiment in the arrangement of the substrate W. Other than that, it is the same as that of the first embodiment, so the description will not be repeated here about the part that overlaps with the above description.

[0110] Figure 6A The plasma chemical vapor deposition apparatus 300 of the third embodiment is shown. Should Figure 6A is corresponding to Figure 4A A plan view for explaining the operating state of the continuous plasma chemical vapor deposition apparatus.

[0111] Such as Figure 6A As shown, the plasma chemical vapor deposition apparatus 300 includes: a chamber having a vacuum chamber 302 as a film forming chamber 301 including a plasma chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com